Most PLCs will do, but only some will Do-more!

Starting at $197.00 (BX-DM1-10AR-D) with FREE Software

The Do-more! BRX PLC series is loaded with hardware and software features that provide an extensive toolbox to satisfy even the most demanding projects.

• Four form factors to choose from

• Serial/Ethernet comm ports included on most models (with support for Modbus RTU/TCP, ASCII, EtherNet/IP, MQTT and HTTP)

• Built-in discrete, analog and high-speed I/O with advanced motion control

• Internal RAM and microSD data logging

• Free PLC programming software with over 200 easy-to-use instructions, integrated video help, and a convenient project simulator

Check out what’s new:

• NEW! Temperature combination modules combine RTD or thermocouple inputs with current outputs for monitoring and control from the same module!

• NEW! Two high-speed I/O expansion modules (BX-HSIO1 and 2) and a serial communications module (BX-SERIO) have been added, giving BRX PLCs even more motion and communication capabilities

• NEW! High-density 16-channel analog input modules and space-saving combination analog in/out modules

• NEW! JSON PARSE/BUILD instructions, along with the HTTP protocol addition, enable communication between BRX PLCs and data rich web servers

• NEW! The DMX512 protocol allows BRX PLCs, using the BX-SERIO module, to control stage/theater lighting and effects

Orders over $49 get FAST FREE SHIPPING

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days. Order by 6pm ET and in-stock orders ship the same day!

*2-day free shipping does not apply to drop-ships, or orders requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Batch of one

As the increasing granularity of consumer demand drives down batch sizes, manufacturers are facing the prospect of upgrading their automation infrastructure By

Jacob Stoller

16 Adopting additive

How Canadian manufacturers can use additive manufacturing to streamline design processes for mass production of parts By

Grant Cameron

control

An award-winning AI and simulation application has potential in process manufacturing By Jim

Meyers

It’s time for manufacturing companies to step back and assess their cybersecurity priorities By Graham

Bushkes

OVERHEARD ON TWITTER

@Nour_hach

We made it on the cover of a magazine! Thank you Kristina for featuring @ Build_ADream on the cover and highlighting the important role women in play in the industry.

@InvestOntario

Fantastic new @ AutomationMag feature: How young women are bridging the #STEM skills gap in Windsor. bit .ly/2vitQJz

@YvonnePilon

There are no words to express just how magical this @ AutomationMag article is. It showcases a region that is truly working together to #movethedial. Well done @ Build_ADream.

@machinery_ trade

Thank you @ AutomationMag for sharing my journey [...] I discovered trades through @ AssumptionH, @ CANFIRST & @ StClairCollege. Thanks @ WESTofWindsor for training #womenintrades!

FROM THE EDITOR

BY KRISTINA URQUHART

Education the answer to automation’s image problem

There’s a common public misperception that manufacturing jobs are dirty, repetitive and slow to change. Those of you working in the industrial automation market know that’s just not the case – and that with the increasing use of robotics, automation software and cloud-enabled material movement, public misperception is getting to be further and further from the truth.

T he confluence of all of these advances in automation is flexible manufacturing, or lot-size-one, where manufacturers are able to reconfigure their traditional production lines into work cells that facilitate custom batches in small runs. Writer Jacob Stoller explores this new trend on p. 13 and what it might mean for Canadian manufacturers.

A side from catering to changing consumer preferences, these new Industry 4.0 workflows are helping in a secondary way by mitigating the skills shortage. The manufacturing industry’s ongoing image problem is that automation is “killing” jobs. But it’s actually creating new categories of jobs – these are roles that may not even exist yet, or that may require the worker to reskill. Flexible manufacturing, for example, is backed by new technologies such as machine vision, machine learning and 3D printing (see p. 16) – autonomous processes, to be sure, but ones that still require human operators to maintain them.

O vercoming public misperceptions about the role of automation requires the undoing of longstanding opinions. One way to rewrite the

CONNECT

@AutomationMag

story is with the future workforce –students who haven’t made up their minds yet.

For much of my career, I’ve developed projects that provide students accurate industry information to assist them in their decision-making on where to do post-secondary study or training. So it is with excitement that I share Manufacturing AUTOMATION is producing a new digital magazine called Careers in Automation. The first issue is due on automationmag .com by the end of April.

Our objective is to take away some of the stigma about careers in manufacturing and to show all of the amazing opportunities available in the growing automation sector. Automation in an Industry 4.0 context is a new frontier – there are new jobs for tech-savvy students being created faster than the industry can fill them.

The magazine will be a guide for high school and continuing education students, filled with job descriptions, salary estimates, school programs, market information and profiles of young people currently working in the industry.

The skills shortage in Canada is the biggest challenge facing manufacturers today – so let’s find some ways to narrow the gap. With the Careers in Automation magazine, MA will bring transparency to the industrial automation market for students and workers looking to transition to new roles. If your company has a standout young worker or an education/training initiative that you think I should know about, email me at kurquhart@ annexbusinessmedia.com. | MA

@mfgautomationmag /company/automation-mag kurquhart@annexbusinessmedia.com

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Support Systems Developer, KINITO Support Systems

Your resource for Canada’s industrial automation news

EDITOR

Kristina Urquhart kurquhart@annexbusinessmedia.com Tel: 416-442-5600

PUBLISHER

Klaus B. Pirker kpirker@annexbusinessmedia.com Tel: 416-510-6757

VICE-PRESIDENT & EXECUTIVE PUBLISHER

Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

MEDIA DESIGNER - TEAM LEAD

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221

AUDIENCE DEVELOPMENT MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com Tel: 416-510-5180

COO Scott Jamieson sjamieson@annexbusinessmedia.com

PRESIDENT & CEO

Mike Fredericks

CONTRIBUTING WRITERS

Graham Bushkes, Grant Cameron, Paul Hogendoorn, Jim Meyers, Spiros Paleologos, Jacob Stoller, WSPS

Manufacturing Automation is published seven times a year by:

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600

Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: ugrzyb@annexbusinessmedia.com Tel: 416-510-5180 Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1

SUBSCRIPTION RATES

Canada — $43 per year

United States — $75.50 (US) per year

Foreign — $86 (US) per year

Students — $20.50 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com

Tel: 800-668-2374

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing Automation are copyright © 2020 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

AUTOMATION UPFRONT

ACCOLADES

Manufacturing companies land on Forbes list

Several manufacturing and automation companies have landed on Forbes’ list of Canada’s Best Employers.

To arrive at the results, Forbes partnered with research firm Statista to survey 8,000 Canadians working for companies with more than 500 employees and asked them to rate their employer on a scale of 1 to 10.

Respondents were also asked to evaluate other employers in their respective industries.

The total list ranks the 300 employers that received the most recommendations. Here, we’ve rounded up the industrial suppliers and manufacturers in the top 100: Cisco Systems, Microsoft, GlaxoSmithKline, ABB, Ericsson, Siemens, Pratt & Whitney, Honda Canada, Intel, IBM, Caterpillar, Toyota Motor Manufacturing Canada and SAP.

“The strength of any organization lies in its employees,” says Éric Deschênes, country managing director and electrification leader for ABB in Canada, in a statement. “We know we are our best when our employees are engaged, valued and truly believe that they are making a difference, every day.”

PRODUCTION

Honda of Canada Mfg. builds nine-millionth vehicle

Honda Canada Mfg. (HCM) marked a milestone on Feb. 6 with the production of its nine-millionth vehicle at its Alliston, Ontario manufacturing facility.

Honda Canada Inc., which owns HCM, is also celebrating the sale of its five-millionth vehicle after 50 years in operations.

Over the past 34 years, HCM has invested a total of $4.2 billion in the manufacturing of vehicles in Canada at two auto plants, and

at an engine manufacturing plant. The plants have a capacity of approximately 400,000 vehicles and 260,000 four-cylinder engines.

