Growing Forward 2 Success

BY DR. ABHAY THOSAR

BY LOIS HARRIS

BY GARY JONES

BY DR. ABHAY THOSAR

BY LOIS HARRIS

BY GARY JONES

Three of the four largest greenhouse regions of Canada are facing a similar hurdle. This challenge is politically created, and will require political solutions.

As of this month’s deadline, only one province has reacted positively, though we’re fairly confident the other two will also come on board.

Provincial carbon taxes are developing into a significant impediment to continued growth. For some growers, it may affect their long-term viability.

These new regulations “have the potential to damage Canada’s competitiveness with other jurisdictions,” notes Flowers Canada Growers executive director Andrew Morse. “The fine detail of regulatory implementation,” he adds, “will dictate the impact of this issue on producers.”

Ontario flower and vegetable growers export a great deal of their production. Their ability to compete with growers in regions of North America that don’t have carbon taxes will be significantly impacted.

ers Association (138 growers) has produced an excellent video on the challenge. You can find the link on a story we posted to our website in late October – “Carbon levy latest hurdle to Alberta growers.”

Tree seedling growers in one co-operative in the province, for example, produce about 50 million trees a year. Over the course of their lifetimes the trees will collectively sequester almost 1.3 million tons of carbon.

Alberta is still a net importer of greenhouse products. There is a huge demand for vegetables during the winter months. Consumers increasingly want locally grown foods. Supplying that market would mean higher energy requirements in heat and hydro. Growers in the province could easily capture much of the import market through expansions, but the carbon levy would discourage many of those projects.

It should also be noted that the Alberta government has announced an exemption for dyed farm fuels, so one would assume natural gas in

B.C. growers can claim 80 per cent of carbon tax paid as a rebate

Encouragingly, producer groups in Ontario were talking to provincial officials about the carbon tax issue. There was no news, however, as of our deadline.

Alberta will also soon face a carbon levy, and the impact will be widely felt.

Some 88 per cent of greenhouses in the province rely on natural gas or propane to grow local crops, both for energy to heat the greenhouses and to capture CO2 to feed to the plants as fertilizer. The levy will add $5 million dollars in direct costs to greenhouse operations in 2017 alone.

The Alberta Greenhouse Grow-

greenhouses would deserve a similar exemption. A farm fuel is a farm fuel.

B.C. has been dealing with the carbon tax issue for a few years, and provincial officials there have wisely provided growers with a rebate to cushion the impact. Growers are able to claim 80 per cent of the carbon tax paid as a rebate to their business.

Politicians in both Ontario and Alberta will hopefully follow the leadership shown by their B.C. counterparts. With existing labour shortages and slim margins on too many products, growers do not need a new tax that will affect their ability to compete.

A new garden mum family for both blackcloth and natural season production. Sturdy, round plants with frost tolerance for late season longevity.

The frost-tolerant RhondaTM family provides growers with a vigorous, full color assortment for later plantings to capture end-of-season garden mum sales.

A new pot mum family with unique bicolors with consistent habit and performance for easy growing and shipping for year round production.

To order, contact your preferred sales representative today or visit www.syngentafhg.com

Photos are either the property of Syngenta or used under agreement.

©2016 Syngenta. Some or all of the varieties listed herein may be protected under one or more of the following: Plant Variety Protection, United States Plant Patents, Utility Patents, and / or Plant Breeders, Rights and may not be propagated or reproduced without authorization. The Alliance Frame, the Purpose Icon and the Syngenta logo are trademarks of a Syngenta Group Company. The trademarks displayed or otherwise used herein are trademarks of a Syngenta Group Company or third party.

AccuWeather reports a snowy season is in store for some of Canada’s biggest cities as winter storms dump frequent snow on Eastern Canada.

Stormy weather is also in the forecast for British Columbia and the Canadian Rockies this winter, while the Prairies will face bitter cold.

This winter is expected to play out much differently across Eastern Canada than it did last year, when mild conditions and below-normal snowfall dominated.

“The upcoming winter will likely be a stormy one

across Eastern and Atlantic Canada, especially during January and February,” says AccuWeather senior meteorologist Brett Anderson.

This includes some of Canada’s largest cities such as Montreal, Ottawa and Quebec City.

The Prairies have already had a taste of winter, but the worst of the season will hold off until the arrival of 2017.

A stormy pattern, typical of winter, will set up over British Columbia and the Rockies.

Dr. Masaru James (Jim) Tsujita is the latest inductee into the Olds College Alumni Association Hall of Fame.

The award is the latest in a career of remarkable achievements in greenhouse horticulture. He has been a significant influence on the careers of many Canadian growers and industry specialists.

He grew up on the family’s mixed farming operation in southern

Alberta, which included irrigated sugar beets, seed potatoes and a cow-calf operation.

In 1956, he attended what was then known as the Olds School of Agriculture. Upon graduation, he farmed for a number of years before returning to post-secondary studies. He received his bachelor of science in agronomy/horticulture from Utah State University (1962), and his master’s of science in plant

science and horticulture from the University of Alberta (1964).

He then returned to Olds College, this time as an instructor.

In 1974 he attained his doctorate at Ohio State University and was offered a position at the University of Guelph. He retired in 1995 after 20 years at Guelph and was offered a position as professor emeritus.

Throughout his career, Tsujita main-

tained an active research program with a focus on understanding the influence of new production technology on plant morphology and nutritional requirements. His studies strongly contributed to the widespread adoption of HPS lighting throughout northern production regions of North America.

For more on the award, visit our website at greenhousecanada.com.

$10.1B Estimated total value of produce consumption in 2013 in Canada.

56.7 sq.m of Canadians over the age of 12 don’t eat the recommended 5+ servings of fruits & vegetables/day. 60% $1.5B 2.7% of product sales. Lost revenues in Canada’s ag sector due to labour shortages in 2014 or 26,400

Coverage of largest single tomato plant in the world, found at Walt Disney World Resort. (National Geographic Kids)

16,000

Attendance record (by 1,000) at 2016 FloraHolland Trade Fair in Aalsmeer.

Number of jobs went unfilled in Canada’s agriculture sector in 2014.

891 Greenhouse pepper acreage in Ontario. (OGVG)

11%

Quebec’s share of Canadian greenhouse tomato production, 2014 (StatsCan)

Rethink your mix program! New Plug & Play combos from PanAmerican Seed give today’s shopper easy, grab ’n go gardens in fresh, on-trend colours – spring, summer and fall. Growers will love the easy, economical seed production. Garden centres get big retail shows and big sales. Plug & Play lets you hit every price point with 50+ trialled-and-proven choices. Combos include PanAmerican’s patented seed technology Fuseables® Precision Multi-Pellets, as well as premium perennial combos plus annual combos featuring the popular Wave® brand. panamseed.com

This new series is so beautiful and special. Petunia ‘Queen of Hearts™’ with hearts on its petals is great for a Valentine, for a birthday and even for a wedding proposal. ‘Queen of Hearts’ is part

The fourth in a wildly popular series, the phenomenal new Supertunia® Picasso in Purple™ features vibrant magenta purple flowers with green frosted tips which play off of the deeper green foliage. Though the flowers are similar to Pretty Much Picasso®, the plant habit is much more densely

‘Miss Marvel’ joins the Dümmen Orange ‘Sweetunia’ series. With an eye-popping combination of subtly veined deep plum outlined with crisp white, ‘Miss Marvel’ works well in containers thanks to its mid-range vigour, upright-mounding habit and floriferous bloom set. dummenorange.com

branched and mounded like the popular Supertunia® Honey, and it is covered in flowers from spring into fall without deadheading. Like all Supertunia petunias, it exhibits tremendous heat and humidity tolerance, thriving in hanging baskets and combination planters all season long.

