by Sergei Belski.

By LaU ra a iken

by Sergei Belski.

By LaU ra a iken

Bakers and gymnasts have a lot more in common than first meets the eye. Grit, passion, discipline and precision come easily to mind as comparisons. We know bakers can be as passionate as young gymnasts in training, but can they be as flexible? The ability to contort one’s shape into something new in an instant could very well be the defining characteristic of tomorrow’s bakery.

Flexibility came up multiple times in discussions with members of the bakery industry at this year’s Bakery Congress in Vancouver. However, it means different things to different people. To at least one veteran on the equipment side, the successful industrial bakeries of the future will be those that invest in the technology to be nimble in the fickle marketplace: those that buy machinery that will allow them to be more diverse in their product offerings and continue towards automation. The speed of desire moves so much faster in a world of instant inundation. We don’t really know what tomorrow’s consumer is going to want, but we’d better be prepared to give it to them.

For small bakeries, flexibility is something they likely feel they already have as an advantage over large-scale operations. It is easier for small businesses to bend at a moment’s notice and customize, two traits banked on for a competitive edge. The danger of this thinking, for big and small, is that it encourages getting too comfortable with your lot and stuck in ways of thinking. It’s possible to be inherently malleable, yet rigid as an oven’s feet when it comes to your convictions.

}if you aren’t prepared to accept that you don’t know what’s coming, you may have a hard time handling it when it arrives. How fast can your bakery react to market demands?

All industries suffer from some degree of “I know best” that gets the best of them. I, like many women, am particular about my hair and rarely happy with any haircut so I tend to bounce from stylist to stylist, going as long as possible between trims. It was the highlight of a recent week when I forked over a measly $22 including tip for exactly the haircut I was after. I asked the woman with scissors who seemed to be the owner and whose mirror was ringed with about two dozen sales success awards, why it was so difficult to get such a simple haircut: trim off the split ends, just an inch or so, don’t go crazy with layers, etc. The sassy woman – and she is a card – put it bluntly: “I always hear the girls in here telling customers, ‘Oh, I think you should do this, or this would look best, and I say, ‘I don’t care what you think, just do what the client wants!”

It is human nature to invoke our expertise, but the willingness to put it aside that defines our flexibility. Consider how you might react to the recent headlines about demand for cupcakes possibly being in decline. Some cupcake sellers in the Canadian press said there was no way the petite treats were about to be dethroned. But are these businesspeople ready for the possibility that the headlines are right, at least at some point down the road? This raises the question, what is the next big thing if cupcakes do lose some lustre? Is it doughnuts or pies or brownies? The answer is, it’s all of the above, and more, coming in cycles just as life tends to do. The question is not whether you are prepared to serve the obvious darlings of the press, but whether you can see a return of Bundt cakes coming, as one baker shared was a surprise hot item for their large bakery recently. If you aren’t prepared to accept that you don’t know what’s coming, you may have a hard time handling it when it arrives. How fast can your bakery react to market demands? Consider that in the future, it likely will need to be even faster. / BJ

June | Vol. 73, no. 5

EdiTor | laura aiken editor@bakersjournal.com 416-522-1595 1-888-599-2228 ext. 250

AssisTAnT EdiTor | stefanie Wallace swallace@annexweb.com 1-888-599-2228 ext. 278

TEchnicAl EdiTor | John McColl, Puratos Canada jmccoll@puratos.com

nATionAl AdvErTising MAnAgEr | stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

sAlEs AssisTAnT | Jarah stefek jstefek@annexweb.com 519-429-5176 1-888-599-2228 ext. 219

MEdiA dEsignEr | Gerry Wiebe

groUp pUBlishEr | Martin Mcanulty mmcanulty@annexweb.com

prEsidEnT | Mike fredericks mfredericks@annexweb.com

Mailing Address p o. Box 530, 105 donly dr. s., simcoe, on n3Y 4n5

pUBlicATion MAil AgrEEMEnT no. 40065710. rETUrn UndElivErABlE cAnAdiAn AddrEssEs To: circUlATion dEpArTMEnT, p o. Box 530, siMcoE, on n3Y 4n5 e-mail: subscribe@bakersjournal.com

Issn 0005-4097

published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/sept, oct, nov, dec) by Annex publishing & printing inc.

suBsCrIPtIon rates canada — 1 Year $ 30.00 (with gsT $31.50 #867172652rT0001, with hsT/ QsT $33.90) UsA — 1 Year $ 45.00 Usd Best pricing is available online at www.bakersjournal.com

Send your subscription request to: Bakers Journal p o. Box 530, simcoe, on n3Y 4n5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940

E-mail: subscribe@bakersjournal.com

occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. if you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

opinions expressed in this magazine are not necessarily those of the editor or the publisher. no liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. such approval does not imply any endorsement of the products or services advertised. publisher reserves the right to refuse advertising that does not meet the standards of the publication.

no part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2013 Annex publishing & printing inc. All rights reserved. printed in canada.

briefly | Tim Hortons appoints new CEO | All But Gluten line recieves gluten-free certification | Wild Sweets wins bronze at competition | For more news in the baking world, check out our website, www.bakersjournal.com

las Vegas – The international Baking industry expo (iBie) is enhancing its curriculum with more than 20 new seminars focused on the most relevant issues facing the industry.

iBie 2013, to be held oct. 6 to 9 in las Vegas, is offering more than 70 seminars, now organized into five targeted tracks that include aiB technical, retail and foodservice, business management and marketing, ingredient trends and formulations, and hands-on cake and pastry decorating.

The education program begins on saturday, oct. 5, with the rPia Group’s Business of Baking for Beginners workshop and the Tortilla industry association (Tia)’s two-day technical conference. This year, Tia’s conference will address operation skills, safety regulations, quality control, plant efficiency and best practices to capitalize

on the baking industry’s fastest growing market segment. all other educational seminars will be held during show days, from 8 a.m. to 12 p.m., with a selection of hands-on sessions taking place in the evenings. several of the seminars will be available in spanish.

while the new curriculum is designed to deliver value to all attendees, a number of seminars in the ingredient trends and formulations track are particularly relevant to wholesale and industrial bakers. These sessions, led by proven industry authorities, touch on everything from sodium reduction and whole grains to gluten-free and other hot industry trends.

for more information about the 2013 iBie education Program and to see the seminar agenda, visit www.iBie2013.com/ education. To register for iBie 2013, visit www.iBie2013.com.

