When it comes to moving and storing dry ingredients, we can handle it.

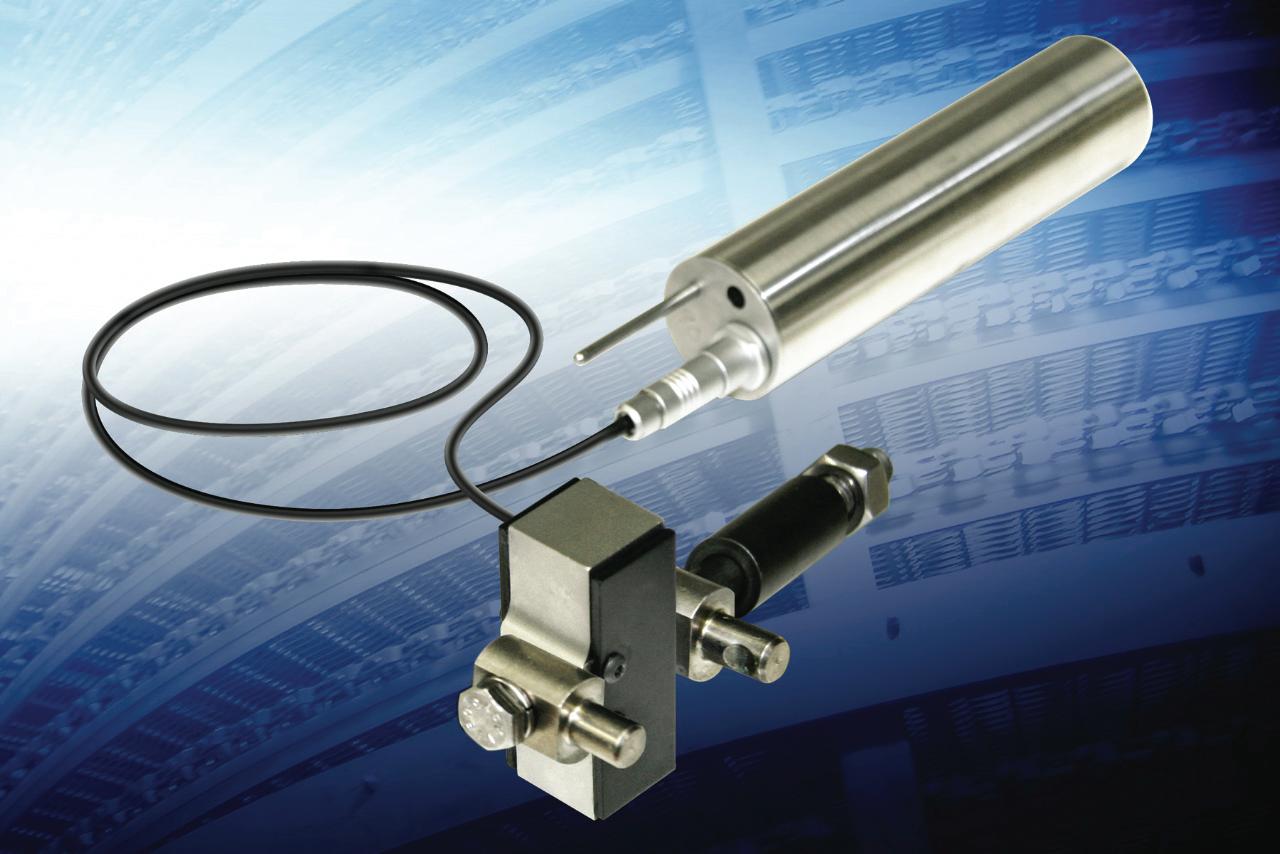

• Delivery, Storage & Inventory

• Conditioning (Drying/Cooling)

• Sifting

• Scaling/Batching

• Vacuum/Pressure

• Dilute/Dense Phase

Shick provides the best services in the industry to support our automated ingredient handling systems.

Process Definition & Functional Design Services

Architecture & Hardware Design Services

Real-Time Software Development Services

Business Systems Development Services

Controls Hardware Manufacturing

A system is only as reliable as the components from which it is made.

Single Source Responsibility for Service, Replacement or Training

Variety of Materials and Finishes Available

Compliance with Specific Industry Standards to Meet Your Needs

• Bulk Liquid Storage & Delivery

• IBC Systems

• Water Blending

• CIP (Clean-In-Place) Skids

• Metering & Dosing Systems

• Cream Yeast Systems

• Slurry Systems

• Liquid Fermentation Systems (Liquid Brew Systems)

A single source for all your liquid processing needs.

When your recipe calls for just a little of this or that, a Shick system will ensure product consistency and quality.

• Consistency

• Accuracy

• Accountability

• Cleanliness

• Reduce Manpower

• Eliminate Waste

• Reduce Liability

Shick understands the customer’s process, plant layout and unique production schedule.

• Installation – Mechanical & Electrical, Site Supervision & Subcontract Management

• Commissioning – Installation, I/O Checkout, Field Engineering/ Support, System “Dry Run” Testing, Pre-Production Testing

• Training & Support

BY BRIAN HARTZ

I’ve been to a lot of trade shows recently, and it seems bakeries and the industries that supply them are busier than ever trying to sell, sell, sell. They’re working hard in this economy to get new clients and keep the ones they have. That’s an encouraging sign that points not only to the resilience of the industry, but also the dedication of the people who drive it to become bigger and better.

In mid-May, baked goods giant George Weston Ltd., buoyed by a first-quarter profit of $863 million, announced it was on the lookout for “huge opportunities” despite the slumping economy that has put the kibosh on many companies’ ability, or willingness, to endure short-term pain for the sake of long-term growth. The headline of the Canadian Press story about Weston’s financial report used the phrase “hungry to grow,” and while execs understandably kept mum about the company’s plans to expand, this bit of sunshine was an inspiring attention-getter in what has otherwise been a gloomy stretch of economic news. Meanwhile, across the pond, Greggs Plc, the U.K.’s largest bakery chain, said in January that it intends to capitalize on Britain’s first recession in 17 years by snapping up vacated stores so it can add new outlets.

}A recession can be a great time to expand, rather than contract or tread water, as less-prepared competitors fall by the wayside or downsize.

Granted, we can’t all be huge, resource-laden companies like Weston or Greggs, but whether you’re big, medium or small, a recession is no excuse not to look for growth opportunities. Businesses, even ones in the so-called “recession-proof” food industry, can’t afford to stand still right now, waiting passively for a turnaround. A recession can be a great time to expand, rather than contract or tread water, as less-prepared competitors fall by the wayside or downsize. This could mean physical growth such as acquiring new facilities or equipment, or market-share growth through advertising and public relations. If you’re a small retail baker and you buy a new piece of equipment, renovate or expand your shop, hire a new employee, or add a new product or service to your store, let your customers know. Hold an open house, use a banner to announce your news, extend your business hours for a week or two, offer facility tours, give freebies away to kids and families – anything to get people through the doors. That’s the kind of mindset that will help you get through these tough times.

If you need more ideas, try consulting your fellow Baking Association of Canada members. Whether you attended this year or not, please join me in congratulating the BAC on its superb Congress 2009 in Burnaby, B.C. It was a pleasure to see the baking industry come together to do business, make and renew connections, learn about new ideas and products, and have a great time in beautiful Vancouver. From the dinner cruise of the city’s waterfront to the evening with Michael “Pinball” Clemons – and, of course, the trade show, wedding cake competition, new product showcase and other business functions held at the Bill Copeland Sports Centre – it was an outstanding event from start to finish.

Last but not least, don’t forget about the annual Bakers Journal recipe collection, which will be packaged with our August/September issue and whose theme is “Classic Canadian Comfort.” We’re soliciting recipes for comfort foods, snacks and desserts such as cookies, muffins, bars, pies, cakes, etc. – but all contributions will be considered. If, like Weston, you are “hungry to grow,” this is a great – and free – way to promote your bakery, so e-mail those recipe ideas to editor@bakersjournal.com.

Happy reading.

June 2009 | Vol. 69, no. 5

EdiTor | Brian Hartz editor@bakersjournal.com 1-888-599-2228 ext. 250

TEChNiCal

EdiTor | John McColl, Puratos Canada jmccoll@puratos.com

NaTioNal advErTisiNg MaNagEr | stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

salEs assisTaNT | Barb Comer bcomer@annexweb.com 519-429-5176 1-888-599-2228 ext. 235

ProdUCTioN arTisT | Brooke shaw groUP PUblishEr | Martin Mcanulty mmcanulty@annexweb.com

PrEsidENT | Mike fredericks mfredericks@annexweb.com

Mailing address

P.o box 530, 105 donly dr. s., simcoe, oN N3Y 4N5

PUbliCaTioN Mail agrEEMENT No. 40065710. rETUrN UNdElivErablE CaNadiaN addrEssEs To: CirCUlaTioN dEParTMENT

P.o box 530, siMCoE, oN N3Y 4N5 e-mail: lmorrison@annexweb.com

Issn 0005-4097

Published ten times per year (Jan/Feb, Mar, apr, May, Jun, Jul, aug/sept, oct, Nov, dec) by annex Publishing & Printing inc.

suBsCrIPtIon rates

Canada — 1 Year $ 31.80 (includes gsT – #867172652rT0001) Usa — 1 Year $ 40.00 Foreign — 1 Year $ 60.00

Send your subscription request to: bakers Journal

P.o box 530, simcoe, oN N3Y 4N5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940

E-mail: lmorrison@annexweb.com

From time to time, bakers Journal may make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. if you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. all advertising is subject to the publisher’s approval. such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2009 annex Publishing & Printing inc. all rights reserved. Printed in Canada.

briefly | Silver Hills Bakery unveils new look | George Brown seeks professor | BAC cake contest winners | New faces at Mettler-Toledo | for more news in the baking world, check out our website, www.bakersjournal.com

The Chef School at George Brown College in downtown Toronto is accepting applications for the full-time position of baking and pastry arts professor.

The successful candidate will possess certification as a tradesperson in the field of baking and pastry arts with at least five years of relevant experience, in addition to previous teaching experience in the methodologies and trends of modern

patisserie work, dessert preparation/ presentation and merchandising techniques, paired with a working knowledge of wines and their suitability to desserts. Applications can be sent via the George Brown website at www.georgebrown.ca/Admin/hr/jobops.aspx. For more information about this opportunity, contact department chairman Keith Muller at 416-415-5000 ext. 2231.

At Congress 2009 on April 26-27, the British Columbia chapter of the Baking Association of Canada held a wedding cake competition to recognize the hard work and creative flair of baking/pastry students and professionals. The winners shared $3,500 in prize money compliments of the B.C. chapter.

The winners in the professional category were:

First Place: Saskia nollen of Cupcakes

Second Place: Stephanie Graziana of

Creating Occasions

Third Place: estrella Palomec of

McJac’s Roadhouse Grille

The winners in the student category were:

First Place: Valerie Low of Vancouver

Community College

Second Place: Meghan MacSween of

Vancouver Island university

Third Place: Tsukasa Shigihara of

Vancouver Community College

SOnOMA, Calif. – The Bread Bakers Guild of America is kicking off its 2010-2012 fundraising campaign with General Mills’ renewed pledge as a Platinum Partner.