Bounce Interspecific Impatiens, from Selecta, gives you colour in the shade. All-new genetics offer resistance to impatiens downy mildew with the habit and flower count of I. walleriana. Watch it bounce back after wilt and thrive in sun and shade. It is suitable for production in small pots up to hanging baskets and available in

This new variety is offered in the Proven Package including the white Proven Winners branded container and an attractive foil coat label that is sure to garner attention at retail. It is best suited to part to full sun, and grows to 6-12” in height with an 18-24” spread. provenwinners.com

Pennisetum alopecuroides

‘Ginger Love’, from Emerald Coast Growers, has thick, dark red blooms over green mounding foliage. This fountain grass waves red inflorescences from August into October. It reaches two to three feet tall and prefers full to part sun, and is hardy in Zones 6 to 9. ecgrowers.com

of the Amore series, a collection of breathtakingly patterned varieties. And we haven’t even begun to talk about the packaging that gives this series a total romantic feeling. danziger.co.il

several key colours, as well as the new ‘Bright Coral’ for 2017 retail sales. It is supplied as unrooted cuttings from Ball Seed and as rooted cuttings from select root-and-sell locations. It does well in shade and sun and grows to 14-20” (36-51 cm) in height, with a spread of 14-20” (36-51 cm).

selectanorthamerica.com

This new series from Darwin Perennials makes a great component plant in combos and blooms all season with bold, bright colour. Available in nine varieties for 2017, Mirage has a self-branching, mounding habit that resists breaking, a true standout in the landscape. It is heat and frost tolerant, making it a great shoulder-season choice. Winter-hardy in zones 7-9. It thrives in the sun. darwinperennials.com

PRO-MIX BX MYCORRHIZAE is a solution for growers seeking to benefit from both the nutrient retention ability of vermiculite and a perlite content providing limited but propewr drainage capacities. Combined with high-quality fibrous peat moss, this formulation is ideal for growers looking for a general purpose medium which creates a well-balanced growing environment.

†

SUPERTUNIA® Vista BUBBLEGUM® Petunia

SUPERTUNIA® Vista Fuchsia Improved Petunia

SUPERTUNIA® Vista Silverberry Petunia

Backyard BBQ –

SUPERBELLS® DREAMSICLE™ Calibrachoa

FLAMBÉ® Yellow Chrysocephalum apiculatum

SUPERTUNIA® Really Red Petunia

Honeybelle –

SUPERBELLS® Yellow Improved Calibrachoa

CAMPFIRE™ Fireburst Bidens

SUPERTUNIA® HONEY™ Petunia

Growers and retailers have seen tremendous success over the years in producing and moving our National Recipes

Now it’s time for you to capitalize on our extensive marketing efforts to boost your spring, summer and fall sales. Find everything you need to build a successful program at www.provenwinners.com/ professionals/national-recipes

Proven Winners is ready to support Canadian growers with patriotic red and white plants and recipes to celebrate the 150th anniversary of Confederation festivities in 2017 We’re also inspiring Canadians to grow memories with the advertisement shown here, appearing this spring in popular Canadian consumer print publications including Garden Making, Canadian Living and Style at Home

We are building demand for our national recipes through print advertisements in these popular magazines:

• HGTV

• Everyday Home

• Fine Gardening

• Domino

• Magnolia Home – Brand new for 2017 from popular co-hosts Chip and Joanna Gaines of HGTV’s Fixer Upper

SNOWSTORM® GIANT SNOWFLAKE® Sutera (Bacopa)

DIAMOND FROST® Euphorbia

SNOWSTORM® SNOW GLOBE® Sutera (Bacopa)

SUPERTUNIA® White Petunia

SUPERTUNIA® Vista Silverberry Petunia

SUPERTUNIA® BLACK CHERRY™ Petun

SUPERBELLS® POMEGRANATE PUNCH™ Calibrachoa

SUPERBELLS® Red Calibrachoa

SUPERBENA® Royale Red Verbena

SUPERTUNIA® Really Red Petunia

Find these patriotic red/whit recipes at provenwinners.co Red, Red Wine

Love Song

Chick Flick Cherry

Diamonds and Rubies, Oh My!

Here are four essential tricks to control greenhouse energy costs

All greenhouses use energy, regardless of size. Whether one acre or 15, heating in winter and cooling/ventilation in summer are critical to maintain the optimal internal climate.

Energy costs have a big influence on profitability; if you know what you’re doing, they can be managed and reduced but the expertise of most growers focuses (rightly) on high quality plants or produce. Small greenhouses are especially impacted as owners often run every aspect of their operation themselves; they have little time to follow the ever-changing energy markets, or to focus on how

ABOVE

Start today on an energy savings program.

to reduce consumption. Working with greenhouse operators across North America to reduce energy costs and improve efficiency through procurement, operations, and equipment is 360 Energy.

Here are 360 Energy’s “first steps” advice for small and large growers alike to begin controlling their energy costs.

Compare energy to other operating inputs: Many growers find that energy costs (natural gas, oil, electricity, diesel and/or other) rank among the top two or three largest input cost categories. Up to 25 per cent savings can be found by taking control of both energy usage and energy rates; knowing how energy costs compare to other inputs can influence how much effort is placed on managing them.

Track monthly bills: Begin by tracking energy use based on monthly bills. Each time you receive a bill, record in a spreadsheet how much gas,

electricity, oil, etc. that you used and how much it cost. Compare these amounts over time; consider what may have caused significant differences between time periods and if there are ways to modify that in the future.

Dig even deeper: break down the three main parts of your energy rates – commodity, transportation and distribution – and use this information to identify your priority focus for reducing rates per unit of energy. Understand the different elements of your bill before making decisions about what kind of contract(s) to enter to avoid accidentally paying more than you expected or needed.

Site assessments: An engineering site assessment can identify how much energy you should expect to use based on greenhouse structure, operating equipment and production scheduling. Knowing this, a greenhouse operator can compare against actual monthly usage to find areas to save, and prioritize actions to address first. Savings may be achievable through strategic purchasing and responsive modifications to operations. Hiring professional advisors to evaluate heating, air circulation/cooling, lighting and technical set points, and inputs/outputs can provide very site-specific insights to enhance efficient use of all commodities.

Customized energy purchasing: How you purchase energy should be informed by your total energy consumption for each commodity, timing of usage, risk management and credit score. If you know what you’re doing and have time, you can purchase wisely. Under certain circumstances, there can be benefits to purchasing energy supply (e.g. natural gas) in collaboration with other growers. Some efficiency can be achieved if very small volumes are aggregated and jointly purchased at once. An energy consultant can assist by screening for the best suppliers, ensuring their quality, and managing a competitive tender to keep prices down.

Written by James Williams and Jennifer Niece of 360 Energy, one of North America’s leading energy services firms. They apply a unique, multi-faceted approach that addresses both energy costs and energy consumption for clients across Canada and the U.S.

CHRISTIE POLLACK | www.learnplantgrow.com

Conclusion of a two-part series on launching a new

Building our greenhouse in 2013 was an adventure from the very start. A rainy summer pushed back our construction by months and we had a deadline that had to be met because we were hosting a wedding in our greenhouse (the greenhouse that didn’t exist yet) in October.

Tanner and I had been approved for a loan from Farm Credit Canada in early 2013 to build a beautiful Paul Boers “Herculon” gutter-connect greenhouse and two freestanding greenhouses.

We had decided from the very beginning that we

ABOVE

“Every year has been better and better.”

would run our greenhouse year round (even though we are ornamental growers), and had come up with the idea of teaching courses and selling giftware through the winter to bring customers into our space. Our tagline was (is) learn, plant, grow.

Rumours were already swirling that the greenhouse was just that, a rumour, and I knew right away that we had to take control of our own story. I started a Facebook business page under the name of our new business and started documenting the construction.

Every few days, I’d snap pictures on my iPhone of the crew (who became more like family to us) from Imperial Greenhouse Construction and uploaded them to Facebook with a description of what we were doing. Instantly we watched the number of people following our feed climb. Within the summer, we reached an audience of 300 without growing or selling a single product.

At that moment, I understood the power of social media.

By November 2013, all the Christmas inventory had been delivered, labelled, priced, and set up but we still didn’t have any power. We opened our doors for the first time on Nov. 12, running three small generators for power. Our electricians were still busy at work and we were waiting for the power company to connect our lines but we had bills to pay and it was time for us to start selling the inventory we had bought.

A week later, our first shipment of poinsettias arrived.

Finally on Nov. 23, we had real power.

In January 2014, a freak storm ripped through High Prairie with winds reaching over 120km/ hour. The winds shook our freestanding green houses so hard it ripped out all the vent brackets and punctured holes in the new poly. In one freestanding greenhouse, the poly was ripped to shreds over the entire building.

We hadn’t even used the greenhouses and they were already destroyed. Luckily, we had green house insurance.

