BY BRIAN HARTZ

BY BRIAN HARTZ

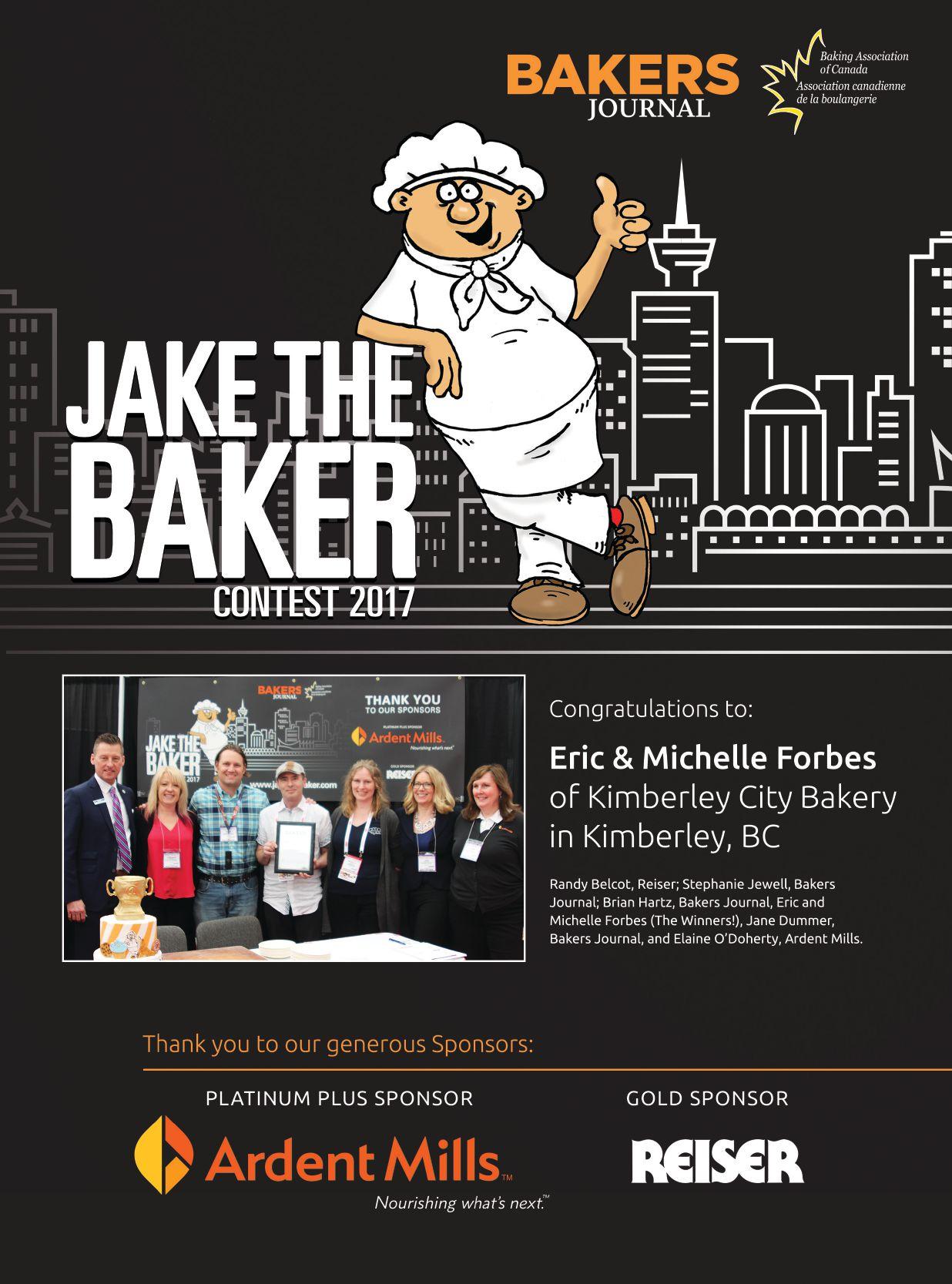

Kimberley City Bakery in Kimberley, B.C., is the winner of this year’s Jake the Baker Award. Thanks to our generous sponsors Ardent Mills and Reiser, Kimberley City Bakery owners Eric and Michelle Forbes won an all-expenses-paid trip to Bakery Congress 2017 in Vancouver, where they were able to accept the award and enjoy a cake made for them by Pikanik Bakery in nearby Surrey, B.C. – last year’s winner of the Jake the Baker Award. Ottawa’s Bread By Us, meanwhile, is our Jake the Baker Award runner-up this year.

You’ll be able to read more about both Kimberley City Bakery and Bread By Us in next month’s Bakers Journal, but I wanted to take this opportunity to thank and highlight the other bakeries who entered the competition for the Jake the Baker Award. This is the third year we’ve been handing out this accolade, and it seems the judging process has only become more and more difficult. That’s a very good problem to have!

One of the most inspiring entries this year came from Veronique Ayling, owner/operator of V’s Cupcakes in Ottawa. Ayling served in the Canadian Armed Forces for 16 years prior to being diagnosed with chronic Lyme disease. That was in 2012, and a couple of years later, she was out of the military, her career derailed by the often mysterious and debilitating illness. Undeterred, Ayling opened V’s Cupcakes – and it’s been nothing but a success. In June 2016, she was asked to provide dessert for the North American Leaders’ Summit – a gathering that included Canadian Prime Minister Justin Trudeau and former U.S. president Barack Obama. Learn more about V’s Cupcakes and Ayling’s story by visiting www.vcupcakes.ca.

JUNE 2017 | VOL. 77, NO. 5

INTERIM EDITOR | Brian Hartz editor@bakersjournal.com 727-575-7025 Mobile: 812-327-4770

TECHNICAL

EDITOR | John McColl, Puratos Canada jmccoll@puratos.com

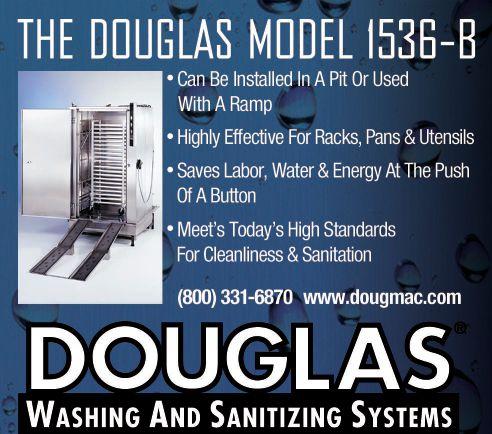

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Shannon Drumm sdrumm@annexweb.com 519-429-5176 1-888-599-2228 ext. 219

MEDIA DESIGNER | Alison Keba

CIRCULATION MANAGER l Beata Olechnowicz bolechnowicz@annexbizmedia.com

GROUP PUBLISHER | Martin McAnulty mmcanulty@annexweb.com

COO | Ted Markle tmarkle@annexweb.com

PRESIDENT & CEO | Mike Fredericks

Mailing Address P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Simply by being nominated for the Jake the Baker Award contest, nearly 20 Canadian bakeries are now on our radar. We were very impressed by all of you who entered …

Christophe Chocolate in Vancouver’s Burnaby Heights neighbourhood is another entrant worth mentioning (really, all of them are, but I have only so much space to work with here). Owner/operator Christophe Bonzon has quickly grown the business from two to nearly 20 employees without sacrificing creativity and innovation in the kitchen. Inspired by Swiss culture, he has introduced a puff pastry stick known as a flute, and his recent travels in Mexico gave rise to the “Tom Collins,” a gin-infused ganache with a lime gelee finished in a brilliant blue chocolate shell, as well as “Pear Bergamot,” a domeshaped bon bon filled with a pear and bergamot dark chocolate ganache. To further illustrate his commitment to innovation and constant improvement, Bonzon is sending his head chocolatier to train in Montreal.

Those are just two examples. I could go on … and on … and on. Suffice to say, the judging process was not something I would wish upon an enemy.

I’d also like to point out that simply by being nominated for the Jake the Baker Award contest, nearly 20 Canadian bakeries are now on our radar. We were very impressed by all of you who entered, so don’t be surprised if you receive a call or email in the coming months asking if you’re interested in being featured in an upcoming issue of Bakers Journal.

Until then, happy reading and happy baking! / BJ

PUBLICATION MAIL AGREEMENT NO. 40065710.

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Business Media.

