growth Alberta Greenhouse Growers Association celebrates four decades of connection, advocacy and change.

BY GRETA CHIU

BY MICHAEL VAN DEN HOEK

PETER MITHAM

growth Alberta Greenhouse Growers Association celebrates four decades of connection, advocacy and change.

BY GRETA CHIU

BY MICHAEL VAN DEN HOEK

PETER MITHAM

It’s been a year since our first print issue during this COVID era. What’s changed?

Judging by the state of the industry report from our January edition, COVID has dominated much of the greenhouse sector’s priorities this past year.

At the Flowers Canada (Ontario) townhall this past March, invited speaker Brett House of Scotiabank Economics took participants through some projections.

From his analysis, it seems that Ontario never fully contained the second COVID wave. And now the province is again in lockdown, but differing from last year, garden centres are allowed to open with 25 per cent capacity.

House also anticipated a strong recovery for the Canadian economy. His data showed an increase in household savings and expects consumers to use it for purchases.

“There’s little interest to pay down debt when interest rates are so low,” he said, predicting that the Bank of Canada may start to raise interest

FCO conducted a survey among floriculture operations in Ontario within a few short months, and presented some key findings.

They found that most farms have enacted some form of automation. Much of it already targets key COVID-risk areas, such as planting and packaging, and 60 per cent of respondents felt it’s helped prevent COVID trasmission in some way. On average, “farms are spending between 2.4 to 6 per cent of their annual revenue on automation, or $20-$49 million across the sector,” according to the presentation.

The top reason for adopting automation was for increased productivity, alongside labour and product quality. Financial barriers were cited as the greatest hurdle to adoption. With $300,000 being the average cost of automation, financial subsidies from current cost-matching programs need improvement.

Interestingly, while additional workers and higher investments in automation each seemed to correlate with increases in productivity,

The survey found that most farms had enacted some automation.

rates at the end of 2022.

In terms of the Canadian dollar, House isn’t expecting any dramatic changes. Driven mainly by oil prices, it’s more or less moving sideways with some short-term volatility.

As economic recovery continues, he doesn’t expect taxes to rise immediately, “but there will almost certainly be changes over the next three years.”

During the townhall, FCO’s Executive Director Andrew Morse also provided updates on a project that explored opportunities in automation and mechanization for reducing the risk of COVID-19 transmission.

generally “farms that [invested] more in automation [did] not see decreases in their workforce.”

Which suggests that automation seems to be a valid way to improve productivity. But as a way to reduce labour? Perhaps less so, and it makes sense. As Morse points out, good employees are hard to find. While incentivizing to automate for COVID may not necessarily be the solution, automation offers a way to grow operational productivity and the sector as a whole.

Visit flowerscanadagrowers.com for complete reports from the townhall.

DLI HORTI-Series 1000W DE HPS

Extra Low-Profile Housing

Less Daylight Interception

Improved Reflector Superior Light Spread & Reflection

Improved Heatsink

Increased Driver Efficiency

Easy Connection & Disconnection

Gore-Tex Plug

Ventilation Plug Wieland Quick Connect

LED indicator

Status & Error Diagnostics

Time for an upgrade?

DLI provides a total grow light solution for both professional greenhouse horticulture and indoor applications. Our experienced team is more than happy to assist with a project specific lighting plan, showing the best suitable lighting solution for your crop and your company.

DLI DIODE-Series LED TopLighting

High Output

High Efficient

Integrated electronics

Intelligent Auto-Voltage Ballast

Light weight

Lowest weight / performance ratio

OUR CORE VALUES

RESEARCH & DEVELOPMENT

CONSTANT IMPROVEMENT

Flat smooth surface

No dirt accumulation

Venturi effect

For optimal cooling

Real Optic For extra light penetration

DelFrescoPure has announced a 25-acre expansion. This first phase of their planned expansion is expected to be in full production by September 2021 to fulfill marketplace demands for Ontario greenhouse-grown tomatoes and strawberries, set for 2021-2022 winter production.

“With the demand for locally grown Ontario greenhouse tomatoes, DelFrescoPure decided to leverage the demand with expansion plans. We’re

planning three phases to keep up with consumer demand for tomatoes and strawberries,” says Carl Mastronardi, president of Del Fresco Produce Ltd.

The expansion features energy curtains and grow lights to provide over three quarters of a half million square-foot controlled microclimate environment for growing tomatoes.

Details on phase two and phase three expansions have not yet been released. Source: DelFrescoPure

Productions Horticoles Demers is expected to more than double its output with the construction of a new, 15-hectare greenhouse in Lévis, Que. Tomatoes, cucumbers, sweet peppers and eggplant will be grown year-round.

“This expansion will help us better meet the needs of the province’s distribution network while reducing our

carbon footprint through proximity to markets, and to further meet the public’s appetite for local products by offering a wider variety of fruits and vegetables,” says Jacques Demers, president and CEO. The new $70M facility is projected to become one of the largest in Que., and will create more than 150 new jobs, adding to 300

An upcoming webinar on May 26, 2021 will explore three on-going projects at the University of Windsor that aim to minimize energy use in greenhouses.

The first will examine the most efficient way to provide plants with an optimum growing environment. This novel growth-climate energy model links the environment surrounding the individual plant to the crop canopy and to the building envelope.

The second project aims to help enable a five-fold expansion of the Leamington-Kingsville greenhouse region, underpinned by the development of smart low-carbon distributed energy resource networks. The final project leverages 3D printing to develop radically new building envelopes for next-generation greenhouses custom-tailored for remote regions. Dr. Rupp Carriveau of the University of Windsor will be sharing highlights from his group’s work. Register at greenhousecanada.com/webinars

existing employees.

The additional acreage is expected to increase the producer’s annual output from 7,500 to 17,500 tons.

Combined, the existing Drummondville and planned Lévis facilities will cover a total of 28 hectares.

DEMERS is one of the largest greenhouse companies to be 100-per cent Quebecowned.

Once the greenhouse complex begins its operations, the Québec Department of Agriculture, Fisheries and Food will pay a subsidy of up to $23.1M in the form of an electricity rebate to reduce the company’s operating costs during the 2022 to 2030 period.

Source: Productions Horticoles Demers

Trends on Pinterest Canada

• “Cottagecore Garden” – 39x more

• “Small vegetable gardens” – 31x more

• “Farm Garden” – 9x more

• “Whimsical Garden” – 8x more

• “DIY Garden Boxes” – 3x more

• “Small flower garden ideas” – 3x more

• “Garden planning layout” – 2x more

• “Perennial Gardens” – 1.8x more

• “Interior Garden” – 1.6x more

• “DIY herb garden outdoor” – 1.25x more

Nova Scotia’s provincial development agency, Perennia, hired a dedicated protected crop specialist last June to support the growing sector.

“It is exciting to see the recognition for greenhouse growing in Nova Scotia, and I’m really looking forward to developing the program,” says Talia Plaskett, who stepped into the newly created role. She currently oversees all crops grown under cover, including flowers, vegetables, berries and cannabis, produced in structures ranging from low tunnels to complete indoor grow facilities.

No stranger to greenhouses, the University of Guelph graduate previously worked at Vineland Research and Innovation Centre in Ont., assisting in plant pathology projects before becoming a senior research technician on their vegetable breeding team.

While the protected agriculture sector in Nova Scotia serves a smaller population compared to other greenhouse-dense provinces, there are many similarities in evolving technological trends.

“We are seeing increased interest in vertical farming and container farms and the adoption of lighting,” says Plaskett. She also notes a growing interest in moving from soil into soilless substrate and maximizing inputs. “The producers here have noticed climatic changes in their lifetimes, and the adoption of a more reliable production system is really on the forefront of everyone’s minds.”

Similar to other provinces, energy costs and labour are two key challenges facing producers.

“Although land costs are cheaper compared to other areas across Canada, the cost to keep a space heated and lit is just not feasible for a lot of people,” says

Plaskett. This has limited growers’ abilities to expand. “Another challenge, like most places, is labour. I think the promise of year-round employment that can accompany greenhouse growing, is more appealing than short seasonal positions that leave you looking for work multiple times a year,” she adds. “Hopefully this is something we can work towards over time.”

Plaskett hopes to increase the adoption of protected production in the province. To achieve this, she’s developing resources that will help new growers transition to protected agriculture and help existing growers adopt new technology.

