Looking back and forth

| 12

New export rules

What to look out for in the new Canada-US export program | 16 Winter warmth Dos and don'ts for keeping the heat in | 26

By Dr. Chevonne Carlow |

Looking back and forth

| 12

New export rules

What to look out for in the new Canada-US export program | 16 Winter warmth Dos and don'ts for keeping the heat in | 26

By Dr. Chevonne Carlow |

Duane Van Alstine

BY GRETA CHIU

DR. JEANINE WEST AND ANDREW MORSE

BRIAN WEBBER

GRETA CHIU | @GreenhouseCan

January – the beginning of a new year, filled with hope for resolutions to the sector's top challenges. As you’ll see from the national state of the industry report and from Gary Jones’ perspective, we’ve inherited ongoing issues of yesteryear – labour, energy, cannabis and uncertainty in general. So what’s there to look forward to?

For one, I’m hopeful for more positive recognition of the seasonal workers program in the media and changing public perception. From the phone conversation I had with Ken Forth months ago, we’re short about 50,000 workers in the agricultural sector as a whole. “And by 2025,” he says, “we’ll be short about 120,000.” Why? The usual suspects – an aging population among farmers and Canadians simply can’t support their families on a seasonal job alone.

“For every [seasonal] worker that comes to work on a fruit and vegetable farm, on average, two Canadian full-time jobs are created, whether it be on the farm or agri-business,” says Forth. What’s more, every seasonal

ened security measures. “It’s 25 pages of stuff, and that’s a long way from three [pages] 20 years ago,” he says.

Forth and F.A.R.M.S’ efforts have not gone unnoticed, receiving recognition through an honorary degree from the University of Guelph and at OGVG’s annual meeting this past year. For 50 years, the Lynden-based vegetable grower has been an employer with SAWP, one of two temporary foreign workers programs in Canada.

It’s also heartening to see more attention being brought to this issue. The Standing Senate Committee on Agriculture and Forestry met back in early October to discuss how the value-added food sector could become more competitive in global markets with respect to temporary foreign labour. See summary of proceedings online.

Second item to look forward to: Grower Day has grown into Grower Days, running from June 18th to 19th. First day will be the original show for flowers and vegetables, still hosted by Greenhouse Canada

...we're short about 50,000 workers in the agricultural sector...

worker supports nearly 10 others back home. Multiply that by 35,000 workers and it’s 350,000 lives on the line, he explains. The earnings pay for their children’s education, bringing changes to their respective nations. But stories picked up by mainstream media don't always reveal the positives.

As president of Foreign Agricultural Resource Management Services (F.A.R.M.S), Forth has not only brought light to the Seasonal Agricultural Workers Program (SAWP), but also helped countless growers with their applications – a process that has become more lengthy due to height-

Second day will be run by sister pub Grow Opportunity for all things cannabis. Full days of great programming to come. Stay tuned.

Third item: more feedback. Did you like the themes in 2018? Were there too many articles on one topic, or maybe you'd like more webinars? Perhaps you caught a spelling mistake too glaring to ignore. Call, email or stop me on the tradeshow floor – let me know what issues matter to you. Because at the end of the day, this magazine is for you, our readers. I’m just the curator. Together, we can make this made-in-Canada magazine something to be proud of.

The Ontario government has announced a change to the delivery of $8 million in existing funding to the provincial greenhouse sector.

Working with The Ontario Greenhouse Alliance (TOGA), the Greenhouse Competitiveness and Innovation Initiative (GCII) has been redesigned to fund additional projects.

Both Ontario Greenhouse Vegetable Growers and Flowers Canada (Ontario) welcome this news.

“The new provincial government has put considerable effort into reviewing several programs to ensure effectiveness, and we support that effort,” says Andrew Morse, executive director of FCO.

“The GCII intake closed last September with unused resources: there was some interest in re-opening the program with some updated requirements to ensure that the full value could be utilized to its best potential.”

Lawrence MacAulay, Minister of Agriculture and Agri-Food Canada, announced a federal investment of up to $5 million to the Automation Cluster under the Canadian Agricultural Partnership.

Led by Vineland Research and Innovation Centre, the Automation Cluster will help address labour costs and availability through automation, artificial intelligence and precision agriculture technolo-

BY

Vegetable greenhouse area grew by 16% from 2013 to 2017 (StatsCan)

FLORICULTURE EXPORTS GREW BY 64% from 2013 to 2017 (FCG)

$1.5 billion in national greenhouse floriculture farm gate sales for 2017

gies in the horticulture sector. Over the next five years, researchers at Vineland will focus their research in three key areas:

• developing and testing robotic harvesters for greenhouse cucumbers;

• developing smart, wireless irrigation technologies for potted flowers and vegetables; and

• developing state-ofthe-art sensors that will help detect and

monitor moisture levels in the soil and air.

Canada’s agricultural sector faces significant labour challenges and the greenhouse industry has the largest labour gap. It is estimated that labour shortages can cost the sector up to $1.5 billion in lost productivity and sales.

“This investment in automation will allow farms and greenhouses to work smarter and deliver higher quality

$1.4 billion

national Greenhouse vegetable farm gate value in 2017 (AAFC release)

$11.2 M less than 2016, the first decrease in 5 years.

1 floriculture greenhouse closed every 5 days over the last 5 years (FCG) (FCG)

jobs, ensuring they continue to meet the growing demand for top-quality products for Canadians and consumers around the world,” says MacAulay. The Canadian greenhouse sector is also the largest and fastest growing segment of Canadian horticulture. This past year, Canadian greenhouse vegetable sales totalled over $1.4 billion, with over $900 million of sales in Ontario.

TOP CROPS IN CANADA IN 2017

Canola

Wheat

Soybeans

Corn

Ornamental horticulture ⑥ Field vegetables ❼ Greenhouse vegetables

Stimulate early spring impulse sales with this irresistible crop in a new colour – a medley of rose-based shades all with undertones of vanilla. Welcome consumers back to the garden centre with large, fully double flowers and bright colours. Reliable uniformity meets the demands of growers and retailers –an early season option that excites consumers. Upright habit. 25-30 cm tall, 25-30 cm wide. syngentaflowers-us.com

Penstemon mexicali Mini-Bells Red

This compact interspecific Penstemon flowers profusely in early spring and reblooms in the fall. It’s a prolific re-bloomer

with vibrant flowers and a compact, full and upright habit. It is heatand drought-tolerant and attracts bees. The red is a stunning rose/ red shade. Also comes in lavender bicolour, which has rich lavender flowers with a white throat. Bloom months are June to August. Zones 7a to 9a. 41-46 cm tall, 41-46 cm wide. darwinperennials.com

