By now, it is a tradition: German Technology Day is taking place for the fifth time. With 22 exciting exhibitors on the floor, GTD 2023 showcases latest innovations in the fields of industrial automation and advanced manufacturing. We are living a high moment of the German-Canadian relationship. State visits back and forth, meetings of Prime Minister and Chancellor in Berlin and Toronto have marked the last year. Our governments have never worked more closely together. Investment between Canada and Germany is at an all time high. Just think of Volkswagen’s historic investment in the new St. Thomas-based battery plant, Heidelberg Cement’s construction of North America’s first carbon-neutral cement plant in Edmonton or Eavor Technologies’ first ever commercial deployment of its ground-breaking geothermal energy loop in Germany. These are just a few examples of the innovations, partnerships and opportunities that will enable us to accelerate our respective green transitions and make us more resilient and independent in the future. Lots of room to grow and plenty of opportunities for our technology industry to contribute and prosper... I want to express my profound gratitude to Andreas Sobotta of Pilz Automation Safety Canada for initiating the German Technology Day. Big ideas and initiatives need drivers. Thank you for driving this event. Thank you to all supporters and sponsors!

Welcome to our German Technology Day guests. It is my great pleasure to introduce you to this special edition presenting the attractive line-up for the now fifth German Technology Day! Having just arrived in Toronto in August, I am impressed by the long list of German companies that have joined forces for this event, and the great cooperation between them in promoting German excellence in manufacturing, automation technology and Industry 4.0. Twenty-two companies gather here this time. They are outstanding companies that represent the expertise and know-how of the much-vaunted German Mittelstand: small and medium-sized companies, many of them family-owned, often from small towns in Germany, who became top in the world in their field through ingenuity, excellence and entrepreneurship. In the next few pages, you will be introduced to these champions, all standing together to showcase not just their own respective excellence, but the impressive quality of German automation in North America.

A special thanks to Andreas Sobotta, whose grand vision and efforts started this event in 2019. Since then, it has grown steadily and has become a permanent institution in our annual calendar. I cannot wait to see you all at this special event in October!

We invite you to join us in a newly reimagined version of the showcase that offers interactive pathways for participation. It is time for all of us to work collaboratively and build up a wealth of best practices so we can better serve our customers in Canada. This year we are excited to offer a host of deep-dive experiences through our Innovation Hub and Technology Workshops. We look forward to continuing to share more about what innovation means to us as GTD comes to a city near you. Whether this is your first GTD or your fifth, we are looking forward to collaborating with each of you as we count down to a great showcase event together! Register today by visiting www. germantechnologyday.com!

October 26, 2023

Living Arts Centre, 4141 Living Arts Dr Mississauga, ON

November 16, 2023 Courtyard by Marriott Montreal Airport Montreal, QC 8:00 am – 4:00 pm ET

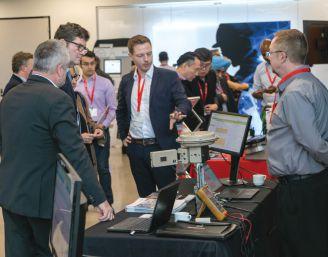

German Technology Day is here in 2023 with the latest solutions and technologies for German automated and advanced manufacturing companies. This year’s event promises a full day of presentations and technical sessions across three rooms, running in conjunction with the exhibition.

Visit www.germantechnologyday.com to register for the location you would like to attend. Registration is currently open, and attendance is FREE for all.

The German Technology Day Innovation Hub is a collective showcase of innovations by our exhibitors. It hopes to help visitors spark ideas and allows them to see new ways to use automation hardware and process solutions from German automation leaders. Come see how the innovation hub can point you to your next automation transformation.

With 22 exhibitors confirmed for this year’s show, it is the largest showcase to date! GTD2023 will be the place to see the latest technology releases from leading German

companies in the Canadian marketplace. From the latest in AI, machine learning led tools, to the solutions of manufacturing, automotive, robotics, building automation, smart city automation, safety and more that solve the biggest challenges facing the industry today, GTD2023 in Mississauga and Montreal will have it all.

The Exhibition Hall will feature factory, logistics and process automation and will be open the entire day to all registered attendees. Technical representatives will be onsite to answer any questions about your applications and solutions. Be sure to come by and check out the latest innovations that can help your business succeed.

October 26, 2023

Living Arts Centre, 4141 Living Arts Dr #4141, Mississauga, ON, L5B 0A1. Living Arts Centre is a premier arts and culture facility located in the heart of downtown Mississauga since 1997. Welcoming more than 400,000 discerning and culturally diverse visitors annually, it serves as a dynamic and accessible gathering place for creativity and inspiration.

