IS CANADA READY FOR AIOT?: AIoT promises to bring the power of AI to operational technology. p. 12

IS CANADA READY FOR AIOT?: AIoT promises to bring the power of AI to operational technology. p. 12

Automated welding system increases speed of production using EtherCAT and PC-based control. p. 14

THE BIG PICTURE: An overview of Canada’s participation at Hannover Messe 2023. p. 22

Your resource for Canada’s industrial automation news

10 UNDER 40

Joshua Pickard from Eigen Innovations shares what motivates him to work in this industry. p.6

The manufacturing sector of Canada’s defence and security industry is a tightly-knit supply chain protecting us from threats. From micro devices to massive machines, Canadian companies work together to deliver value and make our country stronger.

Discover a network of opportunities and a community with real purpose.

Get started at EveryBitCanadian.ca

BY SUKANYA RAY GHOSH

No one is an island unto themselves within the manufacturing industry. Everyone needs support from different corners to remain competitive, successful and relevant in this economically tough market. Networking is key to building those crucial connections. So, how do you network within the industry?

Industry events are an excellent place to begin. Most events today dedicate separate times throughout the day for networking side-events and parties. They serve as an excellent opportunity to start conversations with multiple suppliers and OEMs. They offer the perfect space to dialogue with industry peers and evaluate respective situations, identify common challenges and possible solutions for them, exchange lessons learnt on technology adoptions and much more.

Major industry events and tradeshows are often massive in size and scale and can be overwhelming. It is, therefore, important to be prepared ahead of time. Details of exhibitors and networking events are usually available in advance on the events’ dedicated websites. It is always good to browse through and create a networking “plan of attack” to be able to extract the most out of the time spent there. Of course, many opportunities present themselves organically. So, just being there is a step in the right direction.

While exhibitors love to meet their potential customers, busy trade show floors can often hinder conversations or not allow you to have ample time to build that connection. If there are people or companies on your “must-meet” list, setting up appointments in advance can be helpful. Instead of feeling rushed, both parties can remain focussed and relaxed while discussing topics that you have perhaps decided on ahead of time.

Networking need not take place just on

the trade show floor. Many industry events host networking parties in the evenings that are excellent to have conversations, meet new people and make new friends in a casual setting, while having fun along the way. I was recently at the 2023 Automate Show in Detroit and had the opportunity to attend two such networking parties. With fewer tables available compared to the number of people attending, it was not uncommon for strangers to share a table when having their food and drinks. I was able to meet some amazing new people in the process. My colleague even met someone who went to the same public school as her! I remember having interesting conversations about how terribly mind-boggling and fascinating automation technologies are going to be in the future. I came across familiar faces and connected in-person with people I had only met virtually so far.

Networking is not limited to the major industry events only. Often, suppliers put together day-long events on a smaller scale to discuss their products, services and solutions. Such events can bring in the local manufacturing community in one place for the day, help highlight the area-specific market conditions while discussing solutions that have worked nationally or globally.

It is not enough to stop with the exchange of business cards at events. To realize the full value of networking opportunities, it is worthwhile to drop a message or place a quick call after the event to ensure that the connection continues. Being strategic can help build long-term relationships and partnerships.

Do you have a networking strategy that works for you every time? Share your thoughts with us at srayghosh@annexbusinessmedia.com. | MA

@AutomationMag srayghosh@annexbusinessmedia.com /company/automation-mag

EDITORIAL ADVISORY BOARD

JIM BERETTA, President, Customer Attraction and host of The Robot Industry Podcast

JONATHAN GROSS, Managaing Director, Pemeco Consulting

MIHAELA VLASEA, Associate Professor, Department of Mechanical and Mechatronics Engineering and Research Co-Director, Multi-Scale Additive Manufacturing Laboratory at the University of Waterloo

SHELLEY FELLOWS, Chair, Automate Canada

STEPHANIE HOLKO Director, Project Development at Next Generation Manufacturing Canada

WALTER GARRISON, Former Advanced Manufacturing Business Consultant for City of Mississauga

Your resource for Canada’s industrial automation news

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: 416-510-5113

Fax: (416) 510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR

Sukanya Ray Ghosh srayghosh@annexbusinessmedia.com Tel: 416-510-5225

ASSOCIATE PUBLISHER

Kathryn Swan kswan@annexbusinessmedia.com Tel: 647-339-4880

GROUP PUBLISHER

Paul Grossinger

pgrossinger@annexbusinessmedia.com

MEDIA DESIGNER

Svetlana Avrutin savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-510-5107

AUDIENCE DEVELOPMENT MANAGER Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

PRESIDENT/COO

Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

Jacob Stoller, James Figy, Paul Hogendoorn, Neal Mohammed and Stephanie Holko

Published by Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 • Fax: 416-442-2191

Printed in Canada ISSN 1480-2996 Publication Mail Agreement #40065710

SUBSCRIPTION RATES

Canada — $43 per year

United States — $75.50 (US) per year Foreign — $86 (US) per year

Students — $20.50 per year

ANNEX PRIVACY OFFICER email: privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Manufacturing AUTOMATION will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. The contents of Manufacturing AUTOMATION are © 2023 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Vention opened the doors to its first experience centre located in its Montreal headquarters, on April 21. At this centre, Vention is providing manufacturers with access to the latest innovations in industrial automation through live demos, educational sessions and hands-on training. Within one space, individuals of all levels can experience the full reach of Vention’s Manufacturing Automation Platform (MAP) and leave with the skills and knowledge to design, automate, order and deploy automated solutions themselves, says the company.

Ford to retool Oakville facility into EV hub

Ford Motor Company is investing $1.8 billion in its Oakville Assembly Complex to retool it into a high-volume hub of electric vehicle (EV) manufacturing in Canada. This project is a key part of its plan to scale EV production. The retooling and modernization project will begin in the second quarter of 2024. The retooled plant will feature a new 407,000-square-foot on-site battery plant that will utilize cells and arrays from BlueOval SK Battery Park in Kentucky. Oakville workers will take these components and assemble battery packs that will then be installed in vehicles assembled on-site.

Canada named partner country for Hannover Messe 2025

Canada was officially designated as the partner country for Hannover Messe 2025 at this year’s event. On Monday, 17 April, at Hannover Messe, Isabelle Poupart, Minister and Deputy Head of Mission at Embassy of Canada to Germany, and Dr. Jochen Köckler, chairman of the managing board, Deutsche Messe AG, signed the official Memo of Understanding. The signing finalizes the agreement announced in August 2022 during German Chancellor Scholz’s visit with Canadian Prime Minister Justin Trudeau in Canada.

Mercier, Mechanical Industries receives $1.2M automation funding

Mercier, Mechanical Industries received a repayable contribution of $1.2 million from the Canadian government to increase its level of automation, production capacity and productivity. The company has acquired cutting-edge digital equipment, including a robot welder and a multi-table horizontal milling machine with the funds. | MA

Unlock your new operating mode selection and access permission system with PITmode.

PITreader Keysnew colours are available now for simpler handling.

