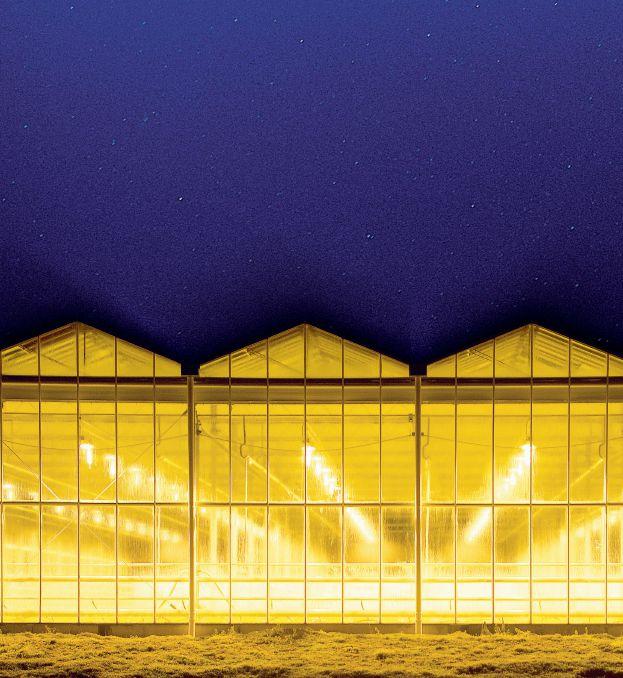

Behind curtains

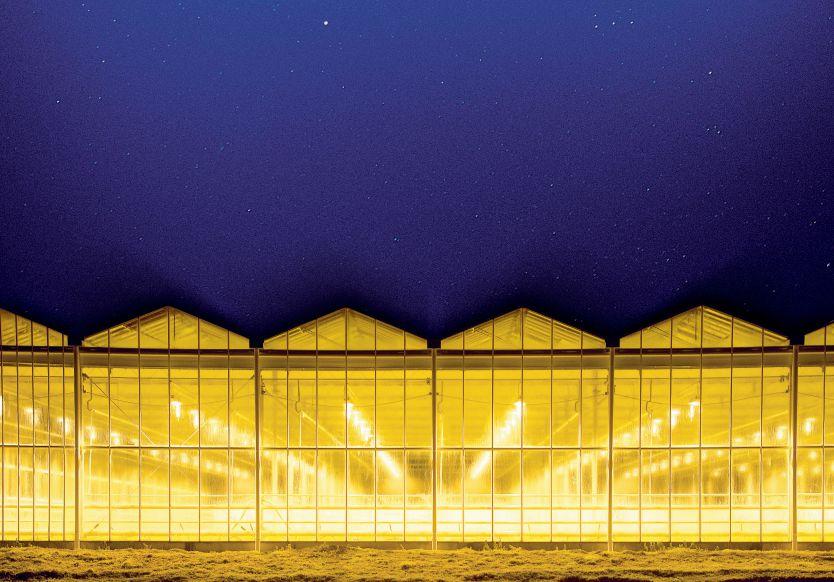

Keeping the greenhouse climate in check amid light abatement bylaws | 28

A lifetime of learning A grower recounts his unexpected journey into greenhouse production | 40

BY GRETA CHIU

JOLI A. HOHENSTEIN

Behind curtains

Keeping the greenhouse climate in check amid light abatement bylaws | 28

A lifetime of learning A grower recounts his unexpected journey into greenhouse production | 40

BY GRETA CHIU

JOLI A. HOHENSTEIN

GRETA CHIU | @GreenHouseCan

It’s the June edition, and that means summer will soon be upon us.

For garden centres, recent reports say they’re seeing some of the busiest seasons ever encountered. As Peter Meijer at Vankampen’s in P.E.I. tells CBC News, this was the busiest April he had ever experienced and the number of visitors climbed more quickly and earlier than before.

In another story, the same news outlet reported a “three-kilometer lineup of vehicles” outside Westland Greenhouses Garden Centre in Grand Bend, Ont. The staff sold 2,500 Boston ferns in six hours using a drive-thru model.

Sounds like it’s going to be another booming year for ornamental plants and gardening, but what about greenhouse vegetable producers?

In January’s edition of Greenhouse Canada this year, the state of the industry feature reported “uncharacteristically high” prices for tomatoes in 2020. The sector saw large swings in wholesale pricing last year, sometimes reaching three times the normal rate. Heightened

Produce in Blenheim, Ont., turned to social media to move their tomato surplus. With food establishments shut down or offering limited takeout and delivery, demand for fresh produce from this segment has gone down. At the same time, Glen Snoek of Ontario Greenhouse Vegetable Growers, says there’s been strong production throughout North American growing areas, including Mexico and Florida, leading to low prices near the end of April. “There is simply a great number of tomatoes available and therefore selling at quite low prices,” he says.

Judging by the outpour of support and lineups at Platinum Produce’s roadside stand, Canadians want to support local. They just need the opportunity to do so. Tim and Bonnie Verbeek also tell us, “90 per cent of [customers] were taking large amounts, back to their communities to either donate to their homeless shelters, to non-profit organizations, or to the elderly in their community.”

What did you envision for 2021 and will they come to fruition this

The garden centre sold 2,500 Boston ferns in six hours.

demand was attributed to reductions in air freight, as well as low levels of greenhouse produce arriving from international markets, particularly from the Netherlands and Spain into the U.S, where production had also declined in some regions.

For 2021, however, it seems that tomatoes have been under pricing pressure. At time of writing, we had just published a story online of how greenhouse producer, Platinum

year? Check out the results of our revived Grower Survey (pg. 24). 75 per cent of respondents said they’re expecting greater sales. 58 per cent said they would be increasing their prices, but with the costs of labour and wages, heating, electricity and supplies all increasing, how can they afford not to?

Thank you to everyone who filled out the Grower Survey and congratulations to our 12 lucky draw winners.

DLI HORTI-Series 1000W DE HPS

Extra Low-Profile

Housing

Less Daylight Interception

Improved Reflector Superior Light Spread & Reflection

Improved Heatsink

Increased Driver Efficiency

Easy Connection & Disconnection

Gore-Tex Plug

Ventilation Plug Wieland Quick Connect

LED indicator

Status & Error Diagnostics

Time for an upgrade?

DLI provides a total grow light solution for both professional greenhouse horticulture and indoor applications. Our experienced team is more than happy to assist with a project specific lighting plan, showing the best suitable lighting solution for your crop and your company.

DLI DIODE-Series LED TopLighting

High Output

High Efficient

Integrated electronics

Intelligent Auto-Voltage Ballast

Light weight

Lowest weight / performance ratio

OUR CORE VALUES

RESEARCH & DEVELOPMENT

CONSTANT IMPROVEMENT

Flat smooth surface

No dirt accumulation

Venturi effect

For optimal cooling

Real Optic For extra light penetration

Vineland Research and Innovation Centre (Vineland) is working with optics and photonics developer, INO, to develop new robotic harvesting solutions.

As Vineland tells Greenhouse Canada, “the robotic harvesting system uses a camera that provides colour images and 3D information to a deep learning vision system that detects fruit, determines its ripeness and locates it within the robot’s workspace.” A robotic arm then reaches out with a specialized tool

to make a cut at the appropriate location. The harvested fruit is transferred back to the robot before moving on to the next plant. “A key feature of the system is its ability to account for the uncertainty in measurements by the vision system, which allows it to move quickly with a high success rate. The robot can also harvest without stopping its forward movement, further reducing the overall harvest time.”

The next step is to find a commercialization partner.

Source: Vineland Research and Innovation Centre

Allegro Acres is expanding its acreage of LED-lit greenhouse peppers from four to 12 acres for winter production.

The first of its kind to take place on a commercial-scale in Canada, the initial four acres of greenhouse LEDs were installed in 2020 and produced a successful crop of peppers this past winter. According to President of Allegro Acres, Gene Ingratta, Allegro

will be installing additional LEDs this summer, in time for use in early October. Allegro will also be implementing light abatement measures to comply with greenhouse lighting bylaws announced in the municipality late last year, as well as a high-pressure misting system to help control temperature and humidity.

LED supplier, Sollum Technologies, also

Greenhouse Canada’s annual Grower Day is back. Running on June 22, the event will feature a mix of live and recorded sessions for greenhouse flower and vegetable growers – all free of charge.

Differing from last year’s event, the new interactive platform allows attendees to interact live with panelists, speakers and other attendees through instant messaging and video.

This year’s theme is focused on business sustainability amid a changing world, addressing energy, integrated pest management, new technology and business practices. Featuring practical advice and thought-provoking discussions, attendees will recognize familiar faces and make new contacts, all across Canada.

Turn to page 27 for a glance at the speakers and sessions. Spots are first-come, first-served. Register for free at growerday.ca.

provided their cloudbased SUN as a Service platform which allowed flexibility in experimenting with different light recipes, comparing yields and determining the best settings for production.

“Not only can we personalize the recipe, we can adjust our greenhouse lighting in real-time according to climate conditions and our observations of crop growth,” notes Ingratta.

“By annualizing our

pepper production, we realized that the possibilities afforded by Sollum’s technology are a gamechanger for us. We look forward to increasing our production thanks to technology made in Canada, which will enable us to supply Canadians with fresh, locally grown peppers year-round. These are exciting times for Allegro.”

With files from: Sollum Technologies

Greenhouse sales in 2020

Flowers and ornamentals +6.5% at $1.7B GREENHOUSE SALES +9.4% TO $3.5B Vegetables and fruit: +12.3% at $1.8B

BEDDING PLANT SALES

• Vegetable +15.9% to $172.9M

• Ornamental +12.1% to $232.7M

• Hanging pots: +65.7%

• Cyclamen: +35.8%

• Potted vegetables: +22.5%

• Rudbeckia: +15.6%

• Tomatoes +12.1%

• Cucumber +9.4%

• Pepper +7.3% POTTED PLANT SALES

Source: The Daily by Stats Can, 2021 (Note: % change is year-over-year)

Two greenhouse products stole the show at the 2021 Canadian Produce Marketing Association (CPMA) New Product Showcase.