November 16, 2023

Courtyard Montreal Airport, 7000 Place Robert-Joncas, Montreal, QC, H4M 2Z5.

Courtyard Montreal Airport is located approximately 15-minutes from the Montreal International Airport. The hotel offers a free shuttle service to the hotel and is located near St. Joseph’s Oratory, Bell Centre, Place Vertu shopping mall and much more.

8:00 a.m. –8:50 a.m.

9:00 a.m. –9:25 a.m.

9:40 a.m. –10:05 a.m.

Registration and opening remarks from the Mayor of Mississauga and the Consul General

Different ways of collaborating with robots

Error Proofing Solutions, from 1D to 3D

Presenter: James Brain

10:20 a.m. –10:45 a.m.

How does decentralization affect power supplies?

Presenter: Nick Vu Smart factory –Autonomous production

Presenter: Felix Weigelt

The highway to efficiency Presenters: Roland Younk and Andre Bousette

Power – Protect – Communicate made Easy!

Presenter: Sergio Andrade

11:00 a.m. –11:25 a.m.

What is an Industry 4.0 machine?

Presenter: Tom Jensen

Deep learning & intelligent inspection: How this technology will change the game for automation and production efficiency in industry Presenter: Prakash Dhanushkodi

IO-Link safety: Transforming the future of safety communication and diagnostics.

Presenter: Guillaume Lavoie

11:40 a.m. –12:05 p.m.

Decentralized installations: Digital, sustainable and cost effective

12:30 p.m. –1:30 p.m.

1:30 p.m. –1:55 p.m.

Presenter: Antonious Messiha, Application Engineer, Wieland Electric

2:10 p.m. –2:35 p.m.

Optimizing uptime: A WAGO case study on predictive maintenance

Presenter: Tyrone Visser

The smart meter valve FOCUS-1”: Simplify & improve process control

Introduction to PC-based control technology with TwinCAT and EtherCAT Presenter: Andy Burleigh

Transforming Machine Safety – Gain Time and Save Money Presenters: Matthew Ernst and Michael Murphy

LIVE! Restaurant located on-site will serve German Food for the day!

*Lunch is NOT included with registration

FREE underground parking available at Living Arts Centre.

Elevating your potential with automated solutions

Since its first ever show in 2019, German Technology Day (GTD) has been on an excellent path of growth and success. What started with four German technology companies, PILZ Automation Safety Canada, Rittal Canada, WAGO Canada and EPLAN Canada, promises to bring more innovation and expertise to the Canadian market every year.

The 2023 edition is the largest GTD showcase yet. This year, prominent companies in automation and advanced manufacturing, based in Canada with their headquarters in Germany are hosting the annual trade show and conference.

From the exhibitors, attendees can expect to see the latest in AI, machine learning led tools, to solutions in manufacturing, automotive, robotics, building automation, smart city automation, safety, and more.

Besides the products show case, all 22 exhibitors will present live sessions, sharing their expertise on the most current trends and technologies ruling the industry.

The 22 participating companies bring with them years of experience, innovation and technical know-how that have helped transform their customers’ businesses. They are the pillars of support, giving every customer the tools to succeed and grow in this highly competitive global market.

So, who are these companies and what do they do? In the next few pages, learn all about their industry vision and what they have to offer. Find their key contact details to connect with them at your convenience.

Beckhoff implements open automation systems using proven PC-based control technology. The main areas that the product range covers are industrial PCs, I/O and fieldbus components, drive technology, automation software, control cabinet-free automation and hardware for machine vision. Product ranges that can be used as separate components or integrated into a complete and mutually compatible control system are available for all sectors. The company stands for universal and industry-independent control and automation solutions that are used worldwide in a large variety of different applications, ranging from CNC-controlled machine tools to intelligent building control.

Since Beckhoff’s foundation in 1980, the development of innovative products and solutions on the basis of PC-based control technology has been the foundation of the company’s continued success. It recognized many standards in automation technology that are taken for granted today at an early stage and successfully introduced to the market as innovations. Beckhoff’s philosophy of PC-based control as well as the invention of the Lightbus system and TwinCAT automation software are milestones in automation technology and have proven themselves as powerful alternatives to traditional control technology. EtherCAT, the real-time Ethernet solution, provides a powerful and future-oriented technology for a new generation of control concepts.

Chris Bladek, Marketing Manager

Phone: 289-627-1900 • Email: c.bladek@beckhoff.com

Calvin Wallace, Managing Director

Phone: 289-627-1900 • Email: c.wallace@beckhoff.com

With more than 225 years of engineering expertise, Bosch Rexroth delivers the most complete, harmonized and easy-to-use factory automation applications for manufacturers around the world. With a factory automation portfolio that offers the broadest selection, the company’s comprehensive solutions go beyond advanced components to include digital engineering tools and customized support that enables you to solve the most intricate engineering challenges. You set the requirements for your machine, your project and your system. Rexroth provides the best and most efficient solution from its broad product portfolio, standard or customized - You decide. Harmonized. Customized. Complete. Sustainable. That’s factory automation from Bosch Rexroth.

