WOMEN IN AUTOMATION

Profile: Emily Heitmen, Schneider Electric, Canada p. 12

EDUCATION AND TRAINING

An upskilling advanced manufacturing program to fill jobs. p. 14

WOMEN IN AUTOMATION

Profile: Emily Heitmen, Schneider Electric, Canada p. 12

An upskilling advanced manufacturing program to fill jobs. p. 14

Industry experts share their predictions for the year p.6

The

Emily Heitman, country president, Canada, at Schneider Electric, discusses

Unlocking

Four

From predictive maintenance to collaborative robots, experts discuss key trends that can revolutionize Canadian manufacturing in 2024.

By Sukanya Ray Ghosh

A new 16-week upskilling program will help fill the need for entry-level jobs in manufacturing.

By Jack Kazmierski

Exploring the complexities of safety standards and compliance obligations for manufacturers in Canada. By Sukanya Ray Ghosh

BY SUKANYA RAY GHOSH

In the landscape of global manufacturing, the integration of automation and digital transformation has become more than just a competitive edge; it’s a necessity for survival and growth. As the world continues to embrace Industry 4.0, Canadian manufacturing business leaders find themselves at a pivotal juncture where embracing technological advancements is no longer an option but a strategic imperative.

To remain relevant in the current market, automation and its many possibilities cannot be ignored. However, priorities and ground realities differ for each manufacturing operation. For example, if the immediate need is to fill critical job roles on the plant floor instead of investing in the latest automation tech, then that is where the dollars should ideally go. The manufacturers are better positioned to understand the pressing issues in their businesses that need to be addressed sooner and allocate their resources accordingly. Additionally, while larger enterprises may have the resources and expertise to invest in automation, smaller businesses often face barriers such as high upfront costs, lack of technical know-how and cybersecurity concerns.

On the flip side, many technologies available today have the capability to prevent critical issues ahead of time, saving manufacturers valuable money, time and effort in managing them after the fact. Automation technologies such as robotics, artificial intelligence and the Internet of Things (IoT) offer unprecedented opportunities to streamline processes, minimize downtime and optimize resource utilization. Leveraging these technologies can help Canadian manufacturers significantly reduce production costs, enhance product quality and accelerate timeto-market, thereby gaining a competitive

advantage in the marketplace.

This is where the leaders and decision-makers come in. Typically, the primary objective of all manufacturing leaders is to ensure sustained growth. In the short term, fighting those urgent “fires” might ensure the survival of the business. However, adopting a long-term vision to keep operations current is essential.

Finding the necessary support from industry resources can make this journey much easier for manufacturing leaders. Industry events and conferences are a great way to connect with automation experts, like-minded peers and even resource facilitators.

On June 4, Manufacturing AUTOMATION is hosting the Canadian Automation Leadership Summit (CALS24) in London, Ont., in partnership with industry association Automate Canada, to facilitate such conversations. This event will bring together industry leaders, visionaries and experts to delve into the transformative role of leadership in harnessing the full potential of cutting-edge automation solutions in Canada’s exciting manufacturing sector. CALS24 will explore best practices, actionable strategies and real-world case studies to empower Canada’s manufacturing leadership to make informed decisions in adopting and optimizing automation solutions.

The event is co-located with Automate Canada’s Annual General Meeting in order to offer attendees the chance to connect directly with automation solution providers and a major industry association.

On behalf of Manufacturing AUTOMATION , I invite all Canadian manufacturing leaders to sign up for CALS24 to discuss the how, what, why, when and where of automation with industry peers and experts. | MA

Your resource for Canada’s industrial automation news

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: 416-510-5113

Fax: (416) 510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR

Sukanya Ray Ghosh srayghosh@annexbusinessmedia.com Tel: 416-510-5225

ASSOCIATE PUBLISHER

Kathryn Swan kswan@annexbusinessmedia.com Tel: 647-339-4880

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

MEDIA DESIGNER

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-510-5107

AUDIENCE DEVELOPMENT MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

PRESIDENT/COO

Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

David Morgenstern, Jack Kazmierski and Paul Hogendoorn

Published by Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 • Fax: 416-442-2191

Printed in Canada ISSN 1480-2996 Publication Mail Agreement #40065710

SUBSCRIPTION RATES

Canada — $43.86 per year

United States — $99.96 CAD per year

Foreign — $114.24 CAD per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com Tel: 800-668-2374

EDITORIAL ADVISORY BOARD

JIM BERETTA, President, Customer Attraction and host of The Robot Industry Podcast

JONATHAN GROSS, Managaing Director, Pemeco Consulting

MIHAELA VLASEA, Associate Professor, Department of Mechanical and Mechatronics Engineering and Research Co-Director, Multi-Scale Additive Manufacturing Laboratory at the University of Waterloo

SHELLEY FELLOWS, Past-Chair, Automate Canada

STEPHANIE HOLKO Director, Project Development at Next Generation Manufacturing Canada

WALTER GARRISON, Former Advanced Manufacturing Business Consultant for City of Mississauga

Occasionally, Manufacturing AUTOMATION will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. The contents of Manufacturing AUTOMATION are © 2024 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Xaba secures $2M in seed funding

Toronto-based Xaba has raised US$2 million in a seed extension round of funding that will help it establish and staff a new robotics lab. The funding will also be used to accelerate the delivery of its two manufacturing platforms –xCognition and xTrude.

Xaba shares in a press statement that it is augmenting industrial robots and cobots with xCognition, an artificial intelligence (AI)-powered software solution. xCognition reportedly leverages proprietary machine learning algorithms to model the elasto-mechanical-dynamic behaviour of industrial robotics and cobots, as well as workpiece variances. This includes variances in location and shape, using proprietary rule-based language models to eliminate coding of robotics programs.

MMTS 2024: Quebec gears up for a showcase of the latest tech innovations

The Montreal Manufacturing Technology Show (MMTS) is returning to the Palais des congrès de Montreal this year, scheduled to take place from June 18 to 20. MMTS, produced by SME, is a manufacturing industry event held in Quebec every two years. This year, it will showcase the latest in Quebec’s manufacturing landscape, encompassing machine tools, tooling and metalworking applications, as well as the smart manufacturing sectors, including automation and robotics, AI, cybersecurity, clean energy, battery technology and additive manufacturing. According to a press statement from SME, MMTS 2024 will bring together more than 5,000

manufacturing professionals interacting with a lineup of more than 250 OEMs and suppliers, 750,000+ pounds of live equipment, 100 new innovative products and 25 educational sessions by industry thought leaders across 175,000 square feet of exhibition space. Attendees will reportedly experience the latest industrial innovations in action through real-time machinery demonstrations, view products setting the pace for the future of manufacturing, learn about an array of innovative solutions elevating efficiency and productivity, gain invaluable insights from top experts and connect with field leaders.

Each evening will feature networking sessions so that the attendees and exhibitors enhance their manufacturing operations without disruptions to their daytime schedule.

North American robot orders declined in 2023, as per A3 report

An Association for Advancing Automation (A3) report finds that robot sales in North America declined by 30 percent in 2023 after record orders in the two previous years. Companies purchased 31,159 robots in 2023, compared to 44,196 ordered in 2022 and 39,708 in 2021. These 2023 orders were divided almost equally among automotive (15,723 robots sold) and non-automotive companies (15,436 robots sold). There was a 34 percent drop in sales to automotive OEMs and automotive suppliers over 2022 and a 25 percent total decrease in all other industries. In 2023, the strongest demand for robots from non-automotive companies came from the metal industry, followed by semiconductor and electronics/photonics; food and consumer goods; life sciences,

pharmaceutical and biomedical, plastics and rubber and others.

A3 notes that the last three months of the year saw higher sales in automotive, metals, semiconductor and electronics/ photonics, plastics and rubbers, metals and the ‘all other industries’ category. This resulted in an increase of 20 percent over the previous quarter (Q3 2023).

