Through consumer

Smart decision-making

How not to overwater Set wet-dry targets and stick to them | 32

Righting

BY GRETA CHIU

Greta Chiu

Through consumer

Smart decision-making

How not to overwater Set wet-dry targets and stick to them | 32

Righting

BY GRETA CHIU

Greta Chiu

By now, you may have heard about a book called Plant Empowerment, written by researchers in the Netherlands. It takes a crops-first approach, emphasizing the importance of plant physiology in climate control and greenhouse production practices. We released a short introduction to it back in January’s Technology Issues feature, where we highlighted some of the key concepts that form the backbone of the book.

Hoping to bring more of these game-changing ideas to you in bitesized formats, one of the authors, Jan Voogt, has graciously agreed to whittle things down to three or four key topics in multiple, shorter articles. The first starts in this issue.

As some of our readers may know, Albert Grimm of Jeffery’s Greenhouses and industry consultant Dr. Theo Blom used to teach night courses on similar concepts in greenhouse production – something I hope they will take up again in the future. In our conversations, Albert shared some key messages that he’s taught over the years:

and evaporation than by any other cause.”

3. “There are two components to photosynthesis: a) the plant captures energy from solar radiation [and] b) the plant stores this captured energy for later use in the form of carbohydrates. It is the job of a greenhouse grower to use greenhouse climate and nutrient supply to dictate to the plant when and where to use these carbohydrates. That is the meaning of the term crop-control.”

4. “We cannot change the development of a plant by adding growth factors. We can only prevent [the] development of the plant by restricting specific growth factors until they become the determining limit for plant development. This means that we have to understand how each growth factor impacts the plant... We have to be able to determine which growth factor is most limiting to the development of a plant before we can create a consciously targeted change in plant development. [For instance,] there is no fertilizer that promotes flowering in potted plants. The best that we can do is limit the access to certain nutrients so that the plant uses

“...our crops experience the floral equivalent of a heart attack.”

1. “We do not heat the greenhouse so that the thermometer reads a given temperature. We heat the greenhouse so that we can supply energy to the nutrient and water transport system of the plants. If we do not supply adequate energy to the plant, the nutrient and water transport system stalls, and our crops experience the floral equivalent of a heart attack.”

2. “… more damage is done to crops by imbalances between root pressure

less carbohydrates (stored energy) for development of leaves. This gives the appearance of larger/more/earlier flowers, because there is comparatively less canopy, but it is merely an appearance.”

As you read through the rest of this issue on irrigation and rootzone management, you’ll find a very prominent theme that resonates throughout – do what keeps the plants happy, not necessarily what makes the grower happy.

to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Do you know a grower, colleague, or employee who goes above and beyond in the greenhouse or industry? Recognize their hard work by making a nomination.

Grower of the Year – New for 2019! Recognize a fellow greenhouse grower for innovative thinking, hard work and dedication to their craft. Nominees must be actively involved in their operations. No age restrictions.

Top 4 Under 40 – Nominate the next crop of young achievers with Canada’s Top 4 Under 40 awards. Nominees must work in greenhouse horti culture, related equipment and technology sectors, and/or allied trades, and be under 40 years of age by December 31, 2019. Help cultivate the next genera tion in the horticultural industry.

Send in your nominations by May 10, 2019 greenhousecanada.com/awards.

Ontario Greenhouse Vegetable Growers (OGVG) has released the HUB Connect app, filled with regional information and contacts to help foreign workers and newcomers navigate rural communities.

Developed in partnership with the Canadian Agricultural Human Resource Council (CAHRC), the app maps out essential services in the area, including health care providers, community

events, transportation, local news and weather, consular information, important contacts and agriculture-specific guidelines.

“These are courageous people who leave their families and loved ones back in their home countries, come to Canada and help our agricultural sector immensely as this workforce fills a critical employment need when Canadian employees cannot be secured,”

notes Joe Sbrocchi, general manager of OGVG on LinkedIn. “This App was developed to assist them in their specific community, by connecting them to all the services available in their general area, everything from A-Z in the palm of their hand on their smartphones.”

In communications that followed, Sbrocchi adds that “OGVG team members – Justine Taylor and Byron Mellon in particular –

have worked seamlessly with the municipalities, CAHRC, and of course, our member greenhouse farmers in the region, to deliver a sustain able model that can be scaled for other areas of Ontario and even the country.”

Currently available in the Kingsville and Leamington regions, OGVG is looking for partners interested in supporting the app in other regions in the future.

Organized by Dr. Sarah Jandricic, greenhouse floriculture IPM specialist at the Ontario Ministry of Agriculture, Food & Rural Affairs (OMAFRA), and Greenhouse Canada magazine, this new webinar series targets key disease challenges in greenhouse ornamental production.

March 14 – Cultural controls for managing and preventing disease, with Dr. John Lea-Cox (University of Maryland). From clean stock and substrates, to irrigation water recycling and sanitation, learn about cultural control methods that could help prevent and manage diseases in your greenhouse operation.

March 20 – Fusarium basics, with Dr. Ann Chase (Chase Agricultural Consulting). Find out how to best protect your crops from fusarium and other root rot pathogens from propagation through finishing. Cultural, biological and conventional control strategies will be covered.

April 2 – Disease diagnostics for ornamentals, with Dr. Karen Rane (University of Maryland). The first step in effective plant disease management is knowing what disease you are battling. Sharpen your diagnostic skills with tips and strategies for identifying problems in your greenhouse crop.

April 9 – Ways to outsmart powdery mildew, with Dr. Jean Williams-Woodward (University of Georgia). Powdery mildew can be hard to control – that’s why prevention is key. Learn about proactive measures you can take in the greenhouse and how to manage the disease when present.

Webinars run from 2pm to 3pm EST, with an interactive question-and-answer period at the end. Discussions will be moderated by Dr. Sarah Jandricic or fellow OMAFRA greenhouse floriculture specialist, Dr. Chevonne Carlow. Archived webinars online.

Register at greenhousecanada.com/webinars.

