It’s the perfect mix of protein and pride. Ask your supplier for flour made from 100-per-cent western Canadian wheat.

It’s the perfect mix of protein and pride. Ask your supplier for flour made from 100-per-cent western Canadian wheat.

BY BRIAN HARTZ

Canada is quietly making strides toward safeguarding its food supply chain – and Canadian bakeries and allied trades are a key part of the solution.

In mid-May, buried under the fervour of hockey playoffs and TV series finales, came an announcement that the federal government would, according to the Canadian Press, spend $2 million on the West Hawk Lake Zoning Initiative, a facility near the ManitobaOntario border that “will monitor the movement of animals and agricultural products between Eastern and Western Canada.”

Then came the news that Ontario-based chemical manufacturer L.V. Lomas, a major supplier to the baking industry, had achieved Hazard Analysis and Critical Control Points (HACCP) certification. Last year, London, Ont.-based glutenfree cookie and biscotti maker Touché Bakery was granted the same certification – becoming Canada’s first bakery to do so.

HACCP, if you’re not already aware, is one of the world’ strictest food-safety systems. Unlike finished-product inspection, it aims to prevent chemical, biological and physical threats to food manufacturing, and thus protect public health. Without going overboard on the details, suffice it to say it’s a certification that’s difficult to achieve and even harder to implement and track, requiring a thorough analysis of hazards, diligent monitoring, establishment of corrective actions, and transparent record keeping and traceability at all stages – or critical control points – of the food-production process.

If all of these steps sound expensive, well, they are. Food manufacturers spend millions of dollars on new equipment and systems that will help their plants meet HACCP standards. But the financial outlay doesn’t stop there – the facility’s daily routines have to change, staff need to be retrained, new suppliers must be contracted, additional personnel might need to be hired . . . you can see where I’m going with this.

Bakeries and other food manufacturers are bending over backward, against their own financial interests, to ensure the products leaving their plants are as consistently safe as is humanly possible.

Bakeries and other food manufacturers are bending over backward, against their own financial interests, to ensure the products leaving their plants are as consistently safe as is humanly possible. Yet, outside trade publications such as Bakers Journal, you wouldn’t know the industry is making any effort whatsoever to protect consumers from contaminated food. In fact, in late March the Ottawa Citizen, in an editorial titled “Food Safety Under Microscope,” bemoaned the fact that the federal government, in the wake of the deadly Maple Leaf listeriosis outbreak in 2008, had been too slow in hiring 70 additional food inspectors, leaving food companies with “too much responsibility for policing themselves.”

Perhaps there’s some truth to that, but what the editorial fails to recognize is how food makers have embraced that responsibility – to the tune of millions of dollars out of pocket. The Citizen’s arbiters of opinion seem to think responsible business practices get thrown out the window when bureaucrats aren’t snooping around trying to turn up dirt. I challenge them to pay a visit to Touché Bakery (as I did last year) or any of the other HACCP-certified food makers in this country and see for themselves the tremendous investment in food safety taking place in this country.

A report published in early 2010 by the Produce Safety Project (PSP) estimates acute food-borne illnesses cost the United States $152 billion per year in health care, lost time in the workplace and other economic measures. North of the border, of course, such losses would be lower, mainly due to the vast difference in population size and gross domestic product. But as more and more Canadian companies step up to take responsibility for the safety of their products and, by extension, the health of the nation’s people and economy, detractors can’t say the food industry isn’t doing its part.

In fact, it’s taking on significant financial risk, all for the sake of a safe food supply – and that’s an investment that’s bound to pay off. / BJ

Happy reading,

JULY 2010 | VOL. 70, NO. 6

EDITOR | Brian Hartz editor@bakersjournal.com 1-888-599-2228 ext. 250

TECHNICAL

EDITOR | John McColl, Puratos Canada jmccoll@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

SALES ASSISTANT | Barb Comer bcomer@annexweb.com 519-429-5176 1-888-599-2228 ext. 235

PRODUCTION ARTIST | Brooke Shaw

GROUP PUBLISHER | Martin McAnulty mmcanulty@annexweb.com

PRESIDENT | Mike Fredericks mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710. RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: lmorrison@annexweb.com

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Publishing & Printing Inc.

SUBSCRIPTION RATES

Canada — 1 Year $ 30.00 (with GST $31.50 #867172652RT0001, with HST/ QST $33.90)

USA — 1 Year $ 45.00 USD Best pricing is available online at www. bakersjournal.com

Send your subscription request to: Bakers Journal

P.O. Box 530, Simcoe, ON N3Y 4N5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940 E-mail: lmorrison@annexweb.com

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2010 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

briefly | Ocean Spray, Klass strengthen ties | Panera launches pay-what-you-want bakery cafe | Pulse industry to benefit from CIGI funding | FOR MORE news in the baking world, check out our website, www.bakersjournal.com

North Dakota-based SK Food International has hired Tawny Ohnstad to provide marketing and logistical support relating to the company’s premium quality ingredients, which include certified organic and conventional non-GMO products. Ohnstad graduated from Minnesota State University Moorhead with a degree in mass communications and advertising.

Floyd Gillis has joined packaging solutions supplier Multivac Inc. as product manager for labelling and printing systems. Gillis comes to Multivac

from SpectraGraphics Labels, where he worked for seven years as an account executive. California food equipment maker FoodTools has promoted Brad Miller to sales and service rep for Alberta. He will continue to serve his current client base in British Columbia. Miller acquires the Alberta area from Chris Clemens, who has moved into the FoodTools marketing manager role in Santa Barbara, Calif. Miller has been with FoodTools since 2001 and has managed sales and service territories in the western United States, Australia, New Zealand and parts of Asia. He can be reached at bradm@foodtools.com or 1-805-962-8383.

Ocean Spray has named Klass Ingredients Canada Ltd. as its sole ingredients broker in Canada to consolidate distribution in the region. Klass will now represent Ocean Spray’s ingredient portfolio exclusively in eastern Canada, which includes Ontario, Quebec and the Maritimes.

The growing popularity of fruit ingredients in the Canadian market has led Ocean Spray to streamline the purchasing process for new and existing customers.

Klass Ingredients Canada Ltd. was founded in 1997, expanding parent company Klass Ingredients Inc.’s reach, but the companies’ longstanding partnership dates as far back as the 1980s.

VANCOUVER – After competing in local competitions across Canada, five top culinary students represented their region in a final competition to prove who is beyond compare when it comes to pears.

Pear Bureau Northwest’s third annual Pear Excellence recipe competition, open only to Canadian culinary students, named a national grand prize winner in early May following a heated competition that took place at the Culinaria Restaurant at the Art Institute of Vancouver. Stephanie Duong of George Brown College in Toronto was crowned the

winner, with her “Spiced Pear Buckwheat Pancakes with Pear Caramel Sauce and Mascarpone Cream” recipe earning her top honours from the judges – and a $5,000 cash prize.

“I wanted to create a pear recipe that could be served both as an entrée at breakfast or as a dessert at dinner,” said Duong.

The four other finalists didn’t go home empty-handed, as each earned a $1,500 cash prize. They were Kyle Mar of the

International Culinary School at The Art Institute of Vancouver, representing British Columbia; Cyril Roach of Nova Scotia Community College, representing the Maritimes; Adam Cenaiko of the Saskatchewan Institute of Applied Science and Technology, representing the Prairies region; and Norelle Donahue of LaSalle College, representing Quebec.

To view the winning recipes, visit www.usapears.org/excellence.aspx.

WINNIPEG – Thanks to an investment of more than $1 million, the Canadian International Grains Institute (CIGI) will embark on a project exploring the processing of pulses into flours for use in food products. Working with Pulse Canada, industry partners, and other food development centres across Canada, the four-year Pulse Flour Milling & Utilization in Food Products Project has been made possible with support from the government of Canada, Saskatchewan Pulse Growers,

Alberta Pulse Growers, and the Canadian Special Crops Association.

“With this investment, CIGI will be able to help establish Canada as a leader in pulse ingredient processing by developing an understanding of how processing affects the functionality of pulse crops,” says CIGI executive director Earl Geddes, adding that the project will enable CIGI to provide superior technical marketing support to Canada’s pulse industry and their customers worldwide.

CIGI conducts research and technical support for the Canadian field crop industry, offering expertise in milling, baking, extrusion, and pasta and noodle production. Canada is a global leader in the production and export of peas and lentils and a major exporter of beans and chickpeas, says Geddes. The Canadian pulse industry has a dominant share in pulse consuming markets around the world, exporting more than $2.2 billion in pulses annually.

CLAYTON, Mo. – Panera Bread Co. is asking customers at a new bakery café to pay what they want.

The U.S. bakery and restaurant chain launched a new non-profit store in Clayton, Mo. – an upscale suburb of St. Louis – that has the same menu as its other 1,400 locations. But the prices are a little different – there aren’t any. Customers are told to donate what they want for a meal, whether it’s the full

suggested price, a penny or $100.

Run by a non-profit foundation, the new store is the first of what will Panera hopes will be many more. If it can sustain itself financially, Panera will expand the model around the United States within months. It all depends on whether customers will abide by the motto that hangs above the deli counter: “Take what you need, leave your fair share.”

– The Canadian Press

GUELPH, Ont. – Guelph Food Technology Centre (GFTC) has been accredited by the American National Standards Institute (ANSI) as a certification body with a current scope to deliver certification to the Safe Quality Food (SQF) and British Retail Consortium (BRC) standards.

Food industry stakeholders, such as retailers and food service providers, are requiring that their suppliers become certified to Global Food Safety Initiative (GFSI)-recognized food safety standards

such as SQF and BRC. To achieve certification to these standards, it’s become necessary for on-farm and post-farm establishments to work with certification bodies such as GFTC. ANSI accreditation assures clients that GFTC’s management system as a certification body is compliant, current and accountable.

GFTC is the first organization with a Canadian head office to receive this recognition and certify to the SQF and BRC standards.

