GRAIN OF TRUTH

These days, people want foods crafted from ingredients they can understand and trust. Simply Milled by Ardent Mills ™ organic flour is just that. It’s nothing more, and nothing less, than family-farmed wheat, ground into flour at our community mill as it has been for close to a century. And with organic all-purpose bread, pastry, strong bakers and whole wheat options, there’s a Simply Milled flour for every need.

For more information, visit ArdentMills.ca or call 888-295-9470.

Stacey Bester, the owner of Sweet Bakery hard at work.

BY NAOMI SZEBEN

GETTING THROUGH GIVING

GJUNE 2019 | VOL. 79, NO. 6

EDITOR | Naomi Szeben editor@bakersjournal.com 416-510-5244

iving is an art form. So is baking. It’s no surprise to anyone that bakers are as gifted at creating beautiful pastry or bread as they are at connecting to the communities they serve. Given that bakery arts are a part of the hospitality industry, most bakers are generous souls: Many have gone into the food industry because they love to put a smile on someone’s face. Today’s bakers are aware that many of their treats are luxury goods, and in some cases, even their most humble of wares, the freshly baked bread loaf, might be out of reach for some. It was humbling to hear stories of bakers who went out of their way to reach out bread banks, to community centres, or even took on an initiative to help out a specific group. Since bakers live to treat people, it was an honour to read the stories from the Jake The Baker Award submissions. In this issue, you will read about the Sweet Bakery, and the heart-warming story of how that shop lives up to its name. Stacey Bester shares her story of how simple acts like providing food, a shoulder to cry on, and ensuring hygienic needs of children are met through her volunteer work at Why Not. I was inspired by Bester’s story of starting out with little more than a dream and a loan from people who believed in her.

TECHNICAL EDITOR | Philip Oxford, Puratos Canada foxford@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexbusinessmedia.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Shannon Drumm sdrumm@annexbusinessmedia.com 519-429-5176 1-888-599-2228 ext. 219

MEDIA DESIGNER | Curtis Martin

CIRCULATION MANAGER l Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-442-5600 ext. 3543

GROUP PUBLISHER/VP SALES | Martin McAnulty mmcanulty@annexbusinessmedia.com

COO | Scott Jamieson

Charitable contributions are more than just a tax deduction: They build communities. Neighbours that feel the love return the favour with word-of-mouth advertising.

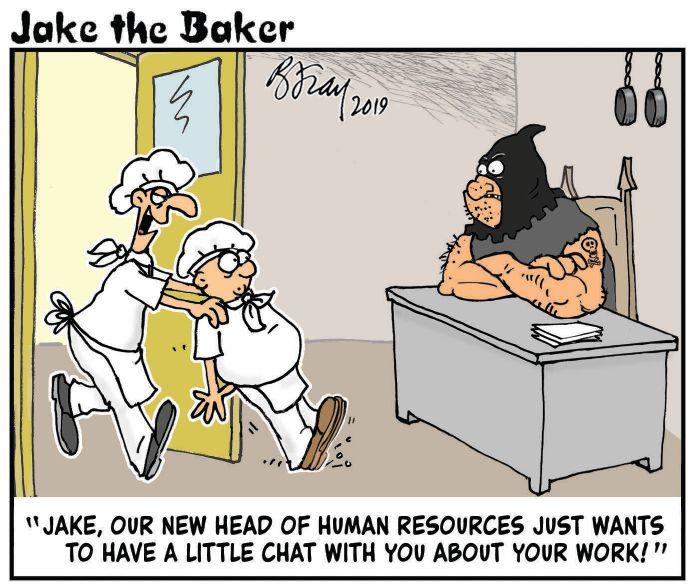

Community involvement is a big part of many baker’s lives, since they treat the people they serve with both delicacies and basic bread, who then share these with their neighbours. Bakeries often hear the town news over a cup of coffee and a cookie, or hear the joyous reason behind the order placed for a celebratory cake. The love that bakers have professed for their neighbourhoods is more than mere lip service. Without the people, there would be no bakery, and good bakeries know that if you get your clients young, you’ll have them for life. But who supports the bakers who do good? Who awards the bakers who make a difference in their community? For that, we have to thank the Jake the Baker Award’s Founding Sponsor, Ardent Mills, and Ireks, the Gold Sponsor, without whom Bakers Journal would be unable to give credit where credit is due. We are honoured to learn about what keeps bakers motivated to donate goods, contribute their time, and help out a stranger. It’s one thing to write a cheque to a good cause, but seeing the change a small donation can make in a person’s life is worth more than the lump sum. Charity work helps invest in the future. When everyone is at their strongest, we all benefit. The added incentive of a tax deduction may be motive enough for some, but for bakers like Bester, being in touch with people and seeing the change means more.

Charitable contributions are more than just a tax deduction: They build communities, Neighbours that feel the love return the favour with word-of-mouth advertising, and more patronage. This means more clients and more revenue. Altruism may be its own reward, but there is a distinct advantage to gaining good PR through works of charity. The Jake the Baker Award helps bakers across North America get the leg up and the PR that their community and bakery need. Furthermore, reading an inspiring story might help spark another idea in a different neighbourhood, or at the very least, give readers something to think about. Sweet Bakery made me think of the basics I often take for granted, and made me wonder if there is a similar initiative in my neck of the woods. As Bester stated in our chat, “we all need a hand up, now and then.” We hope that readers will be inspired by her story, contribute to BRAugust if they can, or do something that will give somebody in need a much needed hand up. / BJ

PRESIDENT & CEO | Mike Fredericks

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710.

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Business Media.

CIRCULATION

lmalicdem@annexbusinessmedia.com

Tel: 416-510-5187

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Subscription Rates

Canada — 1 Year $ 32.00 (with GST $33.50 #867172652RT0001, with HST/ QST $35.90) USA — 1 Year $ $56.50 USD

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com

Tel: 800-668-2374

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2019 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

Jim Fontaine, Reiser Bakery Specialist

briefly | Canadian government funds processed food industries | JB Cocoa names a new sales manager for Canada | for more news in the baking world, check out our website, www.bakersjournal.com

AgriInnovate Program boosts food industry

While visiting a manufacturing facility in Southern Ontario, Minister of Agriculture and Agri-Food Marie-Claude Bibeau, along with Member of Parliament (VaughanWoodbridge) Francesco Sorbara announced a repayable contribution of up to $8.5 million to Riverside Natural Foods Ltd. for the modernization of their MadeGood™ Foods line of products.

Riverside Natural Foods is a family business incorporated in 2013, based in Vaughan, Ontario, specializing in organic, allergen-free and non-GMO granola bars, squares, and cereals under the MadeGood™ label, with approximately 200 employees.

The fund is aimed at supporting small businesses in Canada. “This is a small business-friendly government that is working hard to help businesses, like Riverside Natural Foods, start up, scale up, and access new markets. Today’s contribution will help create good jobs in the York region, innovate our agri-food sector, and strengthen Canada’s economy,” said Francesco Sorbara, Member of Parliament for Vaughan—Woodbridge.

“The government support has been a

tremendous boost to our company, allowing us to invest in sophisticated, best in class production equipment that will allow the MadeGood brand to compete on a global scale. We will continue to produce nutritious foods using Canadian organic agricultural products, provide employment for a skilled and ethnically diverse workforce and generously give back to our community,” said Nima Fotovat, President, Riverside Natural Foods Ltd in a press release.

“MadeGood is focused on becoming a Canadian role model and leader in successful triple bottom line business management.” In 2017, the Ontario food processing industry had sales of $45 billion

and generated $10 billion in export value.

This project, funded under the Canadian Agricultural Partnership, AgriInnovate Program, will enable the company to purchase and install first-in-Canada robotic equipment, customize and automate their granola bar production and create exciting new production lines for allergen-free healthy snacks. With this contribution, Riverside Natural Foods is expected to increase production, inputs and exports sales, while introducing new products to the market and creating well paying jobs to benefit all Canadians.

“This funding will help Riverside Natural Foods stay on the cutting edge through the latest in new technologies, allowing them to grow production and launch innovative, new high-quality products to customers in Canada and around the world,” added Marie-Claude Bibeau, Minister of Agriculture and Agri-Food. “The government is proud to contribute to projects like this, which will help keep Ontario’s agri-food sector strong and growing, increase Canada’s competitiveness and create jobs for our middle class.”.

