BY JACK BURTON

BY JACK BURTON

And just like that, it’s 2025! While the calendar always seems to turn faster with every passing year, there’s still twelve months to get through, along with the exciting questions they bring of where they’ll take us – and how we’ll get there.

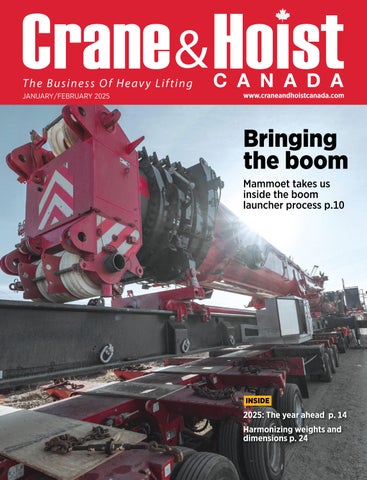

Crane & Hoist’s premiere issue of 2025 is all about “getting there,” in more ways than one. While there’s focus on how the industry is set to move through the year ahead, we’ve also taken the literal approach by looking at what “getting there” means in terms of actual operations, whether it’s transporting your equipment or safely bringing your jobs to completion.

spective that this issue extends to the industry at large.

We sat down with two leaders from across the industry – the Canadian Crane Rental Association’s 2024-25 board chair and VP of TNT Crane & Rigging, Steve Anema, along with executive director of BC Crane Safety, Clinton Connell – to help map out what 2025 might hold and chart the path for navigating what the year may have in store for Canada’s heavy lifting sector.

From equipment transport to the year ahead, this issue is all about “getting there.”

One of the persistent questions I receive from friends and family since covering this sector is how you all get your massive cranes and machines to where they need to be, and this past holiday season was no different. The specifics may be a tad too long to cover over a cocktail meatball, but I’m excited that this issue will be something I can point to next time I’m inevitably asked this question.

While heavy haul is far from the red-headed stepchild of the lifting industry, it is one aspect of the work you all do that doesn’t always receive the same airtime as a heavyweight turbine lift or acing some tightsqueeze Tetris with downtown tower crane work, despite being equally important and necessary to make many of these lifts possible in the first place.

For this issue’s spotlight on heavy haul, we’re fortunate to feature two prominent members of the industry, with Ashleigh Kaliszuk, fresh off her recognition in our last issue’s Top 10 Under 40, providing a first-hand account of lifting and heavy haul superstars Mammoet’s experience with the boom launcher process in Alberta.

Boom launchers offer a way to get your crane boom to where it needs to be, helping with the set-up and installation of it into the crane. Apologies for the metaphor, but getting things to where they need to be and setting them up for success is also a per-

Spoiler alert: while the near future is bright with opportunities across a variety of markets from residential to energy, finding the talent needed to tackle this wealth of work head-on – and set up the industry for future, long-term success in the process – is a challenge that these leaders are hard at work in solving.

During our conversation, Steve Anema offered both a great explanation of some of the key factors behind this labour crunch, along with a proposed solution of how those within the industry can attract future members by showcasing the range of possibilities that Canada’s heavy lifting sector has to offer:

“While the public notices cranes driving around, as an industry it hasn’t got the same exposure as other trades, especially on how to get into it and understanding the great-paying jobs that come with it,” he said. “I see a big push to show the general public what this path looks like on a career level – not just as a crane operator, either. It could be in dispatch, on the business side, or as a project coordinator.”

It’s hard to leave opportunity on the table, but I’ve also come to know you bunch as one that approaches the idea of a good challenge with the same level of enthusiasm. Whatever the opportunities or challenges that the year ahead has in store for you, I wish you all good fortune and growth as we march forward together.

Jack Burton jburton@annexbusinessmedia.com

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | JACK BURTON jburton@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER | LAURA GOODWIN lgoodwin@annexbusinessmedia.com • 289-928-8543

MEDIA DESIGNER | SVETLANA AVRUTIN savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR | FARWA SIDDIQUI fsiddiqui@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER | URSZULA GRZYB ugrzyb@annexbusinessmedia.com • 416-510-5180

CONTRIBUTORS | Ashleigh Kaliszuk

GROUP PUBLISHER | DANIELLE LABRIE dlabrie@annexbusinessmedia.com

CEO | SCOTT JAMIESON sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues) Canada: $37.74 + tax per year USA: $48.96 CAD • Foreign: $63.24 CAD Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

PRINTED IN CANADA ISSN 1923-788X Publications Mail Agreement #PM40065710

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Crane & Hoist Canada are copyright ©2025 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Advertising Deadline: February 21, 2025 Don’t miss the opportunity to be part of this exciting industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: February 26, 2025. For writers’ guidelines and submission requirements get in touch with the editor, Jack Burton, at jburton@annexbusinessmedia.com

MEMBER OF: MEDIA PARTNER:

The Grove GMK4080L all terrain crane is an outstanding four-axle taxi crane that, with its 60-meter-long boom, offers both the longest boom and the lowest gross vehicle weight in its class. Within 10 t per axle, the crane can carry 5.2 t counterweight and even 13.3 t counterweight with 12 t axle load. The GMK4080L can also carry its full 19 t counterweight with less than 16.5 t axle load. This flexibility makes it the ultimate taxi crane.

New and used Manitowoc and Grove Sales, Rentals, Parts and Service.

New crane operator training facility under construction in Ontario

Ground has officially broken in the building of a new training facility focused on mobile and tower crane operation in Ontario’s Oro-Medonte Township.

The $25 million, 21,000 sq. ft. facility will be run by the Operating Engineers Training Institute of Ontario (OETIO) and will feature simulation labs, workshops and an outdoor tower crane training ground, in addition to student facilities and regional office space for OETIO staff.

Bird Construction is overseeing the building of the facility, with an expected completion date of 2026. When finished, the facility is expected to train more than 1,600 students for the province’s heavy lifting industry.

Mike Gallagher, business manager of the International Union of Operating Engineers (IUOE) Local 793 spoke of the impact this new facility will have in growing the industry with both new and safer workers.