“The shift from field production into a structure is a big one, as is the switch from soil to substrate, as is the addition of lights into a grow space!” she says.

“The more support producers have going through those growing pains, the more likely they are to undertake a big investment.”

Plaskett is currently involved in a pilot project to produce soilless long cane raspberry under cover. Other long-term goals include maximizing yearround production and reducing energy costs. “We do have producers that are working throughout the year, but maximizing this production and reducing the amount of food we need to bring in from elsewhere would be great for the economy and for increasing food security.”

What she’d like to see, is a province-wide initiative for adopting climate-friendly practices and energy sources. “It is no secret that we are living unsustainably, and seeing a serious investment into green energy and a focus on efficient growing practices would be huge.”

The National Garden Bureau (NGB) has added one more category to its “Year of” program for 2022: Houseplants.

“More home offices equals the need for more houseplants,” states the press release.

“With National Garden Bureau’s expanding member base and more members offering houseplants, it’s natural to add this category to the long-established

According to the nonprofit organization promoting gardening in North America, houseplant sales were booming before the COVID pandemic and they are in even greater demand now.

“Year of” program.”

For 2022, the houseplant class will be Peperomia.

The other chosen crops (and their categories) for 2022 are Verbena (annual); Gladiolus (bulb); Salad Greens (edible); Lilac (flowering shrub); and Phlox (perennial).

The “Year of” program

chooses crops specifically for the North American market that are easy to grow, genetically diverse, and with lots of new breeding to showcase. Consumer publicity for the 2022 “Year of” crops will begin in January 2022.

Source: National Garden Bureau

With nine colours for the 2021-2022 season, Karmas are specifically bred for cut flower production. The collection offers a mix of flower types with beautiful, vibrant blooms on strong, sturdy stems. Karmas can be harvested at a tighter bud stage for longer vase life. Liners, produced from vegetative cuttings, are available as a reliable, virus-free alternative to tubers. Suited for raised beds in the field or high tunnels. Stem length: 38-46 cm (in field), taller in tunnels.

syngentaflowers-us.com

A new variety for 2021, Bon Dia stands out with its rich colour and good growing habits. The semi-double blooms of Bon Dia belong in the purple or hot pink standard Gerbera variety with average stem length. It is said to offer extremely high production. Flower diameter: 10-12 cm. Stem length: 60 cm. Vase life: 15-17 days. hilverdaflorist.com

A new introduction for 2022, Germini Everton offers quality flowers and good production, all topped with an attractive pink colour combination. This variety is currently in trials with Canadian gerbera growers. Stem length: 50-60 cm. Flower diameter: 7-9 cm. Vase life: 16-18 days. dummenorangena.com

New for 2021, this seedpropagated Spanish lavender is said to be the first ever to offer repeat flowering. Its vigorous habit produces large high-quality flowers with purple flags on top. No vernalization required, first-year flowering.

Stem length: 36-51 cm.

Vase life: 5-7 days. syngentaflowers-us.com

This seed-propagated Antirrhinum majus brings a key colour to the dark pink/rose category in line with newer breeding in the Potomac series. A great match to the Pink, this new addition replaces Rose with a more uniform flowering

Celosia Act Diva has a special copper red colour that complements trendy earthy tones. Offering high production and uniformity, the Celosia Act series is a market leader in Europe with its voluminous flower combs; bright colours; tall, sturdy, unbranched stems and long vase life. The series is said to be more

A great option for summer and fall cut flower programs, Xochi is said to deliver stronger stems and richer colours than competing varieties. Xochi means “flower” or “princess of flowers” and is a shortened version of Xochitl, an ancient Aztec word. Propagated from seed, Xochi offers the uniformity, good shipabil-

variety and improved bud taper. Best for long days, high light and temperatures greater than 16°C. Suited for greenhouses and high tunnels. Density: 106128 plants per m2. Stem length: 99-152 cm. Vase life: 7-10 days. bloomstudios.com

resistant to diseases such as Botrytis and Fusarium. By planting in the greenhouse from early spring (even earlier with additional lighting) until late summer and with a cultivation period of eight to 13 weeks, growers can harvest from spring to late autumn. Stem length: 80-120 cm. Density: 40-56 per m². evanthia.nl

ity and durability to meet the increasing consumer demand for Dia de los Muertos and Halloween celebrations; good for bouquets and grower bunches. Suited for high tunnels and field. 80-100 plants per m2

Stem length: 61-91cm.

Flower size: 8-10cm. Vase life: 10+ days. bloomstudios.com

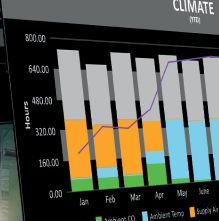

Grodan presents the fully redesigned e-Gro, the ultimate platform to support your knowledge, experience and growing strategy with real-time insights and smart recommendations based on root zone, climate, crop and harvest data. Anywhere, anytime and on any device.

The more you know, the better you grow.

Relevant data from various sources in your greenhouse is displayed together clearly in a single place, in real-time.

Smart recommendations help you optimize your irrigation strategy and guide your crop to the desired balance.

Maximize visibility and control

e-Gro is a web-based application, and is available on all devices, enabling remote access to your greenhouse data anywhere, at any time.

Don’t take just our word for it, try it for yourself. Contact us today to set up your free e-Gro demo and in-house trial: www.grodan.com/e-Gro

Organic fruits and vegetables accounted for approximately three per cent of total horticultural crops grown in Ontario in 2018, according to a survey from COTA and Statistics Canada. This is a slightly higher percentage of organic than for other types of crops. As that demand and total organic acreage continues to increase, Canada’s organic standards continue to evolve with greenhouse growers moving

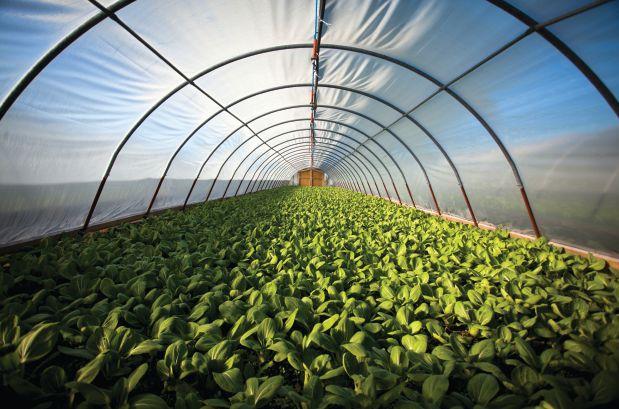

ABOVE

The latest revisions to the Canadian Organic Standards sought to better define greenhouse structures and soil requirements.

towards greener production techniques.

On December 11, 2020, the Canadian General Standards Board revised and published the 2020 Canadian Organic Standards (COS) after a thorough review of proposed changes by the Organic Standards Technical Committees. From this date of publication, all operators have one year to comply with the revised clauses of the 2020 COS.

There were some notable changes that affected crops being produced in greenhouse structures.

Previously known as “Greenhouse Crops,” clause 7.5 of the COS is now known as “Crops Grown in Structures or Containers.” A revised introduction specifies what types of production are and are not covered by this clause. The intention is to make clear distinctions between crops grown in simple structures or those intended for season extension or pest protection, and those which involve production which limits root contact to native soil such as container growing or production which uses supplemental lighting, heating or CO2 enrichment.

Further additions were made in sections 7.5.2.1 - 7.5.9 primarily concerned with defining soil and

setting minimum soil requirements for crops grown in containers.

Organic agriculture is based on growing plants in living soil, which supplies the bulk of the nutrients and provides a habitat for organic soil life. Therefore, some changes were made to the COS to ensure that crops grown in containers and season extension structures are not being grown in “quasi-hydroponic systems,” and where supplemental heat, light, or CO2 are not provided. These changes require that:

• In addition to previous requirements for a complete organic soil, the total amount of minerals in organic soil has been further defined, changing from “some” to “at least two per cent.”

• The volume of soil in containers remains proportional to plant size, growth rate, targeted yield, and length of the crop cycle.

• The minimum amount of soil for crops not covered by 7.5.2.4 (see below) is 2.5 L of soil per m2 of photosynthetic area per week of crop production time.

