Cost-saving teamwork

Employees who are excited and empowered to take control of energy will naturally reduce costs and improve productivity. | 12

DR. MOHYUDDIN MIRZA

DR. M. ISHTIAQ RAO

GARY JONES

Employees who are excited and empowered to take control of energy will naturally reduce costs and improve productivity. | 12

DR. MOHYUDDIN MIRZA

DR. M. ISHTIAQ RAO

GARY JONES

Within a five-minute drive from my home in a medium-size (90,000 residents) city in southwestern Ontario there are three major grocery retailers, a couple of specialty food shops and about 30 restaurants.

Aside from family budgeting limits and my own growing waistband, I don’t have to worry much about concerning the availability of food.

But if I lived in Canada’s North, I would worry about food. A lot. It’s not just the costs, which, in Nunavut for example, are about 140 per cent higher than grocery bills in the rest of the country.

It’s the lack of fresh produce for much of the year. Forget the price tag for a moment, but few veggies will look/taste their best after several days of trucking.

Greenhouses can be part of the solution, a big part. There are some projects already harvesting crops, but more importantly, there is considerable research and development underway.

It combines poultry production with

The International Centre for Northern Governance and Development of the University of Saskatchewan produced an excellent report a few years ago that addressed the potential of northern greenhouses. “Guidelines for Establishing a Northern Greenhouse Project” looked at the challenges and benefits of such initiatives. Among benefits cited in the report were:

• Improved health by consuming more fruits and vegetables.

• Improved access to fresh foods.

• Improved food security/autonomy over food sources.

• Living science lab; great for school

programs.

• Opportunity for volunteerism, contributing to individual and community well-being.

• Work and life skills through responsibility of growing and harvest a crop.

Last year, the first Northwest Territories CanGrow Greenhouse Workshop was held at the Northern Farm Training Institute in Hay River, and was organized by the Aurora Research Institute.

Supplying the North is a huge challenge. Of the 72 communities, 45 do not have year-round road access. Self-sufficiency in some foods for as much of the year as is technologically possible, then, is crucial.

One of the more unusual studies is the current “poultryponics” demonstration project underway in Hay River, NWT. It combines poultry production with a vertical hydroponic system. It’s believed to be the first of its kind in the world and will, if successful, provide both fresh vegetables and eggs.

Developing sustainable growing

Occasionally, Greenhouse Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2017 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

systems for Northern communities will be a major test and a lofty goal for industry technologies.

The federal government launched a northern greenhouse initiative in 2014 through its Canadian Northern Economic Development Agency. Ottawa should maintain this leadership role.

Given the impact sustainable food production systems will have on the health and well-being of northern communities, this should be a major goal for the government and an exciting challenge for the research community.

greenhousecanada.com

The latest in crop lighting strategies, water treatment systems and labour management strategies will be among the topics with Greenhouse Canada’s Grower Day on June 21.

Other topics include the keys to family business success, new age marketing, and mechanization/efficiency ideas. There will also be a discussion of how to set the groundwork for continued business success in greenhouse growing through to

2025 … and beyond!

Check out our mini trade show of leading industry suppliers.

Grower Day is again being held at the Holiday Inn Hotel & Suites St. Catharines Conference Centre. Registration opens at 8:30 a.m., and the talks get underway at 9:15. Visit the microsite at www.greenhousecanada.com/grower-day for more information.

Parkland Nurseries & Garden Centre, of Red Deer, Alta, is one of two winners of the 2016 Retailer of Distinction Award from the Canadian Gift Association (CanGift). The awards are based on criteria that are vital to retail success including visual merchandising and store design, business achievements, advertising and public relations and community involvement.

$197 M – Royal FloraHolland turnover last full week before Valentine’s Day; its highest turnover ever recorded.

92% of people who researched a product on a mobile device made a purchase within a day. (Tallmadge Express)

81% of millennials check Twitter at least once per day. (Pew Research Centre)

The awards were officially presented at the Salute to Excellence Awards Reception hosted by celebrity designer duo Glen Peloso and Jamie Alexander at the Spring 2017 Toronto Gift Fair.

“On behalf of our staff, this award has reinforced the great pride we have in the work we do,” said Gloria Beck, owner of Parkland Nurseries. “Whether it is finding those unique items or providing our

loyal customers with the ultimate in customer service, this award has given us the inspiration to keep our standards high.”

In 1971, Earl and Margaret Beck launched Parkland Nurseries – a seasonal nursery business of 40 acres –as a retirement hobby. In 1982, the business became a year-round operation encompassing greenhouses, a six-acre outdoor plant area, landscape design services

and a garden centre.

In addition, Parkland’s gift shop carries a vast array of giftware, home décor and fashion accessories including an extensive Christmas shop.

Over one million plants move through the greenhouses and sixacre outdoor sales area each year. Giftware and home décor, fashion, Christmas decorations and courses are ever growing the year-round nature of the business.

will grow 600% from 2015 to 2020, a compound annual growth rate of 42%. (Cisco)

shipped by Royal FloraHolland last full week before Valentine’s Day; 1/3 roses, 1/3 tulips.

93% of Pinners have used Pinterest to plan for or make purchases. (Millward Brown)

46% of Canadian businesses have a web site.

(StatsCan 2013) The export of flowers and plants by FloraHolland grew by 3% in 2016.

A perennial first: now growers can produce high-quality, affordable Perovskia atriplicifolia from professional-grade seed. With higher and much more uniform germination, top-notch plugs are easy and efficient to grow as a latespring/summer crop or in fall for overwintering production. ‘Blue Steel’ extends sales, combining the best summer-blooming lavender-blue colour with outstanding late-season performance. As a cost-efficient seed, ‘Blue Steel’ is affordable to use multiple plugs in each pot that finishes with huge retail appeal. It grows to 18-36” (4691 cm) with a spread of 14-28” (36-71 cm).

www.kieftseed.com

This coleus from Ball FloraPlant offers stunning colours and patterns for full sun and full shade gardens. ‘French Quarter’ is a versatile, premium variety that is very late to never flowering. This low-maintenance, high-impact plant is perfect for large potted plant programs and

landscaping. The foliage features pink, magenta and green leaves – a familiar pattern of seed coleus, but more vigorous and much later flowering. It does well in the sun and shade and grows to a height of 18-36" (46-91 cm) with a spread of 24-28" 61-71 cm.

www.ballfloraplant.com

New this year ‘Brother Stefan®’ does well in full sun and part shade in Zones 4-9 and grows to a height of 5-7’. Named in honour of legendary clematis breeder Brother Stefan Franczak, its large and ruffled blue flowers are borne profusely on both old and new wood from early to late summer. It has a smaller, refined habit and is an ideal accent for garden trellises and low fences. Uses include containers, perennial gardens and mixed borders. It has a medium growth rate. provenwinners.com

Heuchera Primo™ ‘Pretty Pistachio’ PPAF CPBRAF Clematis ‘Stefan Franczak’ USPPAF

You’ll be impressed by this big and beautiful plant for both its flowering performance and its garden performance. Starting in spring, the 4.5" wide leaves are chartreuse and mellow to lime green in summer. The huge, 5" wide clusters of medium pink flowers are produced continuously. The breeder is Walters Gardens, Inc. It is best in filtered sun to full shade depending on climate, requires average moisture, attracts butterflies and hummingbirds, makes a great cut flower, offers winter interest and is good in containers and landscapes. provenwinners.com

After winning the prestigious FleuroStar award in 2016, ‘Unbelievable Miss Malibu’ will cross the pond and join the ‘Unbelievable’ Begonia series offered by Dümmen Orange. Fitting perfectly into the existing lineup of strong branching double flowering begonias,

Featuring a fast response time and bright red bracts, ‘Ferrara’ is great for quick, reliable, high-density production, allowing increased units per hectare with fewer inputs. Suitable for all pot sizes, this new backbone cultivar from Dümmen Orange is a superb choice to kick off the holiday decorating season. Growers throughout Canada had phenomenal success with ‘Ferrara’ during the 2016 season. In addition to becoming a new grower favourite, ‘Ferrara’ performed very well in poinsettia trials, even winning first place in the red category at the Millstadt/Heimos trials in November. na.dummenorange.com

‘Miss Malibu’ features excellent garden performance in both sun and shade locations. Boasting rich bronze foliage, an enchanting bloom colour and a compact habit, ‘Miss Malibu’ is sure to turn heads in the greenhouse, at retail, and in the home landscape.

na.dummenorange.com

These are some of the products eligible for the Vetoquinol Club points program. Sign up today at vetoquinolclub.ca and reap the benefits. club

• Low or no wax formulations

• Grains and food grade oils ingredients

• Greater acceptance for better results

• Different actives for rotation

GIVE THEM BAITS THAT THEY WILL LIKE!