OTTAWA – Algonquin College held its second annual baking competition on April 17; winners were Julia Gindra in the bread category, Connie Verbeke in cakes and Cindy Jones in cookies. Gindra was named the overall winner.

The competition’s judges were Ron Eade of the Ottawa Citizen, Willy Utter of Swiss Pastries, Annina Klaese of Klaese Bakery, and last year’s winner, Sylvia Santaromita.

The contest was “a great success,” said program co-ordinator Tony Bond. “I would like to thank all the competitors and their helpers for making it the success it was. All the competitors did a fantastic job and made it hard for the judges, as it was very close in all three sections.”

From left: DecoPac sales consultant Dave Cohen with Traynor’s staff John Traynor, Bill Lloyd, Mark Jones, Bob Chadwick, Randy Maltby and John Vangroningen.

DecoPac recently named its 2009 Canadian Distributor of the Year: Traynor’s Bakery Wholesale in Hamilton, Ont. DecoPac congratulates Traynor’s for a very successful year.

BY DR. JOHN MICHAELIDES

Antioxidants are in high demand, but do you know what they do, where they come from and how to utilize them in your products?

Antioxidant is a buzzword in today’s food marketing strategies. Consumers are increasingly aware of the connection between antioxidants in food and prevention of chronic diseases, such as cancer and diabetes. Recent market research data from the United States indicates that a large number of consumers will select products that contain the phrase “rich in antioxidants” on the package, and many will consider buying products labelled “antioxidants added.”

But what exactly are antioxidants, and how do they work? First, let us define oxidation. Simply put, oxidation is the effect oxygen has on fats and oils during their shelf life.

}In the food industry, fats and oils are used as functional ingredients. These are mainly triglycerides of different composition, and their configuration determines their oxidative stability. For example, saturated fats or partially hydrogenated fats are very stable and resistant to oxidation. However, mono and polyunsaturated fats and oils are more prone to the oxidation process.

process. For example, after being cut or peeled, apples and potatoes will turn brown due to an enzyme naturally present in these foods. This type of oxidation is caused by the activity of certain enzymes such as lipases and peroxidases. This process affects fruits and vegetables as well as grains and other seeds. As soon as the grain kernel or seed is broken open, the oxidation process begins. By exposure to heat, it is possible to deactivate these enzymes and extend the shelf life of cereal ingredients such as wheat germ and bran. However, the auto-oxidation process will continue and the addition of antioxidants will be required to extend the shelf life of these products or ingredients.

Antioxidants are substances that will slow or eliminate oxidation of fats and lipids. Their use will prevent the rancidity of foods or damage to cell membranes in our bodies. Several antioxidants are available for use in food

Recent market research data indicates that consumers will select products that contain the phrase ‘rich in antioxidants’ on the package, and many will consider buying products labelled ‘antioxidants added.’

processing. These include synthetic antioxidants such as butylated hydroxy anisole (BHA), propyl gallate (PG) and tertiary butyl hydroxy quinone (TBHQ), and natural antioxidants such as rosemary extract, tocopherols (vitamin E), cloves and cinnamon.

Grapes are an excellent source of antioxidants.

mination of oxygen radical absorbance capacity (ORAC) value.

The highest quantities of these antioxidants are often present in outer layers such as skin and bran, which, based on traditional processing, are discarded as byproducts. Recently, however, the health benefits of these byproducts are beginning to be recognized. Investigations at the Guelph Food Technology Centre resulted in a new process for the production of grape-skin flour, which is high in the antioxidant resveratrol.

The oxidation process, before it is even detectable, begins with the formation of radicals, which initiate and accelerate the process that will eventually result in rancidity. This process is also referred to as auto-oxidation because is not mediated by the presence of enzymes, as we will discuss later on.

Oxidation also affects plant and animal tissues. For example, human and animal cell membranes contain phospholipids, which play an important role in the functionality of the cells. These radicals will result in the oxidation of the phospholipids and damage to the cells. This process may eventually result in the onset of chronic diseases.

Enzymes can also mediate the oxidation

The recent emphasis on antioxidants, however, focuses on the relationship of these substances and the prevention of chronic diseases. Indeed, much research has been carried out in recent years connecting this relationship. The focus has been in the area of natural antioxidants present in fruits, vegetables, seeds, grains and other plant parts. Many fruits and vegetables have been investigated for their antioxidant ability, and their capacity has been determined. In addition, the actual substances responsible for the antioxidant activity within these vegetables and fruits have been identified.

Natural antioxidant activity can be measured by different methods. One of the most popular methods is the deter-

The food processing industry is pressed to reduce byproducts or find ways to add value to them. There are various reasons for this, including economics, sustainability and environmental issues. Indeed, researchers in many parts of the world are investigating byproducts such as fruit peelings, pulp, seeds, skins and many others for their antioxidant capacity and the production of ingredients from these byproducts. Specifically, skins of tomatoes, apples, peaches, pears, grapes, plums and other fruits were found to often contain more antioxidants than the whole fruit itself.

Commercial production processes for stable ingredients from these antioxidantrich byproducts must be carefully considered. Normally, ingredients for the food processing industry are in the form of powders. The production of powders from these products requires dehydration – which is usually achieved via exposure to heat – but this reduces, and sometimes completely eliminates, the antioxidant activity.

BY DIANE CHIASSON

Want your bakery to be the talk of the town? Here’s how to build brand recognition in six simple steps.

The development of strong brand recognition should be an essential part of your bakery’s business plan. Creating a brand helps you make a statement of what your operation is all about. Your brand should convey quality, consistency, familiarity, and most importantly, trust. Customers want to come into your restaurant and know they will have a good experience because that’s what your brand tells them.

Good branding is more than just a catchy slogan or a memorable logo. It’s about your entire business and culture. But before you start thinking about writing a catchy slogan that will have millions of people singing your song, you need to take a step back and consider the following questions:

}professionals? Are there a lot of offices? Do you get a good lunch crowd, or after-work crowd? You need to cater your brand image to the right people.

Define your brand using as few words as possible, and drive your definition to your customers. You should be able to tell potential customers exactly what to expect from your restaurant bakery by stringing together a few key words such as “homemade,” “comfort,” “stylish,” “elegant,” “fresh” or “fun.” Just by reading the key words, customers should be able to tell what type of establishment you are running.

Everything in your bakery must convey what your brand wants to say, including your interior design and décor, menu,

Good branding is more than just a catchy slogan or a memorable logo. It’s about your entire business and culture.

Where do you see your business in the next five to 10 years? Do you plan to franchise your bakery? Who is your target market? Where do you see yourself in the marketplace? How do you differentiate yourself from your competition? What promises do you want to make to your customers about your products?

After answering these questions, you will have a better sense of what type of brand you wish to establish for your operation. A strong brand image will bring your company added value, command higher prices and attract better employees. Most of all, it will bring you more money. But it needs to be the right brand for the right audience.

Do not try to create a brand that will appeal to everyone. You will end up with a brand that is unclearly defined. Target your brand to the specific demographics to which your bakery will appeal. Consider your neighbourhood – is it full of families, students or condo-dwelling urban

prices, food, drinks, uniforms, marketing, advertising, website and customer service. Your brand has to be cohesive throughout your entire operation, and must reflect your brand’s desired image and vision.

Developing a powerful brand image involves the entire design of your bakery, from lighting and flooring to powerful graphic images and menu boards.

“Ensure that the entire look and feel of your bakery is consistent by keeping to a colour scheme. Have a uniform, recognizable style that is apparent throughout your establishment; whether it be inside, outside, online or in print.”

The most important element of branding is being able to deliver on what your brand is promising. For example, if you say that everything you sell in your bakery is fresh from your oven, make sure that you do not outsource any of your products. You need to gain the trust and loyalty of customers by standing by your brand name and what it offers.

You want your brand to stand out, but also to be consistent and positive.

Signage and point-of-sale (POS) materials are key in developing instant recognition of your brand. Use POS materials to highlight upcoming specials and promotions, but make sure your brand logo and slogan are prominently featured. It is important to create visually stimulating signs and displays so that your customers will remember the images from your POS materials even after they have left your bakery.

Once you have established your brand, you can build on it by offering retail merchandise that features your brand name and slogan, especially if you have a particularly witty slogan with a double meaning that can help you to launch a successful T-shirt sales operation. Other items to consider include baking equipment, serving dishes, aprons or magnets. The possibilities are endless. Also, not only can you stand to make a tidy profit from sales of your merchandise, but it also acts as free advertising for your bakery.

Implementing these six simple steps toward greater brand recognition can make all the difference between everyone knowing your bakery, and being just another name in the phonebook. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping food service, hospitality and retail operators increase sales for more than 25 years. Contact her at 416-9261338, toll-free at 1-888-926-6655, e-mail chiasson@chiassonconsultants.com, or visit www.chiassonconsultants.com.

Well, it’s not just bread. It’s so much more.

Our breads are a means for you to delight your customers, and delight yourself when you see your sales grow. Our breads are available in the local formats your patrons are asking for, and they are customised to your unique needs.

At Upper Crust, we don’t just sell breads & rolls, croissants, bagels, pastries, and other bakery goods — we look to partner with our customers and watch their business thrive!

Please call us right now at 1.800.701.8069. We’d love to partner with you today.

Delicious bakery goods, and so much more.

