IGCs turn to online stores and food gardening courses amid COVID-19 | 16

on Finance 10

financial assistance programs for COVID-19 Business Issues 11 Creating a positive workplace amid a pandemic

Vegetables 12 Adding to your ornamental program Growing Gourds 20 Researchers try the multi-use luffa crop in greenhouses Cannabis Genetics 38 The case for a gene resource bank

in the North 42 Behind the scenes with Diane Blazek

BY BC MINISTRY OF AGRICULTURE

VALERIO PRIMOMO

BY PETER MITHAM & GRETA CHIU

GRETA CHIU | @GreenhouseCan

Hopefully, by the time this issue arrives in your mailboxes, we’ve successfully ‘flattened the curve’ in Canada. If so, now is the time to reassess our operations because life will unlikely return to normal this year.

Experts speculate that the COVID-19 virus will come in waves, and the second may arrive in the fall.

As iPolitics reports (April 1, 2020), this wave-like pattern has been observed in previous outbreaks such as the Spanish flu, cholera, SARS and different forms of influenza. This means that public health officials will be urging citizens to lay low over the summer to reduce the size of the second wave as much as possible. Things have moved very quickly over the past few months. From businesses being declared essential/ non-essential to temporary foreign workers being allowed into Canada, government agencies have been working around the clock to quell the pandemic, all while keeping as many businesses intact as possible and implementing measures to

we need to develop strategies where we identify how we can get people back to work and how to get people out because people can’t live like this.”

To rely less on the transportation of goods, perhaps it’s time to produce more of what we can within our nation’s borders. And for ornamental horticulture, maybe it’s time to use existing facilities to expand into other crops, such as container vegetable plants and herbs or even small-scale vegetable production for the locals.

This print issue is all about diversifying – whether it’s a new crop, new ways of doing business or new workplace protocols. Greenhouse consultant Dr. Mohyuddin Mirza gives suggestions as to which container vegetable candidates could be taken on and quickly (pg. 12). Having to shut down their retail store fronts, independent garden centre operators have been going digital and thinking up creative ways to engage new and existing consumers (pg. 16). If you’re

...this ordeal has shown us where the weakest points are...

address as many basic needs as possible. For agriculture, this ordeal has shown us where the weakest points in our supply chain are, and why we need to have our eggs in different baskets.

To lessen our dependence on foreign labour, perhaps it’s time to revisit efforts in finding local or recently unemployed Canadians, implementing an arrangement that is similar to our temporary foreign workers program. Eventually EI will run out and loans will accumulate. As Valerie Percival, public health specialist at Carleton University, notes in the same iPolitics story, “…

looking for other new crops to take on, there’s an immediate opportunity for sweet potato slips (pg. 30) and a more distant one in luffa gourds (pg. 20). If you haven’t already, consider how you can create a safer, more welcoming workplace for employees (Pg. 16).

Financial advisors always tell their clients to diversify – why shouldn’t we, as businesses, do the same?

Editor’s note: Both Grower Day events have been moved to July 28-29 (Ont.) and Aug 18-19 (BC). This may change to reflect public health recommendations. Visit greenhousecanada.com for updates.

GREENHOUSE

MSc. P.Ag greenhouse@annexweb.com 416.510.5163

Associate Publisher NASHELLE BARSKY nbarsky@annexbusinessmedia.com 905.431.8892

Account Coordinator SHANNON DRUMM sdrumm@annexbusinessmedia.com 416.510.6762

GST - #867172652RT0001 Occasionally, Greenhouse Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Recognizing the challenges in selling through retail during COVID-19, a number of new initiatives were introduced to help growers reach the consumer directly.

The Ontario Federation of Agriculture (OFA) set up an online guide for direct sales to consumers. They’re also offering members a 30-day free trial of the online e-commerce and delivery platform Local Line.

The BC Association of Farmers’ Markets

(BCAFM) received $55,000 in provincial funding for individual farmers markets to join BC Farmers’ Markets Online platform and set up their own virtual market stores.

‘Niagara Grown’ is a non-profit website that helps consumers find local flower growers with farm stands in the Niagara region. Each listing includes the location, crops grown, methods for pick-up, contact information, as well as a brief description of each operation.

Several individuals were recognized at the Canadian Horticultural Council’s annual general meeting in Ottawa earlier this year.

Linda Delli Santi, executive director of the BC Greenhouse Growers’ Association and chair of the CHC Greenhouse Vegetable Working Group, was presented with the CHC Outstanding Achievement Award.

“Her valuable leadership has been pivotal in developing a collabora-

tive national forum for greenhouse vegetable growers,” says Brian Gilroy, president of the CHC, who highlighted her work on a number of issues including farm labour programs, worker safety, energy, carbon pricing, trade, plant health and more. “She readily tackles complex issues and continually steps up to the challenges faced by greenhouse growers.” She also co-chairs the Greenhouse Task Force

Atlantic Grown Organics will receive federal and provincial investments totalling $893,284.

Operated by Schurman Family Farm in Kensington, PEI, this investment will allow the operation to adopt a clean technology boiler system – the first of its kind in North America. The new boiler system will help turn the greenhouse operation into 100 per cent renewable heating, and promote the adoption of clean technologies in the sector.

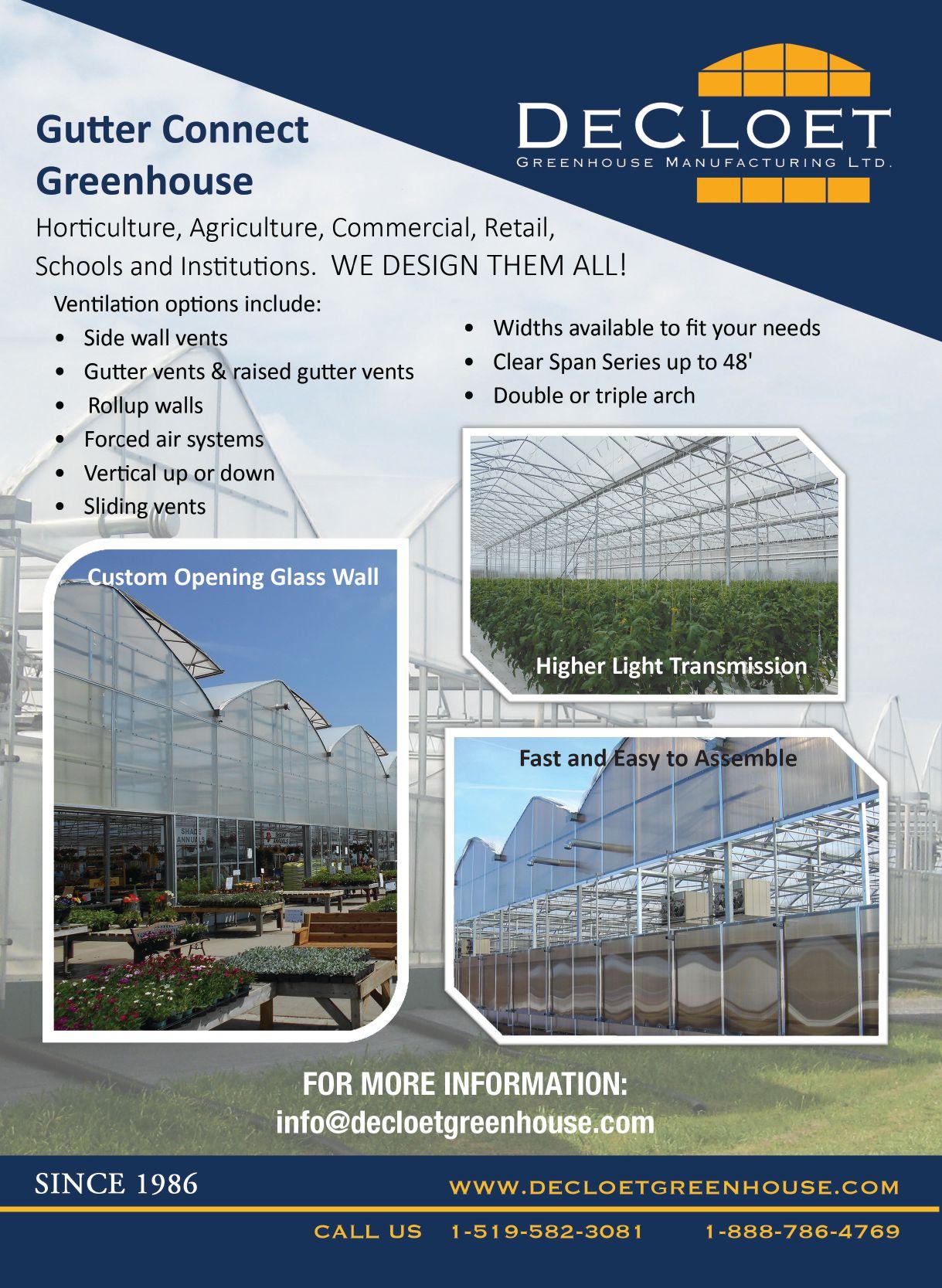

Two other greenhouses in Nova Scotia will each be receiving $300,000 in joint federal and provincial support through Nova Scotia’s Agriculture Business Advancer program. Den Haan’s Greenhouses Ltd. will be transitioning to year-round vegetable production by installing LED lighting technology. Forest Glen Greenhouses Ltd. is planning a major expansion, adding a new 35,000 square foot gutter-connected greenhouse.

that is helping lead the Canadian industry-government response to the tomato brown rugose fruit virus.

Shirley Archambault, was named a CHC Honourary Life Member for advancing grower access to pest management products in Canada, including minor use registrations. Tom O’Neill was named a CHC Honourary Life Member for his success in leading the marketing efforts of Ontario’s fresh apple

program and dedication to the Norfolk Fruit Growers’ Association.

