Top 4 under 40 Meet this year’s determined and forward-thinking winners | 18

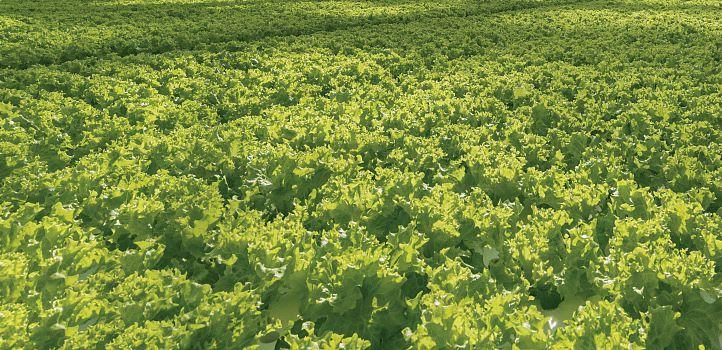

Growing on a small footprint Lettuce grower works to minimize costs | 24

Top 4 under 40 Meet this year’s determined and forward-thinking winners | 18

Growing on a small footprint Lettuce grower works to minimize costs | 24

This year’s leaders and innovators use collaboration and strategy to ensure their forward-thinking works for business success.

Editorial 5

Industry News 6 Les Exceptionelles 8 Combining beauty and high-performance

Small but mighty 24 Minimizing costs to consumers, the environment and the bottom line.

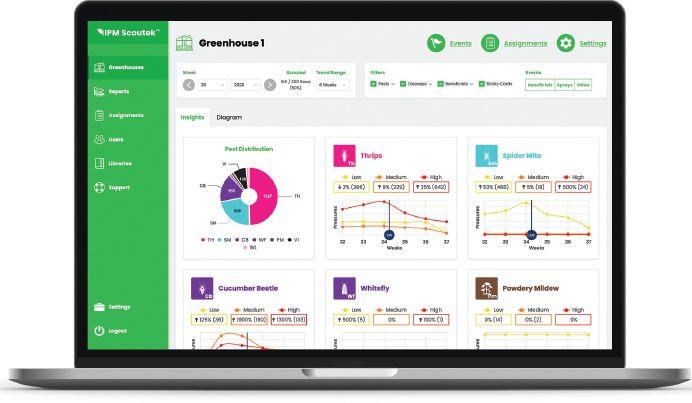

Home-grown tech 28 Knowledge transference: From cars to greenhouses

Inside View 38 Learning must be fun!

10 16 32

Tour with us Day-by-day coverage of the California Spring Trials: What’s new, what’s fun, what works.

CAST 2022 Coverage See page 10. Photo by Rodger Tschanz.

BY RODGER TSCHANZ

Collaborative efforts

Savings in energy and maintenance costs for growers.

BY LOGAN CASWELL

Year-round berries

Record-setting strawberry facility seeks to relieve Canada’s reliance on imports.

BY DOUG JOHNSON

The algorithms have really gotten me.You search for “workplace burnout” once and now I see it everywhere online. I’m usually editing the publications Massage Therapy Canada and Chriopractic + Naturopathic Doctor, and in them I wrote about buzzwords and how annoying they can be. But I neglected to include “burnout” in that, I believe. It’s everywhere, but only because it’s happening everywhere.

Perhaps you are experiencing it, or your employees and associates. Although descriptions vary, according to organizational psychologist Constance Noonan Hadley, burnout involves three distinct symptoms, and is defined by having all three of these symptoms at the same time:

year or so have implemented 4-day workweeks, shortened workweeks or allowed work-from-home schedules to continue to mitigate burnout and loneliness. One recent video on my newsfeed espoused the need of “Weekend Wednesday.”

“The traditional weekend at best is 50% efficient – it takes three days off just to feel like two days off. And two days off feels like one day off.” So, the creator goes on to tell their audience, to simply move a day off to Wednesday. Pros and cons for everything, right? Personally while this wouldn’t work for me, I actually had a “Weekend Wednesday” in university and thrived with that schedule.

But as growers and with this industry as a whole, we know that full schedules are our reality. I had the delight to be in touch with our awesome Top 4 under 40 award winners, and it’s clear that passion and a love for a challenge is what drives them all. From winner Mark Numan: “I love challenges, I love the challenge of learning to grow new

“Passion and a love for a challenge is what drives our growers.”

1) Energy depletion and exhaustion –the kind of exhaustion associated with burnout is more chronic and nonspecific. It doesn’t go away after a vacation, and it is not tied to a particular project or deadline. It feels like a persistent fog weighing you down mentally and physically.

2) Depersonalization and cynicism –what used to motivate and inspire you about your job no longer has the same effect.

3) Reduced efficacy – a drop in work performance. Perhaps you used to be great at your job and now you feel yourself slipping. So, if we know what it is, and how to recognize it, how can you support your colleagues or even yourself when it comes to mitigating the beginnings of, or full-on, burnout?

Many companies over the past

plants, and learning to improve the varieties we already grow, seeding and propagating our own plants.

I love the challenge of an ever changing industry, and finding new ways to innovate and become more efficient to improve our operation.”

And from Nikki Scott: “As cliché as it sounds, I really do get to do what I love everyday. It’s exciting to think I may inspire even one individual to be passionate about growing plants, whether it’s the food on our plates or the trees for our forests”

Keep your passion, and love the challenges.

On May 31, Marie-Claude Bibeau, minister of agriculture and agri-food, announced an investment of up to $734,806 to help five organizations increase the participation of underrepresented groups in the Canadian agriculture and agri-food industry.

The organizations will identify barriers and address issues to help more people from diverse backgrounds enter the industry and pursue careers

as agricultural entrepreneurs. The work includes a national project to address systemic barriers facing women trying to succeed in agriculture, local initiatives to empower Indigenous peoples to create business opportunities through traditional food and medicine, and national research to address gaps in mental health support for under-represented groups working in agriculture.

The Ontario Soil & Crop Improvement Association (OSCIA) has announced a new initiative named Soil For Life, to help improve soil health and sustainable soil management.

The new initiative provides a framework for practical discussions, help make sense of best management practices, and make a lasting impact on the health of soil.

OSCIS is part of a group leading Soil For Life.

Soil For Life focuses on five major principles to break down and simplify the complex concept of soil health and sustainability. These same principles appear in New Horizons – Ontario’s Soil Health and Conservation Strategy that was released in 2019 and will provide a framework for the conversation. They are:

Red Sun Farms has been named Windsor-Essex Large Company of the Year for a second time.

Recipients are nominated from within the community and must demonstrate their strategic goals, including sales, profitability, growth prospects, employment creation, and acceptance in the market. They will also illustrate their commitment to research and the development of advances in the company’s industry sector.

According to Red Sun Farms CEO of the USA and Canada Operations Carlos Visconti, “This recognition is a reflection of our core values and dedication as an organization. The Red Sun family is devoted to our values and commitments in all aspects of our operations. This recognition reaffirms our position as a leader in the produce industry.”

• Build soil organic matter

• Diversify crops

• Minimize soil disturbance

• Keep living roots throughout the year

• Keep the soil covered Farmers know that properly managed soil provides longterm economic and environmental benefits; benefits such as high yields, increased resiliency in soils, reduction in

fertilizer inputs, and increased organic matter. Building on the great work farmers are doing, Soil For Life is designed to be a framework for sharing best management practices (BMPs) based on the five principles. Through sharing and discussion, the goal is to work towards increasing soil health knowledge in Ontario. For more information, visit: ontariosoilhealth.ca.

Vineland examining waste management

Approximately

74% of Canadian fruit and vegetable waste occurs before reaching consumers for a myriad of reasons

Visit greenhousecanada. com/vineland-waste/ for more information.

