Flexing those robot arms

BY CHRIS FIFO

MELHEM SAWAYA

BY JAN VOOGT

BY CHRIS FIFO

MELHEM SAWAYA

BY JAN VOOGT

The pandemic has fast-forwarded our reliance on technology. Contact at work and with colleagues has become less physical, more virtual.

Even before COVID, automation and artificial intelligence were making leaps and bounds in the horticultural sector. 2019-2020 marked the second edition of the Autonomous Greenhouse Challenge, hosted by Wageningen University & Research (WUR) and internet company Tencent. In the initial challenge, 21 teams from 26 countries participated in a 24-hour “hackathon.” The goal was to maximize the net profit of a digital tomato within a video gamelike virtual greenhouse, which meant optimizing yield and quality while minimizing resources.

Associate Publisher NASHELLE BARSKY nbarsky@annexbusinessmedia.com 905.431.8892

Account Coordinator SHANNON DRUMM sdrumm@annexbusinessmedia.com 416.510.6762

Circulation Manager JAY DOSHI jdoshi@annexbusinessmedia.com

The five highest-scoring teams moved onto the next round. This time, the goal was to grow real cherry tomatoes remotely in WUR’s greenhouse in Bleiswijk, Netherlands, while maximizing returns. According to WUR, “Each team had its own compartment (96 m2) in the greenhouse, equipped with the standard actuators and sensors to control temperature, ventilation, screens, artificial lighting, CO2 and irrigation. Climate and irrigation set points, as well as pruning strategies, were designed remotely using AI algorithms.” Not only did each team create their own AI algorithms, but once the challenge began, it was up to the AI to adjust any climate and cultivation setpoints as necessary, further pushing the boundaries of machine learning. As a reference point, a group of Dutch growers cultivated the same tomatoes as they normally would in the greenhouse. After six months, the highest

scoring team (‘Automatoes’) won with a net profit of 6,86 Euros per m2, using the lowest amount of energy (12.9 MJ per kg tomatoes) and water (25 L per kg tomatoes) among their competitors. In comparison, the ‘hands-on’ growers in the reference greenhouse were the most heat-intensive at 33 MJ per kg of tomatoes, second most water-intensive at 27 L of per kg, and came in last at 3,10 Euros per m2 in profit. (However, their ability to visit the greenhouse in person was constrained by COVID.) This round might have gone to the machines, but not every AI team excelled to the same degree. The top two teams netted above 6 Euros per kg, while the bottom four ranged between 3,10 and 3,59 Euros per kg. The reference grower group landed in the middle of the pack with their electricity use, which varied between 17.6 and 24.0 kWh per kg among all the teams. It would seem that the success of AI is still contingent on the programmer’s knowledge and skill. However, given that machine learning requires time to build from

If AI could maximize your earning potential, would you switch?

previous situations, it would be interesting to see whether the AI algorithms from this challenge could improve in yield and profit over the course of another season or two and go head-to-head again in a rematch. This puts the greenhouse sector at an interesting crossroads. With AI, you could potentially automate the entire growing process, minimize the need to find skilled labour and reduce the introduction of disease. But for someone who loves walking the greenhouse, caressing the plants and taking care of their daily needs, would you hesitate to hand over the controls? Food for thought.

- #867172652RT0001

Greenhouse Canada

mail information on behalf of

and

groups whose

we believe may

If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Cleanfarms is looking for greenhouse growers to participate in a market research study about current practices and attitudes toward disposal options for the agricultural plastic waste generated in their operations.

The survey results will help Cleanfarms determine how it can provide farmers with more opportunities to manage plastic waste in environmentally responsible ways. The insights will inform the development of potential pilot projects throughout the agriculture sector to demonstrate best practices in

ag waste management.

Greenhouse growers interested in participating in the survey can do so anonymously and confidentially by contacting Stratus, an independent research company at marinusvandijk@stratusresearch.com.

The survey is part of Cleanfarms’ in-depth study of Canadian agriculture entitled Building a ZeroPlastic Waste Strategy for Agriculture. This project is partly funded by Agriculture and Agri-Food Canada’s Canadian Agricultural Strategic Priorities Program (CASPP).

The BC government is contributing $355,000 toward energy-efficient improvements at Windset Farms in Delta through the CleanBC Industry Fund. These changes will reduce the amount of natural gas used to heat the facility by half, lowering its carbon footprint, increasing its energy efficiency and supporting a clean economy.

The project will install a retractable thermal curtain at one of the company’s greenhouses to trap heat in lowlight conditions during cloudy days and at night.

The partnership with Windset Farms is expected to reduce nearly 26,000 tonnes of carbon dioxide equivalent over the next decade. This is roughly the same as taking more

For growers in BC looking to hire temporary foreign workers though federal programs where an LMIA is needed, they will soon be required to register with the provincial government.

As of Dec. 15, registration will be mandatory to receive an approved LMIA by Service Canada. This applies to employers intending to hire a temporary worker through most federal foreign worker programs including the Temporary Foreign Worker Program (TFWP) and Seasonal Agriculture Worker Program (SAWP). If approved, employers are issued a certificate of registration valid for up to three years.

The Western Labour Agriculture Initiative recommends employers register as soon as possible to prevent delays with hiring workers, as wait times for LMIA approvals are likely to increase once the December 15th requirement comes into effect. There is no fee to register.

Source: WALI, BC Ministry of Agriculture

than 9,000 cars off the road for a year.

“By investing in new energy-efficient technologies, we’re reducing our impact on the environment, saving on energy costs and creating new lowcarbon opportunities thanks to funding through CleanBC,” says Steve Newell, CEO of Windset Farms.

The CleanBC Industry Fund uses carbon

tax revenues paid by industry to fund emission reduction projects around the province. To be eligible, applicants must have emissions over 10,000 tonnes of carbon dioxide equivalent per year and be a reporting facility under the Greenhouse Gas Industrial Reporting and Control Act. Projects were chosen and evaluated based on established criteria in a competitive process.

Source: BC Ministry of Agriculture

Source: IESO Greenhouse Energy Profile Study, 2019

Compared to an unlit vegetable greenhouse, electricity consumption is:

10x more in a lit vegetable greenhouse

4x more in a lit flower greenhouse

3.5x more in an indoor cannabis facility

Indoor cannabis facilities use

1.4x more electricity than cannabis greenhouses

LEDs cost 4 to 5 times the price of HPS fixtures

The Ontario agricultural exemption on boilers and pressure vessels will be lifted in 2021, and greenhouse growers should take note.

“As of July 1, 2021, all boilers, pressure vessels or piping used exclusively for agricultural purposes must comply with the Boilers and Pressure Vessels regulation. There will be no changes to the exemptions under the Operating Engineers regulation or the Elevating Devices regulation –these exemptions will remain in place,” states Lisa Thompson, Minister of Government and Consumer Services, in a letter sent to stakeholders dated July 24, 2020.

Without the exemption in place, the Technical Standards and Safety Authority (TSSA) can now help enforce proper boiler use in agricultural operations. All pressure vessels must be registered with the TSSA by March 1, 2021 and inspected by July 1, 2021.

Jan VanderHout, president of The Ontario Greenhouse Alliance (TOGA) and co-owner of Beverly Greenhouses in Waterdown, Ont., see this decision as a positive measure to enhance public safety and emphasizes that the operating engineers exemption remains intact.

“We will have a little more accountability in that our equipment is operating up to standards,” says VanderHout. For over three years, TOGA had been working with the government of Ontario on a pathway to compliance. “I would like to thank

Toundra Greenhouses took home top honours in multiple categories of the 2020 Mercuriades awards virtual gala this year, including Business of the Year as the small to medium-sized business recipient.

With investments of $85 million over four years, the StFélicien, Québec-based greenhouse producer is known as a key player in economic and regional development in the Saguenay Lac St-Jean region. With a

Minister Thompson, Flowers Canada (Ontario) and Ontario Greenhouse Vegetable Growers for their diligence.”

According to Thompson’s letter, the appended TSSA guidelines will first bring “high-risk equipment into compliance and then lower-risk equipment at staggered timeframes over the next five years.”