In May 2014, the last bill for the installation of our furnaces and electrical work was paid. May was even busier and our sales were much higher then we had estimated.

Lessons learned:

ough business plan and detailed financial estimates (even adding on a percentage in each category for overages), we learned that things happen and you just have to roll with it. We took time each day to reset our minds when things may not have been going the way we wanted. Keeping a positive attitude is the greatest gift a person can give them selves – in the end things work out and often work out better.

I also learned that persistence is one of the keys to success. Every year has been better and better. If we hadn’t persisted through the hiccups as we were building, we wouldn’t be standing here today attempting to make what we do even greater.

Christie and Tanner Pollack are owners of Christie’s Gardens and Greenhouses, located near High Prairie, Alberta, one of the province’s newest garden centres. Christie was named one of this year’s Top 10 Under 40 award winners by Greenhouse Canada

Getting tomato and pepper crops off to a good start requires optimal temperature and irrigation management. Since every variety and farm is different, look at your own plant model before making any changes.

BY PETER VAN PAASSEN

Since most farmers start the growing season in December and January, the space at propagators is limited. Up to 48 heads per square metre spacing is not an exception. This results, in most cases, in a vegetative plant with a few tiny hairy roots. It will be the job of the grower to transform the plant into a strong generative fruit producer. In the following paragraphs I will outline the start of an early January planting.

Temperature: Since the humidity on the farm is lower than at the propagator, start on the planting day with a moderate 20 C. If the greenhouse has a curtain, keep it closed so the plant can slowly adjust to the new climate

conditions. If you have snow pipes, use them as well since there is less direct heat to the plant. Start with a night temp of 18.5 C / 19.5 C and a day temperature of 21 C (+2 C on light – if it is sunny you increase the day temperatures 2 C extra).

Depending on the number of sunshine hours these temperatures should be increased or decreased. As a rule of thumb, don’t increase the day temperature until the plant has good strength and lower the night temperature when the plant doesn’t have enough strength due to the dark conditions. Keep in mind that the roots are the last in the line of getting energy. For that reason don’t “push” the temperature level too much until you have good roots in the block of the plant.

Irrigation: Since the uptake of water is too easy for the plant we start next to the hole. During the first few days, one to three irrigations (for a 42-day-old plant) per day is enough in most winter situations. The plant needs a lot more water if the outside temp is -10 C with a low humidity, compared with a day of -3 C and a south/west humid wind.

The time of irrigation is very important for the development of strong, thick roots. If the plant needs one irrigation, then 11 a.m. is a good time. If the plant needs two irrigations, then give a shot at 11 a.m. and another at 1 p.m.

The plant is forced to “work” almost 21 to 23 hours to take up the water from the block and transport it to the leaves. This searching for water leads to strong root development throughout the block. When the plants gain in size, the irrigation hours during the day have to be extended, but make sure that the plant has a slightly darker green colour half an hour before sunset.

A bit of drain in the middle of a sunny day is always good to freshen up the block (though not in the first five days). When you notice that the blocks are too light in weight at the end of the afternoon, give a night irrigation around 10 p.m. When you enter the greenhouse in the morning at 7:30 a.m. and the blocks are very light in weight, give a small irrigation, but don’t fill up the whole block, just continue your normal irrigations in the middle of the day. Depending on the plant size and pipe temperatures a night irrigation could become standard when the first cluster starts flowering.

It is better to stop on time in the afternoon and give a night irrigation so that the plants are on “colour” before sunset than to irrigate until late in the afternoon. When the first cluster starts developing the first tomato the plant is ready to be placed on the slab hole.

Temperature: On the day of planting start with a temp of 20 C and in a glass greenhouse keep the curtain closed. A day temperature of 21 C (+2 C on light – if it is sunny you increase the day temperatures 2 C extra), and a night temperature of 19 / 19.5 C is a good start for a V-system. If the greenhouse has a four-row system these temperatures can be 0.5 C higher because the light interception is better. Depending on the radiation sum and plant strength, the temperatures can be increased or decreased. It is better to make small adjustments on a two-day basis than drastic adjustments on a weekly basis.

Irrigation: The plants will be planted directly on the hole. The goal for the first 10 days is to anchor the roots of the block into the slab. For the first week the plants will need two or three irrigations in the middle of the day between 11 a.m. and 1 p.m. depending on pipe temperatures, and one or two night irrigations at 9 p.m. and 2 a.m. to encourage root development into the slab. As soon as the roots are well established throughout the slab, stop with the night irrigations and extend the day irrigation hours a little bit to form a strong plant model. The relatively short irrigation period will encourage the roots to search for water during the late afternoon/night and early morning, which will result in a well-developed root system throughout the slab.

Since every variety and farm has its own characteristics look at your own plant model before making any changes.

Peter van Paassen is a former Dutch farmer and owner of Peter van Paassen Greenhouse Consulting Inc., specializing in growing, labour and pack-house efficiency. • peter.grhconsulting@gmail.com.

Registered for use on cannabis raised indoors, KOPA insecticidal soap controls whiteflies, spider mites, aphids and other soft-bodied insect and mite pests on contact.

OMRI® CANADA Listed for organic production, KOPA can be used right up until the day of harvest. KOPA is lethal to pests, yet it is of low risk to workers and the environment.

KOPA. When clean product is your only marketable option.

AA veteran greenhouse crop specialist discussed ‘LED Lighting – A Commercial Possibility: Myth or Reality” in a presentation at last fall’s Canadian Greenhouse Conference in Niagara Falls.

BY DR. ABHAY THOSAR

s one of several plant specialists on the Philips Lighting horticulture global team, I regularly talk with growers about the benefits of using LEDs in their greenhouses. Often growers comment to me that LEDs are too expensive or that the technology is too new or that LEDs haven’t been proven to work. And often growers tell me LEDs are not needed because they have sufficient lighting in their greenhouse either through natural light or through their use of supplemental light, i.e. high-pressure sodium fixtures.

However, the reality is that many growers, whether growing floriculture crops or indoor vegetable and fruit crops, could benefit from more light in both duration and intensity

and many growers would benefit specifically from the light spectrum that can be provided by LEDs. Regarding LEDs being new and unproven, the reality is that LEDs aren’t new. In fact, LEDs have been used in greenhouses in Europe for almost 10 years and have been proven to improve the quality of crops as well as the speed in which crops grow. And while LEDs may appear expensive if comparing in simple terms as a fixture-to-fixture cost, there are several additional factors that need to be considered to accurately determine return on investment and payback.

To begin the conversation, light is visible radiation. Light is measured in nanometers and describes only a portion of electromagnetic energy that

