voice of the canadian baking industry

voice of the canadian baking industry

BY NAOMI SZEBEN

In the words of Laura Aiken, former Bakers Journal editor: “The first and last editorials are so hard to write. It’s hard to say goodbye, but it’s also hard to say hello.” Having Laura’s kind support and mentorship means so much to me, particularly as this is my first issue. I’m proud to say “hello” to our talented columnists, my gifted co-workers at Annex Business Media and the creative bakers and pastry chefs that I will get to know over time. I look forward to breaking bread with you all – literally and proverbially.

Bread is by nature a communal food. It’s eaten at the start of a meal and can symbolize a new venture or even the start of a new season in some cultures. The term “breaking bread” is shared by many and intended to break down barriers. Symbolically, breaking bread means sharing an experience, taking part in a social gathering. I’m proud to start my new venture as editor of Bakers Journal and hope to serve a readership that will enjoy the contents of this publication.

Wheat sheaves are the original “staff of life.” Wheat was traded in kind and in coin throughout antiquity: One of the earliest forms of currency found in an archeological dig featured an ear of wheat stamped on a coin, representing what humans valued most for survival: Food. Flour is both the simplest and most complex of wheat’s possibilities. Sourdough bread starts with only three ingredients: Water, flour and air. From these simple basics, wonderfully complex flavours emerge. Bread is often seen as a metaphor for life; So much can happen with so few ingredients.

Sourdough’s mystique comes from air, in the millions of airborne particles that help ferment the wild yeast in its culture. Bakers Journal was honoured to speak with Karl de Smedt, the sourdough librarian who keeps and catalogues an international store of sourdough cultures in an attempt to understand the complexities of this modest food.

Small wonder bread is often seen as a metaphor for life. So much can happen with so few ingredients.

Flour is deceptively simple. As Karen Barr’s article, “Flour Power” demonstrates, regional differences in flour can result in a different texture to pastry. The gluten content in each country’s flour can help identify and make a locality’s piecrust unique. It’s not summer without biting into a crisp, flaky crust enveloping fresh berries. Barr discusses the delicate balance between filling and crust and what makes pies a popular international summer dessert.

We can all become loyal – even too loyal – to the tastes that we identify in our local “chomping grounds.” Nostalgia plays a big part in taste, and sometimes, getting clients to try something new may present a challenge to the creative baker. How do you get customers out of a rut they didn’t know they were in?

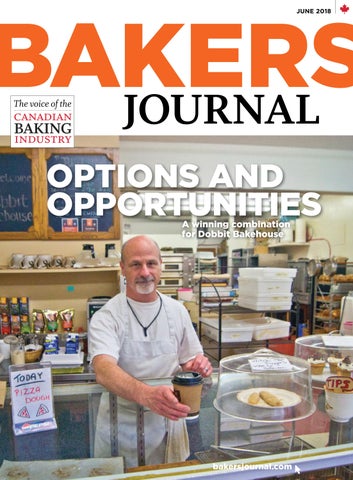

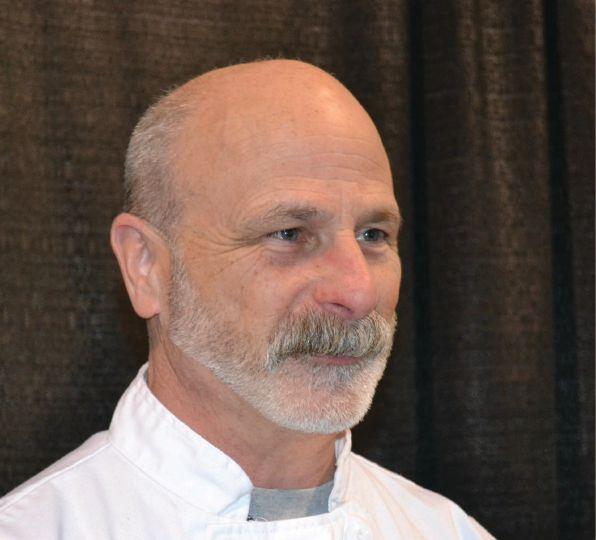

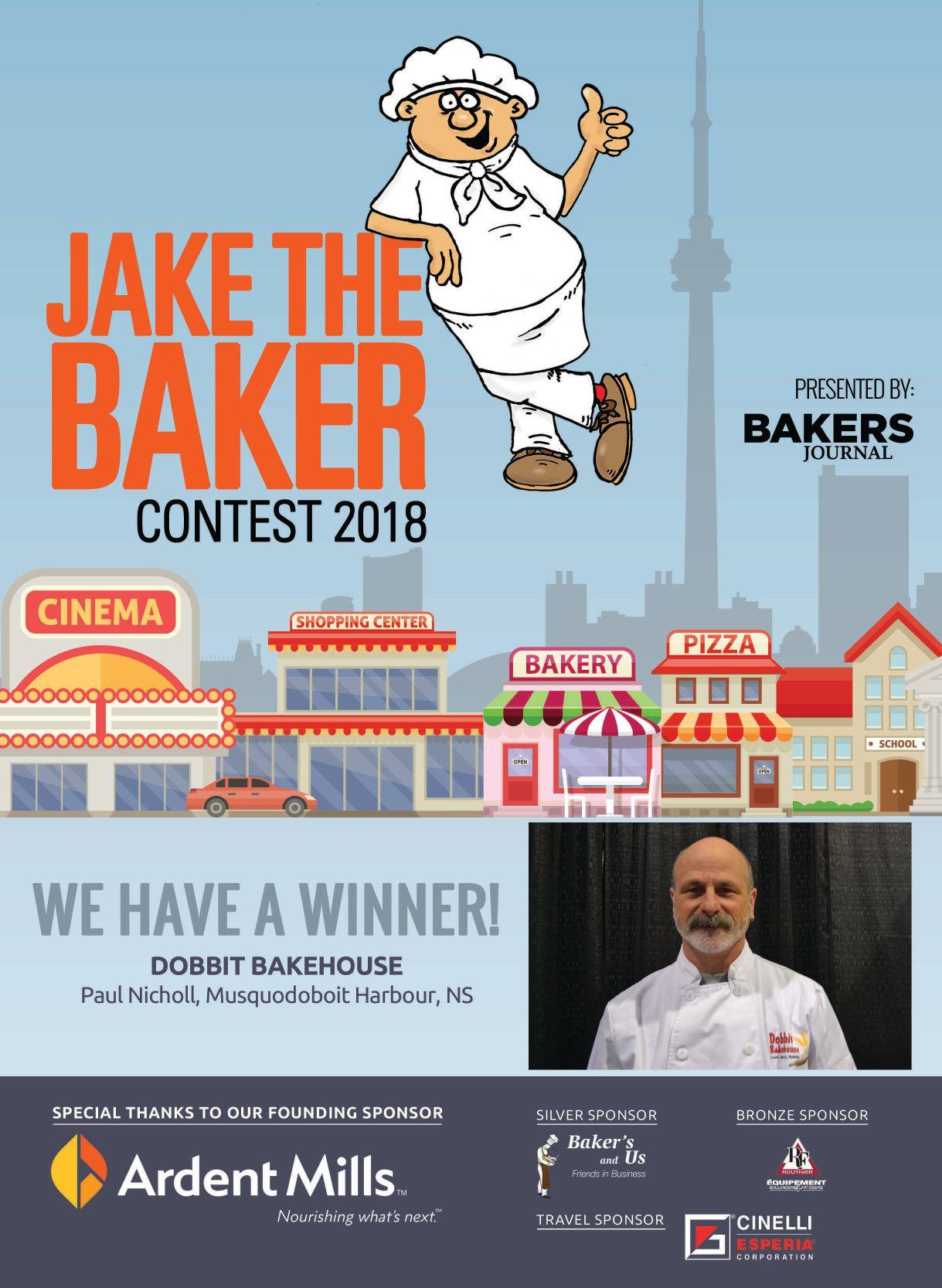

In this issue, we celebrate the 2018 winner of the Jake The Baker award, Paul Nicholl, who shows us how to guide potential customers around the often baffling array of bread choices. The Dobbit Bakehouse owner demonstrated how he contributed to bringing more than baked goods to the town of Musquodoboit Harbour, N.S., and shows us how bread brought his community together.