CIRCULATION

email: blao@annexbizmedia.com

Tel: 416-442-5600 ext 3552

Fax: 416-510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

Subscription Rates

Canada — 1 Year $ 30.00 (with GST $31.50 #867172652RT0001, with HST/ QST $33.90)

USA — 1 Year $ 45.00 USD

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbizmedia.com Tel: 800-668-2374

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2017 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

When you have the cargo capacity that ts your business, there’s no limit to where you can go. Ford Commercial Vehicles have the right one for yours. The full-size Transit offers two wheelbases, three heights and three lengths. The compact and versatile Transit Connect delivers a car-like drive with cargo space to spare. Ford has something more: specialists who can help make choosing and up tting the van you need for your business easy. We’re sure you’ll like the sound of that. FORD.CA/BUILTFORBUSINESS

briefly | Lesaffre breaks ground on new facility; Dealers Ingredients hires new VP; SIAL show celebrates strong growth | for more baking industry news, see pages 12-13 and 19, and check out our website, www.bakersjournal.com

Dealers Ingredients Inc., is pleased to announce that Ryan Crelinsten has joined its team as the new vice-president of marketing and sales, providing additional leadership and support as Dealers Ingredients continues to strengthen the brands they represent and expand its focus on creating natural food ingredient solutions that positively impact healthy lifestyle choices.

Crelinsten brings extensive, strategic business experience, having spent over 12 years at Reebok – CCM Hockey in various marketing roles with increasing responsibility, including the last four years as a

business unit director. Crelinsten completed his undergraduate degree in biology at Queens University and received his MBA from Concordia University in 2010.

Chuck Harvey, president and CEO of Dealers Ingredients Inc. and its affiliates, said: ”Ryan’s extensive senior level management experience is a key addition to Dealers Ingredients Inc. With Ryan joining our team, we view this as our commitment to continue to strengthen the brands of our suppliers and provide innovative ingredient

Ryan Crelinsten

solutions to our industry. With the increased demand by consumers for healthy food choices and alternative protein sources, there will be even more pressure and demand on food ingredient manufacturers and suppliers to deliver cost-effective, environmentally sustainable, healthy long-term food solutions. I have great confidence in Ryan in this key role and his potential to drive the growth of Dealers Ingredients Inc. and its affiliates.”

In early May, Lesaffre Yeast Corporation broke ground on a new state-of-the-art blending facility in Cedar Rapids, Iowa. The facility will include a large production and blending area, offices, and a warehouse. Construction at the five-acre facility has begun and is scheduled to reach completion at the start of 2018. The plant will produce enzyme blends, concentrates, and dough improvers under the Saf-Pro ingredients brand. These

products will be supported by Lesaffre’s existing world-class Baking Center located in Milwaukee, Wis., and Lesaffre’s experienced team of scientists and baking technicians who test and perfect each product.

“We are proud of the latest investment to increase our capabilities to meet the needs of our baking customers.” said Tom Benner, president of Milwaukee, Wis.based Lesaffre Yeast Corporation.

TORONTO – The 14th edition of the international food and beverage tradeshow (SIAL Canada) and its equipment and technology section (SET Canada), held May 2-4 at Toronto’s Enercare Centre, saw a 32 per cent jump in the number of registered visitors compared to the previous show in 2015. The event drew 1,005 exhibitors and brands from 50 countries, and overall attendance was 16,578 food industry professionals representing more than 60 nations.

SIAL Canada executive director Xavier Poncin said the rise in attendance represents “tremendous, unparalleled success which can only be summed up using three keywords: innovation, multiculturalism, and local know-how.”

SIAL Canada also featured the 10th annual SIAL Innovation contest, which prompted a record 92 entries. A Canadian company, Taj Food, won the prestigious competition with its Saffron Sugar Cube product, developed in collaboration with Minamic Inc., a Sri Linkan firm.

The SIAL Innovation 2017 Grand Prize went to the Saffron Sugar Cube because of its interesting mix of flavours and the fact that it is 100 per cent natural and sold in highly convenient re-sealable packaging.

By winning the SIAL Innovation 2017 Grand Prize, Taj Food and Minami Inc. will receive a comprehensive marketing package valued at $120,000.

“i need a problem - solving partner to meet today’s baking challenges.”

ADM feeds your baking business with over a century of milling expertise.

Discover ADM’s expanding portfolio of perfected ingredients, along with unmatched expertise and personal care from farm to table. Enhance your product line with our range of flours, oils, flavors, starches, fibers and proteins. ADM also offers ancient grains, whole grains and gluten-free options to help you fulfill today’s food experiences. Learn more at ADM.com.

HARTZ

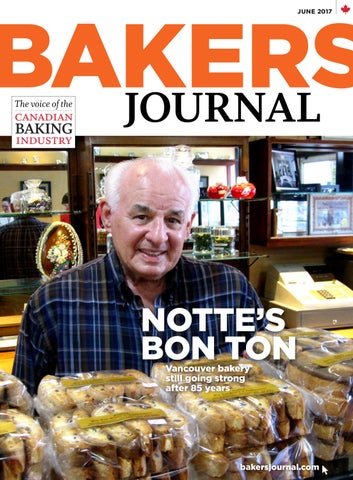

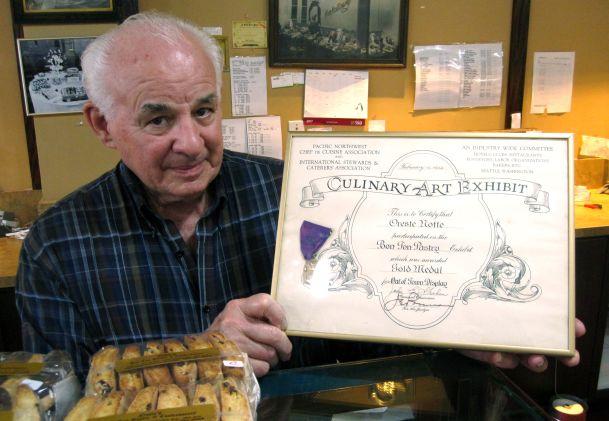

Notte’s Bon Ton Bakery will soon mark its 85th year in business in Vancouver, B.C. Since first opening in 1933, it hasn’t always been in the same location, but as the decades have rolled on, it’s retained the same charming character and adherence to pastries, cakes and other desserts made in traditional, time-tested ways. Notte’s has also retained a familiar face behind the scenes for much of its history: Alain Notte, a second-generation

Canadian whose father, Oreste Notte, initially emigrated from France to the United States as a teenager but didn’t like New York City and decided to try Canada. He moved to Montreal and landed a job with the Canadian Pacific Railway. He got sent from Montreal to Niagara Falls, and then from there to the iconic Empress Hotel in Victoria, B.C., where he worked as a pastry chef. “He was working at the Empress when they started the tradition of serving high tea in the afternoons,” Alain said.

The roots of Notte’s Bon Ton (“bon ton” means “good taste” in French) stretch back even earlier, to 1926, when Oreste left his job at the Empress to go into business for himself in Victoria. Alain’s mother, Agnus, also emigrated from France, but she was very young at the time – just two years old. Her family returned to France for several years but wound up moving back to Canada. Agnus, 19 at the time, met Oreste in Victoria. In 1930, they married and decided to move to Vancouver, “where my father was the boss

Alain Notte, former owner/operator of Notte’s Bon Ton in Vancouver. He still works at the bakery.

in the back, and my mother was the boss out front,” Alain said with a smile.

Oreste and Agnus Notte moved to Vancouver because its much larger population would be better for business. The moved worked out well and their family grew to include four children – three boys and a girl. Alain and his eldest brother, Alessandro, both chose to enter the family business. When asked about how he learned to be a pastry chef, he said, “I trained the

hard way – under my father!”

After moving to the mainland, Oreste quickly made quite a name for himself as a pastry chef, winning a gold medal in 1952 at a culinary arts competition in Seattle, Wash. Alain proudly displays his father’s medal and certificate on the wall of the bakery’s current location at 3150 W. Broadway in Vancouver, which opened its doors in 1998 after being located next to the Orpheum Theatre on Granville Street for 65 years.

}Alain recalled how his father would supplement his income on the weekends by supplying hors d’oeuvres for cocktail parties. Eventually, the bakery business got so busy that he had to stop making hors d’oeuvres, “so those people stopped having cocktail parties,” he said. “They said, ‘That’s it, no more.’ My father’s cocktail party food was very popular.”

Alain said it wasn’t always a sure thing that the bakery would remain in the family after Oreste retired, as he and Alessandro both moved to Switzerland to study the hotel business. Although they both received degrees in hotel management, and Alain worked for a time in restaurants and bakeries in

Austria, Italy and the United Kingdom – “I had great experiences in Europe,” he said – the Notte brothers were called home to take over the bakery from their father.

Today, Notte’s Bon Ton employs about 10 people – six preparing food in the back, and four front-of-house staff members. In the past, the bakery employed more people

what to do. She always ran the front of the shop.”

Alain has a son, but his son chose not to follow in his father’s footsteps because of a nut allergy. “He went into the commercial painting business and has done very well for himself,” Alain said.

Notte’s Bon Ton doesn’t bake

It’s wonderful to have so many third-generation customers coming in. It’s because the quality of our products is still there and has been there all the time.

to keep up with its busy catering-supply business, but in recent years it’s narrowed its focus to solely retail. “All the caterers and big clubs have their own pastry chefs now,” he said, explaining why Notte’s Bon Ton decided to change its business model.