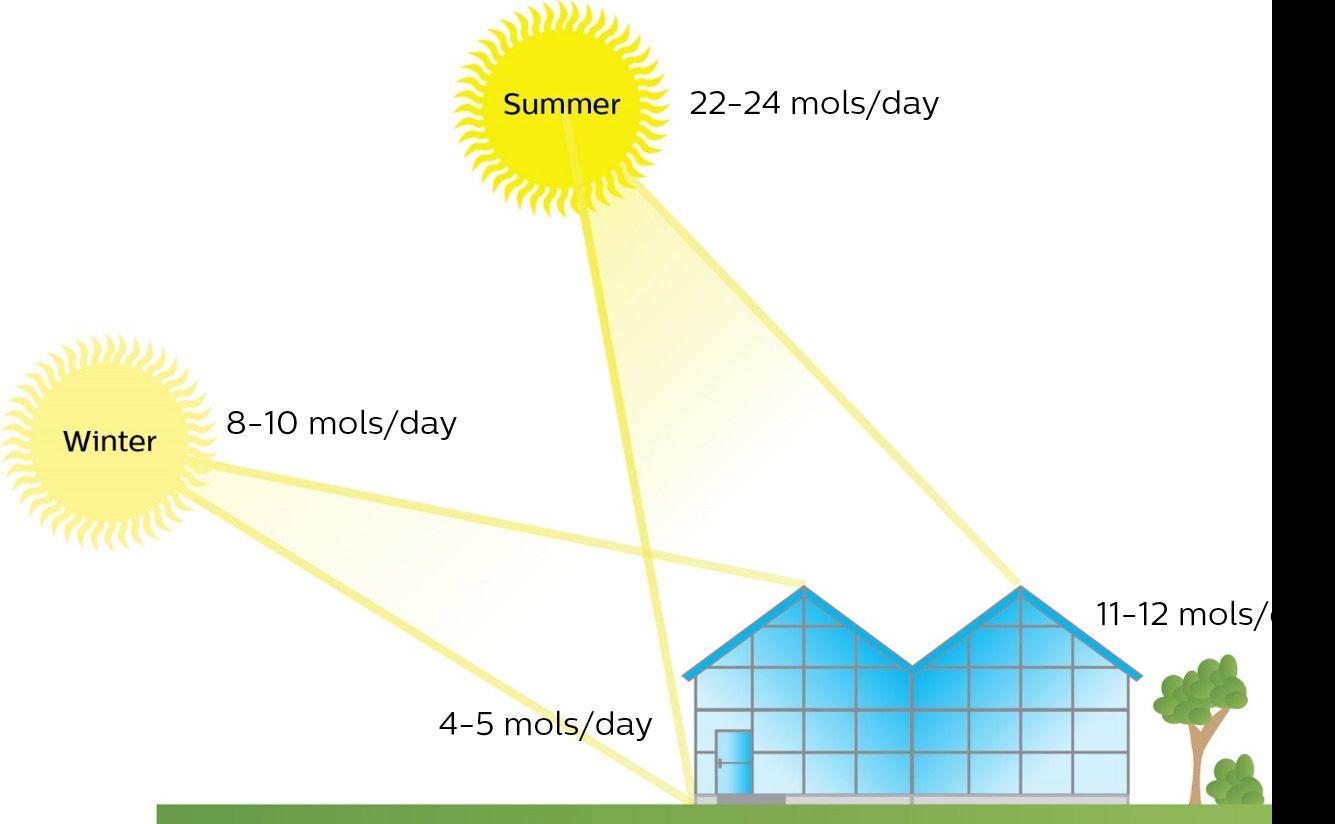

LEFT Light intensity in different growing seasons. ABOVE Recommended Average Daily Light Integral (Mols per Day).

is detectable by the human eye. Most importantly for growers of any crops, light is the energy source that drives plant growth. Let’s look at the three most common myths about LEDs as they pertain to greenhouse lighting.

MYTH 1: LED LIGHTING IS NOT NEEDED BECAUSE WE GET ALL THE LIGHT WE NEED

Too often humans define light as the light they see. Growers may think it is extremely sunny outside and “I have lights in my greenhouse, therefore, my plants are getting the light they need.” To know if this is true in your greenhouse, one must first start with a solid understanding of four key lighting terms and specifically, the importance as the terms relate to horticulture: photosynthetic active radiation; micromole; mol; and daily light integral.

Photosynthetic active radiation: Photosynthetic active radiation, most commonly referred to as PAR, is the spectrum of light ranging from 400-700 nanometers and is the range of light used by a plant’s chlorophyll pigments in photosynthetic activity.

Micromoles: Micromoles is a measurement of PAR photons delivered per square metre per second.

Mols: Mols is a measurement of PAR photons delivered per square metre per day.

Daily light integral (DLI): Daily light integral or DLI is an accumulated measure of light expressed as mols per day.

In North America, growers measure greenhouse lighting using a variety of units including lumens or lux, foot candle, joule and micromole. The latter, micromole, is the light measurement unit preferred by horticulture researchers because it is the only unit that measures PAR photons – again, PAR photons drive plant growth.

Now there are three factors of horticulture lighting that are fundamental to developing your greenhouse lighting protocol: 1) intensity; 2) duration; 3) spectrum.

Intensity: For horticulture lighting, intensity refers to the amount of mols being delivered to the plant at the plant canopy level.

Due the type of greenhouse structure (glass, poly, double poly, etc.), age of greenhouse, greenhouse location, and the growing season, the light levels inside a greenhouse can be reduced by 50 per cent or more from the levels outside a greenhouse. A grower may think it’s really bright outside but unless light levels are being measured inside a greenhouse at the plant canopy level using a high-quality light meter, you cannot assume your plant is receiving all the light it needs.

Duration: Very closely connected to intensity is duration, how long a crop should be lighted to achieve optimal photosynthesis.

Roberto Lopez, Ph.D., through his research at Purdue University, developed a comprehensive guideline for the recommended average daily light integral (DLI) for the most common cultivars. Through his research, Dr. Lopez found that in order to produce a high-quality crop, most plants need a minimum of 12-20 mols of light per day.

During the winter months when the days are much shorter, the sun is less intense and sits lower on the horizon and inside light levels at the crop canopy measure 4-5 mols per day. (Illustration on facing page.)

This means that crops are not receiving the recommended light levels (DLI) that will result in a “high-quality” crop. If you’re growing season begins in November, December or January, your crops are most likely not receiving the correct intensity and/or duration. Instead, your crops would benefit from more light.

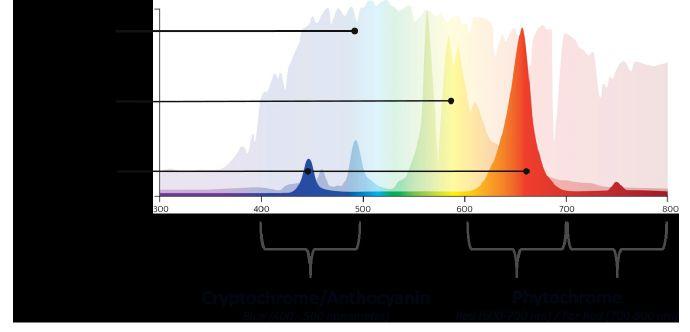

Spectrum: Plants have highly sensitive mechanisms for perceiving light and regulating developmental changes to help maximize light utilization for photosynthesis.

Both Cryptochrome and Phytochrome are the important pigments in the chlorophyll A and B for optimum photosynthetic activity. Chlorophyll utilizes the blue and deep red wavelengths efficiently and effectively for plant growth, development and morphology.

Cryptochrome/Anthocyanin are the plant’s photoreceptors that are sensitive to blue light (400-500 nm) and can affect a plant’s morphology (compactness), stomatal activity and pigmentation.

Phytochromes are photoreceptors that are sensitive to red light (600-700 nm) and affect a plant’s morphology (elongation), flowering and germination.

The focused spectrum of LEDs supports photosynthetic activity. In spite of what many growers may believe, most can benefit from LED lighting because LED lighting can provide the needed intensity, duration and spectrum. In other words, LEDs deliver the right light spectrum for the right amount of time and the right intensity for optimal plant growth.

Since the commercial launch of Philips GreenPower LED toplighting in 2016, Philips has continued to work with many growers and researchers to demonstrate the effectiveness of growing under LEDs. Above is an example of side-by-side results – comparison of crops grown under Philips LEDs vs under HPS. (Visit our website posting of this feature for more images at greenhousecanada.com.) These are real-world results in which all other

ABOVE

One example of responses to LED and HPS lighting.

crop inputs were constant. The only difference was the supplemental light source over the crops.

LEDs in the right spectrum with appropriate light levels can improve crop production through faster growth, improved plant structure, reduced stretch, stronger rooting, more lateral branching, increased yield and robust growth without PGR. Therefore, I can say with great confidence that LEDs do indeed work.

It is understandable that a grower may believe that LEDs are too expensive if the grower relies on a simple side-byside cost comparison of an HPS fixture to an LED module. However, this is not an equal comparison as there are several missing data points:

LEDs consume significantly less energy: LEDs can result in as much as a 55 per cent reduction in annual operating costs results compared to HPS.

Higher light efficacy: LEDs are more efficient at converting electricity into pho-

tosynthetic light – the higher the efficacy of a fixture, the greater the efficiency.

Very long lifetime: LED fixtures can last up to 50,000 hours, whereas HPS fixtures have a significantly shorter life and will require replacement much more frequently.

Installation costs of LEDs are significantly lower than installation costs of HPS: Due to high power draw of HPS, many greenhouses do not have the capacity to accommodate the supply to run HPS fixtures for the length of time needed to achieve their needed light levels without rewiring their greenhouse.

Utility rebates: Incentives based on installation of energy-efficient light fixtures may be available in local areas; these rebates can have a very positive impact on return on investment calculations.

Tailored light spectrum: Light spectrum of LEDs can be tailored based on your growing objectives and specific crops.

