A timely update on changes within the medical marijuana sector. See story page 38.

Editorial 4

Industry News 6

New Varieties 8

Business Issues 10

Build sales… remove confusion.

Technology Issues 12 Deleafing robot in GreenTech spotlight.

Healthier crops 22 Silicon is often the forgotten element in plant nutrition.

Symposium recap 32

What we know – and don’t know – about lighting.

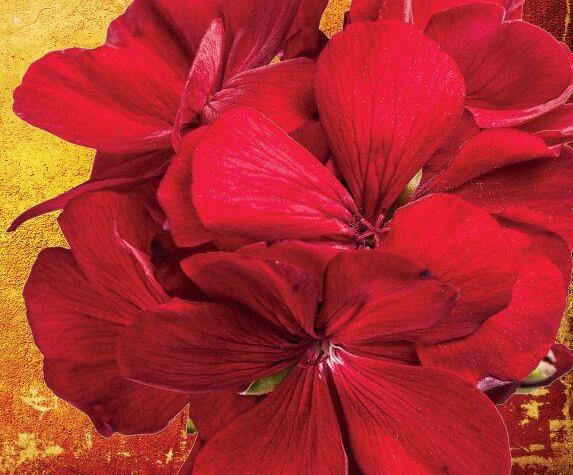

‘Happiness in Bloom’ 42 Spreading floral excitement in the heart of Canada’s largest city.

Reacting to pest threat 44 Controlling an unexpected thrips influx from outside.

Top to Bottom Crop Management

Healthy root zone will help ensure a healthy top zone.

DR. MOHYUDDIN MIRZA

Celebrating growing excellence

FCG pays tribute to three super achievers.

BY DAVE HARRISON

A bright future for LED systems

Researchers identify new benefits and applications BY

GARY JONES

In my hometown there is a “new boy in town” on the food retailing scene.

Farm Boy opened one of the chain’s newest locations a convenient 15-minute walk from my house. The 30-year-old regional food retailer has about two dozen stores throughout Ontario.

What I like about Farm Boy is its level of customer service. The employees go out of their way to ensure you’ve found everything you’re looking for. You’re clearly not bothering them when you ask for something. They smile. A lot.

It’s about as close to the experience of a farmers’ market as you can get, and farmers’ markets offer the gold standard in customer service.

To be fair, all of the food stores in town do a good job in merchandising produce, but some are a little more customer service oriented.

service for which the better stores are well known. But retailers will have to pick up their game if they’re to maintain market share.

A 2011 American Express survey found that 78 per cent of consumers have walked away from an intended transaction because of poor customer service. That same report found that 70 per cent of respondents said they would spend more money with companies who they believed provided superior customer service.

Marketing Metrics reports that the probability of selling to a new customer ranges from five to 20 per cent, while the probability of selling to an existing customer is between 60 and 70 per cent.

GREENHOUSE

And that augurs well for those stores because the future of instore retailing will revolve around improved customer service. There is considerable interest by consumers with online shopping for perceived savings and convenience. What if you could visit a website to select groceries in the evening, and then pick up your order the next day on your way home from work…the boxes packed in your trunk while you wait in a drivethrough. It would be so convenient.

The White House Office of Consumer Affairs says that it is six to seven times more expensive to gain a new customer than it is to keep a current customer. It also notes that for every customer who bothers to complain, 26 others will not bother.

And when it comes to customer service, make sure your website is easy to navigate. More than 70 per cent of

10% of all Canadian retail spending will be done online in 2019.

U.S. shoppers increased their online research in 2015, according to the Omnishopper Guide, and I’m sure the same is true on this side of the border. If your website isn’t helpful and welcoming, you’re losing customers.

U.S. e-commerce sales growth, according to the U.S. Commerce Department is continuing to outpace that of bricks and mortar stores. One Canadian study is forecasting that 10 per cent of all Canadian retail spending will be done online in 2019.

What the Internet can’t match –yet – is the same level of customer

Some 79 per cent of millenials regularly use social media, so if you’re not on Facebook or Instagram, you’re also losing customers.

And then there’s my favourite customer service quote, courtesy of Kate Zabriskie, president and CEO of Business Training Works. “Although your customers won’t love you if you give bad service,” she notes, “your competitors will.”

Agriculture and Agri-Food Canada is providing $1.1 million in funding to grow domestic and international markets. This funding will help the Canadian Nursery Landscape Association (CNLA) promote and showcase nursery products to buyers in Canada and around the world through marketing activities, trade shows and hosting sales missions.

The CLNA will also meet with industry partners in the United States and Mexico to discuss common

issues and future opportunities.

Canada’s ornamental horticulture industry, which includes floriculture, nurseries and turf sod, generated $1.93 billion in farm gate sales in 2015. The U.S. accounted for over 98.5 per cent of exports.

“The increased marketing opportunities for Canadian nursery and landscape products will benefit the entire value chain, from the grower to the consumer,” says CNLA president Rene Thiebaud.

You can now have container-grown organic blueberries at your fingertips, thanks to new production techniques developed at Vineland Research and Innovation Centre (Vineland).

With increasing consumer demand for edible ornamentals, Vineland has been focusing on new technology for growing more potted plants, including blueberries.

“We’ve developed

324 M

– number of cut flowers grown in Canada in 2015 (StatsCan)

a new organic growing substrate suitable to the production of plants in containers, such as blueberries,” said Dr. Youbin Zheng, research scientist, Environmental Horticulture, Vineland.

“In addition, we’ve also devised protocols for growing potted blueberry plants using granular organic, liquid organic or conventional controlled-release fertilizers.”

The organic growing substrate is

ready for licensing to collaborators. Those interested can contact Lana Culley, Vineland’s director of business development, 905-5620320, ext. 747. This project was supported by the Canadian Ornamental Horticulture Alliance (COHA) research and innovation cluster and is funded in part through the AgriInnovation Program under Growing Forward 2 (GF2). GF2

is a federal-provincialterritorial initiative. The Agricultural Adaptation Council assists COHA in the delivery of this research and innovation cluster. Willowbrook Nurseries, Millenniumsoils Coir, Biofert Manufacturing Inc., Blue Sky Nursery Limited, ICL Specialty Fertilizers and BioAg Consultants & Distributors Inc. provided research materials.

33K

People have been using aloe vera for more than 6,000 years when it was known as “the plant of immortality” in early Egypt.

2,978

- number of Canadian greenhouse workers (StatsCan 2015) – number of commercial greenhouse operations in Canada

Agriculture/agri-food generated $108.1 billion – 6.6% of Canada’s 2014 GDP. (StatsCan 2016)

$ $ $ $

SUPER FOOD: a cup of dandelion greens would give you about 112 per cent of daily vitamin A.

70% of Colombian rose production shipped to the U.S. (Royal FloraHolland)

1,700 ha

– Production area in Europe for growing roses. (Royal FloraHolland)

Somebody should set the record straight. Somebody should do something

Well I’m somebody. You’re somebody.

Everyone in ag is somebody

So be somebody who does something

Somebody who speaks from a place of experience, with passion and conviction.

Somebody who proudly takes part in food conversations big or small, so our voice is heard.

Somebody who tells our story, before someone else does.

Be somebody who does something. Be an agvocate.

Somebody who builds consumer trust so our industry can meet the demands of a growing, and very hungry, world.

Somebody who shapes people’s relationship with agriculture

It can be done

But it’s a big job that takes co-operation, patience and respect for every voice in the conversation We need to build lines of communication, not draw lines in the sand.

Be somebody who helps everybody see Canadian agriculture as the vital, modern industry it is. Somebody who helps everybody see people in ag for what they are – neighbours, friends, and family who share the same concern everyone does: providing safe, healthy food to the people we love

Our point of view is important

Our story is important. And people want to hear what we have to say So be somebody who takes, and makes, every opportunity to share it.