“In our trade, there is zero room for error. Lives depend on the work that we do, including our own lives,” said Gallagher. “So right here on this site, we’re going to be training the very best of the best operators to ensure that the sites, whether that be carpenters, labourers, pipefitters, whoever it is that our members are working with, can feel safe and are going to be able to return home at the end of the day.”

Ontario Premier Doug Ford was present at the groundbreaking ceremony on November 12, 2024, where he announced that his government will be providing $4.9 million in funding to the IUOE Local 793 toward the construction of the training centre.

“These are the future builders who are going to be building our hospitals and our

schools,” said Ford. “Our skilled trade workers are the backbone of this province and you only need to look at our skylines to see it.”

BC Hydro has awarded 30-year electricity purchase agreements to nine energy projects from its call for new renewable power generation projects last year.

Combined, the construction of these projects will generate between $5 billion to $6 billion in private capital spending, and when complete will provide power for nearly 500,000 new homes; an 8 per cent increase from BC Hydro’s current capacity.

These projects, along with all other provincial wind projects, will be expedited through an exemption from the B.C. government that will not require an environmental assessment to be conducted prior to construction. Despite this exemption, measures will be in place to ensure First Nations interests and environmental mitigations are maintained.

Eight of the nine wind projects are already confirmed to have a 51 per cent First Nations equity ownership, which represents a total

value of $2.5 to $3 billion across these projects.

“We need these new energy generation projects urgently to meet growing demand for power and accelerate our efforts to build a prosperous and inclusive clean economy,” said Adrian Dix, Minister of Energy and Climate Solutions. “Now that the projects have been selected, we’re going to work together with BC Hydro, First Nations and proponents to get these projects built quickly, responsibly and efficiently, and get those turbines spinning.”

New mandates for tower crane inspection schedules have come into effect across Ontario as of January 1, 2025.

These mandates to the Occupational Health and Safety Act introduce new scheduled inspection requirements in addition to new compliance measures in alignment with the most recent CSA standards for the design, erection and dismantling of tower cranes and other crane types.

With these changes, all components must now be inspected and verified to be sound at 10-year intervals, spanning from either a crane’s manufacture date or date of previous inspection.

These inspections must include examinations of electrical, mechanical and hydraulic elements and control systems that can affect the structural integrity, stability and motion of the crane. Additionally, any non-structural components vulnerable to cracking, damage or wear must also be inspected.

The inspection process must been overseen by an engineer; with this engineer responsible for conducting the inspection with a team of qualified experts and for confirming the validity of the inspection process. Any necessary repairs, overhauls or part replacements concluded by the inspection process must also be conducted with an engineer or the equipment manufacturer on-site to instruct the work required.

The Canadian Crane Rental Association shares news for the year ahead, including member benefits and upcoming annual conference.

On behalf of the Canadian Crane Rental Association’s board of directors and management team, we wish you a very happy and prosperous new year, and hope your Christmas holiday was filled with memorable moments with friends and family.

“What we do not change, we choose” is a powerful statement often attributed to various sources. This sentiment encapsulates the proactive approach of our dynamic board of directors, all of whom are dedicated to serving our members.

The CCRA is beginning 2025 with a wave of new initiatives, starting with the launch of the CCRA’s Group Benefits Plan. In the competitive landscape for talent, employee health benefits are crucial for attracting and retaining employees. From owner-operators to our largest employers, the CCRA’s Group Benefits Plan offers custom solutions for companies of all sizes.

For companies with existing plans already in place, the association can provide cost-effective solutions for better coverage and savings.

In partnership with ICBA Benefits, the CCRA’s Benefits Plan is an exclusive, members-only group health, dental and retirement plan. CCRA members can now enjoy highly competitive rates, exceptional service and the dedicated support of ICBA’s team.

This plan is designed to benefit your workers, their families and your bottom line. Our trusted partner, ICBA Benefits, is one of Canada’s largest independent providers of group health, dental and retirement benefits, serving over 170,000 Canadians and 4,000 companies. You will find more details under Membership at www.ccraaclg.ca. This is a change worth exploring!

The CCRA conference goes West

One of the responsibilities of our association lies in building strong business relationships across the sector, all of which are fortified when we meet in person. The 2025 Annual Conference is the ideal forum for this, and this year, we will meet in Edmon-

ton, Alta., from June 3 to 5, 2025 – the cradle of the CCRA.

The CCRA’s annual conference will once again bring together leaders of the crane industry to share best practices, highlight outstanding engineering feats through the Canadian Lift of the Year Awards competition, and showcase the latest changes and innovations from various manufacturers and suppliers. The changes we have chosen to implement at this year’s conference are the results of your feedback, including a greater focus on the workforce and crane safety.

The J.W. Marriott, our host hotel, is located in the vibrant Ice District at the heart of Edmonton – prepare to immerse yourself in the exhilarating hockey atmosphere that engulfs the city during the NHL Stanley Cup playoffs.

We are also thrilled to announce that Brandon Hitch, CEO of the Crane Industry Council of Australia (CICA) will be joining us to share the remarkable transformation his organization began a decade ago and how these insights can be applied to our own industry in Canada.

Registration is open to all members! Non-member companies are invited to join

the CCRA and benefit from more than 25 years of leadership and positive changes to the crane industry.

As we head into 2025, the CCRA will be more visible and active in marketing the industry to both the public and legislative groups. The creative process has begun for a promotional toolkit to be presented at the CCRA’s Annual General Meeting in June, providing greater support for our members in attracting the workforce needed to remain competitive.

The CCRA Technical Committee will extend its reach this year, moving into new areas identified by you, our members. An active participation with the CSA Group ensures that changes to the Z150 and Z248 Standard are effectively communicated.

The Weights and Dimensions Committee, which has celebrated several successes since its inception, will continue to work towards harmonization for mobile cranes across Canada. Our active presence at the National Task Force on Weights and Dimensions Policy has provided opportunities to enhance our regional impact.

Mammoet’s team of lifting and heavy haul experts use a boom launcher to bring their new Liebherr LTM 1650-8.1 to life in Alberta.

While the term ‘boom launcher’ might sound like it’s all about speed, for James Bunning and his Alberta crew, removing and reattaching the boom is a controlled process requiring meticulous care.