Pledge donations are crucial to the guild’s operations and make up about 35 per cent of its funding. The largest contributors to the guild are designated Metal Level donors: Platinum, Gold, Silver and Bronze.

A Platinum Partner for the last nine years, General Mills has also supported the guild with donations of facilities, ingredi-

ents, resources and volunteer hours for Guild Master Classes, Bread Bakers Guild Team u.S.A., training, and Camp Bread.

General Mills’ commitment of uS$120,000 for the 2010-2012 fundraising cycle insures the guild’s ability to continue to be the premier source of baking education to its members and the u.S. baking industry. The guild’s fundraising campaign will continue throughout 2009 with a budgeted campaign goal of uS$450,000.

VAnCOuVeR – Silver Hills Bakery unveiled its new look in April as rebranded bags of its sprouted whole grain bread were delivered to grocery stores in Canada and the united States. The re-designed packaging offers unique “bread-time stories” and a first glimpse of Silver Hills’ new brand personality developed by Karacters Design Group. Silver Hills says the new look is designed to appeal to a wider, health-conscious demographic and thus boost the company’s sales and broaden its customer base. For more information, visit www.silverhillsbakery.ca.

TRAVeRSe CITY, Mich. – Plasport, a division of Plascon, has named industry professional Bob Robke sales manager for its line of form-fitting poly liners used in the food, chemical and biopharmaceutical industries.

Robke brings 20 years experience in the design, marketing and sales of various innovative packaging concepts involving FIBCs and poly liners for dry, viscous and liquid products. He will be responsible for expanding sales and capacity at Plasport, which specializes in liners for use in FIBCs, Gaylord boxes and IBCs, as well as Y-hood pallet covers and specialty liners.

Prior to joining Plasport, Robke held sales management positions with Scholle Custom Packaging and Container, and Pooling Solutions (CAPS). His involvement in the growth of these companies encompassed many aspects of the business, including manufacturing, management and development. Robke holds a degree in business administration from Ferris State university in Big Rapids, Mich.

Mettler-Toledo Inc., a global supplier in-line check-weighers, metal detectors and x-ray inspection systems to the food industry, welcomes new members to its Hi-Speed and Safeline subsidiaries.

Mettler-Toledo Hi-Speed has appointed Bob urban as operations manager. urban is a seasoned operations management professional and will oversee operations engineering, materials and production functions for the Hi-Speed line of check-weighers.

Throughout his career, urban has

focused on high-quality, lean manufacturing, and continuous improvement initiatives, most recently as president and plant manager of national Refrigeration Company in Honea Path, S.C.

Joel Medina joins Metter-Toledo Safeline as service parts supervisor. Medina will be responsible for all sales and promotional efforts related to the Safeline range of metal detection and x-ray parts and accessories. He previously served as an assistant service manager in the automotive industry for six years.

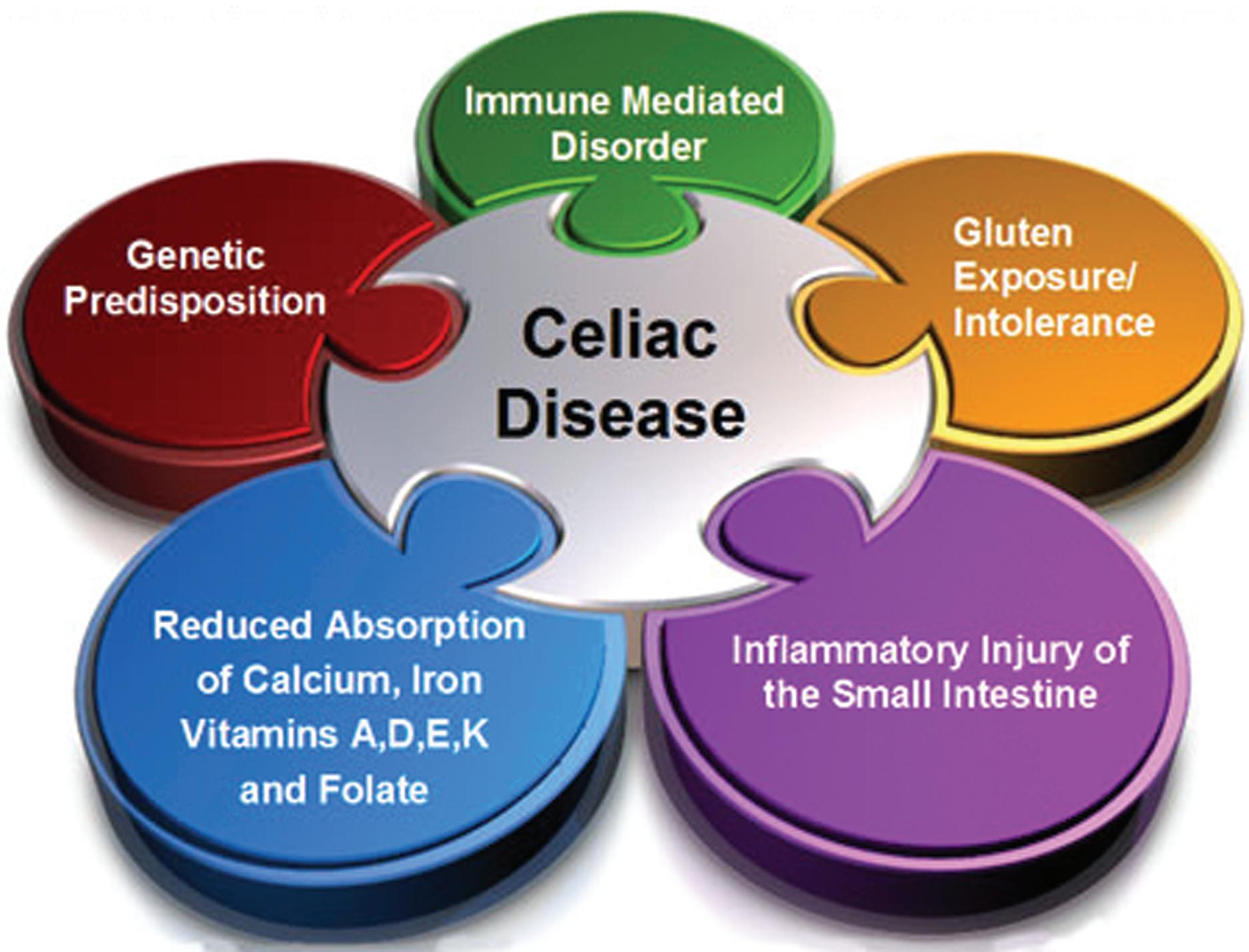

OTTAWA – Health Canada, the Canadian Celiac Association and the Fondation Québécoise de la Maladie Coeliaque have published a pamphlet titled Celiac disease – The gluten Connection. Aimed at people diagnosed with celiac disease as well as their friends and family, the document provides easy-to-understand information about celiac disease and steps that can be taken to manage it.

Celiac disease is an inherited medical condition in which the surface of the small intestine is damaged by gluten, a group of proteins found in grains such as wheat, rye and barley. This damage causes the body to be unable to absorb nutrients such as protein, fat, carbohydrates, vitamins and minerals. Currently, lifelong avoidance of gluten in the diet is the only effective way to manage this disease.

A gluten-free diet can be challenging because it involves knowing what foods contain gluten and determining possible hidden sources of gluten in food products and drugs. It also involves a major lifestyle changes since many foods must be avoided, including pasta, many breakfast cereals and snacks, most breads and other baked goods. Symptoms include indigestion, nausea, abdominal bloating, gas, recurring diarrhea, constipation, anemia, and vitamin deficiencies.

Celiac disease affects approximately 1 in every 100-200 people in north America and is considered one of the most common chronic diseases. In Canada, up to 300,000 people could have this disease, but many remain undiagnosed.

To download Celiac disease – The gluten Connection, visit: www.hc-sc.gc. ca/fn-an/pubs/securit/gluten_connlien_gluten-eng.php.

BY MICHELLE

With charges for plastic shopping bags coming into effect, the time could be right to adopt biodegradable packaging at your bakery.

When belts tightened this year, many pundits predicted eco-friendly solutions would be one of the first casualties. Seriously, all of this tree hugging is expensive and the business world will gladly furlough green initiatives, at least until the panic is over – right? Not so fast.

We got into this financial mess by sacrificing tomorrow’s stability for today’s immediate gratification and many consumers have taken these lessons to heart. Sustainability is the focus moving forward and, because green is here to stay, retailers need to think about which changes they need to make and also about how to implement these changes.

}Beginning in June 2009, the city of Toronto will make it mandatory for retailers to charge for plastic bags. Positive reinforcement administered as points or rebates to forgo plastic bags has gone only so far. Most customers were still leaving their canvas bags in the car and continuing to take plastic at the checkout. That little charge each time is more stick than carrot and intended to be more effective in diverting bags from landfills.

the optimal conditions for biodegradation to occur.

“Landfills don’t offer much in the way of oxygen, humidity or sunlight,” she says. “Archeologists have dug down in landfills and found fresh produce that hadn’t broken down over time. Less is best. It’s better to reduce the use of extraneous packaging at the outset.”

For bakeries relying on bags and boxes to get their beautiful creations from shop to home or event, plastic cake carriers and clamshell packages are staples. If the plastic is recyclable, isn’t that still OK?

“Often it comes down to dollars and cents,” Zweep says. “If one plastic in a bin has a different melting point than another plastic, that’s an issue for recycling. Sorting the plastics is very labour-intensive and therefore not very profitable. Unfortunately, most of it is ending up in the landfill anyway.”

industry and are lying in the wilds of B.C.

“The cutlery is very strong and the knives cut beautifully,” Wayland says.

So what options are available for bakeries

Should you decide to charge for plastic bags or eliminate plastic cake holders or clamshell packages from your operation, be prepared for a wide spectrum of reactions from customers and staff alike.

looking to green up their packaging program?

ZeroWaste Products Inc. in British Columbia distributes a number of sustainable solutions, such as reusable and printable non-woven polypropylene bags. They fold up discretely with a Velcro closure, making them handy to keep in a purse.

The Aspenware production facility runs on hydroelectric power in an effort to minimize any carbon output.

“Paper is a good fallback when some type of packaging is needed,” Zweep says. “Cake boxes instead of plastic cake holders or clamshells are good options. Paper bags instead of plastic are a viable alternative for those who need something to carry their purchases.”

Other municipalities are sure to follow and many major grocery retailers are already charging a few cents each for bags in their stores across Canada. If your store is in Toronto, the decision has been made for you; but if you do business elsewhere, charging for plastic bags might be a tactic you’re considering.

Biodegradable bags are an option, too. These are designed to break down in the presence of light, oxygen and humidity to a lower quality of their original form. This process is different from composting, which means micro-organisms consume the bag.