Pilz Automation Safety Canada L.P. - Mississauga, ON www.pilz.ca - info@pilz.ca - +1 905 821-7459

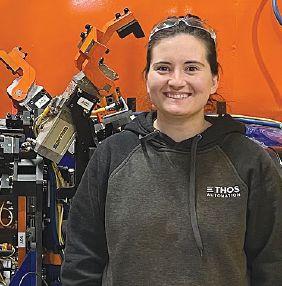

Manufacturing AUTOMATION’s second annual Top 10 Under 40 highlights the next generation of leaders who have demonstrated exemplary work ethic. They are leading the charge in their workspaces and inspiring their peers with their commitment to innovation.

This year, the winners share what they enjoy the most about working in the automation space, what plans they have for their future and suggestions on getting more people into this industry. Congratulations to all the 2023 winners!

ALESSIA ALFIERI Project manager, Ethos Automation

What do you enjoy the most about working in the manufacturing and automation space?

I’ve always been fascinated with the idea of being able to automate any process, no matter the complexity. The manufacturing/ automation industry is constantly evolving and innovating, which provides an exciting and dynamic work environment. There are always new challenges and opportunities to learn and grow as a professional, and the work can be both intellectually stimulating and creatively fulfilling. As a project manager in the industry, I enjoy the fact that I follow a job throughout every step from design all the way to integration. This provides me with the opportunity to work with a dynamic team that allows me to learn and grow in my career.

What are your future plans within the industry?

In the future, I hope to keep growing with the industry. Technology is changing so quickly, and there is always going to be much more to learn and understand. Project management has given me many great opportunities to explore various tech in the field, and I look forward to gaining exposure in other industries within this sector. I hope that I can help encourage more women to enter the manufacturing/automation sector and continue to promote equality in the workplace. With the increasing demand for skilled workers, women have a unique opportunity to break into these fields and make a difference.

How can this industry encourage more people to join and pursue successful careers here?

The industry should partner with more educational institutions to promote careers in manufacturing/automation and offer training programs, apprenticeships and internships to provide students with the skills and knowledge needed for these careers. The manufacturing/automation industry is constantly evolving. Highlighting the industry’s focus

on innovation and technology can attract job seekers who are interested in working with cutting-edge tools and techniques.

JOSHUA PICKARD Director of innovation, Eigen Innovations

What do you enjoy the most about working in the manufacturing and automation space?

The manufacturing/automation space is highly dynamic with endless variations in the implementation of technologies and processes. Each new application can present new challenges. My overarching motivation is to uncover and create technologies that can help solve the big problems that hinder progress to unlock new possibilities in this space. It’s an exciting time to be involved in this industry. With the rapid growth of new sensor

SUKANYA RAY GHOSH

technologies and automation tools combined with continually improving machine learning tools, many old and previously unsolvable problems suddenly become solvable.

What are your future plans within the industry?

Today, the manufacturing and automation space is highly disjointed. Accelerating progress requires rethinking current approaches to adopting technologies and figuring out how to remove existing hurdles and barriers to entry that can make adoption challenging. The main question for me going forward is ‘What innovations are needed to unlock increased technology adoption rates and rapidly push the space forward’. There are endless opportunities for improvements here, but focusing on scalability, flexibility and ease of adoption must be primary considerations.

How can this industry encourage more people to join and pursue successful careers here?

My recommendation for encouraging more people to pursue manufacturing/automation careers is to promote where the space is heading, showcase what the adoption of technologies is enabling and outline the exciting opportunities that are now becoming possible. Opportunities in the space are increasing for open-minded individuals who promote, understand and leverage new technologies.

BRENT BELL Director of project management, JMP Solutions

What do you enjoy the most about working in the manufacturing and automation space?

Constant variety! For the last 15 years at JMP Solutions, I have had the pleasure of tackling technically and operationally demanding applications in multiple industries including food, consumer packaged goods and tube and pipe. My team members, customers and partners all seem to have fun because we get to see the direct results of our efforts. Each automation opportunity has a unique blend of technical and operational constraints and goals that demand creative problem

solving. As an integrator, I love how robot, sensor, actuator and controls hardware manufacturers have continuously innovated because we are able to provide robotic automation solutions to our customers in new ways. It is fun to “wow” a customer with a solution that redefines what is possible!

What are your future plans within the industry?

I plan to continue to help the manufacturing and automation segment grow by bridging the gap between producers and integrators in industries that are not yet heavily saturated with robotic automation. Through empathic listening, coaching, and trust building, I believe I can help manufacturers successfully adopt automation solutions that help them do more with less, make the workplace safer, and provide stability in their own journey to growth.

How can this industry encourage more people to join and pursue successful careers here?

It is important to look at the undeniable trends in the manufacturing

and automation segment; growth is inevitable and virtually limitless. This industry provides many fulfilling opportunities for different career trajectories for those in the engineering field, skilled trades, leadership and even supporting roles in accounting, human resources and IT. For example, at JMP Solutions, we offer a suite of technical solutions that combine industrial robots, autonomous mobile robots, industrial controls, plant-wide data collection, and cybersecurity layered on top.

What do you enjoy the most about working in the manufacturing and automation space?

The manufacturing and automation industry continues to evolve as technology advances. Playing a role in this advancement is something very exciting and unique. You are always working with new challenges and new technologies which is something I enjoy doing on a daily basis. The machines built by Eclipse are continuously incorporating new

advancements to make them first class. Not only do our machines go to many different companies, but the industry that our customers are a part of is constantly changing, ensuring that we too continue to stay with the present times. From one project to the next, you can be working with a customer in a wide variety of industries from life sciences, transportation, energy, consumer products or heavy industrial segment. It really is something new every day.

What are your future plans within the industry?

There are so many different avenues and possibilities. I just always want to strive towards the next step and do the best I

At Reko Automation Group we provide innovative industrial automation equipment and services to help you be more successful. From concept through to installation and support, our team is driven to maximize your return on investment!

We are actively recruiting for the following positions:

• Applications Engineer(s)

• Machine Builder(s) Congratulations to Justin Mladenoski, recipient of this year’s Top 10 Under 40 in Automation!

We want to help our employees create their own successes by providing them every opportunity to thrive. We are continuously seeking out the best and the brightest, like Justin, to become an integral part of a vibrant future at our company. We invest in our people and give them the tools that they need to succeed.

• Mechanical Design Engineer(s)

• Machinist(s)

at www.rekointl.com to learn more!

can with the challenges in front of me. Eclipse is growing at a very rapid rate and the more we can grow the people within, the more success we will have as a team. We have very talented employees within the company and if I can contribute to helping them take the next step to advance their careers, I would be more than happy.

How can this industry encourage more people to join and pursue successful careers here?

This industry has a wide variety of types of careers. Being connected to the schools and connecting with the next generation is where I think the biggest benefit is to encourage people to pursue careers in automation. Currently, I sit on the Program Advisory Committee for Conestoga College which ensures that relevant material is being taught in the Mechanical Engineering Technology programs from trends in industry. This gives the students a chance to connect with employers and prepare themselves for industry.

JUSTIN MLADENOSKI Controls engineer, Reko Automation Division

What do you enjoy the most about working in the manufacturing and automation space?