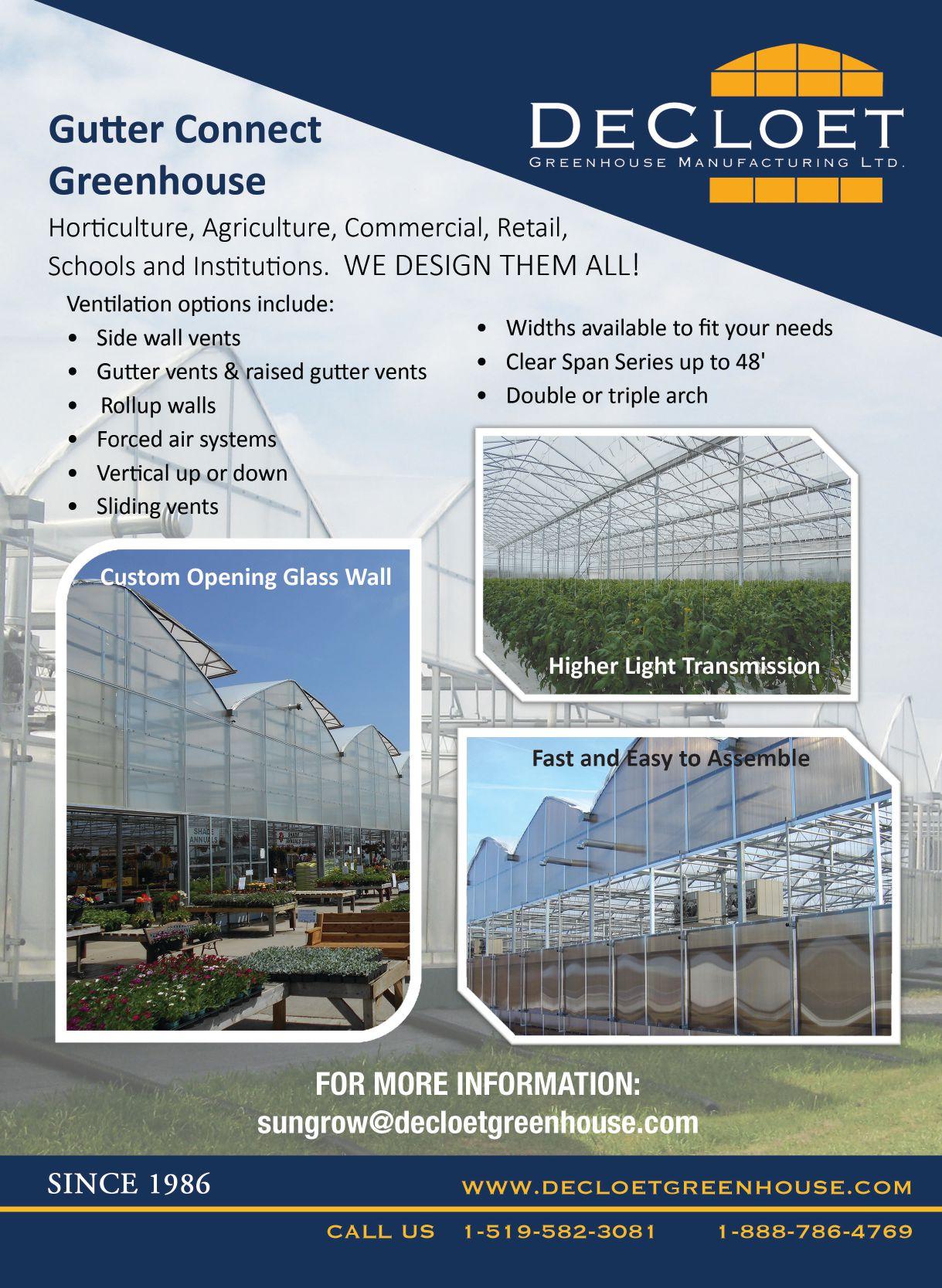

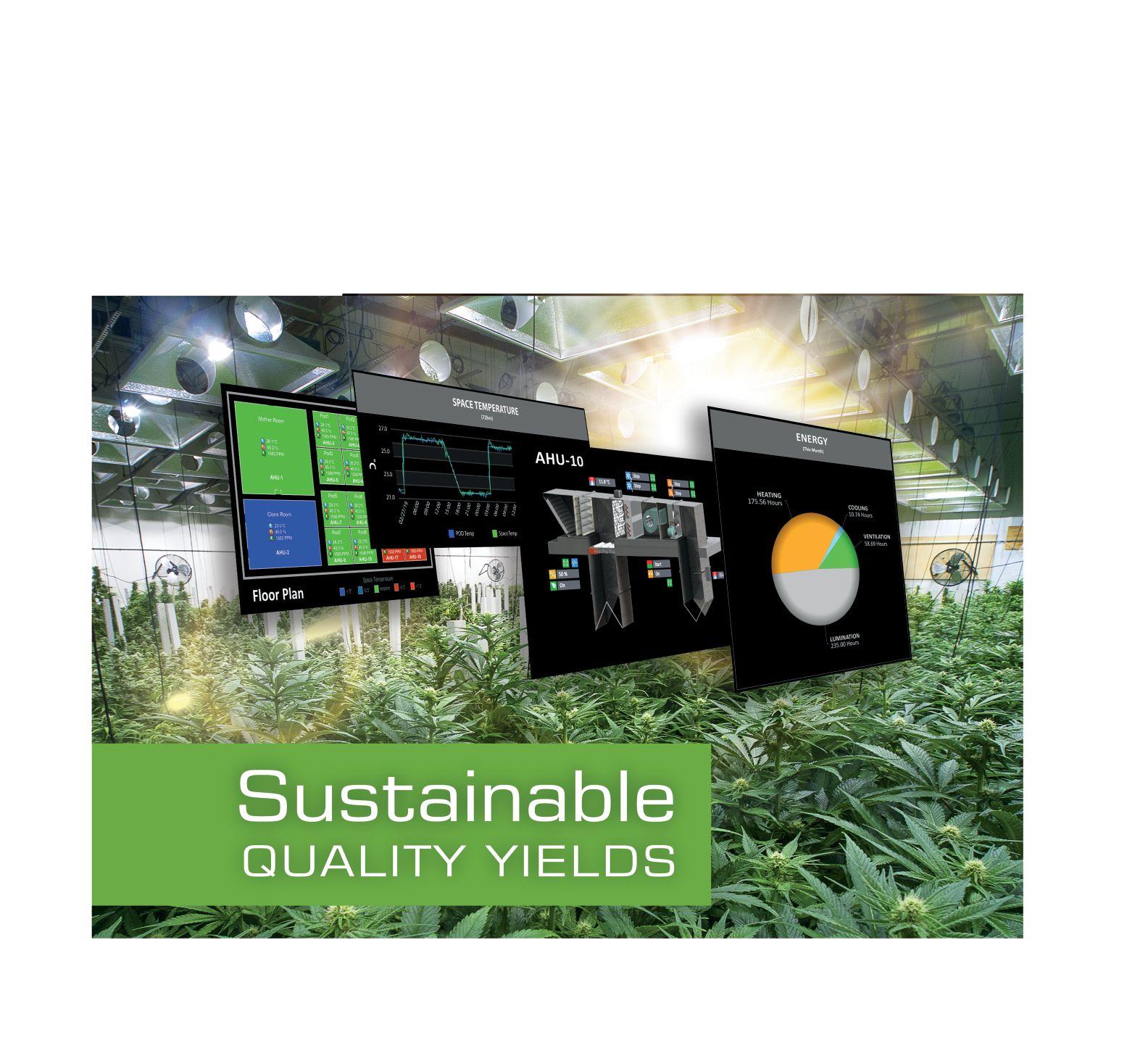

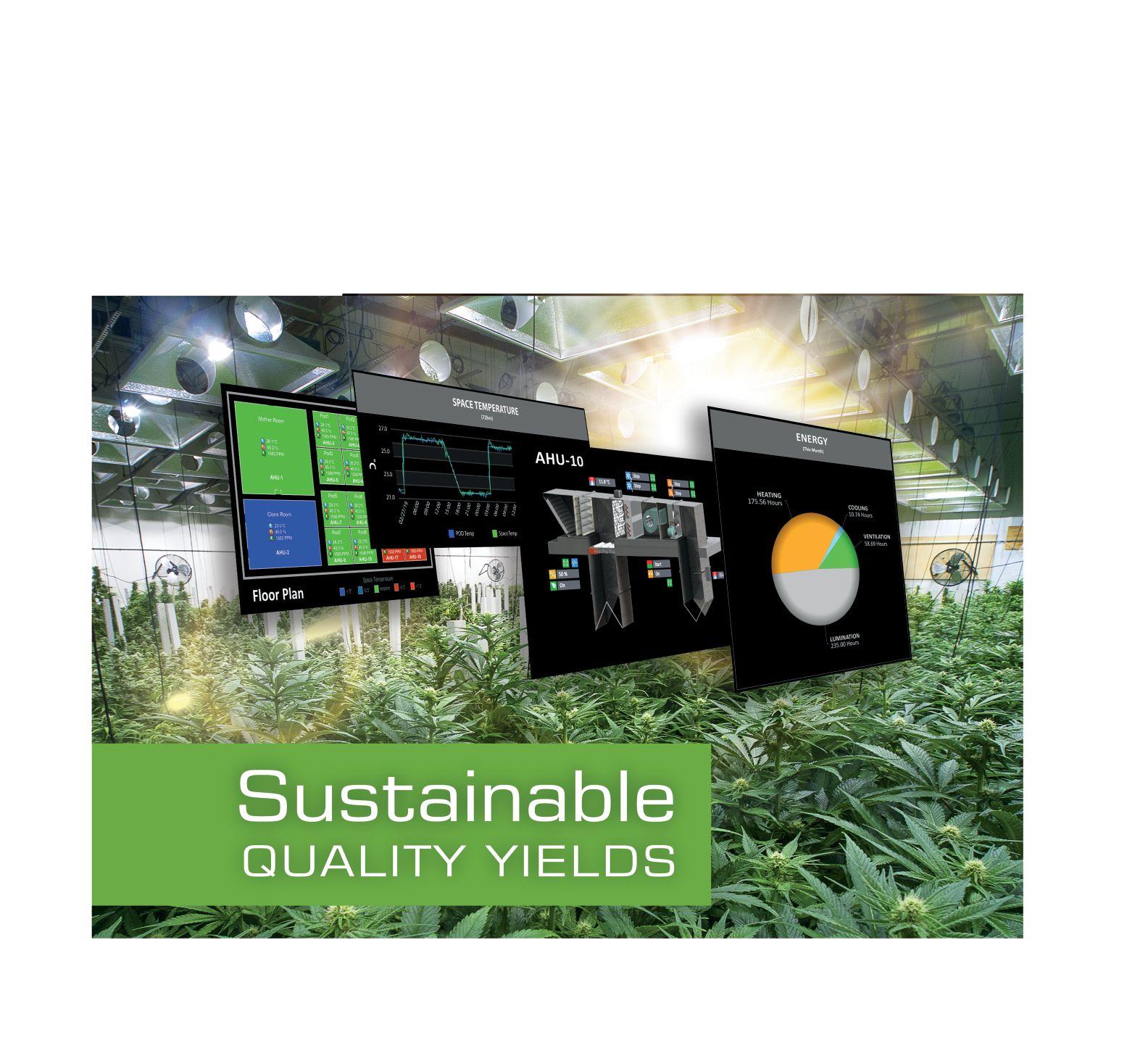

growing environment, a simple, flexible, and sustainable control system is crucial. This is why proactive LPs are turning to Reliable Controls. Our nation-wide network of factory-certified Authorized Dealers will design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely-controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective and Canadian-made solution, please contact a local Reliable Controls

Authorized Dealer near you.

The new Supertunia Blue Skies boasts a full, well-branched habit and greatly enhanced floral display compared to others in this colour class. Flowers open deeper lavender blue and lighten to silvery blue as they age, giving off a beautiful dimensional effect. It matches Supertunia White and ‘Lavender Skies’ for timing; both are early to flower. Expect outstanding all-season performance without deadheading, even in hot, humid climates. 15-30 cm tall, 46-61 cm wide. provenwinners.com

An exciting new addition to the Dümmen Orange garden mum collection, 24KaraMum offers a new flower form to complement their large-flowering line of Magnum garden mums. The mutant duo of Bronze and Yellow are ideal for combinations

Huge, striking 11.5-cm blooms held en masse above attractive foliage make a striking display on the retail bench or in the garden. With a full, bushy habit that easily fills large containers, this heat-loving, drought-tol-

The Vanessa series is bred for mildew tolerance and flower power. Prospective varieties are tested by inoculating the seedlings with mildew. Only those that stay

The cream margins on this summer-flowering groundcover perennial make the plant look bright and yellow all over, sprinkled with yellow flowers during early to midsummer. A fantastic variegated

erant variety creates a dependable product to extend the season for premium retail sales. Improved for earlier timing, better pot fill and shorter stems. Mounded. 25-30 cm tall, 25-30 cm wide. syngentaflowers-us.com

clean and in full colour are brought to market. Cascading varieties are wonderful for hanging baskets, uprights are perfect for pots. Trailing habit. danzigeronline.com

option for groundcover in the landscape, and perfect for rock gardens. Extremely drought-tolerant, rabbit-resistant and many are evergreen. Full sun. 15-20 cm tall, 41-46 cm wide. waltersgardens.com

and single planters with long-lasting colour and round, mounding habits. These mums are medium-vigour varieties and fall into the early flowering group with the expected natural response flowering window around week 36. dummenorange.com

These stunning summer-into-fall garden flowers offer drought and heat tolerance, holding up to the weather. Bloom months are July to September, perfect timing to catch late summer and fall sales. Helenium plants attract bees and butterflies but

are typically resistant to deer and rabbits. The three colours offered in the series are Embers, Golden and Yellow. Wellbranched and compact in size, they also look great in containers. 36-41 cm tall, 30-36 cm wide. darwinperennials.com

This ever-blooming, heavy blooming, rugosa rose bred by Chuck Bock won a gold medal from the American Rose Society in 2009. Lotty’s Love, named after Chuck’s wife Charlotte, has clusters of semi-double cup-shaped blooms of beetroot purple suffused with magenta. The 7-10 cm diameter flowers have gold stamens and emit a strong cinnamon fragrance. Lotty’s Love has the cold hardiness and salt tolerance that makes this species a landscape favorite. Red hips, 1.3 cm in diameter, form in the fall. The dark green glossy foliage is resistant to major fungal diseases. The habit is more refined than the species. firsteditionsplants.com

Consumer psychology may be key to improving sales.

