SUNSHINE® MIX #1, #4 and #5 are our most versatile formulations that expert growers choose for the production of a wide variety of crops including cell packs, large patio pots, and fabric containers.

All three are excellent for propagating cuttings in both indoor and outdoor growing situations and where increased drainage is a priority.

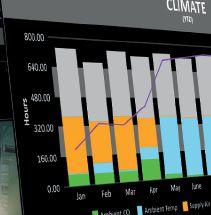

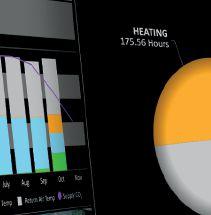

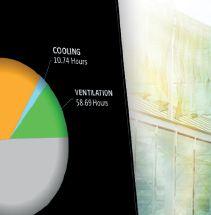

Grodan presents the fully redesigned e-Gro, the ultimate platform to support your knowledge, experience and growing strategy with real-time insights and smart recommendations based on root zone, climate, crop and harvest data. Anywhere, anytime and on any device.

The more you know, the better you grow.

Simplify decision-making

Relevant data from various sources in your greenhouse is displayed together clearly in a single place, in real-time.

Smart recommendations help you optimize your irrigation strategy and guide your crop to the desired balance.

Maximize visibility and control

e-Gro is a web-based application, and is available on all devices, enabling remote access to your greenhouse data anywhere, at any time.

Don’t take just our word for it, try it for yourself. Contact us today to set up your free e-Gro demo and in-house trial: www.grodan.com/e-Gro

of factors that contribute to this.

Ca is critical for cell wall stabilization and integrity, and it plays a key role in promoting shelf life. Ca is also an immobile element, meaning, unlike other elements that move in the phloem, it travels through the xylem and movement depends on transpirational water flow. Because of the higher rate of transpiration through the leaves, more Ca is directed there rather than the fruit.

Water flow itself is also regulated by Ca. The nutrient regulates water movement on the outside of cells through changes in cell wall structure and stomatal openings, and it helps control water flow into cells via membrane channels called aquaporins. This forms a feedback loop where a reduction in transpiration lowers water and Ca movement into cells, and that reduction in Ca reduces water flow even further, which in turn reduces Ca levels further still.

When Ca enters the fruit tissue, it accumulates in the proximal half of the fruit (closest to the stem), which leads to low Ca levels in the distal half of the fruit (away from the stem). The resulting Ca gradient greatly affects fruit development, especially during rapid cell expansion. Insufficient uptake and movement of Ca to the blossom end of the fruit at the early and rapid expansion stages of fruit development can lead to BER. Some studies have shown that when Ca decreases below 0.2 µmol g-1 fresh weight (0.2%) in the distal part of immature fruits, the risk of BER occurrence becomes critical.

Ca shortage and mis-translocation may not, however, be the only determinants of BER.

Some studies have shown that Ca availability to the roots does not always correlate with BER. Fruits exhibiting BER can have similar levels and distribution of Ca compared to healthy fruit.

Recent studies have shown more complex mechanisms regulating BER incidence in tomato fruit. Heat and water stress can trigger oxidative stress and build up reactive oxygen species (ROS). This typical cell stress response can lead to leakiness of the cell membrane and BER symptoms due to the negative affects of ROS on cell membrane integrity.

But there’s a link between oxidative stress and Ca levels as well.

Oxidative stress can lead to a reduction of Ca levels. In other words, low Ca in fruit exhibiting BER may be an effect of BER, and not a cause. This happens in some fruits that exhibit BER, but not all.

Low Ca levels caused by oxidative stress also reduce activity of the main enzymes responsible for ROS detoxification (a.k.a. antioxidants), leading to higher ROS levels, more cell damage and BER symptoms. This is another BER feedback loop where oxidative stress decreases Ca levels, and low Ca levels reduce the activity of antioxidants, which in turn increases oxidative stress levels even more.

BER is more prevalent in large tomatoes, such as beefsteak, rather than smaller ones, like cherry tomatoes. This is known as the “fruit shape effect.” BER is generally associated with large and mostly plumshaped fruits, where the rapid expansion of cells in the distal portion could lead to inadequate Ca translocation.

Cultivars that are more susceptible to BER typically have not only bigger fruit, but larger leaves than BER-resistant cultivars. Owing to their greater need for water, bigger leaves increase Ca uptake by roots, but their greater rates of transpiration also divert Ca to the leaves and reduce Ca accumulation in distal parts of the fruit. Some BER-resistant cultivars have lower stomatal densities in their leaves, which lead to lower transpiration rates and more water and Ca flow into the fruit.

Interestingly, BER symptoms have never been reported in wild tomato species. This is thought to be another example of the fruit shape effect because wild tomatoes are typically smaller in size than cultivated tomatoes. BER-resistant tomatoes have also been shown to have higher fruit antioxidant capacity, which makes them better able at reducing oxidative stress and its damaging effects on cell membranes.

Stress conditions such as heat, drought, water logging, low root zone humidity, and salinity increase the concentration of oxidative stress in young fruits. This causes leakiness of cells and lower Ca levels.

High temperatures and solar radiation also induce higher rates of photosynthesis and transpiration in leaves, which cause more water and Ca to be directed towards leaves rather than fruits. These factors promote BER during high stress conditions.

Foliar sprays: A common way of inhibiting BER is by spraying the fruit with Ca solutions to increase Ca levels in the fruit. This could include 0.3-0.5% solutions of calcium chloride, or 2 to 7 g L-1 calcium nitrate. However, these sprays are labour-intensive in that only

Light abatement control even the neighbors will trust

Single layer Obscura light abatement screens have been preventing supplemental lighting from escaping greenhouses at night for over a decade, letting neighbors get a good night’s sleep.

Effectively reducing greenhouse light emission at night, OBSCURA 9950 FR W* is designed to meet the legislation of various authorities and the well being of neighbors and nature. The white underside of the screen increases light intensity within the greenhouse, while the white upper side of the screen helps to prevent heat build up.

