WAREHOUSES OF THE FUTURE:

Using automation to improve efficiency and boost productivity. p. 7

WAREHOUSES OF THE FUTURE:

Using automation to improve efficiency and boost productivity. p. 7

Why SMEs are poised to jump into supply chain automation and AI adoption. p. 11

HANNOVER MESSE 2025: Attendee experience direct from the trade show floor. p. 18

Meet this year’s class of manufacturing and automation high performers.

With the C-more headless HMI, you can display your factory floor data how and where you choose. The new CM5-RHMI has all the powerful functionality of the C-more Touch Panel HMIs, but without display size restrictions. This HDMI-enabled device works with televisions, monitors, projectors, and most any other HDMI display device or use the C-more Remote HMI mobile app and/or the embedded Web Server if you prefer no local display at all. The choice is yours!

Features include:

C-more Headless HMI

• HDMI video/audio output with multiple resolutions

• Video: VGA 640x480, SD 720x480, XGA 1024x768, HD 1280x720, FHD 1920x1080

• Audio: use USB audio adapter (not included)

• Works with most HID-compatible resistive and pCap touch screen monitors

• The USB A port allows support for most industrial touch screen monitors in the market

• Multiple connections

• (2) Ethernet, (1) RS-232, (2) RS-485, (1) RS-422 ports support programming and device connections

• USB-B port for programming, monitoring, and configuration

• SD card slot for log files, project memory, or graphic media

• 90MB of user memory

The easy-to-use C-more HMI design software can be downloaded free of charge from our webstore. Get started on your project today or take it for a test drive. Download as often as you need, no license or key required.

• (4) USB-A ports for USB HID devices such as USB hub, pen drives, touch screen displays, keyboard, mouse, and bar-code scanners

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Get your copy now at: www.go2adc.com/cmoreswcm5

The

How manufacturers can begin the process of AI integration into their operation.

Protecting modern manufacturing through the use of Privileged Access Management.

What manufacturing leaders can learn from the Stanley Cup playoffs.

How automation is improving efficiency and boosting productivity in warehouses.

By Jack Kazmierski

Where automation is used in the supply chain and how SMEs are poised to leapfrog into adoption.

By Treena Hein

The winners of this year’s Top 10 Under 40 contest share their thoughts on the current state of the manufacturing industry.

By Jared Dodds

Canada shined as the partner country at this year’s trade show. Learn how some attendees capitalized on the international exposure.

By Jared Dodds

BY JARED DODDS

My name is Jared Dodds and, as of the beginning of April, I am the new editor of Manufacturing AUTOMATION (MA). I want to start this editor’s note by saying thank you to this brand’s previous editor, Sukanya Ray Ghosh, who set the bar incredibly high with the magazine’s steady stream of informative and engaging content. The entire MA team wishes her luck in all her future endeavours.

Now, a little about myself. I began my writing career in investigative journalism before transitioning to professional services and, finally, to business-to-business (B2B) media. I have been a member of Annex Business Media, MA’s parent company, for just over a year, with a focus on the emergency service sector. This role gave me the opportunity to learn from the best and get my feet wet in the B2B world before taking the editorial lead on MA.

This path, though circuitous, has been the best thing to happen to my career, exposing me to a number of different writing styles, industries and individuals. My current role is no different: despite my experience as a writer and interviewer, the manufacturing world is relatively new to me.

Because of this, when I took the role, I knew my first task was to talk to as many industry experts as I could, listen and learn. Through all of those conversations there was a running theme regarding the Canadian manufacturing sector: uncertainty.

U.S. President Donald Trump’s tariffs have cast a looming shadow over Canada’s manufacturing market, with enough sudden changes to cause whiplash. People are concerned about the future of their

business. It was one of the leading topics of conversation as attendees went booth to booth at this year’s Hannover Messe trade show, which you can read about in this edition, and that conversation has continued on home soil. As I have been communicating with industry thought leaders in preparation for MA’s upcoming Canadian Automation Leadership Summit, taking place on June 3 in Kitchener, a common refrain has been the impossible nature of predicting what will happen from one week to the next.

So, what are Canadians to do? Lie down and accept our fate? If the phone calls I have been on over the last month and a half are any indication, that is not an option.

Instead, it feels essential to look towards what we can control. To celebrate the upand-coming generation of talent in this industry, some of which are highlighted in this edition’s Top 10 Under 40. To continue conversations with international partners, emphasizing the opportunities for collaboration and growth in the Canadian market. To make it clear to those who think of Canada as nothing more than the ‘51st state’ that they are sorely mistaken.

I understand this is much easier said than done, and, given the lack of clarity from President Trump, the challenges are bound to be unpredictable. But if the first six weeks of my tenure have taught me anything, it is that the members of this sector are resilient, innovative and, most importantly, up for the fight. You can count on Manufacturing AUTOMATION to be there every step of the way, providing the information and insight to ensure that fight is a winning effort. | MA

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: 416-510-5113

Fax: (416) 510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR

Jared Dodds jdodds@annexbusinessmedia.com Tel: 416-510-5225

PUBLISHER

Kathryn Swan kswan@annexbusinessmedia.com Tel: 647-339-4880

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

MEDIA DESIGNER

Jaime Ratcliffe jatcliffe@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-510-5107

AUDIENCE DEVELOPMENT MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

Jack Kazmierski, Jonathan Gross, Paul Hogendoorn and Treena Hein

Published by Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 • Fax: 416-442-2191

Printed in Canada ISSN 1480-2996 Publication Mail Agreement #40065710

SUBSCRIPTION RATES Canada — $43.86 per year • $12.00 single copy United States — $99.96 CAD per year Foreign — $114.24

ANNEX PRIVACY OFFICER email: privacy@annexbusinessmedia.com Tel: 800-668-2374

EDITORIAL ADVISORY BOARD

JIM BERETTA, President, Customer Attraction and host of The Robot Industry Podcast

JONATHAN GROSS, Managaing Director, Pemeco Consulting

MIHAELA VLASEA, Associate Professor, Department of Mechanical and Mechatronics Engineering and Research Co-Director, Multi-Scale Additive Manufacturing Laboratory at the University of Waterloo

SHELLEY FELLOWS, Past-Chair, Automate Canada

STEPHANIE HOLKO Director, Project Development at Next Generation Manufacturing Canada

WALTER GARRISON, Former Advanced Manufacturing Business Consultant for City of Mississauga

Occasionally, Manufacturing AUTOMATION will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. The contents of Manufacturing AUTOMATION are ©2025 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

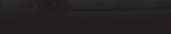

Automate 2025 features 40+ Canadian companies showcasing automation solutions

Automate 2025 took over Huntington Place Convention Centre in Detroit, Mich. from May 12 to 16, bringing more than 40,000 individuals together to celebrate the automation industry and assess the next generation of solutions being brought to market.

The event hosted approximately 875 exhibitors occupying more than 335,000 square feet, along with more than 200 speakers and panelists discussing industry trends and issues, reported a media source for the trade show.

The five-day event featured four keynote speakers, including Brad Holmes and Dan Miller representing the local NFL franchise, the Detroit Lions, sharing their insights on how to build a winning culture, Deepu Talla, vice president of robotics and edge AI for NVIDIA examining industrial autonomy in the era of physical AI, Aamir

It merged with the Vision Show and Motion Control Show to form the first-ever Automate event in 2011.

