BY Laura aI ken

BY Laura aI ken

Meeting people is one of the best parts of my job. I love how many fascinating, intelligent and warm individuals I’ve chatted with since joining Bakers Journal. The Canadian baking industry is bursting with heart, passion and a tireless work ethic. Our inaugural Innovator of the Year contest proved to be one of my favourite opportunities to hear some truly remarkable stories.

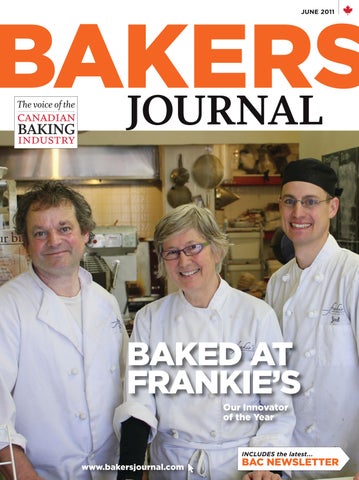

Congratulations to Donna van Veghel-Wood, her husband Frank and son Joel of Baked at Frankie’s for capturing the Innovator of the Year crown. This gluten-free, nut-free, soy-free, corn-free, dairy-free and sometimes egg-free bakery in small-town Ontario is a safe haven for celiacs and others with all types of food sensitivities. We’re very impressed and proud of the calibre of all the nominations we received and those five we short-listed: We Bake In Heels (Vaughan, Ont.), Bunner’s (Toronto), Manoucher Bread (Toronto), Baker Street (Toronto) and Baked at Frankie’s (Uxbridge, Ont.). Thank you for your entries and your time in telling us about your businesses. And, big thanks to the folks at Fuller Landau for their time and input in sponsoring this award. They’re the great advice behind the Ask the Business Advisor column you find in each issue.

During this contest I was reminded of how bakeries take on the personalities of their owners, much like pets can mimic their masters. The mood and the food of food service all flow from the top down. The personal touches can be some of the most intriguing to a customer. As a non-bakery example, I was recently at the Anchor Bar in Buffalo, N.Y., birthplace of the Buffalo chicken wing, only to find motorcycles perched above my head and license plates all over the place. Not sure what two wheelers have to do with chicken wings, but I’d bet the founders have a fondness for bikes. Don’t be afraid to bring yourself into your bakery. Have fun with personalizing your business, even if you break a design rule here and there. It’s yours, after all, and you’re the one who makes the rules.

}Have fun with personalizing your business, even if you break a design rule here and there. It’s yours, after all, and you’re the one who makes the rules.

You’re also probably the one who’s made a second, if not practically first, home out of your bakery. Bakers work diligently, often for long hours. Take time to pat yourself on the back once in a while. It’s truly a vocation sustainejd by a passion forj food and feeding others, one of the most primal of all human activities. We all need to eat and life is made so much better when we eat well.

This edition honours our Innovator of the Year, but every issue of Bakers Journal is dedicated to the innovators, creators and bakery makers that comprise a vital part of our food supply. Memories are made around the kitchen table as, I’m sure, they were made around the fire at the dawn of mankind. Each day you celebrate this fact in the very existence of your bakery. Be sure to take a day to celebrate yourself! / BJ

JUNE 2011 | Vol. 71, No. 5

EdITOr | laura aiken editor@bakersjournal.com 416-522-1595 1-888-599-2228 ext. 250

ASSISTANT EdITOr | Brandi Cowen bcowen@bakersjournal.com 1-888-599-2228 ext. 278

TEChNICAL EdITOr | John McColl, Puratos Canada jmccoll@puratos.com

NATIONAL AdVErTISING MANAGEr | stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

SALES ASSISTANT | Barb Comer bcomer@annexweb.com 519-429-5176 1-888-599-2228 ext. 235

PrOdUCTION ArTIST | krista Misener

GrOUP PUBLIShEr | Martin Mcanulty mmcanulty@annexweb.com

PrESIdENT | Mike fredericks mfredericks@annexweb.com

Mailing Address P.O. Box 530, 105 donly dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGrEEMENT NO 40065710. rETUrN UNdELIVErABLE CANAdIAN AddrESSES TO: CIrCULATION dEPArTMENT P.O. BOx 530, SIMCOE, ON N3Y 4N5 e-mail: lmorrison@annexweb.com

IssN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, dec) by Annex Publishing & Printing Inc.

sUBsCrIPtIoN ratEs

Canada — 1 Year $ 30.00 (with GST $31.50 #867172652rT0001, with hST/ QST $33.90)

USA — 1 Year $ 45.00 USd Best pricing is available online at www. bakersjournal.com

Send your subscription request to: Bakers Journal

P.O. Box 530, Simcoe, ON N3Y 4N5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940 E-mail: lmorrison@annexweb.com

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2010 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

briefly | Congress 2011 | Canada’s first Baking and Sweets Show | Barry Callebaut practicing sustainability | for more news in the baking world, check out our website, www.bakersjournal.com

ZuriCh – Barry Callebaut is focusing on improving sustainability in the cocoa industry.

in April, the company purchased the majority of the first-ever shipment of sustainable uTZ Certified cocoa beans from Ghana’s Cocoa Abrabopa Association (CAA). The CAA is a farmer organization that trains Ghanian farmers to improve cocoa production through proper farm maintenance and responsible use of

fertilizers and crop protection products.

uTZ certified cocoa is independently verified to guarantee it has been produced in compliance with a defined set of economic, environmental and social sustainability criteria. As of last year, more than 3,900 Ghanaian farmers had earned uTZ certification.

Barry Callebaut has also launched an extensive agronomic research program in Malaysia. The program is aimed at

developing new cocoa cultivation techniques to boost the sustainability, productivity and quality of cocoa production and improve profitability for local farmers. The research program will experiment with pruning and grafting methods, various organic fertilizers, other organic cultivation techniques, and agro-forestry principles. research will also look at post-harvest treatment techniques, with an eye to improving Malaysian cocoa bean quality to “zero-defect” status.

MonTrEAL – The BAC’s Congress 2011 brought buyers and suppliers together for a great two days of networking, new products and education. The show was held from May 1 to 2 in the Place Forzani exhibition hall in Laval, Que., just north of Montreal.

Events kicked off on Saturday night with a ticketed wine and cheese tasting at the Côsmodome interactive space science centre. The evening featured an assortment of specialty cheeses, pâtés and breads. Attendees sampled six wines – three whites, two reds and a port – selected by a sommelier who guided them through the tasting. The evening also included a tour of the Côsmodome, and lots of conversation as attendees worked their way through four courses.

The fun continued on Sunday evening during a ticketed gastronomic rally exploring four restaurants in the city’s Centropolis entertainment and dining district. Participants were assigned to one of three groups for the evening. Each group rotated through L’Aromate, Le Tire-Bouchon, and Sterlings, enjoying a different course at each restaurant. Afterward, the groups met up at Le Moomba nightclub to share dessert. on the show floor, more than 70 exhibitors, including more than a dozen newcomers, showcased products and services for the baking industry.

ToronTo – This fall, Canada’s inaugural Baking and Sweets Show will give bakeries a new venue to showcase their products to the public. The show runs Sept. 30 through oct. 2 at Mississauga’s international Centre.

The show will feature a competition stage and a demo kitchen, where attendees and exhibitors can check out decorating techniques, new ingredients, products, equipment and technologies. There will also be celebrity appearances by Buddy “The

Boss” Valastro, Canada’s own “Cupcake Girls,” Lori Joyce and heather White, “happy Baker” Erin Bolger, and professional chef Michelle Bommarito.

Canada’s Baking and Sweets Show is presented by redpath Sugar and co-sponsored by St. Phillips Bakery. it is touted as north America’s first consumer show devoted to baking and sweets. For more information, visit www.canadasbakingandsweetsshow.com.

INTERNATIONAL CENTRE, HALL 3 TORONTO (MISSISSAUGA), ON CANADA

• Join 4,250 industry professionals including bakers (retail, wholesale, commercial), grocer y and foodservice outlets

• Visit the trade show - over 200 companies in 100,000 sq.ft. showcasing ingredients, equipment, services, technology and baked goods (fresh, proof & bake, parbaked, freezer-to-oven, thaw & serve)

• Learn at the informative seminars and workshops

• Held every other year, it is the only baking specific event produced in Canada may

•

laUra aIkEN

Her entry caught my eye right away. Aside from being a poignant nomination, it camej from Uxbridge, Ont., where I spent 17 years of my childhood. Uxbridge has grown from a one-horse town (I literally rode my horse to town in 1988) to a sophistjicated place with big-box stores, McDonald’s and premium golf. On the food front, it’s been a meat and potatoes pub town from my earliest memories. As I read the nomination, I became intrigued to learn more of this specialty bakery born of tragedy.

