By Laura aI ken

By Laura aI ken

In the midst of much discussion around clean labels, two artificial sweeteners were recently approved in North America. The U.S. Food and Drug Administration (FDA) gave the go ahead to advantame. Advantame is a high-intensity product whose maker Ajinomoto claims it has a sugar-like taste that blends well when used as a partial replacement. Canada has not yet approved advantame, but it did give the nod in April to saccharin and its salts as a food additive for certain categories of products. Health Canada did not detail on its website how many studies it reviewed to approve saccharin, but the FDA noted that it considered data from 37 human and animal studies on advantame and found no cause for concern under the guidelines for use.

July | Vol. 74, no. 6

EdiTOR | laura aiken editor@bakersjournal.com 416-522-1595 1-888-599-2228 ext. 250

ASSiSTANT EdiTOR | Colleen Cross ccross@annexweb.com 519-428-3471 ext. 261

TECHNiCAL EdiTOR | John McColl, Puratos Canada jmccoll@puratos.com

NATiONAL AdvERTiSiNg MANAgER | stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

}Thirty-seven studies. That’s either quite a few, or not nearly enough, and the specifics of the science in source and methodology weren’t detailed. Your perspective may depend on where you fall in the contemporary push-pull dichotomy between “naturalize my label” and “take out the sugar/lower the calories/help lower my weight.” We’re hearing that people want to indulge when they pick a sweet treat, and low anything is the palate’s least desire. We’re seeing Panera Bread, a big U.S. bakery outfit, recently announce that they are removing all artificial ingredients from their food by 2016 in response to consumer demand. There will always be a niche for artificial sweeteners, for those with diabetes and on weight-loss diets. I am curious as to how many people choose to consume artificial sweeteners without specific dietary needs or concern for the fact that they are synthetic ingredients concocted in a lab, whether derived from nature or not. How many seek to cut their sugar intake through zero calorie sugar and how many do not? What is it about man-made that has people so uncomfortable these days? Consider aspartame’s long history of controversy spanning back to its original FDA approval in the 1970s that was mired in accusations of poor research, conflicts of interest and shady alliances. Yet time and again, study after study, aspartame has been given the “all clear” for human consumption. Governments and health organizations around the world have stood by the research and aspartame’s approval. Yet fear still abounds. Why?

as a society, are we perhaps a little too comfortable with the equation natural = good and safe? Does natural mean scrutiny should be spared?

If one were to look abstractly at food safety, it would seem much of what there is to fear is found in nature: salmonella, E. coli, Listeria, fatal anaphylactic reactions from nuts, excessive levels of mercury in certain fish, and the too-little-studied effects of various herbal supplements. Pregnant women in Canada are now advised to avoid drinking certain herbal teas, such as chamomile. At first glance one thinks “What? What could be more benign than a cup of chamomile?” There is nothing like the cautious months of pregnancy to remind one that nature is far from a benign bounty.

As a society, are we perhaps a little too comfortable with the equation natural = good and safe? Does natural mean scrutiny should be spared? Let’s not forget the tale of young adventurer, Christopher McCandless, whose story was the basis for the film Into the Wild. He hitchhiked his way from the southern U.S. to the thorny wilds of Alaska, where he ate something poisonous and died. To my knowledge, no one has an artificial sweetener listed on his or her final decree as cause of death.

In a haste to chasten all that is artificial, let’s not lose respect for the maleficence of nature. While the idea of artificial sweeteners will always sit uncomfortably for some, there is also security to be had in the known and widely-studied world of the man-made. Products that were once thought safe have later been declared unsafe, so it must be recognized that product approvals are subject to human systems, which are inherently imperfect. It is very difficult to eliminate all risk and know every variable, but a critical eye should apply as equally to what is thought of as natural as what is considered synthetic, rather than too quickly auto-cast our scientific engineering aside. / BJ

ACCOUNT COORdiNATOR | shannon Drumm sdrumm@annexweb.com 519-429-5176 1-888-599-2228 ext. 219

MEdiA dESigNER | Gerry Wiebe

gROUP PUBLiSHER | Martin Mcanulty mmcanulty@annexweb.com

PRESidENT | Mike fredericks mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 donly dr. S., Simcoe, ON N3Y 4N5

PUBLiCATiON MAiL AgREEMENT NO 40065710. RETURN UNdELivERABLE CANAdiAN AddRESSES TO: CiRCULATiON dEPARTMENT

P.O. BOx 530, SiMCOE, ON N3Y 4N5 e-mail: subscribe@bakersjournal.com

Issn 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, dec) by Annex Publishing & Printing inc.

suBsCrIPtIon rates

Canada — 1 Year $ 30.00 (with gST $31.50 #867172652RT0001, with HST/ QST $33.90)

USA — 1 Year $ 45.00 USd Best pricing is available online at www.bakersjournal.com

send your subscription request to: Bakers Journal

P.O. Box 530, Simcoe, ON N3Y 4N5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940

E-mail: subscribe@bakersjournal.com

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. if you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2014 Annex Publishing & Printing inc. All rights reserved. Printed in Canada.

briefly | Rational hires new VP; Fifth generation to lead Ganong; Upscale oven maker expanding in Canada | FOR MORE news in the baking world, check out our website, www.bakersjournal.com

Markus glueck assumed the post of area vice-president of North America for Rational on April 1. glueck previously held the position of president of Rational USA and will now oversee North America. in his new role, glueck will be responsible for Canadian and American operations.

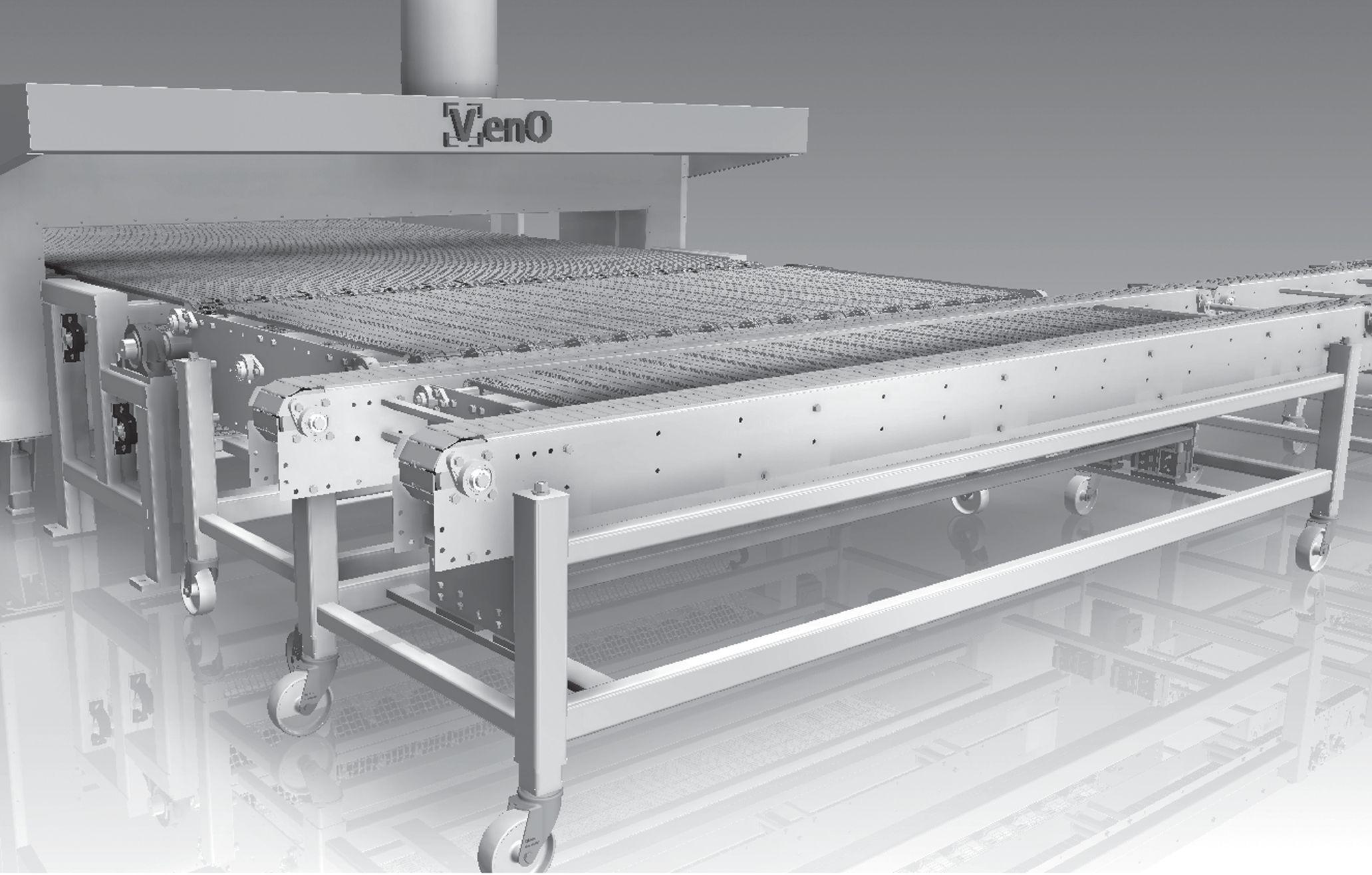

The Alstoft family of American-based v-Tech Engineering/venO America, is growing its Canadian presence with a newly opened manufacturing facility and a recent acquisition.