Once the boom was in the right spot, the next step was engaging the heel pins. These pins lock the boom in place and ensure the rest of the connections will align properly. Afterward, the crew moved on to the cylinder pins, pushing them into place, before the final action of connecting the hydraulic hoses. This series of steps ensures the crane’s stability and enables the boom hoist cylinders to raise and lower the boom during operation.

“On average, this process takes between 1 to 1.5 hours. We have done it in 45 minutes, but everything was perfect to make that happen.”

From here, the rest of the crane build was business as usual – the crew reeved the block and installed the back outrigger beams.

After the launcher disengages from the crane, their transport driver can bring it back to their yard or keep it in a laydown area on-site if they’re working on a longterm project.

Another notable feature of the boom launcher system is its versatility. The crew can repurpose it to load the counterweights for the LTM-1650. With a capacity of up to 125 tonnes, this helps streamline site moves by reducing equipment, time and costs – a huge bonus for project efficiency.

According to Bunning, “On average, this process takes between 1 to 1.5 hours. We have done it in 45 minutes, but everything was perfect to make that happen.”

With everything fully connected and operational, the time had arrived for the crane to “boom up” just enough to take the weight of the boom – so the crew could remove the travel pins from the launcher. At this point, the launcher was essentially free, and the crane could continue booming up to its operating position. Each step builds upon the last, ensuring the crane is ready to lift safely.

Although setting up a crane may seem straightforward, using the boom launcher system is a complex process that requires comprehensive knowledge of the equip-

ment and crane. It takes crane operation to a whole new level, integrating the vehicle regulations that apprentices learn in school into real-world applications.

Not only does this technology ensure regulation compliance and streamline operational processes, but it also provides a significant competitive edge in the workforce. The minimal space required to assemble a 700-tonne (770-ton) crane is impressive, allowing for greater flexibility and efficiency on tight job sites. This compact set-up saves valuable time and reduces logistical challenges, giving companies an advantage in both cost and speed.

I want to thank James Bunning and the entire Mammoet crew for the opportunity to observe and learn about their boom launcher. Their expertise and willingness to share insights were invaluable. I also want to thank Michael Parkinson from Liebherr Canada Ltd. for his practical training on the boom dolly and the knowledge he provided, which contributed to this story.

Jack Burton

With 2024 in the rearview mirror, Crane & Hoist Canada is looking ahead to what the back half of the decade has in store for Canada’s crane and heavy lifting industries with some help from the country’s lifting leaders.

We spoke with Steve Anema, board chair for the Canadian Crane Rental Association and vice president of TNT Crane & Rigging, along with Clinton Connell, executive director of BC Crane Safety, about the high volume of current opportunities across the sector at the turn of the half-decade – and some of the strategies for finding the labour needed to tackle this work.

CHC: What are some of the major highlights from across both the industry and your organization over the last year?

STEVE ANEMA: On the Canadian Crane Rental Association front, there’s been a lot of progress in ensuring we’re the association the industry looks to for things that come down from regulatory government bodies – making sure that we’re getting that first call, so that we can be

part of the discussion on things like weights and dimensions and the general outlook of the crane industry in Canada.

Right now, I think it’s similar to most industries: we have a challenge in getting the labour force set to have the crane operators, mechanics and qualified people in the roles needed to both sustain and grow our business.

There have been initiatives to try to introduce what cranes are to people, what the industry

means and what the jobs in it look like. While I anticipate that challenge to still be there for 2025 and beyond, there is certainly a concerted effort to introduce the industry to the public. We’ve discussed how to introduce that to people making decisions about their careers, whether at a high school or early college level.

At TNT Crane & Rigging, our business must adapt to the availability of qualified people to do the work, too. With that,

we’re always looking to train people and get them through the ranks of the organization, but first that means attracting people to the business.

CLINTON CONNELL: Unfortunately for B.C., 2024 resulted in a spate of tower crane-related incidents, many of which have attracted a lot of scrutiny and media attention – understandably. That’s impacted our organization in terms of shifting our priorities onto the tower

crane sector and ensuring our resource development has a strong focus on their immediate needs.

That includes things like the creation of a registry database for supervisors that oversee those who assemble and dismantle tower cranes, similar to what all the crane operators in B.C. are registered into.

Additionally, WorkSafeBC has recently implemented notice of projects (NOPs) for tower cranes, which require any of the contractors putting up, climbing or dismantling a crane to notify them two weeks in advance of activity taking place. Those NOP submissions require verification that all the due diligence and documentation are in place.

Most recently, we created templated crane binders, which include a documentation organization management sys-

“I think everyone’s looking to have a good year, and I can see the industry as a whole doing quite well,” said Steve Anema, 2024-25 board chair of the Canadian Crane Rental Association and vice president of TNT Crane & Rigging.

(PHOTO: CCRA)

Tower crane incidents across British Columbia over the past year have Clinton Connell and BC Crane Safety hard at work developing resources to bring increased awareness and safety to this issue moving forward.

(PHOTO: BC CRANE SAFETY)

tem. That assists them in organizing all the due diligence and documentation in a sequential order to have handy on-site, as well as the required engineering for those new NOPs to be approved.

CHC: What is the state of the industry and its current opportunities going into 2025?

ANEMA: I have a very positive outlook to our industry. Even when we have challenges like labour shortages, it always provides an opportunity to look at things differently and ask, how do we become an industry that people want to be a part of? And for crane companies and the people running them, how do you produce an organization that people want to be a part of?

There’s lots of work in the industry: cranes are required for

many current projects, whether green energy or infrastructure. So, as far as the business perspective? It’s optimistic. Looking into 2025, there’s a lot of things coming that the industry can look forward to.

If we’re having a busier year, the big challenge is going to be keeping up with the work that we want to deliver on. And that’s going to come back to getting people in the industry.

On the TNT side of things, take the Trans Mountain project, for example: that was an uptick in business for everybody. Now we’re starting to see more infrastructure projects come online throughout the province, along with many energy projects happening to bring that uptick. This all speaks to current opportunities – when interest rates come down, you typically start to see

more activity from a commercial market as well.

CONNELL: We did experience a brief slowdown, but everyone seems to be very busy again. Over here, tower cranes are at an absolute fever pitch: B.C. has over 500 tower cranes standing right now. Compare that with other areas like New York City, which has a population one and a half times the size of B.C.; I think they have around 60 tower cranes up.