Bosch Rexroth’s innovative products and services enables its customers to move everything that needs to be moved with ease and efficiency, helping them to win in their respective industries. Whether it’s for Factory Automation, Mobile Applications, Machinery Applications or Engineering, companies worldwide trust the company to provide innovative components, complete system solutions and expert services.

Bosch Rexroth is a company that is helping to pave the way for the future. With its focus on digital innovation, sustainability, and its own people, the company’s team is not just moving things – they are moving industries to make the planet a better place.

CONTACT INFORMATION:

Kelly Harrison, Marketing Manager

Phone: 905-630-5848 • Email: kelly.harrison@boschrexroth.ca

Wolfgang Wiedorn, Strategic Growth Manager

Phone: 289-230-0077 • Email: wolfgang.wiedorn@boschrexroth.ca

Burkert Fluid Control Systems is a global system solution provider of the most reliable and innovative microfluidic valves, sensors, process valves, pneumatic actuation, controllers and solenoid valves. Burkert Fluid Control Systems provides the following markets custom fluid control systems: medical equipment, biotech, pharmaceutical, food and beverage, water treatment, semiconductor and general industrial processing.

Burkert Fluid Control Systems is one of the world’s leading manufacturers of measuring, control and regulating systems for liquids and gases. Burkert solutions are used in a wide range of industries and applications – ranging from breweries and labs to medical, bioengineering and aerospace technology. With a portfolio of more than 30,000 products, Burkert is the only supplier to offer all fluid control system components, from solenoid valves to process and analytical valves, from pneumatic actuators to sensors.

With its headquarters in Ingelfingen in southern Germany, the company has a wideranging sales network in 36 countries and more than 2,800 employees worldwide. Burkert continuously develops customized solutions and innovative products at its five Systemhaus locations in Germany, China, and the USA, and in four research centres.

CONTACT INFORMATION:

Shante Zaccaria

Phone: 514-946-9009 •Email: shante.zaccaria@burkert.com

James Taylor

Phone: 905-632-3033 • Email: james.taylor@burkert.com

EPLAN offers software and service solutions in the fields of electrical, automation and mechatronic engineering, also known as CAE (Computer Aided Engineering), for machine, plant and control cabinet engineering. The EPLAN Platform leads its users on a journey towards efficiency in design, and engineering of electrical and automation projects. Because the company promotes the usage of common universal standards, users can reuse their efficient designs without wasting time, even when the production quantity is only 1!

You become more efficient when working on EPLAN projects because data flows seamlessly between each step of the production, allowing you to reorganize your workflow and automate some of the most time-consuming tasks of your panel building process in order to deliver your projects up to 33 percent earlier.

Visit the EPLAN booth to discover how you can take advantage of a reorganized production workflow by calculating wire lengths, pre-fabricating wires and using the Rittal Application Center or automation equipment.

CONTACT INFORMATION:

Roland Younk, President, EPLAN Canada

Email: younk.r@eplancanada.com

Ruben Bastien, Marketing Specialist

Email: bastien.r@eplancanada.com

The EUCHNER success story starts in 1940 with the start-up of an engineering company by Emil Euchner. A milestone was set in 1952 with the development of the first “multiple limit switch” in the world. Highly sophisticated in technical terms, this position switch was developed in close co-operation with the machine tool industry. It is used for positioning and controlling machines and systems and is still a symbol of the company’s innovative power today. Safety for people, machines and products has been the maxim of this family-owned company since 1953. Stefan Euchner is the third generation to take the helm.

Safeguarding people, machines and processes is the main focus of EUCHNER’s activities today. The company’s primary objective is 100 percent customer satisfaction without neglecting the well-being of its employees. The hallmarks of the EUCHNER philosophy are therefore quality, reliability and precision. Based on the long-standing experience of its staff, the company always finds the right solution for customers’ individual requirements.

The company employs around 1200 people around the world. In addition to the production locations in Unter böhringen and Shanghai/China, 20 subsidiaries and other sales partners in Germany and abroad work for its international success on the market.

What do many industries have in common? EUCHNER’s safety engineering in markets: automotive, machine tools, packaging machines, renewable energies, construction machines, presses/paper machines, intralogistics, woodworking machines, plastic injection molding machines and assembly technology.