Bo Alstoft, patriarch of the upscale bakery equipment company he started 20 years ago, struck up a conversation at this year’s Bakery Showcase in Toronto that led to the purchase of AHBM Systems, an automation and robotics equipment manufacturer owned by Paul Pink and operated out of Waterloo, Ont. The technology will compliment v-Tech’s existing product line of ovens, conveyer systems and oven loading/unloading equipment. Alstoft has changed the name of AHBM Systems to venO Automation in order to better reflect the core capabilities of the company. AHBM founder Paul Pink will continue to serve as president of the newly named company. in early May, prior to the acquisition of AHBM, Alstoft formed venO Canada. The company moved into a 39,050 square foot building in Richmond Hill, Ont., on June 1. He enlisted Canadian bakery industry veteran Franz Streiter to serve as CEO. His son Benjamin, who is president of venO America, is now vice

president of venO Canada. Alstoft, who has built his company up to a worldwide client base, is visibly buzzing as he talks about his bigger footprint in the Canadian market.

“i am investing in Canada because i believe the future of my business is here,” he says. “The last couple of years, i discovered the infrastructure, skilled labour force, health care system, and quality of life here is the best in North America. We’re going to continue to produce for the U.S. market in the U.S., but now we will produce our tunnel ovens for the Canadian market at our Richmond Hill facility.”

“Our family is so happy about our new presence in Canada,” emphasizes his son. “All employees in our four manufacturing facilities across the U.S. and Canada are excited about the future. Everybody is motivated. in the end you know, it’s all about love and enjoying life. That is what my family brings to the table.”

The new facility will create jobs and opportunities in the bakery market, as the building will serve a number of purposes. A large test bakery is being constructed in the east side of the building. People entering will be able to see the action

ganong Bros. appointed Bryana ganong president and chief executive officer, effective Aug. 12. ganong belongs to the fifth generation of the ganong family, which operates its only manufacturing facility in St. Stephen, N.B.

first-hand glancing through the windows. The two-level site, formerly occupied by Tetra-Pak, has ready-made areas for reception, presentation and meeting rooms, office space, fitness centre, and the extra high vaulted ceilings and mass hydro hook up needed for manufacturing and assembly space. Here, venO Canada will continue v-Tech’s emphasis on customized equipment, particularly with the tunnel ovens, because as the younger Alstoft Benjamin notes: “No two factory layouts are the same.”

The installation of a complete high capacity oven line at Create A Treat in Brampton, Ont., was the first trigger in the series of events that led the Alstoft family to Canada.

May 29 marked the first day of business for Ardent Mills, a flour-milling company that combines the operations of ConAgra Mills and Horizon Milling, a Cargill-CHS joint venture.

“This is a proud day for our employees and customers who have supported Ardent Mills during every step in this process as we begin a new era in grain,” said dan dye, CEO of Ardent Mills in a media statement issued that day. “Today is about many parts coming together to make a new and stronger whole. it’s about a collective strength, history and ability to deliver quality and nutritious ingredients and carry that legacy into the future.”

Ardent Mills will operate as an independent joint venture of its three parent companies, Omaha, Nebraska-based ConAgra Foods, Minneapolis, Minnesotabased Cargill and St. Paul, Minnesotabased CHS. The company will maximize the combined assets, capabilities and experience of its parent companies to bring innovative flour and grain products, services and solutions to the marketplace.

Ardent Mills’ headquarters will be in downtown denver, Colorado. The new company is expected to have a presence in the denver area starting later this year. in addition to its denver headquarters, Ardent Mills operates satellite offices in Omaha, Neb., and Minneapolis, Minn. ConAgra Foods and Cargill each own a 44 per cent stake in Ardent Mills, with CHS at 12 per cent. All three companies have representatives on Ardent Mills’ board of directors.

Bakers Journal would like to add some clarifications to the story “A baker’s path” that was published in our June edition. it is important to note that there are different criteria in each province. The incentive grants are $1000 per year and $2000 on completion. There is also a tax credit for employers who hire apprentices.

Senior executives from 12 of the world’s largest chocolate companies signed a joint agreement with the government of ghana as part of a strategy to make cocoa farming in the country sustainable.

The plan, known as CocoaAction, calls for building a rejuvenated and economically viable cocoa sector through increased co-operation between industry members and the ghanaian government. Companies that have voluntarily committed to CocoaAction include AdM, Armajaro, Barry Callebaut, Blommer Chocolate Company, Cargill, Ecom, Ferrero, Hershey, Mars, Mondelēz, Nestlé and Olam international.

Emphasis will be placed on providing cocoa farmers with a combination of productivity enhancements and community-development interventions. These efforts, by 2020, are expected to enable 100,000 ghanaian farmers to achieve 100 per cent increase in productivity as well as improve lives in their communities. The World Cocoa Foundation will co-ordinate the strategy.

“This agreement represents one of the most significant steps the sector is taking to make cocoa sustainable,” said Barry Parkin, the foundation’s newly appointed chairman and chief sustainability officer

at Mars, in a news release. “This alignment of objectives, commitment of resources, and sharing of best practices is the type of transformative initiative that will really help farmers become more productive and secure the future of cocoa.”

CocoaAction was voluntarily developed by the companies in cooperation with the governments of ghana and Côte d’ivoire. The two countries provide about 55 per cent of the world’s current cocoa supply. CocoaAction will later be extended to other cocoa-producing countries and is already open to participation by others in the public and private sectors that support sustainability in the cocoa sector.

Through CocoaAction, the companies will work closely with the ghanaian government and other national institutions to provide improved planting materials, fertilizer and training to cocoa farmers, while promoting community development through education, child labour monitoring and remediation, and activities to enhance gender empowerment. A series of indicators, currently being developed by WCF, will accompany the strategy and will allow companies and governments to measure and manage CocoaAction progress.

All oven settings are easily entered at the operator panel. Automatic control of bake time, temperature, dampers, and other parameters ensure a consistent and perfect bake. Recipes are easily stored and retrieved for fast oven set-up. Multi-language support is standard.

The energy modules are available in gas, oil, or electric versions. Low NOx oil, and gas burners are standard for all markets. Industrial grade mineral wool insulation is used throughout the oven body to minimize heat loss.

Extra large clean out doors on every single module on both sides of the oven are standard. Stainless steel interior and exterior are standard.

Oven sections are built in 2 meter (6’-7”) long modules to facilitate shipping in ocean containers and on standard trucks for fast delivery worldwide. Modules are easily installed for faster start-up and commissioning.

A wide array of belt types, belt widths, and belt elevations are available to fit new or existing equipment. Numerous oven conveyor options can be applied for maximum performance.

An integrated control system networked with industrial ethernet controls all energy modules and the conveyor. Your control architecture is added with ease.

laura aIken

Laura MacLean’s chocolate cupcakes rode first class all the way to first place. The trip, however, was not without its turbulence.

MacLean, owner of OMG! Cupcakes in Alberta, entered her signature flavour – Oh My Gosh! Ganache – in the Bakers Journal Great Chocolate Cupcake contest sponsored by Callebaut, Cinelli Esperia and Mimac Glaze. The first receipt of her entry came in as a corrupted document (in retrospect, perhaps a small glimpse of the tribulations to come), but her resend opened just fine and inside was the lovely story of her mother’s dear friend who had passed on the recipe that was a family favourite – known as Laraine’s Chocolate Cake. She gave the recipe a kick up for her bakeshop by hand dipping the cupcakes in chocolate ganache to seal in the moisture and provide a shiny base for the buttercream frosting. The entry scored high and MacLean secured her position as a finalist, alongside Janet Somers, head baker at The Flour Shoppe in Ottawa, and Sarah Allman, pastry chef at the Diavik Diamond Mine in the Northwest Territories (home base is Peterborough, Ont.).

