Alberta-based lifting company has found success in limited access space lifts since 2014.

BY MATT JONES

Since 2014, Alberta’s Burnt Timber Lifting Solutions (BTLS) have carved out a niche for themselves in the small crane and limited access space sector of the crane industry. Cam Bridge joined the company shortly after its establishment, but when the original owner left he took over, now serving as both owner and operator of a two-man operation.

Bridge has helped the company evolve over time, but the dedication to serving the demand for smaller cranes has remained constant.

“Tim [Tinsley, the previous owner] hadn’t really developed the company to where it’s at now,” says Bridge. “I worked on the products we have now and the operating side versus just bare rentals or sales. But what it was always thought about was that all of our pieces of equipment, from the smallest to the largest, will either fit through a single door or a double door. That’s what everything’s based around.”

BTLS offer both bare rentals of the equipment, as well as providing an operator should the job require it. Bridge says that larger operators have told him that they consider smaller cranes to be ‘an incident waiting to happen,’ due to the increased hazards of the small quarters where the cranes are often used – a crane operator used to operating outdoors with the sky above their heads now has to remember there’s a roof a few feet up. So, when the situation calls for it, BTLS will provide an operator.

“We are very specific with where we take our equipment, even when we rent it, we want to make sure that we know what our customer’s needs are,” says Bridge. “We don’t mind bare renting, but we want to make sure that they get the right piece of equipment. So, we ask lots of questions. A lot of times, people get these machines and they don’t really know how to use them properly. On certain jobs, it’s easier for us to just come and do the job and not have to come back again rather than drop the machine off, show them how to run it, wait two days and then go back and pick it up.”

BTLS primarily offer Jekko-built mini-cranes and Spydercranes, by UNIC – Bridge cites those two brands, as well as Maeda, as the top names in the sector.

continued

Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor – Jay Koblun

jkoblun@annexbusinessmedia.com • 519-410-0600

Account Manager – Amanda McCracken

amccracken@annexbusinessmedia.com • 226-931-5095

Media Designer – Svetlana Avrutin

Regular Contributors

Saul Chernos, Doug Younger, Nelson Dewey, Matt Jones, Judy Mellott-Green Group Publisher – Todd Humber thumber@annexbusinessmedia.com

COO – Scott Jamieson

Audience Development Manager / Subscriptions – Urszula Grzyb ugrzyb@annexbusinessmedia.com • Tel: 416-510-5180 Fax: 416-510-6875 or 416-442-2191 • www.craneandhoistcanada.com

Annex Privacy Officer – Privacy@annexbusinessmedia.com Tel: 800-668-2374

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $37 + Tax per year in Canada. For subscriptions in the USA the price is $37 USD. Send cheque or VISA/ Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

ISSN 1923-788X

It has been a busy 2019 for the Crane & Hoist Canada team and lifting industry. A few changes editorially, a busy show season, a few game-changing acquisitions, and our first Top 10 Under 40 contest kept us on our toes. It’s getting even more exciting this January as we are happy to be sharing and celebrating 10 years as a publication with you all.

Check out an article on page 18 by regular contributor Saul Chernos on changes some of the biggest players in the industry have seen over the last decade. Some changes for the better and some things that still need to be worked on. Site safety and personal protective equipment concerns are in the forefront these days and you can never worry too much about safety. Whatever it takes to ensure workers in the heavy lifting sector are getting to and from work safely is always a good priority.

Loads of other content to really dig into this issue. We’ve got a safety update from Judy Mellott-Green at Alberta Workplace Health & Safety, a profile on a company in the small crane and limited access space sector by Matt Jones, windmills, trucks, products — heck, we even talk about Fortnite in this issue. It’s a jam-packed issue celebrating what we love to talk about most here at our office; cranes, hoists and heavy lifting!

2020 will likely be one of our busiest years yet as we are hosting the magazine’s first ever event!

Construction sites are inherently dangerous and the presence of cranes and hoists only adds to the risk. Physical safety of workers is just one priority; advances in technology have exposed equipment to malicious hacking and thrillseeking selfie takers have made headlines by breaking in and climbing to dangerous heights.

With our media partners at OHS Canada and SP&T News, we’re presenting an exclusive day-long forum focused on safety. Co-located with Partners in Prevention, Canada’s largest safety conference and tradeshow with more than 4,000 attendees, CraneSafe 2020 is an exclusive opportunity to network with leaders in the crane and hoist industry. Check out cranesafesummit.com for more details. Hopefully I’ll see you there in April at the Mississauga International Centre! Our speakers are going to be hitting on topics that include cybersecurity, job-site safety and best practices for worker safety.

A Crane & Hoist Canada event has been long in the making and we all felt there wasn’t a better time to jump head first into the event world then the same year we’re celebrating 10 years in print. I’d like to thank every contributor, advertiser, client, customer, interviewee and anybody else who has had a hand over the last decade in helping Crane & Hoist Canada be what it is today.

Thank you!

Next Advertising Deadline: January 24, 2020

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Amanda McCracken at our Advertising Department Tel: +1-226-931-5095 • amccracken@annexbusinessmedia.com

Next Editorial Deadline: January 24, 2020 For writers’ guidelines and submission requirements get in touch with the editor, Jay Koblun, at +1-519-410-0600 Email: jkoblun@annexbusinessmedia.com

Manitowoc Cranes was awarded a $28.2 million contract to provide Grove all-terrain cranes to the U.S. Army. The GMK4060HC are specifically engineered for military use and have unique features that make them suitable for job sites on a variety of terrains. The contract is expected to be fulfilled in 2020.

The 60 USt, four-axle capacity cranes that feature a MEGAFORM boom were designed to meet the U.S. Army’s needs, including the ability to ford water up to 48 inches and to operate in harsh conditions. The cranes will also be painted with Chemical Agent Resistant Coatings (CARC) to follow stringent nuclear and chemical attacks, meaning the paint won’t deteriorate under the same conditions as typical paint. The military also asked that the cranes be outfitted to accept armoured cabs. In addition, the cranes are upfitted with military spec lighting that allows cranes to operate in a blackout light condition when using night vision technologies.

“It’s a great honour to be able to provide cranes for the U.S. Army,” said Darryl Mellott, director of government marketing at Manitowoc. “Our first contract was signed in 2015, and we are glad to see that our cranes have performed well and serve the Army’s needs. We designed and built directly to the Army’s specifications and created the GMK4060HC, which is perfectly suited for its bridging and support operations around the world.”

The features on these cranes will enable the U.S. Army to tackle projects on the most extreme sites, even working in high-pressure situations in war zones. The cranes will be deployed for constructing barriers, setting up areas of operation, bridge building and vehicle towing applications, among many other uses. Another benefit for the Army is that the cranes are light enough to be transported via C5 and C17 aircraft, as well as by trains and roads.

“These are very versatile cranes that will enable the Army to perform the lifts it needs for a wide variety of applications,” Mellott said. “These tough, durable cranes reflect what it means to be ‘Army Strong,’ and we’re proud to support our military, no matter where the battle is.”

The Association of Equipment Manufacturers (AEM) has recognized 19 companies for achieving “milestone member” status in 2019, a designation that highlights their off-road equipment manufacturing industry support through longtime and continuous participation in AEM. “AEM could not achieve success without the active and continued involvement of our member companies,” said Paul Flemming, AEM senior director, membership and engagement. “Their participation has been key to the growth and progress of our industry and AEM; we appreciate and are proud to recognize their outstanding support.”

During this 125th-anniversary year for AEM, three companies were honoured as 125-year members:

• AGCO Corporation (Massey Ferguson)

• CNH Industrial America LLC

• Deere & Company

• Achieving 75-year member company status was Wells Fargo Equipment Finance.

• Achieving 50-year-member status was AC Business Media.

• Fourteen AEM members were saluted for reaching t he 25-year-member mark:

• Bay Shore Systems Inc.

• Comer Industries Inc.

• Concentric Rockford Inc.

• Furukawa Rock Drill USA

• Gator Machinery Company

• Kioti Tractor Div Daedong-USA Inc.

• Mahindra USA Inc.

• NPK Construction Equipment Inc.

• NTN Bearing Corporation of America

• O’Neal Industries Inc.

• Palfinger North America

• Solar Technology Inc.

• Topcon Positioning Systems Inc.

• Troxler Electronic Laboratories Inc.

Crane Industry Services, LLC (CIS) joined CM Labs Simulations at the International Construction & Utility Equipment Expo (ICUEE), in Louisville, Ky., in October.