CONTACT INFORMATION:

Kartik Vashi

Associate Managing Director

Functional

Safety Engineer

Phone: 647-242-5863 • Email: Kartik.vashi@euchner.ca

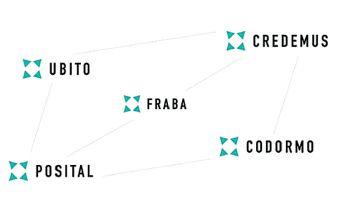

The sensors you want, available when you need them POSITAL, based in Hamilton New Jersey, is the North American member of the international FRABA Group, a family of enterprises focused on providing advanced products for position sensing and motion control. Key products include encoders, inclinometers (tilt sensors) and linear position sensors.

Because position and motion sensors are used in many ways, especially in the robotics industry, there is need for a wide variety of mechanical configurations, electronic interfaces, and performance characteristics. POSITAL has developed design and manufacturing processes that make it possible to produce an extremely wide range of products while keeping prices and delivery times to a minimum. This is due to three significant innovations:

• POSITAL sensors are based on flexible modular designs. Many different variants can be assembled from a common base of technologies.

• Advanced microprocessor technologies are widely used so that in many cases, characteristics can be customized through software, without requiring changes to mechanical components.

• POSITAL-FRABA products are produced through an innovative, data-driven manufacturing process that can deliver specialized devices quickly (typically within days) at competitive prices.

Taisia Osipova

Phone: 609-750-8705

Email: taisia.osipova@fraba.com

ifm develops innovative Industry 4.0 solutions and corresponding software and cloud products to make existing business processes digitally usable and to offer new, holistic control options for sustainable efficiency and cost optimisation.

With automation technologies, ifm contributes to improving the living and working conditions of all people. Products, services and software from ifm help to protect the environment worldwide and to reduce CO2 emissions, energy and material use.

On 29 October 1969, the ifm group of companies was established. The motivation was to do things in a different way than all others – and better. In ifm’s foundation year, the company tasted success with the invention of inductive sensors for 220 V.

ifm’s exceptionally large product portfolio does not only cover all relevant standard solutions but also the special requirements of individual industries. In addition to position and process sensors, sensors for motion control and safety technology are part of the product range. Furthermore, ifm offers products for industrial imaging and communication as well as identification systems and systems for mobile machines.

ifm’s markets include assembly automation, mobile controls, metal processing, food and beverage, water technology, battery manufacturing, logistics automation, facilities machines and semiconductor.

CONTACT INFORMATION:

Lydia Hernandez

Email: lydia.hernandez@ifm.com

General email: cs.ca@ifm.com

KUKA Robotics Canada is best known for its wide range of German-engineered and built industrial robots, which are highly desirable for their performance and lowest total cost of ownership. KUKA also offers a wide range of positioners, slides, mobile platforms and robots, machine vision, as well as Industry 4.0, collaborative and ready2_use solutions. This complete array of products combined with KUKA’s engineering and support services help Canadian manufacturers achieve the highest level of productivity and profitability.

Some of the solutions that KUKA offers involve processes such as arc and spot welding, robotic milling (often combined with a positioner and/or slide), and robotic friction stir welding.

KUKA’s innovative demonstration shows a ready2_educate cell and the highly versatile and intuitive LBR IISY 11 Cobot which will be featured in the GTD exhibitor wall display.

KUKA’s presentation, “Different ways of collaborating with robots,” will cover various aspects of robotics and key advancements that have opened new possibilities in terms of applications, accessibility, and ease of use.

CONTACT INFORMATION:

Yarek Niedbala, VP Industry Management

Phone: 416-930-4976 • Email: yarek.niedbala@kuka.com

Lorraine Dawkins, Executive Assistant

Phone: 437-218-5473 • Email: lorraine.dawkins@kuka.com

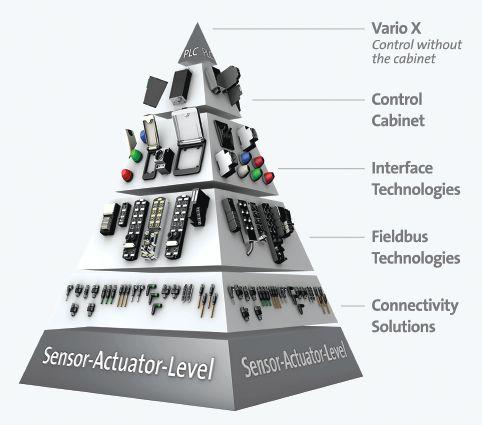

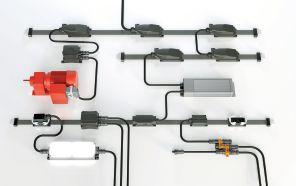

talked about but never achieved…until NOW!! Machine builders and their customers know Murrelektronik for innovative, high quality, connectivity solutions that are simple to install, easy to commission, and easy to own. Terms used to describe the company’s solutions include “Things Simply Connected” (Murrelektronik’s systematic and logical approach to easily connecting your devices) and “Zero Cabinet,” (distribution of I/O connections from the cabinet to the field resulting in cost reductions of 1/3 or more).

