Low-cost Linear Motion

Actuator assemblies, sliding components and accessories

SureMotion® Linear Slides and Actuators

Get reliable linear motion at low prices with the award-winning customer service and support you expect from AutomationDirect! Our line of linear motion products is designed to provide smooth, precise and durable linear actuation. With supreme versatility and low maintenance, these affordable, motor-ready actuators can meet both your linear motion and budget requirements.

Low-cost, versatile linear slide actuator with hard-coated aluminum guide shafts. Unit can be mounted horizontally, vertically, or inverted without loss of load capacity.

• Max load capacity: 110 lb

• Max speed: 15 in/sec

• Travel: 6, 12, 18, 24 inches

• Ready for NEMA 17 motor

Compact Linear Actuator

Self-contained linear slide actuator designed for light loads in harsh or wet conditions in a very small package.

• Compact design

• Stainless steel lead screw

• Max load capacity: 125 lb

• Max speed: 20 in/sec

• Travel: 6, 12, 24, 36 inches

• Ready for NEMA 17 motor

Shafts and Shaft Supports

Create strong, secure shaft assemblies with high-quality shafts and shaft supports.

• Aluminum, steel & stainless steel shafting

• Linear or rotary shafts (with and w/o grooves)

• Standard height and low-profile shaft supports

• Removable top maintains alignment while servicing

Research, price, buy at: www.automationdirect.com/motion-control

Twin Round Shaft Actuator

Continuously-supported round rail slide with ball screw actuation provides a very robust precision linear motion.

• High-accuracy ball screw

• Continuously-supported guide rails

• Max load capacity: 920 lb

• Max speed: 6 in/sec

• Travel: 12, 24 inches

• Ready for NEMA 23 motor

Linear Slide Components

Passive sliding elements can be combined with actuators to build a huge variety of machine mechanisms.

• Linear ball bearings

• High-quality clear anodized aluminum blocks

• Carbon-steel shafts Extensive Video Series on Linear Motion: http://go2adc.com/lm

Orders over $49 get FAST FREE SHIPPING

18 Hannover hit list

Our top takeaways from Hannover Messe, the world’s largest industrial technology fair

By Kristina Urquhart

22 Bridging the skills gap

With automation changing the types of manufacturing jobs available in Canada, leaders look for ways to attract new workers and re-engage existing ones

By Jessica Wynne Lockhart

24 A question of time

What does Time-Sensitive Networking (TSN) mean for decision-makers in the IIoT? By Anil Kumar, Denzil Roberts & Steve Zuponcic

LETTERS TO THE EDITOR

@fpeautomation

FPE Automation, Inc. is proud to be one of the few authorized @ Universal_Robot training partners in the US in this article in @ Automation

Mag ow.ly/ jK2v50uag01join us for UR CORE training!

@AutomationMag

Catch up on @ AutomationMag’s highlights from Hannover Messe, #HM19: ow.ly/4Wk230omwKd

#manufacturing #automation

@sudeep kumarpat9

@nokia showcases modular #factory concept at @ hannover_messe : #digital #Automation

#Manufacturing @ AutomationMag ow.ly/4XH H50uaghQ

@wil_bielert

RT @AutomationMag: “You have to actually change,” says Alam Mohammad of @ Deloitte, meaning you can’t keep doing the status quo just because you’ve done it before. #IIoT #HM19

FROM THE EDITOR

BY KRISTINA URQUHART

The skills gap, from C-suite to shop floor

Addressing the skills gap in manufacturing is a perennial topic at industry trade fairs and conferences. Whether it’s the cohort of retiring workers, the challenge of attracting young people, or the increasingly automated production line that affects the types of roles available, there has been a lot of talk about the future of the workforce. But what are we really doing about it?

When the Canadian Manufacturers & Exporters (CME) trade association released its Industrie 2030 report in 2017, 39 per cent of the 750 senior manufacturing leaders it surveyed were facing immediate labour shortages, with 60 per cent expecting to experience shortages within five years.

We’re now two years into that fiveyear window, so the time has come for more action. At Hannover Messe, I sat in on a panel called “Rethinking Manufacturing Leadership,” which delved into some of the ways manufacturers are cultivating their current talent to take on leadership roles. Succession planning, or lack thereof, is another facet of the skills gap – we’re not only facing a loss of knowledge on the factory floor, but also in the C-suite.

O ne of the panellists was Holly Baumgart, vice-president of information technology at Sargento Foods, who noted that because technology changes so quickly, it would be impossible to keep up with the hiring. She suggested manufacturing leaders look across their organizations and foster talent everywhere. That might mean teaching administrative staff finance skills, or training plant operators to become more IT-minded. “In order to keep up, you have to use everyone you’ve got,” she said.

CONNECT

EDITORIAL ADVISORY BOARD

Pietro D’Arpa, corporate manufacturing director for Procter & Gamble, has a “build, borrow and buy” motto when it comes to procuring talent, whether for a leadership role or not. That translates to hiring the right people and helping them develop their skills, forging partnerships with other companies to fill knowledge and skills gaps, and purchasing the right products so that the team can do their jobs efficiently.

W hen it comes to closing the skills gap, the onus is really on the management. When our writer Jessica Wynne Lockhart interviewed Jayson Myers, CEO of Next Generation Manufacturing Canada, for her article investigating solutions to the skills gap (p. 22), he told her that three-quarters of Canadian manufacturers have invested in advanced technology – but 40 per cent report they didn’t achieve their business objectives after implementation. “It has nothing to do with technology – [it’s] either that they couldn’t manage the technology, the technology was wrong, or the business objective was wrong,” he said. “In either case, it’s a business management problem. It’s the ability of companies to actually manage the use of technology that really counts.”

So what are manufacturers to do? Manufacturing AUTOMATION plans to bring you more stories of companies taking concrete steps to close the skills gap, along with the resources you need to connect with talent. Drop me a line at the email address below to let me know what your organization is doing about jobs. (And for more from Hannover Messe,see not only p. 18 but also automationmag.com/videos to see our highlights reel from the fair.) | MA

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Vice-President, Precision Training, Products and Services Inc.

Your resource for Canada’s industrial automation news

EDITOR

Kristina Urquhart kurquhart@annexbusinessmedia.com Tel: 416-442-5600

PUBLISHER

Klaus B. Pirker kpirker@annexbusinessmedia.com Tel: 416-510-6757

VICE-PRESIDENT & EXECUTIVE PUBLISHER

Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

MEDIA DESIGNER - TEAM LEAD

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221

CIRCULATION MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com Tel: 416-442-5600 ext 3537

PRESIDENT & CEO

Mike Fredericks

COO

Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

Jesse Allred, Jonathan Gross, Paul Hogendoorn, Anil Kumar, Jessica Wynne Lockhart, Jennifer Rideout, Denzil Roberts, Steve Zuponcic Manufacturing Automation is published seven times a year by:

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: lmalicdem@annexbusinessmedia.com Tel: 416-510-5187 Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1

SUBSCRIPTION RATES

Canada — $43 per year

United States — $75.50 (US) per year

Foreign — $86 (US) per year

Students — $20.50 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com

Tel: 800-668-2374

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing Automation are copyright © 2019 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