Crane Industry Services deploys Vortex simulators at its Centred on Safety training centre for crane operator training and qualification. The company has found that it is a more affordable option for operators. Operators are able to transfer skills learned from a simulator to machine operation.

During the show, Debbie Dickinson, CEO of CIS, spoke to attendees participating in ICUEE Field Classrooms. Dickinson explained the importance of simulator training for heavy equipment operation used in utility work.

“Traditional training requires seat time that incurs costs associated with equipment, fuel, supervisors, and riggers. Simulation training helps operators reach a reliable skill level without those costs, as well as an opportunity to learn in a risk-free environment,” she said.

The next step CIS takes is to transition the operators from simulation to actual machines, where operators learn to control loads, place loads on targets, and react wisely to certain conditions.

“We often return from the crane to the simulator to practice skills that proved to be challenging in the actual crane,” said Dickinson.

The ICUEE walking tour “Safety Tech Trek” highlighted the latest in construction technology. Instructor Abby Ferri, a safety professional and President of The Ferri Group, showcased exhibitors, which apply safety technology in the utility industry.

ICUEE’s Field Classrooms brought education and learning to the show floor, with content geared to those new to the industry.

“The Safety Tech Trek was one of many subjects of importance to attendees, including toolbox and tailgate talks, disaster simulation and smart utility infrastructure. The Field Classrooms were curated by experts in the field,” said Brooke Konopacki, director of educational programs for the Association of Equipment Manufacturers.

Participants on the Tech Trek Tour asked Dickinson how the simulator training time compared to training on a crane. “On average, four hours of crane seat time equates to one hour of practice on Vortex simulators from CM Labs,” she said.

Once a strong foundation is established and skills are documented, CIS trainers are able to train on cranes or earthmoving machines. “There is no faster, safer, more expedient way to train heavy equipment operators,” said Dickinson.

Starting in January 2020, Cambrian College in Sudbury will be offering mine hoist training courses through its corporate training department.

The courses focus on different aspects of mine hoist operation, and they are designed to bolster the skills and qualifications of those who want to advance their careers in mining.

Courses will start in January and continue through to the end of March. All participants registered in the course are required to attend the January overview course as a prerequisite.

The courses are:

Jan. 16-17 Overview

Jan. 30-31 Conveyances

Feb. 13-14 Electrical

Feb. 27-28 Safety Controllers

March 12-13 Braking Systems March 26-27 Ropes and Attachments

“We’re working with industry and we’ve made sure that all of our training courses starting in January meet the demands of the industry and especially the millwrights, heavy duty mechanics, electricians, supervisors, and anyone associated with hoist maintenance,” said Kim Lair, director of ancillary business operations at Cambrian, in a Nov. 22 news release.

“The skills they will learn in this course will follow them to any mining operation, across Canada or internationally.”

Cambrian College’s corporate training department works with industry partners to develop and deliver programs that address industry needs. The college is capable of delivering training programs in business, trades, technology, health and emergency care, environmental studies and community services. It’s also planning to offer mine hoist training courses in a separate block beginning in April.

BY DEMAG

“Targe lifting companies with multiple cranes have options to get jobs done. I don’t have that luxury,” said Steve Kelly, owner and operator of Steel Giraffe LLC. The Portsmouth, R.I.-based “boutique” crane company doesn’t search out the typical residential and commercial construction projects. Rather, Steel Giraffe completes specialized lifting projects, and 90 per cent of its lift jobs fall within a 48-km radius of the headquarters location. Many lifting projects last less than a half-day, so Steel Giraffe needs a flexible crane that can get in, quickly finish and get to the next job. However, the company’s 22.7-t carry deck crane previously used didn’t quite fit, and the transport costs were cutting into profits.

Steel Giraffe needed a different type of crane, one that better fit its needs. While Kelly had a 31.8-t crane in mind, Justin Melvin, general manager for Empire Crane, an authorized Demag Mobile Cranes distributor says, “His business model needed the 45-t class Demag AC 45 City crane. It was built for companies who need mobility and work in crowded metropolitan areas.”

A great fit

Kelly worked with Empire to get a preview of the AC 45 City. It has a single cab from which the operator both drives the crane to the project and operates the boom. “For our work, a second cab is just wasted space and time,” he adds. The crane’s capacity chart and boom design were what sold Kelly on working with Empire Crane to purchase the AC 45 City. The three-axle crane offers a maximum main boom of 102.4 ft (31.2 m) and a maximum 145-ft (44.2-m) system length. Boom extension is fully hydraulic, allowing Steel Giraffe to extend or retract the boom with a load and without the need for pinning a boom section.

Melvin explains that pinned boom designs are commonly found on larger cranes for strength but limit the versatility of smaller city-class cranes. Kelly adds, “We handle a lot of pick-and-carry loads, and the ability for us to fully extend or retract the boom under load is critical.”

Steel Giraffe took delivery of the Demag AC 45 City crane in late March. The crane’s versatility and capacity chart were instrumental in helping the company land a tricky project on the Mt. Hope Bridge connecting the Rhode Island towns of Portsmouth and Bristol. The 90-year-old structure that predates the Great Depression is currently in the midst of a10-year, $52 million restoration project.

The current construction phase consists of repairing the bridge pier anchors’ degraded concrete. Work crews needed to have construction materials and containers transferred to the work platform at water level. “One option was to position a crane on a barge in the water to transfer the materials, but this would have been costly,” explains Kelly.

Steel Giraffe quoted the project using its AC 45 City crane positioned on the bridge deck to lower materials more than 100 ft (30.5 m) to the work platform below. The first challenge was to ensure the deck could hold the weight of the crane with load. “The planning software was helpful in determining the weight, radius and outrigger setting to provide printed proof the bridge deck had the capacity,” he adds. “Both Empire Crane and Demag worked with us to help prepare the plan.”

The next challenge for Steel Giraffe was to hoist the materials without blocking both traffic lanes. Melvin explains, “The Mt. Hope Bridge only carries two lanes of traffic, and

each lane measures only 11-ft (3.4 m) wide, so this was a perfect test of the AC 45 City’s compact design.” From counterweight to boom to jib, everything rides on the crane’s trim 28.4-ft-long by 8.3-ft-wide (8.7- x 2.5-m) carrier.

The plan called for the AC 45 City crane to be positioned in one lane, leaving the other open to traffic. Steel Giraffe devised a plan using a 26-ft (7.9-m) boom radius with small outrigger basis. The night lift also helped to minimize traffic disruptions.

Steel Giraffe drove the AC 45 City approximately 6 mi (9.7 km) to the project site and arrived by 9 p.m. The crew had the crane rigged and hook-ready to by 10 p.m. Kelly appreciated the ability to drive and operate the crane from the same cab without needing to exit.

IC-1 Plus – a game changer

A plus for companies like Steel Giraffe, especially on a tight-quarters project like the Mt. Hope Bridge, are the crane’s IC-1 Plus control system and asymmetric outrigger positioning. The system automatically determines the available lifting capacity, based on outrigger set-up and slewing angle, so it does not limit lifting capacity to a 360-degree load chart.

“This is a game-changer for me,” says Kelly. “If we cannot fully extend one of the outriggers, we are not limited to the 360-degree load charts.” Melvin continues, “This allows companies to plan their lifts for maximum available capacity over the outriggers, which can enable them to complete heavier lifts with less counterweight, as it was the case with the 360-degrees load charts.”

Kelly also noticed significant differences with the IC-1 Plus display compared to other crane models in this class. He compared the black-and-white displays with pushbuttons found on other cranes to an old hand-held video game. “The AC 45 City has a nice full-color screen and intuitive touchscreen control to easily navigate,” he says.

Ease of crane operation helped Steel Giraffe to complete nearly 20 picks in less than five hours, where crew members lowered a variety of equipment from compressors and generators to paint and tools to the work platform. The heaviest lifts consisted of two, 10-ft (3.0-m) steel shipping containers loaded with equipment, weighing 6,000 lb (2.7 t) each. Finishing all lifts by 2:30 a.m., the crew then derigged the AC 45 City to make its 10-minute trip back to headquarters.

Kelly believes it might have been possible to complete this project with the company’s old carry deck crane, but it would have been much more time consuming and cumbersome for transport and prep.

“We would have needed a lowboy to move the carry deck crane. Transport limited us to completing only one half-day job per day with the carry deck crane,” he explains. “It was so quick and easy to get back to the shop driving the AC 45 City. We are now completing two to three jobs per day with the AC 45 City.”

Navigating the AC 45 City crane through the crowded Portsmouth streets is getting Steel Giraffe noticed, not only for the crane’s unique giraffe decaling but also for the crane’s capabilities. “We are now receiving calls from larger crane companies to handle their overflow work. We did not get those calls in the past,” explains Kelly.

