Excelling

By Melhem Sawaya

The

BY DR. MICHAEL BROWNBRIDGE

BY CASSANDRA SMALLMAN

BY PETER MITHAM

Excelling

By Melhem Sawaya

The

BY DR. MICHAEL BROWNBRIDGE

BY CASSANDRA SMALLMAN

BY PETER MITHAM

When we started working on this issue, I knew automation was going to be exciting. But perennials? Google spit out results on ‘cannabis’. Go figure. So I picked up my next most trusty technological tool – the phone.

When asked about the most common problems associated with growing perennials, Jim Devereux of Green Fuse didn’t hesitate. “Getting them to bloom at the correct time of year,” he says. “One of the problems with leucanthemum for most people is they don’t bloom naturally until June, so the season’s already over by then.” As it turns out, pretty much all perennials have some sort of daylength requirement to initiate flowering – and they differ between varieties.

“So to get them into bloom,” he continues, “most growers have to use supplemental lighting to trick the plant.” This way, it’s in flower when people are in the mood to purchase. “It’s hard to sell something when you don’t have customers, and it’s even harder to sell a green plant.”

vernalization needed. “Our breeding takes roughly 20 weeks out of a grower’s production,” he says. For Canada, Devereux’s advice is to do multiple medium-sized crops. He schedules his leucanthemum to come on every two weeks, so deadheading is never needed.

But time isn’t the only savings. Labour and energy costs can be cut as well. Plus, Devereux’s First Light varieties are sterile, and bloom times don’t end when seed set begins as traditional genetics do. Given all the possible advantages, do growers still stick with older perennial varieties?

“Some of them are,” he says, because seed is cheaper than cuttings. But based on his experience, five extra months of labour is more expensive than the initial input costs. Growers who really stay on top of trials have all switched to first-year blooming, daylength-neutral varieties, he says.

Right now, Devereux has six to seven hundred leucanthemum waiting to be trialled. “I’ll be lucky to get one or two with the capabilities we want,” he says.

Consumers love perennials because of the value-add, but traditional perennials don’t make returns until the second year. How are breeders working to change that?

The new breeding on perennials within their program, and within others too, is to have them respond like annuals, but still zonehardy, Devereux explains. On an annualized schedule, his First Light leucanthemums can be grown like petunias – brought in around Jan/Feb, set on a 12- to 14-week schedule, and then finished. No

Rather than using radiation, Devereux and his team prefer oldschool population trials, looking for genetic anomalies and breeding for the right traits. “Sometimes you get it in the first cycle, sometimes you get it in the 20th cycle. We let Mother Nature dictate it, and you know you have a stable variety.”

At the end of the day, both perennials and automation are bringing fresh, new ideas to help alleviate issues of labour shortage and input costs. I guess there’s common ground between them after all. greenhousecanada.com

As of December 31, 2018, all foreign workers are required to provide biometrics information, including fingerprints and digital photograph to obtain entry into Canada.

The biometrics expansion will not impact the processing of Labour Market Impact Assessments (LMIA), however special measures have been put in place for 2019 to support employers through this transition.

LMIA applications are now being accepted for

primary agriculture employers requesting workers for January or February 2019. LMIAs for primary agriculture positions that begin in 2019 will be valid until December 15, 2019 or for six months, whichever is longer.

LMIAs can be submitted for Seasonal Primary Agricultural Worker Program (SAWP) positions that have multiple worker arrival dates; applications will need to be for the same position, wage and NOC code.

Source: Government of Canada

If attendees thought the bar was set high from last year’s CGC, this year’s Canadian Greenhouse Conference topped it.

Keeping up with the evolving sector, many topics were covered by the speakers’ programme, including berry production, vertical farming, cannabis, as well as artificial intelligence. Five concurrent speaker sessions were held each day. Many attendees echoed the same sentiment – choosing

just one session among so many concurrent ones proved to be a challenge. But for conference organizers, that’s a good problem to have.

Industry consultant and former University of Guelph faculty Dr. Theo Blom was recognized as ‘Volunteer of the Year’ for his many years of work on the CGC organizing committee. Allan van Staalduinen of Ball Hort was presented with a token of appreciation for chairing the CGC board

of directors.

The conference also recognized exhibitors who went the extra mile with their booths and displays. The Best Booth awards went to:

• Agrolux (Technology, 101-299 sq. ft.)

• C. Frensch Ltd. (Technology, under 100 sq. ft.)

• Dümmen Orange (Plant material, 300+ sq. ft.)

• Express seed (Plant material, under 100 sq. ft.)

• Paul Boers/Prins (Technology, 300+ sq. ft.)

• Stokes Seeds (Plant material, 101-300 sq. ft.)

As CGC executive coordinator Carol Pupo notes in this year’s show guide, “the 2019 planning begins the day after the 2018 show”.

Mark your calendars for CGC’s 40th anniversary conference, from October 9 to 10, 2019 in Niagara Falls. Visit greenhousecanada. com for photo coverage of this year’s event.

BY

Lotty’s Love is a cinnamon-scented rose with large, semidouble flowers that are a deep shade of mauve. The shrub is medium-sized with deep glossy green foliage. Minimal deadheading and pruning is required and its disease resistance makes this a perfect addition to any landscape. Zones 3 to 10. 0.9-1.1 m tall, 1.1-1.2 m wide, firsteditionsplants.com

Helenium autumnale Salud Series

Stunning summer-intofall garden flowers, their drought and heat tolerance hold up to the weather. Bloom months are July to September, perfect timing to catch late summer and fall sales. Helenium plants attract bees and butterflies but are typically resistant to deer and rabbits. Comes in Embers, Golden and Yellow. Well-branched and compact in size, they also look great

in containers. USDA zones 4a to 9a. 36-41 cm tall, 30-36 cm wide. darwinperennials.com

This Agastache from Green Fuse offers fantastically bright colours that will catch anyone’s attention. Not only is the Sunrise series hardy to zone 5, but they are also daylength neutral, self-branching and require zero cooling. Part of the First Light perennial collection. green-fuse.com

The Solanna series is known for first-year flowering with no bulking or vernalization requirements. New Solanna Bright Touch flowers exceptionally early, with blooms covering the plant as early as April – this perennial is ready for early sales. Wonderful in the garden on its own or in a combo. Good in quarts, best in gallons. Zones 5 to 9. danzigeronline.com

Part of the Beauties series, this first-year flowering dianthus from Dümmen Orange has a mounding habit with medium vigour. Recommended for 4 to 8 inch pots. USDA zones 4 to 6. 10-15 cm tall. dummenorange.com

Programmable like an annual for spring sales, this bold, vibrant new series requires minimal vernalization, allowing growers to dial-in production for sequential cropping and retail delivery. It offers excellent uniformity with narrow flowering windows across the entire series, ensuring bench-run sales. Zone 4. Upright habit. 36-61 cm tall, 30-51 cm wide. syngentaflowers-us.com

This Gentiana septemfida var. lagodechiana is a low-mounding, compact form of the popular alpine species “everyman’s gentian.” The wild botanical variety is a great rock garden plant in evenly moist soils and sturdy even in full bloom. Its clusters of blue to blue-purple trumpet-shaped, summery blossoms will have you dreaming of a deep clear alpine mountain lake. Bella flowers in its second summer and seed is available. jelitto.com

Many greenhouse growers in B.C. have implemented some form of mechanization, most commonly in the grading and packing process – but how safe is it for workers?

“There are always considerable risks when dealing with machines designed to make processes more efficient, and worker safety in any agricultural workplace must be a priority,” says Wendy Bennett, executive director of AgSafe BC, the health and safety association that works with the province’s agricultural employers, including greenhouse operators.

In British Columbia there are 61 greenhouse operations that employ approximately 3,500 workers.1 Worker-machine interaction generally occurs at the culling station. Employers are responsible for ensuring that all workers are fully trained in the safe use and operation of specific equipment, wear proper personal protective equipment (PPE), and are properly supervised.

ABOVE

Greenhouse worker safety should always be top of mind.

Bennett says they often advise and educate employers and workers about how to avoid serious worker injury when working with automated systems and machinery.

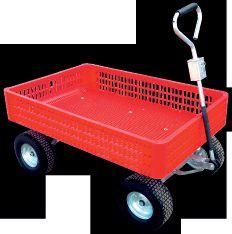

A conveyor system for sorting and packaging is a common example of automation found in greenhouse operations. When working with employers and site managers, AgSafe reviews safety procedures such as making sure that sprockets, gears and moving parts are properly guarded, and that the emergency stop button is highly visible and easily accessible.

Workers are also reminded of ensuring their own safety when working with automated equipment by having hair tied back, and not wearing any loose clothing with dangling strings, straps or ties that could get caught in a machine.

Fall is the time of year when many greenhouse growers in British Columbia conduct their cleanout –removing debris and soil, disinfecting equipment, and power washing surfaces.

During cleanout, work routines change, so a review of equipment operations and safety practices is important before the process begins.