Vineland examined the top seven Canadian produce crops:

• Potatoes

• Apples

• Greenhouse cucumbers

• Onions

• Carrots

• Field tomatoes

• Greenhouse tomatoes

Over 40 companies across the horticulture and food value chain were interviewed.

BY ANNIE CHAMPAGNE

More popular than ever, the Exceptionnelles trials received more than 12,000 votes from the public last summer in four major gardens: Montreal Botanical Garden, Daniel A. Séguin Garden in St-Hyacinthe, Roger-Van den Hende Garden in Quebec City, and Domaine Joly-de Lotbinière. The plants that stood out also passed the test of 16 professional evaluations according to very specific criteria, such as resistance to diseases and insects, flower or fruit appearance, and visual impact. Les Exceptionnelles 2022 were then carefully selected by our two expert committees (annuals and vegetables) among the plants that received the most votes from the public and performed the best.

The public and expert’s choices for 2022 present unique and complementary characteristics while having one thing in common: unparalleled performance at the four trial gardens. These 13 exceptional plants are a guarantee of quality and success for consumers and municipalities who choose them to garnish their flower beds and containers!

Let’s discover these nine annuals and four vegetables that combine beauty, performance and productivity:

Begonia Viking Explorer Rose on Green Leaf (1)

This begonia produces extra-large pink flowers that covers a very glossy green foliage. Thanks to its Viking blood, this begonia is extremely resistant to all the changes of temperature. It is ideal for mass plantings, hanging baskets and large containers.

BidensStellar Orange Star (2)

The bright golden-yellow flowers of this cultivar feature an orange star pattern that adds punch to its delicate foliage. In addition to this spectacular two-tone flowering, this plant plays an essential role by attracting pollinators such as bees.

Bracteantha Bracteata Granvia Gold (3)

The large scaly flowers of this cultivar look like crepe paper and present a remarkable luminous yellow with an orange heart. This plant has a high tolerance to mildew and heat. The flowers can be harvested to use as dried flowers.

Celosia Spicata Kelos Candela Pink (4)

This regional All-America Selections 2021 winner surprised in the Exceptionnelles trial gardens with its truly unique flower spikes above its

burgundy green foliage. This celosia is ideal for container arrangements and borders of flowerbed. Deer resistant.

Centaurea Mercury (5)

This is the perfect plant for decorative leaves amateurs. Its long, greyish, silky bright leaves are wavy. The plant forms a compact mound and performs equally well in full sun or shade. This disease and insect resistant plant is ideal for showcasing bright flowers.

Coleus Scutellarioides ColorBlaze El Brighto (6)

Coleus are renowned for bringing bright colors and textured foliage to gardens: ColorBlaze El Brighto presents a unique pattern with a purple and red center highlighted by a yellow border. Well branched and bushy, this coleus is as comfortable in containers as in ground, outdoor or indoor.

Lantana Camara Shamrock Rose Balshamose (7)

Shamrock lantanas form a beautiful mound with an abundance of flowers; ideal for hanging arrangements. This small ornamental shrub is resistant to summer drought. Its dark green foliage is aromatic when crumpled. The flowers attract butterflies, hummingbirds and other pollinators.

Petunia Crazytunia Mayan Sunset (8)

If you are looking for distinctive colors and patterns, you will appreciate the truly mesmerizing shades of coral, pink and orange of Crazytunia Mayan Sunset petunia. This vigorous petunia will eventually form a pretty mound of cascading flowers ideal for hanging baskets.

Zinnia “Profusion Red Yellow Bicolor” (9)

This zinnia won an All-America Selections gold medal and a Fleuroselect gold medal in 2021. What makes the flowering of this winning plant irresistible is that as it ages, the flower develops magnificent shades of salmon, apricot and pink. These gradual color changes are unique to this zinnia.

Capsicum annuum Candy Cane

Chocolate Cherry (10)

The variegated foliage of this pepper

is very distinctive and gives it an ornamental appearance ideal for containers. Its funny-looking fruits begin to show light and dark green stripes before turning red and chocolate. The sweet taste of this pepper makes it an excellent snack.

Citrullus lanatus Moon and Stars (11)

Watermelons have been cultivated for around 4,000 years. The ‘Moon and Stars’ watermelon was introduced in 1926 in New Jersey and features a dark green rind splashed with yellow spots, which adds an artistic touch to its look. Its seedless round fruits, with pink sweet flesh, generally weigh from 4 to 7 kg, and if the season is good, much more!

Ocimum Basilicum Everleaf Thai Towers (12)

This new basil has a beautiful upright and columnar port and is disease resistant. The purple of its sturdy stems contrasts nicely

with its dark green leaves which are quite large. Its aromatic leaves evoke a Thai anise aroma. The flowering is very late, which allows a much longer use of the leaves compared to most selections.

Phaseolus Vulgaris Amarillo (13)

This selection produces very fine yellow beans which are tasty. The fruits should be picked young, as they are at their best. This plant is sensitive to the cold, so it is necessary to wait until the risk of frost has passed. Fruit maturity occurs after 53 days. This plant acts as an excellent organic fertilizer to enrich your soil.

Since 2006, Les Exceptionnelles has been the 100% Quebec horticultural assessment program. In 2022, the program will be on hold so that the team behind it can reflect on what to do next. Due to this break, there won’t be any winners in 2023. 2022 winners will be displayed in many gardens throughout Quebec.

Breeders showcase innovative marketing techniques and eye-catching colours at the California Spring Trials

BY RODGER TSCHANZ

Dummen Orange has responded to the recent houseplant buying trend by providing growers with an impressive collection of interior foliage plant choices.

Innovation in plant breeding is at the forefront of everyone’s mind when touring the California Spring Trials. “What’s new this year” always captures the headlines, but new technologies and innovative marketing ideas are also showcased. This article will focus primarily on annuals and the highlights at each stop on the CAST tour that caught my attention. Subsequent articles in this series will focus on perennials and edibles.

PanAmerican Seed has just released the SolarScape series of sun tolerant, seed propagated interspecific impatiens. Prior to this innovation, all commercial sunshine tolerant hybrid impatiens were vegetatively propagated. Currently there are four colours in the series with those being: Magenta Bliss, Neon Purple, Orange Burst and White Shimmer. SolarScape XL (height of 28-33cm) is 20% larger than SolarScape (23-28cm height) but is only currently available in the Salmon Glow colour. This selection is also highly resistant to Impatiens Downy Mildew (IDM) like the Beacon (Impatiens walleriana) series. Where the Beacon series is an excellent seed choice for the full shade, SolarScape is best used in light shade to full sun conditions.

While still on the topic of impatiens, let’s look at the double flowered, vegetatively propagated

Glimmer series of I. wallerina from Ball FloraPlant.[1] The innovation with this series is its high resistance to IDM. Glimmer is available in Appleblossom, Bright Red, Dark Red, Burgundy, Hot Pink, Salmon and White. The large double flowers have the appearance of mini roses to the casual observer.

The AngelDance series of angelonia is an eyecatcher. There are currently two bicoloured selections (fuschia and violet) available. In my opinion, the fuschia bicolour has an antique look that is especially attractive. The series has large flowers, strong flexible upright stems, and great heat tolerance.

A new seed canna from Ball Ingenuity caught my eye because of its red and gold bicolour bloom – Cannova Red Golden Flame. This is the first seed propagated canna with a bicolour flower that I am aware of. Cannova Bronze Peach and Scarlet are the other new colour additions to this series.

What about scented cyclamen – this is another new experience for me. The small sized Absolu de Morel has a very pleasant fragrance, mild in intensity. [2]

Selecta One North America is

expanding and enhancing its dianthus assortment for Canadian and US growers for 2023. This company has been breeding carnations for nearly 90 years and continues to have a strong track record with cut and potted carnations. Case in point, is Selecta One’s ‘I Love You’ pot carnation with its multi-coloured (white, light pink and dark pink) blooms. It has a short compact habit suitable for pots and three season landscape applications. (note a 6A winter hardiness zone).