At German Technology Day, the company is launching the Canadian Premier of Vario X: The Decentralized – Zero Cabinet Solution for the automation world of the future! Meet Tom Jensen, head of system sales and inhouse technology evangelist at Murrelektronik who will provide insights on what an Industry 4.0 machine is. With over 75,000 products produced in six global manufacturing facilities, Murrelektronik is the expert in connectivity! On hand will be the company’s local connectivity experts, Anand Mehta, Jamal Kadhum C.E.T., and Bob van den Berg, C.E.T. Stop by the booth to learn how “We Challenge the Way of Automation – Things Simply Connected!”

CONTACT INFORMATION:

Bob van den Berg, C.E.T.• Managing Director Phone: 647-627-3637 • Email: bvandenberg@murr.ca

Jamal Kadhum, C.E.T. • System Sales Manager Phone: 647-633-1624 • Email: jkhadhum@murr.ca

Phoenix Contact is a globally active familyowned technology company that focuses on electrification, networking, and automation to help industry and society achieve a sustainable future.

The company’s solutions are used wherever processes need to run automatically. This can be in industrial production facilities, in the field of renewable energy, in infrastructure, or for complex device connections. Phoenix Contact products are used wherever power or data flows are connected, distributed, and controlled. Your benefits go beyond the pure function: the company’s products help its partners to develop sustainable applications with more efficient processes and reduced costs.

This year, Phoenix Contact is celebrating the 100th anniversary of the company’s founding. Today, the company employs approximately 22,000 people and generated revenues of €3.6 billion in 2022. In recent years, it has experienced especially dynamic growth, which shows that it can provide answers to the key questions of current times with its solutions.

Worldwide, Phoenix Contact manufactures in a production network spanning 11 countries in which the level of vertical integration varies. More than 50 international subsidiaries are part of the Phoenix Contact Group. In this way, the company is always close to the markets and customers.

CONTACT INFORMATION:

Sheetal Modi

Phone: 1-800-890-2820 ext. 251 • Email: smodi@phoenixcontact.ca

Heidi Barriage

Phone: 1-800-890-2820 ext. 263 • Email: hbarriage@phoenixcontact.ca

Pilz Automation Safety Canada – We make Canada Safer. A little bit every day. Pilz Canada is one of the subsidiaries to Pilz GmbH & Co. KG located in Ostfildern, Germany. Founded in 1948, Pilz is a successful, independent family business and has been inspiring its customers with innovative products and solutions.

Pilz, the world leader in safety automation, is represented by 42 subsidiaries and branches on all continents and has become technology leaders with the world’s first and most widely used safety relay “PNOZ”. It is the epitome of a safety relay and has shaped the history of automation technology.

Pilz offers complete automation solutions based around its core skill of safety –from sensor technology to control and actuator technology. The product range is being expanded to include corresponding software tools, diagnostic and visualisation systems as well as services.

CONTACT INFORMATION:

Catherine Tran, Marketing Coordinator

Phone: 905-821-7459 • Email: c.tran@pilz.ca

PULS is the leading manufacturer of the most efficient DIN Rail switched-mode power supplies and dedicates 100% of its resources to designing innovative and high-quality DC power solutions for the industrial automation market. Product families include FIEPOS, DIMENSION, PIANO and MiniLine Series, as well as DC backup power systems, redundancy modules and electronic circuit protection devices.

High efficiency – PULS products feature the industry’s highest energy efficiency ratings, which produces less heat and, in turn, provides longer life expectancies for all components.

Supply chain control – From development to shipment, the entire process is controlled by PULS. Production facilities in Europe and Asia provide capacity and redundancy for product delivery. Significant inventory is maintained in North America to meet your requirements.

Lowest total cost of ownership – PULS engineering-based design optimizes efficiencies and leads to lower heat generation, smaller footprints, longer service lifetimes and reduced replacement and energy costs.

Applications include machine building and construction; control systems for automation and logistics; building automation; mining; oil and gas; marine and offshore; automotive production and manufacturing processes; chemical and pharmaceutical; water and wastewater; material handling; semiconductors; nuclear and renewable energy; and other industrial environments. Visit pulspower.us to learn more.