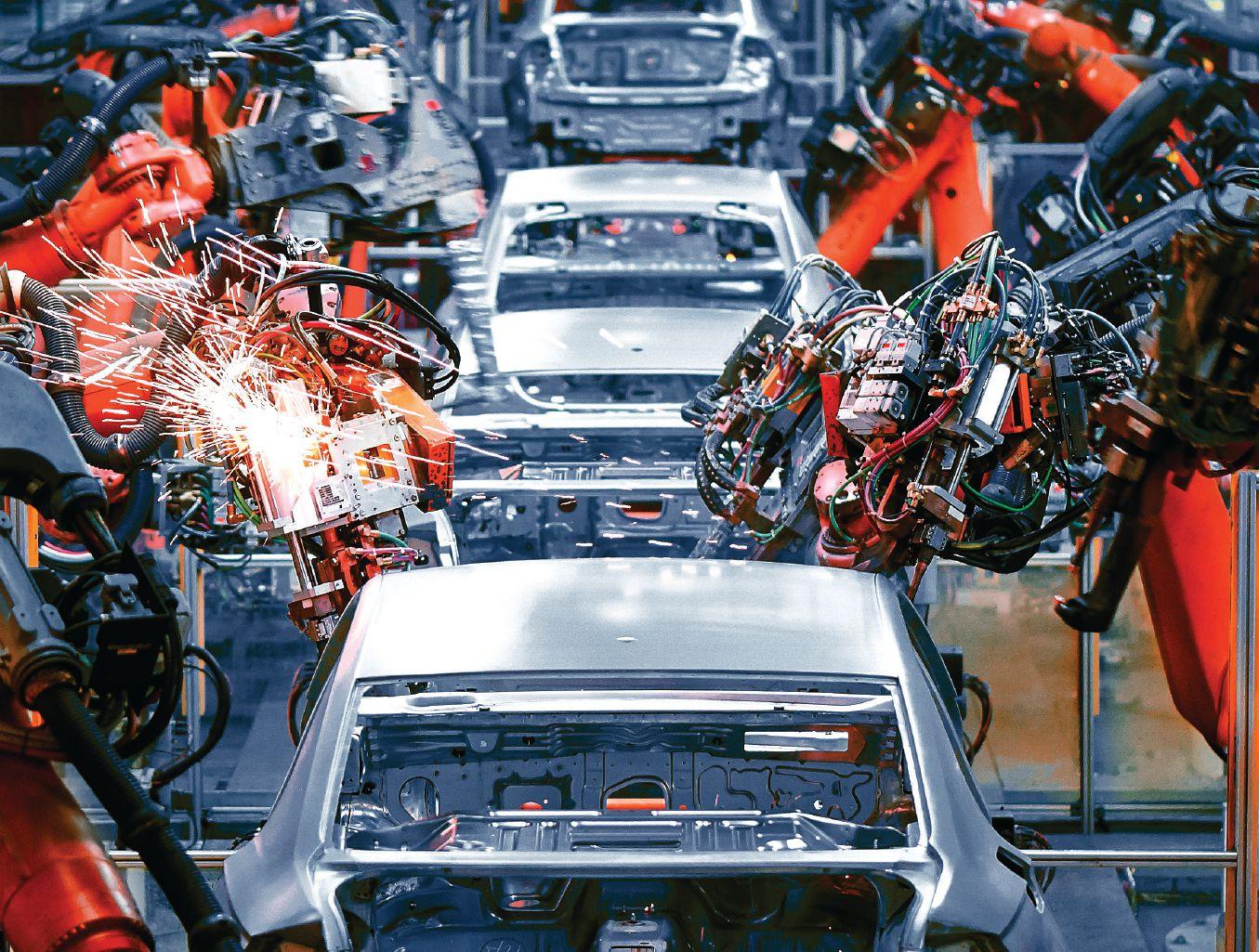

AUTOMATION UPFRONT

AUTOMOTIVE

Toyota reaffirms commitment to Canadian auto sector

Prime Minister of Canada Justin Trudeau was in attendance for Toyota Motor Manufacturing Canada’s (TMMC) announcement on April 29 that it will produce the Lexus NX and NX Hybrid at its Cambridge, Ontario production plant beginning in 2022.

“Today is a great day for Toyota, for Cambridge, and for Canada. Canadian auto workers are among the world’s best, and they have the skills and knowhow to design and build cars that meet the needs of people today and tomorrow,” said Trudeau. “Toyota’s new commitment to its Cambridge facility is a vote of confidence in our auto sector, and will help Canada lead in the new high-tech economy of the future.”

Christine Elliott, deputy premier of Ontario and Ontario minister of health and long-term care, as well as dignitaries, media and Toyota workers were on hand for the announcement.

“Toyota’s decision to produce a new generation of Lexus vehicles in Cambridge is another example of how Ontario’s skilled workforce and advanced supply chain are perfectly suited to build the vehicles of tomorrow,” said Elliott. “Working together, we’re helping create jobs and make the sector more competitive. We’re showing the world that Ontario is open for business and open for jobs.”

TMMC has been producing Lexus vehicles since 2003, when it became the first facility to produce them outside of Japan. Since that time it has produced 1.3 million Lexus RX and RX Hybrid vehicles. TMMC’s history in Canada goes even farther as it has manufactured vehicles in Canada for over 30 years, investing over $8.5 billion since 1985.

“Building on our recent Toyota RAV4 announcement and our recent facility modernization investments, we are excited to

announce that TMMC has been selected to produce the popular Lexus NX and Lexus NX Hybrid models for the entire North American market,” said Fred Volf, president, TMMC.

TMMC currently employs over 8,500 people at its Cambridge and Woodstock plants, and since coming to Canada has built over eight million vehicles.

— Mario Cywinski

GM, Unifor announce 300 jobs to be saved at Oshawa plant

The union representing Canada’s auto workers claimed a

partial victory May 7 after General Motors Canada announced its Oshawa, Ont., plant, which was slated to close later this year, will be converted to a part-stamping and autonomous

aluminum-zinc alloy

Dimensions (W x H x D): 82 x 82 x 40 mm

Prime Minister Justin Trudeau at Toyota Motor Manufacturing Canada, where a new production order for luxury SUVs is starting in 2022.

vehicle testing facility.

Unifor and GM Canada said the transition will cost $170 million and save 300 of the 2,600 union jobs at the plant, with the potential to grow and attract more jobs as the facility attracts new customers.

GM Canada president Travis Hester, who announced the socalled “Transformation Agreement” alongside Unifor national president Jerry Dias, said the Oshawa site will still end vehicle production at the end of 2019.

However, 22 hectares of the facility will be converted into a test track for autonomous and other advanced vehicles, which Hester said will help expand the nearby Canadian Technical Centre.

Dias, whose union suspended a media campaign against GM in March amid what it called productive talks with the automaker, called the agreement “innovative” but admitted it was

For Absolute Feedback,

far from a perfect solution.

A joint statement from GM Canada and Unifor said the company will offer relocations to other facilities in Ontario for those affected, as well as “enhanced retirement packages” to eligible employees.

Ontario Economic Development Minister Todd Smith said in a statement that the province welcomes the agreement, calling it good news for the City of Oshawa and the surrounding region.

“We are glad this historic site will continue to be a hub for vehicle parts manufacturing, technological innovation and regional economic growth,” Smith said.

However, he acknowledged that many workers still face an “uncertain future,” saying the government is working with Unifor and GM to support affected employees and their families.

—The Canadian Press

EXPANSION

Graybar inaugurates new branch

Graybar Canada, a distributor of electrical, comm/data and automation products, held the ribbon cutting for its new branch in Vaughan, Ontario last month.

The 90,000 square-foot facility, which officially opened in December 2018, is Graybar Canada’s largest branch and a consolidation of its Markham and Mississauga locations.

Located near Highway 427 and 407, Graybar Canada Vaughan features a wire-paralleling machine, a modern counter area and a large training room to host educational seminars on-site.

Eclipse Automation opens first U.S. location

Cambridge, Ontario’s Eclipse Automation has officially unveiled its newest 57,000 squarefoot, $4.6-million facility in Rock Hill, South Carolina.

The company hosted a grand opening event for 300 guests with an open house, tech day and ribbon-cutting ceremony at its newly named Eclipse Southeast location. Eclipse Southeast hosted tours and showcased over 27 exhibitors who also sponsored the event.

“South Carolina is the perfect location for our U.S. expansion plan as it sits in excellent

proximity to our customers,” says Steve Mai, owner-founder and CEO of Eclipse Automation. “We are excited to be a part of the Rock Hill community and look forward to offering several job opportunities.”

Eclipse is projected to double its workforce over the next five years in South Carolina alone and generate many career opportunities at the home office in Cambridge, Ontario.

INVESTMENTS

Manufacturer receives nearly $4M for automation upgrades

Maintenance equipment manufacturer Les Produits Gilbert has received $3,976,000 in funding from the governments of Canada and Quebec, along with Investissement Quebec, to acquire robotic welding cells and fully automated machining centres.

The total investment project is valued at almost $5 million and will enable the company to grow, increase productivity and create 18 jobs. Les Produits Gilbert Inc. is a manufacturer of maintenance equipment for snowmobile trail maintenance, and of equipment for the forestry, sawmill and construction industries.

The federal government is providing a $1,316,000 repayable contribution to Les Produits Gilbert under the Canada Economic Development for Quebec

Graybar Canada hosted a grand opening event with a ribbon cutting for its new facility in Ontario on May 2.

Regions (CED) Quebec Economic Development Program.

The Quebec government has awarded a $1,330,000 loan through the ESSOR program to support the acquisition of specialized equipment.

Investissement Quebec has given the company a loan, from its own funds, of $1,330,000, as part of its manufacturing initiative to enhance the province’s innovative manufacturing sector.

Feds invest over $3.5M in two manufacturers

The federal government has announced a combined $6.8-million investment to scale up three Waterloo, Ontario firms.

The investment, which includes over $3.5 million for two manufacturers, is through the Federal Economic Development Agency for Southern Ontario (FedDev Ontario).

XL Tool Inc., a designer and manufacturer of tooling and metal stamping dies that machine complex parts for the nuclear, automotive, and oil and gas industries, is receiving $750,000 to scale up operations and diversify to meet growing customer demand in the nuclear energy sector.

The investment will allow the company to expand its manufacturing facility by 10,000 square feet and to acquire advanced manufacturing equipment to automate and streamline its production processes, creating efficiencies in cost and time.

