Huge Liebherr mobile crane may have been tallest ever seen in city

BY MATT JONES

n May, the skyline of downtown Winnipeg was changed significantly with the removal of the last tower crane on site at True North Square. Phase 1 of the project, involving Tower 1 at 242 Hargrave St. and Tower 2 at 225 Carlton St., began in January 2016. The substantial construction effort required significant crane work, with construction handled by PCL Constructors Canada Inc. and the dismantling subcontracted to Sterling Crane.

“Tower 1 topped off its structural building form in December 2017, reaching its final height of 17 storeys, and subsequently its tower crane was removed in January 2018,” says True North Real Estate Development president Jim Ludlow. “Tower 2 topped off in March 2018 at 25 storeys and its tower crane was removed in May 2018. These milestones have had a visible impact on the skyline of downtown Winnipeg, so they have been very exciting and rewarding to observe as we progress towards a new cityscape.”

TThe Crane Rental Association of Canada hosted its 20th anniversary Annual Conference from June 6 to 9 in Winnipeg. Crane professionals from across the country descended upon The Fort Garry Hotel with 179 people attending the milestone event.

During the annual general meeting, CRAC members offered highlights of the association’s activities over the past 12 months, which included: an update of the boom dolly research committee;

Are helicopters leaving cranes up in the air?

Two hoisting machines co-operate in Ontario

It was thumbs-up as the Sikorsky S58T lifted off from the Brampton, Ont. hangar Sprint Mechanical shares through a partnership with Four Seasons Aviation.

Were it not for their radio communication headsets, the eight crew members would have relied fully on hand signals and yelling as the twin-engine helicopter whirred deafeningly towards Cambridge Centre shopping mall in Cambridge, Ont.

“We’re flying at about 115 miles per hour and we’re at about 500 feet above ground level, so we’ll have to watch out for cell towers,” explained Ian Bergeron, Sprint’s vice-president of safety and legal affairs.

A half-hour later, about the time it took the sun to rise into full view, we had passed over small woodlots, ponds and farm fields and landed onto a parking lot that was empty; save for a fuel truck, 19 large HVAC units and two dozen crew members.

Publications Mail Agreement #PM40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO

Editor – Andrew Snook • asnook@annexbusinessmedia.com. Tel. 289-221-8946

Advertising Manager – Jeremy Thain, jthain@annexbusinessmedia.com

Tel. +1-250-474-3982, Toll-Free (North America) 1-877-936-2266

Art Director – Svetlana Avrutin

Regular Contributors

Saul Chernos, Grant Cameron, Nelson Dewey, Matt Jones

Group Publisher – Scott Jamieson • sjamieson@annexbusinessmeda.com

President & CEO – Mike Fredericks

Circulation Manager – Barbara Adelt

badelt@annexbusinessmedia.com

Subscriptions – Bona Lao – blao@annexbusinessmedia.com

Tel: 416-442-5600 • 1-800-668-2374 (CDN) , ext. 3552

Fax: 416-510-6875 or 416-442-2191

www.craneandhoistcanada.com

Annex Privacy Officer – Privacy@annexbusinessmedia.com

Tel: 800-668-2374

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $36 per year in Canada. For subscriptions in the USA the price is $36 USD. Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875.

Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT.

111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

ISSN 1923-788X

Next Advertising Deadline: July 27, 2018

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Jeremy at our Advertising Department - Toll Free 1.877.936.2266 jthain@annexbusinessmedia.com

Next Editorial Deadline: August 6, 2018

For writers’ guidelines and submission requirements get in touch with the Editor, Andrew Snook, at 289.221.8946. Email: asnook@ annexbusinessmedia.com

When checking out the latest news on the Canadian economy, you certainly don’t need to look very far to find stories filled with dread and worry. Let’s highlight a few of the bigger ones: U.S. President Donald Trump’s steel and aluminum tariffs imposed on Canada and other allies; his frustrations with Justin Trudeau at the recent G7 Summit meetings in La Malbaie, Que.; still no softwood lumber agreement in place; stalled NAFTA talks; and the federal government’s highly criticized purchase of the Kinder Morgan Trans Mountain pipeline. But does that mean its all doom and gloom for the crane industry? Far from it, I say.

Canada’s construction rental revenues are expected to hit $4.3 billion in 2018 and will grow from there for the next five years, according to the American Rental Association’s recent five-year forecast.

On the building front, the latest building permit numbers from Statistics Canada (April 2018) show residential building up 6.5 per cent from the prior 12-month period. And the oil and gas industry is still expected to experience modest growth.

In the Spring edition of the Alberta Oil & Gas Quarterly Update, the Petroleum Services Association of Canada expect 3,807 wells to be drilled in Alberta in 2018, and that the combination of oil expected to remain in the low-to-mid US$50 range, and increased interest in liquid natural gas, should support a four- to five-per-cent increase in activity levels.

And let’s not forget about the ports. Several ports around Canada are in the midst of major improvement and modernization projects (or have recently completed them). Some of these expansions include the need for

new cranes to handle expanded capacity at the ports, in addition to the need for cranes during the various construction phases of the projects.

At Port Saint John the federal government and the Province of New Brunswick have started work on a seven-year, $205-million port modernization project. This will include a wide variety of improvements of its infrastructure, including improved main channel depth, load bearing capacity, berth depth, container yard handling capacity, rail yard capability, truck movement capacity, container handling areas, and more. As part of the project, the port expanded its crane capacity with the purchase of a pair of 1998 Paceco electric drive cranes with a 50-60 ton capacity so it could handle 6,500-TEU capacity vessels.

The Port of Prince Rupert in B.C. completed its expansion project not long ago and can now handle the largest vessels in the ocean. This project included the purchase of three brand-new Malaccamax cranes to complement its existing four Super-post Panamax cranes, as well as the purchase of six rubber tired gantry cranes.

The Port of Trois-Rivières also recently completed its On Course for 2020 project earlier than anticipated. The $131.6-million project significantly expanded the port’s overall capacity. And with the federal government launching its Ports Modernization Review, one can expect more funding announcements in the near future.

Things aren’t perfect right now in our economy –especially when it comes to trade relationships between Canada and our neighbours to the south – but moderate economic growth is still expected in 2018, so try not to buy into everything being all doom and gloom. There’s still work to be had.

This unique crane was submitted on behalf of Ron Burelle, owner of Regional Crane Rentals Ltd. in Ottawa Ont.; a crane company with over 40 years of experience. The company converted an old Volkswagen Beetle into a cool eye catcher. Hopefully it can give the Ottawa Senators a little lift next season.

Have a unique crane you think readers would like to see?

Email a photo and brief description to editor Andrew Snook at asnook@annexbusinessmedia.com.

The Crane Rental Association of Canada recognizes outstanding achievements by member companies for their commitment to safety in 2017.

CRANE

NB

NIWA CRANE LTD.

Medecine Hat, AB

NCSG CRANE & HEAVY HAUL SERVICES LTD.

Acheson, AB

STERLING CRANE

Edmonton, AB

The Government of Alberta recently announced that the 2018 Budget includes a $90-million investment in a new Highway 38 bridge across the North Saskatchewan River, south of Redwater. The new bridge will be able to accommodate heavy and oversized loads of more than 200 tonnes, while forming a critical link in Alberta’s High Load Corridor that is expected to save heavily loaded trucks approximately 200 kilometres of travel.

“This river crossing will save time and money as these critical loads travel into and come out of our northern regions,” said Minister of Transportation Brian Mason. “The new bridge will become a major component of the High Load Corridor and will help the energy sector become more competitive.”

More than 400 heavy loads were transported through the existing High Load Corridor, about 200 kilometres to the east. Alberta Transportation expects carriers to save an average of $10,000 per trip compared to the existing route.

The planning and design stages are expected to start this year. Approximately 2,000 vehicles currently cross the existing Highway 38 bridge on a daily basis.