What I enjoy most about working in the manufacturing/automation space is how technology continuously evolves every day. There is something new to learn whenever

I walk into work. Starting a new job with a customer and seeing it transition from the design stage to the build stage to the programming stage and then finally installing our new machinery into our customers’ facility is very rewarding. I enjoy using critical thinking to optimize processes and improve efficiency whether that be in the design process, robot programming or PLC programming.

What are your future plans within the industry?

I’d like to continue to grow individually as a professional in this space, making my knowledge and capabilities well-rounded as a controls engineer, learning and adapting to new processes and making sure that my skills are up to date with all the latest advancements in the automation sector. I want to eventually get to a point where I can transfer my knowledge to the next generation that comes into this space and try to share the same passion that I have with those individuals, just like I experienced when I walked through the doors of Reko on my first day. Being able to be that go-to person and a mentor is a position that I’d really like to get to one day.

How can this industry encourage more people to join and pursue successful careers here?

I feel that increasing awareness about the industry and its potential is important. Having job fairs and educational campaigns can help inform students, job seekers and the general public about the diverse and rewarding career opportunities available in automation and manufacturing. Reko is a great advocate for this, as we always have a booth at local education facilities and job fairs. Another way to encourage more people to pursue a career in this industry is through social media. Having intuitive videos

of machinery/robots in action on popular social media websites will attract a lot of potential candidates.

ADAM COULSTON Head of industrial engineering seats for North America, Brose North America

What do you enjoy the most about working in the manufacturing and automation space?

For me, it is all about collaboration with the team and using their diverse backgrounds in different fields of engineering to solve a complex problem that no one else has. Watching the team work together constructively to understand the need of our customers, evaluate potential risks, while providing a robust proposal is inspiring. The acquisition phase and design phase of a highly automated piece of equipment is where you need to get it right and this is challenging,. However, watching the end product on the shop floor and turning an idea into something real is what keeps the motivation high and is the most rewarding.

What are your future plans within the industry?

My future plans are to develop a technology roadmap in my current role to ensure that we’re always ahead of the competitors. Keeping my eyes and ears open and listening to all ideas that people bring to the table while using my network to understand what’s next in automation. I am very interested in how artificial intelligence (AI)

plays a role in the near future. As I am responsible for industrial engineering in the region, I will look to collaborate with suppliers and provide funding to ensure success in their development.

How can this industry encourage more people to join and pursue successful careers here?

I think that the government must continue funding and marketing the younger generation to become millwrights, tool and die, etc. Automation companies are also making a big impact as they’re posting their equipment on TikTok and LinkedIn, while also attending job fairs at local colleges and universities to promote their business. Work/life balance, flexible working hours, departmental lunches, etc. will promote the automation culture that I believe is the best thing about the industry.

LAMIA GHONEIM Director of customer success, Raven.ai

What do you enjoy the most about working in the manufacturing and automation space?

I’m drawn to the manufacturing space because of the tangible impact it has on people’s lives. As I moved more into the Industry 4.0 and automation space, I shifted my focus towards leveraging technology to improve manufacturing processes and to solve complex problems that would have otherwise been difficult to overcome. The digitization of

manufacturing data along with the integration of AI, robotics and advanced analytics have created tremendous opportunities for optimizing manufacturing processes and improving product quality for the consumer. Working on projects that leverage cutting-edge technologies to increase productivity and make production workers’ jobs easier and more meaningful, brings me great satisfaction.

What are your future plans within the industry?

My plans for the industry have no boundaries. Being part of a growing company that works on cutting-edge technologies has really opened my eyes towards the possibilities for the future of manufacturing. I will continue to leverage emerging tech, like AI, to optimize processes and improve product quality, while also contributing to the development of sustainable and efficient manufacturing practices. Additionally, I plan to share my expertise with others through mentoring and knowledge sharing, as well as collaborating with industry leaders to drive innovation and growth.

How can this industry encourage more people to join and pursue successful careers here?

I think the first step is to spread more awareness about the opportunities available in the field and emphasize how diverse and rewarding a career in manufacturing is. Providing opportunities for on-the-job training and apprenticeships can help bridge the skills gap and create a pathway for individuals who may otherwise never get the chance to be exposed to the field. Finally, encouraging more women to join the manufacturing space is crucial. The industry needs a diverse workforce to innovate and remain competitive in the global market.

MIKE FISHER Solution architecture manager for Americas, Belden

What do you enjoy the most about working in the manufacturing and automation space?

Industrial automation really is like nothing else. There are real-world problems and the

solutions to them can have a measurable impact. The blend of vintage systems and modern technologies means that there are usually multiple paths to success. The rapid pace of innovation allows us to be creative without undermining the significant achievements that brought us here. While people often talk about how great the cutting edge of technology can be, it’s when you mix reality into the situation that you start to see where risk-taking and innovation can push the boundaries of what’s possible. Not that the point is to suffer through the heart ache and failed promises of emerging technologies, but to discover where pushing limits can take us and to accomplish great things.

Long gone are the days when problems were solved by brute force and collective willpower alone. Even in areas with a seemingly limitless labour supply, people are recognizing the benefits of seeking alternative approaches and tackling problems with a solutions mindset. Helping people get to the root of their issues, develop solutions that take into account the needs of their business, and getting those solutions successfully deployed … each part is rewarding, but being able to see it end-to-end and then getting to help another group of people on their journey is something I don’t think I’ll ever get tired of.

How can this industry encourage more people to join and pursue successful careers here?

To make sure that more people can find successful and rewarding careers in the industrial world, it’s important to remember that helping others doesn’t have to be selfless. Being a mentor, or a coach, or even just a good

teammate can be rewarding. Newcomers to the industrial world are often incredibly bright, and with the right support they can produce amazing results. We shouldn’t shy away from spending a little extra time with them. Rather, we should embrace it. It may take some effort to get them up to speed but they aren’t the only ones that benefit from it.

Control systems designer, Ramp

What do you enjoy the most about working in the manufacturing and automation space?

I enjoy that every job is different. I get to see machines created from the ground up and it is rewarding to be a part of the team that makes them move. Working with new technology means that I’m

never bored with what I’m doing. Whether it is working with 6-axis robots, hard automation, or autonomous mobile robots, there is always something new to learn.

What are your future plans within the industry?

I enjoy the technical side of the job and being hands-on. My plan is to continue to build my technical skills to help lead and guide our growing team. I enjoy mentoring new control system designers and seeing their skills develop. I get satisfaction from knowing I played a part in their success.

How can this industry encourage more people to join and pursue successful careers here?

Automation is the future, more and more production is going to be automated and this industry will continue to grow. We should be promoting these careers in high schools to raise awareness of what happens behind the scenes in manufacturing. I graduated from Conestoga College’s Robotics and Automation program and now sit on the

Program Advisory Committee as an industry representative. Being a part of this committee, I give input to the college to update them on industry standards.

Industrial electrician, Systematix

What do you enjoy the most about working in the manufacturing and automation space?