JB Cocoa appoints Karen Twerd sales manager, Canada

Cocoa ingredients supplier, JB Cocoa is excited to announce the appointment of Karen Twerd as Sales Manager, Canada.

In her new role, Twerd will be responsible for managing and growing the Canadian market. Twerd has extensive sales and product management experience in the food ingredient business in Canada.

Most recently, Twerd provided strong leadership as the Events Director for Women in Food Industry Management, as association for the networking and technical development of women in the Canadian food industry.

SWEET BAKERY, SWEET OWNER

The Sweet Bakery in Brantford, Ontario is a small shop with a big heart. To hear Stacey Bester speak of how lucky she is, and how she “married the man of her dreams,” you wouldn’t know that her bakery was born from a dark, sad time in her life. “I had a marriage that had failed, so I had to work outside of the home, I had a lot of different career opportunities, but none that I was a hundred per cent passionate about,” Bester said. “One day, when my mother and I were driving around, I was expressing how I just wasn’t enjoying the career I was in, I wasn’t enjoying the lack of money, and she said: ‘you need to open up a bakery.’”

Despite Bester’s love of baking that had started with her first Easy-Bake Oven, she was sceptical. Without a support system in place, and limited funds to guarantee a business loan, her future looked bleak.

“I was on my own, my kids were in university. I was really struggling financially, and a close family friend graced me with a private loan to open my shop. I realized, ‘okay, I need to make this go,’” She said. That was a very stormy February morning in 2014. “I signed my lease April 1st, for the location I’m at today, and Sweet Bakery opened the doors June 2nd. Nobody has opened a bakery faster than I did. I had a couple

According to Bester,

months of free rent, and I was going to take full advantage of that.” Bester didn’t want to disappoint her friend nor her family. In her words, she “ate, breathed and slept” her plans to make it successful. “Failure was not an option,” she adds.

“Our motto is, ‘if we don’t make it we don’t sell it.’ And that’s always been my way...I

only use a hundred per cent butter. Pure vanilla. Just the finest quality ingredients I can get my hands on. To me, taste is everything. There’s nothing worse than somebody saying, ‘it looks too pretty to eat.’ I want it to look good, but they have to want to eat it.” Bester’s eye for Instagrammable desserts comes in handy for fundraising. “We also provide

couple

of

free cupcake decorating to local kids every week during the summer in a local park.” The cupcakes that Sweet Bakery sells on National Cupcake Day support the local SPCA.

It’s Bester’s gratitude that makes her pay it forward to youth in their hour of need. Bester and her husband, Justin, are involved with a

“nobody has opened a bakery faster than I did. I had a

months

free rent, and I was going to take full advantage of that.”

IBIE is where the next generation of baking technology is launched, new innovations are unveiled and new trends begin. For this reason, a growing number of professionals from all around the globe make the trip to the U.S. every three years. It’s the biggest opportunity to explore the newest baking technology, ingredients, packaging and trends—and it’s the best investment you can make to keep your competitive edge in the global marketplace.

“If we don’t make it, we don’t sell it,” says Bester of her house-made treats.

Rotary Club group that provides meals for children and teens, makes blankets and helps to raise funds for the Why Not Youth drop in centre. She helps youth at risk of homelessness in Brantford. The name is inspired by its slogan, “Some people see things and say, ‘ Why?’ We dream things that never were and say ‘Why not?’ ”

}She helps run the BRAugust campaign that provides bras and feminine hygiene products to young women.

the donated bras fit, and can cause discomfort and social awkwardness. That’s where Bester comes in and takes them to get fitted with a speciality bra. Bester describes the experience glowingly. “It was a treat to bring this young woman shopping and make her feel special…to have the women in the

Bester knows that business, like life itself, can be precarious. She is quick to expresses gratitude for the hand up she had when she was down, and shares some advice for bakers who are also launching a second career for another shot at a better life. Bester knows the first three years are the hardest to establish a business and build a clientele. “The first few years will always be your biggest challenge. I was very fortunate for great staff when I first opened. My head baker was a friend of my daughter’s who needed a coop placement for Niagara College. She helped me convert my recipes from home baking-sized batches to more commercial sized ones. Of course, you build a great staff, but then, they have other dreams they want to pursue, so you lose that great staff member and then you’ve got to find and train a new one.”

“You also have to stay current with food trends,” adds Bester. “Knowing you have that sellable product, brings them in the door once and makes clients become regular customers that can’t get enough of what you have to offer.”

“Bras are luxury items, to these girls. They need feminine protection every month. And if it comes down to food or hygiene, you don’t want to put them in a position where they’re vulnerable.”

This former home baker who turned professional feels that “it’s really important to give people in life a hand up.” She reached out to help Becca Vandekemp McLellan’s month-long August fundraiser aptly named, ‘BRAugust.’ For some girls, buying one of Sweet Bakery’s famous pecan squares is an affordable luxury. For underprivileged girls, dessert is not only unaffordable, but basic necessities like brassieres are unattainable. “Those are expensive items. Bras are luxury items, to these girls. These girls need feminine products every month. And if it comes down to food or hygiene, you don’t want to put them in a position where they might feel vulnerable.”

Bester helps raise funds for feminine hygiene products, gently used bras and cash donations for underprivileged young women. In some cases, none of

shop treat her with dignity. That’s really what these young women need to experience. They deserve that, they deserve the dignity.”

“These are young people that still have every chance to make something of themselves. I think it’s important for them to be surrounded by people that care about them, and I want to see them succeed in life, not just give them handouts and say, ‘goodbye’, but hopefully to mentor and inspire them to do great things regardless of their current circumstance.” Her charity work is not limited to working with homeless women. She works with another initiative called Socktober, which is a similar program, that collects socks, underwear, hats, mits etc., to keep our homeless warm through the colder months. They have collected and distributed thousands of items each year.

Clearly, her strategy works: Both the bakery and BRAugust will be celebrating their sixth year of operation. While Bester has been treating her community to good deeds, her bakery has been treating the public with house-made goodies. What is the bakery’s speciality? “We cannot open our doors if we do not have our pecan squares. They are synonymous with Sweet Bakery itself. They a very big square, probably 4” by 4” in size, they’re really thick, they’re homemade shortbread crust with homemade gooey caramel and tonnes and tonnes of pecans.”

Quality of life is key to Bester. She clearly puts a lot of love into her goods as she does into her town. “As a small business owner, I felt that my community has supported me...therefore I wanted to make sure that in return, I supported my community.” She laughs as she adds, “I am extremely blessed! I have love, laughter, happiness, and fulfillment in my life. How could I not want to share that with those around me? You never know who you might be an inspiration to, or what small deed you do can impact another.” / BJ

GRAIN OF TRUTH

Bakers Journal asked Elaine O’Doherty about the trends in flour and bread. Is bread still on the menu for Canadian bakeries and restaurants? What does the public want, and what should they know about the future of flour?

What are some of the factors that are changing the way the bread, baking and pastry (BBP) industry is buying flour?

We think the organic trend will continue to grow. We encourage bakeries to view organic as a great opportunity to tap into growing consumer demand, but this does not mean their operations have to be 100 per cent certified organic. Bakers and retailers can offer a 100 per cent certified organic bread, baked good or pizza, or offer options that position their product as “made with organic flour” or another organic ingredient, as a great start. Adding these options to the menu simply requires an organic ingredient or flour—no certification is necessary. While only a small percentage of consumers eat organic all the time, most do seek cleaner, organic labels when they are convenient and readily available. Clean-label preferences are especially appealing to millennial parents who want the best for their children but are budget-conscious. As such, consumers will appreciate having organic options.

More consumers are interested in healthier ranges of bread and organic flour.

}In the past five or so years, consumers have shown strong preferences for foods that are simple, fresh, free of additives, locally sourced, safe and trusted.

trying different grains and flours for taste, nutritional appeal and other benefits. You can also see this trend at work in slow fermented doughs.

What have you noticed as a recurring trend within the last five years?