Carol Zweep, Guelph Food Technology Centre’s packaging and labelling services manager, says most landfills don’t provide

“It’s hard for people to get into the habit of remembering to bring their own bags,” says ZeroWaste’s Dyanne Wayland. “Our bag can be carried along at all times and we can print a business logo and tagline on the bag. Now, in addition to it being a sustainable solution, it provides a bit of advertising for the retailer.”

For operations wondering what to do about plastic cutlery, ZeroWaste also distributes a line of biodegradable forks, knives and spoons called Aspenware WUN (Wood Utensils Naturally). This cutlery is made using a process that laminates and molds aspen and birch veneer into attractive spoons, forks and knives. The wood used in the manufacture of Aspenware comes from birch and aspen trees that have already been felled by the forestry

Should you decide to charge for plastic bags or eliminate plastic cake holders or clamshell packages from your operation, be prepared for a wide spectrum of reactions from customers and staff alike. Some will applaud your environmental stewardship and others will see it as an inconvenience at best or a money-grab at worst. Your front-line team may bear the brunt of customer frustration and there will be questions they’ll have to field.

Give customers a few weeks’ notice before implementing any changes or additional charges. Make sure you arm your staff with answers to questions such as, “Are you donating part of the money you’re charging for plastic bags to an eco-charity?”

Make your business mantra “less is more” and consider returning to simpler options. Sometimes progress means coming full circle. / BJ

Michelle Brisebois is a marketing professional who specializes in helping companies grow their brands. She can be reached at briseboismichelle@sympatico.ca.

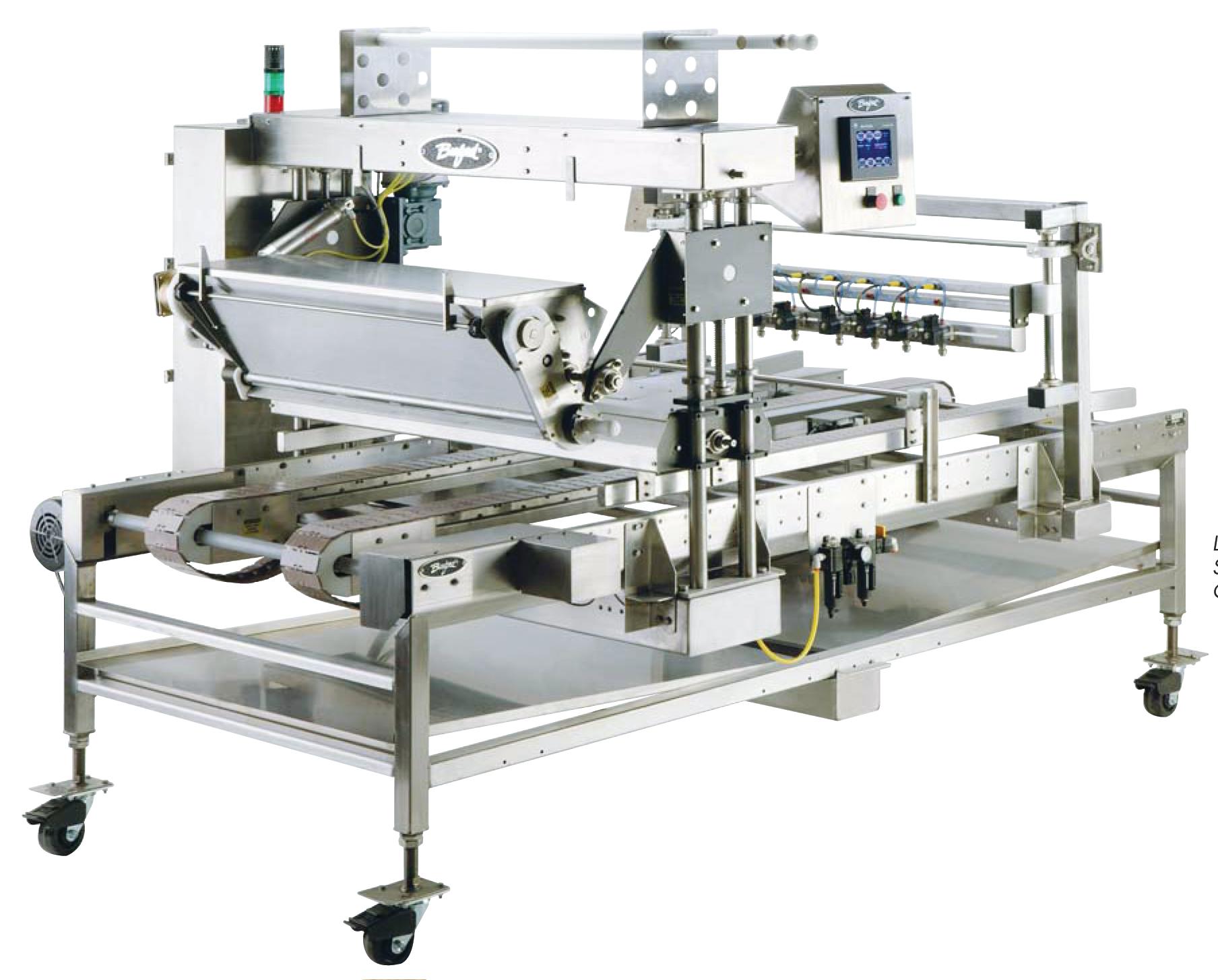

The Vemag Dough Divider produces uniformly spaced dough portions onto the conveyor, eliminating doubles and downtime It can be easily converted to a two-lane set-up to produce up to 200 cuts per minute

What makes the Vemag Dough Divider so special?

Versatility and weight accuracy The Vemag Divider adds versatility to every production line and is perfect for all types of breads, buns, rolls and English muffins It features a positive displacement double screw system that is the most gentle extrusion divider on the market The Vemag is easily adjust able to produce a range of exact-weight portions, dough absorptions and crumb structures

See for yourself – c all us today for a free DVD or to set up a demonstration.

Batch after batch, the Vemag consistently produces precise weight portions at 1% standard deviation

The Vemag does not require mineral oil, saving thousands of dollars annually while eliminating product air pockets and surface blisters

The Vemag is easily adjustable to produce a wide range of portion sizes – from 5g to 20kg

The Vemag is easily adjusted to produce b oth open-crumb and uniform tight-crumb structures

The Vemag can handle absorption rates from 45% to 95% – from stiff bagel doughs to soft English muffins

As we approach the midpoint of 2009, what products and strategies are hot? | By

What drives growth in your bakery in these challenging economic times? We e-mailed this question in an unofficial poll to bakeries across Canada and the United States. The responses are fascinating and inspiring, and full of ideas that others can implement as well.

}These bakeries are prime examples of the inventiveness, tenacity, market-awareness, creativity and optimism that characterise a bakery that will not only survive, but also thrive.

may even grow.”

Brian Hinton is president of Calgary’s Lakeview Bakery. His family has owned the organic and special dietary needs bakery for two decades. Lakeview employs 18 people and has sales of more than $1 million. Hinton provides his recipe for growth, focusing on two themes:

Many customers are driving to our store to purchase their breads, due to lower prices. People are going to the source, they want to see the operation, talk to the bakers, and save money by buying directly from us.

Smaller is better

Downsize the 6-package to four.

Richard Crossman is the corporate bakery manager for Artisano Bakery Café, which operates three cafes in Ontario – in Burlington, Oakville and Etobicoke.

“We have seen improvements in our bottom line through careful negotiating of prices from our suppliers, by expanding our product line, and offering specials,” he reported.

Artisano has also begun pushing catering with local businesses, and offering special-occasion cakes to customers who book functions. Plans include introducing a new line of breads geared toward the health-conscious consumer, and looking at bringing some of the pastry production back in-house.

“We started as a bread bakery with sweet goods mostly purchased from outside suppliers – made to our specs – and we are slowly bringing those back into our own operation, thereby improving our profit margins,” Crossman says.

Effad Sedky, the owner of Vancouver Croissant, a Burnaby, B.C.-based wholesaler of certified organic and non-organic croissants, is also calling for the type of pricelevel co-operation Crossman has negotiated.

“In crises, good people join hands to weather the storm,” Sedky responds via e-mail. “The key is helping each other. If the sellers reduce their prices, helping the cash-strapped buyers, we all survive and

• Although the customer will pay GST, the sticker price will appear smaller. Provide bite-size morsels in a pot

• (with lid) that fits a car’s cup holder –great for snacking in the car.

Go green

• footprint.

Promote local = trusted and small eco

Get rid of plastic. Back to the future:

• The French package products in a wax proof bag, something we used 50 years ago. “Green” can mean

significantly, the retail operation is thriving with consistent annual growth of 20 per cent over the past four years, including last year to-date. Haas suspects that the reasons for this include good control of customer service and quality, plus the fact that, although Haas product is high-end, consumers consider it an affordable luxury treat. Encouraged by the retail success, Haas will open a second retail store this summer in Vancouver on Broadway, next door to his old boss from New York City, Daniel Boulud, who is opening his DB Bistro Moderne in July.

At Vancouver’s Pane e Formaggio, owner David Nonni’s tactics focus on “not compromising but working harder and smarter.” His list:

Consistency of product, honest

• product (Nonni uses the term “honest” in the sense of no frills)

• (such as butter, not margarine “to save money”)

Using only good/natural ingredients

• products to increase bottom line substantially

Innovation – offering seasonal-type

•

Working closely with vendors

Thomas Haas Chocolates & Patisserie’s Chai Bark gourmet chocolate snack.

Doing demos

• Branding of product/product

• recognition

Vera Kobalia of European Breads Bakery in Vancouver describes what is working for her business.

“Even in difficult economic times, B.C. customers care about their health,” she writes. “Our organic, natural and traditionally made products have not suffered. The trend is to buy less, but not poorer quality.”

According to Kobalia, it is important to connect to the customer by “offering value and promotions that people really care about. We did a promotion in April where 10 cents from each loaf was donated to Earth Day Canada. It was very well received by our customers. Green initiatives, sustainable options are definitely on their minds. Also, we have noticed that many customers are driving to our store to purchase their breads, due to lower prices. In general people are going to the source, they want to see the operation, talk to the bakers, and save money by buying directly from us.”

We also heard from several bakeries in the U.S. Lori Karmel, originally from Toronto, operates We Take The Cake gourmet cake boutique in Fort Lauderdale, Fla. She describes her company as being in the celebration business as she e-mailed her thoughts on success.

“We have different segments of the market such as custom-designed cakes, custom cupcakes, wedding cakes (direct or through hotels), gourmet bundt cakes, on-line sales and wholesale to local restaurants, and local Whole Foods Market. We are a special-occasion business and people tend to continue to spend for a special occasion. Marketing with charities and public relations also helps to keep our name out there.”

Chrysta Wilson, founder and owner of Kiss My Bundt Bakery in Los Angeles,

says her bakery is in the experience and comfort business.