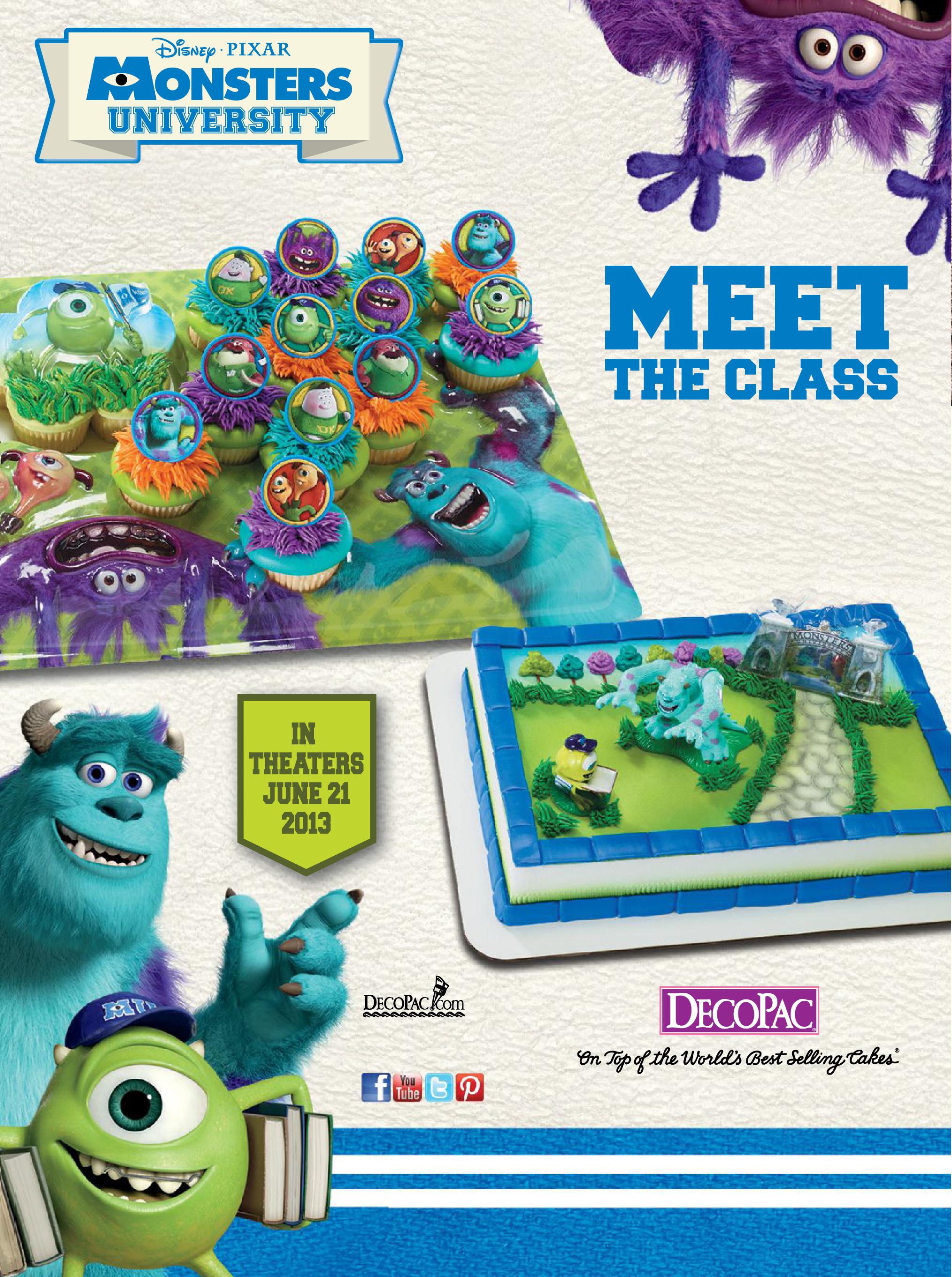

decoPac recognized Traynor’s Bakery wholesale as the canadian distributor of the year for 2012 at the Traynor’s customer show on March 18.

dave cohen, the decoPac sales manager for canada, recognized Traynor’s sales and marketing initiatives throughout the year. congratulations to the Traynor’s team!

red star yeast company and lesaffre yeast corporation have announced an increase in canadian fresh and dry yeast prices, as well as a variety of baking and food ingredients, effective May 1, or as existing contracts expire. John riesch, president of both companies, stated in a news release: “despite gains in productivity and efficiency gained through aggressive capital investment programs over the last few years, rapidly rising commodity and ingredient costs related to the volatile u s agricultural markets, plus distribution expenses, have to be addressed through price adjustments.”

“i am keenly aware of the multiple cost challenges facing our key bakery market; therefore, our pricing action is short of the added cost of yeast and ingredient processing for the coming year,” he added. fresh compressed yeast will increase two per cent per pound, and dry baker’s yeast in all forms will increase three per cent per pound. Baking and food ingredients will increase on average five per cent. customers should check with their local or assigned sales representatives for details of the new price program or any other assistance that is needed.

By Dr. Jo H n

Exploring

The use of wheat and flour is a complex process involving many steps. These evaluation tests are divided into three categories: physical, chemical and rheological.

The physical methods provide information on the appearance, density, hardness and plumpness, and help the buyer and miller obtain wheat with kernels that will produce a high yield of good quality flour. External appearance of the kernels indicates the extent of damage and fungal contamination. Visual examination of wheat kernels is part of the grading system that separates the wheat into different grades.

}Test weight indicates the density of wheat kernel: the higher the number, the denser and sounder the wheat kernels are. The weight per 1,000 kernels in grams is another indication of soundness of wheat. Again, a higher number indicates better quality. These two measurements can be an indication of flour yields during the milling process. Single-kernel characterization is an important single test that can provide a lot of information about its different characteristics. In this test, a sample of wheat kernels is prepared by removing broken kernels, weed seeds, and other foreign material. The sample is then introduced to the single-kernel characterization system (SKCS) instrument, which analyzes 300 kernels individually and records the results on a computer graph. The characteristics analyzed include kernel weight by load cell and kernel diameter. The SKCS test evaluates wheat kernel texture characteristics by measuring the weight, electrical current, and force needed to crush the kernels.

more energy during the milling process to reduce them to flour. There are various methods available to determine the kernel hardness, including the particle size of a ground sample using a specific grinder, or using the calibrated NIR system.

The particle size index, or PSI method, utilizes a grinder to grind the wheat and sifts the ground sample through a U.S. standard 200-mesh wire with a vibrating action. The amount of ground wheat that passes through the 200-mesh sieve is used to determine the PSI. Soft-texture wheat kernels will have a high amount of ground wheat pass through the sieve; hard-texture wheat, smaller amounts. It is important that the grinder used be standardized, as different mills will produce different results.

The basic chemical methods involve the determination of certain compounds that play a role in the functionality of the flour, such as protein, moisture, ash and total

Wheat kernels that are damaged by frost are typically harder and will require more energy during the milling process to reduce them to flour.

carbohydrates. Processors who are interested in the performance of the flour use these methods more, but they are also important in indicating the quality of the wheat. More advanced methods can determine a number of minor components that also play a role in functionality.

Moisture content is a very critical component of the wheat, as it could be a detrimental factor if it exceeds 15 per cent. Values above 15 per cent will encourage the growth of microbes, which can cause serious storage problems. Higher moisture will also encourage the onset of sprouting and the activation of various hydrolytic enzymes within the kernel. Millers can temper wheat in order to condition the wheat kernels by exposing the wheat to a moist environment for a certain length of time prior to milling.

laboratory drying ovens.

Protein content is an important indicator of the quality of the wheat. It is not a direct indicator of the performance of flour in baked goods, but wheat is often traded according to the protein content. NIR is a quick method to determine the percentage of protein. The Dumas method involves measuring the released nitrogen after combustion of the sample. A factor (most commonly 6.25 and 5.7) is used to multiply the nitrogen quantity and convert it into a percentage of protein, depending on the fraction of the wheat kernel. There is no direct method to determine the actual protein in samples. The major proteins responsible for wheat quality are gliadin and glutenin. These proteins are independently present in the flour, and once the flour is hydrated and mixed, they bind together to form gluten. The ratios of these proteins are important in determining the characteristics of the dough formation, such as the elasticity and extensibility of the dough. However, determining the two proteins is not easy based on current methodology, so this is not a standard test utilized by the industry as a quality-testing tool. Some of these quality characteristics may be predictable using newer solvent retention capacity (SRC) methods and the resulting gluten performance index (GPI).

Rheological properties of wheat flour normally involve the changes in the viscosity of slurries due to the quality of starch or the behaviour of the gluten proteins in dough systems. Alpha amylase activity is an indication of sprout-damaged wheat, and higher amounts of this activity will indicate that the kernels have begun to sprout, affecting the characteristics of the starch and its viscosity. Knowing the extent of starch damage of the wheat is very important to the millers. This allows them to blend sprouted wheat with sound wheat in order to control the levels of the enzyme and thus produce acceptable quality flour without discarding all the wheat. / BJ

Wheat kernel hardness and texture has a major impact on the milling properties of the wheat. Kernels that are damaged by frost are typically harder and will require

Near infrared spectroscopy (NIR), which has to be calibrated for each crop year, is one of the various quick methods available for the measurement of moisture in wheat kernels. In addition to other quick methods, such as infrared heating, the traditional methodology involves

For more information, or fee-for-service help with food technical and processing issues and needs, please contact Dr. John Michaelides at John Michaelides & Associates at 519-7438956, or at Bioenterprise at 519-821-2960 ext. 246, or by e-mail at j.jmichaelides@gmail.com.

Suprasel OneGrain is a simple 1-to-1 replacement so no change in recipes are needed. The great-tasting, free flowing Suprasel OneGrain product can be handled and stored just like regular salt, making them a convenient replacement in food manucfacturing.

Dealers Ingredients offers you the knowledge, expertise and experience to deliver product performance solutions –naturally. Since 1976, Dealers Ingredients has supplied quality ingredients to leading food manufacturers and processors across Canada. We specialize in supplying natural source ingredients that improve the quality and value of your products. We have a world of technical knowledge that can help you solve complex problems with answers to questions about your specific products.

Citri-fi from Fiberstar is an innovative Ingredient tailored to deliver dramatic product performance benefits. It has the ability to both maintain or improve taste, texture, mouthfeel and volume while lowering finished product costs. Flavourful, heart healthy, dairy concentrates – Butter Buds. Made from real butter, creams, milks, cocoa butter and cheeses. Providing natural dairy richness, fatty flavour notes and improved mouth feel.