A large segment of consumers define “good food” as using simple ingredients, preferably local, organic and/or prepared from scratch at home; we expect this “good food” trend to reverberate across the country, throughout 2019 and far beyond. We are also seeing “premiumization” and innovation in the bread aisle and at retail bakeries, with new bread offerings that have descriptions like “slow- fermented,” “artisan,” “hand-crafted” and more. Artisan bread is typically seen as healthier than white bread.

Do you feel that the market is aiming more for health, pleasure or convenience?

All three are important, but let’s talk about healthful eating. Manufacturers are supplying more choices to meet needs like higher protein, more fiber, gluten-free options, increased energy or satiety. At the same time, consumers continue to grow more adventurous. They’re seeking out ingredients they’ve never tried before, and they’re curious about terms like “nutraceuticals,” “activated ingredients” and “microbiome.” Microbiome, or gut health is essential, and more people understand that gut health is linked to mental health, skin health and obesity. The important role of fiber in a healthy microbiome and in gut health will continue to be studied. Reflecting this interest in healthful eating, consumers appear to be interested in

How has the interest in ancient grains or wheat alternatives changed in the past five years?

Consumer and bakers interest in ancient grains and heirloom wheats have certainly grown. Rye is popular, perhaps because of the wider fermented-foods trend. This heritage wheat comes with a great backstory connected to many Eastern European baking traditions. Red fife, another on-trend option, is the oldest-known wheat varietal grown in Canada. These ingredients and others allow bakers and food manufacturers not only to create a great product but also to tell a story that consumers connect to.

How do you think the increase in haute cuisine has changed the way people use or buy flour?

We do see ripples of interest starting in cutting-edge dining and spreading out to

www.host.fieramilano.it/en

consumer interest in bread, baked goods and flour. For example, the popularity of Danish and Swedish cuisines has sparked more interest in rye berries and barley, which in turn inspires more interest in using these flours. Rye flour is milled from whole rye berries and is closely related to wheat flour. It has its own distinct flavour and is slightly darker than more traditional wheat, depending on how much of the bran stays intact. The darkest rye, with the most bran left intact, is used in Boston brown bread and pumpernickel, while light rye is widely used in Swedish flatbreads. More bakers are experimenting with rye and breaking away from the familiar application of Jewish rye with caraway seeds.

Another influence we see from fine dining is consumer interest in global sandwich carriers, from bao buns to Indian flatbreads, unleavened roti to leavened naan. Mexican tortas and empanadas are also popular.

How does organic or clean-label affect the BBP industry?

We see great interest in clean-label and organic foods. Consumers want to see labels with ingredients that they are familiar with and may even have in their own kitchens. Consumers are buying breads with bold claims, especially “free from...,” which is part of the evolution of clean labeling. We also know that consumers would prefer organic over conventional products if the price gap were not so wide.

What does “authenticity” or “real ingredients” mean to consumers or bakers?

Consumers are looking for transparency from food manufacturers and most want to know the “who, what, when, where and why” behind their food. This will continue to influence consumer patterns. Ancient grains have great stories to tell, as does wheat flour grown locally and milled in Canada, whether organic or conventional. Ardent Mills has deep local relationships with farmers, some going back four generations. These stories, plus unique varietals, thoughtful harvesting and flavourful preparation techniques, lend richness, quality and a sense of craft to everyday staples.

In the past five years, consumers have shown strong preferences for foods that are simple, fresh, free of additives, locally sourced, safe and trusted. Handmade, hand-milled and handcrafted are all techniques that speak to simple, understandable food. Ingredients that show natural texture such as whole seeds and grains, have great appeal. Terms that evoke good farming practices, like “organic” and “sustainably farmed,” are also important, especially to Millennials.

How can bakers support diet restrictions or use less grain?

According to Angela Ichwan, combining ancient-grain flours and pulse flours, like chickpea flour, is a great way to maximize nutrition and address some dietary needs or preferences related to gluten. Grains are generally lacking a couple of essential amino acids, such as lysine and threonine. By adding pulses, which lack methionine – another amino acid – a product developer will create a product that has all nine essential amino acids. An added benefit is that ancient grains and chickpeas are gluten-free.

Any upcoming trends in baking mixes and frozen dough?

Trends are similar to what we’re seeing in baking generally: organic, clean-label, artificial ingredient-free and, whole grain. That, plus the convenience of using a mix or dough, means the hard work of formulating has been taken care of for the baker. /BJ

Great tasting cake mixes, Eh!

With a history dating back to 1856, when we started our operations in Kulmbach, Germany, we are still quite new to Canada. We are doing our best to fit in as well as possible, just as we do in the more than 90 countries we also have customers. One thing we have learned is that “EH” should be used as much as possible, eh? So, eh, we would love to invite you to bake some of our cake mixes. Try cookies together with some milk to create the, eh, all-time favourite of milk & cookies. Our cake mixes are available from all large wholesalers in the country, eh! Or call us for a free sample, details below, eh. German quality made for Canada, EH!

BUILDING YOUR BAKERY BRAND

Inspirational leaders have commandments they work and live by. Commandments, or guidelines, lay the critical foundation for the development of leadership and business solutions. 1. Be Truthful:

Any leader aspiring to greatness must do two things all the time: Listen and tell the truth. Inspirational leaders own up to their mistakes and correct them as soon as possible. Do not blame others for your for your error. When someone comes up with a brilliant idea, give credit where credit is due. Do not take credit for the idea. You will be respected by your team.

2. Be consistent:

Leaders are always performing like an actor on a stage. you must consistently and authenticaly act out your part in front of your audiences. You must lead with high energy, all day, every day. You must protect your personal brand.

3. Be empathetic:

To start using empathy more effectively, try to see things from the other person’s point of view. Validate the other’s perspective and examine your own attitude. You might be concerned with being right rather than finding a solution. Listen with your heart to learn the other’s feelings.

}4. Be generous: Every relationship needs to be a two-way street. However, before a relationship can be formed, you need to give with zero expectation of receiving anything in return.

5. Be strong:

If you are credible and honest, your personal brand will sell naturally. Your name can open and close doors for you. Guarding your personal brand needs to be a priority.

Inspirational leaders seek and inspire excellence, not perfectionism.

7. Be approachable:

Inspirational leaders bring a light to someone’s life. Become the message of hope and encouragement to your staff. Encouragement comes from focusing on the strength of another person to drive their motivation and perform better.

6. Be Articulate:

Effective leaders put words together based on the needs of others. Good leaders are able to articulate and clarify what many of us have been thinking.

Are you accessible? Do you have sociable body language? How you appear to others is key to being an inspirational leader. Some people have a fear of authority, but it’s your responsibility to remove barriers and establish a trusting environment.

8. Be a brand champion: Passion creates a very attractive personal style of interaction, and inspires your team to become involved. They become a brand champion.

9. Be a genuine spirit

Talk to people: Listen to what they have to say, and what theyactually mean. Sometimes those two can be completely different. There is a beautiful story in everyone, so listen with an open mind. 10. Be credible:

Reputation is about earning credibility, not expecting it. One way to earn credibility is to keep your promises, another is to be honest. If you are credible and honest, your personal brand will sell naturally. Your name can open and close doors for you. Guarding your personal brand needs to be a priority.:Make your brand work for you. / BJ

Michele Wierzgac is a leadership expert, keynote speaker, and author of the forthcoming book, Ass Kicking Women: How They Leverage Their Informal Networks For Success. https://micheleandco.com.

Michele Wierzgac states that most people agree that there is a direct correlation between a person’s reputation and his or her success.

BY JENNIFER POWERS, MCC

PLAYING THE BLAME GAME

How finding fault instead of solutions can hinder your

success

Have you ever found yourself making statements like these?

“I’m miserable at work because my boss is a jerk.”

“I’d work harder if they paid me more.”

“I’d get more work done if my co-workers weren’t always interrupting me.”

Surely you have. You’re human.

But the truth is, when you make statements like these you are blaming other people and circumstances for your reality being what it is. You are holding everyone and everything else responsible for your outcomes, feelings, actions, reactions, and choices. And when you do that you’re acting like… wait for it…a victim.

If that wasn’t ugly enough, when you choose to play the victim you’re giving your power away to the person or thing you hold responsible for your state of affairs. They don’t even ask for it. Your power is far too valuable to give away. If you’re freely giving away your power like that, you’ll find you have less to help you reach your professional goals. Oh, and with less power, your performance will suffer too.