The Star Group’s Inspired Salads were named Best New Product. Based in Alberta, Inspired Salads are prepared with greenhouse-grown ingredients and freshly made dressings, separated by compartments within a hexagonal container.

Mucci Farms’ Naked Leaf Living Basil won for Packaging Innovation. Reducing plastic by 50 per cent, its sleeve is made of 50 per cent paper with a compostable growing pot and a reusable exterior pot.

Other showcase winners included UNITEC Canada Fruit and Vegetables Technology Inc. for Cherry Vision 3.0 (New Technology award), LOOP Mission’s probiotic sodas (Snackable Product award) and EarthFresh’s Organic Golden, Red & Russet Potatoes (Organic Product award).

Each year, CPMA, through its New Product Showcase program, supports fresh produce industry members by introducing their new products to key industry

Nature Fresh Farms has recently introduced a program to sell imperfect produce in an effort to reduce food waste.

Called ‘Waste Me Nots,’ the program leverages tomatoes, peppers, and cucumbers that do not meet the criteria set out by the producer’s quality control team.

Although unique in shape and size, these vegetables still have the same nutritional value and flavour as their perfect counterparts. Nature Fresh Farms wants to create more of an opportunity to fight food waste and give shoppers further access to nutritious foods.

‘We believe it’s important to ensure that nutritious and delicious produce does not go to waste,” shared Ray Wowryk, director of business development. “By creating this program, we are helping our retailers with a ready-made waste reduction alternative.”

Since volume of this type of product is not predictable, the program cannot be guaranteed to supply specific quantities and will depend on the

product grown. However, Nature Fresh Farm feels that the unpredictability is outweighed by the fact that their quality and freshness is worth rescuing and sharing with consumers, making the most of all their product grown.

“Sustainability is at the centre of everything we do at Nature Fresh Farms. Not only does this encompass our packaging and growing processes but also that the food we grow gets utilized completely,” explained Director of Sales, Matt Quiring. “The Waste Me Nots program helps us to reduce waste while allowing us to better service the price-focused shoppers looking for quality-tasting products at a discounted price and let our retail partners bring in some incremental sales to the category.”

Source: Nature Fresh Farms

professionals at its Convention and Trade Show.

The 2021 New Product Showcase featured 56 products from 42 companies. Winners were announced at the CPMA’s 95th Convention and Trade Show, Fresh Week online from April 12-16, 2021.

The largest fresh produce event in Canada and CPMA’s first-ever virtual show, Fresh Week attracted almost 2,900 attendees from 42 countries. The show featured an Expo Hub which hosted 175 booths with 183 companies active in the fresh fruit and vegetable market.

CPMA also carried on its tradition of supporting its community by raising funds for Food Banks Canada. At the end of the show, CPMA exhibitors and attendees raised $16,604.75, surpassing the target goal of $15,000.

During Fresh Week, the 2021 CPMA Lifetime Achievement Award was presented to John Anderson, chairman, CEO, and managing partner of The Oppenheimer Group (OPPY).

With files from: CPMA

Greenhouse Canada is looking to recognize the best in Canadian greenhouse technology.

Debuting this year, the Greenhouse Technology awards will be given annually to recognize technology demonstrating a high level of innovation in advancing the greenhouse and controlled environment agriculture sectors.

The awards offer an opportunity to gain recognition for Canadian companies who develop the technology, helping to spur greater advancements and commercial adoption. Categories include production, pest management, marketing and international (non-Canadian) entries.

Sponsored by the Canadian Greenhouse Conference (CGC), winners will be publicized through the CGC and Greenhouse Canada.

Interested parties should submit a notice of intention to enter, plus the accompanying entry fee ($350 + tax) by June 21. Once the notice is confirmed, applicants will receive additional information on materials due July 21. Head to greenhousecanada.com/awards for details.

Jurassic Dino is one of four new series of Rex Begonias from Ball Ingenuity, under the Jurassic brand. The Jurassic Dino series in particular offers a compact habit and small leaf size making it ideal for 4-6” pots. 36-41 cm tall, 36-41 cm wide. Other series include Jurassic, Jurassic Jr., and Jurassic Megalo. Each offers a size and vigour to meet specific needs. Said to finish quickly and uniformly, these are suitable for any indoor sales or shade container program. ballingenuity.com

The Rainbow series is the newest and one of the most colourful lineups to join the Dümmen Orange calibrachoa collection. These varieties have a unique attribute where, based on daylength, temperature and light levels, the blooms will open in a different colour and give a unique tri-colour effect to the plant depending on when the

All new breeding brings this new Portulaca 24/7 series to market. Like the neighbourhood quick shop, the flowers of the series are said to never close, boasting not only large, 2-3” fully double flowers but it’s also day length neutral. Currently available in five colours: fuchsia, orange, red, white and yellow. Perfect in quarts through basket production. green-fuse.com

bud was initiated. In its unique way, plant colour changes throughout the year. Said to display exceptional vigour and heat tolerance, the series is ideal for large baskets, large containers and even in-ground plantings. Launch colours include: Bermuda Blue, Calypso Coral, Flamingo Flare, Pink Pepperberry and Tiger Tail. dummenorangena.com

New for 2022, Danziger adds three new colours to the Eyeconic calibrachoa series: peach (pictured), pink and cherry blossom. Each one offers large blooms with an intriguing eye pattern and strong colour contrasts. Sporting a controlled, semi-trailing

habit, this early-blooming calibrachoa series is ideal for hanging baskets or larger containers. New additions bring the series to five colours. pH tested Suitable for gallons, 1215 cm pots or hanging baskets, and in combos. danzigeronline.com

Take award-winning Bee’s Knees petunia to the next level by using it in combos for premium retail containers and baskets. Bee’s Knees puts on a high-impact show all season long in the most intense yellow colour. Check out several new MixMasters combos for 2022, including Oh Beehave featuring Double Petunia Midnight Gold. ballfloraplant.com

This is a sneak peek at new introductions for CAST 2021. See full coverage later in the year.

Horseshoe Power and Doef’s Greenhouses are collaborating on a project to turn waste heat and carbon dioxide (CO2) from natural gas production into a valuable local resource for a new 13-acre greenhouse.

In the traditional cogeneration process, natural gas is burned to turn a generator and produce energy. In doing so, heat is created that can be either wasted or captured and used. Doef’s will not

Doef’s Greenhouses will be using waste heat and CO2 from Horseshoe Power’s natural gas production, as well as treating wastewater from the wells for irrigation.

only use Horseshoe Power’s leftover heat for their greenhouses, they’re also taking the CO2 that is produced to feed their crops.

“We have a variety of crops under glass and plastic. We grow peppers, long and short cucumbers, eggplant, and some lettuce. We’re currently in phase one of our new greenhouse expansion,” says Eric Doef, managing partner with Doef’s Greenhouses Ltd. in Lacombe, Alberta.

Doef says, around four years ago, he met with Horseshoe Power, who owns the local gas wells. At the time, getting more natural gas for future greenhouse expansions would have cost a significant amount of money for all the extra infrastructure and piping needed to access it through the traditional grid.

“We had a handful of gas wells around here already. We acquired some more. We brought them all together and reconfigured all the pipe to bring the natural gas into the site. We call it trigeneration because we make electricity, heat, and carbon dioxide for the greenhouse. We also supply electricity to the grid,” says Brad Murray, president of Horseshoe Power.

Horseshoe Power and Doef’s Greenhouses are reclaiming heat and CO2 from generators and using the excess heat in the greenhouse. The exhaust produced is cleaned and cooled into a CO2 supplement for plants. They are also using water distillation technology from large ships to treat wastewater from Horseshoe Power’s wells, creating pure water that Doef’s can use to irrigate crops.

Since Doef’s relies on natural light, which is tough during long Alberta winters, they’re installing broad spectrum LED lights to grow pepper crops in a two-acre trial. The lights are more efficient with less emissions. To detect premature mold that can result in product returns and more waste and emissions, Doef’s is also installing a laser detection system to catch mold before the local produce gets shipped.

“There’s a lot of stuff going on that we’re advancing in this greenhouse, in our energy centre, and in the gas gathering and treatment system. It’s not one silver bullet, it’s all these little things that are coming together to make us more efficient. We are reducing emissions and being more profitable,” Murray adds.

For this project, Horseshoe Power and Doef’s Greenhouses received $2 million in funding from Emissions Reduction Alberta (ERA), which is supported by the Government of Alberta’s Technology Innovation and Emissions Reduction (TIER) fund. This project is one of 17 proposals that received funding from ERA through its $33 million Food, Farming, and Forestry Challenge. Combined, the projects are valued at $107 million in public and private investment. If successful, the projects are expected to lead to cumulative greenhouse gas reductions equivalent to up to 2.7 million tonnes of CO2 by 2030.

Kevin Duncan manages media relations for Emissions Reduction Alberta. He can be reached at kduncan@eralberta.ca

With vents on the leeward side, wind travelling over top creates suction pressure that pulls hot air out of the greenhouse. Vents closer to the ground on the windward side let the cooler outside air into the greenhouse.

Sometimes the simplest forms of ventilation make the most sense.

Temperature and humidity – maintaining this balance can be a constant source of struggle for greenhouse producers. As summer time rolls around, sometimes the simplest forms of ventilation can make the most sense in time and expense.