Vention, Flexxbotics partner to offer advanced robotic machine tending solution

Vention and Flexxbotics have come together to offer robotic workcell digitalization in next-generation machining environments. Customers can

reportedly benefit from the combination of Flexxbotics’ robot machine tending solution with Vention’s Manufacturing Automation Platform offering. Customers will use Vention’s cloud-robotic tools and modular automation hardware to design tailored machine tending robot cells, then take advantage of Flexxbotics’ machine tending SaaS/hybrid solution and professional services for deployment and continuous operation to achieve “lights out” manufacturing. Vention combines 3D design, code-free industrial programming, and a library of 4,000+ modular automation components. Flexxbotics deploys and optimizes the Vention-designed robotic systems along with the Flexxbotics solution for advanced robot machine tending. | MA

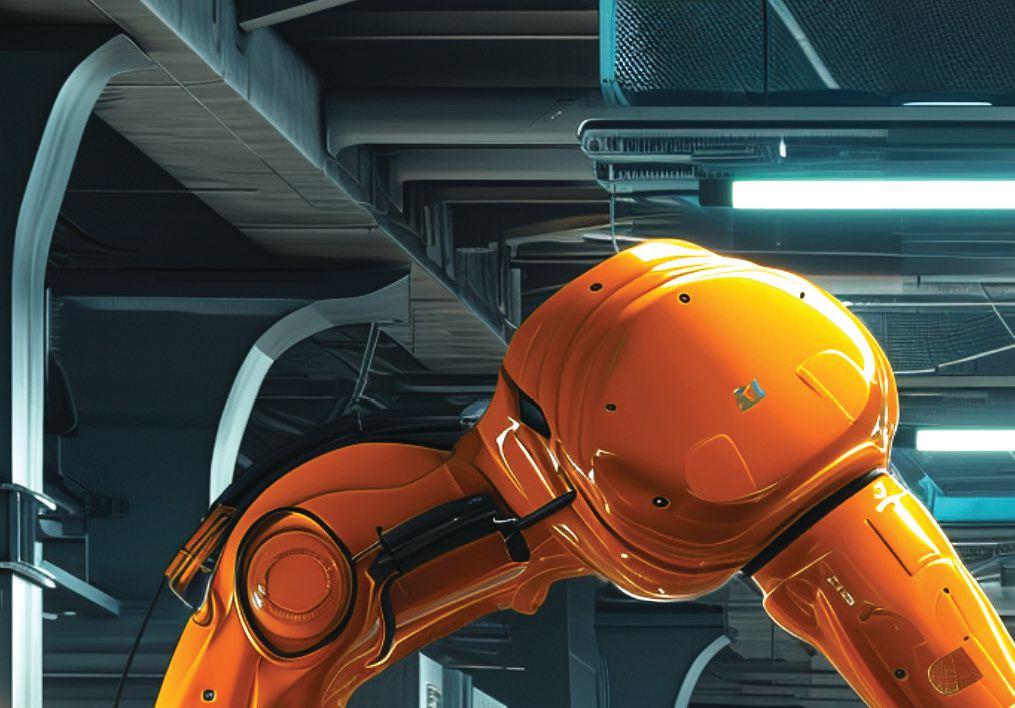

From predictive maintenance to collaborative robots, experts discuss key trends that can revolutionize Canadian manufacturing in 2024.

The dynamic landscape of Canadian manufacturing is not left untouched by cutting-edge technologies that enhance efficiency, productivity and competitiveness. As manufacturers plan for 2024, industrial automation continues to evolve rapidly, driven by advancements in artificial intelligence, robotics, IoT (Internet of Things) and data analytics.

In this article, automation experts take a deep dive into the top industrial automation trends that can be instrumental in shaping the strategies and operations of Canadian manufacturers in 2024. From the integration of AI-driven predictive maintenance to the adoption of collaborative robots on the factory floor, these trends are poised to revolutionize the manufacturing sector, paving the way for unprecedented growth and innovation.

To take a look at the predictions from previous years, check out our digital archive at automationmag.com/digital.

Claire Fallon is executive director of the International Society of Automation (ISA).

A mechanical engineer by training, Fallon previously worked as a design engineer for Bechtel and served on the board of the American National Standards Institute (ANSI) and appeals board for Underwriters Laboratories (UL).

digital transformation

The buzz around increasing investment in new technologies such as generative artificial intelligence (AI), cloud technology and digital twins has put digital transformation investment at the top of the list for 2024 trends in North American manufacturing. Digital transformation efforts were expedited due to COVID and according to Flexera’s State of the Tech Spend report, “74 percent of organizations see digital transformation as a top

priority over cybersecurity (73 percent) and cloud implementation (64 percent) for 2024.”

Digital transformation investment is largely driven today by manufacturers’ increased focus on mining data for business insight. Generative AI and machine learning have set a new precedent – and really broadened the possibilities – for manufacturers to review their data collection, sharing and utilization strategies. As McKinsey and Company stated in January 2024, “AI could contribute to the manufacturing sector a whopping annual impact ranging from $1.2 to $3.7 trillion by 2030.” That report also stated, “Less than 10 percent of manufacturers are using their data to its full potential,” which underscores the need for more investment in 2024.

Investing in new technologies and digital transformation amidst an Industry 4.0 revolution, even before COVID-19, has led to labour gap challenges. The Manufacturing Institute reports a projected 2.1 million unfulfilled jobs by 2030 resulting from a

lack of skilled labour. In the position paper Automation Depends on People to Make the World a Better Place, ISA suggested “We must educate enough people to be well versed in automation technologies, as well as the industry standards and conformance programs that support the automation field.” As part of its commitment to the education and certification of automation professionals, ISA actively supports global efforts to establish training and competency programs. An example is the Automation Competency Model developed by the US Department of Labor. This model defines the key skills, knowledge and abilities that automation professionals need from entry-level to advanced career level and is updated regularly to ensure that emerging technologies are included, recognizing that the automation profession is constantly evolving. Education and certification have become critical pieces of the strategy for those who embrace automation as a tool to repurpose jobs and create new ones to combat the labour gap issues.

Many industry sectors are still reeling from expensive lessons learned about supply chain management during the COVID-19 pandemic. Continued economic uncertainty and international conflicts make reliance on a smart supply chain our third manufacturing trend in 2024. ISA stated in the position paper Automation Drives the Global Quest for Resilient

Supply Chains, “Several key trends are evident as manufacturers have strived to shorten and strengthen their supply chains, starting with a greater focus on uptime considerations in plant designs.” Shortening and strengthening the supply chain gives considerable importance to smart supply chains that use new technology and data analytics to manage the flow of goods and services. A smart supply chain could aid with uptime and assist in operating expenses. ISA’s position paper also stated, “A traditional plant uptime is 95 percent, even a one percent increase in uptime can be a major boost to the bottom line,” further supporting this claim. Resilient supply chain management that is efficient, sustainable, and safe will depend upon automation technologies and people working together to bring the most creative and innovative solutions to bear.

Flexera’s number two tech spend for companies behind digital transformation was cybersecurity. A smart supply chain is a great way to keep the supply chain secure. By utilizing AI systems in conjunction with the implementation of sound industry standards, such as the ISA/IEC 62443 series, more and more manufacturing companies are finding better practices to keep cybersecurity measures in place while increasing productivity.

4. Sustainability initiatives

Prioritizing sustainability and carbon neutrality are great for the environment, but studies show it is also great for the bottom

line. PDI Technologies reports that “68 percent of Americans are willing to pay more for products that are better for the environment.” There are numerous incentives, therefore, to heighten this trend in 2024.

ISA stated in the position paper Achieving Sustainability Goals with Automation , “Cost reduction, increased safety and

greater workforce development opportunities are the immediately apparent benefits, but leaders must also recognize the opportunity to demonstrate their ESG leadership in a climate where environmental responsibility is fundamental to business success and growth.”

The position paper gave examples of the

We understand how you need to reduce complexities at your plant.

You strengthen your plant’s safety, productivity and availability with innovations and resources.

• Best in class flow measurement in custody transfer applications in mass or volume units due to unmatched accuracy for density determination, up to DN 250 (10”)

• Ideal for hydrocarbons with entrained gas thanks to the patented Multi Frequency Technology (MFT)

• Patented Heartbeat Technology for device verification during operation and permanent self-diagnostics

different ways automation can be used to recycle materials, promote sustainable materials for Industry 5.0 initiatives, train and upskill employees and obtain unbiased data analytics for compliance with sustainability initiatives. This information showcases how automation can link this goal with others and how they can productively work together for a larger impact.

5. Industrial connectivity

IoT Analytics reports that “by 2026, more than 50 percent of all products sold by original equipment manufacturers (OEMs) will be IoT connected” and “the number one benefit of connected IoT projects is generating deep insights into customer usage of their products and services (67 percent).” Industrial manufacturers use IoT location data to track assets in their smart supply chains for security and productivity reasons. Then, they monitor energy flows and vibration frequencies of their machines, alerting users to potential failures or uploading software fixes directly to those machines. Such data collection and analysis help manufacturers identify error-prone components to increase productivity and quality. 5G will play a crucial role in implementation as industrial connectivity takes off in the next few years.