I’m somebody

You’re somebody

Together, we can tell everybody

‘Blue

Perovskia ‘Blue Steel’ is a strong performer from PanAmerican Seed. Its sturdy, controlled habit in the landscape is comparable to the vegetative leader. The aromatic, silvery foliage carries clouds of small blue flowers on strong silver stems that do not break or split easily. It has a high flower show rate with one to three plugs per one-gallon container or three to five per two-gallon container. Pinch for optimal branching. ‘Blue Steel’ is heat/drought tolerant and very hardy. panamseed.com

If you love the look and performance of Butterfly argyranthemum, which is one of Proven Winners’ top 50 sellers, take a look at the new White Butterfly™ The two are evenly matched for size and timing, making it easy for growers and retailers to offer them side by side. Never before have we seen the heat tolerance of Butterfly argyranthemum replicated in a pure white colour, so this new introduction is truly a breeding breakthrough. Everyone loves daisies, and here is one that will bloom like crazy from spring through fall. It thrives in part sun to full sun conditions.

provenwinners.com

If you’re looking for a silver heuchera to brighten up your shade area, you’ve found it. Unlike other silver heucheras on the market, ‘Silver Gumdrop’ has vibrant pink flowers instead of the typical white or cream. Match it with its silver, iridescent leaves with a semi-glossy finish and you have a winning combination. ‘Silver Gum-

‘Spintop’ Gaillardia

Bred by Dümmen Orange, ‘Spintop’ gaillardia is a brand new series and the best compact gaillardia on the market. With fantastic colours and intense flowerpower, these gaillardia are perfect for high

Saliva

density production and mixed combos. Containing three different cultivars, ‘Red,’ ‘Orange Halo,’ and ‘Yellow Touch,’ these fresh perennials are a must-try new series. dummenorange.com

Salvia ‘Caramia’ is a 2016-17 introduction from Dümmen Orange. Developed to replace Salvia ‘Caradonna,’ ‘Caramia’ boasts three times more flower power and a growth habit that’s 30 per cent more compact.

Boldly goes where no petunia has gone before, with a never-seenbefore bloom pattern! Night Sky matches the Selecta Headliner™ petunia series for habit and timing. Complete growing culture is available, including

recommendations and environmental elements that influence variation of flower pattern and colour. The consumer buzz on Night Sky is amazing! Don’t miss your chance to grow the year’s hottest item. selectanorthamerica.com

drop’ is a smaller-scale heuchera, the perfect size for a container. Growers and gardeners alike will be pleased that it is a vigorous grower for its size. Its silver leaves take on a rosy blush overtone later in the season for additional interest. The breeder is Walters Gardens, Inc. and its ideal in Zones 4-9 waltersgardens.com

A solid alliance if there ever was one! Salvia ‘Caramia’ is pushing boundaries with a flower power nearly rivaling annuals, but with the low maintenance attributes of a perennial.

dummenorange.com

JOHN STANLEY | john@johnstanley.com.au

We are told the millennial is the new consumer and the more we understand that consumer the better our businesses will be. Building sales is not just about millennials, it is about your whole target consumer base and how you can build trust and their confidence while providing them with an experience.

In this first of a two-part “Build Sales” series I

ABOVE

Avoid confusion with store layout, merchandising and product range.

will focus on removing consumer confusion. It is not about the stuff: Products are important; if you do not have the product you will not get the sale. The key is having the right product in the right amount with the right brands. Many retailers get this wrong and as result have a customer who walks out of the store confused.

The customer of today does their research before they get into the car. Some research suggests they may have up to six “touch points” before they get into the car and journey to a garden centre. Technology today means they will go online and research what they want to purchase and then also talk to friends as well as rely on more traditional methods of research.

Don’t confuse them when they walk into the

garden centre.

Planned merchandising removes consumer confusion and gives them more confidence to buy. The important strategies are:

• Have look at the product range. Where does duplication exist and where can you simplify the range.

The golden rule of retailing is to have a goodbetter-best strategy. Three options is all you need. In some situations, you may want to limit it to the one product. The one you believe in.

• Have unified response to good-better-best. All team members must recommend products based on the good-better-best strategy. All must agree on which is the “best” or “hero” product. Confusing advice soon removes the credibility of the business in the customer’s mind.

• Use shelf talkers and display locations to promote the “hero” product.

Using a “We Use,” “Our Best Seller” or “Our Favourite” shelf talker can build sales and confidence.

• Place the “hero” product in the customer sightline on the shelf and position the “good” and “better” products above or below the sightline to ensure the “hero” product gets the most “eye time” from the consumer.

• If a supplier brings out new products in the range that you feel is superior to what you are already selling, then do not add it to the range. Instead, take a product and remove it from the range and then insert the new product. Make sure the team tells the consumer that you have discovered a better product.

• Link sell. If, for example, it is a fertilizer that is being promoted, ask the supplier for sachets that can be tied to the plants in the garden centre.

Place some “We recommend feeding with XXXX” signs in the plant area and link this into displays in the garden care department.

Removing the confusion gives you more space and makes shopping easier. What you can do with the space to build sales will be discussed in the next article.

John Stanley is a retail business coach, consultant, speaker and author. His expertise is in customerfocused layout, merchandising, marketing and branding, and customer-focused selling and service. Visit his website at www.johnstanley.com.au.

A deleafing robot cleaned up the top award at this year’s GreenTech Show held in mid-June in Amsterdam.

Priva was crowned overall winner of the Innovation Award with its deleafing robot. The GreenTech Innovation Award represents worldwide recognition in horticulture technology.

ABOVE

The award-winning Priva deleafing robot was on display at GreenTech 2016.

“Together with a large group of tomato growers, Priva has developed a robot that removes leaves from tomato plants completely and independently and in an economically profitable manner,” notes the GreenTech website description. “Innovative vision technology and robust mechatronics are used to cut leaves fast and with high precision. Although rather complex from a technology point of view, the robot is still quite simple to operate.”

In the jury’s opinion, the system “provides an innovative solution to a serious issue facing tomato growers. Priva’s robot takes the arduous chore of deleafing off their hands, carries it out entirely independently, is economically appealing, is very accurate as it works leaf by leaf, and can therefore transfer no viruses or almost none from one plant to another. Priva developed the deleafing robot in co-operation with a large number of growers and this means the product received ample field testing. The jury views Priva’s innovation as the start of a large series of robots, which will be developed for and utilized in horticulture over the coming years. In short, Priva’s deleafing robot heralds the start of a new era for international horticulture.”

The showcase of innovation was often cited as the number one draw to this three-day show held every other year.

There were two other major award-winners.

The ISO Plantsampler won in the Production category. The website description is as follows: “The ISO Plantsampler automates the gathering of DNA material. In the germination process it is crucial to know the DNA profile of new varieties. Until now, DNA material has been gathered by manually taking leaf samples of a plant and analyzing these with DNA sequencers. The ISO Plantsampler automates this process by taking samples from a leaf of a seedling and placing them on a microplate.”

The jury was quite impressed. “During the germination process it is crucial to ascertain the new plant species’ DNA profile. The ISO Plantsampler can independently take samples from leaves and collect the DNA material on a microplate. In the jury’s opinion, the ISO Plantsampler offers a great, automated technique that provides 100 per cent accuracy enabling work to be carried out rapidly and precisely.”

The HortiMaX-Go! by Ridder Hortimax Group won in the Automation Solutions category. “The HortiMaX-Go! is the all-new Smart Greenhouse Controller. It is a modern, user-friendly and affordable horticultural computer for controlling both greenhouse climate and irrigation. It can be easily customized choosing unique ‘Smart Switches’ that can be installed in a plug-and-play manner.”

According to the jury, the HortiMaX-Go! “is a modern, user-friendly, affordable climate control and greenhouse irrigation technology. The modular system uses smart switches that can be installed in a plug-and-play manner. The technology fulfills the growers’ needs in a very user-friendly way. This innovation was intended to be entry level even in terms of cost so that everyone is capable of using and operating the technology.”

The GreenTech Community Award was introduced this year, with the winner being “Connected Screening” by Hoogendoorn and Svensson.

Some 9,721 professionals from 113 countries attended the show (97 countries in 2014), with 52 per cent of the visitors coming from outside the Netherlands. The largest growth came from Asia and the U.S.

The next edition of GreenTech will be held June 12-14 in 2018 and kicks off with the GreenTech Summit on June 11.

With eye-catching colors and strong novelty patterns, this new series from Selecta One will give your calibrachoa program a fresh look. Big, brilliant, star-patterned flowers burst from cool green foliage. Blooming from Spring through Fall, StarShine dazzles in hanging baskets and large or small containers. Choose from four glorious colors or mix them up: Apricot, Cherry, Pink and Violet. This stunning series from Selecta One will light up the retail bench like a star!

Visit selectanorthamerica.com to order StarShine Calibrachoa and to find best growing practices.

This ambitious medium-sized operation is learning many lessons about year-round production.

BY TREENA HEIN

SunTech Greenhouses has done considerable research with LED lighting

It was at the age of 44 that Bob Mitchell decided he wanted to try greenhouse cultivation.

“I decided to make a switch in my agricultural career after being in charge of my grain elevator as well as growing cash crops,” he says. “I’ve been in love with agriculture since I was a toddler, so I decided it was time to dedicate my time to intensive agriculture – growing quality greenhouse vegetables.”

Mitchell is the co-owner of SunTech Greenhouses in Manotick in eastern Ontario with his wife Carmen. It’s a four-acre operation that started in 1999 with 1.5 acres.