Tracy Shinners-Carnelley, vice-president of research and quality at Peak of the Market, received the CHC Doug Connery Award for her demonstrated leadership and dedication to the potato sector, effecting change at the local, provincial and national levels.

Full story at greenhousecanada.com.

#PlantsDoThat | Source: NICH, 2018

• ZZ plant

• Snake plant

• Pothos ivy

• Arrowhead plant

• Dracaena

• Calathea

98%

30% say they feel less tired of workers say they are more motivated

12% are faster at completing computer tasks

Anderline, Amblyseius andersoni, offers great control through variable spring conditions. Active at wide temperature range (6–40°C).

Phytoline, Phytoseiulus persimilis, is an active hunter of two-spotted spider mites.

Californiline, Amblyseius californicus, is an effective, industry-standard for control of mites.

Water-resistant Sachets contain a breeding colony, ensuring continuous release over several weeks for long-term mite control. Use loose material for immediate crop protection in mite infested hot spots.

Massive flowers and never-before-seen colours for flowering vinca (Catharanthus) make the all-new Quasar series a must for spring and summer sales. Strong landscape performance and disease resistance bring both grower and consumer success. Colours range from near black-blue to true orange. Pictured: Salmon Orange green-fuse.com

Armageddon is the world’s first F1 hybrid super-hot chili measuring at

1.2 million Scovilles. This gives a fantastic advantage in terms of improved plant vigour and fruit uniformity. It is the earliest maturing super-hot variety, at least 14 days earlier than the competition. Days to harvest: 95100. 61-76 cm tall, 41-51 cm wide. Fruit size: 4-5 cm x 3-4 cm. burpeehomegardensbrand.com

This petunia adds five new colours: Cherry Vanilla, Purple, Salmon, Cardinal Red and Soft Yellow. This innovative petunia performs well in propagation, requires minimal PGR to create a tidy quart and blooms early enough for any petunia program. Capella creates stunning quarts, baskets and combos that draw the eye at retail and continue to perform in the home garden. Pictured: Capella Salmon. danzigeronline.com

The first F1 hybrid seed Echinacea from seed, new Artisan Collection offers consistency of plant structure for uniform and highly branched, full plants. It also provides uniform flowering, so all plants are ready to sell at the same time. Plus, the benefit of seed input provides flexibility for production so it fits better in your schedule. New Amplified seed form is enhanced through a proprietary process, resulting in faster and more uniform germination compared to non-enhanced

A highly uniform spreading petunia series, FotoFinish offers perfectly matched plant habits and flower

seed. 5 to 6 weeks plug time, 13 to 17 weeks transplant to finish. Zones 4a to 10b. 41-71cm tall, 25-64 cm wide. panamseed.com

timing. Lower daylength sensitivity provides extra early flowering in 9-10 weeks from sowing, even under short-day conditions. Its mounded and branching habit is ideal for highdensity growing, holds better at retail and provides faster garden fill due to the need for fewer PGRs in production. Extremely free flowering, FotoFinish offers high impact at retail and longlasting garden displays. 25-35 cm tall, 60-75 cm wide.

syngentaflowers-us.com

With this Camellia sinensis, consumers can now grow their own tea leaves at home. Freshly made tea is much more flavourful and higher in antioxidants than tea that has been packaged and stored over time. Tea is produced by harvesting the

tips of the branches and then drying the leaves. Best to dry them under cover outdoors.

A great patio/container plant.

Bred by John Robb of Kulnara, New South Wales (NSW) in Australia. 30-38 cm tall, 25-30 cm wide.

ballingenuity.com

The enormous 7” Hermerocallis hybrid flower is apricot orange with an incredibly wide, orange red eye. Along the ruffled edge is a matching orange red picotee edge with a razor thin golden yellow margin. Daylilies can survive many harsh conditions that other plants cannot,

including polluted city environments, slopes, poor and dry soils, near pavement that is salted in winter, and under black walnut trees. Rabbit-resistant, attracts butterflies and hummingbirds, beefriendly. Zones 3-9. 61cm tall, 46-61 cm spread. provenwinners.com

