BY MATT JONES

In 2018, the city of Edmonton announced a major three-year renovation plan for one of the busiest river crossings in the city, the Groat Road Bridge. The bridge, which spans 330 metres across the Fort Saskatchewan River, had been

How crane incidents in other areas affect Canadian industry

BY MATT JONES

BY SAUL CHERNOS

Mammoet, a global provider of engineered heavy lift services, is using cranes, hydraulic jacks and massive trailers with hundreds of wheels to help deliver several of the heaviest loads ever transported on Alberta highways.

constructed in 1955 and it has been almost 30 years since the last major work on the bridge. The construction is expected to extend the service life of the bridge by at least 50 years and to improve the functionality of existing sidewalks by widening them.

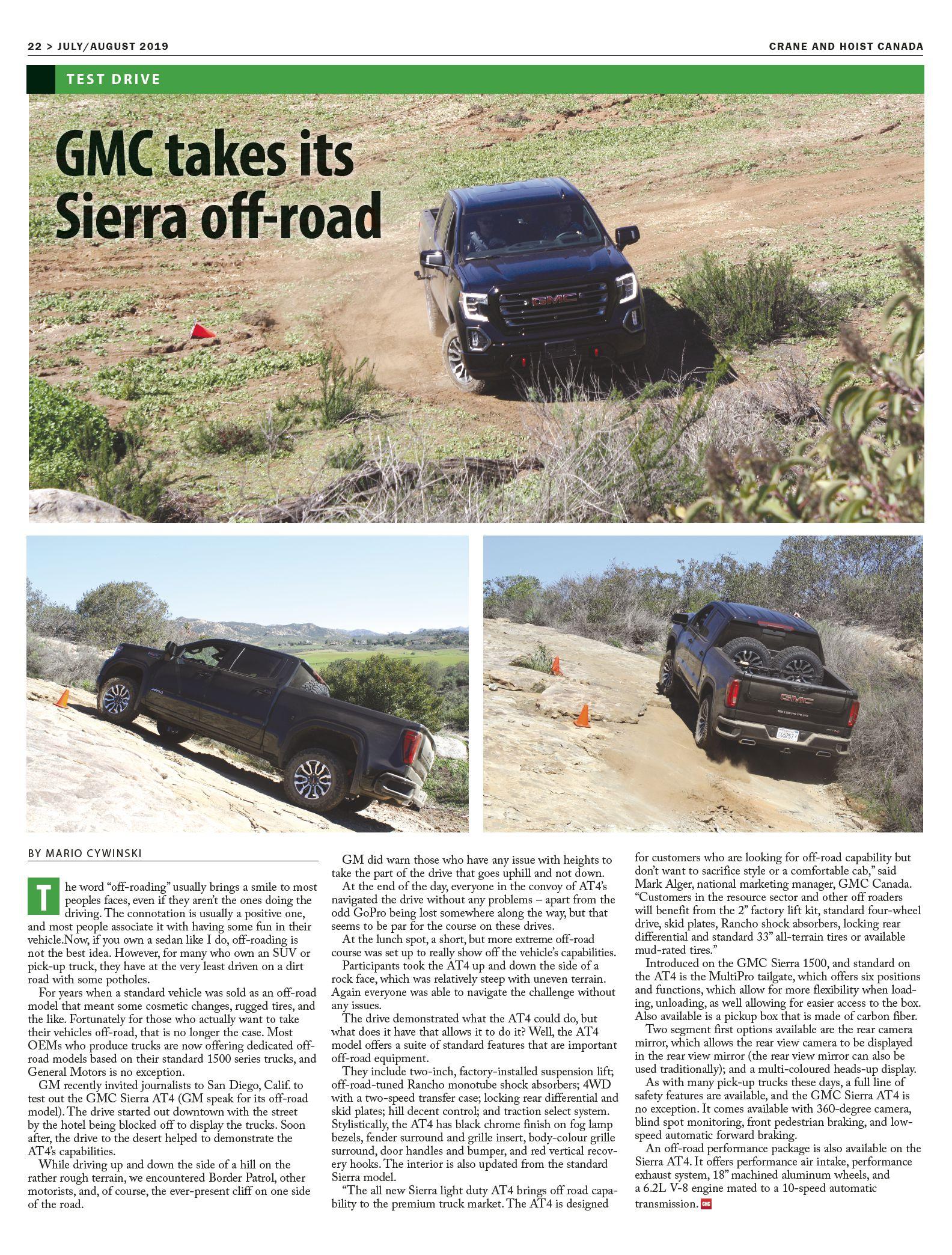

n April 27, a crane working on a Google office building in Seattle collapsed onto the street below, crushing six cars and killing four people. The incident attracted major attention. As news outlets such as CNN and Global broadcast video of the Seattle Mayor Jenny Durkan vowing to ensure that cranes in the city are safe, the grainy dash-cam footage of the crash was being analyzed on a variety of social media platforms. In the modern media age, the shockwaves from a crane crashing onto the street are likely to travel further than ever. As the official investigation into the causes of the collapse continues, how often does the fallout from an incident such as this impact industry in other jurisdictions?

“The unfortunate thing about regulatory requirements is they all seem to be written in blood.”

– Fraser Cocks, executive director, British Columbia Association for Crane Safety

The loads — six in all — involve enormous mechanical and processing units for a new $3.5-billion polypropylene manufacturing plant in Fort Saskatchewan, Alberta. The Heartland Petrochemical Complex, a processing plant owned by Calgary-based Inter Pipeline, will convert propane into plastic pellets for use in everything from computers and automotive parts to food containers and clothing.

Crews literally got rolling January 6 in Edmonton at Dacro Industries, a fabricator of resource industry equipment. Using four 300-tonne capacity hydraulic climbing jacks operating in tandem, they loaded a 97-metre-tall, 820-tonne tube-shaped propane propylene splitter onto the high-end InterCombi trailers.

Not only is the splitter the heaviest of the six loads Mammoet is shipping over the road for Inter Pipeline, but the provincial transportation ministry confirmed publicly this “historic super load” is the heaviest ever carried on Alberta highways.