• The maximum amount of soil required in any case is 60 L/m2 of photosynthetic area

• Crop production time is counted from the start of plant propagation (for example seeding, sticking of unrooted vegetative cuttings, divisions, etc.) until final harvest.

Section 7.5.2.4 requires that for containerized, semi-indeterminate and indeterminate staked crops (for example, tomatoes, peppers, cucumbers, eggplant):

• Additional compost applications shall be included in the fertility program.

• The maintained soil volume shall be at least 60 L/ m² (1.2 gal./ft²), based on the photosynthetic area.

• Having multiple crop cycles within a year (i.e., short cucumber crops or interplanting tomatoes) do not reduce this 60 L/m² requirement. For producers seeking more information on the certification process or for a more thorough understanding of the 2020 standards, please visit organiccouncil.ca.

Stuart Oke is the director of communications and membership for the Organic Council of Ontario. He can be reached at stuart@organiccouncil.ca. The OCO represents more than 1,400 certified organic operators, as well as the businesses, organizations, and individuals that bring food from farm to plate.

Researchers are revisiting ancestral tomato varieties in search of genetic tools against ToBRFV.

BY GRETA CHIU

As the world continues their battle with COVID-19, vegetable researchers and seed providers find themselves racing to develop resistance against a different pathogen.

First identified in Israel in 2014, the tomato brown rugose fruit virus (ToBRFV, a.k.a. the rugose) is one of the most recent members of the tobamovirus genus to make headlines. Over the past several years, the virus has been reported in Mexico and the United States, as well as multiple countries in the EU including Spain, Italy and the Netherlands. According to the EPPO Global Database, Belgium reported its first case earlier this year in 2021, and China in 2019.

“Characteristics of tobamoviruses are that they tend to be very persistent in the environment, they are highly transmissible and easily spread mechanically, and there are very virulent strains that can be damaging to host crops,” said Cara McCreary, greenhouse vegetable IPM specialist at the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), during a webinar held in

ABOVE

April 2020.

The tobamovirus genus contains 35 known species, including the tobacco mosaic virus (TMV) and tomato mosaic virus (ToMV). Resistance genes against TMV and ToMV have been bred into most commercial varieties of tomatoes. Known as Tm-1 and Tm-2, a different version (or allele) of the second gene known as Tm-22 has been cited as the more robust and stable of the three, but it doesn’t seem to work against ToBRFV.

“This Tm-22 gene was the gold standard against tobamoviruses in tomatoes for the last 40 years, and it worked very well until ToBRFV emerged,” says Dr. Jonathan Griffiths, research scientist at Agriculture and Agri-Food Canada (AAFC).

A paper published in scientific journal Plants in 2021 by Israeli scientists Zinger et al. documents how none of the tested tomato cultivars with Tm-2, Tm-22, or either one of the two alleles stacked with Tm-1 were resistant to ToBRFV. This came as a surprise to the authors given the different targets of each gene.

Jonathan Griffiths’ lab at Agriculture and Agri-Food Canada is looking to identify resistance genes against tomato brown rugose fruit virus, so they can be used in the sector’s breeding efforts.

Quality is a customer expectation and a Bayer ® promise. That’s why we developed SHIELD, a comprehensive approach to deliver healthy seeds season after season.

For over 10 years, SHIELD has focused on the prevention, detection and elimination of pathogens at Bayer production and processing sites for De Ruiter ® , as well as third party production and processing sites. Microorganisms can cause plant disease or illness, and when introduced to a plant population under the right environmental conditions, disease leads to plant stunting, wilting, fruit deformation, yield loss or even plant death. SHIELD is Bayer’s promise to take a proactive approach to supplying clean seeds so your confidence can flourish—this season and every season to come.

Our comprehensive process consists of three distinct disciplines: Seed Production and Field Quality, Seed Sanitation and Seed Health Testing.

See the SHIELD process in action by visiting www.deruiterseeds.com/en-ca/resources/shield.html

Health Testing

Where Tm-1 inhibits proteins essential to viral replication, Tm-2 and its allele Tm-22 prevent the virus from spreading between plant cells.

Tm-22 can also trigger a hypersensitive response as part of the plant’s own defense mechanism, adds Griffiths. In the case of ToMV and TMV, this often leads to cell death wherever the virus is found, and effectively prevents it from replicating and spreading to healthy plant cells.

Similar to how Tm-1 and Tm-22 were once found, researchers are using a method called forward-genetics screening to identify candidate genes for rugose resistance. This approach takes a broad range of different tomato varieties and looks for ones unaffected by the virus, then identifies the specific gene or group of genes responsible, explains Griffiths.

To widen the search, they’re using ancestral varieties of tomatoes from areas such as South America and Chile. “Places where they’re undomesticated,” he explains, where they’ve been growing in the wild for thousands of years. This approach allows them to draw from a larger pool of genetic material and naturally occurring variations. “If you screen enough of them, you are likely to find some that are resistant. That let’s you identify what gene it is and then figure out the mechanism of resistance.”

The same Zinger et al. study identified a new gene that can provide tolerance to the rugose.

“Tolerance is good. You don’t get symptoms, your fruit looks okay, but the virus is still there. It’s still spreading and it can mutate and cause problems in the future,” explains Griffiths.

“But they also found a resistance allele,” he adds. Combined, the Tm-1 resistance gene and this new tolerance gene could provide resistance to the rugose together.

Not much is publicly known about the newly discovered gene. The authors of the research paper noted uncertainty around whether Tm-1 plays a direct role in rugose resistance or whether it involves other genes linked to Tm-1

In the meantime, research efforts are not slowing down. As the authors of the study pointed out, they only screened 160 different tomato varieties – a relatively small population. These varieties were chosen for their genetic similarity to the cultivated tomato, which

would help speed up breeding efforts for commercial production.

In Canada, Griffiths’ research group is casting a wider net by expanding the genetics screen to include thousands of different tomato varieties. This will give them much more genetic variation to work with and a greater chance at identifying additional genes for resistance. It means providing more tools to growers and breeders in developing varieties that are not only rugose-resistant, but also commercially viable.

As Griffiths explains, a single rugoseresistance gene might be linked to other traits that promote undesirable characteristics, such as lower fruit quality or undesirable taste. “But if you have multiple resistance genes, then you can find ways to eliminate these negative traits more easily.”

The research will also help the industry gain a better understanding of the virus and its potential weak points. But it also helps safeguard against potential mutations.

“In the event this virus mutates and overcomes the resistance, then you have other sources you can use to rapidly breed into commercial lines and restore resistance against the virus,” says Griffiths.

Currently, Griffiths is collaborating with Steven Loewen at the University of Guelph, as well as Travis Banks and Valerio Primomo at Vineland Research and Innovation Centre. Both research institutions have access to large numbers of varieties and lines which combine genetic diversity from ancestral and wild tomatoes in crosses with commercially adapted varieties. The process of growing, testing and evaluating for resistance and commercial viability is estimated to take about five years.

“This is a very sensitive project that we’re taking every precaution with because of how infectious the virus is and how easy it is to spread,” adds Griffiths. “We don’t want our research to end up contaminating a grower’s crop. In order to contain the virus, we have enacted multiple safeguards and protections including growth room restrictions to ensure we contain this virus.”

Part of those precautions involve testing at different research centres across Canada, located away from major horticultural production areas. The research teams are now in the process of shipping seed to begin screening the different varieties.

Bayer Crop Science plans to launch two varieties with intermediate resistance (IR) to the rugose this year. Both were bred specifically for the glasshouse environment in the northern hemisphere.

Currently being commercially trialled is a cherry plum (grape) tomato called ‘Navetta’ that launches in Canada this fall.

The second variety planned for release in 2021 will be a pink beef tomato known as ‘Yarmaru.’

The Bayer team expects to release tomatoes-on-the-vine and varieties in other tomato segments starting in 2022, with high resistance material in development.

Also targeting the rugose, Griffiths’ research group is starting a separate project that will analyze the feasibility of detecting ToBRFV using greenhouse beehives. Early results have been promising, he says.

Since the emergence of the rugose, seed companies have been fast-tracking their breeding programs to incorporate rugose resistance into the pipeline.

“Breeding doesn’t happen overnight,” says Juan Labastida, marketing specialist at Enza Zaden in Mexico. Anything

Neudorff North America is an innovative leader in ecologically responsible pest solutions for nursery and greenhouse growers, farmers and turf professionals.