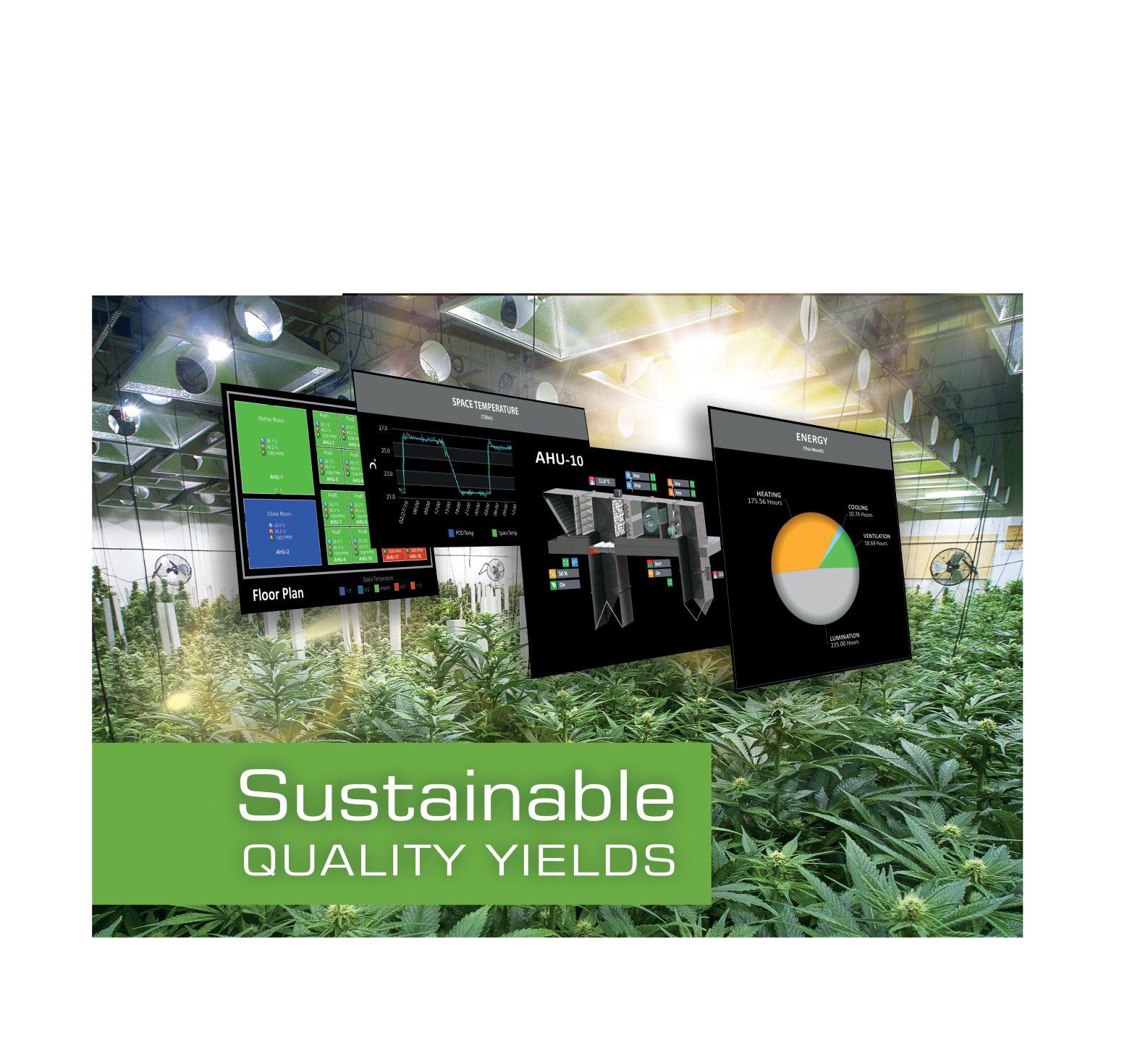

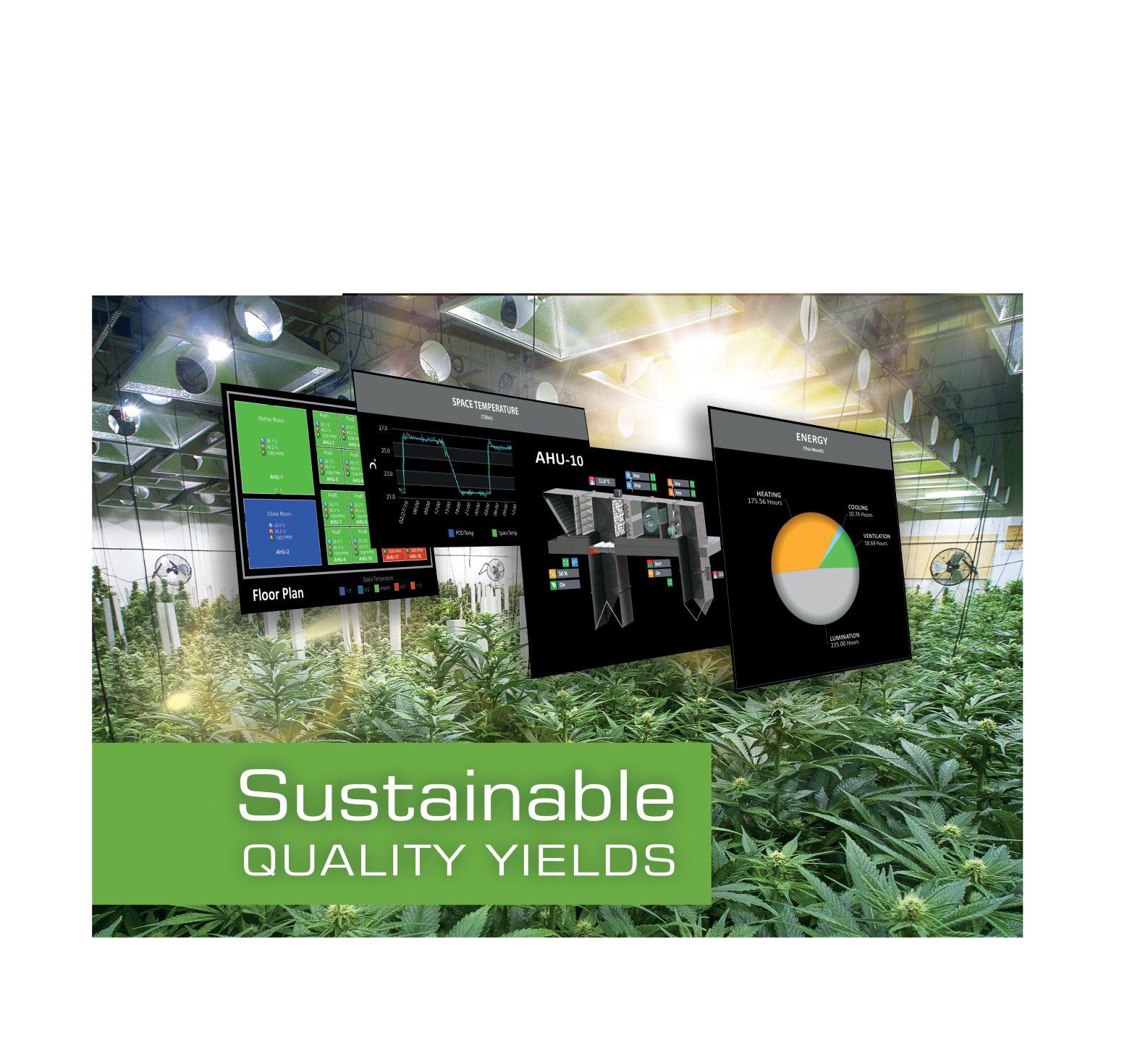

growing environment, a simple, flexible, and sustainable control system is crucial. This is why proactive LPs are turning to Reliable Controls. Our nation-wide network of factory-certified Authorized Dealers will design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely-controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective and Canadian-made solution, please contact a local Reliable Controls

Authorized Dealer near you.

New federal initiatives to help growers get through

Advance Payments Program: Those with outstanding loans from the Advance Payments Program (APP) due on or before April 30, 2020 will receive an extension of six months. The new deadline is October 2020 for 2019 cash advances on flowers and potted plants. This measure represents $173 million in deferred loans. Eligible growers can apply for an additional $100,000 interest-free portion for 2020-2021, as long as their total APP advances remain under the $1 million cap.

Business Credit Availability Program (BCAP): Export Development Canada (EDC) and the Business Development Bank of Canada (BDC) will provide $65 billion in direct lending and other types of financial support at market rates to businesses with viable business models whose access to financing would otherwise be restricted. Contact your financial institution for details.

Canada Emergency Business Account: As part of the BCAP, this is an interest-free loan of $40,000 for qualifying businesses. Up to $10,000 of that amount will be eligible for complete forgiveness if $30,000 is fully repaid on or before December 31, 2022. Businesses and not-for-profits are eligible to apply for this loan if they have an annual payroll of between $50,000 and $1 million.

Farm Credit Canada’s (FCC) higher lending capacity and payment deferral: The lending capacity of FCC rose by an additional $5 billion. FCC can also offer deferral of principal and inter-

as a result of COVID-19. Eligible applicants must have had an income of at least $5,000 in 2019 and are or expect to be without employment or self-employment income for at least 14 consecutive days in the initial four-week period.

Employers who do not qualify for the CEWS may qualify for this program. It allows eligible employers to reduce the amount of payroll deductions required to be remitted to the Canada Revenue Agency (CRA). The subsidy is equal to 10% of the remuneration paid from March 18, 2020 to June 19, 2020, up to $1,375 for each eligible employee and to a maximum of $25,000 total per employer.

Work-Sharing program: This is an adjustment program to help employers and employees avoid layoffs when there is a temporary reduction in the normal level of business activity beyond the control of the employer. The measure provides income support to employees eligible for Employment Insurance benefits who work a temporarily reduced work week while their employer recovers. Effective March 15, 2020 to March 14, 2021.

There are loans, subsidies, and tax deferrals available to farms.

est payments up to six months for existing loans or a deferral of principal payments up to 12 months, plus access to additional credit up to $500,000. Non-FCC customers are also eligible to apply.

Canada Emergency Wage Subsidy (CEWS): This is a temporary wage subsidy for employers. It will cover up to 75% of an employee’s salary on the first $58,700 earned – up to $847 a week. Funds will be retroactive to March 15. If able, employers can pay employees the remaining 25%. Employers whose revenues decrease by at least 30% in March, April or May of 2020 when compared to the same month in 2019 are eligible. The program will be in place from March 15 to June 6.

Canada Emergency Response Benefit (CERB): This provides up to $500 a week for up to 16 weeks and is for workers who stop working

Tax payment deferral: The Canada Revenue Agency will allow all businesses to defer income tax payments until August 31, 2020, on payment owing on or after March 18 and before September 2020. This relief would apply to tax balances due, as well as instalments, under Part I of the Income Tax Act. No interest or penalties will accumulate on these amounts during this period.

Deferral of GST/ HST Remittance and Customs Duty Payment: Businesses can defer until June 30, 2020 their remittances of GST/HST, as well as customs duties owing on their imports. The deferral will apply to GST/HST remittances for the February, March and April 2020 reporting periods for monthly filers; the January 1, 2020 through March 31, 2020 reporting period for quarterly filers; and for annual filers, the amounts collected and owing for their previous fiscal year and instalments of GST/HST in respect of the filer’s current fiscal year. For GST and customs duty payments for imported goods, deferral will include amounts owing for March, April and May.

Existing programs: AgriStability, AgriInvest, AgriInsurance and AgriInnovate.

Sources: Government of Canada, Ontario Federation of Agriculture, Farm Credit Canada.

Not only is physical distancing important in the greenhouse, so is creating an atmosphere where workers feel safe.

COVID-19 has completely changed the way that workplaces function. While working from home and maintaining a two-meter distance is possible for most offices, it’s a little tougher for greenhouses.

“Some producers have been reducing the number of workers in the greenhouse at one time,” says Jennifer Wright, senior HR advisor and stakeholder engagement specialist with the Canadian Agricultural Human Resources Council (CAHRC). Sometimes this means adjustments to the workflow, allowing for fewer workers in small spaces, but it’s a small price to pay for avoiding an outbreak in the workplace.

“You only need one worker that has COVID-19 coming into work and impacting your entire workforce in a negative way,” says Wright.

“You want to be creating a culture and a work environment where your workers are comfortable saying that they don’t feel well. You cannot require them to be at work if they’re not well or if they’re not comfortable.” The last thing any employer or manager would want is a negative work environment, with the fear of job loss hanging over employees’ heads.

“It does mean that you’re going to have fewer workers, and that’s a challenge for a lot of organizations.” Wright recommends that operators first identify the bare minimum that must be

achieved that day, figure out how it can be done with a skeleton crew, then move on to the ‘nice-to-haves’ that might be achievable if a larger team is available.

Employers need to be prepared with a risk management plan, detailing actions to be taken when a large fraction of the staff is unavailable for time-sensitive work. Plans should identify decision makers and their roles and responsibilities, access to medical care, as well as plans for both quarantine or transportation to medical facilities and community services. “This may include having agreements with surrounding farmers for back up support,” notes the CAHRC website.

Greenhouses receiving foreign workers need to follow the most up-to-date federal and provincial self-isolation protocols, and farms should restrict or limit visitors as much as possible. Businesses that provide housing for their workers will need to ensure that their risk management plans consider the most current government protocols for employees being quarantined or requiring health care, notes the CAHRC.

Inside the greenhouse, surfaces should be cleaned with hospital-grade disinfectant and operators should continue with biosecurity and food safety standards. “We’re learning new things about the virus everyday,” Wright says. “Make sure that you’re consistently checking with public health authorities to see what their recommendations are.”

As to the importance of handwashing, Wright can’t stress this enough. “Make sure there are handwashing stations available and maybe increase what you have,” she says. “Have a station coming into the greenhouse so [workers are] washing hands coming in and going out,” and encourage workers to avoid touching their faces as much as possible.

To help farm business operators limit the impact and spread of COVID-19, CAHRC has created a dedicated webpage with the latest information, recommendations, and employee management tools. CAHRC’s AgriHR toolkit is also available with information on health and safety and even a template for a pandemic plan. Greenhouse or farm associations who partner with CAHRC are offering their members complimentary access to this toolkit.

“If you’re taking the measures in the workplace to ensure the highest level of safety and the least amount of opportunity for exposure, your workers will feel better as well,” says Wright.