The first inspection would be conducted as an “initial inspection” by the TSSA, explains Ryan Jones of Farm Mutual Re. Boilers and pressure vessels will be checked against existing installation requirements. The owner would then be allotted 18 to 60 months to complete the inspector’s orders, depending on the type of equipment. Since the TSSA charges on an hourly basis, Jones estimates that inspection costs could reach a few thousand dollars for a larger greenhouse, whereas a smaller grower might expect costs to be around five to six hundred dollars.

Subsequent inspections would be conducted every one to three years by an insurance carrier, Jones adds. For his company, Jones says this was a significant change that came without much notice. “We weren’t anticipating this in such short order,” he says. Their company has started reviewing the new guidelines with their members and clients since.

For over three years, Ontario had been conducting a comprehensive review of the agricultural exemption on boilers, including several items that may or may not have posed safety concerns.

wage-bonus system in place, their employees are some of the highest paid in the greenhouse industry in North America.

In addition to Business of the Year, Toundra won in the Contribution to Regional Economic Development category as well as the RBC Start-Up category for their high-tech, eco-responsible production of greenhouse cucumbers for the Québec market. Notably, the greenhouse

producer has removed polystyrene from their production and uses rainwater or snowmelt to water its crops.

“I would like to thank all of our employees and partners, local and overseas, who have helped Toundra Greenhouses achieve the highest standards in the greenhouse industry, and to recognize the fact that we have achieved all this before our company even hits the five-year mark. I am proud of

the expansion of our greenhouses, which will cover 20 hectares by November,” said Eric Dubé, president and chief executive officer of Toundra Greenhouses. Now in its 40th year, the Mercuriades competition presented by the Fédération des chambres de commerce du Québec (FCCQ) awarded 34 Mercures in 17 categories; each category rewarding one large company and one SME.

Source: Toundra

Canadian robotics developer makes customizable, off-the-shelf solutions attainable to diverse crop growers.

BY GRETA CHIU

Operating from the heart of Ontario’s greenhouse ornamental sector, a robotics developer is building automated solutions to handle the packaging process. But rather than building one machine for each crop, they’re building a separate module for each task, allowing greenhouse operators to pick and choose the functions they need.

“Every grower has their own unique way of doing things and different issues they’re dealing with,” says Bill Vandenoever, who co-founded Bold Robotic Solutions with colleague Willem Bijlsma just over three years ago. Combining their respective skills in mechanical development and automation gained from the steel and lumber industries, the pair set out to alleviate a rising need for labour solutions in the greenhouse sector. It wasn’t long before they connected with Rodney Bierhuizen, owner and operator of Sunrise Greenhouses in Vineland, Ont., who recognized the need for flexible automation in the sector

ABOVE

and offered them a working space in his warehouse.

“One of the biggest challenges is we’re typically much more diversified in North America versus Europe,” says Bierhuizen. European greenhouses tend to be monocrop, allowing for more specialized high-throughput mechanization. In comparison, North American ornamental producers are driven by the markets to supply a wide array of items, with fluctuating volumes depending on the season. “This creates a challenge with payback if equipment is only used for limited periods of the year, usually associated with holidays,” he explains. Adding to this challenge is the volumes that the equipment must process during this period to make a profit.

Balancing flexibility with costs, Bold Robotics set out with their first greenhouse project – the mylar packaging machine. For Sunrise, Bold developed a

working prototype that could handle 12 to 16 different products along with their individual packaging specifications. 4” or 6” pot, the particular crop, sleeve or no sleeve, location of the UPC – all the recipes are programmed into the controls for the operator’s ease of use.

“The robot picks the pot out of the tray and puts it on a belt. Robot arm grabs it, puts on the mylar, UPC, sleeves, and it’s ready for the box,” Bierhuizen says. Though the entire process sounds seamless, each step is a separate module, allowing growers to add, customize or remove each one. “We developed a pot cover module for this machine as well,” says Vandenoever. That way, operators can utilize the UPC printing and other modules to capitalize on their investment.

With all the modules in place, the packaging machine can whip through an average of 1,000 pots per hour, managed by just one staff member or more optimally, two. To optimize economy and packaging price, Bierhuizen has the machine running almost all hours of the day for one specific customer who orders daily and in high volumes.

“It’s not as beneficial if you have an order of around 200,” Vandenoever explains, particularly when it comes to switching between product sizes. “It’s not difficult to change the set-up, but you have to stop production.” While programmed controls will make most of the necessary adjustments automatically, some manual adjustments are required for different sizes. This downtime could be more costly for smaller runs.

Switching between crops is much more efficient as fewer manual adjustments are needed. Bold repeatedly tests each program for every greenhouse product, optimizing the settings before shipping out. “If we’re running tulips,

we change the acceleration of the robot a little bit, just so it doesn’t snap the stem off,” says Vandenoever. “Same with the hyacinthe – especially if it has the bulb on. If you move it too fast, it’ll fall right out of the pot.” More robust plants, such as rosemary or lavender trees, allow them to increase the preset speeds on the controls, and further optimize efficiency.

With the core processes down pat, Bold is now turning their attention to flexible solutions intended for lower volume orders, as well as other repetitive tasks around the packaging process.

“If I look at my production side in terms of potting, spacing, trimming – they’re all one-person operations,” says Bierhuizen, who’s already automated a number of steps in Sunrise’s production process. “I want to see that expand to my propagation and our shipping and processing.”

With a keen eye for identifying gaps in automation, particularly around repetitive tasks, Bierhuizen approached Bold about creating a machine for labelling pot covers. It would complement Sunrise’s newly acquired software, which automatically uploads purchase orders onto the cloud. To achieve this, Bold paired a pot-cover separating robot with a UPC application module. The result was a high-speed labelling system, capable of pulling purchase order data from the cloud, printing the information onto the UPC, and labelling each pot cover at a rate of 1,500 per hour. “Straight out of the box, they can put the pot covers into a conveyor. That will separate them, put the label on, restack them, and out comes a completed labelled stack of pot covers,” says Vandenoever. Capable of running unsupervised, it even comes with a barcode scanner to verify the information. “You can put multiple boxes worth of pot

covers and just let it run overnight.”

Two other Bold originals are currently in use at Sunrise. The first is a bale hydrator that injects an adjustable amount of water into each bale of soil, typically around 50 to 60 gallons for optimal hydration. “You pull in the skids, four prongs come down from above the skid into the bale and the right amount of water is injected,” says Bierhuizen. Not only does it loosen up the soil and maximize the bale’s capacity, the machine reduces the space required compared to using a conveyor. “It’ll slowly release the water into the soil for an hour or so,” adds Vandenoever. From the console, the operator can control the volume of water and rate of flow based on their needs. “Just put the bale in and press play.”

The second is a robot called the Watchdog, which helps keep an eye on the potting stages. “The sensors monitor the system and look for anomalies,” explains Bierhuizen. “Say, if a pot hasn’t passed in four seconds, but passed previous sensors, the operator will get a warning, and a bell and light will go off.”

Depending on the alarm’s severity, Watchdog shuts down the entire system unless the operator pushes a bypass button.

“[This way], you don’t have dozens of pots falling off the belt before you realize something’s wrong.”

Several of Bold’s creations have been sourced by other producers and the team has received a high level of attention since debuting at the Canadian Greenhouse Conference last year. It’s their understanding of producers’ needs and the flexibility built into their customizable off-the-shelf solutions that set them apart.

“We look at automation as the ultimate solution, but you lose flexibility a lot of the times,” says Bierhuizen. “We’re looking for automation that’s flexible.”

The differences between vegetative and seed-propagated perennials, and why moisture is key to good germination.

BY CHRIS FIFO

As a class, the interest in and sales of perennials have been skyrocketing. And why not? Perennials are so much more exciting than annuals! (Granted, that’s just my opinion. But a new series of Aquilegia or a new colour of Petunia? No brainer.)

Breeding has come a long way in perennials. And while the competition among breeders can be intense, this leads to superior-performing perennials that benefit growers, retailers, landscapers and gardeners. Many of the newest introductions have come from the vegetative side. Mainly because this is a much faster process. But there have been, and continue to be, amazing introductions in seed perennials.