*) Made with flame retardant materials alone – adhering to strict North American fire codes

the fruit should be sprayed and not the whole plant. Spraying leaves is inefficient because Ca absorbed by the leaves is not translocated to the fruits. It has also been shown that Ca sprays are more effective on cultivars less susceptible to BER than highly susceptible ones.

A number of plant hormones have been shown to reduce BER when sprayed on the plant. Epibrassinolide (EBL), for example, reduced BER by 44.2 per cent in one study. This effect was associated with a reduction in leaf transpiration, higher Ca levels in the distal portions of the fruit, and increased activity of antioxidants. Another study showed that weekly foliar sprays or root application of the plant hormone abscisic acid (ABA) increased Ca levels in distal fruit tissue and reduced BER.

In contrast, gibberellins (GAs) can reduce fruit Ca uptake, leading to leakier cells and increased BER incidence. GAs increase stomata density and stomatal conductance, which increase Ca transport to the leaves at the expense of the fruit. GA also induces expression of proteins involved in transporting Ca into cellular storage organelles, which leads to lower levels of Ca available for cell maintenance.

Pruning: Regulation of plant density and truss thinning have also been historically adopted for the regulation of tomato fruit size and BER incidence.

A study looking at fruit pruning to one fruit per truss, two per truss, three per truss, or no fruit pruning showed that more fruits per truss had lower BER incidence. This was attributed to the slowing of fruit growth by keeping more fruits per truss, which ensured adequate uptake and distribution of Ca.

Another study showed that de-leafing (removal of alternate leaflets on all three leaves above a flowering truss) increased Ca levels in distal portions of tomatoes, which was associated with a reduction in BER incidence. This treatment resulted in 20 to 30 per cent fewer leaves, but fruit growth rate increased. The authors hypothesized that the reduced competition for water between leaves and fruits allowed sufficient Ca to be transported into the fruits at a critical time before BER was triggered. Interestingly, pruning increased Ca levels to a greater degree in the fruit of BER-susceptible cultivars than in less susceptible cultivars. This is, again, thought to be due to the greater rate of transpiration of BER-susceptible cultivars with their larger fruits and leaves.

Nutrient balance: Ca uptake and

distribution is depressed by other cations such as sodium (Na), potassium (K) and magnesium (Mg,) and this may increase BER. For example, the presence of K, Mg, and Na in the nutrient solution at levels above 400, 80, and 500 mg L-1, respectively, might decrease Ca uptake in tomato.

One study showed that incidence of BER in tomato rose with increasing Mg concentrations (20, 50, and 80 mg L-1) when mixed with 150 mg L-1 Ca. However, the incidence of BER was not affected by increasing Mg concentrations when the Ca concentration was raised to 300 mg L-1

In other studies, higher tomato yields were attained when the K:Ca ratio was between 0.82 to 0.85 in the summer months, but higher Ca levels (0.67 K:Ca ratio) may be necessary in the autumn-winter season. Lower temperatures and higher relative humidity reduce

Reduce irrigation EC in the late afternoon to promote Ca transport during the night.

transpiration rates and Ca transport.

Rhizosphere: It has been shown that the rhizosphere microbiome is important for control of BER.

Incidence of BER is correlated with the relative abundance of microbes in the rhizosphere. For example, a study showed that biofertilizers (fertilizers enriched with microorganisms) with the Gram negative rhizobacteria Pseudomonas LSW25R colonized the rhizosphere of plants and reduced BER presumably by increasing Ca uptake. This demonstrates the importance of monitoring the microbiome of nutrient water solutions in both recirculated and non-recirculated water systems to ensure a proper growing environment for roots.

Growing media: The growing media can also influence BER.

A study compared tomato seedlings grown hydroponically in peat, perlite, and a 1:1 mixture of peat-perlite before being transplanted into rockwool slabs. Plants grown in perlite were smallest, most likely due to perlite’s inability to retain nutrients. While this did not result in significant losses in total yield or weekly yield of marketable fruit, it did

lead to lower production of lower grade tomatoes. The smaller perlite-grown plants also had only 14 g of fruit per plant that exhibited BER symptoms per week, whereas bigger plants grown in peat and peat-perlite mix had 45 g and 44 g of fruit per plant exhibiting BER, respectively, per week. The reduction in BER incidence in the smaller plants is thought to be at least partially related to the smaller size of their leaves and their lower transpiration rates.

There are some key steps growers can take to reduce their risk of BER.

Reduce heat stress: Growers can use whitewashing of greenhouse roofs and/ or shade curtains to reduce high levels of solar radiation and associated high temperature stress. Some of the new energy curtains have light transmissions between 85 to 89 per cent, and they can also be used in the summer as shade curtains. Try to also reduce night temperatures to promote fruit set in the summer. High night temperatures and high levels of humidity reduce the viability of pollen in the summer, causing poor fruit set. Poor fruit set in combination with an abundance of photoassimilates in high temperatures increases BER.

Reduce water stress: There can be big differences in light intensity and temperature between cloudy and sunny days as well as hotter and cooler days. This causes large differences in the level crop transpiration. Irrigation should be adjusted quickly and precisely to match such environmental conditions.

Reduce nutrient deficiency: Regularly test your fertigation solutions and crop for nutrient deficiencies to ensure plants are taking up enough Ca. Reduce irrigation EC in the late afternoon to promote Ca transport during the night. Because water flow through the plant is not predominantly driven by transpiration at night, it is important to reduce irrigation EC in the late afternoon to promote Ca transport at night. This way, the turgor pressure of a healthy root system under low EC can send more Ca to the fruit.