Steel Giraffe finally has the crane it needs to match its small “boutique” lifting company business model in the Demag AC 45 City. “With its capacity and boom length, I know the AC 45 will give me the flexibility to handle many lift jobs,” he says. “If I could design a crane for what we do, this is the crane I would design.”

continued from cover

“The UNIC 295, in my opinion, is probably the most versatile crane [in the mini-crane sector],” says Bridge. “The Jekkos are probably a little bit more sophisticated. They have some nicer options for hydraulic jibs and stuff like that. The way that they operate, they’re a very smooth machine. Not saying that the UNICs aren’t, it’s just that the remote makes them a little bit tougher to operator. It just requires a little bit more skill.”

Bridge says that every piece of equipment BTLS has is specific for certain types of jobs. It’s difficult to have the right machinery for every purposed, as depending on the location and circumstances everyone wants something different, even down to how the unit is powered.

“We have customers that do a lot of curtain wall install, so they’re always outside,” says Bridge. “Working in the cold weather in the winters, battery powered equipment doesn’t

work very well for them. But we also have those same customers that do work inside buildings on maintenance or construction and they all want batteries. There’s a huge variety of equipment that you can have, but its making the choice of what you can work with.” Bridge acknowledges that the smaller overheads related to this business model are both literal and figurative –serving this niche sector does not guarantee a massive lucrative return on investment. And they do end up competing with larger companies that have some minicranes as part of a larger fleet. But BTLS have made it work by diversifying into other small-scale offerings, including vacuum glass lifting products and manlifts.

Between the mini-cranes and the glass work, BTLS’s work has been very intricate – not necessarily challenging, Bridge notes, as they’ve gotten used to it, but certainly intricate and often only with millimeters of clearance. Their mini-crane offerings have been utilized in many unique locations (such as installing a curtain wall on the 30th floor of Edmonton’s stillunder-construction Stantec building), and under very cramped circumstances.

“A lot of people don’t get to experience a lot like crane operators,” says Bridge. “It’s very tight. Sometimes, you have to fish the jib through a hole that’s one foot square to do a pick through there. It’s just interesting work.”.

“I worked on the products we have now and the operating side versus just bare rentals or sales. But what it was always thought about was that all of our pieces of equipment, from the smallest to the largest, will either fit through a single door or a double door. That’s what everything’s based around.”

Deep tread with sturdy lugs

Longer tire life

High crack resistance

Falcon Equipment Ltd. has announced their exclusive partnership with Palfinger AG. Since December 11, 2019, Falcon has been providing sales, rentals, service and parts support for all Palfinger products throughout British Columbia, Alberta, Saskatchewan and Manitoba.

Falcon will no longer be the official distributor for Hiab; however, they will continue to work with the marketplace insuring support for all makes and models of cranes and truck equipment.

“We’ve been in business since 1988, and over 31 years later we are still looking for ways to grow our business and provide better products and support to our ever-changing markets. To do this, we need to offer our customers the best range of products and unmatched service and parts. Working with Palfinger will enable us to accomplish this goal,” said Dan Kielan, president of Falcon Equipment.

“This is a big move for us; change isn’t always easy and it’s often uncomfortable. However, in this case, it will help us move forward and become stronger. Our growth strategy for Falcon is aggressive and well thought out and we are excited about this transition.”

As of December 11, 2019, Falcon will be selling and supporting the Palfinger product line which includes:

• Knuckleboom Cranes

• Material Handling Cranes

• Forestry & Scrap Cranes

• Aerial Lift Trucks

• Hooklifts

• Rail Cranes

• Truck-Mounted Forklifts

“We couldn’t be more excited about this product change as it is important that we are not only listening to our customers but are continually adapting our business to better suit their needs. Sitting back and resting on yesterday’s laurels is not part of our future planning,” vice president Blair Norbeg said. “We have closely observed the global and local shift in our industry over the past few years and Falcon wants to be at the forefront of providing our customers with better solutions to satisfy all their product requirements. Aside from being the global industry leader, Palfinger and Falcon are strongly aligned in their core values.”

Falcon Equipment Ltd., founded in 1988, provides sales, service, and parts support to the lifting, rail, municipal and utility industries within Canada and the United States. They have five branch locations – Nanaimo and Surrey, B.C., Leduc, Alta., Regina, Sask., and Winnipeg, Man. Falcon also works to support the surrounding areas with

sales, service and parts. Their suppliers include National Crane, Boss Railcar Movers, Dieci Telehandlers, Henderson Snow and Ice Equipment, Timberland Utility Equipment and as of December of this year, Palfinger.

Falcon Equipment is considered to be innovators regarding equipment solutions that provide their customers with an efficient, effective and safe competitive advantage.

Founded in 1989 in Niagara Falls, Ont., Palfinger North America is a leading manufacturer of truck-mounted Articulating Cranes, Epsilon Forestry & Scrap Cranes and Truck-Mounted Forklifts. Over the years, added partnerships have allowed the Palfinger brand to become a complete truck-equipment solution provider due to its comprehensive product portfolio. The Palfinger North America Region consists of five manufacturing locations, 11 wholly-owned sales and service locations and a dedicated staff of more than 1000 employees who serve the North American markets.

BY JUDY MELLOTT-GREEN

Designing and handling powered lifting equipment has changed radically in the past 10 years, as they have now evolved into intrinsically designed equipment, complete with on board computers, to ensure lifts are performed safely.

Overhead cranes are not considered a trade, therefore the training the operators received years ago, was basically limited to the manufacturer’s instructions for operation of the equipment. There have been significant changes over the past 10 years to improve safety when operating these types of equipment. Industries across Canada got together approximately 15 years ago and formed committees through Occupational Health & Safety (OH&S) to develop legislation to improve the safety for operating, inspecting and maintenance of this equipment.

This is about the same time that the “Daily Operator Logbooks” became mandatory, requiring operators to perform preoperational, operational and shut-down, dated and signed off by the operator and supervisor at end of every shift. Over the years the legislated requirements have been revised to meet applicable recognized CSA B167-2016 Overhead Crane standards, as well as other applicable standards.

Overhead crane equipment operation has greatly changed over the past 10 years.

Safety training has evolved so every person who operates this equipment must have an operator safety certificate. This has resulted in a major reduction in incidents resulting in downed equipment, loss of production and injury or fatal accidents. In the past five to ten years there has also been an increase in women working in this field, operating all types of lifting equipment. I have also noticed when I go on shop tours, I see far more women working in the trades such as welders, electricians, riggers, as well as crane operators. I have seen a lot of changes throughout all the industries I have worked with over the years. I participated on Alberta Workplace Health & Safety for several years, resulting in publication of two Industry Best Practices. I am an active member on the CSA B167-16 Overhead Crane Standard since it was first developed. I am also the CSA B167-16 Liaison, sitting on the crane standards, giving me an opportunity to participate on ASME committees over the past 12 years. Our company, “ACTi” (All Canadian Training Institute), has been in business for more than 25 years. ACTi provides “Overhead Crane Operator Safety Training Programs” across Canada, as well as the U.S. We have developed and designed several types of safety programs for most industry overhead lifting equipment applications, along with several licencing Train-The-Trainer package programs that are engineer audited, ensuring compliance to the most current national and international standards.

I enjoy what I do and look forward to working longer as there is still so much more to learn.

January 2020

NB RBHCA 2019 AGM January 14 to 15, 2020 Fredericton, N.B. https://www.craneandhoistcanada.com/ events/nb-rbhca-2019-agm/

NSRBA Annual Convention January 22 to 23, 2020 Halifax, N.S. https://www.craneandhoistcanada.com/ events/nsrba-annual-convention/

Canadian Concrete Expo January 22 to 23, 2020 Mississauga, Ont. https://www.craneandhoistcanada.com/ events/canadian-concrete-expo/

February 2020

NLCA Annual Conference February 1 to 8, 2020 Montego Bay, Jamaica https://www.craneandhoistcanada.com/ events/nlca-annual-conference/

2020 ORBA Convention and AGM February 2 to 4, 2020 Toronto, Ont.

https://www.craneandhoistcanada.com/ events/2020-orba-convention-and-agm/

World of Concrete 2020 February 4 to 7, 2020 Las Vegas, Nev.

https://www.craneandhoistcanada.com/ events/world-of-concrete-2020/

2020 OGRA Conference February 23 to 26, 2020 Toronto, Ont.

https://www.craneandhoistcanada.com/ events/2020-ogra-conference/

March 2020

CONEXPO-CON/AGG 2020 March 10 to 14, 2020 Las Vegas, Nev.

https://www.craneandhoistcanada.com/ events/conexpo-con-agg-2020/

Visit www.craneandhoistcanada.com for the latest news, stories, products and industry events.