XL Tool Inc. expects to create 13 full-time jobs in Waterloo.

Nasarc Technologies Inc., a manufacturer of robotic metal inert gas (MIG) welding products primarily for the automotive sector, is receiving $2.8 million to commercialize its patented three-part automated welding tip

cleaning and changing system. The investment will allow the company to acquire state-of-theart equipment and resources to support automated production lines for the three new products.

This project will enable the company to expand its product offerings in the North American, European and Asian automotive manufacturing markets. Nasarc also expects to create and maintain 24 jobs in Waterloo.

The third investment went to a digital forensics company.

SAFETY

Manufacturer fined $165K after worker fatality

A Toronto manufacturer has been fined $165,000 by the Ontario Ministry of Labour after pleading guilty to an offence involving a worker fatality at its plant.

Vinyl Window Designs Ltd. was fined Apr. 24 by Justice Katrina Mulligan in Toronto’s Old City Hall court.

The incident occurred July 18, 2017, when the operator of a machine that performed welding, fabrication and corner cleaning found that there were problems with the operation of the machine. Another worker was summoned to troubleshoot the situation.

The machine was surrounded by a fenced enclosure. The worker entered the enclosure through a gate. The line was not running in operation mode at the time. The worker asked the operator to put the line into operation mode to run a window through the infeed.

While the worker was spraying oil on parts of the machine, the machine’s transfer arms cycled, crushing the worker against the frame of the machine. The

Proximity Sensors with IO-Link and IO-Link Smart Configurator

Inductive Sensors with IO-Link

Rugged Ø4, M5, M8, M12, M18 and M30 housings, offering extended ranges up to 22 mm. Easily configured, providing advanced functionalities such as the detection counter (RPM) and the speed controller. Each sensor is fully programmable, providing the means for hundreds of configurations in a single device.

IO-Link Smart Configurator

Configure any IO-Link sensor or actuator via a wireless device that replaces the need to program via a USB IOLink Master connected to a PC or via a network connected master device. The portable Smart Configurator can be used anywhere, as it’s battery powered and equipped with WiFi for IODD files, sync and cloud storage.

Capacitive Sensors with IO-Link

Popular M18 and M30 diameter sensors provide the ideal solution for applications where flexibility or sensing performance needs to be constantly and accurately monitored and logged. IO-Link mode provides added functions such as: QoR (Quality of Run), QoT (Quality of Teach) and Diagnostic Parameters.

worker died from the injury.

The gate through which the worker entered was always open, and at the time of the incident was tied back with plastic to keep it open.

Apart from the disabled interlock devices, the machine did not have its power source disengaged and locked out as required by regulation. There was a lockout procedure in place at the time of the incident.

The operator, a supervisor and the plant manager, who were at the opposite end of the machine near the operator’s station at the time of the incident, were aware of the open gate but had not received specific training on lockout procedures.

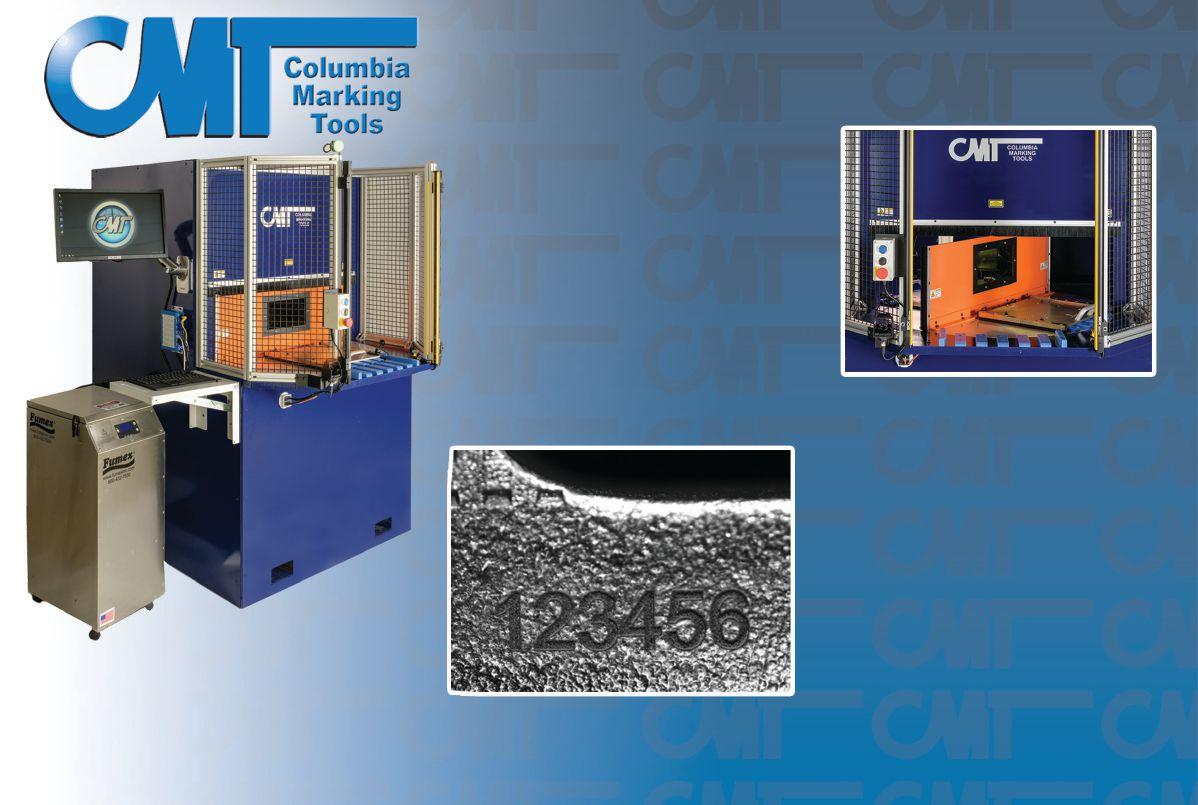

3D PRINTING

HP and Siemens strengthen alliance

Siemens and HP have announced they will expand their current partnership and integrated additive manufacturing (AM) solution to include overall product lifecycle management (PLM), AM factory optimization, industrial 3D printing and data intelligence, manufacturing execution systems, and performance analytics.

The solution combines HP’s 3D printing and 3D data platform, including its new HP Jet Fusion 5200 system, with Siemens Digital Industries Software, including Siemens NX CAD/CAE, and NX AM for HP Multi Jet Fusion software module with direct printer interface (undergoing certification by HP for its Jet Fusion 5200 Series to be available later this year).

It also includes Teamcenter for PLM, Tecnomatix Plant Simulation, Simatic IT for manufacturing execution, and MindSphere for performance analytics and Industrial IoT.

The additive manufacturing solution integrates hardware, software, data intelligence and services to optimize the efficiency of the manufacturing process, from design and simulation through production, execution, quality and control. This environment streamlines every phase of designing and 3D printing serialized parts – which the companies say results in greater scale, higher quality and less waste.

Javelin-Cimetrix opens new 3D printing lab

Javelin-Cimetrix opened an expanded industrial 3D printing lab last month.

The new facility is three times larger than the previous lab and includes some of the most popular additive manufacturing systems. Javelin is displaying technology from Stratasys (Polyjet and FDM) and the new office-friendly Desktop Metal Studio System for 3D printing in metal.

The former lab space includes a part-finishing area and has space to demonstrate Artec handheld 3D scanning technique and reverse engineering applications. A display of finished parts gives visitors a chance to see and touch a variety of the additive manufacturing materials and uses.

This expanded capacity will help Javelin-Cimetrix meet

increasing demand from customers across North America. Besides selling and supporting additive manufacturing systems, Javelin advises on and makes quality advanced prototypes, tooling, manufacturing aids, low-volume production and enduse parts.

LAYOFFS

Siemens to cut 10,000 jobs in major overhaul

Siemens says it will cut some 10,000 jobs in a major restructuring that will involve spinning off its oil, gas and power generation business.

Brought

The upgraded 3D printing lab at Javelin-Cimetrix includes popular additive manufacturing systems from Stratasys and Desktop Metal.

The company said it would spin off its division that makes power turbines to increase its entrepreneurial freedom, while embarking on a sweeping cost-cutting effort at its remaining operations.

The gas and power division has been under pressure due to a broader trend toward renewable energy such as sun and wind power. Competitors in the power business such as Boston-headquartered General Electric and Japan’s Mitsubishi have struggled as well.

Siemens said in the announcement that it would keep a significant stake of less than 50 per cent in the spun-off company and would bundle in a majority stake in its renewable energies company. That would create what Siemens CEO Joe Kaeser called “a powerful pure play in the energy and electricity sector” that could offer products across the entire scope of the energy

market from a single source.

Kaeser also announced cost cuts to increase profitability at the company’s remaining businesses, which range across factory automation, energy infrastructure such as power grid control, and high-speed trains.