When evaluating the option of LEDs, it is important to look at more than just the cost of a fixture. I encourage growers to consider all the many factors and benefits that LED lighting can bring to their operations. As a grower, they will see that LED technology is here, LEDs are ready and LEDs can result in real, tangible benefits.

“This is life in the technology lane. If you always wait for the next price cut or to buy the new improved model, you’ll never buy any technology product because there is always something better and less expensive on the horizon.” –Steve Jobs, 2007

Dr. Abhay Thosar, a senior plant specialist with Philips Lighting horticulture global team, discussed “LED Lighting – A Commercial Possibility: Myth or Reality” at the 2016 Canadian Greenhouse Conference.

Our third annual state-of-theindustry report finds energy and labour among the major challenges. Carbon pricing programs are high –and could possibly grow higher – on the agenda for most grower groups across Canada.

BY TREENA HEIN

Welcome to our third annual state-of-the-industry report, an inside look at some of the factors impacting greenhouse horticulture from coast to coast. It’s another taking-of-the pulse with new and previously included voices and their views on what’s happening today – and what’s to come.

Energy: Overall, interest in LED lights and year-round production continues across Canada, but all thoughts related to energy issues are coloured by serious concerns about carbon pricing.

Andrew Morse, executive director at Flowers Canada Growers, says that in Ontario, electricity costs have been rising steadily, and new costs associated with natural gas will come into effect in January with the province’s “cap and trade” program. While he notes that this is somewhat more difficult to predict across the country, “new [carbon] regulations have the potential to damage Canada’s competitiveness with other jurisdictions. The fine detail of regulatory implementation will dictate the impact of this issue on producers.”

Dr. Justine Taylor estimates that the Ontario program will cost members of the Ontario Greenhouse Vegetable Growers (OGVG) who produce 10,000 tonnes or less of CO2 annually (from burning natural gas) about $6200 per acre. Taylor, the OGVG’s energy and environment coordinator, adds that growers who produce somewhat more than that have the option to join in with growers who produce a great deal more than that, under the large-consumer part of the program. This scheme provides participants a fee exemption in 2017, with a requirement to pay only 4.5 per cent of their calculated fee in 2018, nine per cent in 2019, and 13.5 per cent in 2020. Participants will also have to complete an emissions report verified by third party and fulfill other requirements. Taylor says the OGVG is holding ongoing meetings with the provincial government to discuss this

disparity. On a positive note, she believes cap and trade may spur more partnerships between greenhouses and companies or electricity generators that produce CO2 and heat.

Bob Pringle, CEO of United Flower Growers (the B.C. flower auction) notes that while natural gas costs in B.C. are currently low, he and his organization are watching things closely. “Greenhouse growers in B.C. get an 80 per cent rebate with the provincial carbon tax at this point,” he notes, “but we are concerned this may be affected with a national plan in place.”

On the energy innovation front, Yohan Dallaire Boily notes that last year, several greenhouse businesses in Quebec invested in energy efficiency components and especially in biomass heating. As well, co-generation projects have emerged, says the communications director for the Quebec Ministry of Agriculture (MAPAQ).

Dallaire Boily adds that since 2013, a break on electricity costs has allowed some greenhouses to move to year-round production, but the introduction of LED lights is still slow. In addition, the province will be re-launching two energy efficiency programs (Ecoperformance and Technoclimat) soon, and is also working on a new energy policy to encourage the development of renewable energy and new technologies.

“The development of cheaper technology for biomass burning, (including the gas for CO2 recovery), the recovery of heat (cogeneration) and the production of greenhouse vegetables year-round should continue over the next few years,” says Dallaire Boily.

B.C. Greenhouse Growers Association executive director Linda Delli Santi notes that interest from consumers and retailers in year-round production continues to be strong in her province,

but for this to become reality, lighting must be economical. “As electricity costs are so high, alternate energy sources are required (cogen or co-located with industrial installations that can provide heat and CO2).”

Taylor reports that more and more vegetable growers in Ontario are testing small areas of production with supplemental lighting, and that a recent Ontario government announcement of changes to the Industrial Conservation Initiative (ICI) may allow some greenhouses to access cheaper electricity rates and move towards all-year production. The public comment period on this proposed change ended in mid-November, and time will tell if the proposed change (allowing those who use only 1 MW a month to qualify) will become a reality. Taylor says 1 MW equals about two acres of HPS lights.

Morse notes that the range of LED products in Canada is growing, but that there “remains much to learn about LED use in commercial production.”

Market trends: Overall, market trends for Canadian vegetables and flowers are positive going into 2017.

OGVG general manager Rick Seguin says acreage and production in Ontario continues to expand in line with historical growth patterns, with greenhouse veggies being introduced to additional markets and new consumers.

“We have recently partnered with Gordon Food Service, the Ontario government and four other commodity boards,”

In May 2016, MAPAQ launched a strategy to support organic greenhouse vegetable production.

he says, “to try to get more awareness of locally grown produce in the foodservice industry.”

It is hoped that the projects will increase the sale of Ontario-grown food by $5 million each year.

In B.C., Delli Santi notes that “Buy Local” is definitely still a big draw, but that

sentiment varies depending on the region and retailer.

“Greenhouse produce is definitely perceived as having better food safety from a retailer perspective, but generally speaking the average consumer doesn’t know enough to have this opinion,” she explains. “Veggies are trending to smaller, snacking specialties that drive better flavour. The challenge here comes from whether the reduction in yield and corresponding increase in cost will be accepted by the market.”

In May 2016, MAPAQ launched a strategy to support organic greenhouse vegetable production, which continues to expand in Quebec.

“The concerns of consumers for the environment, and health and safety of food drive the growing interest for the purchase of local products,” Dallaire Boily notes. “Greenhouses in urban areas are expanding to meet these new needs.”

While tomato production (beefsteak, grape, heirloom, etc.) makes up almost 60 per cent of Quebec greenhouse produce sales, diversification is growing. “The range

“We know the work we put in to grow safe, healthy food. We’re the ones who

is expanded into mini-cukes, peppers, varieties of lettuce, herbs and strawberries,” says Dallaire Boily. “Also, with immigration and openness to the world, demand is growing for exotic vegetables in the greenhouse, such as eggplant and napa cabbage.”

On the flower side, Pringle says B.C. growers are getting good prices for cut flowers and plants, with more demand from the U.S. because of the low Canadian dollar. “The wedding demand was good this year,” he reports. “There was lots of demand for white flowers and some non-traditional colours. There was also a good demand for tropical and foliage.”

Morse expects national flower sales to continue to grow. ”We have seen notable increases in sales across the country since 2013, and increases in exports to markets within the U.S.,” he says, adding that “over the last year we have noticed some growth in a number of places, including cut lisianthus, cut chrysanthemums and cut ranunculus to name a few.”

Dallaire-Boily notes that although baby boomers are gradually moving away from gardening as they age, the younger generations are interested in landscape design and ready-to-decorate products for their terraces, with easier-to-maintain planters becoming more popular.

Labour issues: Labour issues remain a challenge for most floral greenhouse operations, according to Morse.

Pringle points to a scarcity of entry-level employees across the board in B.C., and also in mid-tier management positions. “The unemployment rate is low right now here,” he notes. “Growers may have to offer higher wages and also access more staff in the seasonal Temporary Foreign Workers Program (TFWP).

In Quebec, Dallaire-Boily says the difficulty in recruiting managers along with issues with the in TFWP are limiting factors in the economic development of the horticultural sector.

In the U.S., the situation is similar.

Ken Fisher, president of AmericanHort, says the availability of both manual and skilled labour is limiting the ability of many businesses to grow and prosper.

“The direct cost of labour and associated overhead costs are a growing component for nearly all of our members,” he explains. “AmericanHort is coordinating with other like-minded organizations working for sensible immigration reform and reasonable labour improvements.”

Fisher adds that there are growing opportunities in automation and the use of ‘Lean’ thinking to lower labour costs.

Seguin of the OGVG says the current mix of labour programs are working well for Ontario vegetable growers.

Delli Santi in B.C. says availability of labour is always a concern in that province’s greenhouse veggie sector, but “the bigger concern is the disparity in cost of labour for Canadian greenhouses versus Mexican and U.S. imports.”

Moving forward: When asked to identify the biggest challenges and trends facing greenhouse owners in 2017 as well as over the next 10 to 20 years, many industry experts focused on environmental issues.