Editor – Andrew Snook

asnook@annexbusinessmedia.com • 289-221-8946

Account Manager – Amanda McCracken amccracken@annexbusinessmedia.com • 226-931-5095

Media Designer – Svetlana Avrutin

Regular Contributors

Saul Chernos, Doug Younger, Nelson Dewey, Matt Jones, Judy Mellott-Green COO – Scott Jamieson

Circulation Manager – Barbara Adelt • badelt@annexbusinessmedia.com

Subscriptions – Bona Lao – blao@annexbusinessmedia.com Tel: 416-442-5600 • 1-800-668-2374 (CDN) , ext. 3552 Fax: 416-510-6875 or 416-442-2191 • www.craneandhoistcanada.com

Annex Privacy Officer – Privacy@annexbusinessmedia.com Tel: 800-668-2374

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $37 + Tax per year in Canada. For subscriptions in the USA the price is $37 USD. Send cheque or VISA/ Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT.

111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 ISSN 1923-788X

Next Advertising Deadline: July 27, 2019

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Amanda McCracken at our Advertising Department Tel: +1-226-931-5095 • amccracken@annexbusinessmedia.com

Next Editorial Deadline: July 27, 2019 For writers’ guidelines and submission requirements get in touch with the editor, Andrew Snook, at 289-221-8946 Email: asnook@annexbusinessmedia.com

From British Columbia and The Yukon to St. John’s, Newfoundland, Crane & Hoist Canada is searching Canada’s crane industry for the best and brightest young workers in the industry.

This program will recognize 10 outstanding individuals from across Canada who had made significant contributions to the industry before their 40th birthdays. This can include anyone who was under the age of 40 as of December 31, 2018. Nominees can come from anyone who is involved in Canada’s crane industry, including business owners and management within all aspects of the industry, crane operators, technicians, trainers, industry association employees and researchers.

WHAT ARE THE QUALIFICATIONS TO NOMINATE AN INDIVIDUAL, YOU ASK?

Here are the guidelines to the Top 10 under 40 contest:

• Nominees must be younger than 40 before Dec. 2018.

• Nominees must either be working in Canada or of Canadian nationality.

• Nominations are due by September 1, 2019.

MUST THE NOMINEE BE CANADIAN?

No. The nominee can be of any nationality, but must be employed in Canada. We also encourage the nominations of Canadians working outside of the country.

WHO CAN NOMINATE SOMEONE?

Nominators can include advisors, supervisors, coworkers, or colleagues familiar with the nominee’s work and character.

WHAT TYPE OF INFORMATION SHOULD BE INCLUDED ABOUT THE NOMINEE?

Potential information to submit about the nominee can include (but is not exclusive to): Projects or initiatives the individual is or has been involved in; results from past projects; day-to-day job responsibilities; workplace initiatives outside of regular job duties; and community and/or association involvement.

IS A SECONDARY REFERENCE FOR THE NOMINEE REQUIRED?

No. However, the nomination form includes fields for a secondary reference, which is suggested to include. All nominees that are selected for Crane & Hoist Canada’s Top 10 Under 40 program will receive a framed certificate recognizing their achievement, and will be featured in the November/December 2019 issue of the publication. Who knows, one lucky individual might even end up gracing the front page!

STILL HAVE MORE QUESTIONS?

For more information on the Top 10 Under 40 program, or how to nominate an individual, contact editor Andrew Snook at asnook@annexbusinessmedia.com, or give him a call at 289.221.8946.

Good luck to all the nominees. We look forward to featuring the industry’s best and brightest in 2019!

Andrew Snook, editor, Crane & Hoist Canada.

Joyce Crane recently announced at an employee meeting that the company has been purchased in an acquisition agreement with Marmon Crane Services, Inc.

Headquartered in Longview, Texas, with additional locations in Texas, Arkansas, and Louisiana, Joyce Crane serves the heavy duty lifting and rigging needs of refineries, petrochemical companies, and power and manufacturing plants throughout the U.S. South and across the country.

“We are excited to welcome Joyce Crane and its employees to Marmon’s global portfolio of crane businesses,” said John Roberts, sector president of Marmon Crane Service. “Joyce Crane is a company with a strong brand and an excellent service record, and we look forward to its continued growth under Marmon’s ownership.”

The company will continue to operate under the Joyce Crane name and brand. Staff and leadership, including founder and president Joe Bob Joyce, will remain the same with business support by Marmon Crane Services management.

“This is a very exciting time for Joyce Crane. This agreement is a positive move that will strengthen both companies and benefit all of Joyce Crane’s stakeholders, including our employees, clients, and vendors,” said Joe Bob Joyce. “We also remain steadfast in our commitment to the communities where we live and do business.”

Marmon Crane Services is headquartered in Chicago. The company owns and operates one of the largest fleets in the world with more than 1,200 mobile cranes. Its current companies include Procrane and Sterling Crane in Canada and the United States; Advantage Crane, based in Victoria, B.C.; Freo Group, based in Kwinana, Western Australia; and WGC Cranes, based in Wollongong, New South Wales. Marmon’s crane business originated with Sterling Crane in Western Canada in 1954.

Financial terms were not disclosed.

Source:

Joyce Crane.

The Ontario government is launching a review of the Workplace Safety and Insurance Board (WSIB) to ensure workers and their families remain supported and protected in the workplace. The review will provide the government with new information regarding the board’s operations and how it compares to industry best practices.

Specifically, the operational review will focus on:

• Financial oversight: sustainability of the WSIB insurance fund and controls over it;

• Administration: effectiveness of the current WSIB governance and executive management structure; and

• Efficiency: the cost-efficiency and effectiveness of operations, including comparisons to competing jurisdictions and private sector insurers

“Ensuring the long-term sustainability of the WSIB will provide workers and their families with peace of mind, knowing if they are injured on the job or have a work-related illness, they will receive the benefits and services they are entitled to,” said Laurie Scott, Minister of Labour. “Reviewing and improving the WSIB is one of the ways our government is ensuring that Ontario can continue to attract investment and create good jobs.”

The review will be conducted by Linda Regner Dykeman and Sean Speer, who have been appointed based on their respective areas of expertise in insurance and public policy. The review will commence immediately, and a report to the Minister is expected by the end of the year.

Source: Government of Ontario.

The Crosby Group (Crosby), a leading global provider of lifting, rigging, and material handling hardware, announced that it has entered into an agreement to acquire Gunnebo Industrier Holding AB from Segulah, a Nordic private equity firm, and that all closing conditions have been satisified. Gunnebo Industries is a global leader in innovating, developing, manufacturing and selling products for material handling and other related applications.