Boasting shiny violet new leaves, deep purple stems, raspberry-purple buds and fragrant violet flowers. Leaf petioles remain violet well into summer. Dense, upright habit; great choice for hedge or foundation plantings. Full sun. Zones 3 to 7. 1.8-2.4 m tall, 1.5-2.1 m wide. firsteditionsplants.com

New from Dümmen Orange for 2019, Tiger Eyes is a one-of-a-kind flower that brings stripes to the world of garden mums. The flowers transition beautifully from an intense, bright red to a widening yellow stripe as the flower matures. Tiger Eyes is recommended for outdoor production or well-vented greenhouses, finishing naturally in week 37 in Canada. The high vigour and longlasting colour of this variety will have strong impulse appeal in retail displays. dummenorange.com

This compact series features controlled growth with little to no PGR. Bred and selected to be produced in quart pots, Colibri creates nice, tidy baskets that are

bursting with blooms. This early series will flower in ten-hour days. Colibri is available in eight colours, including Lemon, new for 2019. danzigeronline.com

This thornless raspberry offers everyone a chance to enjoy raspberries like never before! Raspberry Shortcake is compact, with a rounded growth habit and thrives in a patio pot or in the landscape. Perfect for children and adults, this carefree nutritious raspberry requires no staking or big garden spaces. USDA zones 3 to 9, full sun. Dense, mounded. 0.6-0.9 m tall. bushelandberry.com

This robust coleus grows vigorously to form a bushy mound of radiant gold foliage with red venation. Like all ColorBlaze varieties, it performs well in both sun and shade. In lower light, Golden Dreams will have more extensive red colouring; in higher light it will be more gold. Pair this colourful coleus with other high-vigour varieties in large container recipes or try it in the landscape. Since it was bred to bloom very late or not at all, its sales window and garden performance will be extended into fall. Sun or shade. 61-86 cm tall, 30-41 cm wide. provenwinners.com

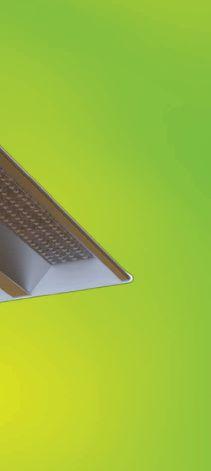

3,100+ μmol/sec/sq ft

ture h ECGL L LED ly active e radiation) lField es and

Engineered using the science of nature, the ECGL LED that under-deliver PAR (photosynthetically active radiation). Increase yields utilizing our proven PPFD FullField™ Coverage. provide proven 15% greater yield, shorter ripening times and under two years. EcoGROW Technology gives you more, so you get more

ECG Full Spectrum LED Grow Light Powered with EcoGROW Technology and featuring an optional mounting frame precisely engineered for optional integrated winch system allowing easy height adjustments to accommodate plant growth. ALSO AVAILABLE FROM

BY DAVID OROSZ

ABOVE

Expansion can be an exciting prospect, but does it make logistical and financial sense for you?

So, you own a greenhouse and things have been going well. You know you need more space to grow, but you are unsure of how to proceed. Do you expand the existing operation or do you sell and buy another?

First, determine if you have room to expand. Expansion may require more than just added production space. Will you need more service buildings, housing for workers and/or other infrastructure, such as water retention ponds, septic beds, loading docks and parking lots? Expansion often requires service upgrades for water, electricity and heat (normally via natural gas) – this can be a challenge. Checking with your local utility and getting an agreement in writing is a must. If new main lines are required, the cost may be too steep to make the project viable.

Second, consider the layout. Does it need to be modified to optimize cost savings for an expanded operation? Efficiency is key in many aspects. The design may allow workers to be more efficient, opportunities for greater automation, as well as changes in the sorting/grading/packing areas of the operation.

It may also include a design that is efficient from a construction-cost or heating standpoint, as well as irrigation, lighting and environmental controls.

Sometimes changes to the existing operation can be effectively and efficiently undertaken. Sometimes it will work with the addition of adjacent land, if it can be acquired. But operators may determine that their existing operation’s layout, scale and/or building attributes are not conducive to growth. If this is the case, your operation might still work for someone else and you might consider moving on to a different site.

Finally, consider the long-term financial aspects. Both you and your lender want you to be on solid financial ground and succeed in the future. You will need to consider cashflow – can you make payments, generate an income and replace capital, as required? Also consider your equity position as fallback if things don’t go as expected and the payback period for any loans that may be required for expansion.

Dave Orosz is a senior relationship manager with Farm Credit Canada in Essex, Ontario.

BY GRETA CHIU | @GreenhouseCan

What if someone told you that plant physiology and physics could change the way you think about greenhouse climate control?

In their book Plant Empowerment: The Basic Principles, climate controls systems specialist Jan Voogt and his colleagues, former cut rose consultant Peter Geelen and former researcher at Wageningen University and Research (WUR) Peter van Weel, have pooled their knowledge and experience to show the interplay between climate conditions in the greenhouse.

The aptly-named book Plant Empowerment was launched globally at the 2018 Canadian Greenhouse Conference, taking a crops-first approach to climate control.

Filled with detailed information on applied theory and best practices, the underlying principle is the need for balance. Crops balanced in energy, water and assimilates are healthier, less vulnerable to diseases and pests, and more likely to produce higher yields and better quality. If the point of every plant process is to maintain balance, then a grower’s job is to guard against stressors that could throw this balance off-kilter. Rather than choosing climate set points independently of each other, such as for temperature or humidity, authors say they should be changed as a system and according to crop needs, which stem from three balances.

Energy balance is about input into the plant (e.g. solar radiation, lighting, heating) and output from the plant. When there’s a high input, says Voogt, the plant’s water balance allows evaporation to cool itself slightly below room temperature. If evaporation exceeds water uptake, the stomata will close partially. Unable to cool itself sufficiently, the plant will continue to increase in temperature, needing convection by air movement to help

transfer heat away from it. “For this reason, it is crucial to align watering with energy input,” explains Voogt.

At night, nutrients are needed by developing cells. They’re taken up through the roots and ‘pulled along’ by evaporation. The rate of uptake must equal that of evaporation to maintain balance. Taking a crops-first approach, ventilation rates should be set to help reach the ideal evaporation rates for the crop, rather than using generic pre-set values.

For assimilates, the authors have found a ‘sweet spot’ – a temperature-to-light ratio that balances assimilate production (i.e. sugars) with assimilate consumption (i.e. growth). Higher light intensity in the photosynthetically active radiation (PAR) range can produce more sugars, while higher temperatures encourage growth. When consumption is too high, says Voogt, fruit set and root development, but also plant health and resilience, can become a problem. “Toolow consumption relative to the production of assimilates, however, means suboptimal growth.” To maximize both, one would need to maintain a consistent ratio between average temperature and PAR light sum.