“World-class infrastructure for the

movement of goods and services is critical for current industry and for attracting new investments for the diversification of Alberta’s energy economy. Alberta’s Industrial Heartland Association is pleased that the Government of Alberta is prioritizing this project and is investing in key transportation corridors in Alberta’s Industrial Heartland,” added Gale Katchur, mayor of Fort Saskatchewan and chair of Alberta’s Industrial Heartland Association. The project is expected to generate 265 direct construction jobs and 190 indirect jobs in associated industries.

In its latest five-year forecast, the American Rental Association (ARA) projects that Canada’s equipment and event rental revenue will total $5.4 billion in 2018 and grow each year to reach $6.3 billion in 2022.

The construction rental revenue forecast for Canada is for $4.3 billion in 2018, up 4.7 per cent, with growth rates of 4.2 per cent in 2019, 5.3 per cent in 2020, 4.7 per cent in 2021 and three per cent in 2022.

In the U.S., ARA Rentalytics have forecasted construction rental revenues to grow by 6.1 per cent to reach $36.2 billion and to increase another 5.7 per cent in 2019, 5.3 percent in 2020, 4.2 per cent in 2021 and 3.5 per cent in 2022.

“The economy is growing somewhat faster than expected and much of that is related to capital spending,” says Scott Hazelton, managing director, IHS Markit, Cambridge, Mass., the global business information provider that compiles data and analysis for ARA Rentalytics. “While construction is not particularly strong [in the U.S.], it has improved. On a year-over-year basis, through the April Census report, construction spending had picked up, with the six-month annualized increase of 8.7 per cent, up significantly from the 12-month increase of three per cent. Despite uncertainty on tariffs, trade and Middle East policy dangers, business and consumer sentiment remain strong,” Hazelton says.

Source: American Rental Association.

By SC&RA

Effective July 1, 2018 all superload permit moves in Ontario, which previously required Ontario Provincial Police (OPP) escorts, will instead require newly certified pilot escorts through the Certified Superload Escort Program.

This is a first of its kind rule in North America in which a state or province replaces all previously required police escorts with newly certified private escorts.

SC&RA and several of its Canadian members collaborated with the Ministry of Transportation (MTO) for over a year as they worked to implement the new rule. There will be a brief contingency period in which the OPP may fill in but it will be short term and will be ended once the MTO believes enough newly certified escorts are available. MTO officials estimate they’ll eventually need over 300 newly certified escorts to handle the approximate 4,000 permit moves per year previously escorted by OPP. Officials expect most municipalities that currently require police escorts within their municipal limits will adopt the MTO’s new private escorts.

On May 8, Minister of Transport Marc Garneau chaired his first roundtable in Ottawa with Canada Port Authorities to discuss the port authority system and what Transport Canada can do to ensure this country is well positioned to innovate and compete for years to come.

In the following weeks, Transport Canada plans to host a series of roundtables and meetings with Indigenous peoples, provincial governments, municipalities, broader domestic and international marine stakeholders, and Canadians. The roundtables are the next step in a review of Canada Port Authorities that was announced in March. The review would optimize its role in the transportation system as strategic assets that support inclusive and sustainable growth and trade.

“Ports are a critical part of Canada’s transportation network and trade corridors,” Garneau said. “They need to remain innovative and competitive in today’s dynamic environment. Collaboration with marine stakeholders and Canadians will help shape the future of Canada’s port system, so that it continues to support sustainable and inclusive growth.”

The current port system has served Canada well in supporting regional economic development and international commerce. However, a lot has changed since Canada Port Authorities was established 20 years ago. This change is expected to continue at an ever-increasing pace.

Transport Canada wants to hear what Canadians and marine stakeholders have to say about how our ports can turn current and future challenges into opportunities. The public is invited to provide input on the review. Information is available at: www.letstalktransportation.ca/ports-modernization-review.

The findings of the review are expected in 2019 and will identify potential policy, legislative and regulatory changes to help Canada Port Authorities remain a critical part of the Canadian economy.

Submissions are due on September 7, 2018. Consultation closes on December 3, 2018.

Source: Government of Canada.

BY GRANT CAMERON

Mike Gallagher, business manager of IUOE Local 793 in Ontario, has been re-elected as seventh vice-president on the general executive board of the International Union of Operating Engineers, which represents nearly 400,000 union members from across North America.

“I consider it an honour and privilege to be re-elected as a vice-president on the general executive board of the IUOE and to represent operating engineers across the country,” Gallagher said. “I feel humbled and will continue to do everything in my power to raise issues that we face in Canada to the IUOE general executive board.”

The election took place recently at the 39th general convention of the IUOE in Hollywood, Fla.

Gallagher, who is also president of the Canadian Conference of the IUOE, said he looks forward to advancing the union agenda.

“The issues that operating engineers face here in Canada are often the same ones faced by our brothers and sisters south of the border, namely organizing new companies and training the next generation of crane and heavy equipment operators,” he said. “I look forward to working with the rest of the general executive board to chart a bright future for our union and its members.”

Local 793 president Joe Redshaw said in remarks at the convention that Gallagher is a dedicated, loyal and hard working union leader who has been an advocate for health and safety.

“Brother Gallagher’s honesty, integrity and work ethic will benefit the membership of this great international union,” he said.

Gallagher is a past president of the Construction Safety Association of Ontario and won the Roy A. Phinnemore Award in 2013 for his contributions to construction health and safety. More recently, he was instrumental in convincing the government that rotary drill rig operators in Ontario require mandatory training.

Redshaw said in addition to his union contributions, Gallagher has also spearheaded events to raise money for charitable causes. He helped raise $170,000 to purchase a bulldozer for an orphanage in Kenya, another $100,000 for victims of the 2010 earthquake in Haiti, and chairs the Gary O’Neill Memorial Golf Tournament that has raised more than $600,000 for esophageal cancer research.

Gallagher was first appointed to the general executive board as an International trustee in October 2005. In May 2011, he was appointed as an International vice-president on the board. He has been a vice-president for seven years.

BY MATT JONES

The Helmets to Hardhats (H2H) initiative helps connect outgoing military personnel and their families with training opportunities to enter the construction industry. The program provides a benefit to both groups – helping the industry address crucial shortages of skilled labour and helping military veterans hit the ground running in the next phase of their lives.

“The initiative actually began in 2003 in the United States,” explains H2H Canada executive director Greg Matte. “If you recall, 2003 was the same time that America decided to reinvade Iraq with ground troops and they were there for a number of years. It was also a period of time in the construction industry in America where there was a shortfall of good skilled workers.”

Joseph Maloney, a Canadian working with the Building & Construction Trades Department, suggested that there would be many reservists and part-timers returning home from Iraq looking for work. Maloney was placed in charge of the initiative and was able to secure funding from Congress to get the program up and running. He then returned home to establish the Canadian equivalent, which was announced by former Prime Minister Stephen Harper in January 2012. Matte, a retired Brigadier-General and former fighter pilot, was immediately intrigued and applied to the national competition for an executive director.

“It appealed to me because I’m a military child,” says Matte. “I grew up in the military, I spent 25 years in the military. They found my background of interest and brought me in. From May of 2012, Helmets to Hardhats Canada began operating and we’ve been going ever since. ”

Results likely only half the picture H2H Canada is a very small operation in terms of staffing. There are only three fulltime staff and one part-time webmaster, all veterans. Matte describes their work as being like an online dating service, but the potential suitors are military veterans and

union halls looking for apprentices.

“We open the door and find pathways for the veterans to get into an apprenticeship so they can undertake the training required to eventually get the journeyperson certificate in whatever trade it may be; and to then carry on with a career in the building trades.”

Matte can confirm that they have helped over 635 veterans begin careers in the construction trades since 2012, working out to one every three days. However, he’s confident that the actual number would be double that or even higher. Between the small size of H2H’s staff and the huge number of union locals and contractors being dealt with, tracking results is often difficult.