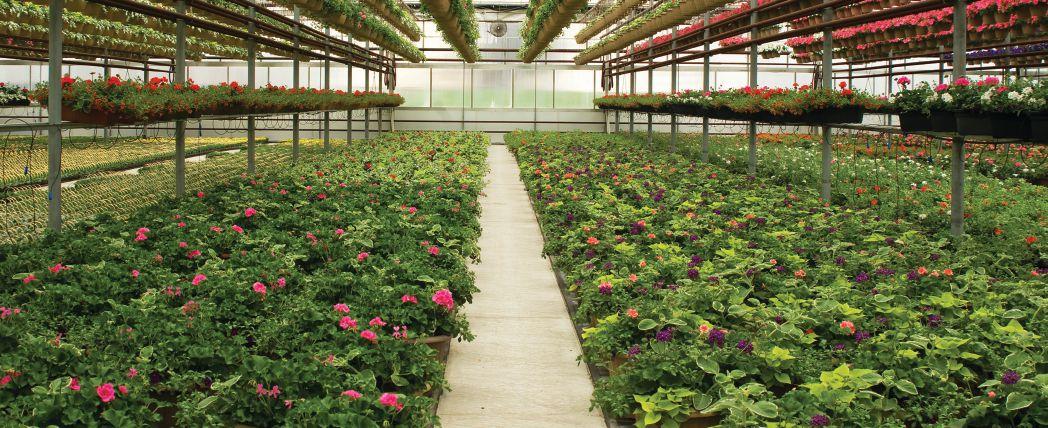

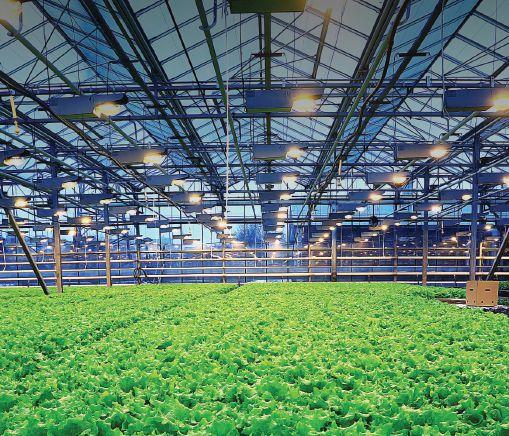

With consumers isolating in their homes during the pandemic, food gardening is expected to rise in popularity this year. Consider including container vegetables in your production.

BY DR. MOHYUDDIN MIRZA

Did you know, that as a bedding plant, ornamental or flower grower, you can produce a significant amount of vegetables in containers? Well, you should consider increasing production this year.

I spoke with several growers who are receiving requests and messages from customers on when to pick up their favorite baskets, both flowers and vegetables. Most of the growers have planned to handle their customers differently due to COVID-19.

ABOVE

They can browse through plants and baskets on the website, then choose curbside pick-up (customer stays in car and staff places order in it) or delivery. Growers are determined to follow all the precautions, legislated or otherwise, to make sure that the needs for gardening are met. I talked to many customers as well. Being at home for some time, they are hungry to get their hands on a few baskets, both of flowers and their favourite vegetables.

Tumbler tomatoes are a great way to entice new or current food gardeners.

Talking to a few growers and supported by Alberta’s 2014 Greenhouse Industry Profile Report, more tomatoes and peppers are being grown in two-gallon containers. Of course, Tumbler tomatoes for hanging baskets and containers have been around for several years, but their numbers are increasing this year due to demand. One of the customers told me that it is very satisfying to be able to pick ready-to-eat tomatoes off of the plant on the same day that they purchase the basket.

Customers go for tomato fruits. They don’t like to buy just leaves and flowers. If they are loaded with tomatoes, they see an immediate benefit and can enjoy fresh picks daily after that.

So here are a few pointers to get ready. Because of their timeframe, multiple plantings of vegetable container crops can be done.

Tomatoes are the most popular vegetable/fruit for production in pots. It will take 80 days from seed to harvest, so if you have 30-day-old seedlings, then plant them right now and they will be ready in another 40 days, right on time. They are generally sold very quickly, so plan a second crop as well.

Peppers take a little longer; 120-130 days from seed to harvest. From the growers I have seen, the peppers are already flowering, so they should be ready by late April or early May. You could always stagger them so that plants with fruit are available over a longer period of time.

Hot peppers are becoming more popular and they set fruit faster than other peppers. Make sure to label them properly because some may be too spicy for some individuals.

Mini cucumbers and pickles are popular in hanging baskets. They are fast-growing and can set first fruit within 30 days.

Lettuce and salads like kale and other leafy vegetables can be grown in 6-inch pots or rectangular containers. They are very fast growing and several plantings can be done.

Herbs are very popular now. Most of the bedding plant growers grow a large number of potted basil, mints, cilantro and others. Very popular in cooking and they are ready to use from the moment they are bought.

Strawberries are easy to grow and require cooler temperatures to set berries. A few ripened berries are very attractive in hanging baskets. Choose everbearing varieties.

Beans, peas and cole crops are in constant demand from gardeners who want to be in their backyards. They can easily follow all the instructions on physical distancing and get some exercise as well.

Consider growing more “ready-made” vegetables so that customers can quickly harvest and enjoy them. People are staying indoors for too long. Stay connected with them through your emails, newsletters and websites. They want to know what you are doing to maintain sanitary conditions in your operations, as well as any suggestions, products and activities that you have for them. As a final thought, try some other plants of medicinal importance. For instance, I love to get purslane from growers and use it in salads and omelettes. It is rich in Omega fatty acids. Try some Echinacea angustifolia roots and plant a few seedlings of Rhodiola, which is said to help combat stress. I think together we will conquer this virus. Happy planting.

Mohyuddin Mirza, PhD, is an industry consultant in Alberta. He can be reached at drmirzaconsultants@gmail.com

Registered for use on cannabis raised indoors, KOPA insecticidal soap controls whiteflies, spider mites, aphids and other soft-bodied insect and mite pests on contact.

OMRI® CANADA Listed for organic production, KOPA can be used right up until the day of harvest. KOPA is lethal to pests, yet it is of low risk to workers and the environment.

KOPA. When clean product is your only marketable option.

By Sarah Brackman

For over 20 years, BioSafe Systems has manufactured sustainable sanitation products for commercial growers; providing unparalleled protection against plant and human health pathogens. Prevention and sanitation are a grower’s best defense from disease and crop loss.

It’s important to identify the potential areas of infection (and re-infection) within growing areas; including non-crop areas, edges, under benches and entryways. Once identified, growers can create an overall sanitation plan that can be followed between crops, at the end of the season and during production. Good planning, direction and the right equipment are key elements in a cleanup program.

A washing step helps to increase a sanitizer’s efficacy by eliminating organic matter, which plays host to a variety of pathogens and insects. Washing surfaces with a detergent, such as GreenClean® Alkaline Cleaner, will emulsify organic matter and rinse it away.

Once areas have been cleaned, sanitizing agents will have the highest possible efficiency. If there was a recent disease outbreak, skipping cleaning or sanitizing opens the risk of re-infection. SaniDate® 5.0 is an ideal sanitizer/disinfectant because it kills pathogens on contact and does not require a post rinse or leave harmful residues; making this sanitation step a spray-and-walk-away application.

Another critical point in facility sanitation, irrigation lines can develop biofilm which can harbor and transport water-borne pathogens such as pythium and fusarium. Using an acid detergent, such as GreenClean® Acid Cleaner, removes fertilizer minerals and strips away biofilm’s protective coating. Follow the acid cleaner with SaniDate® 5.0 to eliminate remaining bacteria. This 2-step program from BioSafe Systems will help keep growing areas clean and reduce emitter clogging.

Remember, sanitation is not just an ‘end of the season’ activity, it must be practiced during production. Standardize practices, such as spraying racks, empty benches, walkways and sanitizing pots, trays and equipment, to maintain a clean environment. Don’t forget to eliminate slippery conditions and reduce the risk of on-the-job injuries with GC PRO™ Oxidizer Treatment.

Placing a BioMat™ in front of entryways will decrease the amount of infection spread in facilities. Keeping the BioMat filled with SaniDate 5.0 is an easy and effective part of regular, daily maintenance.

After assessing risk areas and developing a plan, it’s time to improve production with a cleaner way of growing. Implement something simple; start with the most critical points of control and branch out from there. Once a strategy is in place, execute and evaluate. Adopt a flexible approach and make regular observations and improve your plan based on results. A solid sanitation program results in a strong foundation for your next production cycle.

Foaming applications increase contact time on vertical and hard to reach surfaces and creates an assuring visual, allowing users to achieve complete coverage. The BioFoamer™ is an excellent tool for growers as it limits the amount of water used, creating very little waste. Applications require BioFoamer Foaming Agent™ along with sanitizing solution; SaniDate 5.0 or ZeroTol®

Many independent garden centres shut down their retail store fronts during the pandemic, but these innovative operators found ways to engage new and existing customers.

BY GRETA CHIU

BELOW

Will Heeman says they fulfilled over 250 orders within the first five days of opening their online store.

As the public took on their physical distancing measures in response to COVID-19 recommendations, independent garden centres made the difficult decision to close their retail fronts to visitors. But for some, this experience only served to spurr their businesses forward in new directions.

For Heeman’s, this change drove the garden centre near London, Ont. to build an online store. The response was overwhelmingly positive. Within 28 hours of opening online, Heeman’s received 35 orders that were ready for delivery the following morning. They also managed to keep up with their quick turnaround times and high standards of service. After 5 days, they fulfilled over 250 orders online and over 100 by phone.

Usually the number one reason why a garden centre hasn’t turned to online sales before is because of logistics, says Will Heeman, Chief Daymaker at Heeman’s. Managing in-store stock and online inventory at the same time can be difficult, which is why their business hadn’t sold items online until recently.

At the time, about 75 per cent of their orders were for curbside pickup. “I think people are still

looking for an excuse to get out of their house for a bit,” says Heeman. Customers familiar with their instore offerings had been ordering by phone and requesting seeds, particular pots seen on a previous visit and other specific items.