“I opened about a month after the bottom fell out of the economy. Still, I see my customer base growing – albeit slowly. On one hand, people are seeking basic comforts (i.e. baked goods). On the other, baked goods are an inexpensive ‘splurge,’” she says via e-mail.

“What’s helping my bakery grow is connecting my personal story to my product, and then creating an experience in my shop where people get a few minutes of comfort. They aren’t just buying a cake. They’re buying the experience of someone greeting them, asking them how they are, offering them a free sample of cake, and really providing a welcoming space.

“I’m taking the approach of trying to create a community bakery – a bakery that is a resident in a community. This is setting me apart from larger, more resourced bakeries. Customer service and experience and my product are the areas where I can compete.”

Michael Girkout, president of Alvarado St. Bakery, based in Sonoma County, Calif., is looking at the bakery business from the vantage point of a 29-year-old, employeeowned company that has seen 35 straight quarters of growth, boasts US$24 million in sales, and has U.S.-wide distribution and 120 employees. Alvarado St. Bakery is the nation’s oldest and largest co-operatively owned, certified-organic bakery.

All employees are shareholders, says Girkout, with every dime of profit going back to every employee equally, every quarter. Entry-level employees make around US$50,000 and turnover is virtually non-existent.

Instead of starting with sacks of flour, Alvarado St. Bakery starts by soaking raw whole-wheat seeds until they sprout, resulting in a flourless bread that even those with wheat sensitivity can eat. Their most popular bread is the “California Style Complete Protein Bread,” made with

sprouted wheat and sprouted lentils.

Girkout’s list of success factors:

Whole grains: Ever since the USDA revamped the “food pyramid,” there has been tremendous growth in products made with whole grains. In fact, the pyramid has been changed to include white flour/ refined flours to be in the same category as sugar (use in moderation.)

100 per cent whole grains: Even better (not all products that make the “whole grain” claim are 100 per cent whole grain). All of our breads are made with 100 per cent whole sprouted grains.

Low calorie: Our Essential Flaxseed bread has only 50 calories per slice (very low for bread). All the ‘bigs’ are introducing “100 calorie” packs of anything from cereals, chips, and Oreos to carrots and nutritional bars. Consumers are still counting calories and using that as a determining factor in making purchasing decisions.

Low fat: Still a hot category in breads. All of our products are made without any fat or oil added.

No salt: A growing market segment. People with high blood pressure or on a sodiumrestricted diet are looking for sodium-free or low-sodium products. Our No-Salt Multi Grain bread contains no added salt.

Low glycemic: Becoming more and more in demand as consumers are educating themselves on the Glycemic Index and looking to avoid highly processed foods. Human testing is required to determine GI of food products. Our Diabetic Lifestyles bread underwent testing that verified a very low glycemic index.

Organic: Hotter than ever. There isn’t a retailer in the country not looking at organic products. Now a household word ... organic products are available in every department from produce, dairy, bakery, and even meat and fish. We’ve been certified organic long before it was cool. / BJ

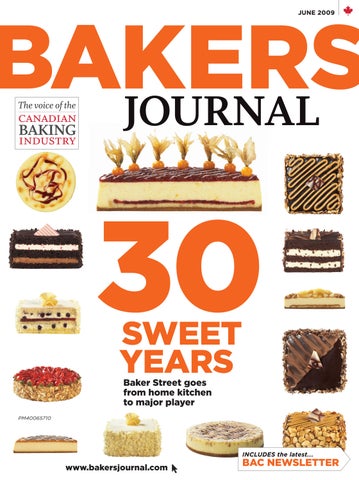

Baker Street will tempt your taste buds with homegrown sweet and savoury delights | By

BrIan Hartz

Baker Street – not only a great song by U.K. rocker

Gerry Rafferty, but also a great name for a bakery.

However, this Baker Street is actually located on Hopewell Street in Toronto, in an unassuming grey building whose appearance belies the beauty and deliciousness of the products made inside it.

Founded in 1978 by two sisters – Mary Somerton and Esther Kravice, who remain actively involved in the business – Baker Street has grown from a humble home-kitchen retail operation to a major wholesale supplier of gourmet cheese spreads and cakes to grocery chains such as Loblaws, Sobeys, Metro, Pusateri’s and Longo’s as well as boutique markets, hotels, casinos, resorts and restaurants.

Despite such rapid growth, Baker Street has remained family owned and operated. Esther Kravice is the company president, while the sales team is made up of her son Jason and her husband Jerry Kravice. Her other son Dylan handles the finances and Jason’s wife, Marla Kravice, handles public relations and marketing.

}Mary Somerton is vice-president and very much involved with the research and development department headed by Denise Stemmler, a former culinary instructor at institutions such as George Brown College. Mary’s daughters Leah Somerton-Barr and Jessica Somerton are Baker Street’s plant manager and quality control director, respectively.

I used to work at Queen’s Park, as a legislative assistant for the NDP.

But I’ve found it’s much easier to influence people through dessert than politics.

of our customers is what keeps us going. We’re still at it because we have a lot to work for.”

carrot cake, are still around today, in their original formulations, more or less; while recently branching out with gourmet cheese spreads –herb, sun-dried tomato pesto and the popular red pepper jelly – has been a successful venture into an entirely new, non-dessert category.

For someone who’s been in the baking business so long, Mary Somerton has one of the more unusual backgrounds you might encounter.

“I used to work at Queen’s Park, as a legislative assistant for the NDP,” she says.

“But I’ve found it’s much easier to influence people through dessert than politics. I never thought it would turn into this, though – you couldn’t back then.”

“It’s been hard work, but the reaction

Judging by the diverse range of desserts and spreads Baker Street produces, the company’s influence is spreading not only to a variety of markets, such as those mentioned above, but also manufacturers of private-label and customized products.

“Our R&D team has become very highly respected in the culinary industry,” says Marla. “Chefs and restaurateurs looking for something new will come to Baker Street and ask us to develop products for them.”

Baker Street started off with a very simple lineup of products: carrot cake, pecan flan, classic vanilla cheesecake and chocolate cake. Some, such as the

“At the time they started, it was very much a male-dominated, pastry chefdriven industry,” Jason says, “and here came these two ladies with some great, solid, home-made recipes, and those became the foundation of a product line that essentially is still constructed the same way. Obviously some of the ingredients have changed but essentially the philosophy behind it hasn’t changed. And the trends have come full circle, especially with the way the economy is these days – these kinds of products are pretty standard on most menus.”

Baker Street isn’t trying to re-invent the wheel, but it is committed to innovation and wants to take traditional desserts to the forefront of culinary excellence.

“We’re taking these traditional flavours and putting a very current spin on them,” Marla says. “We’re making them more current, like taking cheesecakes and doing a crème brulee cheesecake.”

Jason agrees, adding, “The crème brulee cheesecake is a great example of a name and a flavour profile that’s recognizable to everyone, but we’re putting a twist on it. Turning crème brulee into a cheesecake is another way to get people to experience something they might have enjoyed when they were young, but with a new modern twist.”

Baker Street’s desserts have drawn rave reviews from The

Globe & Mail, The Toronto Star, The Sunday Sun and The National Post, with the Phantom Torte, the Palais Royale and the classic carrot cake garnering the highest praise. Its website, www.bakerstreet.ca, offers excerpts from these reviews as well as an online catalogue divided into four categories: jumbo cheesecakes, cheesy tortes, cakes and tortes, and pies and flans. Each item is accompanied with a mouth-watering professional photograph, a detailed flavour profile and an indicator of in what size – usually 8- or 10-inch – it’s available.

“We want to make the look of the dessert match the taste,” Marla says.

But not at the expense of a high-quality formulation, she adds.

“You can have something that’s beautiful to the eye and pleasing to the pallet that’s made with quality and fresh ingredients instead of dyes and impurities,” Marla explains.

“Over the course of 30 years we’ve seen consumers’ tastes change, to the point where people are much more conscious about natural ingredients. But one thing that hasn’t changed is our commitment to using the finest ingredients. In the past we’ve been asked to go sugar-free or use sugar substitutes, but that is an area we won’t go to. Our products have always been of the highest quality and will always remain so.”

Adds Jason: “We don’t make any desserts that we wouldn’t take home to feed to our kids. If my two-year-old, six-year-old or eight-year-old won’t eat it, then we won’t produce it.”

Baker Street’s production plant is HACCP-certified and all products go through a metal detector and weight checker before being packaged. Also, individual batches of ingredients, no matter how minor, are entered into the HACCP tracing system.

During a tour of the facility Jason pointed out many of the other precautions staff were taking, ranging from proper sanitation to constantly monitoring the temperature of various parts of the plant. Temperatures are precisely controlled to ensure the highest level of quality and consistency in the products before they are packed and shipped.

Jason also pointed out the ingredient stock room, which was surprisingly sparse.

“We don’t keep a lot of stock on hand; it’s replenished on a daily basis,” he says. “The idea is to have the freshest ingredi ents and put them into the products as fast as we can and get those products into the customers’ mouths as fast as we can.”

Adopting HACCP standards, says Marla, “is about traceabil ity from when the ingredients were brought to the door to when the finished product goes out.”

From safety to innovation, Baker Street has found a solid formula for success while remaining a family-first business that hasn’t forgotten its roots. They also are savvy enough to know that no matter how bad the economy gets, dessert will never fall out of fashion.

“The biggest compliment we get is when we get a call from someone who’s planning a party and they start their planning with a dessert from us – they plan their entire party around it,” Marla says.

“I’ve found that more and more restaurants, major chains, supermarkets, or even individuals who are planning a dinner party … are starting with the dessert first,” Jason says. “It’s the last experience that your guest or your customer has with any meal. The dessert can make or break a good evening. It’s something that everyone can share and ooh and aah over. It’s just pure pleasure.” /

• Join 4,250 industry professionals including bakers (retail, wholesale, commercial), grocery and foodservice outlets

• Visit the trade show - over 200 companies in 35,000 sq.ft. showcasing ingredients, equipment, services, technology and baked goods (fresh, proof & bake, par-baked, freezer-tooven, thaw & serve)

• Learn at the informative seminars and workshops

• Located in the Toronto area, the facility is easily accessible by public transportation (Mississauga Transit & GO Trains), major highways, 5 minutes from the Toronto International Airport and provides plenty of free parking

• NEW Show Features

Held every other year, it is the only baking specific event produced in Canada

By

BrIan Hartz

Born in Ethiopia to Armenian parents and now firmly established in Montreal, the husband-and-wife team of Rita and Levon Djerrahian have starkly contrasting skill sets yet are perfectly matched as producers of some of the highest-quality cakes in Canada.

Together they run La Gâterie in Pointe-Claire, Que., where they turn out stunning pieces for weddings, graduations and other special occasions.

Readers might recall seeing Rita featured in our March 2008 issue. Since then, she has gone on to win the grand prize in pastry decoration at the 2008 Salon of Culinary Arts competition last November in New York City. As the winner of the competition, sponsored by the Société Culinaire Philanthropique, she received $1,500 and a medal of honour

from the French government, which has been recognizing the Salon’s promotion of French cuisine in the U.S. since 1912.