Fadi Al-Daoud, PhD, is the greenhouse vegetable specialist at the Ontario Ministry of Agriculture, Food and Rural Affairs. Xiuming Hao, PhD, is a research scientist at Harrow Research and Development Centre, Agriculture and Agri-Food Canada. They can be reached at fadi.al-daoud@ontario.ca and xiuming.hao@canada.ca

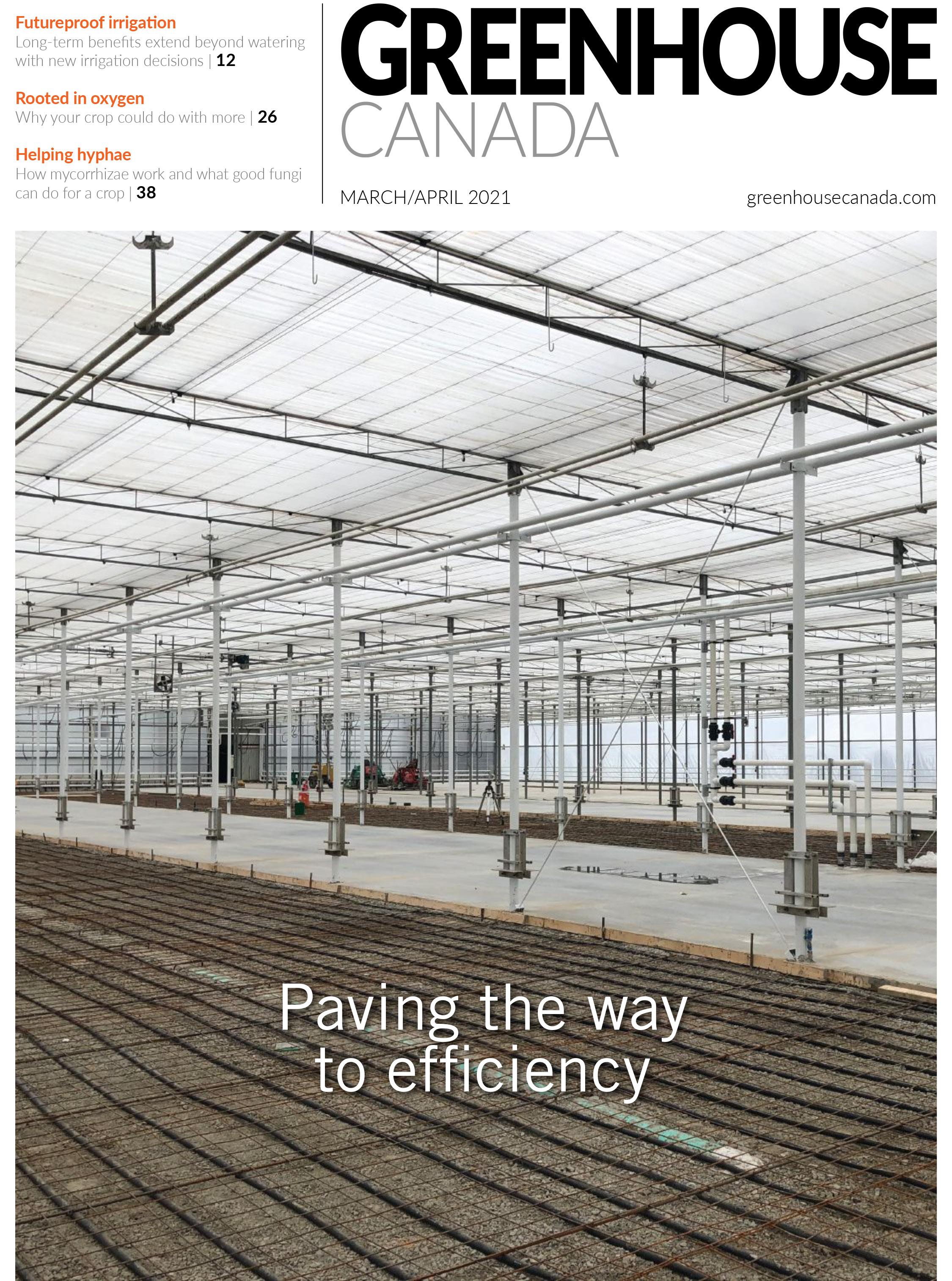

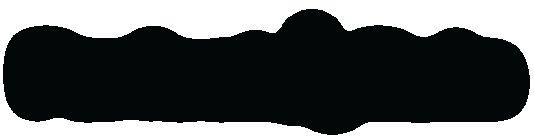

Using lighting, automation and data, Mucci Farms meets the rapidly growing demand for fresh greenhouse produce.

BY AJIT SAXENA

Today, almost every industry in the world can attribute a significant amount of their success and progress to the advancement of technology.

Among the major industries in Canada, the manufacturing, service and energy sectors have each grown tremendously, in large part due to the rapid growth of automation, robotics and data analysis through advanced hardware and software. However, one industry that isn’t often thought of when discussing technological progress, is the agriculture industry. More specifically, the greenhouse agriculture industry.

As poly-greenhouses and fully manual labour of decades past begin to fade from the industry standard, more robust high-tech glass facilities are becoming common place with a variety of technological advantages that assist in all aspects of greenhouse farming.

Kingsville, Ont.-based Mucci Farms, a greenhouse grower with over 60 years of experience, has been at the forefront of new technological advancements. Centered around lit culture and a heavy dose of automated harvesting, sorting and packaging, the company employs a forward-thinking mindset and aggressive commitment to finding the best available solutions for all areas of their vertically integrated operation.

“Greenhouse farming is highly sustainable at its core. We use rockwool and coconut husk growing mediums, we don’t spray any harmful treatments on any of our crops, we use less water which we disinfect with UV and recirculate so nothing is flushed out into our lakes,” Mucci explains. “Not only does technology help us with sustainability, it maximizes our production as well. We produce over 15 million pounds of tomatoes from a 25-acre block which is 10 times the production of a field farm, all made possible by the data we have as a result of greenhouse tech.”

With an emphasis on maximizing local and regional production during the winter months, Mucci Farms makes annual investments to expand their lit culture program, which boasts the largest acreage of supplemental grow lights in the North American greenhouse industry. In addition to a large percentage of their Ontario greenhouses under lights, their first project in the United States, specifically in Huron, Ohio, is growing tomatoes on-thevine throughout the winter months.

“Improving efficiencies in every area of our business has been paramount to our growth strategy,” says Bert Mucci, CEO of Mucci Farms. “Market demand today is focused on quality, maximum shelf life, local and regional production, corporate social responsibility and safe growing practices. All of these priorities are dramatically improved by the impressive innovation in automation and tech for the fresh produce industry.”

Modern technology in their greenhouse space is largely centered on controlling and creating optimal growing conditions for healthy plants, maximizing yield, speeding up production times, and minimizing environmental impact.