Although Alain and Alessandro sold their ownership stakes in the business to Alessandro’s son (Alain’s nephew), Alain continues to be closely involved with the business (Alessandro has retired). “I’m in here everyday,” he said. He’ll likely continue to do so – longevity runs in the family. “My mother just passed away last year at the age of 110,” he said, “and before she died, she was still telling us

bread but it does produce savoury treats such as croissants and brioches, and it usually doesn’t stray from tried-and-true formulations.

“We’ve maybe added a few things over the years here and there but we’ve always kept our products limited to the traditional ways,” Alain said. “We get the same customers coming in all the time. They like the pastries but their favourite is what we call the Diplomat Cake. It’s three layers of puff pastry, two layers of sponge, with a rum syrup on the sponge cake, and it’s all rolled in butter cream, which is made of pure butter. And we don’t use any essences of liqueurs whatsoever. Whenever we say a liqueur is

in something, it’s the liqueur, not the essence of something.”

Notte’s Bon Ton makes a smaller version of the Diplomat Cake that can be used as a birthday cake. “The only difference is that the birthday-cake version has a little bit more liqueur in it,” Alain said with a chuckle.

Alain said the bakery hasn’t really done much over the years to celebrate its longevity. “We just keep going,” he said. “It’s wonderful to have so many third-generation customers coming in. It’s because the quality of our products is still there and has been there all the time.”

People notice such commitment to quality, Alain said, and they return to the bakery time and time again when they have occasions to celebrate. “I had a lady come in here to order a wedding cake for her daughter. I said, ‘Sorry, we’re fully booked.’ She said, ‘You can’t refuse this. You made my parents’ wedding cake, you made my wedding cake, and now you’re going to make my daughter’s wedding cake. You have no right to refuse it!’ We have a lot of people like that.” / BJ

For more bakery profiles, visit www. bakersjournal.com.

BY YVONNE DICK

Some successful bakeries discover their winning formula early and manage to keep it through decades of time. KUB Bakery in Winnipeg is one such place.

Since 1923 KUB has been rolling out rye bread dough. Using traditional methods, KUB bakers have created an interesting and big-selling rye bread recipe that’s become one of their trademark items. The company is so confident in its work that it offers a replacement guarantee for anyone who might be unsatisfied with the results.

Manager Lisa (nee Einfeld) Perkovic says that with a few adjustments, the company has been using the same rye bread recipe since its opening 94 years ago.

When baker Alex Kucher bought out his partners, the business became KUB, which stands for Kucher’s Ukrainian Bakery. The bakery was started by Alex Kucher, A. Andrychuk, N. Doskuch, and L. Stoyich, bakers from the Ukraine who immigrated to Canada. In 1982, the last of the original bakers, Alex Kucher’s son Bill Kucher, wanted to retire. He searched for just the right person to take over his business, and found a match in the Einfeld family, specifically Lisa’s father.

}Perkovic says, “My dad and his brother were the bakers; it was a family operation. He already owned a couple of small bakeries and was the manager for the bakery at Safeway for a time.”

Perkovic and her brothers Jeff and Matthew are the latest generations of KUB owners and managers. In spite of a few changes in location and ownership, the name has endured. For Perkovic, her part in the legacy began sometime after 2000, when her father, also a baker in addition to owning several bakeries, decided it was time for retirement. Then Lisa and her two brothers took their turn.

While the younger generation does not bake the bread themselves, “We

was

People do prefer a bread that is made by hand compared to manufacturing machines. There is nothing like a loaf of fresh baked bread.

1923 and continues to produce breads using tried-and-true methods. to their TransCanada trail location and find bakery space to lease on a temporary basis.

have excellent bakers who do that. We are better at the administration side of the business,” Perkovic says. The ovens are going night and day turning out the same recipe which was used in the beginning for the hearth-baked rye bread. At least two days a week require three shifts of bakers. A loaf (or dozens) can be baked in 1.5 hours in any of the local KUB kitchen locations. There have always been at least two stores in operation, and some years a third location. Jeff Perkovic is the company’s main salesman. He is responsible for cold calls to new stores. KUB also engages in social media campaigns, coupons, and special promotions.

In 2008, the main location on 66 Stella Street in Winnipeg caught fire. This set the company back a little until they could relocate the vital operations

Perkovic says it took three years to transition to a new location. She and her brothers insisted on finding the most suitable piece of real estate while they waited for their insurance policy to pay out.

By 2011, KUB Bakery was restored and two full operations back in place. Today you will find KUB at 850 Erin Street and 1530 Regent Avenue in Winnipeg. At each location, you can find a small retail storefront. Though walk-in clients have decreased with time, there are still regulars who enjoy coming and selecting their baked goods on-site.

In addition to the famous rye bread, KUB also creates a number of other bread including Red River multigrain, french, harvest, garlic, pumpernickel, white, brown, marble rye, onion rye, raisin, and cherry/fruit bread. Dinner, hot dog, hamburger, sub, Kaiser, and sub sandwich buns are also on the list.

Three or four expert bakers are on hand during production to keep the end result consistent. Perkovic says competition is stiff for hearth-bread bakeries.

“People do prefer a bread that is made by hand compared to manufacturing machines. There is nothing like a loaf of fresh baked bread. We like to use local products in our baking, as well as sourcing Manitoba ingredients. We are a Canadian made, artisanal bakery,” she explains.

If you are looking for a side of something sweet, not to worry. Kub pastries include danishes, turnovers, cookies, muffins, apple baskets, cinnamon loaf/buns, poppy-seed loaf/buns and other delights. KUB Bakery will ship wherever their goods are requested and have expanded to Minnesota and North Dakota through a distributor where there is high demand for artisanal, handmade bread.

Perkovic says competition among rye bread bakers is also stiff in Winnipeg. While larger-scale operations can turn it out in huge quantities, people can taste the difference between bread made by hand and that which has been mixed and baked by machine. The advantage that mega companies have over artisan bakeries is volume. As with any food product, baked goods made in great amounts can be sold – sometimes for less than a traditional bakery could afford. KUB feels that fresh is still the best, and local grocers agree.

With long-standing agreements, locals can find KUB goods for sale in Sobeys,

industry news ¦

KUB produces a wide variety of breads, ranging from cinnamon loaves to sandwich buns and beyond.

Costco, Safeway, Food Fair, Co-Op and Save on Foods. Here the buns and cinnamon loaves are especially popular.

Along with grocery store partnerships, close to its centennial, Kub Bakery is well known within the city of Winnipeg and surrounding areas of Manitoba. Perkovic believes this is a definite boost to sales. Word of mouth is always a critical way to get people involved in a bakery, and KUB has a longstanding relationship within the community of Winnipeg. It is a proud supplier to the Winnipeg Arena for the National Hockey League Winnipeg Jets

events, MTS Centre for the Manitoba Moose, and Shaw Park for the Winnipeg Goldeyes baseball team, where fans extoll the virtues of the Jumbo Dog for which KUB provides the extra-large buns. Each year KUB provides bulk orders for the Manitoba Homecoming and during wedding season.

The success of KUB is likely a matter of several factors, but for Perkovic the enjoyment of the product is the most important thing. She loves the onion bread and rye bread, and judging from the feedback of customers, so do they.

/ BJ

TORONTO – River Road Bakehouse, a new meaningful lineup of quality artisan breads, hit the shelves across Canada in April with the mission of helping reduce Canada’s $31-billion-dollar food waste problem. In Canada, more than 400 pounds of food is wasted each year per person. This is the equivalent of wasting an 18-ounce T-bone steak every single day. River Road Bakehouse will be launching a #RoadtoZeroFoodWaste campaign to support food waste awareness and education.

“Food waste is a fundamental

problem in our nation today,” says River Road Bakehouse vice-president John F. Kennedy. “The launch of River Road Bakehouse and the #RoadtoZeroFoodWaste program is an engaging way for consumers to try great bread and think twice about food waste reduction.”

The brand has partnered with the University of Guelph, renowned for their related work, with a $15,000 donation to the Guelph Food Waste Project. The partnership will support food waste research aimed at

uncovering new and actionable insights that will contribute to reducing food waste across Canada.

“At the University of Guelph, understanding causes and volumes of food waste is our passion, and partnering with River Road Bakehouse is a natural fit,” states Michael Von Massow, an associate professor in the university’s food agriculture and resource economics program. “Together we will give Canadians the information and tools they require to reduce food waste in their day-to-day lives.”

In addition to its partnership with the University of Guelph, River Road Bakehouse is teaming up with 12 non-

profit organizations across North America, each with a mandate to reduce food waste in the communities that they serve.

To support these charities, River Road Bakehouse has developed an engaging and educational food waste quiz on their website (www.RiverRoadBakehouse.com). For every user’s first completion of the quiz, River Road Bakehouse will donate 25 cents to one of the charities, with an additional 25-cent donation if the results of the quiz are shared by the user on social media. A 50-cent donation to an organization is the equivalent of diverting one meal from landfill and supplying it to someone in need.