Christie Pollack (right) and Nadine Stielow (left) are finding new ways to engage gardeners.

online experience doesn’t come anywhere close to the in-person store experience. Heeman’s was designed to be a destination, incorporating a café into their retail store, hosting a number of crowddrawing events each year and even adding a hard cidery to their operation. “I feel very passionately that we are a retail experience,” Heeman says. “But for now, this is what we need to do to serve our customers and keep our staff employed.”

Back in the greenhouse, Heeman says they cut back on production, reducing transplants of spring annuals. Though he estimates only making a small fraction of their normal sales, it’s still something. Plus, they were able to keep their staff employed during a time of layoffs and losses for the floriculture sector. “Greenhouse workers is considered an essential service,” he explains. They reassigned their retail employees to e-commerce duties, including pulling orders, answering phones and coordinating deliveries. With much of the public isolated in their homes, Heeman expects a later purchasing and buying season than normal, but at a higher level of engagement. They’re going to want to be outdoors even more, he predicts. “People are going to be even more interested in growing their own food.”

The popularity of food gardening is expected to rise even more this season.

“Our goal is to have as much of the [retail] store online as possible,” says Heeman. Within a week of opening, the online store listed over 250 different products, each with options for colours and sizes. “We started with seed-starting supplies, soils, houseplants, hard cider and spring plants,” he continues, and from there, they planned to expand online listings to include pottery, nursery stock and perennials.

It goes without saying that the

Food gardening has been a steadily growing trend, but with selfisolation and social distancing measures in place, its popularity is expected to rise even more this season for its healthy, outdoor appeal.

Seeing the rapidly evolving COVID-19 situation months ago, Christie Pollack had a feeling that she would eventually have to shut down her garden centre in

High Prairie, Alta. But the owner of Christie’s Gardens and Greenhouses strangely wasn’t panicked. In fact, she was feeling invigorated at the chance to start something new.

A known influencer who creates online resources for new plant aficionados on her website, Learn. Plant. Grow., Pollack kicked off a new online venture to help beginners take up food gardening from the comforts of their own home. Inspired by her own life coach, Pollack launched the aptly named Grow Your Own Food Challenge to help participants

Retail staff at Heeman’s were reassigned to e-commerce duties, including pulling orders, answering phones and coordinating deliveries.

through the process of starting a garden over the course of two months.

Joined by fellow Albertan growers Nadine Stielow of Thiel’s Greenhouses, Jason Anderson of Kathy’s Greenhouses and Debbie Foisy of Deb’s Greenhouse, participants not only receive regular prompts from these four professionals, but personalized coaching along the way. All this takes place through their private Facebook community, and participants are free to post photos and questions as they need.

Not only is this challenge designed to give them information, explains Pollack, participants learn how to conduct their own research and how to decide whether the information is reliable. “They have to be able to find the information on their own after the course is over.”

Pollack and Stielow both see this as a healthy outlet for quelling feelings of anxiety and of unease over COVID-19 in their communities. “Right now [the group] is a positive space away from all the noise,” says Pollack, “Let’s focus on something they can do…something that is actionable.” Stielow agrees, “People need to know that we’re connected in our community and we’re ready to help out.”

Both avid supporters of using biological controls in the greenhouse, the duo debuted another new initiative shortly after. “It’s called Bug School,” says Pollack. From scouting to targeted control, the online resource teaches home gardeners how to protect their plants from pests. “We talk a lot about biologicals, and where to look on the plant for pests, their lifecycle, and how to treat them.”

“A lot of people, when they see mechanical damage, they think bugs,” says Stielow, “but it isn’t always. Sometimes it’s disease. And if it is a bug, is it piercing or sucking? What are they watching for?” Similar to the goals of the food gardening challenge, Bug School is about arming participants with the right tools. “It’s about simplifying the language but still giving them enough information so they can keep researching,” says Pollack.

As for their own operations, Pollack closed her retail business to visitors in mid-March, opened up her online store and offers curbside pick-up options. Depending on how COVID-19 conditions and restrictions change, she’s hoping to re-open the retail operations to small groups in May.

With the help of friends and family, Stielow set up her online store in just four days and also offers curbside pick-up.

“I think it’s going to be a phenomenal spring,” she says. Their production has stayed the course, though like Heeman, she predicts a later start to the spring sales season. Her customers started phoning about vegetables, herbs and food-related products in March, but notes that flowers were still at the forefront of people’s minds.

“I’m looking forward to see how the season plays out,” says Pollack, who views the situation as a challenge – one that has pushed them to innovate. “We’re going to come out with better ideas for our business in the long run.”

BY DR. MUHAMMAD ARIF AND DR. PETER K. PAULS

Luffa or Chinese okra (Luffa aegyptiaca Mill. and Luffa cylindrica) is typically cultivated in tropical and subtropical environments, but current research at the University of Guelph is looking into how this crop could be grown locally in greenhouses.

There are different uses for the crop depending on its stage of development. Their immature fruits are consumed as vegetables, while their mature fruits are used for household cleaning and personal hygiene.

Fresh luffa fruits are low in calories (20

ABOVE

kcal/100 g), and rich in antioxidants and vitamin A (123 mcg), C (12 mg) and iron (0.36 mg) (USDA National Nutrient database). Furthermore, luffa is consumed by some because of purported health benefits in relation to asthma, splenic enlargement and skin diseases. As the fruit matures on the vine, its fibrous flesh dries out, leaving behind a sponge. The sponges are sold commercially as a skin exfoliant and as cleaning supplies. Industrial uses of luffa sponges include ecofriendly marine steam engine filters, sound

With both nutritional benefits and industrial uses, researchers are looking into the possibility of growing luffa in Canadian greenhouses.

absorbers, door mats and table mats.

The luffa plant is an annual climbing vine that typically requires sandy loam soils, good sunlight and humid conditions for rapid growth in the field. Male and female flowers develop independently and indeterminately in clusters on the same plant. Luffa is a cross-pollinated plant and the bright yellow flowers attract pollinating insects like honey bees.

Approximately 16 per cent of Canada’s population is from regions of the world where luffa is used regularly as a main vegetable (Statistics Canada 2006 population census). According to the Food and Agriculture Organization (FAO), China, India, Japan, Indonesia, Malaysia, Philippines, Hong Kong, Brazil and the Caribbean are the major luffa-producing countries of the world. To meet demand, luffa is imported into Canada from Central America, Asia and Africa. Although the Canadian environment is temperate, other cucurbits such as pumpkin, squash and cucumbers, are successfully grown locally, suggesting that luffa gourds could be introduced into Canadian agriculture as well. Moreover, Canada has one of the world’s largest, most well-established, greenhouse sectors with 2,338 facilities covering a total area of 113.82 million square feet. Hoop houses are also being considered for extending the season and creating an environment favourable for luffa production in Canada.

The Department of Plant Agriculture at the University of Guelph collaborated with OMTEC Inc. in Ridgetown, Ont. to demonstrate the potential for producing luffa in a greenhouse using rockwool slabs and hydroponic cultivation for both ridged and smooth luffa. In a greenhouse, at 24°C, a relative humidity of 50 – 70% and a 16 h light/ 8 h dark photoperiod, the luffa

plants grown in a hydroponic system required: ~3.0 litre nutrient solution/ day with pH ~5.5 and electric conductivity (EC) ~ 3.0. A large variation in plant growth and fruit production characteristics were noted among different luffa varieties. For example, flower initiation occurred between 41 – 66 days after planting of the different luffa gourds. Similarly, the first fruit was ready to pick in 60 – 87 days after planting in different varieties in a greenhouse containing a bumble bee hive from a commercial source. The immature fruit was ready to harvest in 6 – 7 days after pollination. The average fresh fruit weight ranged from 118 – 257 g; fruit girth ranged from 10 – 15 cm and the length varied from 20 – 60 cm. The number of fruit per plant ranged from 0 –16 over a two-month fruiting period. The best yields were seen with 16 gourds/ plant and averaged 7 kg of fruit/ square meter of greenhouse space.

The initial work at the University of Guelph laid the foundation for longer term studies of the potential for commercial luffa gourd production in Canada, including studies of the genetics, breeding, agronomy of this crop, as well as manipulating the environmental conditions for high economical yields. The addition of a new crop to Canadian agriculture will increase the choices of vegetables available to consumers and could replace produce that is currently imported with locally grown product. This work could also add to the choice of crops that can be grown in rotation in greenhouses.

Acknowledgements: This research was supported by NSERC Engage grants. Muhammad Arif, PhD, is a research associate, and Peter Pauls, PhD, is a professor in the Department of Plant Agriculture at the University of Guelph.

Left unchecked, Pythium can lead to significant crop losses.

BY BC MINISTRY OF AGRICULTURE

Pythium species are fungal-like organisms (Oomycetes), commonly referred to as water molds, which naturally exist in soil and water as saprophytes, feeding on organic matter. Some Pythium species can cause serious diseases on greenhouse vegetable crops resulting in significant losses.

Pythium infection leads to damping-off in seedlings and crown and root rot of mature plants. In Canada, several Pythium species, including P. aphanidermatum, P. irregulare and P. ultimum, are known to cause damping-off and crown and root rot in greenhouse cucumber, pepper and tomato crops. There are no Pythium-resistant varieties available, although some varieties may have disease tolerance.

Overwatering, poor root aeration, root injury and improper root zone temperatures can weaken the crop and trigger Pythium outbreaks. Saturated growing media that are either too cold or too warm can be conducive to Pythium build-up and spread in water and recirculating nutrient solution. Plants grown under optimal environmental conditions are less susceptible to Pythium than plants grown under poor conditions.

