BY: MIKE FISCHER

DR. CHEVONNE DAYBOLL

Krause

ERICH WEBER

BY: MIKE FISCHER

DR. CHEVONNE DAYBOLL

Krause

ERICH WEBER

What better way to start off the year than a review of the past for a glimpse into the future?

From the arrival of the tomato brown rugose fruit virus to dealing with the aftermaths of the BC pipeline rupture, 2019 certainly had its challenging moments. What’s to come for 2020? Cucumber exports to the U.S. continue to rise in Ontario, while pepper acres are growing in BC. In Alberta, energy-conscious growers are turning to co-generation, and vertical farming is on the radar. Quebec’s buy-local, eco-conscious mentality is stronger than ever. See pg. 34 for the report.

At the Flowers Canada (Ontario) Inc. (FCO) annual general meeting in December, several key achievements were highlighted, including an 80% carbon tax rebate for growers in certain provinces and a $6M investment into floriculture research through the Canadian Ornamental Horticulture Alliance (COHA). Industry training for the new United States-Canada Greenhouse-Grown Plant Certification Program (GCP) has been successful in standardizing training across Canada, just in time for its transition in 2020 from the previous CGCP. New pest

tors that some boilers may not be maintained as well as they should be,” says Jan VanderHout, president of TOGA and co-owner of Beverly Greenhouses.

As VanderHout explains, Ontario is conducting a comprehensive review of many items that may or may not pose safety concerns to the public. This includes the agricultural exemption on boilers.

“We’re working with government to come up with a plan to create a pathway to compliance [but] without the exemption and without having our boiler rooms attended by operating engineers,” says VanderHout. “Part of it will be the registration of the pressure vessels when they’re installed,” he explains, which is the identical process for burners in the greenhouse. Modifications and repairs will need to be completed by certified personnel.

Without the exemption in place, the Technical Standards and Safety Authority (TSSA) can help enforce proper boiler use. “If you’re operating your facility safely, there’s no reason to be concerned.”

management product registrations are anticipated for 2020, which is good news in the face of multiple pesticide re-evaluations and considerable tools lost for cut flowers.

The Ontario Greenhouse Alliance (TOGA) and its partners have been working on changes to requirements for boiler safety for the past three years now. “It stems from concerns from insurance inspec -

VanderHout envisions some level of boiler training in place. “Even the smallest boiler needs proper and ongoing maintenance, which is daily in the case of steam boilers,” he says. Though most greenhouse boilers now use hot water, and any steam boilers typically run at 15 psi or less, all the right safety devices still need to be verified, he says. Who has the authority to enforce boiler safety? Under the current exemption, no one.

For more on the state of the industry, turn to the story pg.34 and Gary Jones’ column on pg. 38.

to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Use Amblyline to effectively wipe out thrips with a breeding colony of predatory mites (Amblyseius cucumeris), released onto your crop every day for several weeks, even before thrips are present. Also targets broad mites and cyclamen mites.

Use Amblyline loose material for high dose, immediate crop protection. % % %

Use water-resistant Amblyline Sachets under mist during early propagation.

Use Amblyline sticks for easy, quick introduction into plug trays or pots.

519-839-4778 Kam’s Growers Supply Inc. orders@kams.ca 877-821-1684

Location

Held during the 2019 Green Industry Show and Conference in Calgary, the Alberta Greenhouse Growers’ Association (AGGA) revealed this year’s award winners at their annual garden party.

Grower of the Year (Ornamental):

Sharon Stepanick of Brenneis Greenhouses

Grower of the Year (Vegetable):

Dawn Buschert of Shirley’s Greenhouse

Meritorious Service Award:

Carol Maier of Country Road Greenhouses

The award was accepted on behalf of Maier by Dietrich Kuhlmann of Kuhlmann’s Market Gardens and Greenhouses Ltd.

Herb Knodel Award: Nellie Simpson of RedHat Co-operative

Congratulations to all the winners.

In an effort to reduce movement of the tomato brown rugose fruit virus (ToBRFV), new restrictions were imposed on tomatoes and peppers being imported into the United States.

“Under the previous requirements, tomato and pepper plants and seeds moving from Canada to the United States needed to be accompanied by a phytosanitary certificate. Under the new U.S. requirements, these items now require

an additional declaration added to the phytosanitary certificate for ToBRFV,” the Canadian Food Inspection Agency (CFIA) says of propagative material.

For tomato and pepper fruits, the import order only pertains to shipments from Mexico, Canada, Israel and The Netherlands, according to the APHIS website.

For Canada, previous shipments of fruit into the U.S. were accompanied by a

The Fédération interdisciplinaire de l’horticulture ornementale du Québec (FIHOQ) has changed their name to Québec Vert.

The change reflects the sector’s commitment to the environment, says the press release. By taking on a new identity, image and mission, Québec Vert aims to better represent and promote ornamental, environmental and food-producing horticulture, bringing together all areas of the sector and supporting their members’ continued growth. This repositioning will allow the organization to develop in new strategic directions, with goals to enhance the sector, support adaptation to climate change, develop markets, foster innovation and facilitate access to the workforce.

Quebec’s horticultural sector generates economic spin-offs of over $6 billion, according to the release, and provides more than 40,000 jobs per year.

certificate of origin from the exporter. “Under the new requirements, in addition to the certificate of origin, they now need to be accompanied by an inspection certificate that is issued by the grower or packer containing the information specified in the U.S. federal order. This document attests that no symptoms of ToBRFV are found. Exporters may experience delays at the border as customs and border

protection officers adjust to enhanced inspection procedures,” says the CFIA.

Consignments without the required accompanying documents will be refused entry.

“Alternatively, if a grower or packer issued inspection certificate is not available to an exporter, a CFIA inspection and phytosanitary certificate can be used to facilitate trade, but is not a U.S. requirement,” adds the CFIA.

Results of 2018

Canada’s farm cash receipts:

Canola

Wheat

Soybeans

Corn

Ornamental horticulture

Field vegetables 7. Greenhouse vegetables

Flower exports have grown by 46% since 2014

Source: Flowers Canada Growers

Canadian floriculture farm gate sales increased by 3.51% to $1.556 B year-over-year

Designed as an affordable automation solution, BigTop solves the repetitive task of moving and spacing pots. AIS’s flagship patented, autonomous mobile robot uses a set of sensors to observe its surrounding environment, enabling it to operate autonomously and make decisions. Suitable for indoor and outdoor use, it can carry up to six or more pots at one time, handle pot sizes from six to 12 inches wide, and carry up to 30 kg (65 Ibs) per load. Operating independently or controlled remotely via an app, precise spacing is chosen by the operator. Full training and support is provided by the manufacturer. agrinomix.com

With cloud solutions, IoT, AI learning and big data, merging and analyzing the information can be complex and timeconsuming. Enter eGro. First launched in the Netherlands and now in North America, eGro is an award-winning software platform that allows growers to collect and combine relevant data from the greenhouse, giving them a comprehensive picture of the rootzone, the crop, climate conditions, irrigation and harvest results all in one place. It also provides intelligent, data-driven recommendations to help growers optimize their production. Developed with growers worldwide, the software platform is and will be continuously developed based on feedback. It can be connected to the most common climate computer systems and is available for smartphone, tablet and desktop. grodan.com

The HV-100 by Harvest Automation is a fully autonomous robot for containergrown plant movement (spacing, collection, consolidation) both indoors and outdoors, in full-sun and fulldark environments. Effective in the greenhouse, hoop house and nursery, HV-100 offers high placement accuracy and can handle all common container sizes and materials. Robots work safely alongside people and require minimal training and setup. No programming required. Quick swap rechargeable batteries. public.harvestai.com/

is a greenhouse AI platform that uses computer vision to monitor crop growth in your greenhouse. At first glance, LUNA reminds you of an upside down train riding on tracks above the plants. The camera vision captures endless images as it rides around your greenhouse and then sends those images to the company’s greenhouse data collection to be translated onto an app that can be accessed on your cellphone or laptop. If there’s a problem with your growth rate, temperature or even a couple of mites, LUNA notifies you immediately, even if the problem is only in a 3 foot x 3 foot section of your operation. LUNA sends you a warning, and you solve it before it’s a problem. iunu.com

This SMC grading and tray pack system from Total Operations Performance Inc. (TOP) in Waterloo, Ont. analyzes mini cucumbers and places them into specific tray pack configurations. It features a vision system that grades each mini cucumber by length, width, taper and bend; a tray de-nesting feature that loads industry-standard trays; and the ability to pack up to 7,200 mini cucumbers per hour. In addition to reducing labour costs, this self-contained, portable turnkey solution can record and report data on a daily, weekly or monthly basis, as well as integrate data from the greenhouse climate computer. topinc.ca

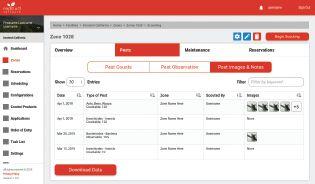

Built by growers for growers, RedBud delivers modern agricultural software to keep ongoing records of the greenhouse in one place. It’s designed to help growers make data-driven solutions, improve crop outcomes and ensure regulatory compliance. The browser-based software offers tracking of plants and available space for more efficient use, a readily accessible record of pest observations with costs and measured effectiveness of product applications, a task management feature for assigning tasks to team members with records of who completed the tasks and when, and a maintenance module to track greenhouse equipment and its upkeep. RedBud is built to operate intuitively and consistently with existing practices. redbudsaas.com

growing environment, a simple, flexible, and sustainable control system is crucial. This is why proactive LPs are turning to Reliable Controls. Our nation-wide network of factory-certified

Authorized Dealers will design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely-controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective and Canadian-made solution, please contact a local Reliable Controls

Authorized Dealer near you.