This is a new location for Greenfuse Botanicals with greenhouses built within

a lemon orchard. First impressions at this stop were enhanced by the enjoyment of freshly squeezed lemonade. I’ll talk more about the Greenfuse stop in the next installment of this series.

A new kalanchoe type caught my eye at the Beekenkamp display. Variegated Bongo is being marketed as a foliage plant, but it also blooms with scarlet flowers. Judging from the number of showy new experimental cultivars in the Sunny osteospermum and Tropic lantana series, a lot of new offerings are on the verge of being released.

Westhoff’s new Rift lobelia series was striking with its unusual white variegation on purple and blue blossoms. This plant

Container gardening provides boundless, exciting opportunities for both novice and experienced gardeners.

In this stunning book, Kathy Brown gives expert advice and shares her latest ideas on how to transform patios, walls, courtyards and doorsteps. In addition, step-by-step recipes guide the reader through the process of both planting and aftercare, either for short-term seasonal schemes or for longer-term projects.

$29.95 Item #1847972750

series has a well branched mounding habit. If the Crazytunia series needed more colours it has them with eight new colours for the coming year. The improved Swiss Dancer with its red and white coloration is a good fit for patriotic Canada Day displays.[3]

Our first stop was at the Santa Barbara Polo Club where Suntory had its display of plants. I noticed the new colour additions to the Surfinia XXL series of Watermelon Jazz and Salmon Vein. This series grows in an upright mounding habit and produces large, 9.5 cm diameter blooms. It also demonstrates good weather tolerance having survived a severe downpour a few days earlier. Suntory does select for landscape performance when breeding for this series. In the plant world we know of Suntory as the breeder of many fine plants such as the Million Bell series of calibrachoa but the company is predominantly a multi-national food and beverage producer. On show at CAST was a marketing move to pair these two business interests with Orangina (a beverage owned by Suntory) and an orange calibrachoa in the new release, Million Bells Mounding Orangina.[4]

The next stop was the Filipponi Ranch Winery where Dummen Orange had temporarily taken up residence. The site was surrounded by Californian hills and wild turkeys and was a wonderful setting for showcasing Dummen Orange plant breeding. What stood out to me at this stop were the Smartunia and the Smartunia Windmill series of petunias. [5] This is the first commercial release of a Tobacco Mosaic Virus (TMV) resistant petunia series and is one of the results from the new Intrensa advanced breeding program at Dummen Orange.

TMV has a very wide host range of plants that includes other Solanaceous garden plants such as tomato, pepper etc. This viral disease can cause severe stunting and marking of the infected plant. Since it is spread easily by handling and insect feeding, having a resistant cultivar available is highly desirable. The Smartunia Windmill series with its bicolor white star pattern is available in three colours (purple,hot pink and burgundy) and has strong, vigorous trailing habit. The Smartunia series with its five solid colours (raspberry gem, purple halo, hot pink, red, and white) has a mounding habit, similar to the Potunia Plus series.

Also on display was a new marketing scheme for houseplants: “Welcome to the Jungle.” Dummen Orange has responded to the recent houseplant buying trend by providing growers with an impressive collection of interior foliage plant choices. This marketing scheme also appears to be very consumer friendly.

The new Sallyfun Blue Lagoon (Salvia farinacea) introduction got a lot of attention at the Danziger CAST stop. It’s an improvement over the popular Deep Ocean with a deeper blue colour and sturdier, more upright habit. All other growth characteristics are similar making it easy to replace Deep Ocean in production programs. [6]

On a totally unrelated topic, Danziger gets full marks for creating the most engaging “selfie” backdrop/booth that I saw on the entire trip. After two years of COVID inspired entrapment, the Canadians on our tour readily embraced “California Dreamin”!

This year American Takii is introducing Crystal, the first series of glossy leaved flowering kale to hit the market with red, white, pink and deep red colours

available. In pot production it would appear to have a slightly more compact habit than the Glamour series with plant heights of 15-25 cm.

On display at the Sakata stop were two new series. The first is the Flamma celosia available in five colours and a mix, the orange being a recent AAS winner. This series has a compact habit, great heat tolerance and the characteristic that older bracts remain colourful without fading. The second is the compact primula series – Dania. This compact primula is the product of Danish breeding and is ideal for early spring programs without PGR’s and growing pot-to-pot. Available in eight colours and a mix.

I remember years ago when SuperCal was first introduced. This series was the result of an intergeneric cross between petunia and calibrachoa and created a new plant class – Petchoa. Garden performance is excellent, but the consumer has not embraced this new plant type and does not recognize petchoa. Marketing research discovered that if it looks like a petunia, it should be marketed as a petunia. SuperCal is now newly released as a petunia. At this visit I learned that the SuperCal can survive and continue blooming after temperature exposure to -3°C temperatures. This fact and the range of yellow and orange SuperCal colours available have given suggestion to the use of this plant in fall programs. Of course, this idea begs the question of whether the buying public can be persuaded to forgo fall mums for cold hardy petunias? The autumn coloured SuperCal displays at CAST2022 were attractive; maybe a blending of SuperCal and fall mums in mixed containers would be a way of introducing the concept.

At the Syngenta Flowers stop, showy Louisana-inspired marketing displays were being used to promote the new Bandolista lantana series as well as with a

new zinnia series. The new Zydeco series of Zinnia marylandica has excellent powdery mildew (PM) resistance like the Zahara and Profusion zinnias. What seems to set this series apart from the competitors is its 25% larger bloom size. The Holy Grail of zinnia plant breeding has been to come up with PM resistance and a bloom size and form comparable to those of Zinnia elegans; with Zydeco Syngenta Flowers seems well on its way to reaching that goal.[7]

Another exciting introduction from Syngenta is the new interspecific Calliope Cascade geranium. It has a vigorous spreading habit and season long bloom performance. Currently it is only available in vibrant violet colour with semi-double

flowers. We can expect more colour selection in the coming years.

The genus Ptilotus was first introduced to the industry with the cultivar Joey. Joey now has a big sister with the release of Matilda. This heat lover is suitable for cutflower applications with sturdy stems of 50-80 cm lengths and long shelf life. A wedding themed display at CAST provided a wide range of ideas for its use in the floral industry. [8]

I also want to mention the new pansy series, Cats Plus. It is available in five colours patterned with “whiskers.” This

series has an improved habit over Cats and can finish up to 10 days earlier.

Acknowledgments: I would like to thank Ball Horticulture and Greenhouse Canada for sponsoring this trip.

Rodger Tschanz is the Trial Garden Manager at the University of Guelph. He can be reached at rtschanz@uoguelph.ca

Collaboration between the University of Guelph and FlorNergia Inc. seeks to save energy and maintenance costs for growers.

BY LOGAN CASWELL

New water pump technology currently applied in the aquaculture sector could mean savings in energy and maintenance costs for growers in the controlled environment agriculture sector thanks to a collaboration between FloNergia and the University of Guelph.

Based in Burlington, Ont, FloNergia Inc. was incorporated in 2016 to offer sustainable solutions for moving fluids using less energy. The innovative, patented “FloMov” airlift pump technology was developed with the engineering expertise at the Gryph Energy Lab at the University of Guelph (UofG) with support from the Research Innovation Office and funding from the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), and is currently being sold to and used in the aquaculture and wastewater markets around the world, including the USA, Germany, Australia, India as well as at home in Canada.

“The technology was developed for one [part] of the food sector back in 2016, and we were focusing initially on aquaculture applications,” said Wael Ahmed PhD, P.Eng. Chief Technology Officer at FloNergia and a professor at UofG. “Now we are extending this…Now we are in the second phase of this technology and [looking at] how to really adapt this technology to indoor and vertical farming.”