The three cupcakes were set to square off at Bakery Showcase. Given the option to ship their cupcakes or bring them personally for presentation, all finalists chose to come to the show with treats in hand. MacLean was the only one who needed to fly with her 30 cupcakes, a Grande Prairie to Toronto jaunt of connecting flights. It was a challenging compromise for MacLean, as she bakes fresh daily and the logistics of the location and competition meant she would need to serve the judges more-than-day-old cupcakes. She baked within hours of boarding the plane, and gently dipped each in ganache before packing her frosting and decorating tools in her bag and departing for the airport. She carefully packaged her product and put a big red fragile sticker on it, but was still hesitant to put them through the bin for x-ray. The cupcakes made it through, but she was told her tub of frosting wasn’t allowed in her carry-on. Frustrated, she proceeded to check her bag and was told to keep the cupcakes with her. This meant the cupcakes would need to go through the x-ray again. Luck was no lady at this juncture, as the

}On Valentine’s Day of 2011, she held the store’s grand opening and found herself with an unexpected line-up out the door. Things were looking more than okay – they were really looking up.

security woman standing behind the machine calmly informed her that the cupcakes rolled out of the bin on their way through. A total cake wreck, all tipped upside down with ganache all over everything greeted MacLean at the end of the conveyer belt. Stifling the urge to cry or scream, she boarded the plane and tucked the tumbled treats under the foot space of the empty seat next to her. She transferred flights in Calgary and decided to try and secure an empty space beside her again but was told the flight was full. Customer service advised they couldn’t guarantee they would have anywhere safe for the cupcakes on the flight, but that there was lots of room in first class. MacLean shelled out $380 for

the one-way, first-class ticket from Calgary to Toronto rather than risk having nowhere to put them in economy. Finally arriving at her destination, MacLean was faced with how to fix her cupcakes before the contest the next day. She decided to start by re-dipping them, and with the help of product from the Callebaut booth and the Blodgett Oven booth, she rounded up a measuring cup and enough chocolate and cream to make the ganache. Her hotel gave her access to a private lounge so she could use their microwave and loaned her a scale from their kitchen. With her cupcakes all “double-dipped,” she was then ready Tuesday morning to pipe the frosting on and present them to the judges. Over at Bakery Showcase on Tuesday afternoon, the judges and contest organizers were wondering where she was. The contest was slated to start at 1:00 pm and there was no sign of MacLean. Surely she couldn’t have come

DeaDline: Sept 30th, 2014

Questions? Contact Laura Aiken, editor of Bakers Journal, at laiken@annexweb.com or 416-522-1595.

all this way and not show up? After enough time passed to warrant serious concern, a call was made only to discover through some miscommunication MacLean thought the contest started at 2:00 pm. Bakers Journal took the responsibility, and she was asked to just come on over as soon as she could. The judges would wait.

Now thinking that she’d for sure blown any hope of a good first impression, she went to find the shuttle service from the hotel to the event. There was the shuttle, but they were changing shifts and the next driver was late. Just as she was calling back to say she would forfeit, the driver showed up and she was once again on her way. She gave herself a reminder she often cites: “I’m not in the business of saving lives, it’s only cupcakes!”

Several deep breaths later, she presented her cupcake to a panel of judges who know their chocolate and cupcakes: Mandy Kan of Dessert Lady, Joseph Montinaro of Dolcini by Joseph and West Finch Bakery, Heinz Hubbert, president of Badger International and a fourth generation master baker, and Colleen Cross associate editor for Bakers Journal

Keeping her cool, MacLean made her picks for presentation and for photography, then chatted with the other finalists (admiring their cupcakes all the while) as the judges made their notes.

After the whole rigmarole of getting the cupcakes to their final destination, and feeling they were not her best having not been baked fresh that morning, she felt she had very little hope of winning.

But they were darn good cupcakes, and win they did!

“I was just totally so shocked. I had accepted this is a series of events and I’ve got a fun story to tell but my chances of winning are probably not good. I’m not a crier but I had a few tears then. I was just really, really surprised. I would love those judges to know what it took for me to get those cupcakes there.”

And now they do, but there’s a lot more to her story and how her bakery came about.

Desks aren’t for everyone, and at age 46, MacLean decided that a life in accounting and small business consulting had left her tired of being stuck behind one. Raised by a stay-at-home mother that loved to cook and bake, she adopted the passion and decided to go back to school. Her parents are snowbirds, so she enrolled in the

Arizona Culinary Institute where they made their winter home. After graduating, she went on to cake decorating at the Wilton School in Chicago.

She returned to Grande Prairie and landed a job as an executive chef at a local restaurant, but it wasn’t long before putting in crazy hours for someone else’s business had her itching to just put time into her own.

She spent two years researching and planning before opening OMG! Cupcakes in December of 2010 in Grande Prairie, the town she’s lived in pretty much her whole life. It didn’t have a cupcake store, so she brought it one.

“The concept was to do one thing and do it well.”

Things weren’t easy though, as they seldom are when starting up a business. In her personal life, she was going through a separation and it had left her on a shoestring budget. She sourced used equipment from the classifieds, and her father helped her build tables and renovate the space. Her marketing efforts consisted of, and continue to largely be, word-of-mouth, by donating to charities and other organizations, as well as consistent use of Facebook.

She received some early encouragement. The store had been open just a few days, and she had been functioning on only four hours of sleep for what seemed like too long already. She was in the kitchen cracking eggs in a bowl when she noticed that the yolks had formed a perfect smiley face of two eyes, a nose and a mouth.

“I was right in the nitty gritty of it, and it was like, ‘you know what Laura, I think things are going to be okay.’”

On Valentine’s Day of 2011, she held the store’s grand opening and found herself with an unexpected line-up out the door. Things were looking more than okay –they were really looking up. In her first year of business, the Grande Prairie chamber of commerce named her store the city’s best new business. In 2013, OMG! was voted best new bakery in a best of Grande Prairie competition. Now in her fourth year, MacLean says she feels a renewed sense of confidence at having come this far.

After a routine of little sleep and personal sacrifices, MacLean is striving to work more “on the business than in the business.” She is still in the store every day for the majority of hours as she believes there’s a different energy to a shop when the owner is there. She’s built her staff up to six or seven, including an administrative

How good are Dunford Bakers’ Double Fudge Chocolate Cake Donuts? Good enough for special request deliveries to the sky boxes at Mile High Stadium during Denver Broncos games. Good enough for private jets to make special stops to pick them up from the bakery. Now known as Dunford Bakers, the company began as the Dunford Bread Company in 1931 in Salt Lake City, Utah. John Stevens, the president of Dunford Bakers, oversees one of the largest wholesale bakeries in the Salt Lake City area. Dunford is in production 365 days of the year. This popular bakery has one retail location, and supplies baked goods to area grocery stores. In addition, it produces many private label brands. While Double Fudge Chocolate Cake Donuts are Dunford Bakers’ most famous product, the Pumpkin Chocolate Cookies have many fans. Mr. Stevens is proud that Dunford Bakers provides 100 people with employment, many of whom are long-time employees.

The secret of Dunford Bakers’ success over the years is the reputation it has built for taking care of its customers by supplying a quality product at a reasonable price. “We put quality into everything we do. We don’t cut corners and we use the best ingredients in order to produce the best product for our customers,” said John Stevens. To that end, Dunford Bakers uses International® Bakers Services’ flavors such as BLO&V®, B&V®, Raspberry and Pumpkin Pie. “I have known of International® Bakers Services’ flavors my whole life,” said Mr. Stevens. “We are always experimenting with new flavors in order to offer a variety of tasty treats to our customers.”

Whether you are looking for consistent quality in your products or new flavors, turn to International Bakers Services to reach your goals. Contact us toll-free at (800) 345-7175, by fax at (574) 287-7161, or in writing at 1902 North Sheridan Ave., South Bend, Indiana 46628. We have the flavors your customers deserve. ®

Batter

Butter 1/2 cup

Sugar 2 cups

Eggs 2

vanilla 2 tsp

Cocoa 1/2 cup

Flour 2 1/2 cups

Baking Powder 2 tsp

Baking Soda 2 tsp

Water (lukewarm) 2 cups

Ganache

High quality 8 oz semi-sweet or bittersweet chocolate chopped into small pieces

Heavy whipping 1 cup cream (33% or more butter fat)

Buttercream frosting

Butter 1/2 lb

icing sugar 4 cups

Heavy cream 1/3 cup

vanilla 1 tbsp

Directions

Batter

1. With the oven rack in the middle position, preheat the oven to 180 °C (350 °F). Line 24 muffin trays with paper liners.

2. in a bowl, combine the cocoa, flour, baking powder, baking soda. Sift and set aside.

ingredients alternately with the water until the mixture is smooth.

4. Fill each baking cup 2/3 full. A cookie scoop works great for this!

5. Bake for approximately 20 minutes or until a toothpick inserted in the centre of a cupcake comes out clean. Cool completely and prepare to hand dip in the chocolate ganache.

Ganache

1. Place chocolate in a heatproof bowl. Set aside.

2. Pour cream in small saucepan over medium heat and bring to a simmer.

3. Pour cream over chocolate and let sit for one minute without stirring.

4. Using a rubber spatula, gently stir in a circular motion until the chocolate is all melted and cream and chocolate are combined into a silky smooth chocolate mixture.

5. Let mixture cool until slightly pudding like, but when you stir it, it is glassy smooth. Consistency is important so that when you dip your cupcake it does not run off, but at the same time is not too thick as to pile up on the cupcake.

6. dip cupcakes into the chocolate ganache and shake in a circular motion to shake off excess ganache. Let rest until ganache is set before frosting.

1. On low speed, beat the butter, icing sugar, cream and vanilla until incorporated.

assistant, Tananda Popielarz, who shared her feelings about working alongside MacLean.