Bread and community often go hand-in-hand. I look forward to learning from the baking community, and putting each issue together with the same care and creativity bakers put into their wares. I thank you all for your warm welcome. / BJ

JUNE 2018 | VOL. 78, NO. 5

EDITOR | Naomi Szeben editor@bakersjournal.com 416-510-5244

TECHNICAL

EDITOR | Philip Oxford, Puratos Canada foxford@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Shannon Drumm sdrumm@annexweb.com 519-429-5176 1-888-599-2228 ext. 219

MEDIA DESIGNER | Curtis Martin

CIRCULATION MANAGER l Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-442-5600 ext. 3543

GROUP PUBLISHER | Martin McAnulty mmcanulty@annexbusinessmedia.com

COO | Ted Markle tmarkle@annexbusinessmedia.com

PRESIDENT & CEO | Mike Fredericks

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710.

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Business Media.

CIRCULATION lmalicdem@annexbusinessmedia.com

Tel: 416-510-5187

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Subscription Rates

Canada — 1 Year $ 30.00 (with GST $31.50 #867172652RT0001, with HST/ QST $33.90)

USA — 1 Year $ $55.50 USD

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com Tel: 800-668-2374

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2018 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

When you have the cargo capacity that fits your business, there’s no limit to where you can go. Ford Commercial Vehicles have the right one for yours. The full-size Transit offers two wheelbases, three heights and three lengths. The compact and versatile Transit Connect delivers a car-like drive with cargo space to spare. Ford has something more: specialists who can help make choosing and upfitting the van you need for your business easy. We’re sure you’ll like the sound of that. FORD.CA/BUILTFORBUSINESS

briefly | International sourdough library keeps starters from around the world; Cross-border wheat study may hold clues to gluten sensitivity. | for more news in the baking world, check out our website, www.bakersjournal.com

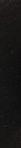

The Puratos sourdough library specializes in strains of naturally fermented yeast cultures from around the world. This unique library houses samples of flour, water and starter from various countries, in an attempt to research the global biodiversity of sourdough bread.

The wood-panelled library features a forest canopy on its ceiling, emphasizing its natural interest in organic matter. It stores over 100 specimens of sourdough cultures and refreshes each one with local flour and additional ingredients directly from its specific region.

For bakeries to have their starters preserved for posterity on the shelves of the Puratos sourdough library, each inductee is asked to provide the ingredients needed to keep the cultures alive. Each inductee must provide local flour and additional specific ingredients from their region in order to feed the starter.

Sourdough librarian, Karl De Smedt is

excited about this project, as it allows researchers to locate certain strains of yeast not only by region, but also by latitude. Several different micro-strains and properties of flour can also be filed and catalogued from around the world.

Of particular interest, de Smedt has found a strain of benevolent bacteria from a culture extracted from a bakery in the Swiss alps that was nearly identical to a strain found in Chile. In this particular case, de Smedt hopes other bakeries at the same latitude will come forth with their sourdough strains, in order to help add data to the study of latitude on the effect of bread-making.

Toronto bakery, Blackbird Baking Company is the first Canadian bakery to have its sourdough culture inducted into the Puratos sourdough library. The bakery is based out of Kensington Market and known for its sourdough breads, unique flavour and of course, it’s sourdough starter.

Puratos welcomes viewers to tour the virtual sourdough library: www.bit.ly/PuratosVirtualLibrary.

Two different Canadian wheat commissions and an American council are collaborating on research into sourdough bread.

The Alberta Wheat Commission (AWC), Saskatchewan Wheat Development Commission (Sask Wheat) and the Minnesota Wheat Research and Promotional Council (MWRPC) are funding a three-year project to determine whether the process used to create sourdough bread could lead to more easily digested bread for the wheat-sensitive.

Headed Dr. Michael Gänzle, a food microbiologist at the University of Alberta, the study will focus mostly on the fermentation process, which breaks down the proteins and the carbohydrates in flour, which have been linked to wheat sensitivity. Inspired by anecdotal evidence that sourdough is easier to digest for those who identify as being sensitive to wheat, the project hopes to develop more easily digestible products for the glutensensitive. However, it will not create any new products for people with celiac disease.

In a press release, Sask Wheat Chair Laura Reiter stated, “this is a unique project that has exciting potential for the baking industry. We hope the results will lead to products that more people can enjoy while creating new market opportunities for grain farmers.”

Funding for this project includes $70,000 from AWC, $57,250 from Sask Wheat and $20,000 from MWRPC for a total of $147,250 over the three-year period. This cross-border initiative looks forward to working with Gänzle to report the results of this project upon completion in 2021.

From a natural way to reduce acrylamides to new safety features on packaging equipment, Bakers Journal keeps you

“in

the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

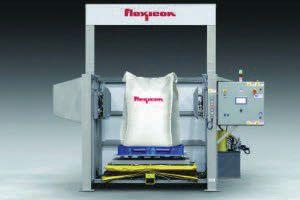

Flexicon Corporation created a BlockBuster® bulk bag conditioner with a laser safety curtain that automatically stops the system’s hydraulic rams, scissor lift and turntable if the laser beam is obstructed. This eliminates the need for safety-hinged doors and interlock switches for operator safety.

The number and pressure of hydraulic ram actuations, the height of the turntable, and the number of 90-degree

Lampados International, Ltd. created Liteez, a 3D meringue kiss sweetener for hot beverages. A new eco-friendly facility was just completed to reduce energy and water use. The company has developed an entirely automatic, closed-system production process for Liteez that ensures product safety according to the strictest certifications, with full control over every step, including packaging.

Production of meringue is typically highly sensitive to contamination, especially during the foaming stage. Many meringue manufacturers do this stage manually, which is labour intensive. The new closed system prevents contamination throughout every step.

“When we set out to create a new sweetener, while we certainly strived for exceptional characteristics and functionality, we wanted to do so with responsibility,” explains Noam Kaplan, CEO of Lampados in a press release. “Consumers expect manufacturers to be a part of the community and take care of the environment. Part of Lampados’ mission is to make Liteez a better-for-you product in every aspect.”

rotations are user adjustable. The system controller and hydraulic pump can be mounted on the exterior of the frame or remotely.

The new conditioner is intended for bulk bags containing hygroscopic chemicals, certain types of spice blends, heat-sensitive products, and other materials prone to solidifying to the point at which pneumatically-actuated flow promotion accessories integral to bulk bag dischargers are inefficient or completely ineffective.

Available as a stand-alone unit or integral component of a bulk bag discharger, the unit measures 2210 mm high by 3378 mm wide and 1981 mm deep. It accommodates bulk bags of all popular sizes, and requires only an electrical power connection for operation.

http://www.flexicon.co.uk/Bulk-HandlingEquipment-and-Systems/Bulk-Bag-Conditioners/index.html

The new production process of the 3D meringue sweetener allows water savings by reducing the water in the mixture by nine per cent, which saves energy in the drying process.

Further energy reduction was achieved by shifting to a continuous process, washing equipment and utensils only once in each production, saving a further 47 per cent on water usage.

Lampados Ltd., a family-owned company, was founded in 1975. The company specializes in tabletop sweeteners and health products, such as sugar-free syrups. CEO Noam Kaplan joined the company in 2009. The manufacturing site has BRC Grade A certification.

Frutarom Food Protection Solutions announced the creation of two all-natural, highantioxidant products for reducing acrylamide.

Acrylamide is a naturally occurring chemical that has been linked to cancer. The chemical forms in certain plant-based food when baked or fried at high temperatures. Acrylamides have mostly been found in foods that are rich in carbohydrates and low in protein, such as baked goods.