Operating out of zero-waste bakeries, River Road Bakehouse breads are made using simple ingredients, and traditional European baking methods. The brand’s Canadian family of breads include Demi-Baguette, White and Multigrain Ciabatta Buns, Sliced French Loaf, Sliced Light Rye, and a delightful Sesame Focaccia. For an authentic bakery experience, products can be warmed in the oven for 5 minutes at 400 F.

River Road Bakehouse products are available in Canada at most Real Canadian Superstores, Loblaws, Your Independent Grocers, Zehrs, and Dominion stores.

Bakery students from Vancouver Island University, Vancouver Community College, Pacific Institute of Culinary Arts and Northwest Culinary Institute participated in a two-part contest held by Renshaw Americas during Bakery Congress 2017 in Vancouver, B.C.

Part one was covering a cake (dummy) with fondant in the shortest time possible; part two was decorating the same, using their own design and imagination.

In part one, using Renshaw’s Ready-Rolled Icing – sheet fondant that does not require kneading or rolling – Northwest Culinary Institute student Jennifer Sherlock covered the dummy in exactly five minutes, to a very high standard of finish and won first prize overall in the advanced category.

For part two, the students

had 25 minutes to create their own decorations using Renshaw’s Gum Paste, Marzipan and Royal Icing –novelty products that constitute Renshaw’s launch in Canada, which coincided with the show.

All students truly enjoyed the experience. Ready-Rolled Fondant is a very easy way for bakeries to get into fondantcovered cakes to reap the benefits of much higher profit margins compared to conventional cakes. www.renshawbaking.com

BY DIANE CHIASSON

The 150th anniversary of Canadian Confederation should lead to an uptick in visitors

The 2017 summer season will likely bring more tourists to your city or community since it will include a major birthday for Canada.

There will be many of festivities and events from coast to coast across Canada to celebrate the 150th anniversary of Confederation. Additionally, Montreal is celebrating the 375th anniversary of its founding in 1642, and to top it off, the city will also celebrate the 50th anniversary of Expo 67.

These and other summertime events could bring thousands of visitors to your community. Have you started planning your summer 2017 celebrations and marketing plan yet?

}vases, tablecloths, cheerful umbrellas and colourful wall décor. As well, take the time to design a great window display that tells a good story and that will encourage customers to peek in just out of sheer curiosity. Your window display must be your personal invitation to tourists and should showcase your best bakery products.

If you have a small café or eating area, offering your guests free Wi-Fi access will build customer loyalty and boost sale. Travellers have come to expect fast, convenient and reliable Wi-Fi. This is the number one thing that tourists have on their mind these days … being able to connect their devices to the Internet via Wi-Fi, and smart bakery shops provide Wi-Fi to their customers. Most people travel with their laptops, smartphones, and iPads, and they need to keep up-to-

Your window display must be your personal invitation to the tourists, and should showcase your best bakery products.

Tourists will be looking for quick snacks and yummy and healthy meals while attending events, or on their way to or from these events. Every bakery owner wants more new customers, so get going.

Here are some simple tips that will help you draw more tourists to your bakery.

People judge books by their covers, and as you know, first impressions matter. Your storefront’s curb appeal is a make-or-break factor when it comes to attracting customers inside your bakery. Neglecting your bakery’s front area could also mean missed opportunities for owners to catch the potential new customer or tourist wandering by, so make sure that your storefront is free of debris, and spruce it up so it’s clean and inviting.

To add some warm-weather cheer to your bakery, apply a fresh coat of paint or wallpaper, new plants and fresh flowers,

date with their emails, but many do not want to pay the exorbitant roaming charges that telecommunications companies like to charge. Customers will love to enjoy a nice cup of coffee with some baked goods while catching up on their emails and posting to their social networks.

Today many people love to research online before visiting a café or a bakery shop. They can find you when in your area via your website and social media sites. Be sure to update your website frequently with an easy-to-read menu, and with many high-quality, tantalizing photos of all the great bakery products you have to offer. As a bakery owner, you must provide high-quality images, even if it means hiring a professional photographer. This is incredibly cheap to do these days and lets people see what you can deliver and gets them excited. With social media apps, you can generate a following by offering special social media deals. Offering a 10 per cent

reward to followers who bring their friends in to your bakery could make you the destination of choice for someone going to an event in your area with their friends. The power of social media is undeniable, and it’s an essential tool to marketing your bakery this summer. Just like tourists search for what’s new in your area, the search engines also favour websites that have fresh and relevant content.

As you know, exceptional service and delicious products are time-tested ways to get customers coming back to your bakery. Eating something yummy and unique will make people talk and even get them to write online reviews. Tourists going to events out of their area often use online reviews to decide on the best possible hotels, coffee shops, restaurants and bakeries.

Thus, your website and social media platforms should have customers’ reviews on them and should encourage customers to review your bakery and menu items. This will help improve your star rating and surveys have shown that star rating is the number 1 factor used by consumers to judge a business. And you know how the saying goes – 12 people tell four of their friends, and those friends try your bakery products, like them and tell their friends, and so on, and so on. Since customers love helping out businesses they appreciate, make sure to ask them to leave feedback after their great experience. / BJ

For more marketing ideas, visit www.bakersjournal.com.

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 30 years. She is recognized as the industry leader in providing innovative and revenue-increasing foodservice and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or chiasson@ chiassonconsultants.com, or visit www.chiassonconsultants.com.

BY BRIAN HARTZ

When’s the last time you upgraded your oven or mixer?

Perhaps it’s been a while.

Even if it hasn’t, it’s never too soon to think about your goals for your bakery and how your equipment is going to help you achieve those objectives. And that means taking a look at two of the key components of your kitchen: ovens and mixers.

A successful commercial bakery, of course, needs many more pieces of equipment, but ovens and mixers are about as basic and fundamental as you can get. They also happen to represent costly capital expenditures so it’s important to make sure you’re getting exactly what you need – both today and in the future.

According to the 2016 Commercial Foodservice Market Forecast Report by the Manufacturers’ Agents Association for the Foodservice Industry (MAFSI), 25 per cent of foodservice operators in 2016 expected to increase their budget for equipment and supplies, while 62 per cent of operators planned to remain consistent – a 20 per cent jump from 2015.

}A number of trends are driving change in the equipment sector, so if you are looking to invest funds in a new oven or mixer, you’ll also want to make sure you’re up to speed on the latest innovations. According to the MAFSI report cited above, energy efficiency and space savings are two of the most-desired attributes in new foodservice equipment.

Sweden-based Revent is tackling trends head-on with its line of round ovens dubbed the One Series. These ovens feature a smaller baking chamber and sliding pocket door that reduces their footprint by 45 per cent. Revent’s ovens are used daily by bakeries in more than 100 countries, and it has a North American headquarters and production facility in New Jersey.

We are constantly reviewing our product portfolio and evaluating platform needs because space is such a constraint.

“It’s been a huge, huge hit,” says Revent national sales manager Ron Schumacher. “Energy efficiency was one of the key design factors. We totally redesigned the burner system, the heat exchanger system has been redesigned, and the steam generating system has been redesigned. Nineteen new patents have been applied for as a result of this oven design process.”

Revent’s ONE Series, which currently consists of two models – the ONE26 single-rack oven and ONE39 mini-rack oven – was showcased at the NAFEM show in Orlando, Fla., in February. Revent business development manager Brad Winnaman, a trained baker, put the ovens through their paces for attendees, turning out high-quality baguettes and rolls. Thanks to the ovens’ large, all-glass doors, the baking process could easily be viewed

by people walking past the booth – that’s definitely by design, says Schumacher.

“You have the lighting and curved glass and everything that helps show off the product while you’re baking it. It fits with the trend toward more visual, experiential interactions with food. When you go into a bakery, you want to see what’s going on.”

Schumacher says that in 2008, when Revent first set about the task of redefining the bakery oven, the company wasn’t sure where it should focus its efforts. “The company was looking down the road to see how we could continue to be a market leader and separate ourselves from our competitors,” he says. “We thought, ‘You know, there’s not a lot you can do with a bakery oven nowadays.’ But then we thought maybe we could make the burners better and more efficient and add a bit of new technology – basically just touching it up around the edges, nothing ground-shaking.”

The key, Schumacher explains, was

going out and talking to bakers. “We asked them, ‘What would you want if you could have a new oven?’ A few key points came back from just about everybody we talked to. One, make it smaller. They said, ‘Space is tight, our bakeries are cramped, and we’d love to see a smaller oven with greater efficiency. If you can get some greater efficiency, that’d be great because the cost of energy is going nowhere but up.’ Two, ergonomics. They said, ‘Can you make it easier to work with? We’re always burning our arms on the doors and stuff like that.

“And three, make it a showpiece. They said, ‘Add some theatricality to it, like in the deli they have the big rotisserie chicken ovens that let you see the flames. It provides some nice visual effects.’ So, after we got those core ideas, our team went to work. You see it about once in a generation a piece of food equipment is redesigned from the ground up and that’s really what the One Series represents.”