“We always ask to let us know if things work out,” says Matte. “They usually get back to us if things don’t work out but when they do work out, quite often they don’t even tell us. They just kind of keep moving forward and forget about us. We often get the results of successful placements through

the union training coordinators, through the union halls and sometimes from the vets themselves. Despite many efforts to improve on the tracking, we’re pretty confident that the number is much higher.”

Most H2H applicants range in age from 28 to 42 years of age, and come from the army, often from occupations such as infantry, artillery or armoured operations. Veterans with these experiences often have a harder time translating their skills to the civilian job market in comparison to someone who had been working as a mechanic on a vehicle, for example. Matte says, however, that the skillset is really irrelevant to potential employers. Skills can be taught, but the qualities that allow someone to work in the military are very attractive to construction employers.

“What they’re looking for is the quality of the individual – that’s why the military is so appealing,” says Matte. “They want people who are going to show up on time, that are going to be professional about their work and take pride in it. They want people that are able to show initiative and eventually become site-supervisors and foremen – people with leadership abilities. These kinds of qualities and maturity are found in military veterans even if they’ve only done a short stint of three to five years, which is not uncommon. Once they get their qualifications, I’m very confident that they will find themselves in leadership positions either on the jobsite or in the union hall as executives.”

The biggest difficulty with H2H’s model is that the needs of each individual veteran are often very personalized. Between fluctuations in the economy and related opportunities, it can be difficult to match a veteran with their exact preferences.

“We quite often find it challenging to align the stars for a veteran to find the trade that they would like in the part of Canada they would like to be and to be ready to

get underway when they’re ready to get underway,” says Matte. “Sometimes they will contact us and start the discussion while they’re still serving and they’re quite interested in trying to make the timing perfect – they get out one day and the next day they start. But that’s not how things work in the construction industry because the training cycles are often fixed and the economy determines where the employment opportunities are, which is a key element of getting into an apprenticeship. You have to be indentured to an employer.”

On the other hand, Matte says that if veterans are open to more flexible time frames, or are not set on being in a specific region, there’s a greater probability that they can get them started sooner in the trade they want.

“Fortunately, military people tend to be nomadic in the sense that we do move around a lot,” says Matte. “Those that retire after 20 years of service are afforded the opportunity for a fully paid move anywhere in Canada. So they have that option as well.”

In addition to their direct work with veterans, H2H has lobbied for a variety of veteran-specific government initiatives. They successfully lobbied all-but-one provincial government to recognize military commercial vehicle licenses, thus removing the need for veterans to obtain a separate civilian commercial vehicle license. They have also lobbied strongly for Bill C-42, which is currently before Parliament. The bill would provide funding for former military personnel to obtain training or education. Some veterans who H2H speak to, for example, would be good candidates but cannot afford to pay for their training or to pay for living expenses while pursuing their training.

“I’m very proud of the program,” says Matte. “I believe in what we’re doing. It’s very fulfilling and very rewarding every time a veteran gets accepted into an apprenticeship and into a union and a new career. We know that’s really a game changer, transforming their lives.”

2111-80th Avenue

Edmonton, AB, T6P1N3 1-800-319-7787

Tel: 780-440-4010

Fax: 780-440-4787

Contact: Kevin Maguire kmaguire@essltd.com

Contact: Drew Paton dpaton@essltd.com since 1946 essltd.com Western Division

Division 1030 Martin Grove Rd. Toronto, ON, M9W4W3 1-800-268-0679

Tel: 416-249-8141

Fax: 416-249-8912

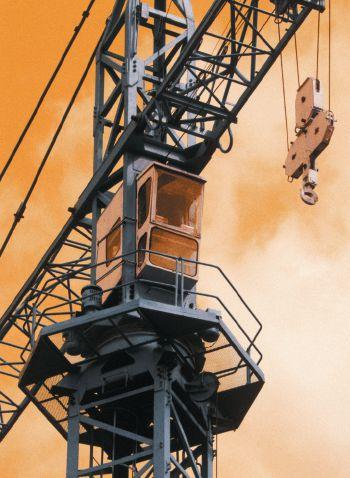

PCL project manager David Enns says his company was responsible for the cast-inplace concrete structures on both towers. This involved supplying the concrete, the placing of concrete and rebar, form work, concrete pumping, and the installation of precast stairs and landings, and other material handling. For much of the heavy lifting, PCL utilized two cranes – a Liebherr 316 ECB12 and a Liebherr 316 ECH12.

“They were the best choices mostly because of the overlapping coverage,” Enns explains. “When we sized them, we made sure that it could accommodate the form work systems that we wanted to use. It was based on them working in conjunction with each other with the overlap in height and the jacking sequences, including how they would tie into the structure in order to be efficient.”

The way the cranes were staged required them to be tied into the structure, once the structure progressed past a certain height. When PCL began work on Tower 1, the timing of the construction of Tower 2 was not yet known for certain. In order to ensure that there was sufficient coverage for the full site, both tower cranes were tied to Tower 1.

“Both were top climbing tower cranes,” Enns says. “The biggest reason for that is because of the limited real estate that we had. We couldn’t afford to bring in big mobile cranes every time we needed to jack the cranes up as the structures progressed. They were able to climb themselves up, and then when we were done, they had the ability to climb themselves down prior to full dismantle.”

Preparation for the selection of tower cranes involved a detailed review to ensure the cranes had the right capacities to accommodate the required lifts and the size of the flyer cables, core forms and gang forms. They also had to reinforce the foundation walls around the tower cranes to prepare for the mobile crane load imposed on the structure during the dismantling of the tower cranes.

“It’s pretty common to see tower cranes with a couple of precast piles under the foundation, but for our tower cranes, our foundations were cast-in-place concrete raft slabs, with four caissons a piece to support them because they were freestanding fairly high right off the bat,” says Enns.

The key challenge for this job was limited space – city roads and the St. Mary’s Church bound PCL on three sides. With limited room to maneuver or stage materials, there was a constant focus on scheduling and sequencing to make sure that they had material delivered as needed.

“Otherwise, not only would the site get overrun, but the tower cranes would be so booked up that we couldn’t keep them focused on the high-priority activities,” Enns says. “They’d just be stuck moving non-critical material around all day and night.”

On both towers, Sterling Crane was subcontracted to dismantle PCL’s tower cranes following the construction. Scott Baraschuk, branch manager for Sterling Crane in Winnipeg says that the dismantling was a very straight forward operation, however it did require the use of a very large mobile crane.

“Whatever they need, we’ll handle for them,” Baraschuk says. “In this scenario, it was the dismantling – to provide a mobile crane to dismantle their tower crane; just to provide a means of hoisting everything down. This particular one was the Liebherr LTM 1500 8.1. When we erected these towers a few years ago, the intent was to down climb the tower back to roughly 150 feet for dismantling. We now have the LTM 1500 available so I suggested we look at taking the tower at full height. This reduced the dismantle time by several days and eliminated the need to climb the tower crane down.”

The Liebherr LTM 1500 8.1 was utilized for the dismantling operations on both towers, however, it was used in two different configurations for each tower. During the dismantling for Tower 2, the crane was configured in a way that made it one of the tallest cranes ever seen in the Winnipeg skyline. Media coverage of the project claimed it was the single tallest crane ever used in the city, but Baraschuk can’t confirm that.

“I can’t say for certain, but it is certainly a contender,” he says. “It had roughly 380 feet of tip height in this configuration.”

It was an easy choice to use the Liebherr LTM 1500 for Tower 1, since it was locally available and easily capable of performing the job. Tower 2 had the same demands, but the flexibility of the 276-ft. telescopic boom was an added benefit given the site restrictions and their setup.

“We were able to maintain our setup into one city block, avoiding the closure of an intersection to build a long luffing jib. This resulted in significant time and cost

savings to the customer.” Baraschuk says.

“The biggest challenge is site congestion with a crane this large. When working in a downtown setting, you have got a lot of obstacles – you have public safety to be concerned about and numerous underground utilities as well.”