Cybersecurity company Fortinet have released the 2025 Global Threat Landscape Report from FortiGuard Labs, providing a snapshot of the active threat landscape and trends from 2024, including a comprehensive analysis across all tactics used in cyberattacks.

Key findings from the report include:

making cyberattacks more effective and difficult to detect.

• Targeted attacks on critical sectors intensify: In 2024, the most targeted sectors were manufacturing (17 per cent), business services (11 per cent), construction (nine per cent) and retail (nine per cent). Both nation-state actors and Ransomware-as-a-Service (RaaS) operators concentrated their efforts on these verticals, with the United States bearing the brunt of attacks (61 per cent), followed by the United Kingdom (six per cent) and Canada (five per cent).

Paul, president of North America operations for Schneider Electric, speaking about the opportunities the new era of American manufacturing creates for the U.S. workforce, and Ujjwal Kumar, group president of Teradyne Robotics, separating tech hype from industrial needs.

Other sessions provided insight into collaborative robotics, motion control and conveyance, machine vision, imaging and inspection, automation systems, design and integration, the business case for automation and cybersecurity, to name a few.

On the trade show floor, 41 Canadian companies made the trip to put their portfolio of products on display, including OTTO by Rockwell Automation, Teledyne, Black Controls Company Inc., RoboTape by Innovation Automation, DataRealm Inc., Samuel Automation Solutions Group and more.

Automate is produced by the Association for Advancing Automation (A3), North America’s largest automation trade association, and dates back to 1976 when the first Robots Show was established.

• Automated scanning hits record highs as attackers shift left to identify exposed targets early: Active scanning in cyberspace reached unprecedented levels in 2024, rising by 16.7 per cent worldwide year-over-year, highlighting a sophisticated and massive collection of information on exposed digital infrastructure.

• Darknet marketplaces fuel easy access to neatly packaged exploit kits: In 2024, cybercriminal forums increasingly operated as sophisticated marketplaces for exploit kits, with over 40,000 new vulnerabilities added to the National Vulnerability Database, a 39 per cent rise from 2023. In addition to zero-day vulnerabilities circulating on the darknet, initial access brokers are increasingly offering corporate credentials (20 per cent), RDP access (19 per cent), admin panels (13 per cent) and web shells (12 per cent).

• AI-powered cybercrime is rapidly: Threat actors are harnessing AI to enhance phishing realism and evade traditional security controls,

• Cloud and IoT security risks escalate: Cloud environments continue to be a top target, with adversaries exploiting persistent weaknesses such as open storage buckets, over-permissioned identities and misconfigured services. In 70 per cent of observed incidents, attackers gained access through logins from unfamiliar geographies.

• Credentials are the currency of cybercrime: In 2024, cybercriminals shared over 100 billion compromised records on underground forums, a 42 per cent year-over-year spike, driven largely by the rise of “combo lists” containing stolen usernames, passwords and email addresses.

To read the full report, visit fortinet.com/resources/reports/ threat-landscape-report.

Ontario investing $1.3 billion to protect manufacturing workers and jobs

The government of Ontario is enhancing and expanding the Ontario Made Manufacturing Investment Tax Credit, providing an additional $1.3 billion over three years to help lower costs for businesses that invest

in buildings, machinery and equipment that are used for manufacturing or processing in Ontario.

“Manufacturing workers here in Ontario are already feeling the impact of President Trump’s tariffs, including job losses that are the direct result of the economic uncertainty he has caused,” said Peter Bethlenfalvy, minister of finance, in a press statement. “In response, our plan to protect Ontario will bring in new investments to create new jobs and opportunities for our worldclass manufacturing workers, so we can build a stronger economy capable of withstanding whatever comes our way.”

The proposed changes, part of the 2025 Ontario budget, would take the Ontario Made Manufacturing Investment Tax Credit rate for Canadian-controlled private corporations to 15 per cent from 10 per cent, as well as expanding eligibility to non-Canadian-controlled private corporations as a non-refundable tax credit, to support their investments in Ontario.

With these changes a qualifying corporation could receive a tax credit of up to $3 million

per year.

“Today’s announcement will provide important support to the more than 830,000 men and women who work in the manufacturing sector and who are worried about the impact of tariffs on their jobs,” said Vic Fedeli, minister of economic development, job creation and trade, in a media release. “In the face of heightened global economic uncertainty, we are doubling down on our plan to protect Ontario by bringing in new investments and good-paying manufacturing jobs.”

Announced as part of the the province’s 2023 budget, the Ontario Made Manufacturing Investment Tax Credit was created to help Ontario manufacturers lower their costs, innovate and become more competitive.

invests $150M in new AI manufacturing technology centre in Ontario

The Ontario government has announced a $150 million

investment from Siemens to establish a Global AI Manufacturing Technologies Research and Development (R&D) Center for Battery Production at its Oakville headquarters.

This initiative aims to develop artificial intelligence manufacturing technologies to support electric vehicle (EV) battery production, creating up to 90 new jobs across the province and enhancing Ontario’s EV battery supply chain.

“Siemens’ latest investment in Ontario is a vote of confidence in our world-class workforce, our investment-friendly business environment, and our growing end-to-end EV supply chain,” said Doug Ford, premier of Ontario, in a press release.

“I’m thrilled to welcome this investment and build on our productive partnership with Siemens, which stretches back more than a century.”

The R&D centre will focus on advancing battery efficiency and refining production processes through cutting-edge AI manufacturing technologies. The investment was announced during Ontario’s mission to Germany, where a delegation

of over 30 Ontario companies showcased the province’s industrial innovation at the Hannover Messe trade show.

“Thanks to our world-class workforce and competitive business environment, Ontario continues to be a global destination for investment and job creation, particularly in our EV and EV battery sector,” said Vic Fedeli, minister of economic development, job creation and trade, in a media relase. “We’re thrilled to welcome this latest investment by Siemens, along with the up to 90 jobs it will create here in Ontario.”

Once operational, the centre will leverage collaborations between battery manufacturers and universities to upskill the province’s auto workforce.

Expected outcomes of the work to be conducted at the R&D centre include higher, consistent quality in battery production, increased workforce productivity and capacity, reduction of battery scrap and improved recycling and circularity. In support of this investment, Ontario is providing $7.2 million in funding through the Invest Ontario Fund. | MA

Automation is the key to improving effiency

BY JACK KAZMIERSKI

As human civilization has evolved, the concept of warehousing goods has evolved alongside us. Thousands of years ago, the ancient Romans built large structures near rivers in order to store a variety of goods that would arrive on ships from other parts of the world docked at nearby ports.

Much has changed since the fall of the Roman Empire, including the fact that today’s warehouse facilities leverage the power of technologies that the Romans could have never dreamed of, namely cutting-edge robotics and artificial intelligence (AI), designed to improve efficiency and boost productivity.

The key to efficiency and productivity is automation: enlisting machines and computers to manage tasks previously overseen by humans. “Without exception, every warehouse interested in continuous improvement would like to implement some type of automation or expand their existing automation,” said Peter Gerbitz, system sales manager at Matthews Automation Solutions. “The degree of automation varies widely. Very small, low volume facilities may have difficulty justifying the expense (ROI). In most cases, the higher the volumes, the higher the level of automation.”

Despite the fact that automation can

boost productivity, it’s not as widely embraced as one might think. “While warehouse automation is growing rapidly, the industry is still relatively early in its development,” said Gina Chung, vice president of corporate development at Locus Robotics. “According to industry estimates, less than 20 per cent of global warehouses are fully-automated today.”