Revent’s ONE Series ovens aren’t just nice to look at, however: The sliding pocket door makes it much easier for bakers to navigate around the oven and load dough, in addition to offering additional benefits, Schumacher explains. “It allows you to move that oven closer to your customers, making it easier to engage with the customers. It also helps with not having that big door swing and

that helps reduce the overall operating footprint by well over 40 per cent, depending on the oven and the door, which is huge – if I’m a baker, I can now roll my racks in from any direction. It doesn’t matter where my racks are coming from. And it certainly does minimize the risk of burns to the bakers. If you hang around bakers long enough, they like to show you their scars on their arms and elbows. So sliding the door out of the way dramatically reduces the opportunity for that to happen. The overall, look, feel and design of the oven, it’s a generational leap forward.”

One of the biggest and most venerable names in mixers, Troy, Ohio-based Hobart – founded in 1897 –manufactures a wide range of heavy-duty mixers and mixer accessories for bakeries and pizzerias. Hobart is now part of ITW Food Equipment Group, a division of Illinois Tool Works, and manufactures and services equipment in Canada, the United States, Brazil, China, France, Germany, Italy, and the United Kingdom.

Hobart product line manager Julie Heinrichs says the trend toward food machines that take up less space is a design priority for the company.

“We’ve got customers that are requiring certain footprints within their

facilities, so we are constantly reviewing our product portfolio and evaluating platform needs because space is such a constraint,” she says. “We are getting feedback that smaller-footprint mixers is something that people are asking for, so we want to make sure we have the right equipment sizes available.”

Heinrichs says this is particularly true of Hobart’s line of spiral mixers.

Currently, Hobart offers a four spiral mixer models, ranging from 180 pounds to 350 pounds, but is working to develop a smaller model for specialty bakers that aren’t making large batches of product and don’t need a large device taking up valuable floor space.

“We are looking to launch a new 130-pound model,” she says, “and eventually our 180-pound model is going to take up the same platform. We try to save as much space as possible by putting in the larger horsepower motor, while the surrounding structure is as compact as we can keep it. Anyone who is looking to grow a business or needs versatility –the ability to do large batches and small batches – that’s one of the nicest attributes of the Hobart spiral mixer.”

Spiral mixers, Heinrichs adds, are also appealing because of how they function.

“The beauty of a spiral mixer is that the bowl moves around instead of just beating the dough against the side of the

bowl,” she says. “Also, it uses a pulley system instead of gears, so it’s very quiet when it’s running and also easy to maintain. The pulleys causes less stress on the inside and leads to greater longevity for the mechanical components.”

Hobart mixers in particular, Heinrichs explains, employ a double-pulley system that results in additional effectiveness and longevity.

“Basically we are taking and reducing the work required on the components inside because we’ve enhanced the mechanics behind it,” she says. “So, ultimately, we could reduce the motor’s horsepower but we’ve kept it equivalent to our competitors and we’ve added in double-pulley systems that give us the ability to overcome limitations on capacity while maintaining consistent mixing without lagging.”

Routine maintenance is also much easier and less frequent, Heinrichs claims, with a double-pulley system.

“Our double pulley system is much easier to maintain,” she says. “If something should stretch or go wrong after a long period of time, our data shows that it won’t require a lot of significant amount of maintenance. There isn’t a gear system, like with a planetary mixer, that’s constantly knocking around.

“Double-pulley systems also make for very quiet and very easy-running machines,” she adds. “The double-pulley system causes less stress on the components on the inside. That’s how we are preventing even less maintenance cost than the typical spiral mixer. When you add in the extra pulleys, you’re taking strain off your components. It’s like when you’re riding a bike, in one gear you’ll be pedaling really hard, and in a lower gear it’ll be easier. That’s what we’re doing by adding in a second set of pulleys. It makes the system work much easier. As a result of that, the interior components have longer longevity.”

Shiny new ovens and mixers are nice, says Ross McMillan, co-owner and sales manager with RF Bakery Equipment in

Coquitlam, B.C., but make sure you keep good records of when equipment was purchased and when it’s due for service.

“All equipment has wear parts, but generally speaking, dough makeup equipment has a useable lifespan of 20 to 25 years, give or take five years,” he says.

“Things that are more wear conscious, like ovens with heat exchangers, or a proof box, things that have parts that are critical to their operation that have a limited lifespan, the overall lifespan can be much shorter, somewhere closer to 10 years. For instance, maybe you’ve got a proofer and you are proofing sourdough bread every day, it’s producing a very corrosive vapor. Your proofer’s going to have a shorter lifespan. Or you’re using rack ovens 20 hours a day, seven days a week – they’re going to have a shorter lifespan, because you’re using them hard.” / BJ

On May 8 at the lively Raca Café & Bar in Toronto’s Parkdale neighbourhood, Cacao Barry invited 20 chefs to discover an exclusive menu as part of its latest Flavour Dinner.

Hosted by executive chef Ivana Raca, the Flavour Dinner started with a refreshing cocktail infused with caraway and citrus notes. The cocktail was inspired by what was revealed as the secret ingredient: caraway, the seed with anise-like aromas.

While guests enjoyed the last rays of sunshine, appetizers were served: a delicate shrimp ceviche and a crostini with whipped feta, dill, mint and grilled radicchio.

Inside the cozy restaurant, guests discovered the menu Raca had prepared using caraway and Cacao Barry chocolates.

The whole experience was actually initiated 175 years ago with a Scottish man named Charles Barry, who started a quest for extraordinary chocolate flavours. Cacao Barry is thrilled to continue this journey today by exploring and sharing chocolate flavour pairings. This is what the night was all about – an opportunity for the 20 selected chefs and members of the media to share experiences, discover an exclusive menu and be inspired.

The dinner started with a crispy tartlet filled with a creamy purée of white asparagus, celery and Zéphyr white chocolate topped with wild mushroom and fresh asparagus delightfully paired with a Pinot gris, Beamsville Bench VQA, and Malivoire 2015.

The menu then took us to a decadent

venison dish beautifully paired with the rich flavour of dark chocolate. The spiced caraway rubbed venison loin was served with a Tanzanie origin chocolate jus, a sour cherry croquette balancing the dish with a touch of tartness and a silky carrot puree with Saint Domingue origin chocolate.

To end their dinner, guests enjoyed an Ocoa and Inaya chocolates, caraway and hazelnut tart with rhubarb coulis.

Nothing would have been possible without Raca and her fantastic team. She accepted the challenge to play with chocolate flavours and imagine the most delicious pairings, and the guests enjoyed a fascinating dinner, sharing their experience and inspirations; they left the restaurant full of new ideas for their own creations. www.cacao-barry.com

Believe it or not, it’s possible for baker tenants

As we explain in our new book, Negotiating Commercial Leases & Renewals FOR DUMMIES, free rent is just one negotiable factor in a commercial lease. Even if you did not receive a rent-free period when you signed your first lease, you may be eligible for one when you renew (although you may have to work harder to get free rent on a renewal).

This is probably the most unpredictable but most interesting part of the lease agreement we negotiate. Some landlords are quite flexible when it comes to free rent but others are not so liberal. To demonstrate, we remember one tenant we negotiated the first four years minimum rent free (on a 10-year lease term). For another tenant, we negotiated for 18 months free plus a $180,000 tenant allowance on a 10-year term. Free rent on lease renewals is not unreasonable and often achievable in some situations – if you know what buttons to push with your landlord. Here are some tips to remember for baker tenants:

Some landlords are very concerned with achieving certain rental rates on paper

}As a general negotiating rule, always ask or negotiate for more free rent that you need or want.

cash value by up to 20 percent. You will have to weigh the pros and cons of your particular situation to determine if cashing in free rent minus a discount for the landlord still makes sense for you and your bakery business.

Free rent is often the easiest concession for a landlord to make. As a general negotiating rule, always ask or negotiate for more free rent that you need or want. This is especially pertinent if other commercial spaces in the premises are vacant and have been so for some time. Aim for at least one month of free rent for each year of your initial or lease renewal term. But remember to begin your negotiations at more than that. If you begin your negotiations at five months of free rent, you may be counteroffered three months of free rent.

but have no problem making other concessions. Suppose you want seven months of free minimum rent but the landlord will give you only three months free. Rather than concede your position, you might counter propose that months 4, 5, 6, and 7 are half rent free; that is that you pay only half the agreed-upon monthly rent. When renewing your lease, you will have more history on your side (you will have a track record of paying your rent on time), so you can easily ask for more.

You may find it necessary to raise capital at some time in your business. If you have negotiated a free rent period for your lease agreement or your lease renewal, it may be possible for you to exchange that free rent for cash. Mind you, there is often a price to be paid! For example, if your rent is $3,000 per month and you have five months of free rent, the cash value is $15,000. However, because this means an outlay of cash for the landlord, he or she may want you to discount this

If your lease is coming up for renewal and you see signage on the outside of the building offering landlord-supplied inducement packages for new tenants, speak up! As an existing tenant (and proven customer), you should qualify for these same – or even better – inducement packages.

