DR. PAUL ABRAM AND TRACY HUEPPELSHEUSER

MELHEM SAWAYA

MICHAEL BROWNBRIDGE

DR. PAUL ABRAM AND TRACY HUEPPELSHEUSER

MELHEM SAWAYA

MICHAEL BROWNBRIDGE

My colleague told me he had purchased a $25 Christmas tree from a Swedish big box furniture store just before the holidays.

I couldn’t help but wonder what the profit margin must’ve been for the tree producer. Surely growing Christmas trees was a full-time, yearround task that would take several years to complete before the farmer could profit from their harvest. What we do know is that the costs of production are rising across the board. Between 2017 to 2018, StatsCan reported an increase of 1.6% in total greenhouse operating expenses. Labour accounted for the largest share at 29% of total expenses. While the number of employees decreased by 1.5%, payroll also rose by 1.5%.

If you look back through personal print archives or digital copies of Greenhouse Canada, there was an article on pricing in the December 2018 issue entitled ‘How does the cost of production affect the cost of a plant?’ As it turns out, I had missed an email sent by a thoughtful reader who pointed out a fundamental mistake. In calculating the selling price of the product, the calculation shown was for markup rather than margin – an important difference. Markup is calculated as a fraction of total costs, while margin is calculated as a fraction of the selling price.

In essence, the formulas are:

Margin = (Selling price – Total costs) ÷ Selling Price

Markup = (Selling price – Total costs) ÷ Total costs

Using the original example from the article, if fixed and variable costs amounted to $1.65 per plant and the margin was set at 30%, the selling price would have been $2.36 per plant. If incorrectly calculated as markup, it would have amounted to $2.15 per plant, leaving substantial

How can growers ensure that products are priced correctly?

To make ends meet and perhaps make some profit along the way, how can growers ensure that their products are priced to cover their costs? According to Mel Sawaya, indirect costs tend to be calculated incorrectly and labour is often underestimated. (Turn to page 24 for more, along with a cost-calculating tool.)

With consumers becoming increasingly aware of plastic waste, could plastic alternatives help your bottom line? One study showed that 32% of surveyed Canadians are willing to pay more for sustainably packaged non-food items. From using recycled plastic pots to communicating your sustainability story to the consumer, clearly more than one method is needed to succeed in this changing marketplace. (Pg. 30)

margin on the table.

This reader also suggested setting the margin at 40 per cent rather than 30. This would give the sales team a bit of leeway. In this case, the selling price would rise to $2.75 per plant. Many thanks to the reader who pointed out this error.

Costs will also be a focus for this year’s Grower Day event, to be held June 16-17 in St. Catharines, Ont. and new for 2019, June 23-24 in Abbotsford, BC. !

to

please contact

circulation department in any of the four ways listed above.

part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Use Amblyline Sachets to effectively wipe out thrips with a breeding colony of predatory mites (Amblyseius cucumeris), released onto your crop every day for several weeks, even before thrips are present. Also targets broad mites and cyclamen mites.

Use Amblyline loose material for high dose, immediate crop protection. % % %

Use water-resistant Amblyline Sachets under mist during early propagation.

Use Amblyline sticks for easy, quick introduction into plug trays or pots.

519-839-4778 Kam’s Growers Supply Inc. orders@kams.ca 877-821-1684

Location

Known greenhouse floriculture consultant and founder of Focus Greenhouse Management, Melhem Sawaya celebrated 30 years of business last fall.

A known supporter and vocal advocate of the horticultural industry, Sawaya is also involved in a number of initiatives, such as programming for the Canadian Greenhouse Conference and Grower Day, as well as regularly contributing to Greenhouse

Canada magazine. He’s also coordinated the annual Sawaya Garden Trials in Simcoe, Ont. for the past 19 years. What first began with 150 varieties, the trials now showcase over 3000, allowing growers to see how new varieties perform in the southwestern Ontario climate.

Over 150 people attended the festivities in Brantford, Ont. Read more at greenhousecanada.com.