Bullying and harassment are behaviours intended to humiliate or intimidate an individual. These issues occur in many workplaces, including some greenhouse operations, and they pose a potentially serious risk to the mental and physical health, well-being and safety of workers.

As of 2013, Canada’s Workers Compensation Act requires employers to have a bullying and harassment policy in place or a respectful workplace policy as part of their health and safety program.

Because bullying and harassment can come from co-workers, supervisors, employers, or other sourc-

es that aren’t always onsite, the respectful workplace policy applies to everyone.

Behaviours that indicate bullying or harassment in the workplace include targeted verbal aggression, personal attacks, spreading of malicious rumours, alienation and sabotaging others’ work. Incidents can arise as a result of personality conflicts, personal or workplace stress, or preconceived perceptions about cultural or language differences.

If unchecked, the situation can have serious consequences for the target as well as co-workers, family and friends. In the workplace, bullying and harassment might lead to health and safety issues, such as distraction during dangerous tasks, physical and/or psychological injury, lower productivity and morale, more absences and greater staff turnover.

It’s important to note the difference between family- and non-family-owned operations. In family-run operations, familial dynamics and conflicts must be kept separate from workplace dynamics, especially if non-family workers are involved.

Mitigating bullying and harassment starts with workplace policy, but employers can also role model and foster positive, respectful behaviours. Learn how to recognize the signs of bullying and harassment within your operation. Educate your workers and supervisors about its dangers, and train your staff on how to address the issues respectfully. Implement an open-door communication policy. Listen to concerns and investigate incidents or complaints when they arise.

Co-workers can also mitigate bullying and harassment by not engaging in gossip, speaking up against bullying, and being supportive by listening and reporting incidents.

The benefits of having a respectful workplace policy are many, as it:

• Shows that you value your employees as individuals

• Easily identifies the difference between one incident or a pattern of behaviour

• Allows issues and complaints to be addressed in a neutral non-personal manner

• Helps retain good employees who are loyal and productive, helping them feel respected and well-treated

In contrast, not having a policy in place can lead to:

• A dysfunctional workplace environment

• Financial and legal implications, such as loss of productivity, fines, or legal action

• Poor workplace morale, employee time loss or high worker turnover

• Costly follow-ups and investigations

• A negative impact to the company’s reputation

To start building bullying and harassment policies and procedures for your operation, visit http:// agsafebc.ca/bullying-and-harassment/, which houses resources such as sample reporting and investigative procedures, templates for worker complaint forms and more.

AgSafe BC’s “What is Bullying & Harassment” video, available at http://agsafebc.ca/tools/videos in English and Spanish, further explains behaviours indicating bullying or harassment and how to address them. The video also explains what actions are not considered bullying or harassment but are reasonable workplace management protocols.

TJ Garcha is the senior safety advisor at AgSafeBC, the health and safety association for agricultural employers in British Columbia.

Fast

Self

Low

Long

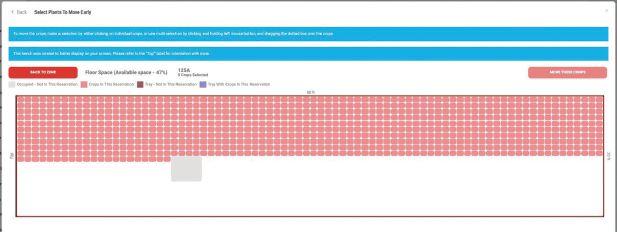

Managing scarce space in a large greenhouse operation can be a daunting task. It’s like a puzzle the grower has to manage—starting with the basic fact that plants get larger as they grow and may require different environmental conditions at various times.

Critical tasks can be associated with different stages of the plant’s development and have to be tracked. Ideally, the grower will have a usable permanent record of where a plant has been in in the greenhouse and what has happened to it throughout its journey, so they can evaluate what’s working and what isn’t.

Space is expensive too. It’s important for the grower to be able to see how much space is being

used and how much is still available, not just today, but at any given point in the future to aid in planning.

Many growers attempt to manage this very complicated issue with spreadsheets. If the operation is growing only one crop at a time and the cycle is fairly straightforward, spreadsheets can be one way of tracking space.

or retires, a lot of business-critical information usually leaves as well.

Modern software can make space management a lot easier, and can provide a lot more useful information. A good software system should provide visibility to everyone in the organization who needs it, both of the current space occupied, any available space and planned space utilization at any point in the future.

Modern software will also provide the grower with the ability to create templates based on the growth cycles of each crop in the greenhouse. Plants don’t always grow the way you expect. Even in a greenhouse, results can differ between seasons of the year, based on outside temperatures, light levels and other factors. A good software system will allow the grower to plan for these types of differences and make changes on the fly.

A well-designed software system should provide visibility not just of space usage at a macro level, but also down to the bench and individual plant level. Ideally, the system will include a mobile app with phone-based QR codes for plant tracking, so plants can easily be identified in the software and manual record-keeping can be kept to a minimum.

A thoughtful software system not only tracks space availability, but can also provide a visual head’s up of potential problems in the greenhouse. This could include pest and disease issues, which can be highlighted on a heat map. Numbers and reports don’t always draw attention to the biggest problems.

ABOVE

Plants grow up and move around in the greenhouse. Tracking where they’ve been, where they’re going and when can help you better manage your space and generate more reliable records.

Spreadsheets have a number of drawbacks though. A spreadsheet is often not available to everyone who may need access to the information, and spreadsheets typically do not display information in the most useful way for visualizing space.

To get more in-depth analysis from the information, the grower has to be a “spreadsheet jock”, and this isn’t a skillset that every grower possesses. Recording data on a spreadsheet also represents precious time spent in the office being a “bookkeeper” instead of being out with the plants. Spreadsheets like this can also become ponderous over time, and when the staff member managing the spreadsheet leaves the business

Modern software can also track inputs and conditions that affect each plant, based on the various zones that have housed the plant throughout its time in the greenhouse. In order for the grower to start using data for tracking trends, the information must be accumulated, searchable and easy to analyze. Tracking the various inputs that affect each plant—including temperature, humidity, light, soil conditions, pest and disease issues and much more—can provide extremely useful information over time that can help improve production and quality.

Bob Wiggins is CEO of RedBud SoftWare, Inc., www.redbudsaas.com.

