THE MODULAR PLC

A

A

Jack Kazmierski

What do you think the future of manufacturing will look like?

I was recently at the 2024 Automate Show in Chicago where industry experts and thought leaders envisioned factory floors with efficient automated systems and processes and human beings in charge of highly-skilled tasks only. They envisioned a future that included more robots, more artificial intelligence (AI), more data, more connectivity and certainly more automation.

On the show floor itself this year, AI-related solutions and technologies and solutions dominated the aisles. At the same time, robots of every type, shape and size were visible all around.

Innovators in the automation space are certainly working zealously to improve the technologies of today and pave the way for that automated future that seems like a dream at present. An example of this was the presence of a couple of humanoid robots on the show floor. The industry, however, is still quite far away from seeing humanoid robots walking around in manufacturing facilities.

The real picture of today’s manufacturing facilities in Canada and around the world is still starkly different from that fantastically automated future that innovators have envisioned.

Not all manufacturing facilities are automated alike. While some businesses have invested heavily in automation, some have chosen to add a select few items based on specific needs. There is still plenty of scope for growth in this area. For example, yearly numbers from the International Federation of Robotics show that the adoption of industrial robots in Canada is far less than its North American counterparts and also well

behind many European and Asian countries. Canadian manufacturers in general have proceeded with caution when it comes to implementing automation. Many solution providers have shared that while the latest technologies interest potential customers, they often want to know if someone else has implemented them first. They want to hear about success stories. They want proof that the solution will work and bring in the promised rewards.

Where significant monetary investments are concerned, it is not wrong to tread with caution. While the cost of implementing certain automation solutions has indeed gone down over the years, it is by no means inexpensive. Interestingly, speakers at the Automate Show noted that while innovation can open up endless possibilities, automation should be considered for its very practical uses that address the ground realities.

So, it is perfectly sensible for manufacturers to evaluate and reevaluate any automation piece that they are considering for their facility. However, it is important to remember that in this very competitive global market, businesses that establish themselves as leaders sooner will have the edge. While automation technologies do not automatically guarantee that hold, they certainly pave the way for sustained success.

We live in an era where everything around us moves and changes quickly. It is worthwhile to take a pause and chart out the road ahead with a proper plan. Understanding the risks and the rewards of automation is key to achieving the desired results.

It could also be worth taking a wellplanned, carefully evaluated leap of faith once in a while to get that head-start in the global rat race. | MA

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: 416-510-5113

Fax: (416) 510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400

Toronto, ON M2H 3R1

EDITOR

Sukanya Ray Ghosh srayghosh@annexbusinessmedia.com Tel: 416-510-5225

ASSOCIATE PUBLISHER

Kathryn Swan kswan@annexbusinessmedia.com Tel: 647-339-4880

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

MEDIA DESIGNER

Emily Sun esun@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-510-5107

AUDIENCE DEVELOPMENT MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

Frank Defalco, Jack Kazmierski, James Figy, Jonathan Gross, Paul Hogendoorn and Treena Hein

Published by Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 • Fax: 416-442-2191

Printed in Canada ISSN 1480-2996 Publication Mail Agreement #40065710

SUBSCRIPTION RATES

Canada — $43.86 per year • $12.00 single copy United States — $99.96 CAD per year Foreign — $114.24 CAD per year

ANNEX PRIVACY OFFICER email: privacy@annexbusinessmedia.com Tel: 800-668-2374

EDITORIAL ADVISORY BOARD

JIM BERETTA, President, Customer Attraction and host of The Robot Industry Podcast

JONATHAN GROSS, Managaing Director, Pemeco Consulting

MIHAELA VLASEA, Associate Professor, Department of Mechanical and Mechatronics Engineering and Research Co-Director, Multi-Scale Additive Manufacturing Laboratory at the University of Waterloo

SHELLEY FELLOWS, Past-Chair, Automate Canada

STEPHANIE HOLKO Director, Project Development at Next Generation Manufacturing Canada

WALTER GARRISON, Former Advanced Manufacturing Business Consultant for City of Mississauga

Occasionally, Manufacturing AUTOMATION will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. The contents of Manufacturing AUTOMATION are © 2024 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

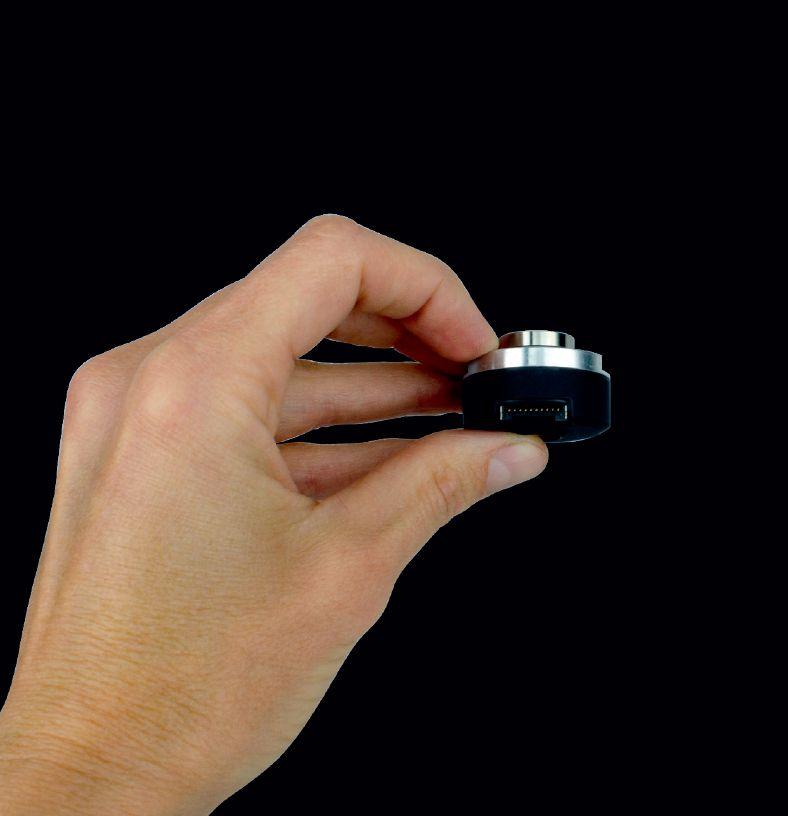

Forcen secures $8.35M to enable (super)human robotic manipulation

Forcen, a Toronto, Canada-based robotics sensing and edge intelligence company, recently closed a CAD$8.35M funding round.

The round was co-led by Brightspark Ventures and BDC Capital’s Deep Tech Venture Fund with participation by Garage Capital and MaRS IAF, and returning investors including EmergingVC.

The company will use this investment to scale up prototype production facilities to support more customers and continue developing its force/torque sensing technology and edge intelligence designed to enable robot companies to effortlessly deploy (super)human robotic manipulation in complex and unstructured applications.

Forcen’s technology is already moving into production with customers in logistics, surgical and space robotics.

“We’ve been focused on delivering custom solutions showcasing our world-first technology with world-class quality … and we’re excited for our customers to announce the robots they’ve been working on with our technology,” said Robert Brooks, founder and CEO of Forcen. “Providing custom solutions has limited the number of customers we take on, but now we’re working to change that”.

To accelerate development for current customers and allow more robotics companies to start working with Forcen’s technology earlier on, the company is launching a rapidly customizable offering as well as off-the-shelf development kits. The rapidly customizable offering will reportedly use generative design and standard subassemblies to allow customers to select the

size, sensing range/sensitivity, overload protection, mounting bolt pattern, and connector type/location with fulfillment in as little as four to six weeks.

The off-the-shelf development kits are launching later this year covering 3DoF and 6DoF force/ torque sensors as well as crossroller bearing free 3DoF joint torque sensor and 3DoF gripper finger.

Quebec-based Averna acquires automated test solutions provider ELCOM

Averna, a global test and quality solutions provider, has acquired ELCOM and its subsidiaries. ELCOM specializes in test and measurement, power engineering and industrial automation.