According to Voogt, when the first closed greenhouse appeared in the Netherlands about 15 years ago, researchers found that these plants behaved differently from those in open greenhouses. That triggered a collaborative research project between Hoogendoorn and WUR, the findings of which were incorporated in ‘Het Nieuwe Telen’ (HNT, which translates into ‘Next Generation Growing’ in English), an integrated approach based on different principles of crop balance. Originally based on Dutch growing practices and climate, HNT has since been refined and renamed ‘Growing by Plant Empowerment’ (GPE) for application in different crops and conditions worldwide.

Voogt also notes that the principles of Plant Empowerment should be implemented over time, not all at once. The son of a nursery grower, he understands the complexity of greenhouse production practices, comprised of “knowledge, experience and ‘green fingers’ that are often handed down from generation to generation,” as he puts it. “One should start monitoring climate conditions and plant development, and then implement improvements step-by-step,” he advises. The book contains detailed roadmaps to guide the grower through this process.

For more, visit plantempowerment.com

Labour, energy, trade agreements and herbs – what went on in 2018 and what’s ahead.

BY GRETA CHIU

2018 was a year of expected – and unexpected – change. Labour and input costs continued to rise, carbon levies in the works, and the shortage of experienced labour continued. Cannabis and the renegotiation of the North American free trade agreement left large periods of uncertainty.

But it’s not all doom and gloom. There’s been growth in both ornamentals and vegetables, with clear trends towards tasty, local products – some grown in consumers’ own backyards. Here’s what experts had to say in this year’s state of the industry report.

In Alberta and BC, things have remained relatively stable for greenhouse vegetables. Andre Solymosi, general manager of the BC Vegetable Marketing Commission, has seen continued growth in snacking tomatoes, paired with a “downward trend in beefsteak demand” due to increasing preference towards tomatoes on-the-vine (TOV).

“Newer cocktail tomatoes with different colours are attracting considerable attention, especially at farmers’ markets,” says Alberta industry consultant Dr. Mohyuddin Mirza. He notes how winter vegetable production has “shifted slightly more towards tomatoes from cucumbers” with LEDs gaining success in winter tomatoes.

In Ontario, the tomato category has been broken down into many separate SKUs as retailers try to entice buyers with new packaging, varieties and flavour profiles, note economic policy analyst Glen Snoek and general manager Joe Sbrocchi of Ontario Greenhouse Vegetable Growers (OGVG).

says OGVG. While losing land to cannabis hasn’t yet made a significant impact on greenhouse vegetables, it’s something the organization is monitoring very closely.

ACROSS THE OCEAN OR AROUND THE CORNER

According to Solymosi, US markets aren’t a big source of growth for BC greenhouse vegetables. Their sights are set on Japan. “We do see opportunity there,” he says, but it’s also exchange-rate driven. “If it’s more favourable, then there’s more demand for Canadian product.” The markets have really opened up for Canadian-grown peppers in the past few years, he adds, and it’s been 25 years in the making for access to the Japanese market due to long market export processes.

For Ontario, tomato exports to the US have remained relatively flat, says OGVG. Cucumbers continued to show strong performance, and peppers “saw a return to previous planting levels in 2018, with decent, although not spectacular, export volumes” broadly similar to 2017.

While all tomato, cucumber and pepper volumes increased year-over-year, the markets were not favourable in 2018, notes OGVG. Cucumbers “started out higher and then hit a prolonged depression”. They have experienced significant upward trends in the weeks leading up to the preparation of this report, however, they note that “even if the overall average return to growers meets or exceeds last year, it’s only the growers who stayed in for the long haul that will reap the rewards”.

2018 was also plagued by uncertainties around the renegotiation of NAFTA 2.0 and possible acreage losses to cannabis, which hampered planning and orderly marketing of crops,

Even with the new United States-Mexico-Canada agreement in place, we may not be out of the woods yet. “US trade rules and regulations remain a significant unknown, even with the signing of USMCA/ CUSMA," says OGVG. "Recently introduced US trade remedy laws targeted primarily at Mexico may yet hit the Canadian greenhouse industry as collateral damage.”

Alberta has taken a different approach. While the province remains a net importer of greenhouse products, says Mirza, “the emphasis has been more on increasing local supply to the domestic market”.

Increases in natural gas prices are causing some unease among Alberta growers, especially with the carbon levy on greenhouse fuel. “Temporarily, there has been relief by the government of Alberta in the form of an 80 per cent rebate,” says Mirza. “At this time there is no announcement by the government if this rebate will be extended beyond December 2018." He also notes that co-gen systems are attracting interest from growers.

BC’s gradual increase in carbon tax is also accompanied by an 80 per cent rebate on natural gas costs. A more pressing issue

Bicolor flowers continue to be hot sellers and Superbells Star patterned varieties are certain to add star power to your bottom line. We’ve improved the collection with expanded color patterns, bold hues and outstanding bloom power from spring into fall. Earlier bloom times, impressive heat tolerance and disease resistance mean they’ll deliver a five-star performance every time. Who could resist this all-star lineup?

though, is the ramifications of the gas line explosion near Prince George back in October. This has, and continues, to curtail national gas deliveries, says Solymosi. Uncertainty around natural gas has caused growers to delay the planting of new crops and to pull their crops sooner. With the pipeline capacity constrained, gas prices have spiked and remain variable, he says. Quebec vegetable and floriculture consultant Michel Senécal identifies rising input costs as one of the top challenges. “From many studies in the greenhouse sec-

tor, inputs increased [by] 25 per cent since 10 to 12 years [ago], but the increase of the gross price at the farm is five to eight per cent or less, depending on the product.”

Marijuana production has put a strain on greenhouse capacity. But new greenhouses built prior to cannabis legalization are offsetting that impact, says Solymosi. There’s still plenty of demand for new builds, putting additional strain on labour and building suppliers. “Costs will likely

go up as we continue to build greenhouse capacity to supply the growing market."

Labour is still a challenge, both in terms of costs and supply. Coinciding with new cannabis job opportunities, minimum wage hikes were planned or executed across the nation. “The cannabis sector attracts people and leads to competition for manpower, especially for crop managers,” says Senécal. “We are looking for people with experience.”

Farm succession is also a key issue. “In Quebec over the next five years, 37 per cent of entrepreneurs plan to leave their company to retire. This proportion rises to 41 per cent in the rest of Canada,” says Senécal.

For Alberta, there's the added issue of identity. Michiel Verheul of High Q Greenhouses notes that they're watching their hours as greenhouses have lost their status as farming operations. “We have to pay overtime,” he says. “Also we pay general holiday pay that is 5 per cent, and that works out to nine hours a month on months that have a statutory holiday... In Canada that is nine [holidays] per year.”

“While most of the Alberta government departments regard greenhouses as farming operations, the labour department does not,” explains Mirza. “There is no easy or quick solution to this problem, as changing the law is a lengthy process. Growers are working with the government on this issue.”