SunTech gets its pride, Mitchell says, from “producing tomatoes that taste like tomatoes,” according to a lot of faithful customers.

With time and a lot of hard work, SunTech built its brand and grew its reputation. Expansion and diversifying into more tomato varieties, cucumbers and green beans helped them stay in the black.

It was late summer competition that made Mitchell look into winter production. “With yearround production, we’d have an alternative to battling the late-season market flood of foreign, field and garden tomatoes every year,” he explains.

“Our feasibility study gave us positive direction on the installation of high pressure sodium grow lights, but our supplier suggested we look at LEDs. HPS mimic sunlight the best, but their energy cost (for us) is beyond feasible.”

The LED manufacturer provided research done in Japan as a reference point (a latitude similar to Los Angeles), but that was basically all Bob and Carmen had to go on.

“We didn’t realize we were entering unknown territory,” Mitchell remembers. “We were told our blue and red LEDs were the right lamps for winter beefsteak high-quality tomato production, so we finished installing them in January 2015.”

Crops have different nutritional needs when grown under LEDs.

“We didn’t realize we were entering unknown territory,” Mitchell remembers.

The lights covered about 1.7 acres of tomato plants, for a little over $1.1 million.

Mitchell now knows much more than when he started about how the nutrient mix, temperature routines, irrigation timing and irrigation volumes have to be changed when using LEDs. Indeed, he found that cherry, grape and beefsteak plants had a different response to the same lighting regimen, which he speculates is related to nutrient use capability.

Mitchell had to adjust his nutrient recipe not only according to the plant’s health and production performance, which varied according

to variety, but also according to the age of the plants and the “pretended” time of the year (with grow lights trying to mimic summer).

Beefsteak tomatoes presented more problems than the other types, edema being one of them.

“Whether or not that’s a light effect, is still debatable and will be subjected to further tests,” Mitchell says. “Grape tomatoes were healthier, but the product size shrunk. Cherry tomatoes performed OK.”

To help understand nutrient use details, Mitchell did leachate analysis, but it only provided an indirect picture. He added leaf tissue analysis to nail down exactly which nutrients the plants were lacking or using up too quickly, and was therefore able to carefully adjust fertilizer to improve deficiencies and correct excesses (one of the surprises picked up by the tissue analysis was that some plants were absorbing certain nutrients to toxic levels).

“After adjusting, we saw recovery in the plants’ health, especially when the days started to get longer and the plants received more natural light,” he says. “But having being that ill, not all plants were able to recover so we decided to replace them with new ones this April.”

In terms of different light colour wavelengths, Mitchell says he’s learned a great deal, but points out that the science of how specific tomato varieties utilize them is only in its infancy. And as far as his conclusions about when to turn LEDs on and off throughout the winter, all Mitchell is prepared to say at this point is that he believes seven hours of darkness are required.

Dr. Mike Dixon is a professor and the director of the Controlled Environment Systems Research Facility at the University of Guelph –an expert on greenhouse production

• Cost e ective

• No wasted packaging

• 220 cu.ft. of material when loosened on each pallet

• Easy to open

• Soil Analysis provided with shipment

Also available in smaller bag sizes:

• Canadian Sphagnum Peat Moss

• Grower Mix

• Prof. Mix - VPW 20

• Seed & Plug Mix

in harsh environments who has been in touch with Mitchell since June 2015.

perfection in production would cover the electricity costs. The second reason is that we are installing a combined-heatand-power generator, which will make winter production really feasible.

Dixon has described SunTech’s activities with winter LEDs as a commercial-scale field trial of some of the space program research he and his colleagues are working on.

Dixon believes the most significant lesson discovered at SunTech so far is how the nutrient mix needs to change with using LEDs.

“Corollary research at universities also shows this very clearly, that changing the light means you have to change nutrient combination,” he notes.

“It’s already been shown in other plants like basil. The biochemistry of a plant is affected, in terms of overall performance, taste compounds, colour, nutrients and medicinal compounds (consider cannabis and cancer treatment drugs).”

Any future research will have to wait, however, as SunTech is taking a year off from using the lights.

“There are two reasons for that,” Mitchell says. “The first is insect control. I need a total cleanout, because only absolute

“But even with taking a year off, our ultimate goal remains to have the entire greenhouse successfully producing from November to August!”

Mitchell is determined to keep learning and to share what he’s learned with others. One thing that has continued to motivate him is the attitude of neighbours.

“The LEDs release a nice fuchsia glow, which many people around just love to see every winter morning while they go to their jobs,” he notes.

For his part, Dixon affirms that “there is lots of interest” in the controlled environment agriculture sector.

“We are discovering that we can affect a plant as much with environmental modification as we can with genetic modification, but we have to keep up with advances so people don’t get it wrong.”

Treena Hein is a freelance writer in Ontario.

Cervello RZ F1 (24-240)

• Late winter, early spring variety.

• Suitable for high wire and traditional umbrella systems.

• Remains in balance when winter changes into early spring.

• A really fresh presenting cucumber fruit.

• True winter variety, strong in low light periods.

• Easily makes the required fruit length.

• Fruit quality is premium level.

• Easy to grow, more open than the current main winter variety.

Distributor for Ontario: RZH Canada Ltd | Phone 1 519 324 0632

Distributor for BC/Alberta: Terralink Horticulture Inc. | Phone 1 604 864 9044

Distributor for Quebec: Seminova Inc. | Phone 1 450 454 5155

Advisor Greenhouse crops: Rijk Zwaan Export B.V. | John DeVries | Phone (519) 324 6669 | E-mail j.devries@rijkzwaan.com

The plant is a totally integrated system in which the function of one part affects the performance of other parts.

DR. MOHYUDDIN MIRZA

Talking about root zone is always fascinating to me because it is the foundation of all greenhouse crops and it is hidden from our eyes. The tops we can easily see but the tops depend on the roots, and the roots depend on the health of the tops!

I last wrote about root zone health in the January 2016 issue of Greenhouse Canada. I discussed various aspects of what happens when inputs in the root zone are ideal and noted that when something goes wrong in the root zone the top of the plant is affected.

In this article I would like to focus on interactions between the environment and root zone performance. It again must be emphasized that the plant is a totally integrated system in which the function of one part of the plant affects the performance of other parts.

Hot weather was reported in almost all parts of Canada this summer. Many growers observed temperatures inside the greenhouse over 35 C and a relative humidity of less than 50 per cent.

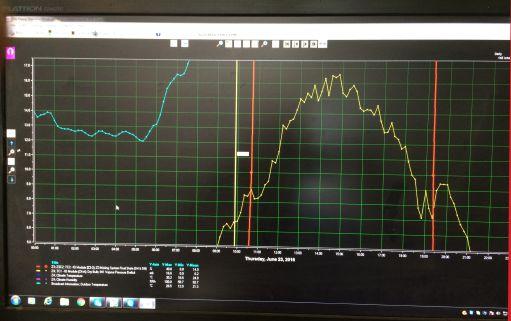

Photos A and B were sent by growers. Photo A showed a collapse of young tissue in a tomato crop. Photo B is of a tomato crop that is being grown after bedding plants. There is no nighttime heat used. The sidewalls are opened during the daytime. One can see serious leaf roll and catfacing on some of the fruit – even the fruit has bleached somewhat. The root zone consisted of coir in the first case (Photo A) and a soilless growing medium in the second case (Photo B).

Case # 1: The air temperature was around 35 C and there was very high ventilation. I am guessing

the relative humidity was around 50 per cent. If you calculate Vapour Pressure Deficit (VPD), it will be 28.2 millibars. This is a very stressful situation for the plants. The VPD will be higher when leaf temperature is taken into consideration. Without any assistance from the grower to humidify the greenhouse air, the message is sent to the root zone to send more water to the leaves. The roots will try their best to send water to the leaves but the roots quickly found out that Electrical Conductivity (EC) was very high. It was around 4.0 mmhos. The roots did their best but could not supply enough water to leaves and those are the symptoms you see in Photo A.

So, here are some points to remember:

• Understand VPD. This is a calculation based on temperature

and relative humidity. It is better to use leaf temperature to get a better reading of VPD.

Most of the vegetable growers can see this reading on their computers but this is based on air temperature. So once in a while check the leaf temperature and relative humidity to calculate this number. VPD tables are available in millibars and also in grams/m3 of air. Know the ranges that are recommended. There are several good publications available on this subject of VPD. Your computer companies can help you as well in adding this calculation to your database. An understanding of VPD helped to diagnose this problem with tomato tops.

Photos C and D are screen shots showing VPD graph (yellow line). The time is plotted on the Y axis and VPD in

millibars on the X axis. In Photo C, the VPD was out of the recommended range of between 8 and 10 millibars from 11 a.m. until 5 p.m. when plenty of light was available. This means the plants were not “working” or doing their business.

