Recruiting and retaining quality staff is a challenge and a top concern for many bakeries. Any business is only as good as its people, and its people are often only as good as the culture that motivates their performance. Certain conditions need to be in place for staff to thrive and grow, but discovering which are important for each particular employee requires time – a commodity that always seems to be in short supply.

In this issue, Bakers Journal explores Stone Hearth bakery and its program to help rehabilitate people who, because of mental health issues or other barriers, have had difficulty maintaining employment. The bakery employs paid staff that work alongside the unpaid members of the program, and it is easy to imagine that the permanent employees need to possess an abundance of patience and respect. Since each person that comes into the program carries their own particular challenges and circumstances, including not necessarily any interest in becoming a baker, individual needs must be carefully tailored if his or her tenure with Stone Hearth is to result in continued success in the workplace at large. This serves as an important reminder that all the people who work for you come with their own circumstances, motivations, quirks and otherwise decidedly human traits.

People need room to be themselves at work in the same way they need to have personal relationships that allow them to be themselves. We are very much creatures who love the feeling of being known, understood and treated like individuals. In the workplace, this is a symbiotic and rewarding relationship for all. If it were easy to achieve, retention and performance wouldn’t be such a huge concern for bakeries and other industries, assuming one has hired right in the first place.

}Managers strive to hire people who will fit in with their organization, and there is no shortage of articles online and books on the shelves dedicated to building successful corporate cultures. Such principles apply to small companies too. The success stories seem to create that mystical balance of individuality and uniformity whereby the staff actually “becomes the brand.” There is no shortage of case studies, from Apple to Honda.

Pressure and stress are everyday realities for most anyone working in today’s world, but grace, good-naturedness and a sense of humour about it all are mandatory to keep work fun.

All the knowledge in the world has yet to make this problem of retention and successful staffing any less prevalent. I will throw a hypothesis out there as to one reason why this may be the case – sometimes people simply take themselves too seriously. This behaviour can filter down to those working around them, often with disastrous effects. Pressure and stress are everyday realities for most anyone working in today’s world, but grace, good-naturedness and a sense of humour about it all are mandatory to keep work fun. Stress gets the best of most everyone sometimes, and we live in a general culture of obsessive productivity, so it’s easy to see how the taking of oneself too seriously happens. But when a job stops being any fun for too long, you can pretty much guarantee you will get mediocre performance or an employee looking for another position. Fun can be underestimated as something a company is in the business of providing its staff. It can be interpreted as something people are responsible for coming up on their own, but it is really a value that is ingrained then incorporated throughout a business.

So what’s your bakery’s fun factor? Are there a decent amount of smiles, jokes and laughs seen and heard? Do you hire people who demonstrate a sense of humour? While this can be a tough trait to figure out in a job interview, it’s one worth looking for. A sense of fun also makes it easier for people to feel at ease being themselves, which makes a manager’s job easier in the way of determining how best to motivate their team on an individual basis. / BJ

JUNE | Vol. 74, No. 5

eDItor | laura aiken editor@bakersjournal.com 416-522-1595 1-888-599-2228 ext. 250

aSSIStant eDItor | Colleen Cross ccross@annexweb.com 519-428-3471 ext. 261

technIcal

eDItor | John McColl, Puratos Canada jmccoll@puratos.com

natIonal aDvertISIng manager | stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

account

coorDInator | shannon Drumm sdrumm@annexweb.com 519-429-5176 1-888-599-2228 ext. 219

meDIa DeSIgner | Gerry Wiebe

group publISher | Martin Mcanulty mmcanulty@annexweb.com

preSIDent | Mike fredericks mfredericks@annexweb.com

mailing address p o box 530, 105 Donly Dr. S., Simcoe, on n3y 4n5

publIcatIon maIl agreement no. 40065710. return unDelIverable canaDIan aDDreSSeS to: cIrculatIon Department, p o box 530, SImcoe, on n3y 4n5 email: subscribe@bakersjournal.com

IssN 0005-4097

published ten times per year (Jan/Feb, mar, apr, may, Jun, Jul, aug/Sept, oct, nov, Dec) by annex publishing & printing Inc.

sUBsCrIPtIoN ratEs

canada — 1 year $ 30.00 (with gSt $31.50 #867172652rt0001, with hSt/ QSt $33.90) uSa — 1 year $ 45.00 uSD best pricing is available online at www.bakersjournal.com

Send your subscription request to: bakers Journal p o box 530, Simcoe, on n3y 4n5 tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940 email: subscribe@bakersjournal.com

occasionally, bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. opinions expressed in this magazine are not necessarily those of the editor or the publisher. no liability is assumed for errors or omissions. all advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. publisher reserves the right to refuse advertising that does not meet the standards of the publication.

no part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2014 annex publishing & printing Inc. all rights reserved. printed in canada.

A

With eight mills across Canada and a vast distribution network we are able to serve your complete bakery needs. P&H milling is focussed on providing high quality grain based products with a commitment to delivering customer value each and everyday wherever you are.

A complete line of Hard & Soft Flours. Products include Bread, Pizza, Cake & Pastry, Whole Wheat, Organic, Whole Grain, Durum, as well as Bran, Cracked Wheat, Barley, Rye & Pea products.

Over 100 offerings such as bread, cake, pastry, cookies, muffins, pizza, doughnuts, bagels and batters. Available in branded and private labels.

New product innovation, private label, research, testing, technical support, bulk, totes and bags.

For more information please contact the P&H Milling Group sales and service representative in your area:

Halifax, Nova Scotia 1-800-663-6837

Montreal, Quebec 1-866-934-3234

Acton, Ontario 1-800-621-0588

Cambridge, Ontario 1-800 621-0588

Hanover, Ontario 1-800-621-0588

Saskatoon, Saskatchewan 1-888-313-6837

Lethbridge, Alberta 1- 403-328-6622

Parrheim Foods: Saskatoon, Saskatchewan 1-306-931-1655

briefly | Loblaw purchased Arz Fine Foods; Fed Up documentary says sugar added to food causing obesity; 1,000-plus women prepare for “Mega Challah Bake” | for more news in the baking world, check out our website, www.bakersjournal.com

Elisa Luz Pinto of Le Cordon Bleu Culinary Institute in Ottawa swept all categories of the Canadian Intercollegiate Chocolate Competition.

The competition was sponsored by Cacao Barry/Callebaut and held at Humber College’s School of Culinary Management April 12 and 13.

Four young women competed for chocolate glory in a weekend-long event that pitted bonbon against bonbon: Luz Pinto, Jessica Cat of London’s Fanshawe College, Amber Robinson of Humber College, and Kelsey Lamers of Canadore College in North Bay. The students showed off their chocolate-making skills by conceiving and creating spectacular showpieces based on the “History of Chocolate” theme and crafted delicate hand-dipped bonbons, moulded bonbons and a plated dessert.

Luz Pinto emerged as overall winner, placing first in all categories: Best Artistic Showpiece, Best Hand-dipped Bonbon, Best Moulded Bonbon and Best Plated Dessert. Cat finished second overall and Lamers took third place.

Luz Pinto’s first-place showpiece celebrated chocolate history by tracing its roots from raw cocoa to the present

Kelsey Lamers of Canadore College, Amber Robinson of Humber College, Jessica Cat of Fanshawe College and Elisa Luz Pinto of Le Cordon Bleu competed in the Canadian Intercollegiate Chocolate Competition.

and featured colourful, murano-glasslike leaves and cocoa beans.

Judging the competition were Olivier Tribut, chef instructor at l’École hôtelière de la Capitale in Quebec City and winner of the World Chocolate Masters Canadian Selection; Sergio Shidomi, head chocolatier and pastry chef at the Old Firehall Confectionery in Unionville, Ont., and winner of the World Chocolate Masters Brazilian Selection; Chris Kwok, corporate executive pastry chef at La Societe, and runner-up of the World Chocolate Masters Canadian Selection; Andreas

Registration is now open for the 2014 Louis Lesaffre Cup, which will feature three categories: baguette and world bread, Viennese pastries and gastronomic bread making, and artistic piece. National selections will be held in 2014-15, with the Coupe du monde de la boulangerie taking place in 2016 and the Bakery Masters following in 2018.

Preselections will take place for the following four geographic divisions: Europe, Asia Pacific, Africa Mediterranean and The Americas.

To register, or for more information, visit www.facebook.com/CoupeLouisLesaffre.

Schwenger, bakery and pastry arts instructor at the Southern Alberta Institute of Technology and president of the Pastry Chef Guild of Alberta; Charmian Christie, food writer, recipe developer and cookbook author; and Colleen Cross, associate editor of b akers Journal.