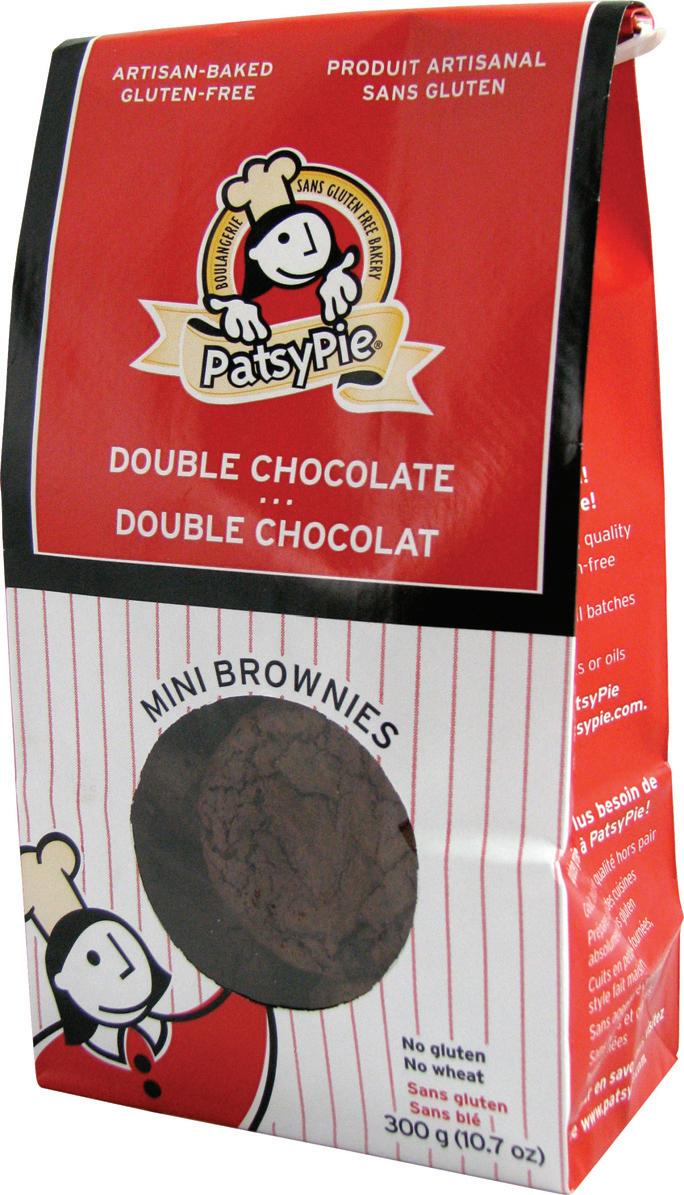

Patricia Libling has turned her dreams of gluten-free deliciousness into reality | BY

life’s work making

PatsyPie goes straight to the source and looks to the public for new product suggestions. They not only try out their goods on clients but they also get non-celiac clients to taste-test their treats. And they take all the feedback they receive very seriously.

“We never take clients’ letters lightly,” Libling says.

The most recent addition to PatsyPie’s line of gluten-free baked goods is lemon shortbread, which came about after the bakery was flooded with

requests for a good GF shortbread cookie. In fact, at the time of this interview, PatsyPie was preparing to ship a top-secret prototype of a new product to a client in the Maritimes who was the one that suggested it.

“Our research and development department consists of only myself and one other baker,” says Libling. “We try and come out with a new product every year.”

Just before this issue went to print, Libling told us PatsyPie had become a certified kosher bakery, meaning new

products in that category are on the way.

“We are now kosher through Earth Kosher,” she said.

PatsyPie reaches clients and sells through a master broker in Ontario called Canadian Natural and Specialty Brands. Libling really credits her North America-wide distribution success to this company.

“I was going to sell on my own but this has worked out perfectly – they brought the products to territories I

MONTREAL – Patricia Libling of PatsyPie

Bakery often receives calls from clients who say, “Oh no, the worst has happened – I found out I have celiac disease.”

However, Libling thinks, in a certain way, this can be considered almost good news because at least they know what the problem is.

“Yes, it’s a change of food lifestyle, but you also feel better,” she says.

That wasn’t the case for this busy mother, who suffered from lifelong digestive problems and was only diagnosed with celiac disease later into her adulthood. She went through years of pain, medical appointments, tests and prescriptions, and even had her appendix removed (unnecessarily, she believes) when she was pregnant. It was only when she was finally diagnosed that she was able to gain control of her symptoms and find a proper diet to help her feel healthy again. And the regimen that finally ended up working for her was to change her diet and eat glutenfree (GF) foods.

As most of us know thanks to the rapid growth of the gluten-free market, gluten – or the “glue” that binds proteins in bread products – is found in wheat, rye, barley and oats. Celiac disease is an autoimmune disorder of the small intestine, and when gluten is ingested, it irritates the lining of the small intestine, which can cause everything from chronic diarrhea to abdominal swelling, pain, flatulence, itching, rashes and anemia.

}I didn’t like what was out there. I had always baked, so I went back to my old recipes and came up with a product that tasted ‘normal.’

“I didn’t like what was out there,” she says. “I had always baked, so I went back to my old recipes and came up with a product that tasted ‘normal’.”

Libling isn’t the only one in the family who has to deal with celiac disease –one of her daughters has it, too. This has made her search for delicious, wholesome gluten-free food even more crucial. However, Libling wasn’t at all impressed by what she found on the market.

Her first gluten-free homemade goodie was biscotti, one of the company’s most popular products today. “I started peddling my biscotti around the neighbourhood,” she says, “and I had quite a bit of luck – everyone liked it. A week later I was picked by my first distributor.”

That was eight years ago. Today, PatsyPie (a nickname Libling’s husband gave her years ago) gluten-free baked goods are carried in every province and across the United States. They’re even sold in Puerto Rico and served on Air

Canada flights. Located in a modest facility in St. Laurent, just outside Montreal, 12 employees, including Libling herself, hand-make each cookie, brownie and muffin.

That’s right – apart from the fact that they sell only gluten-free baked goods, PatsyPie also prides itself on being an artisan bakery.

“We have no big machinery – everything is handmade in small batches,” Libling says proudly. “It’s not a factory cookie – I know my product is the best because it’s real.”

Ensuring that the products remain gluten-free throughout the manufacturing process is paramount, and every step of production is closely monitored.

“We test all of our products here, and I make sure that I have a paper trail so I always know where all my supplies come from,” Libling explains. “And our employees, while they are here, only eat gluten-free.”

didn’t even know about and really put me on the map,” she says. “Our broker also bought a gluten-free bread company and, coincidentally enough, two years later, his granddaughter was diagnosed with celiac disease. So he really understands GF products.”

Marketing and advertising for PatsyPie is a relatively straightforward process for Libling – her husband Michael has been in that industry for more than three decades and volunteered to lend his expertise.

“He thought I was nuts when I started, and I think he felt badly for me, so he came up with a logo,” she says. “Then, with his friends at Catalpa Design, they came up with my bags. Today, Michael does all my advertising – he’s the one who puts ads in all the celiac magazines and newsletters (including the Canadian Celiac Association’s “Celiac Circular” as well as its various chapter newsletters). I’m really lucky.”

Libling attends most of the major natural food shows, including the Canadian Health Food Association’s Expo West in Vancouver last month, and her broker represented her products at the May 16-18 Bakery Showcase in Toronto.

What some people would view as a challenge, Libling has embraced with open arms and open ovens. While celiac disease may have affected her for many years of her life, Libling is taking the knowledge she’s gained from living with the disease and combined it with her love (and obvious knack) for baking, helping hundreds of people along the way enjoy desserts again.

PatsyPie’s line of specialty baked goods is truly giving celiac clients a melange of guilty pleasures without the guilt (or the gluten). / BJ

On the web:

PatsyPie Gluten-Free Bakery: www.patsypie.com

No contradiction – just the MIWE econo: • Holds up to 10 trays • Double-layered large glass viewing window with halogen lights • Built-in steam system capable of pulsing or full steam cycle • 4 speed reversing fan in the easy-to-clean baking chamber

• 30 baking programs, 12 of which are preset keys with programmable pictograms

• 5 baking phases per program

• Real-time clock with programmable night start-up function

• Computer interface for storage of programs on a PC, laptop or handheld.

Sounds great? That’s what it is! Call us today. www.miwe.com

Food safety as a corporate culture and adherence to global standards were two overriding themes at Guelph Food Technology Centre’s (GFTC) Safe Food Canada 2010 symposium.

The symposium, held in Toronto in March, emphasized the need to take responsibility for food safety and quality in a proactive manner across the supply chain. Speaker after speaker stressed the importance of going above and beyond the minimum standards.

Their point was that a food safety crisis doesn’t just affect the company, the brand and public health; it affects the entire sector and supply chain. For instance, when a company recalls a deli meat product, deli meat sales decrease across the board. That affects everyone from the farmer to the retailer.

The answer is twofold: global standards and a corporate culture of food safety.

At the symposium, GFTC vicepresident Frank Schreurs hosted a presentation on the Global Food Safety Initiative (GFSI). GFSI benchmarks and recognizes certain food safety standards. To a buyer, compliance to a GFSI-recognized standard says that the food safety program used by the company adheres to globally accepted standards.

}GFTC vice-president Frank Schreurs

Companies have so much at stake when it comes to food safety that it’s important to create a ‘culture of courage’ to tackle the issues, regardless of cost.

Schreurs explained how various global industry stakeholders have formed GFSI in an effort to standardize and streamline food safety initiatives. He talked about how North American retailers such as Wal-Mart and Loblaw Companies Ltd. are demanding their suppliers become compliant to a GFSI-recognized food

safety standard. Schreurs gave examples of GFSI-recognized standards:

• BRC Global Standard Version 5

• FSSC 22000 (Conditional Recognition)

• International Food Standard (IFS)

• SQF 2000/1000 Level 2

• Global Gap

For companies considering adopting one or more global standards, Schreurs recommended that first they need to understand their customers’ requirements and any deadlines for adopting new sets of standards. The next step is to learn about each global standard so they can decide which is the most appropriate for their company and products. Another key step is choosing a certification body by reputation, experience, location and knowledge in the industry.

“Not all certification bodies are the same,” said Schreurs. “Some understand the supply chain and the food processing industry better than others.”