The gap between labour demand and the domestic workforce in agriculture has doubled from 30,000 to 59,000 in the past 10 years and projections indicate that by 2025, the Canadian agri-workforce could be short workers for 114,000 jobs.

This is a key finding of newly released

Agriculture 2025: How the Sector’s Labour Challenges Will Shape its Future research by the Canadian Agricultural Human Resource Council (CAHRC).

“Among commodities, the ‘greenhouse, nursery, and floriculture’ industry will continue to have the largest labour gap,” notes the report.

“With an expected gap of 27,000 workers in 2025, this commodity group will account for nearly one-quarter of the sector’s labour gap.”

The research also revealed that primary agriculture has the highest industry job vacancy rate at seven per cent.

“The sustainability and future growth of Canada’s agriculture and agri-food industry is at risk,” says Portia MacDonald-Dewhirst, CAHRC’s executive director. “It is critically important that this risk is acknowledged and mitigated in an intentional and strategic way.”

The industry has been encouraging young people and workers from other sectors to get into agriculture as a career. Despite extensive efforts gaps still exist and there

still will be a large void in the future.

Labour shortages create risks to farmers who can only hope they will have the same or greater access to both domestic and foreign workers in the future as they do now.

The study examined only primary production. Agri-food industries such as food and beverage processors or input suppliers, which have additional labour demands, were not considered in the study.

The research indicates that the worker shortage is critical today and will be even more so 10 years from now, with potentially serious consequences for business viability, industry sustainability and future growth.

Access to less labour for Canadian farmers now and into the future will affect food security for Canadian consumers and will also affect export potential of Canada’s entire agri-food industry.

To address the labour issues identified in the research, CAHRC, with the help of the federal government, has developed agriculture-specific human resource (HR) tools designed to support modern farm operations to manage their workforce.

CAHRC offers Agri Skills, online and in-person training programs, and the Agri HR Toolkit – an online resource guide and templates to address the HR needs of any business. For agricultural organizations there are customized labour issues briefings that apply the new research to specific commodities and provinces, to explore the labour implications within their specific area. For more information on these and other CAHRC offerings visit www.cahrc-ccrha.ca.

The Agriculture 2025: How the Sector’s Labour Challenges Will Shape its Future report can be downloaded at http://www.cahrc-ccrha.ca/ agriLMI.ca. It was validated through industry consultations conducted Canada-wide including: 1034 surveys of employers, workers and industry stakeholders; 80 phone interviews; six focus groups for a total of more than 100 participants; and seven webinars focused on specific commodity groups with 100 participants in total.

The Canadian Agricultural Human Resource Council works with industry leaders, governments and educational stakeholders to research, develop and communicate solutions to the challenges in employment and skills development in primary agriculture.

With PRO-MIX CC40 MYCORRHIZAE discover a new generation of coir growing media. The unique structure of the coir found in CC40 provides on optimized growing environment for plants such as long term crops especially under drought conditions. The well-designed air porosity and water retention qualities provided by this peat-coir based medium give growers the opportunity to react efficiently to a more hostile environment at the same time as balancing financial requirements and productivity.

The top four ways to make energy savings stick

Spring is a time of hope and renewed energy with longer days of sunshine and warmer weather. It is also a great time to reflect on how energy costs in the past months have impacted your bottom line, and to work with your team to make your greenhouse more cost-effective for the year to come.

ABOVE

Discussing energy management with team members at Doef’s Greenhouses in Lacombe, Alta.

Many companies introduce new initiatives to engage employees and increase efficiency, but over time these can fizzle from lack of direction and competing priorities. You will succeed in energy management by engaging all employees and making energy-related thinking part of your dayto-day activities. Greenhouses are well positioned to excel at this. A relatively small number of employees at a greenhouse (for example, compared to a large manufacturer) and fewer tiers of management make greenhouse businesses fertile ground for success.

Here are four tips to help launch your greenhouse energy program and sustain enthusiasm over time.

1) Diversity: Energy management succeeds when owners set clear direction, and engage a range of staff to understand the energy bills coming in. When experts in crop management, climate control, accounting and operations examine the when, where and how much of energy use, they bring a diversity of perspectives. This helps clarify and quantify both opportunities and constraints,

and will lead to realistic and sustainable changes. Your team can build knowledge and maintain momentum by holding regular group meetings (we suggest monthly) to discuss the current status, report on successes and look at market projections.

2) Education: Nobody likes doing things they aren’t good at. If your employees don’t feel equipped to do what is asked, their enthusiasm will quickly disappear and energy management will too. Provide your staff with expert training on energy markets and rates, data analysis, and operating approaches to achieve both cost and usage savings. Engaging an external energy coach to provide on-going mentoring and support to staff will help embed energy firmly in your company’s culture.

3) Empowerment: Provide your teams with a mandate to find energy savings, but give them autonomy in decision-making so they can own the program and determine their best way to achieve targets. Once your employees have built their base energy knowledge, they will naturally start to bring forward savings opportunities based on their own detailed knowledge of your greenhouse.

4) Celebration: Celebration of success naturally follows the first three steps. It reinforces that energy is a critical component of the greenhouse, and that management values the team’s efforts. It supports efforts to track and verify savings, which helps you know when and what to celebrate. Showcasing the organization’s successes will motivate employees from all levels of the greenhouse to think more about how they each contribute to your organization’s energy savings. Once they are thinking about it, they will want to find additional ways to improve.

Once a greenhouse begins to track energy usage and learn about how they are billed, it doesn’t take long for energy team members to get excited about savings opportunities. A greenhouse team that is excited and empowered to take control of energy will naturally reduce costs and improve productivity. While there is no one fail-proof recipe to sustain a strong energy management program, programs that succeed over the long term share these four key principles.

This feature is supplied by 360 Energy, one of North America’s leading energy services firms. Browse the Energy microsite on our website (greenhousecanada.com) for more 360 Energy features.

Well-Managed Root Zones are an Asset to Greenhouse Crops while Those Poorly Managed are a Liability

BY DR. MOHYUDDIN MIRZA

Writing about root zones for greenhouse crops has been an important subject for me and I have written a number of articles on this subject in Greenhouse Canada.

In the October 2016 issue I emphasized the importance of climate conditions in influencing root zone environment. Since roots and root zones are the foundation of the entire crop, I keep on reminding growers about this subject.

In this issue I am going to share many pictures with you and explain what the plants are trying to tell us.

I am seeing different types of roots especially in indoor farms where plants are grown in water enriched with nutrients.

Photo A: I recently took this picture from a floating hydroponics unit and was pleased to see nice white roots with lots of root hair. The tops of the plants were similarly very good – dark green

and with no signs of any deficiency.

Root hair and the importance of oxygen: An abundance of root hair indicates good dissolved oxygen in the water. It is a well-established fact that solubility of oxygen depends on temperature. The maximum solubility of oxygen is at 4 C and is around 9 ppm. As the temperature rises to 20 C, the oxygen level drops to around 5-6 ppm. Root rot issues set in once it drops below 4 ppm. The damping off fungus pythium likes low oxygen levels for its growth and development.

My good friend Trevor Schriemer from Precision Produce Ltd. (Otterburne, Manitoba) loves to look at roots and shares the photos with me to comment on.

Photo B This is a picture he sent in January of his cucumber seedlings. Notice how strong and visible the root hairs are. These root hairs absorb water and nutrients and transport them to the leaves via water

conducting tissue of xylem.

Most of the observations on roots are visual. Nice, white roots are an indication of good top growth of the plants.

Photo C: This photo, also sent by Trevor, shows the top growth of cucumber seedlings. It is my practice to turn a rockwool block upside down and look closely at the roots. Root tips, especially, provide very good information on efficient absorption of water and nutrients.

If root tips are brown, then it could be an indication of the start of an attack by the fungus pythium. As mentioned earlier, this fungus reduces the uptake of water by destroying the root hair. It appears that once this fungus attacks the roots, the plant begins to “fight back.” Photo D highlights the point I want to make. It was taken from a hydroponics lettuce production unit. A “fight” is going on between pythium and the plant defence system. The roots are

rotten on the lower part and the plant is producing new roots above that.