I enjoy getting to build machines that simplify processes and working with new technology. When you’re building custom automation it’s always new, never repetitive or boring and you’re always learning. With automation, repetitive and time-consuming tasks are done quickly and accurately, reducing the chances

of mistakes and increasing the customer’s efficiency. The facility where I work isn’t like a typical factory – it’s clean and bright, and the equipment is always new. You get to play with robots as well!

What are your future plans within the industry?

I enjoy teaching our electrical apprentices how to wire properly and develop their skills including critical thinking. I am at the point in my career where I am the lead electrician on builds. I enjoy planning, mentoring people on the team, and seeing everything come together. I would enjoy future leadership opportunities at Systematix.

How can this industry encourage more people to join and pursue successful careers here?

Taking advantage of high school co-op programs and the Ontario Youth Apprenticeship program are a great way to try out a field. After spending my grade 12 co-op at Systematix, I worked full-time in the electrical department before entering a 442A apprenticeship at Conestoga College. | MA

BY SUKANYA RAY GHOSH

The Automate show this year, held in Detroit, U.S., from May 22 to 25, brought together the latest innovations and technologies in automation for North American manufacturers.

While robotics displays were in abundance on the show floor, it was easy to spot motion control solutions, communications and networking components, data acquisition tools, AI solutions, options for industrial control and more along the many aisles spread out across four halls at Huntington Place Convention Center.

Manufacturers and systems integrators stopped by the many exhibitor booths to look at the latest innovations, network with suppliers and bag the literature on the various products on display. Show attendees also had the option to attend conference tracks every day covering trending industry topics, including AI and smart automation, autonomous mobile robots, collaborative robots, automation applications and innovations, how to automate and more.

Automate 2023 had four keynotes this year, presented by Tom Izzo, Michigan State University basketball coach, Gregory Robinson, former director, NASA James Webb Space Telescope project, Barbara Humpton, president and CEO, Siemens Corporation USA and Jan Diekmann, technical account manager, Ericsson.

The Motor City Mingle opening reception on May 22 and the Automate Networking Party on May 23 were buzzing with excited chatter as attendees and exhibitors forgot about the exhausting day to have drinks and dinner with old industry friends and strangers.

When asked about their goal for Automate 2023, many exhibitors shared that they were at the show to increase their brand awareness, showcase their latest innovations and listen to what potential customers were looking for. As several exhibitors launched exciting products for the North American market during the event, interactive displays and innovative demos were a common sight in the aisles. | MA

AIoT promises to bring the power of AI to the operational technology that runs our factories. BY JACOB STOLLER

The widely quoted phrase “the network is the computer”, coined in 1984 by Sun Microsystems VP John Gage, signified a trend that saw the transport of data become an essential pillar of information technology (IT). Today, computing devices that do not connect to the internet are virtually extinct.

In manufacturing and other fields, a similar fusion is taking place between cloudbased artificial intelligence (AI) technology and installations of Internet of Things (IoT) devices. The trend will see the operational technology (OT) that is used in industrial automation being enabled with the same computing power that is now being used to analyze medical images, predict disruptions in global supply chains and identify vulnerabilities in a corporate financial plan.

“AIoT is the fusion of two disruptive technologies, IoT and AI,” says René Breyel, AIoT strategic advisor at Montreal-based consulting firm Claridion. “IoT provides access to the state of any object or device in the physical world, and AI gives us the analysis of that data in order to understand and act on it.”

Connecting sensors to computing systems is nothing new – supervisory control and data acquisition (SCADA)–based monitoring systems date back to the 1960s. “We’ve had connectivity for oil rigs in the ocean for fifteen or twenty years,” says Breyel. “But those were multi-million-dollar solutions that were adopted because these rigs were really critical. Today, with the pricing drop of electronics and wireless connectivity, and with computing capacity and AI we get in the cloud, those amazing technologies are becoming widely available to every industry.”

Breyel sees three key areas where manufacturing will benefit from AIoT. “One key area is performance,” he says. “Because we get better information about machines and processes and their level of performance in real time, we are able to process them more

efficiently to make smarter decisions and produce more.”

The second benefit is better quality. “This is basically the same idea,” says Breyel. “You get more and richer data about what you produce, so you can control quality more effectively.”

Last but not least, AIoT can monitor the location of employees, forklifts, robots or machine tools to identify and mitigate safety risks. “Again, with more and better information, enriched by intelligent analytics, it becomes easier to understand and manage risk,” says Breyel.

Europe leads the charge European companies, typically ahead of North America in industrial automation, are taking the lead in developing AIoT applications, and the most advanced use cases for the technology are in European countries.

Bosch operates a fully AIoT enabled semiconductor plant in Dresden, Germany. The IoT network monitors sensors, systems and products throughout the manufacturing processes, collecting the equivalent of 500 pages of text per second. AI-powered algorithms

analyze the data in real time to predict trends and mitigate problems.

One of the advantages of this new capability is that the scope of data management can cover an entire manufacturing process from end to end. Waggeryd Cell Pulp Mill in southern Sweden, with production capacity of 175,000 tonnes per year, worked with Asea Brown Boveri (ABB) to deploy 156 smart sensors that monitor the entire power chain. This allows AI-enabled software to predict plant-wide trends based on power consumption, speed, vibration and temperatures.

To respond to this growing trend, Breyel joined with a few colleagues to found AIoT Canada, a not-for-profit cluster dedicated to educating Canadian business and government leaders about AIoT.

“It’s a story we started five years ago,” says Breyel. “We saw that we really needed an organization of people that are really involved with this to push the idea forward in Canada.”

At the outset, the organization turned to Europe for advice. “Bosch in Germany is a global leader in Industry 4.0 solutions and IoT connectivity,” says Breyel. “Four years ago, we brought them to Montreal to provide

IoT training. They presented a digital innovation model but came to the conclusion that we didn’t have the maturity to push this kind of training at this level in North America at that time. For me, this was a wake-up call.”

It’s not just about technology

One of the big challenges is that AIoT involves connecting factory devices to the internet –something that was off limits in the past, for security and intellectual property concerns.

“There has traditionally been a gap between IT and operational technology (OT), the large industrial platforms that were implemented by companies like Siemens, Omron or ABB,” says Breyel. “These are used to manage all the different components in the factory. They have their own networks, their own protocols, their own security stack, and their own databases. But now we are coming up with solutions where IoT sensors are being connected to an IP wireless network going into the cloud. So now we want to bring those two networks together and implement IoT and AI stuff on top of that. This becomes quite challenging.”

One of the problems is that OT networks are completely new territory for IT people. “IT people are not used to managing OT systems because they were never allowed to interact with those operational and very sensitive infrastructures,” says Breyel. “The problem for them is that this factory equipment is in production 24/7, so as soon as you touch anything, it is risky and complicated. So, companies will need a strategy to deal with that.”

In general, it is the people issues that will be most challenging. “The technology is there, and people in manufacturing understand their processes and see the value in this, which is why AIoT is moving forward so quickly,” says Breyel. “The difficult and risky part is that the right people don’t have access to the training and education required to learn how to bring these two silos together. That will take a new degree of digital literacy across the organization, and a digital transformation plan.”