In a statement regarding the acquisition, president and CEO of Averna, François Rainville said, “We are excited to welcome ELCOM into the Averna family. Their expertise and strategic positioning in the automotive/ EV, energy, and machine vision markets perfectly complement our own. The diverse skillsets of the 150+ new teammates will benefit Averna’s customer base worldwide.”

The acquisition of ELCOM, which included its subsidiaries RH-Tech and ELTIA, aims to leverage the talents and resources of ELCOM’s well-established teams. Averna shares in its press statement that with ELCOM’s qualified management and engineering bench strength, this union aligns with its long-term vision to serve its customers’ automated test needs on a global scale.

“Joining forces with Averna presents exciting opportunities for growth and innovation.” agreed Daniel Kaminsky, former president and chairman of the board at ELCOM and now

vice-president of Averna Czech Republic. “We believe that our joint values and combined efforts will benefit our respective companies and customers.”

Accenture invests in Sanctuary AI to support AI-powered humanoid robotics applications

Accenture has made a strategic investment in Vancouver-based Sanctuary AI, a developer of humanoid general-purpose robots that are powered by AI and can reportedly perform a variety of tasks quickly, safely and effectively.

“AI-powered humanoid robots are essential to reinventing work and supporting human workers as labour shortage is becoming an issue in many countries and industries,” said Joe Lui, Accenture’s global advanced automation and robotics lead. “Sanctuary AI’s advanced AI platform trains robots to react to their environment and perform new tasks with precision in a very short time. We see huge potential for their robots in post and parcel, manufacturing, retail and logistics warehousing operations, where they could complement and collaborate with human workers and automate tasks that traditional robotics can’t.”

Sanctuary AI’s general-purpose robot PhoenixTM can reportedly perform a multitude of work tasks. For instance, Accenture shares in a press statement that at a Mark’s retail store in Langley, B.C., Canada, Phoenix has performed more than 100 tasks, including choosing and packing merchandise, and correctly cleaning, tagging, labelling and folding items. Phoenix is powered by the company’s AI control system, CarbonTM, which mimics subsystems found

in the human brain, such as memory, sight, sound and touch, and translates natural language into action in the real world.

Geordie Rose, chief executive officer and co-founder of Sanctuary AI, said, “Robots with human-like intelligence will completely transform the workforce of the future. By combining Accenture’s expertise in disruptive technology with Sanctuary AI’s industry-leading robotics, we can help some of the biggest companies in the world manage this change and provide the best solutions for its clients.”

Honda to invest $15B in Canada to strengthen EV supply chain

Honda has announced its plan to invest $15 billion in Canada to build a comprehensive EV value chain. This investment will reportedly allow the company to strengthen its EV supply system and capability to prepare for a future increase in EV demand in North America.

Honda has begun evaluating the requirements to build an innovative and environmentally responsible Honda EV plant and a stand-alone Honda EV battery plant in Alliston, Ontario.

The proposed Honda EV value chain will also include a cathode active material and precursor (CAM/pCAM) processing plant and a separator plant. Honda expects EV production to begin in 2028.

To support this project, Honda is collaborating with the governments of Canada and Ontario to drive innovation in low-emissions manufacturing by accessing performance-based initiatives available through the federal government’s new Investment Tax Credits and provincial direct and indirect incentives. | MA

Contour, pixel count, and multicode detection all in one sensor! O2U5

BY FRANK DEFALCO, DIRECTOR OF MEMBER RELATIONS AT NEXT GENERATION MANUFACTURING CANADA (NGEN)

Canada made a significant stride at the 2024 Hannover Messe Show by expanding its presence from one pavilion last year to four this year. This expansion demonstrated Canada’s commitment to manufacturing excellence and built excitement for next year’s show, when Canada will be the partner country. With over 80 Canadian exhibitors showcasing their products and innovations, Canada demonstrated its potential on the global stage in the historic major trade crossing point – Hannover, Germany.

Hannover Messe is more than your average trade show. As a state event, it pulls in leading experts, executives, innovators and government officials from across the globe to accelerate all sectors of advanced manufacturing. Hannover Messe kicked off with the theme “Energizing a Sustainable Industry,” featuring prominent figures such as German Chancellor Olaf Scholz and Norwegian

Prime Minister Jonas Gahr Støre, reflecting Norway’s role as this year’s partner country. The opening ceremony at the Congress Center drew thousands of attendees, which was followed by an engaging networking reception.

Monday marked the official opening of the fair, featuring an impressive lineup of 4,000 exhibiting companies and drawing over 130,000 attendees. With more than 14,000 products and solutions on display, business transactions began quickly on the show floor. One of our exhibitors reported selling to the second person he spoke with – surprise, surprise, a Canadian buyer. It was no surprise to see Canadians actively engaging in partnerships and networking throughout the exhibition floor.

Canada made its mark in four halls across the Hannover Messe show; Hall 7: Automation, Motion and Drives, Hall 12: EV Mobility, Hall 13: Hydrogen and Fuel Cells

and Hall 17: the Digital Hall, which had two large LED screens casting live streams and large lounge area made it a regular stop for attendees of the show. The Livestream stage, which quickly became known as “Jay’s Cabin” in Hall 7, hosted a rotation of insightful presenters, making it a vibrant and happening spot at the Messe.

Fostering partnerships and connections is what Hannover Messe is about. Whether it be a large OEM looking for a key supplier or a small SME with a unique solution, the magic of Hannover Messe happens by meeting the right person at the right time. Here’s a tale worth remembering from Hall 12. EV Mobility Nano One’s Adam Johnson shared he almost stepped away from a person showing interest at his booth but he decided to approach them and met a Tier 1 automotive company looking for exactly what he offered. One conversation might be worth millions.

NGen also hosted a delegation led by

Bridget Bohan, director of Cluster Accelerator at NGen. Her wonderful stories are worth the mention on their own. The tour of the Schunk Pavilion was a major highlight. Schunk was honoured with the HERMES AWARD at the opening ceremony on April 21, 2024, in recognition of an innovative AIbased project.

It is hard to relay the size and scope of such an event. You really need to experience it to understand the full scope of it. One thing is certain, now is the time to start planning for next year. This is a once-in-a-generation opportunity as Canada will not be the partner country again for decades. One notable challenge of the Hannover Messe is the limited availability of hotel rooms to accommodate such a significant event. This underscores the importance of early planning and booking accommodations well in advance. With over 200 Canadian exhibitors expected and an additional 400 attendees navigating the floor in 2025, these figures likely represent a conservative estimate.

Our team was thrilled to help make new connections at the

five-day trade show and showcase an amazing group of exhibitors at the Canada Pavilions. It would be amiss to not list them here as it’s for Canadian companies that we were at Hannover Messe.

Exhibitors Canada Pavilion

Hall 7 Automation, Motion & Drives: ASAsoft, Ayrton Energy, Black Controls, Ethos Automation, Government of Alberta, Government of Manitoba, Invest in Hamilton, KeepWise, Maple Advanced Robotics Inc., Maya HTT, Mecademic, Micro Engineering Tech inc (METI), Nanoprecise, Panevo Services Limited, Prodevco Robotic Solution, RoboTape, Sarcomere, SolarOptim, Synode, University of Toronto, and Zerokey.

Exhibitors Canada Pavilion

Hall 17 Digital: 4D1, AIOT, Basetwo, Boardera Software, Canada Makes, La Chaise Bleu, Deep Tech Canada, Digital, DOT Automation, IMCN, McRae Imaging, OneWAY Automation, Liveline, Prevu3D, Remap, Scale AI, Shoplogix, Soralink, Star Solutions, The Fundry, Untether AI, VKS, and Vooban, Zea.

Exhibitors Canada Pavilion

Hall 12 EV Mobility: Accelerate, Calogy Solutions, E3 Lithium, Exro, Nacora Insurance Brokers Ltd., Nano One, Saskatchewan Research (SRC), Trunexa, University of Windsor

Exhibitors Canada Pavilion

Hall 13 Hydrogen & Fuel Cell: Awesense, Blue-O Technology Inc., Greenlight Innovation, Illuming Power Inc, Intertek, Momentum Materials Solutions, Powertech Labs, Red River College, CHFCA, The Six Tech, Triple Point Resources, UBC Okanagan, and Vancouver Community College.