“We are very proud of how we’ve grown, how we’ve invested in Canada and the fact that so many Canadians are part of the Honda family,” says Dave Gardner, president and CEO of Honda Canada Inc. “I want to express my sincere thanks to everyone who

has contributed to our success and I’m looking forward to our bright future here in Canada.”

Honda’s first vehicle built in Canada was a Honda Accord Sedan. Today, HCM builds Honda

Honda of Canada Mfg. recently built the nine-millionth vehicle at its plant in Alliston, Ontario.

AUTOMATION UPFRONT

cars and light trucks, including the CR-V and the Civic, Canada’s best-selling passenger car in Canada the past 22 consecutive years.

SAFETY

WSIB unveils new health and safety excellence program

Ontario’s Workplace Safety and Insurance Board’s (WSIB) new Health and Safety Excellence program provides a roadmap for businesses in Ontario to develop health and safety systems based on best practices.

Some businesses may be looking to build a new system, while others want to improve what’s already in place – the Health and Safety Excellence program is flexible to tailor to individual business needs to help boost health and safety outcomes and culture.

Success in the program can also earn premium rebates as well as non-financial recognition.

The program is built on 36 topics spread across three levels – foundation, intermediate and advanced – to help develop and integrate health and safety management systems into workplaces and take a business from awareness to excellence.

For Motion Feedback in

First, a business can choose and register with a WSIB-approved health and safety provider listed on the website at wsib.ca/ healthandsafety. Providers offer different supports to meet business needs, including support through in-person coaching, online or over the phone.

The second step is to complete an online health and safety assessment. The assessment helps to evaluate what’s already in place and what may be missing and suggests program topics that address each business’s unique needs. These topics can be completed at a pace and time that works best for each business – there is no time limitation.

The company, Karmax Heavy Stamping, pleaded guilty to charges after a worker fell and was injured at its Milton, Ontario plant.

Karmax has also been fined a 25-per-cent victim fine surcharge, which is credited to a provincial government fund to assist victims of crime.

A Ministry of Labour, Training and Skills Development investigation found that on March 23, 2018, a worker was assisting another in carrying an automation feeder part while ascending two stairs to reach the top of a platform.

The worker fell while ascending the second step, just prior to reaching the platform, sustaining an injury.

The investigator determined that the stairs were inconsistent in their rise.

A Ministry of Labour ergonomist concluded that the two-person lift-and-carry task required the workers’ attention to be split between the safe handling of the automation feeder, lifting as a team and ascending onto the platform.

At the third and final step, a business will submit simple documentation to the WSIB to show that a topic was completed. Once validated, the business will be eligible for financial and other incentives for every topic completed.

The Health and Safety Excellence program can also help businesses achieve a best practice standard, such as COR2020 or ISO 45001, and can also help businesses meet the Ministry of Labour, Training and Skills Development’s Supporting Ontario’s Safe Employers accreditation standard.

Parts maker fined $60K after worker injury

An Ontario manufacturer of automotive parts owned by Magna International Inc. has been fined $60,000 in provincial court after a worker injury.

The attention required when performing a team lift – combined with the variances between adjacent steps – was a hazard with respect to tripping and falling on the stairs.

The investigator found that Karmax failed as an employer to ensure that the carrying of the automation feeder in tandem on the stairs did not endanger the safety of any worker.

EDUCATION

Ontario colleges receive funding for apprenticeships

Sheridan College’s Davis campus in Brampton, Ontario is receiving more than $559,000 from the Ontario government for pre-apprenticeship programs in general machining and millwrighting.

The investment will create placements for 50 students at Sheridan College’s General Machinist

excellence program in Ontario facilitates rebates.

Millwright pre-apprenticeship programs.

Lambton College in Sarnia, Ontario will also receive funding from the Ontario government for in-class training programs to prepare students for careers in manufacturing and the skilled trades.

The $926,416 investment at Lambton will support more than 380 students to enrol in six apprenticeship training programs including Instrumentation and Control Technician and Welder.

The funding for the two schools is part of the Ontario government’s recent investment of $20.8 million in Ontario’s Pre-Apprenticeship Training Program for the skilled trades.

Pre-apprenticeship training promotes careers in the trades as an option for all Ontario residents, including youth at risk, new Canadians, women and Indigenous people. The training

programs are free, last up to one year and often combine classroom training with an eight- to -12 week work placement.

The province also recently launched a marketing campaign in Ontario highlighting the skilled trades as a viable career path. The ads, with the slogan “Find a Career You Wouldn’t Trade,” are currently running online, in movie theatres and on Tim Hortons TV.

TRAINING

EMC launches productivity program in N.S.

Excellence in Manufacturing Consortium (EMC) has launched a new program for manufacturers in Nova Scotia to become more globally competitive.

The two-year program will enable local industries to address key issues facing Nova Scotia

manufacturers, such as skills shortages, capacity utilization, the impacts on productivity and the rapid advancement of advanced technologies.

Industry will acquire productivity improvement knowledge, networking/benchmarking resources and advanced manufacturing technology best practices and roadmaps.

The program is divided into three parts:

1) Regional Advanced Manufacturing and Productivity (RAMP) clusters: Open to all Nova Scotia manufacturers, EMC is hosting new RAMP cluster sessions in the Halifax and Truro regions, so that companies can access a network of leaders to share ideas, best practices and benchmarking.

This forum for learning and knowledge exchange will also give access to subject-matter speakers, facilitated discussions,

business, technical and operational overviews and potential project identification.

Topics will be driven by participating industries and may include (but are not limited to) advanced manufacturing, automation and robotics, additive manufacturing, future skills, AI / machine learning, next-generation production systems, cyber technologies and security.

2) Lean Leader & Management Systems Certificate training: EMC is also launching a Lean Leader & Management Systems Training Certificate program for up to 15 select manufacturers in Nova Scotia, hosted in both Truro and Halifax.

This advanced training will take place over 10 one-day modules and will allow participants to learn to measure, adjust and implement their own company’s strategic Lean planning, while at the same time achieving positive

Proximity Sensors with IO-Link and IO-Link Smart Configurator

Inductive Sensors with IO-Link

Rugged Ø4, M5, M8, M12, M18 and M30 housings, offering extended ranges up to 22 mm. Easily configured, providing advanced functionalities such as the detection counter (RPM) and the speed controller. Each sensor is fully programmable, providing the means for hundreds of configurations in a single device.

IO-Link Smart Configurator

Configure any IO-Link sensor or actuator via a wireless device that replaces the need to program via a USB IOLink Master connected to a PC or via a network connected master device. The portable Smart Configurator can be used anywhere, as it’s battery powered and equipped with WiFi for IODD files, sync and cloud storage.

Capacitive Sensors with IO-Link

Popular M18 and M30 diameter sensors provide the ideal solution for applications where flexibility or sensing performance needs to be constantly and accurately monitored and logged. IO-Link mode provides added functions such as: QoR (Quality of Run), QoT (Quality of Teach) and Diagnostic Parameters.

ROI impact.

With the added value of networking and benchmarking with peers through this productivity and advanced manufacturing cluster approach, participating companies will also realize project ROI targets ranging from $25,000 to 100,000, achieved while they complete the program.

3) ROI generation: Workplace performance projects and onsite support training: For those manufacturers participating in the Lean Leader & Management Systems Training, EMC will enable on-site support training.

Based on a challenge encountered in their workplace, participants will complete a Workplace Performance Project (WPP) that delivers real-time results and solves, implements and assesses the impacts and implications of their solution.

Each company will receive 12 days of on-site support training and mentoring for building their productivity skills and capabilities, as well as up to three days of facilitated mentoring for project implementation, to increase retention, and to build concurrent return on investment.

In a highly successful pilot recently completed, annual ROI ranged from $50,000 to $400,000+ during the program.