Jim Beretta is president of Customer Attraction, an industrial marketing consultancy. He works with companies in robotics, automation, manufacturing, packaging and capital equipment on branding, marketing and search engine strategies. He graduated from Western University and is based in London, Ont. Jim can be reached at jim@customerattraction. com and you can hear him too, on The Robot Industry Podcast at TheRobotIndustryPodcast.com.

1. AaaS: It’s about time

We already have witnessed companies that have tested out the efficacy of Robots-as-aService and some that have stepped away from this model. I believe over the next few years we will see more manufacturers and integrators consider a new way to finance automation systems and maybe even entire factories. Possibly “Automation as a Service”? Imagine a complete machine or even

a factory financed and supported by others. It’s a complicated discussion with lots of upfront risks, varied financial models and plug-in tech such as Blockchain and remote diagnostics. Manufacturers will continue to seek out innovative partners and models to avoid using scarce CAPEX dollars.

2. Simulation and all the twins

Reducing risk and time to market is all part of the new breed of manufacturing software which actually is not that new – it just works so much better. Digital Twin and Robot Offline Programming (OLP) is software that is becoming easy to use even though it is very sophisticated. With thousands of data points and variables, reliability and cost are now barriers of the past. Now layouts, machines and systems can be proven well ahead of ordering and implementation. Go ahead and check out NVIDIA and generative AI-enabled robotics.

3. Vision: It’s getting artificial Artificial intelligence (AI) is ubiquitous or will be soon, and we’ve all known that AI, ML and machine vision would be a great mix, and in fact a game changer. I predict that we will see more vision and more cameras used in automation systems especially as the technology gets better and we can depend less on variables such as lighting.

4. More robots, more cobots

There is an estimate from Stanford that there are over 3.4 million robots in use in the world. That staggering number is the highest number on record since global organizations such as the International Federation of Robotics started trying to keep count. I am predicting like the ROW that Canadians will buy more robots and more cobots to retain employees, replace retirees, reduce the labour challenges that we are facing and become more efficient with scarce resources, including those who fail to show up for work.

5. Industry innovation rockstars

Who are the rockstars of innovation when it comes to technology or the use of technology? This is not a commercial endorsement, but recently on a webinar, I asked the four independent webinar experts to mention the top companies that they were excited about. Here are the brands: Apera AI 4D Vision, Olis Robotics, Formic, Agility Robotics, Dexterity, Keyence, Flexibowl, Tulip,

Universal Robots and Flexxbotics. These are in no particular order, except that a Canadian company Vancouver-based Apera AI with their 4D vision for robotic automation received a hat-trick of votes.

6. The new trend: Sustainability is sustainable

Automation and robots are great at the dirty, dangerous, monotonous tasks, but what else are robots good at? Reducing waste and increasing quality. They are sustainable and part of the new sustainability conversation. Suppliers to manufacturers and robot integrators have recognized that sustainability is not just a fad or trend with companies starting to use IoT and Industry 4.0 technologies to manage data, reduce waste and install motors and controllers to drastically reduce “fat technologies”. I am also seeing people invest in proving that their business, their machine or their entire facility is sustainable with trusted third-party reports and endorsements. And considering who your new workforce is, this should be a priority for all manufacturers.

7. Robots and robotics is everywhere

In the good old days we really just talked about picking and placing. That was then and this is now. There are almost no industries that automation and robots have not or will not touch. Think construction and housing, medical and surgical, food preparation, material handling, fruit picking, farming and weeding. Personal services too are in the robot and automation bullseye. Need your nails done? Haircut? There’s a robot for that. Even going to the dentist – yup, it is coming. It is dizzying to witness all the innovation. We will see more robots in our lives and they will be safe, easy to use and have around and will deliver data at speed.

8. Robots exploding into new sectors

Because labour has checked out, every other industry seems to have discovered or lost its fear of robots and automation. Construction, farming, consumer and food automation to name a few will be the new leaders in driving out cost, increasing quality and uptime by deploying robots and cobots.

9. Need a job? Manufacturing is attractive again.

A note to teachers, principals, educators and if there are still guidance counsellors out there:

The manufacturing, robot and automation industry offers thrilling career options. It is a job where you are well paid, well-traveled and you become super-educated. You will never stop earning and learning and you get to know about all the next-generation products and projects. Parents, check out your local Robotics First organization, buy your school or your community organization a LEGO Mindstorm robot kit, tour an automation company and potentially spark a hidden desire or talent. After all not everyone can or should work for Google and guess who just laid off a bunch of people? Yup, Google.

Jeff Burnstein

is president of A3, the parent group of the Robotic Industries Association (RIA), AIA –Advancing Vision + Imaging, and the Motion Control and Motors Association (MCMA). Burnstein joined RIA in 1983 and has held a variety of senior positions, culminating in his promotion to president in 2007.

1. Robot sales on the rise in Canada thanks to automotive, but other industries decline

While North American robot sales saw a 30 percent decline in 2023 over a record 2022, Canadian companies don’t seem to be to blame. A3’s 2023 report showed a 12 percent increase in robot sales over 2022, a jump from the slight – and likely inconsequential – four percent dip in 2022 over 2021. The biggest increase in 2023 came from automotive OEMs (up 213 percent!), followed by a 17 percent increase in orders from automotive suppliers. The increase in sales to automotive companies isn’t surprising given the recent investments in Canada from automotive companies such as Volkswagen, which is building a $7-billion electric vehicle battery manufacturing plant in Ontario. Purchases by non-automotive companies, however, declined almost across the board last year. While we’re still hearing plenty of noise about robots from companies who’ve already benefited or are still doing their research, sales were down 49 percent in the food and consumer goods industry, 56 percent in plastics and rubber, 37 percent in metals and 23 percent in semiconductors and electronics. Only the life sciences industry saw an increase, up 16 percent over 2022.

The manufacturing industry continues to struggle to find workers. According to the Canadian Manufacturers and Exporters’ (CME) annual report in January, manufacturing employment fell by 6,200 in January, the third decline in four months and “indicative of the continuing loss

of momentum and weakness in the sector.” It doesn’t help that manufacturing wages declined sharply as well, from 5.3 percent year-over-year in December to four percent in January. Struggling to fill jobs with human workers is a key reason manufacturers automate. Otherwise, they risk productivity declines and an inability to compete with competitors that do automate.

The International Federation of Robotics (IFR) has shared a press statement outlining the top global robotics trends for 2024. The stock of operational robots around the globe hit a new record of about 3.9 million units, shares the organization. This demand is driven by several technological innovations.

Artificial Intelligence (AI) and machine learning: The trend of using AI in robotics and automation keeps growing, says IFR. The emergence of generative AI opens up new solutions. This subset of AI is specialized to create something new from things it’s learned via training and has been popularized by tools such as ChatGPT. Robot manufacturers are reportedly developing generative AI-driven interfaces which allow users to program robots more intuitively by using natural language instead of code. Workers will no longer need specialized programming skills to select and adjust the robot’s actions, shares IFR. Another example, says IFR, is predictive AI analyzing robot performance data to identify the future state of equipment. Machine learning algorithms can also analyze data from multiple robots performing the same process for optimization.

Cobots expanding to new applications: IFR explains that collaborative robot applications offer a new tool for human workers, relieving and supporting them. They can assist with tasks that require heavy lifting, repetitive motions, or work in dangerous environments. The range of collaborative applications offered by robot manufacturers continues to expand. A recent market development, says IFR, is the increase of cobot welding applications, driven by a shortage of skilled welders. This demand shows that automation is not causing a labour shortage but rather offers a means to solve it. Collaborative robots will

therefore complement – not replace –investments in traditional industrial robots which operate at much faster speeds and will therefore remain important for improving productivity in response to tight product margins. New competitors are also entering the market with a specific focus on collaborative robots.

Mobile manipulators: Mobile manipulators – also called “MoMas” – are automating material handling tasks in industries such as automotive, logistics or aerospace. They combine the mobility of robotic platforms with the dexterity of manipulator arms. This reportedly enables them to navigate complex environments and manipulate objects, which is crucial for applications in manufacturing. Equipped with sensors and cameras, these robots perform inspections and carry out maintenance tasks on machinery and equipment. One of the significant advantages of mobile manipulators is their ability to collaborate and support human workers. Shortage of skilled labour and a lack of staff applying for factory jobs is likely to increase demand, predicts IFR.