}When Donna van Veghel-Wood’s entry for Baked at Frankie’s got her shortlisted among our group of judges, a trip back to the “bridge” was in order. Christine Mattear, senior manager with contest sponsor Fuller Landau, and I travelled about an hour northeast of Toronto to find the bakery in a great location, nestled ajmong new and long-standing boutiques on Brock Street, the main heritage jvein of town that swoops down into a gentle valley.

Being sensitive to celiac children feeling left out after having two of her own; d onna likes to make the same products gluten-free that the rest of the children at the birthday party are having.

We stepped inside Baked at Frankie’s, unsure of where to look first or next in surprise at the sheer variety of products. The left wall is lined nearly floor to ceiling with dark wood shelving stocked like a grocery store of gluten-free goods. House-made cookie and waffle mixes, baking soda (which doesn’t inherently have gluten but, as I later learn from our winners, is guaranteed to have been processed in a gluten-free facility), tea, egg replacer, baggies of snack mix and a variety of 100 per cent brown rice pasta that the bakery brings in. Upon closer reading of signage, I see that it isn’t just a gluten-free bakery. It’s also corn-free, soy-free, dairy-free, nut-free and makes limited use of eggs. To the right, treats ranging from sticky toffee bites to butter tarts and chocolates are displayed. For people with all types of allergic sensitivities, Baked at Frankie’s is a safe haven they can trust.

We found Donna behind the counter in

the open kitchen, where she welcomed us with the kind of instantly warm smile your grandmother might bestow upon you. She introduced us to her husband Frank, a carpenter now turned chief bakery bread maker, and her son Joel van Veghel, right-hand man and restaurant manager. We sit down to chat over little plates of goodies with great cups of coffee, and suddenly I find room in my previously full stomach.

Donna is a chef by trade, but her cooking professor told her she’d never make it as a baker after her one baking class. Imagine his surprise to run into her post-grad at a party and find her there as Jamie Kennedy’s pastry chef. However, what she always truly wanted was a Mediterranean restaurant. Two-and-ahalf years ago her ideal location came up at the foot of Brock Street. It seemed destined to be. Then life doled out far more than lemons.

Within a month of finding that perfect spot, her son Frankie died in an auto accident. Life crashed to a halt.

“He was killed and we just shut down everything,” says Donna. “When we got back to doing things, it just had to be gluten-free because he was a severe celiac.”

The restaurant was going to be just a

regular place, but its menu and motive changed in honour ojf their late son ajnd it opened up as a completely gluten-free restaurant. The bakery was born in the back, where Donna made bread and desserts for the restaurant, a foray that grew a clientele just coming in to buy the bread.

“We would have people lined up at the till while the servers were trying to wait tables, so they booted me out,” she says, laughing. Down the street, and one year ago on Valentine’s Day, the bakery got its own locatiojn, now known as Baked at Frankie’s.

The last year-and-a-half of operating Baked at Frankie’s has been an eye-opener for the family in discovering the many food allergies plaguing consumers today. Originally, their flour mixture used in the restaurant was a corn/rice mix. But when they opened up the bakery, half the people who came in said they couldn’t eat corn.

“It took two months to get rid of the corn and make a flour that would do the same thing. That was one big step,” she says. “The next one was no soy, no nuts, but then people would come in and say I am allergic to carrots, or whatever else. We’re very careful that way with sensitivities.”

Frank pipes in with an ironic smile: “We’re finding our limits.”

Life in the bakery is an ongoing experimentation inj what can be done successfully. Donna’s approach is that, if given the time, anything is possible.

Many things are done by the seat of their pants without formulas. One day a lady came in and asked for ladyfingers, and Donna said “give me two days.” She concocted the ladyfingers and says her customer loved them. Another customer asked for gingerbread, so now they have gingerbread. She made a small jar of non-peanut peanut butter that even stuck to the roof of your mouth. The sampling feedback was good, but when she made a bigger batch it just didn’t turn out the same. Donna says she’ll revisit the un-peanut peanut butter when she finds the time.

“We will at least make the effort. It’s doable and it’s a great challenge,” says Donna.

They introduced sugar-free Thursdays, with a line-up of goods that have no sugar added. This was popular enough to go commonplace in the bakery. As it was, Donna says she cut half the sugar in all her recipes and no one even noticed. She uses applesauce and banana as sweeteners instead. They don’t use nuts, and at one time the word “nut-free” graced the window alongside “gluten-free,” but they decided to take it down after a woman came in and said thjat if someone who had just eaten a peanut butter sandwich came in here and then her son touched the same door handjle as that person jit would kill him. The liability just didn’t seem worth it, even though they don’t use any nuts in their facility.

“We’re wheat-free, corn-free, soy-free, nut-free, dairy-free and sometimes egg-free. What will be out there left to eat? I don’t know,” Donna says, shaking her head in pondering the burgeoning population of restricted eaters.

From their all-purpose base, they tweaked the flour to come up with their own specialty mixes, such as waffle and cookie, for sale on their shelves. Their “all-purpose” flour is about seven times the price of wheat flour, says Donna, and Frank adds that they’ve got it down to a little less than that by buying more direct. They are also diligent in controlling waste – baguettes become crisps, which are then bagged and sold on the shelves; leftover bread becomes croutons. They even make dog biscuits.

The business has also found revenue in catering, doing birthday parties and even completely gluten-free weddings. Being sensitive to celiac children feeling left out

after having two of her own; Donna likes to make the same products gluten-free that the rest of the children at the birthday party are having. If the other children are having pie, so will the celiac kids.

The bakery has two staff and they are looking to hire another one or two people. The bakery is its own entity, but on paper it’s tied to the restaurant and all payroll and business functions are done through there, managed by Joel, who calls staffing the biggest surprise of the whole business venture.

“Everybody can work but it’s finding that one person witjh the perfect amounjt of charisma and drive and ready to go. It’s almost there,” he says. “It’s nice. We cherish all our staff but we’ve gone through a lot [of staff] since opening the restaurant.”

Tech-savvy Joel posted a detailed survey on their website, where customers can also order products online. The survey asked questions about everything from their impression the moment they walked in to the restaurant and/or bakery, to the quality of the food and how long they waited for it. He got 150 anonymous responses that were all glowing; and he was shocked that there wasn’t one negative comment.

Frankie was a computer whiz on the brink of big software success when he was killed. His genetics are clearly shared by Joel, who co-ordinated creating a customized POS system at a fraction of the usual cost thatj did just what theyj wanted without unnecessary bells and whistles. They are truly a family of creators – Joel, a non-drinker, nonetheless counts wine-making among the hobbies he’s had. Donna and Frank have two other children. Daughter Ginny operates Elemi Organics, just a few doors down from the bakery. One of her products, called Friggin Lip Balm, was part of the Grammy swag party this year. Another son, Jason, is a chaplain.

Their late son Frankie, who was just six months old when he was diagnosed a celiac, used to have a cooler in the back of his car and just take his food wherever he went. The odd time the family ate out, Donna says he ordered so carefully and particularly that he’d say, “I would like a steak, no salt, no pepper, and if there’s anything on it when it comes out I will send it back. Cooked on a clean grill, if there are any other marks on it I will send it back. He was very, very celiac. When people say it’s all in their head it

just makes me angry, but what can you do?”

It truly must be a tough task accommodating such serious physical consequences to eating certain foods, but they are making a go of it. Extreme caution with cross-contamination is a necessary and serious aspect of the operation.

“Every day is opening our eyes a little bit more,” says Donna, who goes on wistfully to say they should have kept a guest book to track where their customers have come from, some from as far flung places jas England and New Zealand.

“I’m not ashamed of anything,” says Donna of their fare. “Everything tastes delicious . . . . Celiacs deserve to eat better.”

Joel notes that he does see those who don’t want to try something that has no wheat in it, but thjey win people over j with samples. Food made by Baked at Frankie’s restaurant or bakery is natural and healthier in approach than many other foods. The restaurant has no deep fryer and the menu changes with the local growing season. All restaurant meals are made to spec when the person orders, so ingredients can be customized. The philosophy of individual accommodation is followed in the bakery as well.

Joel, his husband Jamie Myslik, and Frank and Donna all took a break from the hectic pace of the foodservice life to join Bakers Journal and Fuller Landau staff at the BAC’s Congress in Montreal to receive their award on May 1. We were warmed by the many family stories in our time with the fjamily enjoying a leisurely dinner at Gibby’s in old Montreal, from Joel’s eagerness to go morel mushroom hunting to their fond memories of Frankie.