A.M.A. Horticulture announced that they have produced and sold over one billion Ellepots.

Ellepots are stabilized media that generate fast, healthy rooting and help growers reduce plastics use, says A.M.A., the North American company to produce and sell Ellepots to growers. They’ve since become a leading supplier of the propagation solution.

“After twenty years of plugging away at Ellepot production – pun intended – it’s been incredible to

see the difference this solution has made for our customers, who have come to count on Ellepots for high-quality liners and more efficient propagation practices,” says Rick Bradt, who co-manages A.M.A. with his wife, Connie Bradt-Monsma.

The company first entered the Ellepot business in the late nineties, when Skip Blackmore, President and CEO of Blackmore Company, placed an Ellepot machine on the A.M.A. truck during a

After 28 years as Ontario’s greenhouse vegetable specialist, Shalin Khosla has retired from his post. His last day was December 18, 2019.

A known extension expert and researcher with the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), Khosla’s work on production systems, energy and nutrient management, as well as climate control for greenhouse vegetable crops was instrumental in advancing the greenhouse sector. His years of dedication were honoured and recognized at a retirement celebration last month in Leamington, Ont.

“It only worked because we’ve had good people to work with – OMAFRA, AAFC, growers, OGVG, and all the suppliers and companies involved.” Without their support, it would have been really tough, he says. Read more at greenhousecanada.com.

regular pickup.

“Ellepots were new to the market at that time, with no more than a small handful of machines across North America, all operated by growers for their own production,” says Blackmore, whose company still distributes Ellepot machines in North America. “A.M.A. was a natural partner to produce the plugs commercially…This new venture opened up a whole new market and together we’ve helped bring Ellepots across

North America.”

“Ellepots are uniquely designed to hold a lot of air in the substrate and they have helped to increase education and knowledge around the benefits of air pruning in propagation,” says Lars Steen Pedersen, CEO of Ellepot in Denmark. “Today, as we increase our assortment of degradable and organic paper options, Ellepots are also helping to promote sustainable propagation.”

Source: A.M.A. Horticulture

Mobile trends

Source: Cira, 2019

46% make purchases from their mobile devices

Nearly 3 in 4 Canadians spend at least 3 to 4 hours online per day

87% make online purchases

65% prefer Canadian retailers when they purchase online

With our Veronica bare roots we focus on the crown, knowing a large crown creates a large plant.

The root cause of better Veronica.

From the beginning we have continuously worked to improve, grade generously, and offer the very best product we can. This goal has led us to become the largest supplier of bare root perennials in North America with one of the most diverse catalogs. Bare root has always been a part of our identity and represents our continued commitment.

Blue Prince Pumpkin certainly scored high against the comparisons in the areas of earlier maturity, yield, fruit size and uniformity, colour, taste and texture. Vigorous trailing vines produce seven to nine beautiful blue flattened pumpkins with nonstringy, deep orange flesh and a savoury sweetness. These pumpkins are as pretty as they are delicious. After fall decorating, the flesh can be baked for a smooth and creamy treat. Of all the varieties trialed, Blue Prince was first to flower and fruit, which is beneficial for gardeners with a shorter growing season. Plus, this winner has slightly better disease resistance than the comparisons. 46 cm tall, 1.5 m trailing vines. seedsbydesign.com

The first bicolour tomato in the Chef’s Choice series, these indeterminate plants produce large 7 to 8 oz flattened beefsteak fruits with beautiful pinkish red internal stripes among its yellow flesh. The lovely stripes extend to the base of the outer fruit skins.