DISEASE CYCLE

Pythium can be introduced into a greenhouse in plug transplants, soil, growing media, plant refuse and irrigation water. Greenhouse insects such as fungus gnats (Bradysia impatiens) and shore flies (Scatella stagnalis) can also carry and spread Pythium. Pythium spreads by forming sporangia, sack-like structures that each release hundreds of swimming zoospores. Zoospores that reach the plant root surface encyst, germinate and colonize the root tissue by producing fine thread-like structures of hyphae, collectively called mycelium. These hyphae release hydrolytic enzymes that degrade root tissue and absorb nutrients as a food source. Pythium forms oospores and chlamydospores on decaying plant roots which can survive prolonged adverse conditions in soil, greenhouse growing media and water, leading to subsequent infections.

SYMPTOMS

Pre-emergence damping-off causes seeds and young seedlings to rot before they emerge from the growing medium, while post-emergence damping-off kills newly emerged seedlings. In post-emergence damping-off, the pathogen causes a water-soaked, soft brown lesion at the stem base, near the soil line, that pinches off the stem causing the seedling to topple over and die. In mature plants, Pythium causes crown and root rot, where plants suddenly wilt when the weather turns warm and sunny and when plants have their first heavy fruit load. Often, upper leaves

of infected plants wilt in the day and recover overnight but plants eventually die.

In the root system, initial symptoms appear as brown to dark-brown lesions on root tips and feeder roots. As the disease progresses, symptoms of soft, brown stubby roots and lacking feeder roots, become visible (Figure 1). In larger roots, the outer root tissue or cortex peels away leaving the string-like vascular bundles underneath.

Pythium rot also occurs in the crown tissue at the stem base. In cucumber, diseased crowns turn orange-brown in colour, often with a soft rot at the base; brownish lesions extending 10 cm up the stem base may be seen.

Routinely monitor your crop for slightly wilted plants and check wet areas in the greenhouse where the Pythium is more likely to be present. Pythium occurs mostly in spring, at early fruit set and later in the season on mature plants.

In cucumber, Pythium can also occur in the summer on young plants brought in for the fall crop. Monitor plants for wilting, and

FIGURE 1

Pythium crown and root rot in greenhouse cucumber showing orange discolouration of the crown area (left) and rotted roots and root tips (right).

in cucumber, check the stem bases for discolouration. Always confirm Pythium diseases by sending representative plant samples with roots, crowns and foliage to a plant diagnostic laboratory or the local ministry of agriculture’s plant health laboratory.

Disease management consists of a combination of cultural, biological and chemical tools to control and/or manage crop diseases

effectively. Cultural controls keep Pythium from reaching the roots while biological and chemical controls inhibit or suppress Pythium in the root zone.

Sanitation: Field soil, debris, irrigation water from pond and stream water, roots, and plant refuse and growing medium of previous crops can contain Pythium. Follow a strict greenhouse sanitation program throughout the year and a thorough year-end clean up. Clean and disinfest all interior greenhouse surfaces and equipment including tools, hoses, walkways, carts, totes, troughs, tanks and water supply lines. Use sterile propagating media. Remove dying plants by placing them directly into plastic bags for disposal away from the greenhouse.

Irrigation water: Untreated water from rivers, streams or ponds poses great risk for Pythium introduction while treated, municipal water is considered safe from Pythium. Water storage and nutrient tanks need to be disinfected periodically and covered to prevent Pythium contamination.

Nutrient solution: Generally, greenhouse vegetables are raised on rockwool in plastic sleeves or bags containing rooting medium (i.e. rockwool slabs, sawdust or coconut fibre) through which water and nutrient solution are circulated. Since Pythium and other pathogens can build up in nutrient solution, periodically disinfest recirculating nutrient solution using physical, biological or chemical methods (Marchuk, 2006).

Physical – slow sand filtration, ultrafiltration (membrane filters), micro-pore filtration (high pressure, rapid flow membrane or sediment filters), heat pasteurization (95-97°C for 30 seconds or 85°C for 3 minutes), UV radiation, sonic energy, magnetism, aeration (i.e. oxygenation), ozonation, etc.

Biological – biofiltration (slow sand or lava rock), water retention ponds.

Chemical – chlorine, chlorine dioxide, copper, hydrogen peroxide, electrochemical, soaps (wetting agents), iodine, etc.

Resistant varieties: Although there are no resistant vegetable varieties, some vigorous varieties may have some tolerance to Pythium. Contact your local seed/ transplant agent for further information on Pythium-tolerant varieties.

Seedlings and transplants: Carry out transplanting in the morning or late afternoon/evening to avoid stress from high day time temperatures. Allow for good air cir-

culation around seedlings by proper plant spacing and good aeration of irrigation water and re-circulating nutrient solution. Use healthy transplants and handle them carefully to avoid wounding plants and roots and practice good sanitation when transplanting; do not let them dry when setting out. Water seedlings in the morning so that plants are not wet overnight.

Plant growing conditions: Ensure that transplants have the proper root zone temperature and adequate moisture when moved into the greenhouse. The growing media must be well drained, as saturated bags with low oxygen levels can predispose transplants to Pythium diseases.

Use warm, aerated irrigation water (1822°C). Avoid low light levels, low pH, high salts and warm growing conditions (above 28°C) which favour Pythium. In greenhouse cucumbers, the nutrient solution should be delivered at pH 5.0 for approximately five weeks followed by adjusting the pH to a 5.8-6.2 regime for one week. (Tu, 2004).

Target rockwool block wetness at 7075% between watering.

Use white/colourless drip lines instead of black or place drip lines on the shaded

side of the grow bags.

Disease monitoring: Plants must be monitored for any signs of Pythium diseases throughout the cropping cycle. Remove and destroy severely infected plants and replant in new growing bag medium. Infected plant materials, including grow bags, must be safely disposed away from the greenhouse by deep-burying, incinerating or composting.

Control fungus gnats (Bradysia impatiens) and shore flies (Scatella stagnalis) which spread Pythium.

Prevent Pythium diseases by practising integrated disease management strategies based on cultural and biological controls. Use fungicides as a last resort at the onset of disease.

Rotate registered fungicides with different chemical groups and strictly follow label directions to avoid resistance development in Pythium.

Routinely monitor plants and evaluate the level of disease control if fungicides are used. Stop fungicide treatment and get professional advice if fungicides fail.

Various biological additives are now available for agriculture and horticulture. The definition of “active ingredients” could be subject to several articles. Some can be applied above soil line to reduce plant diseases or reduce insect pests. Others can be incorporated into growing media to enhance plant growth and/or reduce plant root diseases. Greenhouse and nursery growers often ask if active ingredients are effective, if they can replace chemical treatments, if they can be used in combination with chemical treatments and provide a return on investment. Here is an overview for the use of active ingredients for the plant root zone.

Compared to mineral soil, growing media used in greenhouses and nurseries are ”constructed” with organic based materials, such as peat moss, bark, coconut coir and/or other materials. Other ingredients, such as aggregates, fertilizers, limestone, etc., are added to make blends that have specific physical and chemical properties. Unless active ingredients are added, growing media generally contains low levels of microbes, making them virtually free of the biological component.

If we were to take a sample of mineral soil from an untouched environment, we would find a wide array of diverse biology. Some microbes convert organic matter into nutrients for plants, some fix nutrients in the soil for plant uptake and others interact to protect and stimulate plant root systems. In mineral soil, there can be any combination of microbes consisting of actinomyces, bacteria and/or fungi. Of these microbes, there are saprophytes, which feed on dead material; pathogens, that feed on and damage plants; symbionts that assist plants; and competitors, which can attack or compete with other microorganisms.

Over the years, scientists have isolated and cultured various beneficial microbes for use in agriculture and horticulture. These microbes are produced in laboratories to be sure that strains remain true and continue to provide the desired benefits. Various microbes commercially available to growers can be placed into two general categories by the benefits they provide: biocontrols and biostimulants. Biocontrols are active ingredients that reduce the incidence of plant diseases or insects. They may directly attack the pathogen or insect, or indirectly control by creating barriers, producing a metabolite, blocking food source or excluding a pathogen. Compared to biostimulants, which are microbes that stimulate plant growth or assist plants in acquiring nutrients and/or water to improve the overall growth of plants. Some Bacillus species and mycorrhizae are among popular biostimulants. Bacillus pumilus is a bacterium that induces the proliferation of the root hairs for better nutrient uptake. Mycorrhizae (endomycorrhizae) are symbiotic associations between a fungus and a plant. The fungus grows in and around plant roots to form an extension of the root system and draw nutrients and water for the plant, which often are inaccessible to the plant roots. Mycorrhizae enable plant to be better protected and to resist the stresses caused by transplanting, drought and heat, while maintaining an optimal growth rate.

One of the main advantages of using beneficial organisms is that they are safe to use. They have little to no toxicity to plants, humans or animals. Most have been discovered in mineral soil and are naturally occurring, not genetically modified. Because they are part of the normal checks and balances of soil biology, there is less potential for pathogen resistance. Most active ingredients that suppress pathogens or insects are preventative, not curative; therefore, they prevent the onset of plant disease before it has a chance to affect crops. For insects, they may reduce fungi that insects feed on, hence reducing their populations. Most beneficial active ingredients remain in the root zone of the plant for an extended period, while some can remain with the plant for life. If you are growing organic certified crops, a major advantage is that most active ingredients are certified or listed for use with organic crops.

Unlike chemical fungicides that are wide spectrum, biological controls generally interact with specific pathogens, therefore their range of pathogen control can be narrower that their chemical counterparts. If used in combination with chemical controls or other biological additives, be sure to check the compatibility of the microorganism with the chemistry and other bioadditives used.