Plus there’s the issue of obtaining foreign workers, which has taken longer in recent years to approve with heightened security measures.

Rising costs are reflected on the retail side. Both Christie Pollack of Christie’s Gardens and Greenhouses and Nadine Stielow of Thiel’s Greenhouses have had to raise their prices in response to increased labour and input costs. These will continue to be big challenges in 2019. “Grower margins are too small," says Pollack, "and we need to optimize our operations to take advantage of producing plants that will create better return and profitability for our greenhouses."

Interior plants, small-space selections and edibles are still going strong.

For Pollack, they saw a 10 to 15 per cent increase in sales on interior plants and hanging baskets, and a 41 per cent increase on tree sales compared to 2017. With the volatility of the Alberta economy in recent times, she sees more consumers

growing their own food.

Stielow notes that succulents and small-space selections are still growing in demand. While she doesn’t currently offer houseplants, she sees edibles gaining popularity – and herbs in particular. “Many are asking for very unique herb and edible selections which I’ll incorporate this year,” she says, “like a bigger selection of Asian greens, sorrel, cilantro, epazote and others.”

Both Pollack and Stielow see millennial food gardening as a trend that’s here to stay. “My generation pulled away from growing food, in many cases, because our parents did it [and] made it a chore and a necessity,” says Stielow, but millennials are falling in love with it again. "I see it bridging the gap as an experience that all generations can do together. Grandparents, parents and grandchildren all growing together. It’s shifting from a healthy trend to a lifestyle.”

Senécal says the 2018 season ranks among the best in the last five years for the majority of Quebec greenhouse operators. Sales were mainly propelled by the favourable weather. “Consistent consumer demand has made it possible to simplify the logistics work surrounding deliveries and inventory management during these busy gardening weeks,” he says, reducing stress on growers.

It was a different story for Nova Scotia. “[The] biggest challenges were weather related for the 2018 season,” says Rachael Cheverie, horticulture specialist at Perennia. “Such a late [and] cool, wet spring with late frosts meant that consumers were not interested in purchasing product before early June. From all accounts, product did move in June, but at increased labour costs to producers as much more plant handling and maintenance was required.”

In their 2017 Statistical Highlights Report, Flowers Canada Growers (FCG) noted a national drop in farm gate sales for the first time in five years, by a difference of $11.2 million (-0.74 per cent) from 2016 to 2017. Vegetable bedding plant farm gate sales grew by 20.5 per cent from 2013 to 2017, while cut flower sales continued to decline.

There were differences by province. Farm gate sales for Quebec and the Maritimes grew from 2015 to 2017, by 15 per cent and 10 per cent, respectively. The largest growing regions, Ontario and BC, saw decreases of 2.6 and 2.5 per cent in that same timeframe. Results for 2018 remain to be seen.

While OGVG can only speak to greenhouse-grown cucumbers, peppers and tomatoes, they note that there's growing interest in berries, eggplants, beans and lettuces in Ontario.

Out east, Cheverie notices that “there’s lots of interest in growing strawberries/raspberries hydroponically under cover,” not necessarily in greenhouses, but in high tunnels.

Mirza sees salads and herbs as up and coming crops for winter production. Especially with the demand for local products.

FCG’s 2017 stats report noted that tropical foliage and green plants were the fastest growing potted crop from 2013 to 2017, “at an average yearly growth rate of 11.19 per cent”, second in their top 10 potted crops list. Outdoor potted vegetable plants rank eighth with 20 per cent growth, while outdoor-potted herb plants rank fifth with eight per cent growth, both year-over-year.

For more, see pg. 6 for select highlights from the FCG stats report, pg. 30 for Gary Jones' perspective, and pg. 4 for seasonal workers. Thank you to all industry members who weighed in on this year's report.

Registered for use on cannabis raised indoors, KOPA insecticidal soap controls whiteflies, spider mites, aphids and other soft-bodied insect and mite pests on contact.

OMRI® CANADA Listed for organic production, KOPA can be used right up until the day of harvest. KOPA is lethal to pests, yet it is of low risk to workers and the environment.

KOPA. When clean product is your only marketable option.

BY DR. JEANINE WEST AND ANDREW MORSE

When most people think of ornamental plants they imagine beautiful and fragrant ways to decorate a space, celebrate a holiday, or brighten up someone’s day. Very few consumers think of the challenges associated with growing and moving flowers and plants between the growing facility and the retailer. Ornamental plant growers across North America take significant efforts to ensure that these plants for planting do not pose a biosecurity threat. The requirements for moving plants across borders are carefully crafted to effectively mitigate the risk of pest spread, either known or unknown (new) pests.

The United States-Canada Greenhouse Grown Plant Certification Program (GCP) is a bilateral trade program that is available as of December 2018 (replacing the Canadian Greenhouse Certification Program and D-96-12) and allows facilities to export eligible product without obtaining an official inspection at the time of shipping. This is a critical advantage in a global marketplace where ‘just in time’ business models are commonplace.

The GCP is based on a systems approach, but an evolved version over previous trade programs. The principles of the systems approach in managing phytosanitary risk have resulted in very

successful improvements in mitigating pest spread within North America. The GCP has evolved to have a more demonstrative approach, focusing on pest management over the course of plant production as opposed to the documentation surrounding individual certification activities. The new GCP was developed cooperatively by CFIA and APHIS; details can be found in the technical requirements document dated June 2016 (available here: http:// www.inspection.gc.ca/plants/horticulture/exports/ gcp-technical-requirements/eng/1474666508713/147 4666604536). The document describing how the program will be administered in Canada is the CFIA directive D-16-02, also available online.

There are a number of new opportunities within the GCP that may be particularly valuable to your business, for example:

a) What is particularly useful for many facilities is that the GCP includes the opportunity for shipping potted plants that have had a period of outdoor production. This represents a significant shift for CFIA and USDA-APHIS, and opens the door to quick turnaround exports for a wider range of plants.

b) An additional opportunity is possible for facilities that ship plants with bamboo stakes or ornamental greenery (i.e. “Associated Articles”) that would normally require a Phytosanitary Certificate. If a facility is authorized as a GCP facility, then they can ship these plants under the GCP without a separate Phytosanitary Certificate for the Associated Article.

For both of these options, a facility will be required to have a “Production Module”, defined as:

“Additional pest risk management measures employed to permit an exemption from a requirement of the GCP and/or to address concerns regarding specific production conditions included in the Pest Management Plan.” ~CFIA

“Pest Modules” are similar to Production Modules, but address regulated pests as opposed to production conditions. Not always required, they are another new tool describing actions taken by the facility to prevent pest spread.