ROBOTICS

Teradyne to build $36M robotics hub

Robotics companies Mobile Industrial Robots (MiR) and Universal Robots (UR), both owned by Teradyne, are building a $36-million “cobot hub” facility in Denmark.

The companies have acquired a 50,000-square-metre site in the city of Odense to continue their development of collaborative robots (cobots).

MiR markets autonomous mobile robots (AMRs) that manage internal logistics, while UR produces flexible cobots that are safe for humans to work with. The companies will remain separate entities.

The building site is in Odense’s industrial district close to UR’s current headquarters, which will become part of the new cobot hub.

“Teradyne continues to invest aggressively in the development of new products, solutions and sales channels and this new facility is a key part of our growth strategy,” says Mark Jagiela, president and CEO of Teradyne.

To date, Teradyne has invested more than half a billion USD in MiR and UR, both Danish robotic companies.

“We have found something very special in Denmark. The Danes’ combination of innovative industrial design, combined with a practical business sense, have created a perfect combination for this emerging industry,” says Jagiela.

“The ability to make robots work in collaboration with humans in a user-friendly manner is something we have not encountered to this degree anywhere else in the world and we’re very excited to expand our capabilities in Odense.”

MiR has hired 100 new employees the past year, with UR adding 280 new staff members during the past two years.

UR employs almost 700 people, worldwide while MiR’s staff is around 220 globally.

Quebec invests $825K in aerospace parts maker

Electro-Kut, a manufacturer of complex components for the aerospace sector in Laval, Quebec, is receiving an $825,000 repayable investment from the Quebec government to add robotics, automation and digitization to its operations.

Founded in 1986, the business has developed expertise in the machining of cast and forged parts as well as in exotic alloy materials used in landing gear components.

According to the province, the SME, which has been facing a growing shortage of technical and specialized labour, is no longer able to meet its clientele’s requirements and take full opportunity of

An artist’s rendering of the new collaborative robot development facility for Universal Robots and Mobile Industrial Robots.

business opportunities.

To meet the growing global demand for specialized parts, Electro-Kut will use the funding to purchase equipment that will produce parts autonomously and continuously. Electro-Kut will be able to kick-start its growth in export markets and take advantage of market opportunities.

DEAL MAKERS

Danfoss to acquire Eaton hydraulics for $3.3B

Danfoss will acquire Eaton’shydraulics business for a cash purchase price of 3.3 billion USD (approximately 3.0 billion EUR).

The acquisition is expected to close at the end of the year.

Eaton Hydraulics provides products for customers in markets such as industrial, agriculture and construction.

The business will be transferred into the existing Danfoss business segment, Danfoss Power Solutions, adding approximately 11,000 employees and 2019 sales of 2.2 billion USD (2.0 billion EUR), which will double the Danfoss hydraulics business.

“Hydraulics is our core, and we have for years strengthened our power solutions business through high customer focus, as well as through significant investments in technology leadership,” says Eric Alström, president of Danfoss Power Solutions.

“I believe our customers will benefit from combining these two businesses into a full-line hydraulics player dedicated to innovation and with a broad offering of products, robust distribution channels and tremendous geographic reach.”

Danfoss today employs about 28,000 people and had 2019 sales of 7.0 billion USD (6.3 billion EUR). With this transaction, Danfoss will increase its size by one-third.

MOVERS AND SHAKERS

Lafert North America has added a new inside representative to its team. Sadaf Irfan brings over six years of experience in technical sales and customer relationship management to her new role, combined with focus in manufacturing, engineering consulting and project management. Irfan will concentrate on enhancing Lafert’s customer relationships through her technical support and project collaborations. “With her background in electrical engineering and sound business acumen in the oil and gas industry, she is the perfect fit to succeed as one of our top technical product experts,” the company says.

The Robotic Industries Association (RIA) has appointed Matt Wicks, chief robotics solution architect of Honeywell Intelligrated, as its board chair.

“I’m honoured to accept this role with a talented team of industry professionals as we continue to guide and support the robotics industry in this time of rapid growth,” says Wicks.

“Robotics are playing an everincreasing role in our global economy and adoption rates are climbing.” Ken McLaughlin of JMP Solutions, Melonee Wise of Fetch Robotics and Erik Nieves of Plus One RoboticsCurrent join as board members.

Applied Manufacturing Technologies (AMT) has promoted Craig Salvalaggio, formerly vice-president of operations services, to chief operating officer (COO). He will lead AMT services along with sales, engineering and talent management. Salvalaggio joined AMT in 2003 and was originally hired as a robotics software engineer before being promoted several times. | MA

Sadaf Irfan

BY WSPS

Can your respirator program accommodate physical changes?

You may have employees who are not getting an airtight seal on their respirators. For example, employees with full beards that are worn for personal or religions reasons may start interfering with respirator face seals. Wagish Yajaman, occupational hygienist and supervisor of WSPS’ Technical Services, sees this firsthand in workplaces he visits.

To work effectively, most respirators require an airtight seal between the respirator and the user’s face and/ or neck. Facial hair could interfere with the seal, drawing contaminated air into the workers’ lungs. But that’s not the only threat. Age, changes in body weight, earrings, headscarves, wigs, facial piercings, dental work, facial injury – any of these could compromise respirator seals.

“ Workers may have a false sense of security in the ability of the equipment they’re wearing to protect them,” says Yajaman. “This could cause irreversible damage to their health.” While most workplaces already have written respirator programs, he’s concerned that otherwise conscientious employers may not recognize the circumstances putting their workers at risk. These steps can help ensure the effectiveness of your program:

1. Identify and assess the hazards. Process changes may have eliminated or introduced hazards. Figure out what substances you need to protect people from and how much of it workers may be exposed to (review MSDSs or SDSs).

2. Look at what’s really going on in your workplace. Are people following prescribed practices? If not, why? Do they know what these practices are? Are ventilation controls working correctly? Are any controls missing?

3. Compare the reality to your existing program. For example, are your training records up to date? Has everyone – workers and supervisors – received the training they need to fulfil their responsibilities? Are you using the right respirators for the hazard? Do the respirators

fit properly and have workers been fit tested? Do people know how to look after their respirators? Do you need a policy for clean-shaven faces if respirators are required?

4. Identify solutions. Are there more effective prevention alternatives to respirators, such as mechanical ventilation, enclosure or isolation of the process or work equipment, proper control and use of process equipment, and/or process modifications, including substitution of less hazardous materials? This is one of the first questions a Ministry of Labour inspector would ask. If not, are there respirators better suited to the hazard or that allow people to keep their beards? (For example, for persons that have beards for religious reasons, a powered air-purifying respirator [PAPR] hood would be used.)

5. Create an action plan with achievable goals and timelines. Draw on in-house and external expertise to develop and implement the plan. To manage workload and ensure buyin, involve key stakeholders, such as managers, supervisors, the joint

To work effectively, most respirators require an airtight seal between the respirator and the user’s face and/or neck.

health and safety committee, and safety associations such as WSPS. Include clear objectives and next steps so that everyone understands what to do and how to do it.

6. Conduct a follow-up review. Identify what’s working well and what can be improved. Celebrate successes and set new goals and timelines for implementing improvements.

Suggested components of a respirator program

This is what the Canadian Centre for Occupational Health and Safety suggests:

• Hazard identification and control

• Exposure assessment

• Respirator selection

• Respirator fit testing

• Training program

• Inspection and record keeping

• Cleaning and sanitizing respirators

• Repairing and maintaining respirators

• Proper storage of respirators

• Health surveillance

• Standard operating procedures (in writing)

• Program evaluation | MA

INDUSTRY WATCH

BY PAUL HOGENDOORN

Paul Hogendoorn is cofounder of FreePoint Technologies. For more information on gamification or “reconnecting meaning with work,” contact Paul at paul.hogendoorn@getfreepoint.com.