Driving all of that is a huge amount of infrastructure work taking place in B.C. Unfortunately, we have an exodus of experienced workers from multiple sectors, and thus increased competition for that smaller number of incoming workers. That creates a strain not just on the industry, but especially organizations that

rely on apprenticeship models, where workers typically spend years gaining that necessary experience and competence in their chosen trade.

Historically, apprenticeship systems have struggled to keep up with demand, and when you combine that with the current demand for labour, it’s just exacerbated that situation. A lot of our initiatives for 2025 and beyond are to specifically address that.

We collaborate very closely with our stakeholder partners, including the apprenticeship boards, the labour unions and private training organizations, to support and promote increased availability and capacity. In B.C., we recently nominated tower and mobile cranes for the skilled trade certification program, which are the top two crane types under the 11 crane licenses in B.C.

We’re also supporting the local IUOE’s investment in newer equipment and have worked with SkilledTradesBC to split mobile and tower crane programs: they used to be combined into a common crane program, but the reality is most people choose one path or the other.

CHC: What initiatives do you have planned for 2025, and what issues do they address?

ANEMA: Labour is definitely something we plan to address, as far as providing more accessible introductions to the industry. While the public notices cranes driving around, as an industry it hasn’t got the same exposure as other trades, especially on how to get into it and understanding the great-paying jobs that come with it.

Women in Construction 2025

I see a big push to show the general public what this path looks like on a career level – not just as a crane operator, either. It could be in dispatch, on the business side, or as a project coordinator. There’s a lot of things that can tie themselves into being in the crane industry, and letting people know what those opportunities are is quite important.

The CCRA also has its annual conference this June in Edmonton, which is effectively known as the crane capital of Canada, so we anticipate having a good turnout. These events are quite powerful for the industry, in terms of getting together and looking at what it means to forge ahead. We all attend these based on representing our different organizations, but when we get together like this, we are one industry working together to make things better in all areas.

CONNELL: In addition to furthering the conversation on rigging certification and certification renewal, one of our plans that was shifted into 2025 is creating templated resources for small and medium companies that don’t have formalized preventive maintenance programs.

While the large companies don’t struggle as much, as they have the administrative resources and the depth of experience to excel at those things, I think a lot of the small and medium employers look outside their organization for assistance on that, so we’re well suited to be able to help fill that gap for them.

CHC: What are your expectations for the sector in the year ahead?

ANEMA: Safety continues to be a big priority heading into 2025. It’s always a focus for any organization to ensure its teams are trained and prepared with the right gear, and that all proper processes and procedures

are followed – these are big pieces of equipment, and we want to ensure that the right training is in place for our team. With the expected uptick in 2025 on the business side of things, encouraging this right across the country will be important. I think everyone’s looking to have a good year, and I can see the industry as a whole doing quite well.

CONNELL: Given the housing crisis and the fact that it’s a national issue, I don’t really foresee labour demand letting up anytime soon, particularly for skilled labour.

The recent incidents and the increased frequency we’ve seen them have resulted in increased enforcement. And I don’t think that’s a bad thing either – there’s new regulatory guard rails being put in place, and I suspect there’s more to come, especially surrounding qualifications, supervisors and the type of training available for people that oversee that type of work.

Another focus will be rigging. When we look at the nature of failures and incidents, a lot of them surround rigging practices, which is concerning. Rigging training is readily available: it’s not expensive, it’s not time consuming, but there is no national standard in Canada, so there’s work happening in the background that we participate in as well to try and promote and move a national rigging standard forward.

My sincere hope, given the experience of 2024, is that at minimum, we have increased awareness of everyone working in the space: not just crane operators, but people working in and around cranes, and that employers and workers understand their health and safety obligations with respect to training, especially as we’re transitioning to that next generation of crane and rigging professionals.

When it comes to crane operations, wire rope selection is seemingly simple but immeasurably critical.

When selecting wire rope for a construction crane, the choice you make isn’t just technical; it’s a decision that directly impacts safety, equipment durability and project timelines. Yet, despite its importance, many crane manufacturers, owners and construction managers treat this vital component as an afterthought.

Here’s a bold truth to consider: your wire rope won’t outlast your equipment, but the stakes of its failure – financial, operational and human – could be catastrophic. It’s time to rethink how we evaluate and select crane ropes.

Selecting the right rope isn’t as straightforward as it may appear. Different crane operations require ropes tailored to specific needs, but too often, ill-suited ropes lead to inefficiency, unnecessary costs and even failure risks.

Where do we start with such a complex subject? Perhaps as good a place as any is the subject of suitable applications for non-rotating ropes. The necessity is single-fall applications, or multi-fall applications at great heights. These situations generate torque and rotation that can cause either the rope or hook block to twist uncontrollably unless a non-rotating wire rope is used.

Category 1 non-rotating ropes offer the highest resistance to torque and rotational issues through their unique design, which balances inner and outer strand torque for stability. While it is important to know when to deploy a non-rotating rope, knowing when one is unsuitable is perhaps more important, since rotation resistant rope used in the wrong application will not give any warning to its failure.

Take for example, boom hoist ropes. Boom hoist ropes face some of the toughest conditions, operating under low design factors (usually just 3.5:1 compared to a hoist rope’s 5:1) and poor sheave-to-rope diameter ratios (15:1 versus 18:1 for hoist ropes). This means they are exposed to heavier loads under sharper bending conditions. Any rotation resistant rope here is an absolute do-not. Even traditional 6- and 8-strand constructions experience fatigue

Your wire rope won’t outlast your equipment, but the stakes of its failure — financial, operational and human — could be catastrophic.

failure and hidden internal damage, and common swaged variations are particularly prone to failing from the inside out. These issues make inspections ineffective, significantly raising safety risks. Likewise, pendants, which are exposed to heavy loads, vibrational fatigue and are extremely difficult to inspect due to accessibility issues, must utilize a rope which can best withstand these conditions and when inspected they must show signs of fatigue.

The solution for both applications is modern ropes with high fill factors and protected cores. An 8-strand rope featuring compacted strands and core protection ensures higher endurance under cyclical loads and reduces the risk of core failure. This also promotes inspectable wear on the outer surface, making inspections more reliable.