There are some more detailed requirements on the facility side in the new program. The facility will be taking on more responsibility with the GCP, for example:

a) The development of a List of Plants in Production, where ALL the plants that may be grown at the facility must be categorized for eligibility to be shipped under the program, not just plants intended for export.

b) Plants grown for less than a 28-day crop cycle (called the ‘Growth and Monitoring Period’) may require additional measures to ensure that phytosanitary risks have been mitigated. In

the legacy program, there was no defined growing cycle.

c) The GCP incorporates a “whole facility” approach, meaning the entire facility is managed regularly for pests; the result is a facility where designated personnel are more likely to detect and manage new/introduced pests more effectively.

d) While the “Excluded Plant List” required under the legacy program is no longer required, it is now the facility’s responsibility to verify eligibility under the GCP of all incoming plants for production, and ensure that the requirements of both USA and Canada are met.

Yes! Due to the high incidence of internal trade in the floriculture sector, production facilities (that sell domestically) wishing to sell eligible product to exporting facilities are encouraged to participate in the GCP. The GCP structure encourages ‘intentional and ongoing’ pest management for a whole facility, which means better quality finished product that carries lowered phytosanitary risk. GCP-Authorized Facilities will be thrilled to receive plants that are certified under the GCP, helping to streamline their exporting process.

In preparation for the transition to the GCP, Flowers Canada Growers initiated the development of a nation-wide training platform back in 2016 to support both plant producer and broker facilities in their transition. Developed in collaboration with the CFIA, the nation-wide training platform guides the facility through the principles of the GCP (systems approach, mitigation of risk, plant eligibility) and the administrative processes. Templates for Pest Modules are included in the training, as well as detailed examples of how to complete a Pest Management Plan and the most common Production Modules. By completing this training, facilities will promote increased skill development within the floriculture sector in this critical area, and ensure consistent application and interpretation of the GCP at the industry level.

The platform is provided in two formats: in-person workshops and online (login access available through GCP@fco.ca). The online system allows FCG to reach out to all facilities to provide timely notification of changes to the GCP or relevant import/export information, and has the ability to track acknowledgement of the receipt of these updates.

The immense benefit associated with close industry-government cooperation on the development and rollout of the GCP cannot be ignored. By creating a strong and unified national understanding of program requirements within the industry, facilities are better prepared to manage their obligations in this trade program, reducing the risks to Canada and the United States, and manage resource burdens on the CFIA.

GCP Industry Training is available through a collaboration between Flowers Canada Growers Inc., the Fédération Interdisciplinaire de l’Horticulture Ornementale du Québec (FIHOQ), and l’Institut Québécois du Développement de l’Horticulture Ornementale (IQDHO). Contact GCP@fco.ca for more information; support is available in both English and French. Support is also available from your local CFIA office.

Jeanine West, PhD, is the greenhouse certification program project lead, and Andrew Morse is the executive director at Flowers Canada Growers Inc. They can be reached at jeanine@fco.ca or andrew@fco.ca.

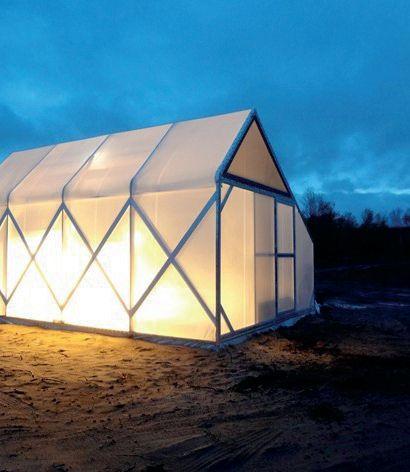

Used correctly, energy curtains can lead to cost savings during the colder winter months.

TBY DUANE VAN ALSTINE

he frigid temperatures that accompany a Canadian winter are hardly a surprise, but for a grower, the high energy costs associated with operating a greenhouse through the cold weather can be shocking. As the temperature drops, energy use climbs, and with temperatures falling well below freezing, heating a greenhouse to maintain an ideal crop environment can be an incredibly costly endeavor. It’s likely that energy costs will continue to increase, so as a year-round grower, finding cost-effective solutions for protecting your greenhouse environment while conserving energy is necessary. It’s for these reasons that more growers are realizing the benefits of energy curtains, an effective and inexpensive method of maintaining the proper climate in your greenhouse during the cold Canadian winters.

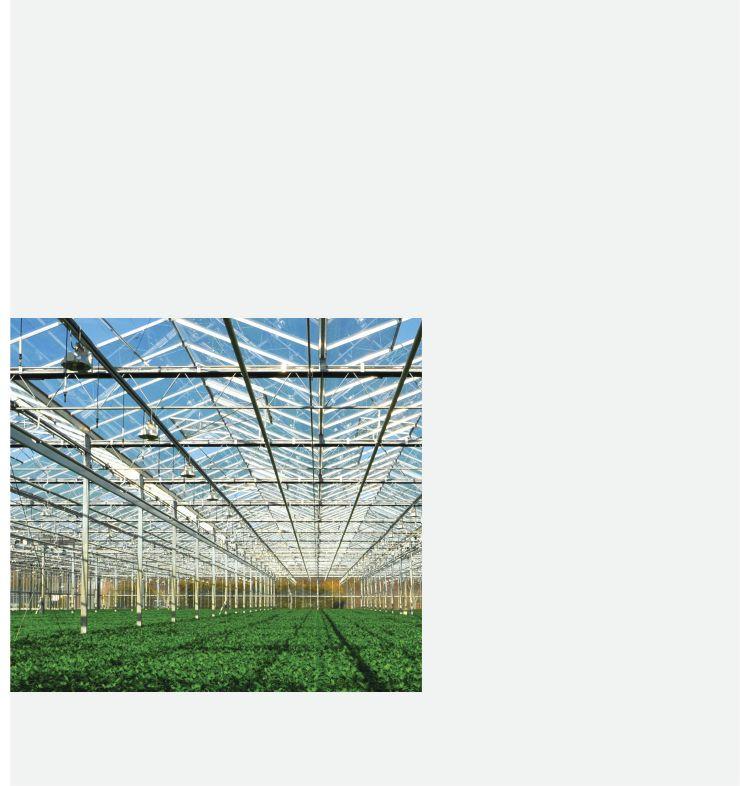

Energy curtains are retractable components made from composite materials, and they are designed specifically for the horticultural industry. Also referred to as energy screens or thermal blankets, energy curtains can provide multiple benefits to your growing environment, but a major benefit are the energy savings realized throughout the winter as your curtains work to maintain a consistent environment. The curtains are typically installed just above or below the trusses in your greenhouse, but most often above to accommodate your supplemental lighting. They can be opened or closed across the greenhouse, from gutter to gutter, or they can cover and retract across the length of the greenhouse. How your curtains are installed depends on the needs of your environment, but typically a flat curtain system will be the most inexpensive to install while offering the greatest reduction in space that requires heating.