Canada faces some particular challenges. One is that Canadian telcos favour cellular technologies and do not deploy LPWAN (Low Power, Wide Area Network), which is well suited to IoT networks and more widely available in Europe. Another is that relative to other countries, Canada has a large number of SME manufacturers that lack the resources to engage in a major technology transformation.

AIoT Canada is building a community that will help mediate these issues.

In spite of the challenges, AIoT Canada is seeing enormous interest from Canadian companies. The speed with which AIoT is developing gives industrial leaders little choice about getting on board with the technology. “The integration of these disruptive

technologies within our factories is no longer an option,” says Breyel. “Industrial leaders must absolutely take them into account and integrate them into their strategic plan for their digital transformation.” | MA

Jacob Stoller is a journalist and author who writes about Lean, information technology and finance.

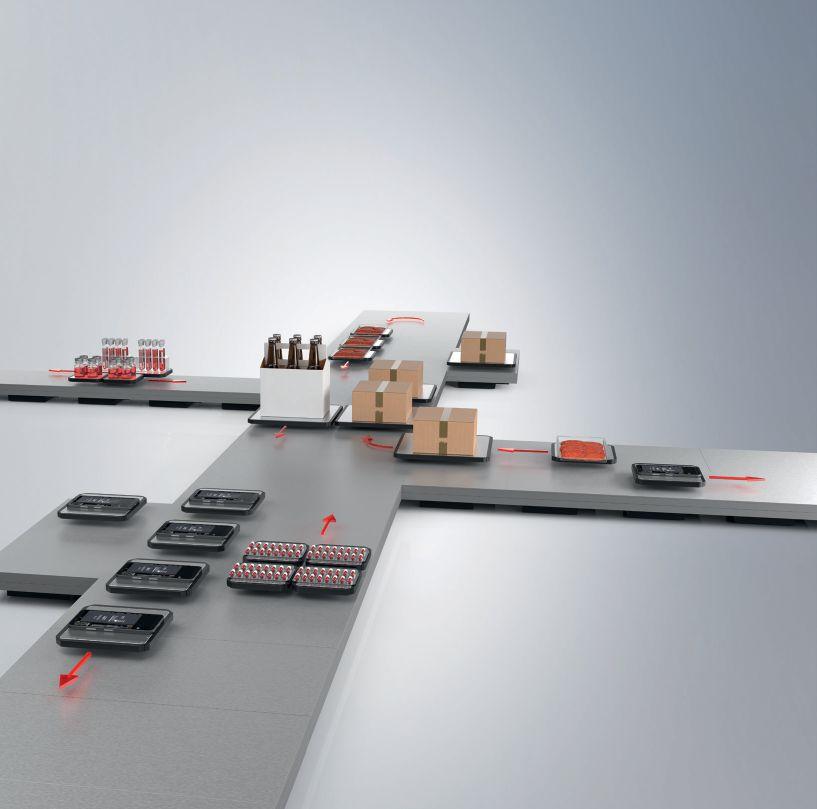

XPlanar enables new dimensions of freedom in product and material handling: Levitating planar movers fly over flexibly arranged planar tiles accommodating nearly any track layout and path planning.

Individual 2D transport at up to 2 m/s

Processing with up to 6 degrees of freedom

Transport and processing in one system

Wear-free, hygienic and easy to clean

Free arrangement of planar tiles enabling totally customized machine and process layouts

Multi-mover control enables parallel and individual product handling

Fully integrated into the powerful and standardized PC-based Beckhoff control system

(TwinCAT, PLC IEC 61131, Motion, Measurement, Machine Learning, Vision, Communication, HMI) For use across all industries: assembly, packaging, food/bev, pharma, laboratory, entertainment, …

Automated welding system significantly increases its speed of production using EtherCAT and PC-based control.

BY JAMES FIGY, BECKHOFF AUTOMATION

Dean Jacobs can describe the world of welding equipment in two words: bolt-on. “People bolt on this subsystem here, bolt on that one there,” says Jacobs, principal automation engineer at LJ Welding Automation. “Soon, your welding cell has seven control panels and needs a massive power bar to feed them all.” The bolt-on approach was born of necessity. However, as technologies advance and equipment end users demand more modular solutions, the design and maintenance of such systems have become unsustainable.

LJ Welding Automation recognized early on that an integrated approach not only provides a cleaner look but is also a key differentiator for machines in a bolt-on world. The Edmonton, Alberta-based company provides wide-ranging solutions, specializing in submerged-arc welding manipulators. With customers in more than 50 countries, it serves industries as diverse as oil and gas, alternative energy, aerospace, transportation, infrastructure, healthcare and beyond.

“When my partners and I bought the company in 2006, it made just six widgets, but it had a great customer base,” vice-president of product development Tim Robinson says. “We took a chance and turned it into an engineering company. Over the last 17 years, we have expanded rapidly, and now we have hundreds of products as well as many custom, application-specific solutions. We can also tie together multiple pieces of equipment and provide complete turnkey plant design.”

With the new Pipe Titan pipe welding system, LJ Welding Automation offers a complete pipe processing centre. The system is optimized for 2- to 24-inch-diameter pipes. One of the first Pipe Titan systems needed to deliver high-performance pipe welding at the Cleaver-Brooks facility in Stratford, Ontario. EtherCAT and PC-based control technologies from Beckhoff helped consolidate functionality into a centralized control architecture and provide a flexible, fully integrated solution.

Optimized welding is not just a pipe dream

Cleaver-Brooks is a global provider of efficient boiler room solutions, with a focus on reducing energy usage, cost and environmental impact. The pioneer of packaged firetube and watertube boilers stands alone in offering an entirely integrated boiler room solution for applications of any size. Cleaver-Brooks had several requirements for Pipe Titan, including reducing costs, improving quality, increasing productivity and enhancing safety, according to corporate welding specialist Joel McLeod.

“Welding is a core competency at Cleaver-Brooks that helps ensure the structural integrity and reliability of our boiler room products and systems,” McLeod explains. “We use a variety of welding processes throughout production to assemble and join various metal components in order to create sturdy and leak-proof boiler systems.”

In addition, the LJ Welding Automation engineering team needed to maintain a clean design with highly deterministic control and

system modularity for changing production processes. They also needed automation and networking technologies to support a highend welder from EWM, according to Jacobs. This welding equipment uses highly tailored programs to limit heat in the workpiece, thus minimizing warping and corrosion in pressure piping. The new welder had to work with the existing recipe management system to guarantee reliable and consistent results.

As he has done before, Jacobs turned to Beckhoff to meet the Pipe Titan project’s challenges. “When I started at LJ a decade ago, it was a blank slate in terms of automation platforms,” he says. “A major draw of PC-based control was – and continues to be – the ability to integrate third-party technologies on one platform. I was blown away by the technology as well as the service from Beckhoff Canada back then, and a complete solution cost less than just the HMI and controller hardware did from our legacy PLC vendor. We have continued to use Beckhoff on our machines ever since.”