Gamification: why it matters to manufacturing

Think about the importance of people in your manufacturing business for a moment. Yes, they are your employees, and yes, they are most likely your biggest input cost and your biggest monthly expense. Yes, they may be your most valuable resource, and yes, your biggest headache at the same time. People are important to your operation, sustainability and viability. But they are more than that – they are representative of your most important audience – your customers.

In North America, the middle class was made by manufacturing companies and continues to be sustained by the industry. The healthier our manufacturing industry, the healthier our economy, and, likely, the healthier our society in general. It’s all connected. But things are changing, and our manufacturing companies need to change, too. And the biggest change is because our people are changing.

A whole generation is approaching retirement and manufacturing companies are struggling to replace them. The incoming generation is very different from the exiting generation. Marketers have already identified the differences and have helped companies tailor their product and sales methods to reach the new generation – but the same transformation process hasn’t happened when it comes to trying to attract the generation to the workplace, and that’s a mistake. We compete for the young generations’ attention to sell them our products and services, and we need to do the same thing to attract them to our industry. How we think of them as potential employees should be how we think of them as customers – they are critical to our long-term success. We need them just as excited about our jobs as the products we hope to sell them.

My generation – the boomers –wanted white picket fences, two cars in the driveway, and to be able to put our kids through college and university. On average, we worked for three companies over our entire career. Generation X followed, changing jobs a bit more often, with more focus on personal career status.

G eneration Y is very focused on more work-life balance, social engagement, and they tend to change jobs even more often. And following them, we have Generation Z, the most techsavvy and tech-addicted generation of them all. Plus, Generation Z is as passionate about effecting societal change (climate issues) as the boomers were in the late 60s (ending a war).

We compete for the young generations’ attention to sell them our products and services, and we need to do the same thing to attract them to our industry.

As the oldest group moves out of our workplaces, we need to aggressively change our workplaces and careers to attract and accommodate the newest generation. At first glance, the new generation appears to be vastly different from the boomers, but in two critical ways, they are very much the same: they have a strong need for purpose, and a desire to be part of a physical (non-virtual) community. Where they differ is their need of feedback – they need constant feedback to remain engaged, and when they are not engaged, they do not remain.

To attract the best of this generation, and to keep them, we need to offer them a workplace that offers them all three: purpose, community, and lots of feedback to keep them engaged. Think of bowling alleys and movie theatres in the 1980s – they were good enough to meet the needs of the boomer generation, but they both went into rapid decline and many thought they were obsolete. But, check out a bowling and entertainment facility today, or a multi-screen theatre, and you see the exact opposite. The parking lots are

overflowing and the facilities are full every night of the week. Their product is fundamentally the same, but they adapted to their target audience, and they are thriving. Our manufacturing plants need that type of transformation, and gamification can be a part of that.

G amification is simply a matter of making meaningful things more visible, and more interesting, in real time. Your bulletin board by the punch clock, for instance, is likely filled with posters and information that is weeks or months old. The metrics you provide as performance feedback are likely disconnected from the actual work they do in their departments or on their machines, and those metrics are probably days or weeks old. Think of how this generation has grown up, with instantaneous feedback, visually presented in very interesting ways. Every action in a game yields a result, and that drives continued engagement. The other thing noteworthy about video games today is that many are collaborative, with players not playing against each other but playing with each other to build a city or achieve a victory.

The manufacturing companies that will succeed and thrive in the future will be the companies that attract the best people from the coming generation by adapting their workplaces, making them more attractive, the work more engaging, and the time spent more meaningful. | MA

Considering a digital transformation? Don’t go it alone

The world of work is changing: How we do our daily jobs and the environments in which we do them are more innovative than they’ve ever been; workplaces are often overwhelmed with an abundance of technology built to streamline and simplify processes; and, with people living longer and retiring later, for the first time ever, five generations are coexisting in the workforce.

With all of this happening around us, the question arises: How can we bear any more change? The good news it seems as though workers aren’t just ready for change – they crave it. A recent survey from The Workforce Institute at Kronos indicates that 34 per cent of Canadian workers, in all the generations in the workforce today, consider themselves early adopters eager to use new technology and express strong opinions about how new technology should perform.

With this in mind, it’s not surprising that many organizations want to run full-force toward advanced workplace technology. However, it’s important for organizations to realize that today’s workforce isn’t just a beneficiary of the digital transformation movement – it’s an integral part of it.

Manufacturers can digitize their plants with all the technology they want, but unless business leaders consider the expectations and needs of employees – both hourly and salaried – as part of their holistic digital transformation strategy, they may find their workforce uninspired and unprepared to drive innovation and deliver the business results they expect.

Understanding workplace expectations

Employees today expect their entire experience at work, from pre-hire to retire, to be as technologically advanced as possible, but crave an intuitive user experience. This means that leaders need to consider all aspects of a worker’s day-to-day routine and evaluate what may be causing challenges so they can adopt the appropriate technology to meet the needs of employees.

Workplace tech was once far more innovative than and superior to anything that was available for consumer use, but the opposite is true today: Close to half (49 per cent) of manufacturing employees globally, and more than half (52 per cent) of all Canadian employees, agree it’s easier to search for new movies

on Netflix than to check the details of their employee benefits.

Nearly half of employees (48 per cent) wish their workplace technology performed just like their personal technology, and 35 per cent of all global employees (and 39 per cent of Gen Zers) feel their job is harder than it should be because of outdated processes and legacy technology.

It’s vital for manufacturers to understand the dual importance of fostering a technology-friendly work environment and investing in their people resources. For example, a different survey from The Workforce Institute at Kronos found an undeniable demand from the workforce for technology to improve daily tasks like scheduling and shift swapping. Nearly half (47 per cent) of employees have had a time-off request rejected by their employer within the last year, with manufacturers most commonly rejecting vacation requests. At the same time, a staggering 90 per cent of employees worldwide think their organization can improve scheduling – which would inherently impact the work-life balance of the workforce.

Frustrated with how long it takes managers to approve time-off and schedule requests, more than a quarter (28 per cent) of employees wish their organization would embrace self-scheduling, which would allow them to build their own schedules or select preferred shifts that make it easier to manage personal responsibilities outside of work. By and large, employees want solutions that make it easier to work their way: swapping shifts, seeking coverage from colleagues, and opting into open shifts for more hours – especially via a mobile phone or tablet.

Make the transformation conversation a team effort

When embarking on the digital transformation journey, manufacturers should consider both technological and people-centric upgrades, which means including the human resources (HR) team from the get-go.

This will ensure HR-specific aspects are evaluated such as: real-time labour analytics to help managers make informed operational decisions; intelligent self-scheduling and shift-swapping technology; and real-time performance data that can help managers have constructive conversations and provide transparency to employees about what is required of them to advance in the organization.

Manufacturers can digitize their plants with all the technology they want, but unless business leaders consider the expectations and needs of employees, they may find their workforce uninspired.

Involving HR throughout will also help to ensure that manufacturers’ most valuable resource – their people – remains a top priority throughout the process. After all, digital changes that emphasize a positive employee workplace experience are one of the most important differentiators for recruiting and retaining top talent.

E mployee-centric solutions powered by the latest emerging technologies are not only transforming the future of smart factories – they’re integral in engaging employees as the lifeblood of the business, and a competitive differentiator in the war for talent.

By investing in the workforce today, organizations can begin to fundamentally improve engagement and drive productivity, both of which are essential parts of any manufacturer’s digital transformation | MA

Spiros Paleologos is the vice-president and general manager of Kronos Canada.

BATCH OF ONE

As the increasing granularity of consumer demand drives down batch sizes, manufacturers are facing the prospect of upgrading their automation infrastructure. The trend is accelerating the transition to Industry 4.0

BY JACOB STOLLER

Underneath the compelling headline on BMW’s “design your own vehicle” website, there is some telling fine print. “This is a configurator,” the disclaimer reads. “Your ability to obtain the vehicle you build depends on availability.”