Philippe Vancayseele, director of Barry Callebaut’s Chocolate Academy in Canada, served as jury president. Royce Li, another Canadian Chocolate Masters competitor, coordinated the event.

“This competition is all about lifting up students, giving them a boost, and elevating the industry at the same time,” said Callebaut’s Lianne Hubbard.

Le Cordon Bleu was named firstplace college. Pastry chef Hervé Chabert was in attendance as instructor and coach to Luz Pinto.

The students were given a selection of prizes from industry sponsors, including mixers from Thermomix.

Vancayseele said he was greatly impressed by the talent of the competitors and invited them to take a class with him at the academy, which is located in St-Hyacinth, Que., but slated to move to a new facility in Montreal this fall.

Sabine Leidums, owner of Wheat-Free Delights gluten-free bakery in Huntsville, Ont., shared this adorable photo of her grandson August at three months of age in her shop. Thanks for sharing your our sweet bakery moment with b akers Journal!

Elgin County in southwestern Ontario is planning the first sustainable food cluster in the region. A team of local producers, processors, and commercial and industrial food purchasers shared their expertise and identified steps to enhance the local food distribution system.

Elgin is the pilot community for the Sustainable Food System project undertaken by the Southwest Economic Alliance (SWEA). The intent of this regional project is to develop a food cluster in each county in southwestern Ontario to sustainably grow, process, aggregate and distribute as many different types of food as possible for consumption within each local food shed. The Elgin pilot initiative aims to enhance local capacity, create jobs and serve as a template for other counties in the region.

The pilot project is a collaborative effort involving the County of Elgin, the Elgin Federation of Agriculture, Elgin-St. Thomas Public Health, and SWEA. A team of local producers, processors, and commercial and industrial food purchasers shared their expertise and identified steps that will build local capacity and enhance the local food distribution system.

Many institutional organizations and the general public alike are looking for year-round sources of minimally processed local produce. One of the tasks identified was to look at ways to process fruit and vegetables in Elgin County while adding value to local products. Determining ways of addressing unused agricultural capacity was also considered to be an important goal.

“Ontario imports $20 billion of food every year, much of it processed,” said Tom Schell from the Centre for Sustainable Food Systems. “Replacing these imports with sustainably produced local food will not only create jobs in farming and rural communities, but it will also result in a system that operates within the carrying capacity of the environment and improves health and well-being.”

As the project planning moves ahead, broader value-chain input will be sought.

More information on the regional project is available at www.sustainablefoodsystems.ca.

The 45th International Sweets and Biscuits Fair, to be held Feb. 1 to 4, 2015, is expanding its traditional focus on confectionary and snack items.

New themes include products from the snacking and to-go sectors – in other words, all those areas that are directly placed next to confectionery, fine bakery products and snack items in sales outlets.

The show, to be held in Cologne, Germany, aims to reflect the changed eating habits of the consumers, for whom in-between meals or to-go snacks play an increasingly important role.

The focus of the ISM remains cocoa, chocolate, chocolate products, fine bakery products, snack foods, sugar confectionery, ice cream and pastes. The ISM 2015 is adding products that fall under the generic term ready-to-serve savoury snacks, fruit and vegetable snacks, breakfast and frozen sweets to its range of exhibits.

The newly introduced segments are fruit and vegetable snacks; smoothies; fish and meat snacks in ready-to-serve packaging; energy and fitness snacks; breakfast snacks, including coffee and tea; and confectionery at all temperatures, including chilled and deep-frozen.

To make exhibitors’ ranges of products more transparent for buyers, organizers will add trend themes to the exhibitor database, including Halal, Kosher, Bio, Fair-trade products, Sugar-free, Allergy-friendly, Functional, Artisan production, Private labels, Limited editions, and Impulse packages.

The ProSweets Cologne, the international trade fair for the supply industry of the confectionery business, comprising more than 300 suppliers, will be staged parallel to the ISM again in 2015.

The ISM is organized by Koelnmesse. Members of the International Confectionery Fair Taskforce, the AISM, are the conceptual sponsors of the event. For more information, visit www.ism-cologne.com and www.prosweets.de.

At Corbion Caravan, we provide food solutions that nourish the world. Our innovative ingredients, which o er unsurpassed freshness from creation to consumption, initiate a love a air between our customers’ products and consumers. Our bakery expertise and scientific creativity allow us to o er industry-leading bakery products that ensure quality and consistency. We o er a wealth of experience proven by our commitment to the bakery industry, which spans over 100 years. Our future-focused thinking helps you deliver the products your consumers want. Nobody has your best interests or your bottom line at heart, like Corbion Caravan.

Designed by science, powered by nature and delivered through dedication

Our broad bakery portfolio includes functional ingredients, emulsifiers, bread mixes, specialty bases, frozen dough, vitamin and mineral premixes and flour enrichment.

Together we create enhanced freshness and safety solutions.

INTERESTED IN FRESHNESS SOLUTIONS?

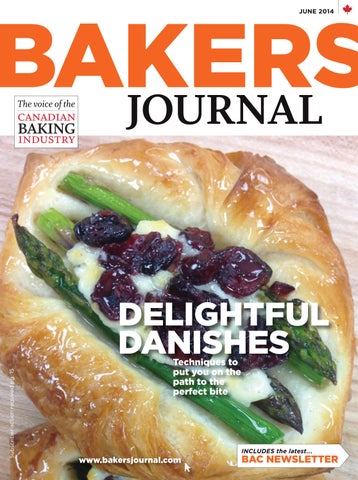

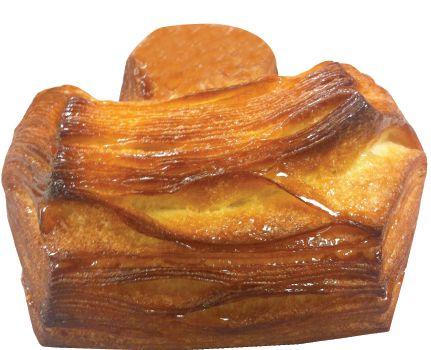

We are reminded every day why we bake for a living. Daily, we take a variety of raw ingredients and turn them into visually appealing, nutritious, flavourful finished products. Having the training and skill to make a rich layered Danish pastry that is loved by your customer is a very gratifying part of being a baker. Making laminated products successfully is certainly one of the more challenging products to make. Challenges are good, because at the end of your day, you go home and reflect on the fact that yes, a baker is highly skilled and trained, and you can take pride in your accomplishments.

Sweet Danish, unlike its laminated cousin the croissant, is a richer dough because it has eggs and increased amounts of butter and sugar. Milk or milk powder are often added to Danish dough. Flavours are often included in the dough, anything from lemon or orange zest, to spices and vanilla to name a few. Danish has a rich flavor, most often complimented with a fruit or nutmeat filling.

}Danish, like the croissant, is laminated with a fat, quite often butter, or a blend of fats such as butter and margarine, or manufactured pastry margarines that are specifically made for laminating. Cost per unit and your retail price points usually determine the type and quantity of roll-in fat used.

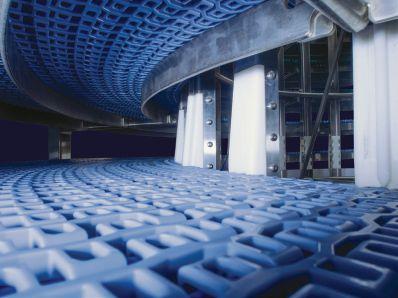

a s technologies continue to evolve for equipment makers, so does the quality of finished Danish pastries coming from industrial manufacturers, with the rich butter flavour and distinctive layers now visible.

Many bakeries, especially in-store, use frozen Danish pastries. Consistency of product and pricing are the main motivating factors for using frozen products. Within the frozen manufactured side of Danish pastries, there is a significant difference in quality. The very inexpensive pastries made with shortening, food colour and butter flavour and emulsions look more like bread dough than a laminated product, but there are also some of excellent quality.

As technologies continue to evolve for equipment makers, so does the quality of

finished Danish pastries coming from industrial manufacturers, with the rich butter flavour and distinctive layers now visible. These products look like the skilled hands of a baker laboured over them for hours to achieve such a nice finish. Of course, with great quality comes a great cost. Balancing your ability to purchase, add gross margin and then retail manufactured products vary from customer to customer.