“I’m just a decorator, but I love what I do,” Rita says. “I’m just so happy that I can achieve what I am here for.

“It’s a passion,” she continues, gesturing around the austere interior of her studio.

“If I wasn’t passionate, this place would be a prison; there are no windows, so I can’t even tell if it’s snowing, raining or sunny.”

Levon, an engineer by training but graphic designer by trade, relishes the challenge of forging the elaborate structures upon which Rita works her decorating artistry, resulting in some of the most stunning novelty cakes to grace the pages of this or any other magazine.

He’s also an amateur pilot and dreams of someday owning his own airplane. Thus, it was no surprise to hear that one his

Rita and Levon Djerrahian at Rita’s La Gâterie workshop in Pointe-Claire, Que.

favourite recent projects was a Learjet cake designed for a client who was either very wealthy or very ambitious.

Over a cup of thick and delicious Armenian coffee, Levon showed us the Learjet cake photo during our early April excursion to Montreal for the SIAL food show. As he scrolled through the photos on his iPhone, he highlighted other recent triumphs, including an iPhone cake that was the spitting image of the device he held in his hand – but edible, of course.

Think what you will about the cultural implications of people eating cakes made in the likeness of Learjets and iPhones – a return to the “greed is good” days of the 1980s, perhaps? A Dickensian spirit of going from rags to riches and overcoming the recession? Maybe, maybe not – but what I took away from these creations was admiration for the skill of these two

different but complementary artists.

“Specialty cakes are very popular right now,” says Rita, “and we’re doing more of them than wedding cakes. It’s a lot of work and a lot of dedication to detail, because each one is so different, but we do it because we love it.”

The couple agree hobbies and pop culture continue to be common themes for specialty cakes. Cars, trains, golf clubs, golf courses and, of course, airplanes are popular not only with customers, but also Levon, who relishes

the challenge of giving foundation and form to such complex designs.

“I want to make the cakes out of Kevlar, but I don’t think that would go over very well,” he says with a chuckle.

Levon could be forgiven for wanting to take a shortcut or two with the cakes – he’s busy handling Canadian distribution for Satin Ice, the popular rolled fondant cake icing made by U.S.-based Satin Fine Foods Inc., in addition to designing menus for restaurants in New York and Philadelphia. He also handles the day-to-day business of

SatinIce_HalfPage:Layout 1 3/2/08 10:09 PM Page 1

La Gâterie, which is the way Rita likes it.

“When the business arrives, I just say, ‘You take care of it and leave me alone; I just want to decorate’,” she says with a brilliant smile.

Whether it’s “the business” of doing business, creating beautiful cakes, or just telling the story of their success, these two halves of La Gâterie combine to make a fantastic whole. / BJ

Contact La Gâterie at 514-695-1444 or fondant@satinice.ca.

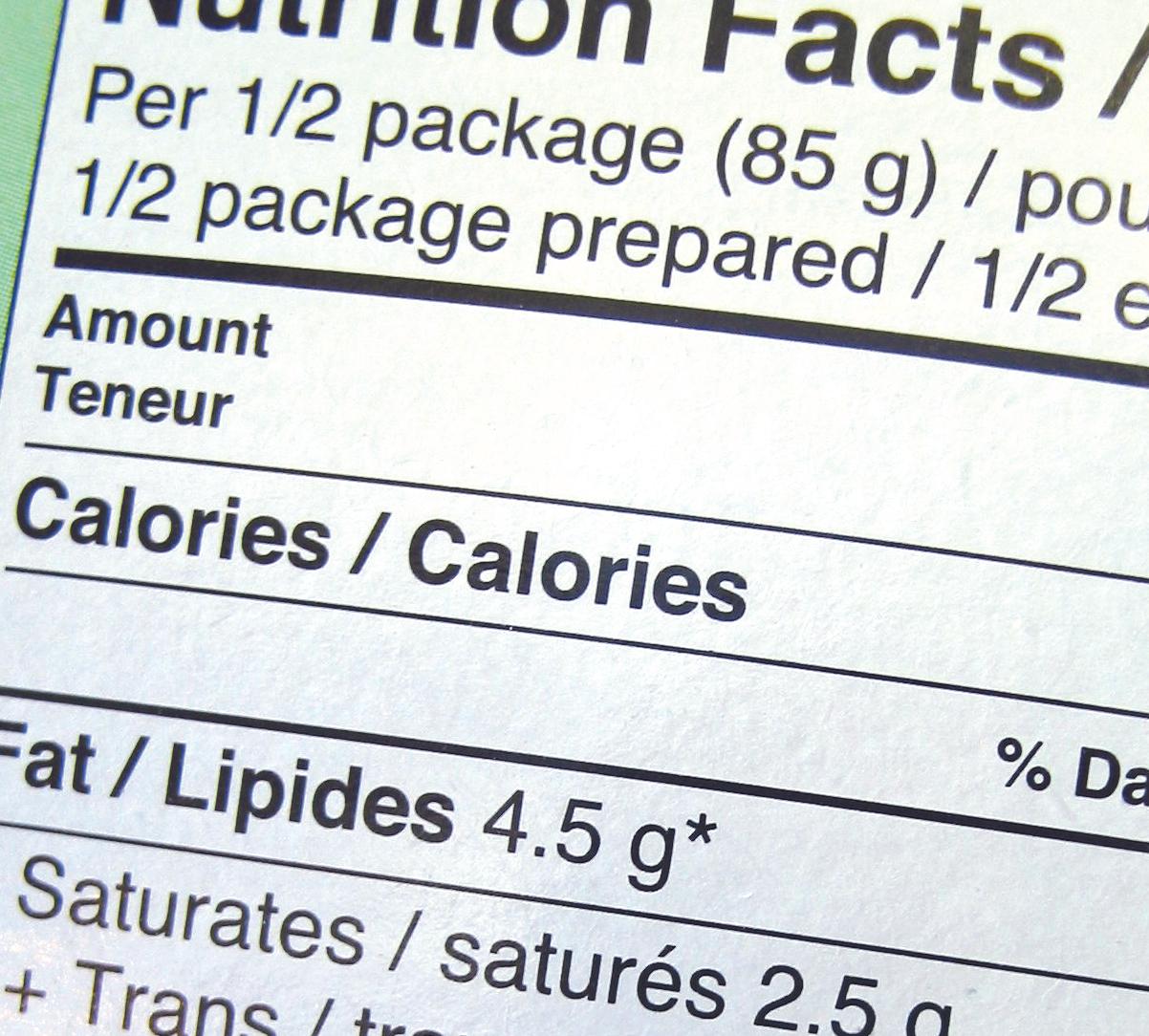

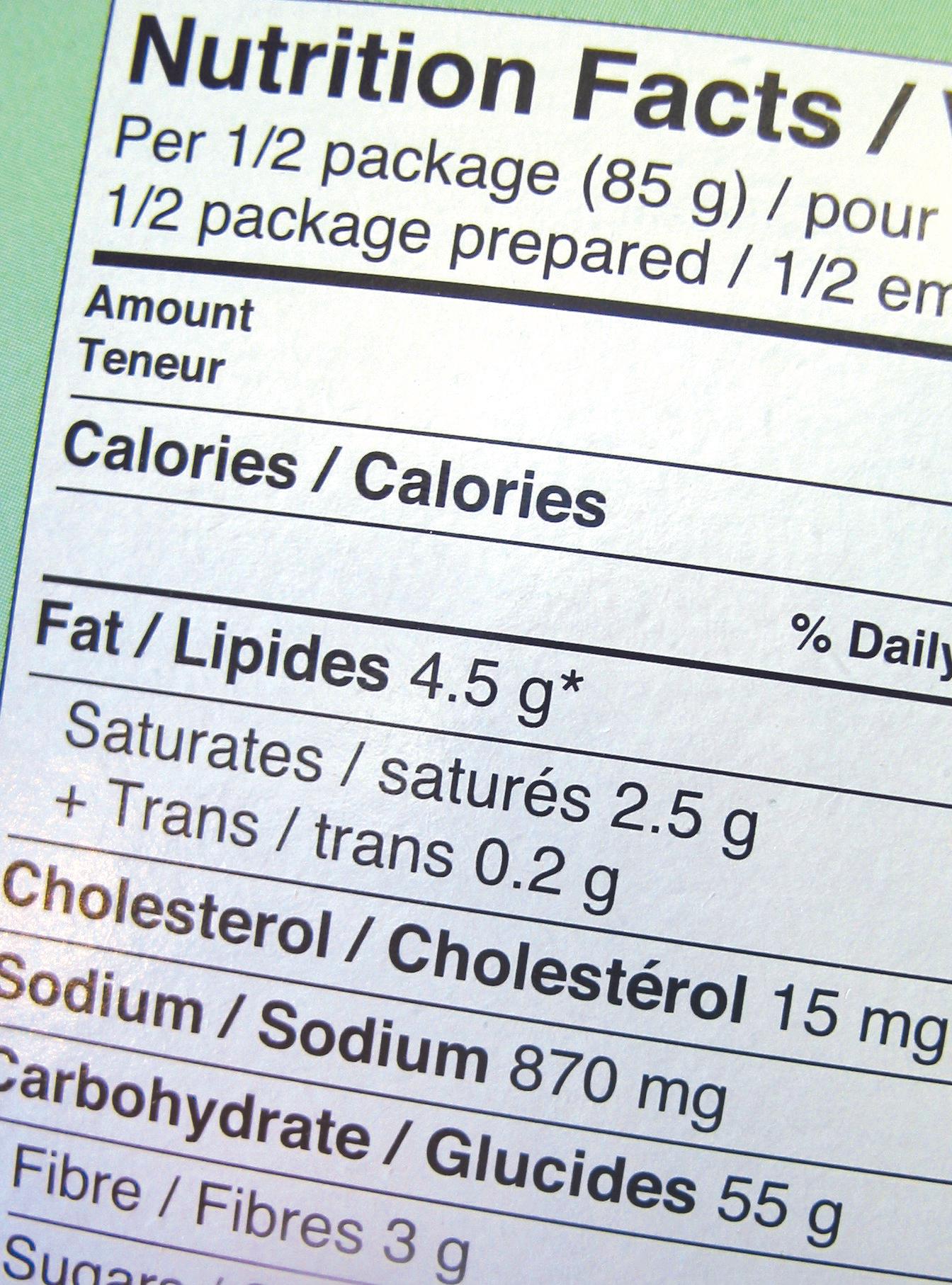

As fast-food restaurants and other foodservice providers face pressure to list calorie counts and even full nutritional information on menus, the importance of proper labelling is coming to the forefront of issues facing the baking industry.

}In April, a war of words erupted between the Centre for Science in the Public Interest and the Canadian Restaurant and Foodservices Association over Bill 156, a private member’s bill in Ontario that would require fast-food restaurants that do more than $5 million in business, to limit trans fats and provide nutrition labels on menus.