I think in this case the grower was not helping these plants. You can see how the top growth is yellow, which indicates nutrient issues. If roots are not healthy and functioning, then deficiencies of various nutrients take place. The oxygen level in the nutrient solution was around 2 ppm, which is very low. In this case the root rot beat up the grower. A new crop had to be started, but first the system had to be cleaned up and water disinfection measures introduced before healthy lettuce production was started.

With the increased production of herbs and other crops in hydroponics system, the physics of root growth is important. Photos E and F highlight the point I want to make. Photo E shows that more roots are coming out of the plug while in Photo F the roots are coming out of one side only. That was evident in the top growth.

Make every effort to have healthy root development and growth on seedlings.

If the roots start intertwining and the seedlings are separated, then root damage can occur. Such seedlings with root damage during transplanting will show leaf edge burn very quickly.

Photo G is just to highlight that how hard the roots must work to transport water and nutrients on such long tomato vines. I once measured the length of these vines and found some were almost 45 to 50 feet long. So root health is not only important for seedlings in pure water-based systems but also in the growing media.

There is a theoretical calculation as well. Tomatoes produce three leaves and one set of flowers (clusters) per week and generally the length is around 12 inches. The size of the internodes depends on 24 hour-average temperatures and the difference between day and night averages. So if the average is one foot per week, then a 40-week-old tomato vine should be around 40 feet long.

I have an ongoing discussion with growers that our growing media volumes are decreasing per plant and thus lesser

amounts of roots are developed to support the top growth of the plants.

Take the example of a tomato crop growing under LED lights I recently visited. Very severe leaf necrosis was noticed. It appears to be more severe than just edema, which is related to root pressure and leaf temperature and ramping from day to night. I also believe the root volume was far less than it should have been. I think we need to revisit proper growing volumes per plant so that optimum roots can be developed.

I was reviewing leach nutrient analysis from a cucumber grower and making recommendations as to how much of leach should be combined with fresh solution. Recycling of water from the leach is practised by many growers in Canada. It is important to understand the dynamics of EC in the root zone. What is an optimum leach percentage? I have seen growers leaching very heavily especially in

Learn how Westbrook Greenhouse Systems can provide you with a

summer, as high as 50 to 70 per cent. Basically, they are using nutrient solution to leach to maintain the desired electrical conductivity (EC). If the nutrient solution EC is 3.0, and leach EC is 4.0, then growers will increase the timing of dripper flow and thus hope to bring EC down to desired levels. My experience is that over 50 per cent maximum is too much leach volume. The growing medium gets saturated and that is an invitation to fungi such as pythium. Water-logged conditions may occur. I suggest to stay close to 20-25 leach percentage.

Why EC can go higher than the feed solution? Normally one should expect that the feed and leach EC should be the same or close in range. But it is never the case because plants can selectively absorb water under very high light conditions. When water is removed from the root zone through transpiration then the ions will accumulate in the growing medium.

I have also seen higher EC in the leach solutions because the growing medium – such as coir – was not flushed properly. Many growers buy pre-washed bags but they may not have been washed properly or according to your expectations. Washing of coir is done in bulk and then dried and put into pillow bags. So be aware of the reasons why EC is higher than the leach.

Can plain water be introduced during high light periods to bring EC down? Yes, when light levels are higher than 1500 joules then plain, pH adjusted water can be used and thus the proper EC can be maintained and managed. Remember the higher the light, the lower will be the EC of both feed and the leach.

Dr. Mohyuddin Mirza is an industry consultant, drmirzaconsultants@gmail.com.

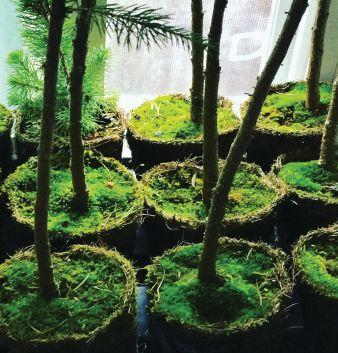

Growing in the cold: innovative new technologies are making cultivation of fresh fruit and vegetables truly feasible in the North.

BY TREENA HEIN

The need to grow food in the North remains strong, and new high-tech innovations are on the cusp of making large amounts of local greenhousegrown food a reality.

In Canada’s northern regions, fruit and vegetable prices have been extremely high for some time. Prices are at least three to four times those of Southern Canada, due to transportation costs and the small market size. Food security is also a strong concern.

A non-profit organization called “Growing North” (growfarnorth.com) claims that almost 80 per cent of Nunavut lives without food security. Read more on their project later in this feature.

ABOVE

Greenhouse food production in the North – already more established than you might think – is ramping up, with exceptionally innovative seasonal and year-round projects. While energy conservation is key at any time, it’s especially important now with the impending national carbon tax, and alternatives to diesel generators for heating are a must.

Before we get into specifics on designs and technology, let’s look at some 2016 large-scale northern greenhouse developments.

YUKON DEVELOPS LOCAL FOOD STRATEGY: 2016-2021

Last year, the Yukon government

Project Growing North co-founders Ben Canning and Stefany Nieto. The project is an Enactus Ryerson initiative.

released its ambitious Local Food Strategy: 2016-2021, with commitments to develop greenhouses as well as farmers’ markets and community gardens.

In addition, in March 2016, the first Northwest Territories CanGrow Greenhouse Technology Workshop was held at the Northern Farm Training Institute (NFTI) in Hay River, organized by the Aurora Research Institute.

ARI community research co-ordinator Jessica Dutton notes that greenhouses are a way for many established northern fruit and veggie growers to further diversify their operations. “Most greenhouse operators are more familiar with growing in soil than hydroponics, aquaponics or aeroponics systems,” she says, “so the workshop was a great opportunity to introduce new technologies.”

Attendees learned about “Titan Wall” insulated panels, developed in part by Professor Tang Gim Lee of the faculty of Environmental Design at the University of Calgary. The panels eliminate the need for framing, insulation and vapour barrier, and do not mould or rot. These characteristics make them extremely suitable for aquaponics operations, such as Lee’s Greenview AquaFarm in Calgary and at Forest Gate Greenhouse and Gardens in Fort Simpson, NWT.

with the waste humidity, nutrients and heat,” he says. “Other countries have a nice climate year-round, but Canada doesn’t have that and this is a good way for Canada to be self-sufficient in terms of protein and greenhouse production.

“Fish have an incredible feed conversion – we have it down to 1.5 pounds of feed per pound of fish – the most efficient of any livestock. We have to farm more fish.”

Also at the workshop, Dr. Phalguni Mukhopadhyaya of the University of Victoria, B.C., introduced the prototype for his vacuum-sealed insulated panels. They have a thermal resistance value as much as three times greater than other types of insulation because a vacuum does not conduct any heat. However, the panels lose their effectiveness if damaged and they are also expensive.

Dieter Krohmer, president of Advanced Technology Structures of Calgary, outlined his prototype closed environment structure made from extruded PVC bricks. The system includes the firm’s “Novo Green” towers that rotate so all plants get about the same amount of light exposure.

Dr. Samuel Mugo of MacEwen University in Edmonton discussed his work on reducing cellulose into extremely small

Lee is a huge proponent of aquaponics for northern food production. “There’s a synergy there, and it’s almost a no-brainer,

ABOVE

Another Growing North season begins.

In 12 years at FCC, Graham’s helped hundreds of Canadian producers build their dreams. Like everyone on your FCC team, Graham knows your industry and he’ll get to know you. 1-800-387-3232 fcc.ca

Graham Bolton FCC Senior Relationship Manager

particles called nanocellulose, which can be made into nanoporous hydrogel films that trap heat for root zone heating. The films can also store and release nutrients, water and pesticides.

Glen Scott of AgriArctic in Whitehorse talked about the “Agridome,” a converted intershelter dome (a type of northern survival structure) made from available construction materials, with vertical hydroponic growing towers, remote computer monitoring and HPS lamps, heated with a standard 1500W space heater.

Scott reports that a feasibility study on the dome completed with the Yukon Research Centre yielded “promising results.” Total average power expenditure over the course of the study was 1.9 kWhr and water usage was less than 1000 L/month for almost 800 plants.

In March of this year, the Agridome is being moved to Hay River, NWT, to support a “poultryponics” project, which (as you may have guessed) combines hydroponics and poultry production. It’s apparently the first project of its kind in the world.

AgriArctic is partnering with PolarEgg and Lethbridge College on the project. Waste plant material will be fed to the chickens (reducing the amount of feed required), and chicken manure will be treated in a bioreactor to produce fertilizer for the plants. The Agridome, where the vegetables will be grown, will sit on a hexagonal base structure where the chickens will be housed, and the chickens will have access to the outdoors in summer.