These words reflect the difficulty, even for luxury brands, of moving away from the traditional paradigm of mass production. While responses to the growing granularity of customer demand – mass-customization, flexible manufacturing, batch-of-one manufacturing – are often touted as the way of the future, many hurdles remain.

The basic idea, of course, is nothing new – the term “mass customization” was coined in the 1990s – but the more recent expectation of consumers that they can order anything they want from anywhere in the world has created a

Lot: 1

The mass customization method of production now goes by several names including flexible manufacturing, batch-of-one and lot-size-one manufacturing.

dynamic where consumers no longer want to buy the car that’s sitting on the local lot.

“Canadians for some reason love their car to be custom,” says Johnston Hall, product specialist with Omron Canada. “Everyone has to be different, and that requires small production runs.”

The impact is being felt by OEMs and parts suppliers. “I know automotive suppliers who used to have to make 20 different variations of a product, and now they have to do 5,000,” says Michael Gardiner, manufacturing industry solution executive at Microsoft Canada.

The trend is putting a strain on manufacturers’ existing infrastructure. “Manufacturers are having to adapt to that philosophy,” says Mike Hutson, solutions architect for Toronto-based software provider Syspro Canada. “The key is, how can they change their manufacturing environment to suit that? If you’re set up to mass produce, then it’s very difficult to change.”

Transition at multiple levels

The difficulty for manufacturers is that the smaller batch trend touches all aspects of the business – production planning, material handling, fabrication, packaging, and delivery through the supply chain. Consequently, there are no magic bullets.

“It’s not just one thing – it’s a combination of things that manufacturers have to do,” says Hutson.

Tech vendors are responding with different pieces of the proverbial jigsaw puzzle. ERP systems are being adapted to configure small batches and orchestrate them through the supply chain. Material handling methods and industrial controls are being re-architected to support small-batch or batch-of-one production with existing infrastructure. Additive manufacturing or 3D printing is dropping in price, making it viable for selected small production runs.

“ Tech providers – hardware and software, automation or robotics – are re-architecting their own systems and methods that may have been in place for decades in order to accommodate this,” says Gardiner, “and all this is happening at the same time. In the last five years, I’ve seen more movement than I saw in the previous 15 in the industry.”

The solutions generally support a modular manufacturing strategy, where a core component is mass-produced, and components that vary by customer preference are made in smaller batches and installed in “Lego-block” fashion. The approach allows manufacturers and distributors to shrink their product

portfolios while leveraging their existing infrastructure.

“Manufacturers have a massive amount of capital geared for pure mass production,” says Hutson, “so when it comes to mass customization, modularization is the most practical way to do that.”

Industrial pumps are a good example. As Hutson explains, the customer can use a software module called a configurator to select a housing, and then choose the motor, valves and other components. Using rules-driven algorithms, the configurator then generates a quote and orchestrates the order into the fabrication or assembly process.

The modular approach can require significant human intervention on the factory floor, however, and the need to mitigate that is spawning a new breed of intelligent machines.

Smarter machines

E fforts to produce in smaller batches are often hampered by the inflexibility of traditional automation technology, much of which may have been in service for decades. The approach, therefore, often involves prohibitive set-up costs.

“A classic robotic line is not adaptable – if a piece isn’t in the right position, the robot won’t pick it up,” says Gardiner. “If you really want your system to adapt, it has to be more cognitive, so that it can adapt to different learning situations.”

Machine learning software, supported by the latest generation of vision sensors, can learn on its

own how to set up a machine for a non-standard order.

“This doesn’t mean you have to buy all new equipment,” says Gardiner. “A lot of what we’re doing in the tech industry is taking existing equipment and making it smarter. For example, adding artificial intelligence (AI) to existing camera systems using overlay software and edge computing.”

One approach is to equip machines with machine automation controllers (MACs), recently introduced by manufacturers such as Omron, which can track components through the production line without involving humans. In automotive, this could match custom parts such as car seats to a particular vehicle on the line. “The machine can read the bar code and know what seats are supposed to go into that car,” says Hall.

Another piece of the puzzle is making production lines more flexible so that they can support modular production. Austrian equipment manufacturer B&R Industrial Automation’s answer to this is to replace fixed conveyors with track-based conveyance systems that allow, in railroad yard fashion, for workpieces to be automatically switched to the right machines.

“At the core is intelligent track technology, in which individually controlled shuttles adapt to each product being produced, assembled or packaged – instead of a volume of products conforming to a rigidly sequential process,” says John Kowal, B&R’s marketing director for North America, who is based in Chicago.

Track systems also require less space. “Track systems can cut production line footprint in half compared to lines connected by conveyors,” says Kowal. “In a clean room environment, cutting the costly isolator space in half can save hundreds of thousands of dollars.”

Gardiner envisions an automotive factory of the future where the arrangement of machinery no longer follows the fixed production line format. “Products will take different routes in the factory depending on which model is selected,” he says. “Instead of a long production line, an automated guided robot will take the product to what area it needs for processing next. There are manufacturers that are already doing this.”

From prototype to production

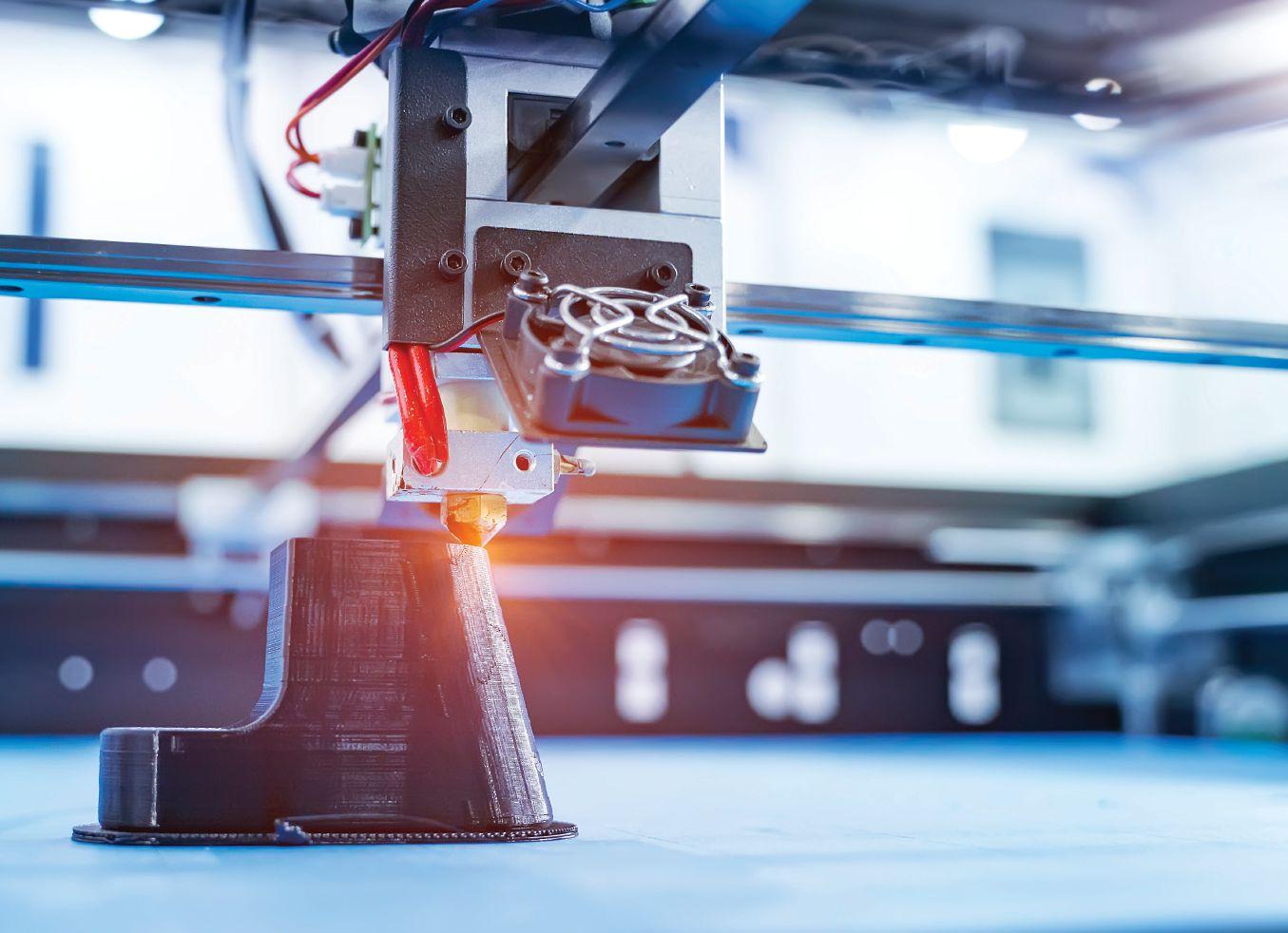

A dditive manufacturing, also known as 3D printing (read more on its adoption in Canada on p. 16), has gained considerable