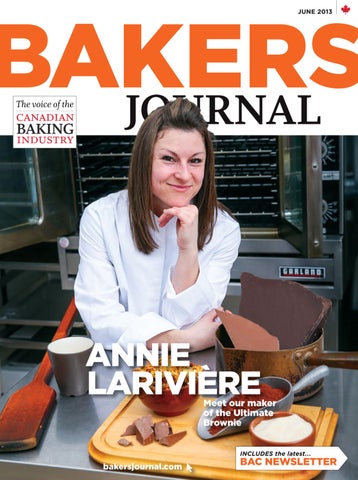

Singing on the job is a sign of one of two things: either you earn your daily bread as a vocalist or you’re having an awfully good time at work. Since Bakers Journal isn’t in the habit of writing about musicians, you can place a blue chip bet that Annie Larivière, who names listening to country music and singing in the kitchen as highlights of her job, is the type of colleague that can brighten her own day right alongside yours. She admits that Brian Beck, president of Cococo Chocolatiers, owners of Chocolaterie Bernard Callebaut, where she is employed, has caught her vocal stylings in action. No wonder he describes her as a fun-loving girl.

“There’s not a lot of French Canadians landing in Calgary for the specific purpose of hoping to improve their English, so right away that tells you something. She has a kind of twinkle in her eye and she was popular as soon as she walked in the door. She has a very lighthearted sensibility and always a big smile on her face, so she became a real character early on and fit right in.”

The mischievous Larivière came up with one funky brownie to win this year’s Bakers Journal Ultimate Brownie contest sponsored by Callebaut, Cinelli Esperia Corporation and Mimac Glaze Ltd. Her Brownie Almond, Maple, Cranberries is an intriguing concoction of sweet s’mores flavoured finish, tart cranberry pucker, nutty crunch, smooth chocolate and something or other that made it difficult to stop eating. The combination of flavour balance, texture contrast and layers of surprise landed Larivière’s brownie on top during a very competitive tasting event.

}Her Brownie a lmond, Maple, Cranberries is an intriguing concoction of sweet s’mores flavoured finish, tart cranberry pucker, nutty crunch, smooth chocolate and something or other that made it difficult to stop eating.

four test runs to create this particular brand of sinfully delicious.

WIll anD WanDerlust

“I’m really a big fan of maple syrup and I thought maybe I should do something with it. I know if you want to have success in your pastry it’s very important that your pastry have a good look, texture and good taste.”

Larivière knew her brownie was just right when she could check off all the requirements on her list of what will make it just right, with just the right bake time. It took

Larivière took her first independent breaths in Montreal in 1981, and it seems the first taste of wanderlust from the mothership was not to be her last. As a little girl she dreamed of being a veterinarian, but it was no surefooted conviction.

“I didn’t know much about what I wanted to be when I grew up, so I took a while to really decide what I want,” she says.

She discovered a fondness for all things crafty, and was drawn to the art of chocolate making in her early 20s but was first given some advice that it wasn’t the best way to

make bank. Pennies or lack thereof aside, Larivière did take alternative career advice and entered the pastry arts field, completing a year and a half of culinary education in Quebec (which included a two-week stint in Sicily) before heading off to work for two years at Chocolaterie Le Cacaoyer. After one Easter, when chocolate sales grew slow, she hit the road for six months, landing in Guadeloupe and Haiti.

“One thing about travelling: I learned a lot about myself and what I really want in life. I always want to be in customer service. I always want to learn more and if one day I don’t have a chocolate place maybe I will have my own bed and breakfast and I can make my chocolates there. I always love people and I love to help them.”

Through her church, Larivière spent a few months helping the homeless, bringing coffees to them and sometimes chocolates. It was at that time that she realized she wanted to learn English. She nearly landed

in Texas to do so, but luckily for Cococo that didn’t work out and she ended up rolling into Calgary. In the true spirit of independence, she said the mountains were calling and she wanted to be far enough away that she wouldn’t be able to come home too easily. A girlfriend helped her out for a few months until she found work and got hired as a baker/pastry chef at Cococo in 2009. Larivière works alongside co-workers making things like macarons, verrines and hot chocolate for Cococo’s retail café settings.

It is fitting that a woman with lots of life stories should end up in a company with an equally intriguing tale. Cococo’s leader, Beck, was a former employee of Chocolaterie Bernard Callebaut Partnership, which is now bankrupt, before coming back after a five-year absence to organize the purchase of the well-established chocolatier’s business from its receiver. The “Chocolaterie Bernard Callebaut” name, which Beck says is deeply rooted as a brand with their dealers and the public, necessarily came along with all of the other business assets of the defunct company, and Bernard Callebaut the man

later reopened a new chocolate shop. The new Cococo name was introduced in 2011 with plans to nurture it in a co-branding environment, says Beck.

Larivière has the opportunity to work with some of the world’s elite talents in chocolate while working for Cococo. It was a real boon for the company to land Derrick Tu Tan Pho, former director of Barry Callebaut Chocolate Academy in Quebec, as its mâitre chocolatier.

“I’m very excited by our team’s skill set,” says Beck. “I’ve got a really wonderfully talented group of people . . . Derrick is certainly a rare person worldwide with his depth of background in chocolate both on the pastry side earlier in his career, and on the pure chocolate side as he did coming most recently from the chocolate academy, so there’s not many things about the handling or manufacture or differentiation of chocolate that we don’t know about. Derrick works with two other chocolatiers in our shop each of whom have more than 25 years of experience making chocolate confections. It’s like that Malcolm Gladwell book which talks about crossing over the 10,000 hours’ threshold of expertise, and the folks around here would have way more

The Brownie

240g bittersweet chocolate

250g unsalted butter

375g granulated sugar

4 eggs

15g vanilla (liquid)

250g all purpose flour

250g slivered almonds

Preparation

in a bain-marie, melt chocolate and butter. whip eggs with sugar in a mixer with whipping attachment. once the chocolate mixture is ready, pour on the batter and add vanilla and flour. do not overmix. Put the brownie mix in a pan (24cm/30cm). Bake at 300°f / 149°c for 15 to 20 minutes (chewy texture).

Maple Ganache

500ml - 35% cream

500g maple syrup

50g invert sugar

100g glucose

250g white chocolate

250g maple chocolate

Preparation

heat cream, maple syrup, invert sugar and glucose to 185°f / 85°c remove from the stove, cool down to 140°f / 60°c and stir in the butter. Pour over the chocolate (in food processor) and mix until texture is smooth.

Maple Ganache Tubes

use a rigid acetate sheet to make a tube. fill the tube with ganache. freeze to solid (about 1 hour). unwrap when ready. while the ganache tubes are freezing, remove the baked brownie from the pan. with a plastic dowel, make holes horizontally at regular intervals into the full width of the baked brownie (brownie may need to be cut into large rectangles or into serving size to make this process easier). insert the wrapped frozen ganache tubes into the holes.

almond and Cranberries Crumble

150g slivered almonds

75g maple syrup

one pinch of salt

50g dehydrated cranberries

than 10,000 hours each doing what they do. That’s exciting because you can throw ideas to them and they throw back more opportunities than we can manage to market as quickly.”

It’s a happening place Larivière landed in, and she’s discovering the countryside while she hones her culinary talent. When she’s not making treats, she likes to stay active at the gym, and get outside, enjoying snowshoeing in the winter. A hardy girl, she is car-less in Calgary, and likes the city but not necessarily the bus ride to work in the winter. She is enjoying the laid-back nature of the west, and dreams of one day travelling to Ireland, Cambodia or India. One day, she says she’d like to have her own little shop where she can sell chocolates, pastries and freshly roasted coffee. There’s no doubt, where there’s a will there’s a way.

“We are our own enemies,” says Larivière. “It’s really easy to give it up if you don’t think you are good at it, but just persevere if you have a dream. There will always be people around to help you reach your goal…whether we make a bad decision or not, we will learn about everything so it is important to continue and not look back.” / BJ

Preparation

Mix almonds, maple syrup and salt together and bake it for approx. 15 minutes at 350°f / 177°c (until golden brown). let cool. in a food processor, mix the almond mixture and cranberries to make a crumble.

Meringue

90g egg whites

63g granulated sugar

Preparation

whip egg whites with half of the sugar in a mixing bowl with the whisk attachment. when the peaks are soft, add the other half of the sugar and whip until hard peaks form.

assembling the Brownies

cut the brownies to serving size. using a knife or a little spatula, lightly cover the bottom and sides of the brownie with a layer of meringue. coat with the crumble mixture. add a dollop of meringue on top. with a torch, caramelize the top to a light brown colour. decorate as you wish!

• Join 4,250 industry professionals including bakers (retail, wholesale, commercial), grocery and foodservice outlets

• Visit the trade show - over 200 companies in 100,000 sq.ft. showcasing ingredients, equipment, services, technology and baked goods (fresh, proof & bake, par-baked, freezer-tooven, thaw & serve)

• Learn at the informative seminars and workshops

• Located in the Toronto area, the facility is easily accessible by public transportation (Mississauga Transit & GO Trains), major highways, 5 minutes from the Toronto International Airport and provides plenty of free parking

• NEW Show Features

Held every other year, it is the only baking specific event produced in Canada

Contact us for more information: Baking Association of Canada

7895 Tranmere Dr., Ste 202, Mississauga, ON L5S 1V9

Tel: 905-405-0288 / 1-888-674-2253 (BAKE)

Fax: 905-405-0993

E-Mail: info@baking.ca www.baking.ca

By Boni Ta Lin

When it’s time to upgrade equipment, what’s the best plan of action?