According to CBC News, the CRFA vice-president Stephanie Jones called Bill 156 “a huge step backward,” in that restaurant chains have already begun providing this information to consumers, and thus the proposed legislation would undo all the effort these companies have put forth so far.

Changes are coming to the way allergens must be listed on nutrition labels, and bakeries need to be aware of the new requirements ...

In rebuttal, CSPI national co-ordinator Bill Jeffery said those chains “have proven themselves to be much better at defeating nutrition labelling bills than delivering on their own promises to provide nutrition information to their customers.”

In the CBC News article, dated April 9, Jeffrey cited 2008 research by CSPI showing that “two-thirds of 27 restaurant chains ‘largely failed’ to give consumers nutrition information, and none of the 136 restaurants visited provided nutrition information on menus.”

To further muddy the waters, changes are coming to the way allergens must be listed on nutrition labels, and bakeries need to be aware of the new requirements to not only satisfy customers’ expectations, but also avoid fines and red tape.

Luckily, organizations such as the Guelph Food Technology Institute stand ready to assist. GFTC’s business development manager Carol Finlan and product development technician Lori Alexander appeared at Traynor’s Wholesale Bakery show in late March in Hamilton to

highlight how regulatory changes to product labelling will affect bakers.

In an overview of GFTC and the services it offers, Finlan stressed the need for bakeries to get any potential new products tested in a laboratory setting prior to putting them on sale.

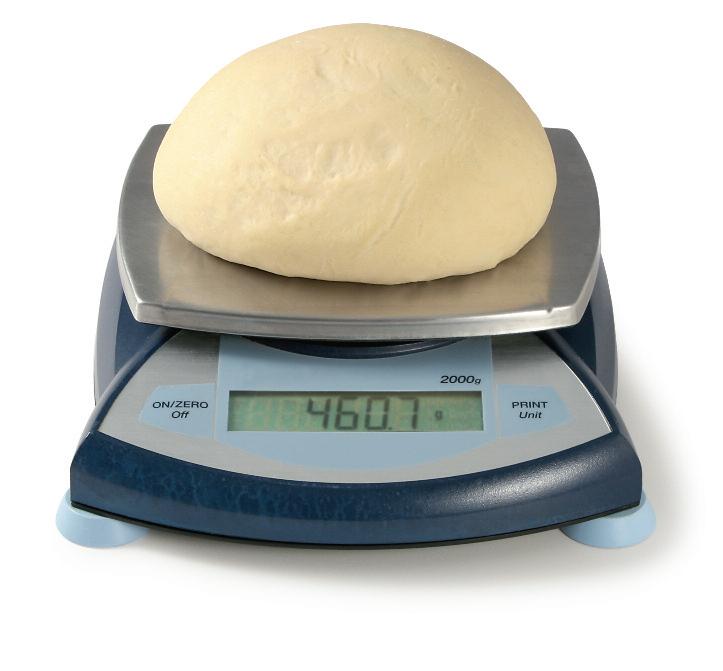

“It’s very important as you’re trying to design a new product to record and keep track of these measurements because later on, when you want to produce the same batch again, you want to make sure you’ve really got the same product,” she told the audience of mostly retail bakers, “and the only way to do that is to have some basic measurements that you continue to look at.”

Also, having your products’ nutrition information certified by an organization such as GFTC can help keep you in the good graces of Health Canada and its enforcement agency; the Canadian Food Inspection Agency – especially, Alexander says, if you are making a health claim about your product.

“Anything that has to do with health or disease, Health Canada and/or CFIA will take a look at these claims,” she says, “and if your products are quite a bit off, they will make you take your products off shelves and re-label them.”

Alexander stressed that laboratory analysis is only one way of getting information for a nutrition label. It also happens to be the most costly method.

“Let’s say we have a cookie and we need to get a nutrition facts panel for it. How do we go about this? Laboratory analysis, nutrient database calculation, or a combination of the two,” she says.

“Laboratory analysis is testing samples of your product by chemical or instrumental means. It can be quite expensive. But sometimes it has to be sent to a lab, if, say, you are making a health claim, if you’re making a fortified product with more vitamins or minerals than our database can calculate, or if you are using ingredients that don’t have a lot of nutritional information available. For example, I just had a client come to me with seabuckthorn berries in their product. Those are fairly new to Canada and we don’t have them in our database, so that product would have to be sent to the lab.

“Nutrient database calculations use the nutrient content of the ingredients you are using, taking into account serving size of finished products. So we would use the product recipe, the ingredient information and anything else we could find

through our database. So what we need for this is nutrient content information for your ingredients. The best-case scenario is having spec sheets from your suppliers if you are buying in large quantities. Having that information is very beneficial for us in assisting you. We can plug that it into our database and give you a more accurate picture of the nutritional information. We can also use it to help you come up with an appropriate serving size for your product.”

All well and good, but how much do these services cost?

According to Alexander, the first label is $350 and each subsequent label is $125. However, for frozen or par-baked items that come with manufacturers’ labels, the cost comes down to $100 for the first label and $75 for each additional label.

OK, so do retail bakers really need nutrition labels on their products? Not always, Alexander says, but for the most part, yes.

“If you’re selling at farmers’ markets, you usually don’t need labels. I’ve heard of a few farmers’ markets that are requiring them because of demand from customers who want to know what they’re eating.”

The rule of thumb, she says, is:

language: english and French, in equal prominence.

font: Sans serif.

type size: 1.6 mm or 1/16 inch.

Colour: Black or dark ink on a white or neutral background. If black is not one of the inks used on your package, you can use the next darkest colour, such as navy blue.

Layout and positioning: Must be printed on a continuous space – no cutting off corners. For difficult-to-label packages, such as pies and buttertarts, the nutrition facts can be printed in a pamphlet for the customer to take home and read.

Weights: Must be in grams; kilograms can be used if product weight exceeds 1,000 grams.

Ingredients list: With some exceptions, such as flavours and colours, must be written in descending order proportional to weight. Components of ingredients must also be listed.

shelf life: “Best before” date must be listed if shelf life is less than 90 days.

Independent baker Fred Piechocki comes from a proud family of bakers. However, during the Great Depression, his grandfather, Stanley, and father, Edward, lost their bakery. As a result, this third generation baker had no recipes or business to carry on.

So what did Fred do? He started his bakery from scratch. In 1979, Fred opened The Cakery Bakery in Philadelphia, Pennsylvania. Ten years later, he moved to Warrington, Pennsylvania, where he and longtime friend, Henry Stoughton, opened the Warrington Pastry Shop. Fred describes his business as a European style, traditional bakery where products are baked from scratch every day.

Best known for the 60 to 100 decorated cakes it produces a week, Warrington Pastry Shop also turns out 10 to 15 wedding cakes a weekend during prime wedding season. It is also well known for Danish, regular cakes, cupcakes, butter cakes, cinnamon buns and donuts.

“My greatest accomplishment is to consistently produce a high-quality product,” said Fred. International® Bakers Services has played a key role in maintaining this quality.

“When I started out, I received a sample of International® Bakers Services B&V® and I have used IBS flavors ever since,” Fred recalled. His bakery also uses chocolate, banana, rum, coconut and hazelnut flavors. “I am very happy with IBS products,” Fred stated. “They are easy to use, very consistent and economical. Most importantly, the flavors hold up.”

“Using ingredients that will keep product quality high will make you proud to be an independent baker,” Fred advised. If you value consistent quality, you should get to know International® Bakers Services Contact us toll-free at (800) 3457175, by fax at (574) 287-7161, or in writing at 1902 North Sheridan Ave., South Bend, Indiana 46628. We have the flavors your customers deserve.

“Anything that’s prepackaged has to have a nutrition facts panel.

“So if you’re packaging it the night before, then putting it out to sell the next day, you must have a label. But if the

client is coming in and picking out the cookies they want, and then you put them in a bag, then you don’t need a label, but it’s something you should be prepared to offer if they want it.”

As noted above, changes are coming to the way allergens are identified on food packaging. Firstly, Health Canada has proposed a new bilingual labelling statement, “Allergen and Intolerance Information – Contains …,” that will be required on packaging. At the moment this information is voluntary, but Alexander predicts it will be mandatory within a year.

“But because you are responsible for your consumers’ safety, allergens are something you’re going to want to identify on your labels regardless,” she says. “This can be done through complete and accurate listing of ingredients, implementing allergen-prevention programs, and cautionary labelling. Cautionary labels are the ones that say, for example, ‘May contain peanuts.’”

However, Alexander says, a bakery cannot use cautionary statements in a generic way, in lieu of using prevention programs in its facility.

“You have to know what’s going on, what else is being processed, what else is going through the lines. You can’t just say ‘may contain …’ and list all the allergens in a blanket statement just to get yourself off the hook.”

Secondly, Health Canada is trying to quash the use of the term “traces” as it relates to the amounts of allergens in food products.

“It is no longer acceptable because it can be misleading for consumers,” Alexander says. “It implies that there is only a very small amount of that allergen when in fact there could be a lot. There’s no way of knowing for sure.”

Finally, the actual list of allergens will be changing. Currently, the nine allergens are peanuts, tree nuts, sesame seeds, eggs, milk, seafood (shrimp, crustaceans), soy, wheat and sulfites.

“Instead of just wheat,” Alexander says, “all gluten-containing ingredients, such as rye and barley, will have to be listed as allergens.”

The Baking Association of Canada has weighed in on this issue with criticism of the new labelling statement as well as Health Canada’s timeline – 12 months – for compliance with the new regulations. For more information, see the BAC Newsletter in the January/February 2009 issue of Bakers Journal. / BJ

Contact Lori Alexander at 519-821-1246, ext. 5042, or lalexander@gftc.ca.

SMYRNA, Ga. – Ed Allen, owner of Sweet Eddie’s, a manufacturer of cinnamon rolls and other baked goods, hopes to return to Pack Expo Las Vegas to find technologies that will help him improve efficiency and facilitate future growth. A visit to the last show led to the purchase of a horizontal wrapping machine and a transfer printer that helped boost speed and supply individually date-coded products.

Allen founded Sweet Eddie’s in 1998 as a small retail outlet serving cinnamon rolls to local customers. Eventually, the company evolved into a wholesale business serving major airlines. The company then transitioned into the food service industry with sales to national retailers, food service accounts and distributors.

}As the company’s business model evolved, so did its product offerings. Aside from the specialty cinnamon rolls that have been produced since day one, the company also produces various cakes and cookies.

ate future, but if the opportunity presented itself, we would consider going international.”

With several transformations behind it, Sweet Eddie’s is now an established distributor to the food-service industry.

To keep pace with the influx of business, Sweet Eddie’s required new wrapping and date coding equipment that would improve the overall line efficiency. Allen headed to Pack Expo in search of both items, knowing he’d meet several potential technology partners and would be able to compare system features and options.

After some post-show follow-up, Allen moved forward with the purchase of a

Prior to this purchase, we only date coded boxes of items, rather than each individual one. The new system changed that, ensuring our customers knew they were getting the freshest product possible.