Our effective and affordable solutions for disease, insect pests, pest slugs and snails have limited impact on applicators, and the environment. They are an important part of integrated pest management programs.

Powerful disease protection for your greenhouse vegetable and ornamental crops with a fraction of the copper found in other copper fungicides.

Fast-acting insecticidal soap. Controls aphids, mites and whiteflies on ornamentals, herbs, spices, vegetables, including cannabis. Effective as a cutting dip to control whitefly nymphs.

A summer and dormant oil. Controls all life stages of insects and mites. Suppresses powdery mildew of greenhouse ornamentals, fruit, vegetables and cannabis grown indoors.

Fact acting. Controls moss, algae and liverworts in and around greenhouses.

A durable pelleted iron phosphate bait. Provides excellent protection of greenhouse crops from slugs and snails.

A durable, fast-acting pelleted spinosad bait that is active against a wide range of ants in greenhousegrown vegetables and ornamentals.

Inside and outside. Neudorff protects.

Last year, Enza Zaden’s tomato breeding team announced the identification of a gene which confers high resistance (HR) to the current strain of the rugose.

The gene is said to allow plant proteins to inhibit the virus before actively breaking it down. The identity of the gene remains undisclosed due to intellectual property rights.

HR varieties with this gene have been tested on nonheated, greenhouse tomatoes and they’ve held up in high rugose pressure areas in the Mediterranean. For heated greenhouse tomatoes including those meant for the Canadian greenhouse market, Enza Zaden will be ramping up their product development trials mid-to-late next year before they head into commercial testing.

on the commercial market has been in progress for the past three to five years, at least.

The industry’s initial breeding efforts have largely targeted the unheated greenhouse market in the past few years. Areas include the Mediterranean, the Middle East and Mexico.

“It’s also where the biggest problems are and where the biggest volumes of tomatoes are grown,” says Freek Knol, Enza Zaden’s regional manager of greenhouse business in North America. “We’re going as fast as we can. Is it as fast as we’d like or as the industry likes? Probably not, but we have to do our homework.”

“The first step was identifying resistance loci in our programs and pipelines, and in our tomato breeding pools around the world, then selecting elite breeding lines establishing an accelerated conversion plan to bring resistant varieties to market as soon as possible,” says Carlos Buzio, who leads strategic marketing for the North American protected culture segment at Bayer’s vegetable seed divisions, De Ruiter and Seminis. “But with or without resistance, the product still has to perform.”

Both Enza Zaden and Bayer are conducting thorough testing and trialling in order to bring the best products to market – not only in resistance, but in yield, flavour and other desirable agronomic and consumer traits.

The International Seed Federation recommends the use of specific terms in describing how a variety interacts with a pathogen. It’s either susceptible or, in the case of resistant varieties, displays intermediate resistance (IR) or high resistance (HR) to a pathogen. The term ‘tolerance’ is reserved for describing plant responses to abiotic stress.

“A susceptible variety is when the virus can freely enter the plant and easily multiplies in [it],” says Knol. “With IR varieties, it’s either a matter of the plant slowing down the development of the virus or the plant being able to live with the virus in it.” IR varieties may be symptomless. Although the crop doesn’t develop signs of the rugose, it still harbours the virus.

“It’s essential to continue to follow best practices in phytosanitary hygiene even with IR varieties, as there may be a low level infection present, even though you can’t see it on the fruit,” adds Marjan Willett, protected market development lead for the Americas at Bayer Crop Science. “It’s important to understand what IR resistance does for your crop.”

But when it comes to HR varieties, the mechanism can be completely different, as is the case for Enza’s latest development. “In an HR variety, the plant will actively block the virus,” says Knol. “The virus will not be able to multiply after it is transferred to the plant, and if I go back to the plant two weeks later and start doing measurements, I will not find the virus in [it].”

That said, resistance genetics cannot be treated as a magic bullet. Crop health and integrated disease management are equally important.

Under controlled conditions, an HR variety may be completely immune to the rugose. However, invading pests, diseases and other stressors can affect the strength of the plant’s immune response. “You could potentially find some living virus on the (HR) plants, but in a very low dose,” says Knol.

Another caveat is that current resistance genes have only been trialled on known strains of the rugose. The emergence of new strains could put

the industry back at square one. This emphasizes the importance of the work being carried out by Griffiths and his collaborators, as well as researchers and seed companies worldwide.

“It’s not just a question of Bayer or another company finding resistance and launching it into the market,” says Buzio. “That is not the solution longterm. We’re looking for multiple sources …. that offer more protection than one solitary source could potentially offer and also give us protection long-term to deal with changes in the virus that could happen as they’ve happened with other tobamoviruses. What we’re pursuing is a long-term strategy to maintain resistance against the rugose over the years to come.”

There are L genes in commercial pepper varieties that are used for resistance against ToMV and pepper mild mottle virus (PMMoV), said Cara McCreary, OMAFRA greenhouse vegetable IPM specialist, in a webinar held last April. “So far, the rugose does not seem to be able to overcome those resistance genes, but more information is needed.”

Research has suggested that other genera from the Solanaceae family can act as potential hosts. Candidates include tobacco, weeds, petunias and certain ornamentals, though the range of plant hosts is still being established.

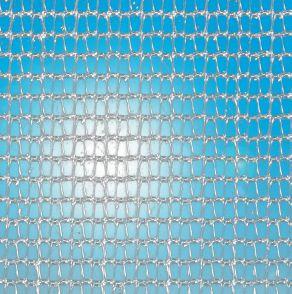

The Ridder Energy Saving Rolling Screen is a highly transparent energy-saving wall screen with the highest light transmission in the NEN 2675 class. With this new innovation from Ridder, you can keep your energy bill in check while maximizing the transmission of daylight through exterior and interior walls - all year round. The all-season wall screen with such a high light transmission that it’s almost

The niche for cut flowers is looking stronger and healthier than a few years ago. Here’s an inside look at what’s happening, plus integrated strategies for keeping cuts healthy amid declining chemical product options.

BY JOHN DIETZ

It’s a bear to pursue year-round cut flower production in the boondocks of Saskatchewan, but credit one Bailey Dueker for lots of grit.

The high-energy flower farmer from Biggar, a western Saskatchewan small town, has been putting seeds and plants into her first unheated hoop house in April. It’s her second year of cut flower production.

Dueker is just one example of grassroots changes in Canada’s cut flower industry. Dueker doesn’t have a degree or a heritage of greenhouse production but she has reasons to hope and lots of growth potential.

For one thing, she is Saskatchewan’s only

member of the Association of Specialty Cut Flower Growers. The ASCFG has 148 other members across Canada and about 2,000 more in the United States. According to insiders, membership is booming and is part of a national trend to revitalize the industry.

Sharing knowledge and helping each other are mandates for the society.

“Why join? Well, they have a Facebook page and come out with a magazine quarterly with all sorts of research. A lot of members are great about sharing information and answering questions,” Dueker says. “They’re committed to learning more about how to improve and to

ABOVE Boondock Flower Farm has 3,000 tulips ready to bloom plus several hundred daffodils. Later, Bailey Dueker plans to sell ranunculus and anemones, then sunflowers, zinnias, dahlias and grasses. INSET Janis Harris of ASCFG says small-scale growers have increased exponentially in recent years.

helping other growers. Plus, we get lots of good information about the business itself.”

While Dueker is the lone ASCFG member in the province, she is one of many newcomers to the cut flower industry.

“Small scale growers have increased exponentially in the past three to five years,” says Janis Harris of Harris Flower Farm, St. Thomas, Ont. and Canada’s ASCFG director. “Demand for fresh flowers is through the roof, even with the pandemic. There was only really a hiccup about a year ago for three weeks that affected the large-scale flower farmers.”

ASCFG members come in all sizes and descriptions, from organic to conventional to hydroponic, from single fields in Saskatchewan to hoop houses in Nova Scotia to massive, automated greenhouses in Ontario and British Columbia.

Harris says, “The ASCFG has a huge wealth of knowledge available. Members have access to learning opportunities, archives of past issues of the quarterly magazine, archives of past conference videos, members-only forums and a connection with ‘Flower Nerds’ from around the world.”