The “FloMov” technology was born when Ahmed and his researchers identified the need to reduce the high costs involved in moving water together with the high expense of energy usage, maintenance costs and expensive and inefficient aeration costs when water quality needed to be improved by oxygenation.

parts; it uses energy for the air supply only, which in turn circulates and aerates water simultaneously. This results in low maintenance costs and a positive environmental impact. In commercial aquaculture trials, farmers reported a 50 to 70 per cent saving in energy costs and a 40 per cent higher aeration efficiency. Ahmed explained this is a significant saving to growers who can spend up to $5,000 per acre on maintenance costs. “On a 100-acre farm, that is a huge part of their costs,” said Ahmed. “Giving [growers] the opportunity to use a very simple, low maintenance device...replacing other pumps is very appealing.”

Ahmed hopes to develop the application for vertical farming by modifying the existing technology to be utilized in a multistage airlift pump which can move water to higher and longer

ABOVE

“Although the technology of the traditional airlift pumping system had been around since the 19th century, it had not been applied to industrial applications...”

Ahmed explained that although the technology of the traditional airlift pumping system had been around since the 19th century, it had not been applied to industrial applications due to its inefficiencies of needing two systems, one for aeration and one for water circulation.

FloMov however is one efficient system with no moving

distances. He said the project already has two growers in Ontario who are supporting the project and will conduct trials in vertical farms this summer which will monitor the efficiencies of the systems for hydrating and oxygenating the plant roots and assist in the wastewater treatment at the facilities.

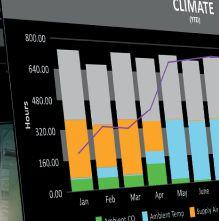

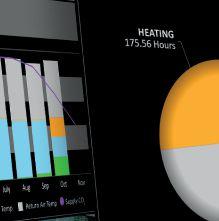

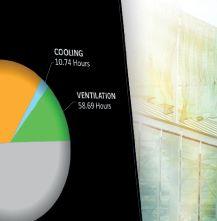

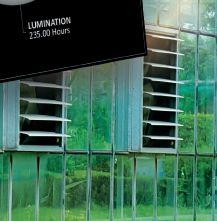

Growers know that when it comes to controlling and monitoring a production environment, a simple, flexible, sustainable control system is crucial. This is why you can depend on Reliable Controls. Our nationwide network of factory-certified Authorized Dealers will help you design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective, Canadian-made solution, please contact a Reliable Controls

Authorized Dealer near you.

Canada: 403.561.4148

Canada: 647.982.7412

This year’s Top 4 under 40 winners bring all this and more to the table.

BY GREENHOUSE CANADA STAFF

Nominated by: The Sandown Centre for Regenerative Agriculture

Why should this person be considered?

“We would like to recognize Ty James for his outstanding, ongoing vital work in building a robust regional food system in the South Vancouver Island region. As an active grower, Ty understands firsthand the essential pieces of infrastructure that market growers need to get going, scale up, and make a right livelihood. What sets Ty James apart is his commitment to developing infrastructure that helps the wider food system, and in particular, help market gardeners who face similar challenges in growing their local food businesses. In a sector with very lean profit margins, Ty’s commitment to partnership and collaboration is truly inspiring.

Ever the innovator, James wanted to help build a network of local growers who could collaborate and tap into larger markets requiring GAP and HACCP certification. He wanted to design infrastructure that would give farmers affordable access to GAP and HACCP-compliant storage and processing. In 2019 he built a first prototype on his own farm, then pursued a $32,000 grant through the Canada BC Agriculture Innovation program to build additional units.

Ty’s unwavering enthusiasm and commitment to local food is inspiring. He is solution-oriented and brings a can-do attitude to everything he touches. His work ethic is phenomenal. He is articulate and passionate, and will present at local Council meetings, mentor emerging growers, or reach out with a phone call or a meeting to help move decisions along. Ty’s work is paving the way for the growth of a robust regional food system and a more collaborative food future for Southern Vancouver Island.”

Starting in the industry just six years ago, Ty began his journey by leasing a small two-acre plot. First growing salad mixes and microgreens, he quickly realized he needed more space in order to grow his business. He then leased a fiveacre parcel and 20,000 square feet of greenhouse available locally.

What motivates you to do what you do today?

Today, I am motivated by creating a truly sustainable farming industry. My operation uses natural processes daily through biodegradable/recyclable packaging materials and mulch fabrics. We use beneficial insects to target caterpillars, fungus gnats and aphids, to incorporate beneficial plants to create a habitat for beneficial insects and birds that eliminate the need for chemicals and pesticides. I see first-hand in the field how incorporating natural processes leads to better crop yields, happier customers and a more sustainable farm.

What’s the biggest challenge in your industry right now that you see as an opportunity for you?

I think plastic is the biggest challenge for the agriculture sector. For companies working in this space, I believe there are endless opportunities for innovation. Everything from mulch plastic, drip line and packaging needs to change for our industry to correct this moral dilemma. My customers are constantly telling my retail partners that this is something that they want and it is something that is constantly front of mind for me.

Ty James

What’s your favourite part about your role?

My favorite part of my role is the ability to be in nature daily. I get to experience each season and gain intimate knowledge of my trade, while watching it all come to life throughout the year. I am extremely lucky to be able to do this work and feel a deep sense of responsibility for my role on the farm.

Nominated by:

Connie Bradt, Managing Director of A.M.A. Horticulture Inc.

Why should this person be considered?

“Karl Schouwenaar is a horticultural innovator and a thoughtful observer with a long-range vision for growing his family business, and the horticulture industry broadly. For Karl, it’s not just about

Luke Den Haan

Den Haan Greenhouses, Lawrencetown, Nova Scotia

“Several years ago, I traveled to Delphy in Holland and it opened my eyes to the idea of using LED technology for winter production. We decided to go with the best on the market, Philips LEDs. In 2020, we installed Philips LED toplighting over our cucumber crop and Philips toplighting and a single row of Philips interlighting in our tomato crop. The production forecasts have worked out exactly as Signify predicted with a 40% increase. And growing under LEDs took out the peaks and dips in our production. We are very satisfied with the results of growing under Philips LED lighting.”

right now – it’s about five or ten years from now. Innovating operations, cultivating leadership and defining strategic goals are part of his recipe for success. At 22, he officially joined Orchard Park Growers full-time after spending his early years playing supporting roles in the greenhouse. At 27, he’s now a partner in the family business that has grown to become North America’s go-to source for favourite specialty ornamentals, from agapanthus to gerberas to zygocactus. Successful operations are rooted in strong leadership and strategic direction. That’s why Karl has also turned his attention to supporting and cultivating leadership at all levels of the business, guided by a newly formed five-year strategy to help steer decisions from the day-to-day to the big-picture. Ongoing education and training are also vital, and Karl regularly meets with mentors and coaches on various topics including leadership development.”

Karl grew up in the industry, living on the same property as the greenhouse. Most days off of school were spent either helping out or playing in the greenhouse. Karl says there wasn’t ever much thought of doing anything else but continuing on in the industry as he grew older.

What motivates you to do what you do today?

Motivated to keep improving, there is always a different way of doing something, that will make things more efficient, or help improve the quality of work for our employees, and the quality of the plants. It excites me when we can make tasks around the greenhouse easier and improve the quality of the plants at the same time.

What’s the biggest challenge in your industry right now that you see as an opportunity for you?

The biggest challenge at the moment is finding talented employees that desire to build and contribute to the industry. That has forced us to reevaluate who we are as a company with regards to our culture and core values to make Orchard Park Growers a desirable place to work for a career.

What’s your favourite part about your role?