“Grow lights have dramatically changed the entire dynamic of our industry because all of a sudden, we could grow the same tomato in the same facility in July and January,” remarks Mucci. “We began trialing grow lights a little over five years ago with mini cucumbers and haven’t looked back. Today we have several varieties of cucumbers, tomatoes and lettuce under lights, and we are currently trialing bell peppers which would be another game changer.”

The company predominantly uses high pressure sodium (HPS) lights as well as LED depending on the crop. The controlled environment is beneficial for optimizing growing

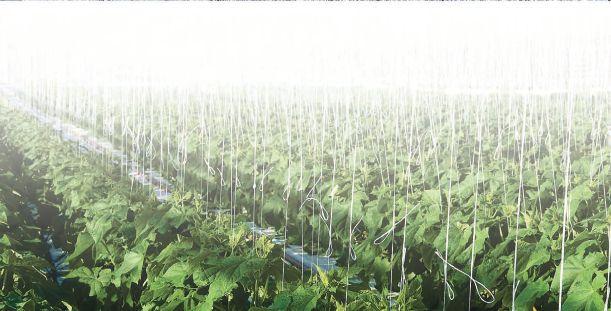

ABOVE

The lit culture program at Mucci Farms has dramatically changed the way they grow.

conditions, and the use of diffused glass also plays a role in improving production and quality.

“Diffused glass on top of our greenhouses increases our production by eight per cent as a result of having much more uniform light throughout the plant canopy. This also creates favourable conditions by reducing stress on the plants. In fact, we can actually grow a more consistent product under lights in the winter because of minimal fluctuations in the growing environment,” says Mucci.

On the sales and marketing side, the lit culture program has been instrumental in securing and reinforcing partnerships with retailers.

“One of the greatest challenges for our partners is consistent supply. Growing locally in the winter has allowed us to deliver fresh produce 365 days a year,” explains Joe Spano, VP of sales & marketing. “We can forecast production a lot more efficiently, and with sustainability at the top of everyone’s minds these days, growing locally during the winter reduces food miles and our impact on the environment—a great selling feature to today’s demographic that is increasingly more interested and aware of what they eat and where their food comes from.”

Technology and robotics also play a significant role in automating major tasks related to harvesting, packing, labeling and palletizing. At Mucci Farms, automation is on full display in all of their operations, but none more than their state of-the-art cucumber facility.

“Automation in our cucumber range starts at harvesting. Our team harvests product into the carts, which are automatically

delivered to the pack lines via induction wire by a driverless M-Track or Bumble Bee train,” explains Guy Totaro, grower manager of cucumbers at Mucci Farms. “The system scans the tag on the carts to identify the product when it’s being offloaded and then sorts it for the appropriate pack line. Our team then grades and packs it and our automatic palletizer uses infrared technology to determine the pallet configuration.”

The entire automation system was built as a proprietary unit and greatly assists with efficiency in labour, cost, and production time. As the agricultural industry is predominantly located in rural regions with small populations, finding skilled and unskilled labour has been an ongoing challenge for all of Canada’s farming industry.

“Finding labour can be challenging in our area, so technology really helps us close the gap by automating some of the mundane tasks. This helps us maximize the expertise of our team members by placing them in the highest areas of need while robots can do many of the less desirable tasks,” says Totaro.

A macro benefit of deploying technology in the greenhouse space is to provide growers with the ability to manage larger acreages and larger teams.

“My team is a lot more efficient because many of the tasks that would have been back-breaking work in previous decades, has been addressed by automatic scissor lifts and waist-high troughs. On the management side, we use the Priva system which is an excellent labour management platform that allows us to be much more efficient and productive,” explains Totaro. “It makes things easier and quicker and raises the level of our team, since we have to train many of them to operate the tech.

•

•

•

•

Technical

kams.ca

Guelph: 1-877-821-1684 · orders@kams.ca

Kingsville: 519-839-4778 · kvorders@kams.ca

How much dissolved oxygen is enough? Higher levels could potentially generate greater yields and lower costs.

BY BRUCE SCHOLTEN AND DR. FEDERICO PASINI

The availability of oxygen in the root zone is a key contributor to the productivity of greenhouse crops. However, it is often overlooked in comparison to water temperature, light intensity, carbon dioxide concentration and other production variables.

Insufficient or inconsistent availability of oxygen in the irrigation water results in suboptimal metabolic rates in root cells. On a cellular level, there is reduced generation of adenosine triphosphate (ATP), the main form of energy used to drive metabolic processes. A lack of dissolved oxygen (DO) concentration in irrigation water is therefore a limiting factor in root cell growth and overall plant growth.

How much dissolved oxygen is enough? It is generally believed in the greenhouse horticulture community that DO concentrations of 4-8 mg/L, typically generated by traditional water aeration systems, are sufficient to ensure adequate plant growth and health. However, research has shown that elevating DO levels to very high levels (18-25 mg/L) provides much higher rates of growth, better plant health and higher yield.

For example, a 2019 study conducted by Delphy Research Institute, a leading horticultural research entity in the Netherlands, confirmed the impact of very high DO levels in achieving more productive greenhouse crops, along with reduced operation and maintenance costs related to other technologies for oxygenation and maintenance of irrigation water quality. Specifically, this study demonstrated how highly elevated, stable DO levels of 18-25 mg/L are associated with the accumulation of respiratory metabolic enzymes that facilitate absorption of micronutrients by root cells, resulting in more ATP production, higher plant growth rates and higher yields. In addition, the presence and properties of the nanobubbles responsible for highly elevated DO levels also reduce the surface tension of the water and

increase the “wettability” of surfaces, facilitating more efficient absorption of water from the substrate and transpiration through the leaves.