The longer someone interacts with plant material, the more likely they are to spend money, says Dr. Bridget Behe, professor of horticulture at Michigan State University. But she’s not talking hours or minutes – they’re mere seconds.

This is why there are classes, planting parties, wine and chocolate events, explains Behe, while speaking at the Green Industry Show in Edmonton last year. It’s capitalizing on the social nature of people while keeping them in the retail space, she

ABOVE

Heat map shows areas of higher (red) and lower visual intensity (green).

says. In the US, over 80 per cent of the purchase decision is made at retail.

To better understand what draws – and keeps – consumer attention, Behe’s research group conducted over a dozen eye-tracking experiments using specialized glasses. Two cameras were positioned over each eye in the glasses, allowing Behe to tell what someone was looking at to the accuracy of her thumbnail.

“The way we look at the world when we drive a car is very different from the way we look at the world when we’re going to buy something,” she says. “And so what we’re doing with these glasses is we’re trying to understand what people look at in order to make a decision to buy a plant.”

In one study, participants were presented with several randomized displays, each containing either 6, 12 or 24 plants. As the number of plants went up, the percentage of plants viewed went down from 87 per cent to 46 per cent – that’s less than half the plants. “If you don’t see it, you can’t buy it,” says Behe.

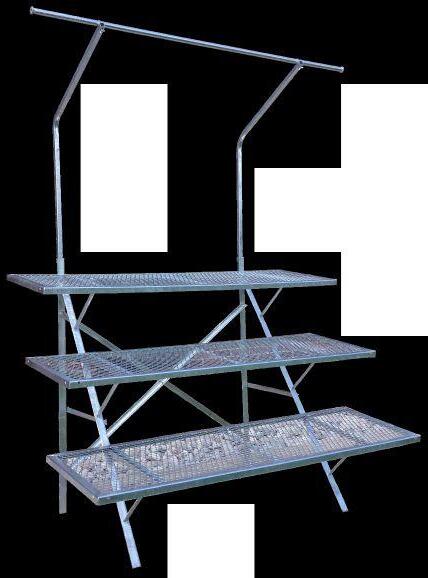

What about the location of the product? Their research showed that people were more likely to buy from the right side of the display than the left, which makes sense since most North Americans are right-handed. Consumers were also more likely to buy from the front of the display (47 per cent) versus the middle (31 per cent) and last (22 per cent) rows. “They don’t even see three or four rows back,” says Behe. That front row has got to be really stellar.

Height is also a key factor. Behe’s research group looked at the effects of having a three-tiered display. Most bought from the top shelf, middle shelf came in second, and the bottom shelf was dead last.

What about the number of genera or species? Testing out displays with one, two, three or four genera, Behe’s group didn’t find a big difference in the percentage of plant views. While customers were more likely to buy from the integrated display, they weren’t looking at 80 per cent of the plant material. Customers found what they wanted, and they made the purchase. “So this tells me, we’re going to max out at a number of plants that people cognitively can handle,” says Behe. “We’ve got to simplify these displays.”

Signage is another important element and placement matters. “They found the high to medium prices on the left faster than moderate prices on the right,” says Behe, likely because nearly all North Americans read from left to right. So where should prices we placed? Buried on the right, she says, buying just a few more seconds to interact with the merchandise, especially when things are at a very high price point.

When selling at a higher price, Behe’s group found that information on plant benefits helped. Features are what a plant is, while benefits are what people get from that plant, she explains. For instance, rather than simply showing that a plant requires full sun, it could be advertised as a great choice for a new subdivision where there’s little shade. Take the products that aren’t selling, list the features and translate them into benefits on the signs, says Behe. “When we elevate the benefits, we elevate the perceived value. When we elevate the perceived value, we can elevate the prices.”

Acknowledgements: Funding for this research was provided by grants from the Horticultural Research Institute and the USDA Federal-State Marketing Improvement Program.

DR. MOHYUDDIN MIRZA | drmirzaconsultants@gmail.com

Cold temperatures, low light change direction of growth.

ABOVE

Cucumber [left] and tomato [right] plants experienced rapid elongation. What happened?

Looking at these photos, do you know what happened to these cucumber and tomato plants?

Growers were expecting a compact and strong plant, but within a short span of a few days, the plants were already touching the wire, internodes were unusually elongated, and weak sets of leaves developed, looking thin, misshapen and not fully expanded. The first cluster of tomatoes appeared five feet on the stem.

These pictures were taken in the third week of January. When seedlings were planted on the blocks, they were about three weeks old. The plants grew very fast. Although the flowers were set after about five to eight leaves, the stem elongated and one could see weak flowers developing towards the tops of the plants. Weak flowers do not show a typical deep orange colour, do not appear to have vitality and strength, and have weak stems (pedicles). There will be a delay in harvest and first fruit in tomatoes will likely be showing unbalanced shape (catfacing).

WHAT TO DO WHEN LIGHT IS LOW AND WATER AND NUTRIENTS ARE UNLIMITED

It is about managing electrical conductivity (EC) in the growing medium. Aim for higher EC values,

over 3.5 mS in cucumbers and over 4.0 mS for tomatoes. When I asked a grower to check the EC in rockwool cubes, he told me that it was 4.0 mS in the squeeze from the cubes in which the seedlings were growing.

Use feed EC of around 3.0 to 3.5 mS and let the leach go over by 1.0 mS. In this manner, the plant will stay compact and will become generative quickly. There will be good balanced growth. Many growers use potassium sulfate 0-0-50 to raise the EC. In this way, the nitrogen to potassium ratio changes from 1:1.5 to almost 1:3.

If plants have stretched like what’s shown in the pictures, then remove the first cluster in the case of tomatoes. Remove any weak flowers as early as possible for both cucumbers and tomatoes.

An important note: When tomato fruit starts sizing up, start dropping the EC by 0.5 units. EC management by light can be used during cloudy and dark days, keeping the growth in balance. During summer periods, used lower EC values.

Mohyuddin Mirza, PhD, PAg, is a greenhouse specialist and consultant. Questions or comments? Contact him at drmirzaconsultants@gmail.com

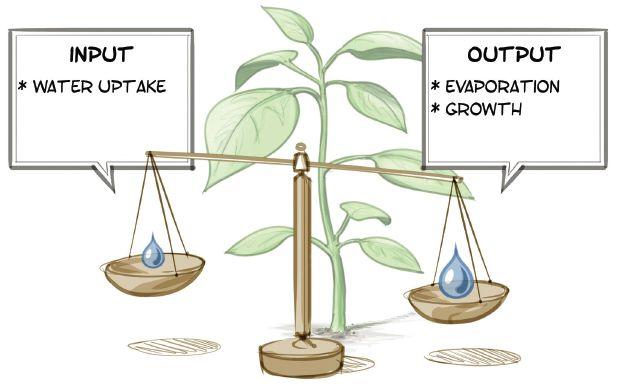

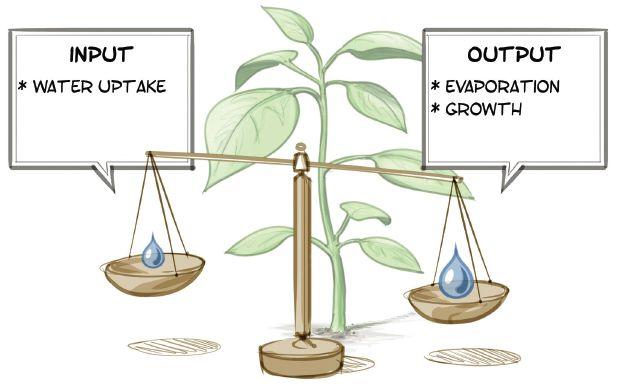

The goal of every greenhouse irrigation strategy should be to maintain water balance in the crop.

WBY JAN VOOGT

hat is plant empowerment? Typically, traditional plant production methods are based on a mixture of blueprints, best practices, common knowledge of plant physiology, as well as the ‘green fingers’ and ‘emotional perception’ of growers. This approach has been successful, but also has several limitations.

The concept of ‘Growing by Plant Empowerment’ (GPE) brings experience and knowledge together in an integrated approach. Its starting point is the natural behaviour of plants related to the greenhouse environment, as described by six balances concerning energy, water, CO2 and assimilates. Monitoring these balances with sensors, combined with crop measurements in a coherent framework based on physical and plant physiological knowledge and insights, provides hard facts required to control and improve the cultivation process.

In this first article of a multi-part series, we’ll explore the importance of GPE in a greenhouse’s irrigation strategy.

Typically, an irrigation strategy consists of a mixture of different methods, based on clock times (such as start time, stop time and time intervals), radiation intensity (W/m2) and light sum (J/cm2), the measured percentage of drainage water, water content or weight of the slab, and so forth.

factors, can also be used to refine this estimation.