NGen would like to thank everyone who stopped by one of our pavilions to chat and explore. We would also like to thank the Government of Canada for their support in making this event happen. A great show awaits us in 2025. | MA

BY SUKANYA RAY GHOSH

From May 6 to 9 this year, the Association for Advancing Automation (A3) welcomed the North American manufacturing industry to the Automate Show for four days of technology showcases, education, trending discussions, networking and more. With ever-increasing interest in the latest technologies, the show was announced as an annual event in 2023 instead of the previous alternate-year schedule.

A3 shared that the 2024 show had 40,000+ registrants and over 800 exhibits, making it the largest show in the event’s history. More than 250 speakers shared their expertise during the four-day event, leaving every attendee with something to think about.

With a sharp focus on every aspect of automation, exhibitors featured products from a vast range of categories, including additive manufacturing, artificial intelligence, robotics,

data systems, industrial controls, drives, IIoT, material handling, motion control, software, vision systems and more.

The show’s education component was on par with the trade show exhibition, featuring discussions on topics such as AI applications, automation safety, robotics, cybersecurity, machine vision and inspection, logistics and supply chain automation and emerging applications, to name a few.

The event kicked off with a featured keynote each day, inspiring attendees to take in the variety of automation technologies displayed on the show floor. Del Costy, president and managing director of Siemens Digital Industries focussed on sustainable automation technology during his keynote address. He explained that the world needs digital transformation platform that makes things easy. MIT Professor Daniela Rus offered the opening keynote on the third day

of the show, spotlighting the potential of robotics technologies and sharing her insights on how pervasive robots can help people with physical and cognitive tasks. Wendy Tan White, CEO of Intrinsic (an Alphabet company) offered the keynote on the final day of the show on the topic ‘Realizing the value of AI in industrial automation.’ Tan White discussed AI’s transformative impact on robotics and how emerging technologies evolve into practical applications.

Collaboration was an important aspect

of the technology showcases. Companies with different types of expertise partnered to offer advanced solutions to potential customers. Automation cannot be imagined without robotics. While traditional robots and collaborative robots still captured the attention of the attendees, the capabilities of autonomous mobile robots were also on full display at the tradeshow. Also seen on

the floor were two humanoid robots!

AI is still a major part of the conversation in the industry. This year, attendees were introduced to the vast scope of applications for AI. It is no secret that data is a very powerful tool for every manufacturer. Automate exhibitors demonstrated the different means to collect and analyze data and use it

to their advantage.

Attending in-person events open up opportunities to network. The Automate Show networking reception in the evening of May 6 was standing room only as exhibitors, attendees, speakers and show hosts mingled over food and drinks to exchange their insights and share their experiences. | MA

Sharing, analysing and processing data is crucial for being able to utilize new technological applications related to Industry

Think

services and databases that help to enable predictive maintenance, for example. But also, simply pushing PLC variables to the cloud offers insight to make production more efficient, for example. This can be done by providing insight into the most important information from various production locations on an online dashboard.

It is important that both the data in the cloud and access to the machine or installation in the factory are maximally protected. This can only be achieved through a deep integration of various security mechanisms and processes at all levels of industrial control, the associated development environment, the communication protocol and the cloud environment.

Dashboard in the Proficloud.io

Not every PLC programmer has the necessary IT knowledge to realise this. It is therefore important that these services are also made easily accessible to them, in a way that is known and safe to them. The PLCnext Technology therefore offers both onboard cloud connectors and the necessary security (Security-by-Design) out-of-the-box, so that PLC variables can be easily and safely pushed to the cloud.

The PLC programmer does not need any IT knowledge for this: by only checking PLC variables, they are automatically pushed to the cloud and encrypted. Using our dashboard system in the Proficloud, you can create your own dashboards and visualizations without actually having to program anything. Creating a new dashboard is already done with a few mouse clicks and is just as easy as linking the variables to the graphical objects. In addition, the dashboard system can also send notifications via e-mail, Slack, Microsoft Teams, etc. to inform people about the status of your machines and installations.

BY JACK KAZMIERSKI

Years ago, quality control started off as a human being examining a product on an assembly line. Over time, we have progressed to machine vision, and more recently, to artificial intelligence (AI).

As promising, and as efficient as AI may be, according to Hugues Foltz, executive vice-president of Vooban, it’s not as widely used as it could be. “AI is not being used enough,” he says. “Instead, we see a lot of old vision systems that are not using AI at all.”

Foltz argues that older machine vision technologies are underperforming and are nowhere near as accurate as modern AI systems. Part of the problem, Foltz explains, is that AI is misunderstood, and is still a bit of a mystery. “The other part of the problem is that there aren’t a lot of companies that can implement these solutions,” he adds.

Moreover, AI is not a plug-and-play technology that can be easily implemented with out-of-the-box solutions. In order to effectively harness the power of AI, you first need a human being who can fine-tune the right algorithms.

Foltz says that these complex algorithms are the domain of AI scientists, which may be hard to find. “You need a certain level of expertise to understand and to fine-tune these algorithms,” he explains, “which is why an AI scientist is normally someone with at least a Master’s Degree in AI, along with a background in engineering, and that’s at a minimum. Ideally, you want someone with a PhD or a post-PhD.”

Fast implementation and equipment needs

While writing and fine-tuning advanced algorithms sounds complicated (and it is), according to Foltz , it doesn’t have to be time-consuming. In fact, he says that putting

AI in place for quality control and defect detection doesn’t take long at all.

“It’s pretty fast,” Foltz says. “We can normally do a proof of concept within three or four weeks, maximum, if it’s something complex. The proof of concept demonstrates that we can see with accuracy what we are looking for, and in some simple use cases, that can even be done in a few days.”

Humera Malik, CEO of Canvass AI agrees, adding that data is a key factor. “Success depends on many things and starts with data,” she says. “However, in most cases, the data is already there. Companies have been gathering it, but not doing much with it until now. For any of our typical projects, going from training to implementation takes six to eight weeks. For success, ROI must be within immediate reach for any AI effort to be sustainable. For every dollar invested in industrial AI, we have seen an ROI of 10X and beyond, with operational efficiencies alone.”

As far as equipment is concerned, Foltz says that AI requires two basic elements: algorithms and cameras. “The equipment shouldn’t cost much,” he adds. “Cameras are common, they’re not expensive, and they already have a small processor in them that can run the algorithms.”

The fact that cameras are small and relatively inexpensive means that manufacturers can place them at various points in the production process in order to spot defects. In other words, rather than simply analyzing the final product, AI can be employed in conjunction with multiple cameras to spot defects at strategic points in the production process.

“We call this segmentation,” Foltz explains. “So, for example, we can have one camera looking at the shape of a part, another camera analyzing the colour later on the assembly line. This can save time and money because you’re not painting a part

that should have been disposed of earlier in the production process because it’s the wrong shape.”

Today’s cameras and processors are so advanced, and so quick, that they can analyze an assembly line at incredible speeds, Foltz explains. “Speed doesn’t matter anymore,” he adds. “We have deployed AI in industries where the conveyor belts are moving so quickly that human eyes can’t see anything, yet the cameras catch 100 percent [of the defects].”

Perhaps the best news is that it doesn’t necessarily have to cost a lot to implement AI technologies for quality control and defect detection. Foltz says that depending on the size of the project, it can cost between $100,000 to $200,000 to deploy AI and train it to the point where everything works effectively and runs smoothly. “In contrast,” Foltz adds, ‘machine vision used to cost millions of dollars to implement.”