With hoist ropes, flexibility, lateral stability, fatigue resistance and strength are all factors that play into the rope decision. For tower cranes, the choice is made easy since all standards and regulations prevent the use of typical Category 2 and 3 rotation resistant ropes. The only question is whether a non-rotating rope or a standard rope is required.

For mobile cranes, the decision is less obvious. While the best choice, where rotation resistance is required, is a Category 1 rope (known colloquially as non-rotating), Category 2 rotation resistant ropes may find a home on smaller cranes with small drums, more than three drum layers, and low duty cycle. Here, the rope will commonly be destroyed by multi-layer spooling issues with mechanical damages resulting in visible rope damage.

For larger mobile cranes, like crawlers, more sophisticated rope constructions are a necessity due simply to the higher demands of these machines. The three-layer design of Category 1 rotation resistant ropes distribute pressure more evenly across the rope structure, dramatically enhancing fatigue resistance, rotation resistance and lateral stability. They also boast superior breaking strength, making them ideal for high-load, repetitive operations on mobile and tower cranes.

With substantial risks like operational failure, financial loss, or even endangering human lives, engineering standards demand vigilance. Wire ropes are not merely components – they are, as the definition rightly puts it, machines in themselves. Hundreds of high-carbon steel wires work in harmony to create the strength, flexibility, and endurance required for crane operations. But this complexity also means that choosing the right rope has cascading impacts on your entire system.

The demands of construction cranes today – higher capacity loads, increased lifting heights and cycles – mean traditional rope solutions can no longer keep up. The wrong rope disrupts performance, causing not just premature failure but also long-term inefficiencies across your fleet. A high-performance rope, meanwhile, reduces risks and provides better return on investment (ROI) through increased safety and equipment longevity.

Now is the time to act. Review your crane’s wire rope selection and consider whether you’re using the right tools for the job. If you’re uncertain where to start, consult your rope supplier or a wire rope specialist for guidance. Remember, the choices you make don’t just impact efficiency – they determine safety and success.

The rope you choose isn’t just supporting your load; it’s supporting your entire enterprise. Choose wisely.

Effective company storytelling can help build the workforce needed to grow alongside the construction sector.

Canada’s construction industry employs more than 1.6 million people and is projected to grow through 2033, driven by residential sector rebounds and major infrastructure projects. But amidst this growth, companies face a dual challenge: attracting and retaining a workforce – particularly younger talent – and navigating ongoing industry disruptions.

While economic forces and technological advancements influence the landscape, how a company communicates, both internally and externally, plays a pivotal role in shaping its success. Effective public relations (PR) and communication strategies can make your company a top employer of choice, helping you stand out in a highly competitive market for skilled labour.

Top talent isn’t just looking for a paycheck: they want purpose, growth and alignment with a company’s values. To capture their attention, construction companies can invest in employer branding. PR can help position your company as an industry leader by highlighting your culture, values and growth opportunities. Does your company foster innovation, prioritize safety, or offer development opportunities? Use storytelling to showcase these attributes through press releases, trade media features, social media campaigns and internal communication platforms. Video testimonials from current employees, day-inthe-life posts, or open-house

events can give potential hires a peek into your company’s world.

Position your leadership team as thought leaders by contributing op-eds, participating in industry podcasts, or speaking at industry conferences. Leadership visibility helps shape perceptions and inspires confidence in both current and prospective employees. The more aligned your company appears with industry trends, safety innovations and technological advancements, the more attractive it will be to skilled professionals eager to be part of a forward-thinking organization.

Safety is paramount in crane and heavy lifting operations. The sector’s highly skilled workforce seeks employers who prioritize their well-being. Companies that effectively communicate their safety protocols, training programs and technological innovations will not only comply with industry standards, but also attract workers who feel secure in their roles.

Make sure you are communicating these efforts, whether that’s developing case studies on how these initiatives are being implemented or using your website and social media channels to highlight your commitments to keeping workers safe. The construction workforce is more discerning than ever, with safety being a key factor in job satisfaction and retention. Real-world stories from the field that emphasize a company’s commitment to safety can help attract like-minded individuals, while also building trust with current employees.

Highlighting pathways to growth and advancement is essential for retention as younger generations seek opportunities for career progression.

Make sure your internal communications foster an environment where growth is encouraged: highlight promotions, peer mentorship programs, or specialized training programs in internal newsletters or employee spotlights. External PR can then take those success stories and use them to demonstrate to potential recruits that your company invests in its people.

One way to attract younger workers is through partnerships with trade schools and technical institutions. You can sponsor scholarships, host recruitment events, or provide apprenticeships. PR campaigns can highlight these partnerships and demonstrate your company’s commitment to developing the next generation of construction professionals.

The construction industry is undergoing a digital transformation. Younger talent is techsavvy and expects their workplace to be similarly advanced. The integration of technologies like Building Information Modeling (BIM), drones and advanced crane operation systems is not just about efficiency; it’s about attracting a new generation that values innovation.

PR can tell the story of how your company is leveraging technology to make work easier, safer, and more efficient. Interviews with technology partners

or internal experts can explain how these advancements create a better working environment and establish your company on the cutting edge of industry trends; appealing to young professionals eager to work with the latest tools.

Internal communications play a massive role in retention. Employees value transparency, especially in industries with inherent risks like construction. Regularly update employees on company progress, future projects and any business challenges.

Ensure that communication channels are two-way. Employees should feel heard and able to express concerns or share feedback without barriers. Platforms like town hall meetings, anonymous surveys, or even opendoor policies can significantly boost morale and retention. From a PR perspective, ensuring internal satisfaction will naturally amplify external reputation.

The competition for skilled labour is fierce. By adopting strategic PR and communication practices, construction companies can not only stand out in the market but also build a reputation as an employer of choice. Compelling storytelling can help companies attract and retain the best talent — positioning themselves for long-term success in a growing industry.

Katie Pringle is the CEO and co-founder of Marigold PR, an award-winning public relations agency that has been serving companies across North America since 2016.

Tadano cranes are engineered to excel in challenging cold-weather environments, offering unmatched reliability and performance when conditions are at their toughest.