Basically, what happens is that photosynthesis is reduced, respiration increases and any food reserves in the leaves are utilized to keep the leaves cool.

1Growers must assist the plant under such conditions. I recommend introducing plain water when VPD goes over 10 millibars or over 8 grams/m3 of air.

The VPD graph in Photo D is relatively better. The plants were working for a longer period of time compared to the graph shown in Photo C.

Growers may have noticed that under very high VPD conditions, the EC in the root zone could jump by one to two units.

I have seen such sudden jumps in

tomatoes from 2.5 to 4.5 millimhos and increasing the leach percentage with the feed solution doesn’t seem to help.

• Understand the role of EC in water uptake.

Higher EC values mean less water is available in the root zone to be transported to where it is needed. Under such high VPD conditions, that is, above 10 millibars, plant roots will absorb more water and leave the nutrient ions alone. If more water is extracted from the root zone, then the EC will rise. I have seen more development of blossom end rot of tomatoes under such situations of high VPD.

Made possible by the generous support of our sponsor

Case # 2: I want to refer back to the first set of pictures and Photo B. This crop is being grown under “bare minimum” conditions. No control on climate. There is no heat to maintain proper night temperature. There is no system or effort to control daytime temperature. Many bedding plants growers follow this practice after the space is empty.

One can see from the picture that plants become very generative. Leaves roll mostly inward and fruit is highly exposed. The fruit starts ripening before it reaches full maturity.

Canada is full of young, skilled and knowledgeable people who are driving the greenhouse industry forward. From commercial growers and wholesalers to manufacturers, equipment suppliers and service providers, they are the best and brightest in our industry. Join us as we celebrate the future of horticulture in Canada.

Winners of the Top 10 Under 40 will be featured in the November issue of Greenhouse Canada and will be announced during “The Gathering” on October 5th at The Canadian Greenhouse Conference in Niagara Falls.

In such situations, the root zone has to work hard to keep up with the supply of water and nutrients. Many symptoms on the leaves, which look like phosphorus deficiency (purple spots) and magnesium deficiency, become common. The EC in this case was over 5.0 millimhos.

Growers just let it go, primarily due to the fact that they can harvest and sell fruit through their own channels. I think paying some attention to root zone EC, shading the greenhouse roof and using any other practices to improve the climate can produce better quality tomatoes.

The point we’re making is to understand the relationship of the root zone with the top zone. Roots depend on food from the top and tops depend on roots for water and nutrients. Keep that relationship healthy.

Dr. Mohyuddin Mirza is an industry consultant. He can be contacted at drmirzaconsultants@gmail.com. You can also talk to him next month at the Green Industry Show and Conference, being held Nov. 17-18 at the Edmonton EXPO Centre.

Although vital to plant health, silicon is not considered an essential plant element here in North America. This has led some growers to believe it is not necessary to add it to their nutrition regimen.

BY FRANK HOUBEN

Silicon (Si) is the second most abundant element in the Earth’s crust next to oxygen . It is a major component of plant tissue. It is found in varying concentrations in virtually all living tissue, plants, animals and humans. Though there has been research into the role silicon plays in biology, scientists are really just cracking the code of this often ignored plant nutrient.

Although vital to plant health, silicon is not considered an essential plant element here in North America. This has led some growers to believe it is not necessary to add it to their nutrition regimen.

Technically, a plant can grow without silicon but there is a significant gap between survival and optimal health. It is clear that optimal plant health requires a constant supply of plantavailable silicon. Now with new instrumentation and ambition to solve the world’s food crisis, silicon is surging to the forefront of plant science research.

BENEFICIAL IN VARIOUS WAYS

Silicon is beneficial to plant health, yield and crop quality in various ways. One of the bestknown effects is the strengthening of the cell walls, which helps the plant build strong branches and stems that can uptake and transport more water and nutrients.

Silicon forms a protective coating on an intracellular level that decreases transpiration and enables plants to continue functioning during high-temperature or low-moisture conditions. As a resistance measure, the plant uses the silicon to build up an additional mineral barrier making it more difficult for diseases, pathogens and insects to penetrate the cell walls.

Silicon also plays an important role in enhancing the uptake of nutrients, reducing antagonistic action between elements and increasing the plant’s natural resistance to pests, diseases and climate stress.

Enhanced metabolic functions are observed

The benefit of Energy curtains has been widely accepted. It’s no longer why get Energy curtains, but when. Call us to take advantage of our knowledge, competitive pricing, and unique products designed to reduce your maintenance costs, and start lowering your energy costs now! We also offer

Greenhouse parts

Heaters Now available – Marketplace with over 70 used greenhouse equipment items for sale At our Marketplace, you will be able to showcase your used greenhouse equipment to other greenhouses who are always looking for good quality equipment at a good price.

Since 1963 we have been providing high quality insurance protection to our clients from coast to coast.

Experienced, local service is available through our national network of offices.

For a quality product, local service and very competitive pricing give us a call today.

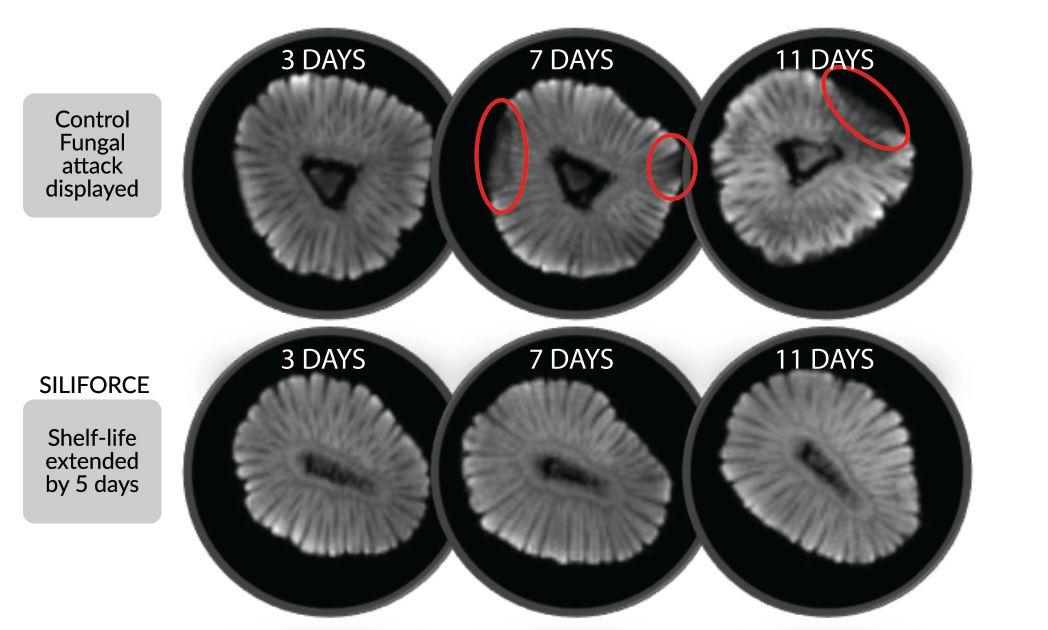

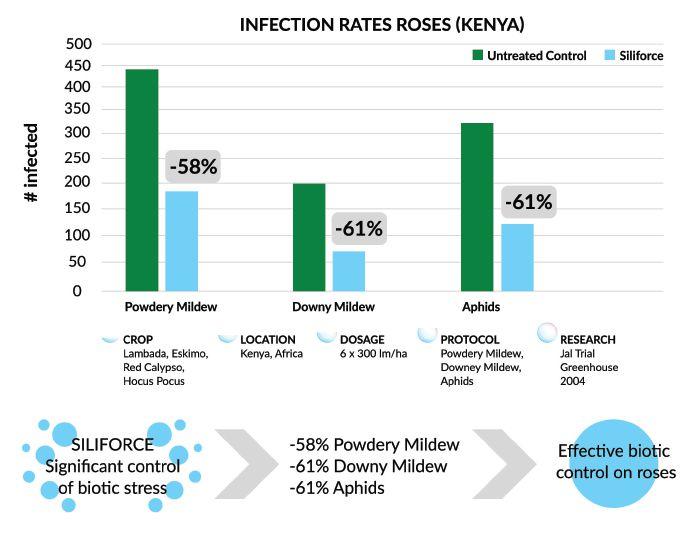

TOP SILIFORCE® on Roses in Greenhouse BOTTOM

when plants are grown with the use of soluble silicon; they show higher concentrations of chlorophyll in their leaf tissue compared to plants grown without it. Silicon also enables plants to make more efficient use of CO2

Studies show that silicon should be used throughout the entire life cycle of the plant, from the seedling or clone stage up until harvest.