Pearl horizontal wrapping machine from PFM Packaging Machinery Corp. and an 18 Series thermal transfer printer

colour-touch screen allows users to adjust all the machine settings and save them for regular automatic adjustments to bag length, print registration position, positions of the crimpers, the dwell and the wrapping speed.

The Pearl replaced a smaller wrapping machine from PFM, which Sweet Eddie’s had outgrown. Installing the new system allowed the company to wrap its products faster and more efficiently, resulting in a significant increase in daily productivity and output.

Special features of the Pearl horizontal wrapping machine further improved the efficiency of Sweet Eddie’s operations. A “no product, no film” function saves on packaging waste costs by immediately halting the machine’s crimper and stopping the machine if there is no product on the line. This ensures that no bags will run on the line without product inside. The system’s “product out of place” function stops the line if it senses a product is positioned incorrectly, preventing machine jams.

Additionally, the servo-driven Pearl simplified operations and reduced the amount of manual labour for employees. The computerized settings enabled

over the years, and we’ve been fortunate to experience steady business growth throughout,” Allen says. “There are no major changes planned for the immedi

From Nita’s ShellShock labelling machine to Lesaffre’s SAF-Instant Premium yeast, Bakers Journal keeps you “in the know.” For more on new products for the baking industry, check out our website, www.bakersjournal.com

MAYSVILLe, Okla. – With one-touch setup, Burford’s 9840 and 9940 Smart Seeder/Topper systems automatically adjust their settings to provide a more accurate coverage and seed savings. Pan guides, sensor location, seed quantity, hopper height, nozzle height and mandrel recognition are fully automatic. Accurate topping coverage and seed savings are a given from operator to operator by automating the setup process. For more information, call 1-877-BuRFORD (287-3673) or visit www.burford.com.

saf-Instant Premium yeast by lesaffre MILWAuKee, Wis. – Lessafre Yeast Corp.’s SAF-Instant Premium is granular, free-flowing yeast for use in doughs with sugar levels of

LACHenAIe, Que. – Made in Quebec, nita’s ShellShock clamshell labelling machine is designed specifically for the baking industry. It can not only automatically add labels to the top and the bottom of clamshell packages, but also in a C-shaped tamper-evident seal. It also boasts print-and-apply ability, allowing the operator to change ingredient listings on the fly. Other features include peel plate with top brush kit, laterally adjustable belts, label positioning brushes, and precision rulers for easy setup.

For more information, contact Claudio napoleoni at 450-961-4000, ext. 233, or visit www.nitalabelingequipment. com.

no-time doughs and high-speed processes. It can provide finished products with significantly larger volumes and has a much better oven spring. It can also reduce your dry yeast usage by as much as 30 per cent in most formulations.

For more information, call 1-877-677-7000 or visit www.lesaffreyeastcorp.com.

belt life and prevent unexpected breakdowns. Its tension tests utilize the company’s proprietary Tension Gauge, which records belt tension throughout each tier in a spiral. By analyzing the results, Ashworth can make recommendations to correct any unforeseen or potential problems.

The Ashworth Tension Gauge can

KIAH, Calif. – Pamela’s Products has launched a new gluten-free cornbread and muffin mix.

Packaged in 12-ounce bags, the new gluten-free cornbread mix can be used to bake cornbread muffins, cornbread, cornbread dressing, sweet and savory tart crusts and many other delicious variations.

Pamela’s Products Glutenfree Cornbread & Muffin Mix provides a gluten-free alternative to this traditional food. The mix can be morphed into savory and sweet recipes for breakfast, lunch and dinner. All of Pamela’s Products baking mixes may be used in place of wheat-based mixes. For more information, visit www.pamelasproducts.com.

measure spiral belt tensions of up to 650 pounds with tier spacing as low as two inches. It can operate in freezing and ambient conditions, so tension measurements can be taken in fully operational freezers and coolers. The Tension Gauge can be used on any spiral belt. For more information, see www. ashworth.com or call 1-800-682-4594.

Munson’s new mixer

uTICA, n.Y. – Munson Machinery Co.’s new Inline Miniature Rotary Batch Mixer blends batches up to 5.0 cubic feet (142 litres) in parts as small as one per million with complete uniformity in less than three minutes, evacuates the batch with no residual, and can be sanitized rapidly with no tools.

Model 700-TH-5-SS features a stationary inlet and outlet for inline operation, and a rotating drum with proprietary mixing flights that tumble, turn and fold material gently, imparting minimal energy to the batch while rapidly achieving uniformity regardless of disparities in the bulk densities, particle sizes or flow characteristics of batch ingredients.

The mixer is said to be equally efficient across its useable capacity range of 5.0 to 0.25 cu ft (142 to 7.1 liters). Batch weight capacity of 500 lb (226 kg) is standard, with higher capacities optional. For more information, call 1-800-9446644 or visit www.munsonmachinery.com.

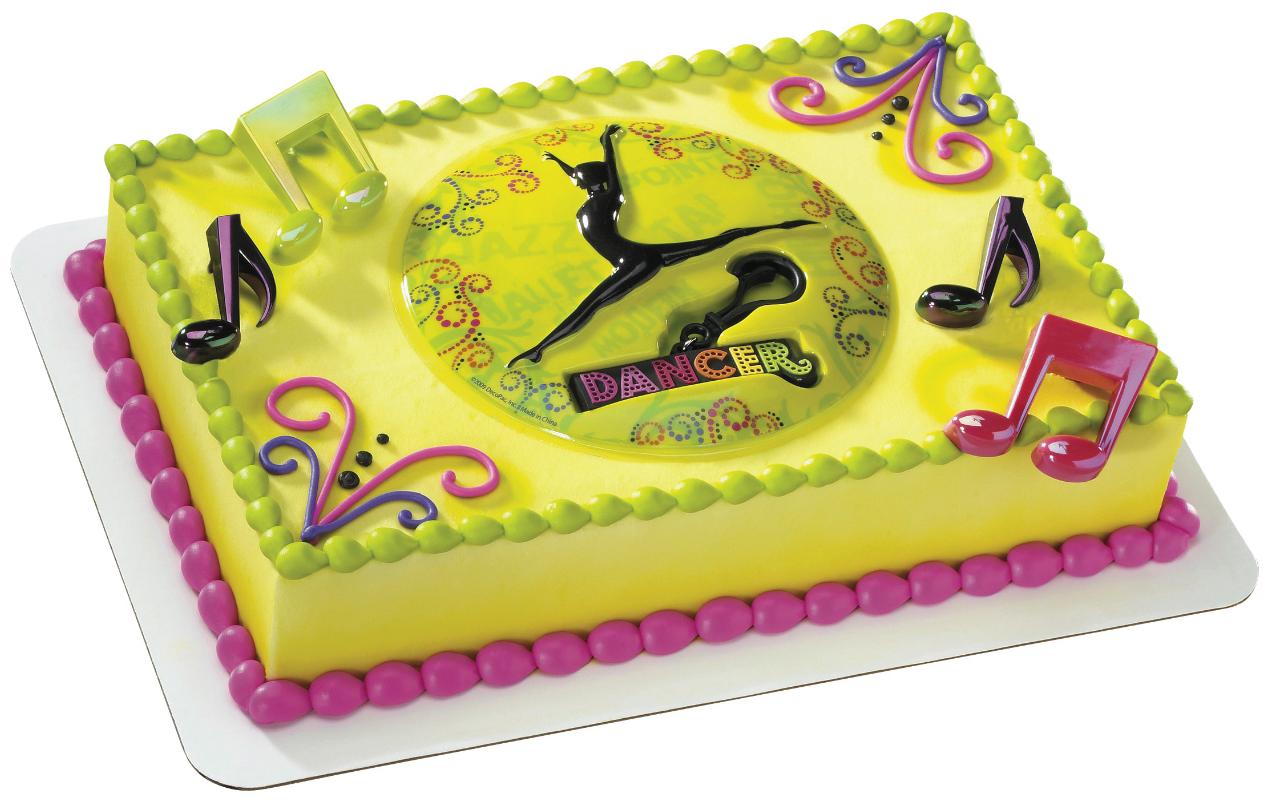

Buddies and Dancer by DecoPac

DecoPac’s new Jungle Buddies DecoSet features a gorilla, elephant and lion, three of kids’ most favorite jungle animals.

gyrdis gxl crepe machine

CHICAGO – Gyrdis has been making baking molds and automatic crepe machines since 1970. The latest addition to its crepe machine range, the GXL, uses state-of-the-art technologies to meet the needs of creperies, bakeries, caterers and restaurants. With the GXL, cooks can make crepes up to 36 centimetres in diameter with the ability to vary crepe thickness and doneness, using wheat and buckwheat flour mixes and flours free of preservatives, artificial colors and GMOs. The user can select the 36-centimetre diameter (one crepe at a time) or the 20-centimetre diameter (two crepes at a time). GXL guarantees an output of 180 to 360 crepes per hour depending on the chosen diameter and will automatically stack 35 to 40 crepes without any handling. For more information, call 312-327-5260 or e-mail contact.ftpo@ubifrance.fr.

Suitable for any occasion, this DecoSet is gender neutral and sure to be a hit at parties.

Ciranda sustainable palm shortening

HuDSOn, Wis. – Ciranda has released the ecoSocial-certified Palmfruit organic shortening to support sustainable, fair trade agriculture in the tropics. Palmfruit palm products are produced by AgroPalma and certified by IBD Brazil. The ecoSocial certification assures that Palmfruit oils are produced in a sustainable way that is preserving the environment and bringing economic and social benefits to communities.

For more information, visit www. ecosocialnet.com or www.ciranda.com.

The trendy Dancer DecoSet features a dancer plac with a removable backpack clip. Check them out at www.decopac.com or call 1-800-DeCOPAC to order.

Pizzey’s Whole-Milled BevGradTM and SelectGradTM flaxseed is an excellent source of Omega-3 fatty acid (22%). Also a good source of dietary fiber and protein, Pizzey's flaxseed does not require refrigeration and is gluten free.

Email: sales@pizzeys.com www.pizzeys.com

BY D R . Jo HN M ICHAELIDES

Continuing our series on the basic ingredients of baking, what is the function of eggs and egg products in baking, what is new in this area, and what are the alternatives?

Eggs and egg products are important ingredients in the manufacture of baked goods, and although in the past their contribution to dietary cholesterol has been cause for concern, recent emphasis on their nutritional value and new scientific investigations has led to a more balanced opinion; thus, consumer perception of eggs has improved.

This article will deal briefly with eggs’ nutritional value, health benefits and basic chemical composition, but the main focus will be on their role as a functional ingredient in baked goods.

}Eggs contain a high amount of water, with approximate moisture levels of 73 per cent for whole eggs, 49 per cent for yolk and 86 per cent for egg whites. The typical physical composition of eggs is 10 per cent shell, 58 per cent whites and 32 per cent yolk. Eggs without the shell contain about 65 per cent whites and 35 per cent yolk. These ratios are important to know when formulating baked goods with different egg constituents, and especially dried egg products.

and vitamins – that are essential for the human diet. But the functional properties of the proteins in egg whites are substantially different. For example, ovoglobulins have high foaming and whipping properties. On the other hand, ovomucin, with high viscosity properties, is very effective in stabilizing foams. The combination of these two properties enables us to produce angel-food cakes with large volumes.