If using a gas powered pressure washer, it is vital that appropriate ventilation and an exposure control plan are in place to ensure workers aren’t exposed to carbon monoxide. The exposure control plan should include checking the weather forecast for changes, such as an inversion, that may require increased ventilation to avoid carbon monoxide build-up.

Carbon monoxide limits the body’s ability to carry oxygen in the blood, potentially causing health problems and possibly death. The gas is especially dangerous because it has no colour, odour or taste.

Falls are also a risk for workers when using trolleys or picking carts. The cart can become unstable if moving too quickly or when there is an additional equipment load resulting in a loss of balance. Proper railing height and harness systems will help prevent falls.

Young and new workers are more at risk of injury due to inexperience and lack of hazard awareness. Provide proper equipment safety training and supervise their activity until they become competent.

Introducing automation to your greenhouse operation, especially where it involves worker interaction, requires a review and assessment of your workplace health and safety program. Before you begin to use any new piece of equipment, make sure that you have updated all pertinent safety information and protocols in your health and safety plan and that you have reviewed all changes with your team.

Be safe.

1 B.C. Greenhouse Growers’ Association Quick Facts 2017

AgSafe (formerly FARSHA) is the non-profit health and safety association for agricultural producers in British Columbia. For over 25 years AgSafe has provided site-specific safety education, consultation and resources to agricultural employers and associated industries in B.C. AgSafe also offers a Certificate of Recognition (COR) program for large and small employers. Visit agsafebc.ca or call 1-877-533-1789.

From seed to table, higher quality with better taste.

A better-quality product for the consumer. An integrated, innovative greenhouse solution for you. That’s what Syngenta provides through quality genetics and new variety innovations. Your customers, and their dinner tables, deserve nothing less than the very best.

To learn more about varieties from Syngenta, contact Plant Products at 519-326-9037 or info@plantproducts.com

GRETA CHIU | greenhousecanada.com

When it comes to the future of horticulture, the media is alive with buzz words like automation and artificial intelligence – but where do they fit in?

Automation usually has to do with a single process, says Adam Greenberg, CEO of iUNU (pronounced “you-knew”), a horticultural technology startup based in Seattle, WA. “If you’re automating a planting line, you’re using a very specific automated process.” He calls it ‘non-contextual’.

“That’s very different from AI (artificial intelligence), which is the concept of contextual learning,” continues Greenberg, who prefers the term machine learning, a subset of AI. “The concept is that over time not only does it get better and more honed, but it becomes more personalized and customized to each individual user. So the older the machine learning is in terms of timeline being used, the more valuable it becomes.” One would need to say ‘it looked like this when we harvested last time, please tell me when it happens again’, or, ‘notify me if something is way out of whack compared to the last 12 months’.

How do automation and AI fit together then? “A lot of automation replaces arms or legs,” Greenberg explains. AI often finds the issues in the operation. “It [saves] you from having to walk around and look at the majority of plants that are doing just fine.”

There’s a big misconception that AI is going to replace growers, he laughs. “Machine learning is something that augments, it’s something that helps growers be more effective, more efficient.”

Rodney Bierhuizen, agrees. “Maybe not replacing the grower, but giving the grower more insight and ability to use the data that we’re collecting.” The owner of Sunrise Greenhouses, Bierhuizen and his father Robert are known for their love of new technologies and their involvement in the development and testing process. He foresees fully automated greenhouses in about 20 years, which is good news for a sector facing a wave of retirement and a shortage of incoming labour. Machine learning could help soften the blow of losing 30 to 40 years of experience per grower, providing some continuity between generations.

Being a seasonal grower, Bierhuizen estimates that machine learning could take three years in their operation to come up to speed. “I say the same for myself. When I’m doing a new crop, it takes me three years to do a good job – never perfected, but to be happy with what I’m growing.”

Bierhuizen’s wholesale potted plant operation recently installed iUNU’s AI camera system known as LUNA. It combines machine learning, high-resolution 3D imagery and real-time information to continuously monitor and model individual plants throughout the day, including changes to canopy colour and individual plant health. Described as ‘Google Earth’ indoors, images of every plant can be monitored in real-time from a mobile device. The software itself, which is free to download, also allows the user to create, assign and track other tasks in the greenhouse.

“The argument can be made, yes it’s a very expensive system,” explains Bierhuizen, “but it’s something that we’re passionate about, and we think long-term that’s the way it’s headed.”

“The early adopters are going to [be] rewarded,” Greenberg points out. Seeing his father’s work as an orchid grower, Greenberg is all-too familiar with the time and physical constraints on growers. “It’s very much a reactive, a very-little-time-to-catch-yourbreath profession,” he continues, and machines can help with that.

How application methods could affect viability and coverage.

BY DR. MICHAEL BROWNBRIDGE

Let’s face it, chemicals have been around for some time now, and have allowed us to successfully manage pests through each growing season. But it’s telling, that we still have to battle the same suite of pests and diseases in greenhouse crops, only now these are resistant to many of the chemicals that have been used against them. While pesticides undeniably have a place in greenhouse production systems, our access to effective materials continues to decline. Many older products have been withdrawn owing to the environmental and health risks they pose and few new products are registered. Moreover, societal pressures are adding constraints as never before, with consumers pushing for sustainably-grown and pesticide-free produce and flowers.

We have witnessed a major transition away from conventional chemistry in the Canadian greenhouse industry over the past 10 to 15 years. Biological

ABOVE

control is now successfully implemented in a diverse variety of ornamental and vegetable crops. Microbial pesticides make up part of the biological mix and are ideal companion products in integrated pest management (IPM) where their unique mode of action brings value in resistance management. They contribute to the control of several challenging pests while being compatible with natural enemies.

Available commercial products are predominantly based on bacteria or fungi. Containing living microorganisms, they must be stored and applied in ways that preserve their viability. Dead organisms simply do not work! Several products contain microbes with the same or similar names, but that does not mean they all have the same spectrum or level of activity. It is important to select the right tool for the job, and apply it in the right place, at the right time, using the right method. Like other

Biopesticides are compatible with most biocontrol agents, such as predatory mites, which are widely used in greenhouse ornamentals.

biocontrol agents, they are only part of the solution. They are best used preventatively within an integrated strategy and in a crop system that supports their success. Most are applied by spraying or drenching, depending on the disease or pest being targeted.