The other theme that came up repeatedly at Safe Food Canada 2010 was the idea of companies taking food safety and quality to a new level of corporate responsibility. That was the topic of the keynote speaker, Unilever Canada vice-president John Coyne. According to Coyne, Unilever is highly committed to food safety as a culture throughout the different levels of management.

Coyne said companies have so much at stake when it comes to food safety that it’s important to create a “culture of courage” to tackle the issues, regardless of cost. That starts at the research-and-development level, where prototypes and products should be designed with safety in mind. And it has to move through the levels of stakeholder relationships, so people are empowered to offer feedback about food safety and companies are committed to listening, whether it’s a consumer, customer or employee speaking up.

“We need to do the right thing, regardless of the expense.” Coyne said. “It’s about beating the standard.” / BJ

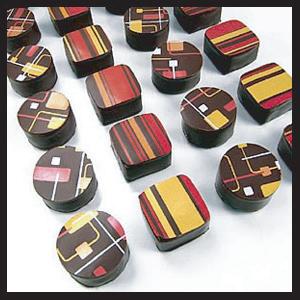

In Europe, you don’t just make “dessert.” Anyone worth his or her sugar will have a specialty –whether it’s pastry, breads (sweet or savoury), ice cream or chocolate.

Here in Canada, much to our European colleagues’ chagrin, we often end up with a “jack of all trades” scenario where our bakers are asked to be proficient in bread, chocolate and pastry. But there’s something to be said about diving deep and becoming a specialist, as I recently witnessed at the Cacao-Barry/ Callebaut Canadian Pre-Selection of the World Chocolate Masters competition. And while I was delighted to see the pros shine, I was at Humber College to judge the Ontario Intercollegiate Chocolate Competition – the first of its kind.

On the judging panel with me were French chef Jean-Pierre (JP) Challet, Donald Duong of Dessert Trends and Belgian chef Bruno Elsier. We began our day at 7:30 a.m. and shortly afterward set about our task: To taste our way through one hand-dipped and one moulded praline (or bon bon), as well as a plated dessert creation – all made in real time on-site by the five competing students. The students had to present one of each confection to every judge (and couldn’t exceed a certain weight in some cases), while staying within the parameters of this year’s theme: “Cocoa, Quetzalcoatl’s Gift.”

Quetzalcoatl was an Aztec god, who, as legend has it, created cocoa as a divine gift to relieve fatigue and provide pleasurable rest. The early history of cocoa and its connections with South America and Mexico, in particular, had to be nuanced in all of the competitors’ creations. Luckily, this is a part of the world I know something about, as I was born in South America and have spent time living there and exploring the vast region’s culinary history.

I took a moment to wander around

Niagara College student Ruth Bleijerveld was the winner of the Ontario Intercollegiate Chocolate Competition.

the students’ stations, observing as Jessica Cat of Conestoga College hand-dipped her almond praline in tempered Venezuelan chocolate, while Humber College’s Chris King did the same with his Cayenne-infused honey truffle. You could feel the tension in the chocolate-filled air as the auditorium started to fill slowly with an expectant

Student division

1st – Ruth Bleijerveld (Niagara College)

2nd – Kateryna Olifrenko (Humber)

3rd – Christopher King (Humber)

4th – Akeele Constable (Humber College)

5th – Jessica Cat (Conestoga College)

Professional division

Plated dessert – Michael Cotard of Marius & Fanny Chocolatier in Montreal

Entremet – Sergio Shidomi of Old Firehall in Unionville, Ont.

Dipped bon bon – Veronique Rousseau of Choco Daisy in Drummondville, Que.

Moulded bon bon – Gloria Donato of Patisserie Monaco in Richmond Hill, Ont.

Overall winner – Veronique Rousseau

public, many of whom would get to taste the delights as the day wore on.

The students were understandably a little tentative in their approach, and when asked how she felt she was doing, Niagara College student Ruth Bleijerveld replied, “Not too bad, considering I didn’t have any chocolate skills three weeks ago,” then adding, “this handdipped praline has been the hardest for me to do so far.”

Bleijerveld, a wife, mother and former greenhouse owner, decided “better late than never” and chose pastry as her second career. She worked with her mentor, Niagara College pastry department professor Peter Storm, to hone her chocolate-tempering and flavour-combining skills. We could see and taste the hard work pay off in her Spicy Mayan White Chocolate Ganache with Mexique Origin Chocolate, Candied Red Peppers and Lime Salt creation. Clearly, serious thought and purpose had gone into this well-composed creation.

We judges were all on the same page until we got to the Moulded Praline portion of the competition. Ukranianborn Kateryna Olifrenko of Humber College, who completed a psychology degree in her native country, created a beautiful offering poetically titled “Tlaloc Tear (the gift of the Mayan God of Rain).” Hand-brushed, edible washes of red and gold topped the truffle dome, lending it an iridescent sheen like the armour of a scarab beetle. It was a masterpiece,

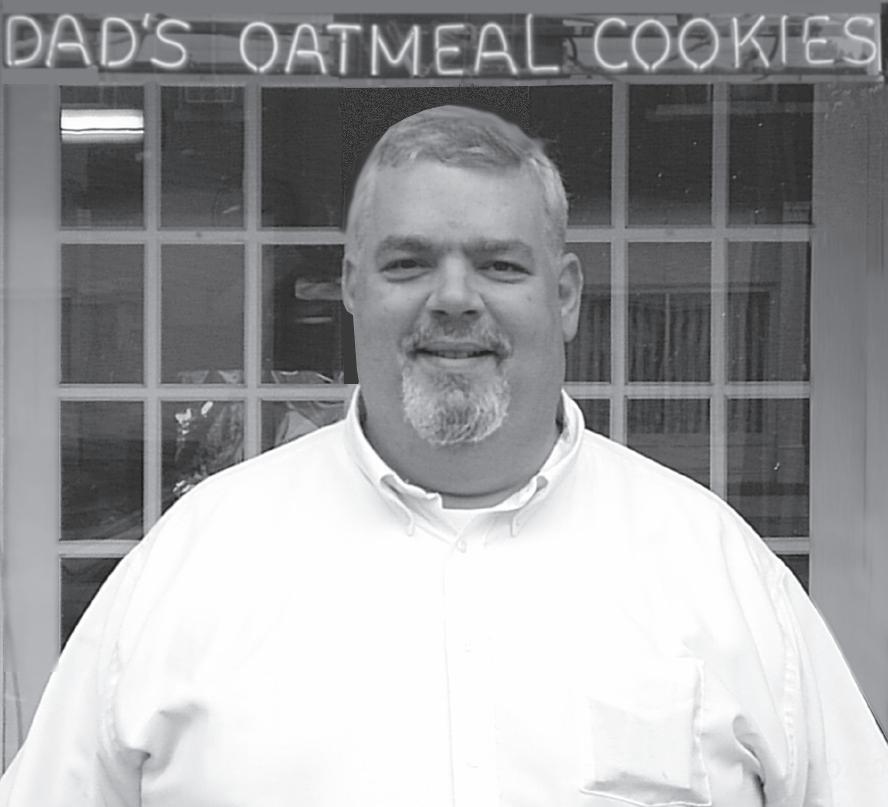

Dad’s Original Scotch Oatmeal cookies, an old fashioned crisp cookie, are still baked and sold in a building that opened in St. Louis, Missouri in 1912. The business, and its 1900s era oatmeal cookie recipe, has been in Dad’s President Ken Hastey’s family since 1938.

Dad’s produces eight varieties of cookies, but the oatmeal cookies account for 87percent of Dad’s production. Every baking shift starts off with at least 500 pounds of oatmeal. In addition to 300 wholesale accounts in the St. Louis area, Dad’s has a large corporate gift business and mail order business that ships nationally.

Customers can still buy cookies in bulk from the old glass and wood cases at Dad’s. A St. Louis tradition, Dad’s customers bring in their children to buy cookies at the same bakery their grandparents knew. Ken Hastey knows what creates that kind of loyalty: consistency in the taste of Dad’s oatmeal cookies.

“We still use the original 1900 era recipe and keep our ingredients in line with what was available back then,” Ken relates. “Shortenings change, the way of processing oats changes, but the taste must remain the same.”

When Ken bought Dad’s from his uncle in 1988, he also received this advice: “Never use anything but International® B&V® Dry 16-to-1 for Dad’s oatmeal cookies. It’s the best product to use and don’t ever change.”

Let International Bakers Services keep your classic products consistent. Contact us toll-free at (800) 345-7175, by fax at (574) 287-7161, or in writing at 1902 North Sheridan Ave., South Bend, Indiana 46628. We have the flavors your customers deserve.

especially given that a week before competition, the highly driven Olifrenko almost dropped out because she didn’t consider herself ready.

}We need this more and more to bring students’ skill levels up and to give them a challenge. By doing this, we slowly push students, tomorrow’s professionals, up to international standards.

One bite of this confection and I could instantly discern a Chinese Five Spice overtone that, while delicious, unfortunately didn’t correspond to the competition’s core theme. For Donald Dung, the truffle provided a break from all of the pepper, while for me it excluded a key ingredient in Mexican cuisine. Challet commented that this was the best-looking truffle and Elsier agreed. There was no arguing that fact. On flavour, however, this was a panel divided, highlighting just how subjective flavour preferences around chocolate can be.

Waiting for our final plated dessert, I took a walk and caught up with Humber’s Akeele Constable, who was visibly sweating. I can’t say I blame him – he, like all competitors, had been at his station working diligently since about 7 a.m. It was now approaching 3 p.m.

The auditorium was full; the glass windows at the side of the kitchen acting like portals to a delicious fantasyland for the ever-gathering crowds. On the menu: Constable’s “Aztec’s Delights – Marquise Chocolate Mousse with spice Caramel and chewy Darquiose.” When I asked him who his competition was, he smiled and answered “everyone!”

With humility, Constable explained that his pralines weren’t tempered properly and he was a little disappointed with that, but that “this one will be OK.” And he was right.