The Israeli company has been researching ways to decrease oxidation and extend shelf life with two of their products, INOLENS and SyneROX. Both formulas are customized blends of rosemary oil and/or water-soluble extracts in powder and liquid forms. Ohad Cohen, manager for Frutarom Food Protection Solutions stated in a press release, that this could be an “all-in-one solution” to reduce acrylamides and oil rancidity while extending shelf life.

“INOLENS and SyneROX portfolio are a natural and cost-effective solution to the acrylamide reduction challenge,” explains Dushka Dimitrijevic, director of technical sales and applications for Frutarom Food Protection Solutions. “They’re heat-stable, easy to use, and have no negative impact on the sensory profile of fried or baked foods. They ensure significant reduction of acrylamides in food products.”

High-heat cooking such as baking and frying can impart potentially carcinogenic acrylamides. In other words fast food might be a contributing factor to cancer. Several countries have established legislation to set new benchmark levels for the amount of acrylamide in foods for various products. www.frutarom.com

The Baking Association of Canada was proud to sponsor the 2018 Bakery Showcase. This year, there were over 200 exhibitors in the Mississauga International Centre, showing Canada their best.

The exhibitors came from around the world, including Asia, Europe and the United States, sharing innovations in equipment, packaging and food trends. For food trends, most noticed a swing towards reducing sugar, clean labels or smaller ingredient lists with whole foods.

Chef Anna Olson discussed the trend towards customers wanting more of a connection to their food, asking about ingredients’ origins, whereas a few years ago, people were more interested in how the food was prepared. Both Olson and speaker Tony Chapman explored how emotions can be used to market bakery goods. As Chapman noted, bakeries are “steeped in emotion.” By appealing to the public’s emotion, you can market your goods through advertising your goodwill, or calling attention to your shop’s community or charitable donations.

}Liesbet Vandepoel (left) of Puratos discussed the major Macrotrends of 2018.

A store with a story that a client can relate to may fare better than a large grocery store with a more competitive price. “Price is not a driving force anymore,” says Tony Chapman.

Chapman urged listeners to share their story through social media. This theme of learning the story behind food was carried through with speaker Tony Chapman, who discussed how clients want to feel they are a part of their local bakery, and may want to empathize with a value that their food provider may espouse, whether that would be an environmental, social or gourmet trend.

“Clients are more likely to ask what their shop stands for,” added Chapman. A store that has a story that a client can

relate to may fare better than a large grocery store with a more competitive price. “Price is not a driving force anymore,” he added. “It’s a race to zero.” Chapman urged the audience who owned small businesses to look at the emotional side of their story, and use that in their marketing tool.

Liesbet Vandepoel, of Puratos, also shared the discovery that cost was not a large consideration in clients’ buying choice. Citing a Mattson macro-trends food study, “people want to feel in

control of their food choices,” Vandepoel shared. Indicating that the study showed that people were drawn to healthy foods with “power ingredients” such as whole grains or anti-oxidants, as these perceived ingredients gave a halo effect to most products.

Vandepoel noted that online or automated food choices such as online food ordering or meal kits had very little impact, as only 21 per cent of Canadians would order their bread online.

In all, the Bakery Showcase speakers were informative and the vendors displayed a multicultural appeal. The BAC reports that this was a larger turnout than last year; we can’t wait to see what the showcase will bring us next year. / BJ

ATRUE STORY: We met a baker who was producing gourmet cookies –heavy, thick cookies with lots of large chunksof chocolate, fruits, nuts and other inclusions. In an effort to increase production, she went from hand-scooping to a wire-cut cookie machine. However, she ran into big problems with the wire-cut machine: she couldn’t maintain portion control; her large chunks were getting cut into smaller, less impressive ones; and the remaining chunks were smeared under the cookie dough. Then she called Reiser. The solution was our Vemag cookie dough depositor with a guillotine cutoff. Even at high production speeds, the Vemag allowed her to run all of her recipes with precise portioning accuracy. Her chocolate chunks and inclusions came through whole. And the guillotine cutting system actually exposed the chunks and inclusions. Now she is able to produce mouth-watering cookies with great eye appeal that out-sell all the other cookies in the bakery case.

This year’s winner of the Jake the Baker Award knows about being given options and finding opportunities, and wants to share that advantage with those less fortunate. Paul Nicholl, owner and chief baker of Dobbit Bakehouse in Musquodoboit Harbour, N.S., is often found mentoring students through the O2 program and helps out local small business starting up their first venture. In both paths, Nicholl believes that information is the key to success.

Nicholl rekindled his first love to fire up his second career. “I’ve always loved baking,” Nicholl answers when asked what inspired the career change. “My mission was to start a small bakery in a small town. I had spent twenty five years in the high-tech sector…so I switched from high tech to low-tech.” Nicholl has no regrets. The bakery, a playful abbreviation of the town’s name, Musquodoboit Harbour is now a popular bakery that serves a range of treats to locals and tourists alike.

“I thought if I’d have my own little bakery, I wouldn’t have to worry about shareholder value, I wouldn’t have to worry about the board of directors. And in my high-tech world I thought if I opened a bakery, I wouldn’t have to worry about any of that.”

}I’ve always loved baking. My mission was to start a small bakery in a small town. I had spent twenty five years in the hightech industry...so I switched from high tech to low tech.

Like any entrepreneur, his new venture was not without its hurdles. In Nicholl’s case, it was all about the two “L’s:” Locals and Locale. “I was looking for the perfect location, and I was looking around. It had to be very small, and there just happened to be a pizzeria that closed, so space was available. The place was a dump, so we had to clean it up a lot to bring it up to standards. So it was a challenge to get the place ready; it took several months to do that.”

The second challenge lay in discovering what product mix would appeal to his new clientele. “The customers are looking for a source of food that they can trust. You know, nutrition-wise, is it going to have a lot of additives, a lot of ingredients they can’t pronounce. I have an open kitchen, so standing there at a regular counter, you can

see me cutting the butter. It keeps it very open and transparent. The clients can come by and say, “wow, is that an entire block of butter they are cutting up?” That gets them every time, seeing me cut up a 25kg block of butter.”

Winning the small town locals over with his Pane Siciliano and Pain de Campagne was no easy feat, but it was nothing compared to the challenges he faced when mentoring high school students. The Options and Opportunities Program, known as the O2 program, was designed to help students who are not academically inclined to find a trade. Nicholl wanted to help youth find a vocation, by sharing his passion for baking.

“I try not to be a parent, and I’m not their teacher,” Nicholl speaks of the delicate

balance between being an employer, trainer and figure of authority to high-school students. Some students came from troubled backgrounds, but there was a touching success story: One student with family troubles succeeded in the O2 program and even went on to graduate from the two-year culinary arts program at the local community college. “He said he didn’t want to disappoint me,” added Nicholl with pride.

He sees parallels between baking and starting businesses. “It’s about precision, how to be part of a team. If you make a mistake in the beginning, it’s going to come out a mistake in the end. Magic doesn’t happen in the baking process. You have to fix your errors as you go along.”

This advice holds true for business owners, and he gladly helps out start-ups with their business plans, among them, a local barber. “Again, another mid-life career change,” said Nicholl, relating to the situation. “He knew he wanted to be self-employed but he didn’t know how to go about starting a business. I’d coach him on

things to be aware of. He’d bounce ideas off me, and I’d tell him about things like cash systems. These were things that I’d regretted when I first started my business.”

One mistake that Nicholl’s made involved finding the right product mix for his location. “When I opened, one of the first things I realized was that the breads I enjoyed making were not necessarily the breads my customers were looking for. European breads, I love doing them, but they were not popular. What they were looking for were basic white breads, basic brown breads from the Maritimes. And I didn’t offer those until two years after I opened. That was me, living my dream.” Only after a sobering look at his accounts, did Nicholl realize that his finances needed to improve by catering to regional flavours. “My demographic, it wasn’t what they wanted. I should have realized this sooner in the game.”