Taylor says that “the move to a low-carbon economy in Ontario will lead to significant changes over time in the technologies used and methods of production of greenhouse vegetables. Growers will need to find new efficiencies, new products and enhanced value for consumers in order to remain competitive with other jurisdictions that have not moved to a low-carbon base.”

Delli Santi agrees. “Government programs such a carbon tax and recycling fees are further creating competitive imbalance versus other regions that do not have the costs associated.”

In the long term, she sees concentrated production centres losing ground to new greenhouses in regions previously without them. “Retailers are getting larger so margins are being squeezed very tightly,” Delli Santi adds. “The world is getting smaller, pests and diseases travel quickly … and they can have significant impacts on our production.”

Pringle lists many challenges ahead for United Flower Growers members, from growers being forced into either marketing directly themselves or hiring marketing companies to make direct sales to large retailers, to costs related to more layers of regulatory bureaucracy on recycling, water restrictions and more.

“Real estate values are very high in B.C., allowing those who wish to sell a good opportunity,” he says. “It’s been hard to sell for years for some growers. Some offshore investors have come into the market … Over the last few years, we’ve lost a few members, but we don’t necessarily lose volume because other members step up production.”

Claude Laniel, general manager of the Syndicat des producteurs en serre du Quebec, says in the near future, he expects a rebuilding of research into clean energy. Over the next five years, his organization has a goal of adding 40 hectares of veggie production, with a focus on products that meet the needs of

consumers, including organic veggies and those produced with minimal pesticides as part of their IPM programs.

Morse adds that several crop protection products are being re-evaluated by Health Canada, and loss of some notable registrations will require producers to seek alternative products.

The Syndicat des producteurs en serre du Quebec also hopes to increase provincial household spending by at least $50 per year on greenhouse floral and nursery products.

Fisher at AmericanHort notes spending on landscaping is also growing among U.S. homeowners.

“As breeders and growers innovate to differentiate their products, intellectual property management becomes an important success component,” he adds. ”Domestic and international movement of plant material would benefit from better processes and standards. Generational transfer of family businesses and successful assimilation of emerging professionals into our maturing industry will be necessary in the next five years to ensure the continued growth.”

Morse reports that Canada and the U.S. officials have completed negotiations

ABOVE AND PAGE 22

Microgreens are an increasingly popular crop for Quebec growers.

on the Greenhouse-Grown Plant Certification Program (GCP). ”This program will become an important program for Canadian flower growers accessing the U.S. market or sourcing propagative material from U.S. producers,” he notes.

The new program is expected to begin its rollout in 2017 and is expected to require some change in common export practices across Canada.

Treena Hein is a freelance writer in Ontario.

Eligible greenhouse growers can reduce labour, water and energy costs through the popular Growing Forward 2, a popular five-year federal-provincialterritorial initiative.

BY LOIS HARRIS, OSCIA

Ian Adamson, owner of Greenbelt Greenhouse, credits the Growing Forward 2 (GF2) program for helping him carefully examine his financial position and then significantly improve it by installing innovative packing equipment that increased productivity and his bottom line while decreasing water consumption in his operation.

GF2 is a five-year federal-provincial-territorial initiative designed to encourage innovation, competitiveness and market development in Canada’s agri-food and agri-products sector through costshare funding opportunities. It was launched in 2013 and is delivered to farmers in Ontario by the Ontario

ABOVE

Soil and Crop Improvement Association (OSCIA).

The next application intake period in Ontario is Feb. 3-23 of this year. Note: GF2 is national, but the delivery to producers and growers differs somewhat across the provinces. Check with GF2 officials in your province for more information.

Adamson’s company – based in Gormley, Ontario – produces microgreens (plants like arugula, basil and broccoli that are picked when they’re still very young) for the restaurant and grocery markets.

“Because the plants are so tender, we needed equipment that had gentler washing, drying and handling than regular packaging systems,” he

says. “We could not process our products fast enough to maintain quality as the product would deteriorate after harvest.”

With $100,000 in funding from GF2, Adamson had special equipment developed and manufactured in Germany. The system is unique in North America, which is how he received extra funding from the program for innovation. With it, his operation can now process 10 times the product with a quarter of the labour.

“This has not decreased our need for labour as our sales have more than doubled since the installation,” he says. Adamson also points out that his water usage is less than a quarter of what it used to be because now the water is filtered, treated and recycled.

In addition, the equipment had a lot to do with the operation becoming GAP (Good Agricultural Practices) certified for food safety, since it’s designed to be cleaned easily.

In the first two years of the program, GF2

funded more than 1,700 projects with a government cost-share of about $17.7 million. An additional $7.4 million was allocated through a special program to deal with the porcine epidemic diarrhea virus.

ABOVE

GF2 has been popular with growers across Canada.

In year three, 700 more projects received $8.6 million for which claims are still being processed. Over the three years, about $79 million has been invested in Ontario’s agriculture industry by

For over 30 years, Hillen Nurser y Inc. has remained dedicated and passionate about the nursery industr y. We invite you to visit our website with easy access to our complete up-to- date listings of hundreds of varieties, look ing good photo's and more........

Mark Endicott

General Manager

23078 Adelaide Rd. Mount Br ydges, ON N0L 1W0 Cell: 647.923.5182 • Fax: 519.264.1337 mark@hillennursery.com

producers and government.

Program funding is also available for education and training courses, marketing and a whole host of other improvements. There are over 40 different project categories from which to choose.

Here’s an overview of just some of the many areas for which greenhouse growers can apply under GF2. Full details of eligibility criteria are available through the GF2 program guide.

Farm Financial Assessments: “We started with GF2 to assist with, first, understanding our business’s financial position, and then gaining an in-depth understanding of the cost of production,” Adamson says. “This, in turn, steers analysis of what products and processes need improvement to achieve higher margins.”

To qualify for funding under this category, growers must have completed the Growing Your Farm Profits (GYFP) workshop or an equivalent within the past five years.

Eligible activities include hiring a consultant to assess the operation’s finances

and costs of production. It also covers costs for data gathering and analysis, writing the report and reviewing the report with the grower.

Funding of up to 50 per cent of project costs are available to a maximum of $2,500.

Business plans: GF2 has funding available to develop business plans, succession plans, human resource plans, feasibility plans, expansion plans and diversification plans.

Eligible costs include paying for an ad-

visor to develop the plan, as well as costs associated with putting the plan into action, including necessary documents (e.g. purchase and sales agreements, wills as they relate to succession plans, and shareholder agreements). GF2 also helps cover costs for specialized contracts, licensing agreements, the initial set-up of a management system and certification that increases market access (e.g. ISO, organic) as it relates to activating the business plan.

Funding is available at up to 50 per

cent to a maximum of $10,000.

Labour productivity: As shown in the Greenbelt Greenhouse operation, improving efficiency through increased employee productivity and automation decreases costs and increases bottom lines. To receive funding under this category, growers must have completed the Grow Your Farm Profits (GYFP) workshop and developed an action plan in the last five years or done equivalent training and planning.

Assessments and plans: Growers can apply for funding to have productivity assessment done to reduce waste and decrease downtime for employees. Included among eligible expenses are benchmarking, data gathering and analysis and report writing. Funding is available at up to 50 per cent of project costs to a maximum of $2,500.

Funding is also available to defray the costs of developing a plan that identifies ways to increase productivity through increasing employee skills and upgraded

Ian Adamson’s GF2 advice to growers:

• Find a good consultant to analyze your financial position.

• Perform an in-depth cost of production analysis.

• Plan for improvements to your process.

• Implement the improvements to processes and procedures.

or new equipment and technology. Up to 50 per cent of project costs are available to a maximum of $10,000.

Installing equipment/technology: Growers can apply for funding to put in place technology or equipment that will improve productivity in the operation. In addition to having completed a GYFP workshop in the last five years, applicants need to have a productivity plan showing how installing the equipment/technology will improve labour productivity.

Among the activities that are eligible are:

• Retrofit, upgrade or buy new equipment to increase automation.

• Modify existing equipment to increase efficiencies and save labour costs.

• Pay for advisory services to train

employees on new equipment and/or technology.

• Pay for advisory costs to develop and translate policies, maintenance procedures and standard operating procedures (SOPs).

Funding is available up to 35 per cent of project costs to a maximum of $30,000.