“Natural ventilation is by far the most popular form of ventilation for modern greenhouse growers in the Northern Hemisphere,” says Leigh Coulter, president of GGS Structures, based in Vineland, Ont. As she explains, natural ventilation is equally popular for gutter-connected and ground-to-ground freestanding greenhouses, where this type of ventilation can excel. To understand why, Coulter draws a literal picture shown above.

“Roof vents operate on the principal of the chimney effect. Hot air inside the greenhouse rises naturally. By placing a vent on the leeward side, wind travelling over top the vent creates suction pressure that pulls the hot air out of the greenhouse. Vents closer to the ground on the windward side let cooler outside air come in to replace the hot air that is being pulled out.”

Built from taller posts, the height of gutterconnected structures allows for a greater chimney effect. Freestanding greenhouses can make use of both roof vents and rollup sides to increase the amount of natural ventilation. In a correctly designed greenhouse, the results would be even cooling within the crop, for a more uniform product.

That being said, there are situations where natural ventilation may not be as suitable.

“If you need your greenhouse temperature to be below ambient temperature and you are in a dry climate zone, then fan and pad cooling is better than natural ventilation,” Coulter explains. “But fan and pad do not work as well in humid climates, so natural ventilation is better in those situations.”

Before the summer heat peaks, Coulter recommends checking airflow from vents, having racks greased and conducting a proper maintenance check. “To visualize airflow you can use coloured smoke bombs as a low tech solution to see how the air flows through the greenhouse. This technique can also be used to see where you have air leaks that you may want to eliminate or reduce before winter.”

She emphasizes that ventilation is only one part of environmental control. “Humidity and temperature and light levels also play a roll in determining how the greenhouse systems operate. A good environmental computer will take inputs from both the outside environment and the growing environment and determine what needs to be adjusted to maintain the ideal environment for the crop.”

For those looking to retrofit older greenhouses, Coulter says they’ve been able to add natural ventilation to many older greenhouses over the years.

“All that is required is for us to know the structural details of the existing greenhouse, the geographic location for climate data, and the crops you are growing. From there we can build a plan with the grower.”

How to set traps, identify and scout for the pest.

BY CARA MCCREARY, CASSANDRA RUSSELL AND AMANDA TRACEY

Pepper weevil is an economically damaging pest of greenhouse and field peppers. Successful management begins with diligent monitoring programs aimed at early detection followed by a rapid response.

Here’s how you can monitor for pepper weevil inside and outside of the greenhouse, using pheromone-baited sticky traps and proper scouting practices.

The most reliable tool to assist with early detection is a pheromone trap, which often consists of a large yellow sticky card and pheromone lures. These lures contain chemical compounds that work as aggregation pheromones to attract both male and female adult pepper weevil.

In greenhouses, traps should be set up around the outside perimeter of the greenhouse and inside the pepper crop. Traps should be in place as soon as the new crop is planted, but they can also be used in a clean, empty greenhouse before planting to capture any residual weevils.

For greenhouse use, a minimum of ten traps per hectare, or four traps per acre, is recommended. Increasing the number of traps can improve the likelihood of early detection.

There are kits available for setting up pheromone traps. In the accompanying video to this article on GreenhouseIPM.org, the kit being shown uses a large yellow sticky card with one hole on the bottom and three holes at the top.

For use outside, begin by placing the bottom of the stake through the bottom hole of the large

TOP As pepper weevil is diurnal, monitoring for adults should occur in the daytime.

BELOW If there are signs of pepper weevil on the outside of the fruit, cut it open for a look inside.

Is the moisture content in the growing substrate too high?

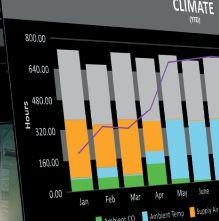

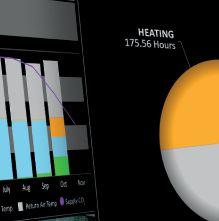

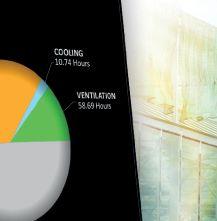

Ridder HortOS Grower is the online tool that brings together all the relevant climate, production, cultivation and crop data from the various crops and greenhouse locations, and presents this in one place. The Grower Module is available within the HortOS platform and provides direct insight into the progress of the crop in relation to set long-term goals. In the presentation of these data, the emphasis is on monitoring yields and efficiency. So whether it involves day-to-day greenhouse operations or long-term strategic decisions, HortOS enables the entire organization to work together to drive growth and profitability. RIDDER.COM/HORTOS

ABOVE

Signs of damage indicative of pepper weevil may include dimples or egg-laying scars on the fruit [left], as well as yellow calyxes, circular exit holes [right], and holes in flowers and leaves.

yellow sticky card. Remove the paper from the top down on both sides just enough to reveal the three holes at the top of the yellow sticky card and slide the top of the card through the top loop of the stake.

This particular kit also contains two different lures. The first lure is a long clear tube with a cap on the end. Leave the cap closed and slide it into one of the outside holes on the top. Carefully slide the second rubber lure into the outside hole on the opposite side. Lastly, remove the rest of the paper coverings and place the stake in your desired location. In the field, this should be at plant height.

For placement inside a greenhouse, use a twist tie or clip to secure it to a wire or post.

The pheromone lures should be stored in a refrigerator prior to use and placed in a cooler during transport.

Once set up, be sure to check the traps once or twice per week.

If you spot a weevil caught on the

sticky card, it is important to properly identify it. Use a hand lens to get a closer look at the captured insects, which may include other weevil species.

Understanding pepper weevil’s distinguishing features can help with identification. These features include: a long snout; strongly arched body; white or yellowish scales covering the thorax and elytra; mahogany to nearly black body; spurs on all six legs; and a circular concentration of scales just above the elytra.

If you are unsure or want confirmation, reach out to a trusted IPM specialist or send it to an identification service.

Refer to Greenhouse Canada’s June 2020 edition for a detailed guide on weevil identification, entitled “How to know when your weevil is evil.”

Once an adult pepper weevil has been identified on the trap, it’s important to conduct more thorough plant inspections.

Focus your monitoring efforts on

ABOVE

Affected fruit may contain pepper weevil larvae, pupae and/or new adults.

inspecting smaller fruit and buds, where females prefer to lay their eggs, as well as larger fruit, aborted fruit, foliage, and stems.

Damage may include dimples or egg-laying scars in the fruit, yellow calyxes, circular exit holes, and holes in flowers and leaves.

Be sure to inspect flowers and young folded leaves for adult pepper weevil. Pepper weevil are diurnal, so monitoring for adults should be restricted to daytime.

If any symptoms of infestation are observed on the outside of the fruit, the pepper can be carefully cut open to look for signs of pepper weevil on the inside.

Behind the egg-laying scar will be egg tissue. Inside there may be larvae, pupae, or a new adult, and signs of feeding such as blackened seeds and cores.

If you spot any infested fruit, be sure to remove it promptly and properly discard it.

To avoid re-infesting greenhouses or fields, do not pile or spread infested peppers or plant material near the crop. Check with your grower organization or local specialists for disposal recommendations.

Being proactive and diligent with your monitoring efforts will allow you to catch infestations early, improving your ability to manage pepper weevil and reduce crop losses.

This article accompanies one in a series of videos on GreenhouseIPM.org, generously funded by the Canadian Greenhouse Conference, with support from Greenhouse Canada and Flowers Canada.

Cara McCreary is the greenhouse vegetable IPM specialist, Cassandra Russell is former acting vegetable crop specialist, and Amanda Tracey is a vegetable crop specialist at the Ontario Ministry of Agriculture, Food and Rural Affairs.

Grodan presents the fully redesigned e-Gro, the ultimate platform to support your knowledge, experience and growing strategy with real-time insights and smart recommendations based on root zone, climate, crop and harvest data. Anywhere, anytime and on any device.

The more you know, the better you grow.

Relevant data from various sources in your greenhouse is displayed together clearly in a single place, in real-time.

Smart recommendations help you optimize your irrigation strategy and guide your crop to the desired balance.

e-Gro is a web-based application, and is available on all devices, enabling remote access to your greenhouse data anywhere, at any time.

Don’t take just our word for it, try it for yourself. Contact us today to set up your free e-Gro demo and in-house trial: www.grodan.com/e-Gro

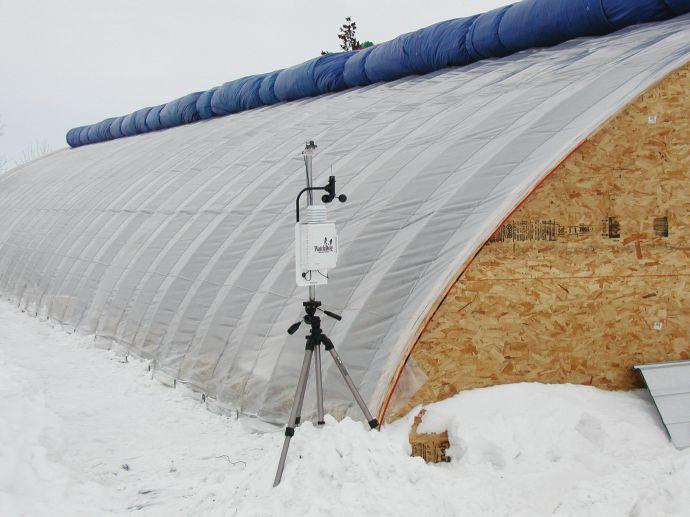

A research group at the University of Manitoba is working to supply northern communities with indoor cultivation technology, delivered in a shipping container.

BY GRETA CHIU

A research group at the University of Manitoba is working on a customizable and shippable growing system to help address issues of food security in northern communities.

Spearheaded by Dr. Qiang Zhang, professor in the Department of Biosystems Engineering, the design makes use of old shipping containers then adds insulation to the walls, installs grow lights, and builds other customizable parts tailored to the community’s needs.