She adds, “Many growers are producing courses and online classes. For new growers like Bailey, the best way to learn is to try and understand the ‘why and how’ of things that grow.”

According to Statistics Canada, the greenhouse cut flower trade in 2019 ($133.5 million) represented 10 per cent of farm gate sales for Canada’s greenhouse ornamental industry. Ontario accounted for 69 per cent of sales, followed by B.C. with 29 per cent.

Comparatively, field-grown cut flowers totalled $14.9 million in sales, but this time, Ontario held 39 per cent of the pie, while B.C. held 57 per cent.

A trade association, Flowers Canada Growers (FCG), represents the industry to all levels of government and institutions as well as the public.

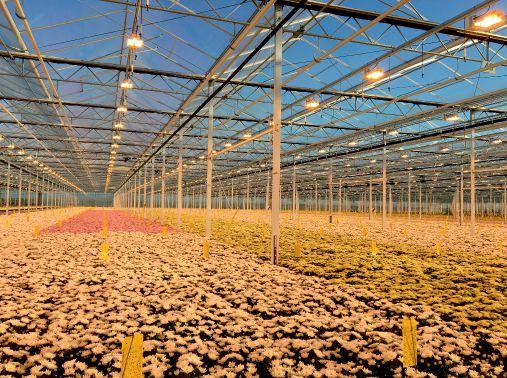

FCG’s Pest Management Director, Cary Gates, estimates that 20 to 30 per cent of greenhouse growers are growing cut flowers. Tulips, gerbera, snapdragons and chrysanthemums are the top four, based on the number of stems produced. “Tulips can be mass-produced hydroponically.

In reality, there are probably more farms dedicated to growing chrysanthemums,” Gates says.

It would seem that Boondock Flowers is coming into an industry on the upswing, with a bright outlook after some challenging times.

Since 2005, many small greenhouse operations have exited the industry, but medium to large farms have adapted and grown.

The flower profile also changed. The roses and carnations are gone.

“Today, the rose industry in North America is dominated by Colombia and Ecuador – and the quality is very good,” Gates says. The shift began in the 1990s when governments encouraged South American farmers to leave cocaine production in favour of other crops. These war-on-drugs incentives were followed by favourable free trade agreements in the next decade.

Regulatory changes have further changed life for cut flower growers.

Gates says, “By their very nature, cut flowers require a lot more handling and interaction. We started to see, around 2001, new health and safety concerns coming out of Health Canada. As a result, pesticides registered in other countries were not as easily registered in Canada for the cut flower segment of our greenhouse industry. For years, we’ve had a lighter toolbox.”

The number of greenhouse flower farms continues to shrink, declining from 1,811 in 2016 to 1,591 in 2019. Canada lost an average of 55 flower greenhouses each year during that time.

For greenhouse cut flowers in particular, national sales declined by five per cent during the period.

But it was another story for fieldgrown operations, where the number of farms rose by 42 per cent, and acreage by 56 per cent. Sales grew by 13 per cent, pointing to opportunities ahead.

One veteran of the industry who’s been adapting steadily is Gerard Smit, owner-manager of Smit Nursery Ltd., Abbotsford, British Columbia. Smit is on the national board of directors for Flowers Canada and is a former director for United Flower Growers. He’s also been a member of the ASCFG for twenty years.

You’d think that a fungicide registered for strawberry protection would also be safe for the cut flower industry. Not necessarily.

According to Flowers Canada Growers’ Pest Management Director Cary Gates, Health Canada maintains a risk-based database of human activities for almost all tasks used to grow every crop in Canada, including cut flowers. Gates says:

“They assign default values in terms of risk. Harvesting flowers presents a very high risk of dermal (skin) interaction. If you’ve applied a pesticide to the flower crop, and depending on the toxicity, your interaction risk could be very high.”

“According to Health Canada’s database, they have determined that hand-harvesting strawberries is considerably safer than hand-harvesting cut flowers. To harvest a strawberry you reach in and pluck the berry, then drop it in a basket. Strawberry growers spray leaves but not the berries, so the degree of pesticide exposure can be lower when harvesting fruit.”

“When you harvest a flower, you cut the flower and bunch it in your arm. You cut several more, you assemble them, put them in a sleeve, then put them in a bucket. There can be a lot more skin interaction with the crop while conducting those activities.”

“With that said we have been very effective in bringing new products to the ornamental industry as well as in collaborating with regulators and private industry to address these issues. It’s a part of my role to find science-based approaches to navigate around issues like that for Flowers Canada members –and we do.”

Smit Nursery operates 16 sites planted with astilbe, lysimachia, peonies, viburnum and other crops of cut flowers. Unheated for most of the year, Smit uses rolling greenhouses to turn up the heat inside and is cutting flowers in a couple of weeks.

“Nationally, I think it’s on the upswing,” Smit says of the cut flower industry. “It was on a decline. We’re very vulnerable to imports (there’s only one rose [grower] left in B.C. greenhouses) and you see the same trends in California and Holland. Roses are grown in countries like Kenya, Ethiopia and Turkey now. So, people are adapting.”

Years ago, Smit Nursery left tulips to produce viburnum and peonies as the main cut flowers. It also adopted new technologies. The producer uses four rolling greenhouses on tracks, and that has allowed him to significantly scale up in production to supply the local market.

Noting the current popularity now in Canada for gerbera and chrysanthemum, he says, “It’s not easy to grow gerbera in Colombia so gerbera became popular as a locally grown flower. Chrysanthemum, too. The two chrysanthemum growers here expanded hugely and pushed out the imports with a better quality product.”

In the ‘old days,’ Smit relied on an arsenal of artificial chemicals and soil steaming in a constant war against pests and diseases. No longer. He’s engaged in a biological war with approved ‘green’ biological products.

Nematodes and aphids are his perennial pests. Disease agents are led by botrytis, a fungal disease that can attack roots, stems, leaves and flowers.

“Now we use good nematodes to kill the bad nematodes,” he says. “I value my soil microbes a lot more than I did ten years ago, so we use microbial enhancements. We inject a

liquid microbial into the irrigation system to keep the roots more healthy and I rotate crops so I’m not in the same soil with the same crop every time.”

No longer does he steam the soil to kill nematodes and diseases.

“Now we’re using white mustard and a green attitude,” he says. “I seed mustard in early summer in one field and work it back into the soil as green manure, then seal it up. It produces a gas that’s lethal to pests while it decays. In the fall, I put barley into that soil and, the next year, I use it again to grow my perennials. I can’t say it’s 100 per cent, but it sure reduces nematode trouble. It’s altogether better for the soil.”

Some of the most concentrated flower production in Canada is located in Ontario’s Niagara region. The Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) supports the greenhouse industry with two full-time extension specialists stationed in Vineland.

Dr. Sarah Jandricic has a focus on integrated pest management for floriculture pests and diseases; Dr. Andrew C. Wylie is the acting floriculture production specialist.

They share growers’ concerns that disappearing chemical products are making it more difficult to manage disease and make a profit, particularly with a cut flower crop.

“Botrytis is a really good example,” says Wylie. “It tends to be managed environmentally – but it takes quite a bit of effort

to make sure you’re not encountering the kind of humidity that allows botrytis to thrive.”

“We’ll have to do a lot more cultural management and sanitation efforts to prevent it or minimize it before it becomes a problem,” Jandricic adds.

Fusarium is another big disease issue. Jandricic says, “It can be really difficult to control chemically once it gets into a big greenhouse because we only have two registered products for it. Growers should think about where it comes from and how to stop it from getting in again.”

But, the specialists agree, a reduction in chemical control methods for growing healthy, productive cut-flower plants may become a long-term boost for the whole industry.

“Microbial fungicides go through the same PMRA registration process as chemical fungicides. They are fairly widespread now for use in potted crops and are gaining traction in cut flowers,” says Jandricic.

“A potted crop takes eight to twelve weeks. But a cut flower crop like potted gerbera is in production for three years. You need constant reapplication of products like this and, any grower who’s had an issue like root rot has seen the benefit of microbial fungicides,” she says. “Biocontrol with microbials can get you off the pesticide treadmill and get you into additional benefits like better root growth. I think that’s going to become a regular thing in nearly all greenhouses.”