What are the primary differences between vegetative and seed-propagated perennials, and when would I choose to go with the seed option?

varieties from

I’ll answer these questions for you and will then offer a few pointers to one of the primary pain points for those considering seed: germination.

Seed perennials won’t offer you as many choices in species, colours or flower forms as their vegetative counterparts simply because of genetics.

Many vegetative varieties are developed from a single plant that has expressed one or more recessive gene traits, where the combination of all those attributes is collectively known as a “phenotype.” This plant with desirable attributes is then cloned to become a new variety. This process can happen relatively fast, which is why you have hundreds of vegetative Echinacea and Heuchera to choose from.

more than a decade,

as this

A new variety from seed can take more than a decade to develop. Controlled inbreeding is first performed to eliminate recessive traits and have dominant, but different, desirable attributes consistently expressed in both parent lines. Flowers are then cross-pollinated by a controlled process, and the resulting seed are known as F1 hybrids. When a new series is developed from this process, it is exceptionally exciting!

Seed perennials are an attractive option for growers for several reasons:

Price point: Seed is almost always a more cost-effective option. This allows growers more flexibility for container sizes and marketing options than some vegetative counterparts, which may have to go into larger containers or branded programs to achieve comparable margins.

“Seed in the bag beats tissue culture in the lab”: Most new Echinacea are propagated by tissue culture in a laboratory. This is a slow process and inventory can sometimes be limited. Meanwhile, seed is harvested by the hundreds of thousands and, unlike tissue culture, can be stored until it is needed.

Hardiness: Though this cannot be generalized, and maybe not even scientifically proven, there has been a general perception that some of the latest and greatest vegetative perennial varieties are losing some of their hardiness compared to the original seed varieties.

First-year flowering: There are still genera that require vernalization for full flowering. Breeding advancements are reducing or eliminating this need for some. However, first-year flowering makes plants much easier to grow and accurately schedule seed perennials for flowering.

Uniformity: Because F1 hybrid seeds are produced by controlled pollination between the two parental lines, the resulting hybrids are an immense improvement over standard open-pollinated (OP) varieties, offering greater uniformity and vigour in growth habit and flowering.

Enjoyment: Growing perennials from seed is fun!

Okay, that last point was purely subjective from my experience. I understand not everybody shares that feeling. Perennials have traditionally been perceived as difficult to germinate, at least compared to annuals. This can make growers shy away from seed propagation in favour of rooting cuttings. However, this does not have to be the case. Anyone can be successful at germinating and growing perennials from seed.

Not only have there been advancements in breeding and seed production, but seed processing and treatments have also come a long way. This makes it easier for growers to sow and grow seed perennials. Below are some treatments being advanced by seed companies to help growers better succeed with perennials:

• Cleaned and de-tailed seed that doesn’t bunch together;

• Coated seed will run through a seeder more easily;

• Fungicide coating for crops like Lupine can minimize disease issues;

• Pelleted and multi-pelleted seeds for crops like Campanula that are very small and perform best with several seeds per cell and;

• Proprietary treatments to enhance germination and vigour.

In the end, it is up to the growers for success, but here are a few guidelines to help you along the way.

From my experience, perennials are not too picky on temperature – anywhere from 17ºC to 24ºC seems to work fine. The biggest difference is the rate of germination. Likewise, I have not experienced differences in light versus no light for germinating commercial varieties.

Another misconception for some perennial seed is that they need to be cold stratified to overcome dormancy issues. This is not the case these days. Those “proprietary treatments” have solved that problem.

The primary factor affecting germination of perennials is moisture. It is that simple, and it can be that challenging. If

Aster Y 7

Coreopsis Y 5

Delphinium Y 10

Echinacea Y 8

Gaillardia Y 4

Gaura Y 4

Hollyhock Y 3

Leucanthemum

Experience ultimate control of your greenhouse with iSii

Hoogendoorn’s next generation iSii monitors and controls all climate, irrigation and energy equipment in all types of greenhouses. The iSii is equipped with advanced controls that work according to the principles of Plant Empowerment, which resulted from Next Generation Growing (NGG) research. This way light, temperature, humidity and CO2 are aligned with each other for a maximum photosynthesis. In addition, to prevent water stress, irrigation is driven by the evaporation energy and water balance of the crop. With the iSii process computer, you set the base for high quality production.

LEFT General guidelines for common seed perennials germinating at moisture levels between 3.5 to 4.

info@hoogendoorn.ca www.hoogendoorn.ca

you’re having difficulties germinating perennial seeds, evaluate your moisture.

I trust everyone is familiar with the 1 to 5 media moisture scale: 5 being saturated, 1 being completely dry, and 3 just turning from dark to light coloured. Most issues occur from growers keeping their seeds at a 5 for germination. Even those crops that like to germinate wet will prefer a 4 to 4.5 for moisture.

How is a grower to know? First, do a little homework. There is information available through resources provided by seed breeders, such as PanAmerican Seed. If you can’t find information there – such as if you’re germinating older genetics or native plants – look at the seed itself and use your instincts.

Is it a smaller, hard seed like a Dianthus or Salvia? Then it probably needs to be kept more wet and does not need vermiculite or media covering on the seed. Is it a larger seed? The size of a BB gun or larger like a Centaurea or Lupine? Then maybe it needs covering, but don’t bury it more than the diameter of the seed.

Is it a larger, soft seed like a Delphinium or Echinacea? Then it probably prefers to have a little covering and be germinated on the dry side, around a 3.5 or 4.

Germination is easily done on the bench for the wet germinators. Managing moisture for the drier germinators is more challenging. The use of a germination chamber can help keep the humidity around 85 to 90 per cent. That way, if a plug tray goes into the chamber at a 4.5, it will gradually dry to a 3.5 by Day 3 or 4. Perfect. By this time, the seed has absorbed all the moisture it needs to germinate. Using a mist nozzle after this to avoid desiccation is all you need to maintain the perfect moisture level and have success germinating perennial seeds.

Chris Fifo has more than 30 years’ experience as a technical services advisor. His expertise lies in best practices for perennial production and is a product representative for both Kieft Seed and Darwin Perennials. He can be reached at cfifo@ballhort.com.

Pablo Costa Van Belle Nursery, Abbotsford, British Columbia

“The light intensity is very low so we need supplemental light to reach the early spring window for sales of our retail-ready Hydrangea. We work together with Philips and with Philips Plant Specialists. We looked at plants, the light intensity and the quality of the light that we have in the period that is critical for our crops and we design together the best option for the crop we grow. We obtain finished plant with color of three to four weeks early. We are proud of the quality of the plants and we are very happy to partner with Philips.”

New and notable varieties that survived the Ontario summer in this year’s Sawaya Garden Trials.

BY MELHEM

This article concludes a two-part series covering highlights from the 2020 Sawaya Garden Trials, held annually in Simcoe, Ontario. Find part one of my trial coverage in the October 2020 edition of Greenhouse Canada with details on groundbreaking new developments for the trials in 2021, as well as #1 to #24 of my varietal highlights.

As always, they are not listed in any particular order. Some may not be new varieties, but remain notable mentions. Here are #25 to #46.

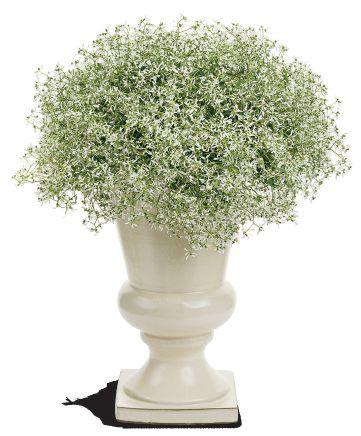

[25] Gypsophila Gypsy White. This picture was taken at the end of July and still looks perfect amid a summer that saw higher-than-average temperatures. This variety is grown from seed and can be sold in 4” containers for landscape or in larger patio pots. No deadheading required. Neither rain nor heat ever affected the Gypsy negatively. When we held the charity sale on August 15, Gypsy was still looking good and it was one of the first ones to be purchased.