The favourite part about my role is coordinating between our departments to help all our plans come together. There is always a lot of work put in behind the scenes, and at the end of a

growing season it is always rewarding to see the greenhouses empty out and start filling up with the next season’s crops.

Nominated by: Jennifer Numan

Why should this person be considered?

“Mark works harder than anyone I know, he puts in very long days and is steadfastly committed to quality with extremely high standards. [2020 was his] first year working as the Grower, since the previous one left to pursue a career in the cannabis industry. Mark jumped in with both feet, and researches and reads everything he can get his hands on, soaking up everything our consultant says to him, taking meticulous notes, and of course paying very close attention to our plants and how they’re responding. He’s very humble…and committed to this business: When he was living in Alberta, he learned that his father (who owned a greenhouse with his wife) had brain cancer, and within six weeks Mark had packed up his life there and moved home to support his family through the growing season. His father, John, was the Grower in that greenhouse and passed away shortly after. Mark’s sister, the owner of another greenhouse, also found out she had cancer around the same time, and Mark joined that greenhouse to then help them out which is where he is now. (She’s recovered! That was the 2017 season). His commitment to this industry and his family working in it is tremendous, I don’t know how anyone would exemplify going above and beyond for the good of the business

more than Mark has.”

Although Mark’s interest in growing didn’t come until later in life, Mark credits his father and his sister Rachel Gondosch at Westwood Greenhouses for getting him started in the industry.

What motivates you to do what you do today?

I love the challenge of learning to grow new plants, and learning to improve the varieties we already grow, seeding and propagating our own plants. I love the challenge of an ever-changing industry, and finding new ways to innovate and become more efficient to improve our operation.

What’s the biggest challenge in your industry right now that you see as an opportunity for you?

When the pandemic began we very quickly revamped our website and set up an online store from scratch –we learned a great deal through this experience. With the ease of online shopping and the convenience we believe online is something customers will continue to desire. We plan to take steps to be able to provide that service moving forward.

What’s your favourite part about your role?

Customer success. Customers that have success fall in love with gardening and are excited to come back year after year. We always keep this in mind with the varieties that we grow, and sending a quality plant home with them to set them up for success.

NIKKI SCOTT, TOLKOREFORESTATION

Nominated by:

Mary-Ann Fargo

Why should this person be considered?

”Nikki Scott joined Eagle Rock Division with Tolko in May of 2020 at the height the COVID pandemic. At a time when we weren’t sure if the nursery would be able to operate, Nikki stepped up and allocated as many resources as possible to mitigate the challenges and established a safe work environment for the staff. As the youngest superintendent to lead this division, Nikki has never let her age be a barrier to leading a diverse and senior demographic of employees. She dove right into the job without hesitation and earned the respect of everyone. She has faced unprecedented challenges with a high number of key employees retiring but has not missed a step in keeping the division operational and moving it forward. Nikki will jump in and help the crew in any way possible to get the job done successfully. Nikki is effective at overseeing 30+ employees during harvest season providing them with guidance and training while managing the logistics of harvesting, sorting, packaging, and transport

of 7+ million tree seedlings. She leads by example every day and is prepared to admit when she has made a mistake or misstep. She puts a lot of effort into promoting the work we are all doing and tries to give meaning to each task – her passion and belief in the industry and every little seedling is contagious.”

At 7-years-old, Nikki Scott brought home a western red cedar seedling and planted it in her front yard. Three decades later that tree still stands in the same spot. But she says she owes her career in the greenhouse industry to one of her professors and mentors from Olds College, Peter Johnston-Berresford, and says the position at the University of Alberta was a catalyst for her career.

What motivates you to do what you do today?

My greatest motivation for what I do is the hope that I can inspire individuals to care about where our food comes from, be passionate about plants and advocate for the trees of this land. I am responsible for growing the next generation of forests and that is the greatest motivation in and of itself.

What’s the biggest challenge in your industry right now that you see as an opportunity for you?

Labour is the biggest challenge we face but it presents an opportunity for change and innovation. In seedling nursery production, the trees are ‘lifted’ or extracted from the blocks, graded, wrapped in bundles, and packed into boxes destined for cold storage until the spring planting season. This process is highly dependent on a substantial labor force for a short period of time each year and has gone unchanged for years. This has created an opportunity especially as someone new to the reforestation seedling industry to really look at different approaches and question the status quo to achieve the same outcome.

What’s your favourite part about your role?

My favorite part of my role is the opportunities I get to provide presentations, tours, and outreach to the community. I recently hosted the Western Red Cedar Lumber Associations Cedar School group in May to advocate for the work that is being done to promote healthy forests. It’s a privilege to share my knowledge and passion for trees with others. Last year I was fortunate to deliver 300 seedlings to the students at the same school I attended 29 years ago.

As cliché as it sounds, I really do get to do what I love every day. It’s exciting to think I may inspire even one individual to be passionate about growing plants, whether it’s the food on our plates or the trees for our forests just as I was by a little tree seedling all those years ago.

Nikki Scott

Tolko, Eagle Rock

Reforestation Division, Armstrong, B.C.

Karl Schouwenaar

Orchard Park Growers, St. Catharines, ON

Sponsored by

Greenhouse Canada is proud to celebrate Canada’s rising young greenhouse stars.

Mark Numan

Colour Paradise Greenhouses, Mannheim, ON

Ty James

Blaine Consulting, Victoria, B.C.

Learn more about their stories in this month’s issue. Know someone worthy of Top 4 status? Nominations open again in early 2023.

Brought to you by

Lettuce grower works to minimize costs to consumers, the environment and the bottom line.

BY GRETA CHIU

When he switched from investment management to horticulture, Rob Lyle had a clear goal in mind – to grow fresh, local produce yearround using the least amount of resources possible.

“We wanted to grow vegetables in a northern climate in a highly energy-efficient way,” he says. “We needed a greenhouse that’s got a small footprint [and] can produce a good portion of greens within 30 km of the greenhouse, day in and day out, all year.”

Searching for a solution, Lyle came across the concept of a passive solar greenhouse paired with a geoexchange system – both designed by Ceres Greenhouse Solutions based in Colorado, U.S.A. The result was greenshaus Inc., a 2,000 sq. ft. facility in Almonte, Ont. which opened in 2019. Today, the producer harvests 1,000 to 1,200 heads of live-root lettuce each week, among other leafy greens.

The greenhouse structure itself was built to maximize retention of the sun’s energy. “We only have glazing on the south roof and half of the south wall. The rest of it is all insulated steel panel,” Lyle says. Even the slope of the roof was designed to capture more of the sun’s rays, particularly in the winter when the sun is lower on the horizon.

In pairing a passive solar greenhouse with a geoexchange system, any extra heat can be stored then used at a later point in time.

Unlike deep geothermal where users tap into the Earth’s intrinsic heat or use the secondary heat from geothermal power generation, geoexchange leverages the ground as a battery. When temperatures in the greenhouse are high, the heat is gathered and stored in the ground. When greenhouse temperatures drop, the stored heat is brought back above the surface.

the greenhouse goes below 12 degrees Celsius, our geo system comes on.” It’s when the temperatures drop by too much that he switches to a high-efficiency 65,000 BTU propane heater.

“Our energy cost to run the greenhouse last year was $16,000,” he says. “$4,500 of that was propane, and the balance was [hydro] at 19 cents a kilowatt.”

That cost included electricity for the winter LED grow lights, the intensity of which are adjusted based on historical light levels in the local area as well as the crop’s needs. Every month, Lyle works with Ceres’ greenhouse engineer, Hervé Maumus-Hue, to tweak the lighting program as needed.