The next station over, I could tell Humber’s Chris King was in his element: “I like when things get a little crazy. I like knowing that when it gets nuts, I can still compete.” He added that despite the adrenalin rush, he knows that his biggest rivals are Bleijerveld and Olifrenko, saying, “Just look at their stuff! It’s really good!”

Humber College Baking and Pastry Arts instructor Joe Kumar looked on nervously as his pupils’ plated toward the finish line. “There were severe time constraints on how much I could teach them,” he explained with a smile. Kumar wanted to spend more time teaching all three of his charges how to hand dip pralines, but mostly, he says, “I want them to cherish this moment for a long time.! This was a major learning process for us all!”

Back at the judge’s table, I asked JP Challet what this kind of competition means for our future pastry chefs. He tilted his head in thought and replied, “We need this more and more to bring

students’ skill levels up and to give them a challenge. By doing this, we slowly push students, tomorrow’s professionals, up to international standards.”

No one would agree more than chef Derrick Tu-Tan Pho, director of the Canadian Chocolate Academy. “The students today have won knowledge by participating. I’m impressed with their passion, now we just have to take what they can do to the next level,” said Pho. Regarding the professionals, he said, “Today is significant – we can see the talent level in Ontario and, while good, we’re still … behind Quebec.”

As if to prove his point, it was Quebec’s Veronique Rousseau who won this year’s World Chocolate Masters competition. She will represent Canada at the World Chocolate Masters final in Paris next year. Then it was time for the students to shine. Standing next to Niagara College instructor Peter Storm, I watched as he anxiously looked on while the winners’ names were being announced. With the same excitement as an expectant father who learns he’s a new dad, Storm’s face lit up when Pho said, “And first place goes to Ruth Bleijerveld!”

“I was more nervous than she was. I was chewing my nails off,” said Storm as he made his way past the crowd to congratulate his star pupil. Olifrenko took second place and King came in third. It seems the former green thumb and psychologist have sweet futures ahead of them. / BJ

Changes abound at Bakery Showcase 2010, but event’s strength shows industry is revitalized | By

MISSISSAUGA, Ont. –

Canada’s premier baking industry show recently celebrated a new location and a whole new vibe to match, wowing visitors May 16-18 at the International Centre near Toronto’s Pearson International Airport.

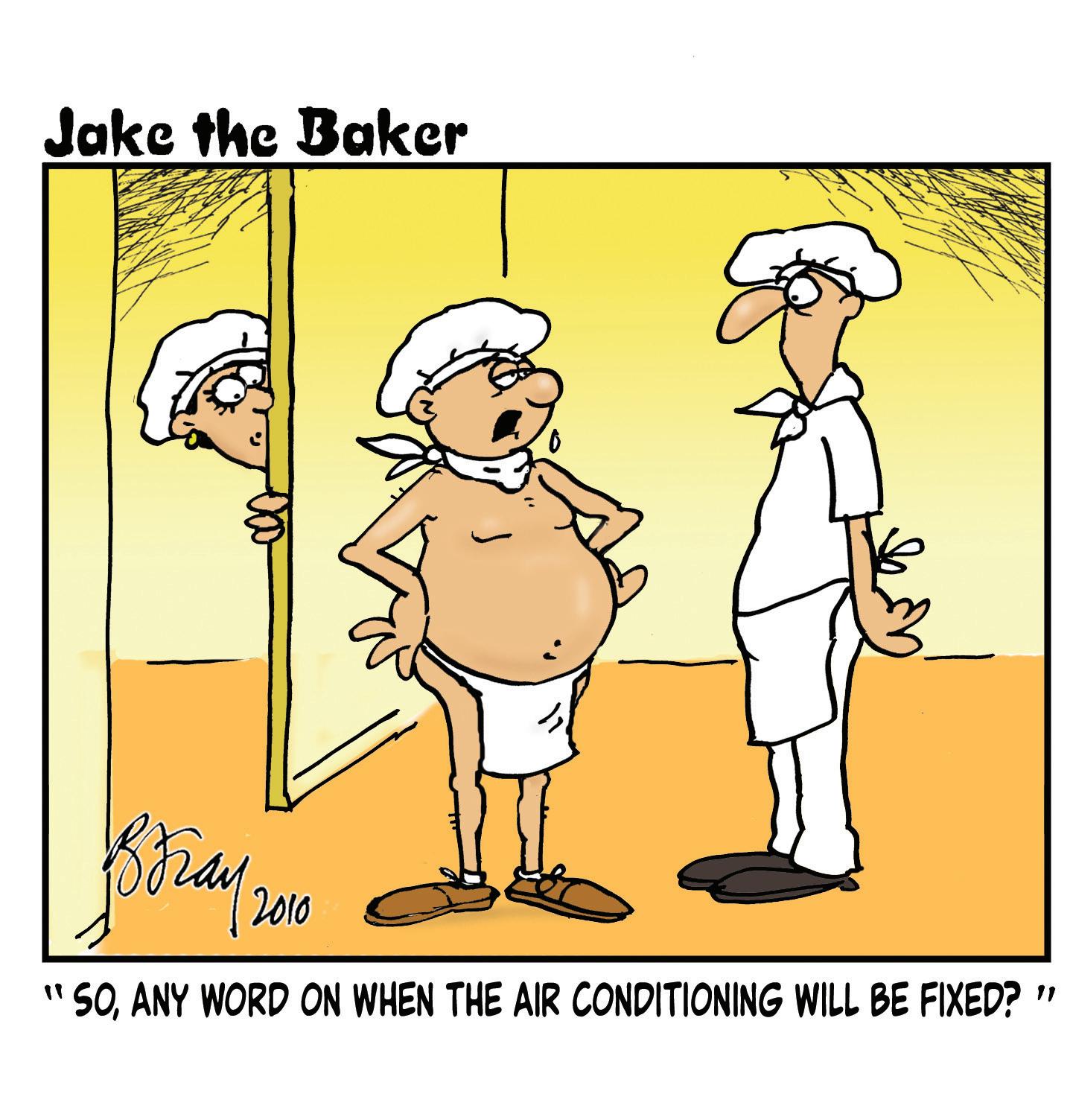

With hundreds of vendor booths and more than four thousand attendees, Bakery Showcase gave bakers and allied trades a chance to evaluate new trends, equipment and ingredients, and to network with other business partners. It was a pulse check on how the industry is doing and where it’s headed. And based on the tone and excitement of this year’s show, our industry has every reason to feel good about the future.

The world was in a very different place when Bakery Showcase was last held in 2008. The economy was struggling and many businesses were focused on survival. For many bakeries and suppliers to the industry, innovation and investing in new equipment took a backseat to more urgent financial matters. Based on the robust attendance of exhibitors and show visitors, it’s clear that bakery products and the businesses that help produce them are very much on an upswing.

}The response by the industry to Bakery Showcase this year indicates that they’re re-engaged. Attendance to the show was up 20 per cent over 2008 and exhibitor sales were up 15 per cent.

“The response by the industry to Bakery Showcase this year indicates that they’re re-engaged,” says Baking Association of Canada (BAC) president Paul Hetherington. “Attendance to the show was up 20 per cent over 2008 and exhibitor sales were up 15 per cent.”

While solid attendance is certainly one key indicator pointing to a revitalized industry, the tone of the show suggested that suppliers, manufacturers, retailers and bakers are more than ready to position this industry for success.

If there was one theme that seemed prevalent, it was health.

“The number one trend we’re seeing right now is the health and wellness trend,” Hetherington says. “We were

pleased to see from the show that the industry is looking at these issues and addressing them to help us meet changing consumer needs.”

Exhibitor N2 Ingredients exemplified this trend, announcing the launch of ALTERNA, the gluten-free alternative to wheat and other gluten-containing flours and grains. ALTERNA is designed to replace flour in traditional bakery and other food products. Gluten-free products and ingredients were found at several other booths as well, suggesting this is a trend with significant momentum.

Hemp Oil of Canada exhibited a number of hemp-based products, including flour and oils suitable for dipping with

a wonderful nutty flavour. Hemp is rich in 18 key amino acids and is gaining popularity as health trends take hold.

NutraSun Foods Ltd. displayed a line of whole-grain scone mixes, natural cookie and muffin mixes, and Snowbird natural white wheat flour.

Sun Opta Ingredients Group promoted fibres from oats, soy and peas, while several vendors offered lower-sodium products to address political and consumer concerns related to added salt. One of these, Nealanders International Inc., showcased its Salt Rite product, which claims to be a 1:1 replacement for salt in recipes while containing only trace amounts of sodium. AB Mauri Low Sodium Baking Powder reduces the amount of sodium while retaining functionality.

In that vein, AB Mauri-Fleischmann’s is one supplier that has transcended its

By all accounts, Bakery Showcase 2010 was a great success for both exhibitors and attendees. Those attending the event were able to experience the products and services of more than 200 companies, a 15% increase over the 2008 show.

For exhibitors, numerous improvements to the event resulted in a 20% increase in attendance. Indeed, the increased attendance was one of the few challenges the event faced according to Paul Hetherington, President & CEO of BAC. “At times we were just overwhelmed by the numbers of on-site registrations. We also appreciate the numbers caused unacceptable delays at times in getting into the show and therefore will be making adjustments for our

2012 event - however as show organizers this is a great problem to have!”

“In addition to the increased interest in the exhibits the expanded New Product Showcase, National Wedding Cake Competition along with changes in the registration rates for bakers, grocery, foodservice and hospitality operators were also very positively received” said Hetherington.

While accolades are still pouring in on Bakery Showcase 2010 planning is well underway for BAC’s next national event Congress 2011 to be held next May in Montreal. Exhibiting and other details will be available shortly for companies interested in being part of this exciting event.

At the May 15, 2010 Annual General Meeting of BAC, members elected a new Board of Directors for the 2010/2011 term and Pete who works for Bee-Bell

Health Bakery in Edmonton is a long time baker and looks forward to leading BAC as it addresses the many opportunities and challenges our industry faces.