Digital twins: Digital twin technology is increasingly used as a tool to optimize the performance of a physical system by creating a virtual replica. Since robots are more and more digitally integrated into factories, digital twins can use their realworld operational data to run simulations and predict likely outcomes. Because the twin exists purely as a computer model, it can be stress-tested and modified with no safety implications while saving costs. All experimentation can be checked before the physical world itself is touched. Digital twins bridge the gap between digital and physical worlds.

Humanoid robots: IFR notes that robotics is witnessing significant advancements in humanoids, designed to perform a wide range of tasks in various environments. The human-like design with two arms and two legs allows the robot to be used flexibly in work environments that were created for humans. It can therefore be easily integrated e.g. into existing warehouse processes and infrastructure.| MA

3. Nearshoring coming to Canada?

While Canadian manufacturers aren’t reshoring at the pace of U.S. companies quite yet, trends that are driving reshoring in the U.S. are also encouraging nearshoring of manufacturing to Canada and Mexico (NAIOP Research Foundation), according to the NAIOP Research Foundation. This investment is generating demand for logistics and complementary manufacturing facilities like the Volkswagen facility in Ontario. These new facilities will require more automation to accomplish many of the dull, dirty and dangerous tasks that are so difficult to fill. We expect to see robot and automation sales increase as more of these facilities open.

4. AI is advancing, bringing new robot and vision applications

Large manufacturers have long been on board the AI/smart automation train but continued advancements in AI are bringing solutions for nearly every pressing manufacturing issue. Robots communicating with one another to work more efficiently on the fly, AMRs buzzing around factory floors alongside human workers and vision systems flagging a single irregular item among a huge batch of manufactured goods are now available and humanoid robots from companies such as Boston Dynamics and Agility Robotics aren’t too far away. How valuable these humanoid robots will really be is still in question, but that’s a discussion for another article.

5. The discussion on robotics becomes increasingly positive

The business world appears to be looking at automation and robotics in a more positive light, as stories continue to emerge about how companies big and small are succeeding in a competitive market because they have used robots to automate certain tasks. Robots are being seen as a key strategy for overcoming labour shortages and increasing productivity, and less on fears that robots might take jobs. Many businesses even notice improved morale and health among human workers who have moved to more value-added tasks. This positive outlook is even more clear as we see higher registrations than ever before for our upcoming Automate 2024 show in Chicago in May. | MA

Where manufacturing leaders chart their path to success!

Join us on June 4, in London, Ont., for a day of networking, education, information sharing and great automation takeaways. Register today to be part of an event that will bring together leaders, visionaries, and experts to discuss the latest automation solutions shaping Canadian manufacturing today and tomorrow!

Why attend CALS24?

• Network with liked-minded manufacturing leaders

• Learn from an automation-focused agenda curated specifically for manufacturing leaders

• Participate in interactive “ask the expert” breakout sessions

• Explore tabletop displays showcasing the latest automation products and services

• Connect with peers to forge partnerships for future collaboration

• Enjoy breakfast and lunch (included for all attendees) June

London, ON Four Points by Sheraton London

Early bird rates end May 6!

For more information, please contact: Kathryn Swan, Manufacturing AUTOMATION, 647-339-4880; kswan@annexbusinessmedia.com Nicole Vlanich, Automate Canada, 519-818-8866; nicole@camm.ca

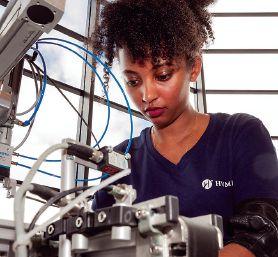

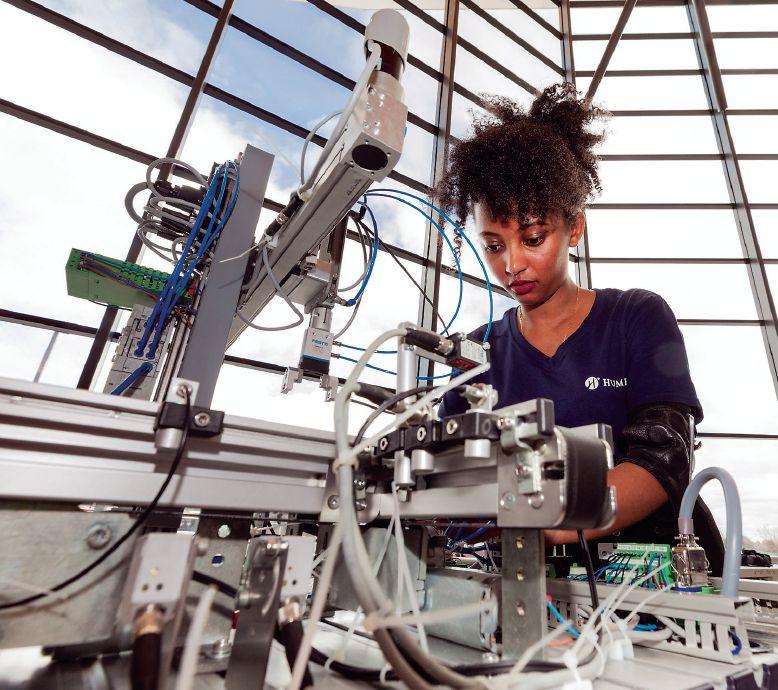

EMILY HEITMAN, country president for Canada at Schneider Electric, highlights challenges faced by women in industrial automation and offers actionable steps for creating inclusive workplaces.

MA: What initially drew you to industrial automation and how has your journey been?

EH: I was always intrigued by manufacturing even as a little girl. When selecting my engineering course for university, I came to know about industrial engineering which involves the design of factories and manufacturing processes. It was an immediate appeal for me. I’m in a company that is a manufacturer and designs solutions for manufacturers – which is an interesting combination. This is my 24th year in the industry. My journey started out as a young manufacturing engineer and led me to eventually realize that I really have a passion for every piece of the process in the business. So, I set my sights on becoming a general manager, which eventually led me to become the country president of Canada at Schneider Electric years later.

MA: What are your top successes and achievements throughout your career?

EH: When I was a young engineer, I worked as a floor supervisor in a plant. Then a young 22-year-old, I was managing 40 manufacturing employees, learning the skill set of understanding what people go through every single day, doing the prep factory assembly on the floor, working with other people twice my age and learning listening skills. I was learning how to make sure that I don’t just improve the efficiencies in the manufacturing process but to make life easier for the people. If I had not had that experience, I wouldn’t actually know what it’s like to be on the floor. Another big

accomplishment is later in my career going into product management and bringing new products to market, listening to the voice of our customers. It was about understanding not to put new technology into the market just because it is interesting and cool, but because it actually solves a problem for a customer. I went through the process of developing a new product, working with all the stakeholders internally and externally and launching it successfully. Finally, the third big success for me is simply being able to turn around a business. I love to walk into an organization that is in need of vitalization to be able to grow. I love to dissect and analyze the market in which we play and be able to create a roadmap and execute against it.

MA: What unique challenges do women face in the field of industrial automation, particularly in Canada and how has this landscape evolved?

EH: It isn’t evolving fast enough. I thought that we would see more representation in engineering

schools today than we did 20 years ago. It has improved, but not enough. The latest numbers show that only 22 percent of engineering undergrads in Canada are women. It was around 19 to 20 percent when I was in school 24 years ago. Women in industrial automation do not have enough peers who are female. A lot of times they are still the only woman in the room. People need to be able to see representation in the workplace. That lack of being able to see themselves in the workplace then leads to a challenge around networking and mentoring opportunities. The more that both women and men who have advanced in their careers can sponsor and mentor young women in the workplace, the better. We will see not just recruitment, but also the development of women within their careers.

MA: How can the Canadian automation sector build an inclusive environment for women in technology roles?

EH: I think it’s important that employers have strong maternity

programs and have flexible workplace environments so that women have the ability if they so choose to have flexible hours to go pick up their kids from childcare and work, not the standard eight to five. At Schneider, one of the things that came out of COVID-19 is that we have a much more flexible workplace. We have much less stringent hours of operation. It’s about getting the job done, instead of about clocking in and clocking out, particularly in these fields. We also offer paternity leave because we need to make sure that we’re looking after both parents.