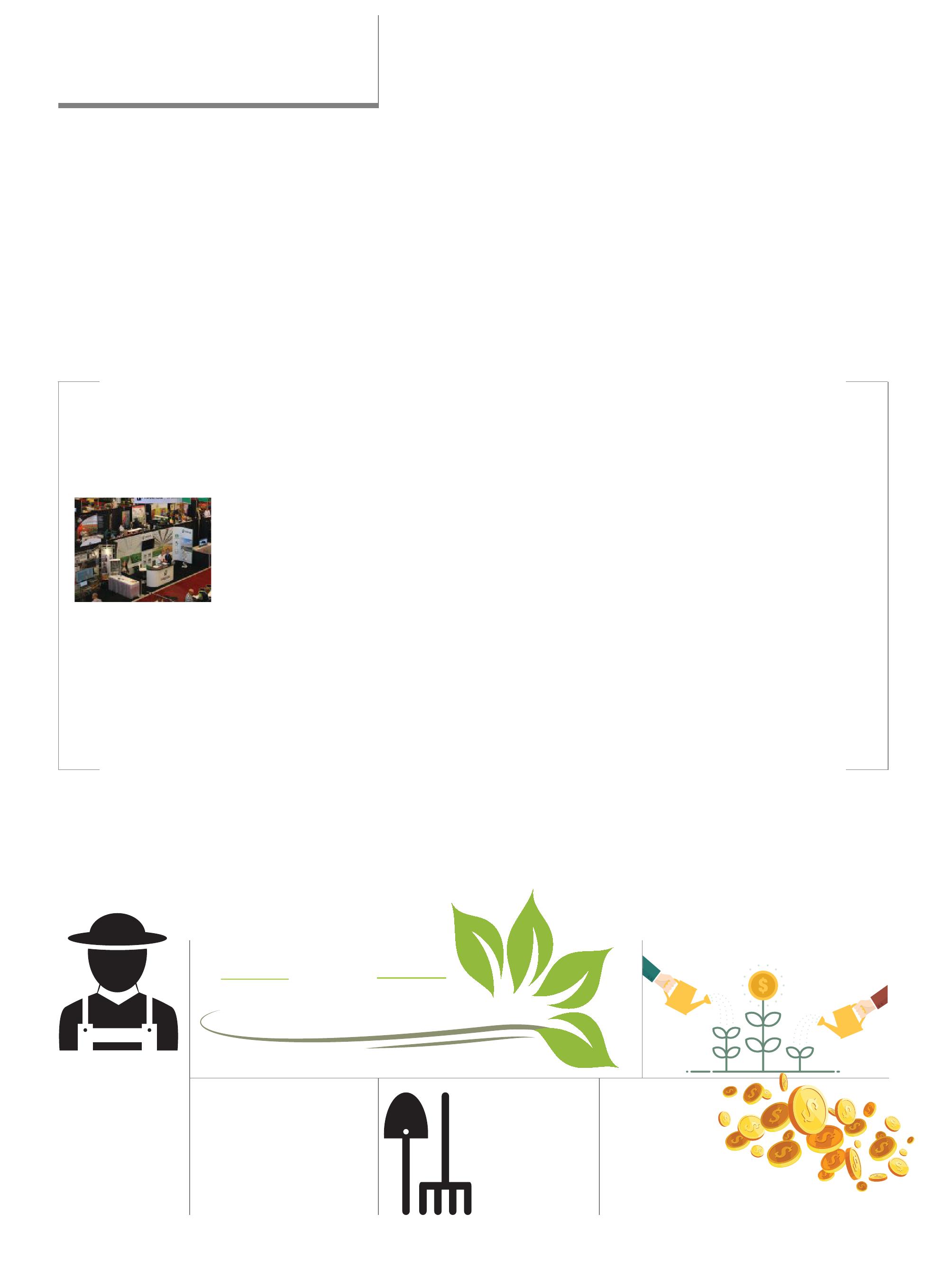

Nematodes – Even though they are not microbes, nematodes share many of the same characteristics. They need to be applied to the growing medium to manage the soil-dwelling stages of thrips and fungus gnats. Heavy sprays or drenches can be made using hydraulic spray equipment, or a Dosatron; some growers even apply nematodes through overhead irrigation systems and drip lines. Whichever method is used, it is important to remove all filters, use a large spray nozzle, and low spray pressure to ensure nematodes are viable when they reach the soil. Soil should be moist at application to allow nematodes to actively search for and parasitize host larvae.

Should nematodes be applied through the entire crop cycle? Application equipment and application strategy must go hand-in-hand. As the plant canopy grows, it acts as an umbrella, so over time fewer nematodes reach the soil with decreasing benefits from each application (Fig. 1). In a crop like chrysanthemum, many growers stop applying nematodes after four to six weeks.

Biofungicides for root diseases –Routinely used in plant propagation at the seedling/transplant stage, biofungicides like Rootshield, Cease, Rhapsody and Serenade can be applied as a drench. The substrate can be treated via low-pressure watering nozzles or an irrigation system. Early application allows organisms to establish on roots, protecting against diseases and aiding root development.

Foliar sprays – Generally, microbial pesticides (fungi and bacteria) are sprayed onto plants to control foliar diseases, insect and mites. Hydraulic sprayers have historically been the workhorse of the industry. They are relatively inexpensive, adaptable and time efficient when small areas have to be treated, and ideal for making spot treatments. All operate on much of the same principles, and require an applicator to direct the spray onto the plants. There is an art to using these sprayers properly as they typically produce large spray droplets and deliver high

Fig. 1. Nematode numbers are lower in the medium when plants are present (Plant) compared to an open pot (No plant). (Vineland data; not to be reproduced).

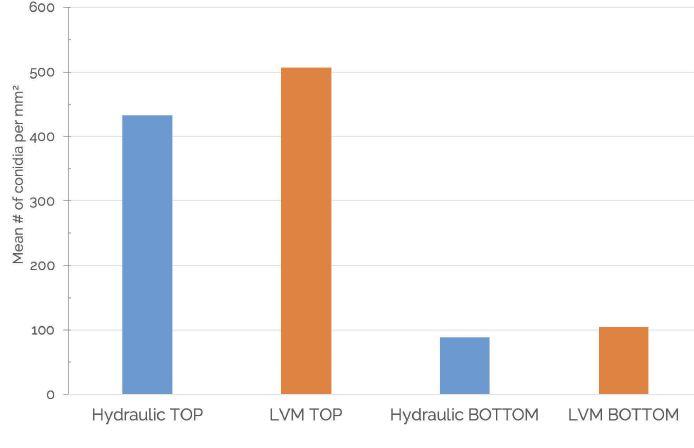

Fig. 2. Coverage on chrysanthemum leaves with Beauveria bassiana (BotaniGard 22WP) spores applied via a Dramm Autofog LVM sprayer or a Rittenhouse 200L hydraulic sprayer equipped with a twin head spray wand with a 4 hole (#45) swirl plate and a D4 disk on each head. Average coverage (from four replicate trials) of the top and bottom leaf surfaces. (Vineland data; not to be reproduced).

volumes of liquid; it is easy to over-apply to runoff, which wastes product and can negatively affect efficacy. As a result, many growers now use low-flow nozzles with their hydraulic systems to produce finer spray droplets and to obtain better leaf coverage.

Low volume mist (LVM) sprayers essentially fall into two categories: cold foggers and thermal foggers. An applicator does not directly target plants with a spray stream. Rather, crop coverage is achieved through movement of the ‘mist’ through the greenhouse and the plant canopy, a process that is assisted by horizontal air flow fans helping to circulate the minute

spray droplets throughout the greenhouse.

VIABILITY AND COVERAGE

Since microbial fungicides are living organisms, studies were conducted at Vineland Research and Innovation Centre to assess the effects of sprayers on biopesticide viability and coverage.

Hydraulic sprayer – The viability of Beauveria bassiana (BotaniGard 22WP) was unaffected when applied through three different types of hydraulic sprayers. In a commercial greenhouse trial, BotaniGard was applied to chrysanthemums using a Rittenhouse 200L sprayer equipped with

Spore Viability

Beauveria bassiana Bacillus subtilis

Hydraulic sprayers Unaffected Unaffected

AutoFog cold fogger Unaffected Unaffected

K-22 BIO PulsFOG thermal fogger90% reduction Unaffected

a twin head at the end of the spray wand, a four-hole (#45) swirl plate and a D4 disk on each head. On average, about four times the number of spores were deposited on the topside of leaves than the underside (430/mm2 vs. 90/mm2, respectively, see Fig. 2), high enough to infect and kill (in this case) thrips. The fine spray mist coated the leaves, avoiding runoff. The two other hydraulic sprayers tested were the Rittenhouse paired with a vertical spray boom and a Dramm BP-4 Battery Operated Backpack Sprayer.

LVM sprayers – LVM sprayers offer several advantages over manually operated systems. However, the mechanisms used to create the spray droplets involve high pressure (cold fogger), or heat and kinetic energy (thermal fogger), which may

damage or kill bacteria or fungi applied through them.

Using an Autofog (cold fogger) to apply BotaniGard 22WP in chrysanthemum, the topside of the leaves received about four times more spores than the underside, and spore viability was unaffected. Coverage was comparable to that obtained using the hydraulic sprayer. When tested on mini-roses, the Autofog again provided similar levels of leaf coverage on top and bottom surfaces. To determine whether this was sufficient to infect and kill thrips, foliage samples were collected from miniroses in both the sprayed area and in an adjacent unsprayed crop. Thrips larvae were released onto them in a contained assay system. After 10 days, thrips infection levels ranged from 30 to 95 per cent across the BotaniGard-sprayed samples. While

some thrips died (less than five per cent) on the untreated leaves, none showed symptoms of infection.

As the side-by-side trials in chrysanthemum demonstrated, comparable leaf coverage was obtained using the Autofog or Rittenhouse hydraulic sprayer (equipped as described before). Both methods are efficient (and there are pros and cons to each), delivering enough spores on upper and lower leaf surfaces to infect and kill thrips.

When applied through a K-22 BIO PulsFOG (thermal fogger) though, only about 10 per cent of the Beauveria spores survived; in contrast, Bacillus subtilis (Cease) spores were unaffected. While BIO PulsFOG sprayers are designed to apply heat-sensitive materials, spores are still briefly exposed to relatively high temperatures. Bacterial (Bacillus) spores are heat-tolerant whereas fungal Beauveria spores are not, which may explain the observed differences in survival.

Although many fungal spores were killed through the PulsFOG, given the high concentration in the spray tank, there are still probably sufficient living spores in the spray fog to infect pests. However, given

the alternatives, the PulsFOG may not be the most suitable choice of equipment for the application of fungal insecticides. To compare biofungicide coverage from different sprayers, Cease (B. subtilis) was applied in tomatoes using either a K22 BIO PulsFOG or a multi-nozzle vertical boom sprayer. The PulsFOG provided more consistent and better coverage of the topside of leaves, whereas underleaf coverage was better from the boom sprayer. However, owing to the density of the crop canopy and the absence of HAF fans in the greenhouse, PulsFOG coverage was probably compromised. With fan-assisted air movement in the crop, deposition on the underside could be improved.

This work led us to the following conclusions (Table 1):

1. Hydraulic sprayers and cold foggers are safe for BotaniGard and Cease (results not reported here)

2. The K-22 BIO PulsFOG is not wellsuited for the application of B. bassiana (BotaniGard)

3. Bacillus subtilis can be applied safely through the K-22 BIO PulsFOG

The value proposition presented by microbial biopesticides in greenhouse production lies in their efficacy and compatibility with other natural enemies, allowing crops to be managed biologically through the production cycle. Bottom line, you have to use them and apply them correctly to achieve success, and the right choice of equipment is critical to that success.