So, here’s something: You are not a victim… unless you choose to be.

}That’s right. In every moment of every day you can choose to either play the victim or the victor. In other words, you get to choose to give your power away or hold onto it. Bam!

FEELINGS

Victims hold other people and things responsible for how they feel. They relish in the opportunity to blame their misery/ sadness/anger on others. This keeps them small and powerless. For example, Steve, blames his boss for his frustrations at work. He says if his boss weren’t so demanding, he would be happier at work.

For Steve to step into the victor role, he would have to take full responsibility and ownership for the way he feels. Sure, his boss may be demanding, and he can’t control that. But he can control how he chooses to feel about his boss and his job. Steve could empower himself by asking, “How do I deserve to feel?”

ACTIONS/REACTIONS

Victims make no connection between their actions, reactions and their reality. On the flip side, victors

In every moment of every day, you can choose to either play the victim or the victor. In other words, you get to choose to give your power away, or hold on to it.

understand how their actions/reactions play a part in their reality.

POWER OF CHOICE

Victims believe and act as if they have no choice. Steve plays the victim when he says he is “stuck with this job” that makes him so miserable. Steve forgets that he is a whole and resourceful being with the awesome superpower of choice. The difference is that victors recognize and exercise their power of choice. They know that they always have at least two choices. So for Steve to step out of the victim role, he could ask himself, “What choices do I have?” It’s not until Steve recognizes and exercises his power of choice that he can take his power back and have more control over his reality. So, all of this begs the question, who or what do you tend to blame for your reality, feelings, actions or reactions? What choices are you not recognizing or making?

By holding everyone and everything else responsible for your life, you are holding yourself back from reaching your full potential. You’re staying small.

Watch yourself bloom, grow, and thrive. Watch yourself be your best self. You deserve that. You are a victor and a very powerful one at that.

In order to choose the victor role and hold onto your power, you must be willing to take some responsibility for things. After all, some responsibility must be yours. It’s your reality we’re talking about here. Once you realize that you own a chunk of the responsibility in any situation, you can then own your power and begin to realize the control you have over the situation. So when you’re ready to be a winner, here are the three areas you’ll want to focus on:

Karen chooses to play the victim when she gets frustrated that her employees never come to her when there’s a problem. She says that she is always “in the dark.” This frustration keeps her from performing her best. To step into the victor role, Karen could try to identify the connection between her actions and her employees’ reluctance to come to her when there’s trouble. Karen could ask herself, “What might I have said or done to make my staff feel uncomfortable coming to me?”

Choose it. Own it. Be it. / BJ

Jennifer Powers, MCC is an international speaker, executive coach, author of the best-selling book “Oh, shift!,” and host of the fun and binge-worthy “Oh, shift!” podcast. Since founding her speaking practice, Jennifer has worked with hundreds of professionals and delivered powerful keynote addresses to over 250,000 people around the globe. For more information on bringing Jennifer Powers to your next event, please visit www.ohshift.com.

TASTE IS KING

Puratos Canada, the Canadian arm of global Belgium-based brand Puratos has released some key insights into the consumer trends and the future of bakeries, with the results of a three-year study.

The 2019 Taste Tomorrow study is the world’s largest independent bakery, patisserie and chocolate consumer survey. Rollo McIntyre shared some consumer insights with attendees.

The 2019 Taste Tomorrow study is the third of its kind, with events that took place in Asia, Europe, North and South America. The study is conducted once every three years on a global scale. The results provided in-depth insights into global and local consumer behaviour while identifying future trends into bakery, patisserie, pastry, and chocolate.

}Taste above all - clients prefer to have food that tastes decadent.

“Taste is king, but experience is queen,” added McIntyre.

For this year’s study, 17,000 consumers in 40 countries were surveyed. The survey also included interviewing 80 foodies in 8 trend-setting cities and conducting additional interviews with both customers and industry experts.

McIntyre revealed that while online convenience is gaining ground, a bricks and mortar building still the preferred choice. “Shoppers still want the presence of a store, they don’t want shops to disappear.”

Part of this preference for a physical space lies in the driving forces behind what compels buyers to select pastry or bread from a shop instead of an online service. The following data was gleaned about what makes a buyer want to go into, buy from and return to a particular bakery:

• 63 per cent of consumers reported that atmosphere is very important to their buying choice.

• 57 per cent of consumers said that presentation was important but smell was more important; 68 per cent said that the smell of a bakery or baked good influenced their decision to buy.

• 56 per cent of consumers stated that “service with a smile,” made them want to choose a personal choice over

the impersonal service of an online or un-manned purchase (such as an automatic cashier.)

The study offers a ‘Foodstep’ into the future by tracking the evolution of trends and unveiling new ones. The top nine trends within the North American region include:

• Taste above all: Clients prefer to have food that tastes decadent.

“Taste is king, but experience is queen,” added McIntyre.

• A healthier future: They are also aware of what they eat and feel what they eat defines them; However, Millennials do not trust big brands. This age group prefers to “discover” smaller venues, then boast of their find online. This presents an opportunity for smaller bakeries to cash in on online social media marketing.

• Freshness defines the consumer’s perception of quality.

• Ethical food choices shape our future - more consumers are looking for Fair Trade ingredients or are concerned about having local farmers get their fair share.

• Clear labels provide transparency: Consumers like to feel that they

gain more clients. have some control over their ingredients.

• Ultimate convenience: 69 per cent of North Americans buy or order their food online.

• Next level experience: 53 per cent of North Americans are willing to try 3D-printed food.

• Hyper-personalization: Food that are catered to specific tastes, dietary requirements or have a personal feature that they can connect to will sell more.

Canadians highly value the quality of ingredients and the authenticity of recipes and packaging - food with a real, human touch. Sixty-two per cent of Canadian consumers are willing to pay more for artisan, handcrafted products.

The report also states that 77 per cent of Canadians are drawn to traditional flavours while 55 per cent want to try exotic new global flavours.

Consumers seek greater transparency and increasingly consult packaging labels to have a more informed choice of consumption. Sixty-five per cent of Canadian consumers read ingredient lists and nutrition labels.

The perception of freshness is based on the manufacturing date for 72 per cent of Canadian consumers followed by the smell at 58 per cent. In short, Canadians still crave hand-crafted goods.

For more facts on consumer buying trends, contact Puratos Canada. / BJ

Bakery clients still prefer a physical location, but bakeries that use social media

¦ new products ¦

From fully automated flow wrappers to enzymes to stabilize your dough, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

Bosch launches fully automated flow wrapper

Bosch Packaging Technology launched its next generation of flow wrappers on the European and Asian markets: The Pack 403.

The Pack 403 is a fully automated horizontal flow wrapper for medium to high-speed wrapping. The narrow machine is ideal for wrapping bars and cookies, as well as chocolate, cookies and crackers.

It features a removable discharge belt, upgrades to the cross-seal and fin seal units, and a highly intuitive, user-centered design.

This machine is designed to produce up to 800 packages per minute at a film speed of 90 meter. Supported pack styles include pillow, gusseted and easy-to-open packs.

To make this device more user-friendly, clear signage, instructive decals were some of the newer features. The 403 also features scales on each component facilitate changeovers between products and minimize waste and downtime caused by “trialand-error” adjustments. The cantilevered discharge belt is one of the Pack 403’s key features: being removable, it is easy to clean. Its detection function rejects faulty packages and automatically ejects them using compressed air. For even more userfriendliness, the film tower has an easy-to-adjust pivot arm and sequentially numbered film rollers for easy film threading have been added.

It will be shown at the ProPak show in Thailand between June 12 to 15, 2019 and at the FachPack trade show in Nuremberg, Germany, September 24 to 26, 2019.

POWERBake 800 unifies dough quality

Dupont unveiled a new line of Danisco Enymes for the Bakery Industry.

DuPont’s POWERBake® 8000 fungal xylanases guarantee a more efficient and stable baking process, increasing the final product’s volume.

In addition to improving the final product characteristics, it also improves the consistency in flour quality.