Inno-3B of Saint-Pacôme, Quebec, outlined its cutting-edge, closed, yearround growing system called the “Yield Factory.” The patent-pending tech converts “waste” photons from greenhouse lighting that is not used by plants into heat. The units are stackable and scalable.

Growing North is planning to build its second greenhouse in Arviat, Nunavut, after finishing its first Geodesic Growing Dome (supplied by Growing Spaces) in October 2015 in Naujaat, Nunavut.

Project Growing North is an Enactus Ryerson project that was launched in 2013. The goal is to help to tackle the need for fresh produce in northern Canadian communities while providing social entrepreneurship opportunities for local residents.

AgriArctic’s “Agridome” is a converted intershelter dome (a type of northern survival structure) made from available construction materials.

BELOW

Lights on in an AgriArctic “Agridome.” The units feature vertical hydroponic growing towers, remote computer monitoring and HPS lamps.

Their dome is 42 feet across, made from wood struts and metal hubs, and covered by polycarbonate glazing panels. It can withstand up to seven feet of snow and very high winds. In the summer, the dome can heat itself to over 30 C warmer than the temperature outside. Project manager Stefany Nieto says exploration into “green” winter heating options is ongoing. The setup is intended to grow about 20,000 pounds of a community’s choice of veggies and herbs in hydroponic towers supplied by Bright AgroTech.

North Star Agriculture in Whitehorse has partnered with Alberta-based NutraPonics to build an aquaponics facility this year. The venture has received an exemption from the Yukon government’s current ban on fish farming, and will be working with the territory to create fish farming regulations.

North Star CEO Sonny Gray says they are currently securing funding and relationships with other entities such as First Nations development corporations. He is not sure what heat source will be used, but mentions geothermal and solar as possibilities.

Professor Mike Dixon of the University of Guelph’s Controlled Environment Systems Research Facility is planning to head a year-round pilot project in Hay River in collaboration with NFTI.

Dixon is the foremost Canadian expert on greenhouse systems for harsh environments, from future off-planet settlements to the North. “The insulated unit is already in place,” he explains, “but we need all the systems – lights, hydroponics, controls and so on –purchased and installed.”

In a report summarizing the Northwest Territories CanGrow Greenhouse Workshop (see link), Dutton and her colleagues describe several hybrid greenhouse/growth chamber designs, including a system already in operation created through the Yukon Research Centre.

“During times of the year with high light intensity, high transmission is allowed through a quad-pane polycarbonate glazing (R-4),” the report states. “During

the shoulder season, supplemental lighting is provided by LEDs. Insulated shading (R-26) is used during the cold, low-light winter months as LEDs become the primary source of lighting. The heavily insulated chamber is heated through inbed heating, and under-bed water reserves as a thermal storage.”

The low-cost CING (Canadian Integrated Northern Greenhouse) is another example of a hybrid summer greenhouse/winter growth chamber design, presented at the workshop by Dr. Mark

Dieter Krohmer, president of Advanced Technology Structures of Calgary, outlined his prototype closed environment structure made from extruded PVC bricks.

Lefsrud of McGill University.

CING consists of a shipping container with clear polycarbonate panels on top and on one side, with rigid foam on the other three sides. Retractable covers retain heat and supplemental light comes from LEDs. “A radiant insulation blanket covers the glazed side in winter along with steel shutters,” the report states. “External air is passed through a heat exchanger chamber, [and] a nutrient-free water tank functions as a condenser for moisture buildup and temperature moderation.”

The report also includes a mention of theoretical hybrid designs based on AgNorth’s Modular Farm Concept, a dense hydroponic growth chamber that employs mechanized systems, LED lighting and recovery ventilators for heat and energy. The system also includes desiccants that capture airborne moisture.

In such a cold environment as Canada’s north, there are many challenges to greenhouse food production, but as you can see, there are no shortage of ideas and new technologies. While Dutton and her colleagues point out that it might be best to keep the northern greenhouse tech simple at this point in order not to alienate potential growers, they also note that as the agricultural community develops and diversifies, “there may be growers who have the skills and interest to expand into higher tech growing.” It seems they may be right.

Treena Hein is a freelance writer in Ontario.

While their main functions are shading and energy savings, they can be valuable for controlling the greenhouse environment in other ways as well.

BY LEIGH COULTER

Curtain systems are an integral part of climate control for many greenhouse growers, yet there are still numerous greenhouses not using this valuable tool effectively, or even at all. The main function of greenhouse curtains are shading and energy savings, however a good curtain can be valuable for controlling the greenhouse environment in other ways as well. Proper climate control is the result of integrating various systems, and no addition to your greenhouse should be addressed in isolation. So make sure your greenhouse heating and cooling systems are working in conjunction with your

ABOVE

curtain systems.

Here are some of the more common reasons growers are not maximizing the benefit of greenhouse curtains:

1. You haven’t installed curtains yet: This one is a bit of a nobrainer. If you don’t have curtains now you are obviously not getting the most out of them. While glass greenhouses almost always have good shade and energy curtains, poly greenhouse growers have been slower to adopt climate screens in their structures. The payback can still be substantial, so if you haven’t looked at curtains recently, now is a good time to call us.

Curtain systems are an integral part of climate control for many greenhouse growers.

State University conducted a detailed experiment to quantify how different greenhouse curtains influenced shoot-tip temperature while keeping the greenhouse ambient temperature the same. The results showed shoot-tip temperature was warmest under blackout curtains.

7. Rollup curtain walls have not been installed: In a blackout system the grower is almost always using a rollup curtain. However even without blackout, rollup sides and ends can provide shading and insulation value that helps keep the perimeter crops healthy. In a gutter-connected greenhouse finding ways to improve the environment for perimeter crops can yield positive returns.

8. You are not using proper sensors to measure light and humidity: If you are growing commercial crops, then light really matters. If you have invested in a proper greenhouse curtain it makes sense to have a proper light meter to obtain actual measurements of the light environment inside your greenhouse. The same goes for humidity and temperature. Today’s sensor technology enables a high-tech greenhouse to take immediate action based on computerized decisions that are impossible for human judgment.

9. Your curtains are not being used to reduce energy needs of cooling units: Remember curtains affect your crops’ light levels, temperatures and humidity so there may be a value tradeoff in reducing light levels at times in order to keep temperature down or boost humidity in the greenhouse for crops that love more moisture in the air.

10. Irrigation systems are not co-ordinated with shading times: A significant benefit of greenhouse shading can be in reducing the plants’ need for water uptake. As water regulations and drought controls spread it is the progressive grower who is looking for ways to obtain maximum value from water resources. Greenhouse shade curtains can be a tool for helping achieve lower water consumption – just make sure your irrigation timing is working in conjunction with shading.

11. Shade curtains are not installed in head house areas for your employees: Your plants are not the only ones who need a break from the heat. Greenhouse workers are happier and more productive in a comfortable environment. Greenhouse areas that do not need shading for the crop’s benefit can also provide a valuable return in employee benefits.

12. Your curtains are not well-maintained: Dust can and will accumulate on shade curtains over time, and this will reduce the light levels that get down to your crop. Ensure your screens are cleaned as part of a regular maintenance schedule. Additionally, watch for snags, loose or broken wires, and bundles that are just not as tight. Just like any mechanical system, curtains cannot operate at their best if they are not kept in good condition.

13. You aren’t reducing temperature spikes in the greenhouse: Most greenhouse operations with curtains are using them to increase temperature levels and expending less energy for heating. But not all greenhouses are timing their curtains to begin opening and closing slightly before needed. By properly timing when curtains move, a greenhouse grower can significantly reduce the temperature fluctuations inside the greenhouse that occur as outside environmental conditions change. In general you want to begin closing your curtains before sunset, and open them just after sunrise. The exact moment of opening and closing varies with the solar radiation level.

14. You haven’t looked for energy savings grants: In many parts of the U.S., Canada and Europe energy grants are available to encourage investment in efficient equipment, systems and processes. Shade and energy curtains can be considered for grants that touch on water reduction, natural gas reductions and electricity savings. If you are considering putting in a new curtain, or even improving upon your existing system, it is worth spending a few hours to explore what funding options may be available to you.

15. The wrong fabric is installed on your greenhouse climate screens: There is a wide spectrum of shade levels available in addition to choosing between open weaves and closed weaves, and then there are features like light diffusion, energy savings or blackout. The crop environment, greenhouse style, the climate of your geographic region and how the curtain will operate all factor into choosing the right fabric to maximize value of your climate screen.