Frank has a cochlear implant to hear and Donna wears glasses. Joel remarked while walking around old Montreal that between them he hears no evil and she sees no evil. I smiled a little at this statement and felt it really was true when I considered the nurturing way they took on the troubled eaters, working tirelessly and speaking so graciously of their clientele that humbjles them with gratitude. It is seen in their gentle nature underscored by the steely strength needed to move forward after losing a child. Many congratulations to the Baked at Frankie’s family for capturing our inaugural Innovator of the Year crown and wearing it with such grace. / BJ

A little knowledge goes a long way in lengthening product shelf life

All food manufacturers are trying to increase the shelf life of their products. This is becoming increasingly important in an era of global trade. In addition, consumers do not purchase foods on a daily basis, so products need to last longer.

The shelf life of food is the period from the start of production until spoiling of the product renders it unsafe to eat or of a quality that is unacceptable to the consumer.

The two main concerns are food safety and quality. Changes during storage can be attributed to the growth of microorganisms. Micro-organisms may affect shelf life in two ways. If storage conditions are favourable, pathogenic bacteria will proliferate, contaminating the food. Spoilage micro-organisms will also grow in food, causing additional j quality issues. There are several food processing parameters and conditions that are required in order to prevent or slow the growth of these micro-organisms. Applying appropriate heat to the food during processing (pasteurization) wijll eliminate most j pathogens; however, it won’t eliminate all micro-organisms. Some pathogens, such as spore formers, require much harsher temperatures for sterilization or retorting in order to be eliminated. Sterilization will eliminate all microorganisms and if the product is packaged appropriately, it will have a long microbial shelf life.

growth rate.

Packaging also plays a critical role. Packaging’s main role is to prevent oxygen presence. This restricts the breeding of aerobic micro-organisms, reducing both pathogens and spoilage micro-organisms. To address these issues, new packaging materials that incorporate antimicrobial nanoparticles or agents to eliminate oxygen are emerging. These materials are more effective in extending microbial shelf life. However, it is important to understand that eliminating oxygen may encourage the growth of anaerobic pathogens such as Clostridium botulinum. When you are dealing with foods that are prone to contamination with anaerobic pathogens, you must also impose other controls, such as refrigeration or antimicrobials.

Eliminating or slowing the growth of pathogenic and spoilage micro-organisms will not solve all shelf-life problems. Changes in the texture, flavour and appearance, as well as other food

}Mono and polyunsaturated fats, such as omega oils, are currently used in many food products due to their health benefits. these oils have a very short shelf life; they oxidize and become rancid.

food must be viable through production until the end of the product’s shelf life. It is therefore important that the processes are gentle enough not to destroy any active components whjile still being effective in keeping pathogens in check. Effective gentle processing technologies have been developed to replace harsher traditional ones.

The pH of the food also plays an important role. A low pH (high acidity) will keep pathogens in check; however, many spoilage microbes will multiply under these conditions. Another factor to consider is the temperature of storage. Refrigeration will help control pathogens, but again, many other microbes will continue to grow, albeit at a lower

characteristics, also play a key role in shelf life. Although food safety is paramount, taste and appearance is very important to the consumer. Health is also a major driver of new food product development. Mono and polyunsaturated fats, such as omega oils, are currently used in many products due to their health benefits. These oils have a very short shelf life; they oxidize and become rancid. To extend the shelf life of products made with omega oils, antioxidants are often added to extend the shelf life. In order to prevent oxidation, some omega oils can be microencapsulated. This can serve dual purposes, extending shelf lijfe and eliminatingj the fishy taste that is often associated with omega-rich oils. Using modified atmosphere packaging can also prevent oxidation by eliminating oxygen from the packaged product.

To deliver health benefits to the consumer, the active components of a

Changes in the texture of foods also play a very important role in their shelf life. We in the baking industry are very familiar with these changes, particularly in terms of staling. Staling in bread is the result of many undesirable changes that occur during storage, including toughening of the crust and firming of the crumb. These changes result from a loss of moisture and the retrogradation (or recrystallization) of the starch in combination with its association with the gluten matrix. This effect is accelerated at refrigeration temperatures but can be reversed with heating or toasting. Many factors are known to decrease the rate of staling in bread and thus extend its shelf life. The addition of surfactants will result in a complex with amylose (a starch component), producing a softer bread with a longer shelf life. Adding shortening will have a similar effect. Recent developments in the extension of bread shelf life involve specific amylase enzymes that are readily available and effective.

Extending the sheljf life of a food product may involve adding ingredients, modifying production processes or applying new technologies. Because of the multiple factorjs impacting the shejlf life of food products, a single change or new technology may not be sufficient to achieve a longer shelf life.

When selecting an ingredient or technology to extenjd the shelf life ojf a food product, one should also take into account its regulatory status in the country of production and any other countries in which the product will be sold. / BJ

For more information or fee-for-service help with product or process development needs, please contact John Michaelides at GFTC at 519-821-1246 ext. 5052, by fax at 519-8361281, or by e-mail at jmichaelides@gftc.ca or j.jmichaelides@gmail.com.

Agave nectar (pronounced uh-gah-vay) has developed quite the reputation in recent years. In a March 2009 Los Angeles Times article, health columnist Elena Conis summed agave’s many applications up quite nicely: “It imparts a subtle sweetness to desserts and can be used to balance the saltiness of meat dishes. Its delicate flavour has made it an increasingly popular ingredient in bottled teas and health drinks. Its chemical composition lends itselfj to making moist, pliajble nutrition bars. The longer chains of fructose that it contains, called fructans, are a type of fiber –which food manufactures can advertise on their labels.” In short, this nectar from a hearty plant that loves the beating sun and nutrient-rich volcanic soil of Mexico and parts of the United States boasts an impressive resumé.

}appearance is similar to that of cacti and yuccas, and they come in a variety of colours. Agave nectar (also known as agave syrup) is usually gathered from the Agave tequiliana. As mentioned, thijs is the same plant thajt gives us tequila.j Agave nectar can also be collected from the Agave salmiana, and the thorny, rainbow, blue, green and grey varieties. All of these agaves are native to Mexico and parts of the southern and western

agave nectar is by turns held up as the very model of wholesome, healthful eating, and vilified as an imposter, merely masquerading as a good-for-you sweetener.

In The Dictionary of Wholesome Foods: A Passionate A-to-Z Guide to the Earth’s Healthy Offerings, authors Embree De Persiis Vona, Anstice Carroll and Gianna De Persiis Vona write: “The ancients considered the agave to be a sacred plant with properties to purify the body and soul. The Spaniards, who apparently had their own ideas with regard to self-purification, took this same juice, fermented it, and created what we now call tequila.”

Proving that everything old is new again, agave has become a buzzword in the food and beverage industries as companies compete to capture the growing market share of health-conscious consumers. Rest easy though –despite increasing demand for agave nectar, the tequila market isn’t in danger of disappearing any time soon.

There are more than 100 varieties of agave plants, which, when fully grown, can range from five to eight feet tall, and seven to 12 feet in diameter. Their

United States.

The way the nectar is collected depends on the variety of agave it is being harvested from, and the company doing the harvesting.

“Agave nectar (and tequila) is made from the sap from hearts (piñas) of the plant,” states the website for Volcanic Nectar, one of the many brands available. “The leaves are removed from the plant, which bares the base of the plant half above and half below ground. The agave base is then removed and taken to a facility to where it is heated to no more than 118F to get the juices flowing.”

The plant base is then chopped,

PUB_LALLEMAND_ANG:Mise en page 1 11-04-15 08:11 Page1

To improve the vitamin D intake–Bread baked with Lallemand yeast is the natural solution!

Health Canada has just tripled the Dietary Reference Intake for vitamin D from 200 to 600 UI* and now allows bakers to use Lallemand yeast, naturally rich in vitamin D, to increase the vitamin D content of bread and other yeastleavened baked goods to a maximum level of 90 UI by 100g.

Please contact us to learn more on how to add sunshine in every slice of bread with Lallemand yeast!

*The Institute of Medicine has also tripled its daily vitamin D recommendations from 200 to 600 UI for children and most adults. Osteoporosis Canada recommends a daily intake of 400 to 1000 UI for adults under 50. The Canadian Cancer Society recommends 1000 UI every day for adults over 50 years old and people that have dark skin or who don’t go outside very much.

Tel.: (800) 840.4047 or (514) 522.2133

www.lallemand.com baking@lallemand.com

Just as moving into a new life stage requires careful preparation, transitioning your business into a new phase calls for thorough planning

At some point, family bakery businesses have to consider an exit strategy, which may include the transition of the business to the next generation, or sale to an employee or a third party. The following case studjy will outline somej of the key issues that can arise when considering succession planning.