“Laura truly is a wonderful person, and not just as an employer, but in her everyday life. I completely believe that her business has done so well not only because she is fantastic at what she does, supplying Grande Prairie with fresh, baked from scratch cupcakes every day, but also because of her generosity, community involvement, and huge caring heart. She has taught me so much, and I am so grateful for her kindness, patience, and all of the opportunities she has offered me.”

MacLean attributes much of her success to keeping her promise to bake fresh daily from scratch. OMG! sells 12 flavours every day: 11 classic, plus one feature. She doesn’t sell ‘day olds,’ closing early if she sells out or staying open late if there are still cupcakes on the shelves. End-of-day cupcakes might also be dropped off to local places like the paramedics or senior’s home.

Estimating how much to bake each day is challenge, and she uses a spreadsheet to consider things such as weather and events going on in the city. Since the beginning, she has kept track of how many cupcakes were sold each day and what factors were concurrent with those sales.

Eventually she brought in ice cream so she would have something to offer customers if she sold out early. With capacity still available in the kitchen of her 1,600 sq. ft. shop, she decided to go the food-truck route and is getting its wheels rolling for the first time this summer. MacLean has no shortage of ideas – she is looking at introducing muffins to her morning crowd and would love to have her own coffee blend to serve at the store.

“Rome wasn’t built in a day. I have lots of ideas but not enough time to do it all,” she says, echoing a feeling shared by many of her peers in the baking industry. It is the sentiment of Laura’s true entrepreneurial spirit, whose cupcakes have now earned the right to travel first class. / BJ oh My Gosh! GanaChe

3. in another bowl, cream the butter and sugar with an electric mixer for a minimum of 3 minutes until light, white and fluffy. This important step incorporates air so that your cupcakes will rise nicely and have a light texture. Add vanilla and then gradually add the eggs one at a time, just until incorporated. do not overmix during this step or you will break down all the air bubbles you have just produced in the previous step. On low speed, add the dry

2. gradually increase the mixer speed to high and whip for a minimum of 5 minutes. Besides using real butter, whipping it good is the key to a smooth and silky, light and fluffy buttercream!

3. Fill a piping bag with your fluffy frosting. Using a tip of your choice, decorate your cooled ganache dipped chocolate cupcakes.

4. garnish with candy sprinkles or decorations.

Anew study in the Journal of Consumer Research

may have you reconsidering the texture of your product based on your target consumer group. The study, “Something to Chew On: The Effects of Oral Haptics on Mastication, Orosensory Perception, and Calorie Estimation”, found that people believe foods that are either hard or have a rough texture have fewer calories than softer, chewier options.

“We studied the link between how a food feels in your mouth and the amount we eat, the types of food we choose, and how many calories we think we are consuming,” write authors Dipayan Biswas, Courtney Szocs (both University of South Florida), Aradhna Krishna (University of Michigan), and Donald R. Lehmann (Columbia University).

The researchers conducted five laboratory studies with a total of 407 participants, asking them to sample foods that were hard, soft, rough, or smooth and then measured calorie estimations for the food.

“For one lab study, we teamed up with a chocolate, store in Tampa, Florida and the owner of the store made the same chocolate, either softer or harder. The chemical composition wasn’t changed. The taste was the same, but people in the main experiment, when they sampled the harder chocolate they rated it lower in calories than when they had the softer chocolate. Anything that was smooth or soft was perceived as much higher in calories than when it was rough or hard,” explains Biswas, associate professor of marketing at the University of South Florida and editor of the Journal of Consumer Marketing.

In another lab study, researchers asked participants to watch and evaluate a series of television ads. As tokens of appreciation, participants were given cups filled with bite-sized brownie bits. Half of the group was not asked anything about the brownies, while the other half

was asked about the calorie content of the brownies. Within each of these two groups, half of the participants were

given soft brownie bits and the other half received hard brownie bits.

“We found in the mindless eating 54

years and we’re still sweetening our o er.

After 54 years of supplying quality ingredients from the world’s finest Principals to clients in the Food Sector, we are delighted to launch the Lomas Technical Center. The concept is simple: To add value for our clients by inviting them on a journey of discovery and invention. Part kitchen, part laboratory and part education nexus, the Technical Center is where our people work with yours, where imagination and possibility can create ingenious new products and opportunities.

Discover the wonderful world of possibilities at lvlomas.com or contact us at 1 800 575 3382

context, people preferred the softer brownies. Watching the ads, they ate mindlessly as much as they wanted. What we found out was that in this mindless eating context people ate more of the soft brownies than the hard brownies.

Interestingly, in the other group, when we asked them to focus on the calorie estimation, people ended up eating more of the hard brownies compared to people who had the soft brownies,” Biswas says. From a marketing standpoint, the findings were exciting.

“There are two things here: One is that people have a mental association between texture and calories, so that’s one factor. The other one is how much effort it takes for chewing. Foods that are harder require more chewing effort, so more effort on the part of the consumer.”

It would appear that the findings have created a bit of a predicament for the food industry. When consumers are simply enjoying a food for its pleasing taste and texture, softer and smoother products take the prize. However,

Dealers Ingredients offers you the knowledge, expertise and experience to deliver product performance solutions –naturally.

We take pride in your successes. Our customer’s products are great tasting and healthier. Labels and declarations are appealing. Dealers Ingredients supplies quality ingredients and valuable technical support.

Doughs, breads, muffins, brownies, cakes, soft cookies, icings, puddings, fillings we are committed to assisting you in preparing the best products.

health-conscious consumers react in an opposite fashion, preferring a product with harder and rougher characteristics.

“From a bakery point of view, it depends on who your target customer is. If it’s customers eating mindlessly, not worrying about calories, then a softer texture is best. But if your target customer group is watching their calories, then a harder texture would make better business sense. A lot of bakeries may have both target groups.”

Consumers adore their favourite bakeries for the delights they offer, but the health and wellness trend that has also become well-entrenched in baking. Based on “Something to Chew On”, staying true to the industry’s roots while also offering healthier options will create the perfect recipe for success.

Although the study is only now being published, its co-authors have been presenting their findings for the last couple of years and Biswas says he has already noticed a change in marketing tactics by other food industry sectors.

“In the last year and half, a few companies have started emphasizing texture. Case in point, when Burger King launched their “Satisfries” –they have much lower calories than their regular fries – interestingly the Satisfries have a ridged texture, what we would call a rough texture, as opposed to their regular fries that are high in calories with a smooth texture. So, they are doing that from a business point of view for the health conscious customers wanting various calorie options. It’s a recent example of a company that has actually carried this through into their marketing practice,” Biswas explains.

“Another example is a brand called SRS. On their packages what we noticed –and it’s a pretty recent phenomenon –is they’re emphasizing the hardness of their product. It’s hard and crunchy and they are positioning themselves as a healthy alternative in terms of food options. So again, these are things that companies can do to target health-conscious customers, which is a growing segment of the population.”

The correlation between texture and calorie perception is an exciting find for the food industry, particularly the bakery sector where texture is paramount. / BJ

Julie Fitz-Gerald is a freelance writer based in Uxbridge, Ont., and a regular contributor to Bakers Journal.

Last year the Canadian Government developed a list of potential U.S. imports to be targeted with retaliatory tariffs in response to failure by the United States to comply with the WTO ruling on certain Country of Origin Labelling (COOL) requirements. This list was to be used as part of Canada’s negotiating position in an effort to have the COOL requirements removed on Canadian imports.

The government’s statement last year on this issue stated that despite consistent rulings by the World Trade Organization, the U.S. government continues its unfair trade practices, which are severely damaging to Canadian industry and jobs. The federal government also indicated that it is preparing to launch the next phase of the WTO dispute settlement process on the new U.S. rule. In addition it will continue to consult with stakeholders as we pursue a fair resolution of this issue through the WTO over the next 18 to 24 months. The Canadian government also clarified that with respect Canada’s WTO obligations, it will not act on retaliatory measures until authorized to do so.