16. Your greenhouse curtain isn’t helping you be a good neighbour: As more greenhouses are adding supplemental lighting to increase daytime hours, and as urban sprawl and farm-to-table movements have brought greenhouses closer to residential homes, greenhouse curtains can be used to help keep lights from disturbing your neighbours. So at night, make sure your curtains are closed.

17. You haven’t considered double screening: Two curtains are better than one. A double curtain system increases your ability to benefit from different curtain fabrics, like light diffusion and energy savings. It enables you to have less shade with one curtain closed, more with the other closed, and more still when both curtains are closed. This helps the greenhouse grower maintain consistent shading at the right levels for the crop. Double screening in a greenhouse also improves natural ventilation in the greenhouse when curtains are fully closed because the gap between the two layers lets air from below the curtains escape through open roof vents.

Leigh Coulter is the president of GGS Structures Inc. and Niagrow Systems Ltd. GGS has been building greenhouses for growers around the world since 1979.

While all the benefits for improving your greenhouse environment with shade and energy curtains are exciting, and labour, irrigation and energy savings can be enticing, be careful you don’t fall into the trap of using your greenhouse curtain too much. The goal of integrated systems in a greenhouse is to provide the best environment for the plants. Over-using the curtains to the point of excess shade could hurt your plants’ growth.

ABOVE

Blackout curtains being used in a greenhouse. BELOW Sales manager Michael Camplin measuring light levels.

Flowers Canada Ontario pays tribute each year to volunteers who have dedicated themselves to industry improvement and advancement.

BY DAVE HARRISON

A pair of longtime industry volunteers have been honoured by Flowers Canada Ontario during presentations at this year’s AGM.

John Valk has added another accolade to his already highly distinguished career in greenhouse horticulture, receiving this year’s Lifetime Achievement Award.

Gina Marchionda, financial controller at Jeffery’s Greenhouses of St. Catharines, received the 2016 Outstanding Contribution to the Industry Award.

JOHN VALK: “HIS FORWARD-THINKING IDEAS STRENGTHENED NOT ONLY HIS BUSINESS BUT ALSO THE INDUSTRY HAS A WHOLE.”

Making the presentation to Valk was his long-time friend and colleague Rob Bierhuizen of Sunrise Greenhouses. The two served on many boards and committees over the years.

Past winners include Jim Meyers (Meyers Flowers), Jim Pepetone (Terra Greenhouses), Jim and Clemens Van der Zalm (Colonial Florists), Otto Bulk (Rosa Flora), Jim Jeffery (Jeffery’s Greenhouses), Rob Bierhuizen (Sunrise Greenhouses), and Leo Reus (Balfour Greenhouses).

Award criteria includes:

• During their lifetime winners have demonstrated forward-thinking and ideas that have strengthened their business and the industry.

• Contributions can be in growing practices,

ABOVE (Top) FCO vice-chair Jan Van Zanten and Gina Marchionda; (above) John Valk and longtime colleague Rob Bierhuizen.

For over 30 years, Hillen Nurser y Inc. has remained dedicated and passionate about the nursery industr y.

We invite you to visit our website with easy access to our complete up-to- date listings of hundreds of varieties, look ing good photo's and more........

Mark Endicott

HUB International is a leading global insurance brokerage that provides risk management services and a broad array of property and casualty, life and health, voluntary benefits and personal lines insurance.

Since 1963 we have been providing high quality insurance protection to our clients from coast to coast.

Experienced, local service is available through our national network of offices.

For a quality product, local service and very competitive pricing give us a call today.

HUB International Ontario Limited

www.hubontario.com 800-463-4700

24 Seacliff Drive East. Unit 100 Leamington, ON N8HOC2

At your service across the United States and Canada.

General Manager 23078 Adelaide Rd. Mount Br ydges, ON N0L 1W0 Cell: 647.923.5182 • Fax: 519.264.1337 mark@hillennursery.com

leadership, mentorship, business and marketing.

• Has spent at least 40 years in the floriculture industry.

Valk’s family immigrated to a Brantford area dairy farm when he was six. His dad had worked at dairy farming and grew cold frame vegetables in the Netherlands. The family soon moved to the small town of Grimsby where a nine-acre fruit farm was purchased and work slowly began on building Valk Greenhouses. The first greenhouse crop featured 4,000 square feet of spring tomatoes.

While in high school John Valk began working part time at Jordan Greenhouses, which was next door to their own farm. He began working with his dad in 1964 following graduation.

“John was very industrious, working four days a week at Jordan’s and then the remaining three days on the home farm,” Bierhuizen explained.

In 1968, John secured an Ontario Junior Farmer Establishment Loan for $40,000 and built a 1400-square-foot bungalow as well as new greenhouses on the farm.

Around this time John and Pauline were married and, working as a team, they built up the farm and their family over the succeeding years. Valk Greenhouses grew to 130,000 square feet, with three acres of outdoor production. Their main crops were hydrangeas, poinsettias and geraniums. Their son Sean was a partner in the farm for 10 of those years.

Even with all of the daily pressures of raising a family and building a business, Valk happily volunteered his time to actively lead many of the industry’s associations.

Over a course of 17 years, Valk was:

• Board member and VP Production for Flowers Canada National.

• Board member and president of Flowers Canada (Ontario).

• Board member and VP of the Cecil Delworth Foundation.

• Board member of the Canadian Ornamental Plant Foundation.

• Founding president of AgEnergy, a position he eventually held for eight years.

While the business was growing, so too was the town. Twelve years ago a developer presented the family with an offer they couldn’t refuse, and they sold the farm.

Bierhuizen picks up the story: “Now

with spare time on his hands and not willing to sit idle, John jumped in once again to help Flowers Canada Ontario. (Then executive director) Irwin Smith needed someone to canvass the industry and get growers to sign a petition to the Farm Products Marketing Commission for FCO to gain Section 12 status. John, of course, was successful in getting enough signatures for that petition.”

And more recently, he has joined Excalibur Plastics part time in sales.

“Over the years, in any business there are ups and downs,” said Bierhuizen, “but John is quick to point out that the many good friends he made in the greenhouse industry have always been a support whenever times were down. And John has made many good friends in this industry.”

Sean Valk was unable to attend the ceremony but congratulated his dad in an email. “I couldn’t agree more with the selection of my father for this year’s Lifetime Achievement Award. Growing up in the industry, my father always taught us the value of a healthy industry.

“In no other business have I ever experienced where, if you had an issue, you would call one of your competitors and they would quickly come to discuss it with you and provide help and expertise to see what could be done to correct the situation.”

He recalled how the industry rallied to assist the family after his brother passed away in 1993 at age 18. “As devastating

as this was, when I look back at those days there are a few things that really stand out that helped us get through that, including the outpouring of support from other growers in the area. There was an army of trucks ready to deliver our products, and people volunteering to manage the crop or anything else we might have needed … This is an industry that feels more like a family.”

In accepting the award, John Valk said he has had the privilege of working with “a lot of great and interesting people on all the boards on which I have served.”

The work on the various boards and committees was very important to him. “I always felt I got more out of serving on them than I put in.”

Associations like Flowers Canada are important in ensuring government officials understand the challenges and needs of the industry. “In talking to the government, it helps to have a strong association.”

He concluded by saying “it’s a great feeling to win this award.”

GINA MARCHIONDA: “THERE IS STRENGTH IN NUMBERS WHEN DEALING WITH ISSUES THAT ARE COMMON TO US ALL.”

In accepting her award, Gina Marchionda paid tribute to her employer for their support of her work in the association.

“My years of service would not have been possible without the full support

and encouragement of my employer, the Jeffery family. Since FCO’s inception, the Jeffery family has supported the work of the association both financially and through participation, encouraging each of its employees and management to participate in the projects and activities led by the association.

“The family understands, as I do, that there is strength in numbers when dealing with issues that are common to us all and that a strong and engaged association contributes to the success of each of its members, small and large alike.”

Marchionda was first elected to the FCO board in 2007 to take on the role of treasurer and has been re-elected to that post in succeeding elections since then.

“FCO has benefited greatly from Gina’s enthusiastic personality and financial skills,” said board vice-chair Jan Van Zanten of Van Zanten Greenhouses in presenting her with the award. “But her passion and understanding for small, family run businesses has been an even greater asset to the successes of the past 10 years at FCO.”

Marchionda has helped steer the FCO through some of its biggest challenges.

Back in 2007 when she was first elected to the board, the association had just submitted its application to the Farm Products Marketing Commission to achieve status under Section 12 to require all flower growers in the province to be paid members of the association.

Marchionda immediately jumped in and helped the board reach out to growers. She participated in all the meetings and convincingly explained the many benefits of FCO membership.