Canvas AI’s Humera Malik agrees. “Getting started can be very easy,” she says. “Typically, companies already collect an

“Today’s cameras and processors are so advanced, and so quick, that they can analyze an assembly line at incredible speeds, explains Hugues Foltz from Vooban.

immense amount of operational data. The upfront cost commitment is minimal as there is no CAPEX investment. No change is required in the current resourcing and workflow. Most of the OT workforce is familiar with working with their data, so no new learning is required. One of the key factors is the organization ’s commitment to learn from AI and implement the learning in order to see the ROI. In most cases, with data in hand, a typical project is implemented and shows results in six to eight weeks.”

As affordable as AI may seem,

Malik believes manufacturers need to consider costs closely.

“The cost of implementing AI may not be justified for all manufacturing processes, especially if the ROI is not clear or immediate,” she says. “While AI has the potential to revolutionize manufacturing, it’s important to assess its applicability on a case-by-case basis, considering the specific requirements and constraints of each application or process.”

As sophisticated as AI may be, it does have limitations, according to Malik. “AI can be incredibly

heavily regulated, safety and compliance are paramount, and strict compliance is required, so AI systems must be thoroughly tested before being given full autonomous control.”

Foltz says that North American manufacturers are behind their European counterparts when it comes to the deployment of AI.

“If manufacturers still have people [on the assembly line] looking at things, they need to stop it, and they need to replace those humans with cameras and AI everywhere,” Foltz says. “I was in Germany recently, and it’s clear that automation in North America is lacking. [Europeans] are implementing AI on a massive scale and leveraging the power of automation. When they compete with us, they’re going to be cheaper because they are going to be faster. That’s something we should be worried about now.”

Malik sees a bright future for this cutting-edge technology. “AI will increasingly be used for quality control,” she concludes. “Today, it’s in the early stages. According to research firm, Gartner, by 2025, 50 percent of manufacturers will rely on AI-driven insights for quality control. That’s only half of the manufacturers, so there is a way to go.”

beneficial in manufacturing, but it does have limitations and may not be suitable for all applications or processes,” she explains. “Some key considerations include the complexity of the task. AI excels at repetitive and predictable tasks, but may struggle with complex, non-routine tasks that require human intuition and decision-making.”

In addition, she adds, AI systems require large amounts of data to learn from. “In processes where data is scarce or not digitized, AI may not perform well,” Malik explains. “In the industries we serve, which are

“In the industrial setting, we expect that AI will, in general, lead to more autonomous systems and further streamline processes. It will also advance to have enhanced predictive analytics capabilities and integrate more closely with IoT devices. So today, for example, the AI solution might be predicting something and alerting engineers when certain parameters veer from set conditions that would impact product quality. In the future, the AI solution could have complete control, and be able to take any necessary corrective action on its own.” | MA

The winners of our annual Top 10 Under 40 lead by example and inspire their peers. BY SUKANYA

RAY GHOSH

Manufacturing AUTOMATION’s annual Top 10 Under 40 winner celebrates the young leaders who raise the bar and set an exemplary example for their colleagues. These young luminaries epitomize the spirit of innovation, driving transformative change and inspiring their peers with their visionary approaches. They are not just shaping the future of manufacturing automation but also influencing the entire industry landscape. Armed with fresh perspectives and a relentless pursuit of progress, these rising stars are set to take the industry forward into a new era of unprecedented growth and efficiency.

This year, the winners share their thoughts on what they enjoy about working in this industry, their future plans, what keeps them motivated and more.

Congratulations to all the 2024 winners!

ADON PORTMAN

Co-founder

and

principal, JAKS Automation

What do you enjoy the most about working in the industry?

I relish overseeing entire project lifecycles in manufacturing/ automation, witnessing the transformation of outdated processes into modern, efficient systems. The diversity of projects across industries like lumber, food and beverage, and general manufacturing keeps me engaged and learning. I particularly cherish moments when operators, previously burdened with strenuous tasks, find fulfillment in new, rewarding positions.

What are your plans to drive the automation sector forward in Canada, as well as advance your career in it?

In 2020, I co-founded JAKS Automation with a mission to propel the adoption of robotics and automation within Canada’s manufacturing landscape. Recognizing the rapid evolution of this sector, I firmly believe in staying abreast of industry and technological trends. Our commitment lies in integrating modern systems to facilitate data-driven decision-making for companies, thus fostering progress.

What keeps you motivated?

The prospect of automation’s trajectory within the manufacturing sector continuously excites me. I am driven by questions like: What upcoming technologies will unlock previously unimaginable processes? How can we spearhead the adoption of automation technology in Canada’s manufacturing landscape? These challenges invigorate me daily, spurring me to persist in this dynamic industry.

What advice do you have for the next generation of manufacturing workforce?

Discover your passion and curiosity within the field. Without genuine enthusiasm and satisfaction in one’s role, reaching full potential becomes challenging. Opportunities abound for those willing to search diligently. Engage in hands-on projects, embracing the learning curve.

ALANNA VANDEN KROONENBERG Section manager, TRQSS

What do you enjoy the most about working in the industry?

I thoroughly enjoy the fast-paced and challenging environment

that automotive creates. It provides ample opportunities for innovation and continuous development, allowing me to stay engaged and motivated. Witnessing the tangible results of our hard work on a daily basis, and knowing that it positively impacts people’s safety, comfort, and well-being, is incredibly fulfilling.

What are your plans to drive the automation sector forward in Canada, as well as advance your career in it? My plans involve leveraging emerging technologies such as artificial intelligence and robotics to streamline processes, increase efficiency, and enhance productivity across all Tokai Rika groups. Additionally, I aim to foster collaborations between academia, industry, and government to facilitate innovation and adoption of automation solutions. Regarding advancing my career, I intend to pursue continuous learning, and networking opportunities within the automation field to stay informed of the latest developments. I strive to climb as high as I can, breaking the glass ceiling for all women in automation who will come after me.

What keeps you motivated?

I most enjoy seeing my imagination become a reality. I enjoy when I am able to come up with a creative and unique solution, and I can convince others to follow my ideas. When my solutions come to fruition, the results are always inspiring further improvement ideas. The

dynamic nature of the industry ensures there’s always something new to learn and explore, keeping my passion for innovation and problem-solving alive. What advice do you have for the next generation of manufacturing workforce? I would advise everyone pursuing this industry as a career to stay curious and learn continuously. Dream big, stay humble, and embrace a mindset of lifelong learning in order to keep up with the rapid pace of technological advancements and evolving industry trends.

Intermediate mechanical designer, Samuel, Son & Co

What do you enjoy the most about working in the industry?

The thing I enjoy most is the new challenges every day. In automation, we are always getting new projects, and with them come new challenges, and new opportunities to learn. When one project is completed, the next one you work on might be completely different, either for a very different industry, or designing for a different process, so it never feels like you are working on the same thing over and over again. This constant change also provides exposure to a wider range of industries and technologies than you might encounter working in any other industry.

What are your plans to drive the automation sector forward in Canada, as well as advance your career in it?

Samuel ASG has been doing a lot of work to attract new customers, from the medical, high-tech, and green technology industries. I have been lucky to be able to work with some of these customers, working together to figure out the best way to use automation to ramp up their production. For me, this has allowed me to get exposure to new processes and industries. I look forward to continuing to help our customers both old and new get the most out of automation technology.

What keeps you motivated? What keeps me motivated is the satisfaction of seeing my design come to life on the floor. Seeing a design you spent months on, moving and working is such an exciting feeling.

What advice do you have for the next generation of manufacturing workforce?

My advice would be to be open to learning from people not just in your discipline, but from all your cross-functional co-workers. Everyone has a knowledge and point of view that can help you become better at your job.

BRIAN BRUBACHER Junior mechanical designer, Samuel, Son & Co

What do you enjoy the most about working in the industry?

I enjoy the thrill of tackling technical challenges head-on to create automation solutions that drive efficiency for our customers. The diverse range of fields we operate in keeps me engaged and constantly learning. Additionally, collaborating with a team of skilled professionals from various backgrounds adds depth and creativity to our work, making every project a rewarding experience.

What are your plans to drive the automation sector forward in Canada, as well as advance your career in it? I plan to continue working with our team to develop improved methods of automation, as well as continue to research new and developing solutions to meet the needs of the customers. Every day is filled with new experiences and more opportunities to learn from my coworkers.