The debate of how we count layers in laminated products is often confusing to most. A common Danish laminating technique consists of the English lock in, where two thirds of the dough is covered in fat, then folded and then three half turns or three single folds are given. The

math looks like this: English lock in = 5 layers (3 dough and 2 fat), a single fold is given which triples the layers to equal 15, but to be precise we subtract 2 from this total to take into account the two layers of dough that touch each other when a single fold is given (in essence there are two thicker dough layers). Now we are at 13 total layers. Add another single fold: 13 x 3 = 39 layers – 2 = 37 layers, add the last single fold =111 layers, the – 2 for a total of 109 layers.

In summary: English lock in = 5, first single (5 x 3 = 15 – 2 =13), second single (13 x 3 = 39 – 2 = 37), and third single (37 x 3 =111 – 2) for 109 total layers

I find this method to have too many thin layers that are less visible. I prefer to use a French lock in, with 3 single folds or turns, resulting in only 55 layers. The math is as follows: French lock in = 3, first single (3 x 3 = 9 – 2 =7), second single (7 x 3 = 21 – 2 = 19), and third

single (19 x 3 = 57 – 2) to equal 55 total layers.

Another quicker method is to use the English lock in with a book fold and a single fold. The Danish pastry results in thicker, more visible layering. What also makes this method so effective is you can be completely laminated with one trip to the sheeter, and in a matter of 10 minutes all of your laminating is completed. You can do your lock in and two turns back to back. To be successful with this technique you need to ensure your dough is very cold. A note in the math difference: when using book folds, three dough layers come in contact with each other, so we must subtract three from our total layer count. The math is as follows: English lock in = 5, first single (5 x 4 = 20 – 3 = 17), second single (17 x 3 = 51 – 3) to equal 48 total layers.

Method

• Mixing method: short mix

• Final dough temperature: 23 C - 25 C

• Bulk fermentation: 2 hours

• Roll in butter: 2 lbs

• Mix poolish at 4:00 pm with 12°C water by hand in a bowl for 1 - 2 minutes.

• Place in a container large enough for a 3x rise in volume, cover and store overnight at room temperature.

• Mix all ingredients for four to five minutes on 1st and two minutes on 2nd.

• Refrigerate dough overnight. Remove from cooler and degas, shape into a rectangular dough and place in the freezer for 15-30 minutes.

• Laminate dough with roll in butter and give three half turns. Give first two turns, place in freezer for 10 minutes, then give last half turn or 3-fold. Rest for at least 30 minutes in cooler before making final shapes.

• Make up Danish varieties.

• Proof in a proofer at 27 C – 29 C and egg wash.

• Bake at 350°F for 18 minutes

Increase profitability. Minimize product orientation issues. Enhance production capacity.

Discover how Intralox’s DirectDrive™ System eliminates overdrive and operates with zero slip, transforming our customers’ spiral systems.

Visit us at go.intralox.com/DirectDrive

• Toast hazelnuts in a warm oven.

• Place in a commercial food processor, grind finely, then add all other ingredients. P

Whichever method, or methods you choose, have the end in mind. Do you want to profile the layers as a key selling point? Go with the last option of English lock in with a double and a single turn.

Most of the make-up principles that I outlined in the croissantmaking article “Quintessential Croissants” in the March issue of Bakers Journal apply to Danish making.

• Toast pistachios in a warm oven.

• Place in a commercial food processor, grind finely, then add all other ingredients

• Allow cream cheese to warm at room temperature.

• Place in a bowl with a paddle and cream until smooth.

• Add the butter and sugar and mix until well incorporated. Add yolks and vanilla, then flour.

• Mix until smooth.

Here’s an example of beautiful layering on a baked Danish.

Use a weaker flour. Winter wheat is preferred and if that is not available then use a weak break flour or an unbleached all-purpose flour. Protein levels under 12 per cent are beneficial.

To reduce the protein strength further, blend in 20 to 25 per cent pastry flour.

Use a short mix technique, once again to prevent too much protein development.

Keep everything cold! If the dough warms through the laminating or make-up process, the layering will be compromised. Have your dough in the freezer and while warming your butter to 9º C to 11º C.

Once in the final shape, proof in a cooler temperature of 27°C to 29°C. Depending upon how cool your shapes are coming off the table, proofing times can vary dramatically. If you are able to keep the dough very cool through make up you may find a two to three hour proofing time is required. If the dough really warms on you then you may only need one and a half hours of final proof.

Be very careful when egg washing. Use fresh eggs only with a dash of salt.

Competing in the Louis Lesaffre cup, my favorite product by all was my gianduja chocolate pistachio 5 braid Danish. Danish varieties are ever evolving, and savoury products are making their way into bakeries and pastry shops. Explore, and be creative. Make a lemon or orange curd filling, and then make a seafood-filled Danish! The days of simply having a cherry Danish have come and gone, new flavours and techniques are required to make your bakery unique. Why do customers choose to come to you versus your competitor down the road? Be creative, you may even surprise yourself with some of the flavour combinations you create. / BJ

Alan Dumonceaux, C.B.S., is a member of Baking Team Canada and chair of the baking certificate program and the school of hospitality and culinary arts at NAIT.

By John Mi C haeli D es

Freezing is a convenient way to extend shelf life, but formula changes are needed to get a great finished product when thawed

Freezing is an excellent way to completely inhibit or greatly reduce the staling of baked goods (especially breads). Although anti-staling agents can be incorporated into formulations to extend shelf life, freezing provides a much longer solution. Today, production of baked goods is carried out on a massive scale in centralized locations; therefore, such products need to be transported to final consumers at great distances. Freezing baked goods can be achieved at the different stages of the baking process. Frozen dough is often available for many uses, but partially baked goods as well as frozen finished baked goods can be produced to serve the consumer markets. Products that are destined for the frozen market, whether in the dough state, partially baked or finished frozen, need changes to their formulation and processes in order to result in a good finished quality that will satisfy consumer demands.

Freezing the dough prior to proofing and baking was largely expanded due to the introduction of in-store bakeries where dough is thawed, proofed and baked as a process that requires semiskilled bakers.

The process to produce frozen dough involves mixing and developing the dough, which is then divided into appropriate pieces and frozen until used. The dough, as a biological and chemical system, needs to be protected from the adverse conditions of freezing. For this reason certain changes to the formulation are required.

Yeast is the most sensitive dough component when freezing. In order to ensure full activity of the yeast, the amount should be increased. For best results, the baker’s yeast has to possess certain physical characteristics, such as high levels of cryoresistance, high level of

trehalose and high speed of adaptation to various substrates. The flour used should have an increased high quality protein level and lower ash content. In addition, it is suggested that the shortening and salt should be increased. Water has an important role in the process of developing ice crystals during freezing and storage of frozen dough. However, through the application of special quality raw materials and defined technological parameters such as freezing velocity and frozen storing temperature, the negative effect of ice crystals may be minimized.

To develop the desired crust colour in the bread, it is necessary to maintain a higher sugar and nonfat dry milk level in the frozen dough formulation. The dough needs to be fully developed at the mixer but the yeast activity should be kept at the minimum level. For this reason, it is essential to use a good oxidation system and lower or eliminate the normal reducing agents. A good oxidation system is essential when mixing is carried out at lower temperatures (as is the case with dough destined for frozen storage), which will have a detrimental effect on final volume and grain structure of the bread. The lower the temperature of mixing, the higher amounts of oxidants are required for good performance.

Frozen dough stability is the ability of dough that has been frozen for a long time to result in an acceptable loaf volume and quality characteristics of the finished baked good upon thawing. There are several factors that affect the frozen dough stability, including formulation, yeast type and quality, the amount of yeast fermentation prior to freezing, the length of frozen storage and the rates of freezing and thawing.

Flour, and especially protein quality, also plays an important role in extending the stability of frozen dough. The addition of various hydrophilic gums such as Gum Arabic can also play a role in increasing the stability of frozen dough. The rate of freezing plays a very important part. Optimum freezing methods reduce the formation of ice crystals, extending the survival of the yeast cells.

In order to provide further convenience to consumers, partially baked or

completely baked goods are also available frozen. Partially baked goods are products that are baked to the extent that they are fully formed and are their final volume and shape but lack the characteristic brown colour and final flavour development. These products also require formulation and processing changes in order to result in good-quality finished baked goods. The requirement is to fully develop the volume and shape without the colour and flavour. In order to achieve this, the oven temperature needs to be reduced and the baking time increased to reach the desired volume without the crust colour. In addition, other changes to the process such as dough absorption and mixing temperature are needed. The yeasts levels and yeast food need to be adjusted in order to eliminate excessive oven spring.