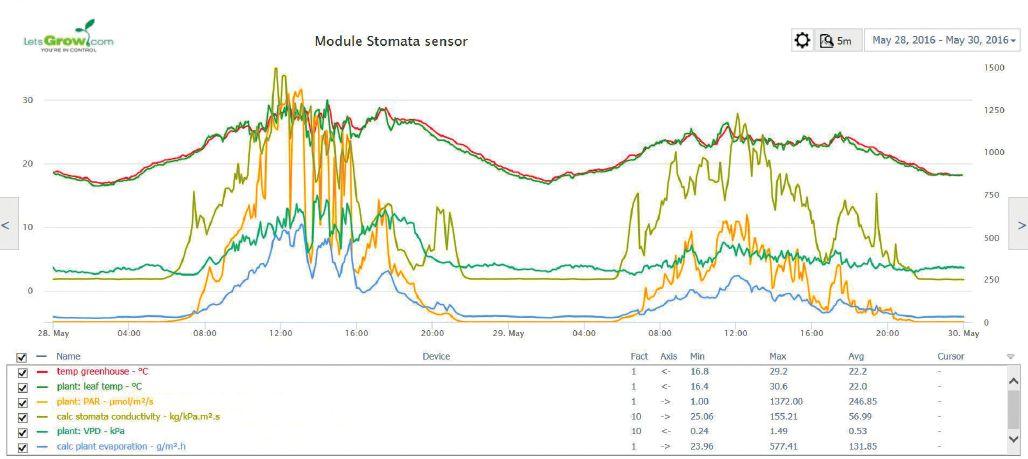

Of course, a method to check the applied irrigation strategy is required. That can be done by monitoring the water supply and the water content of the slab or the pot, but an even better way is by observing stomatal behaviour by measuring plant leaf temperature and monitoring the vapour pressure difference (VPD) between the plant and the air – we will revisit this later.

Energy balance is the balance between the energy flows towards (input) and from (output) the plant. We can distinguish between four different types of flows:

ABOVE

The goal of the irrigation strategy, however, should be to support the plant’s water balance and to ensure CO2 uptake for photosynthesis by keeping the stomata open under high radiation conditions. This maximizes the light use efficiency (LUE) and production of assimilates for growth and development. Therefore, irrigation should be closely aligned to evaporation rates at all times.

Since energy input is the driving force behind evaporation, it is possible to estimate actual evaporation rates by measuring the incoming radiation energy through a pyranometer outside or, preferably, a PAR sensor inside at crop level. The humidity deficit of the air, the heating pipe temperature, as well as other

• Shortwave radiation – this is light from the sun, lamps or LEDs;

• Longwave radiation – also called heat radiation or heat emission;

• Convective energy – transferred by moving air around the leaves;

• Evaporation energy – energy absorbed by the evaporation of water. According to the physical Law of Conservation of Energy, energy cannot be created or destroyed but can be transferred into different forms. If energy balance is the sum of all the different energy flows, the net result must be zero as the total input energy must equal total output energy.

Typically, shortwave radiation only moves towards the plant and thus is always on the input side. Longwave radiation can be towards the plant, but also emitted from the plant depending on the temperature difference between the crop and the surrounding objects, such as the soil and greenhouse roof.

Convective heat transfer plays a decisive role in the balance and underlines the importance of air movement around the plant. The direction of the transfer depends on the temperature difference between the plant and the air, so it can contribute either positively (input) or negatively (output) to the balance.

Evaporation is only possible when the balance has a surplus of energy on the input side. It is also the link between energy

ABOVE

balance and water balance because evaporation is essential for cooling the plant under high radiation conditions.

Recent research has revealed at least five crucial new insights related to the energy and water balance of plants:

• The driving force for evaporation is energy absorption by the plant leaves and not the relative humidity (RH), humidity deficit (HD) or vapour pressure deficit (VPD).

• By identifying two different sources of energy that contribute to evaporation energy (radiative and convective heat transfer), stomatal behaviour can be explained by the plant’s energy and water balance.

• Air movement can stimulate plant activity or evaporation, as moving air supplies convective heat input. On the other hand, air movement can help the plant stay cool if not enough water is available for evaporation (plant temperature is higher than air temperature).

• Low air humidity or a high humidity deficit can cause extra unnecessary evaporation under high radiation conditions, thus closing stomata and limiting photosynthesis.

• Heat emission (outgoing long wave radiation, OLWR) has a significant negative impact on the plant’s energy balance during nighttime, but also at the beginning and end of the day when the roof of the greenhouse is cold compared to plant leaf temperature. Evaporation and thus uptake of vital

nutrients, especially calcium, may drop below the critical minimum value. That causes many different problems for the plant’s growth and development.

Water balance describes the input and output of water from the plant. Output is mainly by evaporation. Only a little portion of total water uptake is stored in the plant and fruit. In practice, evaporation is mostly driven by radiation from the sun, supplemental lighting and heating pipes. If there is no radiation, the only source of energy is convective heat transfer by air movement. In that case, evaporation mainly depends on RH or HD.

Plants need to evaporate for two reasons: for uptake and transport of nutrients, and for cooling. To keep the water balance in equilibrium, uptake of water from the rootzone must be equal to at least the evaporation rate. For the short term, the plant can also extract water from the fruits, which thus work as a buffer. That explains why the water balance reacts differently in the morning compared to the afternoon. The same goes for sunny days versus dark days. However, to ensure sufficient water availability for the longer term, irrigation needs to be aligned with evaporation rates.

The degree of opening of the stomata is directly related to water availability in the leaves and reveals if the crop is properly

irrigated. Because of their microscopic size, the openness of the stomata is hard to measure directly. However, the effect of stomatal closure, which causes a proportional rise in plant leaf temperature, can be monitored relatively easily with an infrared sensor.

The infrared plant leaf temperature sensor is (Fig. 1), without a doubt, the most essential plant sensor for practical applications. It shows how plant leaf temperature is influenced by different factors such as changing air temperature, RH, solar radiation, artificial lighting, opening, and closing of screens, vents, and so on, including irrigation strategy. Thermal behaviour reveals the status of the internal energy and water balances, and is, therefore, also directly related to stomatal behaviour.

Figure 2 illustrates how data measured by different sensors changes over two days. During the night, plant temperature (bright green line) is slightly below air temperature (red line) due to evaporation (also called the wet bulb effect). Varying PAR light intensity (yellow line) influences plant temperature in relation to air temperature. Typically, a steep increase in PAR light makes plant temperature rise temporarily above air temperature because the evaporation rate cannot be increased as quickly by the plant (see boxed area). If plant temperature is continuously above air temperature, however, this may indicate a lack of water availability and stomata are likely to be partially closed. Evaporation rate (light blue line) can be

derived from the energy balance by calculating the surplus of energy on the input side. Combining this with the calculated VPD between the plant and the air (green line) reveals the behaviour of the stomata: the higher the VPD in relation to evaporation, the lower the stomatal conductance (yellow-green line).

VPD values above 1.5 to 2 kPa signal that stomata are closed and plants are suffering from water stress. This also hampers CO2 uptake for photosynthesis.

Irrigation strategy is not the only factor that determines the water balance of the plant. Root development, which is directly related to assimilates balance, also plays a crucial role here. Furthermore, rootzone temperature, EC and pH in the substrate deserve attention. For instance, a too-low root temperature or a too-high EC can hamper water uptake under high radiation conditions.

Irrigation should allow the plant to benefit optimally from the available light for photosynthesis. In practice, different strategies can lead to reasonably good results. The best irrigation method, however, takes the energy and water balances of the plant as a starting point, while also making adjustments based on real-time data and the plant’s stomatal behaviour.

GPE is based on the same principles as ‘Next Generation Growing’ (NGG), developed in the Netherlands over the last 15 years. It has been shown that this approach can deliver significant advantages regarding production and quality, plant health and energy savings for many different crops. For the most part, this can be achieved without extra investments in greenhouse equipment.

The basic principles have been further developed, refined and extended, focusing on optimal growth in a sustainable way and going by the new name ‘Growing by Plant Empowerment’. For more on GPE and the book Plant Empowerment: The Basic Principles, visit plantempowerment.com. Copyrights of text and illustrations: LetsGrow.com, 2019.

Jan Voogt is a senior researcher at Hoogendoorn Growth Management and is one of the authors of Plant Empowerment: The Basic Principles.

Ornamental plants with unusual, but pleasing, characteristics attracted the most attention at the Guelph Garden Trials this past year.

TBY RODGER TSCHANZ

rialing new varieties can serve many purposes. Not only can they show off container and bedding performance in different climates, they can also be used to gauge public interest and identify emerging trends. This past year was no exception. The climate from June to August 2018 was warmer and drier than normal, but at the same time was plagued with random intense rain events that affected bloom performance for some of the annuals.

Each of the four partner trial sites – Landscape Ontario’s Milton headquarters, Royal Botanical Gardens, Vineland Research and Innovation Centre, and the University of Guelph – had ground bed and/or container trials which appealed to different stakeholders, including greenhouse growers, landscapers, garden writers, public parks and the general public.

A list of the best-received and best-performing varieties was compiled based on votes by visitors and by trial garden staff over the entire 2018 growing season:

1.Calibrachoa Superbells Doublette Love Swept: This was selected by visitors as one of their favourite container plants, even though its flower diameter was one of the smallest (1.6 cm) in the calibrachoa trial. The doubled flower with dark pink petals edged in white is reminiscent of a small carnation.

per plant. The most popular annual in the 2018 ground bed trials, mass plantings in landscape beds were quite eye-catching but mixed container applications with other compact plants should also be considered. In the different trial beds, it reached heights ranging from 22-39 cm and a spread of 30 cm by the end of the season. The maximum inflorescence diameter reached 30 cm.

4. Gerbera Garvinea Sweet Fiesta and Sweet Sunset: This series continues to perform well in the landscape and outdoor container plantings, providing early season bloom and lasting into the fall where it can even tolerate and continue to bloom after a light frost. Fiesta and Sunset were two new colours that were trialled in 2018 with great success.

2. Calibrachoa MiniFamous Uno Double PinkTastic: Another double-flowered calibrachoa that was popular with visitors, but the flower diameter is larger (2.8 cm), the pink centre is more intense and the narrow white ribbon along the petal’s edge is replaced with a wider white to white-blush coloured border. As a whole, the Uno series is semi-compact and displays very well on the greenhouse bench.

3. Celosia Dracula: Short, stocky and substantial are three words that come to mind when describing this wine-coloured cockscomb celosia. Although we did not weigh the flower heads, it is clear that the plant’s thick stalk was required to support the cockscomb’s mass; only one flowerhead was produced

5. Pelargonium Super Moon Red Zonal Geranium: This is a large-flowered, dark red zonal geranium with attractive contrasting foliage. The vigorous growth habit and heat tolerance helped this selection provide exceptional bloom performance throughout the warm 2018 trial season; suitable for both landscape and container applications. Individual floret diameters can reach 5 cm.