Tower crane professionals from across North America and beyond met in Richmond, B.C., Nov. 20 for the second annual Tower Crane Conference, hosted by WorkSafeBC and the BC Association for Crane Safety (BC Crane Safety).

The sold-out conference hosted more than 160 industry representatives, and was designed for tower crane industry suppliers, owners, engineers, erectors and technicians.

“There have been some tragic, high-profile incidents in recent years involving tower cranes, and this conference is an opportunity to share best practices and lessons learned so that we can address tower crane safety issues, and ensure the health and safety of workers and the public,” said Al Johnson, vice-president, Prevention Services, WorkSafeBC, in a release.

The theme of this year’s conference was “Taller. Safer. Stronger.” The keynote speaker was Dr. Story Musgrave, who was instrumental in repairing the Hubble Space Telescope and who understands the importance of equipment and worker safety.

There are about 300 tower cranes in B.C., with about 250 of them located in the Lower Mainland.

“While tower cranes are dotting the skyline across the province, particularly in the Lower Mainland, they continue to increase in height and lifting capacity,” said Fraser Cocks, executive director, BC Crane Safety, in a release. “Increasing construction activities and the development of high-rise commercial and residential structures is driving tower crane use.”

Between July 1 and November 1 of this year, there have been 22 crane incidents in B.C. Of those incidents, 58 per cent were due to operator error, 37 per cent to mechanical failure and 5 per cent to control failure.

BY JAY KOBLUN

LCrane dealer makes gamechanging move in the North American wind energy sector

eavitt Cranes has supplied a Canadian wind farm project with a Kroll tower crane, making it the first tower crane used in the construction of wind turbines in North America. By providing this unit, Leavitt Cranes aims to showcase the benefits of tower cranes in the North American wind turbine industry.

Leavitt Cranes is a crane dealership company that deals tower, mini crawler, and selferecting cranes. They carry Terex, Potain, Jekko, Kroll, Smartlift, and SpyderCrane products.

Dean Arsene, major accounts manager, says this is the first wind project the company has taken part in and is looking forward to more opportunities to serve the North American wind energy market.

“There are 17 Vestas V-136 turbines going up,” he says. Adding that the turbines, manufactured by Vestas, have a 132-metre hub height [the distance from the turbine platform to the rotor of an installed wind turbine]. “Our goal is to keep this crane in North America and bring more of them to service the U.S. and Canadian markets for wind.”

The wind turbines are part of a wind farm project called Romney, just north of Wheatley, Ont. Leavitt is Kroll’s North American dealer and was interested in their wind turbine crane range, so they began to look more into how it could benefit North America. How they started work on this Ontario wind farm started in 2018.

“We went to a Canadian wind energy event in 2018 and started a conversation with Black & McDonald about a project they were working on. The longer we got to talking the more it seemed like a great fit,” Arsene says. Black & McDonald is an integrated, multitrade service provider that safely delivers high quality construction, facilities management, and technical solutions. Black & McDonald rented the crane from Leavitt.

LRT 1090-2.1: 47 m / 154 ft full power boom

LRT 1100-2.1: 50 m / 164 ft pinned boom

Safe & Strong High lifting capacities with a maximum of safety due to VarioBase®

Globally uniform load charts conform to ANSI, EN and further standards

Safe access points and flat deck

Comfortable Simple and easy to operate

Operator friendly, extra wide and tiltable cabin

Sales and service directly from the manufacturer

Liebherr-Canada Ltd. 1015 Sutton Drive Burlington, Ontario L7L 5Z8

Phone: +1 905 319 9222

E-mail: info.lca@liebherr.com www.facebook.com/LiebherrConstruction www.liebherr.ca

“It’s a big deal. There’s potential for us to be changing the industry with this project.”

- Dean Arsene

Amanda Stieva, Black & McDonald project manager on Romney, said they selected Leavitt’s Kroll tower crane for their project for several reasons.

“Restricted buildable area, the vertical build of the crane, timeline for movement, capacity and hook height,” said Stieva. “Mobilization and demobilization times are shorter with the tower crane, less space required for the build out and operation of the tower crane, able to lift in higher wind speeds, the tower crane is powered with a portable generator so no hydraulic breakdowns or spills, and we are able to install the generator on the ground and lift the nacelle as one piece therefore saving a lot of time and work in the air.” Arsene also says now is a great time for Leavitt to focus on wind energy.

“We see renewables are in the news and all know that reducing carbon emissions is important,” he says. Renewables is a huge sector that’s growing in North America. You look at Asia and Europe—the obvious leaders in renewable energy—and see that there is quite a bit of potential in wind here.”

Arsene says the craftmanship that Kroll puts into their cranes, the attention to detail, the care—is over the top.

“They’re incredible machines that are designed to a T. They shipped this crane from Thailand and when it came off the boat it was perfectly dialed in and we didn’t have to make any adjustments. It’s a tremendous crane and anybody who has seen it, who knows cranes, just marvels at it.”

For wind turbine applications, Kroll’s tower cranes offer the following benefits:

• Fully operational in wind speeds up to 15-20 metres per second.

• Capable of lifting a nacelle up to 167-metres high without tying into the turbine tower.

• 3.3-metre wide loads allows for a much easier transport.

• Fast cycle time (1.5 wind turbines per week, per crane).

• Ideal for logistically difficult job sites due to the ability to split the crane into sections. These sections can also be transported via standard trailers.

“It’s a big deal. There’s potential for us to be changing the industry with this project. It opens doors for projects in difficult locations where maybe a conventional crawler might not be the most economical in terms of cost and time. For the longest time turbines have been put up with crawlers so trying to get the word out there that we have this alternative option is important,” says Arsene.

Another feature of the Kroll crane is how little time it takes to get hook ready to hook ready. “If you’re at turbine, no.1 and the last piece or blade has been installed, and that turbine is complete—we can be hook ready to hook ready in 30-36 hours,” said Arsene. “That’s great in this industry.” Arsene said the project was expected to wrap up before Christmas and he is already actively looking for jobs for the crane this spring.

M LINK-BELT VISION PACKAGE SERVICE IN MIND WITH REMOTE MOUNTED FILTERS, FLUID CHECKS, AND CENTRALIZED GREASE AND PRESSURE CHECKS

BY SAUL CHERNOS

With Crane & Hoist Canada elebrating 10 years in print, what better time to note some of the changes the industry has experienced. A marked increased in urban density coupled with an array of technological developments has altered the landscape in remarkable ways. Improved safety measures, shifting attitudes about who can operate a crane, and newfound cross-industry co-operation have proven noteworthy.

Approach any urban centre and the first thing you’ll see is a tower crane, or maybe even a cluster – reminders that construction is a big deal across Canada. As managing director of Bigfoot Crane in Abbotsford B.C., Ryan Burton has a front-row view of changes in building types and sizes and in the machines used to complete projects.

“There’s been a lot more big, multi-family apartment buildings,” Burton said, noting a shift from three and four-storeys to six storeys and a consequent demand for self-erecting tower cranes because these slightly taller buildings are beyond the reach of telehandlers and telescopic forklifts yet too low-rise for conventional tower cranes. The largest self-erecting tower cranes are smaller than conventional ones, cheaper to purchase or rent, and don’t require large mobile cranes for assembly.

Burton added that self-erecting tower cranes are also popular in remote areas such as ski resorts, mainly because there’s no need to transport mobile cranes to help with set-up.

Engineered wood-beam buildings up to 20 storeys high have also emerged on the landscape. “They’re going up in a matter of eight to 10 weeks, sometimes, so we’re definitely seeing the shortened duration of construction time,” Burton said, adding project haste is good for proponents but does shorten crane rental periods.

Smaller cranes aren’t always the rage. Steve Matthews, area manager with the structural steel and bridge division of Niagara Falls, Ontario-based contractor E.S. Fox, said hydraulic cranes are gaining in size at the upper end of the scale.

“We’re doing a bridge in Toronto right now and need a 900-tonne hydraulic,” Matthews said. “No other crane that will do that job.” While the crane will be a good fit for the job, the challenge is often availability. Matthews said crews used to find more machines with the right specs in Ontario but are now having to source them elsewhere.

“It creates small problematic pockets in the industry with pricing and supply and demand,” Matthews explained. “Larger cranes are normally on longer-term projects – wind farms, power plants – and are sometimes tied up for months. It’s hard to get pencilled in sometimes.”