One of the greatest challenges in the baking industry is the variation in the flour quality that can result from using wheat. The quality of the flour depends on factors inherent to each wheat grain harvest: place of origin, soil, humidity, temperature, and baking manufacturers cannot always control this variation.

Additional advantages of the includes:

• Improves the gluten quality by the removal of WU-AX (water-insoluble arabinoxylans)

• Adds stability to the dough system and overall production process, creating faster development of the gluten network.

The company has a long history of investing in research on enzymes, emulsifiers, and other ingredients and a strong knowledge of how these ingredients interact in food. Coupling that knowledge with customer insights and meeting local needs of the food industry makes DuPont a strategic partner for bakers.

New refrigeration leak detectors

AMF’s pan cleaning system awarded patent

AMF Bakery Systems announced that the United States Patent Office has awarded the company a patent for their Pan Cleaner System and method.

AMF’s Pan Cleaner is comprised of a supply system, an inverting system, and a cleaning system. These structures work together to create a synchronized continuous line that allows the pans to be received, transported, cleaned, and released in one cycle.

The Pan Cleaner System is groundbreaking in that it improves the process of automated bread pan cleaning by mitigating the production line from being stopped to ensure proper cleaning of baking equipment. In the past, pan cleaners were only able to focus on either cleaning speed or cleaning quality, but not both. The AMF pan cleaning method improves the cleaning process by limiting the risk of breakage, loss and improper pan flow.

“The pan cleaner uses gravity to its advantage releasing crumbs or bread loaves left in pans. The automatic product reject conveyor is particularly beneficial when a run of under proofed products occurs,” mentioned Bobby Martin, Executive Product Manager for AMF in a press release. “In this unlikely situation, the bread pan cleaner will remove the loaves from the pans in a continuous motion. Loaves are then conveyed to an outside recuperation bin to eliminate potential jams within the enclosed bins, as seen in other conventional pan cleaners when a surge of products occurs.”

This new pan cleaning system is filed under Patent #62/563,940.

Bacharach, a provider of HVAC-R gas instrumentation, announced the addition of 22 halogen refrigerants for its MGS-400 gas detectors in commercial and industrial gas leak monitoring applications.

The MGS-400 series product family uses three different sensor types, depending on the measurement range, temperature and gas types when detecting for hazardous refrigerant leaks. The variety of sensor types within the product line offer significant user benefits, including flexibility with refrigerant leak detection and providing peace of mind when helping to protect personnel and achieve compliance with safety standards like ASHRAE 15, CSA-B52 and EN 378 inside of machinery rooms, mechanical equipment rooms, chiller plants, cold storage facilities and walk-in freezers.

Other user benefits include a mobile app interface for easy commissioning and maintenance without special tools and an added sensor life of 5 – 7 years with plug and play pre-calibrated sensor modules for quick, simple sensor replacement. Generating calibration certificates from the mobile app makes calibration documentation easy to create and send by email or store in the cloud. A Modbus RTU interface and analog and relay outputs enable easy safety alarming and automation control.

concepts for success ¦

BY DIANE CHIASSON

6 EASY WAYS TO CUT COSTS

Diane Chiasson shares easy ways to save money without compromising quality

Apenny saved is a penny earned. There are many ways to lose money in your bakery business. It could be in the kitchen, storage areas or in the office. There are also dozens of small changes that can save your bakery money every year such as taking proper inventory, re-evaluating your food orders, and using your bakery products creatively. These small changes will definitely make a major impact on your profit margin. Here are six ways to cut costs at your bakery.

1.

KEEP YOUR EMPLOYEES INFORMED

}It’s very important that you share all the facts with your staff first, including the cost of your food, what your new cost-effective changes are, and how much money they will save your bakery business. Your staff should understand everything about reducing waste, being aware of potential problems, improving efficiency and understanding overall profitability. It’s also important to acknowledge and reward your employees for helping you to meet your goals.

2. START IN THE KITCHEN

3. SET A MONTHLY REALISTIC BUDGET

As they say, you can’t improve what you can’t measure. Your monthly earnings will depend on how effectively your bakery is run. Preparing a budget will serve as a road map to continue building a successful bakery business. You should know where every dollar of your budget goes. You must map out a realistic budget and approximate about how much money your bakery business needs on a monthly basis to stay afloat.

4. CHECK YOUR INVENTORY LEVELS ON A REGULAR BASIS

Over ordering food is another common habit for many bakeries and very often they have more food on their shelves than what they really need. These bad habits will leave to food spoilage and food waste, and will prevent you from cutting your bakery costs. Controlling

Cutting bakery costs starts in the kitchen. Food waste is often the leading cost in bakeries, as bakers tend to over-prepare.

Excel spreadsheet to help you prepare an accurate costing for all your menu items and recipes. Using your spreadsheet inventory will help you calculate the cost of every menu item and every recipe for comparison with the selling price of each menu item. You should also use your POS system to track the sale of each menu item in order to identify the worst sellers. This will give you an immediate opportunity to replace them with some more popular items.

6.

USE RECIPE CARDS AT EACH STATION

Cutting bakery costs starts in the kitchen. Food waste is often the leading cost in bakeries, as bakers tend to over-prepare. You should always buy only what you need. If you consistently prepare too much then your waste and food costs will rise. You should prepare a daily prep checklist sheet, which will help you and your staff learn how much prep you should do every day. This prep sheet will help your kitchen staff to properly plan and control food production.

the portions of each bakery item is also an excellent way to reduce waste. Checking your inventory on a regular basis will give you a good idea of how and at what rate your food is being used or wasted. Try to evaluate and optimize your inventory levels product by product, and be creative by using the same ingredients throughout your bakery menu. Turn stale bread into house-made croutons, breadcrumbs, and bread pudding. A lot of food is thrown away past its expiration date. Train your staff using the FIFO method (First In, First Out). You should definitely label your food with its expiration date so that the oldest ingredients are in front to be used first. You should also start taking inventory on a daily basis, as this will reduce the chance of employee theft and food waste.

5. COST OUT EVERY MENU ITEM AND RECIPE

You should set up a menu and recipe master inventory cost template on an

As you know, baking is more like a science since it has a lot to do with chemistry. Ratios are very important to achieving the desired result. It’s also very important to measure the ingredients properly, and as such, I highly recommend getting a professional digital kitchen scale. The right amount of flour, liquid, and fat will make or break a pie crust, a cake, or other baked product. A great method for ensuring consistency is to follow a recipe accurately when baking, and you should definitely have recipe cards at each station. Each recipe card should contain a list of the ingredients and portions for each menu item. The most important thing in any foodservice business is consistency, and the only way to get consistency all year round is through well-written and accurate recipes with detailed methods and good photos.

© 2019 Chiasson Consultants Inc. All rights reserved. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 30 years. She is recognized as the industry leader in providing innovative and revenue-increasing foodservice and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or chiasson@chiassonconsultlants.com, or visit www.chiassonconsultants.com

A NEW LOOK AT QUICHE

How do bakers and pastry chefs keep tradition alive, while accommodating health and wellness, intolerances and a wide variety of preferences?

I decide to call Patisserie Duc de Lorraine in Montreal, Quebec, arguably the quiche eating capital of Canada. At the helm is pastry chef Bruno Cloutier, Montreal-born and Paris-trained.

Most would agree that a crust made from shortening just doesn’t have the same flavour as an all-butter crust. Yet, many feel an all butter crust is too hard to work with and add 50 per cent shortening.

To make his quiche dough Cloutier starts with good quality, cold butter and a mix of all-purpose flour and pastry flour. As a general rule the lower the protein, the more tender the crust. So, mixing high protein Canadian all-purpose flour with pastry flour makes it easier to handle, while keeping it tender.

}Once combined, ice water and salt are added and mixed into a firm dough. It is then refrigerated, for two hours to relax the gluten. Dough that hasn’t been chilled long enough will shrink back in the pan.

Bakeries, especially smaller ones, seem to be less aware of the health implications of trans fats.

To make his quiche dough Cloutier starts with good quality, cold butter and a mix of all-purpose flour and pastry flour. As a general rule the lower the protein, the more tender the crust.

freshly grated nutmeg. Finally, it is baked in a gas oven at 365 F for 1 hour.