Once built, individual elements are dismantled, packed into the container and shipped, ready for assembly at its destination.

Zhang’s group is now building out a prototype with a local company, using steel containers from Canadian Pacific Railway. If all goes according to plan, they hope to have it installed in an Indigenous community located in northern Ontario later this year.

“For the first demo unit, we’re going to be us-

ABOVE

ing an electric boiler to heat the container,” Zhang says. Other heating options that his group has explored include a wood pellet biomass boiler as well as a solar-powered hot water system designed by Natural Resources Canada. Both could be options depending on a community’s needs.

The container is also designed to hold an onboard water treatment system, as well as enough capacity to store weeks’ worth of water. Because residents of the partnering community showed greatest interest in tomatoes and strawberries over leafy greens, researchers opted for a soil-based growing system. But the container could just as easily be outfitted with a hydroponic system.

For ventilation, they’ve created a negative pressure system within the growing container. Using the exhaust fan, air is drawn into the container through holes in the walls and distributed along perforated air ducts that run within.

Once the prototype is in place, Zhang’s group

This shipping container is being turned into an enclosed growing environment, the prototype of a customizable and shippable system being developed at the University of Manitoba.

hopes to figure out the best growing conditions for different crops, and in this particular case, tomatoes. “In the demo unit, we have all of the controls built in – temperature, humidity, CO2, lights. Everything can be controlled and monitored through wi-fi.”

He adds, “We will also monitor energy consumption, water consumption, and see how much it’s going to cost to run a system.” By tracking yields, they’ll be able to quantify the amount of resources needed for production.

“The idea is to have clusters of these containers,” he says. “The master container is the main one with all of the controls and heat source in it. Then you can hook up a few ‘slave’ containers to share the same brain and heat source.”

But their vision for these enclosed container systems doesn’t end there.

solar radiation. After sundown, the wall releases retained heat back into the greenhouse.

“This type of greenhouse is actually very energy-efficient,” he says. Zhang’s group tested this design without supplemental heat near Winnipeg. “Our tests showed… we can actually maintain the temperature in the greenhouse at night, pretty much above zero throughout the winter. Occasionally, it dipped a little below zero for extended cloudy periods, but it recovered very quickly.”

As for the south-facing side, they found that there was no need for a glazing surface at night, “so we put an insulation blanket on top of the glazing surface to further reduce heat loss.”

With its energy-efficient design, this type of greenhouse could be used in northern growing conditions as a way to extend the growing season. Two have been deployed commercially so far: one in Elie, Man. and another in St. François Xavier, Man for vegetable production.

“Typically in Manitoba, most people

About a decade and a half ago, Zhang’s team successfully designed a solar energy greenhouse that replaced the north-facing side with a solid wall.

“If you think about it, why do you need a transparent surface on the north side of the greenhouse? There’s not much solar radiation coming from the North,” poses Zhang. “By putting a wall there, it does two things to make this greenhouse more energy-efficient.”

First, the design cuts down the glazing surface by half, which reduces heat loss. The wall also helps stop the infiltration of cold air, which would otherwise displace the warm air within the greenhouse and lead to greater heat loss.

Second, the wall acts as a heat reservoir. “The wall is actually built with two main layers. The interior surface of the north wall is a solid material – it could be concrete, it could be gravel. We used rammed earth, but that layer is about six inches of solid material acting as thermal energy storage, and then there’s another layer of insulation.”

During the day, the wall soaks up

When you need proven, biological plant protection for greenhouse vegetables, greenhouse

ABOVE and RIGHT

The solar energy greenhouse replaces the north-facing side with a solid wall and uses an insulation blanket to reduce heat loss.

wouldn’t even start the greenhouse until late March or early April, and then everything has to be shut down by October,” he says. “But with this system, you can actually…start in February and you can grow all the way until November without supplemental heating.”

“The final idea is to put these two together,” Zhang says of the enclosed container system and the solar energy greenhouse. “We can actually build the greenhouse components, put them into the container and then take it north.”

In addition to serving as the north wall of the greenhouse, the growing container could be used for cultivation in the winter as well as a spot to start seedlings. “Then by April, you can move your plants from the shipping container into the greenhouse.”

The integrated system is still in its early design stages, but Zhang says it’s something they would prioritize if there’s

enough interest.

In the meantime, the group hopes that their work can help relieve issues of food security, spur interest in horticulture and serve as a hub for northern and remote communities. Their shipping container project has received support from T&T Seeds, Winnipeg Environmental Remediations Inc., True North Aid, and Indigenous Innovations Corporation.

There are challenges and the most important one is energy, says Zhang. With many remote communities relying on diesel, electricity becomes expensive and fresh food becomes unaffordable.

“I thought, as an engineer, why not try something from the engineering perspective? We can use technology to make it possible to grow in northern communities.”

Growers know that when it comes to controlling and monitoring a production environment, a simple, flexible, sustainable control system is crucial. This is why you can depend on Reliable Controls. Our nationwide network of factory-certified Authorized Dealers will help you design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective, Canadian-made solution, please contact a Reliable Controls

Authorized Dealer near you.

Canada: 403.561.4148

Canada: 647.982.7412

Bumblebees may be self-sufficient outdoors, but to get the most from their pollination activity in greenhouses, it’s important to understand their needs and how to best meet them.

BY MELISSA HARGREAVES

BELOW

Bumblees use a unique technique to access pollen deep within tomato flowers.

In the late 80s, the bumblebee was discovered to be the best pollinator for greenhouse tomatoes. Since then, they have been used in almost all instances of greenhouse tomato production.

The secret to their success is their “buzz” pollination technique.

Tomatoes have pollen-bearing stamens hidden deep within the flower. Most insects are unable to reach these stamens, causing poor fruit development and small yields.

Bumblebees, on the other hand, are able to vibrate these flowers to release the pollen that is firmly held by the stamen. While this type of pollination increases the overall yield of the crop, greenhouse growers sometimes forget that bumblebees also require attention. They cannot be placed, then forgotten.

Here are six key factors to be aware of when using bumblebee hives in your greenhouse.

At the bottom of each hive, you will find a bag of sugar water. This acts as a nectar source and is important for crops like tomatoes which do not produce nectar.

Due to the lack of nectar from the crop, it is important to have a constant source of sugar water, either with the sugar water bag underneath the hive, or if that is depleted, in supplemental bags placed on top of the hive stocks.

When bees run out of sugar water, they can

become aggressive, stinging workers and fighting with other hives to steal sugar water. If there is not a sufficient amount of nectar inside, the bees will leave the greenhouse to find it once the vents begin to open, causing a drop in pollination levels.

Too many hives or pollination levels that are too high can result in starvation.

In most situations, healthy tomato crops provide more than a sufficient amount of pollen for the hive to develop properly, provided that an excess of hives have not been introduced.

Pollen provides fat and protein. Too many hives and/or pollination levels that are too high can lead to an insufficient amount of crop pollen and result in the starvation of hives. Telltale signs include the appearance of extremely dark, bruised flowers and aggressive bee activity. This can dramatically reduce the life expectancy of hives, increasing pollination input costs.

It is best to try and maintain a medium level of pollination or four to five bites per flower. In the event where there is an insufficient number of open flowers in the crop or perhaps none at all, hives need

As tomatoes do not produce nectar, it’s important to have sugar water sources in the greenhouse.

to be fed a small amount of pollen every other day, roughly a quarter of a tablespoon.

In greenhouse pollination, the majority of significant pesticide side effects stem from neonicotinoids, especially imidacloprid (Intercept). Even extremely low doses, such as the treatment of plants at propagation or contamination in recirculated solutions, can cause serious side effects that sometimes last for months. It is best to follow product recommendations and research potential side effects, which are typically listed by reputable bumblebee producers.

Artificial lighting is known to create a more challenging pollination environment. This is because bees become disorientated with an insufficient amount of natural light, especially during the winter months. Artificial lighting also speeds up hive development, expediting a decrease in the viability of the hive compared to a non-lit greenhouse.

When introducing hives into greenhouses that use artificial lighting, the hives need to be timed to open and close every day on a specific schedule. They should be open once the sun reaches the side wall of the greenhouse, and two hours prior to sundown. This way, the bees are foraging with sufficient natural light. Roughly, the hives in eastern Canada should only be open between 10 am and 3 pm, giving the bees enough time to return home before sunset.

Automatic openers are available and can be easily connected to environmental control systems, replacing the labour of opening and closing hives on a daily basis.

Here are a few important tips when placing hives inside the greenhouse.

First off, it is best to always face the hive doors away from each other, so the bees do not drift. Bee drift causes worker bees to move from one hive to the other, eventually starving the brood and rendering the hive useless.

Secondly, when stacking hives on top of each other it is important to place the newest hives at the bottom of the stack. This will make things easier when hives need to be pulled out of the greenhouse.

Third, hives should be placed in a location that is easily accessible to the

central greenhouse pathway for visibility, as this is their runway.

To ensure a healthy bumblebee population, removing hives is also extremely important for many reasons. Old hives can steal sugar water away from a new hive. They can also increase the chances of developing pests and diseases, which can spread from colony to colony. Furthermore, they are known to drain worker bees from newer hives, as the bees are attracted to larger colonies.

Hives

The greenhouse environment can also cause pollination issues.

Higher temperatures (e.g. summertime, over 30°C) can cause the bees to stop foraging for pollen, as they are more likely to be fanning the brood. This is when worker bees use their wings to ventilate the hive, keeping the larvae cool in the intense heat.

A high relative humidity (over 85% RH) will cause the pollen to become sticky and adhere to the stamens. Many growers tend to add extra hives to compensate for poor air conditions, however this only compounds the situation, particularly when the temperature and humidity levels return to normal and there are too many hives competing for the same flowers.