“Given our shared commitment to safe rigging and lifting and our equally committed and talented teams, this acquisition is a natural fit,” said Bob Davies, CEO of Crosby. “Together we complement each other perfectly. Crosby and Gunnebo Industries will be able to deliver enhanced value for customers and channel partners by providing a broader product portfolio, enhanced support and training, expanded geographic presence and greater ability to offer innovative solutions.”

Financial terms of the transaction were not disclosed. Alantra served as financial advisor to Crosby and Kirkland & Ellis and Vinge served as legal advisors.

Source: Gunnebo Industries.

BY JAY KOBLUN

Entitled, lazy snowflakes with big dreams and a constant need of approval. That’s how the keynote speaker at this year’s Crane Rental Association of Canada (CRAC) conference in June described how many people view millennials—the generation of workers born between 1980 and 2000.

David Coletto, CEO of Abacus Data and expert on millennials, shared at the Charlottetown, P.E.I. conference many of the different reasons why millennials are the way they are; act the way they act; and followed up with ways employers can recruit, retain, and motivate them.

He addressed the current problem that trades and the crane industry itself seem to be having a more difficult time bringing in young fresh workers who are committed to a new company, and that no matter how much employers may hope to live forever — they won’t. And that employers need to get involved in making their workplaces places where millennials could see themselves thriving in, because they are the ones who will be the new bosses and managers and CEOs in the not so far off future. He added that millennials have no problem bouncing around jobs until they find the most pleasurable work environment for them, which greatly differs from the mindset of the generation before them.

“Millennials love working towards a common goal and working with a purpose. Gone are the days of just putting your head down and working because you were told to. Millennials will ask why and will need a little more handholding than the generations that came prior,” he says. Coletto broke it down quite simply and said that despite

today’s employers being used to a more traditional leadership style, of employees just being happy to have a job, they will need to make concessions and meet millennials where they are, get to know how they work and more or less pat them on the back more than they’re used to.

“You need to shift the way you think about millennials in the workplace and try not to view them in such a negative light,” he says. “If you go into this with the mindset that they are annoying, needy and lazy, you’ve already lost.”

A millennial himself, Coletto asked the audience why they think they are lazy, and answered his question by saying it is partly the fault of their parents and a lot to do with technology.

“It has to do how we were all raised but also the role technology played in our upbringings and lives today still,” he says. “Us being lazy is often overexaggerated. Millennials are the most culturally and ethnically diverse generation to date, the most tech-savvy and also the most educated. Millennials also understand the dynamics in the workplace.”

Coletto’s company produces the largest re-occurring report on millennials in Canada and knows his stuff. With 2,000 Canadian millennials surveyed twice a year, his team asks them for their thoughts on current affairs as well as track their perceptions on brands, governments, ideas, and lots more. He finished off his talk by listing off the following five ways employers can better engage millennials:

• Remember that the fundamentals still matter. Millennials are still like everybody else in the sense that they want job security and want to be able to have the basics needs of living comfortably met.

• Give them the tools they need to succeed. Show them what to do and how to do it well. Even if it seems like making concessions and compromises — it’s the last generation that raised them to be this way.

• Communicate openly and freely.

• Uniqueness and personal expression is important. Give them opportunities to express who they are.

• Tell your story. Millennials love to tell their stories and help others share theirs. Get involved.

More CRAC AGM coverage to come in the Sept/Oct issue.

Photos by Andrew Snook and Phillip Stewart.

BY ANDREW SNOOK

Careers in cranes, rigging and specialized transport were on display on May 30, when Matcom hosted more than 200 students from high schools and colleges across Ontario at the company’s facility in Vaughan, Ont.

Matcom hosted Lift & Move, an industry-led initiative to address the skills gaps in the crane, rigging and specialized transport sectors, along with partners the Crane Rental Association of Ontario, and Anderson Haulage. The event featured opportunities for students to interact with professionals at 10 different career stations that each offered a look at careers in various skilled trades, such as welding, rigging, project management, and heavy hauling.

“Popular shows like ‘How It’s Made’ represent only a small part of the industrial sector,” stated Matcom president Matthew Rix. “It’s time to show the next generation of workers how the industrial machines they were watching were installed in factories. With the help of Lift & Move, Matcom and its partners will deliver a peek inside the world of rigging, heavy hauling, and cranes. Students will learn that this industry is the backbone of the industrial sector, and how these services impact their daily lives.”

LRT 1090-2.1: 47 m / 154 ft full power boom

LRT 1100-2.1: 50 m / 164 ft pinned boom

Safe & Strong High lifting capacities with a maximum of safety due to VarioBase®

Globally uniform load charts conform to ANSI, EN and further standards

Safe access points and flat deck

Comfortable Simple and easy to operate

Operator friendly extra wide and tiltable crane cabin

Sales and service directly from the manufacturer

Liebherr-Canada Ltd. 1015 Sutton Drive

Burlington, Ontario L7L 5Z8

Phone: +1 905 319 9222

E-mail: info.lca@liebherr.com www.facebook.com/LiebherrConstruction www.liebherr.ca

continued from cover

When operations commence at the Heartland Complex, the splitter will separate propylene gas from the propane, essentially helping set in motion the conversion of propane into recyclable polypropylene plastic.

“We don’t lift stuff like this every day,” said Craig Middleton, a project manager with Mammoet.

Crews used a 107-metre-long self-propelled modular transporter to move the splitter to a yard where it could be placed above the four jacks. Crews attached each corner of the splitter to a corresponding jack and lowered it on top of the trailers with its 97 metres running lengthwise. The overall length of the transport configuration, including trucks and trailers, was 180 metres.

Manufactured by Scheuerle, a German supplier of modular vehicles, the InterCombi transportation system consists of two trailers side-by-side under each end of the load, each with 26 rows of axles, for a total 832 trailer tires plus another 80 tractor tires. “There were over 900 tires on the road with that load,” Middleton said. “It’s pretty crazy when you think about it.”

The InterCombi system included load spreading mats and saddles to even the weight distribution, and a turntable on top of the load spreader and underneath the saddles provided a pivot point for rounding corners.

“Something that long doesn’t turn corners very well,” Middleton explained.