The dough is rolled on a laminator, until it is two millimeters thick. Then it is cut and placed in a one-piece tart mould measuring 10 inches round and two inches high. Cloutier insists this is the perfect pan for the job. “You want your quiche to be thick. At least that’s how I like them,” the jovial Cloutier tells me.

As a stylized choice Cloutier leaves part of the dough straight edged following the rim of the pan. with small areas of the dough randomly fluted.

For the filling Cloutier combines six to nine eggs depending on the type of quiche being made to one litre of liquid. He alters tradition by replacing 30 per cent of the 35 per cent of cream with homogenized milk. Cloutier then adds salt and pepper and

Once in the oven the butter in the crust gives off steam, which in turn separates the layers resulting in the perfect flakey texture. Their most popular quiche is its name sake, Quiche Lorraine, made with ham and onion cooked in butter. These fillings are removed from the pan and mixed into grated Swiss cheese.“It is important to mix it well before adding it to the quiche. You want to taste everything in every bite.”

Other quiches include market fresh Vegetable Quiche, Spinach Quiche and Salmon Quiche. For the latter, Cloutier cooks fresh salmon in butter, but also adds smoked salmon to heighten the flavour.

Over at the Silly Yak Bakery in Kingston, Ontario, baker Sarah Rose and her business partner Keven Pearson ensure

customers can enjoy wheat-free quiche. “It’s a big gluten-free town,” Rose tells me. Rose uses her own blend of flour. Rice flour is the predominant grain, with the addition of tapioca flour and cornstarch. Eggs are added to the flour mix. Then, non-dairy margarine, which is added both in solid form and liquid, combined with a bit of water. After relaxing the dough and refrigeration, it is hand-rolled out into a traditional pie plate. “Customers tell us the crust is nice and flakey. Guests don’t even notice it is gluten-free,” says Rose.

As for non-dairy margarine Rose adds, “Often people who have celiac disease are lactose-intolerant as well. Coconut milk is used in place of dairy. For every litre 15 eggs are used. “Coconut milk is much thinner, so many eggs are needed to thicken it,” she explains.

A classic quiche or its contemporary cousin allow for endless options. Explore. Evaluate. But, most of all, enjoy! / BJ

Karen Barr writes about arts, culture and cuisine. She is a graduate of George Brown College and is a Red Seal pastry chef.

For most companies, employee salaries are their largest expense. The costs associated with finding, training and retaining employees is high. Investing in new employees is often seen as a gamble, as the new employee might not be a good fit. When employees quit, energy invested in training goes to waste. In addition, investing in training existing employees is often overlooked due to cash flow constraints. For most companies, discovering there is easy access to Government funding to offset the costs of training is a welcomed relief.

FUNDING FOR BAKERIES?

There are a number of Government employee funding programs available to bakeries, including:

- Apprentice Salary Refunds: Up to $12k per apprentice per year

- Hiring Grants: Up to $10k per new hire

- Training Grants: Up to $10k per hire

A company may use all of these funding programs as long as they meet the funding criteria. There is no upper limit to how much a company may receive and they may be used yearly.

APPRENTICE SALARY REFUNDS

Apprentice Salary Refunds have been available since 2004 and are incentives

given to businesses to hire and train apprentices. Since it takes years of training for an apprentice to become a master in their trade most companies are reluctant to hire apprentices and invest valuable time and money in training them. By making the apprenticeship salary refunds available to employers the Government is setting the stage to encourage more employers to take on apprentices.

HOW MUCH FUNDING IS AVAILABLE?

Employee incentives for training apprentices are very generous. Ontario offers the largest amount of funding with up to $1ok per apprentice per year,

EMPLOYEE FUNDING GRANTS Get the ultimate in Foodservice Equipment

In order to qualify for funding, your bakery needs to apply for funding at least one to six weeks before the employees receive training.

retroactive three years. This applies to the first four years of the employee’s apprenticeship, whether or not the apprentice is still with the company. It does not matter how short a period of time the apprentice was with the company. It could be a week or four years.

HOW DO MY APPRENTICES QUALIFY FOR FUNDING?

For apprentices to qualify for funding they must be: On staff, receive a regular paycheque and be registered as an apprentice in a qualifying trade in the province where your company operates.

The funding available for bakers and chefs yields up to $2k per year for two years. You will not qualify for funding if your staff are not registered. If you are hiring an employee who is already a registered apprentice you need to call your Government Apprentice Training Representative and make sure that the new employee receives a transfer of apprenticeship to your company. Your company will miss out on funding without it.

Two of the biggest reasons companies do not receive apprentice salary refunds are because they have not

additional payroll tax revenue for the new employee for as long as the employee is with the business. For the Government, the return far exceeds the cost of the hiring grant.

HOW CAN NEW EMPLOYEES QUALIFY FOR FUNDING?

registered their apprentices with the Government or they did not receive transfers of apprenticeships for new employees who were registered apprentices elsewhere.

The Apprenticeship Salary Refund program applies to foreign owned companies, and even divisions of companies that are now closed. As long as the company is not dissolved it is able to apply retroactively for the last four years for funding.

HIRING GRANTS

Hiring grants are a redirection of Employment Insurance. Why does the government provide hiring grants to businesses? The Government makes hiring grants available to businesses, as they would prefer to compensate a business to train new employees than have unemployed people collecting Employment Insurance. Working for a business allows a new employee to gains new skills and knowledge that will allow them to be employed for years to come.

Hiring grants have longevity because they benefit all parties involved. The new employee receives a job, the business is subsidized while the new employee gets training and the Government receives

Hiring Grants are available for any new employee you plan to hire that is not an apprentice. This applies to all potential new hires including staff for administrative, customer service, general labour, production and sales. To qualify for funding, potential employees must be unemployed. Also, the new employee cannot leave a current job to take a position with your company. Funding is available to a variety of hiring candidates including recent graduates (high school, college and university), new

immigrants to Canada, self employed people taking on a paid position with a company, women re-entering the workforce after raising a family, and anyone else that is currently unemployed that requires on-the-job training. The position must be a paid hourly or salary position. Commission jobs do not qualify. Also, the job must be a full-time position with a minimum of 20 hours per week. Temporary and part-time positions do not qualify for funding. The goal of the hiring grant program is to create long-term employment.

Businesses may apply for hiring grant funding as often as required, with no upper funding limit. Businesses may also apply for funding every year. As long as the new employee being hired qualifies, the business is entitled to receive a hiring grant.

HOW DO I GET FUNDING?

Hiring grant funding works very differently than apprenticeship salary refunds. In order to qualify for funding, your company needs to apply for funding before the new hire starts their first day of work. Once you know you would like to hire a new employee, submit a hiring grant application to the government. The government will get back to your company within two days, and if the new employee qualifies for funding, a meeting will be set up to meet the new employee to

determine the grant funding amount for your company to train the new employee and prepare the Hiring Grant Agreement. It can take up to seven business days to get a Hiring Grant Agreement in place.

HOW MUCH FUNDING IS THERE?

Hiring Grants vary depending on the province and are up to 50 per cent of an employee’s wage to a maximum of $10k for a period of six months. Once an employee qualifies for funding, the company will receive funding for the

period of time the new employee worked even if the employee is fired or quits. The Government understand the employment relationship don’t always work out, and since it was the company’s intention to hire the employee on a full-time permanent basis, they cannot be held responsible if the employment relationship does not work out.

TRAINING GRANTS

Training Grants are available to existing employees to increase their skill set. Training must be through a Canadian third party including colleges, universities and specialized training providers. This includes sales training, customer service training and quality system training (HACCP,BRC and SQF). The Canada Job Grant Program was introduced in 2014 with funding committed to 2020. Routine training such as WHMIS, Health and Safety, Forklift recertification and Fall Arrest do not qualify for funding.

Funding is up to $10,000 per employee. If your company has under 100 employees you will receive a reimbursement of 80 per cent of the Training costs. If your company has over 100 employees, the reimbursement rate will be 50 per cent.

HOW DOES FUNDING WORK?