Joe is the owner of a successful bakery operation that has been a family business for two generations. Joe acquired his shares from his father about 40 years ago. Joe’s son and one of his two daughters are actively involved in the business. Anthony is in charge of operations and Elena is responsible for sales. Joe’s other daughter, Emily, is married to Robert, an investment advisor. Joe, age 70, is not ready to retire, as he still enjoys coming in to work and does not know what he would do if he were not working. Joe’s wife, Arlene, would like him to retire so they can travel together and enjoy life with less stress. Arlene is concerned about how much money they will need in their retirement years and how they will manage. When it comes to selecting a successor, Joe’s vision has always been that Anthony will take the reins. While Anthony, age 45, did not go to university, he has been involved in the business longer than Elena. Joe acknowledges that Anthony has a temper that jsometimes puts peojple off, but he thinks Anthony will be able to overcome this trait as he matures.

the company. However, she does not have experience on the operations and finance side of the business. Elena is married to Scott and they have one young child.

Anthony and Elena do not own shares of the business.

All major management decisions are made by Joe. He does discuss certain issues with Anthony and the chief financial officer, Richard, but ultimately, Joe makes the decisions. Richard has been with the company for five years and wishes to have an ownership interest.

Joe decides it’s time to arrange a meeting with Bill, ja family business j advisor. During the meeting, Bill helps Joe outline points to consider in his business successionj plan. As business j advisor, Bill will do the following:

• Meet individually with Joe, Richard and each member of the family, including those not working in the company (such as

}develop a governance system that will define management roles and responsibilities, and consider establishing a board of directors. Prepare employment agreements.

Arlene, Emily, Robert and Scott), to learn their visijon for the business, as well as their values and their goals.

• Create a strategic plan for the business with input from Joe, Richard, Anthony and Elena.

• Determine Joe and Arlene’s income needs, including how to fund this income, and to establish Joe’s role in the business going forward.

• Obtain an independejnt assessment of the skill sets of Anthony and Elena to recommend who would be the most appropriate successor. This may include retaining an interim manager to improve and/or assess the skills of possible successors.

that Anthony and Elena work in the business and Ejmily does not.

• Plan for income taxj consequences of a sale of shares. For example, if the business satisjfies the criteria for a Qualified Small Business Corporation, a sale of shares could qualify for a $750,000 capital gains exemption. If the business does not satisfy the criteria, it may be possible to impjlement a plan that would result in the exemption being available.

• Obtain a current valuation of the business prepared by a chartered business valuator. A valuation will be required for a non-arm’s length transaction and to proactively manage the value drivers of the business: contracts, rights and trademarks, suppliers and customers.

• Prepare a shareholders’ agreement at the time Anthony, Elena and Richard become shareholders. A shareholders’ agreement will cover issues such asj death, divorce, disability or retirement of shareholders, and provide a mechanism for dispute resolution.

After the two-hour meeting with his family business advisor, Joe realizes there is a lot of work to do in order to properly plan for the succession of his business. By planning carefully, Joe can help make the process smoother for everyone. / BJ

Bruce Roher is a pardtner in the businesds valuations practice at the Toronto office of Fuller Landau LLP, Chartered Accountants. He can be reached at broher@fullerlandau. com or at 416-645-6526.

Anthony and his wife have three children, ages 10, eight and five. Elena, age 38, is an MBA who worked for a beverage company for four years before joining the family business. She is much more outgoing than her brother, is well liked and has excelled in growing the sales of

• Develop a governance system that will define management roles and responsibilities, and consider establishing a board of directors. Prepare employment agreements.

• Consider an equitable allocation of Joe’s assets, bearing in mind

QUEstIoN / I own a chain of pizza stores. I would like to retire in five years. My son has been the VP of sales for the last two years, but I’m not sure that he has the skills to be my successor. Do you have any suggestions?

for thE aNswEr, VIsIt thE BUsINEss aDVIsor lINk oN www. bakersjournal.com.

This layered dessert uses low-fat ingredients to create a scrumptious trifle that’s as pleasing to the eye as it is to the palate. / BJ

INgrEDIENts

2 cups fresh blueberries, divided

4 tbsp sugar, divided

1 1/2 tsp cornstarch

6 oz non-fat vanilla yogurt

4 oz neufchâtel cheese (reduced-fat cream cheese), at room temperature

2 tbsp sweet sherry or orange juice

2 1/2 cups fat-reduced frozen pound cake cut in ½ inch cubess (half of a 10to 11oz package)

DIrECtIoNs

in small saucepan, stir together 1/2 cup of the blueberries, 2 tbsp of the sugar, the cornstarch, and 3/4 cup water. Bring to a boil; cook and stir until sauce is clear and thickened and berries pop, about 5 minutes; cool. Add 1 cup of the blueberries. Meanwhile, in small bowl, combine yogurt, neufchâtel cheese and remaining 2 tbsp sugar until smooth; stir in sherry.

To serve in individual 6-8 oz glasses: Spoon about 1/4 cup of the cake cubes into the bottom of each glass; top with heaping tablespoon sof the blueberry sauce and about 1-1/2 tablespoons of the yogurt mixture; repeat; garnish each glass using remaining 1/2 cup of blueberries. Cover and refrigerate for at least one hour. Alternatively, serve blueberry trifle in a one-quart glass bowl by arranging in layers, half of the cake cubes topped with half of the blueberry sauce and yogurt mixture; repeat. Garnish with remaining 1/2 cup of blueberries. Cover and refrigerate for two hours.

YIELd: 4 portions

This recipe is courtesy of the U. S. highbush Blueberry Council, www.blueberry.org

Bulk material from A to B. Technology from A to Z. We understand that the efficient handling and processing of raw materials has a decisive impact on the cost-effectiveness of production in industrial bakeries. As a result, Buhler works with you to develop and implement solutions for every stage of the process: secure product intake, careful storage, exact dispensing, and precise weighing. System controls allow for customized recipes, and can easily be integrated into your production planning system. Buhler, providing the speed and precision you demand.

Buhler (Canada) Inc., 7270 Woodbine Ave, Suite 202, Markham, ON L3R 4B9 905-940-6910 buhler.minneapolis@buhlergroup.com

Innovations for a better world.

BY

Adding pizza to your product range can help build your bottom line and make your customers happy with a well-loved comfort food

Wherever you go in the world, you’re sure to find pizza on the menu. The definition of a “great” pizza is not necessjarily the same forj everyone. Some people prefer thin crust over thick, or a mojuntain of meat overj a garden of fresh local veggies. No matter the toppings, all great pizzas have one thing in common: great dough.

Pizza dough can be made into different shapes, stretched for thin or thick crust, sold garnished, freshly made, parbaked or frozen, and prepared with levain or sourdough. It can be baked on a pizza pan or directly on the stone of a deck ovejn. Today we also have frozen, rising crusts available for home baking.

}restaurant chain in order to get consistency and ensure pizzas taste the same from one city to the next.

The basic ingredients in pizza dough are based on total flour weight (flour = 100 per cent):

• salt, which enhances the flavour of all of the other ingredients and controls fermentation (1.5 to 2%)

• sugar, to control the softness of the crust (1.0% for crusty dough to 5.0% for soft dough)

• fat, such as vegetable oil, shortening or lard, in order to facilitate stretching and add tenderness (2.0 to 8.0%),

• spices to taste, as desired

• yeast, to help ferment the dough (from 0.25 to 5.0%)

• water, to control the texture of the dough (from 50 to 60%)

some people prefer thin crust over thick, or a mountain of meat over a garden of fresh local veggies. no matter the toppings, all great pizzas have one thing in common: great dough

To make the dough, use flour from a hard wheat variety. Most restaurants that make their own pizza dough use all-purpose flour, which may be either bleached or unbleached. Industrial operations use a higher protein flour to reinforce the dough. This is especially true for frozen doughs. You can also use whole-wheat flour for variety, or other cereal flours, including rye, buckwheat, oat, spelt, barley, and quinoa. All of these flours can be used with wheat flour. Absorption will vary according to the quantity of each cereal.

Some pizza flours are available, but be sure to do your homework before purchasing these products. Some are prepared from hard wheat and are mostly all-purpose flour. In other words, calling them “pizza flour” may be nothing more than a marketing tactic.

You may also come across pizza mixes, which include all the ingredients for pizza dough, minus the water and yeast. Private label pizza mixes are made according to the specifications of a

Some formulations jinclude other ingredients such as eggs, baking powder, or even 7Up.