The 9.5-metre-wide load occupied much of the twolane roadway, so as the convoy crawled along at 10 to 15 kilometres per hour, crews directed opposing traffic to safe spaces on the side such as approaches, pullouts, and turning lanes. Likewise, the convoy periodically pulled over so vehicles travelling behind could pass.

Mammoet used up to 10 trucks to push and pull the trailers towards the final destination, arriving at the Heartland Complex three days later, on January 9. But the job was hardly done, with five loads remaining using various configurations of the same jacking and InterCombi trailer systems, with modifications for lighter loads.

A 63-metre, 682-tonne de-ethanizer stripper, which will separate ethane from propane, moved over four days in late January. Built by Dacro, it garnered second-heaviestload status for a few weeks until a 48.5-metre, 725-tonne polypropylene reactor edged it into third place. Manufactured by Cessco Fabrication in Edmonton, the reactor will convert propane into polypropylene resin. A 116-metre, 293-tonne de-propanizer, moved in late March, while a relatively small rectifier was slated to ship in May, and a 50-metre-long, 300-tonne purge bin is set to move in July.

The convoys followed an approved high-load corridor, which extended trips just beyond the suburbs into 150-kilometre journeys along an indirect path. This helped minimize the number of bridges, low-clearance overpasses and overhead wires. The transport crew used off and on-

ramps to bypass a few remaining low overpasses, and while load-spreading mechanisms worked well, engineers reinforced one bridge with an I-beam structure.

Weather was another challenge. Travelling with the splitter, crews lost traction on one icy hill and had to hook up additional trucks to get moving. The reactor, meanwhile, took a couple weeks to reach its destination, delayed by temperatures plunging below the normal operating temperature range of the transportation equipment.

Why travel during the coldest winter on record in northcentral Alberta? Even with serious weight distribution, the procedure required a travel permit, which in turn required winter travel for the two heaviest loads.

“There’s seasonal restrictions with axle weights to prevent oversized loads like this traveling in the summertime,” Middleton said. “There’s the potential to damage the roads, so certain levels of frost are needed.”

The journey doesn’t end with the delivery of the vessels. Mammoet sourced a 430-foot-tall, 1,600-tonne PTC35DS platform twin-ring containerized crane from its global repository to hoist things into place.

Designed by Mammoet in partnership with Huisman Equipment, the ring crane has 24 hydraulic jacks underneath to enhance stability. The crane also requires two designated operators and a supervisor as opposed to a single operator.

Just getting the crane to site took considerable planning. The machine is designed to be reconfigured into selfcontained shipping containers for transportation on-board ships. Josh Tremblay, a Mammoet project manager who oversaw crane and other logistics activity at the Heartland site, says crews had to reconfigure container weights and sizes to travel over highways.

“Those containers were too heavy to transport over the road on standard trailers,” Tremblay explained. “Quite a bit of engineering went into that and it took 30 days of loading and transport just to get it from Texas to Alberta.”

When the crane arrived in October, crews used a 275tonne crawler, a 180-tonne crawler and a 265-tonne allterrain crane to assemble it.

“It took 21 days to fully erect,” Tremblay said.

The manoeuvre to lift the 820-tonne splitter — upped to 975 tonnes thanks to piping, platform and related infrastructure that needed to be attached prior to hoisting —

was extremely tight.

“We had to make sure it was precisely located so there wouldn’t be any interference for tailing the vessel,” Tremblay said. “Because the vessel was so heavy, the crane during the lift was at 97 per cent, so there was limited room for the operator to actually boom out further from the crane. We had to ensure the placement of the vessel, when it came on-site, was as-per the engineered lift study because we were playing with inches.”

Crews used a 750-tonne Liebherr LR1750 crawler for tailing. And, because the lifts are in slightly different locations at the outdoor facility, and it’s difficult to move the ring crane on its own, Mammoet configured a 76-axle selfpropelled modular transporter, also made by Scheuerle, to go underneath the jacks to drive the crane as needed.

Steven Noble, a spokesperson with Inter Pipeline, says massive industrial vessels are generally built where they will be installed in order to avoid complicated travel arrangements. But a cost-benefit analysis determined it was optimal to build off-site and do the extra heavy lifting, and the ring crane and InterCombi trailer system enabled this.

“It was an incredible feat of logistics,” Noble said. “The complexities were extensive, so when the splitter and the reactor were put into place with the ring crane, these were

significant milestones that everybody at Inter Pipeline was really thrilled to see finally fall into place.”

Noble said it’s hard to fathom anything big and strong enough to lift 975 tonnes. “You see the crane arrive in rail containers and then they build it like a Lego set over three weeks. If you’ve never seen it before you wonder how that’s all going to come together. And then all of a sudden it’s hoisting these giant vessels in an incredibly short period of time.”

With completion expected by late 2021, the Heartland Complex stands to become Canada’s first integrated propane dehydrogenation and polypropylene facility, equipped to convert locally sourced propane into 525,000 tonnes of polymer-grade polypropylene annually.

Until now, Canadian producers have shipped propane to the U.S. for conversion into polypropylene before reimporting it at a higher cost.

“The significance to the project is really the story of diversification,” Noble said. “Finding new ways to use the oil and gas products that we have and for the province to expand its economy and get our products to different markets by means other than pipelines. The impact of hundreds of millions of dollars coming into Alberta each year once this project is operational will be felt nationwide.”

Photos courtesy of Mammoet.

continued from cover

The work would require a specialized crane solution, so Masco Crane and Hoist were contracted to deliver one. Collaborating with Inkpen Engineering and Drafting, they designed, drafted, engineered and fabricated two 40-metric-ton live gantry cranes capable of operating in tandem to remove sections of the concrete bridge decking and girders and to install new steel structure girders. Masco named them Goliath Outdoor Gantry Cranes.

“In the past, the typical way of doing this was to build piers into the river bed and they would mount big mobile cranes down there,” says Masco vice-president Steven Beck, on why gantry cranes were the ideal solution. “To have mobile cranes down there would be quite costly and there would be environmental impacts. So they used the existing bridge piers to mount the support structure for the gantries so it was a very limited environmental impact on the river, the river bank or the surrounding area.”