Training Grant Funding works similar to Hiring Grant funding. In order to qualify, your company needs to apply for funding at least one to six weeks before the employees receive training. The application is completed and submitted online. It will take up to seven business days to hear back from a Government clerk who will review your application and let you know if the application is approved. Once approved, the employees are now able to take the training. The Government will send out the refund cheque four to six weeks after receiving the invoice. / BJ

Bonny Koabel CPA, CGA is the President of AKR Consulting Canada, a firm specializing in Government Grants, Subsidies, Tax Credits, Refunds and Rebates since 2003. Bonny has specialized in assisting businesses with obtaining Government funding for the past 15 years. Her expertise is working with companies and developing strategies to utilize Government funding. Bonny can be reached at bonny@akrconsulting.com or 905-678-6368.

ADM MILLING CO.

7585 Danbro Crescent, Mississauga, ON L5N 6P9

Contact: Debbie Bell

Phn: 905-819-7000

Fax: 905-819-9768

e-mail: debbie.bell@adm.com

Plants: 2 Montreal, QC; Mississauga, Midland, Port Colborne, ON; Winnipeg, MB; Calgary, AB.

Sales offices: Montreal QC, 514-846-8533; Toronto, ON 1-800-267-8492; Calgary AB, 403-267-5656; Vancouver, B.C. 604-2990710.

Products offered: A full flour and mix product line for the bakery, donut, muffin, food service, biscuit, pasta, frozen, in-store bakery, pasta and industrial segments. Other products offered are stoneground whole wheat, cracked wheat, graham and cereal bran and rye flours.

ARDENT MILLS ULC

Ardent Mills is working for the good of grain and committed to pioneering what’s next, with value-added, nutrient-rich, on trend grain solutions that deliver superior performance and consumer appeal. But that’s just the beginning, because we are also the company behind some of the most trusted and iconic brands in the commercial bakery and food service industry today. Our premium white, whole wheat and whole grain flour, oats and bakery mixes are backed by over a century of milling heritage and excellence.

6860 Century Ave. Suite 301 Mississauga, ON L5N 2W5

Contact: Elaine O’Doherty Phn: 905-494-2600

Email: Elaine.ODoherty@Ardentmills.com

Website: www.Ardentmills.ca

Plants: Flour Mills in Mississauga, ON, Montreal, QC, and Saskatoon, SK. Bakery Mix plants in Burlington, ON and Saskatoon, SK. Oat and Durum plants in Saskatoon, SK. Products Offered: A full line of highquality flour with legacy brands that include Baker’s Hand™ All Purpose, Keynote® Strong Bakers, Tulip®, Velvet® and Peach Pastry® Cake & Pastry and All-O-Wheat™ Whole Wheat. As an industry leader in innovation we also offer Simply Milled by Ardent Mills™ Certified Organic Flour, Ultragrain® White Wheat Whole Grain Flour and Primo Mulino® Neapolitan-Style Pizza Flour. This is complimented by Oats, Durum, Specialty Grains and a broad range of bakery mixes, bases & concentrates, many formulated specifically to customers’ needs.

Delivery: Across Canada by rail or truck and throughout North America.

Distribution: Direct from plants, regional warehouses, or distributors, depending on product availability and location.

Major Customers: Bakery and Food Processors, Retail & Wholesale Bakeries, Grocery Retailers & In Store Bakeries, Food Service Operators, Bakery and Food Service Distributors.

FARINART INC.

1150 Rang Saint-Edouard, Saint-Liboire, QC, J0H 1R0

Contact : Rory Lesperance

Phn: 416-770-2310

e-mail: rlesperance@farinart.com

Website: www.farinart.com

Products offered: Ecocert, Kosher, Halal, HACCP and SQF 2000 certified. Farinart is a leader in processessing custom grain, flour, seed and pulses blends - both conventional and organic. Farinart also provides select line of gluten free blends, flours and processed grains. We have earned a strong reputation for delivering innovative solutions, superior expertise, product consistency and best-inclass service to retail and commercial bakers and food manufacturers.

Distribution: We deliver across Canada and overseas.

Delivery: 20 kg bags, tote bags and bulk products.

Company comments: We are a friendly and versatile company that can adapt to our clients’ requirements.

GRAIN MILLERS CANADA CORP.

No. 1 Grain Millers Drive Yorkton, SK S3N 3Z4

Sales Contact: Andrew Eilertson

Phn: 1-800-232-6287

Fax: 952-829-8819

Email: andrew.eilertson@grainmillers.com

Website: www.grainmillers.com

Plants: Yorkton, SK and U.S.

Distribution: Throughout Canada and U.S.

Products Offered: Full line of conventional, organic, & certified gluten-free oats including quick & rolled flakes, flour, bran, steel cut, food-grade fiber, and other innovative products. Complete product line includes other milled grains and custom blends of wheat, corn (yellow, white, non-GMO), barley, rye, triticale, and other specialty grains.

Certifications: Organic, Gluten-Free, Kosher, GFSI

Pack Type: Bags, totes, bulk, retail pack (500g-2.25kg)

Company Comments: Privately owned, Grain Millers delivers whole-grain solutions to the modern world of food manufacturing. Customers rely on our quality, service, and innovation to meet today’s high expectations and tomorrow’s challenges. Learn more what about we can do at www.grainmillers.com.

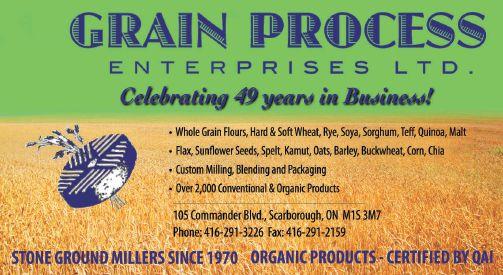

GRAIN PROCESS ENTERPRISES LTD.

105 Commander Blvd.,

Scarborough, ON M1S 3M7

Contact: George Birinyi Jr., Carl Griesser

Phone: 416-291-3226

Fax: 416-291-2159

e-mail: gbjr@grainprocess.com

Products offered: Over 2,000 products including a full range of whole grains. Hard/ Soft Wheat, Triticale, Corn, Millet, Barley, Rye and Durum and organic products certified by QAI (Whole Wheat Flour, White Flour, “Ancient Grains” Spelt, Kamut, Quinoa, Seeds, etc.) Precooked and stabilized grains and flours, Whole Bean Flour, complete range of grains including Cracks, Flakes and Grits, Seeds (Sunflower, Sesame, Golden Yellow and Brown Flax), Beans, Peas, Lentils, Sugars, Nuts and Dried Fruit. Food processing also includes custom blending facilities for multi-grain formulas (Bread, Muffin and Pancake Mixes, etc.) packaging, granola cereals, toasted grains, Turbinado and Demerara Sugars.

Distribution: Across Canada and the United States.

Major customers: Bakeries, biscuit and cookie manufacturers, food service, bulk, health and natural food retailers and distributors and manufacturers.

Company comments: We pride ourselves as being the only stone flour mill in Canada to offer such a wide variety of products. Our product development team is ready to develop mixes and specialty grains for any application in the food industry.

HOWSON & HOWSON LTD.

232 Westmorland St., PO Box 390, Blyth, ON, N0M 1H0

Contact: Jeff Howson

Phn: 519-523-4241, Ext. 60

Fax: 519-523-4920

e-mail: jeff@howsonandhowson.ca

Contact: Dan Greyerrbiehl

Phn: 905-792-2962

Fax: 519-523-4920

e-mail: dgreyerbiehl@rogers.com

Plants: Blyth, ON

Products offered: Durum semolina, durum flours, durum whole wheat semolina, Atta flours.

Delivery: Bulk truckloads, bulk bags (750kg), 20kg bags, 40kg bags, 50lb bags and 100lb bags to Ontario, Quebec and United States.

Distribution: From Blyth, ON, Plant by truck or distributors.

Major customers: Manufacturers of dry pasta, fresh pasta, frozen pasta, and snack crackers. Assistance offered: Technical assistance.

Company comments: Howson & Howson Ltd. have been quality wheat millers for over 135 years. We are continuously modernizing our durum mill in order to supply our customers with high-quality durum semolina, durum flour and other durum products.