Freezing is a convenient way of preventing the staling of baked goods but the freezing process and storage has to be done properly. Various freezing methods are available, including mechanical air blast, cryogenic, and contact plate equipment. The cryogenic method uses liquid carbon dioxide (temperature of -79 C) or liquid nitrogen (temperature of -195 C). After the initial freezing, the holding temperature of -18 C is satisfactory to yield good results. Bread and other baked goods are normally wrapped or packaged during frozen storage to prevent moisture loss. Moisture and flavour loss, as well as absorption of odours from other products during frozen storage, are common problems.

Many convenient frozen foods contain a combination of dough (or baked shells) and other food materials. The challenge is to prevent the liquid of the filling formulation from affecting the quality of the dough or baked shell. This can be achieved by carefully formulating both the dough and the filling. / BJ

For more information or fee for service help with food technical and processing issues and needs please contact Dr. John Michaelides at John Michaelides Consulting at 519-7438956 or at Bioenterprise 519-821-2960, by email: j.jmichaelides@gmail.com

Arecent phone call to the Ottawa apprenticeship office revealed that they were willing to answer questions about obtaining the Red Seal for baker-patissier, but they did not have an outline to send out. This begs the questions: how does an aspiring apprentice even know the correct questions to ask? How can they navigate their way toward the Red Seal?

First and foremost, this is a voluntary trade, which means it is not mandatory for a worker to obtain a designation to work in the industry. Obtaining the Red Seal does, however, show potential employers that the applicant has achieved a set of standards and skill set. Most provinces have a Red Seal program for baker, except for Manitoba and Saskatchewan. Ontario calls their Red Seal baker-patissier.

There are two main paths toward the Red Seal baker/baker-patissier. Both involve apprenticeship.

}Jean Miller, employment and training consultant at the Hamilton apprenticeship office, describes it best: “It’s a style of training that focuses upon on-the-jobtraining and is complemented by in-school education.” After 25 years in her field, she says, “I really respect apprenticeship, because I’ve seen it work.”

While baking is a voluntary trade that doesn’t mandate a designation to work, achieving a designation shows potential employers that the student has a certain level of experience.

Many red seal bakers and patissiers suggest working for more than one employer during the length of an apprenticeship. each has something different to teach.

program done in blocks. The potential students must be registered as an apprentice and hold a high school diploma.

apprenticeship classes are 80 per cent subsidized by the government.

The distinguishing factors in these paths are the order in which the two components are pursued. The most recognizable route is by enrolling in a baking program at a culinary school/ community college. Completion of Grade 12 is required. These are preparatory classes, with hands-on labs and theory classes, which help ready students find entry-level employment in the trade. The programs are one to two years in length and rounded out with elective courses. When employment is found, the apprenticeship can begin.

Aspiring bakers and pastry chefs who already work in the field can fast track themselves through a shorter school

There are two levels to the educational component within the baker/ bakerpatissier apprenticeship. Level 1 teaches theory and basic techniques such as fermentation, pastry and cookies craft. Level 2 reaches forward into cakes and decorating. The blocks may be offered full or part time. Level 3 is optional. The 150-hour block features more advanced specialty work, such as chocolate and sugar work.

One of the pluses is that these classes are full of students who are already employed in the industry, offering a more advanced environment. Generally students enrolled in Level 1 already have a year or more of work experience. And here is an extra sweet treat—these

For Ontario students who know what they love to do at an early age, there is the Ontario Youth Apprenticeship Program. With 16 high school credits already obtained, students in Grade 11 and 12, at the minimum age of sixteen, may enroll in this program. The high school places the student in a co-op within the field, and the student registers as an apprentice. Co-op hours count toward both high school credits and apprenticeship hours. Upon high school graduation, the apprentice has a step ahead in the work place and continues on with their apprenticeship, in one seamless transaction.

How does one register as an apprentice? Once an employee finds an employer to sponsor them, they need to contact the Ministry of Training, Colleges and Universities. In Ontario, it is mandatory to become a member of the Ontario College of Trades within 90 days.

Sponsors agree to train apprentices, while they earn the income from working for the employer. The

apprentices strive to learn as much as they can on-the-job. They also must complete the Training Standards manual. Currently 45-50 pages in length, it contains a set of competencies for the apprentice to achieve and have signed off by the sponsor. An employment and training consultant, from the local apprenticeship office, is available throughout the training process to provide guidance.

Once the Training Standards manual is complete, there are still other considerations. To write the Red Seal exam, 720 in-school hours must be obtained, including 150 hours of straight theory. There is also something referred to as benchmark hours. This simply means the number of industry hours required before writing the exam. This number is 6,130. An apprentice may claim 2,000 hours per year. However, this number is a gray area. Apprentices may be allowed to write the exam before the hours are met if they feel ready. An example of this is the early completion of the Training Standards manual. But, why rush

this important part of training an development?

Tatiana Vorobej, a patissier who owned her own cake shop for over 15 years, has a great deal of experience training apprentices. In 2008, she won the Ministry of Training, Colleges and Universities Apprenticeship Award. She offers her advice by saying, “The only way to hone your craft is through experience and time. You can’t fall short on either.”

Vorobej appeared on SLICE Network’s Cake Walk: Wedding Cake Challenge and won. She feels television is a valuable tool in promoting the industry, but cautions those interested in a baking career.

“Television shows only the artistry but not the time spent on the craft.” Her 30-minute spotlight on the television show was actually filmed over a period of three long, 14-hour days.

Many Red Seal bakers and patissiers suggest working for more than one employer during the length of an apprenticeship. Each has something different to teach. It is also advantageous

to work within different divisions of the industry. Hotels, restaurants and catering companies all offer a depth of variety. Now there is one final way of obtaining the Red Seal, and it is an exception to all of the above. This is by challenging the exam. One may write the exam if they have worked over 7,000 hours in the industry—without having completed the in-school component. Each set of rules has its exceptions.

For the icing on the cake, there are $2,000 completion grants for those who write and pass the Red Seal. The employer also receives a grant of $1,000. Navigation involves paths, choices and decisions. Use this information to help you decide whether pursuing a Red Seal designation is right for you. / BJ

Karen Barr is a freelance arts and culture writer, as well as a Red Seal pastry chef.

For more on education and training, visit www.bakersjournal.com

May and June 2014 have been and will be busy months for release of information related to the modernization of our food safety regulations. The Canadian Food Inspection Agency has been consulting for the past two years on the transformation of our food safety system since the Royal Assent of the Safe Food for Canadians Act (SFCA). Specifically, CFIA has been working on the Safe Food for Canadians Regulations (SFCR) and supporting Guidance documents that will be released in draft form later this month.

The SFCA allows the government to simplify and consolidate three CFIA inspection statutes and 10 corresponding regulations with a single set of food inspection regulations that apply to all food imported, exported and prepared for inter-provincial trade. The only two statutes that will apply to the baking industry will be the Safe Food for Canadians Act and the Food and Drug Act.

The proposed SFCR will consist of four key elements:

• Licensing requirements

• Food safety requirements

• Preventive control plan (PCP)

• Commodity specific requirements

Everyone who imports, prepares, manufactures or packages food for inter-provincial trade will require a license. The cost for a license will be approximately $250 per license, which will require renewal every two years. A company can choose to have multiple licenses if they have multiple facilities or conduct different activities (i.e., manufacturing and importing). CFIA will have the ability to suspend or cancel licenses for non-compliance. The only exemptions will be businesses with less than $30,000 income. Most license holders will require a preventive control plan that demonstrates how food safety requirements are being met.

Food safety controls will become less prescriptive and more outcome-based to reflect CODEX standards,

including HACCP and good manufacturing practices. This will allow increased flexibility to introduce new technologies and processes that could enhance safety and/or reduce cost. Baseline food safety requirements must be met during manufacturing, preparing, storing, packaging and labelling of a food product.

A key component of the PCP is traceability. Anyone who imports, exports or prepares food for interprovincial trade will be required to maintain traceability records following Codex standard of “one step forward, one step backwards.” Documents on traceability must be provided on request in a format which can be imported and manipulated for recall purposes by standard commercial software. Guidance documents for the PCP will be released at the end of May along with the Safe Food for Canadians Regulations.

Commodity-specific requirements will be maintained for grades, standards of identity, container sizes, country of origin and labelling requirements. Many food labelling changes will occur in conjunction with Health Canada in the upcoming months.

BAC joined a coalition of industry associations to advocate for lower merchant credit card redemption (swipe) fees. Canadian credit card swipe fees are some of the highest in the world, with fees ranging from 1.5 per cent to 4 per cent of a transaction’s value therefore negatively impacting the profit margins for small and medium sized businesses.