Water Protection – Nutrient Recovery:

The Greenbelt Greenhouse example shows that recovering nutrients from wash water or irrigation systems helps protect the environment and reduce operational costs for greenhouse growers. Applicants in this category need to have completed a third or fourth edition Environmental Farm Plan (EFP) within the past five years.

Eligible activities include modifying existing irrigation systems to recycle water and recover nutrients (collection, storage, transfer and treatment) and putting in place systems to recover wastewater from washing to recover nutrients. Constructed wetlands and other similar structures must be designed by a professional engineer. Producers can also get up to 50 per cent cost-share under project category

A.0.2 Planning, to complete abatement or wastewater management plans up to a maximum of $5,000.

Funding is available for up to 35 per cent of project costs to a maximum of $30,000.

The efficient use of energy resources saves money for growers and benefits the environment. For this category, growers must have completed a third or fourth edition Environmental Farm Plan within the past five years. Eligible activities include paying for qualified consultants to conduct energy-use assessments including a greenhouse survey and inspection, thermal imaging, data analysis, report preparation and review of the audit with the grower.

Funding of up to 50 per cent of project costs are available to a maximum of $5,000.

Growers should consult the GF2 Program Guide for full details.

What do growers need to apply to GF2 (see program guide for full details)?

• Have a farm business that’s a legal entity.

• Produce agricultural commodities in Ontario.

• File business and/or farm income/loss taxes in Ontario.

• Have a valid and up-to-date Premises Identification Number (PIN) for the farm property where the proposed project is taking place.

• Have a valid Farm Business Registration Number (FBRN) or an equivalent. Only proposed projects with the

highest merit or biggest impact will receive cost-share funding. That means the project must address a demonstrated need or business improvement. Criteria are specific to each project category. See Appendix 2 of the program guide.

The Ontario Soil and Crop Improvement Association (OSCIA) is a unique non-profit farm organization that represents all commodity groups across the province. It is a leader in producer education, local association development, program delivery and consumer outreach. www.ontariosoilcrop.org.

Seedlings of lodgepole pine and white spruce doubled in height after two months. It was also used to grow greenhouse tomatoes, and a 15 per cent higher yield was achieved versus use of synthetic fertilizer.

BY TONY KRYZANOWSKI

“The fact is that if we don’t learn how to recycle nutrients and water, we are doomed. We will start dying off from hunger. This is just one approach to prolong our existence on this planet.”

That ominous warning comes from Dr. Nick Savidov, who recently assumed the position of senior research scientist at the Centre for Applied Arts and Sciences/Centre for Applied Research and Innovation at Lethbridge College.

By recycling nutrients and water, he means extracting the valuable nutrients from waste streams like animal manure by using micro-organisms in an oxygen-rich environment within a device called a bioreactor to mineralize and dissolve the

nutrients in a liquid solution. The nutrients can then be re-used as plant food.

Savidov describes this as a sustainable approach to agriculture that could help save humanity from starvation down the road.

Tapping into this source of organic fertilizer from aerobic biodigestion is critical to continued human life on Earth, Savidov says, because current synthetic fertilizer sources are non-renewable.

For example, he says that according to a recent survey by the International Fertilizer Development Centre (IFDC), 85 per cent of all phosphorus rock reserves on the planet, which are used to produce phosphorus fertilizers are located

TOP Lodgepole pine seedlings fed with mineralized nutrients from poultry manure doubled in height in just two months.

BOTTOM Researchers constructed a device that fed a consistent source of oxygen into the bioreactor, which is critical to the conversion process.

Talus Insect Growth Regulator offers selective and persistent control of key Hemiptera Whitefly pests, with no harmful effects to beneficial insects and pollinators.

Talus offers outstanding efficacy on hard to control pests, and is highly compatible with IPM & resistance management programs

TALUS PRODUCT DETAILS

For use on: Greenhouse cucumbers, tomatoes, peppers, and ornamentals.

Active Ingredient: Buprofezin – 70%

Formulation: Dry Flowable

Packaging: 4 x 500 grams

Group: 16

Key Pests Controlled: Whiteflies

Talus is a trademark of Engage Agro Corporation GH_EngageAgro_half_october2016_CSA.indd

FujiMite Miticide / Insecticide is a contact miticide / insecticide with broad spectrum control of mites.

FujiMite stops feeding damage immediately after application. Fujimite is highly effective on all developmental stages of mites, and provides ovicidal activity on eggs.

FUJIMITE PRODUCT DETAILS

For use on: Greenhouse tomatoes, peppers, eggplant, cucumbers & ornamentals

Active Ingredient: Fenpyroximate

Formulation: Commercial suspension

Packaging: 6 x 1 L jug

Group: 21

Key Pests Controlled: Spider Mites, Cyclamen Mites, Whiteflies (suppression)

Fujimite is a registered trademark of Nichino America Inc.

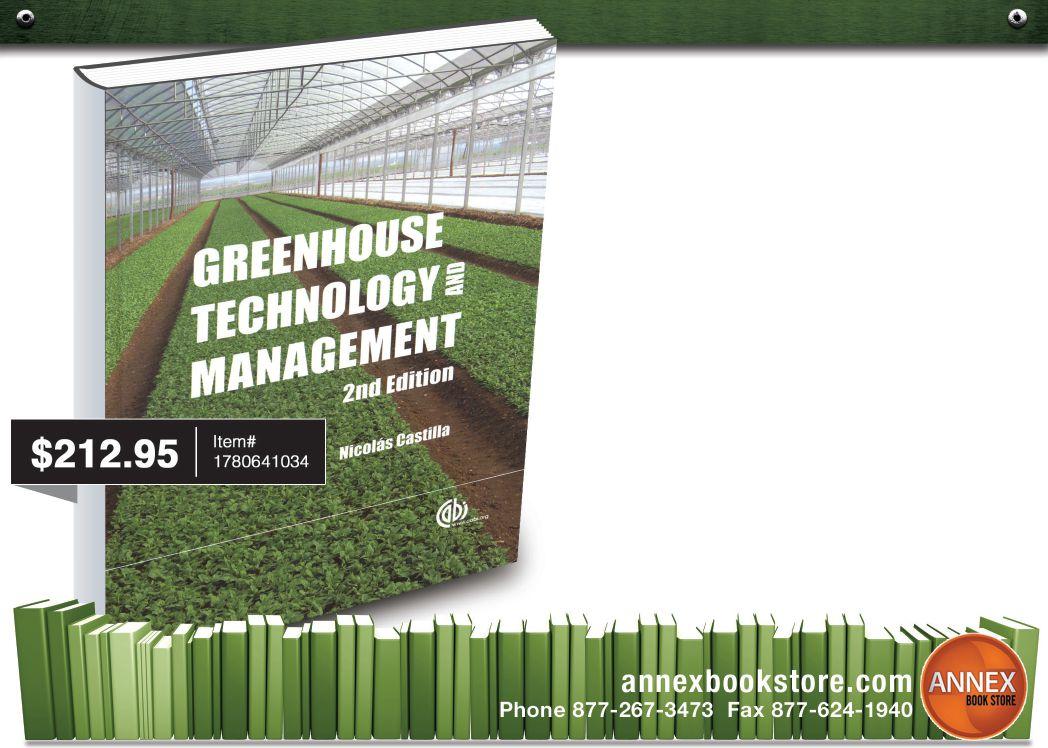

Greenhouse cultivation has expanded in recent decades with increased demand for horticultural production. This book covers current technologies and management practices of general greenhouse production, with a particular emphasis on plastic greenhouses and vegetable growing.

The author begins by addressing the natural greenhouse microclimate, in the context of managing greenhouse systems such as ventilation, cooling, heating, carbon dioxide enrichment, light management, crop physiology, greenhouse design and construction criteria.

The book then moves on to cover other issues of greenhouse management including irrigation and fertilization, soil and substrate cultivation, plant protection, regulation, economic analysis, environmental impact, and post-harvest production strategies and marketing.

in just one area – in Morocco and the Western Sahara. Also, current nitrogen synthetic fertilizers can only be produced using non-renewable fossil fuels.

Savidov has worked with an Alberta Agriculture and Forestry (AF) research team that included engineer and system designer, Marc Legault, to demonstrate the use of an aerobic bioreactor to mineralize nutrients from raw poultry manure. They used the dissolved organic fertilizer, called “digestate,” to grow tree seedlings and other commercial plants in a soil-less growing environment.