“Lettuce is probably the least energy-hungry – it’s a very cold crop that works well in the winter. You don’t need to heat as much, and you don’t need to supplement as much in terms of light,” says Maumus-Hue. He suggested and helped install the grow lights in 2019 to improve the size of the

ABOVE

Any extra heat stored can be used at a later point in time.

On a sunny day, Lyle says they use the geoexchange system to cool the greenhouse, storing the warmth below ground. In this instance, it’s a proprietary system known as GAHT (Ground to Air Heat Transfer), also designed by Ceres. “When

lettuce heads. For the greenhouse engineer, other key areas of focus have been centred around environmental control –humidity and temperature in particular – to keep the vapour pressure deficit as stable as possible. “One of the main constraints is sticking to a budget,” he adds. Anyone with

enough financial resources will likely be able to find a solution – albeit a costly one – but that’s not what they’re trying to achieve.

“You could have one of these greenhouses on every corner,” says Lyle. His ultimate vision is to create a network of small local greenhouses across Canada, each supplying their own locale like a fast-food chain, but healthier. “It has to be done extremely efficiently. You can’t do it in a big-box greenhouse and pay that kind of money in a town that has 5,000 people.”

One thing he finds is that the carbon footprint created by food distribution is often neglected. “It far outweighs any efficiencies you can create in a greenhouse,” he says. Taking their customer in Almonte, Ont. as an example, his calculations suggest that the trip from his greenhouse to the independent grocer generates 0.7 kg of CO2. In contrast, a one-way trip to the same destination from southern Alberta generates around 3,027 kg of CO2 – over 4,300 times more. “That’s happening day in and day out to billions of grocery stores in Canada and the U.S.”

Not a stranger to numbers, Lyle has a degree in finance from the University of Texas at Austin and worked for a number of large Canadian financial institutions before making the switch to horticulture. Having lived in the Niagara region, he had heard about the high energy costs involved in greenhouse production and decided to take on the challenge.

“The fact that I’m making money out of this is a function of how good the systems really are,” Lyle says, “because I knew nothing about growing lettuce three years ago.”

The operation doesn’t use conventional insecticides or pesticides either, deferring to biocontrols instead. “When we get an overrun of aphids, we shut down and start again when we have to.”

Their efforts to minimize impact to the environment also extend to their packaging, opting for recycled paper rather than clamshell. “We found a cool [product] from Germany that allows us to put the live root in water and send it to the store.” Not only can the water stay in the sleeve for three weeks, the packaging can be dried out and reused again.

As for next steps, there are many. Lyle has already started on preliminary designs for their next facility, estimated at 4,000 sq. ft. and located on the same property. He’d even like to take their electricity off-grid. Now that they’ve had experience with the first build, he’s looking to construct subsequent greenhouses at a lower cost and in higher quantities.

Maumus-Hue is hoping to see even greater gains in greenhouse efficiency. “One of the things we can improve is the control side of [the equipment].” He’d like to add sensors and adjust for light levels in real-time, which will help save on electricity. Another key improvement would be to automate the switch between geothermal and propane. “If you have more sensors, you can measure the difference in temperature [between] the inlet of the geothermal system and the outlet,” he says. “It can tell you if it’s just enough

to heat the greenhouse. Once this condition is met, you can then turn your geothermal system on. When the geothermal system does not have enough energy to do so, you can turn on…the propane.” Maumus-Hue says Ceres is in the process of tweaking and exploring this technology as a potential option for future builds. “The algorithms and the rules that you put behind [the technology] can make a big difference,” he adds.

Dreams of establishing a nation-wide network will take some research, based on local demand and population size. In the meantime, Lyle is looking into crowdfunding and financing options to jumpstart his next greenhouse.

“Everything we do [is about] being local, making the food fresh and inexpensive, [and] lowering our carbon footprint,” says Lyle. “If it carries on because we started it, then we’ve accomplished something.”

BY FRED GROVES

In the spring of 2022, Highway 3 which stretches from Windsor to Leamington, Ontario, was undergoing a transformation.

The transportation causeway, which enables greenhouse growers to easily access the Ambassador Bridge, opening the gate to United States marketplaces, was expanding.

Between the two points there is a glaring opportunity that, to date has not been utilized and one, which local greenhouse operators hope to tap into in the very near future.

Windsor and Essex County have, for decades, produced some of the finest vehicles in the world and with that comes a remarkable amount of technological know-how.

An interesting question is beginning to bubble to the surface in the region – if innovative technology is available to make cars and trucks, why can’t that knowledge be transferred to the greenhouse sector and build necessary automation systems?

“It’s not for a lack of desire or will to make this a reality. It takes time,” says Aaron Coristine, Manager: Science, Regulatory Affairs and Government Relations for the Ontario Greenhouse Vegetable Growers, based out of Leamington, Ontario.

Growers in the area have always looked outside of North America to provide the necessary technology to automate irrigation, ventilation, cooling and heating and Coristine and the OGVG seem confident that the resources to research and develop and build what they need is just down the road.

He says the idea has been explored and that, “the question has been asked on both sides. There is a mutual interest to collaborate and create something,” he adds.

“The Netherlands are wonderful at what they do. They are pioneers in their own right. They are technology geniuses, but we have technology geniuses here,” says Coristine.

ABOVE WE Tech Alliance Director of Operations and Partnership Adam Castle, left; and President and CEO Yvonne Pillon.

ABOVE

He says that local greenhouse operators want to partner with local manufacturers especially with resources in the immediate area.

Bridging the gap between the agriculture and automotive sectors is in the future it seems, but not just yet.

Connecting the two – automotive technology specialists and greenhouse operators, has got the attention of WE Tech Alliance, a think tank of sorts that specializes in bringing partners together not only in the Southwest Ontario region but globally. It is one of the groups that are looking into bringing the automotive and agriculture sectors together.

According to WE Tech Alliance Director of Venture Services Adam Castle, the fact that more and more vehicles are going electric and less parts are being made in Windsor-Essex, could be a factor in whether or not automotive manufacturers and greenhouse operators begin to form working partnerships.

“Our manufacturers have not been traditionally asking, how do we get into this (agriculture) sector,” said Castle.

And while greenhouse growers continue to get their automation technology primarily in the European markets, that does not mean they aren’t open to the possibilities.

“To move an industry from buying imported goods to a domestic good is not a quick process. So, what we are doing is identifying the greenhouse growers we have good relationships with,” notes Castle.

Perhaps the biggest obstacle that greenhouse operators in Windsor-Essex face is that since they are constructing new operations at a quick pace, the time

to redefine how they do things is nearly impossible and as Castle points out, “if it’s not broke, why fix it.”

“I think you will see a whole lot more of it in five years and ten years even greater numbers,” he said of utilizing home-grown technology. “There is a lot we have to get right in terms of mechanism.”

One of those is bringing as many players to the table as possible.

On May 11, WE Tech Alliance invited Niagara College’s Greenhouse Technology Network to a round-table discussion that was hopefully expected to attract both greenhouse operators as well as automotive manufacturers.

Greenhouse Technology Network, according to its website is, ‘a network of research-focused centre that collaborate

small-and-medium sized organizations to advance the development, adoption and implementation of technologies to support the greenhouse industry.

Rita Sterne is the Project Manager for GTN and says that her group is not really concerned with what the crop may be, as long as it is undercover.

“We look at greenhouses and related technology. With funding from the federal government, we are able to work with small businesses that face some kind of a greenhouse related technology challenge,” she said.

“We understand that the greenhouse space needs this technology and the advancements.”

What those advancements seem to be locally anyway, is, as Adam Castle from WE Tech Alliance points out, is having the technological know-how come from the area.

“Solving the technological challenges is

a mountain but we know we can do it and it takes time,” says Sterne.

One of the local tech companies that WE Tech Alliance encourages to work with local greenhouse operators is Windsor’s Splice Digital.