During the colder winter months, your energy curtains act as a barrier by keeping heat below the curtain in the growing zone. The types of curtains you install will directly determine your energy savings.

The three most common categories of curtain materials are nonporous, porous and semi-porous. Nonporous materials, such

as poly film, are generally not ideal for greenhouse curtains as they don’t allow for condensation from the roof to penetrate. The water will pool up on the curtains and the weight of the excess water can cause damage to your curtains or cause the supports to fail. On the other hand, while porous materials allow for condensation to drip through, they do not insulate the growing area well enough. A semi-porous material is generally the most practical choice for both shading and heat retention. They’re usually made of strips of alternating pieces of aluminized and clear polyester or acrylic fabric that’s woven together tightly. Condensation is allowed to get through the material, but there is little exchange of air from either side of the curtains when closed. The aluminized curtains are engineered to reflect the infrared radiation given off by the structure, the benches and the plants back into your greenhouse which is especially important during the winter. Be sure to work closely with experienced industry professionals to decide what material is best for your greenhouse environment.

When used properly, your energy curtains can help modify the climate of the growing environment to improve the conditions inside. The curtains can be closed when they’re able to improve the environment, but can be opened if outside conditions are favourable. Ideally, curtains are used for shading if the natural light outside is too great, if energy consumption is too high, or if the humidity is too low. Orchids, for example, are highly sensitive plants that require shading as they can burn if the sunlight allowed into the growing area is too intense, but since light levels are usually lower in the winter, curtains are used more often when light levels cannot keep up with the required temperature. Most greenhouses are made of either glass or poly, neither of which have a high R-value, so the curtains provide the insulation necessary in the cold weather to maintain the desired climate.

Typically, your curtains will be closed completely at nighttime

when there is no useable natural light. Since a majority of the heating in a greenhouse takes place at night, having your curtains closed entirely will help retain the heat inside the greenhouse while keeping out the cold, winter air. However, while curtains can certainly provide benefits to your greenhouse during the winter, it’s important not to fall into the trap of overusing them. In order for your curtains to provide the greatest benefit in the fluctuating temperatures of winter, your curtains should begin closing before the sun sets and be opened just after sunrise. These opening times will vary depending on solar radiation levels, but ultimately you need to strike a proper balance and ensure that the curtains are not closed too often. Many growers will install a double layer of curtains which provides even more insulation, and while this may sound costly, for growers with greenhouses in cold climates, the return on investment is quickly earned back in energy savings. When used properly, growers with curtain systems tailored for winter use are seeing energy savings of anywhere from 20 to 75 per cent with nighttime energy savings specifically on the higher end.

Similar to your supplemental lighting, irrigation and ventilation, you will see the most benefit from your energy curtains if they’re controlled by a central environmental computer. Not only do your energy curtains affect the amount of natural sunlight that’s allowed into the greenhouse, but it affects lighting, temperature, airflow and humidity, which can be a lot to consider if you’re only using a manual or semi-automatic operation. You need to set your parameters to control exactly what temperature you want the inside of your greenhouse to stay at, while also considering radiant heat and heat from supplemental lighting. It’s recommended that you look back at your controls over as many seasons as necessary, and look at the tendencies and averages of the winter season to determine how you should set your parameters for the current winter season. Some growers set their curtains to open or close based on light levels in the greenhouse so they don’t have to change their parameters seasonally. However, it’s

equally important to set your parameters based on temperatures to ensure your curtains will help maintain a consistent climate in your greenhouse, despite fluctuating temperatures outside. The most important thing is to not become complacent with the parameters you have set. The biggest mistake a grower can make is not making the necessary changes to their controls seasonally, which can have negative effects on their crops and can result in a lot of wasted energy.

Ultimately, the curtain system and material that work best in your greenhouse will depend on various factors including the crop environment, the style of greenhouse and the regional climate of the area your greenhouse is in. There are numerous options available, so be sure to work with knowledgeable professionals to ensure you’re getting the best curtains at the best value for your needs.

Duane Van Alstine has been in the horticulture industry for 20 years, previously having been the operations manager of a 380,000 square foot facility. In 2011, he left the greenhouse to take on Special Projects for GGS Structures Inc. For more on energy curtains, visit ggsstructures.com

Study suggests that full-spectrum LEDs could lead to higher yields. Given the current average price of cannabis, the cost of each watt is returned at five times the value.

BY BRIAN WEBBER

In a recent webinar by Professor James Eaves at Laval University, he presented the results of his latest research, looking at the impact of spectrum and intensity on cannabis yields. He found that light emitted by LED fixtures produced higher yields compared to using high pressure sodium (HPS) lights with equivalent wattages.

Light intensity – more than spectrum – drives yield, the potential of which is underserved by HPS fixtures. As Eaves notes in the webinar, growers need to focus on the dollars spent per PPFD – and less so the dollars spent per watt. PPFD is short for photosynthetic photon flux density, a measurement of the amount of photosynthetically active radiation (PAR) that actually arrives at the plant. Or as a scientist might put it: “the number of photosynthetically active photons that fall on a given surface each second” (measured in μmol/m2/s).

In Eaves’ study at the Green Seal cannabis facility, each experimental plot consisted of a 4’x4’ growing bed with 36 cannabis plants, using equivalent wattage HPS and LED at +/-5% wattage equivalency, 1400 PPM CO2, with 22-28°C ambient temperatures. Transpiration was relatively equal. Areas were walled off with some photon spillage from adjacent HPS, due to its inherent wide-angle distribution.

His initial study compared 1060W HPS mounted at 36” above the canopy with an average PPFD of 477, to a 960W high-bay LED fixture

mounted and maintained at 18” above crop canopy with an average PPFD of 708. Note that light distribution can be more focused from the LED fixture because it covers a 110-degree angle, compared to the wider angle of HPS that leads to more uneven light.

From Eaves’ initial results, LEDtreated plants reached peak ripeness five days earlier. LED treatments also yielded 15 per cent more dried flower, and LED-grown plants were about 2” shorter at maturity. Unlike HPS, LEDs can be placed closer to the canopy without burning the plants, delivering more light and thus increasing the potential for greater yield.

In addition to intensity, light spectrum also matters. Historical and ongoing spectrum research and related findings are well-correlated. Current conclusions are that, although certain wavelengths convert to energy more easily than others, generally providing full spectrum light allows plants to take the wavelengths they need.

Assuming $5/gram, revenue increased by $0.40 per 4’x4’ bed. A $0.17 per kWh cost implies additional wattage costs of $0.087 over 52 days, producing an increase of 457% in ROI over the cost of electricity. Estimated returns may differ as the value of cannabis changes over time, but current calculations would suggest a very profitable return per wattage increase.