It’s a question all businesses face when they are looking to purchase new equipment – should we lease or buy? It is important to understand that there are pros and cons to either route. There are several key factors to consider before you make your decision.

Put simply, cash flow refers to the amount of money coming in and going out of a business. With that as the backdrop, leasing can be considered a source of financing if you do not have cash available for the purchase. Leasing allows you to make steady fixed payments over a set period of time. If you don’t have cash available to buy new equipment, it will be necessary to obtain other forms of financing, such as bank financing. It is often easier to arrange lease financing than it is to secure bank financing, since the leasing company owns the asset while you lease it.

Even though it may be easier to arrange lease financing, depending on the credit rating of the company, you may be able to obtain a better borrowing rate from your bank. However, bank borrowing often comes with certain requirements, for example, financial reporting requirements and financial covenants (which may represent additional costs as a result of monitoring the company’s compliance with these covenants).

For accounting purposes, there are two types of leases: operating and capital. Under an operating lease, the company would expense the lease payments (along with the interest) with no impact on the balance sheet. Under a capital lease, the company would set up the leased asset as part of its tangible assets and recognize a liability based on the

overall minimum lease payments using the implicit interest rate. The leased asset is amortized over its useful life as if the company owns it, and the interest portion of the lease payments is expensed as it arises. At first glance, it doesn’t appear either method would have an impact on someone looking at the company’s financial statements; however, a common covenant that creditors look at is the current ratio, calculated by dividing current assets by current liabilities. In the case of a capital lease, the asset is recorded as a long-term asset on the balance sheet and the liability has a current component, which represents the minimum lease payments due within one year. This will negatively impact the current ratio. This will be a concern if the company has a minimum current ratio as a financial covenant in its banking agreement and is close to breaching this covenant.

If you own the asset, you will deduct capital cost allowance (CCA) or depreciation for tax purposes. This is the percentage of the asset cost you deduct from taxable income each year. The maximum percentage of the asset cost that is allowed to be deducted through CCA is dependent on the type or class of asset that was purchased. If bank financing is used to finance the purchase, only the portion of the payments relating to interest is tax deductible. If you lease the asset, regardless of whether it is classified as an operating lease or capital lease for accounting purposes, the lease payments (principal and interest) are tax deductible, as Canada Revenue Agency does not differentiate between operating lease or capital lease.

If you own the asset, depending on the asset class for tax purposes, the first few years (other than the first year with the half-year rule), may provide a larger tax deduction than later years, as the cost base decreases over time while the lease payments remain consistent.

In many cases, the lease agreement will dictate how often equipment must be

maintained. Purchasing the equipment allows you to set your own maintenance schedule.

In many cases, lease terms are set to co-ordinate with the release of new models, which can allow for timely upgrades of your machinery. However, if this is not the case and your leased equipment becomes outdated before the end of the lease, you will have to pay an early termination fee, which can be costly. If you buy the equipment, you may have to donate, sell, trade-in or scrap it.

The bank considers leased equipment a liability, so you can’t use it as collateral for future loans. On the other hand, if you purchase equipment, it can serve as collateral should your operations require financing. From the bank’s perspective, the equipment is considered an unencumbered capital expenditure.

Perhaps the biggest disadvantage of leasing is that in the long run, it costs more than buying outright because of the ongoing interest payments and the fact that you are not building equity. That said, if you have limited access to capital, it might be a better option. It also affords you more flexibility because your money is not tied up in the equipment. If your business has excess cash, buying is likely your best option because you avoid the interest expense and you have an asset that helps build the value of the business – if the equipment has a long, useful life, even better.

Bottom line: the decision has to be based on your unique set of circumstances. Be informed and choose wisely. / BJ

Bonita Lin is an audit and assurance manager at Fuller Landau LLP. Her practice focuses on technical accounting research and provides owner-managed enterprises with technical advice in the areas of tax and accounting. She can be reached at blin@fullerlandau.com or by phone at 416-645-6589.

A

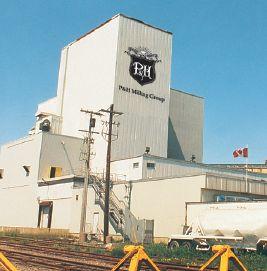

With eight mills across Canada and a vast distribution network we are able to serve your complete bakery needs. P&H milling is focussed on providing high quality grain based products with a commitment to delivering customer value each and everyday wherever you are.

A complete line of Hard & Soft Flours. Products include Bread, Pizza, Cake & Pastry, Whole Wheat, Organic, Whole Grain, Durum, as well as Bran, Cracked Wheat, Barley, Rye & Pea products.

Over 100 offerings such as bread, cake, pastry, cookies, muffins, pizza, doughnuts, bagels and batters. Available in branded and private labels.

New product innovation, private label, research, testing, technical support, bulk, totes and bags.

For more information please contact the P&H Milling Group sales and service representative in your area:

Halifax, Nova Scotia 1-800-663-6837

Montreal, Quebec 1-866-934-3234

Acton, Ontario 1-800-621-0588

Cambridge, Ontario 1-800 621-0588

Hanover, Ontario 1-800-621-0588

Saskatoon, Saskatchewan 1-888-313-6837

Lethbridge, Alberta 1- 403-328-6622

Parrheim Foods: Saskatoon, Saskatchewan 1-306-931-1655

By krIstI GoGan

Customers can be a complex bunch, but a trip to San Francisco shed light on the top five things my clients are going to want from my chocolate business and more. I joined 60 graduates, students and staff from Ecole Chocolat at the Intercontinental Hotel in San Francisco to celebrate the school’s 10th anniversary. “All That Jazz: The Future of Flavor, Texture and Presentation in Bonbon and Bars” was the theme. Four well-established chocolatiers gave us their forecast on the future of chocolate. Philippe Givre of Valrhona L’Ecole du Grand Chocolat in France reminded us that every market is different. He briefly described three global markets. The American market tends to go a little more on the bold side with lots of colour, the European market prefers simple designs with some colour and the Asian market does not care for much colour.

Paul DeBondt of DeBondt Cioccolato Originale in Italy shared his passion for creating his own treats using more than 50 different types of chocolate and cocoa mass. He spoke about the importance of constructing our bonbons and bars so that the chocolate stands out. He presented an air-filled truffle he made especially for the Ecole group that represented the construction process of flavour from the first bite to the last. When I allowed this truffle to melt in my mouth, I experienced a flavour explosion that accented the chocolate flavour with a rose flavour in the airy centre. The flavours were harmonious.

the toP fIVe trenDs InfluenCInG the future of fIne ChoColate

Here’s a rundown of five key things to keep in mind for your chocolate operation, as well as advice from cutting edge chocolatiers.

Quality and flavour: More and more, chocolatiers are choosing the highest quality of chocolate and ingredients that produce the finest flavour. Know where the ingredients come from and how they are produced and manufactured. Have a good

recipe for each creation: one that has a relatively good shelf life so it has the same taste sensation on Day 1 as on Day 21. Control and respect the ingredients, the way you use them and how they combine with the chocolate. It’s important to decide on the right technique for the right flavour combination. The chocolate’s flavour needs to be the number 1 taste. It is important not to overpower the taste of the chocolate itself.

Balance of flavour: Bonbon recipes need to have harmony and logic in their creation. Bart van Cauwenberghe of Dezwartevos Artisanal Chocolates in Belgium spoke about how there is a Chinese restaurant in every town. Why? Because they are masters in the art of balancing sweet and sour as well as textures. Knowing the ingredients you are working with will help you choose those that will harmonize perfectly with the chocolate you are using. If you choose hot peppers, for instance, there are thousands of varieties worldwide. Knowing flavour profiles of the individual varieties and where they are grown will help you decide which ones will synchronize perfectly. The magic of creating a recipe is in the layers of flavour. We taste soft ingredients first (such as ganache or butter) and hard ingredients last (such as nuts or hard candy). The bonbon needs to be constructed so that it will burst with flavour from beginning to end.

Having a fingerprint: We need to be aware of what it means to be artisan chocolatiers.

Dictionary.com defines artisan as: “1. a person skilled in an applied art; a craftsperson.

2. a person or company that makes a high-quality or distinctive product in small quantities, usually by hand or using traditional methods.”

Artisans have a fingerprint that is presented through their design, style and recipes. The chocolatier’s product is recognizable by the presentation and packaging.