6. Pelargonium Moxie series: This series of interspecific geraniums has a compact growth habit and is especially suitable for use in small containers. It has a very strong flowering habit as well.

7. Pelargonium Reach Out series: A series of seed-propagated, ivy-leaved geraniums with a compact growth habit and short internodes. It produced blooms throughout the canopy, showed well on the greenhouse bench and showed best in container applications in the 2018 trials.

8. Platycodon Popstar series: This species is commonly called a balloon flower because its bud appears to expand like a balloon before opening into a cup-shaped flower. This plant is a hardy perennial in our climate, but blooms easily the first year from seed. It branched well and kept producing flowers all season long in both containers and flowerbeds. While native forms of the species typically reach heights of 30-80 cm, the compact

Popstar ranged from 17-23 cm in height with a spread of 24-29 cm in the first garden season.

9. Tagetes Super Hero Spry: This series of French marigolds is the replacement for the Hero series and brings improved uniformity on the bench with a range of eight colours. Super Hero Spry, with its bicoloured (dark maroon and golden yellow) petals, recently became a national All-America Selections award winner for its compactness, earliness to bloom and stable colour pattern. In the 2018 trials, this entry provided consistent bloom all season long.

10. Verbena Lanai Upright Twister Watercolor: This compact verbena with an upright habit kept the bloom front and centre on the greenhouse bench and in the garden. Its compact, mounding habit reduced the tendency of the verbena stems to root into neighbouring pots while on the greenhouse bench. In the garden, this cultivar continued to bloom despite daytime temperatures that often exceeded 30°C.

11. Verbena Empress Sun Red: This series has been selected for its suitability for use in the landscape and containers. It is relatively heat-tolerant and vigorous. Of particular note with Sun Red is its flower colour; the dark red eye surrounded by a lighter scarlet colour creates a very intense red flower that could pair up nicely with Empress Sun White for Canada Day plantings.

The ornamental plants that attracted the most attention this year had unusual but pleasing characteristics such as the celosia Dracula, the calibrachoas Superbells Doublette Love Swept and the Popstars balloon flower. Other groups of fan favourites encompassed familiar flower forms and growth habits with new, exciting and vibrant colours, including the verbenas Lanai Upright Twister Watercolor and Empress Sun Red; the French marigold Super Hero Spry; the pelargoniums Super Moon Red, Reach Out and Moxie series; the gerberas Garvinea Sweet Fiesta and Sunset; and the calibrachoa MiniFamous Uno Double Pinktastic. And because of their resilience to pounding rains, these selections managed to look good no matter what the weather forecast produced.

Rodger Tschanz is the Trial Garden Manager at the University of Guelph. He can be reached at rtschanz@uoguelph.ca

BY DR. YOUBIN ZHENG

I am sure you know of IPM, which stands for Integrated Pest Management, and you have likely been practising this in your operation for years with success. However, have you heard of IRM?

IRM stands for Integrated Rootzone Management which has a concept similar to IPM. IRM is a comprehensive approach to creating and maintaining a rootzone with adequate water, nutrients, and oxygen, within an appropriate temperature range, and without being limited by abiotic or biotic stressors. This can be achieved by considering the interrelated elements of the rootzone.

The rootzone is the environment where roots reside. When growing container crops in artificial growing substrates, from small plugs to large pots, substrate-filled troughs or bags, the rootzone is the environment within the containers. When growing in solution culture, the nutrient solution in contact with the roots can be considered the rootzone.

Solution culture and aeroponic systems have been successfully used on various crops for centuries. Clearly, plants can grow well without solid

Figure 1.

substrates as long as the roots are in an environment with adequate water, nutrients, oxygen, and temperature, and without biotic (e.g. pathogens) or abiotic (e.g. unwanted chemicals) limitations.

While it is not essential to have substrates for plant growth, soilless substrates (e.g. rockwool and mixes containing components such as peat and coir) are commonly used for plant production. For example, potted ornamentals need to be grown in pots with substrates for easy transport and display. Further, when vegetable crops such as tomatoes are grown in large greenhouse areas using substrates, horticultural management is easier and more forgiving (e.g. during a power outage). Substrates have buffering capacity against large disruptions such as water, temperature, pH and EC shifts in the rootzone. Conversely, when plants are grown in solution culture (e.g. nutrient film technique) or aeroponic systems, drought stress can be caused by a few hours without water delivery (e.g. during pump malfunction). When substrates are used, the dynamics of different environmental

A: Basil (Ocimum basilicum) performs better grown in a smaller pot (left) compared to those grown in larger pots (right), both in a peat and perlite mix. Photo B shows a close look of the typical waterlogging injury symptoms observed on plants grown in the larger pots from Photo A.

Choosing the right insecticide makes all the difference to your production and profitability. FMC has you covered, with three proven control products to protect your high-value crops.

Use Exirel® insecticide early to give cucumber, pepper, tomato and eggplant foliage the protection it needs during the most critical stage of development. Translaminar and locally systemic movement, plus rapid absorption ensures the product moves through the plant quickly to control cabbage looper, whiteflies, pepper maggot, pepper weevil1 and thrips1

Coragen® insecticide is a unique broad-spectrum, Group 28 active that controls pests resistant to other insecticides. It quickly stops insects feeding and delivers control at all growth stages. Protect your cucumbers, tomatoes, eggplant and pepper plants from cabbage looper and lepidoptera leafminers.

Beleaf® 50SG insecticide, a Group 29 product, targets piercing and sucking pests effectively. Protect your strawberries, cucumbers, peppers and tomatoes from thrip, aphid, lygus bug and whitefly feeding damage.

factors in the rootzone become more complicated than in solution culture and aeroponic systems. Environmental factors interact with each other such that a change in one factor can affect others. For example, adequate rootzone oxygen promotes strong, healthy plants that are resistant to pathogen infection; however, excessive substrate water content can reduce oxygen levels, creating an environment conducive to plant pathogens, which may, in turn, require the grower to increase pesticide use.

In soilless production, the most commonly controllable elements are: 1) growing substrate formulation, 2) oxygen and other gases, such as CO2, through the choice of growing substrate, irrigation and other supplements (e.g. aeration of irrigation water, injection of certain chemicals such as hydrogen peroxide and aqueous ozone); 3) water status through irrigation; 4) nutrient composition and concentration through fertilization; 5) temperature through the control of atmospheric temperature, irrigation frequency,

and irrigation water temperature; and 6) microbial community. All these elements are interconnected; therefore, to provide a healthy rootzone, an integrated approach is essential when dealing with them. Let’s take a closer look at key components of the rootzone, how they are interconnected, and the limitations caused by taking a non-integrated approach when dealing with these components.

Growing substrates are used for providing physical support, retaining water and nutrients, providing air space for oxygen to diffuse into the rootzone and for harmful gases such as CO2 and ethylene to move out freely. Common components of soilless growing substrates are peat, coir, wood fibre, bark, rockwool, perlite, vermiculite, sand, etc. Efforts have been made to find alternative materials for different regions and for different plant production systems. As agreed by many scientists, there is no one ideal growing substrate. However, in order to characterize and evaluate different substrates, researchers normally measure the following parameters: 1) physical properties, such as total porosity, container capacity, air porosity, and bulk density; 2) chemical properties, such as pH, EC, and the content, composition and availability of different nutrients; and 3) biological characteristics such as microbial community structure. The issue is that there are no internationally accepted standards or guidelines for assessing and reporting these parameters. Different plant species and cultivars, and even the same species at different developmental stages or sizes, require substrates with different characteristics. Further, if the same substrate is used, container sizes and shapes should be matched to the size of the plants. Figure 1 shows the performance of basil (Ocimum basilicum) plants when grown in the same substrate (peat and perlite mix) in either small or large containers. When basil seedlings were transplanted to a too-large container, the substrate in the container remained wet for too long, leading to oxygen deficiency and plant injury. Container size and shape can affect the substrate’s physical properties as well, especially container capacity and temperature. Research with various substrates has also shown that different shapes of containers can affect plant performance.

Currently, methods for measuring both physical and chemical properties of

substrates vary by region. For example, in measuring substrate physical properties such as container capacity and air porosity, many labs in North America use the NCSU porometer developed by Fonteno’s lab at North Carolina State University, where the diameter and height of the sample cylinder are both 7.6 cm. In contrast, many European countries use the European Standard CEN TC 223 WG4 N151, which uses a double ring with a diameter of 10 cm and a height of 5 cm for each ring, and the measurement procedure is different as well. For a given substrate, different methods and devices can provide varying results for parameters such as water holding capacity and air porosity. Therefore, it is difficult to recommend a “perfect” growing substrate by simply specifying the physical properties without considering other related factors. A substrate can also work in one situation, but not for another, For example, different irrigation methods can have substantially different effects on plant performance in a given substrate. The “perfect substrate” simply does not exist. When selecting a growing substrate, ensure that all the constituents are chemically and biologically stable, with no toxic compounds, and are pathogen-free. It is important that substrates are homogenous and consistent from batch to batch. This way, for a given substrate, plant and growing conditions, it is possible to develop effective horticultural management (e.g. irrigation) strategies to create a suitable rootzone environment.

Adequate rootzone oxygen is essential for healthy plants. Low rootzone oxygen is common in soilless production and can cause a variety of disorders in plants. Too much oxygen, which can be achieved by using modern water oxygenation technologies, can also harm plants and has been demonstrated by my previous research. When the rootzone is short on oxygen, plants are more prone to pathogens such as pythium root rot. Chérif et al. (1997) demonstrated that rockwool-grown tomato plants with low rootzone oxygen concentrations developed root rot symptoms earlier than those with higher rootzone oxygen concentrations. When inoculated with Pythium spp., tomato plants with high rootzone oxygen concentrations were less susceptible than plants with rootzone oxygen concentrations less than 5 mg/L. In a survey of commercial

vegetable greenhouses in southwestern Ontario, we often observed crops with rootzone oxygen concentrations less than 2 mg/L. For this survey, rootzone oxygen concentration was measured using in situ oxygen sensors inserted directly into substrate bags of actively-fruiting plants.