Acknowledgements: This research was supported in part by Growing Forward 2, and through Agriculture and Agri-Food Canada’s AgriInnovation Program: Industry-led Research and Development Stream for Project AIP-P216 ‘Improved Biocontrol Strategies for Canadian Greenhouse Horticulture’. Support and contributions from BioWorks Inc. and Dramm Corporation are also gratefully acknowledged. Special thanks to Taro Saito and Bernhardt Steinwender (Vineland), Westbrook Greenhouses, and to Dave Mambella, Ronald Audain and Lou Schenck of Schenck Farms and Greenhouses.

Michael Brownbridge, PhD, is the research director for horticultural production systems at Vineland Research and Innovation Centre.

At Fine Americas, we never stop maximizing your productivity. Now Concise – our powerful uniconazole PGR – is registered for Canada.

• Powerful control you can depend on.

• Broader scope and better control under high-temperature conditions for high vigor plants.

• For denser plants with more compact growth, darker green foliage and longer shelf life.

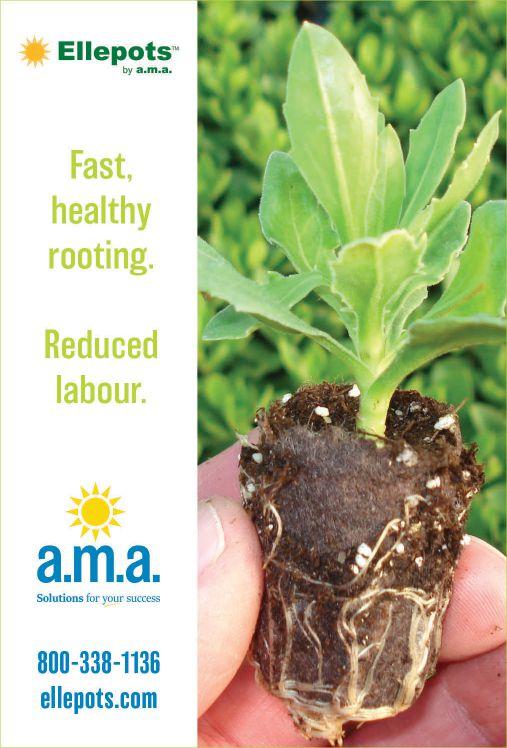

Growing media serves several functions when it comes to crop production. It serves as anchorage for plant roots, a reservoir of water, an air exchange system and nutrient holding/exchange system for plant roots. To get the most out of your growing medium, it starts by selecting the proper blend that works best for your specific requirements.

Growing Media Components: There are many components used in growing media to achieve specific physical properties as well as some chemical properties. Most growing media contain a base of Sphagnum peat moss, which has high water holding capacity but good air space. A growing medium with a high percentage of Sphagnum peat moss requires less frequent watering and the structure of the fiber provides aeration for a great environment to promote root growth. Perlite is added to increase air space, but also reduce water retention. The more perlite added, the higher the airspace and the further reduction of water retention. Vermiculite adds some minor nutrient retention and some water holding, granted that it is not as high as Sphagnum peat moss. Bark is added to reduce water retention and add weight to reduce pot toppling, which is important for crops grown outside where wind can be a problem. Coir fiber has similar physical properties to Sphagnum peat moss but does not require a wetting agent to wet with water; while coir chunks increase water retention over and above peat moss, while still providing high air porosity. Wood fiber is gaining popularity as a perlite substitute since it provides aeration, however it does not provide the same level of drainage as perlite.

Active Biological Ingredients: Although growing media components add value to adjust water retention and aeration, plants roots are also part of a biological system that consists of many types of microorganisms. All growing media have some natural occurring microorganisms, especially components that have gone through a composting process, such as compost, bark, etc. Although these diverse microorganisms can produce benefits, their populations can be variable. It is best to use a growing medium that has precise populations of active biological ingredients added, or they can be added while processing the growing medium or after planting. Various types of Bacillus, Streptomyces, Trichoderma, etc. are registered and proven to suppress root disease pathogens that can attack plant roots. Although there is a cost to add these biological additives, this is often offset by less cost of fungicide drenches, the labor to apply them and a reduction of plant loss

There are also growth promoting or stress reducing active biological ingredients such as mycorrhizal fungi, Bacillus, Pseudomonas, Rhizobium, etc. Most of these microorganisms are host specific, meaning that they colonize some but not all plants. Their main benefit is to help acquire nutrients and/ or water from the growing media to improve plant growth and reduce the effects of nutrient and water stress. This in turn helps plants grow at their optimal levels even if fertilized

improperly. Although most growers provide the water and nutrients needed by plants, these active biological ingredients provide help in case fertilizer is mixed improperly or injector maintenance is overdue. Also, active biological ingredients often continue to colonize plant roots even after transplanting into another container or outdoors in the garden. This improves the homeowner’s success with their plants and they are more likely to buy plants from the same source next year

Calibrachoa cuttings were rooted in the same growing media, except the tray on the right had mycorrhizal fungi incorporated. Notice the difference in growth. Those with mycorrhizal fungi are ready to transplant faster than those without.

Source: Premier Tech Horticulture.

Importance of Stock Rotation: When you receive your delivery of growing medium, use it as soon as possible to avoid any issues that may occur with aging. First, the wetting agent which helps the growing medium uniformly absorb water, can break down causing poor water absorption. Second, if the growing media has a starter fertilizer charge, it can decline with age from the natural occurring biological organisms that are found in the growing medium. Third, if the growing medium becomes wet, the limestone will activate causing the pH to rise to a high level (above 6.5) which can be problematic for crops. Therefore, check the manufacturing date and use peat-based growing medium within 9-12 months and peat-bark based growing medium within 6 months.

Some flats of salvia are green and were planted in new growing media while others are chlorotic and stunted due to older growing media. If plants were fertilized when planted, all plants would have been uniform and green.

Source: Premier Tech Horticulture.

It is best to remember the FIFO rule of “First In, First out” to maintain fresh stock and minimize any problems of aged growing medium by using the oldest growing medium first. If the growing medium is past the dates mentioned above, check for the three aging indicators mentioned. If the growing medium absorbs water slowly, apply a wetting agent to reinstate normal wetting ability. It is best to add wetting agent to the growing medium before filling pots. If containers have been filled, apply wetting agent with a fertilizer injector at an application rate of 300-600 ppm (depending on the product). It may take several passes to thoroughly saturate the growing medium within each container, but once this is done, wetting ability will be reinstated. Second, test the electrical conductivity of the unused growing medium. If the starter fertilizer is very low (less than 0.5 mmhos/cm), water in the crop with a complete watersoluble fertilizer such as 20-10-20, 17-5-17, etc. at a rate of 100-150 ppm nitrogen. Third, test the pH of the unused growing medium. If it is high (above 6.3), consider using it for geraniums, marigolds, New Guinea impatiens and other crops that prefer a higher growing medium pH.

Irrigation Water Quality: Water is the largest volume input applied to crops and it has a significant impact on the chemical properties of growing medium. Water influences the pH of the growing medium, however it is not the water pH that does this but the alkalinity, which is a measure of carbonates, bicarbonates and other elements. Think of alkalinity as the limestone content in water; the higher it is, the faster it can cause the pH of the growing medium to rise. This rise in growing medium pH can be stopped either by using an appropriate fertilizer or injecting acid into the irrigation water. In general, if the alkalinity of water is less than 200 ppm CaCO3, use of a “potentially acidic” fertilizer that is matched to the water alkalinity can prevent the pH of growing medium from rising. Above this, much of the excess alkalinity can be neutralized by injecting acid into the irrigation water

Watering: Growing medium performance is also tied to watering A growing medium that is watered too often and not allowed to dry out will have issues with root disease, algae growth on the media surface and more fungus gnat and shore flies. Improper watering also leads to uneven crop growth and poor root development. It is not the growing medium that causes these problems, but watering practices. The general rule is to water early in the day, apply thoroughly until water runs from

the bottom of the container, avoid frequent irrigations and let crops go into the evening on the dry side. For most peat-based growing medium, the color of the growing medium surface is a good indicator for when to water. When the surface is dark brown to black, it’s wet. When the growing medium dries down to a light brown to tan color, it’s time to water the crop

The color of the growing medium surface can be used to indicate when it is time to water. The surface of the growing medium in the parsley packs on the left are tan, dry and ready to water. The packs on the right are brown, moist and are not ready to be watered Source:

Growing medium is a tool for producing crops. It is best to choose the appropriate product that works best for your specific needs. However, keep in mind that the performance can be easily impacted by water quality, fertilizers used and cultural practices.

Troy Buechel Horticulture Specialist

Ed Bloodnick Director of Grower Services

2018/10/10

DISCOVER THE FULL EXTENT OF OUR LINE OF CUTTING-EDGE PRODUCTS.

Non-native plants can be just as attractive to pollinators.

BY DR. SARAH JANDRICIC, LAUREN VANDERLINGEN, CAITLIN MACDONALD AND RODGER TSCHANZ

In Greenhouse Canada’s August “New Varieties” edition, experts from garden centres reported that eco-friendly plants are a trend that’s here to stay, especially for the newer generation of gardeners. Topping the list for these millennial gardeners are plants that are considered “pollinator-friendly”.