[26] Helichrysum Silver Threads is a soft trailing plant that will complement and enhance any combination. Excellent garden performance independent of the weather. Silver Threads can take the heat and do very well in the cold, which makes it a winner in any combination. This variety can be grown in 4” or 6” pots for landscape, large patio

pots or in combinations – especially all-foliage combinations without any flowering varieties.

[27] Hibiscus Luna Pink Swirl. An excellent garden performer for landscape or in large patio pots, Luna Pink Swirl is a true perennial for southwestern Ontario and doubles in size every year. Excellent for extending spring sales into late June. Flowers naturally in the garden from late June till frost.

[28] Lavandula angustifolia Aromatico Blue improved and [29] Lavandula angustifolia Blue Spear are two standout varieties among the exploding lavender market. Neither variety needed deadheading and looked great all summer long. Excellent garden performance in hot or rainy weather, these two were among the first items that consumers grabbed at our charity sale in August. Lavender is increasing in popularity with consumers and that is why we will expand to include as many varieties as possible next year.

[30] Leucanthemum Sweet Daisy Birdy is hardy to southwestern Ontario. It has four stages of flowering, which means it will reach the fourth stage of flower budding before you need to deadhead the first stage. Many Leucanthemums flower just once in a season, which does not give them a long-lasting flowering period.

[31] Petunia Hybrida Shortcake Blueberry

Grodan presents the fully redesigned e-Gro, the ultimate platform to support your knowledge, experience and growing strategy with real-time insights and smart recommendations based on root zone, climate, crop and harvest data. Anywhere, anytime and on any device.

The more you know, the better you grow.

Relevant data from various sources in your greenhouse is displayed together clearly in a single place, in real-time.

Smart recommendations help you optimize your irrigation strategy and guide your crop to the desired balance.

Maximize visibility and control

e-Gro is a web-based application, and is available on all devices, enabling remote access to your greenhouse data anywhere, at any time.

Don’t take just our word for it, try it for yourself. Contact us today to set up your free e-Gro demo and in-house trial: www.grodan.com/e-Gro

is a semi-trailing medium-sized multiflora variety that does not need any deadheading and recovers extremely well after a rain. Shortcake Blueberry is great for landscape and combinations where it complements any mix.

[32] Petunia Bee’s Knees is one of the best yellow trailing petunias on the market. With a deeper yellow colour compared to other yellow petunia varieties, it works well with many combinations and is great in hanging baskets. It’s shown excellent recovery after a rain, with no signs of Botrytis on the flowers.

[33] Petunia Cascadias Purple Gem is a mounding petunia that has a controlled growth habit, making it excellent for pans or window boxes. The variety has great garden performance that looks better with hot weather and recovers quickly from the rain without any negative side effects. The purple and white flowers stand out even from a far distance, making it an excellent landscape plant.

[34] Petunia ColorRush Blue is one colour in the ColorRush series that is vigorous and produces lots of flowers throughout the whole season. It continues to deliver great garden performance during or after a rain and even when it gets hot. Petunia ColorRush Blue is great in combinations with other vigorous cultivars or in hanging baskets 10” or larger.

[35] Petunia Dekko Blue Improved is one colour in a series where most, but not all, have matching habits. Blue Improved has medium-sized flowers that cover the entire canopy of the plant. Dekkos are one of my favourite petunias for combinations as they can gel very well with other cultivars and work well in hanging baskets. All of the Dekko series performs well in the garden with the exception of red.

[36] Petunia Hippy Chick Violet looks remarkably like Petunia Cascadias Purple Gem – so much so, that you would think they were from the same family. Hippy Chick Violet has a controlled growth habit that will also look great in pans and window boxes, with great garden

performance through rain or hot weather. It works well as a high-density crop due to its controlled growth habit.

[37] Petunia Main Stage Purple is a petunia on steroids. Great for large containers and big landscape areas, this variety has excellent garden performance. It quickly recovers from rain and excels in hot weather as long as it is watered regularly.

[38] Petunia Midnight Gold has a unique double flower colour that stands out from all the others. In contrast to many other double flower petunias, Midnight Gold displays excellent garden performance even after a heavy bout of rain and recovers amazingly fast. With its controlled habit, this variety can be grown in gallons for landscape use.

[39] Petunia Pink Diamond is a little more vigorous than Petunia Midnight Gold, both with the same excellent garden performance of flowers resistant to rain damage and Botrytis. Ideal for upgraded containers and in combinations.

[40] Petunia Supertunia Mini Vista Indigo Improved. Formerly known as ‘Charms,’ this petunia variety is vigorous and produces a massive canopy of medium flowers. Mini Vista Indigo displayed excellent garden performance throughout the whole summer without any deadheading needed. It works particularly well in large hanging baskets and large containers.

[41] Phlox Gisele Light Violet is on the compact side compared to other phlox, but it fills the pot early with dense foliage and a good canopy of flowers. By comparison, [42] Phlox Intensia Blueberry is very vigorous and starts to look great towards the end of May/early June. Annual phlox are underused because we try to sell them early in the season when they do not look their best. Both the Gisele and the Intensia series make excellent performers in containers, in the garden or in combinations.

[43] Plug & Play Seaside Delight is an example of a combination that just makes sense. Not only does it perform,

it’s also profitable because the input cost is equal to three plugs of seed Angelonia and three plugs of vinca. Because this combination should not be sold until late May, the plugs are planted later in the season. There are many great seed combinations on the market, and this one offers excellent performance the whole summer long.

[44] Sedum Lemon Coral is excellent in both landscape and containers. It loves the heat and tolerates dryness, but thrives when moderately moist. Sedum Lemon Coral is grown for its foliage but will flower if old enough and placed in full sunlight.

[45] Trixi Twice as Nice is one of the Trixi liner combinations. It consists of three double flower calibrachoas that show very well in large hanging baskets and patio pots. Excellent garden performance in the heat and rain, its double flowers last longer than single calibrachoa flowers. The double calibrachoas are a must for grower programs.

[46] Vinca F1 Valiant Lilac is one colour in the Valiant series. I like it because of its early branching habit which is key in the vinca’s ability to take off in growth. Vinca is one of the top in landscape genera. Lately, I’ve seen it in many landscapes due to a lack of confidence in walleriana impatiens, but anyone who has tried the vinca has been pleased with its performance.

Like I always say, new varieties are exciting to try on a small scale. If they prove to work well, surpass what you are growing now and offer consumer appeal, then and only then should you expand on that particular variety. Just remember to remove the one that is being replaced. It has been proven over and over again that great quality product and good service is much more important than quantity.

See you next year at our new location for the Sawaya Gardens.

Melhem Sawaya of Focus Greenhouse Management is a consultant and research coordinator to the horticultural industry. Contact him at mel@ focusgreenhousemanagement.com.

TTA recently welcomed Christopher Houweling in his position as Sales Manager Canada, based out of Lowbanks, Ontario. He brings years of experience of growing up in the Greenhouse Industry and is well-known with TTA. It even turned out that in his teens, Christopher worked at a nursery where he operated a transplanting line from TTA.

Canadian Nurseries and Greenhouses who are looking for outstanding equipment for plug consolidation, transplanting and plant selection/grading, please get in touch with Christopher by email chris.houweling@tta-usa.com. We can fully meet your needs and provide you with high-tech solution in a short period of time.

TTA equipment is suitable for handling and selecting pot plants, bedding plants, forestry, vegetables, soft fruits and herbs. Each sector requires a separate approach. Our experienced and motivated team can provide you with the best plant handling and selecting solutions for your specific situation.

» We offer our customers a broad range of equipment, suiting the needs of professional growers.

» We feel strongly about equipment innovation, flexibility and commitment to service.

» We believe that quality and control are of the utmost importance. Therefore the entire production, service and sales is available in-house.

Cultivating by artificial intelligence, these vertical farming modules are bringing fresh herbs and leafy greens straight to the consumer.