In order to produce optimal results, silicon needs to be continually made available to the plant. Once a plant has absorbed the available silicon into its cellular structure, it can no longer be redistributed to other parts of the plant.

The common form of silicon found in the soil is silicon dioxide. It needs to be converted by microbes (and possibly natural chemical reactions) into monosilicic acid, before it can be taken up by the plant’s root system. This process is complex and can take time to occur in meaningful amounts. Mono-silicic acid is the only plant available form of silicon.

The most efficient way to apply silicon to plants is the use of monosilicic acid by foliar spray. Plants can absorb much more through foliar feeding than just absorption through the root zone.

New research shows that monosilicic acid has a profound effect on the transport and utilization of nutrients and also plays a role in enhancing the plant’s natural defence systems. As a monomer (single molecule) silicic acid is easily absorbed by the roots or leaves and quickly transported throughout the plant via the xylem.

During transport through the xylem, most of the monomeric silicic acid is polymerized and then deposited in the outer cuticle of the cell wall. This layer of silicon forms a rigid structure on the outside of the cell, which is responsible for the many commonly known structural and pest resistant benefits of silicon.

acid remain un-polymerized and help increase the sap pressure within the xylem, optimize the transport of nutrients and increase brix and mineral content.

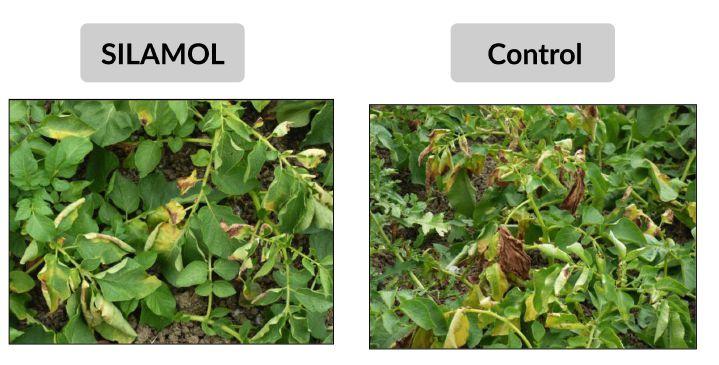

The plot treated with SILAMOL showed significantly less damage due to peronospora FOR MORE ‘FERTILIZER’ FEATURES, VISIT THE ‘INPUTS’ SECTION AT

Smaller amounts of mono-silicic

Today, specific formulas of stabilized mono-silicic acid that can be applied to plants are available on the market (commercial names – SILAMOL, SILIFORCE). The new generation of mono-silicic acid-based products show low silicon content (one to three per cent) but in a plant available form. More and more growers and farmers see the benefits of applying these formulas in vegetable crops like cucumbers, tomatoes, peppers and potatoes. Fruit farmers growing strawberries, blueberries, apples, peaches, nectarines and grapes also see the benefits.

In today’s agriculture the (over) application of pesticides, fungicides and herbicides have become a real concern –plants are weak and weak plants attract opportunistic pests and diseases. Many growers are now looking for a more sustainable and preventive approach to these challenges by building up the plant’s natural defence systems against abiotic and biotic stress.

Mono-silicic acid continues to prove itself as a powerful tool in the grower’s toolbox for creating healthier plants that naturally resist many problems.

Frank Houben is the silicon (Si) technical specialist with Agro-Solutions B.V., info@ibeco.nl.

Flowers Canada Growers says thanks to industry veterans who helped shape the modern day ornamental plant industry in Ontario.

BY DAVE HARRISON

This year’s Lifetime Achievement Award winner of Flowers Canada Growers was a pioneer in North America in growing one of the most popular houseplants.

Leo Reus, who along with his wife Emmy launched and owned Balfour Greenhouses in Fenwick, Ontario, for many years, astutely saw the potential of kalanchoes early on in their business. The farm has been a North American industry leader in the crop since then.

Leo and Emmy sold Balfour Greenhouses in December of 2015 and are now enjoying retirement.

The Lifetime Achievement Award is presented to a grower, distributor or retailer who:

• During their lifetime has demonstrated forward-

thinking and ideas that have strengthened their business and the industry.

• Has made contributions that can be in growing practices, leadership, mentorship, business and/or marketing.

• Has spent at least 40 years in the floriculture industry.

Past winners include Jim Meyers, Jim Pepetone, Jim and Clemens Vanderzalm, Otto Bulk, Jim Jeffery and Rob Bierhuizen.

Leo and Emmy farmed five hectares of tulip and daffodil bulbs in the Netherlands before deciding to emigrate to Canada with their two young daughters.

In August 1976 they arrived here and Leo

TOP Emmy and Leo Reus with Leo’s FCO Lifetime Achievement Award. ABOVE Presenting Wayne Brown with his Outstanding Contribution award were Gerard Schouwenaar of the FCO (at left) and award presenter Dr. Theo Blom (at right).

Talus Insect Growth Regulator offers selective and persistent control of key Hemiptera Whitefly pests, with no harmful effects to beneficial insects and pollinators.

Talus offers outstanding efficacy on hard to control pests, and is highly compatible with IPM & resistance management programs

TALUS PRODUCT DETAILS

For use on: Greenhouse cucumbers, tomatoes, peppers, and ornamentals.

Active Ingredient: Buprofezin – 70%

Formulation: Dry Flowable

Packaging: 4 x 500 grams Group: 16

Key Pests Controlled: Whiteflies

Talus is a trademark of Engage Agro Corporation

FujiMite Miticide / Insecticide is a contact miticide / insecticide with broad spectrum control of mites.

FujiMite stops feeding damage immediately after application. Fujimite is highly effective on all developmental stages of mites, and provides ovicidal activity on eggs.

FUJIMITE PRODUCT DETAILS

For use on: Greenhouse tomatoes, peppers, eggplant, cucumbers & ornamentals

Active Ingredient: Fenpyroximate

Formulation: Commercial suspension

Packaging: 6 x 1 L jug

Group: 21

Key Pests Controlled: Spider Mites, Cyclamen Mites, Whiteflies (suppression)

is a registered trademark of Nichino America Inc.

Gerard Schouwenaar of the FCO (at left) and award presenter Lou Schenck (at right) congratulate Graeme Murphy for his Outstanding Achievement Award.

began his first job at Waterloo Flowers near Kitchener.

Leo and Emmy soon decided to get into business for themselves, and purchased farmland in Fenwick in July of 1977.

“At the time when we emigrated there were so many rules and regulations regarding building greenhouses in the Netherlands,” said Leo. “This was not the case in Canada. For example, when we applied for a building permit for our first greenhouse (in 1977), all that was needed was a simple drawing. We had our permit within 30 minutes.”

They began with a 25,000 squarefoot plastic greenhouse, and Balfour Greenhouses was up and running – and soon eager to expand.

“As you can see by the growth Balfour Greenhouses experienced over the years,” said award presenter Jamie Albers of Flowers Canada Growers, “Leo was a quick learner and was able to build up his customer base as well as the crops he grew. Balfour Greenhouses was the first grower of kalanchoes, a product for which they are now well known for.”

As sales grew, Leo kept on building more greenhouses to meet the demand. “He humbly stated to me that they have had very good success,” said Aalbers, “and that very good success is more than 50 per cent due to his partner in life, Emmy.”

Leo not only built a successful business, but he helped build the industry by serving on a variety of boards and committees over the years. He devoted many years of service to the boards of the Ontario Flower Growers Co-op, Flowers Canada and AgEnergy, along with 15 years service as the Flowers Canada representative on the Farm Safety Association. He was also an active member of the Canadian Ornamental Plant Foundation.

Volunteering comes easily to him.

“I am always interested in meeting people who have other ideas about how to improve situations, solve problems and make our industry a recognized and an important one in the agriculture sector.

“And I also like to help out and share

my knowledge with other people.”

Balfour Greenhouses grew to 380,000 square feet and had between 30 and 40 employees at the time Leo and Emmy sold the business.

“And on top of running a farm, raising a family, and volunteering his time to the industry,” said Aalbers, “Leo also served his community as a volunteer firefighter for 30 years. For 15 of those years he was district chief.”

Leo said the keys to a successful greenhouse business include:

• Finding the right people.

• Getting your staff involved in your vision for the company.

• Growing the best quality plants.

• Having great attention to detail.

• Starting the day early so employees know what needs to be done.

Leo said it’s important to set the groundwork for success by developing business plans for one, three and five years in the future.

“Have respect for all your employees, from the head grower to the people who sweep and clean over the weekends.

“And last but not least, make time for your family and be thankful to the Lord for all your blessings.”