Kristi Gogan, owner of Sweet Odyssey Chocolatier, took an adventure to San Francisco to find out what’s up and coming in the world of fine chocolate.

Local, fresh and seasonal: Consumers love to hear that something is made from fresh, local ingredients. They want to hear the story behind the creation – that the mint was picked from the garden that morning or that the farmer down the road grows the berries you use. Pick flavours from ingredients that are in season at the time. People also love to watch a product being made. The upside to this is they see how much work is involved in creating that perfect bonbon they are paying good money for. They know they are getting a high-quality, fresh and fine-flavoured bonbon or bar.

Traditional and daring: The nostalgia movement is still strong. Traditional flavours will always be tried and true but once in a while someone wants to come out of their comfort zone and try something new. A bold flavour such as Gail Ambrosius’ shitake mushroom truffle or my lemongrass/coconut bonbon brings the people in the door. They may not always choose the most exotic flavours, but it will always intrigue them to see what’s inside. / BJ

Kristi Gogan is a certified chocolatier through Ecole Chocolat, and worked as a certified cook for 15 years in restaurants, resorts and even the Canadian Forces before establishing Sweet Odyssey Chocolatier.

On November 22, 2012, the Safe Food for Canadians Act received royal assent. This Act provides the legal basis for consistent regulatory requirements and inspection approaches across all food.

As a result, CFIA has developed a revised Food Inspection Model – basically a framework of what will be required for food safety and how inspection and enforcement will take place. The Model provides a uniformity of approach across food production sectors, enhances inspector training and competency, bases the inspection oversight on “residual risk,” and applies a less prescriptive and more outcome-oriented approach.

The most significant impact will be felt by the non-regulated sectors. Bakers, their suppliers and any company manufacturing, importing or exporting food across PROVINCIAL and/or NATIONAL borders will be affected by this legislation and the new Food Inspection Model.

“This is a significant change in the baking industry as many of our members will now be required to have a licence for their business,” says Laura Pasut, Director, Food and Nutrition Policy, at the BAC.

The Baking Association of Canada has been very involved in the consultation process in order to obtain clarity regarding what will be expected from members to meet these requirements of the new legislation, as well as to provide CFIA with an industry perspective.

Pasut indicated that “although the revised Food Inspection Model provides more detail and clarification than the first version, we have requested further explanation on a number of issues.” Areas of clarification include:

1

1. Ways in which CFIA will support the baking sector, specifically

a. What sort of “industry education and/or training” phase will be allowed before hard enforcement of the new requirements will occur?

b. What supports, such as resources or training, will be provided to non-regulated sectors?

2

2. The requirement for a licence. Each company is required to have a preventive control plan in place (i.e., a food safety program), fill out the application and pay the licence fee in order to get a licence. As many of our members would be first-time applicants, they may be on a priority list for pre-licence inspections. We wanted to know:

a. What are the steps that would prompt a pre-licence inspection? What would be used to determine who would require the pre-licence inspection?

b. In addition to the fee for the licence, what new costs/user fees will the baking industry face?

c. Why is the licence validity set for two years instead of a longer time frame?

d. Will there be any small establishment exemptions?

3

3. Number of licences that may be required by different companies. Since a critical noncompliance may result in a suspension of a licence, this would potentially have drastic results if companies have more than one facility. We wanted further information on the following:

a. Should there be one licence for each facility/ production plant, which is now the norm for meat, fish, dairy, eggs, and plants? Not only is this a key requirement in international trade but if one plant is found to be non-compliant, then would the entire business not be affected?

b. Will a company’s licence be suspended or cancelled for issues associated with only one product line in a facility if other non-related products are produced within the same facility?

c. If a bakery imports ingredients directly, will they also need an import licence in addition to a licence for their manufacturing facilities?

The second round of consultations closed on May 21st. It is expected that CFIA will finalize this framework sometime this summer. Regulations to support the Safe Food for Canadians Act are expected to go through a consultation stage between now and December 2014. Members impacted by this new legislation will need to ensure that they have a preventive control plan in place in order to get a licence starting as early as January 1, 2015.

was how Rosemary (Rose) ended our telephone conversation and were her last words to me just a few days before she passed away on May 19th after a 3 ½ year struggle with cancer. Rose called to let me know she was back in hospital because in her words “the doctors don’t seem to know what is wrong with me,” which was her way of once again expressing contempt for the disease that she had been fighting since diagnosed in January of 2010. Our call was not about her, but everything else: how our recent Bakery Congress event went, asking who was on the Board, about other members of the team and our respective families. After some 40 minutes of chatting she announced that the nurses had finally arrived with her medication and she had to go.

Members will have been first introduced to Rose when she joined the newly formed BAC back in 1997. I, however, had known her since 1986 when I was part of a selection team that hired her at Landscape Ontario, a provincial horticultural trade association, to work on the association’s trade show and publications. I soon left Landscape Ontario and moved to the Canadian Federation of Independent Grocers where we shortly found ourselves in need of a trade show manager. Introductions were made and Rose subsequently joined CFIG.

In 1994 I accepted the position of President at the Bakery Council and we kept in touch. When BAC was formed in 1997 a key element of the business plan was the production of a trade show and there was only one candidate in my mind. Rose joined BAC in May of that year. Our long-standing joke was that for her to get a new job I had to do so first.

Members may not remember Rose’s face but will certainly know her work. She wasn’t much of an extrovert and therefore not the “front of the house” type. Rose preferred to be in the background designing, marketing and managing Bakery Showcase and Congress along with her other responsibilities at which she excelled. Her dedication and professionalism were a good part of the reason BAC has become successful, especially through those challenging early days.

You see, Rose didn’t just believe in dotting the “I’s” and crossing the “T’s.” She insisted that the entire alphabet be able to be recited backwards-forwards and then in ancient Greek! In producing our events she often worked herself into near exhaustion regardless of being told to go home and leave things be – from her perspective it was never quite good enough. Besides, these events were “her babies.”

And this dedication continued on during her illness. For the first two years after being diagnosed and in between chemo treatments, Rose continued to work and manage

BAC’s events. Rose didn’t want to stay home; besides, who was going to look after her babies?

It wasn’t until January of last year that Rose finally came to me and actually apologized that she could no longer manage our events to her standard and would have to go on disability leave. But even on leave Rose continued to volunteer with odd jobs that needed to be done and was always there to answer questions and provide advice.

In her final months Rose tended to keep to herself rather than get into discussions which she felt were always going to lead to how she was feeling. It was her way of not wanting to be a burden – something with reluctance we accepted.

Rose’s last call to me was therefore in keeping with this attitude, as if nothing really was the matter. And in reviewing that conversation now, I think her final words to me sum up how she would like her passing to be considered, without tears but simply, “I have to go now.”

Paul Hetherington President & CEO

Bakery Congress 2013 was another successful baking industry trade show and conference held May 5th & 6th at the PNE in Vancouver. The two day event featured with educational sessions each morning for delegates and the show floor was packed with 170 booths showcasing the latest offerings for the 1,500 attending bakers and bakery buyers.

The highlight of the event was the continous presentations on the trade show floor by the Vancouver Community College & Vancouver Island University instructors and students, along with special guest presenter Craig Ponsford.

Craig is a Past Chair of the Bread Bakers Guild of America and previous winner of the Coupe du Monde de la Boulangerie in Paris.

Baking Association of Canada wishes to extend sincere thanks to the following companies for their generous support of Bakery Congress 2013

• BakeMark Canada • L.V. Lomas • Numeric Computer Systems • Unilever FoodSolutions • V-Tech Engineering

BAC wishes to extend its appreciation to both the VCC and VIU for their enthusiasm in participating in the Bakery Congress feature area.

A special thanks to the BAC - BC Chapter & PONSFORD’S PLACE

Canada is a world leader in manufacturing foods, beverages and consumer products – a sector that makes significant contributions to our economy and quality of life. There are many groups, including the baking industry, who work each day to produce high quality food and beverage products for consumers in Canada and around the world.

Canada’s agri-food sector has a significant impact on the economy. The agri-food value chain is generating profits, jobs and significant economic activity, which ultimately benefits all Canadians by generating almost 300,000 jobs and contributing $19 billion to our GDP.

Yet despite the positives, the industry faces major challenges.

In November 2012, The Canadian Agri-Food Policy Institute (CAPI) released a report indicating that Canada’s trade deficit in processed food has skyrocketed from about $1 billion in 2004 to $6.3 billion in 2011. Canadian exports of processed foods have stagnated, while imports have steadily increased. There are several reasons why this has taken place: the exchange rate, international trade agreements, the regulatory context, etc.

Food manufacturers need to adapt – and they can learn plenty from the baking industry.

Despite the broader trend, the baking industry has maintained a positive trade balance with the U.S., and globally. Whether it’s through developing new techniques and processes such as par-baked goods, finding new niches in domestic and international markets, like gluten-free or specialty baking, or finding efficiencies right here at home, bakers are leading the way.