Generally, “pollinator-friendly” means any plant that provide bees, flies, butterflies and other beneficial insects with readily available nectar (a sugar source) or pollen (protein) that helps sustain their populations. With all the stressors on pollinators these days – diminishing and fractured habitats, climate change, and ubiquitous pesticides – urban gardeners can provide native bees and other pollinators with a helping hand by planting high quality resources. As such, plants labelled as pollinator-friendly should continue to sell well in Ontario. A study by

ABOVE

our close neighbours in Michigan State, shows that many consumers are even willing to pay a premium for “bee-friendly” plants, especially for outdoor flowering plants.

So which plants should consumers – and therefore growers and garden centres – be choosing if they want to stay on top of these trends, and support Ontario’s pollinators?

The University of Guelph and the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) joined forces for a two-year study at the Guelph Trial Gardens (located at the Guelph Turfgrass Institute) to answer just this question. Undergraduate students Caitlin MacDonald and Lauren Vanderlingen patiently watched flowers for hours at a time, to determine which plants were most attractive to what sorts of pollinators. A visit from a pollinator was considered successful if the

A bumblebee visits the Guelph Garden Trials.

insect in question entered the centre of the flower and stayed there for a few seconds to gather nectar or pollen. They investigated both plants considered “native” to North America, as well as species which could be considered “exotic”, or non-native, with these broken up evenly into annuals and perennials, to determine if there were any major trends.

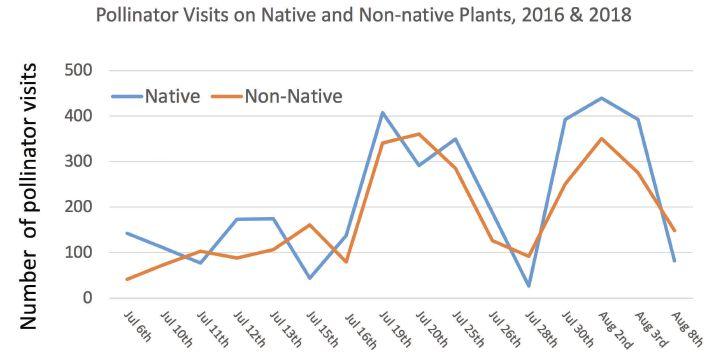

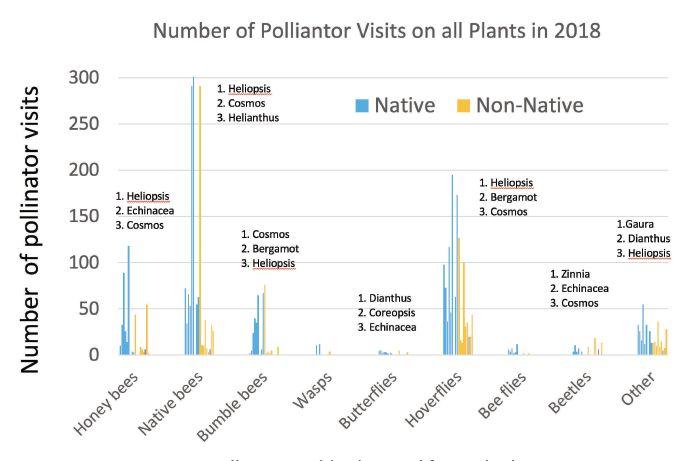

Over the two-year study, our students saw no difference in total abundance of pollinators on native versus non-native species of plants (Fig. 1). But, much of this was due to “stand-out” performers in each category (Fig. 2), i.e. plants that attracted hundreds of pollinators over their period of observation. Many of these were perennials, but there were quite a few annuals that attracted a plethora of pollinators, too.

In 2016, top-performing non-native plants were cosmos, Argyranthemum, and Sedum. These plants attracted an abundance of managed honey bees (Apis mellifera), bumble bees, as well as hover

flies (important pollinators, AND often natural predators of pests). Cosmos also attracted the highest numbers of native bees across the two years of our study, which included species of sweat bees, leaf cutter bees, small carpenter bees, and long-horned bees. These exotic plant species were also highly attractive to pollinators in 2018, along with dianthus, which attracted large, charismatic pollinators like butterflies and hawk moths in our studies.

As for native species, Heliopsis and Helianthus were favourites of managed honey bees and hoverflies in 2018 (Fig. 2). Cultivars of Echinacea (including Summer Sky, Cheyenne Spirit and Eccentric Yellow) were also unsurprising general favourites across both years, attracting a wide range of pollinators, including pollinating beetles. Other stand-out native plant species can be found in Table 1.

Given that all these plants have similar flowering times and were all attractive to

FIGURE 1

Total number of pollinators observed on native versus non-native plants over a two-year trial at the Guelph Trial Gardens.

We saw no trend in attractiveness of native plants over non-native plants (13 native plants studied, 10 non-native plants).

FIGURE 2

Looking at data by main pollinator group (guild), there was little difference between native and non-native species of plants when it came to attracting pollinators. Stand-out plant species for 2018 are listed.

pollinators in the peak of summer (see Fig. 1), retail markets could potentially produce a mixture of these native and non-native plants to be retailed as “pollinator-friendly” planters or seedling trays, as a value-added option.

Despite our results, the top 10 websites from a Google search of “pollinator-friendly plants, Ontario” generally promote native plant species only, like goldenrod, milkweed, and black-eyed susan, which are more commonly available as seed – not from your local grower or retail market. Although lists like these are doing their best to support our pollinators, they don’t help support Ontario’s greenhouse floriculture industry. Such lists also commonly focus heavily on perennials, and miss out on informing gardeners on which annuals they can purchase to add dimension and interest to their garden year to year, and still help out their bee friends.

To help bust the myth that only plants

Plant GenusCommon NamePlant Type Pollinators Attracted

Argyranthemum Marguerite daisyNon-native, perennialNative bees, hoverflies

Bergamot Bee balm Native, perennialBumble bees, hoverflies

Canna Canna Lily

Cosmos Cosmos

Dianthus Pinks

Non-native, annualWasps, native bees

Non-native, annualHoney bees, native bees, hoverflies

Non-native, perennialButterflies

Echinacea Coneflower Native, perennialHoney bees, butterflies, pollinating beetles, wasps

Helianthus Sunflower Native, perennialNative bees, hoverflies

Heliopsis Oxeye, False sunflowerNative, perennialHoney bees, native bees, bumble bees, hoverflies

Phlox Summer phlox Native, perennialHoney bees, butterflies, hawkmoths

Sedum Stonecrop

Zinnia Zinnia

TABLE 1

Non-native, perennialHoney bees

Non-native, annualPollinating beetles

Plants found to be the most attractive to Ontario pollinators at the Guelph Trial Gardens over the 2016 and 2018 seasons. Non-native plants are bolded.

native to Ontario are good for our pollinators, the information from our study was shared with members of the public and the Canadian Nursery and Landscape Association (CNLA) at the Guelph Trial Gardens Open House in August. Flowers Canada (Ontario), will also be updating their pollinator-friendly plant poster so consumers and avid gardeners know to include relevant non-native and annual plants in their gardens.

Lastly, don’t forget that “pollinator-friendly” also means producing the plants in a way that doesn’t hurt sensitive beneficial insects. This means avoiding the use of neonicotinoid

insecticides, like imidacloprid and acetamiprid as much as possible. If needed, plants should be drenched no later than five weeks before sale. Plants in flower should not be sprayed with any insecticide three weeks before shipping.

Sarah Jandricic, PhD, is the greenhouse floriculture pest management specialist for OMAFRA. Rodger Tschanz is the trial garden manager at the University of Guelph. Caitlin MacDonald and Lauren Vanderlingen were part of the Undergraduate Student Experiential Learning (USEL) Program through OMAFRA-UofG.

Practices to lower costs and elevate quality.

BY MELHEM SAWAYA

Easter lily production has declined in the last few years but it is still one of the top five potted crops in terms of sales. 10 million Easter lily bulbs were shipped this past season. In my opinion, the major drop in sales is due to the extra cost of production with minimal increase in selling price. Low profit margins lead to the lack of marketing programs to promote Easter lily sales, so many growers stop producing them and exposure to the lily crop dies down.

The purpose of this article is:

1. To point out to buyers – whether broker or chain store – that they should pay the

costs so growers can have the margin to grow this crop again. If higher volumes are sold, input costs will be stabilized because higher volumes lead to lower input costs.

2. To share a few pointers from my experience in growing this crop for 40 years. They may (or more likely will) increase the return on your investment, and you can look forward to growing a crop with lots of rejuvenated potential.

ABOVE Peter Van Beurden stands among his crop of Easter lilies at Westland Greenhouses. Even without fungicides, this lily crop has excellent roots.

The cultivar ‘Ace’ was the predominant choice between 1960 and 1970. Since 1980, ‘Nellie White’ has been the primary cultivar and continues to the present. Another option is new cultivar ‘Chilly White’, which has a smaller bulb circumference but can produce high bud counts.