BY GRETA CHIU

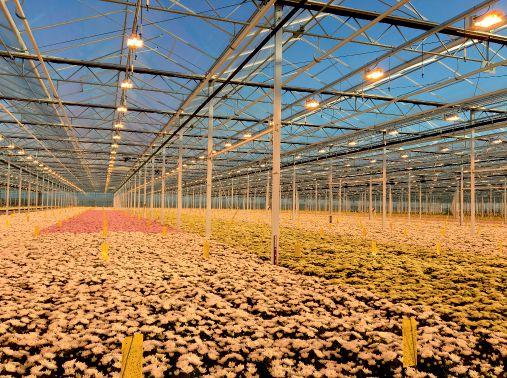

One of the largest and fastestgrowing vertical farming platforms in the world, Infarm’s smart farming modules are bringing a whole new meaning to the word “hyperlocal.”

Best recognized for their grocery store installations that have appeared all over the globe, shoppers are able to watch the growing process and pick from fresh herbs and leafy greens immediately after harvest. Maintained by machine learning and AI technology, each standalone vertical farming unit is continuously monitored and tweaked to ensure optimal growing conditions.

“We control our farms remotely using sensors and a centralized,

ABOVE

cloud-based platform that adjusts and improves itself continuously, so each plant grows better than the one before – providing plant seedlings with an ideal combination of light spectrums, temperature, pH, and nutrients for optimal growth,”

explains Emmanuel Evita, global communications director for Infarm.

Using machine learning, big data and IoT technologies, the Berlin, Germany-based company is able to collect large amounts of data from their farms around the world in real-time, amounting to more than 50,000 data points within a plant’s lifetime. And the modules aren’t just for grocery stores. Infarm

Infarm modules grow fresh herbs and leafy greens by automation, partnering with grocery retailers worldwide.

Ridder is quickly becoming a household name when it comes to energy-saving screens. From our RES series with the highest light transmittance and energy savings to our RBO series with its high moisture permeability, low heat-transmission and the highest possible blackout capability. They all contribute to Ridder’s Dutch standard of quality and excellence. Made in Holland.

says their easily scalable and rapidly deployable technology has been set up in distribution centres, restaurants and other urban spaces to match local needs.

“With more than 1,000 farms in stores and distribution centers, we’re able to use the data on each one of more than 500,000 plants we grow every month to understand their unique growth patterns and offer the highest quality product to consumers,” says Evita.

The company is deeply committed to improving the safety, quality and environmental footprint of food production. Offering an ever-expanding catalogue with over 65 different combinations of herbs, microgreens and leafy greens, the range of products includes cooking staples like Italian basil to specialty varieties such as wasabi rucola. Infarm’s plants are also grown without the use of chemical pesticides and are locally germinated in their nursery farms. The seedlings are then cultivated in-store for another three to four weeks to maturity before being offered to consumers. The vertical farming units are said to require 95 per cent less water, 90 per cent less transportation and 75 per cent less fertilizer compared to conventional soil-based agriculture. 90 per cent of electricity used by the Infarm network is sourced from renewable energy, and the company has set a target to reach zeroemission food production next year.

“We save thousands of food kilometres by not shipping from abroad, removing trucks from the road, and increasing the resilience of the global food system with every farm we install. Our approach supports biodiversity by reducing and almost eliminating the supply chain of food,” says Evita.

Infarm partnered with Empire Company Ltd. and begin rolling out installations in select Sobeys, Safeway and Thrifty Foods in British Columbia earlier this year.

“Our partnership with Infarm is unique in Canada and offers our customers a world-leading urban farming solution,” says Niluka Kottegoda, vice president of customer experience at Sobeys. “By the end of September, we will have fully functional vertical farming units in 28 of our Safeway and Thrifty Foods stores in the Vancouver and Victoria areas with several additional stores carrying the harvested herbs and lettuce.”

Kottegoda says their customers have

been responding very well to this urban farming solution. “Not only do they appreciate the sustainable nature of the farms, but they certainly love having access to the freshest possible leafy greens and herbs all year long.” Empire expects to bring Infarm installations into Toronto soon, with a national rollout on the horizon.

First established in 2013 by Osnat Michaeli and brothers Erez and Guy Galonska to help cities become selfsufficient in food production, Berlinbased Infarm now has operations in 10 countries and 30 cities worldwide. Over the past year, they’ve partnered with 30 of the largest retailers in the world, including Albert Heijn (Netherlands), Aldi Süd (Germany), Amazon Fresh, COOP/Irma (Denmark), Empire Company Ltd (Canada), Kaufland (Germany), Kinokuniya (Japan), Kroger (United States), Marks & Spencer (United Kingdom), Selfridges (United Kingdom) as well as others in France, Luxembourg, and Switzerland.

In September, Infarm announced

Infarm modules can be installed in distribution centres, grocery stores and even restaurants, such as Layla Restaurant in Berlin, Germany pictured above.

another $170 million in the first close of a funding round expected to reach $200 million. That will bring in over $300 million of funding to date.

By investing this capital into infrastructure, research and development, the company expects to grow their installations by 10 per cent, reaching over 5,000,000 sq. ft. in the next five years.

“The coronavirus pandemic has put a global spotlight on the urgent agricultural

and ecological challenges of our time,” says Erez Galonska, co-founder and CEO of Infarm. “As we scale to 5,000,000 sq. ft. in farming facilities across Europe, North America and Asia by 2025, this investment will help us make a truly global impact through our network, preserving the thousands of acres of land, millions of liters of water and ultimately change the way people grow, eat and think about food.”

Growers know that when it comes to controlling and monitoring a production environment, a simple, flexible, sustainable control system is crucial. This is why you can depend on Reliable Controls. Our nationwide network of factory-certified Authorized Dealers will help you design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective, Canadian-made solution, please contact a Reliable Controls

Authorized Dealer near you.

Eastern Canada: 647.982.7412 Western Canada: 403.561.4148

BY ONTARIO’S INDEPENDENT ELECTRICITY SYSTEM OPERATOR

As every greenhouse operator knows, growing any type of agricultural product requires the right inputs, the right conditions and the right investments. For the thriving greenhouse sector, controlling energy costs will be a key element of most operators’ growth strategies in the coming years. A reliable, affordable and sustainable supply of electricity has always been important – but never more than now, as the province continues to cope with the economic impacts of COVID-19.

The greenhouse sector is one of the fastest-growing sources of electricity demand in Ontario. In the WindsorEssex region of southwest Ontario alone, electricity demand is expected to double over the next five years. Vegetable greenhouses are the largest driver of growth, while cannabis is starting to have an impact as growers ramp up their operations.

Responsible for operating the province’s high-voltage power system and administering the wholesale market, Ontario’s Independent Electricity System Operator (IESO) has been working closely with greenhouse owners and operators to ensure they have access to a reliable supply of electricity, while also helping businesses manage their costs through energy-efficiency programs and funding for innovative projects.

brand have enabled businesses to reap the operational and financial benefits of newer, more energy-efficient equipment. For greenhouse operators, the Save on Energy Retrofit program delivers the greatest bang for the buck. It supports projects and upgrades that provide sustainable, measurable and verifiable reductions in peak electricity demand and consumption, including:

• lighting controls and retrofits

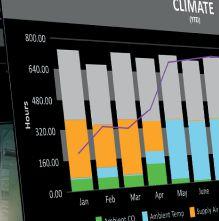

FIGURE 1

Lighting uses more electricity than all other greenhouse end-uses combined.

“Affordable and reliable electricity is critical to supporting economic growth,” said Nik Schruder, the IESO’s director of energy efficiency. “In addition to reducing costs for businesses and making them more competitive, energy efficiency also helps us manage increased demand on the grid and defers the need for new transmission investments.”

Energy-efficiency programs under the IESO’s Save on Energy

• heating, ventilation and air conditioning (HVAC) redesign

• chiller replacement

• variable-speed drives

• building envelope improvements, including insulation, window glazing and roof barriers

Lighting uses more electricity than all other greenhouse end-

• The original silver stabilized hydrogen peroxide disinfectant

• Surface and material disinfection, water treatment, fogging

• Chlorine-free, ecological and biodegradable

• Highly effective, stable and safe

• User-friendly, simple and versatile to use

• Quickly and easily measurable

Huwa-San TR-50 (397B) is a recognized biocidal product. Use biocides safely. Before use, read the label and product information. * Certified for use in organic farming in accordance with EU 834/2007 and EU 889/2008.