attention in the smaller batch conversation, and for good reason – the technology often simplifies the design process, is remarkably versatile for executing complex designs, and eliminates setup and tooling costs that often require high volumes to amortize.

“With additive manufacturing, you have the entire supply chain from raw materials, to design, to manufacturing, all under one roof,” says Mihaela Vlasea, an assistant professor of mechanical and mechatronics engineering at University of Waterloo who specializes in metal additive manufacturing.

Costs are dropping. For example, Vancouver-based 3DQue has developed technology that makes additive manufacturing price competitive for small and medium-sized plastic parts runs. The key has been automating material-handling tasks that have traditionally slowed down the process.

“ We have an automated system for parts release, and software that drives the whole system,” says Stephanie Sharp, 3DQue’s CEO. “So we’ve minimized manual intervention from design to shipping. This way we’re able to be cost competitive with injection moulding.”

Metal additive manufacturing is also advancing rapidly. “The cost of materials has drastically gone down, and there are more options for materials you can print with,” says Vlasea.

That said, additive manufacturing, at least on the metals side, is still expensive compared with

B&R Industrial Automation’s ACOPOStrak flexible transport system uses independently controlled shuttles that accommodate and move differing products.

B&R’s SuperTrak transport system uses magnets to guide products on individual shuttles along a track.

“Manufacturers have a massive amount of capital geared for pure mass production, so when it comes to mass customization, modularization is the most practical way to do that.”

traditional fabrication methods – and significantly slower, notes Mark Kirby, additive manufacturing business manager at the Kitchener, Ontario–based Renishaw Canada Solutions Centre, which helps companies develop metal-based additive manufacturing capabilities.

“ You’re not going to be using it to drive costs out of an existing product,” says Kirby. “You’re trying to develop new products that have to be higher performance –parts that cost more but deliver higher value.”

One example is fuel injectors for aircraft engines. “The fuel injector is one of those poster-child components,” says Kirby. “Because we’ve reduced the number of individual pieces that are welded and brazed together, it fails less often.”

Kirby envisions the emergence of that will expand over time as additive technology improves. “It’s hard to predict, but I think the biggest impacts will be ironically in the places people least expected it,” he says.

Solving age-old problems

Demand for smaller batches may be the burning platform that’s driving a more flexible approach to manufacturing, but the resulting trend to smaller localized facilities has many other benefits.

“ The adaptive machine is great for re-shoring, overcoming the skills gap and addressing growing labour shortages,” says B&R’s Kowal, “and compared to offshore production and long trips in containers, manufacturers will be able to fulfill custom orders overnight.”

“ With additive, I can produce a thousand parts per week, or a few hundred a day,” says Sharp, “so I don’t have to keep tens of thousands of them in inventory. That means I don’t need warehousing

space, and that reduces the environmental footprint.”

The resulting facilities are also more attractive places to work.

“ You can now have urban

factories,” says Vlasea. “If you come into our site [at the University of

Waterloo], we’re in an office building with full metal manufacturing facilities on the main floor. So we can bring all of these manufacturing jobs closer to younger people, who view [this building as] a cool place to be – right downtown. That really attracts a new wave of engineers.” | MA

Jacob Stoller is a journalist and author who writes about Lean, information technology and finance. jacobstoller.com

ADOPTING ADDITIVE

How Canadian manufacturers can use additive manufacturing to streamline design processes for mass production of parts

BY GRANT CAMERON

Canadian manufacturers, it appears, have been a bit more cautious than their counterparts in Europe and the United States in rolling out the proverbial red carpet for additive manufacturing (AM) processes, perhaps due to the dizzying array of options and substantial upfront investment that’s required.

However, experts in the field say manufacturers should consider being a little more hospitable as the technology has evolved by massive leaps and bounds from visualization and prototypes to very efficient processes that can save companies some big bucks by reducing waste and cutting out the time it takes to do assembly work.

“There’s a lot of interest and intrigue but the actual adoption is pretty weak in Canada,” says Curtis Pastorius, managing director of Canadian Additive Manufacturing Solutions in Mississauga, Ont., and technical lead of Canada Makes, a network that promotes additive manufacturing. “Canada’s about five years behind what’s happening in the U.S. and the U.S. is five years behind what’s happening in Europe.”

W hile Canadian companies are curious to learn more about AM, and the fact it can now be used to make fully functional parts in metals and plastics, there’s been so much media hype around it that manufacturers are confused about what will work for them and are cautious about moving forward, Pastorius notes.

The challenge, he says, is to show

manufacturers the value proposition of how AM can make them more efficient by streamlining the design process, enabling them to design for function rather than the manufacturing process, and combine several components so a product can be printed as a single piece.

“There’s greater value because I can cut out the whole assembly process and quality issues with the assembly. I can print it as a single piece. It’s more expensive, yes, but I didn’t have to spend on other components.”

Pastorius notes that tire manufacturer Michelin, for one, has adopted additive manufacturing. The company used to take a block of steel and cut material away to make a mould to form a tire. But, it has since invested in 40 AM machines at $1 million apiece that can print the moulds, giving designers more flexibility and reducing waste.

“Instead of cutting away what you don’t need, you only put on what you do need. They were able to then design the tooling for a better tire because additive allowed them to do that. It’s design for function.”

James Jack, vice-president of business development at Agile Manufacturing Inc. in Uxbridge, Ont., says while adoption of AM in Canada is a bit behind the U.S., inroads are being made across all types of industries. “Companies are still prototyping using 3D printing, but more and more are using additive manufacturing for production.”

The potential applications of AM in mass production are nearly limitless –and faster printing technologies such

as digital light synthesis, selective laser sintering and multi-jet fusion make production realistic, Jack says, allowing the production of everything from car and airplane parts to medical implants and robotics.

200

More than 200 Canadian manufacturing companies have received funding to design and manufacture their own 3D-printed metal prototype parts in the last seven years.

B eing able to craft custom-made pieces for different markets as well as share a file with a printer in Seattle and another in Florida to build the exact same part certainly makes AM appealing, he says.

“ The ability to design for the function and use instead of designing for traditional manufacturability is huge. Reducing waste by adding material versus subtracting makes AM more efficient in many applications.”

Reduction of lead-time as well as the ability to print on demand and maintain a virtual inventory are other cited benefits.

“Not having to justify the expense of an injection mould tool when introducing a new product allows people to create and release products that they previously may not have been able to afford,” says Jack.

“Instead of cutting away what you don’t need, you only put on what you do need. They were able to then design the tooling for a better tire because additive allowed them to do that. It’s design for function.”

Ehsan Toyserkani, professor and Canada Research Chair in Additive Manufacturing at the University of Waterloo, says that for many years, companies have been deploying additive manufacturing for low-volume fabrication, but in recent years manufacturers have been working hard to enable the process for serial production as well.