That said, Chung admits the trend is accelerating, driven by acute labour shortages, rising operational costs and a growing demand for faster fulfillment. “Because of the labour shortages, many companies need to move from traditional manual operations to highly-flexible automation solutions, like mobile robotics, to

meet demand, stay competitive and control operational costs,” she said.

While the benefits of automation are clear, getting started can be a challenge, admits Gerbitz. “While warehouses typically like to begin with something tangible and flashy, the first step should be to ensure that your data is in order,” he said. “Warehouse automation requires readily available and accurate data. How much inventory is on hand? Where is it? What orders are coming in? Once the data is stable, we can begin to look at order profiles: orders per day, lines per order, items per line. Based on this information we need to answer two questions: what SKUs are needed and where do they need to go? Automation systems then execute on these answers.”

Clearly, warehouse managers have a lot of homework to do before implementing any solution. According to Chung, automation begins with identifying the problem that needs to be solved. Doing so will narrow your focus and help you identify the technologies and solutions that make the most sense for your specific warehousing needs.

Another key consideration is where to begin the automation process? Determining where a warehouse will see the most bang for their buck. “Many warehouses start with automating their order picking and fulfillment operations, often the most labour-intensive, costly and time-consuming task,” said Chung. “Deploying AMRs (autonomous mobile robots) to assist human pickers, for example, offers an immediate productivity boost and a fast return on investment without needing to fully redesign the warehouse and spend millions upfront. In addition, it helps improve worker ergonomics, safety and even retention. It’s a logical, scalable first step that allows facilities to gradually expand automation throughout the operation.”

While warehouse automation isn’t a new or novel idea, we’re seeing new technologies emerging with innovative features and advanced capabilities. Innovations like AI-driven robotics, fully automated fulfillment systems and orchestration software are rapidly reshaping warehouses, Chung explained. “We’re also seeing

strong interest in solutions that integrate physical AI – the merging of physical robotics and the latest advances in artificial intelligence – to make warehouse operations smarter, more adaptive and increasingly autonomous.”

Locus Robotics recently introduced LocusINTELLIGENCE, a data science and analytics platform that uses AI to deliver real-time operational insights to optimize warehouse performance. “It provides operators with actionable dashboards, predictive analytics, and performance benchmarking, helping operators make smarter, faster decisions,” said Chung. With this new technology, Locus hopes businesses will gain full visibility into productivity trends, workflow efficiency and ROI metrics, facilitating continuous improvement across their operations.

While we often think of warehouse automation as a way to reduce the number of employees needed to get the job done, Gerbitz noted that in today’s business environment, that’s not always the goal anymore.

“In the past, reduction in headcount was desirable,” he said. “Currently, because labour is more difficult to find, distribution centres need to do more with less. Instead of reducing headcount, they need to make the operation work with a limited labour supply. All of this contributes to maintaining and increasing throughput with the same number, or fewer employees.”

Accuracy is another critical component to consider. “In the case of a mis-pick, this can lead to costly returns or lost customers,” he explained. “In a manufacturing environment, incorrect components can lead to downtime. These have costs.”

Finally, Gerbitz explains that the data collected can also contribute to ROI. “Acquiring data throughout the fulfillment process can streamline other processes related to lot tracking, serial number capture, and item validation,” he said.

When calculating ROI, Chung noted that it’s important to look at how automation improves efficiency, throughput and accuracy while reducing labour dependency and operating costs. She added that ROI can be calculated through a combination of factors: faster order fulfillment, fewer errors, better space utilization, lower

turnover costs and reduced overtime or sick leave expenses. When considering all of these factors, customers can see productivity improvements upwards of two to three times what they would achieve purely through manual operations, simply by utilizing these automated solutions.

Unless all warehousing tasks are performed by robots and computers, there’s always going to be a need for cooperation between employees and their non-human counterparts. Furthermore, whenever man and machine work together, safety becomes a key concern.

Chung agreed that collaboration and worker safety are critical for successful warehouse automation. “Robots that are designed to work alongside humans, augmenting their capabilities rather than replacing them, need to be safe and not intimidating,” she said. Locus focused heavily on making their robots user friendly with an approachable training process, not only saving time and resources but ensuring easy-adoption by workers.

As we think about the future of warehousing, we may well wonder whether we’ll see the day when humans will no longer have to work with robots or machines. In other words, will we see the day when all warehouses are fully-automated, and where humans are no longer needed?

According to Gerbitz, we are already there. “Fully-automated ‘lights out’ facilities exist today,” he said. While that may be true, Gerbitz notes that there’s a major caveat to consider. “This requires a very high level of product consistency (i.e. predictable and consistent shape and size). As automation improves, handling of exceptions and irregular items will be better handled by automation.”

That said, Gerbitz believes that there will always be a place for humans in the process, although the role humans play will continue to change over time.

Chung agreed. “The warehouse of the future will be highly-automated, but humans will still play a vital role,” she said. “Automation will handle the repetitive, physically-demanding tasks, while humans will focus on problem solving, managing operations and optimizing workflows. The future is about finding the perfect balance between human capability and machine efficiency.” | MA

BY GAVIN VERREYNE

Most manufacturers, especially in the mid-market, may feel they’re already behind the artificial intelligence (AI) adoption curve, given the pressure they are under to deploy some level of AI. While it’s true that four in five manufacturers have plans for AI, according to SYSPRO research with Frost & Sullivan, less than one in five complex manufacturers have already adopted AI or are in the process of deployment. It is reasonable to assume the figure is even lower than that in the mid-market manufacturing sector.

What’s more, according to research in the Harvard Business Review, four in five AI projects fail. Manufacturers who are just getting started on their AI journey need not worry. Especially with such a massively influential, disruptive technology, it’s a good idea to spend some time understanding and researching the value of AI for each business. The maturity of the AI technology alongside the organization’s maturity in adopting any new technology should be considered before deployment. Maturing and planning increases the chance of seeing success and rapid ROI. Those who jump in headfirst and deploy AI primarily for the sake of deploying AI are unlikely to succeed.

Today, however, there are several immediate use cases for AI where manufacturers can almost immediately begin seeing value. Some of the most interesting include:

• Schedule and resource allocation optimization: Machine learning can analyze schedules, HR data and other information to streamline production, increase throughput and reduce costs.

• Predictive maintenance: Predictive AI can learn from past work orders, IoT data from equipment, production information and other sources to understand when machines require maintenance to avoid failure and decrease unexpected downtime.

• Demand forecasting: Especially in this era of rapidly changing tariffs, it’s more important than ever to know how much product to produce

to meet future demand. Predictive AI can analyze historical data along with current information to ensure inventories remain at appropriate levels.

• Quality assurance: AI-powered vision systems can identify product defects in real time to increase customer satisfaction and avoid costly recalls.

• Real-time insights and analytics: Analytic AI can leverage company data to provide timely insights that empower data-driven decision making. As a result, managers can make key decisions faster, more accurately and with more confidence.

• Create new design concepts : Generative AI can analyze large datasets, including existing designs, to rapidly create new concepts for new products, accelerating the process of generating initial ideas.

While identifying a solid use case is just the first step, it is arguably the most important phase of a manufacturer’s AI journey. It is critical to create a strong business case for AI that solves a real problem. Doing this will avoid the common mistake that typically results in a failed project: deploying AI without a clear plan for using it to generate ROI.