Key Advantages:

• Purpose-built for extreme climates

• Maximum uptime even in subzero temperatures

• Unlimited access to Tadano factory training

• Free 24/7 technical support for rapid troubleshooting

• E xceptional reliability and resale value

When the job demands top-tier performance in harsh conditions, Tadano cranes deliver.

Heavy haul trailers for hitting the highway to success. By

Crane & Hoist Staff

It’s no secret for any heavy lifting professional that most lifts start long before anyone steps foot on-site. Getting your cranes, loads, or other heavy equipment to where they need to be is its own complex process, with heavy haul trailers providing one of the primary solutions used in these procedures.

If you’re looking for your next haul star, check out this list highlighting some of the current heavy haul trailers available on the Canadian market, and their features and designs for getting both your cranes and your projects to where they need to be.

1.

Brandt’s H650 10-axle square tail trailer is designed with numerous features to support efficiency in the loading and unloading processes, including user-friendly booster connections that can be hooked up without a crane, along with

2

ramps that include built-in ports for quick removal without the requirement of a forklift or sling. With a 65-ton payload, the low-profile gooseneck trailer prioritizes both heavy loads and the durability needed to handle them, as supported through the inclusion of auto-shimming technology and a powder-coat finish. A three-position rideheight valve also adds to its adaptability across a variety of on-highway road conditions.

1

Standing at 10 ft. by 26 ft., the trailer is designed with 7 ft. of wheel slide to optimize handling across a wider range of equipment. Crew safety is also supported through the inclusion of extra-stoke shim legs, which eliminate pinch points, along with built-in lift points on the ramp to lower safety risks during the removal process.

The trailer’s air tank drain valves have also been remotely mounted for safer and more streamlined maintenance.

2.

XL Specialized Trailer’s Hydraulic Folding Gooseneck (HFG) model focuses on providing durability and adaptability during the ramping process. The trailer’s hinged folding

gooseneck provides a seven-degree loading angle, while its automatic adjustment to uneven terrain when folded down allows for use across a variety of environments.

Multiple king pin settings are provided to help users achieve proper load distribution and maximize compatibility across a range of heavy equipment. The trailer’s perimeter frame design, which includes G-channel crossmembers every 18 inches, also adds to its ability to handle heavy-duty loads.

The trailer’s range of loading applications is broadened by features including both a low load angle at the front and an optional winch at the rear, which help in hauling inoperable loads and equipment. The trailer also includes remove-

able swingout outriggers that extend the width of the loading surface, and its self-contained power unit is stored away from the wheel and main deck areas to prevent damage.

The HFG comes standard with a 100,000-lb. overall concentrated capacity and a 26-foot main deck length, with an 80,000 lb.-capacity model designed for railroad hauling also available.

The 5070 model from Penticton, British Columbia’s Peerless is a five-axle, 70-ton capacity hydraulic removeable gooseneck trailer designed for heavy-duty transport needs, including cranes and construction equipment.

The 5 Axle Hydraulic RGN 70T’s detachable front-end gooseneck section provides flexibility during the loading and unloading process, further supported by its robust hydraulic system. This included hydraulic system also drives efficiency in the handling of oversized loads.

Magnitude 55L Plus Fontaine Specialized Trailers’ Magnitude 55L Plus removeable gooseneck trailer, available in Ontario from Rush Truck Centres, features a flat level deck and fixed tridem bogie lowbed.

The unit comes in two models at both 16 ft. and 10 ft. in length, with both sharing a 55-ton capacity and 8.5 ft. width. The 16 ft. model features a 125-inch swing and a 3+1 EQ1, while the 10 ft. model’s swing stands at 102 in. long with four close-coupled axles. Both trailers feature a loaded deck height of 18 in., with a loaded ground clearance of 6 in.

A dial cam pawl comes standard on both models and provides additional gooseneck positions.

The gooseneck also features 7-position ride height control, which provides additional up and down clearance at the front of the trailer deck. Additionally, a hydraulic, removeable shaft and hook-style gooseneck support operations on uneven terrain.

The 55L Plus has a nominal capacity of 25,000 lbs. per axle, with a 54.5-inch spread between axle centres and recessed load bearing bolsters between all axles. Optional load bearing wheel covers and chain lift first axles are available, with air lift third axles being standard. A 3-axle air ride bogie is included, with a dust shield option also available.

No matter how challenging your needs, AIROMAX AM 27 is your best ally for mobile cranes in industrial applications. The tire is particularly suitable for road usage. Thanks to its All Steel casing and the special tread design, AIROMAX AM 27 provides extraordinary traction along with high load capacity.

AIROMAX AM 27 is BKT’s response to withstand the toughest conditions in the construction industry.

Joe Dias

Eastern Zone Manager

Directeur Régional, Est du Canada

BKT Tires (Canada) Inc.

Cell: 514-792-9220

Web: www.bkt-tires.com

The efforts to harmonize crane transportation standards across Canada’s provinces, and the impacts of these changes on the sector.

By Andrew Snook, on behalf of the Canadian Crane Rental Association

When it comes to weights and dimensions, members of the Canadian Crane Rental Association (CCRA) are busy from coast to coast on a variety of projects, initiatives and outreach.

Arguably, the most prominent project that has taken place in recent years was the pilot project for increased axle weight on all-terrain cranes in Alberta, during the province’s road ban season. The CCRA and crane owners worked closely with the Government of Alberta on a three-year pilot project, increasing axle weights from 7,600 kg to 9,500 kg during the road ban season.

“Single-trip permits were used to track and analyze data from all permits and trips made in Alberta during this time period,” explained Mike Lavoie, operations manager for Myshak Crane & Rigging Ltd.

The government was able to take this data and use it to understand the number of cranes travelling on any road in Alberta. It also allowed them to monitor any additional wear or damage done to the roads.

“Having this pilot project led to the successful policy change to increase axle weights on all-terrain cranes to 9,500 kilograms full-time during road bans,” Lavoie says.

In Quebec, the government has been working for years to update two key regulations that

The

apply to crane weights and dimensions. The first regulation is related to vehicle load and size limits.

“This should be the first one updated. That will allow us more flexibility with smaller boom trucks,” said Guillaume Gagnon, executive vice-president for Guay.

The second regulation, Gagnon explained, is the Special Permits regulation.