Nicholl learned from his mistake and while he still offers a range of European breads, he’s known locally for his delicious Granny’s Brown Bread. He offers some advice in winning reluctant customers over: Name recognition is a key to getting

clients to try something new.

“They do try it when we give them a little spiel.” Nicholl recommends trying the sommelier approach, to offer a sample, and make a meal recommendation that would go along with it.

“I found that a tactic that works well, is coaching customers as to how the bread was made, what is in it, and suggesting what goes well with it, kind of like choosing a wine for a meal. We take that approach, and people really enjoy that, they’ll go with our suggestions. Most of the time they’ll go with our suggestions, and they all come back with, “I don’t remember what that was, but it was really good!”

Ever the generous coach, Nicholl offers the following four tips to bakery success:

1. Collect data: “It sounds trivial and it may not be your thing, but with data, you can capture how many customers you have in a day, how much you sold in a day, what people bought in a day. Keep that information, because it will help you staff differently. It will help you explain what product mix works, and what didn’t.

2. Assess your data after 12 months: “At the end of the year you can decide what

products you should ban. If you don’t record that, by next year, you’ll likely forget. There’s a number of ways to record it. It can be as sophisticated or as complicated as you’d like. It can be a sheet you keep by the cash register, or a spreadsheet you fill out at the end of each shift. “

3. Research point-of-sale devices: “Make charts, ask about your debit systems.” Nicholl recommends asking other shop owners about their Interac machines, to see which ones have good customer service, which ones work well and which have a good tech support team. “Do your shopping to see which systems work and which one doesn’t. Don’t jump in headfirst. The banks love to talk to you, but they are not your friend.”

4. Reach out to your clients: Know your demographic, but offer samples of both popular treats and something a little different. “I think the target is to get them to recognize the name, especially if the product looks different, has a different colour, different shape.”

It’s Paul Nicholl’s tradition in sharing information that makes Dobbit Bakehouse the real deal. / BJ

Professional Bread Baking is not only a cookbook providing an array of recipes and formulas for finished loaves. This title dives deeper into the discussion about bread, providing a detailed reference that will be indispensable for a baker.

Written by an Associate Professor at the Culinary Institute of America, Professional Bread Baking provides the tools needed to mix, ferment, shape, proof, and bake exceptional artisanal bread.

Features include:

• An aarray of formulas and unique recipes for finished loaves.

• Detailed discussions of bread which provide a valuable reference for any chef or baker.

• Balancing theory and practice, this text provides both the understanding and performance abilities needed to progress and develop in a successful baking career

• Explores in great detail every type of tool commonly used for producing artisan bread in a professional bakeshop. Beyond this, pros and cons are listed for large items – items like mixers or ovens that can be major purchases for a bakeshop.

Make sure you have the right flour to deliver on your brand promise and business needs. ADM provides superior flours and blends to help your baking business succeed, batch after batch and loaf after loaf. We understand the complexities of natural crop-to-crop variations and offer the best blends available to ensure higher quality, better performance, and more consistent yields, delivering the reliability and trust you need.

Learn more at ADM.com

KAREN BARR

There is just something magical about the summer fruit from the lush Niagara Region, in Ontario. It has inspired many bakers to make their very first pies. In fact, some have gone on to become professionals, with thriving businesses, using the techniques they have learned along the way to make perfect pies.

“Everybody loves pie!” exclaims Wanda Beaver, owner and head baker at Wanda’s Pie in the Sky, the 35-year old business, in Toronto’s Kensington Market. She reminisces about an idyllic childhood growing up in St. Catharines, Ont., in the fruit-rich Niagara Region. A sour cherry tree in her own backyard inspired her as a make her very first pie. She was just nine years old.

“The perfect pie is a balance of flaky pastry and juicy filling. It has to have that contrast,” says Beaver. Today, the sour cherry pie is the top seller in her shop, except when it is peach season. “Niagara peaches are the best,” says Beaver, “And are the most sublime reason to live in this part of Ontario.”

Off season Beaver uses frozen fruit, but never frozen peaches. In season, peach pies fly and the shop makes peach ice cream to top them off.

}All fruit pies, except for apple have a woven lattice crust. “We like pies to have a homemade look, because that’s what they are. And you want to be able to see the fruit.”

The secret she says, is to blend the fat and flour together well, before adding the water, to create an even mix. “Always use cold butter,” advises Beaver, “and in the summer refrigerate the flour.”

So just how is the perfect pie crust made? Beaver uses a mix of butter and non-hydrogenated shortening for the fat. Making the dough by hand, she uses a traditional pastry cutter, which gives her more control than using a food processor. The secret she says is to blend the fat and flour together well, before adding the water, to create an even mix. “Always use cold butter,” advises Beaver, “And in the summer refrigerate the flour.”

High gluten flour will cause a tough crust, while low gluten flour will cause the dough to be weak, unable to support the filling. In Beaver’s book entitled,

Wanda’s Pies in the Sky: Pies, Cakes, Cookies, Squares and More (currently out of print, although Beaver does contemplate updating and republishing) she writes that Canadian all-purpose flour is the best for pie crusts. It has the perfect balance of high and low gluten flour, with slightly less gluten than the American version. Her preference is unbleached flour.

After makeup, Beaver wraps the dough in plastic and lets it rest for 20-30 minutes in the refrigerator. Then, she rolls it out on a counter top liberally sprinkled with flour, keeping the dough moving by rotating it a bit, after a few

rolls of the pin.

At Wanda’s Pie in the Sky, the fruit is not precooked and cornstarch is mixed in with the fruit to thicken, “It produces the best, glossiest baked texture.” As for baking, Beaver suggests, “Start with a hot oven at 375 F then reduce it by 25 degrees. Bake well, until the fruit bubbles in the middle.”

Over at the Itty Bitty Pie Company, in St. Catharines, Ont., co-owner Pam Nicholson shares her thoughts. “We believe pies always taste best when they are baked in your own oven.” That’s why they sell their nine-inch family-sized pies frozen.

“We tell our customers not to thaw them before baking,” says, head baker and co-owner Tara Nicholson. Why? Pie crusts bake that much crisper directly from frozen.

The mother and daughter team their

business several years ago. But, Tara didn’t learn pie baking from her mother she learned it at high school in a food and nutrition course. The class should have been called Pie Baking 101, because according to Tara, that’s all they ever did. And while later she continued baking pies at home, she studied graphic design. Her mother finally convinced her that pies were her future. And so, the team set up a booth at the St. Catharines Farmer’s Market, before setting up shop in the city.

Itty Bitty Pie Company sources fruit from local farms and farmer’s markets. Once June rolls around, customers go wild for strawberries. “We make strawberry rhubarb pies, because both are in season at the same time. It adds both sweet and sour flavours. The top crust is lattice, so you can see the fruit,” says Tara.

Like Beaver, Tara only uses fresh peaches never frozen, so her peach pies are only available in season. At which point, the peach pie is the top seller. “We make our peach pies with a crumble of flour, brown sugar, oatmeal and butter. Cinnamon is added directly to the

peaches,” Tara notes.

But the most popular pies at Itty Bitty Pies are the 3-inch individual pies, made by the thousands, using a pie press. “When we opened the business cupcake shops were really popular. So, I thought, ‘why not pies.’”

Flavours change daily, which gives Tara the opportunity to experiment. These mini pies are baked for customers to take home and they usually leave with a box of least a six mini pies. Apple crumble is the most popular mini fruit pie variation.

In the winter, Tara turns to frozen fruit, which she thaws out first. “I keep the juice, because that’s where the flavour is. I just add more flour to make up the filling.”

James Fink a.k.a. Jay the Pie Guy in Port Colborne, Ont., just moved to a new location double the size of his previous location -- all in a whirlwind of three years since he first started selling his pies at the St. Catharines Indoor Flea Market. Open only 5 days a week, with no digital profile beyond a Facebook page, he still manages to sell 400

eight- inch pies a week.