BAC has been advised that while negotiations continue they have yet to result in a change in the U.S. position. The proposed target list is substantial and includes breads, cakes, pastries and biscuits along with potential baking ingredients and the partial list includes:

• 0406.90: cheese, not including the following: fresh (unripened or uncured) cheese, whey cheese or curd; grated or powdered; processed cheese; blue-veined cheese or cheese containing veins produced by Penicillium roqueforti;

• 0808.10: apples, fresh;

• 0809.29: cherries, other than sour cherries (Prunus cerasus);

• 0812.10: cherries, provisionally preserved (unsuitable in that state for immediate consumption);

• 10.05: corn (maize);

• 1006.30.00: semi-milled or wholly milled rice, whether or not polished or glazed;

• 1702.20: maple sugar and maple syrup;

• 1702.40.00: glucose and glucose syrup, containing in the dry state at least 20 percent but less than 50 percent by weight of fructose, excluding invert sugar;

• 1702.60.00: certain fructose and fructose syrup,

containing in the dry state more than 50 percent by weight of fructose, excluding invert sugar;

• 1806.20: chocolate and other food preparations containing cocoa-preparations in blocks, slabs or bars weighing more than 2 kg or in liquid, paste, powder, granular or other bulk form in containers or immediate packings, of a content exceeding 2 kg;

• 1806.90: other chocolate and other food preparations containing cocoa-ice cream mix or ice milk mix; chocolates; chocolate coated nuts and other confectionery;

• 19.02: pasta, whether or not cooked or stuffed (with meat or other substances) or otherwise prepared, such as spaghetti, macaroni, noodles, lasagna, gnocchi, ravioli, cannelloni; couscous, whether or not prepared;

• 19.04: prepared foods obtained by the swelling or roasting of cereals or cereal products (for example, corn flakes); cereals (other than maize [corn] in grain form or in the form of flakes or other worked grains (except flour, groats and meal), pre-cooked or otherwise prepared, not elsewhere specified or included;

• 19.05: bread, pastry, cakes, biscuits and other bakers’ wares, whether or not containing cocoa; communion wafers, empty cachets of a kind suitable for pharmaceutical use, sealing wafers, rice paper and similar products;

• 2940.00.00: certain sugars, chemically pure, other than sucrose, lactose, maltose, glucose and fructose; sugar ethers, sugar acetals and sugar esters, and their salts;

• 3504.00: peptones and their derivatives; other protein substances and their derivatives, not elsewhere specified or included; hide powder, whether or not chromed;

The formal announcement and complete list of potential targeted product may be found at the following federal government web site: http://www. international.gc.ca/media_commerce/comm/newscommuniques/2013/06/07a.aspx?lang=eng

BAC is seeking member input on the effect of these tariffs and asks that members contact Paul Hetherington phetherington@baking.ca with any comments or questions.

The BAC supported Small Business Matters Coalition has a singular focus to improve business profitability and create a more competitive consumer environment by securing lower credit card or swipe fees for Canadian small and medium size businesses. Currently in Canada credit card swipe fees are some of the highest in the world, with fees ranging from 1.5 per cent to 4 per cent of a transaction’s value resulting in millions in lost revenue to Canadian businesses. Several countries have looked at the impact of high credit card fees and adopted payment sector reforms. For example, a model that was implemented by the Reserve Bank of Australia in 2002 capped processing fees at 0.5 per cent of a transaction’s value, which produced net welfare gains of $100 to $150 million for Australian retailers each year. In April of this year the European Union voted to move on caps on credit- and debit-card fees that extends to commercial cards. The legislation would limit so-called interchange fees to 0.3% of the value of a credit-card transaction and 0.2% or €0.07, whichever is lower, for a debit-card transaction.

A Comparison of Credit Card Swipe Fees in Canada, Spain and Australia

The Budget read:

In 2013, the Competition tribunal found that certain of visa’s and MasterCard’s network rules have an adverse effect on competition, which results in higher costs to merchants. In light of this finding, the Government will work with stakeholders to promote fair and transparent practices and to help lower credit card acceptance costs for merchants, while encouraging merchants to lower prices to consumers.

“

In order to hold the government to its commitment the Small Business Matters coalition was formed. The purpose of the coalition is to act as a united voice for its members to government – on both the credit card issue, and potentially others moving forward. BAC will keep members advised of the Coalition’s efforts and how they can become involved.

This program carries top-of-the-line news on what’s happening in the industry with governments, services, BAC activities, etc.

The E-Bulletin is ONLY available to BAC Member companies and their employees. Don’t miss out on receiving time-sensitive news.

If you’re not currently receiving the E-Bulletin please email info@baking.ca to be added.

BAC has been consulting with the Federal government regarding the baking industry’s use of the Temporary Foreign Workers Program and the impact of potential changes. Members will be aware that this program is under severe scrutiny by the Federal government due to perceived abuses.

Currently the Temporary Foreign Workers Program allows for both low skilled and skilled workers. Low skilled workers would general be classified as those outside of a certified trade such as line workers, maintenance staff, etc. and this program is particularly susceptible to cancellation.

BAC would like to hear from members currently using to the program in order to provide a detailed response to government on any changes. Please contact Paul Hetherington at the BAC office 1.888.674.2253 ext. 23 or phetherington@baking.ca.

The first BAC Baking Program Scholarships at Centennial College have been awarded to students Michelle Shariff and Kera Clyke. The annual scholarship was created in 2013 through a $25,000 gift by the ON Chapter which was matched by the Centennial College endowment fund.

The Alliance of Ontario Processors (AOFP) is proposing to restructure and rebrand itself. The restructuring will eliminate the current Association membership held by BAC which has also provided BAC members with a corresponding membership in the AOFP. Under the new structure any all companies will be required to become members of the AOFP directly. The Alliance is also proposing a name change to Food & Beverage Ontario.

the Healthy Grains Institute (HGI) is a BAC supported not-for-profit Institute guided by an independent Scientific Advisory Council that directs Canadians to the latest research on the benefits of whole grains.

HGI provides consumers with science-backed information about the gluten-free diet, wheat and other whole grains and the impact seen in scientific research on weight management and chronic disease.

HGI’s website includes a number of free resources such as fact sheets and research studies to assist Canada’s baking in responding to consumer questions regarding wheat based foods. visit www.healthygrains.ca to see everything the HGI has to offer.

Monday, September 8, 2014

Mountain Woods Golf Club Formerly Magnetic Hill Golf Club Moncton, New Brunswick

11:00 a.m. Registration & Meet Your Team 11:45 a.m ALL Teams to their designated starting hole!

12:00 p.m. SHOT GUN START (Modified Best Ball Format)

5:30 p.m. Steak dinner and awards presentation

Please fill in the registration form below and return it by August 22, 2014. In the event of a “sell-out” registrations will be accepted on first come first served basis. Disclaimer - golfers and their guests agree to indemnify and hold the Baking Association of Canada harmless from any and all liability or claim for damages or injuries which may arise as a result of participation in this event. Tournaments play rain or shine no refunds or rain checks

Name:

Company:

Address:

Phone/Fax:

Email:

Quantity:

HST @ 13% (BN#887064798RT)

Please enclose cheque or Credit Card Information (Cheque Payable to Baking Association of Canada)

To help us to ensure the teams are even please check the appropriate box below.

Please mail or fax to: Gillian Blakey, Baking Association of Canada 7895 Tranmere Drive, Ste. 202, Mississauga ON L5S 1V9 Tel (888) 674-2253 x21 Fax (905) 405-0993 Email gblakey@baking.ca

We are pleased to announce that you will be able to register your group for the fall tournament either as a play your own ball or as a scramble team. This dual format will ensure an enjoyable pace of play and promotes the competitiveness of the traditional fall tournament as well as an enjoyable team format of scramble for our social members.

Put your foursome together, or if you are only one or two we will arrange playing partners for you. Single or double entries may be subject to filling in open positions for either a scramble group or individual play depending on where space is available. Please enter your group as one or the other only.

September 17th 2013

Station Creek Golf Club

Directions: Take Hwy 404 North to Stouffville Rd.; Go east on Stouffville Rd. to Woodbine Ave.; North on Woodbine Ave. 2 km; Station Creek Golf Club is on the right hand (East) side. Registration & BBQ lunch - 10:00 a.m. to 11:30

am–

Tuesday, May 6 9:30 am – 5:00 pm 10:00 am

10:00 am – 12 noon 12:00 noon – 5:00 pm

10:00 am – 10:45 am Exporter Alert 10:45 am – 11:15 am

10:00 am – 10:45 am

info@baking.ca • Web-site: www.baking.ca

Fondant can be a lot of fun. It’s like Play-Doh for adults, where your imagination is the only limit and the results are razzle-dazzle. But, as with all fun and games in baking, it all comes down to finances. Making those pretty cakes just isn’t as much fun if it’s not paying the rent.

Fortunately, bakeries can charge a nice premium for fondant-covered cakes. It’s labour intensive, but the results cannot be matched by any other medium. There will always be a place for buttercream or ganache-covered cakes, but they are different end products. Fondant is the only one that offers such limitless design possibilities and the beauty that customers are willing to pay the premium for.

“I’ll always say go find me a product that’s as profitable as a rolled fondant cake,” said Kevin O’Reilly, founder and CEO of Satin Fine Foods, creator of Satin Ice fondant, in conversation with Bakers Journal at this year’s Europain show in Paris. “It will always be the most profitable when you look at the bowl cost and when you look at the selling price of a wedding, custom or special occasion cake. Take an 8-inch round that you cover with buttercream and you can it sell for $13 or $15 dollars. Take the same cake with fondant and you can sell it for $35 or $40 dollars. The cake is the same so you have to really look at it that regard and what the consumer is willing to pay.”

There are several ways to ensure you are maximizing the profit on your fondant cakes. Bakers Journal rounded up some tips from inside a cake shop and on the supply side to help you put the right price on your time and special creations.