Offering incredible garden performance, this uniquely dimpled apple-shaped fruit has a deliciously sweet citrusy taste and firm, meaty texture. Indeterminate 1.5 m-tall vines produce abundantly in clusters, resulting in up to 1,000

The first-ever coleus to be named an AAS winner, Main Street Beale Street is an outstanding variety exhibiting deep red foliage that holds its colour extremely well in the garden. Its rich colour doesn’t fade, bleach or get spotty as the season moves into late summer. The lush, bushy plant

These heirloom-looking tomatoes are as sweet as they are beautiful with a better flavour and texture than the comparisons. As with all the colours in the Chef’s Choice series, each plant can produce about 30 fruits per season. 1.5 m tall. seedsbydesign.com

fruit per plant. Fruit are an eye-catching, bright lemon-yellow. Judges were excited that a nonsplitting, long-holding, uniformly shaped tomato had such good eating quality. With just the right balance of sugar and acid in a firm exterior,

Apple Yellow would be perfect stuffed with a savoury cheese. 1.5-1.8m tall. ganaseed.co.kr

Tip Top Rose is a strong yet compact nasturtium with unique and showy rose-coloured flowers set above medium green foliage. These mounded plants were more floriferous than the comparison

plant remained healthy and uniform throughout the season. whereas other varieties struggled. As a bonus, this nasturtium is also great for pollinator gardens and both the leaves and flowers are edible. 38 cm tall. takii.eu

Self

Low

Long

Garden centres are seasonal operations by definition. So, how can a garden centre improve footfall, stay in business, and even turn a profit the rest of the year? Here are 5 quirky ways to make off-season sales slumps a thing of the past.

1.

A growing trend among garden centers is to supplement their revenue with small farming operations and makeshift urban farms.

With only a couple of goats, rabbits, peafowl, and beehives, you can offer your visitors hours of entertainment. Petting zoos also have play areas for

ABOVE

Engage new and existing customers with your garden centre space, bringing in more activity and revenue during less profitable times of the year.

children, which further extend a family visit. Train and tractor rides, farm-themed swings, picnic tables, and mazes are just some of the little extras they can offer. Longer stays make it easier for you to promote your plants, organic produce, and local artisanal products.

2. ORGANIZE WEDDINGS AND PARTIES

Urban farms and wedding venues are not mutually exclusive. In fact, white doves, rabbits, and peacocks would make an excellent addition to both business ventures. But with or without animals, local green-fingered customers may think of your garden centre as the perfect venue for a small and tasteful wedding.

Weatherproofing and fitting a large gazebo or marquee tent with lighting, furniture, and musical equipment is bound to pay off. Decorate trellises and arch tunnels with charming topiary and lush hanging baskets, and stage your event space for photoshoots. Approach local musicians, photog-

raphers, and caterers. Attend trade shows to find inspiration and suppliers, as well as professional wedding planners and prospective customers.

3. HOST FUNDRAISERS AND EVENTS

Fundraiser functions may not generate much revenue, but they do spread the word. Some of the most prominent local figures are bound to attend, and anyone with clout has a large network. Once you gain access to their following, you may start to see people approach you for community events, gardening seminars, winter markets, and other functions.

Consider setting up a small café, and look for reliable local bakeries, restaurants, and catering companies willing to supply produce and staff to diversify your product and service package. Set clear social media sharing policies for video footage of events held at your garden centre to maximize reach and positive testimonies.

4.

Whether you’re a horticulturist, an astute businessperson, or both, you know how to run a garden centre that draws plant lovers from your area. But don’t overlook the untapped gift market. Show off your best blossoms to local florists who are willing to work with you to sell locally-sourced floral arrangements at a premium.

If you think you have the capacity, consider buying an existing online shop and make it your own, selling your flowers, plants, cards, and gifts. Having a website can greatly increase your customer base and also provide fantastic brand awareness. Check out other local florist websites and place test orders to see what courier service, packaging, and promotional tactics they use.

Look up nearby universities, art schools, and other venues that teach fine arts such as photography and painting. Should you be lucky enough to be near an educational institution that offers gardening and landscaping courses, approach them for hands-on learning sessions at your venue. Promote your garden centre as the ideal place for students and professionals to practice their craft in exchange for a small fee.

Bruce Hakutizwi is director of North America for BusinessesForSale.com.