Marchionda has served for many years on a variety of committees for FCO and Flowers Canada Growers. She continues to represent flower growers on:

• The Ontario Greenhouse Alliance (TOGA) human resources committee.

• The Foreign Agricultural Resource Management Service (FARMS) board.

• The International Trade Committee.

• The Cost of Production Project steering committee.

• The management committee for GreenCHIP-Q. This is a quarantine fund now being developed jointly with an insurer and broker to provide coverage to floriculture growers in the event of financial losses due to a quarantine event. It is being designed by growers for growers to fill a gap

unique to the floriculture sector.

Marchionda has worked for Jeffery’s Greenhouses since 2001. Prior to that she articled with KPMG and then worked for private industry in manufacturing and transportation companies.

“Gina feels very comfortable in the family oriented business atmosphere, as she herself was raised in the same environment,” said Van Zanten. “She has commented that she has never seen such an industry as the one she is in now.

“There are few other sectors where

everyone is so willing to get together and talk things out, or where companies are willing to work together to get something that benefits everyone.”

In addition to her work in the industry, Marchionda is also involved in her community. Since 2010, she and her father, now 83, have participated in the Big Move Cancer Ride to support Niagara’s Walker Family Cancer Centre.

“A quick look on their web site shows Gina’s name on the list of top fundraisers for the 2016 event,” said Van Zanten.

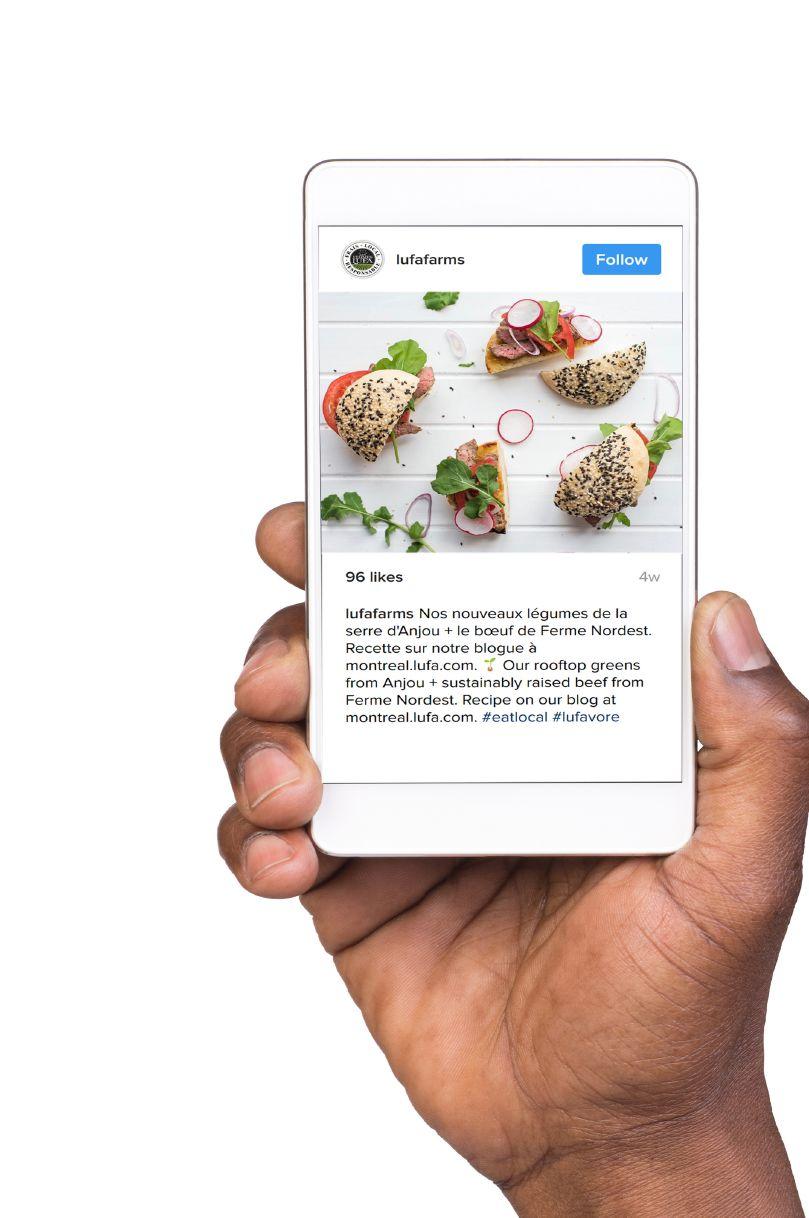

Social media and mobile marketing are essential tools in connecting with today’s consumers

BY KERSTIN P. OUELLET

Questioning whether social media and mobile marketing should be part of your plan? Consider this: the average user spends 50 minutes a day on Facebook – almost an hour! Social media is becoming part of our natural lives – we’re willing to devote a crucial hour to it, even after working 8+ hours and spending time with our families and friends.

Want more proof that mobile marketing remains key for savvy, successful marketing? Tallmadge Express reports that recent studies show:

• 92 per cent of people who researched a product on a mobile device made a purchase within a day.

• 76 per cent of them visited a store as a result of their mobile search.

Mobile digital media time now rivals desktop time. The average mobile user spends 80 per cent of their digital time in apps.

Case in point: the percentage of Canadian

ABOVE

adults who own a smartphone today? It’s 76 per cent, according to Catalyst Canada. That’s compared to 55 per cent in 2014. Three out of four people now own a smartphone. In addition, Canadians continue to adopt tablets at a rapid pace, with nearly 10 million now owning the portable devices.

Added to that, Canadians are the fourth heaviest users of mobile data in the entire world, according to Cisco. In fact, 23.7 per cent of households reported using a cell phone exclusively, compared to 20.4 per cent in 2013. Cisco projects that Canadian mobile data traffic will grow 600 per cent from 2015 to 2020, a compound annual growth rate of 42 per cent. Canadians are spending more and more of their smartphone time on social media – almost 20 per cent of users access social media almost every day, with another 15 per cent reporting at least once a week. Social networking access is second only to photo use and management

Many companies are working in a variety of social media platforms, and with great success.

Greenhouse operations are full of machinery and devices that can seize, snatch, slice, cut, smash, and entangle fingers, hands, toes, and feet, warns Kristin Ho man, a consultant with Workplace Safety & Prevention Services, your farm safety experts. The likely consequences: injury, amputation or death. The hazard peaks during seeding and planting, processing, grading and packaging, and vine tear out.

You can prevent these life-altering incidents. Here’s what you need to know.

where you feed materials into machines

where a machine cuts, turns, drills, shapes, punches, or moves in any way

during cleaning and maintenance, troubleshooting and repairs, adjustments, set-ups, and ongoing operation

at pinch points involving gears, flywheels, cylinders, belts, rollers, pulleys, shafts, couplings, chains, and sprockets

around moving equipment, PTOs, augers, conveyors, fans, soil mixers, potting machines, planting machines, robots, vine pullers, pallet wrappers, box makers, conveyors, and any other equipment that can release energy

WSPS has a wealth of resources, including:

Free downloads in English and Spanish at www.wsps.ca/Farm-Safety-Products/FarmSafe-Plan. aspx#downloads

Machine safety hazard awareness sessions delivered on site. Contact Customer Care for details: 1-877-494-WSPS (9777)

Downloadable machine safeguarding videos: www.wsps.ca/Information-Resources/Videos.aspx. You can also stream them at WSPS’ YouTube channel: www.youtube.com/user/WSPSpromo

Also check out this Ministry of Labour video, Keeping Workers Safe at Ontario Greenhouses, www.youtube.com/watch?v=sZ1dcPXnWXg

Kristin advises building the following precautions into your training program and operating procedures:

1. Stop and think before you act — as you’re planning your day, starting or winding down an activity, altering course, responding to sudden changes…

2. Wear appropriate gear for your day’s tasks — no loose fitting clothing or jewellery, including wedding bands. Button those shirt cu s, and tuck in your shirt tail, hoodie and scarf. Better yet, don’t wear a hoodie or scarf. Tie your bootlaces so they don’t drag. Don’t wear gloves around reciprocating or rotating machine parts.

3. Sporting a ponytail or long hair? Put it under a snug-fitting hat.

4. Heed the warning decals on equipment. Make everyone read them, and then test their understanding.

5. Circle check equipment before starting it. Ensure all guards are in place and in good shape. Look for leaking hydraulic oil.