ProPer PrICInG

Catherine D’Agostino and Adrienne D’Amico are the business partners behind We Bake in Heels boutique cupcake and cake shop in Vaughn, Ont. After several years in business, they’ve learned a thing or two about the business

behind fondant.

For We Bake in Heels, using a high-quality fondant that is properly stored is the first step. The shop portions the fondant by weight to minimize waste. Since spending time on repairs takes a chunk out of labour time, and the women view a less-than-perfect cake as not an option, planning is an essential part of the process.

“It’s very important to have a design, and plan how you are going to carry out that design in order to avoid making mistakes,” the duo shared in an email to Bakers Journal. “Maintaining a neat, organized workspace and taking the time to do nice, clean work also helps a great deal.”

A wedding dress as a cake on display at Satin Ice’s Europain booth shows the kind of intricate detail cake the medium affords cake designers, and the resulting wow factor that lets them charge more for the cakes.

Technique is also paramount to profit. Satin Fine Foods’ booths are showcases for technique, with cake decorators at work throughout the event. The company hosts more than 50 videos on their website covering basic to advanced skills. To keep costs down, it’s very important to roll fondant to the right thickness, O’Reilly says. Another important key is being able to account for the labour time through planning and price accordingly. It is wise to pay attention to how much time you spend with the bride in your wedding cake business. In O’Reilly’s past life, he spent time selling cakes to brides and worked out a system to keep his time on budget. He typically met with the bride for 25 to 35 minutes. He would ensure they were already settled in and sampling cake when he arrived with his clipboard. He kept the niceties brief, asking how the customer is and when is the big day, before moving quickly into the questions on his clipboard. He would usually sketch the cake during that meeting, but ensure it never topped 40 minutes.

“Many times I’ve talked to a cake artist who says the first meeting is an hour,

then they might spend another half hour on phone, then a second or third meeting, and all of a sudden you’ve spent two or three hours of your time and people aren’t calculating that in as far as dollars per hour and including in the cost of the cake.”

At We Bake in Heels, D’Agostino and D’Amico found that developing an average charge per hour or a cake price was helpful to cover minimum costs.

“We didn’t charge a base cake price when we first started, which we learned very quickly was something we needed to do. We also learned never to sell yourself short – that even if you have just started a cake business, you should always charge what you feel your cakes are worth, and remain competitive with your peers in the industry.”

Ensure the budget is on the table during the initial consultation, and that the bakery is realistic with what can be done for the price. / BJ

laura aIken

If April showers bring May flowers, then Bakery Showcase was a blooming benefactor that sprouted a garden of inspiring ideas!

The Bakery Association of Canada (BAC) organized event, which resides every other year at the International Centre, situated just a frog’s leap from Toronto’s main airport, played happy host from May 4 to 6. A swath of information, ideas and new products was presented across a platform of exhibitors, seminars, feature areas and the BAC’s annual general meeting.

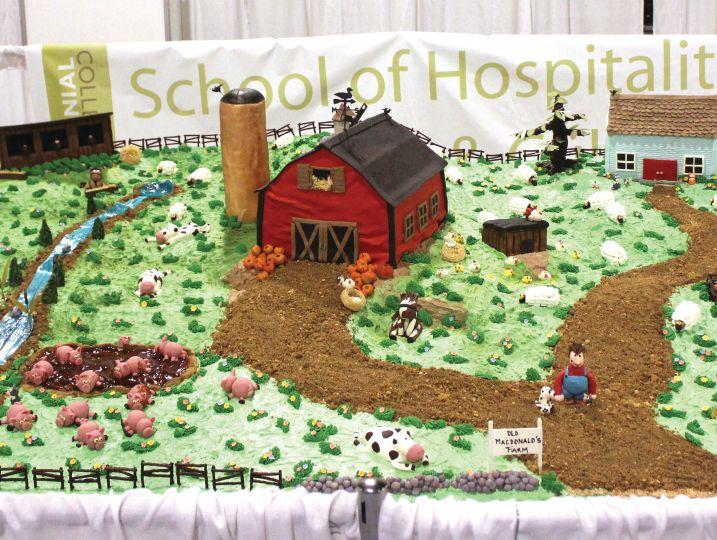

“We were once again delighted by the industry response to Bakery Showcase,” says Paul Hetherington, president of the BAC. “With some 4,000 participants, and 365 plus booths on the exhibit floor along with numerous seminars, Bakery Showcase was once again the place for new ideas and business opportunities. We are also delighted with the response to this year’s College Creative Challenge and would congratulate the baking students from Centennial, George Brown and Niagara colleges for their superb efforts in this fun competition.”

}The college competition garnered its share of aisle-clogging eyeballs with good reason. Who wouldn’t stop to gawk at a cake the size of a backyard shed?.

The college competition garnered its share of aisle-clogging eyeballs with good reason. Who wouldn’t stop to gawk at a cake the size of a backyard shed? Teams of students from three Ontario colleges – Centennial, Niagara, and George Brown – laboured painstakingly at the show over their giant nursery rhyme-themed cakes. Attendees elected the winner by ballot, with Centennial’s Old MacDonald’s Farm and its sprawling scene rising to the top. Niagara built a storybook with 3D characters of the Old Woman in the Shoe and Jack and Jill leaping from its pages. George Brown created a large bed featuring a small child dreaming of various nursery rhymes that seem to have come to life around her. All the cakes were subject to murmured marveling by those who passed by.

The last day of the show determined the long awaited winner of the Bakers Journal Great Chocolate Cupcake contest, sponsored by Callebaut, Cinelli Esperia and Mimac Glaze.

Laura MacLean, owner and chef at Omg! Cupcakes, in Grande Prairie, Alta., was crowned the winner in a tight race with her Oh! My Gosh Ganache Cupcake. MacLean travelled with her cupcakes from Alberta, putting the finishing touches on them in her hotel room before arriving at the show to present them to the judges.

Finalist Janet Somers, head baker at The Flour Shoppe, made the trek from Ottawa to compete with their Nanaimo Brownie Cupcake. Finalist Sarah Allman, pastry chef at Bouwa Whee Catering at Diavik Diamond Mine, NWT, was home in Peterborough, Ont., and able to bring her Classic Chocolate Cupcake, and two

offspring as a cheering squad, to the Tuesday event.

The finalists faced an expert panel of judges: Heinz Hubbert, master baker and international consultant; Joseph Montinaro, chocolatier extraordinaire and industry veteran; Mandy Kan, past winner of the Bakers Journal Growing for Success Award and a reader’s choice favourite in Toronto; and Colleen Cross, associate editor for Bakers Journal, who was able to draw on her recent experience as a judge of the Callebaut Intercollegiate Chocolate competition.

As the cupcakes were presented, attendees were welcome to a sample, and an eager crowd gathered for their own personal bite.

Bakers Journal would like to thank all the finalists for joining us at Bakery Showcase and sharing their fabulous cupcakes with the show floor, our judges for their time and thoughtful scoring, and our sponsors for their support of this year’s Great Chocolate Cupcake contest.

neW anD exCItInG

From tasty samples to machinery in motion, there was no shortage of new

products to check out. Here are some of the highlights:

• Taste of the South: Bon Appé, an Upper Crust brand, extended tempting trays of its new mini fried Danishes to those walking by. The beignets of New Orleans inspired pastries come in five flavours and are kosher and trans fat free.

• The real edible playdough: Virgin Ice showcased their new Doo-z-doh, a flavoured, coloured fondant geared towards crafts with kids.

• Wonder gets an update: Weston Bakeries was making a display splash with towers of Wonder Bread, marking an update to their classic sandwich bread that will now include a new 100 per cent whole wheat plus fibre loaf. Weston will be supporting their focus on Wonder with a multimedia advertising campaign.

• What’s sprouting?: Horizon Milling and Cargill Malt are offering a new sprouted white spring whole wheat flour. The sprouted flour touts several benefits, including bigger loaf volume, decreased proof times and more flour stability.

• General custard: Under the Robin Hood brand, Horizon Milling launched a new custard mix that requires bakers to just add water. The custard can then be customized as its creator pleases with flavours or other inclusions.

• Something new on a stick: Toschi la Gelateria found a way to bring dougnuts into the summer with their Mr. Donuts gelato. It looks like a doughnut, but it’s on a stick and it’s made of gelato. Product holds together well for walking and eating with a uniquely curved stick supporting the gelato at the base. The tools to make and sell the concept can be accessed by Canadian bakers through Alfa Cappuccino.

• PreGel debuted a refreshing new summer flavour for gelato: Peach Ice Tea. The company was also sampling, amongst many other flavours, Birthday Cake Blue, which is a recent newbie to its line-up.

• Gluten-free hybrid: What’s a Brookie? In the spirit of the popular trend to hybridize desserts, Continental Ingredients put together a gluten-free brownie and cookie combo, which was a textural greeting of moist brownie followed by cookie crunch in the centre.