According to President and Founder Brian Hendel, Splice Digital designs custom web technology to serve the needs of a number of businesses both in the United States and Canada, including greenhouse operators in the LeamingtonKingsville region.

When it first started exploring the possibility, Hendel says, “what’s here that we can look at as a business opportunity? We started to talk to OMAFRA (Ministry of Agriculture, Food and Rural Affairs), and the local greenhouse industry.”

After reaching out to the local greenhouse operators and finding out what

Another company that is on the cutting edge of being able to provide local greenhouses what they need is Durobyte Inc.

Branding itself as being able to develop custom automation machines, Durobyte Inc can build high technology products from the initial concept, through to design and right to the actual manufacturing.

Durobyte Inc Business Development Manager Patrick Thompson says they are working on a water jet system that can decap mushrooms and destem peppers.

“It’s one thing that we can do it, but we have to get their trust. We are not the only one doing it.”

Interesting about Durobyte is that they have a test facility and are able to invite greenhouse operators in to see, firsthand, what they can do locally.

Asked why the local greenhouse industry continues to get their technology outside of Canada, Thompson is quick to note, “everybody trusts the equipment from overseas and with trust comes purchase.”

president is certain that Canada can be a tech leader within the greenhouse sector.

“We are pushing hard. We are going to the Netherlands, and we are trying to penetrate globally. It’s a matter of getting the word out,” said Hendel.

The original and trusted brand in sun and heat loving impatiens now come in new bicolors! Thriving in full sun or part shade, SunPatiens deliver continuous color from

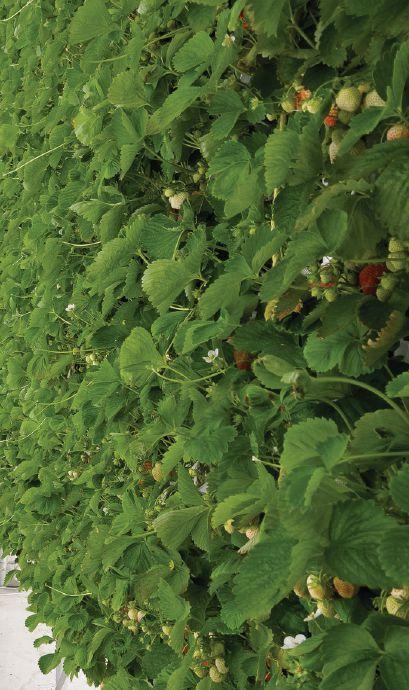

After a successful year, Quebec’s Winter Farm hopes to find new partners, and reduce the amount of strawberries Canada imports each year

BY DOUG JOHNSON

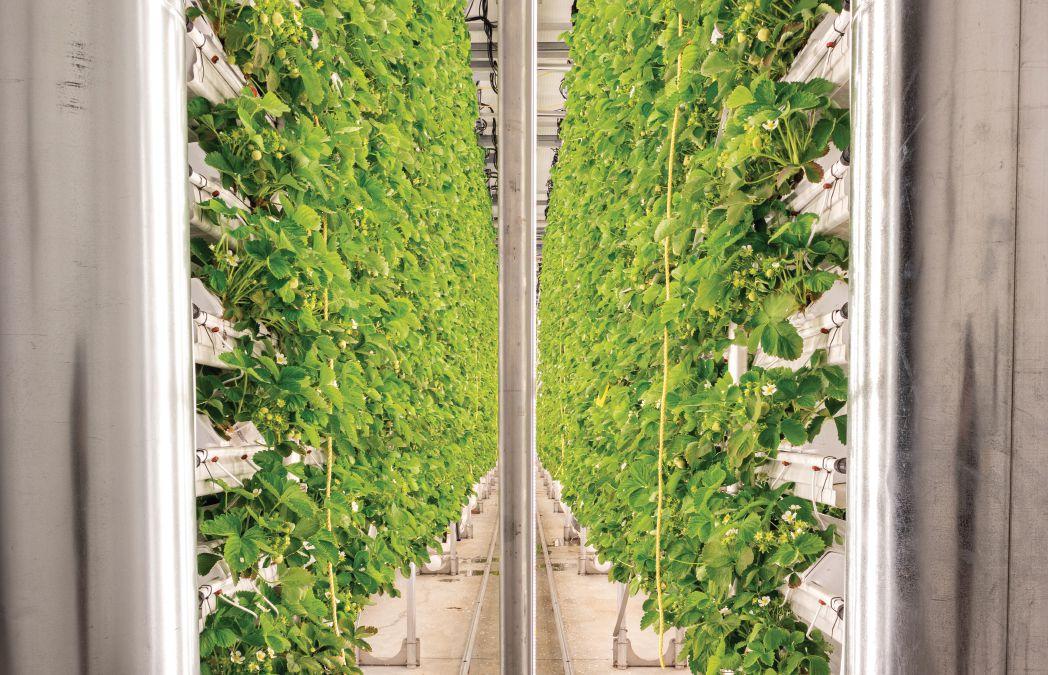

Nestled in Vaudreuil-Dorion, Quebec, is a recordsetting strawberry facility, one that—its partners hope—will provide fresh, local fruit year-round, and relieve Canada’s reliance on imports for much of the year. The facility is a partnership between Winter Farm, a Quebec-based indoor vertical farm company, and Les Serres Vaudreuil, which has been operating in its namesake town for decades.

The operation opened last year, and is the largest vertical strawberry farm in Quebec. The partnership saw Winter Farm provide the tech, and Les Serres Vaudreuil handle the operations. The decision to start growing strawberries was

a deliberate one, according to Alain Brisebois CEO of Winter Farm. Broadly, vertical farms have been used to grow leafy greens. Instead, the partnership between the two groups chose something of an oddity, and what Brisebois calls a challenging crop. “The intent was not to do leafy greens, because we think there is already [too many people] in it,” he said.

Winter Farm, itself, doesn’t grow the strawberries. Rather, it partners with operations like Les Serres Vaudreuil, their first of such partnerships, who handle the growing. According to an email from André Saint-Denis co-owner of Les Serres Vaudreuil, the partnership was an ABOVE

This operation opened last year, and is the largest vertical strawberry farm in Quebec.

Prides Corner Farms Lebanon, CT Better Roots Meilleures racines

Lavender Trial

Essai sur la lavande

Traité

opportunity to grow the company while still “doing what we do best.”

Les Serres Vaudreuil employs 50 seasonal workers, and operates a garden centre and locally well-known fruit and vegetable market. Beyond the strawberries, they grow numerous other kinds of produce in their greenhouse, including tomatoes, cucumbers, and peppers, along with flowers for people’s gardens. In their fields, they grow pumpkins, corn, asparagus, wheat, soybeans, and other crops as well.

Among its rows of lit stacks grow many thousands of plants in what is, in terms of square footage, a relatively small space. In all, the vertical farm sits at a humble 1,150 square metres. However, it has the ability to produce almost 2.5 hectares of what would be possible in traditional greenhouses. According to Brisebois, when people visit the farm, they tend to have an “aha” moment about the actual size of the operation, considering its 25 feet worth of height, and their stacks are 14 levels high. They chose strawberry varieties that are fairly well known in Quebec, including albion.

When the vertical farm was announced, it was anticipated to produce 180,000 kilograms of strawberries each year between October and June, though, currently, they’re sitting at around 100,000 per year, produced by 51,000 plants. The most

productive greenhouse strawberry operations end up yielding between 12 and 14 kilograms per square metres. In Les Serres Vaudreuil’s vertical farm, it’s closer to 116 kilograms per square metre.

“It is a different world,” Brisebois said.