The major advantage of having active ingredients in growing media before you plant is that these microbes are present in the root zone before root diseases have a chance to get establish. Most beneficial microbes are packaged in granular form, powder or liquid format. Some of the liquid products can be applied in the greenhouse with injectors through the irrigation system. Most of the powders can be drenched, however there is added labor and time to apply products in this method. If you add beneficial microbes yourself, the easiest method is to add products to the mixing line. Another choice it to speak with your growing media supplier, since most manufacturers can add active ingredients to growing media for you. Often the best value and return on investment is to have the beneficial microbes added for you. Keep in mind that if the product you are adding to growing media is a PMRA registered biopesticide, handling and use regulations must be respected.

The use of active ingredients is becoming popular for plant growth enhancement and natural suppression of plant root diseases. They are readily available, predictable in the results they provide and are cost effective, offering growers a safer alternative and an additional tool for plant culture.

Ed Bloodnick Director of Grower Services

Vigilance needed for control options to be effective

BY PETER MITHAM & GRETA CHIU

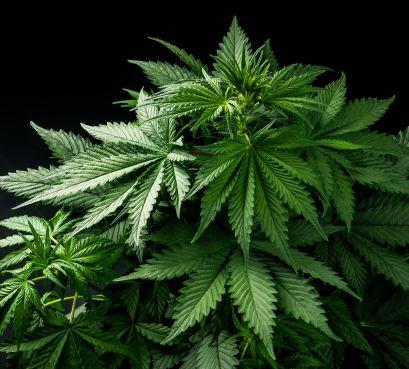

With few effective pest management options in their arsenal, cannabis producers in Canada need to emphasize preventative measures and target their resources towards the right pests.

While greenhouses offer a controlled environment for crop production, insects and other pests eventually find their way into the structures. Being in a closed environment can make it even more challenging to manage them.

This is why Suzanne Wainwright-Evans told growers attending the CannaTech West program, alongside the Pacific Agriculture Show in Abbotsford this winter, that prevention is key. A well-travelled speaker on pest management

ABOVE

and principal of Buglady Consulting Inc. in Slatington, Pennsylvania, she’s seen some spectacular infestations, underscoring the need for proper sanitation, scouting, identification and management.

To head off infestations, one of the first things that growers should do is to implement a stringent quarantine process. ”When you’re designing a facility, it’s important to include a quarantine area. But if you don’t currently have one, look for an area at your facility that you can retrofit or use as a substitute,” says Wainwright-Evans.

New plants, need to be quarantined for a few weeks before they are put into production, giving

The cannabis aphid is a growing concern in the greenhouse. The species acts differently compared to others in the same genus, and applying the same control methods often will not work.

any unknown pests enough time to develop and appear. For early detection and monitoring, sticky cards placed in quarantine and high-traffic areas are a great way to check for adult flying insects such as thrips, fungus gnats and whiteflies, but they’re less effective on crawling pests such as mites. “That’s why you have to physically look at the leaves, do the bang board test and scout the plants really well,” she says. Large mass trapping cards should also be placed as a preventative measure. Because of the strict requirements set out by Health Canada, insects and mites cannot be found in the bud, regardless of whether they’re pests or beneficials. The presence of thrips, for instance, have not been correlated with a reduction in bud yield, but it’s still important to manage them for a better quality product.

“One of the more common pests we’ve been seeing in cannabis are fungus gnats, which feed on the roots of plants,” says WainwrightEvans. What’s more, research has shown that this pest can vector plant pathogens such as Fusarium, a key problem in cannabis crops. For control, the beneficial nematode (Steinernema feltiae) has been highly effective in managing fungus gnat larvae, in addition to a few other pests, and should be a routine preventative step in any pest management program. While they’re compatible with many crop protection products, the key to effective nematode use is knowing how to properly store, handle and apply them. “You have to make sure you read and follow the labelled directions,” she says, as she’s seen growers putting out dead nematodes before.

The cannabis aphid (Phorodon cannabis) is a growing concern, in part because many producers confuse it with the hops aphid (Phorodon humuli). But it’s not, and hops aphids won’t infest cannabis

even when given the chance. Because P. cannabis acts differently from other members of the same genus, producers cannot simply apply the same management techniques and expect them to work.

What is known about the cannabis aphid is that it is highly reproductive, giving birth to live young, and in some circumstances, even laying eggs. However, notes WainwrightEvans, “For indoor cannabis production, eggs are less of a concern.” Up until now, she hasn’t seen any evidence of eggs hatching in greenhouses or indoor grow operations, likely because the environment isn’t quite right for it.

“Cannabis aphids can be challenging to manage,” says Wainwright-Evans. Any operations currently infested with the pest will likely need to apply an initial knockdown spray. This will reduce the number of cannabis aphids to a more manageable level, giving beneficials a chance to get ahead.

“Biocontrol agents are not going to control an infestation of this pest. You have to start when the pest numbers are extremely low,” she says, explaining that biocontrols are not meant to be a rescue treatment. “Once your numbers are down, then you can come in and release parasitic wasps, like Aphidius colemani, A. ervi, and A. matricariae in addition to using more generalist predators like green lacewing larvae. Managing this pest is a multi-pronged approach. There’s no silver bullet.”

Wainwright-Evans also called out rice root aphids (Rhopalosiphum rufiabdominalis) as a particular concern. She’s seen this one in many cannabis production facilities throughout the US and Canada. “The rice root aphid is a classic example of why you need a good quarantine area because most infestations come from people bringing in infected plant material. Since the aphids are in the media, people

While many crops enjoy an established set of tools for managing pests, the relatively new cannabis sector isn’t so lucky. Unlike in the U.S., all pest control productseven minimum risk pesticides - must be registered with Health Canada prior to use in their intended crops. There is no list of exempt “minimum risk” materials in Canada.

This means that using biopesticides is the default backup plan for cannabis growers, according to Caroline Bédard, provincial minor use coordinator with the BC Ministry of Agriculture. She points growers seeking pest control options to Integrated Pest Management for Commercial Cannabis in BC, which lists more than 14 approved biopesticides. These include canola oil, garlic powder, hydrogen peroxide, strains of the beneficial fungus Trichoderma harzianum as well as Beauveria bassiana

Because cannabis is regulated differently from other agricultural crops, provincial minor use coordinators can no longer submit requests for biopesticide label extensions for commercial cannabis grown indoor or outdoor, with the exception of industrial hemp. Crop protection companies are now the sole entities allowed to request label extensions for cannabis.

It’s now up to the major crop protection companies to register additional products for use in cannabis. Bédard hopes that with the legalization of industrial hemp in the U.S. – the same plant taxonomically, but grown with a different end-use and nearly negligible levels of tetrahydrocannabinol (THC) – will create greater openness to the opportunities in cannabis.

often miss the pests that are there. You have to start managing this pest at the propagation stage.”

Targeting major pest issues at the young plant or clone stage essentially gives the crop, and beneficials, a head start.

“If you don’t have a strong program in prop, you’re going to be fighting the pest uphill the whole time.” It’s also less expensive to treat for pests early on. Not only is there less plant material in a smaller area to manage, producers can stop problems before they start, and overall, that means less product needed.

Since cannabis doesn’t have access to many of the traditional agrochemical products used in other greenhouse crops, growers really need to focus on sanitation, good-growing strategies and incorporating a strong preventative biocontrol program to head off any issues.

With commercial cannabis production in its infancy, not only are there limited resources to help producers identify and manage pests, but the information is changing at a rapid pace. WainwrightEvans cautions that there is a lot of misinformation online, and even the right information can become outdated quickly as the results of new studies emerge.

Producers need to make sure that they’ve found the most recent information and from a trusted scientific source.

She also underscores the importance of working with a qualified crop consultant or supplier to help put together the right preventative pest management program for the operation. “Every cannabis facility is different,” she says. “You have to look at what the key pests are at the facility and which products are going to work in your environment.”

Fast

Self

Low

Long operation life

With 66,000 tonnes of sweet potatoes coming from the U.S. annually, there’s an opportunity for local sweet potato production in Canada.

BY DR. VALERIO PRIMOMO

Sweet potato consumption in Canada has doubled over the past 10 years, presenting a remarkable growth opportunity for Canadian horticulture. Approximately 80 per cent of the consumption comes from importing 66,000 tonnes annually from the U.S. Almost all Canadian sweet potato production occurs in Ontario, which accounts for approximately 2,000 acres. In the past few years, production has expanded to new provinces, including Manitoba, Saskatchewan and Alberta.

ABOVE

So far, growth in production has been limited by the lack of adapted varieties to our short growing season and limited access to propagative material.

To address this opportunity, Vineland Research and Innovation Centre (Vineland) collaborated with Louisiana State University to develop a new high-yielding, Canadian climate-adapted variety with desirable consumer characteristics called Radiance.

However, the success of this

The Canadian climate-adapted sweet potato variety known as Radiance.

of slips in the March to May timeframe during which slips are produced. As a result, Canadian sweet potato growers typically obtain their planting material from North Carolina in late May to early June, once soil temperatures are high enough to promote growth from slips. The supplied slips are specific varieties developed by Louisiana State University and North Carolina State University breeding programs tailored to the U.S. market and their growing seasons. It is important for growers to have access to this material early in order to maximize the growth of sweet potatoes during the short Canadian growing season. Canadian growers are facing a number of logistical, timing and disease issues as they import approximately 24 million sweet potato slips each year from North Carolina. They have identified the need for a Canadian slip propagation industry to resolve these issues. As the acreage of sweet potatoes in Canada continues to grow, there is a lucrative opportunity for existing Canadian greenhouse propagators to provide high quality greenhouse slips to meet this growing demand. Sweet potato growers in turn will have access to a new source of sweet potato slips providing the following advantages:

• Avoid deterioration due to transportation and border control delays

• Available in time for the Canadian planting season

• Acclimatized for planting in cool Canadian conditions

• Sufficient quantities of slips available for growers to plant as many acres as needed

• Access to the new Canadian-adapted variety known as Radiance

The process starts in a propagation chamber under conditions that cause the vegetables to sprout. Those shoots are cut, then grown in small soil beds in a greenhouse. Once they reach the right size, the shoots are harvested and ready for pickup by growers. The entire process takes about four months to complete. Because of their timing, sweet potato slip production could be ramped up just after propagative materials for tomatoes, cucumbers and peppers ship out.