For the first project, start small while remaining confident in the ability of the project to create value. A pilot project is ideal. AI can be complex, so IT should not work in a vacuum or bite off more than they can chew. With a first successful project, the goodwill and trust created among key stakeholders and the lessons learned to tackle more ambitious goals, IT can embark on bigger and more impactful AI projects.

The next order of business is ensuring the data AI will use is clean, available and sufficient. If data is disconnected in multiple silos, creating proper learning models for AI will be difficult, to say the least. Make use of as much data as is needed to facilitate the successful outputs expected from

AI. Generally speaking, the more specific and contextual data you provide, the more relevant the results will be.

One way to speed up the process of data cleaning and consolidation is to employ AI solutions that are built or integrated into platforms such as the ERP, which will mostly use ERP data. The data in the ERP should already be clean and accessible, and, for many manufacturers, most company data lives in that platform already. This also creates feedback loops for measuring result integrity, based on the amount of trusted data in the ERP. If more data is required, typically it’s not difficult to connect AI embedded in ERP platforms to additional sources. If IT is not using embedded AI, prioritize integration with other systems. This ensures that AI complements existing systems rather than replacing them outright.

Understanding the different types of AI and available technologies is key, as using the right tool for your purpose is important. As noted earlier, generative AI is very hot, but it’s unlikely to be the right solution for most manufacturing use cases. Predictive AI, analytic AI, machine learning and even emerging small language models (SLM) as opposed to the more well-known large language models (LLMs) may be more appropriate and more feasible.

Finally, don’t forget the human element. You need a plan to get buy-in from all stakeholders, including the C-suite, managers and staff who will be impacted, and, during execution, involve them in the implementation. No matter how intuitive the tools may seem, train your people on how to use them. Employees are often intimidated or suspicious of AI, and, without training, they may avoid using them, which means you’re unlikely to see any value at all from the project. Think of AI as a team sport!

Far from being too late, manufacturers who are just beginning their AI journey are in a perfect position to leverage this transformative new technology. Start small, identify a strong business case, understand the technology and then take the appropriate technical and organizational steps to ensure success. | MA

Among large manufacturers, automation of supply chain management is common. SMEs are lagging behind but poised to ‘leapfrog’ into adoption. Here’s how.

BY TREENA HEIN

Automation within the supply chain is growing, with each aspect, including sourcing, manufacturing, order and inventory management, sales and delivery of product, reaping the benefits of continued innovation.

Some of these benefits stem from robotic process automation software, or RPA. For many manufacturers, RPA bots now handle repetitive tasks such as filling in forms, funnelling sales inquiries, moving files and more – and they do it all around the clock.

Currently, roughly 50 to 60 per cent of large manufacturers are now using RPA, according to Daniel Cascone, vice president and senior partner at IBM Consulting Canada, and Marc Haesen, partner at the Global Industrial Manufacturing Center of Excellence, IBM Consulting. And while the adoption rate among Small & Medium Enterprises (SMEs) is significantly lower, with IBM reporting

only about 10 to 20 per cent of SMEs utilizing the technology, that is expected to change.

This is because, like other simple software systems out there, RPA bots are now being employed in conjunction with AI. Cascone and Haesen report that AI technology in supply chain management is now more accessible than RPA and, because of AI’s ease of integration and broad applicability, “SMEs in particular may embrace AI faster than RPA”, Cascone reported.

In short, as AI’s power grows, the ROI of automating more supply chain management is rapidly coming within SME reach, allowing these firms to leapfrog over the RPA stage to attain a wider array of supply chain automation benefits.

The AI difference

Through aspects like machine learning, natural language processing and computer vision, AI greatly surpasses simple rule-based RPA

functionality. RPA carries out straightforward defined tasks, while AI systems, called AI agents in the supply chain context, examine the data provided to them for patterns, irregularities and more. As they learn over time, AI can change the code of RPA bots so they’re not only better able to handle tasks, but they can take on more tasks and tasks with greater complexity. This represents a true paradigm shift, allowing companies to automate not just tasks but entire processes.

However, Amber Salley, VP of industry solutions at GAINSystems, cautioned that while these entities decide and act, they don’t replace human expertise, only augment it. “Human surveillance is still essential to validate assumptions, avoid scope creep and ensure output fidelity,” she explained. “While the potential is transformational, this new model requires trust, transparency and grounded implementation.”

As to where these systems will make the biggest improvements in supply chain management, Cascone and Haesen first flag customer service. “AI agents are redefining customer service and operations by delivering a new, seamless digital experience for both customers and employees,” Haesen explained. According to a study by the IBM Institute for Business Value, organizations employing AI agents in customer service have seen a 60 per cent improvement in first-contact resolution.

AI agents will also have a large impact on supply chain management in general proactive monitoring and issue detection across a range of areas. “In the long term, AI will play a pivotal role in monitoring KPIs and other key metrics in real time,” said Haesen. “It will proactively alert teams to potential issues well before they become apparent, enabling faster decision-making and reducing disruptions.” He added that, “as AI adoption matures, it will help address complex data quality issues that are difficult to handle manually. By improving data accuracy, companies can enhance operational efficiency and achieve deeper optimization across their supply chain.”

As is the case with implementing any new automated system, company leaders need to ensure their workforces transition effectively as AI and RPA take over some of their supply chain management work. In practice, Salley said this means managers will need to reframe roles, moving employees from transactional tasks to outcome ownership. “Teach teams to interpret AI outputs and model what-if scenarios,” Salley said. “Also, create review loops. That is, build structured processes for validating AI-generated actions and refining models through human judgment.”

In Cascone’s view, an effective initial approach is to provide a select employee with AI tools. “Encourage someone to start using it and demonstrate where these tools are beneficial and where human supervision is still necessary,” he said.

Cascone and Haesen recommend asking two key questions. “First, what repetitive tasks require significant staffing and demand more attention and effort than desired?” said Cascone. “By augmenting these tasks with RPA and AI, employees can focus on more strategic tasks and productivity will improve.”

Second, look at tasks that your organization should be tackling to streamline management of the supply chain, but has not prioritized due to the high level of resources required. “By addressing these two questions organizations can unlock opportunities to streamline operations, empower employees and focus on high-impact initiatives,” said Haesen.

Although many AI supply chain applications are still in the prototype stage or just beyond it, IBM says adoption is poised to boom. A recent IBM survey shows that 56 per cent of Canadian respondents plan to increase AI investment in 2025. Looking five years ahead, AI adoption and implementation into the supply chain is expected to be five orders of magnitude larger than today, with many large firms expected to find effective use cases in the next 12-24 months.

Salley concurs. “Within 12–24 months, we’ll see proven AI applications in forecasting, inventory balancing and lead-time prediction,” she said. “But success depends on modular, composable systems that evolve over time. It’ll also require leaders who understand that even the best AI needs human partnership to be effective.” She added that within the next two years, AI will streamline forecasting, automate replenishment and

predict disruptions. In five, “expect intelligent networks that self-optimize, which is adapting in real time across design, planning and operations,” Salley said. “But that future hinges on blending AI with experience, not replacing it.”