Frozen dough will need an improver to guarantee the best result and a long shelf life. Improvers may include an oxidant, an emulsifier, a reducing agent or preservatives.

The key to a great pizza dough lies in the preparation. The texture and taste of the dough depends on the production method used. Many restaurants use the retarded dough method to prepare their dough, mixing the dough with very little yeast, then dividing it according to the desired pizza size and depositing the rounded dough balls onto plastic trays with oil and allowijng them to fermentj in the fridge for anywhere from six to 36 hours.

In industrial operations, a proofer may be used to speed up the fermentation process, but operations looking to produce frozen dough require a blast freezer.

How you stretch the dough affects the crust of your finished product. The dough

For thick crust, stretch the dough from the middle.

can be stretched by hand, by rolling pin or by sheeting machine. We control the thickness of the dough by controlling the weight of the dough. Two dough balls of the same weight can yield either a six-inch thick crust or a nine-inch thin crust pie. To get a nice thick crust, you stretch the dough from the middle and keep the edges thicker. With good fermentation, the crust will rise during baking, giving a great fluffy crust.

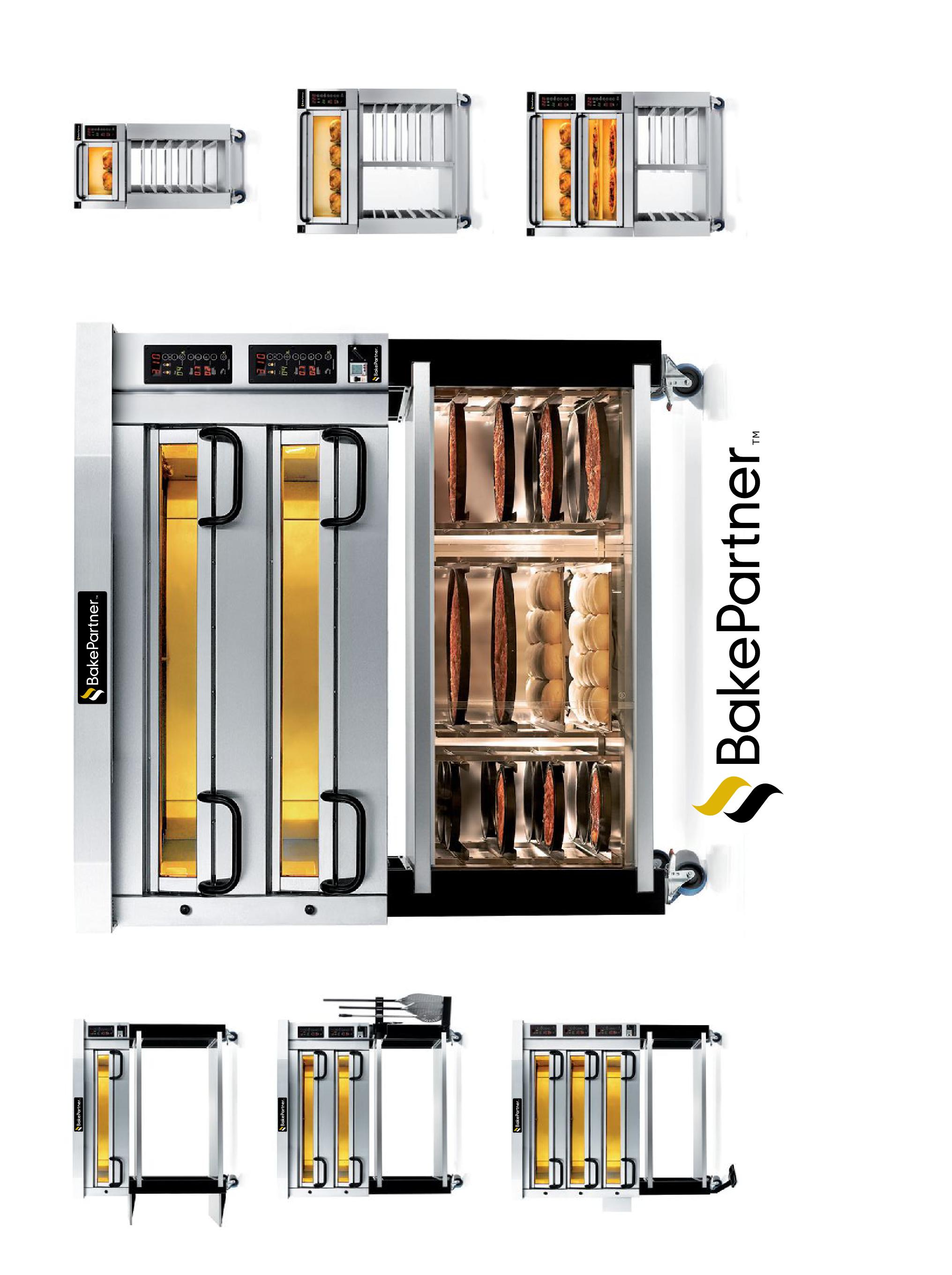

To make a pizza, you’ll need a few basic pieces of equipment: a work table, a scale for weighing ingredients, a mixer with enough capacity for the volume you want to produce, a good refrigerator for fermenting dough bjalls and storing ajll toppings, and pizza plates of the desired size. You’ll also need a good oven for baking. There are multiple styles of ovens available, including decks, tunnels and rotative ovens powered by gas, electricity or wood. You’ll also need a paddle for removing the pizza from the oven.

The baking temperature will vary from 400 to 550 F, according to death heat or with convection.

The best pizza will be one made with a person’s favourite ingredients, whether it’s prepared by a local pizzeria or by the bakery down the street. The key is preparing the pizza properly to achieve the desired results. / BJ

Mario Fortin is an international bakery consultant and owner of FORMA-LAB, a consulting service to bakers and suppliers. If you have a technical problem, send your questions to info@forma-lab.com.

filtered, and run through a centrifuge before being bottled.

Madhava, a company based in Lyons, Colo., takes a different approach. According to the company website, workers, “slice off the top of the plant and hollow out its core. Then the plant is capped with a stone. The pineapple shaped agave plant secretes its nectar into the centre of the plant, rather than into the flowers like most plants do. It collects in the hollow centre for several days, after which the milky white ‘juice’ is removed by ladle, one plant at a time.”

This liquid is then boiled down in much the same way maple sap is when making maple syrup.

Agave nectar is available in light, amber and dark varieties. The colour of the nectar depends jon the amount of heat it’s exposed to during processing. Regardless of how they are produced, all varieties of nectar from all species of these plants contain some measure of calcium, iron, magnesium and potassium. The mineral content varies from one variety to the next.

This syrup has stirred up its fair share of debate since making its way into the consumer consciousness. Agave nectar is by turns held up as the very model of wholesome, healthful eating, and vilified as an imposter, merely masquerading as a good-for-you sweetener.

In her 2009 LA Times column, Conis wrote: “Agave offers no advantage in terms of caloric conjtent: about 16 calories per teaspojon, the same as tajble sugar.” In other words, unlike artificial sweeteners (aspartame, for example), agave nectar doesn’t do a dedicated calorie counter any favours. Conis noted, however, “the syrup’s chemical makeup can differ significantly from that of other sweeteners. Whereas table sugar is composed of sucrose, which is broken down to yield half fructose and half glucose, agave can contain up to 90 per cent fructose.” That difference can be an important one if you’re baking for people with certain medical conditions, including diabetes, as explained below.

In Sweet! From Agave to Turbinado, Home Baking with Every Kind of Natural

Sugar and Sweetener, Mäni Niall notes that because of this high fructose content, agave nectar has a low glycemic index (GI) value. That means the body absorbs the sugars in agave nectar slowly. Sugar, on the other hand, has a higher GI value; it is absorbed quickly, causing a spike in blood sugar.

“Using natural low-GI sweeteners such as agave allows people with certain types of diabetes or hypoglycemia to still enjoy sweet foods without playing havoc on their blood sugar, and is far preferable to substituting artificial sweeteners, or shunning sweets altogether,” Niall writes. But in other respects, agave nectar may be similar to or ejven on par with somje artificial sweeteners. In a study published in the January 2009 edition of the Journal of the American Dietedtic Association, researchers studied the antioxidant capacity of 12 different types of sweeteners, as well as refined white sugar and corn syrup. The study looked at major brand products available at retail outlets in the United States. Agave nectar was found to have a similar antioxidant

When Bill C-28 comesj into effect in Septjember, bakeries will want to make sure their marketing communications methodologies are on the right side of this law. Failure to comply could cost injdividuals up to $1 j million in fines and corporations up to $10 million dollars per infraction. The bill is 79 pages long, and it is complex. This article is not intended to provide legal advice nor a complete analysis of the Act, but rather to inform readers of the potential ramifications for their day-to-day business practices.

what Is BIll C-28?