In these last 30 years, we have learned how important bumblebees are to commercial greenhouses and how to optimize each hive, gaining respect for these pollinators in the process.

At the end of the day, these six key factors should always be in the back of your mind when using bumblebee hives in a greenhouse. Each one will affect the bumblebees in a specific way, which will have an effect on pollination, and ultimately, the final product.

Melissa Hargreaves is an inside technical consultant and media coordinator at Koppert Canada. She can be reached at MHargreaves@koppert.ca

In a survey conducted earlier this year, greenhouse producers shared highlights from 2020 and plans for expansion, technological investments and more in 2021.

BY GRETA CHIU BELOW

More than half are raising prices, and sales forecasts are looking good.

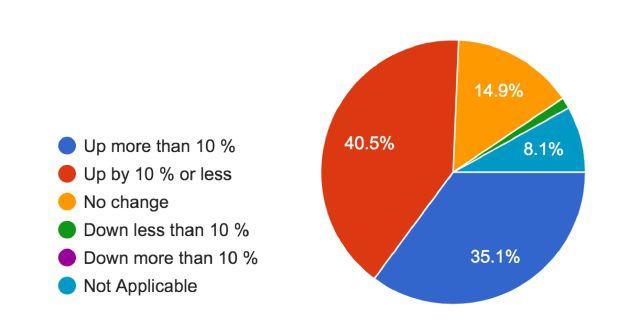

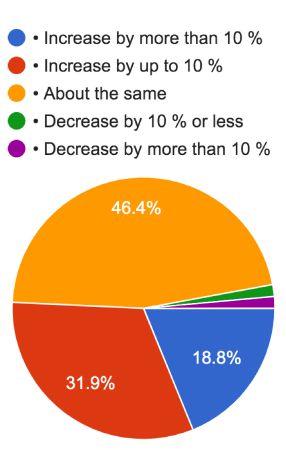

Price change for 2021? Overall, are you:

What are your sales forecasts (volumes) for 2021 compared to 2020?

The Greenhouse Canada grower survey returned for 2021 this year, taking a snapshot of the industry as the Canadian economy continues to deal with the effects of COVID-19.

We received 75 qualified responses from producers in the controlled environment agriculture sector in Canada. Knowing that, it’s best to treat these results as informal or anecdotal. Because some growers selected a mix of different growing spaces and/or crops, percentages won’t necessarily add up to 100.

Among the respondents, 87 per cent were growing in greenhouses and 12 per cent producing in vertical farming or another type of indoor growing space.

Ornamental and vegetable growers were targeted in this survey. 65 per cent identified as retail growers, while another 62 per cent identified as being wholesale and/or young plant growers.

Some chose “other”, focusing on crops such as herbs, plants used for reclamation sites or host plants for pests.

In terms of province, the majority were located in Ontario (43 per cent), followed by Alberta (28 per cent), British Columbia (15 per cent), Saskatchewan (9 per cent), with some representation from Nova Scotia, Manitoba, Newfoundland & Labrador, Quebec, Prince Edward Island, and the Yukon.

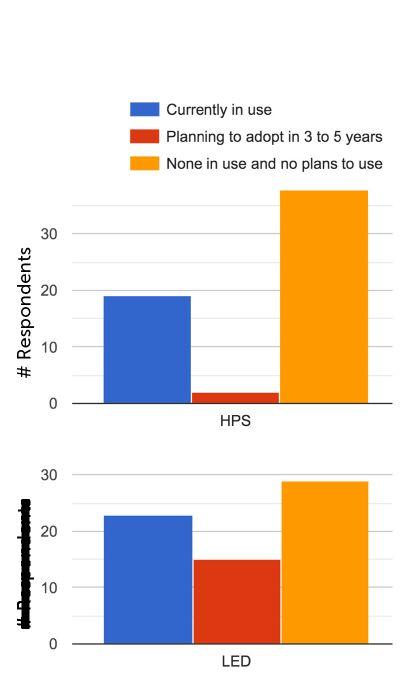

Are you using supplemental lighting in your crops?

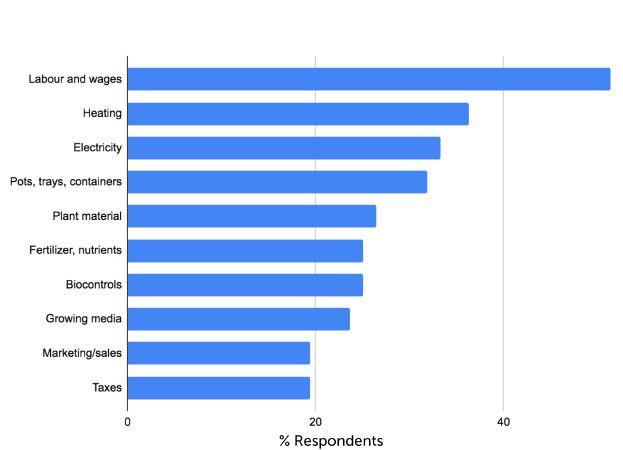

Which input cost rose the most in 2020 compared to 2019?

Over 55 per cent of respondents worked in operations measuring under 50,000 square feet, where half of this group was made up of retail growers. The rest of the operations were fairly evenly spaced out between 50,001 to 350,000 square feet, and over 1,000,000 square feet.

The majority grew product for their own retail shop (43 per cent), wholesalers (33 per cent), and mass merchandisers/box stores (28 per cent), followed by independent garden centres (21 per cent) and other growers (19 per cent).

We also asked growers to identify the crops they primarily grow. Here were some of the frontrunners (i.e. not exhaustive).

Ornamentals: Flowering potted plants (39 per cent), ornamental bedding plants (37 per cent), perennials (33 per cent), tropicals (22 per cent) and cut flowers (17 per cent).

Vegetables: Tomatoes (46 per cent), peppers (39 per cent), cucumbers (36 per cent), strawberries (25 per cent), eggplant (20 per cent), leafy greens (32 per cent), herbs (39 per cent) and microgreens (7 per cent).

When compared to 2019 sales, 70 per cent of respondents reported an increase in sales. 44 per cent experienced an increase by more than 10%, 16 per cent saw increases between 5 and 10%, while 10 per cent said sales increased by less than 5%. 12 per cent experienced declines in sales.

Breaking down the numbers a bit more, 85 per cent of retail growers said they experienced increases in sales. For wholesale growers, this was 62 per cent, whether combined or broken down by crop group.

How did growers net out with costs in tow? 66 per cent reported increases in profit margins, while 14 per cent reported declines.

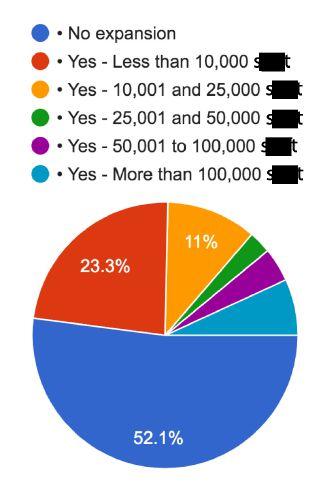

Price-wise, none of the respondents indicated any plans to reduce prices. 58 per cent will be increasing them, with 50 per cent looking to raise prices by up to 10% (rounded up). 32 per cent of respondents will be holding steady.

Sales forecasts are looking great. In total, 75 per cent of respondents said they’re expecting higher sales for 2021 compared to 2020. 41 per cent expect sales volumes to be up by 10% or less, while 35 per cent expect this rise to be more than 10%.

A number of input costs rose in 2020. When asked to identify three inputs that increased the most in cost, 51 per cent of respondents identified labour and wages as one of the top. This was followed by heating, electricity, and pots/trays/containers.

For most growers, there was no change to their use of biocontrol agents and biopesticides, regardless of whether they were applied against mites and insect pests or diseases. To clarify the definition of these products, the survey specifically noted that biocontrol agents included predators, parasitoids, and pathogens, while biopesticides included living microorganisms and chemicals derived from natural sources including mineral oil.

As for lighting, 34 per cent of surveyed growers indicated that they currently use LED lighting, with 22 per cent looking to adopt this technology in the next three to five years. In general, a greater number of producers expressed interest in adopting LED over HPS, supported by a higher level of disinterest in adopting HPS compared to LED lighting.

Cited as the input cost which rose the most last year, over half of the survey respondents said there were no changes to the level of labour employed in their operations last year. 38 per cent found that this number rose.

For 2021 however, 51 per cent believe that their labour needs would rise. Less than three per cent forecast a reduction in labour.

Almost two-thirds of surveyed producers said they did not expand in 2020. One fifth said they expanded by less than 10,000 square feet, while eight per cent expanded between 10,001 and 25,000 square feet.

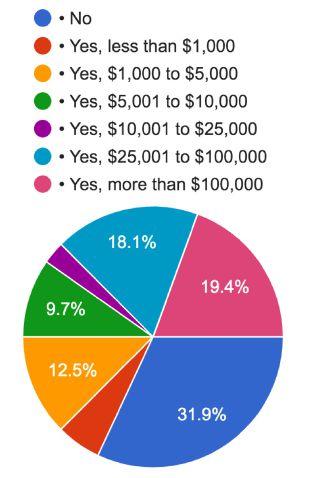

Do you plan to expand/ build in 2021?

Do you plan to invest in new equipment in 2021?