Moreover, the facility can produce locally-grown strawberries between October and June. For most of the year in Canada, the berries are imported from California and Mexico, Brisebois said. In all, Winter Farm has a goal of replacing 10 percent of strawberry importation into Canada. Brisebois noted, however, that of this 10 percent, the locally and vertically grown strawberries are geared towards the premium level, selling baskets at closer to $5.99, compared to imported ones for a few dollars cheaper. However, the locallygrown strawberries are inevitably going to be fresher than ones brought in from abroad, which spend days in transit from when they were picked.

“We thought there was a need for more local production,” he said. “[It doesn’t] cross the entire continent before it gets to you. That’s the overall idea—local production as much as we can.”

Despite being grown vertically, these strawberries are, in their own way, grown in a fairly similar fashion to their kin. They use the regular coco substrate, gutters, and an irrigation system, for example (the operation doesn’t use pesticides, however). They even use bumble bees as pollinators—they were chosen as they are a little less aggressive compared to other kinds of bees. The exceptions being that they are grown in climate-controlled conditions in indoors, and using LEDs, which run each day and also replicate the sunrise and sunset across the rows of plants. “Everything is 100 percent similar,” Brisebois said.

Another difference comes down to the HVAC system.

Considering the facility has upwards of 50,000 plants, there is a great deal of humidity to contend with, so they’ve developed more powerful HVAC and humidity control systems.

Considering the facility has upwards of 50,000 plants, there is a great deal of humidity to contend with, so they’ve developed more powerful HVAC and humidity control systems. Between all of these factors, the operation attempts to mimic the kind of ideal strawberry growing conditions found in most commercial greenhouses.

Each plant is also hooked up with a sensor that feeds information to an AI system. These sensors capture info about what the plants need (more water or more air, for instance). Beyond alerting the growers to the plants’ needs, it also teaches the AI to find the best growing conditions for the strawberries to maximize yield and quality, Briebois said. He added that this is easier than having humans going around and checking each plant’s conditions manually.

The indoor facility also recycles heat, which Les Serres Vaudreuil can use to warm other parts of its operation. Water flows through tubes near aluminum components of the LEDs used to replicate the sun’s light. This heats the water which is, in turn, pumped towards the rest of the operation, providing an alternative to relying on other heating methods. Beyond that, the water also helps keep the LEDs, themselves, cool.

It is still early days for the facility. But, considering it has

only been in operation for one year, it has been able to distribute to 15 different IGA stores near Les Serres Vaudreuil.

“The biggest impact is that for the first time, we are harvesting all year around because of the heat that the Winter Farm gives us,” the email from Saint-Denis said, and added that its heating bill dropped by 90 percent for the farm’s lettuce greenhouse.

Even though Winter Farm’s offerings have only been tested for one year, the group has some big ambitions. While, right now, they are relatively small in scale, they hope to scale up and help produce even more crops. According to Brisebois, they are currently meeting with other interested growers in Canada, the United States, and even Europe. He added that they have received a good deal of interest, and that the company is focused on finding the right partners. According to Saint-Denis, this includes continuing the partnership between Winter Farms and Les Serres Vaudreuil.

“We are currently building the second unit and have a lot of ideas for the future. We aim to remain Winter Farm’s center of R&D. Having a Winter Farm helps us to produce year-round, develop new markets and to better plan our income.”

CLASSIFIED RATES: Minimum order $75.00 or 84¢ per word, word ads must be pre-paid. CLASSIFIED DISPLAYS: $72.00 per column inch. GENERAL INFORMATION: Payment must accom- pany order. Copy required on publication close date. All advertising copy subject to the approval of the publisher. Send order and remittance to: Classified Dept., Greenhouse Canada, P.O. Box 530, Donly Dr. S., Simcoe, ON N3Y 4N5 Canada

I’ve been facilitating horticulture courses in postsecondary for some time now. Over that time there have been changes in content and delivery methods. But nothing too “unconventional” – until 2020 that is. A sudden, drastic, enforced pivot to online delivery of everything. Lectures weren’t too bad, but lab sessions, greenhouse practicals and field trips had to be completely reworked, sometimes cancelled. Not many of us were that happy. But, like everyone else, after a period of painful adjustment, we found a new groove. However….

The boom in Zoom (and other online meeting platforms) created a new market for training possibilities not considered before. Almost overnight there appeared a plethora of diverse teaching and training opportunities from all sources. And with that, a different way of learning. But, I believe the equally significant point was the coincidental timing of what’s going on with the technology of crop monitoring, sensing, data collection, autonomous growing and now augmented reality growing. Perfect timing in many ways.

During a visit to a B.C. producer of high quality nursery plants in November 2021, we discussed possible answers to the ongoing labour issues many growers face. Solutions included creative recruiting methods, innovation in products to reduce labour needs, automation (nothing new there) and robotics. To be successful, automation, robotics, and autonomous growing need great

The boom in Zoom created a new market for training.

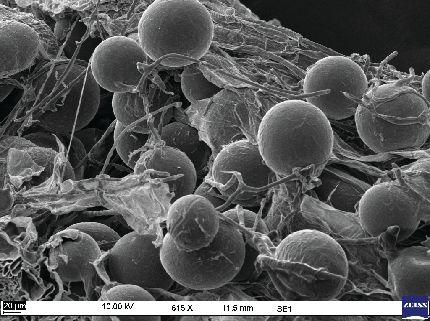

data collection. During the Lower Mainland Horticulture Improvement Association (LMHIA) Growers’ Short Course in March, Quade Digweed from Agriculture and AgriFood Canada’s Harrow Research and Development Centre described new sensor technology his team has been working on and possible new developments including SMART sensors (able to provide information on parameters we cannot really directly measure, such a transpiration), virtual sensors (calculating things we can’t measure, such as yield prediction models), and imaging systems (for example visualizing drought stress in crops). When combined, these applications can be used to inform predictive models for virtual crop trials without risking living crops, and “Digital Twins” (virtual models of real greenhouses).

A couple of recent sessions organized by the

B.C. Greenhouse Growers Association (BCGGA) for members and guests also highlighted similar themes. Ronald Hoek from Blue Radix delved into autonomous growing, posing the question: Since the greenhouse industry is an aging population, “who will be the growers running those operations over the next few decades?” According to Ronald, “Autonomous Greenhouse Management” will require data inputs and analytics for action, and growers of the future will be required to focus more on crop strategy and quality of crop registration rather than on changing set points, which the A.I. system will do. The Blue Radix system is currently being evaluated in two OGVG Association greenhouses. In another session, Dr. Silke Hemming from Wageningen (WUR) described her wide-ranging work on similar topics. Within the context of the Netherlands being emission-free by 2027, pesticide-free in the greenhouse sector, aiming for “circular horticulture” (i.e. no waste) and as we all know with labour as the number one cost, Silke and other (commercial) companies have developed a number of digital applications. These include being able to measure fruit BRIX non-destructively (91% accuracy), “Plantalyzer” (measuring tomato fruit ripeness and eight to 10 day advance yield prediction), “Gerberascout” (gerbera harvesting predictor), “Optima” plant disease detection (Botrytis in potted plant crop canopy and tulip breaking virus in field crops), and “PeMaTo-EuroPep” (forecasting pest and beneficial insect population dynamics, with an 85% accuracy for identifying whitefly and beneficials on yellow sticky cards).

Many of us may fear the elimination of the grower with these paradigm shifts in technology and thinking. Both Hoek and Hemming believe that the grower will still be essential, but their role will be different and more strategic. Computers, sensors, models and applications will be more advanced tools than they are now, but (according to Silke) “the grower will be one who is more focused on customers and business.” So, how will this this perfect storm of technology affect education and training? In short, it may make learning much more satisfying and rewarding. It will require a newer generation of students able to think critically like never before. And it will need educators who are skilled communicators and facilitators. Sounds like fun to me.

Gary Jones sits on several industry committees in BC and welcomes comments at greenhousewolf@gmail.com.