Production-wise, Ace takes the longest time to produce in the greenhouse because it has more leaves to unfold but potentially more buds

than Nellie White. The new cultivar Chilly White take less time to produce with its smaller buds.

As with any genus, more and smaller flowers lead to faster production time compared to larger or double flowers of the same genus.

Flower induction – Flower induction for lilies occurs when daylengths are longer than night. In nature, it occurs in June. This can be overcome with a

cooling period of six weeks, placing moist bulbs at an optimum temperature of 6˚C – a process called vernalization. The reality is, vernalization can happen at any temperature less than 16˚C. Shipping temperatures should always be taken into consideration so overcooling does not occur. Lily bulbs should be shipped at temperatures 17 to 18˚C. Any temperatures above this will speed up sprouting. Overcooling can cause:

• Decr eases in leaf and flower number, as well as leaf length at the base

• Decr ease in time from emergence to flower

• Earlier and mor e uniform shoot emergence

• Incr ease in internode length

Vernalization can be done in four different ways:

• Naturally – done after the bulbs are planted and rooted in pots

• Controlled temperature forcing (CTF) – also done after the bulbs are planted and rooted, in pots or cases

• Interrupted – first partly cooled in cases, then planted and rooted, and then cooled again for the remainder of the cooling period

• Case-cooled

Pot-cooling is a much better way to go, mainly because your bud count will increase by one, on average.

Planting – Here are some key pointers during planting:

• Bulbs should be dipped in a fungicide for Rhizoctonia and an insecticide for bulb mites. Applications of fungicides and insecticides after planting will leave the media too wet, which will lead to more diseases and slower rooting.

• Peat moss from bulb packing should not be used for planting unless it is mixed well with the rest of the planting media.

• Do not pack the soil, and water so it is moistened well but not drowning. This is vital so the bulbs can get all the oxygen they need.

Fertilization – Watering practices determine the fertilizer concentration

Tuesday, November 20, 2018

10:00 am – 10:15 am

Overview of the trials (Emma Johnston, Jeffery’s Greenhouses) 10:15 am – 10:45 am

Process of stock and cuttings production (Dr. Allan Hammer, Dummen Orange)

10:45 am – 11:15 am

Cause and Prevention of Erwinia and other diseases ( Gary Vollmer, Selecta )

11:15 am – 11:30 am

Pooinnsettia cuttings dip proocedure ( D Debbie Palumbo –Saandders, Bio o Woorrks k ) 11:30 0 am – 11:45 4 am

Our experience with h Biollogical contrrol ( Albert Grimm, Jeffer e y’ y s Greeenhhoouses)

11:445 am m – 12: 2 00 pm Quuesti t on o s and comments 12:00 pm m – 12:30 pm Lunch h Provvided e 12:30 0 pm – 2::330 0 pm Tr T iaalls tour

Beeekkenkkampp, Berger Du D m mmen n orangge, S Selecta, Syngentta, a B Bio Works, Jefffery’s Greeenh n ouusees, Greenhouse Cannad a a, Focus Gree e nhouse Managgeemen e t. t J Jeffeery’ y s Gr G eenhousees Pl Plan a t 2 2411 Fourth A Av Jorddan, , Onnt. t , L0 L R 1SS0 Mel Sawaya a 5199 4277 84 8 40

to be used. Lilies need all the oxygen they can get, especially at the beginning until visible bud because the leaf mass is small. Light watering overhead with an EC of 2 dS/m is more than enough, so frequent watering is needed. Checking EC’s and PH is most important in avoiding root damage due to high salts. Lilies also likes PHs above 6.2 to avoid leaf scorch and to make calcium and magnesium more available to the plant. EC’s target is 1 using the ‘two parts water to one part soil’ method. Controlling soil EC can avoid the need for fungicide drenches.

Height control – There are many ways to control the height of lilies. The most important ones are better for plant quality, and include cultural practices, environmental control and chemical control.

Cultural practices include:

• The cooling method – potcooled lilies do not have that stretchy leg at emergence compared to case-cooling

• Plants should be forced at 16 to 17˚C for height control and better bud set

• When close to bud set, normally when stem roots are visible, dropping the temperature to around 10 to 12˚C will result in better bud set and will translate to an extra bud in general

• Low-volume watering at the beginning of forcing is essential to growth control

• Space the plants befor e visible bud and the thick canopy of leaves will keep the plants shorter

• High phosphorous fertilizer will also cause some stretch

Environmental factors include:

• Light levels – the higher the light intensity, the shorter the plants

• When cloudy, day temperature should stay lower for the whole day; this is not DIF (more later), just a lower temperature with low light

• Lower humidity is a big factor in having shorter plants and a vital aspect for calcium uptake by the plant

• Make sur e no incandescent light

bulbs are lit close by because this will increase the ratio of far red to red light and that will stretch the plants

• Closing the blackout curtains half an hour before sunset will block the far red and help in controlling height. Total black out is needed. Half functional blackout curtains will increase far red light

• DIF is the difference between daytime temperature and nighttime temperature. Warm nights and cool days will keep the plants shorter, while cool nights and warm days will stretch the plants. A few pointers for using DIF properly:

• Leaf expansion has to occur before DIF can work

• If day light intensity is lower than 400 fc, DIF will not work; that is why high light glass greenhouses are better for DIF

• A photoperiod of 13 hours; 13 hours of darkness is needed for DIF to work, that is one reason why greenhouses with blackout curtains work better

• I do not r ecommend temperature dips (by 15 degrees or more) in the mornings because many other negative side effects can take place. A dip is when we drop the morning temperatures to below 10˚C for a few hours

• Temperature to drop (by 3 to 4 degrees) in the morning as close to sunrise as possible

• The gr eater the difference between day and night temperatures, the greater the effect

Using chemicals for height control can reduce the quality of the plant and have negative effects:

• Gr eater chance of yellow leaves

• Hollow stems when Sumagic is used, which causes the lily stems to become weak

Fascination – Fascination is mainly GA4, GA7, and BA used to slow down or prevent yellowing of the bottom leaves of lilies.

One spray 3 to 5 cm above the soil

level will stop any yellowing of leaves. No need for two sprays because you will increase the chances of plant stretching. Some growers do it twice because they do not know if the first time was done right. It’s a much better idea to make sure Fascination is sprayed properly the first time.

Diseases – Lilies are prone to Rhizoctonia, Phytophthora and Pythium only when cultural practices are not followed properly. In the last 20 years, we have not applied any fungicides to the lily crops and the roots have been better than ever.

Insects – Aphids, spider mites and fungus gnats are very often seen on lilies, so an application to control these pests is almost a must.

I wrote this article because I know there is money to be made in growing Easter lilies if growers follow the right cultural practices and do not have to take a lot of extra correctional steps:

• Fungicide dr enches

• Moving plants

• Spraying growth regulators unnecessarily

• Shrinkage due to timing, speculated sales, quality and/or not managing space properly so you still can have a spring crop

In all my 40 years in the greenhouse business, I saw the best Easter lily crop this past Easter at Westland Greenhouses in Jordan, Ontario. This was not by chance, but by the commitment of the management team in doing everything that was required on time and correctly the first time around, so we did not have to do it a second time. Easter lilies are one of those crops that actually talk to you if you look and listen and do the things needed to be done on time.

What makes a great grower? 15 per cent is knowing what to do, 15 per cent is knowing how to do it, and 70 per cent is doing it on time.

Melhem Sawaya of Focus Greenhouse Management is a consultant and research coordinator to the horticultural industry. You can reach him by email at: mel@focusgreenhousemanagement.com

Think wholesale pricing and the impact of margin at retail.

BY CASSANDRA SMALLMAN

As a business owner, would you invest in plants that you knew would cost more to produce than the return? Without a compelling return on investment, the obvious answer is no, but there is a chance that you might be doing exactly that. In our last article, we explored how consumers attach value to a plant and how that should be considered when growers assign prices. Now it’s time to look at how the cost of production should affect the price as well.

How do you currently determine your wholesale pricing? Do you review your production costs year after year? Do you ask your customers what they charge at retail? There’s no magic formula that will work perfectly for all businesses, however there are some considerations that all business owners should be mindful of.

Pricing is a mathematical process that takes into account your costs and your margins. It’s an important step in ensuring you are operating a viable and sustainable business, and yet, instead of working through this process, many growers calculate their price based on what others charge. From equipment costs to fertilizer and everything in between, all of these factors should be taken into account when setting your price. Since the value you assign to the shipped end product has a direct impact on the health

of your business, it should be a reflection of all the costs you incur.

These product costs fall into fixed or variable production costs, which are familiar terms to most business owners. Your fixed costs for production include equipment, facility costs, and growers’ salaries. Variable costs are things like labour, supplies (fertilizer, seed, etc.), packaging, and shipping. Add all of these costs together to determine your total cost of production, which can then be used to calculate your breakeven point before adding your margin to each plant.