Several jurisdictions have looked at the impact of high credit card fees and adopted payment sector reforms. In Australia the Reserve Bank of Australia in 2002 capped processing fees at 0.5 per cent of a transaction’s value, which produced net welfare gains of $100 to $150 million for Australian retailers each year.

The Coalition is advocating for a thorough review of the impact of disproportionately high swipe fees and including possible regulatory limits.

At the May 4th Annual General Meeting, BAC members approved the proposed by-law changes that will enable BAC to comply with the new Canada’s Not-For-Profit Act. Once filed with Industry Canada, the changes will provide member with new rights in voting and require additional operational transparency by BAC much in the same way as publicly traded companies. The by-law changes related to representation on the Board will come into effect at the 2015 Annual General Meeting.

At the May 4, 2014, Annual General Meeting, members elected the following slate of candidates for a one year term.

Chair

Glenn Wilde ....................................... Harvest Bakery, Winnipeg MB

Directors

Martin Barnett Vancouver Island University, Nanaimo BC

Dominique Bohec ......................... La Petite Bretonne, Blainville QC

Louis Bontorin............................ Calgary Italian Bakery, Calgary AB

Steven Buckler .................................. McBuns Bakery, Moncton NB

Bill Coleman.......................................Coleman Foods, St. Johns NL

Michel Dion ................................................ Lallemand, Montreal QC

Arthur Gunn ....................................... Gunn’s Bakery, Winnipeg MB

Greg Jenkins............. Weston Bakeries/Ready Bake, Etobicoke ON

Tom Mattes ................................................. Del’s Pastry, Toronto ON

Christian Mitzel Qzina Specialty Foods, Vancouver BC

Peter Plaizier.....................................The Good Oven, Edmonton AB

Kevin Rainey Sobeys Inc, Mississauga ON

Michael Rinella ............. Rich Products of Canada, Woodbridge ON

Phil Robinson Dawn Products, Toronto ON

Don Wilcox ......................................... Canada Bread, Etobicoke ON

An upcoming BAC Member Only Webinar on June 25th, 2014, will provide an overview of the new Safe Food for Canadians Regulations, along with information on what it means to bakers and ingredient suppliers. You will have plenty of opportunity to ask questions and provide input on the regulations. This is available to any member of the Baking Association of Canada. To register, send your name, company name, email and phone number to lpasut@baking.ca.

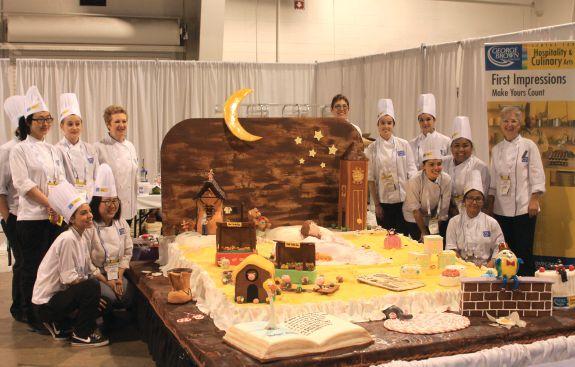

Some 4,000 participants from all parts of Canada’s baking industry came together May 4-6 in Toronto for Bakery Showcase 2014. This year’s event featured a top notch line up of 365 exhibits offering the latest in services, ingredients, finished product and equipment; three days of seminars ranging from industry trends to compliance with the new CFIA regulations; and the return of the College Creative Challenge featuring the efforts of the baking students from George Brown, Centennial and Niagara Colleges in a fun competition featuring the them nursery rhymes.

Student Team: Brittany Robson, Stacie Newcombe, Michelle Shariff, Dylan Marquardt

Student Team: Amanda De Gouveia, Sabrina Meffe, Richelle Tablang, Amanda Rebeiro, Rana Massoud, Siqi Zhang, Zhenyong Jiang, Ruyue He, Diana Rodrigues, Aiting Wang, Abbey Dixon, Portia Estella

Student Team: Hans Hinding, Samantha Humpartzoomian, Cassaundra Drinkwalter, Tehmina Kiyani, Mackenzie Skoezen, Kristin Vandermolen, Amanda Platt

BAC’s Technical and Nutrition Policy

Committee Presents:

June 25, 1 P.M. – 2 P.M. EDT

New Food Safety Regulations Are Coming!

A Webinar for Members of the BAC Only

Ontario Chapter

June 3

Spring Golf Tournament

Carlisle Golf Club, Carlisle ON

September 16

Fall Golf Tournament

Station Creek Golf Club, Gormley ON

Giorgio Calorio Operating A Successful Bakery

Susan Carson Bakery Technology Unit III

Debbie Hammell Bakery Technology Unit II

Susan Morrison

Food Hazard Control: Sanitation & Occupational Health & Safety

Xhevrije Qelaj

Bakery Technology Unit I

For information on correspondence courses for baking industry employees and the Certified Bakery Specialist (CBS) program, please contact ext. 21 at the BAC office or check out our website at www.baking.ca.

BC Chapter

June 25

Annual Golf Tournament

Newlands Golf & Country Club, Langley BC

Atlantic Chapter

September 8

Annual Golf Tournament

Mountain Woods Golf Club, Moncton NB

Howard Hillier Chocolate Smet Canada Inc.

Rachel Lachapelle Il Biscotto

Myroslava Mykytyn

Under the Black Walnut Bakery

Manda Nongauza

Monda’s Tasty Tarts

Normand Nowlan

Alipro-Mistral Ingredients

Art Pelliccione

Milano Bakeries Ltd.

Bruce Russell

Discovered Capital Corporation

Jiro Shimomura

Omori North America

Michael Temos

Frigid Equipment Ltd.

By Phili PP e Tre Panier, CCC

The BAC Ontario chapter shares how it slices up the educational pie

If you’ve ever attended an Ontario chapter of the Baking Association of Canada (BAC) event, such as the night at the races, golf tournament or educational seminar, you have likely been kindly cajoled into purchasing an arm’s length of raffle tickets. Many of you have asked, “Where does the money go?”

Ontario chapter members may not know that all profits from events are carefully managed. The committee decided to use any funds generated by these events in assisting with bakeryfocused education. The committee meets monthly to discuss issues that affect our industry. The focus in recent years has thus been assisting the baking schools in Ontario.

To recap 2013 activity: the Ontario chapter donated $25,000 to the creation of a scholarship endowment for the Centennial College bakery program. Due to our contribution, the college set up a matching fund. In addition, we donated $2,500 to George Brown College, $2,400 to Humber College and $1,000 to Thistletown Collegiate (TCI) in support of their European Culinary Adventure. Many of TCI’s students live at or below the poverty line and would have challenges planning such an event. Most of the money donated by the Ontario chapter is the culmination of many events over the past few years as well as funding that was a result of the past BAC amalgamation.

Funds generated by Ontario chapter BAC events have been earmarked for helping train the future generation of bakers.

}next time you attend one of our events or purchase a raffle ticket, you can be proud that you are helping create educational opportunities for both today’s bakery tradespeople and the next generation of industry professionals.

In 2013, our education committee initiated a program to provide student bakers with tool kits. Each kit has over 24 pieces of equipment, including knives, piping bags, pastry bags and tips, spatulas, plain and fluted cutters, towels, an apron and much more. Last year, 10 kits were awarded to deserving students.

To date, in 2014, our commitment to educational support of Ontario’s future bakers and pastry professionals continues to grow. At the college level, a $25,000.00 endowment donation is scheduled for another Ontario college bakery program. The BAC Ontario chapter will continue to work with high schools and Skills Canada to further prepare students for their post-secondary bakery education. Beginning this year, the Ontario chapter will work to develop programs for experienced bakers to further their education. We are also creating programs for grassroots bakeries so they can stay on top of upcoming trends in the industry.

Next time you attend one of our events or purchase a raffle ticket, you can be proud that you are helping create educational opportunities for both today’s bakery tradespeople and the next generation of industry professionals.

If you are a member of the BAC Ontario chapter and have an accredited Ontario Ministry of Training, Colleges and Universities program that teaches the principals of baking at the high school or post-secondary level in Ontario and believe that your program would benefit from educational assistance, please contact us by email at info@baking.ca to submit your proposal. Please title the email “Bakery program request for financial support Ontario chapter”/ BJ

Philippe Trepanier, CCC, is a sales specialist in bakery division at Handtmann Canada. He is a certified chef de cuisine.