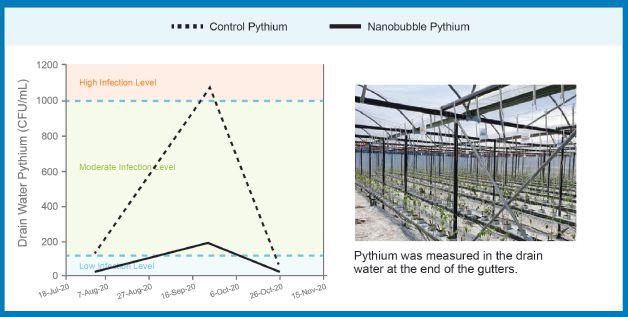

Overall plant health is also boosted by very high DO concentrations. When water temperatures increase in greenhouse irrigation systems due to warm weather, DO concentration is reduced, which favours the proliferation of undesirable pathogens such as Pythium, as well as reduced nutrient uptake and deterioration of the root zone in the long-term. Very high DO levels prevent the creation of these conditions, preventing pathogen proliferation, promoting

1. Supersaturated oxygen levels are sustained between 15-20 mg/L over the course of 25 days using nanobubbles. Most aeration achieves 7.5-9 mg/L max.

the growth of beneficial microbes and reducing the use of disinfection chemicals to little or none.

High-quality irrigation water and sustained high levels of dissolved oxygen have proven essential to achieving high rates of nutrient uptake, photosynthetic capacity and cellular energy production, resulting in improved plant resilience and capacity

ABOVE. Figure 2. Pythium measurements in drain water are lower in a sustained high DO setting compared to the untreated control.

RIGHT. Figure 3. In a 2019 Delphy research study in strawberries grown in peat and coco mix, the untreated crop (top) is compared to the healthier root system of the nanobubble-treated crop (bottom).

to handle stress. This is because the health and growth rate of plants is directly impacted by the health and development of the root system. The root zone is where the plant regulates its delicate interaction with the growing medium (or directly with irrigation water in hydroponic systems), taking in the nutrients, oxygen and water needed for the production of cellular energy.

In plants, nutrient uptake occurs in two ways, through passive and active mechanisms.

In the first instance, dissolved ions passively migrate into plant root cells by diffusion at a rate proportional to the difference in concentration between the water and the interior of the root cells. No energy is required for this type of nutrient absorption, with nutrients moving from an area of high concentration to an area of low concentration, provided the concentration of nutrients in the substrate is sufficiently high. However, passive nutrient absorption is affected by the nutrient concentration gradient, type of nutrient (e.g. anions/cations, mono-, bi- or tri-valent ions), type of growing medium and the schedule/intensity of the irrigation cycle. As this type of nutrient uptake is obviously limited, plants also have ‘active’ uptake.

In situations where the migration of ions is contrary to the concentration gradient (from low to high), root cells use cellular energy (ATP) to bring nutrients across their membranes. It has now been established that higher DO levels in irrigation water boost plant cell metabolic rates; in root cells, this means more ATP is produced and more nutrients can therefore be absorbed. Conversely, if ATP is limited, root cells are limited in their nutrient uptake, synthesis of hormones and other metabolic processes, which in turn decrease both the rate of root growth and overall plant development.

Using irrigation water with sustained high levels of DO favours the growth of beneficial bacteria in the root zone. In a highly oxygenated environment, these organisms can then outcompete pathogens such as Pythium, Fusarium spp. and Phytophthora, which all prefer lower oxygen environments. Higher DO levels also result in a reduced release of phenolic compounds produced in cells during low oxygen (anoxic) conditions and that are generally detrimental to the health and growth of the plant. These phenolic compounds can attract pathogens

such as Rhizobium rhizogenes to the root surface, causing hairy root disease. In addition, promoting the growth of beneficial microbes improves nitrification in root cells and increases their rate of hormone and enzyme production, all of which aid in enhancing nutrient absorption and use.

Traditional aeration systems cannot generally provide sustainable and efficient production of high DO levels. This is especially true in warm water. As the temperature of water rises, its capacity for holding dissolved oxygen lowers. Growers who need warm water are therefore forced to use costly and environmentally unfriendly disinfection agents to prevent pathogen growth. In some cases when the temperature climbs, growers compensate for the limits of their current aeration system with costly, inefficient water chilling systems.

The availability of novel water aeration methods such as oxygen nanobubble technology is therefore a very exciting development in the greenhouse horticulture sector. Very high DO levels can now be achieved using these systems.

A study was conducted in 2020 by Nova Crop Control to investigate the effects of high DO levels in the irrigation water of tomato plants. Results confirmed that very high DO levels improved growth rate, crop yield and colouration.

Figure 1 shows supersaturated DO levels achieved over 25 days of nanobubble injection, measured at multiple points. Figure 2 depicts the effect of the super-high DO on Pythium infection level. In this study, yield increased with super-high DO by 11 per cent due to reduced Pythium levels in the water. Fruit weight was also higher by 9 per cent.

Here are other brief summaries from a small sampling of recent studies. In comparison to greenhouse plants receiving untreated water, plants that received nanobubble-treated (NB) super-oxygenated water achieved the following yield increases (among other performance parameters):

• 23 per cent in tomato (2019, Journal of Agricultural and Food Chemistry, China & UK)

• 18 per cent in blueberry (2019, Elemental Foods, Chile)

• 24 per cent in cannabis (2019-2020, Moleaer, Royal Brinkman & Wageningen University, The Netherlands)

• 18 per cent in pepper (2019, Popoyán, Guatemala)

Growers know that when it comes to controlling and monitoring a production environment, a simple, flexible, sustainable control system is crucial. This is why you can depend on Reliable Controls. Our nationwide network of factory-certified Authorized Dealers will help you design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective, Canadian-made solution, please contact a Reliable Controls

Authorized Dealer near you.

Canada: 403.561.4148

Canada: 647.982.7412

The Ridder Energy Saving Rolling Screen is a highly transparent energy-saving wall screen with the highest light transmission in the NEN 2675 class. With this new innovation from Ridder, you can keep your energy bill in check while maximizing the transmission of daylight through exterior and interior walls - all year round.

Mycorrhizae have been researched for hundreds of years and the science is well-known. The key is learning how to best incorporate them into production.

BY BLAIR BUSENBARK

As the science of mycorrhizal fungi has become more widely known and well understood, most growers already know that mycorrhizae provide many benefits to plants. The question is, will it benefit your particular operation? This article is designed to help decide if the use of mycorrhizae makes sense in your greenhouse, nursery, or landscape/turf operation. The short answer is, “It depends, but in most cases, yes.” For the long answer, read the remainder of this article.