For a copy of our free CD, Leasing Dos & Don’ts for Commercial Tenants, please e-mail your request to JeffGrandfield@ TheLeaseCoach.com.

For more facilities advice, visit www.bakersjournal.com.

Dale Willerton and Jeff Grandfield - The Lease Coach are Commercial Lease Consultants who work exclusively for tenants. Dale and Jeff are professional speakers and co-authors of Negotiating Commercial Leases & Renewals FOR DUMMIES (Wiley, 2013). Got a leasing question? Need help with your new lease or renewal? Call 1-800-738-9202, e-mail DaleWillerton@TheLeaseCoach.com or visit www.TheLeaseCoach.com

DirectDrive System spirals function the way spiral systems should function; with reduced belt tension, with improved product orientation, with increased load capability. This system eliminates overdrive and makes operation of your mission critical equipment reliably smooth, without interruption.

From rotary knife cutters to horizontal-flow wrapping machines, Bakers Journal keeps you in the know | for more new products for the baking industry, check out our website, www.bakersjournal.com

A new stainless steel Rotary Knife Cutter Model #4-SS from Utica, N.Y.-based Munson Machinery cuts corn, spices, roots, grains and other foods into controlled sizes gently, sharply and accurately, with little or no fines or dust. The unit features a rotor assembly with five full-length knives that cut material against four stationary bed knives until particles become small enough to

SleekWrapper, part of the Paxiom Group, has introduced a new fully servo-driven horizontal flow wrapping machine—the Sleek 40 Wrapper— designed to provide smaller or start-up operations with all the efficiency advantages of a four-axis servo drive, at entrylevel cost.

Built in a heavy duty stainless steel frame, the new Sleek40 Wrapper is capable of handling 60-100 packs per minute. A fully adjustable forming box makes it highly suitable for pastries, cookies and various size snack food items.

The economical four-axis Sleek40 Wrapper uses four nonproprietary Mitsubishi servo motors and servo drives that create

pass through apertures in two large, semi-cylindrical screens.

Compared with other types of mills, the Munson Rotary Knife Cutter offers greater shear with less impact, yielding end product with clean cuts in tightly controlled size ranges. The cutting knives, which are milled of hardened tool steel and can be re-sharpened, impart centrifugal force that positions particles between cutting edges of the rotating knives and reversible bed knives.

An extensive selection of screen sizes allows tight control over end-product sizes, making it ideal to cut or crack grains, spices, roots, chips and similar products. www.munsonmachinery.com

quick and easy changeover and adjustment. No chains. No gears. No lubrication needed.

The innovative Sleek40 Wrapper comes with an easy-tooperate color touch screen and is built to quickly recall specific recipes with its 100-product memory setting. Other enhanced features include a no-product no-bag setting, automatic opening of the heated wheels to prevent the burning of film, and automatic homing of the jaws when changing over to different product sizes. www.sleekwrapper.com

7585 Danbro Crescent, Mississauga, ON L5N 6P9

Contact: Debbie Bell

Phone: 905-819-7000

Fax: 905-819-9768

Email: debbie.bell@adm.com

Plants: 2 Montreal, QC; Mississauga, Midland, Port Colborne, ON; Winnipeg, MB; Calgary, AB.

Sales offices: Montreal QC, 514-846-8533; Toronto, ON 1-800-267-8492; Calgary AB, 403-267-5656; Vancouver, B.C. 604-2990710.

Products offered: A full flour and mix product line for the bakery, donut, muffin, food service, biscuit, pasta, frozen, in-store bakery, pasta and industrial segments. Other products offered are stoneground whole wheat, cracked wheat, graham and cereal bran and rye flours.

Ardent Mills is working for the good of grain and committed to pioneering what’s next, with value-added, nutrient-rich, on trend grain solutions that deliver superior performance and consumer appeal like Simply Milled by Ardent Mills™ Organic Flour and Ardent Mills Great Plains™ Quinoa that is grown in North America. We also offer a full line of premium quality flour, oats and bakery mixes backed by a century of milling experience.

ARDENT MILLS ULC

235 Nuggett Court

Brampton, ON L6T 5H4

Contact: Elaine O’Doherty

Phone: 905-494-2600

Email: Elaine.ODoherty@Ardentmills.com Website: www.Ardentmills.ca

Plants: Flour Mills in Mississauga, ON, Montreal, QC and Saskatoon, SK. Bakery Mix plants in Burlington, ON and Saskatoon, SK. Oat and Durum Mills in Saskatoon, SK Products offered: A full line of quality flour including all purpose, strong bakers, cake & pastry, whole wheat, whole grain, Italian Style and specialty. As an industry leader in innovation we also offer SimplyMilled™ Organic Flour, Ultragrain™ white wheat whole grain flour, Sustagrain™ whole grain barley flour and flakes as well as Spouted

whole grain flour. This is complimented by our broad range of bakery mixes, bases and concentrates, many formulated specifically to customers’ needs.

Delivery: Across Canada by rail or truck, throughout North America and select export markets.

Distribution: Direct from plants, regional warehouses, or distributors, depending on product location.

Major Customers: Bakery and Food processors, Retail & Wholesale bakeries, Grocery Retailers & Instore bakeries, Foodservice Operators, Bakery and Foodservice Distributors.

1150 Rang Saint-Edouard, Saint-Liboire, QC, J0H 1R0

Contact: Rory Lesperance

Phone: 416-770-2310

Email: rlesperance@farinart.com

Website: www.farinart.com

Products offered: Ecocert, Kosher, Halal, HACCP and SQF 2000 certified. Farinart is a leader in processessing custom grain, flour, seed and pulses blends - both conventional and organic. Farinart also provides select line of gluten free blends, flours and processed grains. We have earned a strong reputation for delivering innovative solutions, superior expertise, product consistency and best-inclass service to retail and commercial bakers and food manufacturers.

Distribution: We deliver across Canada and overseas.

Delivery: 20 kg bags, tote bags and bulk products.

Company comments: We are a friendly and versatile company that can adapt to our clients’ requirements.

CANADA CORP.

No. 1 Grain Millers Drive

Yorkton, SK S3N 3Z4

Contact: Andrew Eilertson

Phone: 1-800-232-6287

Fax: 952-829-8819

Email: andrew.eilertson@grainmillers.com

Website: www.grainmillers.com

Plants: Yorkton, SK and U.S.

Distribution: Throughout Canada and U.S. Products Offered: Full line of conventional,

organic, & certified gluten free oats including quick & rolled flakes, flour, bran, steel cut, food grade fiber, and other innovative products. Complete product line includes other milled grains and custom blends of wheat, corn (yellow, white, non-GMO), barley, rye, triticale, and various other specialty grains.

Certifications: Organic, Gluten Free, Kosher, GFSI

Pack Type: Bags, totes, bulk, retail pack (500g-2.25kg)

Company Comments: Privately owned, Grain Millers delivers whole grain solutions to the modern world of food manufacturing. Customers rely on our quality, service, and innovation to meet today’s high expectations and tomorrow’s challenges. Learn more what we can do at www.grainmillers.com.

105 Commander Blvd., Scarborough, ON M1S 3M7

Contact: George Birinyi Jr., Carl Griesser

Phone: 416-291-3226

Fax: 416-291-2159

Email: gbjr@grainprocess.com

Products offered: Over 2,000 products including a full range of whole grains. Hard/ Soft Wheat, Triticale, Corn, Millet, Barley, Rye and Durum and organic products certified by QAI (Whole Wheat Flour, White Flour, “Ancient Grains” Spelt, Kamut, Quinoa, Seeds, etc.) Precooked and stabilized grains and flours, Whole Bean Flour, complete range of grains including Cracks, Flakes and Grits, Seeds (Sunflower, Sesame, Golden Yellow and Brown Flax), Beans, Peas, Lentils, Sugars, Nuts and Dried Fruit. Food processing also includes custom blending facilities for multi-grain formulas (Bread, Muffin and Pancake Mixes, etc.) packaging, granola cereals, toasted grains, Turbinado and Demerara Sugars.

Distribution: Across Canada and the United States.

Major customers: Bakeries, biscuit and cookie manufacturers, food service, bulk, health and natural food retailers and distributors and manufacturers.

Company comments: We pride ourselves as being the only stone flour mill in Canada to offer such a wide variety of products. Our product development team is ready to develop mixes and specialty grains for any application in the food industry.

& HOWSON LTD.

232 Westmorland St., PO Box 390, Blyth, ON, N0M 1H0

Contact: Jeff Howson

Phone: 519-523-4241, Ext. 60

Fax: 519-523-4920

Email: jeff@howsonandhowson.ca

Contact: Dan Greyerrbiehl

Phone: 905-792-2962

Fax: 519-523-4920

Email: dgreyerbiehl@rogers.com

Plants: Blyth, ON

Products offered: Durum semolina, durum flours, durum whole wheat semolina, Atta flours.