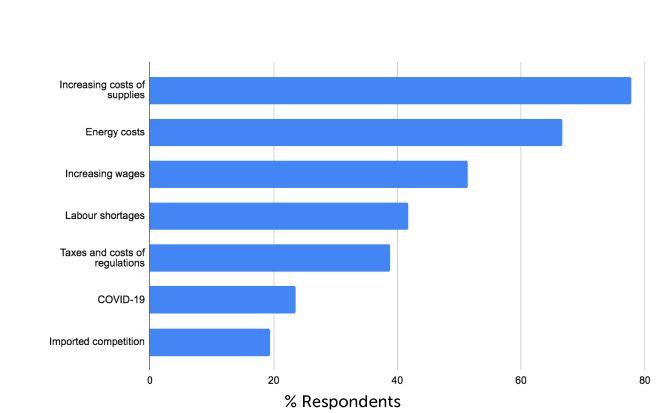

Which of the following do you see as business threats in the next 3 to 5 years? (select all that apply)

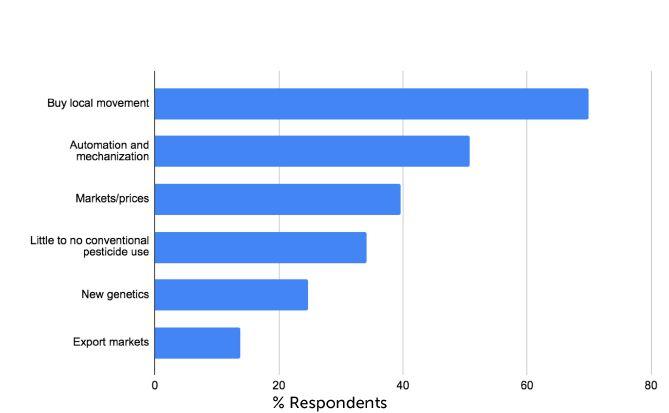

Which of the following do you see as opportunities in the next 3 to 5 years? (select all that apply)

Plans for expansion were a completely different story for 2021. Almost one-half plan to expand this year. Two-thirds also plan to invest in new equipment, with 19 per cent looking to spend upwards of $100,000, and 18 per cent planning to spend between $25,000 and $100,000.

Social media use for work was very fragmented among the respondents. 31 per cent said they use it occasionally (approximately several times per week), another 30 per cent either use it rarely (a few times a year) or not at all. 21 per cent use it frequently to very frequently, checking once or more than once per day.

Looking specifically at the retail segment, this group appeared to have a higher rate of social media use. 15 per cent said they do not use or use social media very rarely. 29 per cent use it a few times a month, while 25 per cent use it several times a week. 31 per cent use it frequently to very frequently.

Also looking specifically at retail, 54 per cent said they already have e-commerce platforms set up on their website. However, 31 per cent have stated that they do not, and have no plans to do so.

Coming out of the first year of COVID, surveyed producers cited the biggest challenges as unclear regulations and temporary closures of sales points. This was followed by difficulty in recruiting local workers. Housing issues, lost or delayed temporary foreign workers, reduced markets, and issues with access to personal protective equipment all rounded out the last of the more popular answers.

Corroborating with previous answers, the majority of respondents identified increasing cost of supplies (78 per cent), energy costs (67 per cent) and increasing wages (51 per cent) as the top three business threats in the next three to five years. Only 24 per cent saw COVID as a potential threat.

As for opportunities, the buy local movement received a nod by 70 per cent of survey takers. This was followed by automation and mechanization (51 per cent) and markets/prices (40 per cent) and little to no conventional pesticides needed (34 per cent).

Looking for more? Check out pg. 6 for an infographic summary on sales in 2020.

JUNE 22, 2021 FLOWERS AND VEGETABLES

Albert Cramer, Rolling Acres Greenhouses, AB

MEET WITH EXPERTS AND GROWERS FROM ACROSS THE COUNTRY, AND DISCUSS THE LATEST IN RESEARCH, TECHNOLOGY AND PRODUCTION PRACTICES.

SESSIONS WILL HIGHLIGHT NEW TRENDS, TACKLE ISSUES FROM A LOCAL PERSPECTIVE AND PROMOTE DISCUSSION AMONG FLOWER AND VEGETABLE GROWERS TO ADVANCE THE INDUSTRY.

Lorne & Kelsey Metropolit, Yukon Gardens, YT

Marc Schurman, Atlantic Grown Organics , PEI

Dr. Rupp Carriveau, University of Windsor, ON

Lucas Semple Under Sun Acres, ON

Marco deLeonardis, Freeman Herbs, ON

Louis Brun, Sollum Technologies

Dr. Fadi Al-Daoud, Ontario Ministry of Agriculture, Food and Rural Affairs

Rodney Bierhuizen Sunrise Greenhouses, ON

Filling The Gaps In Your Business Profit Margins

Melhem Sawaya, Focus Greenhouse Management

Dr. Sarah Jandricic, Ontario Ministry of Agriculture, Food and Rural Affairs

Hailey Ashbee, Kam’s Growers Supply

Ashley Summerfield, Vineland Research and Innovation Centre

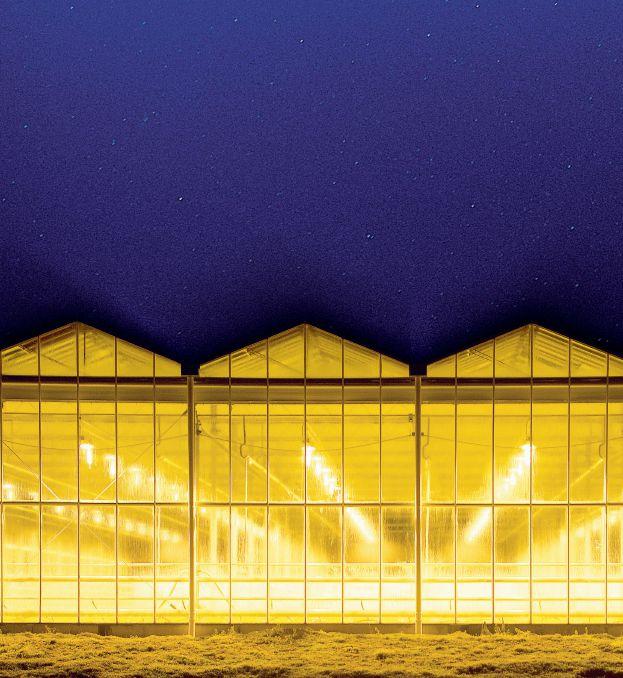

Canada’s low light and temperatures translate to a high light, high temperature requirement for greenhouse crop production. So what are growers to do, when light abatement bylaws impact not just the way they grow but the way their crops yield? In short, adapt and overcome.

Is it possible to comply, without sacrificing productivity and efficiency? There are options.

BY JOLI A. HOHENSTEIN

In Oct. 2020, the town of Kingsville, Ont. enacted light abatement bylaws, and in December, Leamington followed with its own requirements. Leamington’s bylaw mandates complete closure of light abatement curtains on greenhouse ceilings, sidewalls and endwalls one hour before sunset until one hour after sunrise, allowing a 10 per cent gap between 2 am and 6 am. (The provision on sidewalls and endwalls went into effect on Apr. 1, 2021, while the provision on ceiling curtains begins Oct. 1, 2021.) Meanwhile, the regulation in Kingsville does not allow any light to “shine upon the land of others” or

“into the dark night sky.”

Municipalities are implementing strict bylaws for greenhouse horticultural operations that are artificially lighting their crops to extend their growing seasons. Investments in light abatement screens not only provide these operations with the necessary resolve to contain the light but to also reduce their energy costs. To the municipalities, it seems a simple solution, but growers know the challenges are many. The good news: growers can comply with light abatement regulations without compromising crops or the growing climate, although adjustments to the growing strategy may be needed.

What can growers do to keep the light inside the greenhouse, and also use it in an optimal way for the growing process? They can’t eliminate the issues, but they are able to manage them, just in a slightly different way than they’re used to.

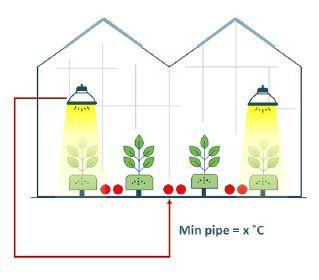

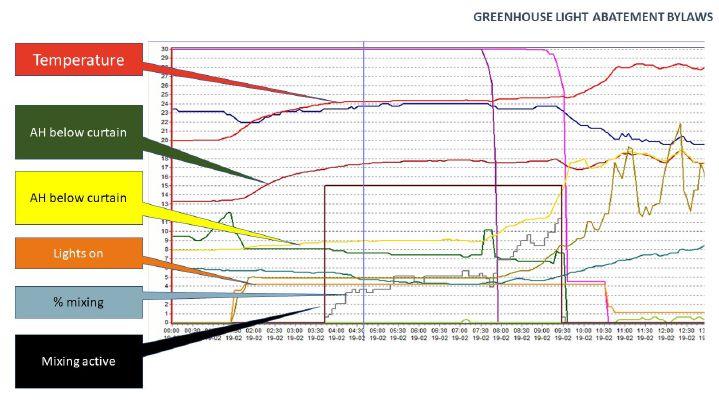

Curtain positions can be activated based on greenhouse conditions and time. Any gaps should come in gradually to avoid compromising the greenhouse climate. (Values are for illustrative purposes only.)

Light abatement blackout screens can be used to contain supplemental lighting. This is one way to comply with light pollution regulations and to keep neighbours satisfied. Furthermore, they can provide light deprivation for daylength control on the most sensitive of plants, such as cannabis, chrysanthemum, and kalanchoe.

There are several available options: horizontal screens for the ceiling and vertical options for gables.

Ton Habraken, greenhouse climate expert at Ludvig Svensson, points to two of the suppliers’ products as examples – the Obscura 9950 FR W which takes away 99.5% of the supplemental light and offers 50% energy savings, and the Obscura 10070 R FR W which offers zero light transmission and 70% energy savings.

“These screens aren’t just plastic strips; they’re knitted together with yarn, and although it might look like just one yarn, in fact it is a bundle of thin yarns,” says Habraken. “The bundle of yarns can absorb the humidity to help dehumidify the greenhouse. They are specially designed to provide high humidity transport.”