The company plans to take out 2.2 billion euros in costs by 2023, in the course of which it will drop some 10,400 positions. It expects growth to create some 20,500 new jobs by 2023, for a net gain of around 10,000. When it comes to job cuts, Siemens said that “all measures worldwide are to be implemented in as socially responsible a manner as possible.”

Siemens AG has said that its net profit fell to 1.92 billion euros ($2.15 billion) in the first three months of the year, from 2.02 billion a year earlier, when earnings were boosted by 900 million euros by a share transfer.

—The Associated Press

MOVERS AND SHAKERS

Yamaha Motor Corporation USA’s Intelligent Machinery (IM) Division has announced Shinji Kuroda as its new sales manager for Yamaha IM’s factory automation product line. Kuroda previously worked at Yamaha Robotics in Japan and has joined the U.S. team in Marietta, Georgia to further expand robot sales in the Americas. “I look forward to expanding our factory automation sales in North America and building on the already extensive network of distributors and system integrators to deliver customized automated solutions to our ever-increasing number of customers in the Americas,” Kuroda says. Yamaha Motor Corporation, USA IM is a

subdivision of Yamaha Motor Corporation, and offers a full line of machines for electric/ electronic parts mounting, factory automation and other production-line solutions.

Pratt & Whitney, a division of United Technologies Corp., has appointed Maria Della Posta as president of Pratt & Whitney Canada, reporting to Pratt & Whitney President Bob Leduc. Della Posta succeeds John Saabas as president of Pratt & Whitney Canada, who has announced his retirement. Della Posta joined Pratt & Whitney in 1985 and progressed through roles of increasing leadership in supply chain, finance and customer service. She was named vicepresident, customer support in 2001, senior vice-president, sales and marketing in 2010 and senior vice-president, Pratt & Whitney Canada in 2012. | MA

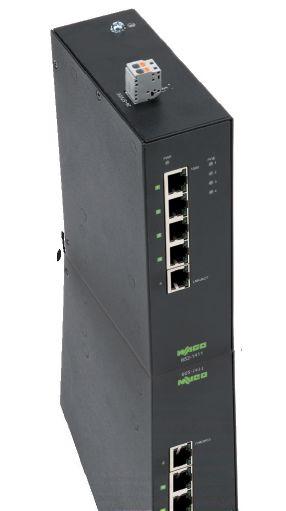

UNMANAGED,MANAGED,PoE+

Shinji Kuroda

GOING DIGITAL BY JENNIFER RIDEOUT

Wi-Fi 6, 5G and your factory

This year, there’s been a lot of talk about Wi-Fi 6 and 5G networks. But if you’ve been wondering what they are (and if they are the same thing), and what impact they will have on your factory environment, you’re not alone. This issue, I’ll explain what each of these technologies are, why they are getting so much attention, and how (…if) they will impact your factory environment.

What is Wi-Fi 6?

Wi-Fi 6 is a new wireless standard, formally known as 802.11ax. Like any new technology, as you’d expect, Wi-Fi 6 improves on the previous standard (Wi-Fi 5). Notably, Wi-Fi 6 allows for faster connectivity and more concurrent users over wireless networks. But while that alone is interesting, there’s something far more significant about Wi-Fi 6 you should know.

Simply put, Wi-Fi 6 is a complete re-imagining of wireless networks. And I don’t say that lightly.

segments so that traffic can be prioritized by need. This allows more devices to send traffic at the same time, assuming the overall channel has capacity. Prior to this, traffic was essentially in a queue – when one client (a.k.a. a device) connected and transmitted data, other devices needed to wait to transmit theirs. This proved problematic as more devices became connected and needed to transmit small amounts of data (think IoT sensors) alongside traditional devices.

In addition to their faster speeds, both Wi-Fi 6 and 5G allow manufacturers to connect more devices reliably over wireless networks.

Rob Barton, a distinguished engineer for Cisco Canada, explains it this way: “[The] goal [for Wi-Fi 6] wasn’t to necessarily increase the speed of existing Wi-Fi networks, but rather to improve the overall efficiency of Wi-Fi so it could meet the demands of modern networks.”

What this means is that Wi-Fi 6 has been built to allow companies, for the first time, to “break” the wireless channel up into smaller

W i-Fi 6 enables maximum efficiency of the wireless channel, which is what makes it possible to vastly increase the number of potential concurrent connected devices and speeds.

What is 5G?

5G is the name of the next-generation cellular data networks that will replace 4G LTE. Canadian wireless operators recently spent $3.5B for 5G spectrum licenses and are heavily invested in bringing this technology to Canadians. Which means it’s coming. And for Canadians that’s a good thing, because – much like Wi-Fi 6 – 5G cellular networks will be faster than 4G LTE. Also just like Wi-Fi 6, 5G networks will bring greater bandwidth and capacity, meaning future cellular networks will be able to handle more users (and traffic).

In short, Wi-Fi 6 and 5G will have a similar impact and provide similar improvements over current wireless and cellular networks.

They are distinct, but complementary, technologies that will usher in a new era of device connectivity and network capacity.

What do Wi-Fi 6 and 5G mean for manufacturers?

The answer to that question depends on your readiness to adopt Industrial Internet of Things (IIoT) solutions. If you are among one of the Canadian manufacturers still hesitant to purchase, implement and adopt IIoT solutions…then the introduction of Wi-Fi 6 and 5G networks will likely have little impact on your operations.

But if you are currently deploying IIoT solutions or piloting these solutions at any scale, or are looking to provide a network that can support both current and future needs, then Wi-Fi 6 and 5G could be significant. And that’s because Wi-Fi 6 and 5G will transform how we use IoT devices.

Here’s why. In addition to their faster speeds, both technologies allow manufacturers to connect more devices reliably over wireless networks. To get technical (and to quote Rob again), “[ T]hey share scheduling technology that makes wireless more deterministic, which is important for mission-critical IoT assets being used in manufacturing automation.”

This is a callback to the channel segmentation I mentioned above, allowing for more concurrent devices and traffic. When your factory has hundreds, if not thousands, of IoT sensors sending small packets of data at the same time, being able to use all of your wireless channel to move and action on this data in real-time is vital. As a bonus, this segmentation also provides a significant improvement in battery life for any IoT sensors that require them as a power source.

On top of this, both standards support software-defined network segmentation. This is a complicated way of saying that they ensure traffic from a particular device can only go where it is supposed to. That keeps IoT networks safer and more secure, a distinct advantage for any business.

In summary, Wi-Fi 6 and 5G networks are coming this year. Both technologies will vastly improve the wireless experiences for users, but also hold the key to unlocking the power of the Industrial IoT for manufacturers. If you’ve been hesitant to adopt IIoT solutions in the past, the introduction of Wi-Fi 6 and 5G may be the opportunity you’ve been waiting for. | MA

Jennifer Rideout is the manufacturing marketing manager for Cisco Canada. She is responsible for developing go-to-market strategies for the manufacturing sector in Canada, including channel alignment and content development.

Connecting you to productivity!

The Core product range from Festo featuring the Stars of Automation:

Festo quality at a competitive price covering 80% of your automation tasks. From actuators to accessories for factory and process automation.

Reduce your procurement complexity for both the electric and pneumatic control chain by simply following the stars.

ACROSS THE ENTERPRISE

BY JONATHAN GROSS

Industry 4.0: How manufacturers are integrating predictive maintenance

Does unplanned equipment downtime cause your maintenance team to scramble?

How much do unexpected outages cost your company? What’s the value of delayed or cancelled customer orders?

According to a 2018 GE Digital survey, an average unplanned downtime event lasts four hours and costs US $2 million. Unplanned downtime also erodes customer trust. Forty-six per cent of respondents said that unexpected outages caused them to miss their customer order promise dates.

Exposure to unplanned downtime is pervasive. Seventy per cent of respondents said that they’re not fully aware as to when equipment is due for maintenance, upgrade and replacement. And, in our firm’s experience, maintenance departments don’t often reassess long-established static maintenance schedules. When services are scheduled too far apart, companies increase the risk of unplanned downtime. When services are scheduled too close together, companies incur avoidable parts and labour costs. It’s a no-win situation.

If unplanned downtime events were anomalous and difficult to treat, companies would have to live with the impacts. But many are not. Most reactive maintenance events are predictable. Parts wear over time. Output slows. Product quality begins to suffer. With routine monitoring and analysis, companies can do a better job of predicting failure, setting maintenance schedules, and planning part, people, and tooling resources.

With an industry-wide focus on delivering exceptional customer experiences, manufacturers can no longer expose themselves to unplanned constraints on production capacity. This is why, as a foray into Industry 4.0, many are setting their sights on integrated predictive maintenance.