Vineland has published a business case and best production practices to support the development of a national slip propagation industry in Canada. The new guide offers information on various aspects of production to efficiently grow high quality sweet potato slips in existing Canadian greenhouses. Highlights include:

• A nomenclature system to describe the three generations of sweet potato root seed stock

• Equipment requirements and technical details for field production of root seed stock

• Greenhouse requirements for producing slips

• A detailed step-by-step process to produce virus-indexed slips in a greenhouse using root seed stock and single-node cuttings

• An itemized list of direct and fixed expenses used to calculate the costs of production for each generation of root seed stock and slips

• Potential net revenue models based on sale price per slip and number of slips produced per square metre.

new sweet potato variety is contingent on growers’ abilities to access propagative material since sweet potatoes are vegetatively propagated through unrooted vine cuttings known as slips. Slips are 20 to 30 cm in length and are produced by planting a mature sweet potato referred to as sweet potato root seed (pictured above).

Currently, the majority of sweet potato slips are produced in the southern U.S as climatic conditions are conducive to outdoor production in early spring. This method is not appropriate for Canadian slip production since outdoor temperatures are too low to support the growth

Currently, an estimated 24 million slips would be needed to fill the 2,000 acres of sweet potatoes grown in Ontario. To offset sweet potato imports from the U.S., an additional 4,000 acres would need to be grown from 48 million slips.

The production season for sweet potato slips begins early March and ends late June. Because sweet potatoes are native to tropical and sub-tropical environments of the Americas, greenhouse temperatures between 24°C and 26°C are required throughout the growing season. Supplemental lighting may be required during the early months of production.

The guide is available for download in English or French on Vineland’s website: http://www.vinelandresearch.com/sites/default/ files/canadian_sweet_potato_slip_production_manual.pdf

http://www.vinelandresearch.com/sites/ default/files/canadian_sweet_potato_slip_production_manual_in_french.pdf

Appreciation is extended to the Ontario Ministry of Agriculture, Food and Rural Affairs, the University of Guelph and Agriculture and Agri-Food Canada for their generous financial support.

Valerio Primomo, PhD is a research scientist in vegetable breeding at Vineland Research and Innovation Centre. He can be reached at 905-562-0320 x873, valerio.primomo@vinelandresearch.com.

Post-harvest quality is undoubtedly one of the most important issues for the cut flower industry.

With consumer appeal based entirely on its appearance at retail, post-harvest care is critical to the quality of the end product. Unlike most bedding and potted plants, cut flowers compete with other gift items such as wine, cheese and chocolate.

BY GRETA CHIU

“Anytime a consumer has a bad experience with flowers, we have the potential to lose them…or they become more sensitive to the price point,” says Dr. John Dole, professor, associate dean and director for academic programs at North Carolina State University (NCSU). “If they

ABOVE

spend $100 on roses and they last for two days, then maybe they’re only going to spend $50 the next time around and be more wary.”

With over thirty years of research in the sector, Dole’s work has played a critical role in improving cut flower production. He’s also worked closely with the Association of Specialty Cut Flower Growers (ASCFG) for more than three decades.

In a survey of over 200 cut flower growers conducted by NCSU in cooperation with the ASCFG in 2017, vase life was identified as one of the key complaints from consumers. But there’s no silver bullet to this problem. Every step in the post-harvest process plays a role.

Ensuring post-harvest quality isn’t an easy task.

Every step in the post-harvest process can help prolong the life of a cut flower. Four key areas include temperature, flower foods, hydration and storage time. Some practices cut across the entire cold chain, and not just for the grower.

Temperature is by far one of the most important factors in the vase life of a cut flower, says Dole. He emphasizes the importance of keeping it cold through the entire cold chain from harvest to consumer. Cooling effectively lowers the rate of degradation, prolonging floral appearance.

With most cut flowers, the goal is to store them below 40°F (4.4°C) and ideally closer to 35°F (1.7°C). Very few species will suffer from cold damage at those temperatures. “I’d love to see even colder, but the problem is, there’s often a cold spot in the cooler,” he explains. Areas too close to zero could lead to frozen flowers, so growers should keep a close eye on the temperature reading.

“When flowers are harvested, there are a number of factors that dictate how long they’re going to last. One of them is the amount of sugar that they produce… called endogenous carbohydrates,” explains Dole. As cut flowers use up their own sugar stores, flower foods help to replenish them. It’s important to note that flowers foods are not a substitute for good production practices, but rather, an important supplement.

“The quality and diversity of species is just wonderful,” says Dole. “I absolutely love it.”

“Cold-tolerant species such as ranunculus, anemones, carnations – they can all be held very cold. But something more tropical, say a bird-of-paradise or heliconia, they should be kept at around 55°F (12.8°C) or higher,” he says. Storage temperatures can vary by crop and should be held as cold as possible. Though the threshold may be different, the end effect is the same, so a bird-of-paradise held at 12°C will not necessarily fare worse than a carnation at 2°C.

“You cannot replace endogenous carbohydrates solely with the ones we provide. A well-grown flower will last a long time. A well-grown flower with flower food will last an even longer time”. With different products available on the market, it’s important to use the right ones for the right species and occasions. As with low temperatures, Dole says there are very few crops that don’t benefit from flower foods, but the vast majority do.

“It should start with the grower and be carried on through,” he explains, which means the onus is not only on the producer, but other players involved in the cold chain as well. “The most species- and situation-specific [foods] are used at the grower level. When you get to the wholesaler or retailer level…there are one or two products that cover all the flowers.”

“We’ve seen a lot of changes in the cut flower industry over the last few years,” says Dole. Working with the ASCFG, he’s noticed a sharp rise in their membership numbers, which has tripled over the past five years. He attributes this change primarily to the buy-local movement and a growth in integrated grower-florist businesses.

“The cut flower industry has really responded,” he says. Not only are growers selling to farmers’ markets and other local businesses including wholesalers, florists and supermarkets, they’re able to offer a better, more appealing product that would not otherwise be possible coming from a distant country. “To ship a lily, you generally don’t want any open flowers on it. [But] if you’re selling local, you can let a flower or two open for better colour, a bigger flower –just a little nicer product,” says Dole.

Andrew Morse, executive director of Flowers Canada (Ontario) Inc. (FCO), suspects that growth may be in the number of smaller outdoor cut flower growers in Canada, noting that local events held at flower farms have become increasingly popular with the public. “Any flower farms of more than a half acre report their production areas to FCO, and we have not seen an uptake in licensing,” Morse says. “If any are starting, they must be quite small.”

In general, the vast majority of cut flowers produced in Canada comes from larger greenhouse producers. It’s been increasingly difficult to maintain large cut flower operations in recent years, particularly given reduced options for crop protection, difficulty in moving product and competition with cut flowers coming from South America. “The statistics on cut flower production in Canada has shown a decline over time,” Morse says.

According to Statistics Canada, total cut flower production dropped by three per cent from 2016 to 2018. But for field-grown cut flower operations, numbers grew by 62 per cent during this time, total area increased by 44 per cent and gross sales rose by 41 per cent. Even though they accounted for 12 per cent of cut flower sales in 2018, the local field cut-flower grower has clearly found a way into consumers’ hearts with different offerings and a focus on consumer experience.

Having tested many of the available flower foods on the market, Dole can honestly say that they work. But some in the industry still abstain from using flower foods, interpreting the lack of complaints from their customers as positive feedback. “The lack of complaints is not a metric I want to go by,” he says. “I would rather see positive comments… Unfortunately it’s the [customers] that don’t complain and have a bad experience that we need to be worried about.”

Dole emphasizes the importance of getting cut flowers into water when they need to be. It’s an important step after harvest.

In their 2019 peer-reviewed paper summarizing the results of their North American cut flower survey, Dole and his co-authors note that commercial hydration solutions are available, providing optimized pH and quality to help promote water uptake and reduce microbial growth in the stems.

Storage time is another problem that can appear throughout the cold chain. Product is sometimes stored by producers, wholesalers and retailers for much longer than they should prior to being sold.

“I know they’re trying not to throw product away, reduce shrink,” says Dole. But with cut flowers, appearances can be deceiving and the last thing the customer needs is a cut flower with a short vase life. “[The flowers] can look just fine and die two days later, when they should be lasting seven to 10 days.”

Products left in the cooler for too long might simply show a yellow leaf or two when pulled out by the retailer. “But then it just totally falls apart and dies within a couple days,” says Dole. “That’s the industry’s responsibility to not send out old flowers. Storage duration cuts across the whole industry.”

Growing cut flowers isn’t easy. Their 2017 study took a survey of growers’ production challenges, detailing a lengthy list of pest and disease issues in addition to climate, post-harvest and business management. “It really reaffirms my love of working with growers,” says Dole, and so much so that Dole and his colleagues at ASCFG compiled a detailed guide aptly titled Post-harvest Handling of Cut Flowers and Greens. Published in 2017, this resource covers more than 200 genera, including annuals, perennials, bulbs and woody plants, as well as foliage and tropical species.