The technology is beginning to garner interest in Canada and industry players seem keen to learn how to adopt metal AM, in particular, as part of their production lines, he says, noting that companies such as Burloak Technologies in Burlington, Ont., and Promation in Oakville, Ont. are developing AM systems. AM is also being adopted in Canadian aerospace and nuclear industries.

While it is expensive to get off the ground, Toyserkani notes the process helps manufacturers in a number of ways, allowing for faster development of products and lighter parts,

while also saving energy.

AM also gives designers the ability to implement “personalization” while mass-producing parts, he says, So, for example, without any extra tooling, a company could produce thousands of parts with multiple designs.

The fact that AM results in less waste is another bonus, says Toyserkani. Another luxury is that it provides freedom to use less material to design lightweight structures that can perform the same as conventional parts.

In plastic, AM is being positioned as a viable solution to replace injection moulding, while in metal, there is major work being done to address quality assurance tools for mass production, he says.

“This promotion from prototyping to a serial production platform has opened up many research and development opportunities,” says Toyserkani.

Companies that serve the auto industry

are looking at AM to enable the production of components that have integrated functionality without the need for tools. Laser sintering technology, for example, often allows for components such as springs, hinged joints or even pneumatic actuators to be produced in a single step, saving manufacturers not only time and money but also minimizing the likelihood of production errors.

While the cost of switching to AM for metal, in particular, is what deters a lot of companies, there are relatively few experts in the field so that makes it difficult for companies to navigate a changeover. Toyserkani suggests manufacturers work with universities and leading additive manufacturing companies to bridge that gap.

There is help available for manufacturers that are looking to make a changeover. A federally funded program managed by Canada Makes helps Canadian manufacturing companies de-risk and learn more about metal AM. In the last seven years, more than 200 Canadian manufacturing companies have participated and received funding to design and manufacture their own 3D-printed metal prototype parts. | MA

ADVANCING AUTONOMOUS CONTROL

An award-winning AI and simulation application has potential in process manufacturing

BY JIM MEYERS

What if you could run an entire plant autonomously? ANDRITZ Automation is working toward that goal, and thanks to its progress thus far, the company’s plan is attracting a lot of interest.

ANDRITZ recently won a major award for a pilot project that involves training an artificial intelligence (AI) controller to run an industrial plant. In addition to AI, the project includes machine learning and ANDRITZ’ own IDEAS process-simulation software. The company says it believes this is the first application of reinforcement learning to control continuous industrial processes.

ANDRITZ Automation is a supplier of machine and plant control systems based in Austria, with four sites in Canada and 110 worldwide. The company provides automation services and tools for a wide range of industries, including pulp and paper, mining, lime and cement, hydropower and wastewater.

ANDRITZ’s AI project won the top prize in the 2019 Goldcorp #DisruptMining competition, a public showcase for new technology

that focuses on digital transformation of the mining industry to optimize profitability and competitiveness.

“ We won the competition, and with that came a CA$1-million opportunity to implement a pilot project at one of Goldcorp’s sites,” says Arthur Gooch, director of innovation for ANDRITZ. “Along with the pilot project, that win showed us — and our board that had funded us — how appealing this technology is to industry.”

The award-winning project was originally a research and development effort by ANDRITZ. “We’ve used our simulation tools to train plant operators for over 20 years,” says Gooch. “Some of our controls engineers realized that this same technique could be used to train an AI. We applied this concept to a company-wide internal innovation contest. Our executive board selected our proposal for seed funding, which allowed us to develop the technical solution into something we could sell.”

As ANDRITZ is a major supplier of pulp and paper equipment, applicability to pulp processing was one of the deciding factors when the executive board supplied the initial R&D funding. At this point, ANDRITZ is moving forward rapidly. “We’re currently implementing three pilot projects at operational sites,” says Gooch. “Two are in the mining industry and one is in pulp and paper. We’re on track to have all three pilots running by the middle of 2020.”

The application is built on Inductive Automation’s Ignition, an industrial application platform with tools for building solutions in human-machine interface (HMI), supervisory control and data acquisition (SCADA), manufacturing execution systems (MES), and the Industrial Internet of Things (IIoT).

Because it was an R&D project, ANDRITZ

needed a platform that would allow it to create a robust prototype quickly, with minimal cost. Ignition fit the bill. Python code, visualization, historian and reporting capabilities are key aspects of the project.

AI brings impressive benefits

The solution is a combination of modern AI and industrial process simulation. The project trains AI based on a digital twin replica of a plant. In other words, the software learns how to do the plant’s work. It provides autonomous control for an industrial plant the same way a self-driving car can pilot itself. With autonomous control, plants can see more consistent performance, and can respond faster to changing plant conditions — potentially bringing improved productivity, greater efficiency, lower costs and better safety.

It starts with the creation of a realistic model in a simulated environment of the process. The model is deployed in a cloud environment. Then the machine-learning algorithm spends months to years of simulated time exploring and learning every possible way that the system can fail.

Once it’s been trained in a virtual environment, the autonomous controller is subjected to the same kinds of certification tests a human operator would be expected to pass.

Next comes taking it to the real world. At first, the controller operates in an advisory mode, where it’s making recommendations for operators. Then it’s allowed to pick up more and more direct control. Eventually, it runs in a fully autonomous mode.

“ We’re excited about this, because we feel autonomous control is the next logical step for how to run a plant,” says Gooch. He adds that seeing the application running was a big

milestone. “Showing that the proof-ofconcept actually can control a plant was important,” he says. “The team was confident that our idea was sound, but it’s different to see it actually working in front of you.”

The application could appeal to numerous industries. “If control room operators regularly need to interact with an HMI, this technology can respond to routine events faster and more consistently than a person could,” says Gooch. “Any industry where existing programming methods or control technology can’t deliver a system that runs completely automatically most of the time would benefit significantly from this new system.”

Gooch said it’s particularly suitable to sequential decision problems where an agent must take multiple discrete actions in sequence in order to achieve a

3target state. That makes it applicable to a variety of control tasks that heretofore could only be controlled manually, like plant start-up or upset recovery where the operator must start several motors or swing valves in a particular order defined by plant conditions.

The AI has also demonstrated itself suitable for continuous optimization problems where a plant might otherwise use model-predictive control or expert systems.

Powerful software

The two ANDRITZ teams working on the project collaborated from Canada and Germany. Using Ignition, they built software that could control the IDEAS software and pass data back and forth between the virtual plant and the AI.

With our modular safety gate system you can built an individual safety gate solution optimally tailored to your application!

• Safety gate system PSENmlock: safe interlocking and safeguard locking in one product with optional escape release

• Safety gate system PSENslock: Safe position monitoring with process guarding in one system

• Pushbutton unit PITgatebox: Simple operation of your safety gate system

• Safety Device Diagnostics (SDD): Comprehensive diagnostics and economical series connection of the safety gate sensors PSENmlock

Eventually, this same software needed to pass data back and forth with the running plant, using industrial communication protocols.

It also needed to function as an administration interface for training the AI. This new software needed to allow a user to set up training scenarios, like a particular plant malfunction that the AI should learn. The software would then manage the training, recording results to history and reporting on the outcome.

“The industrial customers we’ve talked to so far have been extremely positive,” says Gooch. “Several are paying for pilot installations. There are a lot of control problems that people assume must be managed manually by operators, so the possibility of a software solution is very exciting for these sites. And the payback for automating certain problems is huge.”

Part of the success of this AI project depends upon people being open to AI in general.

“Managing the human reactions to this new technology has required a delicate balance,” says Gooch. “Talking about AI conjures a range of emotions from enthusiasm, to skepticism, to fear. Engineers love to focus on the technical aspects, but understanding what the AI means to people has been more important to making progress in development.” | MA

Modular safety gate system: Your gate. Our system. Your safety

Pilz Automation Safety Canada L.P. - Mississauga, ON - www.pilz.ca - info@pilz.ca

Jim Meyers is communications manager for community alliances at Inductive Automation.