In Québec, Grues Guay vice-president Guillaume Gagnon said work on bridges, roads and other infrastructure has been ongoing. And while wind turbine installations levelled off after peaking in 2011 and 2012, maintenance work remains strong.

The past decade has also seen significant equipment innovations. “We see more electronic, more safety features, more efficiencies, more pollution management,” Gagnon said. “We worked on the Champlain Bridge and all our equipment was required to be with bio-sourced oil so that if there’s a leak or accident it has less impact on the environment. We see a lot of features coming up in our market that were not a priority 10 years ago.”

A marked increased in urban density coupled with an array of technological developments has altered the landscape in remarkable ways.

Gagnon credited new computerized features such as sensors for enhancing safety. “If you do any kind of operation that is wrong, the crane will block you. Some cranes have a detector on the outrigger so if it’s not positioned in a good way or if you don’t have a good amount of counterweight on the crane the computer will tell you.”

Safety also received a legislative boost when a Québec contractor was sentenced to 18 months in jail for manslaughter following the death of an employee after a trench collapsed in 2018. “If you’re negligent you can be arrested,” Gagnon said. “You didn’t see this 10 years ago. When we meet our people, we talk about these cases.”

Further on the safety front, Judy Mellott-Green, CEO of All Canadian Training Institute in Edmonton, participated in revisions to Canadian Standards Association B167-2016, which governs overhead and gantry cranes and monorails.

“It’s far more detailed now than it was 10 years ago,” Mellott-Green said, highlighting what she considers the most significant improvement – a new requirement for operator logs. “There’s been maintenance logs because manufacturers have insisted on those, but there’s never really been anything required from overhead crane operators.”

The updated standard is more precise about maintenance, repair and operational requirements. While it’s too soon to quantify improvements statistically, Mellott-Green said operators now more routinely perform pre-operational checks and inspect their rigging.

Another significant development in overhead cranes is increased wireless control. A decade ago operators carried pendants hooked to the machines. Now, operators walk around more freely and observe loads, Mellott-Green said.

Advances in engineering and high-tech are also boosting safety and productivity. Dr. Ahmed Bouferguene, a researcher in civil engineering with the University of Alberta in Edmonton, said increased reliance on prefabricated modules, which require assembly rather than more laborious on-site construction, is coinciding with new computer modelling techniques to help entire teams visualize lift planning like never before.

“We’re doing more planning beforehand, before the time of assembly,” Bouferguene explained, describing access to three-dimensional computer modelling where everyone, from mobile crane operators to clients, maps the entire process. “There’s more reliance on analytics, visualization, and simulation before you even go to a site,” he said.

In Ontario, the Operating Engineers Training Institute of Ontario, the training arm of the International Union of Operating Engineers Local 793, teamed up with training products vendor CM Labs to develop and refine training simulation tools.

“The goal of the latest project has been to introduce a trainee performance management system which monitors and records parameters including collisions, load pendulum and rough load handling,” Local 793 business manager Mike Gallagher said.

Gallagher said crane simulation tools have dramatically evolved over the past decade with the incorporation of real-life conditions such as wind, precipitation and low-light settings, as well as visual distractions, boom deflection and sensations such as pulling and resistance.

On the legislative front in Ontario, Gallagher called 2017 Working At Heights safety legislation “significant” but said it will take time to be absorbed into everyday practice. “It’s not something that you can just put up a bunch of posters all over the place and expect everything to change overnight. It has to become accepted and routine.” Gallagher added he’d ultimately like to see national safety and training standards.

Crane swings also made headlines with courts rejecting applications to prevent tower cranes swinging over neighbouring properties when material impacts aren’t proven. Even when property rights are breached, damages ordered are generally nominal.

“The courts are saying we have to balance property rights with commercial and practical reality,” said Leor Margulies, a lawyer with Robins Appleby & Taub in Toronto. “The question is always going to be the impact on the adjoining owner’s lands. That’s where the courts have gone.”

Negotiating agreements in advance, perhaps in conjunction with other neighbourly issues such as tiebacks, can help a developer establish good faith should the matter end up unresolved and before a judge, Margulies said. “Injunctions are equitable remedies and the court will look at the behaviour of the parties as one of the factors in determining whether this discretionary remedy will be awarded.”

The human side of the business has also undergone transformation. Valerie Brennan, vicepresident of Amherst Group, a Toronto crane and services provider, said members of the Crane Rental Association of Canada (CRAC) and some regional counterparts are collaborating to resolve issues of mutual concern, including challenges that come with transporting mobile cranes and other heavy loads along roads and bridges.

“Crane rental companies have become more and more involved as a group rather than individually in negotiating what government should be doing to improve the infrastructure and what we can do to not damage or wear out road surfaces and bridges,” Brennan said.

CRAC has also provided a forum for ongoing discussion about increasing the presence of women in the crane sector, most notably as operators and mechanics. Brennan said acceptance has grown in recent years. “There’s still obvious concerns because of the physical nature of the job, but people are less likely to balk at it,” she noted.

At Canadian Crane Rentals in Wingham, Ont., owner Sheldon Baker said recruiting the latest generation of new employees has become increasingly challenging.

“It’s really hard getting apprentices that want to come into the industry,” Baker said. “Everybody wants to run a crane, but they don’t want to put in what it takes to get there. They want 9 to 5 [o’clock] and they want Monday to Friday. But we’re a taxi house. It’s high and low spikes, and millennials have a hard time dealing with that.”

BY ANDREW SNOOK

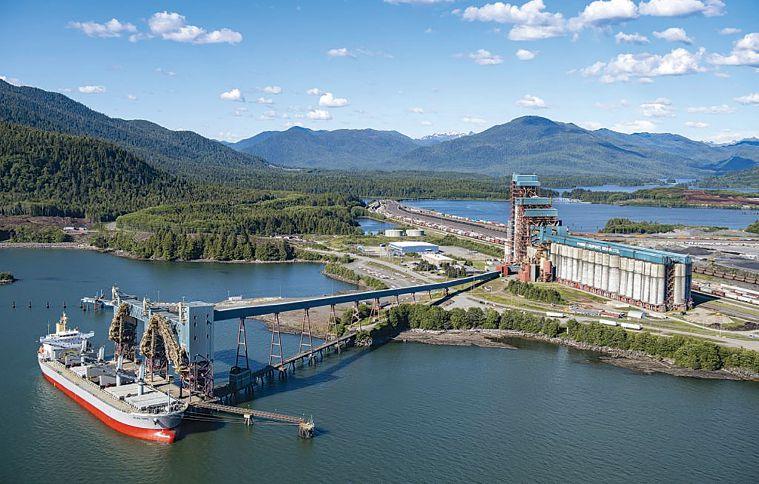

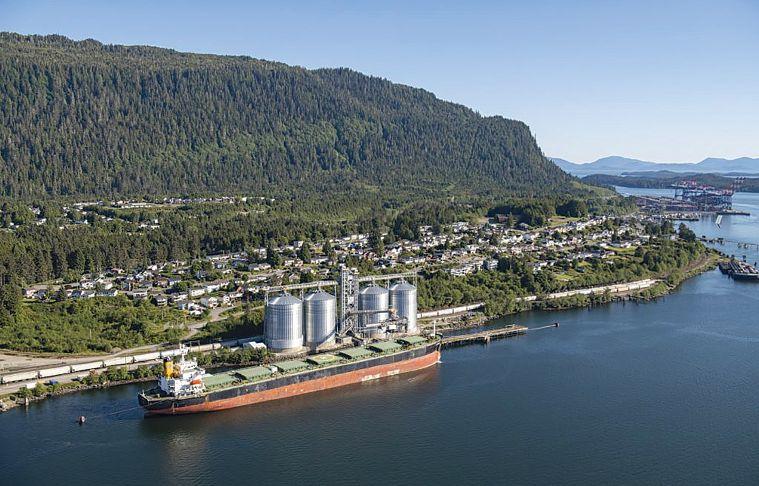

The Port of Prince Rupert will be getting some more serious upgrades over the next few years with the help of the federal government.

The feds recently announced $153.7 million in federal funding for three separate infrastructure projects at the Port of Prince Rupert through its National Trade Corridors Fund: the Zanardi Bridge and Causeway project; the Ridley Island Export Logistics Platform project; and the Metlakatla Import Logistics Park project.

The total cost of the three projects is estimated at approximately $311 million.

The projects are designed to expand the port’s capacity so it can keep pace with the country’s growing trans-Pacific trade. The Port of Prince Rupert is the closest North American port to Asia by upwards of three sailing days, with the port 36 hours closer to Shanghai than Vancouver and 68 hours closer than Los Angeles, according to the Prince Rupert Port Authority.