JAMESTOWN MILLS INC

(OFFICE)

49888 Nova Scotia Line

RR2 Aylmer, ON, N5H 2R2

e-mail: info@jamestownmills.com

Phone: 519 933 2648

Website: www.jamestownmills.com

Products Offered: stone ground, non gmo gluten free flours

teff, pulses, quinoa, amaranth and millet

Supplier of sorghum, corn and rice flours, as well as starches and gums

Supplying the gluten free industry

MARQUIS MILLING AND GRAIN LTD. &

NUNWEILER’S FLOUR CO.

P.O. Box 310

Rosthern, SK S0K 3R0

Contact: Russ Schroeder – President

Phn: 1-888-726-2253

e-mail: info@nunweilersflour.com

Website: www.nunweilersflour.com

Plant: Alsask, Sask.

Certifications: Our products are Certified organic by Pro-Cert Organic Systems and Certified Kosher by Kosher Check. We are members of the Baking Association of Canada.

Company info: Marquis Milling and grain was incorporated March 2016 to facilitate the purchase of Nunweiler’s Flour Co. Nunweiler’s Flour was established in 1988. Our production facility is located in Alsask Saskatchewan. Construction of our new facility in Hague Saskatchewan will begin March 2018. We will be adding a dedicated gluten free mill as well as updating and adding some milling equipment. We will then be able to offer a light or almost white versions of our flours.

Our whole grain flours are milled at low temperatures (typically less than 25C) from high quality certified organic Canadian grown grains. No additives or preservatives, No GMO’s. Superior quality for optimal nutrition. Products offered: We currently mill 8 varieties of certified organic whole grain flour: Hard Wheat, Soft Wheat, Rye, Spelt, Buckwheat, Kamut, Barley, and Red Fife Wheat. We package the flours and grains in to 1,2,10,20 and 1000 KG bags. We offer private label, custom milling, blending and packaging services.

Major customers: Retail and wholesale bakeries, specialty product bakeries, retail mass market and natural food stores.

NUTRASUN FOODS LTD.

6201 E Primrose Green Drive

Regina, Saskatchewan S4V 3L7

Phone: 306-751-2040

Contact: Kerry Keating, General Manager Phn: 306-519-7931

Website: www.nutrasunfoods.com

Certification: NutraSun Foods Ltd. is certified Organic by Quality Assurance International (QAI), Kosher Certification, HACCP, FSSC

22000:2011, ISO 22000:2005, HACCP and Non-GMO Project Verified.

Delivery: We deliver bakery ingredients across Canada and the United States as well as shipments offshore.

Products offered: NutraSun’s high quality Organic and Conventional flour is milled from Hard Red Spring and Hard White Wheat. We are the exclusive miller of premium Snowbird White Wheat flour and also offer a variety of Whole Grain flours. In addition to flour, we are continuously expanding our product line of organic and conventional bakery mixes and bases to include breads, muffins, cookies, pancakes and whole grain pizza crust mix or base. We also offer customized grain blends and organic and clean label dough conditioners. NutraSun offers a variety of packaging options for the industrial, bakery and retail markets including 20 kg, 25 lbs and 50 lbs bags, one-tonne totes, bulk truck loads and trans-loading. Our retail packaging line uses re-sealable pouch packs for weights ranging from 600 grams to 2.5 kg.

Major customers: NutraSun serves industrial and retail bakeries as well as retailers selling consumer packed re-sealable pouches.

Company comments: NutraSun Foods is a division of Paterson GlobalFoods, a wholly owned Canadian company which has been serving the Canadian agricultural and food industry for over one hundred years. NutraSun is a fully modernized mill located in southern Saskatchewan, the heart of Canada’s Hard Red and White Wheat growing region. NutraSun Foods contracts directly with producers across western Canada in sourcing the highest quality grain to ensure consistency and quality for our flour and mixes.

P & H MILLING GROUP

Corporate Office, 1060 Fountain St. N

Cambridge, ON N3W 0A1

Phn: 519-650-6422

Fax: 519-650-6429

e-mail: sales@phmillinh.com

Website: www.phmilling.com

Description: Canadian owned, the P & H Miling Group is Canada’s second largest flour producer. Built on the strengthof nine mills, P & H Milling Group is stratgically located in: Acton, ON, Cambridge, ON Halifax, NS Hamilton, ON Hanover, ON Lethbridge, AB Montreal, QC Saskatoon, SK

For more information about our flour mills and products, please contact Customer Service 1-800-621-0588 or sales@phmilling.com.

PARRHEIM FOODS

(P&H Milling Group)

817 48th St. East

Saskatoon, SK S7K 0X5

Contact: Glenn O’Hara

Phn: 306-931-1655 ext. 3223

Fax: 306-931-2664

e-mail: gohara@phmilling.com

Website: www.phmilling.com

Products offered: Parrheim Foods produces pulse concentrates (starch, protein and fibre) and flours from locally grown peas, beans and lentils. From our BRC Certified plant, we produce high quality products that are natural and functional as well as free from any additives.

Delivery: From our office in Saskatoon, we ship all across North America or anywhere in the world.

Distribution: Direct from our Plant in Saskatoon

Company comments: Being in this industry since 1989 has enabled us to perfect our separation process which means that we can create the right product to meet your needs whether it be conventional or Organic.

ROGERS FOODS LTD.

Rogers Foods has been proudly milling quality flour and cereal products from Canadian grain for over 60 years. With 3 mills in both Armstrong and Chilliwack, British Columbia, we produce wholesome cereals and highest quality flour and grain products for home and commercial bakers alike.

Plant and Head Office

4420 Larkin Cross Road

Armstrong, BC V0E 1B6

Toll free: 1-800-356-8735

Fax: 250-546-8228

e-mail: store@rogersfoods.com

Website: www.rogersfoods.com

PORT ROYAL MILLS

240 Industrial Parkway S. Aurora, ON L4G 3V6

Contact: Kresho Petrovich

Phn: 905-713-1712

Fax: 905-713-0074

e-mail: orderdesk@portroyalmills.com

Website: www.portroyalmills.com

Plant: Aurora, ON

Certifications: SQF, Certified Organic by Pro-Cert, Kosher Kashruth

Products offered: Custom blended whole grain cereals, stone ground flours, cracked,

flaked, pearled and whole grains including: rye, spelt, barley, quinoa etc. Importers and distributors of other fine bakery ingredients.

Delivery: Direct throughout most of Ontario

Major customers: Bakeries, cookie manufacturers, frozen dough plants, bakery mix manufacturers and food processors.

Company comments: At our milling facility in Aurora, Ont., we meet the continuing demand for whole grain milling and custom blending. We at Port Royal continue to provide the highest quality products and personalized service to our customers with industry leading food safety standards.

RICHARDSON MILLING LIMITED

2800 One Lombard Place

Winnipeg, MB R3B 0X8

Contact: Richard de Kievit

Phone: 1-800-663-6287(OATS)

Website: www.richardson.ca

Company Comments: Richardson Milling offers a broad range of oat ingredients including oat groats, flakes, flour and bran. Our value added flaked and expanded whole grain based ingredients are designed to be an integral component in your products. We utilize the very best ingredients to create innovative coated whole grains and granola clusters that meet the unique requirements of our customers. They are specially formulated to enhance appearance, taste, texture and functional needs. Our extensive grower network and four manufacturing facilities provide the most extensive oat supply chain in North America. Richardson Milling is a division of Richardson International, Canada’s largest agribusiness. Recognized as a global leader in agriculture and food processing, Richardson is headquartered in Winnipeg and has more than 2,500 employees with facilities across Canada and the U.S.

¦ classified Ads ¦

Phone 705-826-2254 | 1-888-599-2228, ext. 268

Fax 1-866-810-8111 (secure line)

BY JANE DUMMER, RD

THE FUTURE GLUTEN-FREE FLOURS

The next generation of wheat-free flour are no longer rice or nut-based: Get creative with sorghum or plaintains.

As consumer interest in gluten-free products has grown, the category has transitioned from a niche to a mainstream market segment. This has resulted in access to better quality ingredients including a broad range of gluten-free flours. I’m observing the next generation of gluten-free flours to be in two categories: 1) nutrient-dense ancient grains or pseudocereals like sorghum and buckwheat, and 2) grain-free flours including fruit and vegetables like plantain and cauliflower.

}”Customers are thrilled to find a glutenfree pizza crust that actually tastes like its gluten-filled counterparts. The golden, crisp crust wins over our target market.”