“We pride ourselves on having a fleet with industry leading technology and we have purchased a number of these units to capture new markets and niche jobs where you need a certain type and size of crane to perform,” adds Jeff Chernish, director of business development for Sterling Crane.

“We provide efficient customer solutions similar in nature throughout Canada and we appreciate the visibility that this has brought us in Winnipeg.”

Tower 1 at 242 Hargrave Street is quickly approaching substantial completion, scheduled for the end of June 2018. It is comprised of retail and office space, and construction crews are currently focused on lobby finishes, amenity floor finishes, and mechanical, electrical, and elevator commissioning.

Tower 2 at 225 Carlton Street is scheduled to be completed a year from now. It contains some retail and office space but is predominantly comprised of residential rental suites. Construction teams are currently installing a high-performance glass curtain wall, after which internal finishes in the lobby and suites will become the focus, with an aim to welcome residents next spring. Phase 2 of the project is a hotel and condominium complex being developed by Sutton Place Hotel & Residences. They aim to break ground this summer and be complete in 2020 or 2021.

Bergeron took attendance and ran through safety considerations. The chopper’s carrying capacity is 4,500 pounds and the HVAC units range from 760 to 2,700 pounds, so no looking away from the load or standing directly underneath. And watch out — the rooftop is slippery. A 50-foot kevlar longline offered sufficient distance to protect the ground crew from gale-force winds the blades exuded, and each load rose and returned down at a precise angle

to ensure safety. In eye-pleasing synchronicity, crews released their straps and the first load rose to the heavens.

The sheer effortlessness made a compelling case for using a helicopter rather than a crane when circumstances warrant.

Nineteen HVAC units went up and eight old ones were hauled off in little more than half an hour on this suburban mall.

“There wasn’t much to set up,” Bergeron said. “We didn’t have to bring in any

load-bearing beams for shoring, or any cribbing. We didn’t need a trailer or counterweights, or another crane to set up the (main) crane. We took 15 minutes to set up and 10 minutes to clean up. We were in and out in less than an hour.”

Depth and reach enhanced Bergeron’s case. The two-storey mall wasn’t terribly high, at roughly 50 feet, yet its 720,000 square foot roof equalled a half dozen downtown city blocks, and Bergeron said he’s worked with rooftops three times larger.

“We could reach areas of the roof you couldn’t reach with a crane without moving the crane,” Bergeron said. “It’s a big deal to move a 350- or 400-tonne crane, whereas we could locate our helicopter anywhere we wanted. And there wasn’t space to locate a crane on the far side of the mall without tearing up a garden.”

A helicopter also offers considerable flexibility at a jobsite. Materials can be loaded and unloaded pretty well anywhere, and scrap can be taken directly to designated piles.

“We can take things anywhere you want and not just put it next to the crane, so you don’t have to handle the material again,” Bergeron said.

The ability to compress a schedule from days to hours helps minimize and even avoid traffic congestion. Fire routes remain open. And work can be done in the scant time between dawn and mall opening hours.

“Time is money,” Bergeron said. “If your crane takes up 100 parking spaces during a revenue day that’s a lot of lost revenue for the mall.”

Bergeron also stands by his Sikorsky in terms of project costs.

“For what we did (in one morning) in Cambridge you’d need a 600-ton crane, and a 600-ton crane with 500 feet of boom and a luffing jib will take you several days to set up and take down and will cost you $160,000,” he said. “With a helicopter, the cost to set it up might be just over $40,000.”

Still, Bergeron recognizes there are jobs meant for cranes. In fact, the company maintains a 5-ton boom truck and an 8-ton carry deck crane for work it does as a mechanical services provider. “We use them mainly for installing piping underground in downtown Toronto,” he said.

Helicopters could literally dance circles around a crane, yet Dwight Crane president Brian Dwight doesn’t see them as competing. In fact, the Ajax, Ont. crane service provider subcontracts to SprintFour Seasons when helicopter services are optimal for a particular task.

“I see them as very complementary,” said Dwight, who wasn’t involved in the Cambridge project. “Any time we have something that’s within the range or

practicality of a crane, or where it’s going to take two or three days to set up and take it down just to put up one unit, it makes sense. Any smart crane operator should have a helicopter company in their back pocket.”

Dwight’s confidence in helicopters might enjoy a boost because he flies one recreationally. Nevertheless, he said he farms out the work because he considers flying professionally as outside his company’s core expertise.

“Being a helicopter pilot myself I’ll know if a job is really doable in this way. This puts us in the right position to suggest the right choice to the customer,” he says.

In the case of Cambridge Centre, SprintFour Seasons was commissioned by PCL Constructors Canada (Toronto), which is overseeing renovations at the mall. Project manager Jason Toste said PCL has used helicopters for previous, similar hoists.

“We only had a short window of opportunity,” Toste says. “So at the end of the day, from a schedule point of view and to lessen the impact on our client, Morguard (the mall’s owner), and mall operations, it was best to go with the helicopter.”

Still, Toste and PCL acknowledge appropriate occasions for each machine. PCL retained Sprint-Four Seasons for an initial lift of 23 units in March, with 12 old ones coming down, and a second visit in April saw 19 units go up and eight come down. However, in early May PCL used a mobile crane to hoist eight remaining units and retrieve 14 units where the rooftop HVAC set-up was relatively concentrated and the units were easily accessed.

“We were able to get a [Liebherr] LTM 1130-5.1 165-ton mobile in there and place the eight units in a little over an hour and a bit, and then do the same taking the old units down,” Toste said.

Ian Bergeron concurred.

“They were small units, probably 60 feet from the edge of the roof, so it wouldn’t make sense to use a helicopter when you can reach easily and efficiently [with a mobile crane],” he said.

For Sprint, much of the preparation for helicopter lifting is comparable to using a crane. Bergeron supplies engineering designs and plans, including the rigging, shackling, lifting points and centres of gravity. Four Seasons Aviation operates the aircraft under Transport Canada licence and handles piloting and maintenance.

Dave Tommasini, president and chief pilot with Four Seasons, said it makes sense for crane companies to team up with a helicopter provider because of the complexities required to meet Transport Canada protocol.

“It’s quite involved and expensive and it takes time to get everything accomplished,” he says.

While Four Seasons works with contractors such as Sprint, the company also maintains working relationships with Dwight Crane and has made inroads with other crane companies, Tommasini said.

“Originally we were concerned we might be taking business away from them,” he says. “But I think they realize we can be a nice complement to what they do. There’s certain occasions when a crane can’t do a job, or where we can be an option. So it’s become more of a cooperative effort. We respect each other’s capabilities and it seems to work pretty well.”

The Terex® Crossover 8000 — setting standards in reliable performance.

The 80 USt capacity class Terex® Crossover 8000 boasts a unique X-pattern outrigger design to offer a 360-degree load radius that outlifts any other boom truck in North America. The crane combines easy setup and transport with quality and serviceability for reliable performance on the road and on the job.

expanded relations working with fellow international committees; a newly adopted CRAC logo; expanded relationships with media partners; further developed association policies related to finances, code of conduct, and updated vision, values and mission statements; established the inaugural CRAC Safety Awards; the launching of the first electronic member directory; a revamped website; and the start of working on a member survey.

The first-ever CRAC Safety Awards were presented during the annual general meeting to the following recipients: All-West Crane & Rigging Ltd. (Quesnel, B.C.), Canadian Crane Rentals Ltd. (Wingham, Ont.), Canuck Concrete Pumping & Crane (Yellowknife, N.W.T.), ENTREC Corporation (Acheson, Alta.), Irving Equipment Ltd. (Saint John, N.B.), Niwa Crane Ltd (Medicine Hat, Alta.), NCSG Crane & Heavy Haul Services Ltd (Acheson, Alta.), Sterling Crane (Edmonton, Alta.).

Several board of director three-year terms ended in 2018, including Shawna Boreen (Sarens Canada), John Roberts (Sterling Crane) and Gijs Verdeijn (Mammoet Canada); as well as the two-year term for Curt Jabben (Associated Wire Rope & Rigging) on the supplier side the board. All three directors were re-elected to new three-year terms, while Jose Perez of Broderson Manufacturing Corp. was elected to the supplier side of the board for a two-year term to fill the vacant seat.