Earlier this year, the FCG awards program also paid tribute to a pair of retired extension specialists.

Ontario Ministry of Agriculture, Food and Rural Affairs retirees Wayne Brown and Graeme Murphy received “Outstanding Contribution to the Industry” awards.

• Murphy, who served for 26 years as the greenhouse floriculture IPM specialist, received the 2014 award. He was out of

the province last year when the award was announced.

• Brown, who had a 35-year career as the greenhouse floriculture specialist, received the 2015 award.

The two had offices at the Vineland Research and Innovation Centre next door to one another, and collaborated on numerous research projects and workshop presentations.

Both were quite humbled with the awards, noting they learned as much from growers as the growers did from them.

Past winners include Terry Colasanti (2009), Cole Cacciavillani (2010), Rej Picard (2011), Andy Kuyvenhoven (2012), and Dr. Theo Blom (2013).

Wayne Brown was quite persistent in his problem-solving. “Wayne became fully immersed in our industry, bringing his keen sleuthing skills to any production problems a grower could throw at him,” said Blom, the award presenter.

Brown completed his master’s degree at the University of Guelph and headed west to teach at Olds College in Alberta.

A year later, he applied for and was selected to be OMAFRA’s greenhouse floriculture and mushroom specialist.

He took over from Blom, who had transferred to the newly created position of floriculture scientist at the Horticultural Research Institute of Ontario.

Brown started his new duties late in the summer of 1979. In November of that year, the Canadian Greenhouse Conference debuted at the University of Guelph.

“This did not give Wayne much

time to devote to planning the first conference,” Blom noted, “but he has been very actively involved in the CGC board for every conference since. Even in his retirement, Wayne still serves on the executive and trade fair committees.”

Brown has always found growers to be hungry for new information and keen to look at new technologies. However, some of the new systems were developed without the plant in mind. He was able to work with growers to adapt the way they grew plants so that the technologies

worked for them.

“Early supplemental lighting, early flood floors and ebb and flow systems all presented challenges to growing that Wayne enjoyed solving,” said Blom.

Brown is well known for his annual poinsettia and vegetative annuals variety trials. The poinsettia trials began in 1999 when poinsettias were the number one potted flowering crop in Ontario and were also grown by the largest number of growers.

It was more than a job or a career

how Westbrook Greenhouse Systems

to him, and what stands out most are the many friendships that developed over the years. “There is a real sense of community,” Brown said. “When I was working with growers to solve production issues, their issues became my issues.”

In addition to his extension work, Brown served on many committees and was constantly involved in research projects. Though he retired early in 2015, he still coordinated that year’s poinsettia trials.

Graeme Murphy was a key OMAFRA resource over the years until his retirement in late 2014, said award presenter Lou Schenck, of Schenck Farms and Greenhouses.

“His expertise provided support to growers when new and invasive pests arrived. He still remembers, as many of us do, when western flower thrips were not a big concern here in Ontario.”

Murphy provided behind-the-scenes support by working on the registration of new pesticides, researching new pest control strategies, and developing educational programs and publications for Ontario growers.

Murphy developed and delivered oneday and two-day IPM courses for growers and Canadian Food Inspection Agency (CFIA) staff. As well, he was involved with FCO’s night school program for growers for many years.

Murphy has written extensively in grower trade publications throughout North America, including Greenhouse Canada. He has also spoken at numerous conferences and workshops, both locally and internationally.

When Murphy began at OMAFRA in 1988, it was all pesticides, all the time. However, today almost all growers go to biocontrols as their first line of defence. “His expert entomological experience and knowledge helped many growers in Ontario as they managed that transition.”

Schenck noted that Niagara is widely regarded as a world leader in biological controls. This is largely due to a lack of registered chemicals in Canada, but also to the research at the Vineland Research and Innovation Centre, along with the dedication of industry suppliers, and to “Graeme’s leadership.”

Murphy is now a consultant, helping growers fine-tune their pest management programs, focus on in-house research projects, develop a better understanding of pest management economics, and present staff training sessions.

Acrylic glazing now provides twice the protection for your valuable greenhouse crops.

For decades, leading growers have relied on the strength and weatherability of ACRYLITE® high impact acrylic multi-skin sheets to provide long-term growth results. Now, with double the impact strength of our previous generation, our new, more robust acrylic sheet provides even more protection from hail. You can now expect even higher performance and protection from the industry’s most weatherable greenhouse covering.

Backed by our new and improved 30-year non-yellowing & 10-year non-prorated hail & light transmission warranty, building new or recovering with ACRYLITE® high impact acrylic is a choice you’ll be glad you made for decades to come.

Test it for yourself. Call us at 905-984-1598 or visit acrylitebuildingproducts.com and we’ll ship you samples of our new products free of charge.

Michigan symposium clearly illuminates what we know and don’t know about lighting for plants in controlled environment.

BY DR. YOUBIN ZHENG AND DAVE LLEWELLYN

Lighting is one of the most important inputs in controlled environment (ex. greenhouse and plant factories) plant production that we have the ability to manage in order to achieve our production goals. There is an astounding variability in how plants utilize light for photosynthesis as well as perceive and respond to their lighting environment. However, the strategies and effects of modifying the lighting environment (i.e. intensity and spectral quality) in order to achieve specific production outcomes are often poorly understood or even misunderstood.

In this article, we will summarize some of the interesting points, including some challenges

PHOTOS 1 AND 2

to old ideas, that were discussed at the VIII International Symposium on Light in Horticulture, May 22-26, 2016, Michigan, U.S.A., that are particularly relevant to crop production.

At this symposium, there were 245 participants from all over the world with most of the world’s horticulture lighting experts and suppliers gathered under one roof. It’s almost unbelievable how much more we have learned from horticultural lighting research in the past decade, and how much more we still do not know. We were also struck by how many concepts about crop/light interactions found in textbooks are now being challenged. Many of

Salvia grown under greenhouse condition with LEDs as supplemental lighting then moved to growth chamber with 100 per cent fluorescent lighting for about two weeks (above), compared to plants left in the same greenhouse (below). PHOTOS BY

• Electricity and Natural Gas

• Cap and Trade Guidance

• A sset O ptimization Solutions

Market View

Inter

Founded by greenhouses, our co-operative continues to be owned, lead and operated by the agricultural community. Support from the Ag industry has allowed our business to thrive for over 28 years. Let us put our experience to work for you. Call us to get your free energy consultation.

Vegetatively propagated varieties are the hottest plants in the market today, with more introductions and research than with seed varieties. By far, the majority of these vegetative crops are propagated by cuttings.

Drs. John Dole and James Gibson have gathered the most up-to-date information about cutting propagation to help you root and grow the best crops possible.

All the bases are covered—propagation basics, stock plant management, media, temperature, light, nutrition, plant growth regulators, insect and disease management, equipment, and postharvest handling.

From these general subjects, the book focuses in on specifics for specialty bedding plants, perennials, specialty cut flowers, and foliage plants. More than 60 important floriculture crops are covered in detail, allowing propagators and growers can provide high-quality cuttings and young plants to the market.

these advancements have arisen directly from recent developments in LED technologies, which have opened the doors to practically limitless research and application opportunities in spectral science.

To make this article easy to read, we will do it in point form.

For some basic horticultural lighting background you may like to read our previous article in this magazine’s March 2016 issue entitled “Are LEDs the right choice for my operation?.” Among other topics, this article highlights the differences between HPS and newer LED technologies.

1. The photon efficiency (i.e. quantity of photosynthetically active radiation [PAR, 400 to 700 nm] produced per unit energy input, normally described as µmol [PAR] J-1) of LEDs has been continuously getting better.

A paper published by Nelson and Bugbee in 2014 stated that “the two most efficient LED and the two most efficient double-ended HPS fixtures had nearly identical efficiencies at 1.66 to 1.70 micromoles per joule.” Only two years later, Dr. A.J. Both described one commercial LED fixture that had a photon efficiency of 2.39 µmol J-1, which is about 30 per cent more efficient as the best double-ended HPS they measured. With so many commercial companies working on the LED technologies, we expect the photon efficiency of LED technologies to continue to improve.

2. Some LED companies are able to provide fixtures with control systems to adjust light intensity (sometimes wirelessly, through software). There is strong potential to integrate intensity control into feedback systems that could adjust supplemental light levels based on instantaneous ambient light levels, weather predictions and crop requirements. Work is also being done towards developing feedback control systems to control light quality (i.e., spectra) in order to provide plants with the right lighting recipes. This is more challenging due to the lack of information on the specific needs of different plant species and grown in different environments. By using these feedback systems, LEDs can further save energy in plant production compared to other lighting technologies that have fixed intensities and spectral combinations.