Building your predictive maintenance technology architecture

For many, the big picture end-game is an environment where systems optimize

machine performance, predict failures, suggest planned maintenance work orders, and pull the impacted machine resources from available master scheduling, material requirements planning and production capacity plans.

With routine monitoring and analysis, companies can do a better job of predicting failure,

setting maintenance schedules, and planning part, people, and tooling resources.

To pull this together, machines need to be connected to sensors and control systems. The data that’s generated needs to be consumed by artificial intelligence (AI) and enterprise asset management (EAM) systems. The EAM system needs to be able to create suggested maintenance plans based on the AI system’s predictive analysis and perhaps initiate changes to process controls. And, the ERP system needs to be able to incorporate EAM maintenance plans into its production scheduling and capacity-planning engine.

Planning your predictive maintenance strategy

Here are six tips to develop and execute your integrated EAM strategy: 1. Break down silos and build cross-functional teams.

Traditionally, maintenance departments operate in silos of their own, separated from the rest of operations and the business. If your business is serious about integrating maintenance into the enterprise, it needs to take a holistic approach that covers organizational structures, business processes, data and systems. All impacted business functions should be involved. These often include maintenance, IT, finance, purchasing, inventory, and planning and scheduling.

2. Build an integrated technology architecture. Your integrated technology environment should consider production equipment, control systems, sensors and IIoT connectors, cloud, AI and BI, business applications, middleware, and infrastructure. If the long-term play is smart maintenance automation, you need to think big. What components are needed? What specific roles should each piece of

technology play? What’s your middleware strategy to tie the pieces together?

3. Build your implementation plan. You’re not going to be able to implement everything at once. Break the long-term architecture down into manageable projects. First, build a strong digital twin foundation. This means ensuring that your digital world is a mirror of your physical world. Make sure that key systems are properly implemented, and that data are timely and accurate. You can’t risk having key assets pulled out of available production capacity if required parts aren’t available to complete the work order.

4. Then, dip your toes into predictive maintenance. It’s important that you trust the system. And trust takes time to build. Today, would you be comfortable sitting alone in

“the back seat of an autonomous car? Probably not. But, would you be more willing to trust automatic braking or lane assist technology? Probably. The same psychology applies to systems. It’s hard to give up manual controls. So, wade slowly. When you first connect your equipment systems to EAM, consider establishing user-defined parameters to trigger suggested predictive maintenance activities. For example, set upper and lower tolerances on conditions that can be captured by sensors, such as: vibrations, temperatures, flow rates, output and pressures.

5. Once you’ve built trust, take the plunge. Even though you probably won’t use the AI engine until some time in the future, you’ll want to set it up early so that it has a strong base of data for machine learning.

Make sure your AI system is collecting and analyzing all relevant machine, process control, EAM and ERP data. Eventually, let your AI system predictively suggest planned maintenance activities based on relationships and trends that it’s self-discovering. In the long-term future, and to fully close the digital-physical loop, you might eventually have your EAM system integrate to your process control systems for real-time optimization. For example, where equipment starts overheating, your EAM system could signal your control systems to increase flow rates.

6. Ignore risk at your peril. If you’re using IIoT connectors, you’re exposing your production equipment to cybersecurity threats. An attack can halt production and even lead to a catastrophe. It’s important to

think ahead. As you plan your implementation, you should consider a lockstep deployment of a broad and deep defensive cybersecurity strategy. Manufacturers are hungry for Industry 4.0 initiatives that can drive measurable efficiency and customer experience benefits. Integrated predictive maintenance can help in both areas, which is why many manufacturers rank it near the top of their priority lists. A sound approach to planning and delivery of predictive maintenance is critical and worth repeating. Work cross-functionally. Architect a solid technology environment. Build a strong digital twin foundation. Dip your toes into predictive maintenance. Take the plunge | MA

MACHINES CAN LEARN BUT THEY CAN’T READ MINDS.

“

Tired of hearing the Buzz words AI, AR, 4.0 and industrial IoT? Then stop hearing about them and start seeing what is relevant to your business today? SEW’s Live Lab is now open at Humber in the Barrett CTI. See sophisticated system solutions in “actual reality”. Follow us on our social channels for more information or contact us directly.

Brendan Daniel, Chief MAXOLUTION ® Engineer, Canada.

INDUSTRY WATCH

BY PAUL HOGENDOORN

Paul Hogendoorn is president and co-founder of FreePoint Technologies. He can be reached at paul.hogendoorn@getfreepoint.com or getfreepoint.com. “Measure. Analyze. Share. Don’t forget to share!”

Why innovation is lagging in Canada

There’s been much written over the years about how the Canadian manufacturing industry lags other countries as far as investment in innovation is concerned, and there’ve been many attempts and well-intended initiatives launched over the years to try to change that. But despite those attempts – and sometimes as an unexpected consequence of those attempts – Canadian companies, by and large, in my opinion, lag their American and international counterparts.

T here are some that may take offense to this position, and there are certainly exceptions, but based on my experience visiting and promoting innovation in hundreds of plants throughout North America over the last few decades, Canada is a slow adopter of innovation and innovative ideas, whether evolutionary (incremental) or revolutionary (fundamental). This isn’t a surprise to many, but the reasons may certainly be a surprise to some. Here are my top three reasons why our companies lag.

1. Management.

For the last five years, I have been demonstrating an out-of-the-box solution that delivers empirical, real-time data, which answers what many manufacturers have said are their two biggest data questions: “What is my true actual machine utilization?” and “What are the reasons my machines are not running as they should be?”

To mitigate risk (by reducing the initial investment to a very digestible price), I follow up with a “getting started proposal” for six to 10 machines, targeting a productivity improvement of eight to 15 per cent with 90 days. The response from American prospects is usually either a yes or a no. The response from Canadian companies is something like, “Well, this is interesting. Can you give us a quote for three?” Which, a month later, becomes “Can we try one, and, can we have it for free for 90 days?”

This typically results in a failure to even get started, but even if a project is started this way, the lack of commitment trickles down to the plant floor

and the inertia needed for innovation is not achieved.

2. Government programs.

In recent decades, the Canadian federal and provincial governments have recognized the trend of the Canadian manufacturing industry falling behind as far as investing in technology and innovation is concerned. To encourage more investment by manufacturers, they have come up with numerous new funding programs (loans, grants, matching contributions, etc.). Although this does often result in a manufacturer making an investment they otherwise may not have made, it is not necessarily the investment in the technology or solution they needed to make, or at the time they really needed to make it.

The stimulus programs that are created are often specific to machine types or software solutions that have been identified as areas where our companies are behind, meaning companies in competing countries are already there. Those competing companies are now investing in the next technology or innovation, not the last one. With decades of “success” waiting on the next investment stimulation program, Canadian manufacturers often end up

just trying to get on the innovation train that already left the station.

3. Empire building.

This is prevalent to a degree in most companies, and it can take several forms. Sometimes, it’s because people in the organizational chart are glass ceilinged, and best they can hope for is to hold on to the position they currently have. When this happens, they are less likely to take risks on new ideas because there is nothing for them to gain, but plenty to lose. They may stymie others that have more new ideas because they do not want to be surpassed.

Sometimes, it’s a department or group that has spent so much time and money developing or deploying a system that they become (as the poker expression goes), “pot committed.” They have too much invested to consider alternatives that are easier to deploy, less expensive and more effective. When new ideas are brought forward, they are shot down or dismissed by the people with the most to lose. And sometimes, it’s a plant in a large corporation that competes for top billing (or future work, or managerial bonuses, or even promotions) with other plants. Their innovative ideas do not make it into other company plants, at least not quickly.

Canadian companies have to have more willingness to make quick “yes” or “no” decisions on ideas and small projects that have potential, not just projects that fit a government funding program.

There are other reasons that make innovation challenging, of course. Lack of funds, lack of time and lack of available talent, for instance. But these are simply an indication of a company’s lack of will. The drive to innovate constantly can’t be artificially stimulated – it needs to be part of the company’s basic culture, starting at the top, and encouraged through all the managerial layers, right to the plant floor. Canadian companies have to have more willingness to make quick “yes” or “no” decisions on ideas and small projects that have potential, not just projects that fit a government funding program. To me, the measurement of true innovation is how fast a successful innovation spreads to other parts of the plant or other plants in the company. Innovation needs to be relentless, and in Canada, it is not. When it comes to innovation, what’s holding your company up? | MA

MACHINE SAFETY

BY SHAWN SMITH

Safely automating food & beverage applications

Food and beverage is one of the fastest-changing industries in business today. Consumers are demanding products that can be more difficult to process, and companies need to respond with safe, quality goods that are not going to put off the buyer in terms of price. To stay ahead of their competition and contribute to the bottom line, companies must remain flexible and diligent in making sure their facility is clean in order to ensure food safety.