CONTACT INFORMATION:

PULS North America • 2640 White Oak Circle, Suite A, Aurora, IL 60502 USA

Customer Service: 630.587.9780 • Technical Support: info@puls-us.com Website: pulspower.us

Rittal Limited headquartered in Mississauga, Ontario, is the Canadian subsidiary of Rittal GmbH & Co. KG, with headquarters in Herborn, Germany. It is one of the world’s leading system suppliers of enclosures, power distribution, climate control, IT infrastructure and software and services. Customers from all sectors of industry, from mechanical and plant engineering to the IT and telecom market, are making use of system solutions from Rittal. Founded in 1961 in Germany, Rittal is now active worldwide with eight production sites and 64 subsidiaries.

Rittal’s innovative range of products includes industrial, IT solutions, climate control, hygienic design solutions, and more. At this year’s German Technology Day, the company will also introduce its new Rittal Application Center, a brand-new stateof-the-art facility featuring EPLAN software and Rittal Automation Systems. This is where the magic happens to empower customers to become faster, better, and more efficient with their control cabinet production.

CONTACT INFORMATION:

André Bousette, President, Rittal Systems

Email: bousette.an@rittal.ca

Marketing Rittal Systems

Email: marketing@rittal.ca

Established in 1907, SAMSON AG has become a market leader in control valves for industrial process automation. The company is trusted in many of the world’s most challenging applications to achieve precise control with a high level of safety and reliability. Valves are SAMSON’s core business. As a trendsetter for over 100 years, the company is further expanding the valves decentralized intelligence.

The modular design of SAMSON’s products allows customers to benefit from a tailormade solution at an affordable cost. Furthermore, the interchangeability of spare parts between different valve models and sizes contributes to keeping inventory costs low. The SAMSON product portfolio offers engineered solutions from a single source. The company’s linear and rotary control valves are carefully selected and sized to ensure reliable operation with reduced maintenance requirements. The latest in positioner technology offers precise control, seamless integration into process control systems, and advanced diagnostics to allow for predictive maintenance. Major products are valves, self-operated regulators, actuators, accessories, signal convertors, automation systems, sensors and thermostats and digital solutions.

SAMSON celebrated 40 years in Canada this year, marking a significant milestone since its founding on April 8th, 1983. Known for excellence, innovation, and success, the company has built a strong reputation for quality, reliability, and customer service.

CONTACT INFORMATION:

Joseph Ferraro, President & CEO

Phone: 647-280-3949 • E-mail: joe.ferraro@samsongroup.com

Faisal Ahmed, Regional Sales Manager

Phone: 519-464-6018 • Email: faisal.ahmed@samsongroup.com

The Schmalz Group unites more than 1,800 employees at 29 locations around the world. Schmalz is the market leader in vacuum automation and ergonomic handling solutions. Schmalz products are used all over the world, for example in applications in the logistics industry, the automotive industry, the electronics sector or in furniture production. As the market leader in automation with vacuum and handling systems, the company moves things forward with its innovative strength. It is the basis of its success and drives its employees.

With comprehensive consulting, a focus on innovation and first-class quality, Schmalz offers its customers long-lasting benefits. The company’s specialties are in vacuum technology for automation (components and gripping systems), vacuum lifters and crane systems, vacuum clamping technology and robotic end-of-arm-tooling.

CONTACT INFORMATION:

Ian Warden, General Manager

Phone: 647-522-2123 • Email: ian.warden@schmalz.ca

Akshay Chaudhari, Regional Sales Manager Phone: 647-237-2123 • Email: akshay.chaudhari@schmalz.com

SCHUNK Intec corp. is a family-owned company and a global player in one. SCHUNK is a competence leader for gripping systems and clamping technology with about 3,500 employees in nine plants and 34 directly owned subsidiaries and distribution partners in more than 50 countries throughout the world that ensures a intensive market presence.

With 11,000 standard components, SCHUNK offers the world’s largest assortment of gripping systems and clamping technology from one source. SCHUNK offers the largest product range of standard grippers with up to 2,550 companies with assembly, handling, and metal-cutting processes. The customer base includes the Who’s Who of mechanical engineering, robotics, automation, assembly handing, and all the renowned automotive brands and their suppliers.

CONTACT INFORMATION: Talyssa Ferrer • Email: talyssa.ferrer@ca.schunk.com Jim Stevens • Email: jim.stevens@ca.schunk.com

As a market leader in drive and automation technology, SEWEURODRIVE moves applications, processes, systems, and machinery in virtually every sector. With its strong workforce consisting of approximately 21,000 employees, it is playing a key role in shaping the future of drive technology and its customers’ future.

SEW-EURODRIVE’s range of drive technology products, solutions, and services is one of the most extensive and comprehensive on the market. Its unique modular concept for drive and automation technology offers millions of potential combinations, which is why it can always deliver the ideal solution for countless applications in virtually any industry.