MA: How important are mentors for women in tech roles?

EH: Mentors are critically important. I had a mentor early to mid-career who really helped me dream bigger. I couldn’t see beyond a certain level or position because that was all I had visibility to. Mentors allow people to be able to see where they could be. It is not just the one step ahead, but the 10 years from now, and how do I create a roadmap to that. When it comes to mentoring and networking, it goes both ways. I’ve been mentored. I’ve mentored young women and I try to give them the same advice around playing the long game. Don’t just think about today. Manage your today while also planning for tomorrow. And that’s not something you learn in school. That’s something you learn on the job from people that you work with, and being able to talk to people who are further along in their career. To aspiring women in industrial automation, I would say if you don’t already have a mentor, seek one out. That’s going to help you develop

a skill, give you the ability to get visibility into a position you don’t have access to today and build your network. I once heard it said it doesn’t matter who you know, or what you know; it matters who knows what you know. Networking is a strategic skill. It’s about being able to be strategic in figuring out who I need to network with, what they need to know about me and what can I learn from them that will help advance my career.

MA: How has the move towards digital transformation impacted the role of women in industrial automation?

EH: With the Internet of Things and the digitalization of manufacturing operations, we’re bringing in an entirely new skill set into the workforce. We’re not just recruiting the traditional

engineers. We’re now looking to recruit software engineers and IT professionals, where there is generally a bigger representation of women, into our space. It also brings a diversity of thought processes into the workplace which only further develops better innovation. With the digital shift, we have flexible ways of working where we’re at the office two to three days a week. So, more women have the flexibility to be able to work remotely when needed.

MA: What can companies do to improve retention rates and support the career progression of women in technology roles?

EH: It’s important to allow women to be able to flex into new roles. Maybe for a time period, they may want to move into a different type of

position. It’s important that we provide education, training and flexibility to help them prepare for another position that might be more conducive to either their next promotion or their lifestyle. At this point, it’s an expectation from employers to educate employees and provide training. At Schneider, we have a program called My Learning Link in which we provide 14,000 courses on digital learning, business marketing, safety, technology, soft skills and more. The platform allows people to educate themselves around whatever skill that might interest them to develop themselves. As most learning at this point is online (it is 80 percent e-learning since 2020), the access to this training and education is even more accessible for everyone.

MA: What actionable steps can organizations, governments and individuals can take to encourage more women to pursue careers in industrial automation?

EH: I want to continue to see more investment in STEM programs and their availability across the country for young women to participate, whether from small towns or big cities. Organizations can get more involved in their communities to engage in outreach, mentoring and volunteering. I want to emphasize the importance of male allyship. If there are not enough women to do all the mentoring and volunteering, we need our male counterparts to make that future possible for the next generation. | MA

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid state relays & contactors, energy meters, monitoring relays, soft starters or sensors, available with or without IO-Link.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified OEMs.

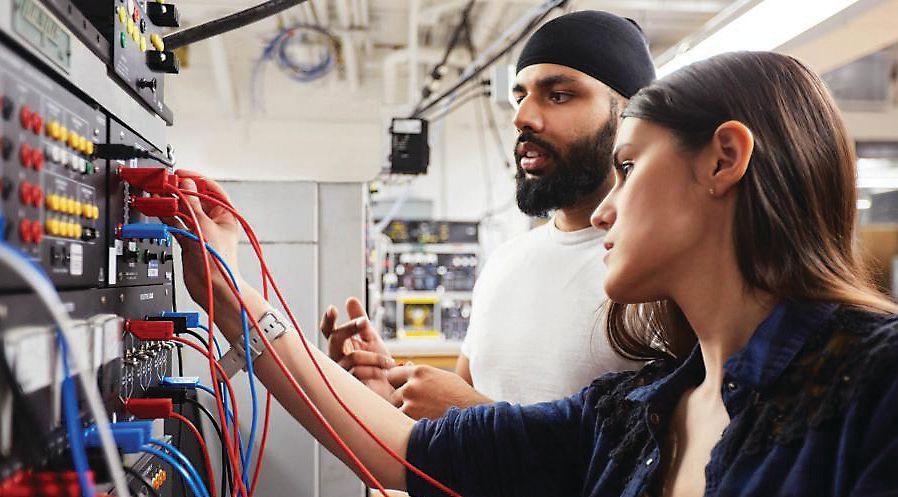

JACK KAZMIERSKI

ACCES Employment is offering a new program, delivered through Humber College, that’s designed to fast-track mid-career workers into a job in manufacturing. The “Connecting to Careers in Advanced Manufacturing” is a 16-week program, funded by Upskill Canada, powered by Palette Skills, and offered free of charge to individuals who qualify for the initiative.

“We’re seeing an upswing in manufacturing in Ontario,” says Dr. Dave Smiderle, associate dean of continuous professional learning within the Faculty of Applied Science and Technology at Humber College. “And in terms of advanced manufacturing, they’re predicting billion-dollar growth.”

While manufacturing is growing in Ontario, the pool of skilled labour isn’t keeping up with industry demand, Smiderle adds. “The biggest problem right now is a lack of skills in this area, at the entry level,” he explains. “When we talked with our industry partners and asked about their challenges, they told us that they hire good people, who are often promoted very quickly, and then they don’t have candidates to fill the entry-level positions left behind.”

The obvious solution is to train individuals who can fill those entry-level manufacturing positions. “However,” Smiderle adds, “manufacturers can’t wait years for us to train someone, which means that the traditional method of schooling where someone studies for a year or two is no longer practical.”

Since time is of the essence for manufacturers, this 16-week program teaches program participants the basics, which allow them to get into the entry-level manufacturing jobs that need to be filled urgently.

Self-paced study

Since this initiative is aimed at mid-career workers who may already

them solve a company problem.

“While manufacturing is growing in Ontario, the pool of skilled labour isn’t keeping up with industry demand,” says Smiderle.

have jobs or other responsibilities, the 16-week program was designed with a large self-paced component that allows program participants to complete the theory part of the curriculum online. Then, program participants come to the lab at Humber College on a Saturday or Sunday to cover the practical side of the curriculum. “The program was designed specifically for people who have lives outside of academics,” Smiderle explains. “These individuals are working right now, so we want to get them in and out as quickly as possible.”

This program isn’t designed to turn program participants into experts in the field or prepare them for advanced positions in a smart factory. Rather, it’s designed to help them master a particular set of skills that will allow them to succeed in an entry-level position in manufacturing.

Key topics covered during the 16 weeks include lean manufacturing, mechatronic control systems, program logic controllers, electric motors,

actuators, drives, electric pneumatics and hydraulics.

“On top of that,” Smiderle adds, “there’s a work-integrated learning component, which means that they’ll get the chance to work with a company to help them solve a company problem.”

Program participants also benefit from instruction offered by ACCES Employment. “The program offers personalized coaching sessions focusing on personal branding, goal-setting, accountability, and skills development,” explains Robert Tortian, director of bridging services at ACCES Employment.

“Through targeted job search assistance and future-proofing workshops, participants are equipped with the tools and strategies necessary to secure employment and thrive in professional settings,” he adds. “By combining technical training with career preparation and effective communication skills, the program not only addresses current labour shortages but also future-proofs participants for long-term success in the dynamic field of advanced manufacturing.”

Since the program is free, and space is limited, all candidates are vetted before they’re accepted into the program. Although prior experience in the industry is not a requirement, all candidates need a high-school diploma with Grade 12 English and Math. “Our goal is to take a non-technical person and turn them into a technical, and hireable person in 16 weeks,” Smiderle adds.

“Candidates are evaluated based on their adaptability, critical thinking skills, and motivation to succeed in a dynamic and fast-paced environment,” Tortian adds. “While past academic and professional qualifications are considered, they do not play as significant a role in the selection process as candidates’ potential to thrive in the program and contribute meaningfully to the manufacturing industry. By prioritizing learning ability, commitment, and core skills, we ensure that our program attracts individuals who are not only capable of succeeding academically but also possess the drive and passion to excel in their careers.”

In a perfect world, this program would be able to take on as many new participants as the manufacturing industry would need in order to fill all the entry-level jobs currently available, as well as any future jobs in the coming years. However, since this program relies on outside funding, there’s only room for a total of 120 learners.

With the current funding, a total of four cohorts (30 learners per cohort) will be accepted into the program. The first cohort is already well underway, while the second, third and fourth cohorts are scheduled to begin in May, July and November 2024, respectively.