That’s the good news. The less than good news is that growth in net exports for baked goods are at best stalled – down seven per cent compared to 10 years ago.

So what to do? Any real, long-term solution needs to be based on good information. That’s why Farm Credit Canada is supporting a new CAPI research project that seeks to

understand the drivers behind the food manufacturing sector’s growing trade deficit. The project will also include an action plan to help the industry succeed in a changing food world.

The research program has three phases:

• understanding the issues and implications

• identifying inspiring practices and guiding principles

• enabling change and positioning for success

In the meantime, there are opportunities for quick wins.

Increasing productivity through process automation and innovating by creating new products hold real promise in the Canadian and international markets, where consumers are looking for healthy and practical new products.

This is particularly important, given the gains of U.S. competitors and the possibility that free trade negotiations with the European Union may be concluded in 2013. This could lead to greater market access for Canadian products, but also trigger greater competition in our home market.

The opportunities this brings are as great as the challenges. Together, Canada’s food industry can meet them head on.

BAC is saddened to report the passing of Fred Seiffert, founder of Snow Cap Enterprises, on May 6, 2013. Originally from Germany, Fred came to Canada and built an amazing and successful life both personally and in business. A fixture in western Canada’s baking industry; Fred was also a great friend and supporter of BAC and will certainly be missed. BAC wishes to offer its condolences to Fred’s family, friends and extended Snow Cap family.

7585 Danbro Crescent, Mississauga, ON L5N 6P9

Contact: Debbie Bell, 905-819-7000

Fax: 905-819-9768

e-mail: debbie.bell@adm.com

Plants: 2 Montreal, QC; Mississauga, Midland, Port Colborne, ON; Winnipeg, MB; Calgary, AB.

Sales offices: Montreal QC, 514-846-8533; Toronto, ON 1-800-267-8492; Calgary AB, 403-267-5656; Vancouver, B.C. 604-2990710.

Products offered: A full flour and mix product line for the bakery, donut, muffin, food service, biscuit, pasta, frozen, in-store bakery, pasta and industrial segments. Other products offered are stoneground whole wheat, cracked wheat, graham and cereal bran and rye flours.

1150 Rang Saint-Edouard, Saint-Liboire, QC, J0H 1R0

Contact : Rory Lesperance

Phone: 416-770-2310

e-mail: rlesperance@farinart.com www.farinart.com

Products offered: Ecocert, Kosher and Halal certified. Farinart is a Canadian leader in the production of grain, flour, seed and pulses blends, both traditional and organic; and emerging gluten free capabilities. We deliver innovative processing solutions, superior expertise, product consistency and best in class service to the baking and food manufacturers.

Distribution: We deliver across Canada and overseas.

Delivery: 20 kg bags, tote bags and bulk products.

Company comments: We are a friendly and versatile company that can adapt to our clients’ requirements.

(CANADA) INC.

5951 McKee Rd., Suite 201

Fitchburg, WI 53719

www.glanbianutritionals.com

Contact: Dan Verhasselt, Sales Director, Flax Ingredients

Phone: 608-449-0891

Fax: 608-316-8504

e-mail: Nutrition@glanbia.com

Products offered: Advanced Grain Technologies including Flaxseed, Chia and Ancient Grains. Portfolio for baking also includes OptiSol Functional Flaxseed for use in shelf life extension and hydrocolloid replacement. Whole flax seed, milled flaxseed, fine milled flaxseed, flaxseed bran, lignan/fiber complex, flax/fish oil blend. Major customers: Retail and Wholesale bakeries, food, beverage, nutritional and supplement companies.

Company comments: NOT ALL FLAXSEED IS CREATED EQUAL. When it comes to flaxseed, nobody can compete with the quality or nutritional value found in our MeadowPure® line of flaxseed ingredients.

Whether you’re looking to enhance your project with flaxseed’s powerful antioxidant benefits or its abundance of essential Omega-3 fatty acids, our MeadowPure line of flaxseed delivers the nutritional and functional requirements your application demands.

MeadowPure® Process – MeadowPure is a patented seed selection and cleaning process found exclusively at Glanbia Nutritionals. First, we work with contract farmers to select flaxseed that’s superior in colour, uniformity and flavour. The seeds are then processed using proprietary patented technology that protects the integrity of the flaxseed during all stages of production. The result is a superior flaxseed that remains stable under a wide variety of food processing, distribution and handling conditions for up to two years after the milling of the seed. The full nutritional value of flaxseed is delivered where it’s intended – in the food products that reach consumers.

105 Commander Blvd., Scarborough, ON M1S 3M7

Contact: George Birinyi Jr., Carl Griesser

Phone: 416-291-3226

Fax: 416-291-2159

e-mail: gbjr@grainprocess.com

Products offered: Over 3,000 items including a full range of whole grains. Hard/Soft Wheat, Triticale, Corn, Millet, Barley, Rye and Durum and organic products certified by QAI (Whole Wheat Flour, White Flour, “Ancient Grains” Spelt, Kamut, Quinoa, Seeds, etc.) Precooked and stabilized grains and flours, Whole Bean Flour, complete range of grains including Cracks, Flakes and Grits, Seeds (Sunflower, Sesame, Golden Yellow and Brown Flax), Beans, Peas, Lentils, Sugars, Nuts and Dried Fruit. Food processing also includes custom blending

facilities for multi-grain formulas (Bread, Muffin and Pancake Mixes, etc.) packaging, granola cereals, toasted grains, Turbinado and Demerara Sugars.

Distribution: Across Canada and the United States.

Major customers: Bakeries, biscuit and cookie manufacturers, food service, bulk, health and natural food retailers and distributors and manufacturers.

Company comments: We pride ourselves as being the only stone flour mill in Canada to offer such a wide variety of products. Our product development team is ready to develop mixes and specialty grains for any application in the food industry.

Horizon Milling, a Cargill Joint Venture, is a leading bakery solution provider, offering a broad range of high quality flour, oats and bakery mixes/bases/concentrates to manufacturers, retail and wholesale bakery and foodservice. To learn more visit www. horizonmilling.ca

®ROBIN HOOD is a registered trademark of Smucker Foods of Canada Corp., used under license. 235 Nuggett Court, Brampton, ON L6T 5H4

Contact: Elaine O’Doherty, 905-494-2600 www.horizonmilling.ca

Plants: Flour mills in Montreal, QC, Saskatoon, SK, bakery mix plants in Burlington, ON and Saskatoon, SK. Oat mill in Saskatoon, SK.

Products offered: A full line of quality flour including all-purpose, strong bakers, cake & pastry, whole wheat, pizza, specialty flour, durum and oats. Plus a broad range of bakery mixes, bases and concentrates, many formulated specifically to customers’ needs.

Delivery: Coast to coast in Canada by rail or truck. Minimum quantities vary.

Distribution: From plants, regional warehouses and local distributors, depending on product location.

Major customers: Bakery & Food processors, Retail & wholesales bakeries, Foodservice Operators, Grocery Retailers & Instore Bakeries.

232 Westmorland St., PO Box 390, Blyth, ON, N0M 1H0

Contact: Jeff Howson, 519-523-4241, Ext. 60

Fax: 519-523-4920

e-mail: jeff@howsonandhowson.ca

Dan Greyerrbiehl, 905-792-2962

Fax: 519-523-4920

e-mail: dgreyerbiehl@rogers.com

Plants: Blyth, ON

Products offered: Durum semolina, durum flours, durum whole wheat semolina, Atta flours.

Delivery: Bulk truckloads, bulk bags (750kg), 20kg bags, 40kg bags, 50lb bags and 100lb bags to Ontario, Quebec and United States.

Distribution: From Blyth, ON, Plant by truck or distributors.

Major customers: Manufacturers of dry pasta, fresh pasta, frozen pasta, and snack crackers.

Assistance offered: Technical assistance.

Company comments: Howson & Howson Ltd. have been quality wheat millers for over 135 years. We are continuously modernizing our durum mill in order to supply our customers with high-quality durum semolina, durum flour and other durum products.

Box 28009 RPO E. Kelowna, Kelowna, BC V1W 4A6

Contact: Ross Nunweiler 1-888-726-2253

Fax: 1-888-688-2288

e-mail: info@nunweilersflour.com www.nunweilersflour.com

Plant: Alsask, Sask.

Certifications: Pro-Cert Certified Organic Systems, Kosher Certified.

Products offered: Nunweiler’s Flour Company is a 100% dedicated Certified Organic flour mill located in Alsask, SK with our sales office in Kelowna, BC. Our family of products include Whole Grain Wheat Flour, Dark Rye Flour, All Purpose & Pastry Flour, Spelt Flour, Buckwheat Flour, Red Fife Flour and Kamut Khorasan Flour. Distribution: B.C. – Snowcap Enterprises, Snowcap Interior, Aarsen City Delivery. Major customers: Retail and wholesale bakeries, specialty product bakeries, retail mass market and natural food stores.