• Gluten-free handling: Handtmann’s VF 608 divider with a shorter product path and gentle dough handling coupled

with a Tri-Mach single lane cutoff and conveyor was in display for bakers looking for better gluten-free handling or needing to reduce friction and maintain better integrity of delicate inclusions in traditional dough. Handtmann’s larger, more powerful VF 628 divider was also on display for bakers running higher volumes and denser dough.

Bakers Journal sat down with Benoît Keppenne, general manager of Sensient Flavors Canada, to discuss the company’s 2014 debut in the Canadian bakery market. Sensient is a long-standing global player in the flavours industry with a heritage spanning more than 125 years. Its reputation is built on flavours, and the company has been selling to the dairy industry (ice cream and yogurt in particular) for a long time.

Sensient’s bakery solutions portfolio includes offering technical solutions, colours, flavours and clean label fillings with no preservatives that maintain shelf

life through aseptic processing and packaging. The flavour range goes from artificial to all natural and even organic. The company also offers a natural origin line with extracts that claim provenance, such as Sicillian Lemon, and are designed to deliver a powerful true and natural taste. Some of their technical solutions, such as DairyBoost, aim to allow bakers to reduce the fat in the product but keep the rich mouthfeel and intensity of taste. Sensient is offering a variety of ‘taste modulation systems’ to tweak to keep the flavour while reducing sugar or salt, masking undesirable notes, or replacers to reduce amount of a cocoa or MSG required.

toDay’s

Bakery Showcase offered a number of educational sessions prior to show hours, with one by Karen McPhee of the NFS-GFTC called “What the trend is going on?” that captured six key areas of consumer focus for the industry.

Clean label is still a biggie, with recent research showing that 75 to 90 per cent of consumers are now reading ingredient declarations on the label. Since clean

label is not regulated terminology, it can mean different things to different people, noted McPhee. It doesn’t necessarily mean natural, because natural is regulated and it is prescriptive.

Gluten-free is on McPhee’s list… hesitantly. From her research, some are predicting the market to grow 48 per cent from 2013 to 2016. Other findings are predicting gluten-free has peaked, or is nearly peaking, as the lifestyle adopters are abandoning the diet in face of a dearth of health community and dietitian statements in the media reinforcing that it is a medical diet. McPhee shared a diagram from Mintel that outlined the reasons other than medical that people were eating gluten-free foods. Thirty-six per cent said “for reasons other than sensitivity.” Sixty-five per cent opted to because “they think it’s healthier.” Twenty-seven per cent “believed it aided in weight loss.” Seven per cent thought it “helped reduce inflammation.” Four per cent had adopted the diet to “combat depression.”

Ancient grains are still drawing consumer interest. For companies formulating with gluten-free grains, of which there are a multitude to choose from, McPhee identified Teff as an up and comer.

Sugar reduction is an inevitable member of any trend list. “It’s the new bad boy; the new salt,” said McPhee. There are plenty of recent headlines to speak to this fact. Recent Mintel research shows that 21 to 60 per cent of consumers are concerned about the total sugars in their diet. So far, the beverage industry has taken the brunt of it, says McPhee, and it is too early to tell the extent to which the bakery industry will be affected.

Ethnic flavours remain a popular source of experimentation. Brazillian cuisine is going to step into the limelight as the host of the upcoming soccer world cup and then the summer Olympics in 2016. Upcscale Mexican, Malaysian and Peruvian flavours are also poised to draw consumer interest.

One would be remiss not to include the aging population as a demographic fact to keep on the baker’s radar. The retirees have new needs, such as high calorie items, because they are eating less, and fortified products that are high in protein and/or fibre. Health is not the only focus for this group. Packaging that opens and reseals easily is also a concern, and

marketers should consider communication that appeals to this audience while being careful not to patronize.

Paul Hetherington, president of the BAC, offered an additional closing comment to McPhee’s list by drawing attention to the low FODMAP diet. FODMAP stands for Fermentable Oligo-Di-Monosaccharides and Polyols. The FODMAP diet is currently being prescribed for those suffering from irritable bowel syndrome and focuses on a more all-encompassing gut health

scenario than a gluten-free one. Stanford University’s digestive health centre identified these items as being FODMAPs in the diet: “fructose (fruits, honey, high fructose corn syrup (HFCS), etc.; lactose (dairy); fructans (wheat, onion, garlic, etc., fructans are also known as inulin); galactans (beans, lentils, legumes such as soy, etc.); and polyols (sweeteners containing sorbitol, mannitol, xylitol, maltitol, stone fruits such as avocado, apricots, cherries, nectarines, peaches, plums, etc.” / BJ

Searc h i n gfora

Getting into gluten-free has never been easier than with the versatile Vemag.

A single Vemag will prove to be the most flexible machine in your plant. The Vemag incorporates a variety of innovative attachments that allow it to produce all types of gluten-free products. It can easily handle the stickiest and most fluid gluten-free doughs and batters The Vemag’s modular design allows it to be used as a dough divider, cookie dough depositor, brownie sheeter, bar extruder, batter depositor and more. As your product mix changes, the Vemag can adapt with you.

The Vemag’s double-screw pumping technology sets the standard for portioning accuracy, speed and product quality…while never overworking the product And its stainless steel construction and an easy-to-clean design with total access to the product path allows complete sanitation of the Vemag, while eliminating any cross-contamination risks Test the Vemag for yourself –schedule a demonstration at the Reiser Customer Center today.

2480 Viking Way, Richmond, BC V6V 1N2

Contact: Richmond: Debbie Fawcus 604-303-1700 or 800-665-9441

Calgary: Lennie Lardeur 403-243-5493 or 800-661-1248; Edmonton: Chris Rossnagel 780-483-2831 or 800-363-8234; Toronto: Shawn Boodhram 905-829-9187 ext. 109 or 800-361-4998; Montreal: Nancy Beecraft 450-667-8888 or 800-361-0758

Products offered: Clean labelled and kosher dough conditioners for use in the production of frozen dough, par-baked and frozen baked goods. Deliveries: Supply bakers across most of Canada from key locations in B.C., Alberta, Manitoba, Ontario and Quebec.

Major customers: Wholesale bakery manufacturers, independent bakeries, in-store bakeries, foodservice and the food industry.

Assistance offered: Sales, marketing and technical expertise.

Company comments:BakeMark Canada offers a variety of frozen dough conditioners. We also supply pre-made and par-baked products for your baking ease and convenience. Contact your local branch for all your bakery ingredient needs.

70 Whitmore Rd., Woodbridge, ON L4L 7Z4

Contact: Sandra L. Zanette, Director of Marketing & Business Development

Tel: 905-850-9229 Fax: 905-850-9292 Website: www.backerhausveit.com

Products Offered: Artisan Breads, Rolls & Soft Bavarian Pretzels; Frozen par-baked or fully baked; Sliced or Unsliced; Prepackaged or Bulk Deliveries: Canada and the United States with local broker and distribution support.

Major customers: Retail in-store bakeries, Foodservice Commercial/Industrial Operators, Independent bakeries, Private label, Co-packing Distributors.

Assistance offered: New product development, Technical support and Merchandising assistance can be provided.

Company comments: Backerhaus Veit remains a true Craft Artisan Bakery offering European handcrafted quality breads, rolls and pretzels in a wide range items that meet current market demands. Backerhaus Veit is a Food Safe company with a BRC Grade ‘A’ Rating and certified with WBE Canada (affiliated with WBENC).

7905 Quivira Rd., Lenexa, KS 66215

Contact: Bob Feuerstein

Tel: 303-589-7617 Fax: 913-888-4970

Email: bfeuerstein@caravaningredients.com

website: www.caravaningredients.com

Products offered: Artisan breads and rolls, specialty bread and rolls including holiday items, grain bread and rolls, Hispanic products, focaccia, pizza dough balls, rye and pumpernickel bread, white bread and rolls including French and Italian breads, pan bread, dinner rolls, Kaiser rolls, long and round sandwich rolls, hamburger and hotdog rolls.

Major Customers: Retail and In-Store Bakeries, Wholesale Bakeries, Foodservice, Foodservice Distributors

Company comments: Caravan Ingredients is a leader in food ingredients. We encompass over 100 years of experience delivering consistent quality to our customers. With a broad portfolio of ingredients including bread mixes, specialty bases, frozen dough, vitamin and mineral pre-mixes, functional ingredients, emulsifiers & flour fortification, we serve a wide range of customer channels.

We care. Our desire and commitment to our customers’ success

We can help. Our ability to bring products and ideas that help our customers sell

GOURMET

Suite 502-4190, Lougheed Highway, Burnaby, BC V5C 6A8

Website: www.gourmetbaker.com

Contact: David MacPhail, Senior Vice President and General Manager

Tel: 604-298-2652 Fax: 604-296-1001

Products offered: Manufacturer and marketer of baked and unbaked desserts and breakfast pastries. Broad range of frozen bakery products including dessert bars and squares, un-iced sheetcakes, puff and Danish pastry, crumpets, croissants, cinnamon buns, round cakes, loaf cakes and slab cakes.