Meanwhile, AI in the supply chain is expected to follow the historic pathway of other technologies. “As AI companies

gain experience deploying their tools, and clients become more familiar using them, the cost and effort required to deploy them are expected to decrease,” explained Haesen and Cascone. “At the same time, clients’ confidence and willingness to adopt AI are likely to grow as they see its effectiveness and the tangible benefits it delivers.” | MA

BY MARCELO PINTO

While the drive to merge IT and OT systems in manufacturing certainly boosts efficiency, this integration creates significant new cybersecurity vulnerabilities. Real-world attacks, ranging from production-halting ransomware to direct manipulation of machinery, painfully illustrate that traditional IT security measures often miss the mark in OT settings. Different environments demand different approaches. Recognizing this gap, industry-specific frameworks like ISA/IEC 62443 are becoming essential tools for protecting industrial operations. Privileged Access Management (PAM) plays a critical role here. Far from being just another checkbox, controlling privileged access is truly fundamental to managing the unique risks inherent in OT.

Understanding the ISA/IEC 62443 approach

Priorities within OT systems look quite different from the usual IT concerns. Operational technology heavily emphasizes safety, uptime (availability) and the trustworthiness of data and processes (integrity), often ranking confidentiality lower. This focus exists for good reason: any small disruption, unauthorized adjustment, or safety failure in an OT environment can cascade into major operational problems, significant financial loss and potentially physical harm.

To navigate these specific challenges, the ISA/IEC 62443 standards provide a structured, risk-aware methodology tailored for OT. Some core ideas include:

• Zones and conduits : Breaking the network into logical chunks (zones) and carefully controlling the connections between them (conduits) helps limit and watch data flow.

• Security levels (SL): These levels,

from basic (SL1) to highly protected (SL4), define how strong security needs to be for different zones based on the risks involved.

Far from being just another checkbox, controlling privileged access is truly fundamental to managing the unique risks inherent in OT.

• Foundational requirements (FR) : ISA/IEC 62443 outlines seven key areas, like controlling who can log in, what they can do once logged in and restricting data movement.

Putting these requirements into practice demands real, practical security steps, especially when it comes to controlling and monitoring privileged access.

So, how does PAM specifically help tackle OT security headaches, especially in line with ISA/IEC 62443? It hits several key areas:

• Dealing with shared logins : Lots of OT systems still use generic or shared accounts, making it impossible to know who did what.

PAM tools fix this by storing these credentials securely, tracking their use and linking every action back to a specific person. This vastly improves accountability.

• Managing widespread privileged access: In OT, engineers, maintenance crews and outside vendors often need privileged access. PAM pulls control of this access into one place, making it easier to see who has what permissions and enforcing strict rules.

• Securing vendor remote access: Letting third parties connect remotely is often necessary for support, but it opens a risky door. PAM systems offer fine-grained control. Vendors can be allowed access only during specific times, to specific machines, while everything they do is watched and recorded. This is much safer than older VPN methods.

• Handling hardcoded credentials: It’s common for passwords or API keys to be embedded directly in

applications or automation scripts – a major vulnerability. PAM keeps these secrets safe, only providing them when needed, instead of storing them insecurely.

• Acting as a gateway for OT protocols: Many older or specialized OT protocols (like Modbus, Profinet, S7) weren’t built with security in mind. PAM solutions can act as secure gatekeepers, applying strong access rules and keeping audit trails even for these tricky systems.

Getting PAM into an industrial setting isn’t always easy. You might face pushback, deal with old equipment and absolutely cannot afford downtime. Here are some practical ways to make it work:

• Choose agentless options : Look for PAM setups that use gateways or proxies. This avoids needing to install software directly on sensitive or old OT devices.

• Roll it out in phases : Don’t try to do everything at once. Start with less critical systems or a specific problem, like securing vendor access. Build on success.

• Minimize impact: Make sure the PAM system itself doesn’t slow things down or become a single point of failure that could halt operations.

• Get everyone talking: Good communication between the OT experts, IT teams, and security folks right from the start is key. This ensures the PAM solution respects how things actually work on the factory floor.

Today’s factories and industrial plants are

more connected than ever, making strong cybersecurity non-negotiable for staying safe and operational. Standards like ISA/ IEC 62443 give us the blueprint. But blueprints need tools to become reality, and that’s where Privileged Access Management becomes essential. By locking down who can

access sensitive OT systems, tracking what they do and managing critical passwords securely, PAM makes a massive difference in security. For manufacturers serious about protecting their operations, PAM isn’t just about ticking a compliance box – it’s a smart move to safeguard their future. | MA

The winners of this year’s Top 10 Under 40 contest share their stories and provide insight into the current state of the manufacturing industry. BY JARED DODDS

This year’s Top 10 Under 40 winners highlight the next generation of industry leaders, marked by their drive, commitment to excellence, hunger for innovation and dedication to positivity in the workplace.

Whether on the shop floor or leading a company of their own, these individuals are highly regarded by their superiors and peers and recognized for their work ethic and performance.

Congratulations to this year’s winners!

ADELE SHAW

Technical Specialist –Production Engineering, TRQSS

What does your experience in the industry encompass, and what brought you to the field?

My father and older sister are both engineers, so I decided to follow in their footsteps and pursue a degree in engineering. I attended Carleton University in Ottawa and received my bachelor’s degree in biomedical electrical engineering with a minor in mathematics. It was exactly as difficult as it sounds, but I loved the challenge and discipline.

As a technical speciality – production engineer for TRQSS, my responsibilities include sourcing and maintaining specialized

production equipment and initiating process improvements while meeting stringent quality targets. I enjoy the challenges in this field of work and have been recognized for my initiative, tenacity, and drive for continuous learning as well as for my calm composure, positive outlook and quick action during high pressure situations.

What do you feel your industry does well today and where could there be some improvement?

Today’s automotive manufacturing industry is dedicated to continuous improvement by prioritizing consistency and efficiency. This focus enables better resource utilization, saving both time and labour, which in turn helps lower production costs. As a result, quality becomes a key emphasis, as poor quality can lead to waste, downtime and even failure to meet safety standards. To achieve these goals, the industry is constantly adopting new advancement in technology, unafraid to experiment and lead the way.

I believe that the automotive industry could show improvement through prioritizing sustainable practices. Not just the development of future electric vehicles,

but a focus on facilities and suppliers making an effort to be more sustainable. This can be done through CO2 reduction activities, implementing green technologies, and investing in employee education and engagement.

ZAC CUTT Research and Development Group Leader, Innovative Automation

What does your experience in the industry encompass, and what brought you to the field?

I studied mechanical design and began my career at Innovative Automation in the machine shop, fabricating parts for our custom automation systems. Within my first year, I began splitting my time in the mechanical design

department, and, for the next four years, I worked across both areas— design and machining—while earning my General Machinist Trade Ticket.

In 2019, I transitioned fulltime into our newly formed R&D department, where I was part of the small team that developed the RoboTape system from the ground up. I stepped into the R&D leadership role between 2020 and 2023, beginning work on a new automation concept. I helped assemble the team and guide development, and within just a year and a half, we brought that new product—RoboClip—to market.

What do you feel your industry does well today and where could there be some improvement?

What we do well is adapt—we’re always pushing forward with new technologies, and the pace of innovation is impressive. That said, keeping up with new tech can be challenging, and it’s something we need to be intentional about. Staying connected through networking, trade shows and digital platforms is critical to staying relevant.

One area I think we could improve is attracting the next generation. I was lucky to stumble into this field, but I often wonder how many talented builders, engineers, or programmers never get exposed to automation as a career path. We need to do a better job of reaching high school and college students early, showing them what’s possible and making the industry more visible and accessible.

Technical Specialist –Production Engineering, TRQSS

What does your experience in the industry encompass, and what brought you to the field?