A key driver for many manufacturers looking at robotic solutions is economics. Because the unemployment rate has dropped significantly, particularly in the area of general labour, and the minimum wage has increased, it is difficult to meet the demand for people. Robots can fill the gap. In addition, cleaning duties on a food line tend to be the toughest positions to fill and keep filled, so robots can solve that issue as well.

Robots are becoming more and more integrated in processing applications in order to save time and space, as well as to improve cleanliness and safety. As government regulations become more stringent and competition intensifies, the need for robots is increased in the food and beverage industry. For example, the Safe Food for Canadians Regulations (SFCR) came into effect on January 15, 2019, requiring, among other things, developing, implementing, and maintaining a written preventive control plan that documents how food businesses meet food safety, humane treatment and consumer protection requirements. Robots can also increase operational efficiency, throughput and quality, protect employees and the company, and maximize process flexibility.

Contamination risks

G ood manufacturing practices (GMP) include many basic operational conditions and procedures that are required to be met by food processors. These include the adequate maintenance of equipment and utensils used within the processing business, the use of suitable chemicals within and around the plant including cleaning chemicals, pest control chemicals and machine lubricants, and the cleanliness of the food manufacturing facility, equipment, utensils, floors, walls and ceilings.

addition to this process. By limiting contact with human beings, robots reduce the risk of contamination leading to foodborne illness.

From a food safety perspective, robots can be designed to prevent bacteria, they are easy to clean in high temperatures, and they do not collect dust. That means that they can help prevent food contamination. Robots feature smooth surfaces that are not subject to the harsh corrosive effects of chemicals used to clean the equipment, which is beneficial for use in the food preparation process.

Cleaning powerhouses

Robots can be designed to prevent bacteria, they are easy to clean in high temperatures, and they do not collect dust.

A key application that robots can play a role in is Clean-in-Place (CIP) within the plant processes. Clean-in-Place is a procedure for cleaning interior product manufacturing contact surfaces such as process pipes, vessels and equipment, without disassembly. CIP applications have been around for more than 50 years, and use of a mix of chemicals, heat and water to clean machinery. CIP systems circulate detergent and disinfectant solutions and water through the processing equipment. This ensures consistent and high-quality cleaning of equipment surfaces, which is critical to food safety.

the cleaning is faster, less labour-intensive and more repeatable, and poses less of a chemical exposure risk. In fact, processors can employ a high-speed robotic solution that picks product by day and then self-cleans at night.

Safety considerations

As pick and place becomes a more prevalent application for robotics in the food industry, it is important to factor in the safety aspects of this growing trend. Robots do speed up the process of food manufacturing and can be customized to fit specific production requirements. Ideally, they combine the dexterity, flexibility and problem-solving skills of a person, with the strength, endurance and precision of a machine. These robots can safely work on tasks whether or not a human is working nearby.

They also can increase output in the plant, as they don’t need to take breaks and work at a consistent and efficient speed throughout the shift. In addition, in packaging applications, robots can be equipped with intelligent vision systems that allow accurate placement of products on a belt or in a container that ensure consistency and efficiency.

Robots, with their small footprint, low cost and high throughput rates, are a valuable

Typical food and beverage applications that are cleaned using an automated CIP system are product transfer lines, processing tanks, homogenizers, mixers, blenders and fillers. The benefit to food and beverage manufacturers that use CIP is that

As manufacturers look to automation to make a difference in their business, they should take a hard look at adding robotics to their food and beverage manufacturing operations. Robots provide consistency, they are always available, and they are easily programmed and tooled to provide accuracy, increase quality and keep their products, and their businesses, safe. | MA

Shawn Smith is a business development manager of sales and marketing for the automation and robotics division at JMP Solutions.

CHRIS CLARINGBOLD, area sales manager for Universal Robots (UR) in Canada, talks cobot adoption north of the border and how the human-facing robots can help

MA: You’ve been in the role of area sales manager for a few months now, after a stint as CEO of KUKA Canada. What’s been your focus at Universal?

CC: The role as area sales manager for Canada is organizing our sales efforts. Prior to my joining the company, we tried to support the Canadian industry through salespeople that were focused in the U.S. and came to Canada when they had the time to support the distributors here. So my role has been to go out and meet the distributors and the other partners that UR has in Canada already, find out what they’re working on, where they’re successful, where they have issues, and try and smooth all that over to try and make life easier for them.

It’s difficult – as Canada is the large geographic expanse that it is, it’s hard to cover everything. It’s even hard for me just to cover it from the Toronto area. So having people come up from the U.S. made it even more of a challenge. We knew that we had to be closer to our customers.

MA: What does the market look like in Canada right now?

CC: Prior to my joining Universal, I wasn’t quite sure how many people [in Canada] were using the cobots. But once I’d joined and met several of our distribution partners, I found there are actually people who are in their fifth or sixth year of using Universal Robots in Canada. It’s growing rapidly. The technology is becoming more mainstream and understood. People now recognize that it is not a typical industrial robot and that it is easier to use in different applications. Many of our customers in Canada are small companies. The first question they have is, “Do I have to go hire an engineer?” We show them the robot, the demo,

to close the skills gap.

and how easy it is to set it up, and they recognize that with their own skill sets internally, they can take some of these on. The factor in the past that scared [people] about integrating robots was that they’d always thought they need a controls person, an engineer, a robot programmer. And when they realize they don’t need all of that to maintain this, they’re jumping on it and integrating it quickly themselves.

MA: How does the collaborative robot envrionment differ from that of traditional automation?

CC: I spent many years in

automation [...] and it’s about trying to solve the process issues. You start looking at things where it’s like, “Well, if we leave that up to the person, it’s going to be very difficult.” You end up over-automating things. Now, you don’t have to automate as much and you can rely on a mixture of the cobot and the person. It’s actually changing the mindset of the people who are automating.

I was just talking to a customer the other day, and he wasn’t even looking at the cost of automation or the people. One of his big things was downtime. If he has one of his current

industrial robots shut down, it’s heavily guarded and there’s a proper lockout/tagout procedure that has to be followed. To fix it, you have to find the right maintenance guy, he comes out to the line, gets down, says he’s gotta go into the cage, he goes and gets his key, does the lockout/tagout, opens the gate, goes in, tries to figure out what’s wrong, tries to restart the robot. And this guy could lose an hour on the production line for something that’s simple. If he can simplify his process, and doesn’t need the extent of guarding around there, and gets a safe product so a person can actually go in, correct whatever’s wrong, and leave the cell very quickly, his efficiency of production will go way up. There’s a lot of interest in cobots from that side of the business as well.

MA: What is the general sentiment regarding the investment in automation among Canadian manufacturers?

CC: As true Canadians, we’re all a little bit pessimistic – we don’t want to be the first. But I find that it’s not like the traditional robot market. One thing Canada does well is we have a lot of people involved with technology research and development. But then those customers or companies usually take the technology globally or to the U.S. Small companies don’t have those large projects so they’re willing to take [cobots] on.

Once we get past the education part, there’s a very high level of interest in the cobots. And it’s really stemming from two main things that I see. One is that manufacturers cannot find or retain the people that they need. In Canada, we have a lot of work that becomes cyclic, so [manufacturers] hire,

run through the season and then lay off, and the people don’t come back. The other is there’s a lot of business outside Southern Ontario that doesn’t get well looked after by companies because they are deemed to be too small or too remote. In Western Canada, these guys are self-sufficient. They don’t rely on integrators. Bringing [cobots] to the market for them – they’re very quick to adapt to it and use it to streamline their own processes.

MA: Is the fear of automation a real concern that manufacturers have when you’re out in the marketplace?

CC: I was at a plant yesterday and the operator himself said, “You gotta get one of your robots in here.” He said, “This job is brutal. I can’t do it.” It was an ergonomic nightmare. And the company wasn’t looking to replace him. The company was looking to add the robot to make his job easier. They knew if they could do that, they could improve productivity. They were going to get more product out the door and they were going to hire more people. It’s the message and how it’s being delivered. To anyone who says, “Robots are taking my job and I’m not looking at improving my processes or getting more efficient or building my business” – they’re going to end up going out of business. Anybody who’s serious about it is growing their business, anyway. They’re just going to be hiring and training people differently.

Anyone who knows the Canadian market knows that geographically, there are different challenges in different areas. The one thing I find is it doesn’t matter where I go coast to coast, everybody has the same concern: they can’t find enough people. That the people who are doing the jobs now are getting ready to retire, and the young people don’t want to come in. Many of them are thinking of a strategy to bring in things that

make manufacturing interesting and fun. It’s not the dull, dirty job that it used to be. So there are these progressive companies that are looking to get people into manufacturing by bringing cobots into their plants. | MA

A version of this interview originally ran in the Spring 2019 issue of Robotics Insider, a quarterly e-book produced by Manufacturing AUTOMATION. See past issues at automationmag.com/digital.

than 4,000 components for handling and assembly.

Etalex, a Montreal manufacturer of racking systems, installed a cobot that works beside humans, freeing up seven worker hours a day.