While old pesticides disappear, Jandricic and Wylie point out emerging tools being studied, such as the use of LED spectra for disease suppression. In the meantime, they’ve identified a number of preventative steps that growers can take to help ensure the health of their crop. This includes the use of water treatment systems and applying ozone as a cleanup and sanitization tool. Even simple sign-in sheets, footbaths, booties, special gloves and full suits can provide barriers to organisms from outside.

To identify pathogen species, growers can take water samples to testing labs. There are DNA multi-scan tests that look for specific pathogens like fusarium or botrytis. On-farm tests developed by the Soil Research Group can track live counts to determine how well a treatment system is working.

For a holistic approach, some growers are turning to remotely operated, high-resolution cameras and multispectral scanning for early detection of emerging greenhouse infestations. Pests, such as thrips, can also do direct damage and quickly vector viruses throughout greenhouses. Every grower should have a management program for thrips, as well as fungus gnats and shoreflies, which spread fungal spores.

Flowers Canada and Health Canada are evaluating if approved personal protective equipment for greenhouse tasks, including cut flower production, can offset health and safety concerns from using pesticides. In the next few years, a research project is proposed to evaluate and develop protocols for using nitrile gloves and other protective gear.

“Altogether, we’ve seen a heavy shift from just chemical control, generally, to biological control of diseases and insect pests,” says Gates. “We are miles ahead of counterparts with more access to pesticides, like the U.S. We’re heavy, heavy users of biological pest control. We’re world leaders in many ways.”

The two OMAFRA specialists agree, the industry is in a time of flux. “It’s going to be really interesting to see where this goes in a decade.”

Here are six tips from OMAFRA extension specialists Dr. Sarah Jandricic and Dr. Andrew Wylie for keeping cut flowers healthy so fewer fungicides are needed.

1. Keep plants free of stress! Pathogens find footholds in stressed plants. Test your soil and water regularly to make sure environmental factors are within optimal ranges. For do-it-yourself testing, make sure your equipment is properly calibrated!

2. Know the signs and symptoms of your diseases. Use detailed pictures of diseases and pests in specific crops to turn yourself and your employees into scouts. At regular staff meetings, discuss new pathogen challenges and how to avoid spreading them. Often, microbial or cultural approaches can control an emerging problem. Usually, quicker control is cheaper control.

3. Start using biocontrol for pathogens in cut flowers. Registered microbial fungicides, regularly used, can prevent disease and strengthen a crop. Learn about limitations as well as best practices (e.g., some must be applied early, others should follow a chemical fungicide).

4. Lean hard on cultural controls. Increased ventilation, decreased watering, and constant cleaning of dead leaves and excess soil are essential tools for Integrated Disease Management (IDM). And don’t be afraid to hand rogue your problem plants.

5. Invest in water treatment. At some point, expect your water supply to become a source of disease (unless it is city water and not recirculated). A water treatment system isn’t an off-the-shelf product, so give yourself a year or two to budget, research, plan and install the system that makes the most sense. See the FCO guidance document here: flowerscanadagrowers.com/uploads/2018/04/ guidance%20document.pdf

6. Evaluate your farm! One online tool is the Floriculture Sector Biosecurity Guide for greenhouse and nursery crops created by industry, education and government specialists. It reveals where insects and diseases can enter and guides you through an interactive Biosecurity Self-Evaluation Checklist to identify gaps and plan to fill them. Go to: inspection.canada.ca/plant-health/plant-pests-invasivespecies/biosecurity/national-voluntary-farm-levelbiosecurity-standard/eng/1456344248841/1456344 249699

THESE ACTIVE INGREDIENTS WORK TOGETHER TO POSITIVELY INFLUENCE PLANTS, FOR HIGH-PERFOMANCE RESULTS.

AND

These high-quality growing media enriched with cutting-edge active ingredients provide ideal growth environments for plants. By inducing the proliferation of root hairs, the Bacillus acts as a BIOSTIMULANT, and ensures better germination. By expanding the root system growth, MYCORRHIZAETM enhance nutrient and water uptake, reduce transplant shock and increase tolerance to stresses.

Ed Bloodnick, Horticulture Director, Premier Tech Grower Services

In biology, a tripartite association occurs when three living organisms form a synergistic relationship that mutually benefits each other. Specifically, a Tripartite association between MYCORRHIZAE, BACTERIA and PLANT has been proven to benefit plant productivity, increase crop yield, improve acquisition and uptake of certain nutrients and photosynthetic rate of plants.

Each partner of a Tripartite association plays a crucial role to help other organisms thrive in the process. It is important to know that mycorrhizal fungi are obligate symbionts and need a plant to survive and complete their life cycle, compared to Bacillus bacteria which occur naturally in soils around the globe.

MYCORRHIZAE: By enhancing root system growth and creating a network of filaments, mycorrhizae help plants with uptake of nutrients, such as phosphorus and certain micronutrients. In exchange, the plant provides carbon to the fungus and, by extension, to the root microbiome, including our Bacillus pumilus growing along the mycorrhizal hyphae.

BACTERIA: Bacillus are gram-positive bacteria which colonize plant roots. Their high motility gives them the ability to form a biofilm around the root system that ensures protection against pathogens. Some of them, like Bacillus pumilus, secrete biostimulant molecules (auxins) that stimulate root growth and induce the proliferation of the root hairs to favor the absorption of nutrients and water. Biostimulation benefits are: accelerated seed germination and plant establishment, increased nutrient and water uptake, increased plant vigor and yield, increased plant tolerance to environmental stresses (drought, salinity, compaction).

The Benefits of the Value-Added Combination

The combination of mycorrhizae and Bacillus enhances PRO-MIX® growing media to maximize and optimize plant growth. Now that we explained the biological process, it is important to understand how the benefits from both active ingredients will improve crop quality and yield. These include:

1. Reduction of abiotic and biotic stress tolerance

2. Reduced incidence of root diseases

3. Improved plant nutrition

4. Decrease mortality rate of plants

5. Regulated and predictable plant growth

6. Uniformity of plants within a crop

7. Increased plant productivity (overall plant growth, more flowers and fruit)

Plant roots colonized by MYCORRHIZAE (Glomus intraradices, PTB297 Technology).

Mycorrhizal structures (arbuscules and vesicles) mean that the symbiosis between the fungus and the plant is taking place.

Source: Premier Tech

Watch the tripartite in action

Plant gives carbohydrates to the fungi

The hyphae explore the soil/growing media, exuding carbon

Bacteria absorb this carbon and multiply along the hyphae

Bacteria liberate lipopeptides and/or hormones

The key to this interaction is the high level of compatibility between mycorrhizae and Bacillus bacteria. As mycorrhizal hyphae can explore the growing medium further than roots, the bacteria multiply along the way for a higher population and wider-spread providing a multiplied biostimulation effect across the whole substrate.

Watch to see inside the biofilm formed around a mycorrhizal hypha. You will witness the real-time speed of nutrients and water moving inside the hypha, and Bacillus bacteria in action.

Premier Tech, the owner and manufacturer of PRO-MIX® since its inception, has more than 50 years expertise in formulating high quality growing media and more than 35 years of expertise in biological active ingredients.

Joined with state-of-the-art quality control processes in aseptic laboratories and production facilities, PRO-MIX® makes a difference for your crops with the consistency of proven of products, no contamination and reliable active ingredients.

Thoughtful changes to in-store displays and online content can help streamline the pandemic shopping experience.

BY MICHAEL VAN DEN HOEK

Let’s face it, we’ve all had at least one of those moments. You walked into that store with a very specific list, but 10 minutes later you find yourself holding something from a display rack that you didn’t know you “needed.”

The subliminal power of a well put together display cannot be understated, but what about during these chaotic COVID times? Many of us find ourselves in the position where we’re more worried about running out of stock to sell (and disappointing customers with lack of inventory) than we are of figuring out how to push our products. Combined with the requirement to limit capacity for physical

ABOVE

distancing, and lineups of customers waiting to get in so they can buy their flowers, who has time to make a display? This stuff basically sells itself right now... right?

In some ways, this is true. With record numbers of new gardeners, a general increase in interest for home and garden projects, and worries over demand outstripping supply this year, you probably won’t have to worry too much about sales and promotions to move your plants. We all know though, how long it takes to build that customer trust, and how quickly it can be lost. Here are a few things to think about for your displays during the pandemic to streamline your customers’ visits.

Showcasing a variety of pollinator-friendly perennials in bloom can give customers ideas of what’s possible in their gardens.