Bill C-28 is called the Fighting Internet and Wireless Spam Act (FISA). Its intended effect is to deter and prevent

deceptive and damagjing forms of spam j and Internet practices. After long consultations with industry, organizations, legal experts and interested parties, Canada has now passed a bill that is intended to increase the reliability and trustworthiness of the digital economy for Canadians. The full version of this bill can be viewed on Industry Canada’s website at www.ic.gc.ca.

The legislation will deal with how, when, where and why you are authorized to send commercial electronic messages. Commercial electronic messages that may affect your business include e-mails, text messages, instant messages, social media messages, telephone calls, and voicemail messages that are intended to solicit business.

You may be asking yourself the following question: “As a legitimate

business, how can FISA affect the day-to-day operation of my bakery?”

In a nutshell, under the new rules of the FISA you are now required to obtain permission (either implied or expressed) from your potential customers before you can legally send them electronic messages about your business and services. In addition, you would be well advised to maintain records so that you are able to prove, if needed, that you have received this permission.

what Is a CoMMErCIal MEssagE?

A commercial message is a message that contains content thjat is intended to j solicit business or commerce. FISA covers more than just the words con-

The organic wheat selection process is extremely rigorous. It begins with lab milling of samples, which are then farinograph and bake tested. Only the best organic samples are accepted and extensively blended to give the best bake results of any organic flour in the world. Try it. You’ll be amazed!

RogeRs Foods Ltd. Customer Service and sales office: Brad Duggan, National Sales Manager #104, 3999 Henning Drive, Burnaby, BC V5C 6P9

Tel.: (604) 434-4900 Fax: (604) 294-4800 Toll-Free: 1 866 590 4900

The following are amended remarks of BAC Chair Pete Plaizier from the 2011 Annual General

social programs that increase the industry’s understanding of key issues and promote

BAC has been at the forefront of issues such as sodium reduction and been proactive in its representation of other baker concerns.

Through our efforts we have reached into the offices of key politicians and policy makers including the Prime Minister’s Office to convey our message. This is the type of strength and impact your association has.

BAC has also worked to foster industry fellowship and education at the local level through the activities of our Provincial and Regional Chapters. The Chapters, managed entirely by volunteers, consistently deliver education and

groups and government policy makers to place future restrictions and costs on bakers like never before. Taxes on sweet goods, bans on product marketing, new regulations on ingredient use, and new costly labelling regulations are all being actively promoted as the low cost, government imposed solution.

Addressing these and other issues is beyond any one baker or company. It is only through a united industry voice that we will be able to make an impact. It is BAC that has united that voice in the past and with your continued support will do so in the future.

This year’s tournament will be held at the Inglewood Golf & Curling Club, a premier course nestled along the banks of the Bow River, just five minutes from downtown Calgary. You will love the amazing views of the Bow River and the adjacent Inglewood Bird Sanctuary with the nearby city sky line beyond.

Randy MacDonald............... ..(403) 225-0943

Scott deBoer....................... ......(403) 201-0043

Ken Tynan............................ .....(403) 585-3145

Louis Bontorin................... ......(403) 255-3515

Joe Swiston.....................

828-8750

Len Lardeur............................ .(403) 690-2551

Hanif Hirji.................................(403) 250-9560

250-9874

Please RETURN this form by Monday, July 4th. Please send the information along with payment to: Dan Moir c/o Horizon Milling, GP 14671 Deer Ridge Dr. S.E. Calgary, AB T2J 6Y3

Mailing Address

Email Address

City / Prov / Postal Code

Phone Number Rental Clubs Needed? (circle) Y / N If yes, LEFT or RIGHT? __________ Clubs, payable at clubhouse

Bakery Showcase 2012

May 6-8

International Centre

Toronto (Mississauga), ON

Alberta Chapter

July 26

Annual Golf Tournament

Inglewood Golf Club

Calgary, AB

Atlantic Chapter

September 12

Annual Golf Tournament

Magnetic Hills Golf Course

Moncton, NB

BC Chapter

June 15

Golf Tournament

Newlands Golf Club

Langley, BC

Ontario Chapter

June 7

Annual Spring Golf Tournament

Carlisle Golf Club

Carlisle, ON

September 20

Fall Golf Tournament

Glen Eagle Golf Club

Bolton, ON

Kevin Andrews Intralox

Dennis Green go2

Darren Rodrigues Hub Sinclair Cockburn

Tammie Sarra Allergic Solution

Maryann Scandiffio Square Snacks Inc

Lonnie Willard Tribeca Oven

Bradley Gosselin Bakery Technology Unit I

William Hussein Bakery Technology Unit III

Manivannan Nadarahhah Bakery Technology Unit II

Lisa Pearson Bakery Technology Unit III

Wajahat Khaleeque

Certified Bakery Specialist (C.B.S.) Diploma

For information on correspondence courses for baking industry employees and the Certified Bakery Specialist (CBS) program, please contact ext. 21 at the BAC office or check out our website at www.baking.ca.

The road to profitability is paved with well-controlled costs. While expenses related to ingredients and supplies can be regulated with some careful planning, wrestling your labour costs to the ground can be a bit more challenging. Customers may trickle in or descend in a swarm without rhyme or reason. It can be incredibly difficult to predict your staffing needs, but balance can be achieved by controlling the things you can.

kNow yoUr NUMBErs

Your payroll for the week divided by your total sales for the week equals your labour as a percentage of total sales. As a rule, many restaurants target a labour spend of less thanj 20 per cent of saljes while bakeries may run as high as 29 per cent. Only you can determine what the best target is for your operation. Track your labour as a percentage of sales for a few weeks to get a sense of what “normal” is for your bakery. With this baseline, you’ll be able to see fairly quickly if you’re veering off target.

kNow yoUr PlayErs

}when a shift or two a week is just right. Investigate if it’s a win/win to let younger, less expensive team members take a larger part of the load.

Plan your schedule weekly for all employees instead of posting the same schedule every week. Relying on a fixed schedule week after week doesn’t take into account the shifts in projected sales, variations in the weather or other factors that can affect your business. If you’ve created a business plan for the year, you should have your projected sales, which can be broken down by week. Forecast your projected labour spend as a percentage of your projected sales, then you’ll know how many employees to plan for. Adjust the number of staff scheduled each week to comply with weekly budget constraints.

Are there value-added frozen dough products that could be used strategically? While your signature items may be made

as a rule, many restaurants target a labour spend of less than 20 per cent of sales while bakeries may run as high as 29 per cent. Only you can determine what the best target is for your operation.

List your staff members and their hourly pay rate. Chances are there are some people on your team who make more than others because of tenure or other skills. When business is slower, you’ll want to schedule these people carefully, as their associated labour cjost can add up quicjkly over a few shifts. These veterans may be quite valuable because they bring a variety of skills and expertise to the business, but this means you must be extra diligent about how and when you utilize them. If you’re hesitant to cut back their hours bejcause these employees have been with you a long time and have been loyal, you may be surprised to find out they’re at a stage in their lives

from scratch; perhaps there are smaller categories where a frozen dough or par-baked product could fit the bill? Many portioned frozen dough formats can still be customized, saving you labour costs, yet ensuring consistency.

Make sure you have some flexible team members who won’t mind being sent home if it’s slow or, conversely, mind being called in at jthe last minute ifj it gets busy. We can’t always predict traffic patterns, so there will be times when an extra pair of hands could help generate more sales or fewer hands could mean

greater efficiency. While being able to give employees stable schedules is important, so is the health of your business. Tough calls have to be made.

If you have fewer than 20 employees, chances are that you’ll need a good team of generalists. If anyone on the team doesn’t feel comfortable opening, closing or using your POS system, you’ll have to bring another person in to address these gaps. Try to train everyone to be capable of handling a customer transaction adeptly from start to finish. If they’re resistant to the training, you may need to look at addressing the issue formally. Also, try not to succumb to hiring under the pressure of being short-staffed. This can lead to hiring errors. You need to be thorough and patient when hiring staff in order to get a desirable team together. More problems are created by hiring when desperate.

kNow whEN to fIrE yoUrsElf

It can be tempting to start taking more shifts yourself to control labour costs. This is a short-term solution because, as the business owner or leader, your skills are better deployed elsewhere. Businesses need a captain tjo plan, negotiate jand manage. If you’re busy working in the bakery instead of on the bakery, you may need to fire yourself from that hourly position so you can grow the business. When the costs begin to climb, anxiety levels rise as well. Keep in mind that simply paying your employees less will not solve labour cojst issues and it wijll hamper your ability to attract strong talent. The keys to controlling labour costs are improving workplace productivity and scheduling your employees wisely. After all, who needs labour pains? / BJ Michelle Brisebois is a marketing professional with experience in the food, pharmaceutical, financial services and wine industries. She specializes in retail brand strategies.