“This would have a big impact on our industry. The complexity for the government is that all types of equipment are governed by this regulation for its transportation,” Gagnon said.

“With the Association of Crane Owners of Quebec (APGQ), we had a meeting in July with the government to present our concerns and demands with the new regulation and present the importance of modernizing the

regulation to evolve with the new crane technologies. We have also insisted that the cranes should have a separate analysis because they are different than the other types of equipment, and they don’t use the roads that much.”

Work is currently underway to attempt to harmonize weights and dimensions across Canada.

Ryan Long, president of A.W. Leil Cranes & Equipment, one of the largest crane rental companies across Atlantic Canada, highlighted the importance of harmonizing weights and dimensions across all Canadaian provinces.

“Many crane service providers are required to cross provincial borders on a nearly weekly basis. Having a uniform set of

rules would result in better preservation of our roads and structures, boosted productivity in transportation, and improved predictability and reliability of schedules when moving OS/OW loads,” he said.

Lavoie agrees, stating that harmonization offers multiple benefits to industry.

“It gives the ability to move province to province without the requirements to strip components off cranes; or change, manufacture or fabricate new crane dolly systems,” he said.

National harmonization would also reduce the amount of equipment required to transport cranes from location to location, increasing public safety on the roads, Lavoie noted.

“It also reduces emissions with the reduction of equipment travelling on the roads. It adds benefits to all crane manufacturers, making a larger range of cranes more popular across all of Canada,” he said.

In Quebec, one of the challenges facing crane owners presently is that many of the new all-terrain cranes being manufactured cannot be used in the province due to current road restrictions, with Gagnon sharing that this restricts companies’ abilities to modernize their fleets.

“We would like to have harmonization with the rest of Canada to simplify our operation, and have access to newer equipment that is safer, greener

and more productive. We would also like to be able to travel between provinces to support others crane companies; but with some models, it’s just impossible to do so,” he said.

The CCRA has been working to create awareness in the provincial and federal governments of the issues faced by crane owners, and has successfully begun to facilitate to change, particularly in Western Canada. Through its Weights & Dimensions Working Committee, the association is forming strong relationships and creating an understanding of the work within the various public offices to enact change.

“The CCRA has the privilege of representing an entire industry, rather than a single voice. The weights and dimensions team takes that seriously and has a focus on using data to tell the story of our industry. As they say, without data, it’s just an opinion,” Long says.

On December 10, 2024, CCRA representatives attended the annual meeting with the National Task Force on Vehicle Weights and Dimensions Policy for the third consecutive year.

“We were thrilled to see the advancements pertaining to mobile cranes, especially in Western Canada. Our recommendations have been heard and when possible, are being implemented,” Lavoie said.

The Bridge Formula Research Project initiative was created to explore ways to overcome critical limitations in the application of bridge formulas for all-terrain cranes, with this project having the potential to benefit the industry across Canada.

“I feel that the Bridge Formula Research Project will likely have a number of benefits to industry, governments, and the

“Cranes have a big impact on our country and the more efficient we can be, the better we could serve the community.”

– Mike Lavoie, Myshak Crane & Rigging

taxpayers that ultimately pay to maintain roads and structures,” Long said. “An ideal result would be one where provincial governments recognize the benefits of having a uniform approach to managing their bridges and the permissible loads that cross them. With uniformity would come efficiency: efficiency in the transportation of goods and heavy equipment, efficiency in the permitting system, and efficiency in how we maintain and repair bridges.”

Lavoie says the Bridge Formula Research Project will bring light to weights and dimensions and highlight what the current bridge formula is and how it relates to all-terrain cranes, and the new technology that crane manufactures are using to mitigate weight transfer and distribution.

“Through the research, we are hopeful it will highlight new ways to improve how cranes are moved throughout the provinces, and to access to more routes,” he said.

If the Bridge Formula Research Project could be used to help determine real impacts on road infrastructure in Quebec, and help the province update their calculations, it would be considered a game changer for the crane sector and the province, Gagnon noted.

The national Task Force on Vehicle Weights and Dimensions Policy has the potential to help the sector with some of its

weights and dimensions challenges. Would a national crane-focused task force have the potential to add more value to the crane sector and help it move forward in its harmonization goals? It depends who you ask.

“While a crane-focused task force would be great, I recognize that we are a niche industry and there can’t be a task force for every interest group,” Long said. “I think a lot could be achieved if the national weights

and dimensions task force formally recognized mobile cranes as a sub-category within the larger OS/OW discussion.”

“I feel if there was a task force for cranes it would add additional value to the harmonization of Canada for weights and dimensions,” Lavoie said. “It would give the crane industry a bigger voice, and aid in the advancement of our industry.”

“Cranes have a big impact on our country and the more efficient we can be, the better we could serve the community,” Gagnon said. “Cranes are particular and need to be evaluated as cranes and not like any other pieces of equipment. We need to find a way to have more influence on the decisions that impact our industry to be sure that the decisions that our taken are well aligned with our reality.”

The CCRA has partnered with ICBA Benefits to introduce an exclusive, members-only group health, dental, and retirement plan. CCRA members can now enjoy highly competitive rates, exceptional service, and the dedicated support of ICBA’s local team. This plan is designed to benefit your workers, their families, and your bottom line.

Tadano launches North America’s first fully electric RT crane

Tadano is introducing the North American market to its first fully electric rough terrain (RT) crane with the company’s new 100-ton capacity EVOLT eGR-1000XLL-1.

A zero-emissions upgrade to its GR-1000XLL-4, the new eGR comes with an on-board battery pack that can power up to seven hours of lifting, or up to five hours of lifting when combined with up to 5.5 miles of jobsite travel.

The eGR-1000XLL-1’s

high-performance lithium-ion battery eliminates fuel use, leading to annual CO2 emission reductions of up to 48,500 lbs. The crane can be charged on a 480 VAC grid power or a CCS1 rapid charging system, with a charge time of 4.5 to 5.5 hours on a normal system and two to three hours when using a rapid charging system.

The crane’s battery power source also leads to significant reduction in operating noise when compared to traditional diesel-powered machines.

Link-Belt revealed its new 225 US ton capacity all-terrain (AT) crane, the 225|AT.