• Enriched with micronutrients

• Foliar application or add to irrigation water

• Provides higher yields and more consistent harvests

• Reduces the need for pesticides and other chemical treatments

• All silicon: 100% soluble and 100% available for plant uptake

• Increases natural resistance against biotic and abiotic stress

These products are distributed by Global Horticultural Inc, Beamsville, ON. For any information, or for tailor-made advice based on your specific needs, please contact: E: herman@globalhort.com • C: 1-289-407-0132 • P:1-800-668-9567

uses combined.

Traditional high-intensity discharge lighting, with double-ended highpressure sodium (DE-HPS) grow lights, are increasingly being replaced with high-efficiency LED lighting. LED lighting uses up to 50 per cent less energy than HPS lights. It also lasts between five and 10 times longer than DE-HPS, cutting down on replacement costs. In many cases, greenhouse operators who invest in energy-efficient LED lighting see a payback within two to three years.

In addition to customizing spectral light to suit the crop or the growth stage, LEDs also run cooler than traditional lighting technologies, resulting in less waste heat and lowering the demands placed on HVAC equipment –potentially leading to even more energy savings.

Dehumidification, which requires mechanical cooling, can also drive up energy use. Installing variable frequency drives on exhaust fans, heat buffering systems, zone pumps and mixing valves can deliver significant savings by controlling the speed of motor-driven equipment so it doesn’t use energy unnecessarily.

With more than 1,300 megawatts of Ontario greenhouse load seeking to connect to the grid by 2025, the province’s infrastructure is facing significant increases in demand for electricity. To manage this, the IESO’s

Grid Innovation Fund (GIF) financially supports innovative projects that either enable customers to better manage their energy consumption or that reduce the costs associated with maintaining reliable operation of the province’s grid. Since 2005, the GIF has provided financial support to more than 200 innovative energy projects across the province.

In November 2019, the GIF issued a targeted call for novel projects focused on reducing electricity demand from indoor agriculture during local and bulk system peak periods. With up to $2.5 million available in total for approved projects, applications represented a broad range of technologies and solutions, including energy management, load curtailment, dynamic voltage controllers, microgrids, artificial intelligence, lighting, program design, HVAC and electrolyzer research.

One of the successful proponents was a partnership between Allegro Acres, Harrow Research and Development Centre, the University of Windsor, Red Sun Farms and Sollum Technologies. They are piloting a project to evaluate the performance of low-intensity LED lighting and controls used over a 24hour period against the current practice of using high-intensity HPS lighting over a 16- to 17-hour period. This new approach to lighting has the potential to reduce electricity consumption by 15 to 33 per cent, while maintaining or improving crop growth and yield.

“Testing and implementing

Starting in November, family-owned Allegro Acres will be implementing Sollum Technologies’ smart LED lighting. This makes Allegro the first Canadian commercial greenhouse producer to grow peppers under lights in the winter.

Manufactured in Montréal, Que., Sollum says the key to their patented smart lighting technology is the cloudbased SUN as a Service platform, which uses the fixture’s capacity to recreate, perfect and modulate the full spectrum of the sun’s natural light. As a result, it is said to reproduce Southern Australia’s light cycle just as it can do for Northern France’s light, which enables the cultivation of fruit or vegetables regardless of its native climate and the location of the greenhouse.

Beginning with four acres this year, Allegro will be working with Harrow Research and Development Centre to test and further develop lighting recipes and regimens for optimizing pepper growth.

FIGURE 2

A lit vegetable greenhouse uses 10 times more electricity than an unlit one. Electricity consumption is expected to increase by 280 per cent from 2018 to 2024. Consumption related to cannabis growth is projected to increase 1,253 per cent by 2024 as a result of new greenhouses and indoor facilities.

sustainable agricultural practices has always been a high priority at Allegro,” said Gene Ingratta, president of Allegro Acres. “With the growing demand for locally produced food, this project was the perfect opportunity to really make a difference in the supply chain. For this pilot project, we intend to reduce light pollution and our carbon footprint while managing the strain on the electricity grid with Sollum’s fully dynamic LED lighting system. Now, for the first time ever, we’ll be able to supply our customers with year-round, locally grown Canadian peppers.”

Another successful application was from Great Lakes Greenhouses in Leamington, who will be involved in developing an artificial intelligence (AI)-powered program that uses data and a learning algorithm to increase energy efficiency without reducing crop yield in large-scale commercial greenhouses.

It is important that greenhouse operators and their respective communities have input into electricity decisions, voicing their electricity needs as well as their preferred solutions. Ontario’s greenhouse operators can join Regional Electricity Networks to hear first-hand about issues or innovations impacting the province’s electricity sector, and to provide input into future electricity planning in their communities. For more information, visit http://www.ieso.ca/Get-Involved/ Regional-Planning/Electricity-Networks/ Overview.

Although recovering from the economic damage resulting from the pandemic will take time, greenhouse owners and operators have options. Energy-efficiency and demandmanagement programs, plus other forms of energy innovation, can help reduce operating costs and boost bottom lines. Need guidance? Contact the IESO and/or your local distribution company for additional information. We’re here to help.

Ontario’s Independent Electricity System Operator (IESO) works at the heart of the province’s power system ensuring there is enough power to keep the lights on, today and into the future. Find out more at ieso.ca

Introduced about two and a half decades ago, the idea of using a sharp temperature drop to encourage fruit production is still a source of contention.

BY JAN VOOGT

As a teacher of the “HNT (Het Nieuwe Telen) Learning Groups”, an educational program where Dutch growers are taught the principles of Next Generation Growing / Plant Empowerment, I am frequently asked whether I am in favour of the pre-night drop (PND) and morning dip (MD).

As I recall, the idea of the pre-night drop in tomato cultivation popped up in The Netherlands about 25 years ago. At the end of the afternoon, the temperature in the greenhouse had to be lowered considerably in one rapid motion – the faster the drop in temperature, the better. It was believed that this pushes the assimilates towards warmer fruits, so they become bigger. Besides, it was assumed to promote strong plant heads and trusses.

However, there have been questions from the beginning as to whether this hypothesis is correct. I still remember how one renowned crop adviser argued, that after a sunny day, you should allow the plant to process the assimilates produced during the day; however, the pre-night drop would make this more difficult. This adviser published yield figures of growers who used the pre-night drop and of growers who didn’t apply it. Although there was no noticeable effect of PND, it did not help to support his case. It was like crying in a desert.

More recently, the idea of the socalled morning dip arose, which is very commonly applied as well. After a night under a closed or non-closed energy screen, you should theoretically let the greenhouse temperature make a short dip. This is supposed to promote strong, short trusses. Both the PND and the MD are widely considered to be generative actions and form the basic tools of any serious tomato grower and crop consultant. There have been no discussions about this for a long period of time.

more assimilates, but colder leaves also release the formed assimilates more slowly. So, with quick cooling during the prenight period, wouldn’t you shoot yourself in the foot? Moreover, this stagnates the supply of nutrients, including calcium, to the growth point. Wouldn’t this increase the risks of, for instance, blossom end-rot and tip-burn? A rapid build-up of root pressure can also cause guttation. And after preparing the crop for the day with a slow warm up, what does a morning dip do to the activity of the plant? Which runner would take a cold shower after his warm-up exercises, just before starting the race?

In response to these doubts and questions, Wageningen University & Research (WUR) conducted an extensive study into the effects of temperature treatments on greenhouse crops.