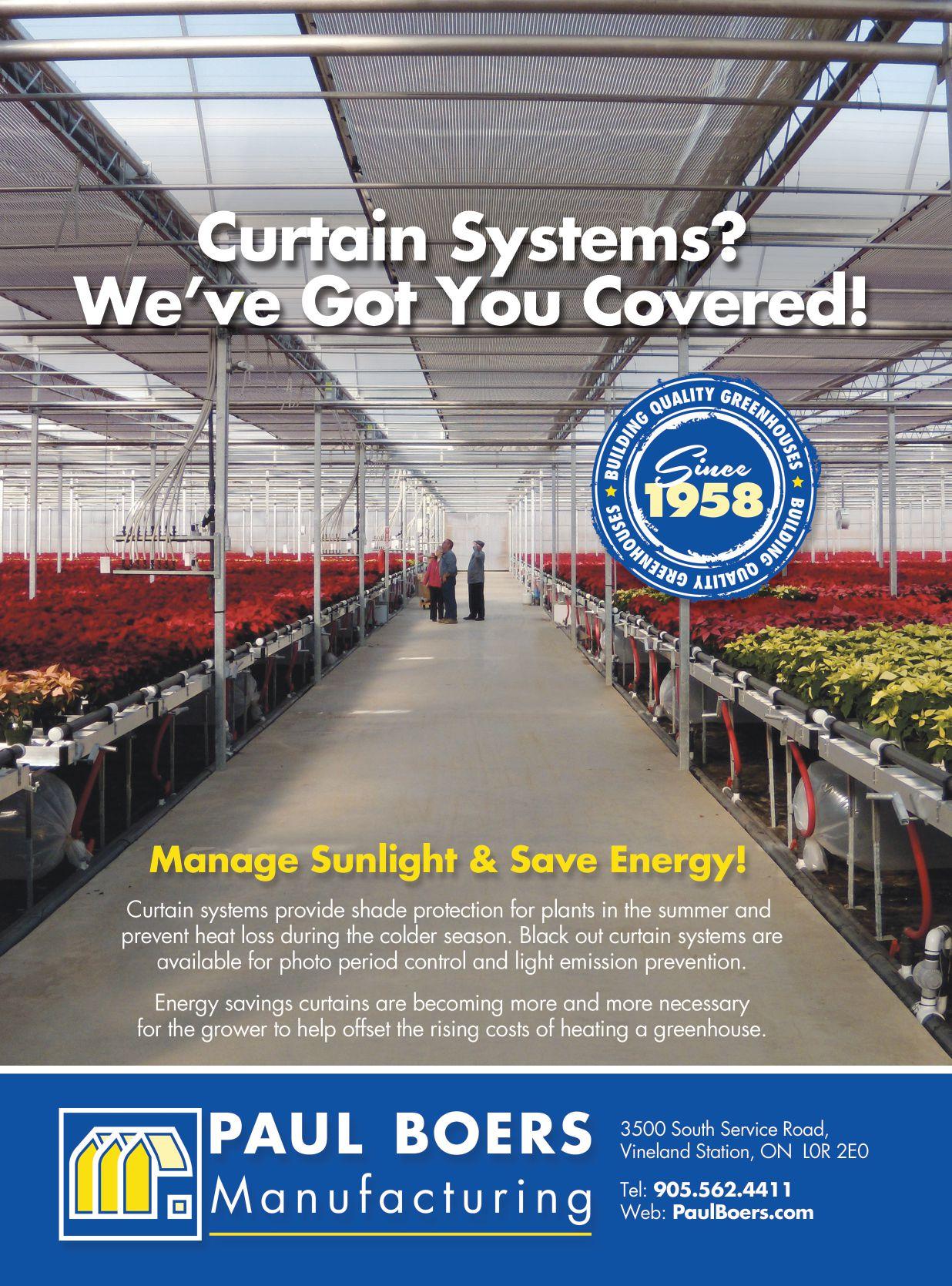

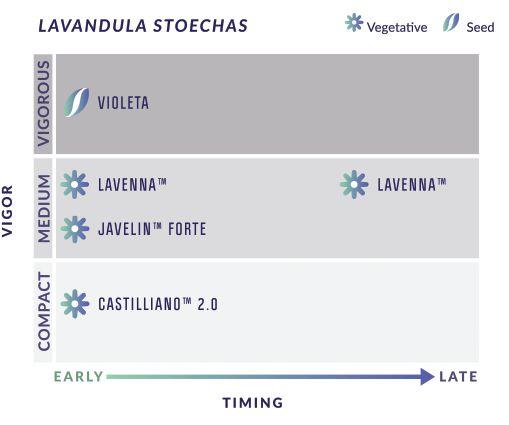

Greenhouse curtains aren’t just for heat retention anymore.

BY TREENA HEIN

Even though natural gas prices are not extremely high right now in Canada, the Canadian climate makes energy curtains a must. They both conserve energy and provide a crop with more uniform temperature conditions, if used properly.

For many years in Ontario, every glass greenhouse and many poly houses have had at least one energy curtain in place, according to Shalin Khosla, greenhouse vegetable specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs. In the last five years, more growers have been looking to install not one, but two curtains in their glass houses.

The first one is usually an energy

ABOVE

curtain that provides about 25 to 35 per cent savings in heat, while the second is usually a partial energy curtain that acts as more of a shade curtain, which saves an additional 15 to 20 per cent in energy use, he explains. “It generally pays for itself in three to four years. The lighter ones can also be used for shading the crop.” Khosla notes that new curtains are more durable and provide better performance in terms of energy savings and light transmission. Some offer extra features such as ease of cleaning, allowing the transmission of moisture and prevention of dripping water.

In BC, Laura Bryce, an instructor at Kwantlen Polytechnic University

With peppers being more sensitive to light, Allegro Acres has seen a greater need to use energy curtains in the early part of the year.

in Langley and a former vegetable grower at a BC Village Farms operation, notes that energy curtains are a standard in any new construction. She adds that there is also merit in retrofitting older greenhouses with curtains, particularly operations with higher-value crops such as some cut flowers or vegetables and cannabis. Two screens are common in floriculture operations that require both photoperiodic control and shading. Being more sensitive to sunscald than other vegetable crops, bell pepper crops also commonly see the use of two screens, she explains, and they benefit from the thermal heat retention properties of the fabric during cooler temperatures.

Gene Ingratta, owner of Allegro Acres in Kingsville, Ont., has been using two sets of energy curtains in the 12 acres of glass greenhouses he built in 2012 – this year for growing peppers and the last seven years for tomatoes. He chose to install two screens to conserve heat because natural gas prices were very high at the time. Working with Svensson, Ingratta went with a ‘Harmony’ curtain for more shading properties paired with the transparent ‘Luxous 1243’ for his second screen (formerly called ‘SLS10’).

Ingratta says his experience with the curtains “has always been great, but you learn a bit more every year about humidity control and opening and closing to avoid damaging the crop and the greenhouse.” Switching his glass house crop from tomatoes to peppers in January 2019, he found that the curtains were in greater need during the first two months of the year for light diffusion, as peppers are more sensitive to light than tomatoes and grow more slowly

Because his SLS10 curtains are starting to show signs of wear, with dirt buildup and age beginning to limit light transmission, Ingratta plans to replace them in the near future with a set of

Luxous 1147 FR. He says these curtains have good light transmission, as well as improved moisture permeability. They also provide energy savings of 47 per cent compared to having no curtains installed, Ingratta explains. With different ways in which they can be used, this model offers him the most flexibility for the type of weather conditions experienced in Kingsville. On colder days, the curtains can be left extended but still allow incoming light without losing heat. On a fairly warm spring day, the curtains can offer light shading without the rigidity of whitewash. As well, the curtains allow for more even humidity control in the greenhouse.

The energy savings offered by any given set of curtains are determined by a number of properties. According to Esteban Baeza, a researcher in the Greenhouse Technology Group at Wageningen University & Research (WUR) in the Netherlands, these properties include transmission and absorption of thermal radiation, as well as aerodynamic properties (mainly air permeability), which affect both the amount of heat lost by convection through the screen, and the amount of moisture it can transport by convection, diffusion and direct transport.

Baeza and his colleagues have developed standardized protocols to measure these physical properties and to also estimate their potential for energy savings. They used samples from energy-saving screens received from different companies and found very different values for the measured properties, which meant different potential values for energy savings. Screens with low emissivity provided the greatest energy savings. Baeza adds that “the highest energy-saving screens are also the ones with lower moisture transport, which has the consequence of increasing

the humidity below the screen to (probably) too high values. In such situations, growers open gaps in the screen closure to enhance moisture transport to the upper compartment above the screen, or use other types of dehumidification systems.”

It is important to note however, that condensation on the screens, which can

LEFT

Baeza

screen is used, can modify the screen’s physical properties – but he and his colleagues are not sure to what extent. “That is why we are now adapting the measurement protocols…and if required, corrections to the simulation models will be made to more accurately simulate the screen performance between fully dry and fully wet stages,” he says.

For the moment, there is no set norm that must be followed by companies in order to provide objective values of the relevant physical properties of screens, he says, so that customers can compare screen models with standardized measurements of their physical properties.

As with most tools, proper use of energy curtains will come with time and experience, but Khosla has a few pieces of advice. “Make sure you don’t open them too

he says. “Don’t delay in opening them in the morning or you will lose the benefit of morning sunlight, but at the same time, they should be closed in the afternoon if there isn’t strong [enough] sunlight in order to reduce heating costs.”

Bryce notes that research conducted in the Netherlands has shown that humidity inside can be managed more effectively by opening the lee and wind side vents together, without gapping the curtain.

The alignment of lee and wind ventilation increases air circulation to remove excess moisture without disrupting the horizontal temperature distribution below the curtain. “This allows the newer, more permeable curtain fabrics to do some of the work of moisture reduction and [not] reduce potential for energy savings,” she explains. “I also think monitoring the temperature above the screen is very important in keeping temperatures stable, especially during active operation of the equipment opening and closing.”

Rob Hanifin, Svensson greenhouse climate consultant, says more and more vegetable growers in Canada are turning to transparent energy screens to help in their climate management. “As growers gain more experience with their screens, they also learn to use them as a tool for best climate management beyond just considering them as heat curtains,” he notes.

Hanifin believes that screens will continue to be engineered for greater transparency, and grower practices will evolve further with more creative screen use, using multiple screens to maximize energy savings and achieve better climate control.