Brian Webber is president and CTO of EcoPOWER Inc. Contact him at bwebber@ ecopowerinc.com or call +1-800-564-8086, 3

for more information.

Note: This article is a summary of a webinar presented by Dr. James Eaves, professor at Laval University and lead author of the study cited here. Though Eaves is not an author of this article, he kindly provided feedback during the writing process and allowed the use of his images.

For a recording of the webinar, visit greenhousecanada.com/webinars/2018 and click on the webinar entitled “HPS or LED for cannabis”.

“Each watt added to the LEDs increased yield by 0.08 grams per 4’ x 4’ bed of 36 plants.”

The proximity of the photon source, distribution of those photons, and intensity (average PPFD) are the major lighting factors affecting overall yield, all else being equal.

In subsequent tests, Eaves and his team tested seven LED fixtures from several different manufacturers. Of the seven, four had very similar spectrums.

As the results in Figure 1 show, yield increased with light intensity for fullspectrum light fixtures, even though the ratios of wavelengths within the spectrums differed. Horticultural LEDS provided mid-range performance, while high-bay LEDs were able to provide the greatest PPFD, and therefore the most yield.

The ROI of using more wattage was also studied in Eave’s experiment. Each watt added to the LEDs’ increased yield by 0.08 grams per 4’x4’ bed of 36 plants.

Hoogendoorn’s next generation iSii monitors and controls all climate, irrigation and energy equipment in all types of greenhouses. The iSii is equipped with advanced controls that work according to the principles of Plant Empowerment, which resulted from Next Generation Growing (NGG) research. This way light, temperature, humidity and CO2 are aligned with each other for a maximum photosynthesis. In addition, to prevent water stress, irrigation is driven by the evaporation energy and water balance of the crop. With the iSii process computer, you set the base for high quality production.

Energy is one of the greatest costs to greenhouses, especially in the winter. Here are three key areas to check out to see what is or isn’t working.

BY DR. CHEVONNE CARLOW

Winter months in the greenhouse are a good time to see where your operation could be more efficient to save on energy, especially heating bills. Now’s the time to check out what is and isn’t working and what you might like to change for next season. Three main areas to look at for improved efficiencies in the greenhouse are energy curtains, boilers and greenhouse coverings.

Energy curtains can have benefits all year round, but are best known for their insulating properties in the winter. Several different styles and materials exist, with varying levels of insulation and light transmission. Materials with greater insulating power have higher R-values and can help to lower heating costs. The right curtain (or curtains) for your

ABOVE

operation will depend on what crops you grow and the level of control you would like over the climate in your greenhouse. In addition to overhead curtains, sidewalls and end curtains help to maintain a more consistent greenhouse environment around the perimeter and should be maintained.

Multiple layers of curtains can increase the control you have over temperature and light levels in the greenhouse. Double layer curtains that open over the course of several stages in a staggered pattern provide better control over the speed with which cold air from above the curtain is allowed to mix with the warmer air below. Curtains that have light diffusion properties to help improve light quality in the greenhouse can be installed under curtains that control light emission or allow for blackout if needed,

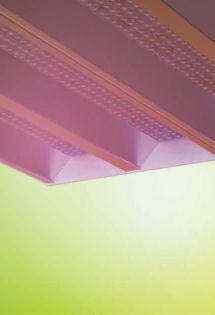

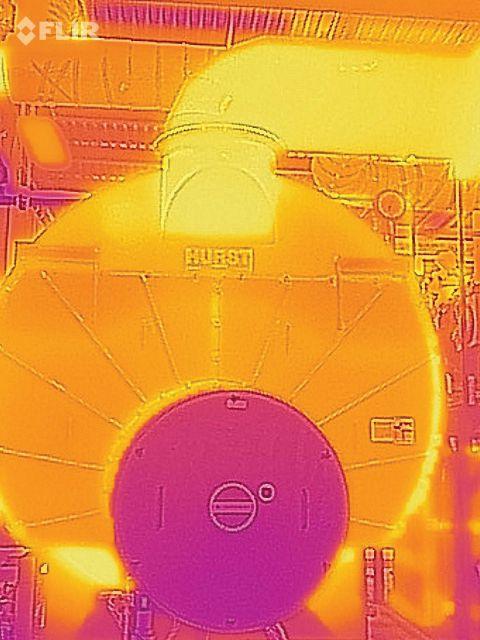

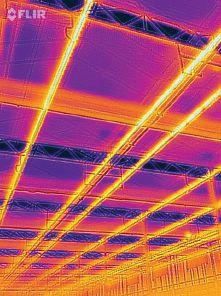

Older style boilers (left) lose more heat compared to higher efficiency models (right). Warmer areas are shown in orange, red and yellow hues.

BY RAYMOND A. CLOYD

This easy-to-read guide will help keep your crops healthy and profitable.

Raymond A. Cloyd, an extension Specialist in Ornamental Entomology/Integrated Pest Management at Kansas State University, discusses the common insect and mite pests of ornamental crops and how to treat their infestations. Cloyd explains insecticide and chemical classes and modes of operation, proper tank mixing procedures, application coverage and timing, and pesticide storage.

He also talks about phytotoxicity and the effects of pH on chemical effectiveness. A final chapter on pest identification describes common insets and mite pests, their feeding patterns and damage to crops, and control methods.

allowing for better control of light in and out of the greenhouse.

Regularly check for tears and holes in your curtains and ensure they are opening and closing easily. Be prepared to replace curtains as they age. Regular visual inspections and checks of your climate control systems settings will help let you know if the curtain is opening at the correct speed, and how the cold air above the curtain is mixing with the warmer air below.

2. BOILERS

Boilers are a necessary part of heating a greenhouse, but they aren’t all created equal. Traditional firebox boilers have expected efficiencies of around 80 per cent, while high efficiency condensing boilers can have upwards of 95 per cent efficiency. A properly sized condensing boiler can also have the ability to fire at a lower output level, therefore causing fewer spikes and dips in the heating load while increasing efficiencies. High efficiency condensing boilers have a much larger upfront cost, but the increased efficiency will result in greater long-term energy savings.

Colder air from above this double layer of curtains mixes slowly with the warmer air below as they are opened in stages.

Consider targeting the majority of the heat to where the crop is located. Perimeter heating and ensuring snow melt from roofs are necessary parts of growing through Ontario winters. However, heated floors and under-bench pipes can help keep heat near the crop, making sure that the growing environment is best at crop level. Fans that circulate air throughout ranges can also help to create a more even growing environment.

Maintenance and servicing of any boiler should be done on a regular basis. Upgrades to existing heating systems such as heat exchangers, variable speed boiler pumps, heat storage tanks and even simply insulating pipes can all help in gaining efficiencies.