The Pipe Titan uses a CP6700 “economy” built-in Panel PC as the central machine controller. Combining HMI and control CPU in one device, the CP6700 offers a 10-inch touchscreen with Intel Atom processors. The Pipe Titan has two separate positioners, and each has its own CX series embedded controller from Beckhoff. “The positioners have their own controller for simple one- or twoaxis P2P applications to rotate the pipe, along with functional safety and an HMI server. This way, they can function as independent machines if needed,” Jacobs says. “You can unplug one positioner, take it to the other side of the plant, and use it. We use this modular architecture on all our larger machines.”

TwinCAT 3 automation software enables this architecture as an end-to-end engineering and runtime environment. Rather than the bolt-on approach of many black-box machine control offerings, TwinCAT combines all functionality on a comprehensive platform for everything from PLC, HMI and motion control to IoT, analytics and even machine learning.

TwinCAT supports programming in all IEC 61131-3 languages and their object-oriented extensions, custom or predefined function blocks, and computer science standards in Microsoft Visual Studio. LJ Welding Automation leverages Structured Text, JavaScript

for HMI development and other languages as necessary. TwinCAT helps the LJ Welding Automation engineering team consolidate to a single tool chain to avoid switching between development environments. It also provides them with advanced source control options, as Benjamin Vandenberg, Automation Engineering EIT at LJ Welding Automation, explains.

“A standout feature of TwinCAT is the excellent integration of source control, especially with all of the custom work we do. This prevents confusion – and space requirements for – unnecessary copies of projects with different dates. The license-free development environment means our team can log in on their own laptops without

issues,” Vandenberg says. “Also, TwinCAT Library Manager speeds up development by allowing us to add or remove large blocks of code instead of writing it from scratch. We can save any changes to the source control to easily fix bugs, update the library and continue to pursue continuous improvement of our products.”

The EtherCAT industrial Ethernet system’s flexibility and scalability proved instrumental to the integrated yet modular design. EtherCAT enables free selection of topology, up to 65,535 nodes on one network and hot connect capabilities. For the positioner modules, the Pipe Titan uses EtherCAT Automation Protocol (EAP) for controller-to-controller communication and safety.

The Pipe Titan has multiple E-stops across its modules, which communicate via TwinSAFE, the integrated functional safety solution from Beckhoff. TwinSAFE works over the standard EtherCAT network using a “black channel” approach. As such, it supports modular machine designs without any hardwired safety controllers to physically adjust, Vandenberg explains: “We essentially have three independent safety systems running, each one with an EL6910 TwinSAFE Logic Terminal. They communicate with each other using Safety over EtherCAT (FSoE), and we can simply turn those connections on and off in software using TwinSAFE features. We can add or remove different pieces of equipment as necessary to make it a more adaptable and scalable system.”

The LJ Welding Automation engineering team also relies on the vast number of available EtherCAT I/O terminals. The EL7211 and EL7221 servomotor terminals provide a compact motion interface in the 48 V range to AM8100 series servomotors. The EL3255 5-channel potentiometer modules ensure accurate speeds on the positioners when controlled by a hand pendant, variable-speed foot pedal, etc. The high conformance standards of the EtherCAT Technology Group ensure third-party devices, such as a VFD on the Pipe Titan, work seamlessly with the EtherCAT controllers from Beckhoff.

EtherCAT also supports connection to more than 30 communication protocols with the addition of a gateway. This promotes flexibility in component selection and avoids bolt-on scenarios. “On the Pipe Titan, the EL6224 IO-Link master terminal was particularly useful for connecting a laser displacement sensor, and we’ve used it in many other applications,” Jacobs says. “IO-Link is a flexible technology to connect sensors and other devices. The nodes can be inputs or outputs, so I don’t have to stock numerous analog cards. The ability to bring the IO-Link devices into an EtherCAT network with a compact bus terminal adds greater flexibility to the system.”

By leveraging PC-based automation from Beckhoff, the team at LJ Welding Automation implemented a system that surpassed the requirements of Cleaver-Brooks. The Pipe Titan led to impressive performance increases, according to McLeod. Cleaver-Brooks reduced arc time by 63 percent on average, which is nearly three times faster. The Pipe Titan also led to a 90 percent reduction in weld clean up time, 10 percent reduction in rework and 39 percent reduction in filler metal spend.

“The Pipe Titan welding system allows us to perform tasks faster and more efficiently than manual labour, leading to increased productivity and capacity. It reduces errors and inconsistencies, resulting in

higher quality output,” McLeod says. “Being mechanized, it can be programmed to perform a variety of tasks and can be easily reconfigured to meet our changing production demands. The Pipe Titan welding system helps reduce the risk of workplace accidents and injuries associated with manual labour, thereby improving employee safety.”

TwinCAT accelerated development, and the built-in software oscilloscope, TwinCAT Scope, enhanced tuning of the machine. EtherCAT enabled commissioning of the machine from a single Ethernet cable through mailboxes that Vandenberg set up. Beckhoff servo technologies saved space through compact drive offerings and One Cable Technology (OCT). Using the IPC Security Guideline from Beckhoff, LJ Welding Automation can safely remote into customer machines for maintenance or troubleshooting. But the team isn’t stopping there.

The next phase for the Pipe Titan and other LJ Welding Automation machines is higher-level connectivity for analytics and continuous improvement, according to Robinson. “For customers with half a dozen machines or more, IoT functionality is important for managing and optimizing analytics and training new employees,” he says. “Having an analytics suite that works together in a central dashboard will be huge for those customers.”

Fortunately, says Jacobs, this is another area where Beckhoff’s technology is not bolt-on. Standard analytics algorithms, no-code dashboards, secure connectivity via OPC UA and more are all built into TwinCAT. The flexibility of the full-system solution continues to help LJ Welding Automation offer unique, highly differentiated solutions to the market. “We strive not to paint ourselves into a corner, because we often have to make changes late in the game,” Jacobs says. “With PC-based automation from Beckhoff, we have been able to make continuous improvements over the years. It has been a robust platform for us, and we’re not even close to outgrowing it.” | MA

Enclosures are a critical element in automation, control, and drives projects.

You need a reliable supplier you can count on for:

• Quality Made Enclosures

• Wide variety of Product Solutions

• Modification Capabilities

You can trust Hammond to be that supplier.

BY THE CANADIAN CENTRE FOR OCCUPATIONAL HEALTH AND SAFETY (CCOHS)

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well-being – physical, psychosocial, and mental health – of workers in Canada by providing information, advice, education and management systems and solutions that support the prevention of injury and illness. Visit www.ccohs.ca for more safety tips.

Automated machinery has revolutionized the manufacturing industry, making production faster and more efficient than ever before. Newer applications for automation, including collaborative robots, have the potential to improve workplace safety by taking on tasks that are dangerous or undesirable for workers. But advancements in automation can introduce new potential hazards, such as being trapped or crushed between machine components, vibration and noise, abrasion or cutting and hydraulic and pneumatic hazards.

Employers have a legal responsibility to ensure the safety of their workers. Following relevant guidelines and standards can help enhance the workplace safety program.

Here are several factors to consider when working with automated machinery.