Company comments: Since 1988, Nunweiler’s Flour Company has been milling Organic Canadian grown grains. Our whole grain flour is processed in a low temperature impact mill at a temperature of 60ºF/ 16ºC in the cool winter months to 95ºF/ 35ºC in the warm summer. We include No Additives, Preservatives or Blending in our freshly milled whole grain flour. Now into our 25th Anniversary Year, we are proud to continue supporting Canadian Organic family farms, committed to producing premium quality products for bakers and consumers wanting wholesome and nutritional foods.

organic and clean label dough conditioners. NutraSun offers a variety of packaging options for the industrial, bakery and retail markets including 10 kg, 20 kg and 50 pound bags, bulk totes, bulk trucks and bulk rail. Our retail packaging line uses resealable pouch packs for weights ranging from 600 grams to 2.5 kg.

Major customers: NutraSun serves industrial and retail bakeries as well as retailers selling consumer packed resealable pouches.

Company comments: NutraSun Foods is a division of Paterson GlobalFoods, a wholly owned Canadian company which has been serving the Canadian agricultural and food industry for over one hundred years. NutraSun is a fully modernized mill located in southern Saskatchewan, the heart of Canada’s Hard Red and White Wheat growing region.

PO Box 1695 Dewdney Avenue, Regina, Saskatchewan S4N 4N0 Phone: 306-751-2040

Contact: Cory Whyte, General Manager 306-751-2440

www.nutrasunfoods.com

Certification: NutraSun Foods Ltd. is certified Organic by Quality Assurance International (QAI), Kosher Certified and H.A.C.C.P. and ISO 22,000 Compliant. Delivery: We deliver bakery ingredients across Canada and the United States as well as shipments offshore.

Products offered: NutraSun’s high quality Organic and Traditional flour is milled from Hard Red Spring and Hard White Wheat. We are the exclusive miller of premium Snowbird White Wheat flour and also offer a variety of Whole Grain flours. In addition to flour, we are continuously expanding our product line of organic and conventional bakery mixes and bases to include breads, muffins, cookies, pancakes and whole grain pizza crust mix or base. We also offer customized grain blends and

NutraSun Foods contracts directly with producers across western Canada in sourcing the highest quality grain to ensure consistency and quality for our flour and mixes.

Company comments: Canadian owned, the P&H Milling Group is Canada’s second largest flour producer. Built on the strength of eight mills, the P&H Milling Group is strategically located across Canada. For more information about our flour mills or any of our other products please contact the P&H Milling Group sales and service representative in your area.

3 Locations to serve:

P&H Milling Group - Hanover 252-14th Street, PO Box 219 Hanover, Ontario, N4N 3C5

P&H Milling Group - Cambridge 140 King St West Cambridge, Ontario N3H 4T3

P&H Milling Group - Acton 45 Church St. West Acton, Ontario L7J 1K1

Contact: Rob Fursman Regional Sales and Marketing Manager 519-650-6422

e-mail: rfursman@phmilling.com

Products offered: Hard Wheat Flour, Soft Wheat Flour, Blended Flour, Heat Treated Flour and Organic Wheat Flour. Other products include Whole Wheat Flour, Durum Semolina and a variety of Cracked Wheat and Wheat Bran offerings.

Company comments: Our sales force will assist in sourcing the best products to meet your needs and will provide timely market information to secure your requirements. Products are delivered on a fleet of company owned and operated trucks and tankers in addition to a wide distributor network. BRC Certified Mill.

PO Box 2185, 730 Marginal Road, Halifax, NS B3J 3C4 www.phmilling.com

Contact: Dave Bryson, 902-429-0622. 1-800-663-6837

Fax: 902-423-9075

e-mail: dbryson@phmilling.com

Products offered: Enriched flours, no-time flours, bread flours, natural flours, whole wheat flour, pizza flour, organic flour, cracked wheat, farina, wheat bran, whole grain; bread, cookie, muffin, cake and doughnut mixes and custom-blended mixes; cake and pastry flours, corn and dark rye flour, coarse rye-meal, rolled oats, oat bran, oatmeal and yeast. P&H Milling-Halifax also produces private label flour, mixes and bases. BRC Certified Mill.

Delivery: Serves Atlantic Provinces with company-owned bulk tankers and delivery trucks, containers and common carriers. Distributors: Sell direct as well as through local wholesalers.

Major customers: Bakeries throughout Atlantic Canada and off shore. Company comments: We mill our flours primarily from Canadian Western Red Spring Wheat known for its consistent quality and baking characteristics. P&H Milling-Halifax is committed to supplying competitively-priced, consistently high quality products, milled, blended and packaged to individual customer requirements for both local and international markets. In our R&D and Quality laboratory, a team of specialists assure that quality of every shipment, develop new products and work closely with our customers. Our management and staff are dedicated to quality products and service and are sensitive to the varieties of specific needs of our customers.

380 Oak Street, Montreal, QC H3K 3G2

Tel: 514-934-3234

Contact: Richard Blais 1-866-934-3234

e-mail: rblais@phmilling.com

Fax: 514-934-5069

Products offered: Enriched flours, notime flours, bread flours, natural flours, whole wheat flour, pizza flour, organic flour, cracked wheat, farina, wheat bran, whole grain; bread, cookie, muffin, cake and doughnut mixes and custom-blended mixes; cake and pastry flours, corn and dark rye flours, course rye-meal, rolled oats, oat brain and oatmeal and yeast. P&H Mills also produces private label flour, mixes and bases. BRC Certified Mill.

Delivery: Serves Quebec with bulk trailers, delivery trucks, containers and common carriers.

Major customers: Bakeries throughout Quebec and U.S. market.

Company comments: We mill our flours primarily from Western Red Spring Wheat known for its consistent quality and baking characteristics. P&H Milling-Montreal is part of the P&H Milling Group and is committed to supplying competitively priced high quality products to meet customer’s needs.

75 – 33rd Street East, PO Box 160, Saskatoon, SK S7K 3K4

Toll Free: 1-888-313-6837

Contact: Jerry Dmytryshyn; 306-667-8016 Fax: 306-667-8129

e-mail: jdmytryshyn@phmilling.com www.phmilling.com

Products offered: Enriched flours, no-time flours, bread flours, whole wheat flours, organic flours, pizza flours, cracked wheat bran, Barley flour and pot and pearl barley. P&H Milling also produces private label flour for the retail and wholesale markets. Delivery: Across Canada, US and off shore. Company comments: P&H MillingSaskatoon is part of the P&H Milling Group. The mill began producing flour in Saskatoon on February 1st, 1949. We mill

our flours primarily from Canadian Western Spring Wheat, known for its consistent quality and superior baking characteristics. We are strategically located in the heart of the Canadian Prairie wheat growing area. P&H Milling-Saskatoon is committed to supplying competitively priced, consistently high quality products, milled, blended and packaged to individual customer requirements for both local and international markets. BRC Certified Mill.

PO Box 400, 1301 2nd Avenue South, Lethbridge, AB, T1J 3Z1

Contact: Bob Grebinsky, 403-328-6622

Fax: 403-327-3772

e-mail: bgrebinsky@phmilling.com

Products offered: A complete line of spring wheat flours, soft wheat flours, rye flours and meals, durum semolina, durum atta and durum patent.

Distribution: Direct and distributor network covering British Columbia and Alberta. Direct delivery available throughout Canada and the US. Offshore shipping globally.

Delivery: Bags in 10 kg, 25 lb., 20 kg. & 50 lb. Bulk by totes, truck and rail.

Major customers: Retail and wholesale bakeries. Pasta and food manufacturers. Foodservice and traditional retail brand private label.

Company comments: Located in Southern Alberta in the heart of the grain growing area and strategically situated on key distribution routes. Our strength is in our ability to consistently delivery flour that meets each customer’s specific needs. BRC Certified Mill.

817 48th St. East

Saskatoon, SK S7K 0X5

Contact: Glenn O’Hara, 306-931-9911

Fax: 306-931-1655

e-mail: gohara@phmilling.com

www.phmilling.com

Products offered: Pea flour concentrates (starch, protein, flour and fibre)-both conventional and organic. Barley flour and beta-glucan concentrated flour as well.