SEWEURODRIVE supports customers every step of the way from concept development and planning to the implementation of their requirements, including fully comprehensive solutions for machine automation and for a modular Industry 4.0 factory. No matter how big the project is or how complex the requirements are, SEWEURODRIVE wants to give its customers exactly what they need, when they need it. It aims to offer the best support possible and, on request, deliver a fully comprehensive carefree service package that spans the entire system life cycle.

This is SEW-EURODRIVE.

CONTACT INFORMATION:

Shane Carnegie, Electronics Product Manager

Phone: 905.791.1553 • Cell: 416.988.6343

Email: s.carnegie@sew-eurodrive.ca

Industrial automation is changing at an extremely rapid pace. As an innovation leader on the vanguard of developing cutting-edge sensor technology, SICK offers solutions today that are ready for the challenges of the future – with intelligent sensors that collect data, evaluate it in real time, adapt to their environment, and communicate in the network.

“Sensor Intelligence” draws on all of SICK’s system expertise, supplemented by its experience in a variety of sectors. The company combines its detailed application knowledge with reliable software architecture to optimally integrate its sensors into your system – because intelligent is the only way.

Intelligent sensors benefit from the availability of ever-smaller, ever-cheaper microcontrollers. These controllers enable SICK’s sensors to process increasing volumes of data directly, using ever more complex algorithms. And this technology helps you to optimize your production and control networks.

SICK’s sensor solutions are keeping industry moving. As a technology and market leader, SICK provides sensor intelligence and application solutions that create the perfect basis for controlling processes securely and efficiently, protecting individuals from accidents, and preventing damage to the environment.

With “Sensor Intelligence,” the company is making Industry 4.0 a reality – and it is doing it today. Learn more at: www.sickcanada.com.

CONTACT INFORMATION:

Prakash Dhanushkodi, Digital Technical Consultant

Phone: 647-202-4596 • Email: prakash.dhanushkodi@sick.com

TRUMPF was founded in 1923. It is a high-tech company offering manufacturing solutions in the fields of machine tools and laser technology. The company drives digital connectivity in the manufacturing through consulting, platform products and software. TRUMPF is a technology and market leader in highly versatile machine tools for sheet metal processing and in the field of industrial lasers.

TRUMPF currently employs nearly 17,900 people in 66 countries and generates more than $5.6 billion (4.9 billion Euro) in gross annual sales. With more than 80 subsidiaries, the TRUMPF Group is represented in nearly every European country as well as in North America, South America and Asia. The company has production facilities in Germany, France, the United Kingdom, Italy, Austria, Switzerland, Poland, the Czech Republic, the United States, Mexico and China.

Find out more about TRUMPF at www.trumpf.com

CONTACT INFORMATION:

TRUMPF Canada Inc.

1-3755 Laird Road, Mississauga, ON, L5L 0B3, Canada, Website: www.ca.trumpf.com Phone: +1-800-306-1077

WAGO is a global innovator in the electrical engineering world. Recognizing the need for adaptable solutions marked the way into becoming the backbone of a smart driven world that WAGO upholds today. It’s simple; electrical interconnection, automation and interface electronic technologies reflect WAGO’s credibility by striving to conquer its mission: Empower Connections.

In 1951, for spring pressure connection technology WAGO revealed the world’s first use of polyamide 6.6 for the housing of rail-mount terminal blocks and the first screwless, pluggable terminals blocks for capacitors. In 1977, the CAGE CLAMP transformed connection technology for all conductor types. In 1995, WAGO broke ground when it introduced a fieldbus system in the automation sector in which fieldbus nodes could be precisely matched to fit a specific application based on the building block principle.

WAGO products are available to customers who seek simple, safe, and maintenance free interconnection technology. Between the field and control level, WAGO’s electronic interface will be there to offer a high degree of efficiency, and ease of handling. WAGO simplifies your production process by shaping the future of automation through seamless communication from controllers to sensors, a high degree of flexibility and freedom of planning, as well as a high degree of reliability even under the harshest operating conditions.

What differentiates WAGO in the engineering industry? Former founder of WAGO Wolfgang Hohorst said it best – “Whether it has to do with wires, people, or thinking, it’s all about making a connection.”

CONTACT INFORMATION:

Laura Andrews, Marketing Coordinator

Phone: 289-962-2529 • Email: laura.andrews@wago.com

Customer Service

Phone: 1-888- 924-6221 • Email: customerservice.ca@wago.com

The Weidmüller Group has production sites, sales companies and representatives in more than 80 countries. Together with its customers, the Detmold-based family business is shaping the digital transformation – with products, solutions and services for smart industrial connectivity and the Industrial Internet of Things. In the 2022 fiscal year, Weidmüller generated a turnover of more than one billion euros with about 6,000 employees around the world.