6. Never perform maintenance or try to clear an obstruction while the equipment is running. Shut down and lock out hazardous energy. If a guard is removed to perform maintenance, replace it immediately after servicing.

7. Wait for rotating parts to stop before working on them.

8. Never step over a PTO shaft, or above or below a conveyor belt while it is running.

9. Use a jack stand when hitching or unhitching an implement so that the hitch pin is supported. If the pin is damaged or bent, replace it.

10. Keep bystanders and children away.

across devices, with 32 per cent accessing social media on desktop computers, 53 per cent on smartphones and 15 per cent on tablets.

Canada is near a multi-platform majority, with more than 50 per cent accessing digital content via both mobile and desktop in the same month. Still, mobile-only users (those who do not use desktop computers) are on the rise, increasing by nearly 20 per cent in just a year.

Even with this digital revolution,

it’s important to note that Canadians remain extraordinarily engaged compared to other users worldwide, with high time and page consumption metrics comparatively. A ComScore

study showed that Canadians rank number 1 in the world for average monthly hours per visitor on a desktop computer.

Another important point to keep in mind: ComScore reports that 73 per cent of Canadians watch video, and on average spend 5.1 more hours per month watching video than Americans. Social media video will be increasingly important for engagement

Here’s a statistic we all should remember: Mobile email will account for 15 to 70 per cent of email opens, depending on your target audience, product and email type, according to eMailmonday. What does that mean to you? If you’re smartly marketing, a tweak in how you’re presenting information. Consider:

• 40 per cent aged 14-18 will always read emails on mobile first, 29 per cent for ages 19-34 and

ABOVE Most consumers rely on their smartphones while shopping.

The Content Marketing Institute defines content marketing as “a strategic marketing approach focused on creating and distributing valuable, relevant, and consistent content to attract and retain a clearly-defined audience – and, ultimately, to drive profitable customer action.”

What does that mean? You’re creating content specifically for specific customers. You’re focused on engaging and enticing them to develop a relationship with your brand, and to create an ongoing dialogue, rather than a onetime hit.

Instead of hard selling our customers, we’re providing them with information they can use, and in turn, they reward us with their business, and their loyalty. Companies like Microsoft, P&G and Cisco are using these tactics with great success. You should be, too.

For example, if you’re a nursery or greenhouse, instead of saying, “look at our great selection of edibles,” you could cite trends in edibles and suggested uses, then circle back to which of your cultivars would be great for that. You could do the same with container combos, trends in perennials, colors, etc. Nobody wants to be “sold to,” but everybody loves to discover something new and useful.

eight per cent of the group of 5667, according to the 2016 Adestra Consumer Adoption & Usage Study.

• Women interact with e-mail for just over a hundred million more minutes per month than the industry average.

• Mobile email opens have grown about 180 per cent in three years.

• Responsive design results in a nearly 15 per cent increase in unique clicks for mobile users.

• The first link in a responsive design e-mail on mobile has a 30 per cent higher click rate than non-responsive design.

Short, bite-size chunks of information make it quickly digested on devices, from phones to tablets. Make sure information automatically sizes to devices, is the right size to be easily read and that it is carefully targeted to your audience’s needs and wants.

So what does it all mean for you? Patience, always in short supply with customers, now stands at almost nil. Rather than wait for a site (or app) to load, visitors will quickly find another, faster-loading stop. That means injecting mobile friendliness into your web site, e-blast, digital advertising, and also tackling analytics and search engine optimization so you’re covered on all fronts.

Kerstin P. Ouellet is president of Pen & Petal, Inc., a marketing, advertising and public relations agency for the green industry. She can be reached at 760-271-7261, kerstin@penandpetal.com or www.penandpetal.com.

MORE MARKETING STORIES ARE IN THE “BUSINESS” SECTION AT GREENHOUSECANADA.COM

Because spider mites do not fly, early detection is only possible by checking all plants in all rows at least weekly. Enlist the assistance of workers carrying out various tasks within the crop daily, and are in close contact with the plants. BY DR. M. ISHTIAQ RAO

At this time of year, the two-spotted spider mite makes its very predictable appearance in greenhouse crops. Despite our familiarity with this pest, it continues to challenge us.

Spider mites observed now, in mid-winter, would most likely be those coming out of diapause. The diapause stage allows spider mites to survive low temperatures; during this stage, they feed minimally and do not reproduce.

Diapausing spider mites appear reddishorange and are all mated females (Figure 6). This latter fact partly explains their ability to quickly establish new infestations in spring crops. It should also be noted that starving

FIGURE 1:

females may be brick-red in colour and therefore can resemble the orange-red diapausing forms although they are not in diapause. Such forms may be observed later in spring and summer. This phenomenon can be caused by poor quality food from senescing leaves or feeding damage caused by the mites themselves.

Spider mites enter the diapause stage during late summer or fall months of the preceding year. The same factors that brought on the diapause state, also affect their emergence from it. The major factors include daylength, temperature, quantity and quality of food supply. Shortening daylengths, decreasing temperatures, and lack of

Spider mite webbing on cucumber is an advanced stage of infestation.

FIGURE 2:

Advanced spider mite damage on cucumbers.

This guide is a comprehensive information source that considers the diversity of situations encountered by growers in businesses of all sizes.

The 220-page book maintains a focus on production and contains information that until now was available only in piecemeal form. It discusses the basics-such as taxonomy and nomenclature, plant hardiness, the physical needs of crops, and types of irrigation systems-as well as cutting-edge, research-based information about perennial propagation and production.

A chapter about forcing out-of-season bloom includes up-to-date information about research on this topic as well as a table of specific forcing requirements for over 120 perennial species and cultivars.

Practical discussions about starting a business, marketing and customer service, setting prices for plants, and designing a production facility are included as well.

or poor quality food supply all favour the diapause state.

By the same token, during the early months of the year when days are getting longer, greenhouses are warm and full of young, succulent growth. The mites, now no longer in diapause but still orange-coloured, crawl out of their hiding places to start feeding and reproducing.

Because spider mites do not venture too far from the last feeding areas just prior to entering diapause in the previous fall, they tend to emerge from the same areas in the new spring crop. It is important to note that spider mites in this stage tend to be more resistant to pesticides than regular, non-diapausing mites, and are reluctantly fed upon by Phytoseiulus persimili (Figure 7), one of the most commonly used biocontrol agents for spider mites. P. persimilis is a highly specialized predator of spider mite, and it’s a useful biocontrol agent because it consumes spider mites of all life stages

Spider mites are notorious for causing economic crop damage (such as in Figures 1- 3), and we need to adopt a multi-pronged approach when managing this chronic pest. Some tips to bear in mind for controlling spider mites are as follows:

Check records of the previous crop for spider mite infestations –Successful suppression of spider mite populations requires early detection of infestations. Do not wait to see webbing (Figure 1) on your crops, because at that point the spider mites have gotten out of control. Having good visual records of the previous year’s “hot spots” provides valuable clues as to where the mites might first appear in the new crop.

Monitor crop thoroughly and diligently – For early detection of spider mites, there can be no shortcuts. Because spider mites do not fly, early detection is only possible by checking all plants in all rows at least weekly. For such a task, it is advisable to enlist the assistance of workers who are carrying out various tasks within the crop daily, and are in close contact with the plants regularly.

Train your crop workers to recognize spider mite damage both on upper and lower surfaces of the leaves (Figures 4 and 5). Early detection is key to save money on spider mite control.

& 5:

Earlier stages of spider mite damage on upper and underside of cucumber leaf.

Use a combination of biocontrols – Usually, it’s best to use a combination of predators because the different characteristics of the various species, released strategically, can enhance the success of a biocontrol program for spider mites.

Fortunately, several biocontrol agents are commercially available for managing spider mites. These include Phytoseiulus persimilis, Stethorus punctillum, Feltiella acarisuga, Amblyseius andersoni, and Amblyseius or Neoseiulus californicus.

Another predatory mite, A. swirskii, though not recommended specifically for spider mites, can assist in suppressing their populations. Competition can

occur among the different biocontrols, but research suggests that this usually happens only after there’s a crash in the prey or pest population, which is the desired outcome anyway.

Be informed on negative potential impact of all pesticides used – Pest control products and their residues can adversely affect the activity and survival of biocontrol agents. Residues of some products can remain toxic for at least a few weeks to the predatory mites. Although some pesticides may not cause immediate death of the predators, they can significantly affect their reproduction and survival, especially when higher rates are used.