John Rossetti presents Pete Plaizier with his gavel as newly elected Chair

CHAIR: Pete Plaizier

Bee-Bell Health Bakery, Edmonton AB

PAST CHAIR: John Rossetti

Italian Home Bakery, Toronto, ON

DIRECTORS

• Rick Barnes

BakeMark Canada, Richmond BC

• Gottfried Boehringer

Stonemill Bakehouse, Toronto ON

• Pierre Boucher

Conseil de la Boulangerie du Quebéc, Saint-Jean sur Richelieu, QC

• Michel Dion

Lallemand, Montreal QC

• Chris Fisher

Weston Bakeries/Ready Bake, Etobicoke ON

• Bob Grebinsky

Ellison Milling, Lethbridge AB

• Arthur Gunn

Gunn’s Bakery, Winnipeg MB

• Tom Mattes

Del’s Pastry, Toronto, ON

• Andrew Pollock

Canada Bread, Etobicoke ON

• Kevin Rainey

Sobeys Inc, Stellarton NS

• Frank Safian

Springfield Sales & Marketing, Ancaster ON

• David Stanfield, Farnell Packaging Limited, Dartmouth NS

• Melissa Timewell

Thrifty Foods, Saanichton BC

• Glenn Wilde

Harvest Bakery, Winnipeg MB

For the first time Bakery Showcase 2010 ran a National Wedding Cake Competition. The response to the competition was exceptional with 30 Professional and 13 students. The quality of entries was inspiring for the thousands of attendees who were able to view the cakes over the three day event. In addition to the recognition associated with the contest, cash prizes were awarded in both the Professional and Student competitions in the amounts of $2,500 1st place, $1,000 2nd place, and $500 for 3rd place.

Heartfelt thanks to Kate Nugent for her dedication in helping organize the contest and the judges. And of course a special thank you to the Judges – Bonnie Gordon, Donna Sanche, Klara Johnsons and Kaye Wong.

Professional Category: 1st Place, Trang Nguyen.

Her inspiration was her passion for creating cakes as well as challenges and learning from others.

Also, congratulations to Susan Trianos, 2nd place and Wendy Suen, 3rd place winners.

In recognition of the growing issues arising in the province of Ontario and the need for greater political representation BAC recently became members of the Alliance of Ontario Food Processors. Adding the baking sector raises AOFP’s membership base to represent all major food processing sectors within the province including dairy, wine, fruit and vegetables, chicken, meat, and baking.

The relationship with AOFP has already demonstrated value in increasing BAC’s political profile as BAC’s President & CEO Paul Hetherington and then Chair John Rossetti participated in numerous meetings with MPPs and Ministers during the AOFP Food Processing Day at Queen’s Park on May 4th. These

Student Category: 1st Place, Emily Rigo, George Brown College

Congratulations to Nicole Sampson, 2nd place and Genevieve Fullan, 3rd place winners.

meetings were used to raise with politicians the major issues affecting the provinces food processing industry.

In response to concerns expressed by Bakery Showcase 2010 exhibitors, BAC will be reviewing Student Day for future events. Student Day has traditionally been held the final day of the event at which students from local high schools and colleges with baking programs have been invited to attend free of charge. The 2010 Student Day attracted some 500 students. BAC received numerous concerns from exhibitors following this year’s show that the number and behavior of students was disruptive to their ability to conduct business on the show floor and as a result the program will be reconsidered for the 2012 event.

Bakery Showcase 2010 and the Baking Association of Canada would like to take this opportunity to thank everyone for their support at this year’s show. Bakery Showcase was considered a success by visitors and exhibitors alike. Exhibitor attendance increased by 15% while visitor attendance increased by an overwhelming 20% from Bakery Showcase 2008! And of course, most importantly we saw the right kind of visitor mix – retail, wholesale and bakers.

A special thank you goes out to all of our sponsor companies for their generous support.

• Sugars are simple carbohydrates. Examples are sucrose (table sugar), glucose, lactose (in milk and dairy products) and fructose (in fruits and vegetables). These are found naturally and are also added to foods to sweeten the flavour. Large amounts of sugars are consumed in drinks like carbonated beverages, fruit drinks, cold coffee-flavoured beverages (e.g. iced cappuccinos or frappuccinos) and sweets.

• Starch is a complex carbohydrate. Starch is a row of glucose molecules attached together. Starch is found in all grain products, vegetables, fruit, nuts, seeds and legumes.

• Fibre is a type of carbohydrate that is not broken down by our digestive system. Fibre is classified as either soluble or insoluble, depending upon how well it absorbs water.

Carbohydrates are an important source of energy our bodies need every day. In addition to providing energy, carbohydrate-containing foods deliver additional benefits. Research shows that people who eat some whole grains daily have a lower risk of chronic diseases and a better body mass index (BMI) than those who do not. Whole grains are found in many breads and cereals. Many fad diets tell consumers to avoid foods that are a good source of carbohydrates (carbs) in order to loose weight. Most research shows that if you consume equal calories of carbs, protein or fat, people will loose the same amount of weight.

Fibre provides important nutrients for the healthy bacteria in our lower gut. It helps with digestion and elimination, in other words, it helps keep us ‘regular’. Some fibres also help bind and reduce cholesterol. Fibre is found in whole grains, whole wheat, bran, vegetables, fruit, and nuts.

More refined grains such as white bread, pasta and enriched corn meal are also beneficial as they are fortified with folate. Folate is a B-vitamin that helps maintain and make new cells. Folate is known to prevent neural tube defects in infants.

Other grains—rye, barley, oats, rice, and corn as well as ancient grains such as spelt and Kamut® provide variety and flavour in a healthy diet.

Centre stage starts with grains

Appetizers

Mini cheese or spinach croissants

French stick for bruschetta

Pumpernickel bread bowl with spinach dip

Mini quiches

Crackers and cheese

Main courses

Pasta

Bread for sandwiches

Flatbreads for wraps or fajitas

Bagel pizzas

Side dishes

Dinner rolls

Cous cous

Rice pilaf

Barley vegetable soup

Garlic bread

Desserts

Cookies

Cakes

Pies or tarts

Squares

Fancy pastries

You can find them in breakfast, lunch and dinner menus. Grains can be centre stage in appetizers, main courses, side dishes and desserts. They are available in low fat, high fibre, and reduced calorie versions, as well as in decadent, higher calorie treats reserved for occasional enjoyment. Visit your bakery or grocery store and enjoy the versatility and benefits of grain products.

For more information contact: Baking Association of Canada

7895 Tranmere Dr, Ste 202 Mississauga, ON L5S 1V9 Tel: 905-405-0288, Toll Free in Canada & USA 1-888-674-BAKE (2253) Fax: 905-405-0993 E-Mail: info@baking.ca May be reproduced without permission provided no changes are made and credit is given. Printed April 2010. Visit www.GrainsEssential.ca to download PDFs of this resource.

A food allergy is when the immune system has an unusual reaction to the protein in a food. A very small amount of the food can cause the allergic reaction. The allergy-causing food is called an allergen. Allergies tend to run in families. While there is much public concern about food allergies, in actual fact, true food allergies are uncommon. Food allergies occur in about 6% of children and in 3-4% of adults. Many children outgrow allergies such as those to milk and eggs. Other food allergies remain for life such as allergies to peanut or shellfish. A diagnosis of food allergy is made by a qualified medical professional. Symptoms of food allergies vary with the individual and can affect different parts of the body. Examples of symptoms are rashes or hives, nausea, diarrhea, and breathing difficulties. In rare cases, a severe, life-threatening reaction called anaphylaxis can occur.

Food intolerance differs from an allergy as it does not involve the immune system. A normal portion or more of food is usually needed to cause a reaction and is a result of not being able to digest or absorb the food properly. A common example would be lactose intolerance—the inability to digest the sugar found in milk.

Milk, eggs, peanuts, tree nuts, soy and wheat are common food allergies. These foods are also ingredients in many foods including breads and baked goods.

The most common food allergies are:

Milk

Eggs

Peanuts

Tree nuts (Brazil nuts, hazelnuts, almonds, walnuts, pecans)

Fish

Shellfish (mussels, crab, shrimp)

Soy

Wheat

Yes you can. Many baked goods are available without nuts, peanuts, eggs and milk. Other liquids can replace milk and products can be made egg free. There are commercial egg substitutes available for purchase. However, products such as liquid eggs do contain eggs or egg whites and should be avoided. If you have food allergies, it is important to read labels and know what you are eating:

1. Check the list of ingredients for the allergy-causing food or ingredients made from the allergen. For example, ammonium caseinate or lactoalbumin are proteins from milk used as ingredients. For a complete list of foods that may contain peanuts, nuts, milk or eggs visit the Allergy and Asthma Information Association at www.aaia.ca or call their national number (1-800-611-7011).

2. Many bakeries and packaged baked goods identify products that are free of allergens, such as “this product does not contain any traces of peanut or nuts”. Many products will state “may contain nuts” if there is risk of crosscontamination. This can occur if nuts are used in other products made in the same facility but not necessarily in the product you are interested in purchasing. If unsure, ask the baker.

For more information contact: Baking Association of Canada 7895 Tranmere Dr, Ste 202 Mississauga, ON L5S 1V9 Tel: 905-405-0288, Toll Free in Canada & USA 1-888-674-BAKE (2253) Fax: 905-405-0993 E-Mail: info@baking.ca May be reproduced without permission provided no changes are made and credit is given. Printed April 2010. Visit www.GrainsEssential.ca to download PDFs of this resource.

Celiac disease is an inherited autoimmune disease. It is a result of damage to the surface of the small intestine caused by the protein gluten. This prevents the small intestine from absorbing nutrients resulting in chronic diarrhea, bloating, cramps and subsequently, anaemia and weight loss. It is estimated that 1 in 133 Canadians have celiac disease.