Delivery: Across Canada, USA and offshore

Distribution: Direct from our Plant in Saskatoon

Company comments: Parrheim Foods, Saskatoon SK, is centrally located amongst the largest growing region of pulse crops in the world. Since 1989, we have been processing concentrated flours from peas and barley. Our pea protein is well accepted for its excellent amino acid profile and low allergenicity; our pea fibre for its high tdf content and our pea starch for its resistant and slowly digestible attributes. To ensure their functionality, all our products are naturally processed and no chemical or aqueous processes are used. All of our products are non-GMO, and processed at our BRC Certified plant in Saskatoon. We are proud to provide the highest quality products delivered in a timely efficient manner in the quantity (bags, totes or bulk) you require.

240 Industrial Parkway S., Aurora, ON L4G 3V6

Contact: Kresho Petrovich 905-713-1712

Fax: 905-713-0074

e-mail: orderdesk@portroyalmills.com www.portroyalmills.com

Plant: Aurora, ON

Certifications: SQF 2000, Certified Organic by Pro-Cert, Kosher Kashruth

Products offered: Custom blended whole grain cereals, stone ground flours, cracked, flaked, pearled and whole grains including: rye, spelt, barley, quinoa etc. Importers and distributors of other fine bakery ingredients. Delivery: Direct throughout most of Ontario Major customers: Bakeries, cookie manufacturers, frozen dough plants, bakery mix manufacturers and food processors. Company comments: At our milling facility in Aurora, Ont., we meet the continuing demand for whole grain milling and custom blending. We at Port Royal continue to provide the highest quality products and personalized service to our customers with industry leading food safety standards.

2800 One Lombard Place

Winnipeg, MB R3B 0X8

Contact: Richard de Kievit

Phone: 1-800-663-6287(OATS)

Website: www.richardson.ca

Company comments: Richardson Milling offers a full range of whole grain oat products including flakes, flour and steel cut groats. Our oat bran products can deliver elevated levels of soluble fiber up to 20% and are perfect for formulating products to meet the new Canadian Oat Fibre health claim. Products are available in bulk rail, flexible super sacs, corrugated totes and 50 lb bags. Our extensive grower network and four manufacturing facilities provide the most extensive oat supply chain in North America. Richardson Milling is a division of Richardson International, Canada’s largest agribusiness. Recognized as a global leader in agriculture and food processing, Richardson is headquartered in Winnipeg and has more than 2,300 employees with facilities across Canada and the U.S.

by F ran C is C o J. M igoya

A professional guide to every aspect of the launch and management of a modern, upscale café.

This exquisitely illustrated volume is packed with professional guidance and master recipes for breakfast pastries, artisanal sandwiches, truffles and treats, and much more.

Additionally, an entire chapter is devoted to the retail shelf, a key contributor to any café’s financial health.

With information on all aspects of the café business-finances, human resources, food production, recipe/menu development, and even décor-The Modern Café offers both inspiration and instruction for anyone who wants to operate a successful café.

Model JN Semi-Auto Divider/Rounder

4-in-1 machine capability, 36, 18, 9 & 6-part heads

Heads can be removed or interchanged without tools in seconds

NSF & UL certified, Made in America

2-Year parts & labor warranty.

Heads can be washed in a sink or dishwasher.

High production rate - low maintenence

Easy to train and operate.

Model BMIH-36/18 Dough Divider

2-in-1 machine capability - 36 & 18-parts

1oz up to 8oz each piece scaling range.

Mounts to a Portable Stand for mobility (Optional) Divide many types of dough including sticky pie and cookie dough in addition to bread and bun doughs.

Contact our Canadian Representative @ eric@bloemhof.com www.dutchessbakers.com - sales@dutchessbakers.com

Bakery For Sale in the B.C. roCky MountainS: Profitable business situated in a four season resort community. Price of $425,000 includes business, building, land, equipment, etc. See website for more details & pictures: www.bakeryforsale.ca or call 250-999-9875.

rare oPPortunity: Very well known, established, luCrative bakery for sale in winfield, bC, in the beautiful okanagan (10 minutes from kelowna airPort). 40 years in the Community and the only bakery in our town. take oVer existing Clientele & ContraCts. the building is leased, all bakery equiPment is inCluded (ie: rotating oVen, walkin freezer, all fridges, 3 new show Case uP front, brand new 2 & 1 door fridges) 2600 sq. ft (2 leVels). bakery is busy all year round. asking PriCe $420,000 For inForMation PleaSe Call JoSeF at 250-766-5536 or eMail: josefz70@ shaw.ca.

Business development via government funding: let’s start counting the ways

When I stumbled across news about the AgriMarketing Program (AMP) recently – with $341 million to spend over five years to develop agriculture and agrifood businesses – I wondered: who was getting this funding? I wanted to see how the baking sector could benefit from some of this cash.

The AMP belongs to Growing Forward, a two-part program, five years each, first launched in 2008. Growing Forward 1, as it’s now known, expired March 31, and on the very next day, Growing Forward 2 was set in motion, but with a little less emphasis on making companies export-ready, and a little more emphasis on “developing new markets.”

I know. What does that mean, exactly, in terms of this program?

}Development. Again, in general terms, this stream focuses on national industry associations, but there is an SME element that can directly help individual business owners. Among the eligible activities for business development are branding, promotions and market research. However, to get this funding, SMEs have to apply through national associations.

“The national association is the door,” says Luc Marchand, director of the AgriMarketing Program. The department, says Marchand, is highly invested in helping individuals and companies with their applications. The spirit is to help applicants succeed. Marchand says that even if your first application gets rejected, the department will work with you to make the changes that will get your application approved.

“We’re open to that, too,” says Powell. “The goal is to increase business,” she adds, and she and her association have done

among the eligible activities for business development are branding, promotions and market research. However, to get this funding, sMes have to apply through national associations.

According to Susan Powell, executive director of the Canadian Food Exporters Association, developing new markets can mean finding a new foreign market for your product, a new domestic market or even creating new business, period.

The AMP has two streams. In very general terms (links will run at the bottom of this column to fast-track you to helpful supporting documents), an Assurance stream is for national, non-profit associations to develop nationwide assurance programs in such areas as food safety. When giant retailers are beginning to restrict their supplier selection to only those who can certify to specific standards (like GFSI) it’s time to help more companies certify to increasingly higher standards.

The Assurance stream is for national associations only. Small and medium enterprises (SMEs) don’t qualify directly in this stream. However, many associations have funding programs in place. (See www.bakersjournal.com under Links for a list of industry associations.)

The other stream is called Market

quite a lot of business-building over the last few years. From Growing Forward 1, Powell’s association took in $2.5 million for its members. Her funding budget for 2012 was $900,000. Last year, she helped two large national cookie companies expand their markets. The baking sector accounts for 10 per cent of her funding program.

Powell also mentioned that there are two more funds that haven’t been announced yet. One is a “generic” fund for trade-show presence, and another is for entrepreneurial SMEs to “develop new markets,” which means, “any new business,” says Powell. “Any new customer is a new market.”

Comparing apples to apples, the other strong national association working with industry to dispense government funding is Food Beverage Canada. Executive director Wendy Hindle reports that her association distributed $3.92 million during Growing Forward 1 and had a little over $1million to dispense in 2012. During those five years, her association also distributed an additional $2 million from the now defunct program known as Advancing Canadian

There are ways the baking sector can benefit from funds made available for agrifood business.

Agriculture and Agri-Food. The baking sector represents 11 per cent of this association’s funding recipients.

But even with help from your association and/or a government funding rep, many companies have opted for more personalized help to sort through details. For that, they’ve gone to Mentor Works, an Ontariobased consultancy specializing in government grant writing and strategic business planning.

MentorWorks.ca is a font of exceptional content on government funding. Sign up for its newsletter, study their blog posts and read their FAQ pages. Ryan Weaver, one of the firm’s marketing analysts, told me that there are two programs that could be great matches for the baking sector. Take a look at the AgriProcessing and AgriInnovation Programs.

Baking Association of Canada President Paul Hetherington says he hasn’t yet had any requests for funding. If he were to get any, says Hetherington, “we would first ensure all members were aware of the program to ensure fairness, and we would ensure that all interested members could apply, to avoid any preferential treatment.” For more information on how your bakery may be able to benefit from this program, visit www.agr.gc.ca. / BJ

CORRECTION: In the April Final Proof, it was incorrectly reported that Maple Leaf’s bakery product group sales were down 73 per cent. Correctly, the company’s adjusted operating earnings were down 73 per cent.

Stephanie Ortenzi (www.pistachiowriting. com) is a Toronto-based food marketing writer.

Ready to expand? We learn how you want to grow, then create a financing package that helps you do it Work with the leading lender to agriculture, agribusiness and agri-food in Canada Let’s talk business www.fccfinancing.ca “ FCC is key to our company

When you talk financing with FCC, we’ll listen

Your New Go-To Source

Posted by Dawn Foods Industry News

Welcome to the new Dawn blog! We know you don’t have time to scour the Internet for all the information you need, so we’re bringing it to you – one

Check

•

•

•

•

•

•

We’re