Currently, Baeza and his colleagues are conducting various research projects involving new materials provided by companies, but it’s all confidential. He can report on another project, however, where he and his team have been able to identify a new material which combines low, far-infrared radiation (FIR, a.k.a. thermal radiation) transmission and high visible light transmission with extremely low permeability to air but high permeability to water vapour. “This would allow for a rather large energy saving, the possibility to use these screens during daytime on dark days, and better control of humidity below them, perhaps preventing the need to open gaps or to use other dehumidification methods,” he explains. “These materials still need to be tested on the field, but simulations show promising results.”

The basics of integrating microbial biofungicides into your current program.

BY DR. MATTHEW KRAUSE AND DR. SARAH JANDRICIC

Microbial biofungicides have come a long way since their introduction to North American greenhouse horticulture in the 1990s. While many growers regularly use one or more biofungicides in their integrated disease management (IDM) programs, others are hesitant to try them. Reasons for this range from “they haven’t worked for us in the past” and “they seem more complicated than chemicals,” to “we don’t see how they’d benefit our crops more than our chemical program.” When thinking about your own reasons, keep in mind that microbial fungicides have gone through a steady evolution over the past 20+ years. Product options, formulations, technical know-how, use-patterns, and efficacy have steadily improved and alleviated many grower concerns. This is similar to the path taken by commercially produced arthropod natural enemies – a group of beneficial organisms which now has a 90 per cent adoption rate across the industry.

This article describes what microbial biofungicides are, why growers are motivated to start and

ABOVE

continue using them on their farms, and how you, too, can incorporate these products successfully.

By definition, microbial biofungicides contain active ingredients that are specific strains of living microorganisms. Their formulations include live microbes themselves, and frequently, their metabolites or byproducts. Most of these products work against diseases via two or more non-toxic modes of action (MOAs), which makes it difficult to develop resistance to them. The most common MOA categories for registered microbial active ingredients are presented in Table 1. In contrast, chemical fungicide active ingredients work by disrupting a single specific biochemical process of a specific pathogen group or by a direct toxic effect against one or more pathogen groups. With repeated use, resistance to many chemical fungicides builds up rather quickly.

Note that ALL microbial products sold in Canada with pest control or suppression claims on the label must be registered with the PMRA, just like

Example of a root rating system to compare the effects of registered biofungicides to a grower’s current chemical program. A subset of plants must first be pulled and ranked from “worst” to “best”, (usually along a 4- or 5-point scale) to provide a visual comparison against which to rank the rest of the plants in the study. Here, root density was ranked from 0 (worst) to 4 (best), from left to right.

Nutrient Competition Restricts or diminishes pathogen growth, development, or activity by consuming or inhibiting consumption of available nutrients

Niche Competition

Limits or reduces pathogen levels by occupying space on and around host plants, or by blocking access to host plants

Parasitism or Predation Reduces and eliminates pathogens by using them as nutrient sources

Antagonistic Metabolites Produces and releases enzymes, surfactants, or other bioactive substances that directly degrade or kill pathogens on and around host plants via non-specific mechanisms (e.g. cell-wall degradation, membrane disruption, or nutrient scavenging)

Induced Host Resistance Interacts with specific plant species to activate plant defences against pathogens, either through systemic acquired resistance or induced systemic resistance mechanisms

ABOVE

Table 1. Common categories and characteristics of microbial active ingredient modes of action against fungal, oomycete, and bacterial plant pathogens.

their chemical counterparts. By nature, this means these products have undergone both safety and efficacy tests before registration. Be wary of products without a pest control product (PCP) registration code; even if such products contain similar microorganisms as registered ones, different strains have completely different biological characteristics, much like different plant cultivars. Products without a PCP code have not undergone unbiased assessment of their effects on pathogens and safety to humans, non-target organisms and the environment. Table 2 provides examples of microbial biofungicide products that are registered in Canada by the PMRA and the specific strains considered as their active ingredients.

It’s also important to keep in mind that while these organisms can be highly effective, they’re not magical. Like chemical fungicides, they don’t offer 100 per cent protection or cure diseases on already impacted plants. Though they work well preventively against low to moderate pathogen levels, they don’t work when disease pressures are overwhelming. For the record, neither do fungicides. Because these products often contain living microbes, their use and care also differ from chemical fungicides. Namely, they are less effective in environmental extremes, have defined shelf lives, and frequently must be prepared, applied and stored under stricter conditions. Always read the label regarding proper storage and application procedures, as these can differ between products depending on the organisms involved and their formulations.

There are compelling reasons why many growers have shifted away from using chemical fungicides to try and “cure”

problems when they pop up (a reactive approach) and have turned towards programs relying heavily on microbial fungicides (a preventative approach). These typically include:

• Greater safety for workers, consumers and the environment than conventional fungicides – this is confirmed by lower REIs, PHIs, PPE requirements, and exemptions from residue tolerances on edible crops

• Reduced likelihood of developing resistant pathogens, since each product contains active ingredients with two or more non-specific modes of action

• Compatibility with many conventional fungicides in disease-management programs, ultimately reducing pathogen resistance to conventional chemicals and decreasing chemical residues on edible crops

• Better prices for “greener” crops on the market, which are gaining traction due to public concerns driving greater consumer demand

Unfortunately, in our industry, integrated disease management seems to simply refer to fungicide rotations for managing resistance, as IPM once did. Developing any true IDM program, using microbial and chemical fungicides alike, requires a proactive systems approach. This means looking at your whole operation, processes and incoming plant material to see where cultural practices and other preventive strategies can be deployed before considering heavier-hitting chemical agents. Below are the major tactics growers can implement for an effective IDM program incorporating biofungicides.

1. Make sure you’re using ALL of

the following cultural practices to prevent introduction and spread of diseases.

Exclusion: prevent contaminated cuttings, seed, transplants, irrigation water, and other inputs from entering your operation.

Sanitation: remove diseased plants and crop residues from growing areas; properly sanitize floors, benches and cutting tools and disinfest recycled irrigation water.

Manage your environment: reduce or eliminate conditions that stress plants and favour the growth and development of key pathogens. Closely monitor humidity, leaf and soil moisture, temperature in and around the canopy and soil, soil pH and EC. Avoid practices and inputs that promote diseases and pests: e.g. overwatering, high salinity, unstable growing medium components, hours of leaf wetness, etc.

2. When it comes to diseases, don’t guess. Since diseases caused by different pathogens often look alike, obtain accurate diagnoses from a qualified plant clinic. Proper diagnosis helps in selecting the correct biofungicides, chemical fungicides and practices to manage diseases that affect your specific farm (not just the ones most commonly associated with your crop).

3. Think in terms of programs instead of products. This means planning for your season, including all preventive strategies for common diseases that have appeared in your crop before. Strategize from propagation to shipment.

4. Select the correct products and formulations for the job. During your planning phase, consider both

Product Active Ingredient(s)

Actinovate SP

Asperello T34

Contans

MycoStop

PreStop

Rhapsody ASO

RootShield HC, WP, Granules

RootShield Plus WP

Streptomyces lydicus strain WYEC108

Trichoderma asperellum strain T34

Coniothyrium minitans strain CON/M/91-08

Streptomyces strain K61

Gliocladium catenulatum strain J1446

Bacillus subtilis strain QST 713

Trichoderma harzianum strain KRL-AG2

Trichoderma harzianum strain KRL-AG2 plus T. virens strain G41

Manufacturer/Distributor Target Diseases

Monsanto

Multiple foliar and soilborne diseases

Biocontrol Technologies, SA Fusarium wilt

Bayer CropScience Sclerotinia diseases

Lallemand Plant Care Multiple soilborne diseases

Lallemand Plant Care

Bayer CropScience

Multiple foliar and soilborne diseases

Multiple foliar diseases

BioWorks Multiple soilborne diseases

BioWorks

Serifel Bacillus amyloliquefaciens strain MBI-600 BASF

Stargus Bacillus amyloliquefaciens strain F727

Taegro 2

Trianum

ABOVE

Bacillus subtilis var. amyloliquefaciens strain FZB24

Trichoderma harzianum strain T22

Marrone Bio Innovations

Multiple soilborne diseases

Multiple soilborne diseases

Multiple foliar diseases

Novozymes BioAg Multiple foliar and soilborne diseases

Koppert Multiple soilborne diseases

Table 2. Examples of the various species and strains of fungi or bacteria found in microbial fungicides registered for use on greenhouse crops in Canada. Please refer to current product labels for specific crop, disease, application, and safety information.

the product that is best suited for managing the pathogen of interest and how you intend to apply it in your growing system. For example, Wettable Powder (WP) or Wettable Granule (WG or WDG) formulations are intended to be mixed with water, then applied as soil drenches, soil sprays, foliar sprays, cutting dips or seed treatments. Since the active ingredients in these formulations are bacterial or fungal cells or spores, they must be kept agitated during application to make sure you’re applying the same concentration of cells/spores all the way through application. Granule formulations, on the other hand, are intended for application to soil or growing media. This is done through pre-plant mixing or incorporation, top dressing, side dressing, or application in furrow.