FIGURE 1

This graph shows an example of a typical pre-night drop strategy. Temperatures are decreased swiftly in the afternoon and after sunset (black arrows). (Red = greenhouse temperature; Blue = RH % (left hand axis, value x 10); Brown = outdoor temperature; Yellow = solar radiation W/m2 )

We have been reconsidering both hypotheses in light of the principles of Growing by Plant Empowerment (GPE). Again, considerable doubts arose. Warmer parts of the plant can attract

The results were published in a 2012 report called ‘Temperature strategies in conditioned greenhouses, Effects on growth, development and underlying processes in tomato’ (Report GTB1123, available in Dutch on the website www.kasalsenergiebron. nl). In short, all three hypotheses considered to be the basis for PND and MD have been proven incorrect in this study: • A pre-night drop does not increase the transport of assimilates to the fruits and does not increase fruit weight;

Thursday, November 26, 2020

9:30AM - 12PM & 1:00PM - 3:30PM

Friday, November 27, 2020

9:30AM - 12PM & 1:00PM - 3:30PM

http://bit.ly/poinsettiaregistration2020 Cherry Creek Greenhouses 3550 Cherry Ave, Vineland Beekenkamp, Dummen Orange, Selecta, Syngenta, Bioworks, Cherry Creek Greenhouses, Jefferys Greenhouses, Greenhouse Canada, Focus Greenhouse Management Mel Sawaya 519-427-8440

mel@focusgreenhousemanagement.com

FIGURE 2

This graph shows an example of a typical morning dip strategy. In the morning, just before sunrise, after a slow warming up, the temperature makes a short dip (red arrows). Here, it is also shown that during the PND (black arrows) the greenhouse temperature is reduced to the level of outdoor temperatures, which requires the vents to be opened to 100%.

(Red = Greenhouse temperature, Blue = RH % (Left hand axis, value x 10), Brown = Outdoor temperature, Yellow = Solar radiation W/m2)

• Plant cell elongation cannot be influenced by a temperature strategy such as PND and MD;

• Most of the cell elongation does not take place in the morning but in the evening.

These findings coincide with the principles of GPE which advocate for, among other things, keeping the screen closed for longer at the start of the day and closing the screen earlier (to 80%) at the end of the day. This helps protect the plants against the negative effects of heat emission by longwave radiation. This screening method also ensures better moisture control and effective use of free energy from the sun.

These new insights on PND and MD have been slowly implemented in practice throughout the last ten years. Fortunately, there are now sensors which provide increasing evidence to support this with hard facts. Total plant weight measurements demonstrate that a PND slows down growth substantially. Thermographic images show that MD can lead to more water stress when the sun’s radiation becomes intense. More and more growers tell me that they have gradually abandoned their familiar PND

and MD strategies only to see positive results occur, including healthy growth at the plant heads, good fruit set, and strong trusses. In the meantime, they have learned that the desired crop development (generative/vegetative) can be achieved more easily by maintaining a steady ratio between the 24-hour temperature and the light sum on a daily basis, and by controlling the plant load. This stabilises the assimilates balance and affects almost all plant processes, including the health of the plant in a positive way.

What concerns me now is that these growers sometimes tell me in confidence that they hardly dare to share this information with their colleagues. They seem to think that, if your opinion differs from the rest of the group or if you question the advice of a well-known crop specialist, you will be considered a non-believer or shunned, and you will no longer be taken seriously. That feels very uncomfortable, and not uncommonly, growers will return to the old methods under this peer pressure. One would almost think that PND and MD are a part of some belief system. Everyone can, of course, have their own opinions, which is always food for thought and good for discussion. But if you are no longer open to new facts and insights, then development stagnates. And, as Dutch growers often say, “standing still is moving backwards.”

Recently, the world learned how the “Automatoes” team won the Autonomous Greenhouse Challenge, which was organised by WUR this past spring. Surprisingly, this was achieved without the use of PND or MD whatsoever. The winning team claims to have applied smart computer algorithms, also known as DataDriven Growing (DDG), in addition to the principles of GPE. Among other things, they maintained a steady temperature / light ratio and protected the crop against heat emission consistently during the cultivation period. This way, they made optimal use of the plant’s natural growing power, leading to the highest yield, the best quality, and growing the most efficiently and sustainably of all competing teams.

SUSTAINABLY

Hopefully, this article will prompt believers to reconsider the supposed

benefits of PND and MD. I also hope this may encourage non-believers to come forward with their experiences. Because efficient, sustainable, and profitable cultivation is the real challenge to which the entire horticultural sector faces, we must all work in unison to test new insights critically and to also dare let go of old, outdated insights. Intelligent computer algorithms can help us because they do not work based on feelings and habits; only on hard facts. Data-driven growing has no difficulty in switching

to new strategies if they result in better yields. The outcome of the Autonomous Greenhouse Challenge clearly indicates how the transition to sustainable and profitable greenhouse horticulture can be accelerated.

Jan O. Voogt is a researcher for LetsGrow. com and Hoogendoorn Growth Management. He is also one of the authors of the book Plant Empowerment: The Basic Principles. For more information, please visit www.plantempowerment.com

Breeders share their top perennial varieties for 2021, tailored for the Canadian market.

BY GRETA CHIU

When it comes to growing perennials in Canada, the first question is – can it survive?

To reach the Canadian market, breeders are trialling new perennial varieties in areas just south of B.C. up to Winnipeg, Man. – and for more than one season – to ensure consumer and grower satisfaction.

In addition to surviving temperature extremes, other perennial trends identified by breeders included first-year-flowering, longer bloom periods and the need to show off some colour at retail. Being pollinator-friendly might be a well-known attribute, but reminders are still a must.

What exciting genetics are in store for 2021?

Seed breeders shared their favourite new and notable perennial selections, along with thoughts for the coming year, all catered towards the Canadian market.

When selecting perennials, there are a number of advantages to using first-year flowering varieties. “Breeders are working to take the cold treatment requirements out of perennials so growers are able to achieve full flowering potential the first year,” says Chris Fifo, product representative at Darwin Perennials and Kieft Seed. “Not only does it have the trickle-down effect of helping growers with scheduling,” it also gets colour on perennials at retail. “Because that’s what consumers want –colour!”

Fifo has also noticed growing interest in summer to fall programs over the past few years and offers an alternative to the classic mum.

“An echinacea in full flower, in a container, in the fall will blow away any mum on any day and will give the customer much more value,” he says.

“It’s going to last longer than a potted mum, long past frost, and they’re going to get a much better return on investment.”

For years, perennial breeding seemed to be headed towards more compact plants. “We wanted to fit more onto a rack in the garden centre [or] cram more into a particular space in the garden.” But for some crops, larger sizes are back on trend again, particularly for those geared towards landscape performance

1. Dianthus Mountain Frost –Ruby Glitter, Ruby Snow (Darwin Perennials): Differing from the hundreds of dianthus on the market, Mountain Frost’s breeding program has focused on landscape performance. Flowering rapidly through the summer with a second flush in the fall, Fifo says they tolerate heat, humidity and summer rains without “melting out in the middle.” A grower of more than 30 years, Fifo says he was never taken by dianthus until he saw Mountain Frost in landscape trials. “They’ve absolutely blown me away as far as performance goes. I have not seen any others that will spread, bulk up and fill out the landscape like these do.” With new additions Ruby Glitter and Ruby Snow (pictured), this collection offers nine different colours. Though these are first-year flowering, growers will have the greatest flower power and success from a fall-planted container. Zone 4.

2. Artisan Echinacea (Kieft Seed): The first collection of F1 hybrid echinacea from seed on the market, Artisan took breeders more than 10 years to

perfect. Because it’s F1, “it offers better consistency, uniformity, branching and plant height,” explains Fifo, especially when compared to open-pollinated seed varieties. First-year flowering and highly consistent among bench runs, cultural requirements are identical to the PowWow echinacea series. Artisan debuts in two colours, Red Ombre and Soft Orange, with five more to come in the next few years. Its breeder, Dr. Jianping Ren, won the 2020 All-America Selections Breeder’s Cup in recognition of her influential work, including PanAmerican Seeds’ Wave petunias. Artisan blooms early to mid-summer in landscape and is suitable for summer to fall programs. Zone 4.

3. Early Bird Aquilegia (Kieft Seed): Minimizing the length and intensity of cold treatments typically needed for aquilegia, Early Bird needs just five weeks at 12.8 ºC or lower to maximize flowering potential, making them easier to schedule. “There is a very tight, 10day window for flowering among the colours,” adds Fifo, so growers can bench run with ease. With stalks reaching just 12” high, the series may be compact but develops surprisingly large, upright facing flowers. “We have some novel colours you will not see in any other aquilegia,” he says, singling out purple-white and purple-yellow as his favourites among the eight colours and mix available. A springtime crop, it’s among the first to flower in landscape and lasts for about six weeks. Zone 3.