3. One of the main reasons that the LEDs found in many commercial

horticultural fixtures are predominantly only red and blue is because the “typical” photosynthetic action spectra, which was described almost 50 years ago using chloroplasts harvested from rye plants, identified that red and blue light can produce relatively higher photosynthetic rates than other wavelengths in the PAR spectrum. As a result, many textbooks tell us that green light (500 to 600 nm) is the least effective wavelength range in the PAR spectrum for driving photosynthesis because plants reflect the majority of the green light; hence their colour is green.

While this may be true with harvested chloroplasts or single leaf measurements, it is not necessarily true in most plant stands where plants are grown with dense canopies (i.e., > one layer of leaves). While red and blue light are efficiently absorbed by the upper leaves in a canopy, green light can penetrate the upper canopy and be utilized for photosynthesis in lower leaves. Further, depending on leaf morphology, green light can penetrate further into a leaf in some circumstances, potentially increasing the total (per leaf) photosynthesis over red or blue alone.

Some research has shown that in some cases green light can even drive photosynthesis more efficiently than red. Light not only drives photosynthesis, it also influences plant morphology (e.g., shape). Certain light spectra can modify the growth habit and leaf morphology of some plants, enabling them to capture more light, therefore increasing the whole-plant light use efficiency.

The light output from many commercially available horticultural LEDs (predominantly red and blue light, often 80 to 95 per cent red) appears as magenta to the human eye. This colour is unpleasant for some people to work in and it is difficult to visually assess plants for disease and other disorders (ex., nutrient deficiencies). Adding a small amount of green light to red and blue can result in a much “whiter” light, which is better for the workers.

4. Far red light (700 to 800nm) is not part of PAR because it is not directly involved in photosynthesis. However, in some scenarios, supplemental FR has shown to boost photosynthetic rates beyond what could be expected for an equal input of PAR photons. This socalled “Emerson Enhancement Effect” is not well understood and it is not yet clear if there are any practical benefits in production scenarios. That said, recent

research has also indicated numerous other potential benefits of supplemental far red in both vegetable and floriculture production, including: increased biomass production, stimulation of root development in cuttings, higher concentrations of phytochemicals, higher fruit yields and reduced morphological abnormalities.

5. Some research showed that plants grow smaller when lighted with artificial PAR having more than 5-10 per cent blue photons. The main reason is that blue light can inhibit cell division and therefore cause smaller leaf area. Further, blue light has been shown to increase rooting in cuttings and the production of root biomass. These functions of blue light can be used to produce more compact plants with stronger roots.

6. The red+blue spectra typical of most commercially available horticultural LED fixtures is adequate as supplemental lighting in most greenhouse production scenarios. However, there is an increasing understanding that additional wavelengths (ex. UV, green and far red) are needed in many solesource scenarios, such as plant factories, in order to prevent abnormalities such as intumescence injury (see Photo 1), and ensure optimal colour and nutrient content (including phytochemicals). It has been shown that these additional light spectra normally are not needed at very high intensities (relative to red and blue) or even all the time.

For example, Dr. Kubota’s group at Arizona University showed that by supplying far red at 6.0 µmol m-2 s-1 for only three minutes at the end of each day can significantly reduce the intumescence injury on tomato leaves when tomato seedlings were grown under 100 per cent artificial light.

7. There is some potential for using supplemental UV for different purposes in plant production. For example, UV-C (100-280 nm) can be used for pathogen and insect control, to increase branching, reduce height and control the speed of flowering of ornamental crops. Lowpressure mercury vapour lamps, which have a peak output at 254 nm, are effective at producing germicidal doses of UV-C. UV-B (280-320 nm), can be used to pre-treat transplants to make them hardier (i.e., less prone to other stresses such as excessive light, pathogen etc.) before being transplanted to the field, can be used to enhance accumulation of

These are some of the products eligible for the Vetoquinol Club points program. Sign up today at vetoquinolclub.ca and reap the benefits. club

• Low or no wax formulations

• Grains and food grade oils ingredients

• Greater acceptance for better results

• Different actives for rotation

GIVE THEM BAITS THAT THEY WILL LIKE!

secondary metabolites (e.g., flavonoids and terpenoids/isoprenoids), and can be used to control branching and height. Night-time exposure to UV-B has been shown to control powdery mildew on cucumber plants. UV-A (320-400 nm) can act similar to blue light for height control and enhancement of certain secondary metabolites. Currently, the energy use efficiency of UV- LEDs is still low and more improvements are needed if LED technology is to be used to provide UV light in controlled environment horticulture applications.

8. LEDs do not radiate much direct heat; therefore research showed that by placing the light fixtures within the plant canopy (ex., intracanopy or shining from bottom up) had some success in improving production in vine crops such as high-wire tomatoes and cucumbers.

9. Light spectra, light intensity and photoperiod can all be used to manipulate the quality of certain vegetable and medicinal crops. For example, some research showed that high intensity red light can be used to reduce the nitrate and nitrite content in leafy vegetables such as lettuce and increase the concentration of beneficial metabolites (ex., phenolics). The interaction between lighting and nutrient uptake seems to be different for different plant species and nutrient supplies.

10. LEDs can be used for regulating plant flowering. For example, Dr. Runkle’s group at Michigan State University showed that for low intensity lighting (i.e., photoperiodic lighting, 1-4 µmol m-2 s-1), a moderate ratio of red to far red radiation promotes flowering of long-day plants, while only red radiation is needed to inhibit flowering of short-day plants.

11. Plants’ response to light seems to vary considerably between different plant species, different cultivars and even the same plant at different stages of maturity. Therefore, it is very important to find out the specific lighting needs (i.e., intensity and spectrum) of one’s own crop(s).

For example, a group of researchers at Wageningen University grew nine tomato genotypes (i.e., same species) under either 100 per cent red or 88 per cent red and 12 per cent blue light and found that only seven out of the nine genotypes showed changes in biomass production between the

lighting treatments, and the red/blue combination increased chlorophyll and flavonol contents only in three genotypes. It may be that each crop will have its individual ‘optimum’ lighting recipe (i.e., light level, light spectra combination and photo period). Understanding the impacts of manipulating the light environment may be especially profitable for some of the higher value crops that are grown in controlled environments.

12. In the field of spectral science, considerable research has already been conducted on some edible and ornamental crops but not others. For example, many studies have already investigated the influence of lighting on greenhouse production of tomato, cucumber, pepper, strawberry and basil as well as indoor production of lettuce, kale, strawberry and basil. While there is still much to learn about how artificial lighting can be used to optimize the production of these commodities, the knowledge-base for other crops such as medicinal and many ornamental commodities is even more limited.

In conclusion, there has recently been a rapid increase in plant lighting research thanks to the invention of

LED lighting technologies; however, there are many things we still do not know. What is clear is that extreme caution should be exercised when extrapolating lighting research results from one cropping scenario to another. We strongly advise growers to search the (scientific) literature to find out the light requirements of their own crops. It is also highly advisable to take what can be learned in the literature and apply it to trials in their specific cropping setting. It is best to understand the influence of a specific lighting regimen (i.e., intensity and spectral distribution) before scaling up to a full production scenario. This is especially true for growing plants under 100 per cent artificial lighting.

Dr. Youbin Zheng (yzheng@uoguelph.ca) is an associate professor and Environmental Horticulture Chair at the University of Guelph and is also a researcher at the Vineland Research and Innovation Centre; Dave Llewellyn (dllewell@uoguelph.ca) is a research associate at Dr. Zheng’s Guelph lab who has extensive experience working with lighting technologies in research and production environments.

A new garden mum family for both blackcloth and natural season production. Sturdy, round plants with frost tolerance for late season longevity.

Rhonda™

The frost-tolerant RhondaTM family provides growers with a vigorous, full color assortment for later plantings to capture end-of-season garden mum sales.

Milton™

A new pot mum family with unique bicolors with consistent habit and performance for easy growing and shipping for year round production.

order, contact your preferred sales representative today or visit www.syngentafhg.com

The Canadian government is still in the process of defining how they will regulate both a medical marijuana industry and a recreational marijuana industry.

BY GGS STRUCTURES

The Access to Cannabis for Medical Purposes Regulations (ACMPR) came into effect in late August. In essence this allows Canadian medical marijuana patients to grow their own or select an independent grower to grow for them, rather than by purchasing through large-scale licensed producers. This is the federal government’s response to the Supreme Court ruling that made affordable access to cannabis medicine a human right. As cannabis legalization spreads globally, local, state and federal governments are all struggling to come up with business models that address regulatory concerns, medical needs and freedom of choice issues.

• In Colorado and Oregon the more free market approach is often described as the Wild West.

• In New York, Minnesota and Florida, a fixed oligopoly with very few winning licenses being given out is at the other end of the spectrum.