The third model in Link-Belt’s range of five-axle AT cranes, the 225|AT features a 14 to 62-metre six-section latching boom, a 13 to 22-metre two-piece hydraulic offsetable SmartFly, a 2.4-metre heavy-lift jib and a 101.8-metre maximum tip height with maximum attachment.

The 225|AT’s modular design

includes a maximum counterweight of 118,000 pounds, a winch line pull maximum of 29,392 pounds and a maximum line speed of 117 metres per minute.

Additional features include a slip-resistant paint deck, fall arrest anchors at all maintenance points and a lighting and vision package comprised of heated and powered side view mirrors, LED indicator lights and HID head lamps.

Link-Belt expects the first models of the AT|255 to be delivered by Q2 of 2025.

BY ALBERT WANG

Winter has arrived – make sure you don’t leave safety out in the cold.

As winter sets in, it’s critical for crane operators to brace for the tougher conditions ahead. Cold temperatures can lead to reduced capacity across your crane components, while mobile cranes carry increased risks in cold weather due to both the commute itself and the temperature’s effect on the materials.

According to WorkSafeBC, nearly 40% of all work-related vehicle crashes that cause injuries or time loss happen from November through February. To navigate winter’s challenges safely and efficiently – and to ensure compliance with regulations – there are a number of essential steps for preparing mobile and tower cranes.

Inspection and maintenance

• Lubricants and fluids: Switch to cold-weather lubricants, hydraulic fluids and greases that perform better in low temperatures, and ensure all fluids are rated for the expected winter conditions.

• Steel structures: The brittleness of steel increases in cold temperatures, which can affect the crane’s structural integrity.

• Wire ropes and cables: Like steel structures, the flexibility of wire ropes and cables can decrease in cold weather, making them more susceptible to breaking. It is advisable to conduct inspections more frequently based on conditions.

• Battery maintenance: Cold weather can reduce battery efficiency, so ensure batteries are in good condition and replace them if necessary.

• Fuel systems: Use winter-grade fuel for diesel-powered cranes and consider adding anti-gel additives to prevent fuel from potentially clogging the fuel filters and lines.

• Rubber components: Cold weather can cause rubber components like hoses and seals to become brittle and crack, leading to leaks. Inspect these thoroughly and replace any worn or damaged parts.

• Pre-trip inspections: Acknowledge that winter conditions can cause delays beyond the operator’s control, such as road conditions or commuting challenges, and provide reasonable flexibility.

• Warm-up periods: Allow extra time for crane warm-up periods. Hydraulic systems, engines and other components should be gradually brought to operating temperature before use.

• Load capacity adjustments: Since cold temperatures can impact the crane’s load capacity, review manufacturer guidelines for operating cranes in cold weather and adjust load limits accordingly.

• Wind speed monitoring: Winter winds can be more severe, especially in open areas. Stop operations if wind speeds exceed the safe operating limits for the crane.

• Ice and snow removal: Regularly clear ice and snow from the crane’s boom, cab, platforms and other surfaces to prevent slipping hazards. Remove snow and ice from loads before operations, as they can add weight.

• Driver preparedness: Evaluate your mental and physical readiness before starting driving.

• Vehicle condition: Regularly scheduled maintenance and a thorough pretrip inspection focusing on tires, brakes, lights and mirrors will ensure your equipment and vehicles are prepared. Properly remove ice or frost from mirrors and windows to ensure there are no obstacles that could hinder the driver’s view.

• Environmental conditions: Consider adjusting deliveries or any high-risk activity around predicted poor weather, such as high winds, snow, sleet, hail or heavy rain. Adjust speed according to road conditions, load weight and vehicle type. Modify driving speed and increase following distances in adverse weather.

• Stay focused: Give the road your full attention and avoid using mobile phones or other devices while driving.

• Anticipate hazards: Scan the road ahead and be ready to react to any sudden movements or unexpected road conditions. Stay vigilant for sudden road changes or movements from other road users.

• Frozen ground risks: Operating mobile cranes on unstable ground conditions can be dangerous. Soil moisture content will affect the stability and strength of the ground. Frozen ground can create a deceptive sense of stability, as it may become unstable upon thawing. Therefore, monitor ground conditions and consult with geotechnical experts regularly. To ensure crane stability, set up outriggers on appropriately sized and robust mats.

• De-icing and snow clearing: Keep access roads, crane pads and work areas free of ice and snow. Look ahead in the weather forecast to ensure there are enough resources available to make this happen.

• Visibility: Visibility can be reduced by environmental factors like reduced daylight hours, fog, overcast skies and precipitation. Ensure adequate lighting on the job site and have contingency plans for operations when visibility is poor.

• Emergency kits: Equip cranes with emergency kits that include thermal blankets, extra clothing, some non-perishable food items and first-aid supplies in case an operator is stranded or needs to stop operations.

• Communication plans: Cold weather can lead to unexpected shutdowns. Ensure operators have reliable communication tools and emergency protocols in place in case of equipment failure or accidents.

Preparing cranes for winter is not just about maintaining equipment but also ensuring a culture of safety and preparedness on-site.

By being aware of these strategies and incorporating them into operations, employers and operators can navigate the challenges of winter effectively, keeping personnel and equipment safe while minimizing disruptions.

The Broderson IC-280 Industrial Carry Deck Crane is the most compact in its 20-ton class, yet it boasts the longest boom and strongest overall load chart. Designed for facility maintenance, refits, upgrades, and expansion projects, its small footprint makes it ideal for operating in tight spaces. Equipped with advanced telematics, the IC-280 seamlessly integrates into modern fleet operations. Exclusive to Broderson, the 3-position outrigger system—offering in-and-down, mid-anddown, or out-and-down configurations—enhances lifting capacity and precision in confined areas.

Mi-Jack Canada is your authorized Manitowoc® and Grove® Distributor in Alberta & Saskatchewan.

New and used sales, rental purchase options, unsurpassed customer support, and factory-trained service technicians. As part of the Lanco Equipment Group, Mi-Jack Canada is part of the world’s largest Manitowoc dealer group, and North America’s largest parts inventory, all on-hand and ready to ship.

New and used Manitowoc and Grove Sales, Rentals, Parts and Service. Serving Alberta and Saskatchewan.