What keeps you motivated? I find it really satisfying to watch my designs and solutions come together on the shop floor and see the end results of our efforts. Working hands-on with machine building has also greatly improved my skills as a designer, giving me valuable insights into how things work in practice and informing my design decisions. The fact that the industry is always changing keeps things interesting and keeps me motivated to keep learning and growing.

What advice do you have for the next generation of people who wish to work in the manufacturing industry? It’s important for us to stay committed to developing new technology while keeping our solutions straightforward and practical. Additionally, I firmly believe in the value of hands-on experience and not being afraid to get your hands dirty.

BROCK BALDASSI Director of business development, Decora Powder Coating

What do you enjoy the most about working in the manufacturing industry? Being a third-generation member of the manufacturing industry, the field is quite literally in my blood. I am particularly drawn to the rapid evolution and the hands-on aspect of manufacturing. There’s a unique satisfaction in turning concepts into real, functional products and seeing the direct results of your work. The opportunity to innovate, optimize, and lead in an industry that’s foundational to our economy is not just a job for me, it’s a fulfilling legacy that I am proud to continue.

How did you lead the automation implementation process at your manufacturing facility?

I led the automation process at Decora Powder Coatings by conducting extensive market research, visiting global manufacturing facilities with advanced automation. This research helped us identify industry best practices, equipment and informed our strategy. Working with the management team, we crafted a fouryear business plan that integrated insights from our research and the contributions of our entire team. This collaborative approach ensured widespread

buy-in and a smooth transition to our new automated vertical powder coating line.

How do you drive the vision for your company?

I drive our company’s vision by setting clear, ambitious goals aligned with our commitment to quality, efficiency, and sustainability. Regular planning and investing in cutting-edge technology, like our new facility and vertical powder coating line, keep us at the forefront of the industry. We embedded this vision in every aspect of our operations to create a unified team focused on excellence.

What advice do you have for the next generation of manufacturing workforce?

My advice is to embrace both the technical and creative aspects of manufacturing. Stay curious, be a problem-solver, and work well in diverse teams. Don’t underestimate the importance of sustainability; the future of manufacturing depends on efficient and environmentally friendly production. Your passion and commitment to innovation will be key to your success.

JACOB WILSON Senior director of solutions engineering, Eigen Innovations

What do you enjoy the most about working in the industry?

I enjoy working on intelligent

automation projects where the introduction/improvement of automatic decision-making can show positive physical change within a process. It is satisfying to see more and more monotonous tasks being automated and, with each process being at least a little different, figuring out how to do these inline inspections in a scalable way.

What are your plans to drive the automation sector forward in Canada, as well as advance your career in it?

Working at Eigen Innovations, I have the opportunity to work on cutting-edge vision applications and see firsthand how advances in processing capabilities are expanding how feedback can be provided during the manufacturing process. Pushing this avenue forward allows for more subjective tasks in manufacturing to be included in automation moving the capability more towards fully automated processes, starting with inspecting every product produced inline so that factory teams can focus on high-value tasks.

What keeps you motivated?

The driving force that keeps me motivated is my interest in the processes and solving the puzzle which is the optimal way to incorporate automation. In my current position, this is focused on inspection vision systems in the quality realm where feedback generated by the solutions I design can not only deliver an inline inspection but also trigger an automated part rejection/ removal or flag a product for reworking.

What advice do you have for the next generation of manufacturing workforce?

If you are interested in working in manufacturing make sure to keep your education broad as possible. In many of these processes, many different disciplines and applications all come

together to create a fully functioning manufacturing process. Having some general knowledge across applications allows you to take a more holistic approach to tackling problems. For example, understanding a process like injection moulding helps me determine what type of cameras we need and what other data from the moulding machine we need to deliver a comprehensive inspection inline. Having this knowledge of manufacturing applications helps build trust and credibility with customers and ensures the most efficient initial solution design.

JULES TOPALIAN Director of engineering, Eclipse Automation

What do you enjoy the most about working in the industry?

As a machine builder, manufacturers from around the world come to you to develop, improve, and innovate their manufacturing processes. I find it incredibly rewarding to transform our clients’ toughest processes and vision into a custom manufacturing line that will last for decades in their facility. It’s an exceptionally dynamic environment, filled with people who are excited about solving complex challenges.

What are your plans to drive the automation sector forward in Canada, as well as advance your career in it?

Automation is about pushing forward into the future. What was unknown or impossible is made a reality. I don’t have the answers on what the next disruptive technology or process will be, but I do know how we’ll get there. To drive that forward, leaders such as myself must focus on two things: our people and our environment. Finding the best people and giving them an environment that enables them to innovate, will create outcomes that shape our future.

What keeps you motivated to work in this industry?

The passion felt in this industry runs deep. From the 30+ year veterans who are enamoured by the technical challenges they are overcoming to our co-op students who soak up all that we have to offer; there is passion in everything we do. Nothing is mundane or tedious.

What advice do you have for the next generation of manufacturing workforce? Come with an ambition to make a big impact, paired with humility to learn from every source.

KIANOUSH JAFARI Engineering lead, AMSAutomated Manufacturing Systems

What do you enjoy the most about working in the industry?

What I enjoy most about working in the industry is the constant

challenges and collaborative problem-solving it entails. Each day presents unique obstacles to overcome, and I find great satisfaction in working with diverse teams to find innovative solutions. The opportunity for continuous learning and growth is also rewarding, as is the sense of purpose knowing our work directly impacts our customers’ success. Overall, the combination of challenging problems, collaborative teamwork, continuous learning, and meaningful impact makes working in this industry incredibly fulfilling for me.

What are your plans to drive the automation sector forward in Canada, as well as advance your career in it?

In driving Canada’s automation sector forward, we focus on pioneering solutions to maintain competitiveness and position Canada as a global leader. This involves embracing external advancements and optimizing internal operations through technology adoption and process automation. By prioritizing both innovation and efficiency, we contribute to Canada’s leadership in advanced manufacturing, benefiting our customers and strengthening the industry.

What keeps you motivated?

What keeps me motivated in the automation industry is the constant drive for growth and competitiveness. Despite the challenges, each day presents opportunities to contribute to company growth, devise innovative solutions, and collaborate with our team. The satisfaction of seeing projects succeed and the collective effort of our team fuels my motivation. Additionally, the ever-evolving landscape of technologies emphasizes the importance of continuous learning to adapt and innovate effectively.

What advice do you have for the next generation of

manufacturing workforce?

My advice for the next generation entering the manufacturing and automation industries is to embrace curiosity and continuous learning. Challenge yourself to understand the ‘why’ behind current practices and seek different perspectives. Genuine understanding of the broader context, including human interactions with technology, is key. With the rise of AI, it’s crucial to grasp the purpose behind actions to effectively implement emerging technologies. By questioning and learning, you can develop innovative solutions that address underlying issues. Embrace curiosity, challenge the status quo, and strive to make a difference in the automation industry.

LAWRENCE LEE Automation manager, Armo-Tool

What do you enjoy the most about working in the industry?

Working within the custom automation sector provides a fast-paced environment which utilizes many facets of my education and past work experiences. As the manager of Armo’s Automation Division, I enjoy being able to work closely with my teams and see ideas come to life. The automation space undoubtedly has its challenges, but I have a strong team of dedicated employees with a wealth of knowledge and a passion for improvement.

What are your plans to drive the automation sector forward in Canada, as well as advance your career in it?

At Armo, we have a strong co-op and internship program which supports high school, college, and university students. Part of my goals within the company is to ensure that we are creating robust processes that not only improve our delivery to customers but also foster training and development to ensure we have dynamic teams comprised of well-rounded individuals.

What keeps you motivated?

With a background in engineering, my passion for creativity and innovation extends toward my leadership style. Within the automation industry, there continue to be deep roots in conventional manufacturing mentalities. I am excited to challenge these traditional ways of thinking and work with my team to pioneer the future of Automation.

What advice do you have for the next generation of manufacturing workforce?