Specific proteins found in wheat, rye, triticale, and barley when mixed with moisture form gluten. Wheat contains two proteins—glutenin and gliadin—which are the best at forming gluten. Gluten makes the flour from the grain become strong and elastic. When heated, the gluten traps air bubbles making the dough rise and become springy. The high level of gluten in wheat results in the best quality bread. Any product made from wheat, rye, triticale, barley or the ancient wheat based grains (e.g., spelt, emmer, etc.) contains gluten.

A number of bakeries, health food stores and specialty shops will offer glutenfree baked goods. These breads, buns, muffins, cakes and crackers are made using flours or a combination of flours that are gluten-free. Baked goods, such as bread, made without gluten have a different look, taste and aroma compared to those made with wheat. The taste and aroma differ depending on which flour is the main ingredient in the bread or baked good. Gluten-free breads also have less volume than those made with wheat.

Gluten-free Flours

Amaranth

Arrowroot

Bean (garbanzo or chickpea)

Chestnut

Corn/cornmeal

Millet

Potato

Quinoa

Rice

Sorghum

Pure, uncontaminated oats are free of any contamination from grains containing gluten. These are now available in Canada and can be eaten safely by most individuals with celiac disease. Check with your local bakery to see if they use pure oats in their baked goods.

Individuals with celiac disease can eat a wide variety of foods from all four food groups in Canada’s Food Guide. However, many foods in the grocery store have wheat flour or wheat starch added as a thickener or stabilizer such as soups, sauces and processed meat and fish. Check the ingredient list to be sure. A full list of ingredients to avoid can be found at the Canadian Celiac Association website http://www.celiac.ca.

Soy

Tapioca

Teff

For more information contact: Baking Association of Canada 7895 Tranmere Dr, Ste 202 Mississauga, ON L5S 1V9 Tel: 905-405-0288, Toll Free in Canada & USA 1-888-674-BAKE (2253) Fax: 905-405-0993 E-Mail: info@baking.ca May be reproduced without permission provided no changes are made and credit is given. Printed April 2010. Visit www.GrainsEssential.ca to download PDFs of this resource.

Cinzia Frantellizzi ................................... Cakes by Cinzia

Tom Clark .................................................. Crust & Crust

Vince Dinovo ..................... Gus & Maria’s Deli & Bakery

Franco Petronio ......................... Deluxe Paper Products

Elisabeth Riesen ........................... El Peto Products Ltd.

Ferenc Kiss ............................................... Inextrade Ltd.

Kate Clipperton ....................... Kate’s Town Talk Bakery

Jessica Lee ......................................... Lee’s Sweet Shop

Rohan Romaniuk ............................................ Life Of Pie

Marnie Lippa ................................. Parties Made Simple Chelan Thomas .... Sweet Thoughts and Cute Buns Inc.

Alberta Chapter

July 19

Annual Golf Tournament

Sirocco Golf Club

Calgary, AB

Ontario Chapter

July 16

Boat Cruise

Cruising the Toronto Harbour & Centre Island Toronto, ON

Ontario Chapter

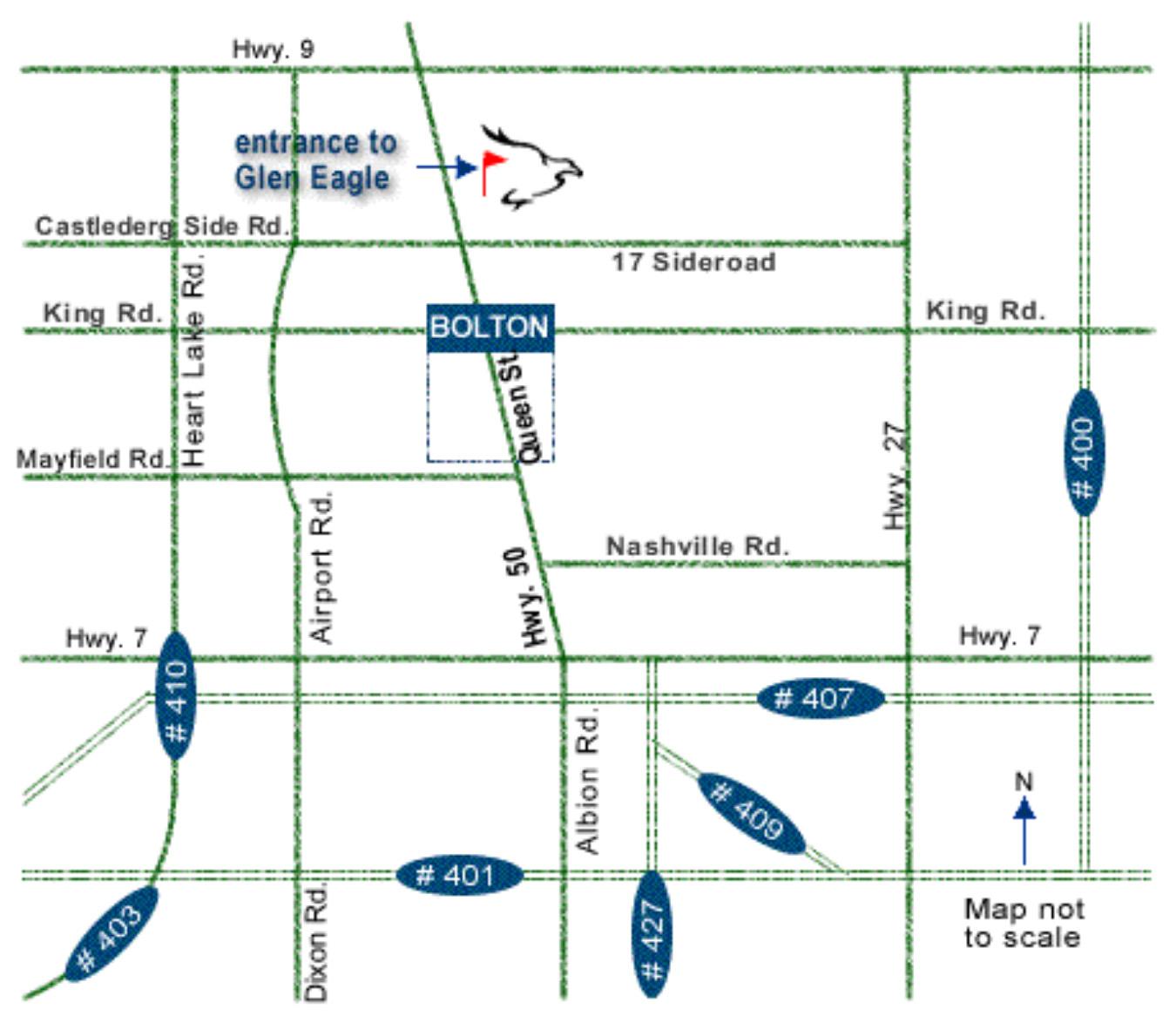

Sept 21

Fall Annual Golf Tournament

Glen Eagle Golf Club Bolton, ON

Atlantic Chapter

September 13

Annual Golf Tournament

Magnetic Hills Golf Course Moncton, NB

Congratulations to Jessica Lee Co-Owner Lee’s Sweet Spot of Toronto who won the Nikon D5000 Digital Camera (MSRP $999.00) which was the draw prize from all new members signed up during Bakery Showcase 2010.

For information on correspondence courses for baking industry employees and the Certified Bakery Specialist (CBS) program, please contact ext. 21 at the BAC office or check out our website at www.baking.ca. Congratulations to Our Most Recent Correspondence Course Grads!

Ruth Bleijerveld Operating A Successful Bakery Bessie De Torres Food Hazard Control: Sanitation

traditional roots as a manufacturer of yeast. While yeast continues to be a key part of its business model, AB MauriFleischmann’s also provides mold inhibitors and AB Mauri Gluten and Emulsifier Enhancer (ABM 310) to allow for gluten and possibly emulsifier reductions. These innovative solutions use enzymes, a natural alternative that allows the baker to remove ingredients from the label, making it “cleaner.”

“By removing the chemicals, you allow the natural flavour to shine,” says AB Mauri-Fleischmann’s technical support manager Michel Dorval.

While ingredients spoke to consumer health, some suppliers exhibiting at the show focused on environmental health. Novelis promotes itself as the world’s largest aluminum can recycler. Its Bakery Showcase stand highlighted the fact that it takes only 60 days for an aluminum can to be recycled back onto the grocery shelf. Novelis displayed packaging solutions using aluminum bases that are 100 per cent recyclable. Meanwhile, another exhibitor, Bottle Box, showcased plastic clam packs made from 100 per cent post-consumer recycled PET beverage bottles. No more guilt about those plastic water bottles!

Innovation on the production side of the equation was evident too. Cinelli/ Esperia Corp. displayed a proofer-retarder roll-in rack that allows the baker to control fermentation over a long period of time. If things get backed up at the oven, the unit is designed to automatically

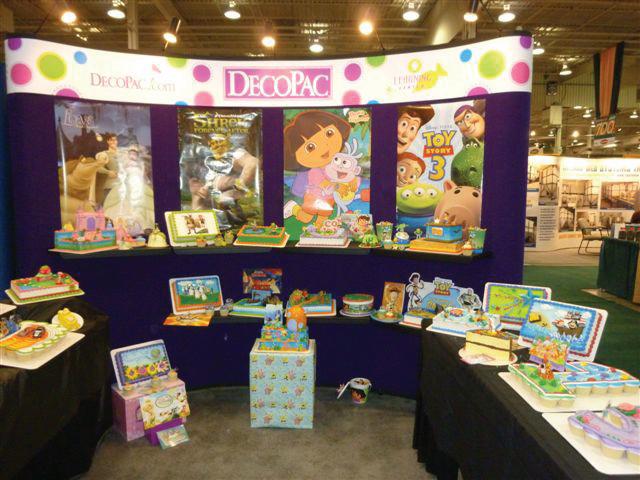

reduce the temperature to slow the proofing process. Quick Shine by Custom Baking Products allows bakers to get a beautiful finish without eggs, which reduces the risk of bacterial contamination. Exhibitor DecoPac displayed myriad tools to create wonderful themed cakes, and Rich Products of Canada highlighted its flavoured icings and new berry cake.