By Diane Chiasson

Statistics show that around 25 per cent of restaurant and foodservice dollars come from tourists. Are you missing out?

With summer nearly in full swing, there are probably dozens of tourists roaming the streets in your bakery’s neighbourhood. Are you taking full advantage of all the out-of-towners in your area in your marketing strategy?

Recent statistics show that around 25 percent of the restaurant and foodservice industry’s dollars come from the tourism business. This number is expected to continue to increase, and more and more people have access to travel around the world. Eating also tops the list as one of the favourite activities of travelers. Many tourists today will go to a particular destination just to eat one single item that they have seen on TV or read about on the Internet.

Here are eight ideas that might help attract more tourists into your bakery operation.

at

sjewell@annexweb.com

Eating also tops the list as one of the favourite activities of travellers. Many tourists today will go to a particular destination just to eat at a certain restaurant.

1. HaVE a UNIqUE sEllING ProDUCt

Your bakery should have one unique, signature product that is a “must-try” for tourists, especially if the product is symbolic of your city. Send information about your signature bakery item to food bloggers, travel bloggers, travel writers, travel shows or any other outlet that would promote your bakery as a must-stop site for travellers.

2. aDVErtIsE IN HotEl loBBIEs/MaGazINEs

Ask the hotels and motels in your area to place your bakery’s menu/brochures in its lobbies and/or guest rooms. Offer free delivery to guests staying at the hotel. Most hotel rooms also have a magazine or booklet for recommendations

on where to eat in the city. Make sure to get your information into that guide. Also consider placing flyers and brochures at car rental agencies, travel agencies, bus charters and event centres.

3. CrEatE a PaCkaGED toUr

Work with other local businesses to create a full package that includes hotel stay, a breakfast, coffee or pastry or sandwich from your bakery, and an activity like spa, golf, theatre, concert, wine tour, or anything else that is a must-do activity in your area.

4. WElCoME toUrIsts oN yoUr WEBsItE

Tourists and out-of-towners are more likely to use the Internet to look for a good place to eat. Make sure that your website is up-to-date, fun and inviting, and make a special welcome for travelers with a 10-per cent discount for anyone who is from out of town. Send a link request to your local chamber of commerce and tourism bureau.

5. offEr rEWarDs froM ExIstING loyalty ProGraMs

There are several rewards networks that exist, like Open Table, SkyMiles Dining or Rewards Network Restaurant, that can help you attract business from customers who frequently travel for business and are trying to collect points.

6. orGaNIzE a strEEt faIr

Draw tourists to your area by organizing a culinary event in your neighbourhood. Hold a street fair or a culinary festival with other restaurants and shops on your street. Have carnival rides, clowns, bands, entertainers, etc. to ramp up the entertainment value.

7. UsE BIllBoarD aDVErtIsING oN HIGHWays

If your bakery is nearby a highway exit or by a major airport, it might be a good idea to purchase billboard space to attract potential tourists to stop in your area for a bite to eat.

8. UsE sIGNaGE to lEaD tHEM to yoU

If your bakery is located on a busy strip or nearby a tourist attraction, use sidewalk boards to direct tourists to

your business. Be sure to make them an offer they can’t refuse. In cold weather, offer hot chocolate, tempting coffees and wintry treats; and during the summer months, offer iced tea, ice cream and other frozen food items that will draw in tourists who are looking to take a small break from their sightseeing.

Try some of these tactics to help draw more out-of-town customers into your store, and give it a helpful summer boost in business. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping restaurant, foodservice, hospitality and retail operators increase sales for over 30 years. Her company provides innovative and revenue-increasing foodservice and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or chiasson@chiassonconsultants.com, or visit www.chiassonconsultants.com

Dealers Ingredients offers you the knowledge, expertise and experience to deliver product performance solutions – naturally. Since 1976, Dealers Ingredients has supplied quality ingredients to leading food manufacturers and processors across Canada. We specialize in supplying natural source ingredients that improve the quality and value of your products. We have a world of technical knowledge that can help you solve complex problems with answers to questions about your specific products.

www.dealersingredients.com 905.458.7766

Suprasel OneGrain is a simple 1-to-1 replacement for regular salt. No recipe changing is required. Great tasting OneGrain products are free flowing and can be handled/ stored just like regular salt, making them a convenient replacement in food manufacturing.

Flavourful, heart healthy, dairy concentrates –Butter Buds. Made from real butter, creams, milks, cocoa butter and cheeses. Providing natural dairy richness, fatty flavour notes and improved mouth feel.

Citri-fi from Fiberstar is an innovative Ingredient tailored to deliver dramatic product performance benefits. It has the ability to both maintain or improve taste, texture, mouthfeel and volume while lowering finished product costs.

Stone Hearth Bakery has a dual personality. To some people, that description might mean an identity crisis. But for this kosher commercial bakery in Halifax, it simply means “two complementary halves of a community-spirited whole.”

On one half, Stone Hearth is a bakery that provides a wide array of kosher, European-style breads, bagels and specialty baked goods that are all baked without using animal fats, preservatives or dairy products.

On the other half, Stone Hearth is a training ground for people who have barriers to employment. The bakery helps them develop good work habits, gain employment experience and build self-confidence.

Stone Hearth Bakery is a social enterprise operated by a non-profit company called MetroWorks that helps people who have experienced various life difficulties, including mental health issues, a lack of economic resources and other disadvantages. The program teaches workers baking skills, but the emphasis is on vocational skills.

}our product is not cookie cutter. There can be a little bit of variability because it’s done by hand.

years. Rideout’s background is in running community programs, not as an employee of the bakery industry by trade.

Health and education professionals sometimes recommend work adjustment training, which focuses on developing the personal skills required for success in the labour market, for people with a past history of unsuccessful employment.

Participants are trained in work behaviours needed to effectively function in the workplace, including responding to change, attendance, accepting supervision and being a productive worker.

Stone Hearth pulls candidates for the program from recommendations by doctors, teachers, social workers and counsellors.

Participants typically stay at the bakery for nine months, but the length of their participation depends on individuals’ needs. The system is tailored to each person’s situation, says president and CEO of MetroWorks Dave Rideout, who has run the program for the last four

Stone Hearth takes on 20 participants at a time and employs eight paid bakers; participants and staff work side by side, with participants shadowing the more experienced, paid workers.

When he hires staff, Rideout says he makes it clear the emphasis is on the program over the bakery. This approach helps him retain sensitive, high-quality people who tend to stay in the job long term.

The paid staff are all qualified bakers, most of whom were trained at Nova Scotia Community College baking program.

Stone Hearth receives some provincial funding for its program, but most of its revenue comes from sales of the bread and specialty products to grocery stores, restaurants and specialty stores in Nova Scotia and New Brunswick. Customers include Atlantic Superstores, Sobeys, Costco, Pete’s Frootique, Ace Burger Co.

and Brooklyn Warehouse.

The enterprise works well because there is no owner and because all bakery proceeds feed the program, says Rideout. The bakery and community program work in tandem and there is a balance between what is good for the production and what is good for the workers.

The bakery is located in a Halifax strip mall near the Bayers Road Centre along with other businesses and organizations. At the 2,500-square-foot facility, staff make several rye loaves: light, dark, caraway, flax and marble. It also offers a variety of bagels, Challah, sandwich and pullman loaves, focaccia slabs and ciabatta bricks. They sell most of the bread directly to outlets such as grocery stores but some through a small kiosk at the centre.

They tried running a bistro for about nine months. It was an interesting but ultimately unsustainable experiment, as staffing challenges were too difficult to overcome.

Staff are always experimenting and trying to come up with viable new products that meet their strict limitations, says Rideout, adding that among them are a number of new Canadians

who bring innovative ideas from around the world to the product development process.

“We’re always looking at new things we can make, especially given the kosher status because that limits what we can do. So we have to be a bit more creative.”

Everybody is involved in that process. They encounter many with new Canadians originally from the Middle East or African countries, he says, which sometimes leads to interesting solutions based on various cultural traditions.

Is there anything customers request?

“Chocolate,” he says, adding that it’s very difficult to find affordable pareve (kosher suitable) chocolate chips, so they can’t bake with it. They do exist but they are incredibly expensive. Also, they can’t do any kind of pastry because it requires butter. It’s a challenge to find pareve products, he says.

Advertising is a challenge for the non-profit, with the limited budget split between product and program (and program generally winning out). For example, last year they had brochures printed to educate people about what they do. That used up that year’s advertising budget.