Hazard identification and risk assessment

Identify the hazards that could exist in all tasks associated with the machine and assess the associated risks. These tasks include the installation and commissioning of the equipment as well as routine maintenance and inspections. Ideally, the hazard identification and risk assessment should be carried out by trained professionals who understand the hazards of automated machinery and are familiar with relevant industry standards. CSA Z432-16 – Safeguarding of Machinery provides guidelines for the risk assessment process.

When identifying potential hazards, consider what types of injuries could happen while working with or around the machine. Hazards may vary depending on the exact machine used but may include exposure to moving parts, energy, heat or cold, noise, vibration, radiation and gas or liquid under pressure. Automation can also affect how jobs are performed, such as increased repetition of some tasks requiring high dexterity that cannot be performed by machines. This can result in an increased risk of repetitive strain injury. There may also be psychosocial hazards related to the pressure to keep up with the performance of automated machines, jobs becoming monotonous because automation decreased the scope for task rotation and variety, or an increase in cognitive

When identifying potential hazards, consider what type of injuries could happen while working with or around the machine.

load because the less cognitively demanding tasks are automated.

Determine the probability of harm by reviewing information about the machine’s operation, including maintenance records, machine breakdown reports and potential human behaviour while performing these tasks. Determine the severity of harm by considering which mechanical, physical or psychosocial hazards are involved and what types of injuries could occur. When rating the risk for each type of injury, assume no protective measures have been installed on the machine to account for the potential malfunction of these measures. This evaluation will help determine if sufficient action has been taken to prevent injury. CSA Z432-16 provides additional details on the assessment process.

It’s crucial that employers provide ongoing education to keep workers up to date on the latest safety standards and practices. CSA Z432-16 provides guidelines for the training and education of workers.

Workers should be trained on how to safely work with or near automated machines and they should be able to list any hazards that may occur. Where are the moving parts, and which corresponding safeguards are currently in place? Workers must also know how to report malfunctions and guard defects because timely reporting is crucial to injury prevention.

In addition, workers need to know how to respond in case of an emergency. Safety and rescue protocols should be covered in training and readily available in a clearly marked place for workers to reference. If an incident happens, they need to know who to notify and how to ensure help arrives as quickly as possible.

CSA Z432 -16 defines safeguarding as: “… protective measures consisting of the use of specific technical means, called safeguards (guards, protective devices), to protect workers from hazards that cannot be reasonably removed or sufficiently limited by design.” Simply put, a safeguard is a guard or protective device designed to protect workers from harm. While there is no current CSA standard for safeguards specific to automated machinery, workplaces should refer to instructions and resources from the automated machinery manufacturer when developing maintenance and inspection protocols, and safeguard accordingly.

Regularly inspect and maintain automated machinery to prevent malfunctions and other hazards. Check for loose parts, replace worn-out components, and confirm that all safety features are in working order. Develop a maintenance schedule that includes routine inspection of safety guards, safety interlocks, and safety barriers. Repair or replace any damaged or malfunctioning safety equipment immediately. Make sure appropriate hazardous energy control measures are used during maintenance and inspection activities to protect personnel from injury due to the inadvertent release of hazardous energy. Refer to CSA Z432-16 for guidelines on the maintenance and inspection of automated machinery. Keeping workers safe around automated machinery requires thorough planning, robust safety protocols, following manufacturers’ instructions, and keeping apprised of the relevant standards and legal requirements in your jurisdiction. Provide a solid foundation for reducing the risk of incidents and injuries in your workplace by also conducting hazard and risk assessments, thorough training, safeguarding and regular maintenance. | MA

WATCH

BY PAUL HOGENDOORN

Paul Hogendoorn co-founded FreePoint Technologies with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people. He can be reached at hogendoorn.paul@gmail.com or linkedin.com/in/paulhogendoorn.

Irecently saw a story from our national broadcaster reporting that 50,000 people have left Ontario, most of whom headed to Alberta. By coincidence, I was in Alberta in March and I heard the same news there: 50,000 people had left Ontario and had moved to Alberta.

In Alberta, it is rightfully seen as a positive thing and an affirmation that they are, or have been, doing something right the last few years. Radio ads running in Ontario boldly state “Alberta is calling”. It can’t be the oil and gas industry causing the positive vibe because we know momentum is not on their side. Around 50,000 people leaving Ontario for Alberta is an alarming statistic, but when that number is mostly young families, it should be seen as an indication that something in Ontario is not working.

Ontario recently announced major expansions with Magna and other automotive-related manufacturers, plus the landing of a major battery manufacturing facility for Volkswagen. We can deduce that it’s not the lack of well-paying jobs in Ontario. The manufacturing sector has many skilled and high-paying non-skilled jobs it is struggling to fill. So, it must be something else that’s driving families out in search of a better future.

Here’s what I think it is: Ontario is still suffering from a post-pandemic hangover. To be completely transparent, I have been a lifetime conservative voter, so it pains me to say that this hangover lies mostly at the feet of Ontario’s current provincial government.

Ontario was quick to put some of the harshest measures in place, but very slow in undoing them. They continued to play the “fear card” to deflect

criticism of the true economic and social cost of their actions while plodding painfully slow towards a resumption of what was “normal”. They continue to associate some problems with the pandemic while completely ignoring the escalated social problems that were exacerbated by the overly harsh and overly long lockdowns.

In the week I spent in Alberta in March, it became clear to me that they weren’t in a postpandemic hangover. They did things differently: they weren’t as extreme in applying their measures, and they were quicker to return to what was normal before.

Whether that’s a measure of the innate differences between people that choose to live in Ontario and people that choose to live in Alberta, or the differences between how the two provinces’ governments reacted during and after the pandemic, we can never be certain. It’s likely a combination of both. Some are more inclined towards “having the opportunity to look after their families themselves” while others gravitate towards “a government that looks after the people’s needs”.

To many, it seems Ontario has drifted away from being the province that is best for their family’s future, and some of them have already left. This is just a warning signal that the Ford government needs to recognize and react to quickly. For everyone that has left, there are likely two, three or perhaps five others that are contemplating it. And the demographic of this pending exodus comprises industrious, hardworking people; young and middle-aged family people; professional and skilled people.

Kudos to the Ford government for its role in attracting new and expanded

manufacturing companies, but it will take more than exciting announcements of new things to keep good people from leaving or dreaming about leaving. I’d suggest that it starts with restitution, reconciliation and restoration. At least 15 percent of the population was adamant that their basic human right included the right to choose to be jabbed or not, even to the point of losing their careers, and far more were opposed to it but didn’t resist it to keep their jobs or to travel.

There is still a huge chasm in our society over this. The government can start the healing process by admitting many measures have now proven to be

overly harsh and these mistakes won’t be repeated. It should start by restoring the jobs of those that were directly affected by the requirement to get the jab. If only a small number of people return, they are all in the fields and services the province needs to fill. And second, find a way to encourage college and university students that aborted their studies to resume them.