Zanardi Bridge and Causeway project

The Zandari Bridge and Causeway project is a partnership between the Prince Rupert Port Authority and CN. The $122-million project is designed to reduce operational conflicts while improving rail capacity to the Port of Prince Rupert. The project includes construction of a new double track bridge across the Zanardi Rapids, rehabilitation of the existing single track Zanardi Bridge, and expansion of the causeway between the Zanardi Bridge and Ridley Island, according to a recent announcement from the Prince Rupert Port Authority. The Government of Canada has announced that it will fund $60.6 million of the cost of the project.

Ridley Island

The Ridley Island Export Logistics Platform project will focus on expanding the existing road, rail and utility corridor to improve train access. According to a recent announcement from the Prince Rupert Port Authority, “The expansion will create a platform to attract private-sector investment in export transloading and warehouse capacity at the port. A full build-out of logistics capability will be able to handle a significant increase in volumes, including dry bulk, forest products and other commodities.”

The project is expected to cost close to $100 million and will receive $49.85 million in funding from the federal government.

This $89-million project will include the development of a 25-hectare site South Kaien Island that will “enable transload and warehouse operations to provide increased flexibility and value-added capabilities for import supply chains,” according to the Prince Rupert Port Authority.

The Metlakatla Development Corporation, the economic development arm of the Metlakatla First Nation, has received $43.3 million in funding from the federal government to go towards the Metlakatla Import Logistics Park project.

The Prince Rupert Port Authority stated that the park will complement the Export Logistics Platform and will be fully integrated into DP World’s Fairview Container Terminal and the Port’s intermodal ecosystem to ensure unparalleled efficiency and fluidity.

DP World’s Fairview Container Terminal in Prince Rupert has been one of the fastest growing ports in Canada of the past decade. The terminal has grown from moving 182,523 TEUs in its first full year of operation in 2008, to surpassing the one million TEUs milestone in 2018.

The terminal was originally built with a capacity of 500,000 TEUs, and had been expanded to a capacity of 850,000 TEUs around the time it was purchased by DP World in August of 2015. Shortly after purchasing the terminal, DP World announced a major expansion project – the Phase II North expansion project – that grew the terminal’s capacity to 1.35 million TEUs after its successful completion only a couple of years later. In addition to an increased capacity, Fairview Container Terminal was outfitted with the equipment necessary to service 20,000-plus TEU vessels.

The expansion project added a second vessel berth to the terminal to increase overall traffic, and the company installed three brand-new Malaccamax cranes built by Shanghai Zhenhua Heavy Industries Co. Ltd. (ZPMC).

The dock gantry cranes allowed the terminal to service 20,000 TEU vessels.

The Phase II expansion project grew the footprint of the terminal to 320,000 square metres, while adding 6,000 feet of on-dock rail and six rubber tired gantry cranes (RTGs).

The expansion project added approximately 200 jobs to the existing 800 positions at the port, which was already Prince Rupert’s largest employer. According to a recent study released this past summer by the Prince Rupert Port Authority, employment connected to moving trade through northern B.C. to the Port of Prince Rupert has grown by nearly 20 per cent since 2016 from 5,200 jobs to 6,200 jobs.

DP World is not finished expanding the terminal. The company started its next expansion project this year, designed to increase the capacity of the Fairview Container Terminal to 1.8 million TEUs by 2022, according to recent news release.

BY MARIO CYWINSKI

After an influx of new products hit the truck market in 2019, this model year is more of a transition year for many brands.

Once exclusive to heavy duty pick-up trucks and a selection of full-size vans, trucks brands are now adding diesel engines to their light duty trucks. While FCA added one to its Ram 1500 a few years ago, it is now introducing a new version on its 2020 truck, General Motors is also adding a diesel option to its Chevrolet Silverado and GMC Sierra, while Ford added a diesel to the F-150 in 2019.

Safety and technology also takes centre stage for 2020, as many brands are adding features not usually seen on pick-up trucks and vans in the past. These include cameras to better see around the vehicle, automatic emergency braking, adaptive cruise control, and options to help with towing.

For 2020, a new player is added to the mix, as the Jeep Gladiator makes its debut in the mid-size segment. Heavy Duty models also see updates for 2020, as both Ford (Super Duty) and General Motors (Chevrolet Silverado HD and GMC Sierra HD) are all-new. Nissan has updated its Titan and Titan XD.

Maintenance Repair and Operations magazine (MRO) looks at what is new, updated, and available in the pick-up truck and van market for 2020.

Super Duty Ford has updated the Super Duty for 2020, with engine, capability, design, and technology changes. A new engine is added to the lineup, as a 7.3 litre V-8 gasoline engine with 430 horsepower and 475 foot/pounds of torque make its debut. The 6.7L Power Stroke diesel engine gets an update and now offers 475hp and 1,050 ft/lbs of torque. The standard engine continues to be a 6.2L gasoline engine. A new 10 speed heavy duty automatic transmissions is also added to the Super Duty and features drive modes that include normal, tow/haul, eco, slippery, and deep sand and snow. The updated diesel engine allows the Super Duty to now offer gooseneck towing of 16,783 kilograms, fifth-wheel towing of 14,742kg, and conventional towing of

10,977kg. Maximum towing numbers are increased for all Super Duty models for 2020 (F-250, F-350, and F-450).

Ford has optimized the front end of the Super Duty to help with cooling, including a new front bumper and air dam. The rear tailgate, taillights, and rear bumper are all updated. LED headlights are also updated, as are DRLS on higher trims.

Technology and safety changes also occur, as Pro Trailer Backup Assist is now offered on and allows the truck’s Trailer Reverse Guidance to be compatible with fifth-wheel and gooseneck trailers. Automatic emergency braking, lane-keeping alert, and blind spot monitoring are now standard on XLT trim and above. Other standard features, now include FordPass Connect with 4G LTE modem, available wireless charging, and Ford Telematics. A new Tremor off-road package is

also added to the line-up for 2020, featuring an upgraded suspension, running boards, 35-inch tires, and Trail Control (described as cruise control for off-road driving by Ford).

For 2020, the full-size Transit van gets a new 3.5L V-6 gasoline engine (replacing the 3.7L engine), it joins the 3.5L EcoBoost gas engine with 310 hp and 400 ft/lbs of torque and now with automatic start/stop function. Both engines are mated to a new 10-speed automatic transmission. An all-wheel drive system is also added as an option for 2020.

Safety is enhanced for 2020, with new standard automatic emergency braking (with pedestrian detection), forward collision warning, post-collision braking, lane keeping system, and automatic high beams. New available safety options include adaptive cruise control, front and rear camera, and a speed limiting device.

Minor changes occur to the exterior of Transit, including available HID headlamps with LED DRLs, unique grille designs for different models, and an available power sliding door for cargo and passenger vans. Interior is updated with subtle changes and improvements, and addition of available swivel front seats. FordPass Connect model with Wi-Fi hotspot (for up to 10 devices) is now standard.

Chevrolet Colorado Carrying over into 2020, Chevrolet has announced an all-new Colorado to come for 2021 model year. It will offer updated lower fascia, front skid plates, and centre bars, new logos, embossed tailgate, and unique looks for each trim. The ZR2 model will feature a lettered Chevrolet front fascia.

After being all-new for 2019 model year, the 2020 model gets a new 3.0L turbocharged inline-six diesel engine that offers 277hp and 460 ft/lbs of torque, with maximum towing for four-wheel-drive models of 4,218kg and maximum payload of 848.2kg. A 10-speed automatic transmission is now available on 5.3L V-8 models. Silverado will also receive available 15 camera views and adaptive cruise control with camera.

GMC Sierra HD

As both the GMC Sierra HD and the Chevrolet Silverado HD are all-new for 2020, and share many changes, we will focus on the GMC model to save space. The Sierra HD features an all-new design that makes it taller, longer, larger and with a longer wheelbase. Redesigned lighting is prominent as headlights, taillights, fog lights, roof marker lights and DRLs are all available in LED. Additionally, the grille is larger and hood scoops are more functional.

In the back, cargo bed volume is improved, 12 corner tie-downs are included, a 120v power outlet is available, cargo bed steps are new and in addition to the current corner steps, and the MultiPro tailgate, which debuted on the Sierra in 2019 is available on HD models.

Technology is also front and centre, as GMC’s ProGrade Trailering system is now available on HD models, as is an available 15 camera views. Additional technologies available are an automatic electric parking brake, park grade hold assist, and tow/haul mode that stays on for the next time the vehicle is turned on (up to four hours).