If additional funding can be secured, then more learners will be able to take the 16-week program in the future. “ACCES remains committed to supporting and sustaining the program’s impact beyond its initial phase of 120 students,” Tortian says. “Recognizing the program’s significance in addressing key challenges facing the manufacturing sector, ACCES is actively exploring avenues for continued funding and expansion.”

Although the program is still in its initial phase, results have been encouraging. “Feedback from both students and industry stakeholders has been overwhelmingly positive,

underscoring the program’s effectiveness in addressing critical needs and fostering a culture of innovation within the manufacturing sector,” Tortian says. “Participants commend the program for its comprehensive curriculum, hands-on learning opportunities, and personalized coaching sessions, which have equipped them with the skills and confidence to pursue rewarding careers in advanced manufacturing.”

Not only are the learners happy with the program, but so are the companies that need skilled help. “Industry partners have also lauded the program for its role in bridging the skills gap and supplying the sector with highly skilled and adaptable technicians,” Tortian adds. “They recognize the value of the program in meeting the evolving needs of the industry and ensuring its continued growth and competitiveness on both national and global scales.”

This new program has the potential to make a big impact on manufacturing, and Smiderle says that he is committed to making this a success for all involved.

Speaking of the 120 learners who will ultimately go through this program, Smiderle says that he can see a real win-win situation

for everyone. “I want companies to hire these folks, and I want companies to be happy with the quality and the type of person that they’re getting,” he says. “Ultimately, the goal is that we grow business in Ontario.”

ACCES Employment seems to be equally dedicated to the program and to the success of everyone involved. “Building upon the program’s early successes and the positive outcomes it has generated, ACCES is dedicated to securing the necessary resources to scale up its reach and maximize its long-term impact,” Tortian concludes. “By leveraging partnerships, securing government support, and engaging with industry stakeholders, ACCES aims to ensure the sustained growth and sustainability of the program, thereby furthering its mission of empowering individuals and advancing innovation in manufacturing.”

Employers who would like to participate in this program and work-integrated learning, hire program participants, support mentoring or coaching the learners, or help in steering the program by participating in the program advisory committee can reach out to Robert Tortian at ACCES Employment (rtortian@ accessemployment.ca) | MA

SUKANYA RAY GHOSH

Factory floors today are equipped with automated assembly lines, traditional and collaborative robots, automated mobile robots, high-voltage equipment, and more. For manufacturers, protecting against the risks and staying compliant with the most current safety standards will help keep workers safe and ensure fewer liabilities.

While the basic framework and intention behind machine safety standards are very similar everywhere, the specific standards vary according to region and even country. Canada has its own set of safety standards and regulations that manufacturers need to be aware of and compliant with, in order to minimize risks to workers and liabilities to their businesses.

Douglas Nix, co-owner of Compliance InSight Consulting, and a machine safety expert, shares that each province or territory has occupational health and safety (OHS) legislation governing the employer’s employee safety obligations. Federally, safety is governed by the Canada Labour Code, which covers workers employed in the federal sector.

Nix shares that every province and territory has its own legislation that governs electrical products that are connected to power supplied by a public utility. Equipment powered by the public utility is required to bear a recognized Canadian electrical safety mark. This can be a certification mark or a field evaluation label. Industrial equipment is also required to meet Industry Canada regulations for electromagnetic interference.

“Machinery safety is handled differently depending on which province, territory or federal sector the employer is in. Canada, unlike the EU, for example, does not have legislation that requires manufacturers to build and sell safe products. They meet their legal obligations as long as the product has an electrical safety mark on it,” explains Nix.

However, he adds, Ontario enacted the Pre-Start Health and Safety Review (PSR or PSHSR). The employer is obligated through O Reg. 851 to conduct a PSR on the equipment. The PSR must be conducted by an Ontario-licenced Professional Engineer (P.Eng.). The result of the PSR is a report that either says the product complies with the requirements or it doesn’t. If it doesn’t, the report must include

recommendations for modifications to bring the equipment into compliance.

Discussing the most recent updates to the standards, Nix shares that the general safety of machinery standard CSA Z432 was updated in 2023 and the lockout standard CSA Z460 was updated in 2020. CSA Z462, the workplace electrical safety standard, was updated in 2021.

“Staying current with the relevant standards in your industry is important. These standards, despite being voluntary, govern how machinery is built and used, including, in the case of Z460 and Z462, how maintenance work is done on these machines. If you don’t know the rules of the road, you can’t meet your legal obligations regarding protecting workers,” says Nix.

Nix notes that manufacturers must stay current with changes in the OHS legislation in the province or territory where they operate. If businesses have operations in more than one, they must stay current in all regions. The same principle applies to the standards.

“A manufacturer needs to know what standards are applicable in their industry and what they require. Machine builders and integrators need a standards library in their engineering office that holds current copies of the relevant standards so the designers

can reference them as they develop product design. They also need to know what kinds of inspections and markings are required where the product will be sold. This can be a big job for companies selling products outside of Canada,” he says.

Machine safety standards are not discussed in any real depth in colleges and universities, shares Nix. Consequently, he says, new engineers usually learn about standards and applications while working with seniors.

“Learning to read standards is a challenge once you know that standards exist. Standards use certain keywords to indicate whether they are talking about a mandatory requirement by using the word “shall,” a strong recommendation when using the word “should,” or when they are permitting certain things when they are using the word “may.” The word “can” is also sometimes used when suggesting options,” explains Nix.

Nix shares that where the nuances of the specific language used are considered, the sense of a sentence or even a word as the standards committee sees it might not be what people may commonly understand.

“Many standards are written using performance-based language, which can be deliberately vague,” says Nix.

Understanding the nuances Nix explains that international machinery standards fall into three types, defined in ISO 12100: Type A, B, and C. Type C standards apply to a specific type of machine, e.g., CNC turning centres, and are the most common. However, not every type of machine has an available type C standard. In such cases, manufacturers can fall back on the type A and B standards.

There is only one type A standard: ISO 12100. It defines the general process for the design of safe machinery. The type B standards are divided into type B1 and B2 standards. Type B1 standards cover particular safety aspects (for example, safety distances, surface temperature, or audible noise emissions). Type B2 standards cover safeguards (for example, two-hand controls, interlocking devices, pressure-sensitive devices, and guards).

“When designing a machine, the first step is to decide where the product will be sold. If you intend only to sell it in Canada, you likely only need to pay attention to CSA standards. If

you’re also planning to sell in the U.S.A., then the ANSI standards should also be included in your research, and so on for other jurisdictions. Once you have that information, research to determine if a type C standard exists for the kind of machine you want to design. If there is one, buy it and follow it,” says Nix.

He adds, “If there isn’t a type C standard available, follow CSA Z432, or for the USA, ANSI B11.0, or ISO 12100 for international markets outside the EU. As you decide on various safety aspects, guided by the risk assessment, select the relevant type B1 and B2 standards. Follow those standards, ensuring the design meets every “shall” statement and documenting conformity at each step.”

Following these steps prepares manufacturers for conformity assessment.

Purchasing and placing a standard on the shelf doesn’t add value. The document must be in the hands of the people making the design decisions. There need to be checks in the

Finds the smallest leaks in the noisiest environments

Improves system e ciency

Reduces operating costs

Helps maintain product quality

design process to ensure that the standard(s) are being used and that all requirements are being met. Once the enforcement is in place internally, use of the standard(s) will become second nature.

Failing to use the standards can come with significant downsides, says Nix. “In cases where injuries or fatalities have occurred, engineers doing forensic analyses will reference any relevant standards, not just the national standards. Every point of non-conformance will be identified and brought out in the forensic reports. In Ontario, a workplace fatality can result in a $250,000 company fine and a $25,000 personal fine for the supervisor(s) involved in managing the work. Other jurisdictions will have different limits.”

Nix adds that the Westray Act can be applied to cases where corporate negligence is found. This places such cases under the Criminal Code of Canada, section 217.1 [10]. Section 217.1 does not limit the size of the fines and prison sentences are possible for managers and supervisors, cautions Nix.| MA

Scan the QR code to access the FLIR ROI Calculator.

BY DAVID MORGENSTERN

David Morgenstern is president of Accenture in Canada, where he supports leaders in business and government to embrace change, transform their organizations, and become more resilient for the future. He is passionate about advancing Canada’s position as a global leader in innovation, technology, sustainability and energy transition.