5. Always follow instructions on manufacturer labels and check the technical bulletins. Proper application rates and timings are critical to maximizing efficacy, as they are suited for either specific pathogens or specific conditions where microbials function best. Following safety requirements is not only essential to protecting

worker and consumer health, they also promote better treatment of crops. Since microbial biofungicides are living organisms, it is crucial to follow storage and handling instructions to ensure they remain viable and effective throughout their defined shelf lives.

6. Consider compatibility with other products. This helps you build the most cost-effective programs. Tankmix or rotational compatibility can help economize programs by decreasing application labour and increasing control by attacking pathogens with more than one MOA. Incompatibilities can often be overcome simply by staggering applications by a few days.

Along with the above, one of the most important things you can do to ensure success with microbial biofungicides is to test products on a smaller area before going “all in”. This helps you learn about the unique properties of the products (storage, handling, application) and lets you compare head-to-head with your current disease management practices. Before you begin, always identify which criteria you’ll use to define “success” for both the microbial fungicide and your comparison treatment(s). Examples include disease

severity, overall root or plant health, quality level, marketable yield, overall shrink, and ultimately, cost in use for the same or greater yield.

More information on conducting onfarm tests can be found at ONFloriculture. wordpress.com. Document your comparisons regularly throughout the crop cycle; an easy way is by taking pictures with your smartphone to record the good, the bad and the unexpected. Make sure to label treatments!

Lastly, don’t be afraid to ask for more information. Contact manufacturers, qualified consultants, and specialists in your province for advice. A lot of great application information that complies with the label is not on the label, including several years of real-world experience from other growers in your area who may regularly rely on microbial biofungicides for disease management.

Sarah Jandricic, PhD, is the floriculture integrated pest management specialist for the Ontario Ministry of Agriculture, Food and Rural Affairs, sarah.jandricic@ontario.ca. She also runs ONFloriculture.wordpress.com, filled with timely information for growers. Matthew Krause, PhD, is the North America technical lead for covered crops at Lallemand Plant Care, mkrause@lallemand.com.

BIG® Begonia, the most trusted begonia in its class. Period.

BIG® Begonia at its home turf on a hot August day in Germany, near the Deutscher Reichstag. BIG has been thriving in the rain, heat, full sun, and shade of the Berlin summer. Looks better than ever!

With multiple series available for popular perennial crops, the season can be extended for both the grower and the retailer.

BY MIKE FISCHER

Iremember a simpler time in my life. The only decisions I had to make were what I was going to wear that day and if I wanted a hot or cold lunch at school. The task of scheduling perennial production was equal in its simplicity not all that long ago. Only a handful of traditional varieties were available to choose from and all required vernalization. The only real decision was how many Salvia ‘May Night’ a grower wanted to produce that year.

As all things in life like to change, so did consumer interests. As more families were owning homes and succumbing to demanding schedules, there was a growing appeal to being able to add colour into their landscapes with just a single planting. With increased perennial demand came new breeding, new young plant forms and a need to have perennials on the shelf year-round. Flash forward to today, breeding has come a long way to accommodate this flourishing market, offering new and interesting products that can be grown throughout the season. That is why we are seeing more breeding companies collaborate in their perennial portfolios. ThinkPlants is one example of a larger collaborative effort involving multiple breeders, pooling early-season perennials with first-year flowering selections to keep products on shelves

throughout the season.

Perennials will always be limited by seasonality with regards to when they can go to market, however, new breeding has helped to blur those lines. First-year flowering perennials have removed the need for costly vernalization and over-wintering on crops like Leucanthemum, Lavender, and Coreopsis. Western Star Leucanthemum and Lucille Leucanthemum series are great examples of how new breeding has made it easy to have high-selling perennials blooming outside of their normal season. There are other selections that have traditionally required vernalization, but with new genetics, are now firstyear flowering, including certain varieties of Gaillardia, Salvia, Agastache, Campanula and Achillea. These offer growers the ability to have plants in front of the consumer before they would typically start blooming in the landscape.

Varieties that require vernalization to bloom can still have a special place in a grower’s early-season assortment. These species are planted in the fall of the previous year. They can then be bulked, vernalized, and forced into flower in early spring. Vernalized plants tend to be hardier and more coldtolerant. Certain series of Iberis, Saxifraga and Aubrieta for instance, will not flower without a cold treatment, so be sure

to check with your breeder.

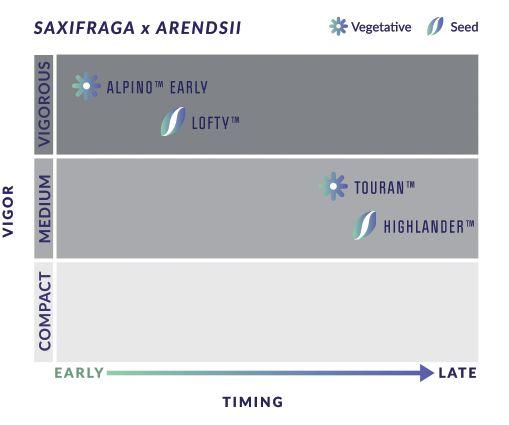

In both the first-year flowering and traditional varieties, different series can have multiple bloom times ranging from early spring to late spring. Having multiple selections can assist in spreading out and lengthening overall bloom time throughout the season. There are also differences in vigour and input forms (seed vs. vegetative) to better fit varying production models and streamline the planning process. Here we’ve used Saxifraga, Iberis and lavender as examples.

Saxifraga has several selections to help conform the crop

to multiple production schedules. Figure 1 shows how these series differ in vigour and bloom time. By using both the Alpino and Touran series in a production program, the grower has the ability to spread out their season. Lofty, Syngenta’s seed form of Saxifraga, is perfect for small container production. Lofty can also be grown in 2.5-gallon containers, but the series lacks the depth in colour that can be found in vegetative breeding. Figure 1 depicts how these options can be used to best fit each grower’s program.

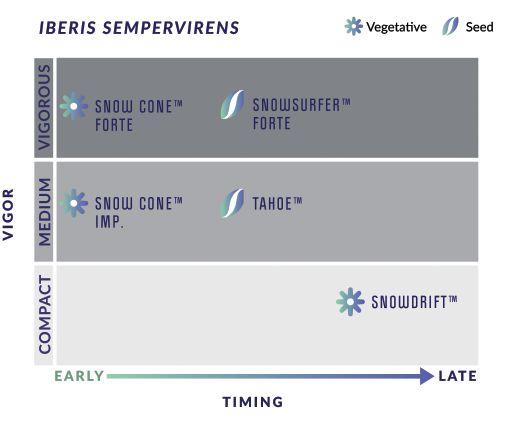

Iberis also has multiple selections to address different

climatic regions and cultures. Similar to Saxifraga, they allow growers to have a single plant date with varying bloom times. This delay in blooms allows for an extended shipping season. The most recent introduction, Snow Cone Forte possesses higher vigour, allowing for a shorter time period to bulk a 2.5-gallon container before starting vernalization. This can be beneficial if there is a lack of space in the greenhouse or high temperatures which may make traditional planting dates difficult. If a grower struggles with propagation or is in need of a more economical option, Tahoe, a variety propagated from seed could be a solution. Refer to Figure 2 for examples of variety selections and how they might fit a customer’s needs.

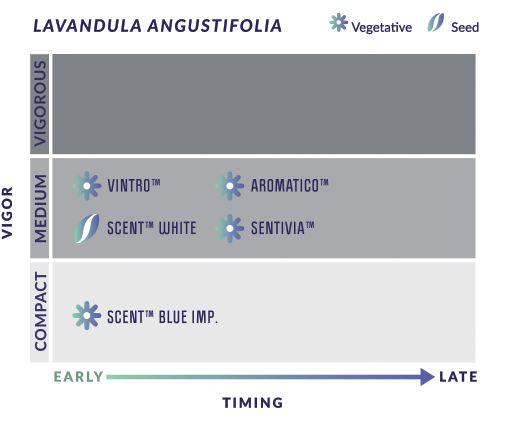

Because of its popularity, lavender has multiple varietal solutions to fit any program. Whether it is Spanish or traditional English, seed or vegetative, new breeding has expanded this market far beyond the original Hidcote or Munsted. With Vintro, there are now improved genetics that produce a more attractive plant. Though Vintro still requires vernalization, this option allows you to have lavender in stores earlier than the first-year flowering series. To lengthen the season, the grower could then follow with a spring planting of either Aromatico or Sentivia, which are both first-year flowering varieties (Figure 3).