Ensure compatibility of biocontrols and host plant – Host plants can influence the effectiveness of biocontrols in several ways such as via their surface characteristics. For example, biocontrol of spider mites is comparably easier on peppers than on tomatoes. This is because peppers have relatively smooth leaf surfaces that allow for free movement and predatory activity. By contrast, the presence of sticky hairs on tomato plants can hinder the activity of the predator, thereby reducing its efficiency.

Note impact of greenhouse microclimate – Activity and efficiency of biocontrols are affected by the greenhouse environment. For instance, under optimum conditions of about 20 to 25 C, P. persimilis can increase its numbers at about twice the rate as those of the spider mite. However, within a cucumber crop, temperatures in the upper leaf canopy often exceed 30 C, and humidities are often under 60 per cent during late spring and summer. Above 30 C, P. persimilis does not thrive, whereas its prey, the spider mite, reproduces rapidly. Below 60 per cent RH, egg-laying and life-span of P. persimilis are sharply reduced whereas such dry conditions favour the spider mite.

In managing the two-spotted spider mite, we always need to be mindful of its biology and that of its biocontrols, and the many accompanying influencing factors encountered in the production of greenhouse crops. If, in addition, we are diligent and timely about implementing

the strategies necessary for suppressing their populations, our chances of successfully managing them will be greatly increased.

Dr. M. Ishtiaq Rao, CEO of Crop Defenders Ltd., is a PhD in entomology who is dedicated to the eradication of

horticultural pests through IPM methods. Crop Defenders Ltd. utilizes biological knowledge of pest and beneficial insect species in order to manage pests costeffectively and in a way that is cohesive with a healthy environment. ishtiaq@cropdefenders.com

BY MAURICIO MANOTAS

While the benefits of diffuse light for plants in the greenhouse have long been proven, recent research reveals that the quality of diffuse light is also an important factor in plant quality and productivity.

Most growers tend to simply follow the approach of “diffuse” or “non-diffuse” but new research has proven that there are major differences with respect to the light spectrum. Haze values defining the angles in which light is spread show large variances between diffusion screens and various types of diffuse glass.

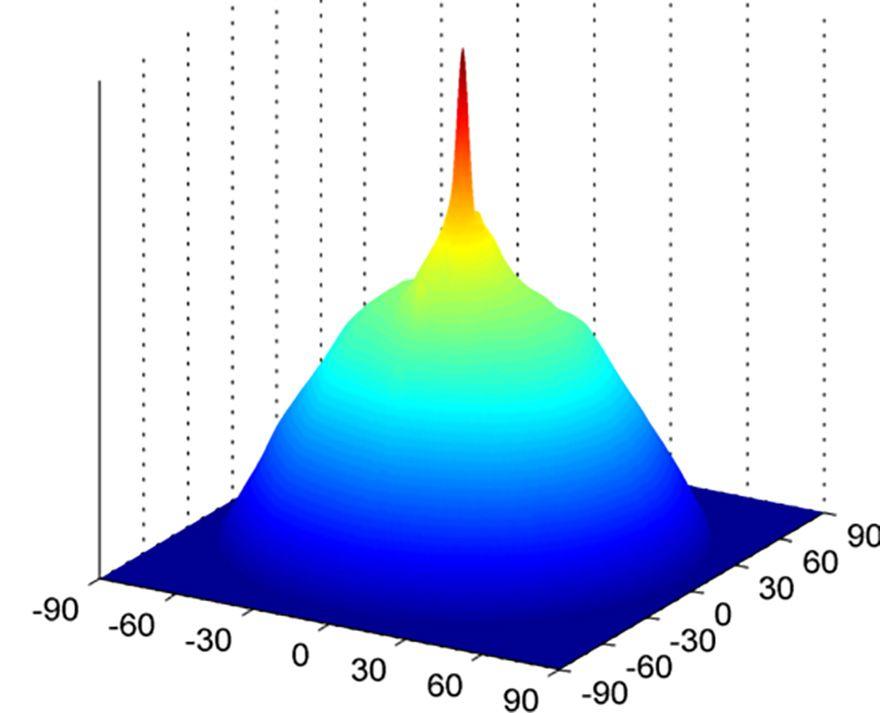

When looking at the haze values shown in Figure 1, the top graph illustrates how light is spread around a plane when passing through a

light-diffusive screen while the second graphic above shows the same beam of light hitting the surface but in a more vertical way, even though both illustrate what is considered to be light diffusive products.

Researchers at Wageningen University (WUR) in the Netherlands have found that another widely used option, diffuse coatings, provide variations in light transmission and diffusiveness, depending on the concentration and application. Light levels and diffusivity vary when not applied evenly, so much that in some cases, greenhouses are actually receiving less light than

Wageningen University (WUR) Haze values. (Top) Figure 1, Harmony 7247 FR, Haze: 100 ± 5 per cent, F-scatter: 100 ± 5 per cent. (Above) Low haze glass, Haze = 41.4 per cent.

without the diffusive coating (up to seven per cent).

Moreover, studies discovered that plant temperature is also impacted. With a diffuse glass or coating, plant temperature tends to be higher when compared to another greenhouse using a diffuse screen with ventilation windows open.

Why? A diffuse screen provides protection when ventilation windows are open. The sun warms up the greenhouse in the morning, meaning less energy is needed, and screens allow for high light transmission even when the sun enters from a low angle.

One of the studies was conducted at an Ontario pepper operation.

Studies at a Canadian pepper greenhouse in Leamington, Ontario, compared two greenhouses with the same temperatures, one with a diffuse coating applied and one with a diffuse screen installed. Researchers found that with a diffusive coating, growers won’t achieve a better climate compared to a diffuse screen. Rather, they will lose the flexibility of having more light on demand.

As growers seek to improve light transmission, they also wish to provide consistent light exposure. Vertical distribution of light penetrating the plant canopy is as important as horizontal light distribution across the greenhouse, minimizing shadows from fixtures and trusses. Scientists in the Netherlands moved two PAR light sensors throughout identical sections in a greenhouse, one section equipped with an original Harmony screen and the other section with New Harmony 2315 O FR, a Svensson screen with 23 per cent shade protection. The sensors continuously measured the light intensity, plotting all points on a graph.

® Gro-Bark® has been producing soil ingredients since 1980 and custom soil mixes since 1996. Today, a professional team of specialists support a large infrastructure of material and equipment resources to make any soil formulation.

Better work environment due to lower average temperature.

Stronger and healthier crops because light reaches deeper into each plant. Less risk of burning the plant head because actively scattered sunlight reduces crop temperatures.

Better growth consistency because all plants get the same amount of light.

More intense colours, as diffused light intensifies the colour of the flowers.

Faster growth with a diffused light of better quality.

Currently, more diffuse light studies are underway in greenhouses across Europe and the Americas, at locations including Spain and Netherlands and in the U.S. and Canada, with results to be forthcoming. As research advancements continue forward, we will certainly continue to better explore diffuse light’s benefits and expand our understanding of the connection between light quality and plant productivity.

These field tests found that New Harmony allows plants in the shade 32 per cent more light than classic Harmony. Structural shadows are significantly diminished, resulting in all plants receiving more uniform light both per moment and cumulatively. This results in homogeneous growth.

Rose cultivator Peter Lansbergen sees the benefits of his light-diffusive New Harmony screen in his crops. “The shoots receive more light, and my buds are not at risk of being damaged by any direct sunlight. This has improved the quality of the buds. The light in the greenhouse is better distributed over the crop, which results in better outgrowths and better protection of the rose buds.”

Lansbergen’s goal is to maintain over 20 moles in the greenhouse throughout the year. Typically this would mean intensive lighting in the winter months, as there wasn’t enough light outside. “With this screen, it is easier to reach these PAR values with the use of daylight,” he says.

Mauricio Manotas is president of Ludvig Svensson, Inc., 704-357-0457 or Mauricio.Manotas@Ludvigsvensson.com.

MORE STORIES ON SCREENS ARE IN THE ‘STRUCTURES AND EQUIPMENT’ SECTION AT GREENHOUSECANADA.COM.

(Please note: this item was originally published in our February issue, but with an incorrect headline.)

TALUS™ from Engage Agro is a highly effective group 16 insect growth regulator that selectively targets whiteflies with no harmful effects to beneficial insects and pollinators. It is highly compatible with resistance management and IPM programs that include the use of biological control agents. www.engageagro.com

The next generation of decorative containers has arrived with Bondshell from McConkey, a revolutionary process that applies

photo-realistic finishes to pots and baskets. Bondshell products allow unprecedented design flexibility to reproduce virtually any pattern to complement home and outdoor – tile, carpet, furniture, wallpaper and more. www.mcconkeyco.com