Let’s first review the science. Mycorrhizal fungi have existed since the

ABOVE

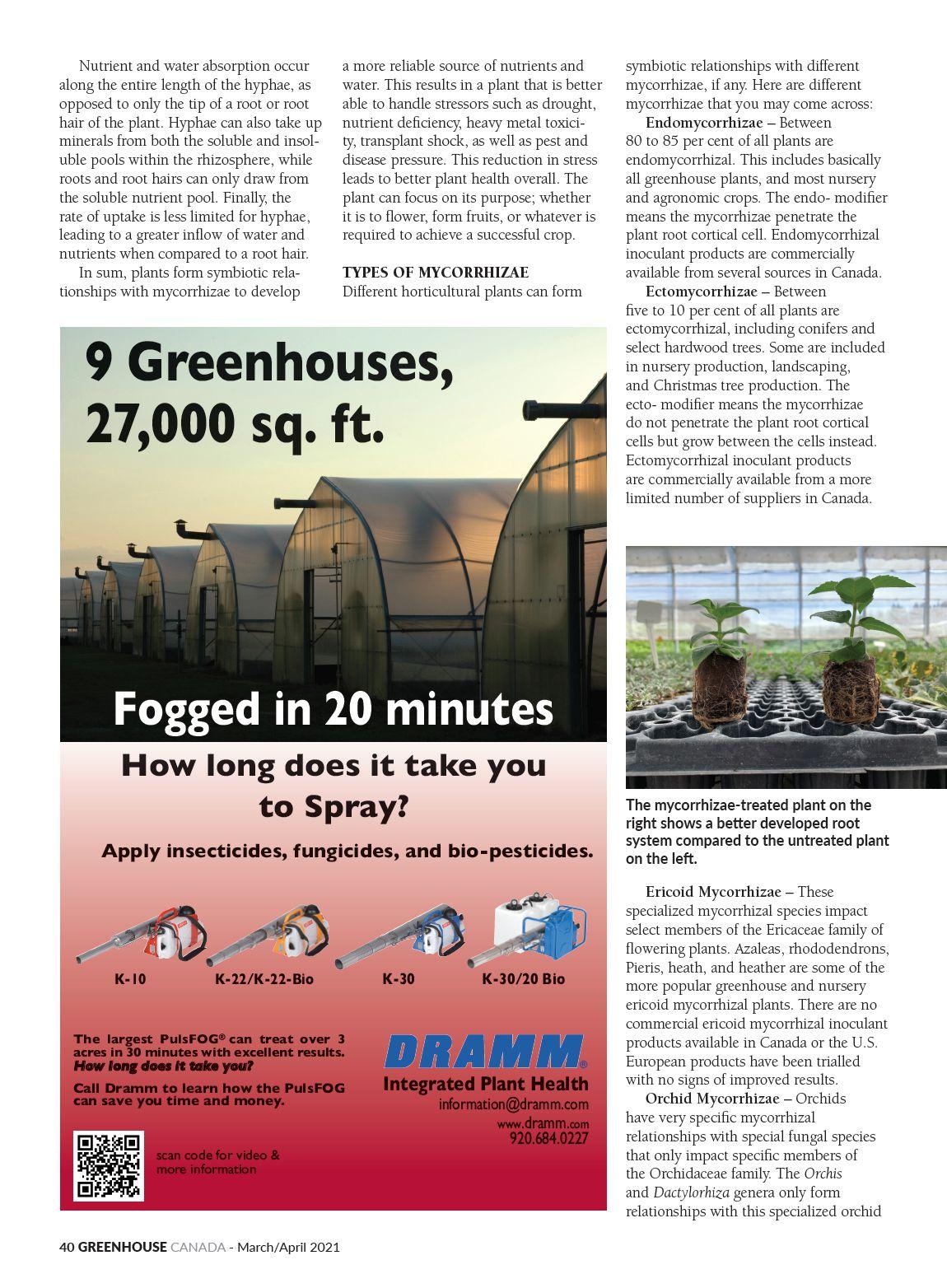

first plants appeared on dry land over 450 million years ago. They are naturally occurring biological organisms that form symbiotic relationships with almost 95 per cent of all plants. What is the value that mycorrhizae offer to plants? Simply put, mycorrhizae can help expand the root absorptive area of the plant by up to 50 times. This is accomplished by developing a mycorrhizal hyphae network in the growing medium. Each of these hyphae can extend up to 50 to 60 centimetres in the soil beyond its attachment to the root. Aside from providing greater reach, hyphae can also do more.

Most fungicides can be used in tandem with mycorrhizae without negative impacts.

mycorrhizae. The other genera in the family can sometimes form relationships with endomycorrhizae. There are no commercial orchid mycorrhizal inoculants available in Canada.

Non-Mycorrhizal – This group makes up about five per cent of all plants. Members of this loosely organized group can either be variable in their relationship with mycorrhizae (i.e. they get no significant benefits from their mycorrhizal associations) or be highly resistant to forming a relationship with mycorrhizae. Some of these plants are what you would commonly associate as opportunistic weeds.

For more information on which plants are associated with which mycorrhizae, please refer to the Families and Genera document on the Mycorrhizal Applications website.

As they say, “Timing is Everything”, and that is once again true for a grower or landscaper when it comes to mycorrhizal use.

With endomycorrhizae, the plant will begin to benefit three to four weeks after the initial mycorrhizal symbiotic relationship is formed. An active root needs to be present for the symbiotic relationship to be initiated by the plant. The clock starts once the plant root and the mycorrhizal propagule come in contact.

In another four weeks, or around eight weeks total, growers and landscapers will start to visually see the difference. Ectomycorrhizae are slower in forming their relationships. It can take up to six months in some ecto plants, which makes sense as most ecto plants are woody ornamentals.