I think this is the underlying reason people who have lived in Ontario a long time are now leaving: the provinces’ politics don’t provide a view of a future they see as promising for themselves or their families. They are looking west to Alberta, and they start to see one. | MA

BY NEAL MOHAMMED

Neal Mohammed is the director of the Barrett Centre for Technology Innovation at Humber College, an all-encompassing hub of resources and activities that aims to have a positive impact on industry, small to medium-sized businesses (SMEs) and the workforce of the future. Reach out to neal.mohammed@humber.ca to learn how to get involved.

Canada’s manufacturing industry is experiencing a skills shortage, and the demand for automation technology experts is growing rapidly as our world increasingly relies on these industries. Humber College’s approach to preparing students for the field includes a focus on hands-on work, extensive research opportunities and a culture of innovation to train the next generation of automation technology experts.

Located on the College’s North Campus, the Barrett Centre for Technology Innovation (Barrett CTI) is a 93,000-square-foot facility designed to be a powerhouse of technological innovation which leverages Humber’s expertise in advanced manufacturing, digital transformation, automation and robotics, systems integration, as well as augmented and virtual realities.

The Barrett CTI is a hub for students to work alongside industry partners and members of the Advanced Manufacturing Skills Consortium: Cisco Canada, DMG MORI Canada, Festo Didactic, Trimech Solutions (formerly known as Javelin Technologies), KUKA Canada, Magna International, Rockwell Automation, SEW-EURODRIVE and SICK Canada. These partners have provided support on equipment, technical expertise, professional development opportunities and scholarships, and some have even built modern labs inside the Barrett CTI. Experiential learning opportunities are essential to developing the practical skills needed to work with automation technologies. Industry trends are fast-paced, and emerging technologies are changing the way we work. By getting ahead of the curve, students with hands-on training are better equipped to meet the demands of industry when they enter the workforce.

At Humber, students work alongside industry experts and faculty to come up with innovative ideas and create solutions in a risk-free environment. This

technologies, as well as equipment employing machine learning, AI, auto ID and industry 4.0 functionalities, students and staff were able to leverage the expertise of industry partners and develop their skills in systems integration technologies from various manufacturers.

To innovate, you can’t be afraid to challenge the status quo.

allows students to embrace innovation, think outside the box and explore new possibilities. These industry-focused spaces provide a platform for collaboration and innovation that can drive progress in various fields, benefiting not only students but industry as well. Humber provides companies with spaces to do applied research, access to advanced equipment and technologies, and a team of faculty and students to build proof of concepts.

To innovate, you can’t be afraid to challenge the status quo. Students view things through a different lens. Their exuberance and courage to take risks make them a perfect fit to work and create unique ideas that, in turn, help industry partners.

Training at the Barrett CTI prepares individuals in advanced manufacturing, robotics applications, automation, systems integrations and digital transformation. Students work on industry projects in Industry 4.0, IoT, machine learning, condition monitoring, data analytics, mobile technology, visualization and blockchain cybersecurity.

The successful completion of recent industrial capstone projects is evidence of the fruitful collaboration between the Barrett CTI and its industry partners. Students and faculty of the Electromechanical Engineering program collaborated on several advanced manufacturing stations with SICK Canada and KUKA Robotics, including robot guidance applications. Using varying types of vision and sensor

“There really is no experience quite like working on your first-ever industrial project. Working with SICK Sensor Intelligence in creating the machine vision and auto ID demo cell was a fantastic opportunity,” said Hassan Ismail, a student in the Electromechanical Engineering program. “I was able to learn so much within the eight months of this project that I probably wouldn’t have been able to learn within the first few years of my career.”

Barrett CTI benefits can be seen beyond post-secondary students and industry partners. The Centre offers programming for K-12 students to visit the labs, learn about the latest technologies and connect with industry professionals.

Humber also collaborates with industry partners to offer practical and concise micro-credentials that enable professionals to expand their skills and knowledge in specific fields. The college hosts workshops and professional development activities that are led by industry experts. A recent example is a workshop on 3D scanning technology, which showcased how it can improve product design and stability with millimetre-level accuracy. The Barrett CTI also serves as a venue for hosting technology events that bring companies from around the world together to present their latest technologies and share best practices.

A recent $30 million donation from the Barrett Family Foundation will enable Humber to continue to advance and support industry-driven skills designed to enhance employability through workforce training, upskilling, and reskilling that will lead to a pipeline of diverse industry professionals. | MA

AutomationDirect recently added newest A-coded sensor and signal connection cables from Murrelektronik. According to the company, the cables provide connections between panels and field devices. They offer several configurations, including axial or right-angle female M8 or M12 screw-lock connector to pigtail, axial male to axial female with M8 or M12 screw-lock connectors, and right-angle male to rightangle female with M8 or M12 screw-lock connectors. These sensor and signal connection cables have a PUR/PP jacket ideal for applications with sunlight exposure. They are also suitable for repetitive flexing applications like robotics. The new Murrelektronik A-coded sensor and signal connection cables are available in various colors, lengths, and pole configurations at AutomationDirect. automationdirect.com

Electric alternative to pneumatics

SMAC’s new LDL Programmable Electric Linear Actuator is designed as an alternative to pneumatics. According to

Electromate, the SMAC LDL series actuators come with several features, including stroke [mm] of 10 – 100; peak force [N] of 90 (48VDC); and encoder resolution [µm] – five standard, one optional. They are fully programmable in force, position and velocity and feature SMAC’s patented “Soft-Land” technology. Built-in controller type is available for this product. SMAC electric actuators are reportedly ideal for high cycle positioning, measuring, inspection and pick and place applications, particularly where 100 percent verification is required. electromate.com

WAGO’s newly released Pro 2 EtherNet/IP with MQTT communications module (2789-9023) has reportedly added a new level of monitoring as well as control of power supplies and DC subsystems. The product features an intuitive web interface. This communication module is designed to quickly commission the power supply and also help identify potential problems in real-time with data such as current and voltage along with other warnings. This module can be used on newly designed systems or existing systems with upgrade capabilities and comes with the ability to be reconfigured. WAGO is offering add-on instructions to make integration with other PLCs easy. wago.com

Mitsubishi Electric Automation’s MELSOFT MaiLab software uses the company’s Maisart intelligent technology to enable companies to analyze and diagnose factory data. Through analysis of past manufacturing data, the software makes data decisions. MaiLab’s software design with a user interface reportedly includes single-tool capability, enabling both offline analysis and real-time diagnostics, with direct feedback to the production site. Its integrated open concept, such as the Python programming language or web-based environment, ensures the software’s longevity and future-proof design. mitsubishielectric.com

IDEC Corporation’s new HT4P Safety Commander has reportedly incorporated end user feature requests for additional networking and operator interface functionality. The HT4P Safety Commander allows users to securely hold and protect a human-machine interface (HMI) tablet, while providing power, networking, and hardwired emergency stop (e-stop) and other operator interface devices. OEMs and automation designers can reportedly provide safety-rated operator interface options for equipment, robotics, collaborative robots, automated guided vehicles, autonomous mobile robots, and other manufacturing system applications. The HT4P can hold tablets ranging from 10-inch up to a 13-inch using adjustable grippers. In addition, a guard is available to protect against inadvertent operation of the e-stop button. IDEC.com