Additional highlights from the conference included keynote speaker best-selling author and financial advisor Jane Blaufus; an update of the CSA Z150; a presentation on the future of EN13000; tours of the city of Winnipeg and the Canadian Museum for Human Rights; The Journey to Churchill networking event in the heart of the Assiniboine Park Zoo; a presentation on the Threads of Life, the association’s chosen charity for the conference; and supplier presentations from Manitex; A1A software and Enerpac.

The CRAC’s 2019 Annual Conference will take place at the Delta Prince Edward Island in Charlottetown, P.E.I.

For more detailed coverage of the presentations from the 2018 CRAC Annual Conference, check out the September/October issue of Crane & Hoist Canada and visit www.craneandhoistcanada.com.

BY STAFF REPORT

Designed for excellent performance over a broad range of applications, the Crossover 8000 crane’s four-section main boom offers a 126-ft. (38 m) length with a 189-ft. (57.6 m) maximum tip height. Two available jib designs (fixed length of 33 ft. and extendable to 57 ft.) offer 0-, 15- and 30-degree offset positions, providing easier reach when lifting over objects. With a rated 80USt (72.5 t) lift capacity at a 10-ft. (3 m) radius, the crane provides a strong lift capacity.

The X-pattern outrigger positioning also eliminates the need for the front stabilizer jack, typically required for boom cranes to counteract the weight of the engine when lifting. This decreases overall crane length and weight. The crane’s three-position outrigger – minimum 6.5-ft. (2.0 m), middle 19-ft., 9.3 in. (5.9 m), and maximum 26-ft. (7.9 m) position span – allows the Crossover 8000 to be used in confined spaces and further enhances crane maneuverability.

With speeds in excess of 70 mph (113 kmh), the Crossover 8000 quickly moves from job to job at highway speeds. Once on site, the crane is designed to deliver quick levelling and set up with its independently controlled outriggers and jib that quickly swings and pins into position.

Crane & Hoist Canada checks out some of the latest boom trucks for the Canadian

The Crossover 8000 can be equipped with either one or two winches. The crane’s top swivel ball with hook and latch is rated at 7 tons. Alternatively, the available quickreeving hook block features five sheaves to offer an 80-ton capacity. The Terex Crossover 8000 is the first boom truck to feature the latest Terex Cranes operator’s cab. www.terex.com/cranes www.cropac.com

The Iowa Mold Tooling Co. Inc. (IMT) Dominator family of mechanics trucks meet the field-service needs of oil, gas and mining applications with a spectrum of options, including the Dominator IV body. With enhanced strength and stability for higher crane loads, numerous configuration possibilities, and a body rating of 95,000 ft.-lb. (13.3 tm), the IMT Dominator IV mechanics truck offers exceptional performance in virtually any industry. With the Dominator IV mechanics truck, you don’t have to bring your equipment into the shop for service, because the shop comes to you.

www.imt.com

The Manitex TC Series TC 50155HL Taxi Crane has a 50-ton capacity and a 155-ft., five-section boom; a maximum tip height of 164 ft. and a jib length of 210 ft. Its features include 360-degree area of operation with continuous rotation; an A92.2 dual rating for lifting and man basket applications; ROC Solid radio remote controller for outrigger, winch and FBS setup; externally routed A2B cable with lockout (radio A2B option eliminates ext. cable); and a grooved drum hoist with machined flags providing excellent lead-time spooling. The crane is built with a full view 20-degree tilted cab with standard heating and A/C for maximum operator comfort; a full colour load moment indicator display in the cab with audio/visual alert and shutoff; and high torque free swing and no-free selection from the operators cab with electric over hydraulics controls. Load line rollers to extend the life of wire rope coming soon.

www.manitex.com

Falcon Equipment prides itself on being experts in custom solutions. This Western Star 4900 is outfitted with a National NBT40-127, which has a 40 US-ton load capacity and 127 feet of boom length. The unit has been completely customized to the utilities industry. Features include 400 feet of winch cable; a boom rest for the jib; and custom toolboxes and toolbox steps on either side of the truck. This build is being used by a utility provider to complete transmission line maintenance – it comes complete with a Barehand jib making it possible for the operator to work with live transmission. The Barehand-765R jib has a hydraulic rotator with up to 210-degree articulation, and a fiberglass boom with desiccant for maximum dielectric strength. The inclinometer switch ensures that the jib angle does not exceed the vertical to maintain stability. The jib comes complete with a two-man aluminum platform and shielded radio remote controls.

www.falconequip.com

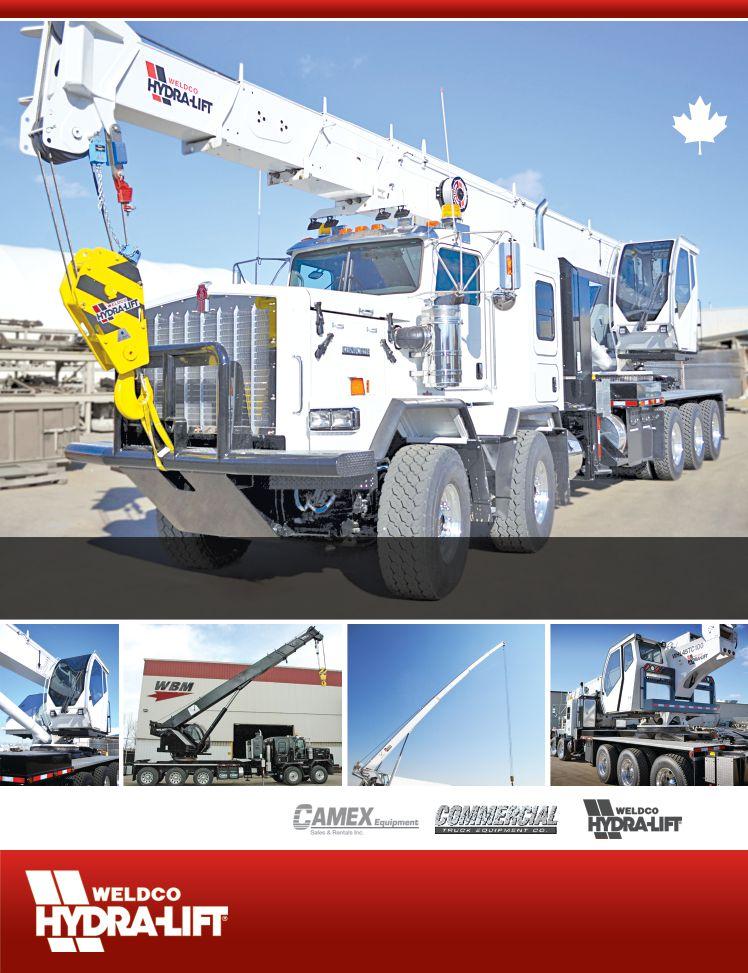

Manufactured in Canada with 45-ton lifting capacity combined with a 125-ft. reach boom and a sub-frame suitable for fifth wheel installation, the Hydra-Lift WHL45TC125 Swing Cab Cranes offer heavy lifting capacity with extended reach capabilities. Out and down outriggers with independently operated horizontal extension cylinders and vertical jack cylinders give the operator true stability on uneven surfaces or in tight locations. The fully equipped cab provides the operator with a comfortable working environment in all weather conditions. WHL45TC125 cranes can be mounted on a tandem steer tri-drive rear axle chassis with fifth wheel, or single steer tri-drive rear axle chassis, or tandem steer tandem drive rear axle chassis without fifth wheel to best suit the operator’s needs. www.weldco-beales.com

Stand-up models range: 9,1 t (10 USt) - 29,9 t (33 USt)

Swing seat models range: 27,2 t (30 USt) - 54,4 t (60 USt)

Built on the field-hardened NBT40 Series DNA

Improved access/egress ladders and stronger aluminum decking

Perform more lifts without a jib

Longest boom in size range: 110 ft

User-friendly, fully integrated control system with all truck engine information available at the crane control station.