Delivery: Bulk truckloads, bulk bags (750kg), 20kg bags, 40kg bags, 50lb bags and 100lb bags to Ontario, Quebec and United States. Distribution: From Blyth, ON, Plant by truck or distributors.

Major customers: Manufacturers of dry pasta, fresh pasta, frozen pasta, and snack crackers. Assistance offered: Technical assistance. Company comments: Howson & Howson Ltd. have been quality wheat millers for over 135 years. We are continuously modernizing our durum mill in order to supply our customers with high-quality durum semolina, durum flour and other durum products.

49888 Nova Scotia Line

RR2 Aylmer, ONT, N5H 2R2

Email: info@jamestownmills.com

Phone: 519 933 2648

Website: www.jamestownmills.com

Products Offered: stone ground, non gmo gluten free flours, teff, pulses, quinoa, amaranth and millet. Supplier of sorghum, corn and rice flours, as well as starches and gums

Supplying the gluten free industry

NUNWEILER’S

Box 28009 RPO E. Kelowna, Kelowna, BC V1W 4A6

Contact: Ross Nunweiler

Phone: 1-888-726-2253

Email: info@nunweilersflour.com

Website: www.nunweilersflour.com

Plant: Alsask, Sask.

Certifications: Pro-Cert Certified Organic Systems, Kosher Certified.

Products offered: Nunweiler’s Flour Company is a 100% dedicated Certified Organic flour mill located in Alsask, SK with our sales office in Kelowna, BC. Our family of products include: Whole Grain Wheat Flour, Dark Rye Flour, All Purpose & Pastry Flour, Spelt Flour, Buckwheat Flour, Red Fife Flour and Kamut Khorasan Flour.

Distribution: B.C. – Snowcap Enterprises, Snowcap Interior, Aarsen City Delivery. Major customers: Retail and wholesale

bakeries, specialty product bakeries, retail mass market and natural food stores. Company comments: Since 1988, Nunweiler’s Flour Company has been milling Organic Canadian grown grains. Our whole grain flour is processed in a low temperature impact mill at a temperature of 60*F/ 16*C in the cool winter months to 95*F/ 35*C in the warm summer. We include No Additives, Preservatives or Blending in our freshly milled whole grain flour. We are proud to support Canadian Organic family farms and we are committed to producing premium quality products for bakers and consumers wanting wholesome and nutritional foods.

6201 E Primrose Green Drive Regina, Saskatchewan S4V 3L7

Phone: 306-751-2040

Contact: Cory Whyte, General Manager

Phone: 306-751-2440

Website: www.nutrasunfoods.com

Certification: NutraSun Foods Ltd. is certified Organic by Quality Assurance International (QAI), Kosher Certified and H.A.C.C.P. , ISO 22,000 Compliant and Non GMO Project Verified.

Delivery: We deliver bakery ingredients across Canada and the United States as well as shipments offshore.

Products offered: NutraSun’s high quality Organic and Conventional flour is milled from Hard Red Spring and Hard White Wheat. We are the exclusive miller of premium Snowbird White Wheat flour and also offer a variety of Whole Grain flours.

In addition to flour, we are continuously expanding our product line of organic and conventional bakery mixes and bases to include breads, muffins, cookies, pancakes and whole grain pizza crust mix or base. We also offer customized grain blends and organic and clean label dough conditioners. NutraSun offers a variety of packaging options for the industrial, bakery and retail markets including 10 kg, 20 kg and 50 pound bags, bulk totes, bulk trucks and bulk rail. Our retail packaging line uses re-sealable pouch packs for weights ranging from 600 grams to 2.5 kg.

Major customers: NutraSun serves industrial and retail bakeries as well as retailers selling consumer packed re-sealable pouches.

Company comments: NutraSun Foods is a division of Paterson GlobalFoods, a wholly owned Canadian company which has been serving the Canadian agricultural and food industry for over one hundred years. NutraSun is a fully modernized mill located in southern Saskatchewan, the heart of Canada’s Hard Red and White Wheat growing region.

NutraSun Foods contracts directly with producers across western Canada in sourcing the highest quality grain to ensure consistency and quality for our flour and mixes.

Canadian owned, the P&H Milling Group is Canada’s second largest flour producer. Built on the strength of eight mills, the P&H Milling Group is strategically located across Canada. For more information about our flour mills or any of our other products please contact the P&H Milling Group sales and service representative in your area.

4 Locations to serve:

P & H Milling Group – HAMILTON 229 Burlington St. East Hamilton, ON L8L 4H2

P & H Milling Group - HANOVER 252-14th Street, PO Box 219 Hanover, Ontario, N4N 3C5

P & H Milling Group - CAMBRIDGE 166 King St West Cambridge, Ontario N3H 1B6

P & H Milling Group - ACTON 45 Church St. West Acton, Ontario L7J 1K1

Contact: Geoff Wright, Regional Sales and Marketing Manager

Phone: 519-650-6422

Email: gwright@phmilling.com Website: www.phmilling.com

Products offered: Hard Wheat Flour, Soft Wheat Flour, Blended Flour, Heat Treated Flour and Organic Wheat Flour. Other products include Whole Wheat Flour, Durum Semolina and a variety of Cracked Wheat and Wheat Bran offerings.

Company comments: Our sales force will assist in sourcing the best products to meet your needs and will provide timely market information to secure your requirements. Products are delivered on a fleet of compnay owned and operated trucks and tankers in addition to a wide distributor network. BRC Certified Mill.

PO Box 2185, 730 Marginal Road

Halifax, NS B3J 3C4

Contact: Denise Muise

Toll-Free: 1-800-663-6837

Phone: 902-429-0622

Fax: 902-423-9075

Email: dmuise@phmilling.com

Website: www.phmilling.com

Products offered: Enriched flours, no-time flours, bread flours, natural flours, whole wheat flour, pizza flour, wheat bran, whole grain; bread, cookie, muffin, cake and doughnut mixes and custom-blended mixes; cake and pastry flours, corn and dark rye flour, coarse rye-meal, rolled oats, oat bran, oatmeal and yeast. P&H Milling-Halifax also produces private label flour, mixes and bases.

BRC Certified Mill.

Delivery: Serves Atlantic Provinces with company-owned bulk tankers and delivery trucks, containers and common carriers.

Distributors: Sell direct as well as through local wholesalers.

Major customers: Bakeries throughout Atlantic Canada and off shore.

Company comments: We mill our flours primarily from Canadian Western Red Spring Wheat known for its consistent quality and baking characteristics. P&H Milling-Halifax is committed to supplying competitivelypriced, consistently high quality products, milled, blended and packaged to individual customer requirements for both local and international markets. In our R&D and Quality laboratory, a team of specialists assure that quality of every shipment, develop new products and work closely with our customers. Our management and staff are dedicated to quality products and service and are sensitive to the varieties of specific needs of our customers.

380 Oak Street

Montreal, QC H3K 3G2

Contact: Richard Blais

Toll-Free: 1-866-934-3234

Phone: 514-934-3234

Fax: 514-934-5069

Email: rblais@phmilling.com

Website: www.phmilling.com

Products offered: Enriched flours, no-time flours, bread flours, natural flours, whole wheat flour, pizza flour, farina, wheat bran, whole grain; bread, cookie, muffin, cake and doughnut mixes and custom-blended mixes; cake and pastry flours, corn and dark rye flours, course rye-meal, rolled oats, oat bran and oatmeal and yeast. P&H Mills also produces private label flour, mixes and bases.

BRC Certified Mill.

Delivery: Serves Quebec with bulk trailers, delivery trucks, containers and common carriers.

Major customers: Bakeries throughout Quebec and U.S. market.

Company comments: We mill our flours primarily from Western Red Spring Wheat known for its consistent quality and baking characteristics. P&H Milling-Montreal is part of the P&H Milling Group and is committed to supplying competitively priced high quality products to meet customer’s needs.

75 – 33rd Street East, PO Box 160, Saskatoon, SK S7K 3K4

Contact: Ken Tynan Toll Free: 1-888-313-6837

Phone: 306-667-8000

Fax: 306-667-8129

Email: ktynan@phmilling.com

Website: www.phmilling.com

Products offered: Enriched flours, no-time flours, bread flours, whole wheat flours, organic flours, pizza flours, cracked wheat bran. P&H Milling also produces private label flour for the retail and wholesale markets.

Delivery: Across Canada, US and off shore. Company comments: P&H MillingSaskatoon is part of the P&H Milling Group. The mill began producing flour in Saskatoon on February 1st, 1949. We mill our flours primarily from Canadian Western Spring Wheat, known for its consistent quality and superior baking characteristics. We are strategically located in the heart of the Canadian Prairie wheat growing area.

P&H Milling-Saskatoon is committed to supplying competitively priced, consistently high quality products, milled, blended and packaged to individual customer requirements for both local and international markets. BRC Certified Mill.