Canada is on the cusp of seismic change in manufacturing. Innovative technologies, advancements in sustainability and a new generation of talent are reshaping the industry. They’re also creating new opportunities for Canadian companies to scale and build resiliency through technology. This change is desperately needed after several years of historic disruption.

Geopolitical unrest, high energy prices, rising materials costs and demand fluctuations during the pandemic – each of these and more have challenged businesses like never before. Globally, businesses missed out on more than $2 trillion CAD in revenue growth, according to a recent Accenture report. These disruptions have also exposed dangerously low levels of resiliency within engineering, supply chains, manufacturing and operations.

As a result, businesses are taking action to rebalance operations closer to home, localizing sourcing and production, to reduce risk and cost. By 2026, 73 percent of Canadian companies plan to buy key items from regional supplies, while 91 percent plan to produce and sell most products in the same region.

For years, Canada has had a reputation for producing high-quality, precision-engineered goods, while developing cutting-edge technologies and processes such as automation, but as global demand calls for even faster innovation, Canadian manufacturers will need to take action not just to gain competitive advantages.

There is a noteworthy increase in automation investment, driven by the need for rapidly changing consumer demand, a diminishing pool of skilled labour and supply chain disruptions. Simultaneously, companies are recognizing the hyper-flexibility and high customization capabilities of autonomous production, which are pivotal for their capacity to adapt to change and reconfigure effectively.

Today, in Canada and the U.S., only 10 percent of factory labour (maintenance and operations) use technologies that enable remote workers. Just 27 percent of companies use artificial intelligence (AI) extensively. Companies that use advanced technologies like data, the cloud and AI to make their

factories and plans smarter will see more productive, responsive, sustainable and safe results.

For example, automated machines streamline operations resulting in greater outputs in less time than traditional methods. These automated systems also provide an opportunity to reduce waste and energy consumption through resource optimization and decreased downtime. Ultimately, manufacturers who deploy automation across their production lines will be better equipped to handle fluctuations in demand and scale up and down as appropriate.

Automation also benefits workers. In hazardous environments with heavy machinery and strenuous labour, it can increase their safety by reducing the role of humans in dangerous or repetitive tasks. Workers can prioritize maintaining and improving automated systems and increasing efficiency.

An increasing number of manufacturing executives are coming to understand highly adaptive plants which are closely integrated into the supply and product chains. This means leveraging massive amounts of data and AI to optimize operations automatically, requiring a new approach to manufacturing operations management. As a result, interest in digital twins has been growing at a rapid pace.

It’s important to remember that resiliency isn’t just a matter of agile supply and production; it’s also about getting products right from the start. By moving engineering activities to earlier in the development process – the socalled “shift-left approach” – companies can

assess the potential impacts of disruption on the product at the time of design and reduce lead times.

Digital twins and simulations are vital enablers of this approach, and these solutions help build resiliency by enhancing transparency and offering real-time visualization of production activities. The digital replicas allow product designers and engineers to identify and troubleshoot potential prototype issues or defects and iterate the design before production begins. They also democratize access to valuable product data and insights, fostering improved collaboration during research and design phases.

As operational digital twins gain traction, generative AI will be imperative for accessing and managing the massive amounts of data they generate. There is already work being done to deploy “operations co-pilots,” allowing workers to interrogate the twin as they would an experienced manager to get support when completing tasks or solving issues. Generative AI will support the early resolution of issues before they can be addressed with repeatable and validated AI solutions.

By the end of 2024, generative AI experimentation will accelerate and lead to concrete realizations. With the right foundation, businesses will be able to easily adopt these emerging technologies and apply generative AI to functions across the organization, such as:

• Maintenance job planning, which is currently a manual, human-intensive and repetitive process involving highly skilled practitioners.

• Generative design and prototyping to help engineers and designers explore a broader range of design options for plants and products alike, as well as quality testing, supporting innovation and product differentiation, all in the same or shorter time, and reducing the number of iterations. For example, automotive crash tests are no longer required because they can all be simulated.

• Code conversion from legacy automation equipment, which is often cost-prohibitive and where industrial engineers and maintenance technicians lack multiplatform

skills. Generative AI offers the opportunity for assisted or even automated code conversion that is much more cost-efficient – and potentially more reliable.

Whether it’s using generative AI for prototyping purposes, improving human-robot collaboration or optimizing supply chain processes, there are efficiency gains to be made to improve overall productivity and growth.

The need for more skilled labour isn’t new for manufacturers. In Canada and other developed economies, an aging workforce and the ongoing reshoring of production capabilities are driving the competition for talent to new heights. The higher the companies set their ambitions to reinvent manufacturing with digital technologies, the bigger the issue becomes.

This scarcity is acute among data scientists and other technology and IT specialists. As automation evolves into semi-autonomous and, eventually, fully autonomous operations, a manufacturer will only survive with strong data and AI expertise. But the technology will also require new skills on the shop floor. One crucial skill that all workers need to have –and which companies must ensure workers can obtain – is the ability to use data to make decisions at the frontlines of business.

The growing impact of data and AI will also create new roles. The role of production engineers will evolve from keeping operations running to optimizing them via the twin. Maintenance technicians will prevent failures and plan interventions rather than react to crises once they happen.

Eventually, how people work together will change, as well. So-called autonomous teams will operate, maintain, schedule and quality manage lines or shops independently, rather than having line or shop operators and departments for planning, scheduling, quality control, maintenance, etc. A digital twinbased, real-time hypervisor (software that uses virtualization technology to create, run and manage virtual machines) will support them.

Fundamentally, achieving lasting resilience depends on a strategy for enhancing and updating skills, which involves uniting people and technology. Developing customized interventions, such as personalized learning pathways, offers a practical, scalable, and cost-efficient approach to addressing the skills gap. By adopting this strategy, businesses can more effectively cope with shortages in crucial

skills, foster an agile culture, and offer swift, adaptable upskilling.

With Canada’s strength across energy, mining, nuclear, utilities, products and automotive sectors, manufacturers have a significant opportunity for growth and to become more

resilient. This begins with making strategic investments in automation and technologies, such as operational digital twins and gen AI. These will only go so far, however. To achieve its full potential, organizations will need to put equal investment and dedication into building skilled workforces and re-imagining what and how work is done. | MA

Realize your vision with Festo’s approach to smart automation. Partner with Festo today.

IDEC has expanded its SmartAXIS touch family with the new FT2J Series combined PLC+HMI. A compact all-in-one form factor combines built-in fullfunction controller features and functions, both onboard and expandable I/O, and a 7” touchscreen display. The integrated PLC and HMI each have their own dedicated CPU and user memory for optimized scan time performance, and they communicate natively with each other. Built-in I/O includes 14 points of DC discrete inputs (5 of them configurable as highspeed counters) and 4 points of analog inputs (configurable as 0-10VDC or 4-20mA). A relay version provides 8 points of relay outputs, while transistor versions provide 6 points sinking

or 6 points sourcing of discrete outputs (4 of them configurable as pulse outputs) and 2 points of 0-10VDC or 4-20mA analog outputs. The HMI features projected capacitive touch panel (PCAP) advanced technology. It is reportedly water- and scratchresistant, responsive and provides a high tolerance to resist false signals when dirt or water droplets are present on the face of the HMI. idec.com

Beckhoff’s new CX5600 Embedded PC series expands on its workhorse machine control line with AMD Ryzen processors, additional interfaces and operating system options. Retaining the same form factor as previous generations, these DIN rail-mounted embedded PCs reportedly provide the

flexibility to support an even greater range of applications that require PLC, HMI, motion control and much more. The new CX5600 series currently includes two device versions, both with AMD Ryzen processors: CX5620 (1.2 GHz) and CX5630 (2.0 GHz). The embedded PCs deliver many standard features, such as two independent Gbit Ethernet interfaces; four USB 3.0 interfaces; one DVI-D interface; a flexibly assignable multi-option interface ex-factory and 4 GB or 8 GB RAM options. The system can be expanded on the left-hand side with a CX2500 module. With an extended operating temperature range from -25 C to +60 C, the CX5600 series devices can be used even in applications with demanding climates. beckhoff.com