HANNOVER HIT LIST

Our top takeaways from Hannover Messe, the world’s largest industrial technology fair

BY KRISTINA URQUHART

The annual Hannover Messe conference and trade show, held in Hannover, Germany April 1-5, drew more than 215,000 visitors from 75 countries. With over 6,500 exhibitors (up from 5,800 last year) and more than 1,400 events and 80 conferences and forums to choose from, Manufacturing AUTOMATION highlights the key learnings from the week.

1. 5G is coming – and may help connect your plant

The next generation of wireless communications is almost ready for commercial launch – Canadian telecom companies are expected to implement 5G capabilities by

2020. 5G is touted as the first real solution for manufacturers to achieve total, reliable wireless coverage – even indoors, so it will be useful, for example, to connect SCADA centres to the shop floor.

5G technology uses cellular “nodes” (like base stations, mounted to ceilings or walls)

to transmit signals from point to point. 5G has ultra-low latency with a bandwidth that is 100 times faster than LTE networks, and is said to offer 99.999% reliability. A company will have the ability to have many private, secure channels all operating in the same overall network infrastructure (for more on 5G, turn to p. 10).

For the first time at the fair, Hannover Messe hosted the 5G Arena, which acted as a test bed for eight applications, including 5G-controlled robots and Nokia’s 5G-powered replica of an

automobile manufacturing plant. (Hannover Messe plans to be the first fully 5G-enabled fairground in the world and is set for total coverage by 2020.)

At Ericsson, a spider robot (pictured on p. 19) moved its legs around the floor, demonstrating proof-of-concept of 5G communications using a radio frequency to emulate the same latency as 5G. Motion control computation was completed in the cloud-edge and then transmitted back to the robot within 2.5 milliseconds.

S everal manufacturers MA spoke with said they would wait for use cases, especially with regards to reliability, before cutting any cords. They also said they would be more interested to test 5G networks to improve intra-operations communication, rather than rely on them for transmission of sensitive data on the factory floor.

T homas Pilz, CEO of Pilz Automation Safety, says that in the early stages of 5G, he remains concerned about its reliability. “If you lose the connection, you shut down,” he said. “5G needs to give the same reliability as wired networks.”

2. Smart solutions lead to improved performance

Eight years after the introduction of the Industry 4.0 concept at Hannover Messe 2011, developments for the future factory are in full swing, with a focus on smart technologies. More than 500 application examples for Industry 4.0 and artificial intelligence solutions were on display as part of the 2019 fair’s “Industrial Intelligence” theme.

Beckhoff Automation has added machine learning to its TwinCAT controller software suite – over time, the software will learn to

recognize anomalies, and then correct the operation to achieve optimal energy and performance, helping to extend the life of the machine.

A BB showcased its Ability dashboard, which connects operators to the Industrial Internet of Things by gathering information from devices such as PLCs and sensors. The dashboard then aggregates the data, provides context against other industry data, applies predictive analytics, and generates insights for operators.

The company has also partnered with Tetra Pak on smart manufacturing solutions, including a health and safety assessment that monitors the vital signs of workers wearing wristbands equipped with sensors. The software can issue warnings when it’s time for workers to take a break.

Tetra Pak was part of the pavilion for Official Partner Country Sweden (which provided 160 exhibiting companies to this year’s fair), and also launched a new connected packaging platform that harnesses data through QR codes affixed to beverage cartons. The goal is to move to printable RFID to transform the cartons into embedded data carriers.

More than 500 application examples for Industry 4.0 and artificial intelligence solutions were on display as part of the 2019 fair’s “Industrial Intelligence” theme.

Johan Nilsson, vice-president of Tetra Pak Services, says that he believes artificial intelligence, big data and predictive analytics will be important tools to food and beverage manufacturers in the future – and that connected packaging is one way to enable them.

For producers, the packaging offers end-toend traceability to improve the production of the product, quality control and supply chain transparency. It will have the ability to track and trace the history or location of any product, making it possible to monitor for market performance and potential issues.

For retailers, it can offer greater supply chain visibility and real-time insights, enabling distributors to track stock movements, receive alerts when problems occur, and monitor for delivery performance. For shoppers, it will mean the ability to access vast amounts of information, such as where the product was made, the farm the ingredients came from and where the package can be recycled.

Top tech at Hannover

Festo’s BionicSoftHand (also pictured at right) is controlled pneumatically using a very small module with 12 actuators. The soft structure of the hand enables collaborative tasks and object rotation. Pressure is applied to the finger chambers to control movement, and sensors on the top and bottom of the hand, supplied by Bosch, allow for position control.

Beckhoff Automation showed its XPlanar motor system, in which tile movers hover freely using electromagnetic forces. The devices, which offer six degrees of freedom, can be driven on walls or ceilings to a top speed of four m/s with 2G acceleration. The X-Planar is suitable for hygienic applications such as food manufacturing, as it offers no abrasion.

and safety in machine

using an RFID reader to provide permission to use HMIs or other machine tool interfaces to certain employees only if they have been fully trained. The technology can also be used to provide time-sensitive access for short periods before expiring.

3. Digital transformation in the cloud and at the edge

There was a lot of talk about digital transformation at Hannover Messe – and what it really means is the digitalization of your operations. As Canadian manufacturers move from Industry 3.0 solutions and into the Industry 4.0 mindset of connected manufacturing, they will start to amass more and more data.

All of that information needs somewhere to be stored and contextualized. Many automation software providers offer cloud and edge solutions – but what’s the difference? The cloud is especially good for remote access if a company has multiple locations. For example, if a manufacturer in Windsor wants to check data sets from a plant in Winnipeg, storing data in the cloud can help facilitate that.

E dge computing, where information is stored on local servers near the physical asset, has its own merits: it can be used to store large amounts of data, and it is perceived as more secure. Sometimes you don’t have to choose: ABB’s aforementioned Ability dashboard gives users the option of connecting data to the cloud or keeping it at the edge.

Be warned: both the cloud and edge have their own risks. But with the proper security infrastructure in place, data can be safely stored and transmitted using either solution.

4. Cybersecurity in IT/OT is an immediate concern

There have been several reports of cyberattacks on manufacturers in the news in recent months, from an aluminum manufacturer in Norway whose information technology (IT) systems were held for ransom to pharmaceutical giant Bayer reporting that it had thwarted an attack on its IT system.

Think of cybersecurity as the underbelly of Industry 4.0 – because everything is becoming more connected, there are more ways for malicious operators to hack into your industrial systems. So you need a strong security infrastructure as the foundation for all of your systems, especially the previously ignored operations technology (OT) side.

For example, Dr. Marco Balduzzi, with TrendMicro Research, gave a presentation about protecting industrial controllers. Many controllers are 20 to 30 years old and were developed with no security procedures in place. Unless a controller is encrypted or uses a communication language to transmit signals that differs every time, it can be operated or reprogrammed by outside parties through a simple hack.

“Security is important, but it can’t be an impediment to doing the job, to manufacturing the product,” said Daniel Behrens, technical

Think of cybersecurity as the underbelly of Industry 4.0 – because everything in manufacturing is becoming more connected, there are more ways for malicious operators to hack into your industrial systems.

The PITmode Fusion from Pilz combines security

access,

PHOTO: © BECKHOFF AUTOMATION

marketing engineer, Industrial IoT Network at Cisco during a talk on IT/OT security. “The real need is for us to have a methodology for all these devices to come online.” Cisco is among several companies working to further develop vendor-neutral security standards.

5.

Flexible production is central to the future factory

In 2019, flexibility and modularity are king, from an overall operations standpoint right down to the individual components used in manufacturing. Flexible production has great gains in custom or small-batch manufacturing, or on the supply chain for pick-and-place applications that identify disparate SKUs.

Some examples on the component side: At HARTING, modular power distribution and flexible connectors make it possible to swap components in and out as needed, from HARTING or other manufacturers. “You need modular technologies for the future factory,” advised Uwe Gräff, managing director of HARTING, at a press conference.

OnRobot won the 2019 Robotics Award for its Gecko Gripper system, a modular gripper that mimics the grasp of a lizard and can hold objects without using additional energy. The Gecko Gripper is modelled on structures found in the feet of certain reptiles. Millions of microscopically fine hairs create so-called van der Waals forces when they contact smooth surfaces. This results in strong adhesion and anti-shearing force without the need to use any power for the

purpose. The object is released by tilting the gripper surfaces.

Meanwhile, Omron showcased flexible manufacturing cells with machine tools that can create a wide range of parts just by a change in software. Bosch Rexroth demonstrated a “Factory of the Future,” powered by connected production software and mobile robots called “The Enablers” (pictured at right). And sensor company SICK showed visitors its brand-new 4.0 NOW Factory concept, which was profiled in the May issue of Manufacturing AUTOMATION. 4.0 NOW is a working factory in Germany that manufactures SICK components through just 12 fully automated production cells and a handful of manual workstations. The idea is to show the potential power and flexibility of Industry 4.0 when applied to its fullest capability.