For a grower to maximize their benefits, mycorrhizae should be applied during propagation. For growers who buy plugs and rooted cuttings, it is best to drench/dip the plugs/liners with mycorrhizae before you plant them in their finished containers. An additional benefit of this strategy is, the smaller the soil volume, the smaller the quantity of mycorrhizae needed for treatment. This translates into lower costs for treating each plant and a greater return on the input investment.

For most of us, we are often on a quest to get the best value for the dollars we spend. It could be the best house for a certain price point, or simply the best lunch for the amount you want to spend. This same quest for value occurs in plants

Business Observable benefits At retail Consumer experience

Grower-retailer

• More flowering

• Greater shelf appeal

• More uniform crop

Large grower or box retailer

Commercial growers, independent garden centres and landscape customers

• More uniform crop

• More bench runs for picking and shipping

• Potential for a shorter crop time

• Improved plant health

• More flowers and/or fruits

• Darker foliage

• Higher perceived customer value

• Less potential for wilt and lighter foliage

• Higher pay-by-scan

• Quicker turns on retail shelf

• Plants look better coming off the truck

• Quicker plant sales by retailer

• Perception of premium quality plants produced by grower

and their interest in forming relationships with mycorrhizae.

In a natural setting, plants can form mycorrhizal relationships with a variety of mycorrhizal species and at the same time. Why? To maximize the value provided by the mycorrhizae species in return for the amount of sugars and lipids offered by the plants.

Each species of mycorrhizae offers different functional benefits. If a grower or landscaper uses a product that only has one species, this single species of mycorrhizae can only offer the benefits that the single species can provide. In order to maximize the value of mycorrhizae to a plant, it is best to use mycorrhizal products that contain multiple mycorrhizal species to ensure the largest possible array of functional benefits to the plant.

Now that we have covered the science of mycorrhizae, let’s now move to the next question: Does it make sense for your operation?

• Reduced transplant shock

• Less plant loss

• Greater yields

• Higher consumer loyalty to store

• Reduced transplant shock

• Greater yields

• Fewer returned plants and deductions

• Greater appreciation by retailer

• Improved garden performance

• Lower plant replacement costs

• More sell-throughs by retailer

• More follow-up orders

The benefits of mycorrhizae usage vary depending on the type of grower/ landscaper you are. The table above should be helpful in explaining the benefits for your type of business.

In general, plants will start to benefit from a mycorrhizal application after four weeks, improving their ability to handle different stressors. Growers and landscapers will start to see observable benefits about eight weeks after application. At retail, plants will look better in appearance and have greater sales potential. The end consumers will have greater success in their gardens, leading to their return.

Hopefully this article has helped you better decide if the use of mycorrhizae makes sense in your operation.

Blair Busenbark is the Northeast & Mid-Atlantic sales account manager at Mycorrhizal Applications. Questions? Contact inquiries@mycorrhizae.com

Plant Empowerment -The Basic Principles

Plant Empowerment was launched globally at the 2018 Canadian Greenhouse Conference, taking a crops-first approach to climate control and has since overhauled concepts in greenhouse production.

Filled with detailed information on applied theory and best practices, the underlying principle is the need for balance. Plant Empowerment: The Basic Principles details how an integrated approach based on physics and plant physiology leads to a balanced growing method for protected crops resulting in healthy resilient plants, high yield and quality, low energy costs and economic greenhouse concepts.

This book details a new approach to growing crops in greenhouses, also known as “Next Generation Growing.”

BY GORDON SCOTT CAMPBELL

The law of “nuisance” has a long history in the common law, where a qualified right to quiet enjoyment of real property includes a right to be free from unreasonable intrusions by neighbours. Every sort of disturbance – from noise, to smoke, to water – can pose a nuisance to a neighbouring property if taken to an extreme. There are no limits to nuisances in type, only in quantity.

A little noise, a little smoke or a little water won’t necessarily get you to the point of nuisance. The same principle applies to light, though light may be subject to more liberal limits. For about half of every day we’re all subject to lots of light, and few have any complaints. Plus, it’s arguably easier and less expensive to completely block out light from the interior of buildings than is the proactive elimination of other types of nuisances.

As enjoyable as a dark night sky might be, there are lots of modern activities which impinge on that darkness, the most common of which may be street lights advanced as public safety measures. There is very little jurisprudence considering to what degree light qualifies as a nuisance, with the 19th century cases more focussed on considering whether the obverse blocking of natural light could be a nuisance.

Complaints about excesses of light are definitely not new in Canadian courts. In Noyes v. Huron & Erie Mortgage Corp, 1932 CanLII 141 (Ontario High Court of Justice), the Court found in 1932:

The plaintiff who was operating an advertising

business by means of slides projected upon a screen on the roof of a building on a business street complained that the flood-lighting of the defendant’s new building across the road had damaged his business.

Held, (1) that flood-lighting does not come within Rylands v. Fletcher (1868), L.R. 3 H.L. 338, as light is not noxious or dangerous, (2) that on the facts and evidence no actionable nuisance and no substantial injury had been shown, (3) that the plaintiff’s business was of an extraordinary nature, and not entitled to protection from interference by a neighbouring owner in the exercise of his reasonable rights on his own property, which was the defendant’s situation.

Ontario’s Farming and Food Production Protection Act, 1998, S.O. 1998, c. 1 explicitly exempts farmers conducting a normal farm practice from being liable in nuisance or being subject to court injunctions for a “disturbance.” The Act’s definition of disturbances includes “light,” as part of a closed ended list which also includes odour, dust, flies, smoke, noise and vibration, but not other things like water. Essentially, the Act seems to limit farmer protections to things that travel through the air (other than vibration which could also come through the ground). The “agricultural operation[s]” protected by the Act explicitly include “greenhouse crops.”

In Dell v. Zeifman Partners Inc., 2018 CanLII 107015 (ON NFPPB) the Ontario Normal Farm Practices Protection Board, in applying the Farming

and Food Production Protection Act, found against a greenhouse operation which had installed a large anaerobic digester system involving significant delivered feedstocks stored outside. The Board concluded that both odour and flies had significant impacts on neighbours and that the digester’s operation wasn’t a normal farm practice. Notably, the neighbours had also complained about “light coming from the … site. This was allegedly coming from delivery trucks, the generator and the frontend loader used to feed the macerator or hammermill,” but the Board declined to find fault over the light. Likewise, in Rutt v. Ejavu Raw Energy Farms Inc., 2004 CanLII 76798 (ON NFPPB) the disputed issue for the greenhouse operator was odour from composting, not light.