Optimum versatility through many available options:

Two-stage jib

Personnel platforms

Wireless radio remotes

Contact your local Manitowoc dealer today. Visit www.manitowoc.com and click “dealer locator.”

Elliott Equipment Company is proud to present its new 40142, 40-ton capacity crane. The unit offers a state-ofthe art tilting cab, with no seams in the glass for maximum visibility. The cab features A/C, heated seat, stereo and outstanding ergonomics. The unit’s full hydraulic oil/oil controls offer smooth operation that is further enhanced by the machines proprietary friction-free boom design.

The 40142 comes standard with a Hirschman LMI giving the operator a clear and easy to use feedback aid. Available with a two-stage jib, the 40142 has a maximum tip height of 207’ and 211’ with optional radio-controlled work platform. Like all Elliott cranes, the 40142 has a two-year parts and labuor warranty and lifetime structural warranty. www.elliottequip.com

National Crane currently offers the NBT40-1 Series of boom trucks that are available with an aerial lift configuration. When equipped with this aerial package, this series of three new models—the NBT36-1, the NBT40-1 and the NBT45-1—is aimed at the utility market and will enable companies to perform both crane lifting and aerial lift projects more efficiently with just one machine. For the core crane markets, this updated series of cranes will continue to provide the performance customers expect from National Crane.

Fully compliant with both ANSI/SAIA A92.2 aerial lift and ASME B30.5 mobile crane industry standards as well as OSHA standards, the NBT40-1 Series will result in higher utilization and less setup time for National Crane owners, which will increase both efficiency and return on investment for many companies.

The dual-rated NBT40-1 Series is especially useful for the utility sector, where energy work on de-energized power lines and new transmission infrastructure construction often require the use of both a crane and an aerial lift. The tree care, signage and millwright industries, among others, will also find these new National Crane models ideal for their projects. All three models feature the option of a two-person, 544 kg (1,200 lb.) maximum capacity, quick-attach yoke platform with wireless radio remote control.

www.manitowoccranes.com/en/cranes/national-crane

Weldco

Designed & Manufactured in Western Canada, Purpose-Built for the Oil & Gas Sector

to 125 feet

New model in Technic line is toymaker’s largest and tallest crane

BY MATT JONES

This August, LEGO will release the largest and tallest crane in their long-running Technic line, the 42082 Rough Terrain Crane. The crane was inspired by a variety of real-world rough terrain cranes and features many authentic crane functions.

The Technic line is focused on creating more advanced models that perform more technical functions than are found in traditional LEGO sets. As such, they are more challenging to build but provide a greater sense of authenticity. Many Technic sets, including the new rough terrain crane, include small electric motors that drive power functions.

The new set will include an upper and lower crane mode, stabilizer legs, a full 360° rotatable superstructure and a boom that can extend a full metre into the air. Also included are manual functions, such as 4-wheel steering, 4-wheel drive, a detailed V8 engine with moving pistons and a fan, adjustable wing mirrors, a detailed operating cab and two compartments complete with tools, chains and a fire extinguisher. The set can also be rebuilt into a mobile pile driver.

It will take a lot of building to utilize those many features, however – the set has 4,057 pieces.

BY DOUG YOUNGER, OCCUPATIONAL SAFETY OFFICER, PROVINCIAL CRANE INSPECTION TEAM, WORKSAFEBC

In recent years, British Columbia’s worksites have seen several potentially deadly incidents involving load failures that were found to be a result of certified operators’ lack of experience with the cranes they were using. This has brought into focus the difference between being certified as an operator and being qualified and competent to use a specific kind of equipment to do a specific job.

As part of WorkSafeBC’s three-year Crane Industry Initiative focusing on tower cranes, we are aiming to raise awareness about the distinction between the two.

Since 2007 in B.C., all crane operators must be certified and registered with BC Crane Safety, which administers the Crane Operator Certification scheme in the province.

Beyond certification, however, crane operators must be qualified, as broadly defined in Section 14.34 of the province’s Occupational Health and Safety Regulation. Employers in B.C. must ensure that crane operators have received instruction on the crane or hoist they will operate, and that they have demonstrated competency on that equipment. Competency includes the ability to safety operate, inspect, and maintain the equipment.

Operators must be familiar with the operating instructions for the machine and be able to understand the information in the crane operator’s manual; identify potential worksite hazards; select specific equipment components and configurations; assemble and disassemble the crane in accordance with the manufacturer’s instructions; determine the machine’s gross lifting capacity using the load chart; and select, configure, and test the machine’s computer and/or limiting devices.

In addition, operators must regularly inspect, maintain, and document equipment-component inspections in accordance with the manufacturer’s requirements; operate the equipment in a safe, controlled and smooth manner; and use hand or radio protocol signals for hoisting operations.

In ensuring that operators are qualified and competent, the stakes could not be higher. In one case in which disaster was narrowly averted, an employer hired a certified operator to operate a tower crane, but did not require the operator to demonstrate competency before operating the crane.

During the operator’s second shift, the tower crane was lifting a load of concrete weighing 8,800 lb. After lifting and slewing the third load, the concrete bucket began to slip uncontrollably through the hoist drum brake. The bucket plunged downward, striking a site office trailer.

While no workers were injured in this incident, several were working nearby. An investigation determined this crane operator was unfamiliar with safe operation of this contactor-equipped (mechanical) tower crane as they had previously been operating a frequency-drive-equipped (electronically controlled) machine.

For more information on regulation requirements and resources:

• Guideline G14.34, Operator qualifications and competencies: www.worksafebc.com/en/law-policy/occupational-health-safety/searchable-ohsregulation/ohs-guidelines/guidelines-part-14

• Safety bulletin: Ensure crane operators are qualified and competent to operate a specific machine: https://www.worksafebc.com/en/resources/health-safety/hazard-alerts/ensurecrane-operators-are-qualified-competent-operate-specific-machine-ws-2018-07

For crane operators, certification is just the first step

BY GRANT CAMERON

Federal Employment, Workforce Development and Labour Minister Patricia Hajdu recently announced $936,162 in funding for the Operating Engineers Training Institute of Ontario (OETIO). The funds will be used to purchase an all-terrain crane for the OETIO campus in Oakville, Ont. and equip a number of dozers with global positioning systems and laser technology at the Morrisburg Campus.

Hajdu made the announcement at an event attended by apprentices, Local 793 business manager Mike Gallagher and president Joe Redshaw at the OETIO in Morrisburg.

In remarks at the event, Gallagher thanked the government for the funding and for being a trailblazer in recognizing the important role that unions play in training the workforce.

“The federal funding will greatly benefit our apprentices and members as well as people from Aboriginal and Inuit communities who are referred to the Operating Engineers Training Institute of Ontario for training by mining companies and communities in the far north.”

The money is part of $10.2 million being made available under the Union Training and Innovation Program to help unions purchase new and up-to-date training equipment and materials.

Gallagher said he’s pleased that Local 793 and the OETIO received nearly 10 per cent of the funds.

“One thing that’s challenging for operating engineers, as I’m sure you all realize, is that our tools are a little bit more expensive than most of the other trades, so that will help us.”

Under terms of the program, the federal government is providing 48 per cent of the cost of equipment purchases while Local 793 is providing 52 per cent.

Gallagher said the union will use part of the funds to buy a mobile all-terrain crane which should be on site in Oakville by October.

He said a request for proposals went out on April 6. Total cost of the crane will be $1,130,000. The union is contributing $587,438 and the government is contributing $542,562.

The funds will also be used to outfit six dozers at the OETIO campus in Morrisburg with GPS systems. The union will contribute $335,400 and the government will contribute $309,600.

Another six dozers at the Morrisburg Campus will also be outfitted with laser capabilities. The union will contribute $91,000 and the government will contribute $84,000.