There was no permanent power source on site, so each crane was outfitted with a 125 kVA diesel generator. Masco had to build a platform to mount those generators, as well as electrical components. Another challenge was that the end user wanted the crane to be able to navigate the gradeability of the bridge.

“They wanted the runway beams to follow the camber of the bridge,” says Beck. “A typical installation, you would try and build your runway system as flat as possible, but because of the design of the bridge, and the design of their runway system, it had to be able to negotiate the gradeability.”

The crane also had to have an adjustable span, as the bridge was taken apart in two phases – one side of the bridge would allow traffic to pass while the other side was being worked on. But, due to the pedestrian walkway, the two spans weren’t identical. The cranes were built to accommodate the different spans, so that once one phase was complete, the gantry would be lifted and turned onto the other side of the bridge.

“We’ve got a fixed leg, a permanent leg that is with an angle brace under the girder to keep that rigid, but on the other side we have a pivoting leg, so that leg – as it travels down the track – is actually able to rotate around those pins,” Beck says. “We had to do that because there is going to be some variance in the span of the runway system just based on the movement of the bridge structure over the duration of the project, because we’re going from extreme cold in the winter to extreme hot in the summer, and there’s going to be a lot of movement in all the bridge structures, so there was some concern about the span changing during the project. We were able to make it pivot so that during the course of the project, if the bridge moves, it can accommodate without having to do a bunch of adjustments of modifications.”

Masco erected and installed them on site and did some early testing. They also completed on-site training with all the crane operators and certified them for use with those gantries and the specific lifts that would be performed.

“A regular crane course is going to be about a full-day course for this type of application and capacity of crane,” says Masco CEO Matt Beck. “This was a two-day course that was put on right at the bridge itself, day one was in the classroom with all of the operators going through the legislations, safe operating practices and how these cranes will operate in their safety features. Day two, we spent the entire day on the bridge deck, taking the operators through how to do a correct pre-shift inspection, how to start the cranes up, how to do lifts. It’s definitely a little bit different in that the cranes are very specific for these applications, right down to how they start up, how they use them, operating the remote controls in tandem and all the different safety features.”

Masco started fabrication in early May 2018 and started installation in mid-November. By January 2019, the gantries were fully installed, tested and in use. The Goliath Outdoor Gantry Cranes are expected to be in use on the bridge well into 2020.

Employers, supervisors and workers all share a responsibility and play an essential role in the safe placement, operation and inspection of concrete pump trucks.

Concrete pump trucks are part of WorkSafeBC’s Crane Inspection Initiative, which sees prevention officers focusing on the pump trucks’ major inspectional requirements, safe set-up location, operation, and maintenance, to help prevent injuries from occurring.

The Crane Inspection initiative is one of 17 industry initiatives designed to align prevention efforts with specific industries that present a high risk of serious injury to workers. From 2013 to November 2018, WorkSafeBC accepted 104 time-loss claims, and there was one workrelated death in the concrete pumping industry.

Work sites with concrete pump trucks are often congested, with multiple pieces of complex equipment working simultaneously. In many cases, the soil has been disturbed or major excavations are underway.

There are a number of variables to consider in the evaluation of a safe pump truck set-up location:

• Has the pump-truck set-up location been identified and evaluated for potential hazards?

• Are there traffic control arrangements to allow the pump truck to arrive and set up at the workplace?

• Have overhead power lines and underground utilities been located, identified and considered?

• Can the machine’s outriggers be fully extended and set?

• Is the pump truck being set up adjacent to an excavation, shot concrete wall or elevated structure?

• Is there appropriate outrigger cribbing available at the workplace?

• Are there overlapping equipment procedures and communication in place?

Failures related to the set-up location, poor ground conditions, insufficient cribbing or short-rigging outriggers on concrete pump trucks are a risk on worksites.

WorkSafeBC is working with all parties — the prime contractor, sub-contractor, concrete-placing crew and concrete pump-truck owner/operator — to review what’s required to ensure a safe machine arrives on site and is correctly set up in a safe work environment.

Concrete pump trucks can flip over due to ground condition instability. The truck has to be level so the boom and slewing mechanism aren’t stressed. If the ground fails with the boom extended, the pump truck will roll over. The trucks can reach up to 70 metres, and the industry trend is towards larger trucks with farther reach, which further heightens the risk.

It’s imperative that owner/operators read the manufacturer’s instructions. The instructions confirm safe set-up and operating procedures for the machine, including maximum outrigger loading force, and identify the outrigger cribbing size that must be used for specific soil conditions. Correct set-up and placement are both requirements under Part 20 Construction, Excavation and Demolition, of B.C.’s Occupational Health and Safety Regulation.

WorkSafeBC officers who conduct inspections on pump trucks will also be confirming that annual inspectional requirements are met. The regulation requires pump trucks be inspected in accordance with the CSA Z151-2009 Standard.

The standard requires that pump trucks’ critical components, including structural, mechanical and control elements, be inspected annually. Employers are also asked to provide documentation confirming all critical machine components have been inspected and that a professional engineer has certified them as safe for use.

This information is covered in sections 20.26.3 and 20.47 of the regulation.

WorkSafeBC works in collaboration with the industry association, ConcreteBC. Members of the association and WorkSafeBC organized four training and education events in 2017 and 2018. These events entailed the exchange of industry information and regulatory requirements, with the goal of helping to prevent future concrete pump-truck incidents from occurring.

Learn more at worksafebc.com.

WorkSafeBC resources: Guidelines Part 20 – Concrete Pumping WorkSafeBC Bulletin.

Doug Younger is an occupational safety officer with WorkSafeBC.

MI-JACK CANADA offers unsurpassed customer support, led by the best Factory Trained Service Technicians, the most knowledgeable Parts Professionals, all backed by North America’s leading equipment group. As a part of the Lanco Equipment Group, along with Walter Payton Power Equipment and Western Pacific Crane & Equipment, we are now part of the World’s Largest Manitowoc Dealer group.

New and Used sales along with Rental Purchase options, MI-JACK CANADA is your source for Immediate Availability on the full line of Manitowoc and Grove cranes. Your Authorized Distributor in Alberta and Saskatchewan for Manitowoc and Grove Sales, Parts and Service. STRONG LOAD CHARTS | LONG BOOM LENGTH | LOW GROSS VEHICLE WEIGHT NOW AVAILABLE FOR IMMEDIATE DELIVERY

MI-JACK CANADA stocks Manitowoc and Grove cranes and is part of North America’s largest parts inventory, on-hand and ready to ship

The Crane Rental Association of Canada congratulates the following companies for their commitment and dedication to safety.