While seed is typically segregated to small pot production, new breeding has introduced a stoechas lavender that rivals vegetative lines. Violeta, introduced for 2019, has the bloom size and repeat flowering to compete with both Javelin Forte and Laveanna (ThinkPlants vegetative varieties). This solution can be helpful to those growers that may find vegetative propagation of lavender difficult. Figure 4 shows how selecting from the available varieties can fit a season-long program.

While it would be nice to treat perennial production planning like Steve Jobs’ wardrobe, the market demands more than just a black turtleneck sweater every day of the week. This article highlights just some of the ways that new breeding has taken perennials from backyard finds to finely tuned varieties similar to their annual cousins. Despite sounding more complicated, this has streamlined production planning and allowed growers to produce the diversity demanded by this industry’s customers.

Mike Fischer is the perennial technical services representative at Syngenta Flowers, a participant of ThinkPlants (ThinkPlants.com), a marketing initiative among different breeders and other horticultural experts. He can be reached at Mike.Fischer@syngenta.com.

Registered for use on cannabis raised indoors, KOPA insecticidal soap controls whiteflies, spider mites, aphids and other soft-bodied insect and mite pests on contact.

OMRI® CANADA Listed for organic production, KOPA can be used right up until the day of harvest. KOPA is lethal to pests, yet it is of low risk to workers and the environment.

KOPA. When clean product is your only marketable option.

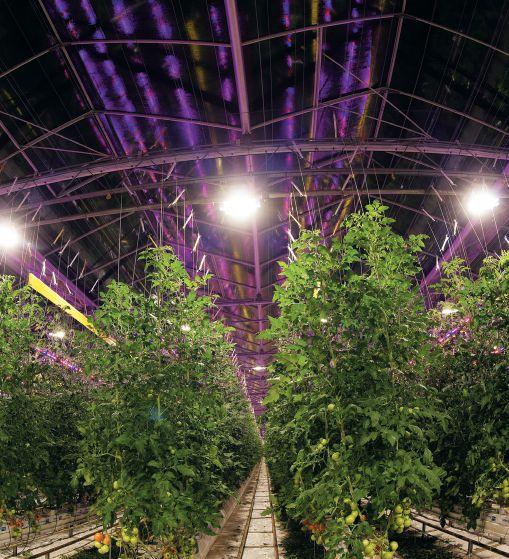

Looking to try out new lights for your operation? Don’t start before answering these questions.

BY DR. CHEVONNE DAYBOLL

A significant number of research projects in Ontario and elsewhere have focused on understanding how LED lights affect plant growth and development. These studies are important, but the next step is for growers to learn how their own varieties and greenhouse environment will react to the change. The best way to understand if LED is right for your operation is to trial it out on your own farm.

You’ll need to decide on a few important parameters before you start trialing new lights in your own operation. Don’t proceed with an installation without first answering the following questions.

WHERE SHOULD A TRIAL TAKE PLACE?

The trial should be somewhere that is representative of your greenhouse, and where staff can comfortably work to collect data. Don’t put it in the dark back corner of the greenhouse where

ABOVE

plants never seem to grow right, just to get it out of the way. Remember that the goal is to see if it can fit into your production system, so make sure it is in an area that you use!

You’ll want to make sure that you have room for a treatment, the LED lights you plan to trial, and a control (what you are doing now). Finding space can be tricky. Consider the options in Figure 1. Having both the treatment and the control in the same range is okay (Setup #1), but it’s best to keep them separated by a few benches so you don’t run into any light overlap (Setup #2). The best option would be to use two similar areas or ranges that are separated (Setup #3), although depending on your greenhouse design, this might not be an option.

WHO WILL RUN THE TRIAL AND COLLECT

Dedicated staff are the best people to have looking

Before trialing new lights, it’s important to answer some key questions, such as who’s in charge, where it should be held and which parameters to measure.

Improved results thanks to Svensson’s

A little extra light makes a big difference. And sometimes it’s what you don’t see that makes the biggest difference. The energy-saving climate screen LUXOUS 1147 FR lets more light through without compromising on energy efficiency or moisture permeability. It contributes to a better growing climate so that you, the grower, can reap the fruits of untapped potential. We gladly share our knowledge – both international and crop-specific–with you because we realize that your success is our success.

Setup #1

Could get overlapping light treatments which will affect results

Setup #3 ABOVE

Setup #2

A buffer zone keeps treatments separate but in the same range

Separate ranges can make running a trial more costly, but with no light overlap and more data!

Examples of various lighting trial setups. Orange = Light treatment, Purple = Control, Blue = Buffer zone.

after a trial. Make sure they are interested in the project and aren’t biased towards a certain result. They should have strong

attention to detail, be able to take good measurements and notice anything that might be of interest. The ability to “stick with it” is important, since collecting data can be tedious and sometimes boring work!

The types of measures should be something you care about in production. So, if you care about improving the rooting of cuttings, try measuring rooting levels (e.g. how long it takes for roots to emerge from cuttings, reach the edge of the pot, cover 50 per cent of the media, etc.). Some common plant growth measures you might want to think about taking for lighting trials are: rooting time, height, time to flower, number of nodes, internode length, canopy shape or size and dry weight. These measures can be taken during a specific part of a production cycle (e.g. propagation) or over the whole crop cycle, which will require more effort.

You might also want to look at investigating how LED lights change your entire production system and look at metrics beyond plant growth. For example, LED lights don’t generate as much excess heat as HPS, and you may need to compensate for this loss of heat. Tracking the temperature at crop level and your heating inputs might be

important for you to make decisions about further investments. Are you interested in knowing how LED lights might affect your biocontrol program? Measuring the number of pests and beneficials caught on sticky cards in each zone throughout the trial can help to get a picture of what might be happening. If you want to know if a certain light spectrum can help to cut down on PGR applications, try measuring the number or volume of applications, hours spent grading a crop, or the size of the plant canopy.

Remember that taking measures doesn’t have to be all numbers. You can take weekly photos of whole plants or plant parts, like blooms, leaves or roots, grown under different treatments, then compare them visually or with a computer program. Just make sure to sample many different plants from across the treatment and control areas.

Ready to start a trial after reading all of this? Don’t be afraid to ask for help! Extension specialists, researchers, consultants and lighting company staff are all good resources that are available to help you establish lighting levels and spectrum, tailor the right equipment to your operation and more.

Chevonne Dayboll, PhD, is the greenhouse floriculture specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs. She can be reached at chevonne.dayboll@ontario.ca

Points you should consider as a potential landlord or tenant.

BY ERICH WEBER

Farm business and greenhouse owners are presented with all sorts of opportunities. You might be looking at expanding your operation and need another greenhouse, or, you may be thinking of slowing down and reducing production. Either way, it is always a good idea to weigh the options available to you. In this article, we are going to focus on leasing greenhouses, and what greenhouse owners (landlord) and farmers (tenant) need to consider before signing on the dotted line.

Leases can be beneficial to both the landlords and tenants. To the right, you will see the pros and cons of entering a lease, both from a landlord’s standpoint and a tenant’s standpoint.

As you can tell, there are both advantages and disadvantages to entering a lease. Before entering into a lease, you need to weigh the pros and cons to see if it makes sense to do so. If you do decide to participate in a greenhouse lease, either as a landlord or tenant, then you need to find someone to work with.

thorough lease agreement will, in the long run, be more beneficial to both parties. All written lease agreements should include the name and contact information for both the landlord and the tenant, as well as the legal description of the property that the greenhouse is being rented on. The following are some considerations for a written lease agreement, in addition to the basic information.

In order to have a successful lease, the landlord and the tenant will need to be able to work together. Asking for references can help ensure that both the landlord and the tenant are being truthful and fully transparent with each other. Honesty is very important for the lease to be successful. If it is believed that the lease can be successful for both parties, then it is time to start creating a written lease document. This will help both parties understand what each person is responsible for, and if there are any disagreements, how to solve them.

A written lease agreement can be as simple or as complicated as the landlord and tenant want it to be. A well-written and

The greenhouse would be kept repaired and in good order, which could lead to a higher sale price in the future, if you decided to sell.

If you are retiring from farming, leasing your greenhouse can help ease you in this transition.

How do I get paid if the tenant becomes insolvent or walks away from the operation?

Your revenue and expenses from leasing the greenhouse could be taxed differently.

If the lease is short term (1 year), there is a risk that the tenant is not able or willing to make improvements to the greenhouse.

Monthly lease payments are fully deductible for tax purposes.

You can share the risk of the greenhouse operation with the landlord.

If a change is needed for whatever reason, it can be expensive to terminate the lease before the end of the term.

You do not own the greenhouse at the end of the lease term, and therefore may not be able to grow the crops that you wish to.

Credit could be more difficult to obtain as the tenant would not have access to the equity of the greenhouse.

Our #1 grade Daylilies are generously sized at 3-5 fans for fast finishing plant.