Manufacturing is a very broad sector and there are many avenues for the next generation of workers to take. With emerging technologies in vision systems and artificial intelligence, it will be crucial for the youth of today to maintain a broad understanding of capabilities and apply lateral thinking to be innovative.

RYAN BABEL Director of systems engineering at ATS Automation

What do you enjoy the most about working in the industry?

The people. Magic happens when our teams and customers collaborate to create, execute, and deliver a custom solution

in this industry. Challenging problems will be encountered, however, the feeling of pride and accomplishment when shipping a successful program motivates us to continue pushing the boundaries of what is possible.

What are your plans to drive the automation sector forward in Canada, as well as advance your career in it?

I am fortunate to work as part of an amazing team and supporting our collective growth is certainly within my primary focus; from mentoring and coaching, encouraging curiosity, removing roadblocks and providing what is needed to be most successful. Driving the automation sector forward is a result of powerful teamwork that I am humbled to be part of daily within ATS.

What keeps you motivated?

Continuous learning and overcoming challenges to solve our customers’ most difficult automation problems is a powerful motivator for any driven engineering team. From innovating with new technology, supporting a winning proposal, to shaking hands with a happy customer upon successful project completion are all truly rewarding experiences.

What advice do you have for the next generation of manufacturing workforce? Be curious. Use data. Be driven to learn and practice critical thinking. As Jocko Willink puts it – be an “Extreme Owner.” | MA

Powerful modular PLCs connect using globallyopen industrial protocols, extending connectivity beyond a single manufacturer’s scope.

A look at current applications and where the technology will be applied next. BY TREENA HEIN

The modular PLC offers many benefits in a manufacturing plant, from flexibility, ease of upgrade/expansion and custom setups to simplified troubleshooting and enhanced system dependability.

Specifically, this type of PLC is an advantage in today’s manufacturing environment through its ability to connect to current fieldbuses and hardwired safety. This enables factories to start becoming more flexible, explains Thomas Kuckhoff, product manager of core technologies at Omron Automation, in a non-intrusive manner, “by integrating into existing architectures.”

Tyler Burke, product manager for industry management and automation at Phoenix Contact, explains that modular PLCs have seen wider adoption due to the

shifting boundary between a PLC and a PC. He explains that devices with additional PC functionality are available on several of the most recent control systems, some coming with Linux preinstalled and some with Windows – and direct datalogging on these devices is one of the new capabilities made possible by this blending of PC and PLC.

“Additionally, it’s enabling the controller to run programs from many sources,” Burke points out. With modular PLCs, “customers have frequently logged data using open-source solutions before adding a graphical front end. Previously, a local PC would have been used to accomplish this kind of solution.”

Kuckhoff adds that modular PLCs which support multiple communication protocols set up companies for the future. They’re

“suitable for tomorrow’s manufacturing environment,” he says, as they offer the flexibility to use plug-and-play hardware as well as drag-and-drop programming, allowing factories to integrate newer technology on their own schedule.

Burke agrees that the ability of modular PLCs to support multiple protocols ‘futureproofs’ devices, enabling them to keep up as demands and requirements change. Control systems are engineered to last over a decade, he says, so software needs to enable new applications and not hold existing control systems back.

The fact that PLCs are slowly adding more PC functions, he says, makes the futureproofing all the more apparent.

Based on what Burke is seeing in plants these days, most of the

latest modular PLC applications entail novel methods of data collecting or modification. “The push toward digitalization has resulted in increased data collection from devices in order to enhance machine efficiency and accurately anticipate problems,” he explains. “Applications have been seen where OEMs feed data to a database, including temperature and cycle counts. This enables them to keep an eye on a machine’s condition and alert clients when maintenance is necessary.”

In Kuckhoff’s view, the newest applications where modular PLCs are becoming anchors in automation architecture are the applications that require all three of the defining qualities of a truly modular PLC design: IO construction fluidity, programming software unification

and PLC CPU flexibility. One example of this is in plants that are being updated or redesigned, where modular PLCs simultaneously communicate to a breadth of different fieldbuses required to connect to existing equipment and integrate higher-performing safety systems (e.g. devices on Fail Safe over EtherCAT). Other examples are plants where novel technologies are being integrated into new products such as electric or hydrogen-powered vehicles and batteries, or in manufacturing labs/design centers.

An example of how the modular PLC can empower faster adaption to new manufacturing scenarios can be seen in the area of high-speed/high-quality part traceability at high volumes. Kuckhoff explains that it’s now standard to use handheld

Modular PLCs allow for scalability of and customization of automation when the manufacturer needs to expand operations.

scanners that quickly connect through open protocols and are intuitively integrated into a modular PLC. “In many food and beverage facilities, we have

seen these handheld scanners be installed without interrupting downtime,” he says, “a result of the defining qualities of a truly modular PLC design.”

Not all alike

There is some variation of modular PLCs on today’s market, and Kuckoff notes the real source of power for modular PLC users is in the number of connections that they can access out of the box. That is, the top 25 percent of high-performing modular PLCs not only have hundreds of off-the-shelf IO part numbers for plug-and-play installation (while also having a single software with drag-and-drop programming).

And the very most powerful modular PLCs? They connect using globally open industrial protocols, extending connectivity beyond a single manufacturer’s scope, says Kuckhoff.

“By using EtherCAT, Fail Safe Over EtherCAT, EtherNet/ IP, CIP Safety, IO Link, MQTT, OPC UA and SQL, all as each was intended to be used, the

most-powerful modular PLCs have been designed to adopt new technologies quickly from the very beginning and without introducing undue complexity to the factory floor,” he explains. “Manufacturers of these modular PLCs know this all too well, and users can expect a lot of thirdparty connectivity guides and function blocks to help bridge the gap between manufacturers while maintaining the modular PLC off-the-shelf ethos.”

As an example, Kuckhoff shares the story of a manufacturing team that needed to improve the reliability of the AC motors on their conveyor system. The existing modular PLC was able to accommodate the replacement of a previously-installed IP67 remote IO master with an IP67 remote IO master that communicates over IO Link. “The

Modular PLCs support multiple protocols ‘futureproofs’ devices, enabling them to keep up as demands and requirements change.

engineering team was able to use sensors already installed on the AC motors that were previously only showing if the motor was

on or off through the current draw,” Kuckhoff explains. “The team modified the PLC program to use IO link to read the exact

current draw of the motor. The team then pushed the update to the modular PLC during planned downtime. Now, the

Are

If so, expand your business and represent Canada in Germany with NGen at the premiere advanced manufacturing tradeshow, Hannover Messe.

June 03 | 9:30 AM

June 04 | 4:00 PM

June 05 | 8:00 AM

June 05 | 1:30 PM

June 06 | 8:30 AM

June 07 | 9:30 AM

June 19 | 4:00 PM

Ottawa (RBC Foundry, Bayview Yards)

London (Four Points by Sheraton London)

Hamilton (McMaster Manufacturing Research Institute)

Toronto (Ontario Investment and Trade Centre)

Mississauga (Mississauga City Hall)

St. John’s (St. John's City Hall )

Montréal (Palais des congrés de Montréal)

To register for Hannover Messe Information Session near you for free, visit ngen.ca!

factory floor can trend the current load on the motors and set acceptable thresholds for operation, shifting maintenance from reactive to proactive.”

Kuckhoff notes that this solution was able to be deployed without any capital costs and without interrupting production, and calls it “textbook modular PLC.”

But while being able to leverage multiple manufacturers’ breakthrough technologies through open protocols is valuable with modular PLCs, Kuckhoff adds that what’s often more valuable is the confidence that new technology will quickly connect with the current design.

“Modular PLC manufacturers, due to the inherent design of using globally-open industrial protocols in the PLC development, stay very close to the standards that govern these networks, explains Thomas Kuckhoff from Omron Automation.”

using Python, JavaScript and C++ will become standard. “This not only allows for greater connectivity to the ever-growing data analytics space,” he says, “but also allows factories to invite all of their factory talent to contribute to automation design progress.”