The National Wedding Cake Competition joined the Decorative Bread Competition this year for the first time at Bakery Showcase. The competition featured two categories: one for professionals and one for students. The first-place winner for the professional category was Trang Nguyen of Gateaux Fleurs de Paris Inc., with a beautiful classic cake decorated in white with gold lace and tuxedo accents. A beautiful burgundy rose on top punctuated the white-and-gold colour theme.

Emily Rigo of George Brown College triumphed in the student category with her elegant white and silver Cameo cake worthy of a vintage Hollywood star. All of the cake entries were stunning and it was especially exciting to see the future of the industry so aptly represented by the student contestants.

“The skill levels were evident in the quality of our professional and emerging talent,” Hetherington says. “We were pleased with the response for the first time having the wedding cake competition, and we’re looking at how we take it to the next level for 2012.”

At the Bakers Journal booth, our very

1. Cinelli’s impressive lineup of ovens.

2. DecoPac’s booth

3. Novelis displayed its wide range of environmentally friendly aluminum foil pie plates and other containers and packaging for bakeries.

4. The team at N2 Ingredients brought an impressive display.

5. Cinelli’s impressive lineup of equipment.

own Brian Fray – the creative genius behind the popular Jake the Baker cartoons – met attendees and autographed posters. He thoroughly enjoyed having a chance to meet the people who read his cartoons and no doubt glimpse a little bit of themselves every issue through his art and humour.

The show’s new location at the International Centre, with its easy access to Pearson International Airport, proved to be a great fit. But the enthusiastic response to the show resulted in a spike in attendance that provided some congestion at the registration area.

“We’ll be looking at changing the registration process for the next show,” says Hetherington.

When queried as to whether he was satisfied with the show’s success, Hetherington deferred to his constituents.

“It’s really a question of what do the attendees and exhibitors think of the show? That’s what’s important.”

Based on the excitement and innovation at Bakery Showcase 2010, it seems Canadian bakers and their suppliers have an abundance of reasons to look forward to where the industry is headed – and to eagerly anticipate the next edition of Bakery Showcase in 2012. / BJ

Michelle Brisebois is a marketing professional with experience in the food, pharmaceutical and financial services industries. She specializes in helping companies grow their brands and can be reached at briseboismichelle@sympatico.ca.

Dealers Ingred ie nts ' pro du ct c on sulta nts us e their broad knowledge and deep experience to deliver prod uct pe r formance solutions – naturally

Our unique natural sourced Specialty Produc ts ca n i mprove product quality, per fo rmance, nutritional value and profit margins Whether you are buying Base Ingredients, improving your product's value propos ition or tweaking margin s, trust Dealers I ngredients to deliver results.

Butter, cream and cheese natural dair y concentrates reduce fat while enhancing flavour characteristics at a lower total cost Improve your product p er formance – naturally Citri-fi

C itri- fi offers excep tion al v alu e and per formance by imp roving m oistu re m anagement, reducing fats and c alories while enhancing taste and texture It s a winning formula for you and y our consumers – naturally

It’s not just that steaming loaf of artisan bread that’s hot. These days, professional baking programs across Canada are sizzling with exceptionally high enrolment rates and delighted graduates finding jobs quickly. Meanwhile, schools are keeping pace by investing in up-to-date equipment and revamping curricula to match industry (and consumer) demand.

What’s the rationale behind this surge in demand for professional bakers?

Much of it focuses on the trend toward authentic, natural foods made from organic and green ingredients.

“There’s a demand for classic breads and that’s part of this demographic,” says Martin Barnett, an instructor in Vancouver Island University’s professional baking department. “People are willing to pay the price for fresh cream, real butter, high-quality breads and organic produce.”

“Way up!” That’s the sentiment expressed by baking program co-ordinators when asked about enrolment numbers. “All of our apprentice programs are full and our regular [baking] programs are full, too,” says Barnett.

The same holds true for George Brown College in Toronto. “It’s so ‘way up’ I can’t keep up with it,” says program chairman Keith Muller.

Elsewhere in Toronto, Humber College officials are also working hard to keep up with demand in their baking programs. “It’s way up – we are 50 per cent up in applications – and we’re waitlisted for the 2010-11 session,” says program co-ordinator Rudi Fischbacher.

And it’s more of the same in Niagara and Ottawa. At the School of Culinary and Wine Studies at Niagara College, approximately 36 apprentices are working in various levels right now, and “the demand [for the program] remains high over the past years,” says program chairman Craig Youdale.

Likewise at Algonquin College: “Enrolment is way up,” says baking and pastry arts program co- ordinator Tony Bond.

To keep up with the demand from restaurants, resorts, cruise ships and pastry shops, which frequently hire baking program graduates, many schools have invested thousands – even millions – of dollars on new machinery, labs, technology and equipment.

For instance, at George Brown, new facilities abound. “We spent over $2.3 million on renovating the labs, and everything in it is industry standard,” Muller says. “We [now have] different kinds of equipment such as a rotating oven, rack oven, deck oven, plus blast freezers and individual work stations.”

Similarly, Humber College has invested about $6 million on new technology and machinery, including two dedicated labs and a dedicated chocolate room. New program options stemming from these investments include chocolate tempering and pastillage.

}The culinary school at Niagara College recently purchased a variety of equipment, including chocolate tempering machines, spraying machines, a food dehydration machine, thermal circulators, new combination ovens and an Anti-Griddle for cold searing.

We run our program like a real bakery. The students bake as if they’re at work with real-time deadlines and customers. It’s hard work and it’s early mornings (they start at 5 a.m.), and that makes us unique.

And in Ottawa, Algonquin’s baking program recently ran its second annual baking competition complete with industry judges and three separate categories – breads, cakes, and cookies.

The Vancouver Island University Culinary Institute has a new wood-fired brick oven, which is generating a lot of interest. “As the only culinary institute which currently has a wood-fired brick oven, we can offer more specialty artisan bread-making programs,” Barnett says.

Looking at industry trends, building relationships with recruiters and professional bakers, and listening to feedback from students … these are just a few of the ways in which the right mix of baking and pastry arts programming is created. But what makes each school unique?

To incorporate the demand for fine chocolate products, staff at George Brown recently began offering a

Lallemand bakers yeast is now a natural source of vitamin D. Your customers can get the benefits of vitamin D everytime they enjoy your products. This added benefit will put the sunshine in your profits. www.lallemand.com

From Hobart’s new spiral mixer sizes to an Edmonton inventor’s bagel and bun slicer, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

SK Food International has added identity preserved, certified organic and conventional non-GMO precooked quinoa and amaranth flakes to its range of ingredients. Custom milled from heirloom grains, the flakes are gluten-free and kosher. Amaranth and quinoa are commonly known as “supergrains,” each touting high levels of protein in addition to many other health benefits. Product applications include, but are not limited to, cereals, tortillas, snack foods, baby food, flat breads, baking mixes and energy bars. Visit www.skfood.com.

The Last Airbender is an action-adventure fantasy film coming to theaters July 2, 2010. The story follows the journey of Aang, a young successor to a long line of Avatars, who must put his childhood ways aside and stop the Fire Nation from enslaving the Water, Earth and Air nations. DecoPac is pleased to offer a full line of The Last Airbender items for your bakery, including the Windrider DecoSet. Visit Decopac.com or call 1-800-Decopac.

Edmonton-based inventor Nick Verklan, while watching food preparation staff struggle to get orders prepared quickly, was inspired to create the CanCut, an automatic slicing machine to quickly and safely cut bagels and buns. His invention is being manufactured and sold by Bloemhof Inc., also of Edmonton, and was officially launched at this year’s Bakery Showcase in Toronto. Visit www.bloemhof.com or www. cancut.net.

Call our Canadian Distributors to request our catalog:

BakeMark of Canada

3202 - 9th Street S.E. Calgary, Alberta T2G 3C3 (800) 663-CAKE (604) 303-1700

Cake Top Inc.

151 Carling View Drive, Unit 2 Etobicoke, Ontario M9W 5S4 (800) 584-9883 (416) 798-1777

Catalog Sales Division (800) 428-4413

L & M Bakers Supply Co. 2501 Steeles Ave.W., Unit 1 Downsview, Ontario M3J 2P1 (800) 465-7361 (416) 665-3005

Nicholson Equipment Ltd. 3975 Kitchener Street Burnaby, B.C.V5C 3L9 (800) 668-3722 (604) 291-1901

Nicholson Equipment Ltd. 11640 - 147th St. Edmonton, AB T5M 1W2 (800) 661-9026 (780) 451-6262

Traynor's Bakery Wholesale

191 Victoria Ave.S., Hamilton, Ontario L8N 3C8 (800) 263-9239 (905) 522-2730

Vincent S.Varietes Ltd.

433 Rue Saint Paul LeGardeur, Quebec J5Z 4C7 (800) 263-1687 (450) 585-1687

Vixit Products Ltd.

290 Henri Bourassa Ouest Montreal, Quebec H3L 1N7 (800) 463-8782 (514) 337-0814

Hobart’s mixers are now available in 81.72-kilogram (180-pound) and 99.88-kilogram (220-pound) spiral mixers. The new HSL180 and HSL220 mixers combine the consistent speeds and mixes Hobart is known for with Hobart’s well-established longevity. The spiral mixers are meticulously designed to control oxidation and create a more consistent mix. The mixers combine the action of the spinning dough hook and the rotating bowl, allowing the ingredients to mix faster, limiting oxidation and generating superior quality dough. Visit www.hobart. ca or call 1-866-334-2371.