3. GREENHOUSE COVERINGS

Take a look across the greenhouse floriculture industry and you’ll see a wide

variety of greenhouse covering materials. Glass, polyethylene film and various types of polycarbonate are all used for various purposes and crops. Some growers like the control that glass gives them, others prefer the energy savings of double-walled polycarbonate.

When choosing a new covering, a balance between good light transmission and heat insulation is needed. This balance may differ depending on which crops you grow and when in the year. For example, some glass and poly materials can be made in a way to improve light diffusion, which may provide additional benefits. Certain acrylic materials are able to allow UV into the greenhouse, creating an environment that’s protected but has lighting that is more similar to an outdoor field. As with energy curtains, covering materials with greater insulating power have higher R-values and can help lower heating costs.

It’s also good practice to ensure that coverings are well-fitted around pipes, vents and gutters to avoid gaps where heat can easily escape the greenhouse. Try to replace ripped loading dock curtains and weather stripping around doors promptly. Keeping an eye on these seals may also help increase your biosecurity.

Overall, it’s important to remember that proper upkeep and maintenance (including scheduled replacement) is necessary to see efficiencies. Scheduling the opening of curtains or cycling of boilers only works if your climate control system is correct; so be sure to check how they operate and adjust as necessary! Knowing the energy savings you expect to see from a more efficient boiler or upgraded greenhouse covering is important to determine if the payback period on an investment is right for your business.

Interested in how the images for this article were obtained? We used a heatsensitive camera. Warmer areas can be seen in shades of red, orange and yellow, whereas areas that are cooler are in purple and blue. A relatively inexpensive attachment for your smartphone ($500) and the free FLIR One app are all you need to check out your greenhouse in this way too! Thanks again to the greenhouses that allowed us to take these images.

Chevonne Carlow, PhD, is the greenhouse floriculture specialist at OMAFRA. She can be reached at chevonne.carlow@ontario.ca

T: (519) 429-3966 • F: (519) 428-3327

CLASSIFIED RATES: Minimum order $75.00 or 84¢ per word, word ads must be pre-paid. CLASSIFIED DISPLAYS: $72.00 p er column inch. GENERAL INFORMATION: Payment must accom- pany order. Copy required on publication close date. All advertising copy subject to the approval of the publisher. Send order and remittance to: Classified Dept., Greenhouse Canada, P.O. Box 530, Donly Dr. S., Simcoe, ON N3Y 4N5 Canada

PLEASE INDICATE THE NATURE OF YOUR BUSINESS (Please Check One:) Commercial Grower

Commercial Grower with Garden Centre/Nursery

Commercial Grower and Wholesaler

Wholesaler Only

Educational/Government Extension Manufacturer/Distributor

Other Please Specify

YOUR JOB TITLE (Please Check One:) Owner/President Head Grower Manager/Supervisor Sales Representative Other Please Specify

GARY JONES | Gary.Jones@kpu.ca

One word to sum up the ‘state of the industry’. Precarious? Bewildering? Exciting? Such a ‘review’ is, of course, a momentary snap-shot, and no doubt by the time this is in print, things may have changed. For now however, a number of critical issues for the greenhouse industry (veg, cut flowers, bedding, nursery, potted crops) came to mind. It was a long list, so I canvassed the thoughts of BC industry leaders to identify priorities.

GAS: For once, for a short while at least, cannabis is not the number one topic of conversation in BC. On October 9th, a major gas supply pipeline in northern BC ruptured. The effect on growers’ businesses has been nothing less than catastrophic. Gas prices sky-rocketed, supplies were cut overnight to practically nothing and have since only returned to but a bare minimum. This at a time of year when veggie and poinsettia growers are finishing crops and temperature management is critical. Executive director of the BC Greenhouse Growers Association Linda Delli Santi said that the “Gas pipeline is the BIG issue right now for [BC greenhouse] growers. Reductions in availability mean the National Energy Board is capping supply (85 per cent maximum), and locations near the end of lines are unlikely to get what they need. Growers will not have full heating capacity at the beginning of the [vegetable] growing season, meaning that many have decided to delay planting by about 6 weeks on average. The dramatic price increase (up to $18/GJ in October,” [even closing one night in

in new glasshouses, this wholesale change will likely affect the vegetable marketing agencies, additionally now dealing with the gas issue and likely delays to 2019 production. The politics and unpredictable permitting delays of cannabis greenhouse planning applications, and simply the amount of new construction, is further complicating any greenhouse build and repair scheduling.

WORKFORCE: Effects of rising minimum wage are felt immediately and impact business bottom line directly. Minimum wage disparity across Canada means short-term workers favouring one province over another, leading to chronic shortages in some. Says Delli Santi “Minimum wage and ‘Employer Health tax’ cuts into bottom line very hard.” Requirements for large growers to pay health tax have gone largely unreported but this will kick in starting January 1st.

Not to sound too pessimistic, but one potted plant producer emphasized this, saying “Three hits to the bottom line (gas, minimum wage and ‘payroll tax’): makes you wonder why we beat ourselves over the head all these years.”

“Gas pipeline is the big issue right now for [BC greenhouses]...”

mid-Nov at $103/GJ!] “makes planning and budgeting difficult.” The Ministry of Agriculture sees it similarly, “The gas pipeline explosion may have a huge impact on the sector. Industry expects the cost of natural gas to increase and use to be curtailed this winter. Both will negatively impact the bottom line,” said David Woodske, BC Ministry of Agriculture. Another potted plant grower said, “We have gas, as well as oil and propane, and had to switch to alternatives for three days (schedule 27 interruptible). But that costs money (at the time, the equivalent $ per GJ puts our alternates at 5X higher than the pre-explosion rate).”

CANNABIS: Large glasshouses, including major propagators, continue to sell out, merge, or form new partnerships. While much of the veggie crop area converted to cannabis may ultimately be grown

Simply sourcing labour got a whole lot worse this year. Attracting new entrants has been one long-standing aspect we all know about. But as Woodske says, “Access to SAWP [Seasonal Agricultural Workers Program] labour was a huge issue this year. Will it be resolved in 2019? Industry hopes it will.” SAWP has been going for 52 years, currently brings in 30,000+ workers across Canada each year and according apple producer John Ardiel “There would be no horticultural industry in Ontario” without SAWP (The Grower, 2018). Current changes to the process and the ensuing chaos are certainly causing headaches.

While the dairy industry seemed to be the sacrificial cow of recent negotiations around NAFTA and its replacement USMCA, global trade politics will always continue to provide uncertainty for those growing perishable products. Of course, new (foreign) pests and diseases continue to keep dayto-day crop management, let’s say, interesting. Next time, we’ll take a look at some positives and opportunities.

Gary Jones is co-chair of horticulture at Kwantlen Polytechnic University, Langley, BC. He sits on several industry committees and welcomes comments at Gary.Jones@kpu.ca.