“We use only half a cup of sugar per pie,” says Fink. But unlike other pie bakers, Fink precooks his filling, adding cornstarch immediately after the sugar, to quickly boil the filling, without breaking down the fruit too much. “When we cook the filling down, we are making sure that every pie filling is consistent, ” he says. Most of the pies at Jay the Pie Guy have a top crust or a crumble made with butter brown, sugar and oats.

He used to brush his pies with an egg wash to give colour, but felt it changed the flavour of the crust. “I now realize it’s not about the way the pie looks, but the way it tastes.”

One trend Fink notices is more requests for vegan pies. He uses all vegetable shortening in his dough and now without egg wash, vegans can enjoy his pies too. “But, I haven’t yet attempted a gluten free pie,” he says with a laugh. Pies are pure comfort foods that make good use of summer fruit. They are a casual dessert indulgence, filled with the nostalgia of home. / BJ

BY CHRIS SEMENUK, RMT

Your muscles are your tools: You “knead” to learn ways to protect them from damage.

Your physically demanding career means that you should treat your muscles like a professional athlete to avoid aches and pains.

Stretching is an easy and effective way to make sure that baking doesn’t become a major pain. In this article I’ll discuss stretches that are specific to bakers.

There are different types of stretches: Static stretching means holding a position for a set period of time, while dynamic stretching means continuing to move through a stretch. Dynamic stretching has been shown to have the greatest benefit for avoiding aches and pains, but it is suggested to use both together.

Static stretches only need to be held for 20 seconds to be effective. Try doing two to three sets of 20-second holds, stretching the muscle groups that tend to give you the most hassle at the end of the day. When holding, try stretching the muscle so that you can feel the stretch, but not to the point where it feels painful.

Hold your arm out straight in front of you, bend your wrist with your fingers pointing downward, and with your opposite hand pull back on the hand of the arm you are stretching. You should feel this stretch in the muscles on the top of your arm. Hold this for the 20 seconds, and then bend your wrist the other way with your fingers upwards and pull the hand back towards you again. Repeat this twice and then change arms.

Dynamic stretching gets your muscles used to the movement and builds up tolerance for your actual work. Prepare for heavy lifting by starting

therapy can help get to the areas and the deeper parts of the muscles that you just can’t do yourself.

with some basic back twists, knee bends, and arm circles. The idea is to start with smaller movements, and build up to larger ones that go beyond the range you would actually use.

Begin with bending your knees 20 degrees, stand up straight, and bend to 40 degrees. Stand up straight again, and keep repeating these movements until you are right down close to the ground. This should take about 30 seconds, or so, and you can also hold onto the counter for stability while doing this. This formula can be used with any joints.

If you are moving on to kneading or piping, then get your arms ready for the task. Make circles with your shoulder, elbow, and wrist joints. Just rotate them in the air in front of yourself for 30 seconds, making the circles gradually larger. Again, try to get a range that is larger what you will be using. If your work task, or “working zone” requires you to move your shoulder 45 degrees to each side, then make your circles 60 degrees or more. This will make it easier for your body to get to that 45 degree mark when you’re actually doing the task. This will prepare your muscles and joints so that you feel less aches and pains when

you’re done.

Throughout your shift, and especially when getting back from a break, repeat the key stretches. Make sure to take frequent breaks and change position frequently.

If you’re feeling muscle and joint soreness, applying heat can help relieve some pain. Try a beanbag or heating pad; 10 minutes of heat should be enough for pain relief. If you’re having a hot shower, then let the water run over the sore area for about 20 minutes.

Massage therapy can help get to the areas and the deeper parts of the muscles that you just can’t do yourself. Massage therapy can help increase strength, improve function and reduce pain. Don’t try and work through the pain as that will make things worse. Your body will tell you when it needs help. Don’t ignore your body, it knows what it is talking about. / BJ

A massage therapist for 17 years, Chris has been involved in the profession as a professor, program creator, Pan-Am Lead Medical Professional, and Head RMT for Western University Track & Field and Cross Country.

BY DIANE CHIASSON

If you are not using social media, you are losing business. Social media will help keep your fans coming back.

Aweb presence will give your bakery business great online visibility, which in turn will enable customers to find you easily. Your new website is an effective marketing tool and will help generate awareness, exposure and extend your bakery brand. Your website should allow you to showcase your specialties, menu and services. As a busy independent baker, you may not have a lot of time left for marketing and promotion, but it is a necessary task if you want to keep your business going and expand your customer base. Here is some important information on how to promote your new website and stand out from the rest:

}Just remember that people love pictures more than text. A customer cannot taste your product without buying it first, so the next best thing is to entice them with some high quality photos.

Other than joining your local chamber of commerce and other bakery-related business organizations, you should also claim your listings in local directories such as Yelp, Foursquare, TripAdvisor, and other bakery review sites. These sites provide users with reviews and recommendations of top bakeries, restaurants, tourist destinations, shops and more.

Four in five consumers use search engines to find local bakeries. You will definitely have to invest some time into search engine optimization (SEO) to help your bakery appear in related search terms. Search terms are what your potential and regular customers type into search engines to find what they want to buy. You want your potential customers to find your bakery shop, not your competition.

You have to imagine what your customers are searching for. This means optimizing your website for search engines like Google, so when someone searches for one or more of your keywords, you are more likely to show up on the pages with these search results. The goal is to rank the highest on search engine page results when people use search terms that are relevant to your bakery’s concept, type of bakery products, and location.

To get started, you should research relevant keywords or phrases for your bakery, and use them into your web and social media copy. Find the most basic and simple search terms possible like “artisanal breads”, “gourmet cupcakes”, “custom cakes”, “vegan bakery”, gluten-free and vegan bakeshop”, and “natural and organic vegan bakery”.

If you are not using social media, you are losing business. Social media will help keep your fans coming back again and again. Customers will often visit a

a bakery’s social media profiles to see photos, read reviews and research both the good and bad in a business. Think of these platforms as gateways to your website. A strong online presence is a great way for your bakery to connect with your customers and get instant feedback.

Using social media will help you build a loyal following for your business, find new customers and engage with your current ones. There are multiple user-friendly ways of promoting your company on social media platforms, and I recommend maintaining a presence on one or two of these following platforms:

Facebook is still the biggest and the most popular social media platform for businesses around today. It’s a great tool to maintain customer relationships, promote new products, specials and events, marketing initiatives, customer service, and attracting new customers.

Creating a Facebook fan page for your bakery will not only give you a powerful advertising tool, but it will also help strengthen your brand image. When you are about to start a Facebook page, make sure that your information is complete and up to date. By doing this, your customers will

find you and contact you easily. You should set up your Facebook page as a business page, and you should have the following information:

• Category

• Name

• Address

• Telephone number

• Email address

• Opening hours

• Website address

• Special promotions

• Short description

• Long description

Just remember that people love pictures more than text. A customer cannot taste your product without buying it first, so the next best thing is to entice them with some high-quality photos. Pictures should showcase your bakery products and your expertise and services.

The only thing you will need is a good camera or smartphone and sufficient lighting so that your baked goods look delicious. You should always engage your audience and make sure you don’t create a stagnant page. Nothing is more irritating than following a Facebook page to find nothing new after the first couple of posts. Post a maximum of two to three times per week to avoid inundating your audience. You can ask your Facebook fans what else they would like to see – and pronto – you will receive ideas immediately. Here are some ideas for content to post to Facebook:

• New baked goods

• New seasonal menus

• Special holiday events

• Funny stories

• Contests and events

• Event photos

• Special announcements

• Promotions and coupons

• Job postings

• Blog posts

• Videos

• Media coverage

Instagram is where bakeries shine: It focuses primarily on great visual content. It’s the perfect vehicle for your other bakery photos. It will help you cross-promote content, spread awareness of your brand and promote special contents and events. Keep in mind that visually attractive and professionally curated photos or videos score best. You should post once or twice a day to Instagram. Here are some ideas for content to post to Instagram:

• Colourful photos of bakery items

• Packaging presentation

• Contests and events

• Contests and events photos

• Special entertainment

• Behind the scenes pictures

• Videos

relationships and customer service. One of the best ways to get others to engage with your brand is to ask a question. Tweet questions such as: What is your favourite bakery product? What exotic pastry items have you seen or tasted on a trip? What would you most like to have us sell? Here are some ideas for content to post to Twitter:

• Positive brand news

• Employee recognition

• Promotional codes or coupons

• Short videos and images

• Job postings

Don’t talk about yourself as it doesn’t provide any value. Instead, share your follower’s updates, events happening in your bakery and in your town, and promote your bakery products. Have fun posting!