Power wise, Sierra HD now offers a 10-speed automatic transmission on its 6.6L turbocharged diesel engine that outputs 445hp and 910 ft/lbs of torque. An AT4 offroad version is also added for 2020.

MERCEDES-BENZ

Sprinter

All-new for 2019, the Sprinter sees minor changes to packages and available equipment for the 2020 model year. All crew vans now come standard with wood floor with six d-rings; rear window defroster, storage compartment with net in rear doors, and windows in rear doors; satellite radio now available on all models; and all cargo models now offer a full window package.

Sprinter comes outfitted with a V-6 diesel engine that provides 325 ft/lbs of torque and 188 hp mated to a seven-speed automatic transmission, a four-cylinder gas engine provides 258 ft/lbs of torque and 188hp and is mated to a nine-speed automatic transmission.

Four body types are available (cargo, crew, passenger and cab chassis), two roof heights (standard and high), three wheelbases (144”, 170” and 170” EXT), three rear wheel types (single, super single, or dual), and standard rear-wheel drive and available 4×4.

Metris

Mercedes-Benz Canada also offers a smaller mid-size van, Metris. The Metris is available in both cargo and passenger variants. In addition to new colour, wheel and equipment options, the Metris receives a new instrument cluster design as standard for 2020.

For 2020, Nissan has updated the exterior styling of the Titan, which it dubs the Powerful Warrior design. The new design now offers a unique grille for each of its three trim levels, PRO-4X and Platinum grades now offer standard new headlights, LED DRLs, and available LED fog lights. The bed now has all-LED lighting with four light sources, also the rear of the Titan now has LED lighting. The exterior changes also include an updated front bumper, fog lights, badging and wheel designs.

On the interior, Titan now offers an available nine-inch touchscreen (an eight-inch screen is standard) as part of its integrated command center, which also includes Apple CarPlay, Android Auto, and a Wi-Fi router (subscription required). A seven-inch driver information display is also included. With a new NissanConnect on the 2020 Titan, it now has over-the-air software updates.

For 2020, Nissan has also updated its 5.6L V-8 engine, which now offers 400 hp and 413 ft/lbs of torque, and is mated to a new ninespeed automatic transmission. Nissan Safety Shield 360 technology is now standard on all Titan models. It offers: automatic emergency braking (with pedestrian detection), blind spot monitoring, rear cross traffic alert, lane departure warning, automatic high beams rear emergency braking.

The larger Titan XD model shares the updates of the smaller Titan. It will now be offered in a crew cab body with a 6.5’ bed and four-wheel-drive as the only configuration available in SV, PRO-4X, and Platinum Reserve trims.

RAM

1500

Introduced as an all-new model in 2019, for 2020 a diesel engine is added to the lineup.

The 3.0L EcoDiesel V-6 engine offers 260 hp and 480 ft/lbs of torque, and has a towing capacity of 5,697 kilograms (12,560lbs). It joins the 3.6L eTorque Pentastar V-6 with 305hp and 269 ft/lbs of torque; and the 5.7L HEMI V-8 (with or without eTorque) outputting 395hp and 410 ft/lbs of torque.

Added for 2020 is a Night Edition model that offers monochromatic design with black wheels (22” on Laramie, 20” on Big Horn), black badging, and a variety of colour options. The Rebel model offers a Black Appearance package with black wheels, black skid plate, and a black interior (red is optional). It now

has a safety package with adaptive cruise control, automatic emergency braking, lane departure warning, and automatic high beams.

2500

For 2020, the HD models also get a new Night Edition, with similar options. Ram also adds lane keeping and adaptive steering as available equipment on all trims. Additionally, trailer tire pressure monitoring and blind spot monitoring (including coverage for trailer) are added, as is an auxiliary camera system that can have two cameras added. Crew cab with eight-foot bed now comes standard with an 187L fuel tank. Colour and wheel changes also occur.

Tacoma

The mid-size Tacoma see incremental changes for 2020, with all models now offering Toyota Connected Services Audio with seven- or eight-inch touchscreen, and Apple CarPlay and Android Auto. Some models get multi terrain view monitor and

birds eye view monitor; TRD Pro models get new colours and features; while other trim levels get equipment updates.

Tacoma is available with a 3.5L V-6 engine with 278hp and 265 ft/lbs of torque, mated to a six-speed automatic transmission, with a six-speed manual transmission available on several TRD models. Access cab and double cab are available in 4×4 configuration.

Toyota Safety Sense P is standard on all Tacoma models. It offers adaptive cruise control, lane departure warning, automatic high beams, and automatic emergency braking (with pedestrian detection). All 4×2 and four-cylinder models are discontinued for 2020.

The Tundra full-size pick-up is a carryover for 2020, with Connected Services Audio offered just like with the Tacoma. It also comes standard with Toyota Safety Sense P. Added for 2020 is a Premium trim for TRD Sport and Off-road models. It offers premium audio with a remote and has embedded navigation with destination assist, leather seat cladding and leather-wrapped steering wheel, dual zone automatic climate control, blind spot monitoring with rear cross traffic alert and a spray-in bed liner. Also, for 2020 is standard Smart Key with push button start on TRD Sport/Off Road trims and above.

Mario Cywinski is the Editor of Machinery and Equipment MRO magazine, a member of the Automobile Journalists Association of Canada, and a judge for Canadian Truck King Challenge. He has over 10 years of editorial experience and over 15 years of automobile industry experience, as well as small business industry experience.

Crane service provider Mordefroy Levage used its triedand-true Demag AC 100-4L and AC 140 duo from its fleet to move a 34-tonne TGV locomotive onto a track at the Technicentre SNCF in Romilly-sur-Seine.

TGVs (Train à Grande Vitesse) are known for a number of things, but the most important of these is their speed. However, precision was far more important than speed for this specific job, as every centimetre counted.

“The two Demag cranes had more than the performance characteristics required for this job, not to mention that they work like a charm together, so it was only natural for us to use them,” General Manager Patrick Mordefroy explains after mentioning that his company performed the lifts on behalf of French railway company SNCF.

In addition, there was another advantage behind the two Demag cranes that became readily apparent during their trip to the work site: Everything that the two cranes needed for the tandem lift fit on one single transportation truck, meaning that on-site setup was completed very quickly – in fact, it only took the three-person Mordefroy team one hour to get it done.

When loading the locomotive onto a lowbed trailer, the Mordefroy team was lucky to be working with ideal conditions and ample space. That changed entirely when unloading the locomotive at the new Technicentre SNCF in Romilly-surSeine, however, as the space conditions there were much tighter.

However, the team’s experience and the cranes’ compact design made it possible to easily overcome this challenge. In order to prepare for the lift, the 34-tonne, 22-metrelong locomotive was first positioned parallel to the track with the lowbed trailer and was then slung at the front and rear with spreader beams in order to provide the required controllability during the lift.

The Demag AC 100-4L picked up the front of the locomotive with its hook at a radius of 13 metres so that it had to handle a total weight of 16 tonnes, while the Demag AC 140 worked at a radius of 14 metres and took care of the remaining 18 tonnes. With this configuration, the two cranes lifted the load to a height of 12 metres and moved it right over the track perfectly synchronized. After this, they set down the locomotive and placed it precisely on the track.

The Mordefroy team needed a total of eight hours to complete the job, and their speediness was all the more impressive given the required degree of precision. “We owed a lot of it to the reliability and unrivalled performance characteristics of our two Demag cranes, which is why we really consider them to be an invaluable part of our fleet,” Patrick Mordefroy points out before going on to praise the assistance provided by Demag Support and, in particular, by service technician Jacques Jespere, who for years has proven to be someone Mordefroy Levage can always count on.

Jekko’s new SPX1280 mini crane encompasses new-generation technology that offers varying degrees of versatility.

This results in straightforwardness and versatility for the operators to enjoy a new working experience and endless operating configurations, pushing to the extremes the concept of performance. A closer look at the characteristics and performance of the new SPX1280 will make you feel several light-years have gone since the launch of its predecessor, the SPX1275, that now gives way to Jekko’s newborn after long years of good and loyal service.

“This machine is a real blank page for the operator, who can use endless configurations to be exploited very easily, notably through a completely revised user interface,” says Mauro Tonon, export sales manager. “The SPX1280 has a maximum safe working load equal to eight tons and reaches 26.6 metres in height when the hydraulic jib is installed.”