Plants grow by cell division and cell elongation, controlled by naturally occurring plant hormones. The three hormone classes with the greatest influence on growth are gibberellins, cytokinins and auxins. By mimicking or blocking the actions of these hormones, plant growth regulators can either retard, redirect or stimulate plant growth.

In horticulture, the most frequently used growth regulators are gibberellin inhibitors (anti-GA). They disrupt gibberellin synthesis in the plant and reduce cell elongation.

Lesser known, but no less powerful, are chemistries that affect plant structure and branching. These additional tools can increase lateral branching and/or flowering in different ornamental crops. One such example is 6-benzyladenine (6-BA), the active ingredient in Configure.

Designed to look and act like cytokinins in the plant, 6-BA mimics the activity of naturally occurring hormones. Cytokinins generally promote cell growth and differentiation, and they work in tandem with auxins to influence plant structure.

Auxins are created in the apical meristem. One particular auxin, indole-3-acetic acid (IAA), moves from the top of the main stem and down the plant, preventing the growth of lateral buds. Removing the tip of the plant (apical bud) reduces IAA levels in the plant, allowing lateral buds to form, grow and produce new shoots. While hand pinching has been common practice, chemical options can help gain efficiency and save on labour costs. 6-BA works by

vary by cultivar. 600 ppm is a good starting point. Christmas Cactus (Schlumbergera bridgesii) To increase branching under vegetative condi tions, apply Configure at 100 ppm as a uniform foliar spray after planting and when new vegeta tive growth begins. This stimulates an increase of phylloclades, which helps improve plant branch ing. Note that the application must be made early enough to allow the phylloclades to fully mature before the start of short days.

To stimulate flower bud production, aim for 100 ppm (range is 100 to 200 ppm) of Configure after the start of short days. If using black cloth, apply one week after flower initiation. If relying on natural seasonal daylength conditions, apply with in two days after the first flower buds are visible. This usually occurs in early October. If you make an application in late September while the plants are in the late vegetative state, it will stimulate additional phylloclades instead of flower buds and will delay overall flowering.

Application timing is essential and can produce different effects.

changing the balance of cytokinins to auxins, allowing lateral buds to grow without damaging plant tissue.

Application timing for PGRs is essential. Using research from Configure as an example, here’s how application timing can produce different effects.

Echinacea: When treated at plug planting, plants increased in basal branching compared to untreated plants in as little as three weeks. Applications made up to four weeks after transplanting plugs resulted in a similar number of basal branches when evaluated at eight weeks after transplant. In other words, later treatments “caught up” with earlier ones. Basal branch numbers are generally the same regardless of application timing, but earlier treatments mature/develop more quickly for earlier pot fill. The rate for Configure ranges from 300 to 900 ppm, though rates and timing may

Hosta: 6-BA can increase lateral growth in Hostas, improving crop quality and decreasing the time needed to produce basal branching. Achieving consistent results can be challenging but well worth the effort. The key is to make applications when the plants are actively growing during long days. Applying in early spring or late summer can lead to reduced effectiveness. Plants can be treated after planting in early summer with longer days, allowing time for growth to resume and roots to spread to the edge of the container. Compared to a single application of Configure between 1,000 to 3,000 ppm, many trials have shown better branching using the lower end of the rate range (1000 ppm) applied twice. Treatment regimens vary due to the broad variety of Hosta cultivars. A good starting rate is 1,500 ppm. A second application at 1,500 ppm can be made 14 days later if the desired response is not observed.

Note that non-systemic PGRs, such as Configure require complete spray coverage, especially with multiple cuttings. When trying a new PGR or testing an existing one for a different purpose, conduct a small trial and compare it against an untreated control from start to finish. Be sure to consult the label and speak with a local specialist before applying PGRs to any crop.

Jim Kruger is regional sales manager, eastern Canada, for Fine Americas.