Better roots, better business. That’s the bottom line.

From the beginning we have continuously worked to improve, grade generously, and offer the very best product we can. This goal has led us to become the largest supplier of bare root perennials in North America with one of the most diverse catalogs. Bare root has always been a part of our identity and represents our continued commitment.

We trim our roots to the essentials for a clean, easy to transplant product.

Maintenance and repairs: Who is responsible for maintenance or repairs? Would the landlord be responsible in making sure that the greenhouse is fully repaired at the beginning of the lease, making the tenant responsible for maintenance thereafter?

Crops to be grown: Are there any restrictions to crops that can be grown within the greenhouse (e.g. cannabis)? Are there any restrictions on how the tenant grows these crops?

Municipal zoning restrictions: Are there any zoning restrictions that would prohibit the tenant from growing the crops they intended to? Is it the responsibility of the landlord to guarantee that the municipal regulations would be met, or should it be the tenant’s?

Health and safety: Who would be responsible for ensuring that all proper health and safety regulations are met? Is the tenant responsible for providing and maintaining any protective gear used throughout the greenhouse?

Resolution of differences: If there is a disagreement between the landlord and the tenant, how does it become resolved?

What happens if the staff of the greenhouse are not adhering to the production practices outlined by the tenant? Who becomes the mediator/third party if the differences cannot be resolved between the landlord and the tenant?

Rights to assign or sublet the lease: Can the tenant sublet the lease to someone else? What is the procedure? How much notice must be given to the landlord before the change?

Right to access the greenhouse: How much notice must be given to the tenant before the landlord enters the greenhouse? Is there specific clothing/ protective gear that must be worn before entering the greenhouse?

Lease end date/extension: On what date does the lease end? Is there a lease extension, and if so, for how long? If the lease were to be extended, are there any changes that would need to be made to the lease (e.g. lease price)? What would constitute as grounds for the lease to end before the specified end date (e.g. lease clauses broken by either the landlord or the tenant, illegal activities conducted on the property, etc.)?

Utilities: Is there a separate utility meter at the greenhouse? Does the tenant get billed directly for utilities from the company? Does the landlord reimburse the tenant for any personal use of the utilities?

These are just some of the considerations that the landlord and tenant should consider when drafting the lease agreement. In most cases, there are no specific rules in the terms of the lease. It is the responsibility of both the landlord and tenant to have these conversations and come to an agreement. If you are concerned about any aspects of the lease agreement, it is always a good idea to speak with your lawyer, and make sure that everything in the agreement is appropriate. If you would like more information on the components of a lease agreement, please see OMAFRA’s Factsheet on “Lease Agreements, Farm Buildings,” which can be found at http://www.omafra. gov.on.ca/english/busdev/facts/13-055.htm

Erich Weber is the business financial specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs. He can be reached at erich.weber@ontario.ca

$16,999,000 (With Additional Land Available) INVESTMENT

$16,999,000 (With Additional Land Available) INVESTMENT FEATURES

• 22 Acre Greenhouse located on 70 acres

• 22 Acre Greenhouse located on 70 acres

• 95 Acres of additional land $2,000,000

• 95 Acres of additional land $2,000,000

• 15,000 SF Propagation Area

• 15,000 SF Propagation Area

• Latest PRIVA Operation System (fully integrated)

• Latest PRIVA Operation System (fully integrated)

• Temperature Controlled Processing Area

• Temperature Controlled Processing Area

• Full Generator Backup

• Full Generator Backup

• Nutrient Recycling System with Ozone Sterilization (pathogen controlled)

• Nutrient Recycling System with Ozone Sterilization (pathogen controlled)

• Municipal Water and Sewer Connection

• Municipal Water and Sewer Connection

• Well Sourced Water with Reverse Osmosis System

• Well Sourced Water with Reverse Osmosis System

• Natural Gas Powered Hot Water Heat with Storage Tank

• Natural Gas Powered Hot Water Heat with Storage Tank

• Horizontal Air Flow (HAF) fans

• Horizontal Air Flow (HAF) fans

• Construction: Single Tempered Glass (19.5’ ground to gutter)

• Construction: Single Tempered Glass (19.5’ ground to gutter)

• No Interruption Gas Contract

• No Interruption Gas Contract

Brent Rudell, Broker of Record 519.438.5608 brent.rudell@cushwakeswo.com Jameson Lake, Sales Representative 519.438.8548 jameson.lake@cushwakeswo.com Andrew Johnson, Sales Representative 519.438.8639 andrew.johnson@cushwakeswo.com

Andrew Johnson, Sales Representative 519.438.8639 andrew.johnson@cushwakeswo.com

Brent Rudell, Broker of Record 519.438.5608 brent.rudell@cushwakeswo.com Jameson Lake, Sales Representative 519.438.8548 jameson.lake@cushwakeswo.com

620A Richmond St, 2nd Floor, London, Ontario N6A 5J9 www.cushwakeswo.com

620A Richmond St, 2nd Floor, London, Ontario N6A 5J9 www.cushwakeswo.com

How will 2019’s successes and challenges affect 2020? Experts from across the country weigh in.

BY GRETA CHIU

From growth in acreage to viral concerns, the biggest topics of 2019 differed somewhat depending on the area of Canada. Though these issues will likely continue to impact greenhouse growers in 2020, industry experts and representative associations have continued to prepare their growers for the foreseeable road bumps ahead.

“It’s going to be one of the most important issues for tomato growers in 2020,” Niki Bennett says of the tomato brown rugose fruit virus (ToBRFV, a.k.a. ‘the rugose’). As the science coordinator of Ontario Greenhouse Vegetable Growers (OGVG) explains, there are still many unknowns about ToBRFV and limited options in the toolbox, but good sanitation practices seem to be able to prevent and eradicate the virus.

So far, individual countries have each developed their own protocols for testing, which may cause difficulties at the border. To standardize protocols, Canada, the U.S., and Mexico, are working on an internationally recognized test for the virus. DNA sequencing is the only currently available method for confirmation, but it can be costly and timeconsuming, says Bennett. In production environments, a simple test such as an immunostrip can serve as a quick indicator while waiting for the sequencing results to come back. If the immunostrip turns up positive, growers may assume that the plant has been infected with ToBRFV.

“Some loads you could still reship after four or five days,” she says, “but once it gets to the customer, who knows how long it goes before it reaches the consumer?”

Growers facing long wait times can also sell domestically, but removing any specially branded, retailer-specific packaging will incur extra costs, not to mention additional time and money spent on trucking. “It slows down trade,” says Delli Santi, “and it results in less fresh product.” By standardizing paperwork for both BC and Ontario, Delli Santi hopes that it will make the process more seamless for growers.

Ornamental producers aren’t in the clear either. As Dr. Sarah Jandricic, greenhouse IPM specialist for the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) notes on the ONFloriculture website, the U.S. federal order “may restrict export opportunities…on products such as ornamental or potted peppers, tomato seedlings and tomato transplants.” It is recommended that ornamental growers contact their local CFIA office for instructions regarding upcoming shipments.

It takes less work to pull out a single plant or a handful of plants than waiting another week for DNA results, says Bennett. Waiting might allow the virus to spread through the greenhouse even more. “We’re encouraging growers to be vigilant and to stay ahead of it,” she says. “Don’t wait. Take action first.”

In November 2019, the U.S. introduced new regulations on tomato and pepper imports for both propagative materials and fruits, requiring certification that shipments are rugose-free.

“At the border, the grower or company owner must present documents self-declaring that the fruit appears to be virus-free,” says Linda Delli Santi, executive director of the BC Greenhouse Growers’ Association (BCGGA). Each load is to be visually inspected, and suspect samples go to a USDA plant pathologist for further testing, which can delay shipments at the border.

The future looks bright for cucumber growers in Ontario. Glen Snoek, OGVG’s marketing and economic policy analyst says they’ve been seeing a lot of growth in cucumbers. “Opening up of new markets and diversification of product offerings…all of that is helping in terms of sales into the U.S.,” he explains. Going forward, they expect to see new Ontario greenhouses and increases in cucumber plantings, particularly as demand from the U.S. continues to rise. “We saw a 14 per cent increase in seedless long English cucumbers, but the bigger impact was on mini cucumbers – a 35 per cent acreage increase,” he says. “That really had an impact on pricing and availability in the cucumber segment.”

Overall, a substantial increase in Ontario greenhouse vegetable acreage is expected for the coming year. “We’re seeing additional investment into lit acreage,” Snoek says, referring to LED and HPS lighting, as well as “significant changes in how things are grown and how crop cycles work.” New investments in gas and electrical infrastructure will help allow for additional lighting and new greenhouse builds.

Cucumbers were also big in Alberta. The province saw an increase in winter production capacity of mini and long English

Total Ontario Summer Cucumber Exports by Month (kg)

Summer cucumber exports from Ontario continue to rise year-over-year. (Data from Agriculture and Agri-Food Canada.)