Weidmüller understands that overcoming new and diverse challenges requires more than just high-tech products. Connectivity is the key, whether it’s power, signals, data, or finding solutions that bridge theory and practice. It specializes in industrial connectivity. Its solutions are trusted in a wide range of industrial environments, from modern manufacturing plants to power generation and distribution, railroad technology, and new energy fields.

As pioneers in smart industrial connectivity, Weidmüller is eagerly anticipating the opportunity to reveal a range of cutting-edge automation and IIoT products specifically designed to address the challenges of today’s world at the German Technology Day (GTD) 2023. These innovative solutions are based on future-proof technologies like u-OS and SNAP IN, ensuring that customers remain at the forefront of the digital revolution.

CONTACT INFORMATION:

Nicholas Alderson, Product Support Manager

Email: nicholas.alderson@weidmueller.com

Ashish Kokane, Marketing Supervisor

Email: ashish.kokane@weidmuller.com

Electrical installations should be safe, reliable and easy to install! For over a century, Wieland Electric has advanced the electrical industry with innovative technology and top-performing methodologies.

One of Wieland’s standout products is the decentralized power distribution system (PODIS), which sets new standards in efficiency and reliability. By strategically distributing power closer to the point of use, this approach enhances operational efficiency and reduces installation complexity. With remarkable time and labour savings exceeding 80 percent, and the assurance of a robust connection, PODIS presents an irresistible solution for modern factories striving for optimization.

Additionally, Weiland is proud to introduce the samosPRO programmable safety controller, featuring new motion monitoring capabilities. Tailored to applications like ASRS, where precise motion tracking is indispensable, this controller opens up new dimensions of control and safety.

To provide you with an in-depth understanding, Wieland’s field application engineer will be on-site to present a detailed use-case for the motion monitoring application. This will offer a firsthand look at how this technology can help elevate operational standards. Weiland is excited to engage with you at its booth and discuss how these advancements can benefit your operations.

Sorina Van Vroenhoven, Marketing Manager, Americas

Phone: 905-829-6420 • Email: marketingcanada@wieland-electric.com Technical Support

Phone: 905-829-6426 • Email: technical.support@wieland-electric.com

Andreas Sobotta, CEO and General Manager at PILZ Automation Safety Canada; Andre Bousette, President of Rittal Canada; Juliano Matias, President of WAGO Canada; and Roland Younk, President of EPLAN Canada, the four founders of German Technology Days, share their thoughts on GTD 2023 and its theme.

Andreas

Sobotta, CEO and General Manager at PILZ

“Unbelievable – GTD 2023 is already the fifth German Technology Day. What started in 2019 with just four companies has now developed into a signature event in the automation industry. GTD 2023 welcomes 22 highly recognized German companies that are all world leaders in their area. This time we have several new companies from the process industry, and we also opened the event to customers of ours.

This time we are happy to have the City of Mississauga as one of our sponsors, and the GTA event will take place in the beautiful Living Arts Centre in downtown Mississauga. During the past years it was very clear that all companies must change, and the theme of this year’s event is an indicator of how the 22 participating companies can help our guests to be ready: Transformation. Elevating your potential with automated solutions. Enjoy GTD 2023!”

Andre Bousette, President of Rittal Canada

“Ever since its inception, the German Technology Day has always been synonymous with innovation, and today, we’re bringing more of it to you. This will be the biggest GTD to date and it makes me proud to see how much this event has grown over the years thanks to the collaboration and innovation from all companies involved. This year, we are taking a much closer look at how automated solutions allow you to elevate your potential. This is a topic that concerns all of us and I hope the event can help you find answers to today’s burning questions regarding transformations in the industry.”

Roland

Younk, President of EPLAN Canada

“Our role in the German Technology has always been to promote and showcase collaboration between our companies. With the EPLAN Data Portal, a centralized smart data portal hosting more the 1.5 million parts from the vast majority of the GTD companies and beyond, we can help our common customers from design, to manufacturing, through sourcing. We’ve always prided ourselves in helping our partners to elevate their potential through working together. I like to mention a company’s journey to efficiency, and I believe that the GTD is a great opportunity to meet a wide array of different German companies and discover their unique and often transformative technology.”

Juliano Matias, President of WAGO Canada

“This year’s theme brings about the concept of being able to embrace change which will lead us into flexibility and freedom. In the same way that a butterfly soars out of its cocoon in a whole new form, we must face the realization that automation is discovering its new form in this ever-changing world. Let us frame our minds to accept challenges and obstacles over letting them impede our creative ideas. One of the most significant advantages of Automation technology lies in exchanging data to simplify control processes. When we look to our past, we see how the unexpected paths lead us to even greater achievements because we were able to dissect the application further. Each struggle actually determines more advanced opportunities, together with our German technology we are going to transform modern machines, systems and building technology.”

Elevating your potential with automated solutions