I studied mechanical engineering with a specialization in aerospace engineering at the University of Windsor. Currently, I am working in the automotive industry where I get the opportunity to design, implement and improve manufacturing methods and processes while adhering to stringent safety standards. From small 20-minute troubleshooting sessions to multiyear-long equipment development projects, seeing a positive impact around the workplace and being able to improve one’s job or increase a machines output, all while maintaining quality, is very fulfilling.

What do you feel your industry does well today and where could there be some improvement?

In my experience, I believe the industry shows strong adaptability to market changes such as shifts in customer demand, technological advancements and new platforms. Whether it’s responding to increased interest in EV’s or reconfiguring production equipment for new vehicle models, the industry stays flexible and remains aligned with the competitive and fast-paced market.

With the rapidly changing and increasingly-complex technology

that is available across the industry, an area for improvement is developing a skilled workforce capable of keeping pace with the volume and complexity of these new systems. As automation and AI continue to evolve, I believe it will be essential to have a trained and well-educated workforce capable of supporting industry growth.

HAJRA SHAFIQ Project Manager, Samuel Automation

What does your experience in the industry encompass, and what brought you to the field?

I have a degree in mechatronics engineering from University of Waterloo. My program involved a number of co-op placements, most taking place in the manufacturing industry, more specifically in the automotive sector. After beginning in the field working in controls as a programmer, I transitioned to process engineering and eventually moved into a project management role, launching automotive projects for internal customers improving aspects of production, safety, quality and efficiency.

What do you feel your industry does well today and where could there be some improvement?

Automation systems have revolutionized the manufacturing environment: improving efficiency, consistency, and safety for team members. The flexibility and level

of customization available allows solutions to fit the ever-changing demands of today’s work environment.

The industry could benefit from an increased level of data collection, control and monitoring to allow us to elevate existing processes and provide additional value.

What does your experience in the industry encompass, and what brought you to the field?

I went to Conestoga College for their mechanical engineeringautomation and robotics program, with the intention of moving into industrial controls. During this experience I discovered the satisfaction of building things with your own hands, instead of only on a computer screen, which led to my transition into welding during a sojourn in Alberta and brought those skills with me back to Ontario, where I’ve been given the opportunity to expand my skills into machining and fitting, as well as expanding my welding experience into TIG and using some of my design skills from college. It has been an interesting journey thus far from behind a keyboard to actually building the parts that make the design come alive.

What do you feel your industry does well today and where could there be some improvement?

I think this industry is keeping alive the tradition of high-quality goods produced in Canada, an important capability to maintain. I think we need to continue to invest in supporting young people entering into trades so that the industry can continue to thrive, and to pass on the tribal knowledge of our experienced tradespeople before they retire and it is lost.

What does your experience in the industry encompass, and what brought you to the field?

I am a pioneer in industrial automation and the co-founder and CTO of Clearpath Robotics by Rockwell Automation and OTTO by Rockwell Automation. In 2009, after completing my mechatronics engineering degree at the University of Waterloo, I co-founded Clearpath with three classmates. In 2015 we established OTTO, the industrial division that brought Clearpath’s autonomous technology to the manufacturing industry—developing material handling solutions that increase safety and efficiency in production environments. Our success led to both businesses being acquired by Rockwell Automation in 2023.

I am also a board member of the Open Source Robotics Foundation, co-founder of ROSCon, and co-founder and co-chair of the Canadian Robotics Council.

What do you feel your industry does well today and where could there be some improvement?

The industrial automation industry excels at understanding the diverse needs of manufacturing customers and delivering trusted, reliable, and scalable solutions that integrate seamlessly into their operations. However, there’s room to improve how we balance the strengths of traditional industrial automation with the agility and innovative spirit of startups—even if their fast-paced, experimental approach doesn’t always align with the reliability needs of their customers. The industry can also draw insights from advancements in software —an area that has evolved significantly since industrial automation first emerged—as well as from the open-source community and academic research. Thoughtfully integrating these influences can help accelerate progress while maintaining the trust and dependability the industry requires.

PABLO MOLINA, CTO and Co-Founder, AvidBots

What does your experience in the industry encompass, and what brought you to the field?

My passion for robotics began

during my undergraduate studies at the University of Waterloo, where I earned a bachelor of applied science in mechatronics engineering with a physics option. I later went b ack to the to school to earn my master’s degree in aerospace engineering, specializing in space robotics, from Carleton University. Following my studies, I applied my knowledge at Neptec Design Group as an autonomous navigation engineer designing moon rovers for the Canadian Space Agency.

In 2014 I co-founded Avidbots with Faizan Sheikh and have led the product and engineering teams ever since. I actively participate in developing international robotics safety standards as part of the IEC SC61J group and support the robotics community as a board member and co-chair of the industrial committee at the Canadian Robotics Council.

What do you feel your industry does well today and where could there be some improvement?

Canada stands at a critical crossroads for robotics. The country boasts exceptional talent, strong educational institutions and robust support for early-stage startups. However, outside of the country’s automotive sector, Canada has the lowest robotics adoption rate among G20 nations and lacks dedicated programs to support the commercialization, scaling and broader adoption of robotics and automation.

To secure a sustainable position in the rapidly expanding global robotics economy, Canada needs a comprehensive national robotics strategy. This strategy should aim to promote wider robotics adoption and actively support the growth and commercialization of scale-ups.

What does your experience in the industry encompass, and what brought you to the field?

I am a mechatronic engineer with a Certified Functional Safety Expert (CFSE) certification, currently serving as product manager – automation for the Americas at Wieland Electric. I’ve worked across many areas of automation, including helping engineers design safe systems, assessing risks on machinery and ensuring safety meets international standards. I have been recognized throughout my career for leading high-impact safety and automation initiatives, including receiving the MS&TSTAR (Manufacturing Science and Technology Star) award for a safety automation project. I am passionate about sharing knowledge by leading training sessions and webinars to assist OEMs, integrators and end users navigate the complexities of machine safety and automation standards.

What do you feel your industry does well today and where could there be some improvement?

The industrial automation and machine safety industries do a great job of continuously innovating to keep up with new technologies and regulatory demands. There’s a strong focus on creating smarter, more connected systems that improve productivity and

operator safety.

However, many end users, especially those in small and mid-sized companies, often find it tricky to apply safety standards effectively. There’s a great opportunity to make things easier for everyone by bridging the gap between technical complexity and practical implementation. We need to simplify access to training, tools and guidance to make safe automation more approachable and scalable for all companies, not just the largest players.

What does your experience in the industry encompass, and what brought you to the field?

I am the head of growth at Real Life Robotics, a Canadian company transforming last-mile logistics through autonomous delivery solutions. I lead strategic public-private partnerships and citizen-first pilot programs, including Canada’s first municipally sanctioned sidewalk robot delivery deployment, supported by OVIN, Rogers and the City of Markham.

Over the past decade, I have worked across the last-mile, automation and quick commerce sectors, helping early-stage ventures launch, expand and commercialize innovative delivery models. I held a leadership role at Tiny Mile, and my work has contributed to over $20 million USD in last-mile food delivery sales for some of Canada’s leading food brands.

What do you feel your industry does well today and where could there be some improvement?

In recent years, the robotics and automation space has gotten much better at iterating and self-correcting. As an industry, we’ve become open to identifying our blind spots, learning from real-world deployment and improving quickly, especially when it comes to collaborating with regulators and government partners.