In baking, eggs and egg ingredients are most commonly used in cake production. They are an essential ingredient in such formulations – and often the most expensive.

Eggs are crucial in cake batters because they are multifunctional. They contribute to the leavening, water control, tenderizing, volume, texture and other attributes of the finished product. Egg whites contribute to the leavening action of angel food and sponge cakes as

Many attempts have been made to develop alternatives to eggs that will perform as replacements. However, it’s proven extremely difficult to completely replace egg functionality in baked goods.

well as in binding for snack cakes, and yolks control viscosity in doughnuts.

All egg products contribute to the texture and flavour of baked goods. Their binding and stabilization action in combination with gluten enables batters to form a complex matrix in which, at the oven stage, the proteins coagulate to form the cake’s rigid crumb structure.

flavour is transferred to the cakes. It is therefore important to select fresh eggs or ingredients made from fresh eggs for such products.

Eggs also contribute to the colour of the finished product. In particular, egg yolks are important in yellow cake formulations, while particular attention should be paid to the selection of egg whites when formulating angel-food cakes.

Yolks contain substantial amounts of lipids and protein while whites are almost completely free of lipids. Egg whites contain a high amount of protein as their major constituent, but it is diluted in a solution because of its high amount of water.

Many types of proteins are present in egg whites, and they play different roles in food formulations. The proteins in eggs are considered highly nutritious. In fact, ovalbumin, one of the major proteins in egg whites, is one of a few pure proteins that contain all the nutritionally essential amino acids.

Eggs contain other nutritional components – such as lipids, minerals

This is particularly important for light foam type cakes. For heavier cakes in which the eggs are not whipped, the egg protein films are also important because of their leavening action – they trap and retain the gas generated by the baking soda.

Another important function eggs contribute to cakes is their tenderizing action. The proteins of egg whites, although very functional, result in toughening of the cake crumb. Egg yolks are responsible for counteracting this effect, resulting in more-tender cakes, and the components responsible for this action are the lipids in the yolk. Eggs are normally mild in flavour, but when used in high amounts in a formulation this

Eggs can be sold as whole, yolks or whites, and are available as an ingredient in three basic forms: liquid, frozen or dried.

It’s essential that eggs and egg products are safe and devoid of any pathogenic bacteria such as salmonella. For this reason, manufacturers usually pasteurize liquid eggs at temperatures between 60 and 62 C for not less than 3 1/2 minutes.

Frozen whole eggs, whites and yolks are pasteurized first and then frozen. The whole egg is mixed into a homogeneous mass and then pasteurized prior to freezing. A small amount of salt, sugar or glycerine is added to prevent coagulation.

Dried egg ingredients are a convenient and safer alternative for large manufac-

turers of baked goods. These ingredients are produced either by spray drying or pan drying. Although pan drying was the original method, spray drying is the preferred method because in combination with certain additives it will produce eggs that are equal in performance to the fresh ones. Freeze drying with control heat is another method of drying but is considerably slower and more expensive.

Recent advancements in research have found uses for some of the egg proteins beyond food applications. For example, the proteins lysozyme and avidin can be used as antimicrobials, while new research in the processing of eggs has led to increased performance in food applications.

Eggs, particularly egg yolks, are well known for their emulsification properties. Treatment of egg yolks with specific enzymes will result in an increase in their emulsification capacity. This is important for mayonnaise manufacturers because it allows them to reduce the amount of yolk in their formulations without compromising the quality of the finished product, while at the same time producing a lighter product. Such an enzymatic

modification will also result in improved performance of egg yolks in the manufacture of baked goods.

Because of their importance and cost, many attempts have been made to develop alternatives to eggs that will perform as replacements. However, it’s proven extremely difficult to completely replace egg functionality in baked goods.

Alternatives have been developed from soy and whey protein concentrates and isolates, but it is important to remember that when considering these alternatives for reformulation, a substantial amount of experimentation is required to achieve good results. / BJ

Funding for this report was provided in part by Agriculture and Agri-Food Canada through the Agricultural Adaptation Council’s CanAdvance Program.

Dr. John Michaelides is Guelph Food Technology Institute’s director of research and technology. For more information, or fee-for-service help with product or process development needs, please contact GFTC at 519-821-1246 or gftc@gftc.ca.

BuRGDORF, Switzerland – Rondo Doge has become ROnDO, the result of a strategy and branding process at the Swiss-Italian manufacturer of bakery machines and systems.

The new brand will also manifest itself in the new names of individual companies worldwide. The Rondo Doge Group becomes the ROnDO Group. All companies in the ROnDO Group will have ROnDO as their company name.

The headquarters of the ROnDO Group, which has used the traditional name of Seewer AG, has been renamed Rondo Burgdorf AG.

ROnDO began a process to redefine its strategy and brand in 2007.

“The challenge was to develop new international positioning that fits in with the segment ‘sheeting and shaping dough,’” said ROnDO Group CeO Robert Rohrer. “With the new brand we have managed to create an unmistakable international identity that perfectly embodies our values.”

already well known for top quality and consistent our, is now promoting ORGANIC:

e organic wheat selection process is extremely rigorous, it begins with lab milling of samples; which are then farinograph and bake tested. Only the best organic samples are accepted and extensively blended to give the best bake results of any organic our in the world, TRY IT, you’ll be amazed!

#2024, 7445 – 132nd Street, Surrey, B.C. V3W 1J8

E-mail: Dand@rogersfoods.com

Phone: 1-866-590-4900 or 604-590-4900

Fax: 604-590-4800 www.rogersfoods.com

BY D IANE C HIASS o N

‘Greening’ your bakery with these simple steps can attract new customers, reduce costs and boost your profile

In aspiring to become a more environmentally friendly business, it’s time to start thinking about real, sustainable practices that you can apply to your operation. By going green, you can not only can save money on frivolous expenses such as extra paper, bags and fancy packaging, but perhaps even increase sales by attracting a new clientele of environmentally conscious shoppers, as well as by using reusable green products to advertise your name.

And let’s face facts: Conscientious shoppers today will feel a whole lot better about purchasing products from an environmentally friendly supplier. Psychologically, your greener packaging and labelling will also convey a feeling to your buyers that your products are also more healthful and nutritious.

}added incentive for customers to purchase the bag, throw in a free loaf of bread or half a dozen cupcakes when someone buys a bag.

3. sell PlastIC storage ContaIners

You can sell environmentally friendly plastic carrying cases made with PLA plastics and branded with your logo. The carrying cases should have handles and a cover, and be made to fit standard sizes of cakes, cupcakes, muffins, breads and other products. Customers can use them not only for purchasing items at your store, but also as a practical storage system to use in their homes, or for carrying their baked goods to social occasions. You again receive added exposure, as they will bring your brand name into other people’s homes.

Let’s face facts: Conscientious shoppers today will feel a whole lot better about purchasing products from an environmentally friendly supplier.

Here are a few steps you can take to make your bakery a greener place to shop:

1. u se C orn- B ase D PaC kag I ng for PlastIC ContaIners

Make the switch from petroleum-based packaging to corn-based products (PLA), which are biodegradable. Corn-based plastic containers, forks, knives, plates, cups, etc., break down easily, and so are considered more environmentally friendly, as most cities still do not recycle plastic containers.

2. Create a reCyClaBle ClotH Bag

Design your own recyclable cloth bag that is clearly branded with your logo. This will ensure free advertising to your operation, as your customers will not only use your bag when shopping at your store, but also walking down the street and into other stores. Sell your bag for a reasonable amount, and as an

4. enCourage CustoMers to BrIng tHeIr oWn Bags anD Boxes

Offer a small discount to customers who bring in their own bags, boxes or containers to take your products home, and use this discount as another incentive for your customers to purchase more products.

5. use natural ProDuCts

Instead of using regular ribbon for cake boxes, or tie twists or elastics for plastic or cellophane bags, consider using natural products like raffia or eco-ribbon to tie up your products. By tying a piece of raffia to your products, you will also convey a sense of homegrown earthiness and European style, and add a touch of elegance to your products.

6. attaCH a HanDMaDe or HanD-PrInteD laBel

To create a more organic, homemade feel for your products, consider creating labels by hand. Use sturdy,

recycled paper cut into label sizes and handwrite – in clear and concise penmanship – the information and prices of your products. Use a holepunch to punch a hole in the corner of the label, string a piece of raffia or eco-ribbon through it, and tie it to your bags of breads and other baked goods.

7. use stICkers or laBels for BranDIng

Instead of spending extra money on costly fancy paper bags and boxes, consider getting a roll of stickers and labels printed with your branding and affixing them to generic recycled bags and boxes. You can also use these stickers and labels on your gift baskets.

8. PrInt all Menus on reCyCleD PaPer

Make sure any paper products that you have in your bakery – including menus, flyers, recipe handouts, tent cards or other point-of-sales materials – are all printed on recycled paper. You should also have a clearly mapped out recycling program for recyclable products, green bin for compost and small trash bin for actual garbage for customers to throw out their trash. Use pictures and signs to make sure customers know into which bin they should throw waste.

9. researCH WHat you Buy

Ensure your printer has a chain-ofcustody certification, which ensures that the printing company has all the proper structures and processes for you to be able to print certifications and logos for your packaging and labels to give your store eco credibility. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping food service, hospitality and retail operators increase sales for more than 25 years. She provides innovative food and retail merchandising programs, interior design, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888-9266655, e-mail chiasson@chiassonconsultants.com, or visit www.chiassonconsultants.com

company also saw a reduction in changeover time.

“Workers have found the new machine to be very user-friendly,” Allen said. “We don’t change the product out on the machine too often. However, if we were to run cookies for three hours and switch to running muffins for six hours, it saves time to have the automated settings.”

Though the machine is primarily used to wrap the company’s cinnamon rolls, it also has the capability to wrap other offerings in different sizes, leaving the door open for future expansion.

neW Date CoDer offers IMProVeD ProDuCt safety

The trip to Pack Expo also led to the purchase of an 18 Series thermal transfer printer from Markem-Imaje to meet customer demand for date-coded individually wrapped products.

“Prior to this purchase, we only date coded boxes of items, rather than each individual one,” Allen explains. “The new system changed that, ensuring our customers knew they were getting the freshest product possible.”

The 18 Series features real-time digital coding, a 1mm gap between prints, a dockable LCD handheld user interface and the ability to set automatic date rollover, eliminating manual type changes. The compact coder is designed to maximize the use of ribbon consumables to reduce waste. It requires little maintenance and allows the user to change information instantaneously, for reduced downtime.

lookIng aHeaD to exPansIon Allen looks forward to fostering future growth for his business with the help of more innovative packaging technology. He plans to be at Pack Expo Las Vegas 2009, possibly with his production manager in tow, to search for more cost-saving and productivity enhancing equipment.