A similar approach can be taken to allocate fixed costs. A common approach in plant production is to calculate the total of your fixed costs and divide it by the total square feet of growing space. Assign each plant an approximate percentage based on how much growing space it occupies. That same percentage can be used to determine how much of your fixed cost should be assigned to each plant.

Here’s an example to help illustrate this process. ABC Greenhouse has 50,000 sq. ft. of growing space allocated to one of their varieties. Each individual plant requires 0.5 sq. ft. of space, so they can grow 100,000 plants at a time. Fixed costs (FC) for the greenhouse add up to $75,000 and incur an additional $90,000 in variable costs (VC) each

growing season. By doing some simple calculations (shown below), they’ve established that the FC for each plant is $0.75 and the VC is $0.90. That means the breakeven point (how much they need to charge to cover the costs of production) is $1.65 each. An industry average of 30 per cent margin is then applied, establishing a final wholesale price of $2.15 each.

Fixed costs per plant = (Total fixed cost) ÷ (Total growing space) × (Growing space per plant)

Sample calculation:

$75,000 ÷ 50,000 sq. ft. × 0.5 sq. ft./plant = $0.75/plant

Total plants = (Total growing space) ÷ (Growing space per plant)

Sample calculation:

50,000 sq. ft. ÷ 0.5 sq. ft./plant = 100,000 total plants

Variable costs per plant = (Total variable costs) ÷ (Total plants)

Sample calculation:

$90,000 ÷ 100,000 plants = $0.90/plant

Price per plant = (FC/plant) + (VC/plant) + 30% margin

Sample calculation:

$0.75/plant + $0.90/plant + $0.50/plant = $2.15/plant

HOW YOUR MARGIN RELATES TO THE RECOMMENDED RETAIL

Do you know how much customers are paying for your plants in-store? That’s a number that all wholesale greenhouse and nursery growers should know for all of their plants. The going retail price of your product provides you with a benchmark for how much you can charge your wholesale customers, while still providing them with a fair margin for themselves. It also gives you a key indicator for how well you’ve priced your plants. If the retail markup is unusually high, that may indicate an opportunity to raise your own margin as well. In contrast, a very low markup could mean that demand for your plants is low, and retailers are struggling to sell them. A lower markup from the grower could give the retailer enough incentive to continue committing shelf space to their plants.

The retailer will need to apply their own margin to the wholesale purchase price to keep their business operational as well, while ensuring that customers will pay their retail price. For a 100 per cent markup of $2.15, that puts the retail price at $4.30.

If the grower’s markup is already too high, retailers will stop ordering those plants or seek a further discount from the grower. That can be a difficult hurdle to overcome as a wholesaler because you are then taking a loss on the product you have already grown. Understanding how a consumer values a plant before investing in growing it will ensure that your wholesale business doesn’t take any unnecessary losses. A retailer will always protect their margin, and a consumer will seek the best prices, leaving you to determine whether a plant is worth growing, or if you can grow another species that offers

a better margin for everyone in the supply chain.

By considering all the factors discussed here, not only will you ensure your wholesale business’ profitability, but it will help to standardize the way retailers and wholesalers calculate pricing.

Cassandra Smallman is a marketing specialist for LinkGreen, an online ordering and supply chain technology company in the lawn and garden industry. For information about how LinkGreen could help your business, visit linkgreen.ca

heavy soils conditioning improvement used in potting soil mixes odorless mixes with peat moss

natural soil conditioner for lawns, gardens and plants improves soil aeration neutral PH

quantity and size available upon request

increases water and fertilizer retention in soil

preserves bulbs and roots germinating seeds and rooting cuttings improves potting and transplanting

natural soil conditioner for lawns, gardens and plants improves soil aeration neutral PH

Robotic scans pick up 400,000 data points on plant health and development.

BY PETER MITHAM

The human eye feeds 10 million bits per second to the brain, but when workers walk a greenhouse to check plants there’s only so much info they can take in, let alone absorb. Often, they’ll conduct spot checks and make decisions based on what they see.

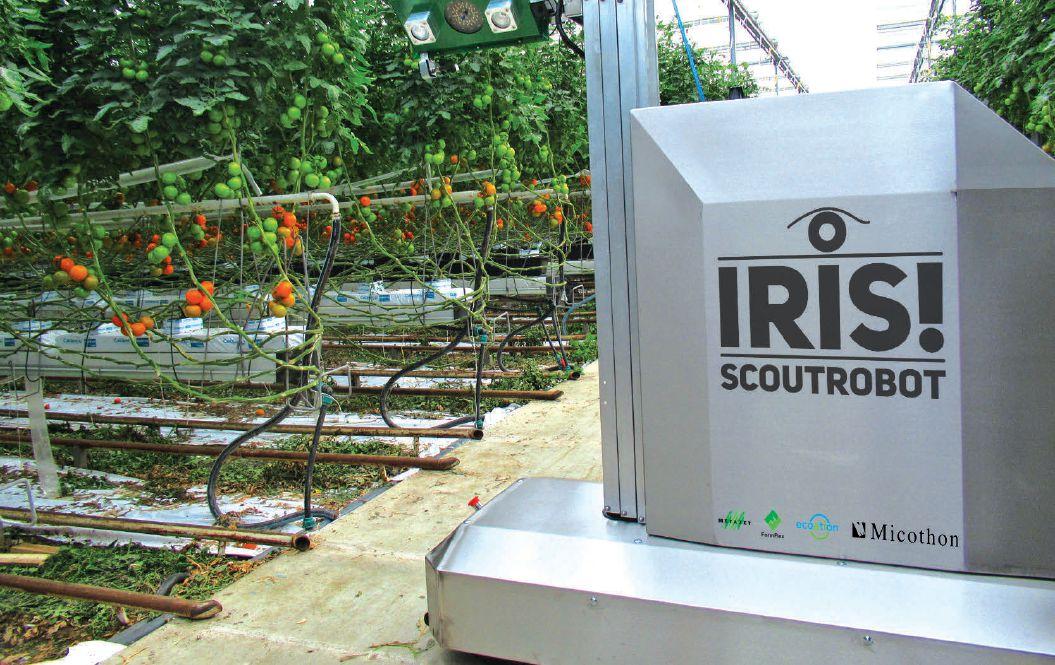

But a sensor developed by a North Vancouver company is giving growers the potential to collect and analyze data from every plant and make more accurate management decisions across the entire greenhouse. Known as ‘SABER’ – a Spanish verb meaning “to know,” or “to be aware” (distinct from Miresmailli’s own name, the Persian word for ‘patient’) – this sensor is at the core of their first product, a trolley-mounted robot named ‘IRIS!’ that runs autonomously on a greenhouse pipe rail.

Built with Dutch partners Metazet FormFlex and Micothon (creators of the mobility platform), IRIS! received the 2018 GreenTech Innovation Concept Award at the GreenTech

ABOVE

trade show in the Netherlands this past June.

“The philosophy of the technology is very simple. If you have good quality information, you can make better decisions,” says Saber Miresmailli, a former greenhouse grower who started Ecoation Innovative Solutions Inc. with his wife Maryam, an engineer, in his living room in 2010. “Usually, human scouts or workers select every other row, or one row per bay, to monitor. Our robot essentially goes [down] every single row, and it monitors and scans every single post in that row.”

In fact, the robot can automatically switch between rows and scan crops at two different heights – low to mid as well as mid to high –without human intervention. The result is a wealth of data rooted not just in observation but measurements of plant health based on subtle shifts in plant chemistry. Robotic scans of less than 50 milliseconds pick up 400,000 data points that indicate plant health, development

Using the SABER sensor, this trolley-mounted robot named IRIS! is able to scan and monitor individual plant health based on its chemical composition.

and – when correlated with a library of stress indicators – problems.

“We believe the most accurate source of information in any greenhouse is the plant itself,” Miresmailli explains. “The technology that we have assesses the chemical composition of the plant.”

Scans occur every four to five days, ensuring regular data collection. Data analysis takes place within 12 hours, accelerating grower response times when problems start to manifest.

“The pests and the disease don’t stop spreading during this time,” he says. “[So] we wanted to make sure the moment this information is collected, it’s available to the decision-maker.”

Scanning plants to determine health is nothing new, but the systems available today are a step beyond older technologies such as NDVI (Normalized Difference Vegetation Index). NDVI examines the absorption and reflection of solar radiation as an indicator of plant health, but Ecoation’s system focuses on plant chemistry. Its proprietary process uses various light-

based chemical analytical techniques that allow it to assess the displacement of multiple nutrients and their bioavailability.

While other technologies

simply measure NDVI or other indices, we create fingerprints of defensive secondary metabolites in plants that can help us gain a clearer understanding of the crop’s status and health, he explains. We discovered – by accident – that there is a small time delay between the two types of plant

responses, and we focus some of our specific measurements within that window, providing a clear snapshot of nutrient and defensive signal status, he says. “We get the true response of the plant.”

Combined with climatic information, such as temperature, moisture and carbon dioxide, the system is able to identify plants that are stressed as well as those that are thriving.