Put your little corner of the web to work with these simple steps to boost your company’s visibility online

Your website is one of your most important marketing tools.

A recent report indicated that around 76 per cent of people use their computers to search for information before they head out to eat or shop. There are also more and more consumers using their smartphones to research what to eat and where to get it.

This means that you not only need to ensure your website appears high in search rankings, but also that the information it contains is useful and relevant.

UP yoUr sEo

}You have probably heard the term SEO (short for search engine optimizatiojn) being thrown around a lot these days, not to mention a lot of tjalk about the need to improve it. It may not be necessary to pay a computer expert thousands of dollars to improve your ranking, but do make sure that you have the basics down. This means including your town or city name in your keywords, especially in page jtitles and page headings. Be sure to include your address and phone number on every page of your website, and include your local area code in order to make it easier for Google to match it to your area.

claiming your Place page, you can increase traffic and give customers the opportunity to share reviews. You can also post photos, operating hours, a link to your website and other information to your page. Make sure that all the information about your bakery is accurate and up-to-date.

Getting listed on Google Places can improve your search engine ranking in local search results. For example, someone who searches for “bakery, Toronto” might find your website at the top of the list, bringing you a lot of extra business. Note that Google keeps changing the way it ranks results as more and more business are added. Google currently places particular emphasis on the quality of the information provided on various websites to determine which businesses deserve to be at the top of the list. What you put on your website also remains critical in determining how your site will rank in search results.

authentic testimonials from your loyal customers are invaluable. encourage your customers to write a testimonial online or, if they pay you a verbal compliment, ask permission to quote them on your website.

One way to increase your chances of being listed in the top search results is to have your customers submit brief reviews of your bakery to Google Maps and third-party review sites like TripAdvisor, Yelp and UrbanSpoon. You can also, feature customer testimonials on your own website.

More than three-quarters of consumers turn to online research when deciding where to eat or shop.

having too much on your plate. To ensure success, tackle one social media platform at a time, making sure you’ve mastered the skills needed to use it effectively, before moving on to another.

Videos get special priority in search engine results, so upload some of your bakery to YouTube and post them on your website. You can get very creative with your videos. For example, consider posting videos on how to decorate a cake, bake bread, make cupcakes or roll pie dough. The possibilities are endless.

Try to incorporate words like bakery, bread, cakes, desserts, cookies, sweets or any other words that describe your operation on multiple pages, using these words as many times as possible.

If you haven’t done so already, add a directions page, preferably with an embedded Google map, giving instructions to find your bakery by car or by public transit.

ClaIM yoUr PlaCE

A Place page is a bjusiness listing onj Google that gives ujsers detailed infojrmation about any business in the world. By

People don’t want to hear what you have to say about your bakery – they want to hear what other customers think. Authentic testimonials from your loyal customers are invaluable. Encourage your customers to write a testimonial online or, if they pay you a verbal compliment, ask permission to quote them on your website.

By getting a lot of people to talk about you in social media, you can improve your search rankings and gain a lot of free marketing from word-of-mouth advertising. Set up a Facebook page and a Twitter account, or look into locationbased marketing tools like FourSquare. Be careful not to get bogged down by

The most important step in making your website work for your business is to update it regularly. There is nothing worse than a stagnajnt site that never j changes. Make sure you change your photos, post weekly promotions and newsletters, or keep a blog on your site. The information needs to change regularly to keep customers coming back.

A well-tended website will keep your bakery top of mind for loyal customers, while bringing new faces through the door. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping restaurant, foodservice, hospitality and retail operators increase sales for over 25 years. Her company provides innovative and revenueincreasing foodservice and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888-9266655 or chiasson@chiassonconsultants.com, or visit www.chiassonconsultants.com.

tained in the message. It also includes commercial website page content, but only if a link to thatj page is included ijn the transmitted message.

As mentioned, FISA requires that you receive permission from your customers and potential customers before you communicate with them electronically about your business and services. Within the act, both expressed and implied permissions are acceptable. What is the difference between the two?

Express permission describes a situation in which customers, or potential customers, have formally “opted-in” to receive commercial messages from you. They check a box on a website registration form, or mail in a point-of-purchase postcard requesting your communiqués. This is, by far, the strongest form of consent, as it is very clear what your clients’ intent is with respect to you marketing to them.

Implied permission, on the other hand, denotes consent that is not actually stated, but is inferred by another action taken by your customers. For example, when you already have an existing business relationship with customers, it is implied that they expect ongoing business-related communications from you.

In addition, implied permission may include persons you may not even know, as long as their business and duties are relevant to your business and their contact informationj has been made publicly available to you. You do, however, need to ensure that persons who publish their cjontact information j have not also published a disclaimer along with it, statjing that they do njot wish to receive commercial messages.

When you stop to think about this for a minute, you will quickly recognize that it can be very easy for you to obtain permission from your clients without deviating from your regular day-to-day practices. Here are just a couple of ideas

you may want to consider implementing:

• If your bakery offers customers the option of ordering products ahead of time, why not add a checkbox to your order form that simply states, “I understand and agree that I may receive communications from you electronically about your products and related services.” Once checked, this would be an example of clients giving you expressed permission for you to communicate with thejm about your business and services.

• An example of implied consent would be when a new jclient visits your website and requests information about a class your bakery offers. This action is inviting a business relationship with you and therefore is implied permission for you to communicate with thejm.

In both cases, there will be adequate documentation for you to provide proof of consent later, if you are ever required to do so.

P ro du ct Per f orm anc e Sol ut i ons - Natu rally

UNI QUE SO LUT IO NS THAT IM P ROVE PRO DUCT Q UAL IT Y, P ERFO RMAN CE A ND NUT RI TI ONA L VALUE, NAT URA L LY.

De al e rs In gredi e nt s' p ro duc t c on sul t ants use the i r bro ad k no wl e dge an d de e p ex peri e nc e to de l i ve r p ro duc t p e r form an ce s o l uti o ns – nat ural l y.

Ou r uni que natu ral so u rce d S pe ci al ty Pro duc ts can i m prov e p rodu c t qu al it y, per fo rm anc e, nu tri ti o nal val ue a nd p ro fit margi ns. Wh e the r y ou are b uy i ng B ase In gredi e nt s, im pro vi ng y o ur p rodu c t's v alu e pro po si ti o n o r twe aki ng margi n s, tru st D eal e rs I n gredi e nt s to de l i ve r r e sul ts

But te r B uds

But te r, c ream a nd c he e se natural d ai r y co n ce n trate s r e duc e fat w hi l e en han ci n g fl av ou r ch aract e ris ti c s at a lo we

Prod uc t o f t he U n i ted S t at es

There are two more very important issues that FISA compliance requires and that may affect the way you presently communicate with your customers. These include, but are not limited to:

• All the commercial message e-mail and electronic newsletters you send to your customers must contain the full name of the sender along with valid contact information. You are likely already doing this, as it is only common sense to provide your customers with a way to get back in touch with you. That said, with FISA, it is no longer an option, but a must-have.

• All of your commercial messages must provide the recipient with a working mechanism, jmanual or otherwise, for them to opt-out of receiving any further electronic correspondence from you. It is also very important that you monitor and honourj these unsubscribe requests to ensure FISA compliance.

thE sky Is Not fallINg FISA in no way should reduce or hinder your legitimate business practices. So don’t panic. The core requirements of FISA are straightforward to adopt into your day-to-day operations, and are not costly.

One of the results of this legislation will be the desirability for bakeries and other commercial ventures to maintain relevant and legitimate contact with customers and potential customers. There are affordable management systems available that will help you build your business by engaging your customers and potenjtial customers through professional, interactive website tools and legitimate e-mail correspondence. These systems also will help you maintain your client list and minimize the time required to legitimately correspond with your customers through mass e-mailing tools and automatijon – all the while j maintaining FISA compliance.

While visiting your website, potential customers will gladly provide you with

Bakery (including Delicatessens, Pastry, Donut/Muffin Shop, Supermarket)

Baking Wholesaler

Restaurant, Caterer

Hotel, Resort

Institution, Hospital

Baking Supplier

specify

consent if by doingj so they believe itj will be beneficial to them. They will welcome the convenience of online website tools such as newsletter subscriptions and class registrations, to name a few, through which they may willingly provide you with their e-mail address and consent to receive further communications from you, all well within the rules of FISA.