Thomas Pilz, CEO of Pilz Automation Safety, stressed the idea of modularity as key not only to the shop floor, but also to his core

business model. “If you do modularity, you don’t need to dominate,” he said. “Our aim is to collaborate. I like that freedom for the end user.

“I see the future of robotics as having a machine where you don’t have to learn a proprietary system,” he said. “It will be a haptic way of communicating with machines.” | MA

BRIDGING THE SKILLS GAP

With automation changing the types of manufacturing jobs available in Canada, leaders look for ways to attract new workers and re-engage existing ones

BY JESSICA WYNNE LOCKHART

It’s been two months since the grand opening of the Barrett Centre for Technology Innovation (Barrett CTI), a 93,000 square foot facility – but the excitement is still palpable in Darren Lawless’ voice. “ It’s been absolutely phenomenal. People leave gobsmacked. It’s an amazing facility,” he says.

As the dean of applied research and innovation at Toronto’s Humber College, Lawless spent years working on the building – from securing funding (including $15.5 million from the Canadian government, and $10 million from the Barrett Family Foundation), to lining up industry partners (Cisco Systems Canada, KUKA Robotics Canada and Rockwell Automation are just a few.)

students can test out the latest software and robotics technology. The SEW-EURODRIVE Innovation Lab showcases advanced manufacturing that uses the latest augmented reality devices to assemble products with step-by-step instructions. In the SICK Sensor Intelligence Room, the focus is on the Internet of Things and automated sensor solutions.

“There’s a feeling that this could be part of the solution, rather than just a ‘same-old, sameold’ type building,” says Lawless.

$45.6M

The price tag for Barrett CTI, a newly opened advanced manufacturing education and training hub at Humber College.

Then, in April 2019, his dreams were realized when the doors to the $45.6 million “factory of the future” opened. Located on Humber’s north campus, Barrett CTI isn’t just designed for students – it’s also a customizable training facility for companies gearing up for Industry 4.0, with a focus on robotics, automation and systems integration.

In the KUKA Advanced Automation Lab,

The “solution” he’s referring to is for a problem that’s been brewing in Canada’s manufacturing sector for the last 20 years. Perhaps counter-intuitively, job loss has been compounded by extreme labour shortages, with vacancies for skilled positions numbering in the tens of thousands. The culprit, say some, is automation changing the nature of jobs. However, an aging workforce is also to blame, with one in five manufacturing employees in Canada currently eyeing retirement.

W hatever the cause, Barrett CTI’s purpose isn’t just about raising Humber’s profile with shiny new technology – at its root, it’s about improving Canada’s competitive edge and attracting investment. The alternative, says Lawless, is the collapse of an industry that employs 1.7 million Canadians.

“Despite the thoughts of protectionism,

we’re in a global marketplace. If we’re not filling the skills gap, it’s really simple – companies will go where the talent is.” says Lawless. “It’s not doomsday; it’s not a prophecy. It’s just reality.”

The push for upskilling

In 2016, when the Brookfield Institute released its latest report, “The Talented Mr. Robot,” alarm bells sounded. A whopping 42 per cent of jobs in Canada, it reported, were susceptible to automation, particularly in manufacturing. In Ontario alone, this equated to more than 370,000 jobs. The future was finally here, and we were all about to be replaced by robots.

“It got misinterpreted. It’s more nuanced than that,’” says Sarah Doyle, Brookfield’s director of policy and research. “Automation doesn’t mean a job is going to disappear. However, it may require some new skills.”

There’s already evidence of the consequences of failing to modernize. Between 2009 and 2014, industrialized countries around the world expanded investments in robotics, automated systems and advanced technologies, resulting in productivity increases ranging from 30 to 98 per cent. In contrast, Canadian manufacturers reduced their investments in technology by nearly five per cent, triggering a drop in productivity growth. There was also job loss; between 2001 and 2011, Ontario had a 5.5 per cent drop in employment. Yet, Germany – where automation was adopted at higher rates – only saw a drop of four per cent. Low technology adoption, reported the Brookfield Institute, “may have undermined Ontario firms’ competitiveness and put more workers at risk.”

Adopting new technology, though, means training a workforce to use it. The problem, says Doyle, is that it’s still not entirely clear how to best train new and existing

employees, particularly when we’re still not entirely sure what “jobs of the future” will look like – and when it can feel like change is coming at a breakneck speed. One thing is clear though: The traditional post-secondary model isn’t working.

“If you talk to universities or colleges, they’ll tell you that employers aren’t able to give them the information they need. If you talk to employers, they’ll say the colleges aren’t giving them the skills they need,” says Doyle.

Doyle, like many others, believes the answer may be in developing upskilling programs for existing workers, through the use of training modules that don’t require multi-year degrees. Some of these are already in existence, with organizations such as TOOLING U-SME offering online training modules that can be adapted to each worker’s needs.

Others believe that apprenticeship programs and on-the-job training are the solution. When I ask Jayson Myers, the CEO of Next Generation Manufacturing Canada, for examples of strong apprenticeship programs in Canada, he doesn’t even take a breath before rattling off a long list: Linamar has work-integrated learning programs, Siemens has its own training academy,

Rockwell works directly with students. However, he notes that these companies all have one thing in common: ample resources.

“If you’re a small manufacturing company, you probably don’t have the expertise to do a training program in-house, and you don’t have time to take your employees off the production line to send them to school,” says Myers.

Rebranding an industry

That’s why reskilling is just one part of the puzzle. Sree Ramaswamy, a partner at the McKinsey Global Institute (MGI) who studies the economics of multinational corporations, believes that while it’s possible to retrain workers for specialized skills (such the ability to work with a particular model of CNC machine), the real challenge is finding employees with strong foundational skills in basic programming, digital literacy and critical thinking skills. Or, as he puts it, employees who have the ability to understand “mountains of data.”

“Firms are relying on public systems to develop those foundational skills. But if a worker or engineer has those sorts of skills, there’s a strong diversion rate into non-manufacturing occupations or industries,” says Ramaswamy.

“Only 40 or 50 per cent of STEM degree holders actually work in STEM-related occupations.”

Ultimately, the skills gap can’t be solely blamed on a lack of sufficient training or upskilling programs. More than anything, it’s a PR problem. For years, high school graduates have been pushed into STEM programs, all so that they can avoid ending up in factory jobs. Yet automation has the power to change this stigma. Today, a career in manufacturing means that those with skills in engineering, programming and technology are sought-after – and compensated accordingly.

Lawless understands this all too well. How do we get recent graduates interested in careers in manufacturing? How can we rebrand an entire industry?

“It’s great that we can retrain people, but if we can’t get people excited in the automation processes, then the pipeline will dry out and we won’t have the people with the necessary skills,” says Lawless. “We want the talent to be developed here and that means changing the way we do things.” | MA

Wynne Lockhart is an award-winning freelance journalist.

Jessica

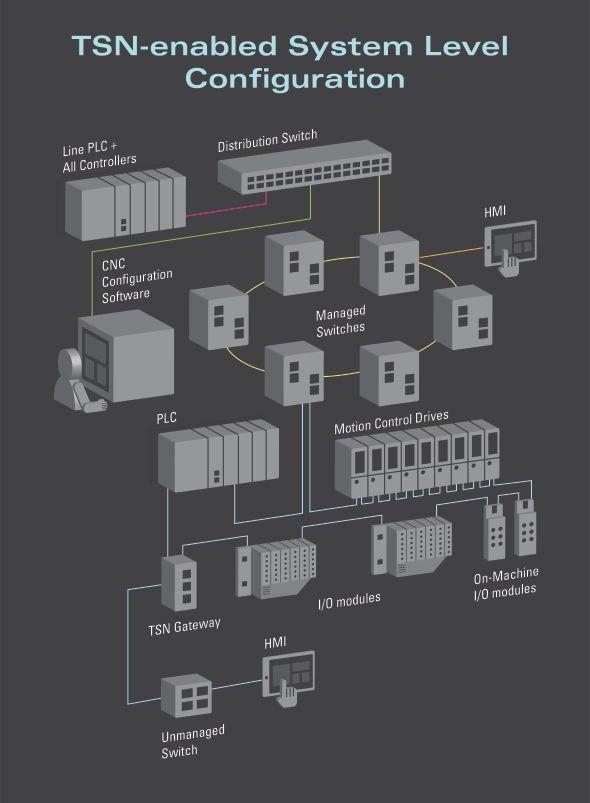

A QUESTION OF TIME

What does Time-Sensitive Networking (TSN) mean for decision-makers in the IIoT?

BY ANIL KUMAR, DENZIL ROBERTS & STEVE ZUPONCIC