ABOVE

You don’t always have to reinvent the wheel. Consider adjusting the display based on the time of year. This same butterfly display is shown, but earlier in the season, with grab and go containers full of pollinator-friendly, bloom-heavy annuals.

Don’t worry, I’m not going to rant about ecommerce and webstores, but there is no denying that more and more customers are checking out your operation’s online presence before they pay you a visit in-person. In 2020, we found that we had eight times the number of unique website visits compared to 2019, and that was with effectively no changes to how we promoted our website. With all of the restrictions that change from week to week and vary greatly by area and industry, your customers want to know when you are open, what you have, and what they have to do if they want to come shopping. So why not capture their imagination while you have their attention? If you can spend an hour or more putting together a perfectly beautiful display, only to have it torn apart by customers 10 minutes after opening, then you can take five extra minutes to capture a photo of it and post it online with a simple caption. You’ll be glad you did.

For our operation as a grower-retailer, the focus of our displays has changed. Where before we designed them to draw customers deeper in-store and spend

more time browsing the aisles, there is now more of a focus on helping the indecisive ones make a selection. The key is to have large, bold visuals and simple descriptions with less to read. If it can be seen and understood easily from a distance, you’ll engage more of your physically distancing customers who may not be able to read it up close. It also lessens the chance of a customer getting stuck and frustrated behind slower moving traffic.

As for the types of displays, try going back to some of the basics like easily interchangeable examples of the thriller/ filler/spiller formula for containers and baskets. Other simple displays could be around low-maintenance garden combinations, hard-to-kill houseplants, or safe things to plant early for your local zone. These may sound boring to those of us who have been in the industry for a long time, but remember that now more than ever, we have a huge influx of new gardeners who may not know what they are looking for, so basic is not necessarily bad.

That brings us to pinch-points. If you didn’t know where they were in your

operation before COVID, then you were probably made painfully aware of them last year. With occupancy limitations and physical distancing requirements, keep these in mind when moving or setting up new displays. In this case less is definitely more, and it’s better to have fewer or smaller displays with an open layout and clear traffic flow than a confined space around a display. The latter is where you may risk customer confrontation, potentially policing each other’s behaviour.

Finally, that lineup waiting to get into your store is a literal captive audience –why not set up some displays outside? Putting up a rack with some of your most popular hanging baskets, with simple care instructions and variety information, will help them narrow down their choices before they even get inside. Switch up your outdoor displays so that waiting customers are always visually engaged. This way, they are less likely to become bored or frustrated before entering, starting their visit on a positive note.

Michael van den Hoek is co-owner of Lowland Gardens in Great Village, N.S. and vice-president of industry association Greenhouse Nova Scotia. He can be reached at vandenhoek.michael@gmail.com

Members of Alberta Greenhouse Growers’ Association celebrate four decades, embrace change.

BY DR. MOHYUDDIN MIRZA AND CHRISTIE POLLACK

It was in May 1980 that the Alberta Greenhouse Growers’ Association (AGGA) was established.

Compelled by the vision of growing a profitable, globally competitive, and environmentally sustainable greenhouse industry in the province, the voluntary, non-profit organization emerged from a grower meeting held at what was then known as the Alberta Horticultural Research Centre, in Brooks, Alta.

Producers from across the province were in attendance, and many had been working with Dr. Mohyuddin Mirza, then provincial greenhouse crops specialist, to lay the groundwork for the AGGA.

“There was a diverse group of growers involved in the production of vegetables, bedding plants, ornamentals and nursery material,” Mirza recalls.

“The needs were common [among] protected crops. Energy and marketing were two major motivators to have an association of greenhouse crop growers,” says the greenhouse consultant.

[Left

Bill DeVos, a cucumber grower from Redcliff, Alta. became the first elected president of the association and Mirza became secretary.

Over the next 40 years, the AGGA would become an essential body representing greenhouse growers from across the province. The organization is run by a devoted volunteer board of directors, made up of growers from all aspects of the industry along with key representatives from research, extension, teaching, and the allied trades.

Though the sector has evolved substantially, the association has not wavered in their mission to provide resources and assistance to its members in supporting research and technology transfer initiatives, marketing, education, and the profitability of the sector.

The period from 1980 to 1985 was a particularly challenging time for the industry in Alberta.

Ongoing education is a key mandate for the AGGA. Workshops and continuing education opportunities are top of mind.

Diseases and root knot nematode in soil led to drops in vegetable yields, threatening the sector’s economic viability. “Those early days were very interesting because greenhouse structures were very different. We were growing in soil, in dirt. There was no concept of hydroponics at the time,” Mirza recalls.

A sharp contrast from the climate in the Netherlands, Alberta researchers and extension specialists had to test and adapt techniques for their use. Through collaboration between the AGGA and Alberta Agriculture, soilless cultivation was adopted by 1985, turning the industry around.

As soilless systems and nutrient systems evolved, so, too did greenhouse structures. Hit by intense hailstorms, Alberta’s growers started turning from all-glass greenhouses to double poly. “But we are going back to tempered glass greenhouses,” says Mirza of recent years. Glazing materials have improved, allowing producers to harness more natural sunlight while standing up to the challenges of Mother Nature.

In the mid to late 80s, the AGGA and Alberta’s extension teams started a big push towards the use of biological controls, a technique widely adopted by the industry today. Combined with new varieties, advancements in production techniques, and innovations in energy efficiency, producers have been able to grow much more per unit area than they did in the past.

“It was 50 cucumbers per square meter. And now, our average is about 150, but our top growers are going 200+ consistently,” says Mirza, as an example.

In 1983, the value of the industry was estimated at $25 million. Nearly a quarter of a century later, a second report in 2005 put the value of Alberta’s greenhouse sector at $140 million. And the Alberta greenhouse industry continues to expand significantly, with vegetables at the forefront.

The first five acres of winter-lit vegetable crop emerged in Lacombe, Alta. 13 years ago, says Mirza, followed by expansion in southern Alberta. “We are now at over 60 acres of dedicated winter vegetable production.”

In addition to supporting crop research and technology transfer activities, the AGGA actively lobbies on behalf of its members to government and industry, reacting to sudden events and effecting long-term change.

Relationships with provincial governing bodies have been very good, says Dietrich Kuhlmann, one of the founding directors and a past president. “Through the thick and thin of changes in political leadership and policies, we were able to convince the government that the greenhouse industry is a very important part of agriculture and thus needed support.”

In 1983, at the request of the AGGA, a greenhouse task force was created to examine and enhance the profitability and sustainability of the greenhouse industry, continues Kuhlmann. The resulting industry profile became a benchmark study for the Alberta greenhouse industry and many of the recommendations were later adopted by the province, leading to major improvements in energy conservation and resource sharing for marketing, extension and research. This also led to the creation of a greenhouse specialist position for Central and Northern Alberta, further unifying the industry across the province.

Since the first report’s debut in 1984, subsequent editions have been published every four to five years to help determine the health of the industry. The most recent industry profile was completed in 2019.

Energy has always been a key issue. In 1992, the AGGA played an instrumental role in developing and operating an energy conservation matching grant program. This helped growers upgrade their greenhouses and save on energy use. Then in 2019, following the introduction of a carbon taxation program by the provincial government, the AGGA was able to negotiate a carbon levy relief for its members, helping producers move forward with new investments and sustain their business.

At the peak of the first COVID pandemic wave, the AGGA advocated on behalf of ornamental producers and garden centre

members for essential status. Their efforts were successful, setting an important precedent to the essential nature of ornamental horticulture in the province.

Education is a key mandate of the AGGA, and members not only benefit from workshops and seminars, but through multiple avenues of industry news.

Albert Cramer, current president of the AGGA, notes that the founding members had profound foresight into the future of education and knowledge. As a result, members are regularly informed of research advances, advice, market trends, and association activities through a regular newsletter and members’ web site, and subscribed to national grower trade magazine, Greenhouse Canada

In 1979, the AGGA collaborated with Alberta Agriculture’s greenhouse research program on a newsletter called Alberta Greenhouse Notes. Eventually, the AGGA started its own newsletter for members, which continues to this day. As the provincial government continues to consolidate horticultural resources, the AGGA newsletter remains a major point of connection for the industry.