So far, the results have been highly successful.

For example, seedlings of lodgepole pine and white spruce fed with this mineralized organic nutrient stream “doubled in height after two months. The results exceeded all our expectations,” Savidov says.

The organic fertilizer was also used to grow greenhouse tomatoes. A 15 per cent higher yield was achieved versus use of synthetic fertilizer because of enhanced nutrient uptake by the plants.

“We demonstrated that we can pro-

duce vigorous growth of major nursery crops grown in Alberta and British Columbia, using biologically active poultry manure digestate,” Savidov says.

He emphasizes, however, that before greenhouse food producers in particular adopt this nutrient recycling and organic fertilization method, they should have a well-developed, on-farm food safety program in place.

In addition to demonstrating this nutrient recycling method, one of the major objectives of this study was to consider protocols to minimize the potential for food contamination pathogens, for example, of poultry manure through aerobic biodigestion and then the use of the mineralized nutrients within a greenhouse setting.

“There is always a risk of cross-contamination even for hydroponic greenhouses,” Savidov says. “That’s why a robust on-farm food safety program is necessary to minimize the risk for commercial growers. Some greenhouse techniques will have a lesser chance of cross-contamination, for example, drip irrigation in vine crop production versus the deep flow technique.”

However, he still is a strong proponent

for the widespread use of this nutrient and water recycling system within the greenhouse industry.

“It is my strong opinion that there is no alternative for zero-waste nutrient recycling technologies where the agricultural waste is used for food production in future,” he says. “We just need to do it in an intelligent way.”

In addition to enhanced growth, researchers have discovered another benefit to using recycled organic fertilizers instead of synthetics: they are biologically active with beneficial micro-organisms.

In addition to exceptional growth over a short period of time, the tree seedlings also experienced enhanced root biomass development, robust health (such as better resistance to root pathogens), and improved nutrient uptake, meaning that they experienced exceptional growth in low nutrient solutions. In other words, growers can use small amounts to achieve big results, which could be a huge economic benefit.

Furthermore, the water used in these soilless growing systems is recycled so there is less pollution released to the environment and the grower achieves greater water use and nutrient uptake efficiencies.

Researchers chose to work with poultry manure as their raw material because it was readily available, rich in nitrogen, and less fibrous than cattle manure, which because of its fibre content, takes longer to ferment. The processed poultry manure resulted in organic fertilizer with low sodium content, which can be toxic to plants in higher concentrations, and pH within the tolerable range for plants.

Savidov says when implemented properly and monitored carefully, an aerobic biodigester eliminates harmful pathogens.

“Elimination of pathogens from the reaction mixture is a part of the protocol of aerobic biodigestion of poultry manure,” Savidov says. “The process is assumed completed when free from E. coli and salmonella.”

He adds that biodigestion is an exothermic process with a pasteurization phase. Researchers observed that at a temperature of between 55 C and 63.5 C in the reaction mixture for two to four days of fermentation, pasteurization “eliminates the original microflora from the reaction solution.”

Savidov says it is possible to extract valuable nutrients from all forms of animal manure or other food and agriculture byproducts using their bioreactor system.

Savidov says there is no odour during the reaction process, except when the raw manure is added because oxygen reacts with common odour-causing compounds like hydrogen sulfide.

Because all components within the raw manure will completely mineralize over different time intervals, there will be some solid material left in the liquid outfeed stream after three weeks.

After about three weeks, the bioreactor is stopped and the processed liquid is removed to a filtration tank. The solids are separated from the liquid and returned to the bioreactor for further fermentation, while the liquid stream is ready for use as organic fertilizer. Maintaining pH below 6.5 is most critical for producing consistent results.

“To be honest, it’s not really an absolutely new system,” Savidov says. “It’s using bits and pieces of what is already used in the agriculture industry for manure treatment.” He adds that greenhouses and nurseries would have to change very little to convert from synthetic fertilizer to this type of organic fertilizer.

Tony Kryzanowski is a freelance writer and photographer in Alberta.

CLASSIFIED RATES: Minimum order $75.00 or 84¢ per word, word ads must be pre-paid. CLASSIFIED DISPLAYS: $72.00 per column inch, or $5.14 per agate line. GENERAL INFORMATION: Payment must accompany order. Copy required by the 1st of the month preceding publication. All advertising copy subject to the approval of the publisher. Send order and remittance to: Classified Dept., Greenhouse Canada, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

EQUIPMENT FOR SALE - Greenhouse Flat Seeder, Old Mill model 615-3 with detachable coater/ grittier. Will seed any size seed in any size container. All manuals included. Will ship for a fee.

$7500.00 OBO pictures available Phone 403 949 2808 or email kjboyce@telus.net

For details contact Anton Van-Zevenbergen Trocobel USA LLC. Perrineville, N.J. 08535 USA Tel: 1-609-448-1300 • Fax: 1-609-448-8119 E: anton@trocobelusa.com www.trocobelusa.com

(Please Check One:)

How do we get a realistic measurement on the “state of the industry?”

The logical way is to do a survey. Ask those involved in the industry how they feel things are going. But outcomes of such a survey depend on asking the right questions and on potentially the subjective views of respondents. And we all know that some of us are “glass-half-full” people and others are, well, not. So quantitative measures of this “state” are essential.

We also need to identify where the industry is that we’re discussing. Do we mean local, provincial, national or perhaps even global? Horticulture is, of course, a very global industry. So is that our scope?

For example, in the greenhouse sector, what’s going on in China, or Russia or eastern Europe? Anyone keeping an eye on newsfeeds these days will see the rapid expansion that’s taking shape in all of those areas. Construction projects there cover large areas and have potential to put out significant volumes of produce. And while perhaps on a global scale these are relatively small volumes, is there potential for these developments to affect our greenhouse industry here in Canada?

Talking of Europe, how will the newly signed CETA deal affect the state of our industry?

how do such businesses use “right to farming” legislation? Certainly from an educational perspective, urban agriculture is one of the topics driving new students into our universities and colleges. Here at KPU, for example, we’ve seen increased enrolments. I’m convinced it’s partly due to people not seeing these activities in the same way, as they have (mis-informed) prejudice about getting into dirty, poor pay agriculture. So, should the conventional greenhouse industry embrace this new sector and call it part of our own?

A couple of other topics may also impact how we see “the state of the industry.”

Firstly, the B.C. Greenhouse Growers Association (BCGGA) recently held a cucumber growers seminar. Dutch consultant Herman Hermans of Innocrop Consulting presented information on the usual topics of environmental management, training systems and LEDs.

But he also suggested that questions around “Bio Growing” (a.k.a. “organic production”) are “a puzzle that needs to be figured out.” In particular, we need definitions of how much soil has to be in a substrate for it to be considered certifiably organic or can we develop acceptable organic hydroponic systems?

Do we include emerging sectors such as urban agriculture?

I guess also when we are looking at this, we need to actually identify what we mean by “industry.”

Presumably, it’s the conventional (relatively) large-scale greenhouse production business. But at what point do we include emerging sectors such as urban agriculture? That term often conjures up images of community gardens, small plots of kale and lettuce or backyard chickens.

But should the greenhouse sector now include the influence of basement or rooftop micro-green production, or high-tech container systems that are as “controlled environment” as any 50-acre tomato greenhouse?

Digressing a little into urban agriculture, how do municipalities view such ventures? How can they classify agricultural activities that take place on residential or industrially zoned land? And

Interestingly, going back to one of the previous thoughts above, the seminar attracted growers from Alberta and California for the first time – so what exactly are the geographical boundaries for the state of the industry?

Secondly, the day after the BCGGA meeting, Graeme Murphy and representatives from Flowers Canada were here at KPU setting up a flower growers biocontrol project.

After a while, the conversation (almost inevitably!) turned to marijuana production. With news that CornerWays Nurseries in the U.K. is switching all production from tomatoes to marijuana for pharmaceuticals, we wondered if we’re at one of those unusual, unique watershed moments for the greenhouse sector?

Perhaps. And if so, how does that represent “the state of the industry?”

Gary Jones is co-chair of horticulture at Kwantlen Polytechnic University, Langley, B.C. He serves on several industry committees and welcomes comments at Gary.Jones@kpu.ca.