Guelph: 1-877-821-1684 orders@kams.ca

Kingsville: 519-839-4778 kvorders@kams.ca

cucumbers primarily from the expansion of existing growers, says long-time greenhouse consultant Dr. Mohyuddin Mirza. With greater adoption of LED lights, capacity for winter tomato production “gained a stronger foothold,” he says, along with organic winter production of both cucumbers and tomatoes. “Although Alberta growers are still price ‘takers’ and not price ‘makers,’ they did make some progress to influence winter prices,” he adds. As well, the “supply of fresh lettuce and other salad crops improved considerably with large-scale greenhouse facilities in Southern Alberta.”

In BC, new construction for greenhouse vegetables has mainly been in peppers. “It’s been the same for years – just slow and steady growth,” says Delli Santi. While tomatoes seem to be holding steady and cucumber area has experienced a slight decline, Delli Santi says their members will grow what the market demands, and some are looking into new crops such as greenhouse strawberries.

The gas pipeline rupture of October 2018 was easily the biggest challenge for BC, says Delli Santi. Prices skyrocketed from close to $3 per GJ up to $201 per GJ after the rupture, rising and falling erratically. “There was nothing you could do about the price of gas,” she says. “You can use it more efficiently, but you can’t do anything with the actual price.”

Foreseeing other sectors tapping into the pipeline, the BCGGA has been presenting their members with alternative options for natural gas suppliers such as Fortis BC. “Fortis BC doesn’t make money on the sale of gas,” she explains. “They only make money on the pipeline and the distribution system – at least on the commercial side.” As well, because Fortis BC owns pipeline north of the rupture, pricing has been less volatile than the area south of the rupture near the border. However, pipeline capacity has still not yet reached 100 per cent and that could lead to pricing volatility in the coming year.

For Alberta, energy was also a major challenge, but owing to changes in political climate and regulations. “The carbon levy weighed heavily on growers’ minds,” says Mirza, “[but] with good negotiations with the government, a rebate program helped to achieve some sustainability.” It offers an 80 per cent rebate to greenhouse growers on natural gas and propane used for crop

production – a structure similar to rebate programs in other provinces. As growers turn to more energy-efficient options, active conversations on carbon footprint reduction will continue to take place well into 2020 and beyond.

Labour was another key issue on growers’ minds in Alberta. “Availability of labour on a consistent basis was a challenge, and many growers tried to use as much local labour as possible,” says Mirza. To tackle this problem, the Alberta Greenhouse Growers’ Association (AGGA) was able to help regain farm status for greenhouses. “This has helped to resolve labour overtime issues and tax-related problems,” he says.

Québec-based greenhouse consultant, Michel Senécal says their growers were also having trouble filling key positions, including delivery truck drivers and greenhouse crop managers. “Some have not solved this problem,” he says, but a longer term issue that needs attention is succession planning. “Many greenhouse growers will soon reach the age [when they’re] thinking about retirement,” says Senécal, “and many have no one to take over. It is the same problem for all of Canada.”

Edible garden vegetable and herb plants, organic selections and the buy-local movement continue to trend, says Senécal. Tropical plants, succulents and indoor plants (e.g. Philodendron, Monstera) remain very popular among consumers. Other well-received ornamentals include geraniums, Rieger begonias, hanging baskets (including strawberry) and ready-to-decorate patio pots in 13”, 14” and 16” sizes.

“82 per cent of consumers want to buy products or services that are good for the environment,” says Senécal. Known as “eco-responsible consumption,” Senécal thinks this trend has turned into a habit that will continue to have a positive influence on the industry. However, he also notes an increase in the costs of production in Québec, even though sale prices have not risen quickly enough to catch up, and negotiating with buyers is never easy. “The basic rule is simple. You have to produce what will be sold to avoid losses while changing the product range to suit the consumer.”

For more, turn to editor’s note (pg. 4) and Gary Jones’ column (pg. 38).

CLASSIFIED RATES: Minimum order $75.00 or 84¢ per word, word ads must be pre-paid. CLASSIFIED DISPLAYS: $72.00 per column inch. GENERAL INFORMATION: Payment must accom- pany order. Copy required on publication close date. All advertising copy subject to the approval of the publisher. Send order and remittance to: Classified Dept., Greenhouse Canada, P.O. Box 530, Donly Dr. S., Simcoe, ON N3Y 4N5 Canada

SURPLUS GREENHOUSE & FRUIT PRODUCTION EQUIPMENT FOR SALE:

Formflex steel growing gutters; Aluminum growing gutters; DRIP IRRIGATION - 29,000 30" emitter assembly with 1/2 gph PC emitters; filters, solenoid valves, header lines; MIST SYSTEMS - coverage 38,000 sq ft; AgrylP40 FROST BLANKETS; Niagara Needle SEEDER; Other miscellaneous equipment. Call or text message 519-359-2130 for more details. 12/1t/pd

Last week I received an e-mail from a local industry advisor in which he mentioned that the recent shifts in the scope of the greenhouse industry had put increasing challenges on those seeking experienced growers and it had left ‘several owners in difficult situations regarding their growing operations.’ The cause may be different, but finding experienced growers is not a unique issue in BC, nor even Canada. It’s common everywhere there’s a significant greenhouse industry presence. For example, ‘Access to Labour’ was a topic at the UK Greenhouse Cucumber Growers’ Association meeting in October.1

In the same vein as recruitment, succession of the family business is often a challenging issue. This is exacerbated by competition from other industries that offer career options perceived to be more comfortable and often better paying to the next generation. But some of these may often be cases of ‘the grass is always greener,’ and I know many new generation family business owners who relish the non-financial rewards of working in the greenhouse industry.

Around 56% of the world’s population now live in urban areas. This is expected to rise to 68% by 2050.2 Think of the increased demand for food and market opportunity, but also the potential for urban-rural conflict, as the land base available effectively shrinks to make room for development. This is a global phenomenon; you’re not alone.

Globalization of production means more horticultural products are shipped around the

production costs, cutting profit margins finer and finer. I chatted with a local grower recently who was lamenting that his company’s creative (nongrowing) use of greenhouse space had proven much more lucrative than plant production, in part due to the better returns of the alternative use, but largely due to ever decreasing returns on the crops. This is not a Langley, BC or even Canada issue, and is a sad place for us to be when we have such great products for today’s health-conscious, environmentally-savvy, plant-appreciative customers. This thought was echoed recently by the recipient of this year’s BC Greenhouse Growers Association ‘Meritous Service Award’, octogenarian cucumber grower Ivor Rage.

Which leads into marketing. And social media. We have great products and great messages to communicate and new ways into a marketplace of consumers who shop in different ways compared to just 15 to 20 years ago. Boomers and Gen-Xers, need to make those buying connections with Millennials and Gen-Z’s – the next generation of purchasers and ‘the most diverse generation to date.’3

I’ve mentioned before the challenge of the increasingly fast pace of technological change and how to simply keep up. ‘Running to stand still.’ If you missed it, I also mentioned it in a previous column on Christian Kromme’s ‘Future of Agriculture’ talk (last year’s LMHIA/Pac Ag Show). Check out his theories and ideas at his website. Interestingly, this was also a topic at the 2019 UK Cucumber Growers’ Association conference.1

“...horticulture can often be the scapegoat of trade...”

world, bringing with it new pests and diseases. This creates pressures on plant health and exposes any lack of resilience in monocrop systems. Consider the tomato brown rugose fruit virus. This situation may be made worse by the consolidation of the global seed, fertilizer, and agrochemical industries.

Governments are becoming increasingly demanding about anything perceived as an environmental issue, particularly water use, energy use, and pollution. Growers everywhere are all too familiar with the added levels of knowledge and skills required to deal with these topics just to remain in business. This work often results in added production costs, and it has been documented for years that prices for horticultural products have not kept pace with

My last (for now anyway) ‘global issue’?

How about trade barriers? Or free trade agreements as they are sometimes called. Global trade cuts across many of the topics already mentioned: pest pathways, labour, prices, and marketing, for example. But in an increasingly protective market, horticulture can often be the scapegoat of trade, used as a pawn to satisfy the needs of larger industries. That is a real challenge.

1 www.cucumbergrowers.co.uk

2 United Nations estimates.

3 https://en.wikipedia.org/wiki/Generation_Z#Date_and_age_ range_definition

Gary Jones is a faculty member at the School of Horticulture, Kwantlen Polytechnic University, Langley, BC. He sits on several industry committees and welcomes comments at Gary.Jones@kpu.ca.

Fluence creates advanced lighting solutions for controlled environment crop production.

We apply the latest research in photobiology, evidence-based design, precise engineering and advanced technology to foster a healthier and more sustainable world.

Learn more at www.fluence.science