Burke’s outlook for PLCs encompasses the fact that plant control systems are facing

various current stresses, for example, the risk of cyberattacks. He therefore thinks devices will have more security features to restrict access. Overall, he foresees control platforms “evolving simultaneously to be more open than ever, with support for many protocols and languages, while also being more secure than ever.”

He explains that modular PLC manufacturers, due to the inherent design of using globally-open industrial protocols in the PLC development, stay very close to the standards that govern these networks. This ensures that factories have allies at the table when these networks evolve and that three of the defining qualities of a truly modular PLC design are not compromised during revisions.

Looking at where the use of modular PLCs in manufacturing is headed, Kuckhoff says it’s an exciting time.

He first explains that there has been a lot of discussion around open networks, specifically about connecting to production assets and moving data from the factory floor to a central location for data analytics. However, use of this technology has been commonly limited to PLC programmers and factory floor technicians, leaving computer scientists out.

Kuckhoff therefore believes that over the next five years, modular PLC platforms will likely become more inclusive to those in the IT space, where the modularity to program

BY JAMES FIGY

It’s a sticky situation. The world of adhesives keeps expanding to accommodate even broader applications with highly tailored tapes, foams and other products. However, automated tape dispensing systems have not kept up and offer little flexibility to adapt to wide-ranging industry requirements. Here, RoboTape has staying power.

Innovative Automation, a custom machine builder and systems integrator headquartered in Barrie, Ont., has developed the RoboTape platform. Leveraging advanced robotics and flexible

controls technology, RoboTape is able to deliver a fast, flexible and scalable tape dispensing solution suitable for everything from B2B industrial applications to large CPG companies.

“Innovative Automation started in 1989 with three founding partners and grew over the years by providing custom automation integration services, primarily to Tier 1 automotive manufacturers,” says Michael Lalonde, co-owner and president of both Innovative Automation and RoboTape. “After three decades of success with custom automation solutions, we formed an R&D

Left: RoboTape can take on complex geometries using its maneuverable and compact application head.

an enclosed industrial robot for high production throughput. The capabilities of the system led to a collaboration with 3M, a global leader in industrial bonding solutions, and the development of another offering – the RoboTape System for 3M Tape.

Customers can buy the RoboTape system for installation by a preferred integrator or work directly with Innovative Automation for further value-added services. Either way, end users receive full support. The system suits all sorts of part geometries and adhesive types, and RoboTape engineers are eager to prove it.

“We have set up a dedicated lab and test cell to run production intent trials with customer adhesives and parts. This testing allows RoboTape and the customer to be confident that cycle times and application requirements can be met before committing to a project,” says Zac Cutt, research and development group leader at Innovative Automation. “This service helps to alleviate any hesitancy to adopting a new technology.”

department to develop standard automation products. In the past, we had built a number of specialized taping systems, and this experience gave us the idea to create a more flexible solution, which eventually became RoboTape.”

The RoboTape business unit in Newmarket, Ont., now offers solutions to customers around the globe. One such offering is the compact, stand-alone “RoboTape Lite” work cell. It provides a low-cost and quick-to-integrate entrance to automated taping technology. The next step up is the RoboTape standard cell with

The experts at RoboTape and Innovative Automation are no strangers to problem-solving. During the system’s design phase, they identified multiple mechanical and electrical engineering shortcomings of existing options. These were all opportunities to be, well, innovative.

The main pain point was robot size and maneuverability. Most systems place the tape spool at the end of the robot arm, along with an empty spool to catch the waste liner. Also, operators have to wait until the systems run out

of tape, put them into a safe state, and enter the cell to add more.

“We came up with the idea of a remote feeding module that positions the spool outside of the work cell. That’s now patent pending worldwide,” Cutt says. “It also helps with the robot sizing issue, allows for larger spools and increases system uptime. This is why big automotive clients are latching onto it, it’s currently the only solution that actually solves the entire problem.”

The RoboTape system is designed to catch and chop up the waste liner at the remote feeding module. The design optimizations drastically reduce the size of the robot needed, Lalonde explains: “We were aiming for the 10-kilogram robot class, so keeping the applicator tool light and compact was a top priority. This allows the tool to work in

tighter areas and to reduce the overall size and cost of the work cell. These are all things our customers have been requesting.”

Before RoboTape was ready for prime time in tape dispensing, a variety of challenges had to be removed first. The team had to effectively accommodate a wide range of robots, continuously adapt to new parts for taping processes and gather massive amounts of sensor data for rapid processing. All these demands ultimately led the R&D team to PC-based control.

RoboTape adheres to new automation technology

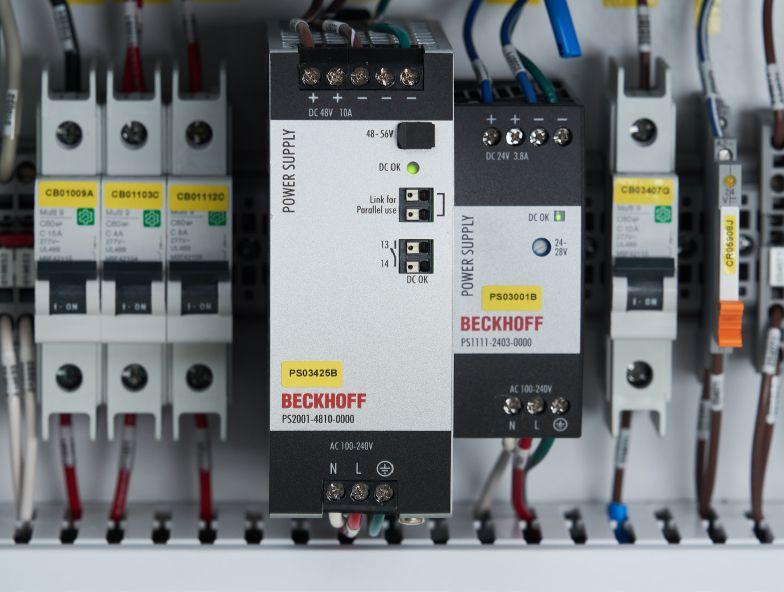

“In 2020, we created a decision matrix comparing four control system providers,” Cutt recalls. “We compared all of the technologies offered, the benefits, the

price, etc., and ultimately, we decided that Beckhoff provided the best fit for the RoboTape system.”

The engineering team was excited to learn. Innovative Automation worked closely with the sales and support teams at Beckhoff Canada. The Innovative Automation team sought advice and technical assistance from regional sales manager Paul Pierre and application engineer Jim Fallowfield on everything from TwinCAT 3 automation software programming to EtherCAT networking. This helped accelerate design, commissioning and operation.

TwinCAT offers an end-toend engineering and runtime platform for all automation functionality from PLC, safety and motion control all the way up to IoT, machine learning and

simulation. It offers support for all IEC 61131-3 programming languages, features object-oriented extensions, preloaded or custom function blocks, and has computer science standards in Microsoft Visual Studio.

Sean Robillard from RoboTape’s controls department appreciated this comprehensive software approach: “With a TwinCAT project, we have one folder with files for each PCbased controller. Within that code, we have all safety and I/O, so development of the system can be easily managed. This helps us implement different recipes, which tell the system how much tape to dispense, how quickly, etc.”

A CP6706 economy built-in Panel PC offers processing power for the application. RoboTape amped up the standard model

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid state relays & contactors, energy meters, monitoring relays, soft starters or sensors, available with or without IO-Link.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified OEMs.

with a dual-core Atom processor, 1-second uninterruptible power supply (UPS), 4 GB RAM and 40 GB Cfast card. The controller includes a 7-inch touchscreen for operator interface and is ready for cloud connectivity right out of the box.

“The user can view all their inputs and outputs, toggle cylinders, lights and sensors, and adjust other aspects of the machine,” says Josh Vander Doelen, project manager at RoboTape. “That’s all bundled into the same TwinCAT package, so it speeds up engineering and keeps the HMI design clean.”