In a greenhouse measuring 20°C and 80% relative humidity (RH) below the screen, and measuring 10°C and 80% RH above the screen, Svensson’s studies show that the Obscura 9950 can transmit water at a rate of 47 g/m2/h. That’s quite a lot of humidity, especially if a tomato crop at

ABOVE

Adjust minimum pipe temperatures to manage any imbalances caused by light abatement. Programming can be specific to screens open (left) or closed (right).

rest, without artificial light or a heating pipe to activate it, produces half that amount of water at 20 to 24 g/m2/h.

Managing those factors is critical, says Lars van Baar, a Dutch grower who has been producing tomatoes under light abatement regulations for 10 years. “You need a strategy for when there are temperature extremes and you can’t vent the greenhouse,” he says. “You have to deal with the temperature.”

The main driver of humidity transfer through the screen is the difference in absolute humidity (AH) above and below the climate screen, says Habraken. Using the same greenhouse conditions described, the AH difference is 6.5 g/m3 This means a possible humidity transport of 47 g/m2/h for the Obscura 9950 FR W.

However, when a greenhouse is heated, the crop’s humidity production will be much higher. If greenhouse lights are on as well, it is a much different circumstance. Humidity is not an issue when the screens are fully open or when they are gapped. Once the screens are fully closed and the lights are on, heat collects in the top of the greenhouse, causing a vertical temperature difference, which in turn causes an imbalance in crop growth.

To get rid of the extra heat and humidity that comes with closed greenhouses, the simplest solution is opening the screens and vents – but not all light abatement bylaws allow that. “So, to get rid of the extra humidity, growers can open the

Single layer Obscura light abatement screens have been preventing supplemental lighting from escaping greenhouses at night for over a decade, letting neighbors get a good night’s sleep.

Effectively reducing greenhouse light emission at night, OBSCURA 9950 FR W* is designed to meet the legislation of various authorities and the well being of neighbors and nature. The white underside of the screen increases light intensity within the greenhouse, while the white upper side of the screen helps to prevent heat build up.

*) Made with flame retardant materials alone – adhering to strict North American fire codes

vents above the closed [light abatement] screen, until the humidity gets too high and the heat is too much,” says Paul Jense, technical trainer and horticultural consultant for Priva. “You’ll also want to have a pipe to heat the bottom of the crop so there isn’t a difference between the roots and the top of the canopy.”

Another strategy is shifting lighting phases. For example, if bylaws allow gapping at 2 am, shift the lighting period to start just before that time. “Switch on half the lights just before 2 am, then switch on the second half when you are allowed to have a gap at 2 am, so you have the full power of the lights,” says Habraken. “This way, you bring the lights a little further into the evening, but when the lights are off, you can gap the screens partially or fully to reach the pre-night temperature. This could be a solution for the Leamington area. In Kingsville, it might be a good idea to switch the lighting period to a few hours later so you can use the coolness of the night to get a lower 24-hour average temperature.”

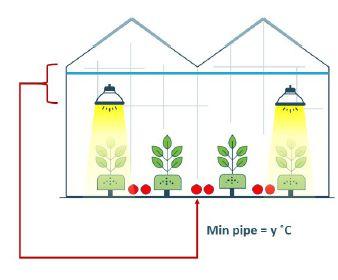

Climate control is still possible with light abatement, says Jense, with a few considerations. “If you are allowed to have a gap in your screen, make sure the gap comes in gradually, and that your computer is configured as such,” he says. “You can lose your climate in just a few seconds if it isn’t introduced gradually.”

Minimum vent openings can be set based on curtain positions, lights and other measurements, but Jense says basing it on the P-band may be a better bet.

Even if a gap is possible, it is still critical to manage the greenhouse climate carefully. To manage the vertical energy imbalance caused by the increased heat that comes from lights and the decreased pipe temperature under a closed screen, Jense suggests implementing a higher minimum pipe temperature. “When you have your curtain closed and lights on, you need an alternative strategy or correction to your setpoint,” he explains.

In turn, this may create another challenge, Jense says, but he has a solution. With the lights on, the crop is very active. Temperature and AH are both high. At some point the plant can’t get rid of its humidity anymore, and growers need to open vents. It’s critical to do that carefully.

“As an additional measurement, it’s

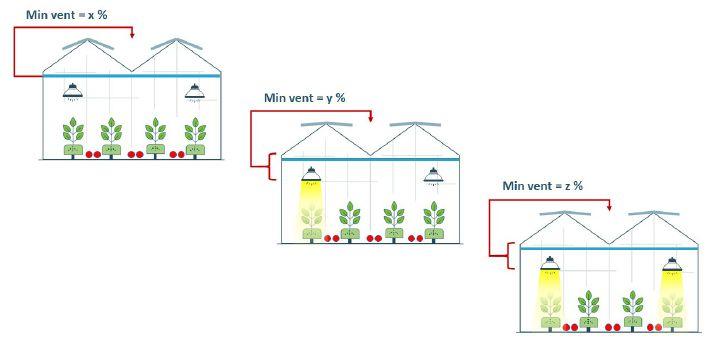

ABOVE

Screen shot of a customer’s actual greenhouse system. Note that as the light switches on, the temperature increases and AH increases. As the vertical fans mix the air (boxed area), greenhouse temperature and AH stabilize below the curtain.

common to have sensors that measure temperature and humidity above the curtain. You can influence minimum vent position based on AH or AH difference,” he says. “Even if you don’t have that, you can still do something. For instance, use different minimum vent positions for curtains closed, curtains closed and lights on, etc.”

There is a downside to adjusting this way, however. At some point the grower doesn’t know whether it’s too much or too little, because it only controls the minimum vent position. “Perhaps a better approach would be to adjust your proportional band (P-band),” Jense says. “That decides how aggressively your vents will react. A smaller P-band translates to more aggressive vent opening. With a smaller P-band, you could have 50% vent position, for example, compared to 10% with a larger P-band.”

Unfortunately, growers aren’t always able to open their vents, or they are limited in their ability to open the vents, such as with storms or rain. Gapping the screens can also cause huge temperature differences in the greenhouse, due to warm air rising above the screen to the attic, cooling down against the cover and traveling to the lowest point, causing a cold draft on the crop. In fact, it can cause a horizontal temperature difference – as much as 5 °C. Heating and lighting can accelerate that. With screens fully closed, growers can make full use of the reflection of the light, which can increase their lights’ efficiency significantly. If there are

no gaps, and growers can’t vent above the screen, they need some extra tools to control the climate in the growing area.

One answer is supplemental dehumidification technology. Habraken uses the Hinova Ventilation Jet system as an example, which combines two fans to provide controlled ventilation of the growing area, even with the screens fully closed. “One speed-adjustable fan draws in fresh air through a slender, rectangular tube from above the screen into the growing area, and then a vertical fan mixes fresh, dry air with warm, humid greenhouse air and distributes it to provide a homogenous climate,” he says.

Vertical air movement also influences the microclimate around the leaf. Good airflow makes it easier for plants to release humidity through the microclimate layer. “Normally we do this through air movement caused by the pipe, but that is rather expensive,” he says. “It’s easier and cheaper to do it with a vertical fan.”

With this system, growers do not need to make any cuts to the screen as they often have to with other similar systems. Instead, the screen runs around the ventilation jet tube without any adjustments. This way, growers can have the screens fully closed and the lights on but still bring fresh air into the growing area.

For growers who aren’t sure where to start with light abatement, or do not want to make large adjustments to their climate control, where can they begin?

“If you don’t have a measuring box above your climate screen, that’s the first and easiest return on your investment,” Habraken says. “Install one with a temperature and RH sensor, and even better, also install an RH sensor outside, so that you can have full control and good visualization [of] where the differences in AH and temperature are and you can take the right steps.”

Used correctly, those steps could be sizeable assets to any installation or light abatement strategy.

Joli A. Hohenstein is a horticultural communications professional, writing on behalf of ACT. ACT is an educational platform dedicated to the needs of the hightech cultivation industry.

Greenhouse environments are already among the most automated and controlled on the planet, but similar to what’s occurring in many sectors, artificial intelligence (AI) systems are now taking control to unprecedented levels.

A close look at how artificial intelligence systems are already making inroads to help growers better manage their energy use, improve yields and more.

BY TREENA HEIN

Because of their ability to process enormous amounts of data and make tiny, continuous adjustments, AI systems are beginning to provide greenhouse operators with a myriad of production-related benefits – and paying for themselves in a very reasonable period of time.

“AI is now providing greenhouse operators with a much greater ability to fine-tune environmental control,” explains Dr. Fadi Al-Daoud, greenhouse vegetable specialist at the Ontario Ministry of Agriculture, Food & Rural Affairs. “To do its job well, to control not only the macroenvironment but also the microenvironment within the canopy, an

AI needs large amounts of sensor data not just for temperature and humidity, but light spectrum, water quality, light intensity and more. Using this data, the system then can adjust vents, curtains, light spectrum or intensity or angle, and so on accordingly, to produce the best crop results. Financially, it’s the better crop results and also the small incremental differences in energy use, day in and day out, that give you the savings over the long term.”

Al-Daoud adds that AI can also be harnessed in terms of modelling to forecast the needs of a crop. “A grower can obviously do this as well, but the program will eventually have large amounts of past data available that’s specific to the operation, and can ‘play the long game’ for the whole growing season,” he explains. “The use of AI also allows labour to be more directed and therefore much more efficient.”

Both Guido van het Hof of Great Northern Hydroponics [left] and Neil van Steekelenburg of CosMic Plants [right] say the IIVO system has allowed them to consolidate greenhouse sensor data and heighten efficiencies.