Carlo Gavazzi’s new series of LD30 PBR IO Photoelectric Laser Sensors come with IO-Link. Developed to operate in both IO-Link environments as well as in traditional automation

systems, the new LD30 PBR IO Photoelectric Laser Sensors with IO-Link offers four selectable application functions: speed and length, pattern recognition, divider function, and object and gap monitoring. These integrated functions help with additional data and decentralized control. Main technical features include Class 1, 1mm visible red laser beam; 100mm, 300mm, and 600mm sensing distances; selectable background suppression, foreground suppression, or dual detection sensing; IP69K ECOLAB approved stainless steel AISI316L housing or IP67 plastic housing; and predefined selectable application functions. It is configurable using IO-Link version 1.1. Carlo Gavazzi’s background and foreground sensing principles, combined with a 1mm diameter focused visible red laser allow detection of small objects or holes over long distances (up to 600mm)

or close to a background. Combined with the new dual detection sensing principle, the sensors can detect clear materials without a reflector. gavazzionline.com

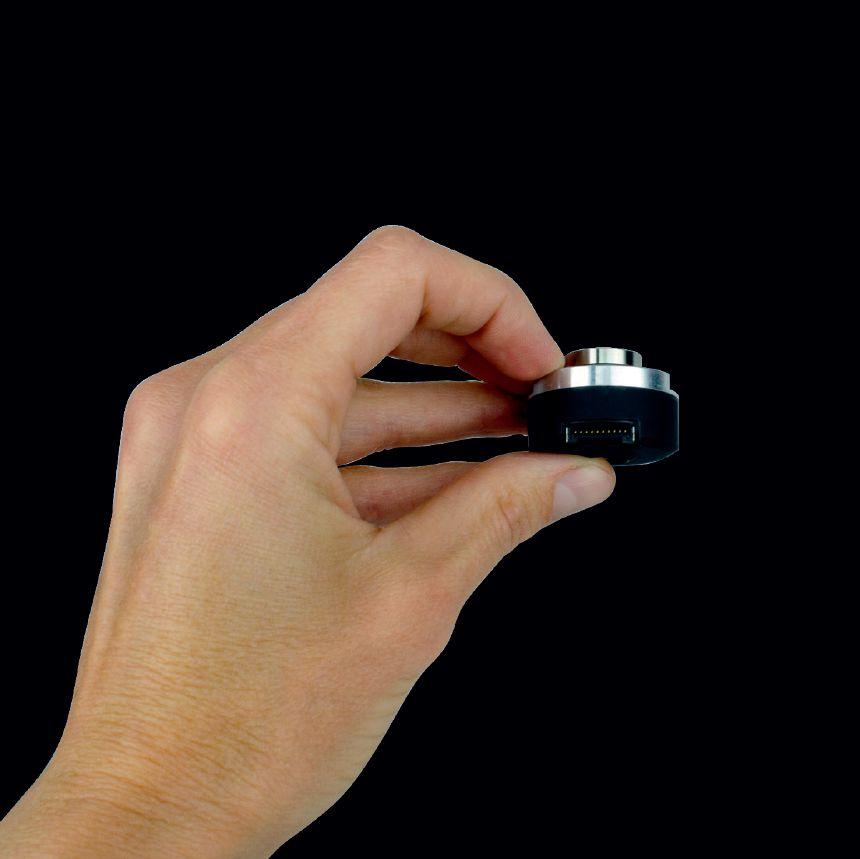

Miniature direct drive linear motor

Moticont’s new miniature 16 mm diameter SDLM-016-03201-01 Direct Drive Linear Motor reportedly features integrated position and temperature

sensors. This smallest of the fully enclosed SDLM series of linear motors features zero backlash, zero cogging, high acceleration, high speed, high resolution, and long life. The compact direct drive linear motor is 16.0 mm (0.625 in.) in diameter and 31.8 mm (1.25 in.) long. The new SDLM-016-032-01-01 direct drive linear motor has a stroke length of 6.35 mm (0.25 in.) and a continuous force rating of 1.14 N (4.11 oz.) and peak force of 3.6 N (13 oz.) The noncommutated direct drive servo motor reportedly features quiet long life, plain linear bearings, an integrated internal 1.25-micron resolution quadrature optical encoder, and a non-rotating shaft. Connections are made via a flex cable terminated in a 2-by-5 polarized connector. Direct coupling of the load or stage to the low inertia

non-rotating shaft eliminates backlash and allows for high acceleration/deceleration. Both ends of the actuator and shaft ends have threaded mounting holes for easy integration into new and existing applications. The SDLM-016-032-01-01

Direct Drive Linear Actuator is also available with a matching servo controller. moticont.com

INDUSTRY WATCH

BY PAUL HOGENDOORN

Paul Hogendoorn is a serial entrepreneur that has built multiple manufacturing and manufacturing technology companies. He has been a regular contributing columnist for 15 years. For more on Paul’s current activities go to www.tpi-3.ca or email him at paul@tpi-3.ca.

There are many conversations today about digital transformation and adopting digital technologies in your manufacturing operation. Doing digital transformation right comes down to understanding what to apply where, when and, most importantly, why After that, the how part is easy.

It is important to look at the four different areas where digital can be adopted and four different parts of a manufacturing company that digital technology is or should be connected to. These are machines; people; business systems; and products and product designs.

Connecting machines is easily accomplished, whether new network connectable machines or even older legacy machines. The goal of connecting and monitoring machines is usually to determine and improve OEE by monitoring uptime and downtime and keeping track of machine conditions.

Connecting workers is becoming increasingly important as the tribal knowledge of a retiring workforce needs to be replaced by a systematic way of helping workers do their jobs right. Technologies that train, guide and develop the workforce are effective tools that companies now leverage to help deal with labour and skill shortages.

Business systems have historically run independently of the actual manufacturing process or have been connected to the daily manufacturing process manually, often after the fact. Many plantfloor-level management tools have been developed over time by production management people while the accounting software was developed for finance and administration purposes. Manufacturers today are looking to

connect and integrate plant floor production systems with administrative and financial systems.

Engineering departments have been using digital tools for design for decades but are now using advanced technologies for product validation, quality assurance, “buy-off”, predictive and prescriptive analytics and product lifecycle management.

This is where challenges and conflicts come in: the four different areas have four different internal drivers and four different internal champions or customers. The goal of machine connectivity is to determine the efficiency of the manufacturing equipment, improve uptime and reduce downtime. The focus is maximizing the return on investment of these expensive investments.

The focus of connected worker technology is to make sure the right products are being worked on at the right time and done the right way. Its focus is on improving the outcomes of the daily activity of the worker.

Connecting business systems seeks to streamline the administration and financial reporting functions of the business, as well as dynamically optimize the production plan to make the best use of resources (machine and skills availability, and capital) while meeting the

customer’s schedule.

Engineering software has likely been in use for decades for design, but new technologies facilitate product validation, the creation of “as-builts”, provide predictive and prescriptive analytics, and expand the data collection scope to include the product’s entire projected life cycle. Here are some tips on how to get started, and how to avoid costly (time and money) mistakes.

1. Alignment: Every technology adoption project should align with the company’s stated objectives. It should include and engage the company’s people and it should be built on proven effective manufacturing or administrative practices.

2. Priority: Consideration should be given to what can be done quickly, what will take more time and cost more money, what can wait, and what can be done through iteration.

3. Business flow: The result of the application of technology is, it should make things “easier, faster, better.” If it is a step backwards in even one of these areas, (it isn’t faster, or easier, or better), that should be a red flag.

4. Always think Lean: “Whatever does not add value to your customer is waste.” Does the investment add value to

your customer? The more directly (and immediately) the technology adds value to your customer, the quicker the return on the investment.

The application of new technology is not the right way to fix bad processes – it often compounds the problem and makes it harder to solve. Look for a process that already works and apply digital technology to it. Start with a small project and get the people who will be working with it daily involved. It’s easier to get buy-in on the digital transformation process with a of couple small wins under your belt and a growing group of people enthusiastic about the early outcomes. Remember that time is money. The focus needs to be on more than just uptime and downtime, it needs to be on reducing wasted time and waiting time as well. Ultimately, the application of any new technology in any of the four areas needs to be about shortening the cash conversion time – which is the time between receiving an order from a customer and delivering the product and getting paid for it.

Technology is a great tool that is available and ready to be applied beneficially in all four areas of your business. Delivering higher-quality products in a shorter time drives top-line and bottom-line growth. Optimizing schedules around equipment and human resources increases an operation’s production capacity. Connected worker technology is one of the best ways to address the current labour issues, replacing tribal knowledge with a systematic and scalable approach that is more conducive to attracting, training and retaining, the next generation workforce. | MA