• In Canada, a very structured industry model with an arduous process and high barriers to entry ensured a limited number of large scale producers would satisfy market demand. Until… the Supreme Court said no. How does the ACMPR affect the cannabis industry in Canada? It creates a new opportunity for licensed producers to supply cannabis gardening plants. There are currently 34 licensed producers of medical marijuana across Canada and they are now the only legal source of starter plants and cannabis seeds. Enterprising LPs may consider producing flats of cannabis plants for the home

TOP The lineup is long for cannabis growers looking to start a profitable business in Canada. ABOVE GGS growing benches used in an indoor facility.

gardener, perhaps packaging it with fertilizer, potting soil, and “How to Grow Cannabis at Home” books.

It creates opportunities for hydroponic businesses and manufacturers like GGS who sell growing benches, lights, environmental controls, greenhouses and a host of other equipment for cannabis growers large and small.

For patients who cannot grow their own cannabis, or choose not to home grow, the ACMPR allows them to designate a cannabis grower. Could this

be a small business model? The rules under the ACMPR restrict the number of patients that a grower can grow for to only two. And the amount of plants grown is based on the patient’s daily gram prescription.

In Canada the maximum medical marijuana prescription is five grams a day. An indoor cannabis grower can grow five plants per gram. If a small business cannabis grower has two patients with the maximum prescription, that grower can grow a maximum of 25 marijuana plants.

Assuming a yield of five grams per day times two medical marijuana patients times 365 days a year, this small business cannabis farm can sell up to 3,650 grams of cannabis a year. If the cannabis producer sells for $7 per gram, the total annual revenue is only $25,550. Subtract from that your operating costs to grow and it is easy to see that small marijuana grow ops are not going to be a viable small business model in Canada under the current regulations.

Enbridge can help you use

energy and save money! We o er financial incentives for: Audits, assessments and engineering analysis The purchase and installation of energy e cient technologies The implementation of operational improvements to reduce energy requirements

Ottawa is still in the process of defining how they will regulate both a medical marijuana industry and a recreational marijuana industry. All indications are that they will continue to support marijuana growing in a controlled and regulated environment designed for corporate marijuana production.

In its statement announcing the new ACMPR, Health Canada reinforced that the new program for patients growing their own cannabis is designed to be a temporary solution to address the Supreme Court ruling, and should not be interpreted as being part of the longer term plan.

If you are an avid cannabis gardener and take great pride in producing the best flower, then the ACMPR will allow you to grow your cannabis medicine for now. Follow the regulations, and purchase benching, irrigation equipment, lights, and whatever else you need to support your cannabis garden.

For cannabis growers looking to start a profitable business in Canada, the lineup is long, and Health Canada is slow to get to your application, but stay the course. Invest in scalable growing equipment, greenhouses, or indoor facilities, so that your initial capital outlay is manageable. You may even be able to get a licence under the ACMPR to grow for two patients so that some of your capital costs are covered during the long application process.

For existing licensed producers, building your brand, ensuring top quality controls, and designing your cannabis greenhouse or indoor cannabis growing facility for maximum efficiency is important as this industry continues to expand and develop.

The most popular GGS products for cannabis growers are hydroponic benches, greenhouses and grow net supports.

This feature was written by GGS Structures specialists. For more information, check their website at ggs-greenhouse.com.

PickOntario displays helps spread floral excitement in the core of Canada’s largest city.

BY PICKONTARIO

Thousands of Torontonians enjoyed a sampling of floral delights one day this past summer, all courtesy of pickOntario.

Yonge-Dundas Square was transformed into a beautiful floral haven.

“Happiness in Bloom was created to make people smile, remind them how beautiful nature is, and increase awareness of Ontario-grown flowers and potted plants, and we did just that,” said Jesseline Gough, marketing coordinator at pickOntario.

“We continued our pay-it-forward idea and gave each person two flowers – one to brighten their day, and one to give to a friend, a colleague, or a total stranger.”

PickOntario, a popular program of Flowers

Canada Ontario, took this event to a whole new level and gave Torontonians the full “Happiness in Bloom” experience, which included:

• A Flower Wall: A 10x10 floral art installation made up of fresh Ontario flowers.

• A Flower Tag Station: Where guests were invited to write a personalized message on the tag of the flower they gave away that same day.

• A Flower Crown Bar: Where a flower expert was available to assist guests as they created their personalized flower crowns.

• A Social Photo Print Station: A custom photo experience for participants to share online, and many of them did.

PickOntario has posted a video of the event at https://vimeo.com/179803740.

TOP Some 25,000 cut gerberas were distributed. ABOVE The flower crown bar was especially popular.

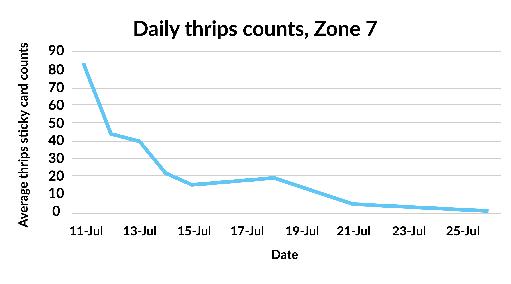

Controlling an unexpected thrips influx from outside – a case study from Niagara, Ontario, 2016. How an innovative grower and his IPM advisors beat back a potentially devastating infestation.

BY GRAEME MURPHY AND DR. SARAH JANDRICIC

In early July 2016, after a very hot and dry start to the summer, reports emerged from a number of greenhouse flower growers of a sudden increase in western flower thrips being caught on sticky traps. This subsequently led to pest establishment and the sudden appearance of (sometimes) severe damage in a number of ornamental crops.

For the majority of these crops, biocontrol had been providing excellent thrips control throughout the spring. However, sudden increases in thrips pressure can make it difficult for predatory mite-based programs to cope. Predatory mites feed only on the first instar larvae of thrips, and a significant fly-in of thrips adults (and subsequent egg-laying) can overwhelm the

mite population.

Chosen approaches to deal with this issue varied by different growers, with some abandoning their biocontrol programs and turning to biweekly pesticide applications. This article highlights a strategy employed in fall chrysanthemums (grown inside), where biocontrol was successful in overcoming a thrips outbreak.

The issue: The grower started to see an increase in thrips on sticky cards at the end of June and noticed severe damage showing up in the last week of June-first week of July (see Figure 1). The plants became heavily stunted and distorted.

Plant tapping at this point showed that all thrips being dislodged were adults. This,

FIGURE 1 Thrips damage on fall mums. Photo taken July 6.

2 Success! The photo was taken Aug. 3. All plants finished and shipped successfully.

With PRO-MIX CC40 discover a new generation of coir growing media. The unique structure of the coir found in CC40 provides on optimized growing environment for plants such as long term crops especially under drought conditions. The well-designed air porosity and water retention qualities provided by this peat-coir based medium give growers the opportunity to react efficiently to a more hostile environment at the same time as balancing financial requirements and productivity.

AT RIGHT: A male (top) and female (bottom) western flower thrips caught on a sticky trap.

plus conversations with other growers who also had sudden thrips increase, strongly suggested a fly-in as the cause of the population increase.

Because there are few curative options for thrips outbreaks, discussions originally centred around the possibility of dumping damaged plants. Previous experience had convinced the grower that pesticides were not the answer. But clearly, their normal biocontrol program of predatory mites could not keep up.

The solution: The grower realized there was probably only one natural enemy with the potential to rapidly control such a large thrips population: the predatory bug Orius. It is able to eat all stages of thrips, including adults (consuming up to 35 adult thrips per day)1, and they kill more thrips than they eat.

SITUATION POSED SEVERAL MAJOR CHALLENGES FOR SUCCESSFUL CONTROL

Still, it was a lot to expect Orius to come to the rescue here, given the level of damage, the size of the thrips population, and that these plants were scheduled for shipping in four to five weeks.

It was also a concern that the crop was being grown under short days, and how this might affect Orius establishment and reproduction.

Greenhouse Canada - August_Layout 1 4/26/2016 10:25 AM Page 1

Given the lack of alternatives, the grower decided to go ahead and replace introductions of predatory mites with releases of Orius. Smaller introductions were made at first, but were increased in July to approximately 2.5 Orius per square metre for three successive weeks. This is close to the curative rate for heavy thrips infestations, recommended by the biocontrol producers.

In terms of chrysanthemum growing conditions affecting Orius, we often hear about how <12 hours of light can induce “reproductive diapause.”

FIGURE 3 Daily counts of thrips in one of the worst affected zones of the farm.

FIGURE 4 Average sticky card counts of thrips throughout the whole farm. Arrows indicate timing of Orius introductions; highest rates were introduced July 5-26.