Plant roots and microorganisms can produce other gases, such as CO2 and ethylene, which may build up to harmful levels. When using growing substrates, it is essential that gas exchange between the rootzone and the atmosphere is

unrestricted. Oxygen can diffuse over ten thousand times faster in the air than in water. This is why supplying dissolved oxygen (DO) in the irrigation solution may not be as effective as using a substrate with sufficient air porosity and good drainage. Our research demonstrated that even by using a nutrient solution with a DO of 20 mg/L to fertigate potted cut roses in coir substrate, there was no difference in rootzone oxygen levels compared to the control nutrient solution – both had DO levels of around 8.5 mg/L.

Hoogendoorn’s next generation iSii monitors and controls all climate, irrigation and energy equipment in all types of greenhouses. The iSii is equipped with advanced controls that work according to the principles of Plant Empowerment, which resulted from Next Generation Growing (NGG) research. This way light, temperature, humidity and CO2 are aligned with each other for a maximum photosynthesis. In addition, to prevent water stress, irrigation is driven by the evaporation energy and water balance of the crop. With the iSii process computer, you set the base for high quality production.

To ensure adequate rootzone oxygen levels, the selection of growing substrate, environmental (e.g. temperature) control and irrigation practices all need be considered holistically. When the growing environment is hot and humid, a substrate with high air porosity and better drainage is desirable for maintaining adequate rootzone DO. In such cases, more frequent irrigation can be used to manage rootzone oxygen levels and temperatures. High rootzone temperatures, which are normally associated with high levels of root respiration and microbial activity, can further reduce DO, raise harmful gas concentrations and can lead to proliferation of soil- and water-borne pathogens.

IRRIGATION/FERTIGATION

When an appropriate substrate is used, irrigation/fertigation management can be used to regulate most of the key rootzone environmental parameters. Aside from providing sufficient water and fertilizer, irrigation can bring in new dissolved and atmospheric oxygen, while helping to remove harmful gases and chemicals from the rootzone. If irrigation water is temperature-controlled, it can also be used to help adjust rootzone temperatures. This explains the old saying “the profit is in the hand of the person who holds the hose” in the greenhouse industry.

The question is when and how much to water? Irrigation frequency and volume are strongly correlated with rates of transpiration and evaporation, which are dependent on plant species, cultivar and size, container volume, the environment in which the plants are grown (e.g. light intensity, air temperature and humidity, etc.) and irrigation method (e.g. overhead, drip, sub-irrigation, etc.). Rather than using the conventional “lift, touch, and feel” methods of informing irrigation management decisions, many scientific studies have demonstrated that sensors (e.g. frequency domain reflectometry water content meters) can be successfully used to manage irrigation in soilless production. However, the microclimate even within modern greenhouses can vary drastically from one location to another. Our recent research has demonstrated that evaporation rate in one location of a modern greenhouse can be double that of other locations within the same greenhouse. These kinds of microclimate variations indicate that when the same substrate is used for the same crop in a greenhouse, either the substrate should

have low water holding capacity for more frequent irrigation, or the irrigation frequency/amount should be varied by location within the greenhouse (which can be very difficult to manage, depending on the irrigation infrastructure).

It is also important to keep in mind that different substrates need different irrigation volumes and strategies. Researchers in North Carolina have shown that plants irrigated in the afternoon perform significantly better than plants irrigated in the morning, with 2 to 3°C reductions in rootzone temperatures when irrigated in the afternoon. Irrigation method can affect the rootzone environment in other ways. For example, our research shows that subirrigation can cause salts to accumulate to harmful levels near the upper surface of the growing substrate due to evaporation, whereas overhead irrigation can leach fertilizers from the growing media (also potentially leading to downstream environmental issues).

The rootzone is a complicated system which demands an integrated approach...

Fertilization is one of the most economical and most environmentally friendly tools in soilless crop production, where it can be used as either the “gas pedal” or the “brake”. By applying the right fertilizer rate and formulation, one can have a crop ready for market weeks earlier, therefore reducing labour costs, improving space-use efficiency, saving water, and ultimately increasing profits.

Fertilizer requirements vary by substrate composition and growing conditions. During the summer months with high light levels, plants normally uptake and transpire more water. Therefore, feeding nutrient solution concentrations should be lower in the warmer months.

Fertilizer type and rate can also be used to manage the rootzone. For example, different nutrient compositions can affect rootzone environment and influence the availability of certain nutrients to plants and microorganisms. It is well-known that NH4+ uptake can decrease rootzone pH, while NO3- uptake

can increase rootzone pH. Rootzone pH can also affect the availability of nutrients such as iron and phosphorus. Antagonistic and synergistic reactions exist amongst certain nutrients. For example, NH4+ competes with K+ uptake, while NO3helps the uptake of Ca2+ and K+

Rootzone microflora is comprised of both beneficial microorganisms and plant pathogens. Some irrigation strategies involve the capture and reuse of irrigation runoff and may spread pathogens throughout the greenhouse. It is common practice in North America to disinfect the runoff before reuse. However, most disinfecting technologies are largely ineffective if pathogens are already present in the rootzone, especially when the substrate is organic material (e.g. peat) based. It is also important to not harm beneficial microbial populations in the rootzone when using water disinfecting technologies that have ‘residuals’ – in other words, chemicals that persist beyond the point of contact, such as chlorine, ozone, copper, etc. Since most contemporary water disinfection technologies are ineffective at killing pre-existing substrate-borne pathogens, the inoculation of beneficial microorganisms into the rootzone is an alternative approach. Research has shown that some microorganisms can suppress plant pathogens in certain plant species when inoculated into the rootzone. A combination of fertigation solution disinfection and substrate inoculation with beneficial microorganisms has been suggested as a synergistic approach to managing pathogens in the rootzone. The effectiveness of beneficial microorganisms in suppressing pathogens can also be affected by other rootzone parameters, such as substrate water content, nutrients, pH and oxygen levels. Therefore, it is again important to take an IRM approach towards promoting beneficial microorganisms in the rootzone.

The rootzone is a complicated system which demands an integrated approach for effective management. Each component requires its own research. When it comes to crop production, all of the aforementioned components need to be taken into consideration simultaneously. When reading others’ research, we need to keep in mind that “science is the intellectual and practical activity encompass-

Light cycles. Growth cycles. Business cycles. We craft lighting solutions to improve all three. With expert lighting calculations, custom designs tailored to your environment, and post-installation performance testing, Gavita has what you need to reach your cultivation goals.

ing the systematic study of the structure and behaviour of the physical and natural world through observation and experiment” (Oxford Dictionary). Quite often, when researchers investigate whether a new material can replace contemporary growing substrate components (e.g. peat and coir), the same irrigation strategy is used for the control treatment. The suitability of the new substrate is evaluated based on whether its ‘performance’ is comparable to the control treatment, without considering the potential need to re-optimize the irrigation strategy (or any of a host of other parameters) to suit the new material. Conversely, when different horticultural management strategies (e.g. fertigation) are used in the aforementioned substrate trials, the researchers may be criticized for not using a ‘true control’. In reality, due to time, space and funding limitations, it is generally not possible to take into account all elements of the rootzone environment in each trial. As long as we keep IRM in mind, and use systematic investigative approaches, the results should be scientifically acceptable and comprehensive. However, for this to succeed, it is essential for researchers

to fully characterize their substrates and growing conditions, using acceptable methods for measurement and reporting, in order for the research results to be broadly applicable. For example, in a trial comparing different substrate materials, if irrigation can’t be included as a variable, the researchers should at least clearly and precisely indicate how the plants were irrigated (e.g. at what substrate water status did irrigation start), rather than simply saying “irrigated as needed”. Some recent studies have begun to consider the synergistic/antagonistic effects of interconnected parameters in the same trial.

In soilless plant production, an IRM approach requires growers to select the correct container (including size, shape and colour), substrate, fertigation strategies, etc., based on their plant species/ cultivar, and climate and microclimate conditions. With so many different rootzone components and management strategies (e.g. irrigation/fertigation), how can a grower select the best combinations of these factors for their production system? Is it an optimized rootzone as long as there is adequate water, nutrients, oxygen and temperature, with no biotic

or abiotic restrictions in the rootzone? If so, can we achieve this ideal scenario by measuring the mentioned rootzone parameters, then modifying them accordingly? More research is needed to address these questions. If it is acceptable, then in situ, real-time monitoring of rootzone environmental parameters would be ideal to help growers manage the rootzone. Currently, reliable and easy-to-use tools/ sensor technologies are available for measuring some of these parameters, such as temperature, pH and water status (both water content and water potential); however, more research is needed to advance technology for in situ monitoring of other parameters such as nutrient composition and concentration, and oxygen levels.

IRM is a practical, powerful and cost-effective approach for successful soilless production. Growers and researchers should be mindful of the principles and practices of IRM, both in research and in production.

Youbin Zheng, PhD, is an environmental horticulture professor in the School of Environmental Sciences at the University of Guelph. He can be reached at yzheng@uoguelph.ca

Smart technologies help confirm greenhouse watering decisions.

BY GRETA CHIU

With so many other tasks requiring attention, modern greenhouses are beginning to integrate automated systems for crop moisture assessment.

At Sunrise Greenhouses, the operation runs on a self-developed, automated irrigation system. Each of the 13 underground concrete tanks feed into different crops, allowing the entire facility to use recycled irrigation – including the fields – and still have separate return drains for each zone. There’s also added flexibility in terms of fertilizer, compared to just one or two feeds.

“Prior to this, all of our tank selections were manual,” says Rodney Bierhuizen, owner and general manager of the greenhouse operation. Needing around 100 valves at a price of $600 to $800 each,

ABOVE

the cost barrier alone would have been prohibitive. By using pneumatic valves and modifying the existing manual ones to a pneumatic cylinder, they were able to drop the price down to around $50 per valve.