Endless operating configurations

The SPX1280 tech offers a completely new approach for the operator to manage different working situations. In the past the configurations that allowed to reach the stability required were extremely limited and affected the work dynamics; nowadays the combination of stabilization system, sensor technology, software and a new user interface generates endless working situations. The core of this crane is its new stabilization system and the well-known hydraulic jib with three extensions that can be stowed either under or on the side of the main boom.

New stabilization system

The SPX1280’s stabilization system considers several factors in order to determine the possible working conditions. Depending on the opening angle and the extension of the stabilizers – as well as the possible use of the counterweight – the machine software can define in real time the maximum safe working load in a specific point. In the past this wasn’t possible at such an extent since partial extensions of the stabilizers and 0 degrees to 45 degrees intermediate angles couldn’t be taken into account. The stabilization degrees have increased from four to seven and their displaying on the interface is easier and user-friendly.

An advanced and precise hydraulic system

With a new hydraulic system, this crane has smoother and more precise operation, which increases the operator’s feeling of control. This 100 per cent electronically-operated supply system has been enhanced to offer new functions such as jib extension and arm lifting at the same time, smoother and more performing tracks, operation while combining four functions at a time.

Reduced consumption, higher performance

The SPX1280 features a 19kW Diesel engine fitted with a variable displacement pump that increases the efficiency of the whole unit while fully exploiting the engine power depending on the operation under way. This means better performance and reliability as well as considerable fuel reduction. The new engine (Stage V, Tier 4 Final) complies with the 2019 EU emission standards.

Everything in the operator’s hands

The SPX1280 is operated via a new user-friendly radio remote control designed by Jekko’s inhouse team. Five configurations are possible: Pick & Carry, crane, stabilizers, crosspieces, and travel. A single radio remote control starts, configures and operates the machine and its tools: no more on-board controls, it’s everything in the operator’s hands.

Specs

Dimensions: 5730 x 1450 x 2040 mm

Stability area: 4600 x 4600 mm

Max SWL: 8000 kg

Weight: 7000 kg (optional tools excluded) + 1500 kg counterweight

Engine: Diesel D1105-E4B + single- or three-phase motor

Max height (with hydraulic jib and three extensions): 26.6 m

Max reach (with hydraulic jib and three extensions): 20 m

Rotation: 360° continuous

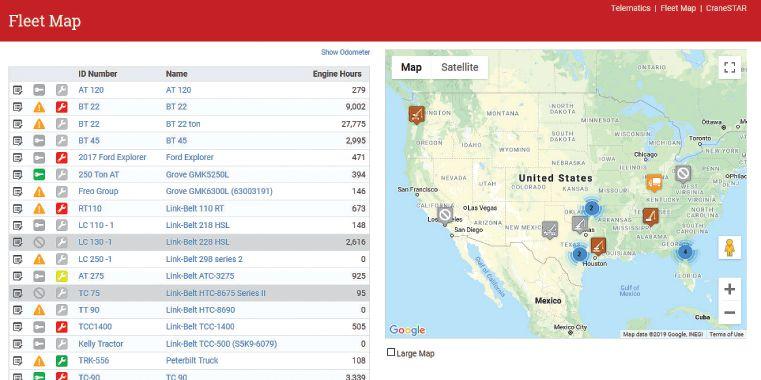

Two updates to iCraneTrax, the fleet and personnel management software from A1A Software LLC, are designed to make life easier for fleet managers and project managers. The new fleet map feature provides, at a glance, a visual overview of the key service items for your fleet. Green, Yellow, Orange, and Red icons are a progressive display of the service intervals for each unit.

In addition, with user permissions enabled, both Link-Belt and Manitowoc dealers can access the telematics interface to schedule maintenance intervals for their customers based on usage, a convenient option for fleet managers.

“With this feature, fleet managers at rental companies or dealers could set up maintenance schedules for internal teams or customers to remind them about upcoming service due items,” said Tawnia Weiss, president.

In addition, all documentation from ICraneTrax can now be saved as PDF files to provide cohesive document management related to employees, equipment, or customers. “Dispatch tickets and all other documentation connected to a specific project, can now be filed together in a convenient location,” said Weiss.

Anew Demag AC 130-5 crane was delivered to Wiesbauer in October.

The Swabian Bietigheim-Bissingen-based crane service provider already has a Demag AC 700-9, an AC 500-8, an AC 300-6, an AC 160-5, an AC 55-3, and various city cranes hard at work.

The new Demag AC 130-5 has now been welcomed into the fold after being picked up by crane operators Jochen Valent, Martin Tiede, and Jan Schöneck in Zweibrücken. The new crane was handed over by Tadano Demag Sales Manager Michael Zieger.

“We’ve had nothing but good experiences with all our Demag cranes to date, and we don’t expect that to be any different with our new Demag AC 130-5,” Jochen Wiesbauer says as a sign of his confidence in the quality and powerful performance that characterize Demag cranes.

He also points out that the Demag AC 130-5’s excellent base counterweight specifications make additional transportation vehicles unnecessary for most jobs, and that this is an outstanding plus.

“Basically put, the AC 130-5 is always carrying what it needs to get the job done. In addition, it’s the most compact crane in its capacity class, which makes it extremely maneuverable and versatile,” he adds.

The crane comes with the innovative IC-1 Plus control system, which enables it to tackle lifts that would otherwise remain the exclusive purview of larger cranes. The “newcomer” to the fleet is being used at the Wiesbauer branch in Waiblingen, and in fact already had a job lined up for it immediately after being handed over.

William Hackett launched the SSL5, incorporating its patented quad pawl (QP) mechanism.

“It’s a piece of engineering innovation that will transform safety levels globally when lifting offshore and in subsea operations using lever hoists,” says Ben Burgess, director at William Hackett. “We’ve designed this hoist to provide the highest level of safety, with increased levels of redundancy and resilience to failure. Its QP offset load bearing mechanism is the best in the market, and it offers enhanced operating performance compared to twin pawl products.”

The patented QP mechanism synchronizes a set of four pawls which constantly work together to minimize the time and distance travelled to the next point of engagement.

“It overcomes jamming and unintended malfunctions that can be experienced when using other simpler first generation products,” says Burgess. “This helps to minimize project downtime or costly delays to work scopes, providing total peace of mind for operators and marine contractors.”

SSL5 also overcomes the current industry-norm of single use immersion hoists.

“Big savings are achievable with this device,” he says. “The capability of the SSL5 to be immersed multiple times means it can significantly reduce capital investment on new hoists per mobilization by up to 80 per cent.”

Customer controlled field trials reveal William Hackett’s SSL5 hoists were immersed 12 times over a 60-day period. It successfully past a rigorous multi-immersion test, inspection and operation programme witnessed and verified by DNV GL.

“We are helping operators to make better choices and overcome purchasing large quantities of single-use hoists,” says Burgess. “The historic paradigm of single-use hoists, which are often used once and then discarded, is very expensive and not good practice from an environmental perspective. The use of single immersion hoists isn’t sustainable for today’s industry and is representative of an out-dated practice. Customer decision-making criteria is beginning to reflect this.”

The SSL5 innovation is the result of William Hackett’s long term investment strategy. “We’ve worked hard to create a technically-superior lever hoist that saves our customers money, delivers improved cost efficiencies and consistently performs on safety for those valuable payloads.”

SAFETY: Enhanced built-in failure resilience. Patented quad pawl technology allows the SSL5 to operate safely should individual pawls or springs fail. With double the number of offset pawls in a lever hoist, from two to four, the load is spread securely against the ratchet gear to provide increased redundancy and resilience to failure for the user.

COST: Eighty per cent reduction in capital spend on new hoists per mobilization with warranted multi-immersion use. SSL5 reduces purchase, servicing and transportation costs, which delivers better cost efficiencies on projects and big savings for operator budgets.

TPERFORMANCE: SSL5’s dual action brake mechanism and intelligent inertia capability improves the user’s safety and rigging productivity in both subsea and topside applications. durability: Lighter in weight thanks to the quality of design and materials used, the SSL5’s performance to weight ratio reduces the risk of injury to the user during handling such as in logistics and rigging (due to its reduced unit mass).

CREDENTIALS: multi-immersion use reduces the number of hoists needed on a mobilization, resulting in less single-immersion hoists being decommissioned after use, which is better for the environment and a more sustainable solution for industry.

PROVEN COMPLIANCE: meets with EN 13157, American Standard ASME B30.162012, Australian Standard AS1418.2-1997, NORSOK R-002: 2017, South African Standard SANS 1594:2007, DNV verification for multi immersion and company standard BP (DEV-AAD-SS-SD-BP-0545).

he new articulated crawler crane by Jekko has compact dimensions, high lifting capacity and can be operated in electric mode.