ABCO CRANE SERVICES – Nisku, AB

AMHERST CRANE RENTALS LTD. – Toronto, ON

ARCTIC CRANE SERVICES LTD. – Grande Prairie, AB

CANADIAN CRANE RENTALS LTD - Wingham, ON

CONCRETE PUMPING & CRANE SERVICES – Yellowknife, NT

ENTREC CORPORATION – Acheson, AB

IRVING EQUIPMENT LTD – Saint John, NB

MAMMOET CANADA – Edmonton, AB

NCSG CRANE & HEAVY HAUL SERVICES LTD – Acheson, AB

RKM SERVICES LTD – Langley, BC

STERLING CRANE – Edmonton, AB

BY RALF NOTHEIS

With our economy continuing to stay strong, the North American population has now exceeded 366 million people. Every day, thousands of cranes are working long hours to keep up with construction demands and well-trained, certified operators are becoming difficult to find.

Most jurisdictions require crane operators to hold a valid certification, which is achieved by completing a written exam and a practical assessment. On larger mobile cranes and tower cranes, the certification process is typically an apprenticeship; which can take years to complete while the certification process to operate boom trucks is competency based and a lot less difficult.

The fact remains that many of the same hazards exist for all crane operators (and everyone around them) regardless of crane type and size.

While overhead power line electrocutions remains the No. 1 cause of injuries and fatalities, workers being struck by loads follows close behind. A large percentage of these incidents are caused by lack of training or poor-quality training, such as bad advice from peers.

Many times I’ve heard operators tell me, “I’ve been doing it this way for 30 years.”

The reality is they’ve been doing things improperly for 30 years and somehow got away with it. It doesn’t make it OK.

During busy times it’s not uncommon for an operator to be hired and running a crane for that new company the very next day.

This is a recipe for disaster. It is an employer’s responsibility to ensure that operators are qualified to operate the specific crane they are assigned to. This involves formal training, an assessment of their level of competence by a supervisor and documentation proving the training and assessment have taken place. This process ensures that an operator is properly trained to safely drive, set-up and operate the unit and identify the different hazards that exist on the specific make and model of crane. From jib erection procedures to maintenance requirements like intervals for checking torque on turret bolts, all cranes have different technologies, components and maintenance needs that operators must be aware.

The three basic components to operating a boom truck are the pre-operational inspection, hazard assessment/crane set-up and operation.

Each shift should start with a preoperational inspection of the crane. This consists of thoroughly looking for defects and completing the checklist in the crane logbook. Ensuring the crane has a valid annual certification from an engineering firm is always a good start. If a defect that may affect the safe operation of the crane is found, the operator must not use the crane until a qualified person has repaired the defect – even if a superior is giving instruction to do so.

Continued from page 13

Aside from safety, a good operator will also use simple tactics such as only telescoping the boom at a high angle to avoid unnecessary wear and tear, or shutting the machine off during breaks to save fuel and avoid a massive spill if a leak occurs while they are not with the machine. These are operating practices that professionals use out of respect for a crane that they rely on to pay their wages.

In closing, I’d like to mention one very important phrase: Never assume anything. This applies while operating a crane or when a supervisor assigns a task to a worker. Assuming no limbs are in the way of an outrigger being retracted or assuming

BY BRADY HAUGO

Boom trucks commonly use aerial work platforms with booms that rotate 360 degrees. This allows the operators more freedom to move the work platform to a desired position. Most of the different styles of aerial work platforms have hydraulic and electrical requirements after the rotation joint. This means fluid power and/or electrical power and signal are needed to pass through the rotational joint.

The rotational joint is key to allowing the boom and operator 360-degree rotation without getting the hoses and wires tangled up. The rotational joint consists of the slewing bearing, which takes the brunt of the mechanical loads and hydraulic swivel and electrical slip ring that transfer the fluid power and electrical power and signal. The hydraulic swivel and electrical slip ring combined are referred to as a combination unit.

The operation of aerial lift platforms entails the operator controlling the position, direction, and speed of the aerial work platform from within the platform. Precise control is critical when working next to potentially dangerous situations. These controls use electric signals to control hydraulic valves that open and close—allowing movement of the work platform. The electrical slip ring and hydraulic swivel work in conjunction to not only get the operator’s input signal to the hydraulic control valve, but also get the fluid power from the hydraulic pump and/or hydraulic control valve to the cylinders and motors that move the platform.

The hydraulic swivel and electrical slip ring (combination unit) sits at the centre of rotation inside the lift platform boom. The combination unit needs to sit at the centre of rotation to allow 360-degree rotation. Due to the relative size and weight of both units, the electrical slip ring attaches to the hydraulic swivel. The hydraulic swivel will have much higher torque values than the electrical slip ring. The hydraulic swivel is also much heavier. Because of this, the electrical slip ring attaches onto the hydraulic swivel and piggybacks the torque restraints of the swivel.

Aerial lift platforms are actually a light duty application for both the swivel and slip ring. The environment lends itself to not needing additional protection from debris; the combination unit is usually well protected deep within the machine. The slip ring in this application typically has more than a few circuits. Within the slip ring, the circuits are stacked on top of each other, so the more circuits, the longer the unit is. The specific requirements of this application tend to favour one type of combination unit over the other.

UEA offers three different types of combination units:

• Fully integrated – The slip ring fits into the housing of the swivel. There’s no additional slip ring cover.

• Partially integrated – The slip ring fits directly on top of the swivel. There’s a separate slip ring cover and no mounting tube.

• Separated – The slip ring stands off the swivel with a mounting tube and flange. There’s a separate slip ring cover and base casting.

With the higher number of electrical circuits on an aerial lift platform, the application lends itself more commonly to the separated style of combination unit. With the lack of debris issues and long slip ring, the separated style is the most economical choice.

The separated style uses a base casting that contains the bearings, cord grip threads, and cover-mounting surface. The partially integrated version still requires the cover mounting surface and cord grip threads, but not the bearings. The core of the slip ring on the partially integrated version mounts to the spool of the swivel. The base casting and brush studs mount to the housing of the swivel.