ANDRITZ is working on three pilot projects for autonomous plant control. All will be up and running by mid-2020.

ANDRITZ is piloting autonomous plant control for a pulp and paper application.

HOW TO LOWER YOUR CYBERSECURITY RISK

It’s time for Canadian manufacturing companies to step back and assess their cybersecurity priorities

BY GRAHAM BUSHKES

If a piece of machinery were to break on the factory floor – how long would it take to fix?

Or if a door to the head office were left open and someone wandered in and began flicking through your plans and customer details – what would your reaction be?

Both of these examples would likely result in fast, decisive action. In fact, a manufacturer would rarely if ever find themselves in that situation, given that physical maintenance, security and safety systems are a top priority.

Ironically, this same heightened sense of security often doesn’t extend to cybersecurity, even though the potential for serious financial and even physical consequences – especially in OT networks – is the same or higher.

The reality is, despite the fact that 88 per cent of manufacturing operational assets are now connected to a converged IT/OT network – leaving traditionally isolated and highly vulnerable systems exposed to external resources, devices, and networks – cybersecurity remains an under-resourced and isolated area of the manufacturing business.

In fact, one recent study commissioned by the Canadian Advanced Technology Alliance shows that only 57 per cent of surveyed manufacturing companies had appointed a cybersecurity official, and 65 per cent had spent less than $100,000 a year on cybersecurity.

While there are many reasons for this, including the need for organizations to reprioritize cybersecurity, one of the biggest gating factors is the currently limited resourcing landscape. Canada alone will need to fill 8,000 additional cybersecurity positions this year, and a global survey of CISOs earlier this year found that a lack of budget was interfering with planning and rollouts. Coupled with the global shortage of skilled cybersecurity professionals, overtaxed IT teams are struggling to keep pace with new digital innovation efforts and dealing with sophisticated threats on their increasingly complex networks. As a result, it’s not only likely but inevitable that there will be a serious breach. In fact, a recent study found that 74 per cent of OT organizations experienced a data breach in 2018.

The time has come, therefore, as we enter a new year, for Canadian manufacturing organizations to step back and reset their cybersecurity priorities and structures.

The three steps outlined below will empower organizations to see their entire distributed and expanding networks clearly and transparently, enabling them to fully integrate a holistic security system that addresses

the evolving threat landscape, while also continuing to meet their business objectives.

Step 1: Set integrated cybersecurity objectives

For most manufacturing businesses, it’s not just the IT and OT environments that are segmented. The teams that run them are as well. What’s more, they usually operate under entirely different objectives, with IT teams prioritizing the confidentiality of critical data while OT teams look to provide safe and continuous operations above all – meaning that resources are never intended to go offline, even for a much needed software or hardware update.

While on the surface these appear to be conflicting priorities, the fact is that in order to maintain safe and continuous operations, all cybersecurity threats still need to be managed. That means that updates, planned downtime, or even new redundant systems to support maintenance should be integrated into the overall business strategy in order to avoid the potential of unplanned system failures or security events that can ultimately cost millions.

B ringing the IT and OT teams together – or deepening their existing connection points – so they can better

According to a recent study, 74 per cent of OT organizations experienced a data breach in 2018.

understand each other’s’ business requirements and associated security implications, should be step one for any manufacturing business in the new year.

Step 2: Create a clear picture

Another side effect of the IT/OT divide is that, like with many IT networks, the security of an OT network is too often only considered at the end of a roll-out plan. But given the sensitive nature of OT systems and the potential impact of a serious cyber event, that approach carries serious repercussions.

As a result, it’s reported that 78 per cent of OT organizations only have partial visibility into what devices are connected to their network and where they are connected. With the need for companies to stay on the cutting-edge to maintain their competitive advantage, and the fact that new roll-outs can often happen fairly quickly, a pause to talk cybersecurity is not usually on an OT team’s to-do list.

Further, with anything between 50 and 500 devices on an OT network, many from different vendors, even if they are given a full picture, most teams would be stretched to capacity to tailor security solutions and customize requirements to each device. The end result is that if a corrupted device enters the network or a malware-infected email is opened, the OT and IT teams might not have the means for detecting and responding to that threat.

It also means that some of the most basic cybersecurity threats – like phishing, malware and ransomware, and mobile security breaches – could be some of the most crippling for the manufacturing industry.

Manufacturers that integrate their cybersecurity strategies into the very core of their business model will be better positioned to handle the ever complex and growing security threats that 2020 will bring.

For that reason, step two for Canadian manufacturing businesses should be to get their frontline OT personnel to walk their cybersecurity team through the manufacturing floor, figuratively if not in actuality, and identify the organization’s most critical assets.

This will empower the cybersecurity team to see the full picture, and then enable them to design a tailored cybersecurity program that works for the business while also preparing them for the ever-advancing and complex threats being rolled out by cybercriminals.

Step three: Find an integrated solution System updates and scheduled downtime will continue to be a source of tension and a weak spot in any company’s cybersecurity hygiene if the IT and OT teams continue to operate in silos. However, there will need to be compromise on both sides, adapting and adjusting processes to ensure production and security needs in equal measure.

Overall, that requires both IT and OT teams to use their greatest asset, data and information, to their advantage. This means selecting security solutions that are flexible and that can be scaled, adapted, and managed as part of a converged IT and OT security system that spans the entire network.

To achieve this, you need to look for tools that extend from the data centre to the cloud to the network perimeter, that include protocols and functions specifically designed to provide visibility, control, and automated detection within an OT environment, and that also include built-in support for industry standards.

It’s also essential that any solution minimizes complexity and reduces the operating expense of OT security management to ensure that the benefits of your new integrated plan are recognized and can be incorporated into a comprehensive strategy that extends across the business.

Manufacturers that integrate their cybersecurity strategies into the very core of their business model will be better positioned to handle the ever complex and growing security threats that 2020 will bring.

Individual systems need to be managed and integrated into a single management system, including SIEM (Security Information and Event Management) and SOAR (Security Orchestration, Automation, and Response) tools, and comprehensive SOC (Security Operations Center) systems that provide comprehensive visibility, control, and response across all IT and OT environments.

That’s something that all teams should be able to get behind. | MA

Graham Bushkes has been the country manager for Fortinet Canada since 2002. He is a direct and channel sales veteran with more than 32 years of experience in the IT industry.

NEW PRODUCTS

Automation software update

ICONICS has announced the release of Version 10.96 of its automation software lineup, containing a number of new solutions for manufacturing. The software contains updates to solutions such as the GENESIS64 HMI/SCADA and building automation suite, AnalytiX data analytics suite, Hyper Historian rapid data historian and tools, MobileHMI data mobility suite, and IoTWorX IoT connectivity suite, among other solutions. The AnalytiX suite includes updates such as an advanced connected field service solution, an on-demand preview, preview caching, visible data types and more. Hyper Historian now includes data archiving and storage options, with export to third-party storage, including Azure Data Lake, Azure SQL, SQL Server, Apache Kafka, Apache Hadoop, and local CSV files. Hyper Historian tags can now be configured from within ICONICS’ ISA-95-compliant asset-based enterprise control system.

iconics.com

Solution for software management

Averna has developed a new test package manager software solution with the release of Averna Deploy, the latest in the company’s smart data management suite. The program ensures all

manufacturing activities remain accurate and reliable with the most up-to-date software versions installed on systems throughout smart facilities. All updated software revisions are automatically deployed to every test station and asset throughout production plants. In addition, users have the ability to select the code they need on the test station they want. The intelligent software comes with a mechanism to prevent tests from running should a machine be outdated, guaranteeing accurate and consistent data. averna.com

CAMWorks with smart manufacturing features