© 2018 Chiasson Consultants Inc. All rights reserved. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 30 years. She is recognized as the industry leader in providing innovative and revenue-increasing foodservice and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns, and much more.

Contact her at 416-926-1338, toll-free at 1-888-926-6655, chiasson@chiassonconsultants.com, or visit www.chiassonconsultants.com.

This is the best platform for short and quick messages that are less than 140 characters. Use it for promotions, updates, customer

BY JEFF GRANDFIELD AND DALE WILLERTON

Planning and allowing ample time can save you aggravation and money.

As we emphasize in our new book, Negotiating Commercial Leases & Renewals for Dummies, the leasing process is not a simple task. Considering the number of steps involved and potential hurdles you may face, property planning and allowing for ample time can save you aggravation and - more importantly – money.

One common mistake that commercial bakery tenants can make is agreeing to terms too quickly with the real estate agent. We routinely hear from frustrated tenants who signed too hastily and realize after the fact, that they may have made a mistake. While they do good work, agents work for the commercial landlord (rather than the tenant.) Real estate agents will often push a prospective tenant to lease a unit that may not be the best choice; it may be too large or too expensive.

}The long-term success of the commercial tenant is of little importance to a realtor or real estate agent. Their motivation is often a promised commission from the landlord, and that commission will typically increase when the tenant leases more commercial space and leases for more years.

amount of work involved with your own commercial lease, it can be a worthwhile investment for bakers to hire a professional lease consultant to help ensure that they get a better – and fairer – lease deal with the landlord. For the best results, everything that needs to be done before signing a lease can take between 20 to 40 hours. Would you have that kind of time to spare?

Moving from time to timelines, scour all documents for deadlines and note these conspicuously. It may be possible to adjust these deadlines depending on the circumstances. You may find that some steps are beyond your control, such as getting financing in order or having a contractor inspect the commercial space. You would then need more time to get everything in order. While you could keep extending your condition periods by several days with your landlord, it is often better to simply ask for a longer condition period (perhaps 20 or 30 days) to ensure everything can be done.

While you may be just starting out as a new bakery owner, remember that timing plays a vital part when your lease renewal comes due. It is not unrealistic for a bakery tenant to begin their lease renewal process 12 to 15 months prior to their lease

Remember that franchise tenants should make sure their lease term matches their franchise term to avoid issues later with the lease running out too soon.

A common mistake for bakery tenants is making an agreement too quickly.

may have other plans: Your landlord may have found a replacement tenant to take over your space and may increase your rent dramatically to effectively nudge you to move out and vacate the space. This isn’t always the case, however, it is something for bakery tenants to think about before it happens.

It’s not uncommon to get a call from an agent who claims that someone else is looking at the space that you looked at last week, so you had better hurry and sign an offer to lease. Don’t let tactics like that sway you. Go at your own speed and get it done right.

As a bakery tenant, you will also want to devote your time to doing what you enjoy and what is best for your business. Smart bakers will often realize that they cannot accomplish everything that needs to be done, so they will hire outside professionals to help them, such as a lawyer or an accountant. Considering the

expiration date. More precisely, look at your renewal-option clause. If this says your cut-off date for exercising your lease-renewal is 6 months before your lease expires, you would need to start the renewal process 6 months before that, or a total of 12 months in advance.

If you have joined (or plan to join) a bakery franchise concept, remember that franchise tenants should make sure that their lease term matches their franchise term to avoid issues later with the lease running out too soon. This happens when the start date of the franchise agreement is prior to the start date of the lease agreement, which may be several months later, when the franchise business actually opens.

Pay attention to your own renewal option cut-off deadline and react accordingly. While you may have intended to stay leasing your current location, your landlord

Timing can also be a factor if you don’t have a renewal option and want to stay where you are currently leasing. If you don’t show any interest in moving, your landlord can take advantage of this situation by increasing your monthly rent. And, if you wait too long before approaching your landlord, you will have less time available to you to move, if necessary.

For a copy of our free CD, Leasing Do’s & Don’ts for Commercial Tenants, please email your request to JeffGrandfield@TheLeaseCoach.com.

For a copy of our free CD, Leasing Do’s & Don’ts for Commercial Tenants, please email your request to JeffGrandfield@TheLeaseCoach.com.

Dale Willerton and Jeff Grandfield - The Lease Coach are Commercial Lease Consultants who work exclusively for tenants. Dale and Jeff are professional speakers and co-authors of Negotiating Commercial Leases & Renewals FOR DUMMIES (Wiley, 2013). Got a leasing question? Need help with your new lease or renewal? Call 1-800-738-9202, email DaleWillerton@TheLeaseCoach.com or visit www.TheLeaseCoach.com

7585 Danbro Crescent, Mississauga, ON L5N 6P9

Contact: Debbie Bell

Phn: 905-819-7000

Fax: 905-819-9768

e-mail: debbie.bell@adm.com

Plants: 2 Montreal, QC; Mississauga, Midland, Port Colborne, ON; Winnipeg, MB; Calgary, AB.

Sales offices: Montreal QC, 514-846-8533; Toronto, ON 1-800-267-8492; Calgary AB, 403-267-5656; Vancouver, B.C. 604-2990710.

Products offered: A full flour and mix product line for the bakery, donut, muffin, food service, biscuit, pasta, frozen, in-store bakery, pasta and industrial segments. Other products offered are stoneground whole wheat, cracked wheat, graham and cereal bran and rye flours.

Ardent Mills is working for the good of grain and committed to pioneering what’s next, with value-added, nutrient-rich, on trend grain solutions that deliver superior performance and consumer appeal. But that’s just the beginning, because we are also the company behind Robin Hood® one of the most trusted and iconic brands of premium white, whole wheat and whole grain flour, oats and bakery mixes in the commercial bakery and foodservice industry today, backed by a century of milling excellence.

6850 Century Ave. Suite 301 Mississauga, ON L5N 2W5

Contact: Elaine O’Doherty

Phone: 905-494-2600

Email: Elaine.ODoherty@Ardentmills.com

Website: www.Ardentmills.ca

Plants: Flour Mills in Mississauga, ON, Montreal, QC and Saskatoon, SK. Bakery Mix pants in Burlington, ON and Saskatoon, SK. Oat and Durum Mills in Saskatoon, SK

Products offered: A full line of quality flour including all purpose, strong bakers, cake & pastry, whole wheat, whole grain, Italian Style and specialty. As an industry leader in innovation we also offer SimplyMilled™Organic Flour, Ultragrain™ white wheat whole grain flour, Sustagrain™ whole grain barley flour and flakes as well as Spouted whole grain flour. This is complimented by our broad range of bakery mixes, bases and concentrates, many formulated specifically

to customers’ needs.

Delivery: Across Canada by rail or truck, throughout North America.

Distribution: Direct from plants, regional warehouses, or distributors, depending on product location.

Major Customers: Bakery and Food processors, Retail & Wholesale bakeries, Grocery Retailers & Instore bakeries, Foodservice Operators, Bakery and Foodservice Distributors.

1150 Rang Saint-Edouard, Saint-Liboire, QC, J0H 1R0

Contact: Rory Lesperance

Phone: 416-770-2310

e-mail: rlesperance@farinart.com

Website: www.farinart.com

Products offered: Ecocert, Kosher, Halal, HACCP and SQF 2000 certified. Farinart is a leader in processessing custom grain, flour, seed and pulses blends - both conventional and organic. Farinart also provides select line of gluten free blends, flours and processed grains. We have earned a strong reputation for delivering innovative solutions, superior expertise, product consistency and best-in-class service to retail and commercial bakers and food manufacturers.