But what really drove Bierhuizen to make the switch, was the retirement of his full-time grower of 35 years. With three irrigation units, Bierhuizen himself manages watering for half of the greenhouse, while an assistant grower oversees the other half. Before, they would need someone to manually select tank suction, return, feed and monitor levels. “Now this is all managed automatically,” Bierhuizen says of the Argus-managed system. All pumps were converted to variable speed frequency drives. “It’s more energy-efficient, and we get

Sunrise Greenhouses uses a historical model, while Vineland’s Darren Ward and Sydney Stavina work on developing a predictive one.

rebates from Ontario Hydro.”

Bierhuizen also attributes the project to funding from the Greenhouse Competitiveness and Innovation Initiative (GCII). Prior to this, he says, only certain projects would receive money, but with GCII, growers became eligible based on square footage. Those who didn’t have the financial resources previously to take on this technology became able to.

A computer spreadsheet helps manage their irrigation frequency, showing historical averages of the number of days between watering sessions at any given time of the year. While growers still walk the crop, the system provides an added layer of confirmation and efficiency, directing the grower to valves which are due for water or flagging possible valve malfunctions. For a third layer of confirmation, iUNU’s automated cameras monitor changes to plant health.

While the historical model works well for Sunrise, the greenhouse operation has also collaborated on an artificial intelligence-based smart irrigation project at Vineland Research and Innovation Centre (Vineland) that allows for predictive modelling in potted crops.

“Vineland came up with the core engine – the AI decision support system,” says Darren Ward, along with methods for training and running it. As the research institute’s manager of business planning and commercialization explains, “The grower would let the system know every time they water, and also put in a height measurement,” from the time they start on the crop until the time it’s shipped, training the system over a minimum of one growing cycle.

The system also connects to a network of wireless sensors for soil moisture and climate. Existing climate computer data

can be used. All the information is fed into the AI-training algorithm, hosted on the cloud-based management system LetsGrow. com. “LetsGrow will send an email or text message, and from there, the grower can trigger their own water,” says Ward.

Slated for release this fall, the system has garnered positive results from tests in commercial facilities so far. One particular case reduced water use by 15 per cent and saved about $2,800 per acre per year on labour. The ornamental potted crop developed better root structure and quality overall,

leading to more product shipped at QC.

As Ward explains, basing decisions on hard data rather than grower perception helps avoid unnecessary irrigation. “We noticed that this was something that happened during our testing. A grower might err on the side of caution and provide a little extra water during really hot periods, but the data itself may dictate that’s not the right thing to do.”

Whether historical or predictive, both systems have one thing in common: users still make the final call on watering.

There’s been growth in both the number of biocontrol users and the extent of biocontrol use.

BY ASHLEY SUMMERFIELD

It has been four years since we last surveyed floriculture growers, and in that time, there have been some big changes in the way Canadian growers are using biocontrol. Our most recent survey, conducted over the spring and summer of 2018, received responses from 47 ornamental greenhouse growers. Primarily from Ontario, operations ranged from less than 5,000 m2 to 100,000 m2 Respondents represent approximately 24 per cent of the ornamental greenhouse acreage in the province. We received responses from wholesale, retail and propagation growers, who produce a total of 43 different kinds of primary crops.

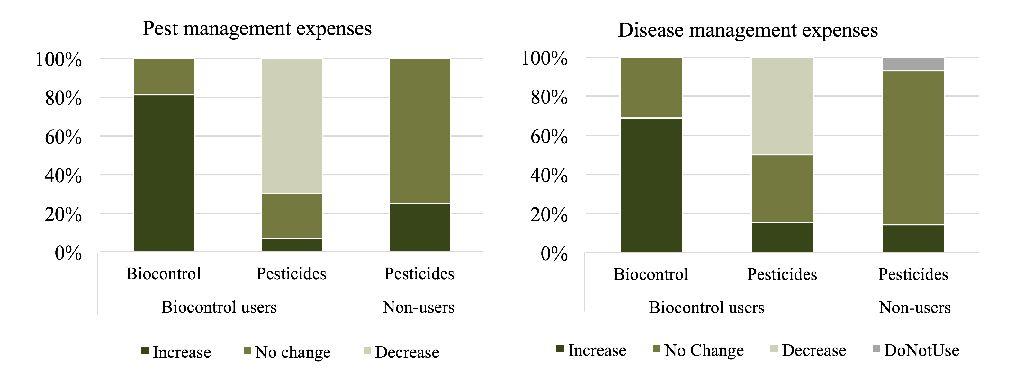

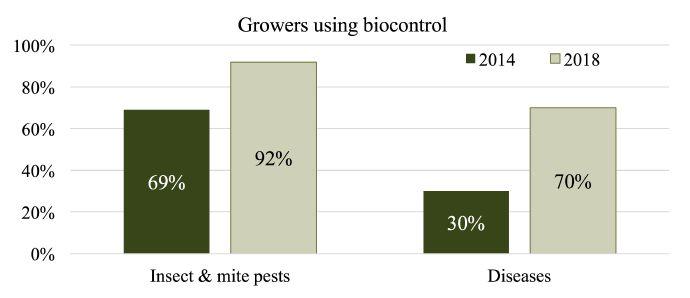

Our survey indicates that biocontrol use for insect and mite pests has increased from 69 per cent in 2014 to 92 per cent in 2018. Gone are the days of routine conventional pesticide applications; biocontrol is the new norm and it’s here to stay. Growth has not only been seen in the number of biocontrol users, but also in the extent to which they are using biocontrol products. When asked

how their spending has changed over the past five years, 81 per cent of biocontrol users said that they have increased their spending on biocontrols for pest management, while correspondingly, 70 per cent have decreased their spending on conventional pesticides. During the same period, the majority of growers who were not using biocontrol have not changed their spending on pesticides.

One of the biggest changes in biocontrol use between 2014 and now is the number of growers using biologicals to manage diseases. Back then, only 30 per cent of growers used biocontrol products to manage diseases. Fast forward to 2018, and 70 per cent of growers are now using biopesticides for diseases! This is a dramatic increase in such a short period of time. As growers are integrating more biocontrols into their integrated pest management (IPM) programs, 50 per cent have been able to reduce their spending on conventional pesticides for disease management. The primary reasons growers gave for using biocontrols for diseases were “better plant health”, “worker health & safety” and “shorter REI”.

• For use on: Greenhouse tomatoes, peppers, eggplant, cucumbers, strawberries, lettuce, Chinese cabbage, celery transplants, basil, ornamentals

• Extremely systemic – one of the highest concentrated phosphite fungicides available

• Unique formulation has both a direct and indirect effect on harmful oomycete diseases on a broad range of crops

• On greenhouse crops PHOSTROL provides effective, convenient and flexible suppression of Downey Mildew, Phytophthora blight and Pythium root rots.

From 2014 to 2018, many biocontrol users increased biocontrol expenses, while reducing pesticide expenses for both pests and diseases. 70 per cent of growers now use biopesticides against diseases, compared to 30 per cent in 2014. Biocontrol adoption also rose for insect and mite pests [right].

When asked about which pests were the most challenging to deal with, it came as no surprise that western flower thrips was public enemy number one. Thrips were the most frequent answer for the most common pest (49%), the pest that caused the most losses (36%) and the most difficult pest to manage (36%). Aphids, two-spotted spider mites, broadmites and echinothrips were also common answers.

The disease category was a much tighter race. Damping off and root rots managed to come out on top in all three categories (most common, most losses, most difficult). Powdery mildew appeared in the top three for all three categories, fungal leaf spots and blights were answers for the most common and most losses categories, and wilts was a common answer for the most difficult to manage. Some survey respondents indicated a lack of variety among disease management products as a major reason to why some diseases were so challenging to manage, and this has no doubt contributed to the increase in biocontrol adoption in this area.

When asked what they needed to improve biocontrol success for pests, a quarter of respondents answered that they

needed better methods for aphid control and sprays that are compatible with biocontrol. While many different biocontrol options exist for some pests, such as thrips, there are others which have few or no good biocontrol options. Needing to rely on conventional pesticides for these problem pests can be disruptive to a biocontrol program and very costly to replace all of the good bugs that have been lost.

Naturally many growers said they needed to reduce the cost of bios in order to succeed, and other responses pointed to areas where efficiency can be improved, thereby reducing the cost of a biocontrol program. Improving the quality, consistency and/or efficacy of bios was important to 17 per cent of respondents; 13 per cent said they needed easier, more efficient or less frequent applications and 13 per cent felt the need for more efficient scouting and pest monitoring methods. Improving the efficiency of existing products and techniques not only saves the grower on material costs, but saves money on labour costs as well.

For disease management, many of the answers were similar to those for pests –growers wanted to reduce costs (15%), improve the efficacy of products (11%) and wanted them to be easier to use and

apply (11%). Many of the answers also focused on the need for information, particularly around how to improve cultural controls such as clean start strategies, proper sanitation or how to better use climate or irrigation controls to manage diseases (33% combined).

The results of this survey demonstrate that Canadian floriculture growers are continuing to adopt new pest management practices and that biocontrol is still an area of active growth. Their eagerness to incorporate new innovations is one of the reasons why Canadian growers are leaders in biocontrol use. This kind of information is also important for us as a research centre. These surveys not only identify issues that are most important to growers, they also help quantify those issues, therefore helping secure funding that will allow us to do the research necessary to find solutions.

The researchers want to thank all growers who participated in this survey. Your contributions inform our research so that we can help provide the solutions needed by the industry to continue to grow and thrive.

Ashley Summerfield is a research technician in biological control at Vineland Research and Innovation Centre.

100,000

Are your plants being watered too much? Watering by weight could remove the subjectivity from this time-consuming process.