4. Echinacea Sombrero Poco (Darwin Perennials): With the original Echinacea Sombrero series now grown to 14 different colours, Darwin started a spin-off series called ‘Poco’ meaning small. “These very compact echinacea have a finished height of 16” tops, and that’s second or third year,” says Fifo. The first-year flowering series debuts with the bold, non-fading intensity of Poco Yellow. “The oldest flowers are just as bright as the newest flowers until they start to turn brown from age,” explains Fifo. In fact, the breeding team has identified the gene responsible for its non-fading trait and applied for a utility patent. An early to mid-summer landscape bloomer, Poco is suitable for summer to fall programs. Zone 4.

5. Super Ka-Pow Phlox (Darwin Perennials): This Phlox paniculata is Fifo’s favourite on this list. A supersized version of the more compact Ka-Pow series introduced a couple years ago, new Super Ka-Pow reaches upwards of 20 to 24” tall – perfect for 1.5 to 2-gallon containers. With tall phlox typically more susceptible to mildew, breeding on Super Ka-Pow has focused on tolerance to the disease with tremendous results. It’s also free-branching with supersized flowers, and a supersized habit, says Fifo. “Phlox breeding has been getting earlier and earlier. You’re seeing them flower around the end of June in landscape now,” which is where Super Ka-Pow fits in. Launching in white, pink, lavender and fuschia, the latter is Fifo’s favourite. Zone 4.

With limited greenhouse space, first-year flowering options can be a good choice for many, but overwintering still has its place. “Some growers prefer overwintering perennials, even if it may be first-year flowering,” says Steffi Hugo, perennial product manager at Syngenta Flowers. She adds that the practice can help fill out different sized containers depending on growers’ needs.

With perennials, Hugo emphasizes versatility and finding the right fit. Her top perennial recommendations include some that are early, in-between and end-of-season flowering, giving growers multiple opportunities to make changes, little by little.

“You can see a dozen different trial places and pictures, but your site is the one where it needs to work,” she says, drawing from her experience as a former grower. “You’ve got to see it in your own circumstances and your own environment, more than anything.”

Other trends she’s noticed include a growing emphasis on heat- and cold-tolerant traits, particularly with the unpredictability of the climate. On the retail side, Hugo urges garden centres to show the many benefits of perennials, particularly for pollinator, environment and human health.

6. Aubrieta hybrida Glacier: The newest addition to Syngenta’s Aubrieta portfolio, the Glacier series flowers in early spring about two to three weeks later than Aubrieta Axcent, lending versatility to a grower’s program. Its compact,

mounding habit makes it perfect for quarts and gallons. “This is one of those items that needs a solid vernalization period to build up some bulk,” says Hugo. “Start this late summer to give it some stability for that overwintering period.” The Glacier series debuts in three colours: Red, Violet and Sky Blue. Zone 6.

7. Phlox subulata GoldiPhlox: “Everybody loves a subulata phlox – it’s one of those perennial staples in many garden programs,” says Hugo. Though there are some ‘oldies but goodies’ still on the market, Hugo says GoldiPhlox is a much needed upgrade from older genetics and has delivered uniform flowering across colours in multiple trials. “Our top pick is Cherry, with its bright, vibrant deep pink colour.” Best suited for quarts and gallons, this versatile series fits into container gardens and perennial landscapes. Vernalization required, GoldiPhlox should be started late summer to early fall for early spring flowering. Zone 3.

8. Campanula Cariboo Forte Blue: The results of interspecific breeding, this first-year flowering campanula boasts earlier blooms with a strong, full habit. Suitable for quarts but with a preference for gallons, the variety lives up to the ‘Forte’ in its name with a fuller habit, stronger stand and large, showy flowers that campanula is known for. This selection is accentuated by its vibrant deep blue colouring and has displayed what Hugo describes as ‘true perennial strength’ in garden trials across the U.S. To satisfy its need for an obligate long-day

response, Hugo suggests starting on short days towards the end of the year, then transitioning to long days. Zone 5.

9. Campanula Spring Bell 2.0

Dark Blue: “The dark blue is very vibrant, very showy,” says Hugo of the latest addition to the Spring Bell 2.0 series. Created from interspecific breeding, Dark Blue offers a tidy, mounded habit with a multitude of blooms. Ideal for small to medium-sized containers, it’s a good option for growers looking to extend their range of sizes in campanula offerings. “[It’s] not only for perennial garden performance, but for pot crops as well,” she says, highlighting its versatility. Spring Bell 2.0 Dark Blue is first-year flowering, mirroring the timing of Cariboo Forte. Zone 5.

10. Helenium autumnale HayDay: “These are exciting new genetics,” says Hugo. “Everyone knows the classic prairie wildflower look, [but] HayDay forms a contained, well-mounded habit…great for production.” The new series debuts in five festive colours including classics Red, Orange and Yellow, as well as two bicolours Golden and Red, bringing warmth to the landscape. Its upright, mounded habit is well-suited for gallons and boasts a dense, branching habit. “It produces a multitude of blooms, which in turn [become] super pollinator attractants with those bright and vibrant colours,” says Hugo. “This is a really great addition to anyone’s perennial program.” First-year flowering, HayDay blooms from summer into fall. Zone 5.

DÜMMEN ORANGE

“People are looking for things that have a longer shelf-life,” says Jeff LaCourse, perennial product support for Dümmen Orange, North America. New genetics are offering longer bloom periods in a greater variety of colours. “We’re finally seeing the movement away from old grandmother plants in the garden, not necessarily away from that type of flower, but to new genetics that perform better with longer satisfaction.”

For LaCourse, seeing varieties that thrive in a multitude of zones brings immense joy, particularly when they flourish from Miami up to Winnipeg and on almost every continent. “We’re excited for the consumer when you know you have something that will return. It’s not going to be planted like an annual and not be there the next year.”

11. Aubrieta Rock On Purple:

Bred for the early spring season, Rock On Purple is the latest addition to this early flowering series of Aubrieta from Dümmen Orange and a member of the breeder’s alpine rock gardening umbrella ‘Fleur de Rock.’ It’s hardy, too, successfully overwintering in trials held in Portage la Prairie, 75 km west of Winnipeg, Man. “We’re extremely excited because most of the Aubrietas on the market do not overwinter,” says LaCourse. In contrast to the short-flowering windows of most Aubrietas, in-ground trials in Washington state recorded long flowering periods that extended until June and handled moisture very well. “Pansy culture fits

Aubrietas extremely well, so you want to grow them cool, not freezing at first… but they will bulk up through the fall.” Most growers transplant in September. Expect to see first flowers around mid- to late-February in B.C., mid-April in the Prairies. Zone 3

12. Leucanthemum Sweet Daisy Rebecca: Dümmen Orange’s Sweet Daisy collection houses a number of varieties with a wide array of traits, varying in size and habit. Rebecca is their newest addition – a fully double frill flower, differing from the traditional daisy-type petal. “The plant has a round, mounding habit, almost like a garden mum,” says LaCourse. Not only does it boast large double blooms, but the plant ‘buries the dead,’ hiding older flowers and lengthening its shelf-life at retail. “Double flowers tend to not abort and drop off, so…that’s an extremely good trait for fully double-type Shasta.” Flowering by mid-June at the latest, Rebecca’s long blooming period continues all the way to Fall. The chilling requirement is very low, allowing for spring transplant. Liners should be planted by the first of March to hit the June window. Zone 4.

13. Phlox Woodlander Series: Debuting in lilac, pink, rose and white, this breakthrough series is bred from an interspecific cross and named for its extreme versatility in growing environments. “There is nothing like it on the market,” says LaCourse. “It can be grown in full sun or as an understory beneath a tree and still flower, which is highly

unusual for phlox.” Woodlanders tend to take on a mounding habit in colder environments, but lean toward a trailing habit in areas with less light. This series blooms just as subulata fades, filling a gap between earlier and later flowering phlox. LaCourse recommends pansy culture for a shorter crop time. July cuttings can be transplanted in September for bulking in a cold frame environment. Zone 3.