The separated style combo unit is more economical, it’s sold in higher volumes, and its component prices are lower due to better economies of scale. We cannot say the same thing for other industries and applications.

The partially integrated combo would be the second most reasonable choice. The partially integrated style uses a spun aluminum cover. The brush harness that exits out of the slip ring needs a liquid tight cord grip. The spun aluminum cover doesn’t provide the necessary strength and rigidity for the cable grip. This requires us to use a partially modified base casting bolted to the hydraulic swivel housing.

UEA sells more of the separated styles of combination units than any other style. The fully integrated style wouldn’t be economically feasible for this application unless there were extreme debris or water intrusion requirements. Due to the higher number of circuits, covering the slip ring with the hydraulic swivel housing as in the integrated version would end up being more expensive than using a spun aluminum cover to cover the slip ring.

Using specific customer requirements to come up with a custom solution to the exact application at hand is our company’s approach to solving issues.

an operator understands how to install an offset jib because they have done this type of work in the past are both situations that have caused many injuries and fatalities. Proper training is required for every aspect of operating a boom truck right down to fuelling up at the end of a shift. In a perfect world there will always be a proud journeyperson there who is happy to share their years of knowledge with industry.

Ralf Notheis is the manager of Bigfoot Crane Academy.

continued from cover

“It could take six months to a year before you get anything officially reported from there,” says Fraser Cocks, executive director of the British Columbia Association for Crane Safety. “There’s a lot that goes on behind the scenes that people don’t realize. And then, of course, it’s all kind of gone out of the public mind’s eye, but it’s still pretty fresh in the industry.”

The mayor’s promise to ensure that cranes are safe carries an implication that, if the investigation finds it warranted, regulations could be changed in the future. Such regulation changes could be copied by other jurisdictions, as they will want to avoid similar incidents. Cocks says that these incidents will cause government and industry to take a step back and review their practices, particularly if the findings clearly identify what the cause was.

“Everybody in this industry, especially in the tower crane industry, they take this very seriously and the government does as well,” Cocks says. “But as everybody says, the unfortunate thing about regulatory requirements is they all seem to be written in blood. Somebody had to be hurt, injured or killed in order for change to occur. That’s not the way it should be done. But all too often, that’s the result.”

A crane collapse in San Francisco in the late 1980’s was the impetus for the institution of crane certifications by the Federal Occupational Safety and Health Administration. A school bus driver was killed in the collapse, but the public was particularly outraged over the potential consequence –what would have happened if there had still been children on the bus? Public outcry from the Seattle incident could drive new regulations for the industry.

“Public pressure is big,” Cocks says. “Those things are over top of everyone’s heads. This is a really good example of how catastrophic it can be. That gets people’s attention… we respond, but how do we get to the place where we’re responding before these things occur? That’s what I do here – try to look at it and engage with industry to identify those issues and possibilities.”

Cocks says that BC Crane Safety is a very proactive group, working full time on certification and working with industry to develop preventative measures. Well beyond catastrophic events, such as Seattle, they also analyze data from smaller incidents to identify trends and opportunities for improvement. Generally, most businesses acknowledge the obvious fact that whatever benefits are gained from cutting a corner are lost when it eventually results in a major incident that can affect not only themselves but the industry at large.

“Eighty per cent of the industry is probably doing the best thing and the right thing,” Cocks says. “It’s that 20 per cent – there’s always that element that they’re pushing the edges, flirting with whatever they can get away with, driven by the need to make money and do it faster, do it cheaper. Our role is to level the playing field to make sure that those that are skirting the edges are kept within and not getting outside of those lines. It only takes one incident.

While the official investigation into the crane collapse in Seattle is still underway and may not conclude for many months, this is a unique incident because there is video of the collapse readily available online. As such, many analysts have examined the footage and determined a few key elements.

Going back to Seattle, we don’t know yet if that’s what this is, how bad that was.”

Whatever changes result from the Seattle collapse, and other incidents like it in the future, it is key to ensure that it’s the right changes that are being made. Simply making a reactionary change to rules and regulations without careful consideration can make things worse.

“It’s a little like the wild west,” says Cocks with a laugh. “The posse sets out to do something because somebody got shot, but they may or may not have got the right person.”

For industry, Cocks insists, the important thing is to come together and discuss how to prevent incidents without making things worse. The better solutions will come from within, rather than being imposed by government.

“If you’re in government, this is crass to say, but it’s all about making the noise go away,” Cocks says. “They don’t like the noise; find a way to make it quiet again, whatever that means.”

In the case of Seattle, because it was such a catastrophic crash, Cocks doesn’t expect the noise to die down soon.

“They’re not going to give on that – this will go all the way and somebody’s going to end up owning that responsibility and made accountable, I would expect,” he says.

September 2019

September 10-12, 2019

CCA Fall Board Meeting Whitehorse, Yukon www.cca-acc.com

September 15 to 17, 2019

BCRB Annual Fall Conference

Whistler, B.C. www.roadbuilders.bc.ca

• Crane Outrigger Pads

• Boom Truck Outrigger pads • Heavy Duty Blocking

• Standard & Custom Sizes

Most important is the observation that the crane cleanly separated into sections as it fell, indicating that the pins and bolts of the entire crane had likely already been removed when it collapsed. Doing so would make the crane more susceptible to the effects of winds.

“The reason this tower fell over is ironworkers and the people working on it did not follow the manufacturer’s instructions for disassembling the crane,” South Carolina crane accident investigator Tom Barth told The Oregonian. “If the pins had been in, that crane would not have fallen over.”

Barth told Crane & Hoist Canada that while there may not be a specific regulation prohibiting the early removal of pins, it is in regulations to strictly follow the manufacturer’s instructions. Depending on the outcome of the investigation into the incident, it is possible that a specific pinremoval regulation may be developed.

September 18-20, 2019

SC&RA Crane & Rigging Workshop Glendale, Ariz. www.scranet.org

October 2019

October 28-30, 2019

Commercial UAV Expo Las Vegas, Nev. www.expouav.com

December 2019

December 5 to 7, 2019

BC Road Builders AGM

Victoria, B.C. www.roadbuilders.bc.ca

Visit www.craneandhoistcanada.com for the latest news, stories, products and industry events.