However, there’s still a persistent blind spot in how we prepare people for this industry. We train technical talent incredibly well, but we rarely teach them how to explain what they’re building, who it’s for, or how to commercialize it. We need to be teaching the next generation of robotics professionals about

the power of storytelling and public communication and how to build trust with technical stakeholders.

ANDREW WESTCOTT

Vision Team Lead, ATS Automation

What does your experience in the industry encompass, and what brought you to the field?

I’m a team lead in the vision

engineering department at ATS, within the life sciences systems group. With a background in engineering, physics, imaging and artificial intelligence, I find that machine vision is a perfect blend of my interests and expertise. My team and I specialize in designing, programming and integrating advanced machine vision systems for the automation solutions that ATS provides. I truly appreciate the incredible variety in our projects—whether it’s the wide range of life-improving end products we work with or the cutting-edge technologies we use, there is always something new to learn.

What do you feel your industry does well today and where could there be some improvement?

One of the greatest strengths of our industry is the people — smart, driven and collaborative individuals who work together to draw from their diverse expertise, specialties and experience. An evolving challenge facing our customers is the need for reducing their product timeto-market. To meet that need, early collaboration between the machine builders and the manufacturers is becoming more critical. Engagement prior to a mature product design and manufacturing process allows for collaboration on product design for automation – however it requires a high level of agility and flexibility from both parties. This is driving increased focus on improving standardization and modularity in the automation “building blocks” we draw upon when designing solutions. | MA

Canada shines as partner country, while companies take advantage of international exposure in the face of U.S. tariffs.

The yearly tradition of Hannover Messe is a trade show unlike any other in the manufacturing industry, unmatched in scale and scope. At this year’s event, more than 200,000 attendees and exhibitors from around 150 nations descended on Hanover, Germany to establish relationships, generate business opportunities and learn more about the latest and greatest in industrial technology.

For Canadians, however, the 2025 show held special significance, as for the first time Canada was selected as the partner country, presenting a unique opportunity to highlight the nation’s economic growth potential, robust manufacturing sector and commitment to sustainability.

Canada’s theme for the event was ‘The future’s here’, a statement which has proven to be prescient for reasons no one could have predicted when the country was selected as the partner

nation in 2022. With the negative economic impact stemming from U.S. tariffs looming, the future and all the uncertainty associated with it has certainly arrived.

As the relationship with Canada’s largest trading partner becomes more and more strained and the economy suffers the consequences associated with that tension, events like Hannover Messe become critical for Canadian businesses and regions to establish partnerships internationally and build resilience across the sector.

Andreas Sobotta, chief executive officer of Pilz Automation Safety Canada, said this message was echoed not only by Canadians in attendance but European attendees as well.

“It was a good time to promote Canada. Germany and the European Union made the same mistake as Canadians did, we were just relying on business with the U.S., not looking for other opportunities because it was

Canada’s partner country status opened the door to more conversations and collaboration with international attendees.

convenient,” Sobotta said. “Now we have to look for other opportunities, which then makes them mutual business opportunities between Europe and Canada.”

A large aspect of that promotion included educating those in attendance about the Canadian market, the level of industrialization that has taken place here and the mutual benefits available from these business opportunities.

“One of the things I heard there is ‘I didn’t know Canada had an industry.’ A lot of Europeans, if they hear someone is a North American company they assume they are American,” he said. “Canada is an important industrial automation market, and not everybody knows that because, in the past, we have been shy in promoting how great Canada is.

“We must not forget to stay as friendly and kind as we are, but you have to push a little bit and say

Canada is something worthwhile to invest in,” Sobotta said.

Our citizen’s famed friendly tone permeated throughout the Canadian pavilion and was reciprocated by attendees, reported Simon Gill and Jacquie Severs, both in attendance representing Invest Durham, an organization supporting and promoting Ontario’s Durham region and its business ecosystem.

“On opening night there was a ceremony for the show, and the Chancellor of Germany spoke, Canada’s special envoy to the EU Stéphane Dion spoke, Germany’s state government leader spoke, and every single one of them was overjoyed to have a partner in Canada present at the show,” Gill said. “It felt like we had friends there.”

Severs said the highlight of the trade show was having the chance to represent Canada, and the opportunity to collaborate with different organizations across the country.

“There were so many different government organizations, businesses, educational institutions and innovation hubs, not just from our [Invest Durham] booth but from Canada more broadly,” she said. “It’s

an environment where the products are quite serious, with multi-million robots and other products on the floor. You could approach that in quite a serious way if you wanted. But I think Canada did a really good job balancing that with a sense of fun that made the experience memorable.”

Despite the looming threat of a trade war, technology still took centre stage at Hannover. Invest Durham brought multiple projects with them to the event, including Project Arrow 2.0, an entirely Canadian-made electric car designed by a team at Ontario Tech University, who have now been chosen to continue with the project as the official research and build partner.

Artificial intelligence (AI) was a major theme of the event, with one Canadian highlight including Maple Advanced Robotics from Richmond Hill, Ont. take home the 2025 Robotics Award for its AI-driven robotics platform MARI AARS.

Other award winners include Siemens, who won the HERMES Award in recognition of its AI-powered industrial copilots and Sarcomere Dynamics Inc. winning the Innovation World Cup 2025 robotics category.

Chancellor of Germany Olaf Scholz sitting in Project Arrow 2.0, an entirely Canadian-made electric car.

Despite closing the books on Canada’s partner country status, Gill said they would be back in the future, even if that requires sending a smaller team, because of the value the event provides.

“It’s the greatest way to be able to meet with a number of companies within that space all at once,” he said. “We’re certainly going to be there to meet with companies and we’re certainly going to be there in partnership with our provincial and Canadian colleagues.” | MA

Advanced imaging and detection technology manufacturer Exosens has launched the Dione XP series under its infrared imaging brand Xenics. This new long-wave infrared (LWIR) SWaP core camera marks a significant milestone in the group’s ongoing commitment to delivering high-performance, compact imaging solutions for demanding applications. The Dione XP series is a VGA (640 × 480) LWIR camera core specifically developed to meet the increasing demand for Size, Weight, Power, and Cost-efficiency (SWaP-C) without compromising performance. The Dione XP series integrates a number of image enhancement capabilities, including XLIE (Xenics Local Image Enhancement) algorithms, edge detection, column noise filtering, extended temperature calibration, and automatic calpack switching. Equipped with a 640 × 480 microbolometer sensor and 12 µm pixel pitch, the camera achieves NETD values of 35 mK or 40 mK, depending on the model. www.exosens.com

CMMT servo drive and motor combination

Festo has introduced a new developer’s kit designed to help controls engineers and programmers familiarize themselves with setting up and commissioning a CMMT servo

and motor combination. The kit includes a CMMT-ST DC drive, EMMT-ST stepper motor, cables, connectors and access to Festo’s multiprotocol family of servo drives that range from 300 W DC up to 12 kW AC. Each of these developer’s kits contains a CMMT-ST 300 W servo drive, EMMT-ST stepper motor with battery-free multi-turn absolute encoder, motor cable and connectors. CMMT-ST servo drives feature integrated safety function safe torque off, fast and easy commissioning with Festo automation suite, data monitoring, dynamic, pointto-point and interpolating movement, control of bldc, stepper and ec motors, direct and secure cloud connectivity and compact design.