All in, Gallagher said, with the government commitment of $936,162 and union contribution of $1,013,938, the purchase budget for the crane and dozer systems is $1.95 million.

“I’m very, very delighted,” he said in his remarks. “I can’t say any more about how well the money will be used to make sure

we have the best operating engineers and tradesmen and tradeswomen in the province of Ontario and in the territory of Nunavut.”

Hajdu said in her remarks that she was very excited to announce the funding for Local 793 and other unions because it will help them buy the equipment they need to train workers.

Hajdu, who has a son in the trades, praised unions and the work that they do, and encouraged apprentices at the event to continue with their training.

“The only reason we have a middle class in Canada is because of the efforts of organized labour,” she said.

Hajdu said unions fought for decent working conditions and to get workers good pensions so they can retire comfortably after working 20 or 30 years in the field and that’s why the government is focused on ensuring they have the tools to keep growing.

She said there are 65,000 skilled trades positions vacant across Canada right now and the stigma associated with the trades is one of the reasons there aren’t enough applicants.

“We still have a narrative out there in this country that college and skilled trades training is okay, but university is better.”

She congratulated apprentices at the event for taking up training and changing the narrative.

“You have made absolutely the right choice for you and you need to be part of the generation that turns that story around and that teaches people that these trades are noble professions that require intelligence and precision and a degree of discipline.”

Hajdu said it’s exciting to see what the Operating Engineers and other trades are doing to get women and under-represented communities into the careers.

She noted there will be a lot of jobs in the future in the resource-rich Ring of Fire area in Ontario and the government wants to ensure there are enough skilled people to fill those positions.

“That’s exactly what the Operating Engineers are doing right here todaymaking sure people have those skills so that when those opportunities come about they can take advantage of that.”

Hajdu said unions, government, industry and employers must work together to get more people into the trades.

Gallagher, meanwhile, said in his remarks to apprentices at the event that a career as an operating engineer is a good one.

“On behalf of Local 793 and our 15,000 members, we really want to encourage you to stick to it and make a career as an operating engineer.”

has been replaced by 150 hours of training, with practical and theoretical sections.”

A key source of contention for the union is an 80-hour training course available to journeymen in other trades to operate boom trucks, 30 tonnes and less, with fixed controls. This training is available solely for handling materials related to their trades. However, the union remains concerned regardless of the relatively smaller size of the cranes.

“From our experience, these boom trucks up to 30 tonnes have very long booms,” says Larivière. “They’re very easy to top over. It’s like playing with a fishing rod. The experience needed is a bit more than 80 hours.”

Malenfant responds that the training is combined with a qualification exam with a pass threshold of 80 per cent, and that in order to maintain their qualification, journeymen will have to prove that they have worked 50 hours per year in the activity.

“We had to proceed with these changes because it was difficult for employers to find crane operators available to operate this type of machinery, which is used sporadically and occasionally on construction sites,” says Malenfant. “In the absence a crane operator, other, untrained workers were called upon to perform this task without holding any particular qualification. It is this dangerous situation that we have corrected.”

One solution that the union proposed was the option of changing some of the regulations regarding apprentices who are training in the field.

“In Quebec, the apprentice is not allowed to operate by himself – he always has to be under supervision,” says Larivière. “But we were willing to say, ‘well, open up the law

enough to let our apprentices operate the boom trucks by themselves.’ They’ve already been to school for at least 800 hours. They have a lot more training.”

Malenfant responded to a question of whether a change to the apprenticeship rules was considered by stating that, “The rules for apprentices are clear: they must be supervised by a journeyman during their apprenticeship.”

Malenfant also stated that the regulatory changes that have come into effect were adopted following approval by official bodies in the industry, which include employer and union associations. The rule change was also approved by Quebec’s health and safety board, Commission des normes, de l’équité, de la santé et de la

sécurité du travail (CNESST).

Larivière is unmoved by the assertion, stating that the CNESST is more concerned that someone is trained, rather than how they are trained. He says the union is looking at other avenues to pursue the issue but they remain uncomfortable with the regulation change.

“Locals are always trying to make sure that safety comes first for all our members and the public also,” says Larivière. “This will affect the public more than my members, actually. Our certified operators are not going to be in the seats, but it’s the public that will end up with the risk of accidents. We’ve already had quite a few of them lately, and with this change going in there are going to be more.”

The ALL Family of Companies has been named the new authorized dealer for Maeda Mini Cranes for the territory of Ontario, Illinois, Indiana, Ohio, Minnesota and Wisconsin. ALL Crane will sell and service Maeda’s full line including spider cranes, knuckle boom cranes, and crawlers.

As authorized dealers for many major manufacturers, ALL recognizes the value in adding new names to the roster with the potential to make customers’ jobs easier, more efficient, and more cost effective. As an authorized Maeda dealer, ALL is committed to offering extensive product and service training support to ensure customers can rely on their efficiency, durability, and productivity.

Game-changing Maeda Mini Cranes have been engineered, designed, and manufactured in Japan since the company’s founding in 1962. These ultra-compact machines are known for excellent performance in tight spots where other cranes simply can’t go. Some are as little as two-feet wide. The construction industry especially values these small cranes for their ability to be placed high up in a structure and assist with glazing and curtainwall installation.

Although Maeda manufactures the most compact crane models in the industry, they have loaded them with features normally found on larger cranes. These include full load moment indicators (LMI) and custom outrigger programs. They also have impressive load charts. Overall, Maeda has earned a reputation for eye-opening power and performance in a compact package with great accessibility to confined work sites.

As a global brand, Maeda equipment not only exhibits peak performance, but will also conform to each country’s environmental and emissions standards. Their eco-friendly and user-friendly machines.

“Maeda is known for its customer support, strong dealer network, and commitment to maintaining inventory in North America,” said Mike Garrity, new equipment sales director for ALL Crane. “This aligns well with our own goals to provide customers with the broadest fleet in the industry, backed up by unmatched service, support, and expertise. Maeda is a valuable addition to the ALL family.”

www.allcrane.com

The latest Vortex Construction Training Pack adds the unique challenges of urban and nighttime operations while providing instructors with customizable scoring and an expanded set of training tools

CM Labs Simulations has announced the release of the all-new Luffing Tower Crane (LTC) Training Pack, the first simulation-based LTC training platform on the market. Immediately available for deployment across the full catalog of Vortex Construction Equipment Simulators, the LTC Training Pack is CM Labs’ most feature-rich crane simulation to date.

Vortex Construction Equipment Simulators are always-available instructional tools that have been shown to accelerate student operator training and reduce costs by up to 75 per cent.

“Cities are tight working environments with most mandating the use of luffing tower cranes for safety reasons,” said Seza Kouladjian, CM Labs technical product manager (Cranes). “While training on a real crane is both difficult and dangerous, our LTC Training Pack changes this dynamic, making training safer for everyone.”

Built on the highly realistic Vortex Studio simulation and visualization software, the LTC Training Pack provides a structured set of scenarios to promote crane skills development. The included load charts and lift plans build awareness of the crane’s capabilities and the tasks to be performed before starting operations.

Kouladjian notes that the new nighttime operation mode will allow student operators to have the opportunity to gain experience working at any time of day—a feature unique to CM Labs’ simulations. “A worksite looks very different at night because of

site lighting. The simulated environment can help LTC student operators become acclimatized to the differences in shadows and perspective presented by nighttime operations.”

The LTC Training Pack also provides an expanded toolset for the training, mentoring, and evaluation of student operators. Scoring for each scenario is now customizable, allowing the instructor to evaluate the operator’s performance according to their own standards. Optional visualization tools allow the student operator to see the boom tip and hook block in relation to lift objects, providing a quick feedback tool for assessing depth.

All simulation and training features included in the LTC Training Pack are also available immediately in a simultaneous update of the existing Flat-Top Tower Crane Training Pack.