How can current AI systems – or systems that approach AI – provide these and other benefits? Here’s a look at current systems being tested or installed in Canadian greenhouses.

The cloud-based Crop Controller system by Blue Radix takes into account the grower’s own unique crop strategy, along with

all available greenhouse environmental data. It changes conditions where needed every 15 minutes to maintain an optimal climate for the crop, crop stage, ambient light and so on. The company does not sell sensors but offers Crop Controller on a monthly subscription basis. The greenhouse’s existing measure boxes and sensors are used, but “if a grower chooses to invest in additional sensors,” says CEO Ronald Hoek, “we advise what is valuable in combination with our smart-steering algorithms.”

ROI depends on several individual elements, he notes, including yield optimization and current yield levels. “We see huge differentiations between greenhouses of the same size and with the same varieties,” Hoek explains. The system makes adjustments to the environment to help improve the crop and to realize ROI gains, he says. It can also correct missteps that may have occurred without it, and significantly increases the area that can be managed by one grower.

Blue Radix is currently working with 16 greenhouse companies – one in the U.S. and the rest in Europe. In Canada, it has announced a project funded by phase two of the Greenhouse Competitiveness and Innovation Initiative (GCII), collaborating with Ontario Greenhouse Vegetable Growers (OGVG). Starting with three producers, the project seeks to identify the value of autonomous climate management in Canada, as well as help Crop Controller address specific needs of Canadian climates.

Koidra also offers its AI system in a subscription model, with greenhouse owners generally needing to purchase some extra sensors, explains CEO and Founder, Kenneth Tran. In Ontario, Koidra is piloting its technology at Great Lakes Greenhouses in Leamington, a project also supported by the GCII and in collaboration with Harrow Research & Development Centre.

In early April, the trial at Great Lakes started with organic eggplant. “We have four acres of this crop in total and we have half of one of those acres as a control, and the other half of that acre with Koidra,” explains Great Lakes Greenhouses’ Research & Business Development Manager, Mark Reimer. “Both halves have the same sensors and equipment as the other acres or

organic eggplant, but there are a few extra sensors and cameras added in the Koidra trial area to enable remote viewing.”

The extra sensors, notes Tran, include infrared sensors to determine plant temperature. “Research shows that the ambient air temperature and plant temperature can be very different, and plant temperature is a much better predictor of plant response,” he says. “When we combine those readings in our model with net radiometer readings and hundreds of other elements, we can get a very accurate determination of transpiration and photosynthesis rates.” A few additional temperature and humidity sensors were also added near the top of the greenhouse to determine differences in these parameters between the plant growing area and above it.

This first trial is focused on seeing how the system functions, notes Reimer, and they expect that yields in the Koidramanaged area will be better than the control area. “We are also looking at inputs,” says Reimer. “We expect that most of the yield boost will come down to micro-managing the lights, dimming

them with more accuracy on sunny days and making changes to light spectrum. We plan to roll Koidra out to other areas of the greenhouse this fall.”

Tran says they are piloting with greenhouses in Ontario and B.C., as well as many in the U.S., including a partnership with AppHarvest in Kentucky.

IIVO, made by Hoogendoorn Growth Management, is described as “combining powerful algorithms, data from the growing environment and plant physiology,” with insights that “can be used to power AI and machine learning to grow ever smarter over time.” There are over 200 IIVO installations worldwide with about 50 sold so far in North America.

Great Northern Hydroponics recently implemented IIVO at its 70-acre tomato facility in Kingsville, Ont. Of the system’s capabilities, Great Northern’s President, Guido van het Hof says, “many ratios are being monitored and controlled such as light, temperature, humidity, screen positions, pipe or heating temperatures and

ventilation settings. There are additional sensors deployed in order to increase the resolution of data monitoring with GearSense cameras, Trutina biomass scale, plant temperature, moisture measurements, etc. All hardware that we already had installed has been integrated.”

The IIVO system autocorrects, explains van het Hof, meaning that his greenhouse no longer depends on the grower to first make the correct observations, then to react by manually changing the climate settings. “This relieves some of the grower’s ad-hoc response responsibilities and the grower can therefore oversee larger areas with less staff.”

In terms of the amount of time needed to fully utilize the system’s capabilities and see the benefits, van het Hof says IIVO’s ‘Data Driven Growing’ is “a completely new concept of climate control and requires a new way of thinking.” Extensive training is therefore required.

“This is why our growing team has returned to ‘plant physiology university’ with Hoogendoorn and LetsGrow, to understand all interactions between

ABOVE

parameters,” says van het Hof. “It is a three-year process and not a one-time switchover. The first focus is to learn, monitor and understand this new method. The second stage is learning by doing, and the last or third stage is total implementation and to run the greenhouse according to these new principles.” He expects ROI to be reached in three years.

In May, 2020, Neil and Mike van Steekelenburg, brothers and co-owners of Beamsville-based orchid producer CosMic Plants, had IIVO installed at one location which produces 18,000 orchids weekly. They liked the system so much that they installed it at their other location two months later, which is forecasted to produce 16,000 plants weekly.

“It’s very easy to use and you can include an unlimited number of settings and influences based on the measurements coming from the many installed

sensors,” says Neil. “You spend a lot of time at the beginning deciding what you need and getting the settings right, and then once it’s set up, it’s so simple. In addition to ease of use, I believe it’s going to allow us to cut our growing phase from potting to flower-initiating. I have worked with Hoogendoorn for eight years and I have faith in their R&D. For example, our cycle between plug stage and flower initiation is 30 weeks, and with IIVO, we will get to 28 weeks through the way it avoids times of growth stagnation for the plants. It makes sure you have the right rhythms all year long.”

Van het Hof believes the use of AI systems will provide significant labour benefits.

“AI will become the new standard in many Canadian greenhouse operations and will allow people to grow their greenhouse

ABOVE

Great Lakes Greenhouses will be trialing Koidra technology in eggplants.

footprint without the need to expand their management team,” he says. “In other words, greenhouses will be able to run a larger cultivation area under the direction of the same number of growers/managers.”

Hoek also lists labour as a main factor that will affect the rate of AI adoption in the greenhouse sector. “Many companies are concerned about the availability of experienced growers. This is an enormous challenge for the industry on a global scale and also in Canada. This urgency drives greenhouse owners to work with new innovative technologies,” he says. But first, they must show results and prove that there is value to Canadian growers.

Tran believes AI systems will be very common in greenhouses around the world within the next five years. The lack of skilled growers is making it harder and harder for greenhouse operations to achieve the yields necessary for profitability, he says, which is where AI comes in. “Even small increases in yield have a very large impact on the bottom line.”

But the technology cannot replace the grower.

“I believe in AI and it’s a huge help for growers, but I think it means also that growers become more important,” says van Steekelenburg. “The greenhouse operation becomes more sophisticated, but also equipment will still every now and then malfunction, so it’s very important to have skilled people to monitor and respond as needed.”

Treena Hein is a freelance writer based out of Ontario.

While it may come as a surprise to many, this grower didn’t always love greenhouse work.

BY ALBERT GRIMM

BELOW

The author working in the remnants of the family greenhouse, circa 1966.

This is my story of 40 years in the greenhouse. It is one of love and hate, a story of times that were difficult, but in the end carried a reward. Before I start, I can honestly say that I have no regrets. Work without difficult challenges quickly turns mind-numbing and monotonous, and I am happy that I was spared such a fate.

I did not always have this perspective. When I came out of high school, I was a beanstalk and a book nerd, void of any form of muscle. Even the German army considered me unfit for compulsory service, because they were afraid that I would not survive base camp. The last thing on my wish list was a career that involved physical work. My real interest was in particle physics, but I would not have turned down an offer to join a professional rock band. However, this was the late 70s. The economy was in the dumps and competition in the music business was fierce. My family was poor, and my stepfather thought that factory work was more honourable and appropriate than university. Student loans, as we know them today, did not exist and this was the end of my aspirations for higher education.

I had to look for something, an opportunity, where I could get paid while being educated, even if just to escape the auspices of my stepfather. My paternal family had owned greenhouses in the past, and this left me with some sentimental attachment to the trade. I found a greenhouse grower who was good enough to hire me as an

ABOVE

Tomato seedlings proved to require constant muscle work in the greenhouses where the author apprenticed.

apprentice for a small retail garden centre and florist shop. We grew everything: cut flowers, tropicals, potted plants, bedding plants, and even market vegetables in the field. Apprenticeship meant that I had to sign a binding, customary contract for two and a half years. I was paid a third of the minimum wage of an average greenhouse worker. I could not be fired, but I also was not allowed to quit without dire consequences. This binding arrangement turned out to be a stroke of luck for me, although it did not sink in until many years later. Within weeks, I had developed a passionate hate for my job and for everything that had to do with greenhouses.

Right out of the gate, my apprenticeship master set out with admirable patience to help me develop some muscle. He assigned me to some of the most physically demanding jobs that could be found. In those days, greenhouse work was very different. Growing substrates were prepared from loamy field soil that was first steamed, then mixed by hand with some peat moss, limestone, and slow-release fertilizer. First, we shoveled clumps of heavy soil into the steamer. Then we mixed each batch of potting

soil by shovelling it three times from one heap to another. For cut flowers, we turned the greenhouse soil by hand using a spade before we steamed between each crop. Staring down the length of a shovel or spade became a daily part of life. When we were not shovelling or spading, we were slugging heavy trays

In those days, greenhouse work was very different.

of plants. Our growing year started with the forcing of tulips and daffodils. In the fall, the bulbs were planted into heavy wooden crates. They were placed outdoors for vernalization, covered with several inches of fine sand and half a foot of leaf mulch for winter protection. When we were ready to force them for Valentine’s Day, we dug out the crates from beneath the snow and mulch. We carefully scraped the frozen sand from be-