At least in Ontario there appears to be no formal consideration to date over whether light emissions could ever be restricted as not amounting to a normal farm practice. However, as these kinds of cases are factually specific, the Normal Farm Practice Protection Board (and similar boards and courts elsewhere in Canada) will likely be guided by fundamental principles of fairness and balance of convenience when considering if an “extreme” case exists which might prompt them to action against a greenhouse or other farming operation (as with odour in Dell v. Zeifman Partners), and in assessing whether a farmer has made reasonable efforts to mitigate any disturbance, while still being able to continue regular operations.

Extremes of odour, dust, flies, smoke, noise and vibration may all risk being found to not be normal farm practice, especially if the employment of newer advanced technology is involved as Dell v. Zeifman Partners demonstrates. Therefore, greenhouse operators should stay aware of how newer technologies could risk a Board finding them to be objectionable. Operators should be ready to demonstrate with evidence why that light still falls within normal farm practices, and that operators remain sensitive to neighbour concerns in only emitting a reasonable amount of light to continue their farming operations, rather than emitting unnecessary light.

Gordon Scott Campbell, B.A., LL.B., B.C.L. is a farm and agri-business lawyer practising throughout Ontario with Aubry Campbell MacLean (acmlawfirm.ca).

CLASSIFIED RATES: Minimum order $75.00 or 84¢ per word, word ads must be pre-paid. CLASSIFIED DISPLAYS: $72.00 per column inch. GENERAL INFORMATION: Payment must accom- pany order. Copy required on publication close date. All advertising copy subject to the approval of the publisher. Send order and remittance to: Classified Dept., Greenhouse Canada, P.O. Box 530, Donly Dr. S., Simcoe, ON N3Y 4N5 Canada

JOB TITLE (Please Check One:)

GARY JONES | Gary.Jones@kpu.ca

I mentioned before that the pandemic has produced a new way of doing conferences, and in January, I was fortunate to attend the Oxford Real Farming Conference (ORFC). This event first took place in 2010, and pre-COVID, limited ticket sales to 1,400 delegates for the two-day event. This year however, it truly deserved its more encompassing name of ‘ORFC Global’. Since it was completely virtual, 5,280 delegates from across six continents enjoyed a full seven days of connecting.

ORFC Global “has developed over the last eleven years to become the unofficial gathering of the agroecological farming movement in the UK, including organic and regenerative farming, bringing together practising farmers and growers with scientists and economists, activists and policy-makers in a two-day event’ … that ‘offers a broad programme that delves deep into farming practices and techniques as well addressing the bigger questions relating to our food and farming system.”1

With this broad agricultural context, it’s not a conference that many Greenhouse Canada readers would likely attend. Nonetheless, I dipped into a number of sessions. Some for the topic. Some for the calibre of speakers. Some just out of curiosity. Here are a few snippets from some of the 150+ sessions.

Frances Moore Lappé is the author of Diet for a Small Planet, “which the Smithsonian’s National Museum of American History describes as ‘one of the most influential political tracts of the times’,”2 and founder of the Small Planet Institute. In discussing Food and Democracy, she brought a number

Next was Helena Norberg-Hodge, author of the 1991 bestseller Ancient Futures and founder/director of Local Futures organization. She described how Local Food Can Change the World, headlining that “the most important thing in the world today is the truth that small-scale biodiverse farms are the only way we can massively increase the amount of food produced.” While being critical of corporate monocrop farming, she said it’s ‘not about good guys and bad guys – blindness to the system is the issue’, and encouraged a paradigm shift to local food economies that don’t just look at physical productivity but also develop ecological and community benefits.

Anna Lappé talked about how corporate agriculture works its PR spin to shape the story of industrialised food, noting that in 2020, 70 per cent of the global agrochemical market was controlled by just four companies, and that global pesticide use nearly doubled between 1990 to 2015, largely due to the use of GMOs.

In other sessions, Colin Tudge (science writer and broadcaster) proclaimed that “agriculture is the one thing we have to get right – then all the other issues will start to fall into place” and Naomi Klein presented her (and others’) latest short movie The Message from the Future II – The Years of Repair. Interesting watch.

It’s easy to throw out these ideas as hippie, fringe or extreme...

of key facts and interesting quotes. She informed delegates that for every person in the world, agriculture produces 2,900 calories (enough for us all) but one third of that food is wasted (according to the F.A.O.). She also noted that “in the USA, for every one legislator Americans elect to represent [our] interests, almost two dozen Washington lobbyists pursue corporate interests.” Moore Lappé’s takehome was that “we need to commit to each other.” Appropriate, in today’s divided America.

I sidetracked into Goats – The Hidden Transformers (there are one billion goats on the planet), and listened to Guru Thiru describe his ‘Street Goat’ community-supported agriculture project in Bristol, UK. Using a few small herds, they’re transforming nooks and crannies of derelict, marginal land into valuable nutrient-rich food supplies.

In this uncertain and divided world, many of the ideas are applicable across nations and society. But how do they connect to our world of protected cultivation? Many of these world-class thinkers are advocates for small, local, community (which is why they were at ORFC, of course). The small farm movement is in part driving the growth of small greenhouse businesses, giving the power of food production and food accessibility back to local entrepreneurs. It’s easy to throw out these ideas as hippie, fringe or extreme, but as Norberg-Hodge says, it’s not about good guy v. bad guy. Remember that 5,200+ delegates attended ORFC Global 21. The small farm movement is not small.

1 Oxford Real Farming Conference ‘About us’, accessed 23 Jan 2021 at https://orfc.org.uk/about/

2 https://en.wikipedia.org/wiki/Frances_Moore_Lapp%C3%A9 accessed 24 Jan 2021

Gary Jones is a faculty member of the School of Horticulture at Kwantlen Polytechnic University, Langley, BC. He sits on several industry committees and welcomes comments at Gary.Jones@kpu.ca.