PO Box 400, 1301 2nd Avenue South Lethbridge, AB, T1J 3Z1

Contact: Bob Grebinsky

Phone: 403-328-6622

Fax: 403-327-3772

Email: bgrebinsky@phmilling.com

Website: www.phmilling.com

Products offered: A complete line of spring wheat flours, soft wheat flours, rye flours and meals, durum semolina, and durum atta and durum patent.

Distribution: Direct and distributor network covering British Columbia and Alberta. Direct delivery available throughout Canada and the US. Offshore shipping globally.

Delivery: Bags in 10kg, 25 lb, 20 kg & 50 lb. Bulk by totes, truck and rail.

Major customers: Retail and wholesale bakeries. Pasta and food manufacturers. Foodservice and traditional retail brand private label.

Company comments: Located in Southern Alberta in the heart of the grain growing area and strategically situated on key distribution routes. Our strength is in our ability to consistently delivery flour that meets each customer’s specific needs. BRC Certified Mill.

(P&H Milling Group)

817 48th St. East

Saskatoon, SK S7K 0X5

Contact: Glenn O’Hara

Phone: 306-931-1655 ext. 3223

Fax: 306-931-2664

Email: gohara@phmilling.com

Website: www.phmilling.com

Products offered: Parrheim Foods produces pulse concentrates (starch, protein and fibre) and flours from locally grown peas, beans and lentils. From our BRC Certified plant, we produce high quality products that are natural and functional as well as free from any additives.

Delivery: From our office in Saskatoon, we ship all across North America or anywhere in the world.

Distribution: Direct from our Plant in Saskatoon Company comments: Being in this industry since 1989 has enabled us to perfect our separation process which means that we can create the right product to meet your needs whether it be conventional or Organic.

240 Industrial Parkway S. Aurora, ON L4G 3V6

Contact: Kresho Petrovich

Phone: 905-713-1712

Fax: 905-713-0074

Email: orderdesk@portroyalmills.com

Website: www.portroyalmills.com

Plant: Aurora, ON

Certifications: SQF, Certified Organic by ProCert, Kosher Kashruth

Products offered: Custom blended whole grain cereals, stone ground flours, cracked, flaked, pearled and whole grains including: rye, spelt, barley, quinoa etc. Importers and distributors of other fine bakery ingredients. Delivery: Direct throughout most of Ontario Major customers: Bakeries, cookie manufacturers, frozen dough plants, bakery mix manufacturers and food processors. Company comments: At our milling facility in Aurora, Ont., we meet the continuing demand for whole grain milling and custom blending. We at Port Royal continue to provide the highest quality products and personalized service to our customers with industry leading food safety standards.

2800 One Lombard Place

Winnipeg, MB R3B 0X8

Contact: Richard de Kievit

Phone: 1-800-663-6287(OATS)

Website: www.richardson.ca

Company Comments: Richardson Milling offers a broad range of oat ingredients including oat groats, flakes, flour and bran. Our value added flaked and expanded whole grain based ingredients are designed to be an integral component in your products. We utilize the very best ingredients to create innovative coated whole grains and granola clusters that meet the unique requirements of our customers. They are specially formulated to enhance appearance, taste, texture and functional needs. Our extensive grower network and four manufacturing facilities provide the most extensive oat supply chain in North America. Richardson Milling is a division of Richardson International, Canada’s largest agribusiness. Recognized as a global leader in agriculture and food processing, Richardson is headquartered in Winnipeg and has more than 2,500 employees with facilities across Canada and the U.S.

Hailed as a “revelation” when it first appeared in 2004, Jeffrey Hamelman’s Bread is a legendary resource praised by baking luminaries from around the world. Explaining complex techniques with simple and helpful illustrations, the book includes recipes for a vast array of breads, including sourdoughs, brioche, authentic rye breads, flat breads, French breads, and much more.

• Features nearly 150 detailed, step-by-step recipes, along with vivid drawings and photographs showing techniques and finished products

• Written by Jeffrey Hamelman, one of fewer than 200 Certified Master Bakers in the United States and a recipient of the Golden Baguette Award (2005), the highest honor bestowed by the Bread Baker’s Guild of America

• Fully updated to include the latest techniques, methods, trends, and bread varieties

Tel: (416) 252-4660 Fax: (416) 252-9993 25 - 8 Connell Ct., Toronto, ON M8Z 1E8

1-800-661-4122

BY JANE DUMMER

Compound back in the news, being studied by U.S. FDA, Health Canada, other agencies

Acrylamide is a naturally occurring compound that forms in certain foods, including breads, cakes, cookies, potatoes, crackers, cereals and snacks that are baked, fried or toasted. Boiling and steaming foods do not typically form acrylamide.

It was only recently, in 2002, that scientists first discovered the presence of acrylamide in food. Since then, the FDA, Health Canada, and the Joint FAO/WHO Expert Committee have been actively investigating the effects of acrylamide as well as potential measures to reduce it.

}Acrylamide is more likely to accumulate when baking, cooking and frying is done for longer periods and/or at higher temperatures. Acrylamide can be formed when amino acids interact with sugars in the presence of heat. Many different kinds of sugars and many different amino acids can interact in this way. However, one particular amino acid, asparagine, has a far greater tendency to interact with sugars and to form acrylamide than other amino acids.

exposure to acrylamide is needed before the risks to human health associated with acrylamide exposure from food sources (not industrial) can be fully understood. Work continues in this area, and as the result of new studies become available, agencies including Health Canada will continue to evaluate the level of risk associated with dietary exposure to acrylamide.

In March 2016, the FDA posted a final document with recommendations for consumers and practical strategies to help growers, manufacturers and foodservice operators lower the amount of acrylamide in foods associated with higher levels of the chemical.

“The documentation provides guidance for best practices and does outline a food systems approach in the reduction of acrylamide in potato products and baked goods,” explains Marianne Smith Edge, an industry thought leader and

The best way to decrease the amount of acrylamide in the diet is to cut back on frying.

founder of Kentucky-based AgriNutritionEdge. “This documentation sets the stage for the food industry to be proactive in instituting methods throughout their procurement and production processes voluntarily and within their own time frame and budgetary constraints.”

Agency (FSA) published its own results showing 29 products exceeding the recommended acrylamide benchmarks including three type of baby food. Also in 2017, a U.S. health watchdog, the Center for Environmental Health (CEH), launched legal action against several U.S. biscuit manufacturers and retailers for allegedly failing to warn consumers about the high levels of acrylamide in their products.

Research indicates that at extremely high doses, such as those in some industrial or manufacturing settings, acrylamide is carcinogenic. However, only traces of naturally occurring acrylamide have been detected in foods such as cookies, crackers and baked and fried foods.

The National Toxicology Program (NTP) is composed of parts of several different U.S. government agencies. In its most recent Report on Carcinogens (2014), the NTP classified acrylamide as “reasonably anticipated to be a human carcinogen” based on the studies in lab animals. Since acrylamide is known to cause cancer in experimental animals, further research on the effects of

For the past 15 years, acrylamide has been in and out of the news. Acrylamide has made headlines again in 2017. This time for food samples analyzed in the United Kingdom and United States. As <i>Bakers Journal</i> interim editor Brian Hartz mentioned in his May 2017 Editor’s Letter, a survey commissioned by the Changing Markets Foundation analysed 48 types of biscuits for infants and young children in the U.K. The highest levels of acrylamide were found in a sample of Little Dish biscuits for oneyear-olds containing a concentration almost five times above the European benchmark and 30 times higher than products with the lowest concentration in the survey.

These March 2017 findings came six months after the U.K. Food Standards

The FDA and Health Canada continue to collaborate with the food industry to further pursue reductions efforts for acrylamide in processed foods. The best way to decrease the amount of acrylamide in the diet is to cut back on frying. High-temperature frying causes the greatest acrylamide formation.

To minimize the presence of acrylamide, toast bread, buns and muffins to a light brown colour rather than a dark brown colour and store potatoes outside the refrigerator in a dark, cool place, such as a closet or a pantry. Studies have shown that using different varieties of crops, particularly ones low in asparagine, time of harvesting to reduce sugar formation, proper handling, and changing cooking and storage temperatures can lower levels of acrylamide in food. / BJ

“We share your passion for baking.”

Rachel Cannon, Bake Lab Technician

AB Mauri North America

We understand that bakers face an increasing number of challenges in producing baked goods for today’s consumers. That is why we provide our industrial and artisan customers with world-class technical collaboration, process support, educational training and customized yeast and bakery ingredient solutions. Every minute of every day, you can count on us.

AB Mauri—Rethinking Baking 24/7™

TIPS ON SELLING WEDDING CAKES TO MODERN COUPLES HOW SUSTAINABILITY CAN BOOST BUSINESS

BREAKING THE MOLD

Learn how piñata cakes surprise and delight

SWEET SWAP

Get to know the demographic seeking sugar alternatives