The system utilizes the EtherCAT industrial Ethernet system for communication with the robot and other field devices. EtherCAT offers real-time speeds, flexible topology and up to 65,535 nodes on a single network, and it’s also incredibly open to integrating with other protocols. Beckhoff offers I/O hardware for more than 30 industrial protocols, including EtherNet/IP, PROFINET and others, which helps the RoboTape team connect a vast range of robots and third-party devices such as sensors and

encoders in customer facilities.

“For example, we use many IO-Link sensors to gather as much data as possible,”

With the TwinSAFE integrated functional safety system, the RoboTape platform can help protect plant personnel and equipment.

Cutt adds. “We simply add EL6224 IO-Link terminals to the main I/O segment as we need more sensors. Now we can gather a significant amount of data about the machine from the different sensors and analyze them for actionable insights.”

The remote feeding module can enter a safe state when operators open its enclosure. A cutting blade utilized to chop the spent liner and other pinch points contained inside requires guarding and protection. TwinSAFE offers safe inputs and outputs that integrators can connect directly to the door of the robot cell, light curtains or floor mats, for example.

TwinSAFE incorporates Safety over EtherCAT (FSoE) to communicate over standard networks using a “black channel” approach. Safety data can travel over the same EtherCAT network, ensuring the necessary cable redundancy with no hardwiring between safety devices.

Applications for manufacturers

With all these technological

developments, RoboTape has quickly gone global.

“Our systems average eight hours of runtime before refills, but this can be greater depending on the material,” Cutt says. “For instance, one customer processed 14,000 feet of felt on a single spool, so they’re making enough parts for about 2,000 cars a day and only changing spools once a week.”

Another Tier 1 automotive supplier shrank the overall footprint of its assembly area by removing two manual taping stations. In addition, it reduced labour requirements at a time when job openings remain difficult to fill. As a result, the customer saved roughly $225,000 per year on adhesive applications in one plant. To date, the RoboTape systems in the facility have processed more than one million

automotive parts with only basic maintenance.

Flexible PC-based control from Beckhoff enables the systems to adapt to new products and send data to higher-level systems as needed. Soon, RoboTape will roll out an optional data collection system to enable users to monitor system data from a dashboard.

“Our new IoT capabilities can allow us to see which machine modes are activated and for how long. So, if a system is in service mode for long periods of time, it could indicate it needs maintenance or that a particular operator requires more training to meet uptime goals,” Cutt says. “We can see the machine’s overall equipment effectiveness (OEE), along with metrics like internal and ambient temperature, to continue to optimize and improve

reliability.”

Innovation, not surprisingly, is a core value at Innovative Automation. However, it was vital for Lalonde and the team to select automation technology that was not just on the cutting edge but also supported worldwide as the company expands.

“That consistent global support and availability are reasons why Beckhoff has proven to be a great choice, and we’re excited to continue working together in the future,” Lalonde says. “Innovative Automation has always been a leader in the industry, and likewise, Beckhoff is constantly pushing the envelope with new technologies. That means we can keep reinventing how automation can maximize our customers’ success – no matter how challenging the application.” | MA

BY JONATHAN GROSS

The artificial intelligence (AI) marketing hype is at a feverish pitch. It’s the main thesis at vendor conventions, in their sales pitches, and in their content. And buyers want in. Today, manufacturers procuring technologies are more likely to shortlist vendors that demonstrate a compelling AI story and eliminate those that don’t.

But do the AI solutions live up to the hype? Or is there a person behind the curtains – à-la Wizard of Oz? Do the solutions offer real business value or are they gimmicky?

Our team at Pemeco annually manages 40 to 60 major technology selection and implementation projects for manufacturing and distribution clients. We get under the hood of the technologies and help our clients separate true AI from vapourware, business value from marketing fluff.

In this article, I break down a few of the notable AI technologies and discuss real-world applications where manufacturers are realizing business benefits. And I dip into our playbook to offer advice on how to separate the wheat from the chaff when evaluating AI solutions.

Agents are as they sound – they do someone’s work. AI agents simulate human interactions with software and are often used to perform mundane tasks such as data entry. We have clients who use agents to export payroll data and create journal entries, create sales orders from emails, and populate Excel reports from ERP systems data.

If you think this sounds a lot like Robotic Process Automation (RPA), you’re right. RPA automates manual tasks by simulating human keystrokes. It looks for, extracts, and inputs data in a prescribed way. AI adds a level of intelligence to RPA to handle unplanned variability. The system learns from and adapts to changes – changes that might have caused unintelligent RPA bots to throw an error.

Generative AI is a type of artificial intelligence that can create new content – text, images, music, videos, and software code. OpenAI’s ChatGPT is among the most recognized generative AI brands.

“Artificial intelligence adds a level of intelligence to robotic process automation to handle unplanned variability.”

Enterprise software vendors are embedding generative AI in their applications. For example, several notable ERP and human capital management vendors now offer functionality that can create job descriptions, product descriptions, and the like. Given how much time it takes to draft, type, and edit long-form text, these innovations offer companies opportunities to free up their very expensive workforce to work on higher-value activities.

Software extension development is another interesting use case. We have managed hundreds of ERP selection projects. Though clients all want “vanilla” implementations, the reality is that each client inevitably protects a few secret-sauce strategic requirements that software does not natively support. Vendors of modern systems recognize this and provide their customers with ‘extensibility toolkits’ – development tools that

allow their customers to extend base functionality with new logic and functions without impacting the source code and upgrade path.

Generative AI promises to streamline the extension development process. It gives companies an opportunity to deliver competitively differentiating functionality quicker and cheaper, reducing time-to-value and increasing ROI. Instead of needing a strong technical architect and coder, businesses can have the AI system generate the code output from conversational descriptions of the business use cases.

Search-related AI functionality offers companies opportunities to drive revenues and reduce transactional overhead.

From a revenue perspective, Canadian company direct-to-consumer (D2C) sales account for between 15 and 20 percent of all online sales. With the average consumer spending 50 seconds on an e-commerce webpage, manufacturers selling directly to consumers need to provide an

e-commerce experience that is fast, relevant, and user-friendly. If a consumer can’t quickly find their desired product, they’ll look elsewhere.

AI-powered search and discovery does just that. It can offer visitors different search suggestions aligned to defined product categories (“you searched for ‘pants’, would you also like to see ‘trousers’”?), it can tolerate typos, and recommend product upsell and cross-sell suggestions even if those relationships aren’t established in the database.

When it comes to transactional overhead, companies tolerate a lot of inefficiency and risk stemming from a need to feed the beast. Intelligent search and generative AI can help users more effectively navigate the system. Instead of running complicated reports and queries to locate a record, users can ask questions in natural language – “How much did Customer ABC pay for Item 123 on its last order?”

Moving from the back office to the shop floor, machine vision combines 2D or 3D imaging with computer system logic to rapidly make decisions. AI is now enhancing machine vision applications. Through a process called deep learning, the system ingests large data samples – often images – to learn new patterns and rapidly spot defects.

Most commonly, machine vision supports quality control processes – a part’s conformity to specifications or the clarity

of an etched barcode, for example. Equipment maintenance is another beneficiary. Machine vision systems can detect wear and tear and interface to enterprise asset management systems to plan preventative repairs. Inventory management is final area worth highlighting. Machine vision systems can efficiently scan and track items as they flow through the warehouse. They can even guide robots to direct putaway, execute picks, and build pallets of different SKUs.

Regardless of the specific application, it’s important that you select a tool that’s valuable and viable. Here are five steps to effectively evaluate proposed AI tools:

1. Validate the business value proposition. Because of technological newness, most manufacturers don’t yet have a clear set of business requirements for AI. When presented with AI solutions, you will want to assess a proposed solutions’ applicability and business value. How much waste will it reduce? By how much will it improve throughput?

2. Consider data risk. AI models train on large datasets. In some cases, customer-specific data remains isolated. In other cases, it’s ported back into the solution to train the model. It’s important to assess whether and how data flows into, is consumed by, and used by the AI models. It’s also important to understand whether

you’re transferring any rights – including ownership – to data that flows into the system.