All Vortex Construction Training Packs can be run on any Vortex Construction Equipment Simulator. This includes the immersive Vortex Advantage, the portableyet-powerful Vortex Trainer, and the new Vortex Edge laptop simulator designed for classroom instruction. www.cm-labs.com

Gerry’s Truck Centre celebrated the opening of its new truck service and sales centre in Woodstock, Ont. with an open house earlier this month.

The event was marked with tours of the new 15,000-sq.ft. truck centre with a variety of new Volvo trucks on display for ride-and-drives, including the 2019 Volvo VNL, VHD and the all new VNR and VNX.

The expansion marks the second facility for Gerry’s Truck Centre, which operates its first location out of London, Ont. The business was first started up by Gerry Wardle in 1981 and has been a Volvo dealer since 1990. It is currently operated by Gerry’s sons Mike Wardle (dealer principal) and Doug Wardle (sales manager).

Mike began checking out properties for an expansion

two years ago, and started construction on the Woodstock facility last year. It opened to the public near the end of 2017, but Mike didn’t want to have the open house until every aspect of the truck centre was in full operation. He says the new truck centre is already buzzing with work.

“The service techs have more work than they can handle,” Mike says.

In addition to selling Volvo’s lineup of trucks, the company also services a wide variety of trucks and can order special custom-built Volvo trucks.

Mike says the biggest demand comes from a combination of highway components for heavy-haul; refrigeration vehicles; dry van; auto parts; but also do custom-order trucks for other types of specialized hauling.

The Woodstock location has room for expansion, although no new construction is planned for the immediate future.

“It may take two years or 10 years, we don’t have a real timeline,” Mike says, adding that it will be dependent on economic growth in Woodstock and the surrounding communities. “We can double the shop size if we need to. We could have the capacity for 18 trucks. We can fit nine now, comfortably.”

One year before the opening of the world’s leading trade show, bauma, on April 8, 2019, Messe München provides an outlook on the latest developments: the site in the east of Munich will be expanded to 614,000 square metres, the number of halls will be increased to 18. The organizer anticipates that more exhibitors will attend than at bauma 2016.

“Two new halls and a site structure that is even clearer—we have further optimized the parameters for our next bauma,” says Klaus Dittrich, chairman and CEO of Messe München.

The next edition of the world’s leading trade fair for construction machinery, building material machines, mining machines, construction vehicles and construction equipment will take place from April 8 to 14, 2019. Currently, the worldwide demand for exhibition space is extremely high.

Expanded to 18 halls, the exhibition will feature an indoor space of 200,000 square metres. The total bauma area will hence span more than 614,000 square metres. For comparison: the last edition in 2016 had 605,000 square metres.

A new hall and fairgrounds map facilitates the orientation on the gigantic site. Thanks to the clear division into the individual exhibition sectors, visitors can be managed in a more targeted way. With the two new halls that together cover 20,000 square metres bauma will provide space for more exhibitors than in 2016, when 3,425 exhibitors took part.

The most important changes at a glance: the largest sector construction machines and attachments is expanded from four to five halls as well as by an additional area outdoors, directly adjacent to the hall complex. The components sector now also has five instead of four halls; formworks and scaffolds moves to Hall B3; and lifting appliances are bundled in Hall C4. New in Hall C6 is the Conference Center North that houses additional conference rooms.

Previously located in Hall B0, which will be used as additional exhibition space during bauma 2019, the special “THINK BIG!” exhibit that shows students career opportunities in the construction and building material machine industries moves to the ICM –International Congress Center Munich. And there is another change that is envisaged: during the trade fair, the traffic-calmed part of Paul-Henri-Spaak-Straße will be turned into the pedestrian zone “bauma Boulevard”, along which visitors and exhibitors can enjoy an international culinary offering.

Source: bauma

Talbert Manufacturing, a North American leader in specialized heavy-haul solutions, has welcomed Steve Gardonyi as Canadian sales manager. Gardonyi assists dealers in Canada with Talbert trailer sales, marketing and customization. He is also helping to bring the 80-year-old company’s heavy-haul solutions to more people throughout the region, broadening the company’s Canadian dealer network.

“There is a lot of synergy between Steve and our team, both in terms of experience and passion as well as a commitment to customer success,” said Troy Geisler, Talbert Manufacturing vice-president of sales and marketing. “The knowledge he brings from multiple facets of the industry will help us continue our mission to provide our customers with the heavy-haul solutions they need to be successful, whether that’s ‘off-the-shelf’ trailers or fully customized units.”

Gardonyi has nearly 30 years of industry experience, which includes operations management, quality control, sales and customer service. He also carries a Red Seal certification in trailer mechanics.

“Success in this market takes hard work, a strong team and quality processes that start from the time we answer the phone until a satisfied driver is pulling their Talbert trailer down the road,” Gardonyi said. “I know Austin Talbert had that same vision, and it’s my honour to lift that torch he lit in 1938 high enough for everyone in Canada to see.”

In addition to carrying the Talbert torch, Gardonyi is active in his community through the Central Ontario District Optimists, where he served a term as governor. The club provides youth services — such as athletic leagues, scholarship essays and local school support — to improve the lives of children.

Gardonyi lives in Burlington, Ont. with his wife, Angelina, and Shih Tzu, Reggie. They have two children, Michael and Natasha, who live in the area.

Hiab, part of Cargotec, appointed Barry McGrane as vicepresident of sales and services, North America, Hiab, as of May 1, 2018. In this position he will lead Hiab’s sales and services operation in the U.S., where Hiab is a leader in on-road load handling equipment and services.

He will report to Scott Hall, senior vice-president of sales and services, as a member of the global Hiab sales and services leadership team. An engineer by education, McGrane has been with the company for over 17 years. He held positions in R&D and since 2015 has been director, sales and product management for Hiab’s truck-mounted forklifts business line, for which North America is the most important market.

McGrane succeeds Russ Parisi, vice-president of sales and services, North America, who decided to leave and pursue his professional career outside of Hiab and Cargotec.

“I would like to sincerely thank Russ for his valuable contribution to the company over the past three years and wish him every success in the future,” Hall said.

2018

July 11-12, 2018

Atlanta Build Expo Atlanta, Ga. www.buildexpousa.com

2018

August 15-16, 2018

Houston Build Expo Houston, Texas www.buildexpousa.com

Sept. 10-13, 2018

2018

ACPA Conference Saint John, N.B. www.acpa-ports.net

Sept. 11-12, 2018

Oil Sands Trade Show & Conference Fort McMurray, Alta. https://oilsandstradeshow.com/

Sept. 16, 2018

BCRB Fall Conference Kelowna, B.C. www.roadbuilders.bc.ca

Sept. 19-20, 2018

Seattle Build Expo Seattle, Wash. www.buildexpousa.com

Sept. 26-28, 2018

SC&RA Crane & Rigging Workshop Louisville, Ky. www.scranet.org

2018

Oct. 23-25, 2018

CanWEA Annual Conference & Exhibition Calgary, Alta. www.canwea.ca

Oct. 24-25, 2018

Tampa Build Expo Tampa, Fla. www.buildexpousa.com

Nov. 7-8, 2018

Buildex Calgary Calgary, Alta. www.buildexcalgary.com

Nov. 26-28, 2018

CCA Fall Board Meeting Ottawa, Ont. www.cca-acc.com

Dec. 5-6, 2018

Nashville Build Expo Nashville, Tenn. www.buildexpousa.com

Dec. 6-8, 2018

BCRB AGM & Winter Celebrations Victoria, B.C. www.roadbuilders.bc.ca

Jan. 9-10, 2019

Austin Build Expo Austin, Texas www.buildexpousa.com

Jan. 22-25, 2019

World of Concrete Las Vegas, Nev. www.worldofconcrete.com

Feb. 5-6, 2019

Dallas Build Expo Dallas, Texas www.buildexpousa.com

April 6-14, 2019 bauma 2019 Munich, Germany www.bauma.de

“We’ve

– Pascal Francoeur, Director of Operations, Grues JM Francoeur