“The beauty of this particular approach and the wealth of the data that we collect is that it can actually be used beyond detecting stress,” Miresmailli says. “You can train this robot to detect the plants that are hurting, so you can go and treat them, or you can design this robot to identify your star plants, and then … try and elevate the rest of the plants to this level.”

The system’s capacity to assess plant health increases with each scan. This has allowed it to create models of how plants respond under specific conditions, allowing it to work on not only analyzing existing plants, but anticipating how environmental

conditions may affect plants in the future.

“In a virtual greenhouse, we can create multiple seasons, multiple angles of sun, multiple lights, multiple elevations and locations,” he says, along with using images and data from real plants. “This is the exact same technology that selfdriving cars are using.”

The technology has started to roll out in locations from Ontario to Mexico, in collaboration with operators such as Houweling’s and NatureFresh Farms. Other than IRIS!, the SABER sensor has also been incorporated into their recently unveiled scissor lift known as OKO. While growers use the lift for other tasks, the sensor conducts automated pest and disease scouting, yield measurements, pipe alignment and environmental monitoring of temperature, relative humidity, carbon dioxide and photosynthetically active radiation. The data is then fed into their interactive software, which will also allow for task management, labour tracking and storage of historical data on yields and crop health per square meter.

“Our software is like the Google street view of greenhouses,” says Miresmailli. “You can virtually walk inside your greenhouse, all the issues will pop on the screen, and you can then go and get more details about it.”

While autonomous greenhouses may be some ways off, the potential exists. Saber’s data can be fed to fertigation, lighting and other systems so that they can work in tandem with the plants to boost health and yields.

Greenhouse industry veteran Peter Cummings, who recently retired as COO of Houweling’s, says Ecoation has the potential to change how growers manage greenhouse crops.

On the one hand, it’s giving them the jump on disease by picking up on cues within the plants that aren’t visible to the naked eye.

“Some disease states in plants have been notoriously hard to detect for human scouts, so if you’re able to isolate a disease situation in a plant before it’s visible, it allows the grower to respond rapidly,” he says.

The faster the response, the more limited it is, too, because the issue is smaller and will typically require fewer materials to address. This saves growers money on labour, replanting, and boosts productivity, which adds revenue. But what really fascinates Cummings is the potential to address issues not just in Canada but also in California.

While greenhouses seem like closed systems, they’re not isolated from the surrounding environment. A greenhouse in a complex growing area – one with a wide variety of crops, something not uncommon in California – faces a greater range of pest and disease risks.

“You get down on that Oxnard plain where there’s so many more different crops out there, you’ve just got a lot more different insects to deal with,” he says. “You’re constantly being presented with this barrage of unknowns, so you get these disease states that are hard to detect.”

This means growers need to be aware of what’s going on, something the Saber sensor helps them do quickly.

Cummings says the next big step for the system will be

Left to right: Aaron Bickell (Viscon), Albert Pinto (FormFlex Canada Inc.), Saber Miresmailli (Ecoation) and Jean-Claude Lachance (Ecoation) with the scissor lift OKO.

yield forecasting. Regular scans of each plant opens the door to practices from initial blossom counts to optical analysis of ripening fruit. An accurate read on crop load and maturation date will help growers know what to promise buyers and how to price it.

“If there’s too much, you have to drop the price to clear it out. If you don’t have enough then you’ve got upset customers and you have to end up sourcing elsewhere to try and fill the gap,” Cummings says. “So the sales guys are always looking for more certainty on what’s in-bound, plus or minus.”

Miresmailli, meanwhile, is continuing to forge ahead. The company now employs approximately 20 people fulltime, recently completed a second round of financing, and is one of the United Nations’ partners in promoting their Sustainable Development Goals.

Ecoation’s high-profile investors include artificial intelligence entrepreneur Barney Pell, Jeff Mallett, the driving force behind Yahoo!, as well as Howard Balloch, former Canadian Ambassador in China. Associate cofounder of Singularity University and former R&D area manager at NASA, Pell sits on Ecoation’s board, and has connected the company with key figures at Amazon and other companies breaking ground in the area of machine learning. Their equally qualified advisory board consists of Casey Houweling of Houweling’s Tomatoes, Peter Quiring of NatureFresh Farms, Vijay Mital of Microsoft’s AI Architecture & Strategy, and Aaron Bickell of Viscon Group. A research partnership with Netherlandsbased Delphy will provide independent third-party evaluation of the technology.

Technology should keep growers in touch with their crop, Miresmailli says, not divorce them from what’s going on in the greenhouse. He believes the technology will enhance traceability, and give growers the information needed to tell buyers exactly how a crop was grown.

“The very knowledgeable, expert grower cannot be everywhere at once,” he says. “If we can bridge the gap, and if we can actually provide information on the status of all the plants in a way that’s as if he or she were walking the plants, they will be able to execute their knowledge or expertise over a broader area.”

CLASSIFIED RATES: Minimum order $75.00 or 84¢ per word, word ads must be pre-paid. CLASSIFIED DISPLAYS: $72.00 per column inch, or $5.14 per agate line. GENERAL INFORMATION: Payment must accompany order. Copy required by the 1st of the month preceding publication. All advertising copy subject to the approval of the publisher. Send order and remittance to: Classified Dept., Greenhouse Canada, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

GARY JONES | Gary.Jones@kpu.ca

Back in the ‘60s, ‘they’ thought there was such a rapid change in technology happening that ‘they’ feared a dramatic change in the workplace. Governments predicted that people would have to accept 22-hour work weeks, 3-day work weeks or retirement at 36. It hasn’t quite panned out, has it?

If I was in any doubt that our labour supply was in crisis, my radio alarm woke me with news this week. Vancouver’s NEWS 1130 cited a new Business Development Bank of Canada (BDC) report that labour shortages are being felt in many job sectors and that the situation “is likely to last at least a decade”. BDC chief economist Pierre Cléroux is quoted as saying that “because of the aging population, it is getting much more difficult to recruit people.”1 ... “The study found just under 40 per cent of Canadian small and mid-sized businesses are already having difficulty finding new employees, which means they’re forced to refuse orders or delay deliveries.”2

Of course this is really non-news to horticulture: we’ve known this for at least the past decade, probably much longer. But now that it’s hit other industries (hospitality, retail, manufacturing, construction), it’s now news-worthy. For horticulture in particular, this isn’t helped by recent increases in minimum wages across all provinces (Greenhouse Canada, p. 26, June 2018).

The BC Landscape and Nursery Association (BCLNA) has been leading a five to eight year Labour Market Information Study. Phase 2 has just been com-

to build a strong Phase 3 (‘Strategy Development Proposal’) which will take 12-18 months to develop after which will come piloting of the resulting program.”4

Back to the BDC. “You might see more and more technology because one way to face this problem, companies will invest in technology to reduce their need for workers,” says Cléroux.2

Again, not news to us. BCLNA states that “With technological advancement, automation in horticulture can bring a meaningful solution to the chronic labour shortage.” But, the BCLNA report also goes on to say, “Many owner/operators currently do not see automation as a viable solution, and as a result need support in exploring the potential value of automation.”3

That said, every day there are reports of ever more astounding automation innovations. HortiDaily.com reports “Sweet pepper harvesting robot close to the finish line.”5 How will this high-tech machinery and fully autonomous greenhouses affect the workplace? Robert Grootscholte, general director of 4Evergreen says, “I am very curious how young people think about autonomous cultivation, in which the computer reads the plant by using big data, and in which the greenhouse becomes completely self-regulating.”6

Not everyone will want (or be able) to make these ... investments

pleted. Some key data makes for interesting reading, for example:

• “Across Canada and BC, the agriculture-horticulture sector is expected to show significant growth”

• “BC’s agriculture sector employed 40,200, with … 6,200 workers in greenhouse and 3,620 workers in nursery operations”

• “The greenhouse and nursery sector in BC employs over half (54%) of its workers on a seasonal basis

• “...unskilled labour makes up 90% of the workforce.”3

“This Final Report is being followed up with industry and other stakeholders, such as DIVERSEcity, being part of the discussion. The purpose is to review the report and consider the recommendations

Of course, such technology comes at a cost. “As always, the financial investment in technology is significant.”3 Not everyone will want (or be able) to make these types of investments, even if they pay off in the long term, as such investments often help reduce worker downtime by alleviating physical demands on the body and repetitive injury issues. If nothing else, I at least know one thing – it sure is difficult to predict the future. Last time I checked, most people were not retiring at 36.

1 Business Development Bank of Canada; 2 Druker and Wong, News 1130 Sept 5 2018; 3 BCLNA “BC Agriculture-Horticulture and Landscape-Horticulture sectors Labour Market Information Study.” Phase II, Final Report; 4 Hedy Dyck, BCLNA; 5 Wageningen University, HortiDaily 5 Sept 2018; 6 HortiDaily, Sept 5 2018.

Gary Jones is co-chair of horticulture at Kwantlen Polytechnic University, Langley, BC. He sits on several industry committees and welcomes comments at Gary.Jones@kpu.ca.