In 1986, the AGGA board of directors at the time, which included then president, the late Ted Hole and secretary Dave Gourlay, successfully brought an international conference to Edmonton, Alta. Hosted by Bedding Plants International (BPI), the event put the Alberta greenhouse industry on the map and helped foster connections between growers in northern and southern parts of the province who experience vastly different growing conditions and cater to different consumer bases. The cost of registration was only $ 25.00 US.

From 1985 to 1992, the AGGA contributed its energy and resources towards the annual Alberta Horticultural Congress. Since then, the AGGA has joined forces with Landscape Alberta to hold the annual Green Industry Show and Conference (GISC). 2020 marked the first virtual edition of GISC, in light of COVID-19.

In 2004, the association established the Dr. Mirza Educational Scholarship Fund and the Dr. Ron Howard Research Fund, promoting horticulture among future generations and continuing to be a

Albert Cramer (left) is current president of the AGGA, and Christie Pollack (right) is an active director of the AGGA board.

voice for new and established members.

For Christie Pollack, owner and operator of Christie’s Gardens and Greenhouses in High Prairie, Alta., she first joined the AGGA in 2012, even before she had built her operation. “My background’s in horticulture, but when you’re stepping into it, it’s so different!”

An active member of the AGGA, Pollack joined the board in Nov. 2017 and witnessed the impact of the AGGA’s work from another perspective, one that spurred her to appreciate the organization’s work even more.

With goals to reach a younger generation of growers, as well as diverse groups across the province, Pollack is spearheading a complete revitalization of the AGGA website that is slated to come online in late April. The new site will allow members to connect with each other and with the association, as well as access exclusive resources.

Through the COVID pandemic, the AGGA has watched the popularity of

Two AGGA members were inducted into the Alberta Agriculture Hall of Fame: Dr. Mohyuddin Mirza in 2014, and garden centre owner Dietrich Kuhlmann in 2018. Dr. Ron Howard, a world-renowned plant pathologist who has played a big role in helping Alberta growers solve diseaserelated issues, was also inducted in 2018.

plants and gardens increase among consumers. A new and invigorated audience seeking plant material has reignited the energy of the greenhouse industry, highlighting a growing area in which the AGGA can play a key role.

“The idea is that we can bring the AGGA forward and now bring the consumer messaging piece that we’ve never had before,” says Pollack. Her passion for plants and approachable plant care expertise has earned her a loyal following on social media. Last year, she kicked off a month-long food growing challenge for consumers and recruited fellow AGGA board members Nadine Stielow of Thiel’s Greenhouses, Debbie Foisy of Deb’s Greenhouses and Jason Anderson of Kathy’s Greenhouses, to coach participants.

Areas such as Pollack’s neck of the woods are less greenhouse-dense, with perhaps one garden centre within a twohour driving radius. That is also why the new AGGA website will include a public directory and map, promoting their members’ businesses among consumers in Alberta.

The COVID pandemic ushered in the need for growers to use digital products including e-commerce websites, webinars, social media, newsletters and more, in an effort to sell and connect with consumers. If anything, this moment in history has helped to unlock more opportunities for the greenhouse industry as a new age of digital-savvy growers expand the AGGA’s role and reach into exhilarating new territory.

The late Honourable Lois Hole was Lieutenant Governor of Alberta from 2000 to 2005. She was also a well-known horticulturist, book author, and educator. She played a significant role in the AGGA’s progression into a true, grassroots growers’ organization.

Growers know that when it comes to controlling and monitoring a production environment, a simple, flexible, sustainable control system is crucial. This is why you can depend on Reliable Controls. Our nationwide network of factory-certified Authorized Dealers will help you design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective, Canadian-made solution, please contact a Reliable Controls

Authorized Dealer near you.

Western Canada: 403.561.4148

Eastern Canada: 647.982.7412

Canadian technology offers a way to diversify crops.

BY PETER MITHAM

Set against a backdrop of snow-capped mountains, what looks like a Quonset hut sits amid blueberry fields in the Vancouver suburb of Pitt Meadows flanked by what appears to be a dozen shipping containers.

But the arched structure is the command centre of a new kind of controlled-environment agriculture system, one that could make plant production more efficient and enhance local food security.

Known as CubicFarm modules, the indoor food-grade stainless steel growing chambers that flank the central work area can produce 6,240 heads of lettuce onsite every three weeks, as well as other produce, herbs, and microgreens.

A conveyor cycles more than 250 growing trays along a patented undulating path in as little as 90 minutes, receiving light and nutrient-rich water along the way. Each module consumes approximately 100 L of water per day, and any excess is collected, filtered and recirculated.

Once the crop is mature, workers in the central production area harvest them and restock the trays for another growing cycle.

“You can stand at the front and do all of your harvesting and planting. You don’t waste any space,” says Dave Dinesen, CEO of CubicFarm Systems Corp., the Langley, B.C.-based company that developed the technology. “It’s just far more efficient on a cubic foot basis than really any other

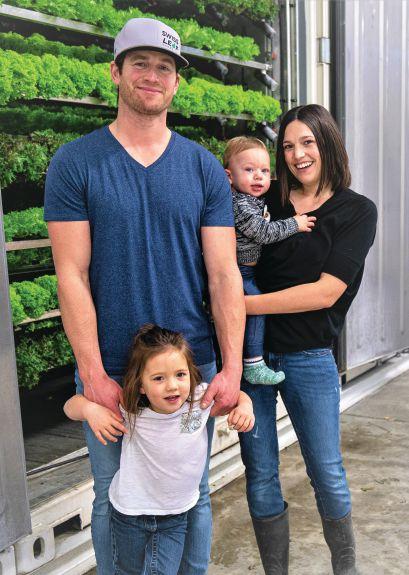

ABOVE A variety of configurations allow the CubicFarm growing modules to be customized to the crop. This image shows spring greens in production. INSET The growing chambers at Swiss Leaf Farms open onto a central work area.

system, and much more efficient from a labour standpoint. It’s been estimated we’re about a quarter of the labour of a comparable rack-and-stack static system.”

Unlike some of the converted shipping containers used by small-scale growers, the commercial-scale technology is enclosed within the module to maximize production space without the need for aisles. The modules are custom-built in China and shipped out to buyers who, with the assistance of CubicFarms’ installation team, can have them up and running in short order just like other forms of modular construction.

“What this allows us to do is manufacture centrally and then ship them, nearly complete, on any train, any truck, any boat. They arrive at the farm and then the team will finish installation onsite,” he says.

Tray configuration and watering can be matched to crop, with reforestation companies, hemp growers and cut flower producers all showing interest in the modules.

“We do have some configurations where you can take a plant up to 15 inches high, but most configurations are ideally for plants 10 inches or shorter,” explains Dinesen.

While the modules make food production more efficient, they’re also used to speed up plant propagation for field growers of cannabis, hemp and other crops.

“They’re accelerating their field crop, and they’re able to grade what they’re planting. It just makes the whole system much more efficient,” he says.

The use for propagation is no surprise, as the systems have their roots in the history of the Benne family of Langley.

The family patriarch, Jack Benne, built a successful plant propagation business that supplied growers across North America. Together with his son Leo, who still holds a minority stake in the company, the family applied its expertise to develop controlled growing environments that let growers raise their own plants.

“All of that history and growing experience has gone into what we’re doing, and now we’re innovating to take our technologies to the next level,” says Dinesen.

The strongest demand is in systems for food production, particularly of salad greens and herbs. The company recently set up a brokerage and consulting division, CubicFarms Garden, to handle product sales on behalf of growers. Distribution is under the ALLWays Local brand, and identifies the individual grower of that local produce

The CubicFarm modules can handle high-volume, quick growth of local produce, including leafy greens, as well as propagation of a wide variety of crops. “One module will propagate almost 120,000 plants every two to three weeks,” says Dinesen. “There’s just an enormous number of crops that the system can grow.”

Dinesen sees the modules as complementing traditional greenhouse production.

“It’s designed to complement a greenhouse type of environment, as opposed to competing with it,” he says. “You aren’t going to grow cucumbers, peppers, tomatoes in a CubicFarm, but you can certainly germinate or propagate those crops alongside, for efficiency. Or you can then diversify and add more cultivars to your growing program.”

The modules also provide an expansion option for landconstrained greenhouses that want to boost capacity within limited space.