The EMMT-ST stepper motor features an absolute encoder, IP65 protection, optional holding brake and control via a single cable. QR codes included with the developer’s starter kit link to Festo Automation Suite software for commissioning and Electric Motion Sizing software for sizing components for the application. All Festo CMMT-ST DC and CMMT-AS AC servo drives are compatible with EtherNet/ IP, EtherCAT, PROFINET, and Modbus TCP protocols. www.festo.com

AutomationDirect has added Helukabel’s HELUKAT industrial ethernet and Profinet cables featuring a halogen-free, flame retardant and durable construction built to support a variety of industrial requirements. New Type B, Type B Hybrid (with power conductors), Type R and Type C Profinet cables are designed to provide data transmission in dynamic or harsh industrial applications while protecting against environmental factors like oil, chemicals, and abrasion. Tray rated, flexible, and continuous flexing versions are offered, the company reported in a press statement. HELUKAT industrial Ethernet cables of varying flexibility have also been added, with Cat5, Cat5e, Cat6, Cat6a, Cat7, Cat7a, and Cat7e versions available to serve a wide range of industrial and robotic applications. www.automationdirect.com

SCARA robot manufacturer Epson Robots is expanding its SCARA lineup with the new GX-C series, powered by the RC800A controller featuring SafeSense technology. The series includes the GX4C, GX8C, GX10C and GX20C, with the entire series offering multiple arm configurations for increased productivity and worker protection while minimizing machine footprint. It also features GYROPLUS vibration reduction technology that helps optimize

workcell throughput with smooth motions and fast settling times, the company reported in a press statement. The RC800A robot controller is built to perform with industrial-rated safety features while optimizing runtime, recovery and error handling. When paired with proper risk assessment, Epson reports this technology enables human-robot interaction with requiring a safety fence, leading to the decreased footprint and overall cost of robotic automation systems. epson.com

Automation solutons provider Emerson has released DeltaV SaaS Supervisory Control and Data Acqusition (SCADA) with Edge Connect system, a preconfigured edge solution engineered to delivery more seamless operational technology (OT) data mobility out of the box. Designed to connect existing field devices to the system in minutes, the solution eliminates much of the traditional engineering work necessary to bring critical operational data into the control system for better visibility and safer, more flexible and reliable control. Built on Emerson’s PACEdge software

for edge computing, the DeltaV SaaS SCADA with Edge Connect edge solution can communicate with all field devices—remote terminal units, flow computers, valves, sensors and more—in their native protocols using an Emerson-tested third-party polling engine that eliminates the need for additional conversion or adapters. PACEdge provides an IIoT application enablement platform designed to integrate information technology and OT domains without disrupting OT assets, architectures or systems, the company reported in a press statement. Data buffering features allow the DeltaV SaaS SCADA with Edge Connect edge solution to store data during communication outages and send them when communication is restored so no data is lost. Dynamic polling resolution automatically changes

polling rates when events occur, helping ensure all critical data is delivered promptly. www.emerson.com

Murrelektronik has added a new member to the MVK Fusion hybrid fieldbus module family: The MVK Fusion CIP Safety. This module utilizes the Common Industrial Protocol Safety, allowing machine builders and system integrators to use this three in one approach for EtherNet/IP applications. The device features M12 L-coded power connections, making it ideal for space-constrained installations. Configuration of safety-related sensors and actuators is handled directly through the controller’s

engineering software, meaning no external tools are needed to transfer the Safety Network Number or device settings. The modules are IP67-rated and feature a fully encapsulated metal housing, making them resistant to shock, vibration and temperatures from -30 C to 60 C. www.murrelektronik.com

BY PAUL HOGENDOORN

Paul Hogendoorn is a serial entrepreneur that has built multiple manufacturing and manufacturing technology companies. He has been a regular contributing columnist for 15 years. For more insight or information from Paul on related topics, please contact paul@tpi-3.ca or visit TPI-3.ca

We have reached the time of the year when hockey is on almost every night. Every game is played with incredible intensity, every loose puck is fought over and every square foot of ice is battled for. Each team must win four games against an equally determined rival, just for the opportunity of going on to the next round and do it all over again. Only one team can lift the Stanley Cup and to do so they need to win 16 fiercely contested games. It is, in my opinion, the hardest prize to win in professional team sports.

Here’s what we as manufacturers can learn from the playoffs: the team with the best offence, the best defence and the best coaching usually wins. Put another way; to be the winning team, you need a good offence, a good defence and the right strategy delivered through great coaching. Take any one of these away and you are likely a runner up. If you take two of them away, you are an early round exit. Take away all three and you didn’t even make the playoffs.

Manufacturing is facing some gruelling challenges of its own, and to “win” requires the same ingredients: a strong offence, sound defence, a strategy that fits the situation and the team and coaching to bring the best out of the team’s players.

In my recent talk at the WMTS, titled Thriving in Challenging Times , I gave some examples of offence and defence. Defensive strategies include things like cash conservation, maintaining relationships with customers and personnel retention. Offensive strategies include sales and marketing efforts, identifying new products for existing customers or new potential customers for existing products and increasing the company’s core capabilities. Some strategies involve both offence and defence, including improving productivity and efficiency and upskilling yourself, your company and your team members. Improving productivity and efficiency can give you a cost advantage, helping you win more business or generate more profit on the business you do have. Upskilling

yourself, your company and your team members, is a great way to invest in your own future and put the company in the best position to compete in the long term.

Strategies should be designed to meet the specific challenges faced. Every company would do well to identify three or four distinct strategies for their offence and defence. Once you have done that, it’s a matter of coaching and execution.

Another slide in my talk at WMTS was on situational awareness, a key skill necessary to identify the strategies you can win with. There’s no sense in coming up with strategies that don’t match the team you have, require more resources than you have available or doesn’t get the right things done to win. You need to be aware of your team’s current capabilities and the specific details of the challenges you face, including the market, the competition and what your customers value the most. You also need a good sense of what your team may be capable of when encouraged, supported and stretched a bit and where

you want your team (company) to be in the future.

It’s important not to confuse “coaching” with “consulting”. Consultants may be helpful defining strategies, or retooling the team for the next year, but it’s the coaches’ job to help the players prepare for the now. Coaches are key to making sure their players are training and focused on being their best, as well as ensuring the team as a whole can play cohesively for the entire series. The players ultimately win the games, but it’s usually the best coached teams that win the last game and have the opportunity to hoist the cup above their heads.

Business, like the Stanley Cup playoffs, comes down to four things: a strong offence, solid defence, sound strategy and effective coaching. You need all four things to win, both in life and on the ice. When the 2025 Stanley Cup is awarded in June, it’s my prediction that you’ll see all four aspects reflected in the last team standing. | MA

Amplify Content Studio is a full-service custom content studio, helping companies share their story, build brand awareness and garner trust through original content.

There are so many ways to reach a target audience. We’ll craft you content for any medium:

• Thought leadership – long-form or short-form articles

• Blogs, whitepapers, infographics and case studies

• Webinars, podcasts and video

• Tradeshow marketing content

• Automated content marketing supported by first-party data ....and so much more!

EtherCAT P integrates EtherCAT communication with system and peripheral voltage supply in one 4-wire standard Ethernet cable. The I/O system for EtherCAT P with IP67 protection takes full advantage of One Cable

Automation: material and installation costs, as well as the required installation space in drag chains, cable trays and control cabinets are significantly reduced. The compact and robust I/O modules cover a wide signal range, from standard digital I/Os to complex analog signals and measurement technology. More than 100 additional EtherCAT P components are available. Find out more now!