As mentioned at thje outset of this article, the new FISA legislation will come into effect in September. This leaves you plenty of time to consider its implicjations and put appropriate business practices in place to ensure your compliance in electronic communications. / BJ

Jessica Foster writes collaboratively with co-staff on behalf of mindZplay Solutions, a developer of websites and online software solutions that enadble small businessdes, professionals and volunteer organizations in a variety of industries to benefit from Internet technologies. Visit www.mindzplay. com or 888-373-6996.

C O nt I nued F r OM PaG e 17

capacity to that of refined sweeteners, including refined sugar and corn syrup. Other sweeteners, including maple syrup, brown sugar and honey, demonstrated higher antioxidant capacities than various types of agave nectars. The best performers in the study were dark and blackstrap molasses, which outperformed the agave syrups tested by a wide margin.

The Dictionary of Wholesome Foods advises that becaujse the nectar is sweeter than sugar, one cup of sugar can be substituted for a three-quarter cup of agave. The book also recommends reducing the liquid in a formulation by approximately one-half, as agave nectar will add moisture to your product.

When baking goods made with agave, also bear in mind that the nectar browns faster than sugar. Set your baking temperature approximately 4 C (25 F) below the temperature your formulation calls for. If you don’t lower your temperature, your products will brown too quickly, becoming overly dark on the outside though they remain undercooked on the inside.

Agave nectar keeps best when it is stored in a sterile, airtight container. Keep that container in a cool dry place, or in the refrigerator. Like honey, agave nectar will keep for more than a year if it’s stored properly. Unlike honey, however, it will not crystallize over time.

Agave nectar has a lot to offer, whether you’re interested in giving customers healthier choices, cleaning up your labels or simply expanding your baking repertoire, but it may not be right for every bakery. As you would with any other aspect of your business, do your homework and evaluate whether the benefits of working with agave are consistent with your company’s goals, brand and bottom line.

7585 Danbro Crescent, Mississauga, ON L5N 6P9

Contact: Debbie Bell, 905-819-7000

Fax: 905-819-9768

e-mail: debbie.bell@adm.com

Plants: 2 Montreal, QC; Mississauga, Midland, Port Colborne, ON; Winnipeg, MB; Medicine Hat, Calgary, AB.

Sales offices: Montreal QC, 514-846-8533; Toronto, ON 1-800-267-8492; Medicine Hat, AB 403-526-2876; Calgary AB, 403-2675656; Vancouver, B.C. 604-299-0710.

Products offered: A full flour and mix product line for the bakery, donut, muffin, food service, biscuit, pasta, frozen, in-store bakery, pasta and industrial segments. Other products offered are stoneground whole wheat, cracked wheat, graham and cereal bran and rye flours.

biologique@videotron.ca

www.biorganic.ca

Products offered: Certified organic ingredients – NOP: organic grains, organic flours, organic nuts, organic seed kernels, organic oils, organic fruits, organic culinary ingredients, organic flavours.

Delivery: By truck – bags or bulk. Distribution: Depending on the customer location, we have a number of warehouses.

14 Brant Mill Road RR 4, Scotland, ON N0E 1R0

www.brantflourmills.com

Contact: Volker Storjohann, 1-888-484-2921

e-mail: info@brantflourmills.com

Plant: Oakland, ON

Products offered: Rye flours, rye meals, and corn products. Certified organic. Custom milling.

Delivery: Shipped by truck throughout Canada and U.S.A.

Major customers: Bakeries and distributors.

43615 Yale Road, Chilliwack, BC V2R 4J6

Phone: 604-823-5543

Fax: 604-823-5546

e-mail: john@anitasorganic.com www.anitasorganic.com

Products Offered: Anita’s Organic sells a wide range of certified organic and kosher flours, grains, seeds, pulses, cereals and mixes in retail, wholesale and bulk sizing. Our milling strength is in fresh stone-milled whole grain flours. Our flours have not been treated with any chemicals such as pesticides or preservatives. We mill fresh every day and quickly turn the inventory. We are a great source for ancient grains and industry leading niche products as well as all purpose flours. Custom bulk milling orders in 1 metric tonne sacs are also one of our strengths along with export services.

Company comments: Anita’s Organic has been stone-milling for over twenty years in the Western Canadian market. Our aim is to take care of the customers needs before, during, and after a delivery. We believe in pure and simple ingredients that are fresh and full of natural nutrition. We are a versatile, efficient and friendly company ready to meet the needs of the organic baker and food company.

7174, Marquette, Suite 1, Montreal, QC H2E 2C8

Contact: Chakib Azizi – Purchasing agent; technical assistance: France Beauchamp Phone: 514-376-7711 or 1-877-476-7711

Fax: 514-729-2100

e-mail: bioorganic@videotron.ca or

1150 Rang Saint-Edouard, Saint-Liboire, QC J0H 1R0

Contact: Julie Théberge

Phone: 1-866-327-4627

e-mail: jtheberge@farinart.com

www.farinart.com

Products offered: Ecocert, Kosher and Halal certified. Farinart is a Canadian leader in the production of grain blends and flours both traditional and organic for bakeries and food manufacturers. Delivering top quality grain blends and flours along with innovative processing solutions, superior expertise, product consistency and best in class service. Distribution: We deliver across Canada and overseas.

Delivery: 20 kg bags, tote bags and bulk products.

Company comments: We are a friendly and versatile company that can adapt to our clients’ requirements.

P.O. Box 190, Angusville, MB ROJ 0A0

www.glanbianutritionals.com

Contact: Marilyn Stieve, Business Development Manager, 608-807-9688

Fax: 608-316-8504

e-mail: Nutrition@glanbia.com

Products offered: Whole flax seed, milled flaxseed, fine milled flaxseed, flaxseed bran, lignan/fiber complex, flax/fish oil blend.

Major customers: Retail and Wholesale bakeries, food, beverage, nutritional and supplement companies.

Company comments: NOT ALL FLAXSEED IS CREATED EQUAL.

When it comes to flaxseed, nobody can compete with the quality or nutritional value found in our MeadowPure® line of flaxseed ingredients.

Whether you’re looking to enhance your project with flaxseed’s powerful antioxidant benefits or its abundance of essential Omega-3 fatty acids, our MeadowPure line of flaxseed delivers the nutritional and functional requirements your application demands.

MeadowPure® Process – MeadowPure is a patented seed selection and cleaning process found exclusively at Glanbia Nutritionals. First, we work with contract farmers to select flaxseed that’s superior in colour, uniformity and flavour. The seeds are then processed using proprietary patented technology that protects the integrity of the flaxseed during all stages of production. The result is a superior flaxseed that remains stable under a wide variety of food processing, distribution and handling conditions for up to two years after the milling of the seed. The full nutritional value of flaxseed is delivered where it’s intended – in the food products that reach consumers.

105 Commander Boulevard Scarborough, ON M1S 3M7

Contact: George Birinyi, Carl Griesser

Phone: 416-291-3226

Fax: 416-291-2159

e-mail: gbjr@grainprocess.com

Products offered: Over 3,000 items including a full range of whole grains. Hard/soft wheat, triticale, corn, millet, barley, rye and durum and organic products certified by QAI (whole wheat flour, white flour, “ancient grains” spelt, kamut, quinoa, seeds, etc.) Precooked and stabilized grains and flours, whole bean flour, complete range of grains including cracks, flakes and grits, seeds (sunflower, sesame, golden yellow and brown flax), beans, peas, lentils, sugars, nuts and dried fruit. Food processing also includes custom blending facilities for multi-grain formulas (bread, muffin and pancake mixes, etc.) packaging, granola cereals, turbinado and demerara sugars, roasting and toasting.

Distribution: Across Canada and the United States.

Major customers: Bakeries, biscuit and cookie manufacturers, food service, bulk, health and natural food retailers and distributors and manufacturers.

Company comments: We pride ourselves as being the only stone flour mill in Canada to offer such a wide variety of products. Our product development team is ready to develop mixes and specialty grains for any application in the food industry.

Horizon Milling, a Cargill Joint Venture, is a leading bakery solution provider, offering a broad range of high quality flour, oats and bakery mixes/bases/concentrates. To learn more visit www.horizonmilling.ca

®ROBIN HOOD is a registered trademark of Smucker Foods of Canada Co., used under license. 190 Attwell Drive, Suite 400, Etobicoke, ON M9W 6H8

Contact: Elaine O’Doherty, 416-679-2600 www.horizonmilling.ca

Plants: Mills in Montreal, QC, Saskatoon, SK, bakery mix plants in Burlington, ON and Saskatoon, SK.