Distribution: We deliver across Canada and overseas.

Delivery: 20 kg bags, tote bags and bulk products.

No. 1 Grain Millers Drive Yorkton, SK S3N 3Z4

Sales Contact: Andrew Eilertson

Phone: 1-800-232-6287

Fax: 952-829-8819

Email: andrew.eilertson@grainmillers.com

Website: www.grainmillers.com

Plants: Yorkton, SK and U.S.

Distribution: Throughout Canada and U.S.

Products Offered: Full line of conventional, organic, & certified gluten free oats including quick & rolled flakes, flour, bran, steel cut, food grade fiber, and other innovative products. Complete product line includes other milled grains and custom blends of wheat, corn (yellow, white, non-GMO), barley, rye, triticale, and various other specialty grains.

Certifications: Organic, Gluten Free, Kosher, GFSI

Pack Type: Bags, totes, bulk, retail pack (500g-2.25kg)

Company Comments: Grain Millers delivers whole grain solutions to the modern world of food manufacturing. Customers rely on our quality, service, and innovation to meet today’s high expectations and tomorrow’s challenges. Learn more what we can do at www.grainmillers.com.

105 Commander Blvd., Scarborough, ON M1S 3M7

Contact: George Birinyi Jr., Carl Griesser

Phone: 416-291-3226

Fax: 416-291-2159

e-mail: gbjr@grainprocess.com

Products offered: Over 2,000 products including a full range of whole grains. Hard/Soft Wheat, Triticale, Corn, Millet, Barley, Rye and Durum and organic products certified by QAI (Whole Wheat Flour, White Flour, “Ancient Grains” Spelt, Kamut, Quinoa, Seeds, etc.) Precooked and stabilized grains and flours, Whole Bean Flour, complete range of grains including Cracks, Flakes and Grits, Seeds (Sunflower, Sesame, Golden Yellow and Brown Flax), Beans, Peas, Lentils, Sugars, Nuts and Dried Fruit. Food processing also includes custom blending facilities for multi-grain formulas (Bread, Muffin and Pancake Mixes, etc.) packaging, granola cereals, toasted grains, Turbinado and Demerara Sugars.

Distribution: Across Canada and the US. Major customers: Bakeries, biscuit and cookie manufacturers, food service, bulk, health and natural food retailers and distributors and manufacturers.

Company comments: We pride ourselves as being the only stone flour mill in Canada to offer such a wide variety of products.

HOWSON & HOWSON LTD.

232 Westmorland St., PO Box 390, Blyth, ON, N0M 1H0

Contact: Jeff Howson Phone: 519-523-4241, Ext. 60

Fax: 519-523-4920

e-mail: jeff@howsonandhowson.ca

Contact: Dan Greyerrbiehl

Phone: 905-792-2962

Fax: 519-523-4920

e-mail: dgreyerbiehl@rogers.com

Plants: Blyth, ON

Products offered: Durum semolina, durum flours, durum whole wheat semolina, Atta flours.

Delivery: Bulk truckloads, bulk bags (750kg), 20kg bags, 40kg bags, 50lb bags and 100lb bags to Ontario, Quebec and United States.

Distribution: From Blyth, ON, Plant by truck or distributors.

Major customers: Manufacturers of dry pasta, fresh pasta, frozen pasta, and snack crackers.

Company comments: Howson & Howson Ltd. have been quality wheat millers for over 135 years. We are continuously modernizing our durum mill in order to supply our customers with high-quality durum semolina, durum flour and other durum products.

49888 Nova Scotia Line

RR2 Aylmer, ON, N5H 2R2

e-mail: info@jamestownmills.com

Phone: 519 933 2648

Website: www.jamestownmills.com

Products Offered: stone ground, non gmo gluten free flours teff, pulses, quinoa, amaranth and millet. Supplier of sorghum, corn and rice flours, as well as starches and gums Supplying the gluten free industry

P.O. Box 310

Rosthern, SK S0K 3R0

Contact: Russ Schroeder – President

Phone: 1-888-726-2253

e-mail: info@nunweilersflour.com

Website: www.nunweilersflour.com

Plant: Alsask, Sask.

Certifications: Our products are Certified organic by Pro-Cert Organic Systems and Certified Kosher by Kosher Check. Company info: Marquis Milling and grain was incorporated March 2016 to facilitate the purchase of Nunweiler’s Flour Co. Nunweiler’s Flour was established in 1988. Our production facility is located in Alsask Saskatchewan. Construction of our new facility in Hague Saskatchewan will begin March 2018. We will be adding a dedicated gluten free mill as well as updating and adding some milling equipment. We will then be able to offer a light or almost white versions of our flours. Our whole grain flours are milled at low temperatures (typically less than 25C) from high quality certified organic Canadian grown grains. No additives or preservatives, No GMO’s. Superior quality for optimal nutrition.

Products offered: We currently Mill 8 varieties of certified organic whole grain flour: Hard Wheat, Soft Wheat, Rye, Spelt, Buckwheat, Kamut, Barley, and Red Fife Wheat. We package the flours and grains in to 1,2,10,20 and 1000 KG bags.

Major customers: Retail and wholesale bakeries, specialty product bakeries, retail mass market and natural food stores.

6201 E Primrose Green Drive Regina, Saskatchewan S4V 3L7

Phone: 306-751-2040

Contact: Kerry Keating, General Manager Phone: 306-519-7931

Website: www.nutrasunfoods.com

Certification: NutraSun Foods Ltd. is certified Organic by Quality Assurance International (QAI), Kosher Certification, HACCP, FSSC 22000:2011, ISO 22000:2005, HACCP and Non-GMO Project Verified.

Delivery: We deliver bakery ingredients across Canada and the United States as well as shipments offshore.

Products offered: NutraSun’s high quality Organic and Conventional flour is milled from Hard Red Spring and Hard White Wheat. We are the exclusive miller of premium Snowbird White Wheat flour and also offer a variety of Whole Grain flours. In addition to flour, we are continuously expanding our product line of organic and conventional bakery mixes and bases to include breads, muffins, cookies, pancakes and whole grain pizza crust mix or base. We also offer customized grain blends and organic and clean label dough conditioners. NutraSun offers a variety of packaging options for the industrial, bakery and retail markets including 20 kg, 25 lbs and 50 lbs bags, one-tonne totes, bulk truck loads and trans-loading. Our retail packaging line uses re-sealable pouch packs for weights ranging from 600 grams to 2.5 kg.

Major customers: NutraSun serves industrial and retail bakeries as well as retailers selling consumer packed re-sealable pouches. Company comments: NutraSun Foods is a division of Paterson GlobalFoods, a wholly owned Canadian company which has been serving the Canadian agricultural and food industry for over one hundred years. NutraSun is a fully modernized mill located in southern Saskatchewan, the heart of Canada’s Hard Red and White Wheat growing region.

Corporate Office, 1060 Fountain St. N

Cambridge, ON N3W 0A1

Phone: 519-650-6422

Fax: 519-650-6429

e-mail: sales@phmillinh.com

Website: www.phmilling.com

Description: Canadian owned, the P & H Miling Group is Canada’s second largest flour producer. Built on the strengthof nine mills, P & H Milling Group is stratgically located in:

• Acton, ON,

• Cambridge, ON

• Halifax, NS

• Hamilton, ON

• Hanover, ON

• Lethbridge, AB

• Montreal, QC

• Saskatoon, SK

For more information about our flour mills and products, please contact Customer Service 1-800-621-0588 or sales@phmilling.com.