The biggest challenge to running the hybrid company is maintaining a balance between the two entities and their requirements. “For example,” he says, “we could buy a machine, which is good from a production point of view but doesn’t make sense from a program point of view. Staff would not have enough to do.”

“Stone Hearth’s products tend to reflect in their appearance that hands-on, less mechanized process,” says Rideout, but he believes its customers appreciate that quality in the bread.

“Our product is not cookie cutter,” he says. “There can be a little bit of variability because it’s done by hand. But some people like that kind of ‘homey’ feel.”

Unpaid and paid staff tend to partner up and move around in the bakery to learn every aspect of the operation. One job everyone does, he says, is roll bagels. Their bagels are hand-formed, he says, so there is always rolling to be done. He attributes a lot of the program’s success to patient, caring and dedicated staff that help the participants.

“The broader we can make their experience, the better it will be for workers,” he says. “Everything revolves around benefiting the program.”

When asked if being a kosher bakery is a help or a hindrance, he calls it a draw. “Everybody needs their own niche and being kosher is one we’ve been doing for a long time and people are aware of that status, so I think that helps us. It also limits us.”

Some graduates of the program go on to work full time in other bakeries; some don’t, says Rideout. The program is rewarding for participants as well as for staff. He recalls one young man in the

program who had never worked and had long struggled with mental health issues. After 11 months in the program, he was able to work full time with no reported problems.

“It changed his life. And that happens to us four or five times a year,” says Rideout./ BJ

For more profiles, visit www.bakersjournal.com.

From cake decorating to chocolate equipment, Bakers Journal Keeps you “in the know.” FOR MORE on new products for the baking industry, check our website, www.bakersjournal.com

Creative Cutters has added a new product to its cake decorating line-up that owner Geraldine Randlesome says she spent over 1,000 hours developing.

Wonder Lace, an edible complement that’s designed to easily add lace to anything from cakes to cookies, cupcakes, and macarons. Randlesome’s R&D included ensuring the lace could be frozen, air brushed and highlighted. The lace is nut-free and in the process of applying for Kosher certification. If the lace is overcooked, Randlesome discovered the piece can be brought back by misting with a fine spray of vodka and waiting six minutes, after which the piece should bend or be able to cut again. Pieces can also be made up to six weeks ahead of time and stored in tin (not plastic) and remain pliable, found Randlesome. www.creativecutters.com

Bühler has designed the Finer Chocolate Refiner to be customized to individual customer needs in terms of roller speeds, gearwheel differentials and roller crown. This ensures maximum throughputs while enabling the required product fineness to be achieved. Mass fineness values starting at 10 microns can be produced within a very narrow particle size distribution range. In addition to size reduction, wetting and aroma development of the particles is crucial to the unique fineness of the products refined on the Finer. Up to 80 per cent of the energy introduced into the roller gap is applied for this purpose.

www.buhlergroup.com

Carmit Candy Industries has launched a new line of gluten-free chocolate clusters. The new line will be available in multiple international markets.

A cluster is a snack based on a blend of ingredients that does not have a structured or consistent shape. The gluten-free clusters line offers several combinations of gluten-free cereals and dried fruits or nuts covered in either chocolate or yogurt. The clusters can be custom packed in different sizes and shapes as private-label for marketers, restaurant chains and retailers, and for on-the-go packages or a multi-pack. All are designed to address the needs of a gluten-free diet.

www.carmitcandy.com

ADM MILLING CO.

7585 Danbro Crescent,

Mississauga, ON L5N 6P9

Contact: Debbie Bell, 905-819-7000

Fax: 905-819-9768

e-mail: debbie.bell@adm.com

Plants: 2 Montreal, QC; Mississauga, Midland, Port Colborne, ON; Winnipeg, MB; Calgary, AB.

Sales offices: Montreal QC, 514-846-8533; Toronto, ON 1-800-267-8492; Calgary AB, 403-267-5656; Vancouver, B.C. 604-2990710.

Products offered: A full flour and mix product line for the bakery, donut, muffin, food service, biscuit, pasta, frozen, in-store bakery, pasta and industrial segments. Other products offered are stoneground whole wheat, cracked wheat, graham and cereal bran and rye flours.

Welcome to Ardent MillsTM, a company dedicated to helping you grow in a challenging marketplace. A company that offers the industry’s broadest range of flours, mixes, blends and specialty products, customized to meet your needs and backed by unrivaled technical support, customer service and supply assurance. Our ground-breaking products, responsive services and can-do people are here for you—to help you respond to changing consumer preferences, drive top-line growth, improve profitability and manage commodity risk. We are Ardent Mills, working with you for the good of grain.

Ardent Mills ULC

235 Nuggett Court

Brampton, ON L6T 5H4

Contact: Elaine O’Doherty

Phone: 905-494-2600

Email: Elaine.ODoherty@Ardentmills.com

Website: www.Ardentmills.ca

Plants: Flour Mills in Montreal, QC and Saskatoon, SK. Bakery Mix plants in Burlington, ON and Saskatoon, SK. Oat Mill in Saskatoon, SK.

Products offered: A full line of quality flour including all purpose, strong bakers, cake & pastry, whole wheat, whole grain, Italian style, pizza, specialty, durum and oats. Plus a broad range of bakery mixes, bases and concentrates, many formulated specifically to customers’ needs.

Proud new home of the Robin Hood® brand of flour, oats and bakery mixes for the industrial, foodservice and commercial channels.

Delivery: Across Canada by rail or truck, throughout North America and select export markets.

Distribution: Direct from plants, regional warehouses, or distributors, depending on product location.

Major Customers: Bakery and Food processors, Retail & Wholesale bakeries, Grocery Retailers & In-store bakeries, Foodservice Operators, Bakery and Foodservice Distributors.

1150 Rang Saint-Edouard, Saint-Liboire, QC, J0H 1R0

Contact : Rory Lesperance

Phone: 416-770-2310

e-mail: rlesperance@farinart.com www.farinart.com

Products offered: Ecocert, Kosher, Halal, HACCP and SQF 2000 certified. Farinart is a leader in processessing custom grain, flour, seed and pulses blends - both conventional and organic. Farinart also provides select line of gluten free blends, flours and processed grains. We have earned a strong reputation for delivering innovative solutions, superior expertise, product consistency and best-inclass service to retail and commercial bakers and food manufacturers.

Distribution: We deliver across Canada and overseas.

Delivery: 20 kg bags, tote bags and bulk products.

Company comments: We are a friendly and versatile company that can adapt to our clients’ requirements.

No. 1 Grain Millers Drive Yorkton, SK S3N 3Z4

www.grainmillers.com

Sales Contact: Andrew Eilertson @ 1-800-232-6287 Fax: 952-829-8819

Email: andrew.eilertson@grainmillers.com

Plants: Yorkton, SK and U.S.

Distribution: Throughout Canada and U.S. Products Offered: Full line of conventional, organic, & certified gluten free oats including quick & rolled flakes, flour, bran, steel cut, food grade fiber, and other innovative products. Complete product line includes other milled grains and custom blends of wheat, corn (yellow, white, non-GMO), barley, rye, triticale, and various other specialty grains.

Certifications: Organic, Gluten Free, Kosher, GFSI

Pack Type: Bags, totes, bulk, retail pack (500g-2.25kg)

Comments: Privately owned, Grain Millers delivers whole grain solutions to the modern world of food manufacturing. Customers rely on our quality, service, and innovation to meet today’s high expectations and tomorrow’s challenges. Learn more what we can do at www.grainmillers.com.

105 Commander Blvd., Scarborough, ON M1S 3M7

Contact: George Birinyi Jr., Carl Griesser Phone: 416-291-3226

Fax: 416-291-2159

e-mail: gbjr@grainprocess.com

Products offered: Over 2,000 products including a full range of whole grains. Hard/ Soft Wheat, Triticale, Corn, Millet, Barley, Rye and Durum and organic products certified by QAI (Whole Wheat Flour, White Flour, “Ancient Grains” Spelt, Kamut, Quinoa, Seeds, etc.) Precooked and stabilized grains and flours, Whole Bean Flour, complete range of grains including Cracks, Flakes and Grits, Seeds (Sunflower, Sesame, Golden Yellow and Brown Flax), Beans, Peas, Lentils, Sugars, Nuts and Dried Fruit. Food processing also includes custom blending facilities for multigrain formulas (Bread, Muffin and Pancake Mixes, etc.) packaging, granola cereals, toasted grains, Turbinado and Demerara Sugars.

Distribution: Across Canada and the United States.

Major customers: Bakeries, biscuit and cookie manufacturers, food service, bulk, health and natural food retailers and distributors and manufacturers.