Deliveries: Throughout Canada and the United States. Minimum order 150 cases, shipped via frozen reefer truck through distributors.

Major customers: In-store bakeries, retail bakeries, supermarket chains and the foodservice segment. Assistance offered: Sales and product training is available from our sales network across Canada. Company comments: The Gourmet Baker brand is well recognized throughout Canadian in-store bakeries and the foodservice industry. Gourmet Baker has developed a reputation for delivery of high quality and value products as evidenced by its long-standing customer relationships. Through its extensive product offerings, the company provides customers with considerable choice and the convenience of one-stop shopping.

75 Vickers Rd., Toronto, ON M9B 6B6

Tel: 416-233-5851

OR Customer Service 416-239-3571 or 1-866-277-3663

Website: www.dawnfoods.com

Products offered: Dough Conditioners and Bread

Bases ideal for frozen dough, par-baked and thaw’n sell bread products. Dawn offers a complete line of frozen bakery products you can trust. Developed for today’s bakery with ready to bake, freezer to oven and thaw’n sell varieties.

Deliveries: North American Distribution. Major customers: Craft Bakeries, In-Store Bakeries, Wholesale Bakery Manufacturers, Food Service.

Assistance offered: Technical support, and customized product development. Company comments: Dawn Foods, a world leader in the manufacturing of bakery ingredients and finished bakery products offers a complete line of products to serve bakery customers. Our three pillars of service: We know. Our knowledge of the baking process and industry

4145 Spallumcheen Pl., Armstrong, BC V0E 1B6

Contact: Bruce Glacier, Sales Manager

Tel: 250-546-0311

Email: bruceokfrozendough.com

Website: www.okfrozendough.com

Products offered: Complete line of frozen bread and roll dough, including white, whole wheat, multigrains, ryes, sourdough, and other specialty items.

Deliveries: Snow Cap and other major bakery distributors in Western Canada. Customers In-store bakeries and food service suppliers.

Company comments: OK Frozen Dough provides quality bakery products to complement any in-store bakery program. Through a network of the best ingredient suppliers, and on-time distribution, OK Frozen Dough is a trusted supplier to the grocery industry. Remember our moto: WE help YOU make DOUGH.

75 Green Ct., Ajax, ON L1S 6W9

Tel: 905-426-5188

Email: rburge@olymicwholesale.com

Website: www.olympicwholesale.ca

Products offered: Complete line of dry and frozen products for all your bakery needs including paper, cleaning supplies, cake decorating and frozen finished products. Suppliers of house brands: Olympic, Tasty, Bakers and our all natural Pure Foods Products line since 1936. A variety of spelt, organic, all natural and retail products are available. Areas serviced: All of Ontario (some northern areas excluded) and Quebec.

Assistance offered: Technical support from all manufacturers as well as providing technical documentation upon request.

Company comments: Committed to Service Excellence.

370 North Rivermede Rd., Concord, ON L4K 3N2

Website: www.primepastries.ca

Contact: Steven Muchnik

Tel: 905-669-5883 Fax: 905-669-8655

Products offered: Pastries: Croissants, Danish, Turnovers, Cinnamon Buns. Unbaked Frozen, Freezer-to-Oven, Thaw and Serve

Dough products: Croissants, Danish, Turnovers, Puff Pastries, Cinnamon Buns. Frozen Baked

Croissants, Danish, Cinnamon Buns (Thaw and Sell/Serve). Freezer to oven pastries. Kosher and Pareve pastries.

Deliveries: Throughout Canada, US, Carribean, Middle East and Asia.

Major customers: Supermarket chains, foodservice operators, food distributors, bakeries, c-stores, private label retailers.

Assistance offered: Technical and product development assistance. Custom design service. Designation: BRC, HACCP and Kosher Certified. Company comments: Prime Pastries is a 100% Canadian owned company that is located in Concord, Ontario. We offer an infinite range of products either in the raw frozen, “proof and baked” and “thaw and serve” format. As a contract manufacturer, Prime Pastries is capable of adapting to your needs. We can manufacture according to your specifications for size, ingredients and packaging. Our products can be found in major supermarkets and foodservice outlets in Canada and USA.

2095 Meadowvale Blvd. Mississauga, ON L5N 5N1

Contact: Brenda Williams, Sales Tel: 905-567-0660 ext. 4604

Products offered: Complete line of breads (frozen dough/pre-proofed/par-baked), rolls, sweet goods, donuts, cakes, pies and specialty items.

Deliveries: Throughout Canada from Ready Bake warehouses in Regina/Calgary/Vancouver/ Mississauga/Montreal.

Major customers: In-store bakeries and foodservice operations.

Assistance offered: On-site training in production, merchandising and bakery management. Regular follow-up by technical sales staff comprised of qualified bakers.

Company comments: Your success is the core of our business.

149 Rowntree Dairy Rd.

Woodbridge, ON L4L 6E1

Website: www.richscanada.ca

Contact: Kevin Spratt Tel: 1-905-945-7807

Product Offered: Rich’s has an extensive lineup of breads and rolls, including Roll Dough, Par-Baked Breads, and Fully Baked Breads. Rich’s also has an exceptional lineup of specialtyflatbreads and a premium Gluten-Free offering. In addition, Rich’s offers: sweet goods, cookies, donuts, desserts as well as a full spectrum of whipped toppings and icings & fillings.

Deliveries: National distribution through local and broadline distributors. Mimimum orders vary across Canada.

(DIVISION OF A & L FOOD DISTRIBUTORS INC.)

SUPPLIER OF FROZEN AND RAW INGREDIENTS FOR THE BAKING INDUSTRY

Tel: (416) 252-4660 Fax: (416) 252-9993 25 - 8 Connell Ct., Toronto, ON M8Z 1E8

• BAG CLOSURES & LABELS • BAG CLOSING EQUIPMENT • KWIK LOK TAGS

PIERRE GENDRON Regional Sales Manager

254 Rue De Thebes, Laval, QC H7M 5P2 1-888-KWIK LOK (594) 5565 Cell: (514) 710-9364 • E-mail: pierreg@kwiklok.com

176 SHELDON DRIVE, CAMBRIDGE, ONTARIO N1R 7K1

TELEPHONE: (519) 623-5140 FAX: (519) 623-1421 1-888 KWIK LOK (594-5565)

Model JN Semi-Auto Divider/Rounder

4-in-1 machine capability, 36, 18, 9 & 6-part heads

Heads can be removed or interchanged without tools in seconds

NSF & UL certified, Made in America

2-Year parts & labor warranty.

Heads can be washed in a sink or dishwasher.

High production rate - low maintenence Easy to train and operate.

Model BMIH-36/18 Dough Divider

2-in-1 machine capability - 36 & 18-parts

1oz up to 8oz each piece scaling range.

Mounts to a Portable Stand for mobility (Optional) Divide many types of dough including sticky pie and cookie dough in addition to bread and bun doughs. Contact our Canadian Representative @ eric@bloemhof.com www.dutchessbakers.com - sales@dutchessbakers.com

Hailed as a “revelation” when it first appeared in 2004, Jeffrey Hamelman’s Bread is a legendary resource praised by baking luminaries from around the world. Explaining complex techniques with simple and helpful illustrations, the book includes recipes for a vast array of breads, including sourdoughs, brioche, authentic rye breads, flat breads, French breads, and much more.

• Features nearly 150 detailed, step-by-step recipes, along with vivid drawings and photographs showing techniques and finished products

• Written by Jeffrey Hamelman, one of fewer than 200 Certified Master Bakers in the United States and a recipient of the Golden Baguette Award (2005), the highest honor bestowed by the Bread Baker’s Guild of America

• Fully updated to include the latest techniques, methods, trends, and bread varieties

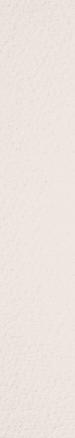

By Jane Du MM er, r D

There are many ways to harness the power of protein in baking for today’s customers, beginning with breakfast

Make protein a priority at breakfast” was an important message from new research presented at the American Society for Nutrition’s Experimental Biology (EB) Conference in sunny San Diego in April. After our long winter, it was great to get the extra vitamin D during the off-hours and hear about the interesting studies during the conference hours. The key takeaway from EB is that we need to distribute highquality protein throughout the day and not just end-load it at the supper meal. Higher-protein diet regimes continue to gain scientific support as solutions to preserve muscle mass, promote weight loss, and to maintain a healthy weight throughout our lives.

}Adding hemp powder to baked goods is one way to increase the protein content.

breakfast is consumed (and there are many breakfast skippers among us) by Canadians and Americans, the protein content each person gets is only about 8 per cent of the meal’s total calories. Leidy confirms that for our traditional

Our research demonstrated that when people consumed 30 grams of protein at a 350 calorie breakfast, this was the threshold to stimulate satiety.

North Americans are accustomed to traditional-carbohydrate and calorie-loaded bagels, muffins, breads and sweet goods for breakfast. There is a great opportunity for the baking industry to design new high-protein breakfast foods to appeal to this market.