(P&H Milling Group)

817 48th St. East

Saskatoon, SK S7K 0X5

Contact: Glenn O’Hara

Phone: 306-931-1655 ext. 3223

Fax: 306-931-2664

e-mail: gohara@phmilling.com

Website: www.phmilling.com

Products offered: Parrheim Foods produces pulse concentrates (starch, protein and fibre) and flours from locally grown peas, beans and lentils. From our BRC Certified plant, we produce high quality products that are natural and functional as well as free from any additives.

Delivery: From our office in Saskatoon, we ship all across North America or anywhere in the world.

Distribution: Direct from our Plant in Saskatoon

Company comments: Being in this industry since 1989 has enabled us to perfect our separation process which means that we can create the right product to meet your needs whether it be conventional or Organic.

240 Industrial Parkway S. Aurora, ON L4G 3V6

Contact: Kresho Petrovich

Phone: 905-713-1712

Fax: 905-713-0074

e-mail: orderdesk@portroyalmills.com

Website: www.portroyalmills.com

Plant: Aurora, ON

Certifications: SQF, Certified Organic by ProCert, Kosher Kashruth

Products offered: Custom blended whole grain cereals, stone ground flours, cracked, flaked, pearled and whole grains including: rye, spelt, barley, quinoa etc.

Delivery: Direct throughout most of Ontario Major customers: Bakeries, cookie manufacturers, frozen dough plants, bakery mix manufacturers and food processors. Company comments: At our milling facility in Aurora, Ont. We continue to provide the highest quality products and personalized service to our customers with industry leading food safety standards.

2800 One Lombard Place

Winnipeg, MB R3B 0X8

Contact: Richard de Kievit

Phone: 1-800-663-6287(OATS)

Website: www.richardson.ca

Company Comments: Richardson Milling offers a broad range of oat ingredients including oat groats, flakes, flour and bran. Our value added flaked and expanded whole grain based ingredients are designed to be an integral component in your products.

Our extensive grower network and four manufacturing facilities provide the most extensive oat supply chain in North America. Richardson Milling is a division of Richardson International, Canada’s largest agribusiness. Richardson is headquartered in Winnipeg and has more than 2,500 employees with facilities across Canada and the U.S.

Tel: (416) 252-4660 Fax: (416) 252-9993

25 - 8 Connell Ct., Toronto, ON M8Z 1E8

1-800-661-4122 ext. 239 nparent@drader.com

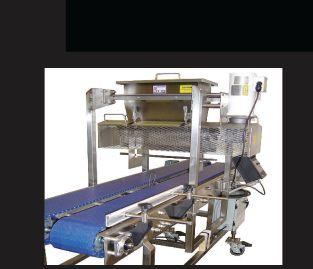

MACHINE & CONVEYOR

Ingredient Dispensing Systems Since 1953

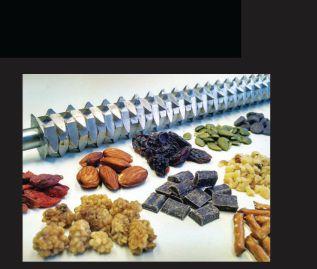

Consistent, reliable dispensing and delivery of dry and moist topping ingredients is why Christy Topping Dispensers and Conveyors lead the industry. Our products durability and engineered simplicity provide topping solutions that have withstood the test of time. Do you have a problem ingredient? Christy's engineers will develop a solution specifically for your needs.

DEPOSIT DRY OR MOIST

• Deposit within a pan/peel, in rows, across the belt or spot deposits

• Easy and fast pattern changes with deposit density controls

• Agitation hoppers in custom and standard sizes

• Affordable, quality stainless steel wash down construction

•Interchangeable components for ingredient and size changes

• Dedicated flour and corn meal dusting systems

• Mounts to existing conveyors or Christy conveyor

•C-Stand mounts on casters

• Straight conveyors

• Offset conveyors

•180 degree curve conveyors

•90 degree curve conveyors

• Specialty performance conveyors

• Incline conveyors

• Reciprocating conveyors

• Right angle transfer conveyors

BY JANE DUMMER, RD

From amateur to professional: Jane Dummer talks with home bakers who took the entrepreneurial leap

There are number of motivators to go into your own business. From offering a better solution to discovering a passion while traveling, the entrepreneurial journey has become a sexy endeavour.However, it takes a plan, vision and hard work to create a profitable business from scratch.

Like many other businesses, the mistakes made during the first two years can mean the difference between success and failure. It’s helpful to source mentors and advisors with food experience. Too often I see start-ups working with mentors who lack food know-how and that can limit progress. Skills like general finance and human resources are transferable; however unique factors specific to the industry including regulatory requirements are necessary to understand fully from the start.

}My advice to anyone starting out is to stick with it. It’s not easy. If it was, everyone would be doing it... I worked 18 to 20- hour days for five years straight when we opened.

it’s gluten-free) in Toronto.”

As a business owner myself, I recommend that start-ups ask themselves “Is it a hobby or a business?” Stephen Goldberg, Owner of Nates Bagels & Gluten Free Foods in Concord, Ontario didn’t start out in the baking or food industry but at the age of 28 decided he was going to be a “great chef”. Hard work, culinary courses and getting a few breaks along the way including a spot on Cook Like A Chef, Goldberg agrees, “When we started, a wise businessman said, ‘If you’re not earning a living it’s really a hobby.’ Ouch, hurts but it is true. My advice to anyone starting out is to stick with it. It’s not easy. If it was, everyone would be doing it. I worked 18 to 20 hour days for five years straight when we opened. As of 2017, in our 6th year of business, we’ve already been graced with three awards including best bakery in Toronto, and best bagel (and

Kelly Kimel, chief chocolate officer of Moroco Chocolat in Toronto traveled to Paris, France and fell in love with chocolate. “The hot chocolate was not the North American style, but rich, velvety chocolate in a cup served with a side of whipped cream. I was hooked!” Today, Kimel a self-taught, award winning baker currently employs seven people. Her biggest accomplishment by far is winning the World Chocolate Awards last fall. Kimel’s advice for going into business, “You have to really love what you do as it will be your life. After all these years I still love chocolate and all the possibilities that can be created with it!”

The digital age has changed how entrepreneurs can accelerate their business. For the baking industry, the social media platform Instagram has been an economical game changer. Instagram has business profiles, complete with a contact call-to-action, allowing users to call, email or text the business. Along with the contact option, business profiles also have access to user analytics. Eric Forbes, winner of the Jake the Baker Award 2017, professional baker, and co-owner

of Kimberley City Bakery in British Columbia explains how traditional and social media marketing has made a pivotal step in their business. “Soon after we started the bakery, there was an April Fool’s Joke that went viral. We had the newspaper, radio station, and even the police in on it, and discovered how far of a reach a story like this could have. It gave us new contacts, and helped us learn to use social media to enhance and connect with locals and the world beyond.”

Forbes recommends having a plan going in. “Have a clear vision of where you want to go, and how you intend to get there. That doesn’t mean it can’t change. We found that switching to 100 per cent scratch baking helped people to re-experience the bakery. People came back for the health benefits and for the superior taste of scratch baking. Scratch baking is actually less expensive, which helps us to keep the costs competitive, and sets us apart in the market as a destination bakery. We have customers from Calgary, Vancouver, Edmonton, Saskatoon, Chicago, Boston, and even New York.”

Jane Dummer, RD, known as the Pod to Plate Food Consultant, collaborates and partners with the food and nutrition industry across North America. www.janedummer.com

Endlessly unique. A whole galaxy of variety, with your success written in the stars.

All the innovations from raw materials and technologies to the finished product

All the stars of the trade for top-level networking All the world-class experiences such as the World Championship of Bakers and Confectioners and iba.OKTOBERFEST

All the latest developments live with entire production lines and equipment for artisan businesses THE WORLD’S LEADING TRADE FAIR FOR BAKERY, CONFECTIONERY AND SNACKS

Only you know all the things that went right to make it happen. The secret is having a partner that can provide the innovative products and personalized support that allow you to be your best. Dawn has nearly 100 years of expertise helping bakers get everything right.

Learn how Dawn can help you create more smiles.