Company comments: We pride ourselves as being the only stone flour mill in Canada to offer such a wide variety of products. Our product development team is ready to develop mixes and specialty grains for any application in the food industry.

HOWSON & HOWSON LTD. 232 Westmorland St., PO Box 390, Blyth, ON, N0M 1H0

Contact: Jeff Howson, 519-523-4241, Ext. 60

Fax: 519-523-4920

e-mail: jeff@howsonandhowson.ca

Dan Greyerrbiehl, 905-792-2962

Fax: 519-523-4920

e-mail: dgreyerbiehl@rogers.com

Plants: Blyth, ON

Products offered: Durum semolina, durum flours, durum whole wheat semolina, Atta flours.

Delivery: Bulk truckloads, bulk bags (750kg), 20kg bags, 40kg bags, 50lb bags and 100lb bags to Ontario, Quebec and United States.

Distribution: From Blyth, ON, Plant by truck or distributors.

Major customers: Manufacturers of dry pasta, fresh pasta, frozen pasta, and snack crackers. Assistance offered: Technical assistance.

Company comments: Howson & Howson Ltd. have been quality wheat millers for over 135 years. We are continuously modernizing our durum mill in order to supply our customers with high-quality durum semolina, durum flour and other durum products.

Jamestown Mills Inc (office)

49888 Nova Scotia Line RR2 Aylmer, ONT, N5H2R2

e-mail: info@jamestownmills.com

Phone: 519 933 2648

Products Offered: stone ground, non gmo gluten free flours teff, pulses, quinoa, amaranth and millet

Supplier of sorghum, corn and rice flours, as well as starches and gums

Supplying the gluten free industry www.jamestownmills.com

NUNWEILER’S FLOUR CO.

Box 28009 RPO E. Kelowna, Kelowna, BC V1W 4A6

Contact: Ross Nunweiler 1-888-726-2253

e-mail: info@nunweilersflour.com www.nunweilersflour.com

Plant: Alsask, Sask.

Certifications: Pro-Cert Certified Organic Systems, Kosher Certified.

Products offered: Nunweiler’s Flour Company is a 100% dedicated Certified Organic flour mill located in Alsask, SK with our sales office in Kelowna, BC. Our family of products include: Whole Grain Wheat Flour, Dark Rye Flour, All Purpose & Pastry Flour, Spelt Flour, Buckwheat Flour, Red Fife Flour and Kamut Khorasan Flour.

Distribution: B.C. – Snowcap Enterprises, Snowcap Interior, Aarsen City Delivery. Major customers: Retail and wholesale bakeries, specialty product bakeries, retail mass market and natural food stores.

Company comments: Since 1988, Nunweiler’s Flour Company has been milling Organic Canadian grown grains. Our whole grain flour is processed in a low temperature impact mill at a temperature of 60ºF/ 16ºC in the cool winter months to 95ºF/ 35ºC in the warm summer. We include No Additives, Preservatives or Blending in our freshly milled whole grain flour. We are proud to support Canadian Organic family farms and we are committed to producing premium quality products for bakers and consumers wanting wholesome and nutritional foods.

PO Box 1695 Dewdney Avenue, Regina, Saskatchewan S4N 4N0

Phone: 306-751-2040

Contact: Kerry Keating, General Manager 306-751-2440

www.nutrasunfoods.com

Certification: NutraSun Foods Ltd. is certified Organic by Quality Assurance International (QAI), Kosher Certified and H.A.C.C.P. and ISO 22,000 Compliant.

Delivery: We deliver bakery ingredients across Canada and the United States as well as shipments offshore.

Products offered: NutraSun’s high quality Organic and Traditional flour is milled from Hard Red Spring and Hard White Wheat. We are the exclusive miller of premium Snowbird White Wheat flour and also offer a variety of Whole Grain flours.

We also offer customized grain blends and

organic and clean label dough conditioners. NutraSun offers a variety of packaging options for the industrial, bakery and retail markets including 10 kg, 20 kg and 50 pound bags, bulk totes, bulk trucks and bulk rail. Our retail packaging line uses re-sealable pouch packs for weights ranging from 600 grams to 2.5 kg. Major customers: NutraSun serves industrial and retail bakeries as well as retailers selling consumer packed re-sealable pouches.

Company comments: NutraSun Foods is a division of Paterson GlobalFoods, a wholly owned Canadian company which has been serving the Canadian agricultural and food industry for over one hundred years. NutraSun is a fully modernized mill located in southern Saskatchewan, the heart of Canada’s Hard Red and White Wheat growing region.

NutraSun Foods contracts directly with producers across western Canada in sourcing the highest quality grain to ensure consistency and quality for our flour and mixes.

Company Comments: Canadian owned, the P&H Milling Group is Canada’s second largest flour producer. Built on the strength of eight mills, the P&H Milling Group is strategically located across Canada. For more information about our flour mills or any of our other products please contact the P&H Milling Group sales and service representative in your area.

3 Locations to serve:

P&H Milling Group - Hanover 252-14th Street, PO Box 219 Hanover, Ontario, N4N 3C5

P&H Milling Group - Cambridge 140 King St West Cambridge, Ontario N3H 4T3

P&H Milling Group - Acton 45 Church St. West Acton, Ontario L7J 1K1

Contact Rob Fursman Regional Sales and Marketing Manager 519-650-6422

e-mail: rfursman@phmilling.com

Products offered: Hard Wheat Flour, Soft Wheat Flour, Blended Flour, Heat Treated Flour and Organic Wheat Flour. Other products include Whole Wheat Flour,

Durum Semolina and a variety of Cracked Wheat and Wheat Bran offerings.

Company comments: Our sales force will assist in sourcing the best products to meet your needs and will provide timely market information to secure your requirements. Products are delivered on a fleet of compnay owned and operated trucks and tankers in addition to a wide distributor network. BRC Certified Mill.

PO Box 2185, 730 Marginal Road, Halifax, NS B3J 3C4

www.phmilling.com

Contact: Dave Bryson, 902-429-0622. 1-800663-6837

Fax: 902-423-9075

e-mail: dbryson@phmilling.com

Products offered: Enriched flours, no-time flours, bread flours, natural flours, whole wheat flour, pizza flour, organic flour, cracked wheat, farina, wheat bran, whole grain; bread, cookie, muffin, cake and doughnut mixes and custom-blended mixes; cake and pastry flours, corn and dark rye flour, coarse rye-meal, rolled oats, oat bran, oatmeal and yeast. P&H Milling-Halifax also produces private label flour, mixes and bases. BRC Certified Mill. Delivery: Serves Atlantic Provinces with company-owned bulk tankers and delivery trucks, containers and common carriers. Distributors: Sell direct as well as through local wholesalers.

Major customers: Bakeries throughout Atlantic Canada and off shore.

Company comments: We mill our flours primarily from Canadian Western Red Spring Wheat known for its consistent quality and baking characteristics. P&H Milling-Halifax is committed to supplying competitively-priced, consistently high quality products, milled, blended and packaged to individual customer requirements for both local and international markets. In our R&D and Quality laboratory, a team of specialists assure that quality of every shipment, develop new products and work closely with our customers. Our management and staff are dedicated to quality products and service and are sensitive to the varieties of specific needs of our customers.

380 Oak Street, Montreal, QC H3K 3G2

Tel: 514-934-3234

e-mail: mduval@phmilling.com

Contact: Richard Blais 1-866-934-3234

e-mail: rblais@phmilling.com

Fax: 514-934-5069

Products offered: Enriched flours, no-time flours, bread flours, natural flours, whole wheat flour, pizza flour, organic flour, cracked wheat, farina, wheat bran, whole grain; bread, cookie, muffin, cake and doughnut mixes and custom-blended mixes; cake and pastry flours, corn and dark rye flours, course rye-meal, rolled oats, oat brain and oatmeal and yeast. P&H Mills also produces private label flour, mixes and bases. BRC Certified Mill. Delivery: Serves Quebec with bulk trailers, delivery trucks, containers and common carriers.

Major customers: Bakeries throughout Quebec and U.S. market.

Company comments: We mill our flours primarily from Western Red Spring Wheat known for its consistent quality and baking characteristics. P&H Milling-Montreal is part of the P&H Milling Group and is committed to supplying competitively priced high quality products to meet customer’s needs.

75 – 33rd Street East, PO Box 160, Saskatoon, SK S7K 3K4

Toll Free: 1-888-313-6837

Contact: Garry Houland 306-667-8004

Fax: 306-667-8129