How wet is ‘wet’, and how dry is ‘dry’? At the Green Industry Show in Edmonton last year, Dr. Will Healy, senior technical and research manager at Ball Horticultural Company, spoke about a method to describe soil wetness using Levels 1 through 5:

• Level 1, Dry: dry, tan to white, crumbles to dust, shrinks from container walls

• Level 2, Medium Dry: light brown, no free water, squeaky soil, crumbles apart

• Level 3, Medium: brown, hard to squeeze water, soil cracks apart

• Level 4, Medium Wet: dark brown, no visible water, easily squeeze water, soil sticks together

• Level 5, Wet: black, free water, saturated, similar to pudding or tofu

The grower then creates and weighs each level (tray + soil + water) to objectively ensure that plants don’t get too much, or too little, water. This is called watering by weight. Following his talk, Healy shared some additional pointers on this influential method with Greenhouse Canada:

1. LOOK AT THE TOP AND BOTTOM OF THE CONTAINER

Avoid a Level 1 in the bottom since roots will not grow into soil that is maintained at that dry level – the soil becomes “salty” when fertilized and concentrates as it dries. When the bottom is maintained at a Level 5, a perched water table forms, which then keeps the bottom portion of the container saturated. If it persists for more than several hours, water roots (smooth, non-branched roots) can develop, which result in limited nutrient uptake due to limited root surface for absorption, compared to a branched root that forms when the bottom is allowed to dry to a Level 2.

top and 2-3 bottom scenario, which is the opposite of what you want (2-3 top and 4 bottom).

We water too frequently, which keeps the soil at a constant Level 4-5. I have worked with growers who simply water when the top approaches a Level 2 and the bottom begins to reach a Level 2-3. The only exception to the strategy of maintaining a Level 4-2 is seed germination. (In a limited number of situations, like Begonia or Petunia, a 4-3 may produce better germination and yields.)

A large, actively growing plant will absorb more water from the soil moisture than a small or slowly growing plant. Wait until the plants reach the critical dry targets and apply sufficient water to reach the wet target instead of randomly watering on a time or convenience schedule. If you maintain the 4-2 targets, then the environment and plant will drive the water removal from the soil.

The challenge growers face is not what one plant is doing, but how to execute this strategy over a wide range of pots in a large production block. This is why we went to water by weight (WbW) since it allows us to quickly assess the weight of a container and determine if we are approaching a point where the entire block is ready for an irrigation (dry target) and if enough water was applied (wet target). What WbW does is it puts a number (weight) to when the crop is dry or wet. Weight is the weight of the entire container (top to bottom, cell to cell in trays). Growers still need to see if the bottom of the container is dry or wet to ensure they are watering correctly, i.e. pushing the water to the bottom of the container when they water.

Look carefully at the moisture level in the top third of the container. If you keep the top consistently at a Level 4-5 and the bottom at a Level 2, then water roots will form horizontally in this wetter area. Growers who frequently water “a little bit” and don’t push water to the bottom of the container end up creating the 4-5

Growers will sample three to five plants in a block to determine what the average weight is between the sampled containers. What if variability between containers is more than 100 g? This means that the previous irrigation was not applied uniformly to all the containers or that some containers are drying out faster.

If you have excess airflow or hot spots in the bench, those containers will dry more rapidly than the containers around them. Apply more water (weight) to drier areas so when you are done irrigating, you have about the same container weight in the hot and breezy areas as you do in the middle of the block . Should the containers all be the same weight? No; that is working too hard. If you can keep the containers in a block within 100 g of the target weights, this is close enough! It is very difficult to have all the containers the same.

4. AVOID WATERING LATE IN THE AFTERNOON

Watering late in the day runs the risk of watering to a Level 5, which creates a perched water table and water roots. Plant cells are like water balloons: When there is a lot of free water, the cells take up more water and the stem stretches. Stem stretch occurs during the night so if there is a lot of free water in the container at night, the plant cells can easily stretch.

Late-day watering also results in elevated relative humidity around the plants, creating the perfect environment for disease. It is easier to manage watering times when you use WbW targets. Growers can determine if there is enough water in the container to survive until the next morning or add only enough water to raise the moisture level to a Level 4 or less.

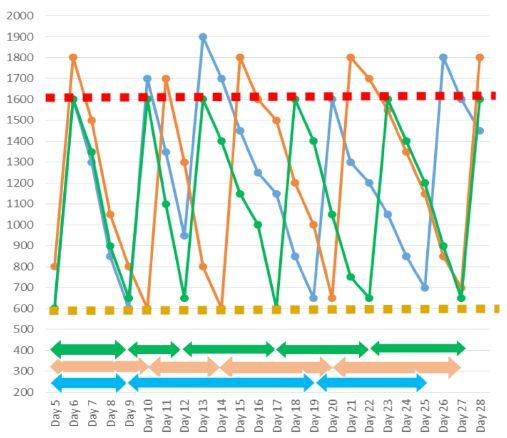

Above

“Green” grower hits the dry (600 g) and wet (1600 g) targets.

GH_AndyLang_June2016 copy.pdf 1 2017-10-17 9:45 AM

5. THE TIMES BETWEEN DRY TARGETS MATTER

“Fish grow in water and ROOTS grow in air.” A strong root system is critical for optimum growth and extended post-harvest. Over the last few years, we have done extensive trials to determine how to optimize root development. What we know is, the time between

dry targets is directly related to the number of branched roots in a container. The longer the duration between dry targets, the fewer branched roots you observe, and the more water roots you see.

The graph above shows three different irrigation strategies that growers used. The dry target was 600 g and the wet target

was 1600 g. They failed to hit the dry and wet targets in the orange and blue curves. Bottom arrows show the number of days between irrigations. By staying within the wet-dry targets, the “green” grower irrigated his crop five times while the “orange” grower irrigated four. The “blue” grower is considered a wet grower – irrigating only three times due to exceeding the wet target and failing to hit the dry target.

When growers fail to reach a Level 4 wet target, the soil is too dry and roots don’t develop. This is why it is important to irrigate to the wet target and allow the plants to reach the dry target.

We train growers all wrong! We train them to “water thoroughly” when in reality they need to know how to “dry the plant to the dry target.” Environment plays a huge role in drying out the crop. Remember the plant uses less than 10 per cent of the water to grow, the rest must be evaporated to prevent soft, stretched plants and diseases. It is a challenge that can be solved by dehumidification strategies.

Hot air contains more water than dry air. Periodically heat up the greenhouse a couple of degrees and then slowly vent the warm-wet air out. If you vent too fast, you will never remove the maximum amount of humidity. If you don’t have top vents, move the air in the greenhouse and vent some of the wet air to help reduce humidity and help dry out the crop.

7. IT IS NEVER TOO LATE

(Well, on the dock at shipping it is!)

Plants are resilient in adapting to our watering practices. If you have a crop that is clearly not being irrigated to your wet-dry targets, the quicker you can achieve the right balance of wet-dry, the faster you can turn the crop around. This is why we recommend growers record the weight when they water (dry weight) and immediately after irrigating (wet weight).

Too many times we see the crop has gone “off the rails,” and when questioned, the grower says they did everything “right.” By graphing the wet-dry weights, you can understand what you did days or weeks earlier and begin remedial strategies to turn the crop around. Create a teachable moment!

For more watering tips from Healy, listen to STEM podcasts from Ball Seed, episodes #21 and #22. Subscribe to ‘STEM: Insider Tips for Greenhouse Pros’.

CLASSIFIED RATES: Minimum order $75.00 or 84¢ per word, word ads must be pre-paid. CLASSIFIED DISPLAYS: $72.00 per column inch. GENERAL INFORMATION: Payment must accom- pany order. Copy required on publication close date. All advertising copy subject to the approval of the publisher. Send order and remittance to: Classified Dept., Greenhouse Canada, P.O. Box 530, Donly Dr. S., Simcoe, ON N3Y 4N5 Canada

FOR SALE: Greenhouse complex with 54,000 sq. ft. of growing space, office, lunch room, work shop, filling and seeding building, freezer/ refrigeration building, storage building, beautiful 4 bedroom home with 1 and 1/2 bath, screened porch on approx 10 acres of land with 30 foot access to fresh northern lake. Excellent infrastructure and extremely high quality/quantity of water. Call 807-355-8432 or email joyneill@hotmail.com. Owner retiring. 03/1t/pd

FOR SALE: 56,000 square feet dismantled Dutch Venlo greenhouses, 13 feet to the gutter. Includes shading system and hot water heating pipes. Need new anchor posts and some replacement glass. Available end of March. Asking $3.00/sq ft FOB Fenwick, Ontario. Will build for a negotiated price. Call Jim @ 519-410-2511 or email genesysgreenhouse@gmail.com 03/1t/pd

FOR SALE: 10 54” Euroemme fans with motors. $300.00 each. FOB Fenwick, Ontario. Call Jim @ 519-410-2511 or email genesysgreenhouse@gmail.com 03/1t/pd

GARY JONES | Gary.Jones@kpu.ca

I’ve been reading a book by Craig Kielburger, founder of Free the Children. This organization works to eradicate child labour and to empower youth to reach their potential. You may have heard of the Me to We1 events that came out of Free The Children. Kielburger started this group when he was but a thirteen year old, and the book documents his first trip to Asia, meeting kids forced to work in various ‘jobs’ in conditions that can only be considered slavery. He references the number of children who don’t have access to safe drinking water, and that for many, water represents “life itself”.

I’ve heard it said, and you may have too, that the next world war will be fought over water rather than oil. Yet how much care do we take of this precious resource? How seriously do we take our stewardship responsibilities?

At the time of writing, last week was the Pacific Agriculture Show2, and the associated Lower Mainland Horticulture Improvement Association (LMHIA) Growers’ Short Course. Apart from just being a fabulous opportunity to catch up with friends and colleagues, the show and short course time is always a great way to hear about the latest pests, diseases, regulations, crops, ideas and so on, in many areas of our industry. This year’s event also saw the first ‘Cannatech’ educational session. With around 150 people attending, this crop is making an impact. You may have noticed.

Anyway, back to the short course. Keynote speaker on the first day was Christian Kromme, talking about ‘The Future of Agriculture’. With

when talking about the future of agriculture? The kids of Free the Children would probably think so. The short course provided 92 presentations. Fabulous. One full morning session was dedicated to agricultural water management, and of its five talks, three were around licensing and other regulations. Two focused on the practicalities of water use. Elsewhere, the program offered another three irrigation-specific talks and five or so that made reference to water or irrigation issues. In other words, maybe five of 92 (5.5%) talks over three days specifically addressed how we could better use probably our most valuable, life-giving resource.

How seriously do we take our stewardship responsibilities?