Liebherr has introduced a new fast erecting crane, designed for civil engineering requirements including traffic bridges, commercial and industrial construction. The Liebherr 125 K was presented at the bauma 2019 trade fair in April and is now available worldwide.

The crane has an initial hook height of 29.5 metres, with the option of inserting five tower sections to reach a total hook height of 41.5 metres. Further, a 30-degree luffed jib position will extend the possible height to 65.5 metres. The crane has an 8,000 kg capacity and an adjustable radius ranging from 35 to 55 metres.

Special features of the crane include Micromove fine positioning, two-line operation Speed2Lift, and options such as external K-crane cabin and LED floodlights.

The 125 K can also be towed as a trailer by a conventional truck or transported via semi-trailer.

The crane features a new axle system called LiTRAX, which has three units that can be used in various combinations allowing flexibility and a variety of options. www.liebherr.com

Where other cranes literally hit their limits, the Demag AC 45 City crane delivers. The 3-axle unit redefines compactness in the 45-tonne lifting capacity class with a total length of only 8.68 metres, a width of 2.55 metres, and an overall height of just 3.16 metres. The AC 45 City is also able to work in buildings with a relatively low clearance while still keeping its boom at a steep angle. This advantage comes in handy, for example, when assembling overhead cranes, as the AC 45 City crane can lift heavy loads at a small radius. In addition, its fully hydraulic 31.2-metre main boom means it can get ready to start working much faster than comparable cranes with booms that need to be set up with pins.

Another feature the IC-1 Plus control system. The system determines the crane’s lifting capacity for every boom position as a function of the superstructure’s slewing angle, and in real time to boot. This means that the lifting capacity for a specific radius is no longer limited to the lowest value for a pre-calculated 360° lifting capacity, as used to be the case. The IC-1 Plus control system also features the capacity radar which determines and shows the working range of the real time lifting capacity within +/-30° slew angle. Moreover, the control system is equipped with an automatic counterweight detection function that the crane operator needs to confirm.

With its new electrohydraulic E-Pack, the AC 45 City can operate with zero emissions, and also makes it significantly quieter. www.demagcranes.com Liebherr

All of Falcon Equipment’s favourite builds start with a vision, this unit was no different. The owner of this truck wanted the longest reach crane that Hiab had to offer to be paired with the cleanest, heavy spec pre-emissions truck on the market. For those of you in the business you can imagine this would not be an easy task, but for Falcon Equipment it was just another day at the office!

The Hiab 858 E8 HiPro with 124-feet reach, features a six-section jib and has synchronized automatic hoist controls. This unit has a maximum pick of just under 40,000 lb. making any job possible. Most recently, the unit has been travelling the narrow downtown Vancouver alleys avoiding power lines to complete rooftop deliveries that a long-reach stiff boom crane would struggle with. www.falconequip.com

Available to North American customers as the GR-1200XL and to customers outside the North American market as the GR-1100EX, the rig has a maximum lifting capacity of 120 tons (110 tonnes) and features a 183.7-foot-long boom (56 m). A prototype of the model was introduced to the industry at the CONEXPOCON/AGG show in 2017. The GR-1200XL is now in full production and available to Tadano America clients for sale.

The GR-1200XL was designed with North American industrial energy sites in mind, filling a niche market demand for cranes in the 120-ton class. These sites often require cranes to have high maneuverability, durability, and lifting performance under tough conditions. The 120-ton GR-1200XL gives buyers a rig between the GR-1000XL and the GR-1600XL and meets their needs for a higher reaching rig with longer boom length and larger lifting capacities.

The GR-1200XL has the largest maximum lifting capacity in Tadano’s rough-terrain crane product line. Its strong yet light, high-tensile steel, rounded boom features a single telescopic cylinder. It gives the crane a 184.0-foot (56.1 m) lifting height and 150.0-foot (45.7 m) load radius. Its jib provides additional reach, extending the lifting height to 241.4 feet (73.6 m) with a load radius of 159.0 feet (48.4 m). The GR-1200XL rig’s ease of transport and onsite maneuverability are largely due to its compact carrier size, with dimensions similar to the Tadano GR-1000XL carrier. Overall rig length is 47 feet 5 inches (14,450 mm), but its carrier is just 28 feet 5 inches (8,655 mm) long.

Additional features include HELLO-NET telematics and Tadano’s new Smart Chart system. HELLO-NET telematics help customers optimize their operations with real-time monitoring of crane activity, history, position data and maintenance information.

The environmentally friendly GR-1200XL comes with both Tadano’s state-of-the-art EcoMode fuel monitoring system and Positive Control. Eco-Mode reduces fuel consumption while the crane is operated. Positive Control economizes fuel consumption while the crane is on standby.

www.tadanoamerica.com

Potain has previewed its first mobile Hup self-erecting crane, the Hup M 28-22, at bauma 2019. The Hup M 28-22 is the third model from the groundbreaking Hup self-erecting crane range but the first to prioritize mobility.

The new design of the Hup M 28-22 provides best-in-class compactness. The model is only 11.5 metres long when folded, enabling work in narrow, restricted job sites, as well as making it easy to transport from site to site. The Hup M 28-22 also features the most advanced transport equipment with double steering axles.The Hup M 28-22 has a 28-metre jib and features 16 configurations, which is unique to this category of self-erecting cranes, enabling it to be easily adapted for a range of job site applications. The crane has a maximum capacity of 2.2t and can lift 850 kg (1874 lb.) at its 28-metre jib end.

Versatility is delivered with the crane’s raised jib that offers four positions: horizontal, 10°, 20°and even 30°. These functions give the crane a height under hook range between 20 metres and 31 metres. Folding or extending the jib is a swift and straightforward operation, with the Hup M 28-22 offering convenient configurations for both short and long jib lengths.

Operator productivity on the Hup M 28-22 is maximized through Manitowoc’s remote control unit. The remote system features a large, colored screen with easy to use navigation and optimized ergonomics for operator comfort. Its Smart Set Up software delivers onscreen, information on automatic folding and unfolding of the crane from the crane’s remote.

Like the other Hup models in the range, this new model also benefits from Manitowoc’s unique Drive Control functionality: three selectable profiles for operators that vary the working speed of the crane to suit the application. On the top of that, the micro-speed function delivers slow and high precision hoisting.

The crane is scheduled for launch in 2020. www.manitowoccranes.com