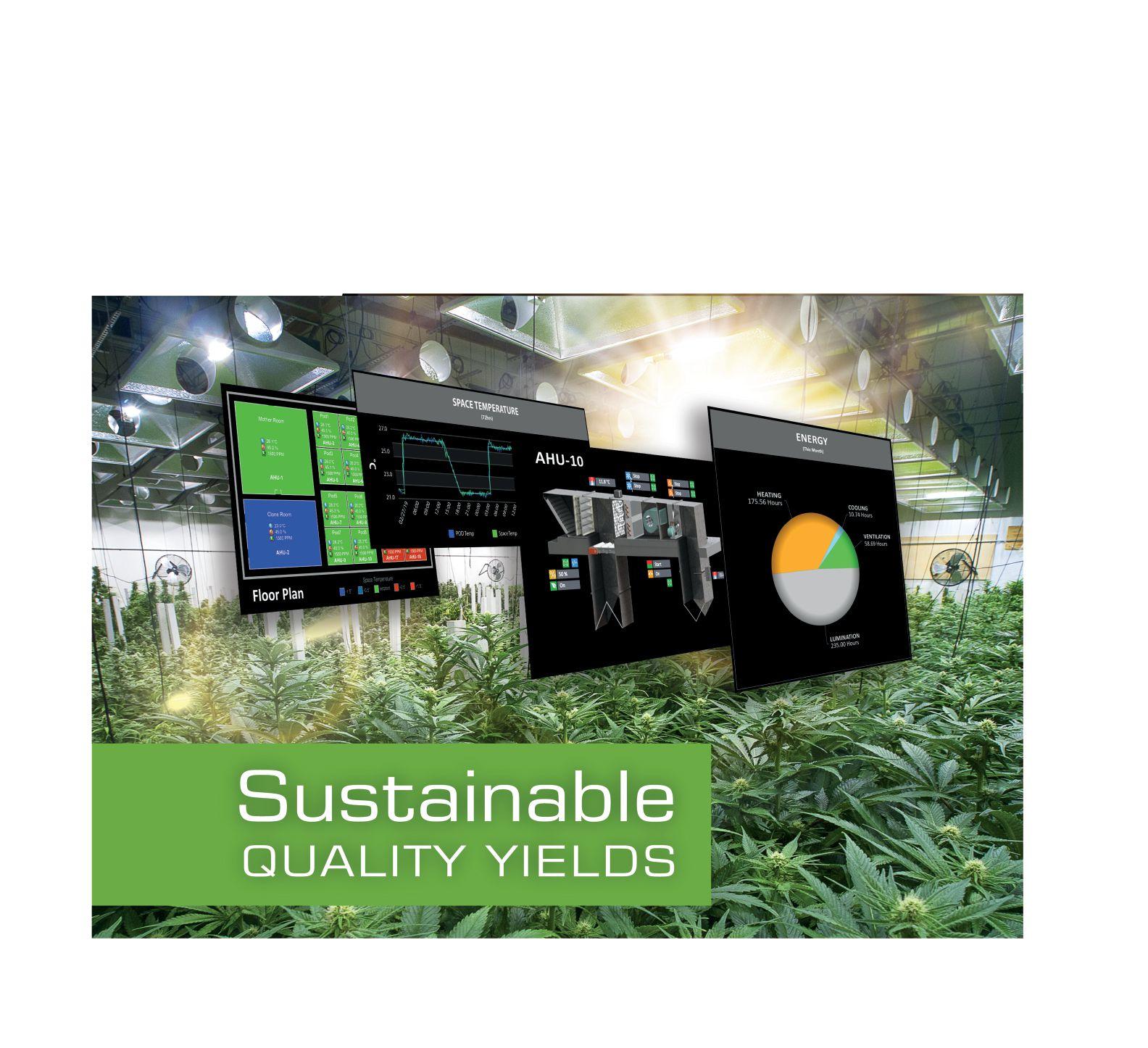

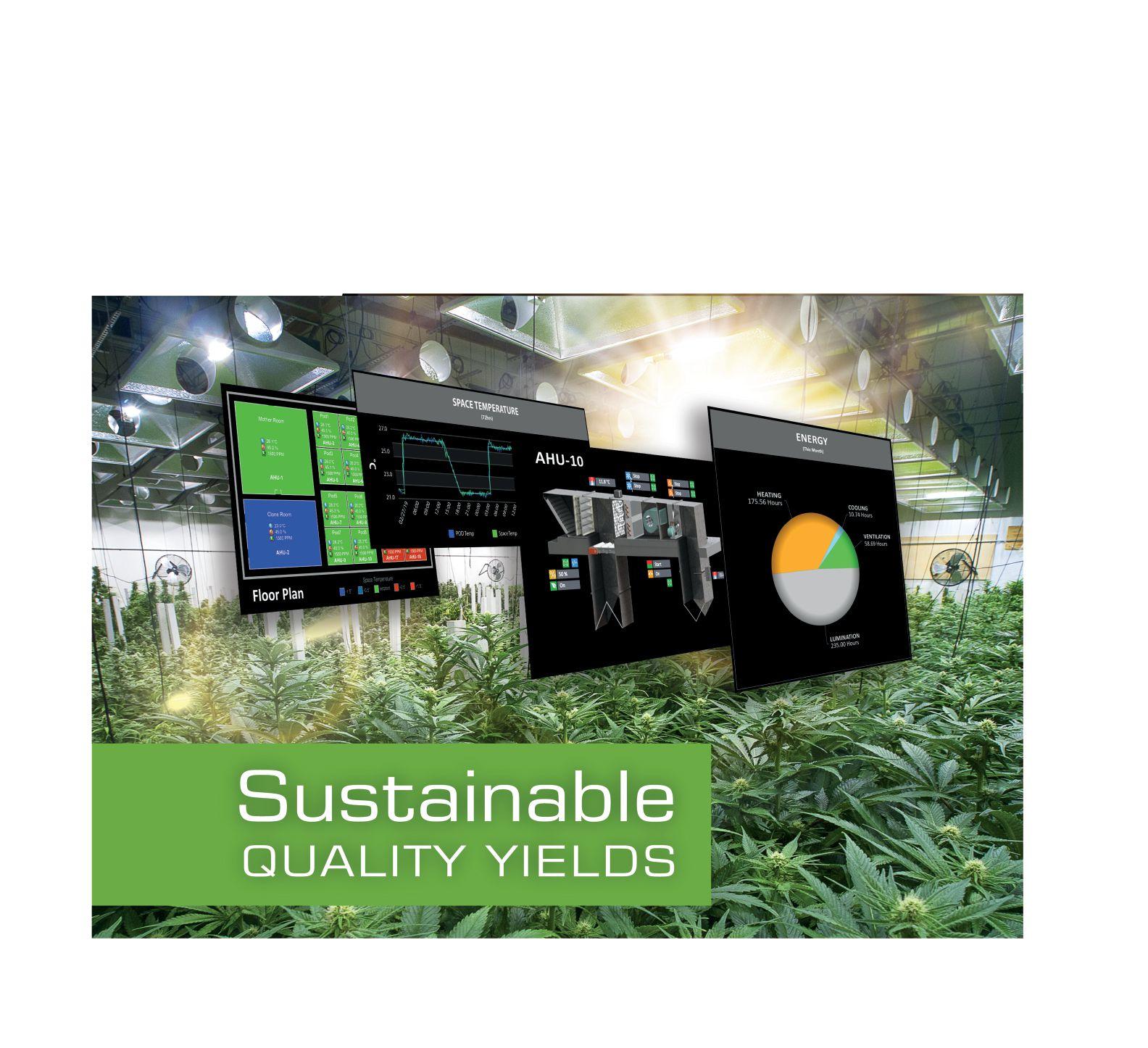

growing environment, a simple, flexible, and sustainable control system is crucial. This is why proactive LPs are turning to Reliable Controls. Our nation-wide network of factory-certified

Authorized Dealers will design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely-controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective and Canadian-made solution, please contact a local Reliable Controls

Authorized Dealer near you.

IGreenhouses aren’t just dealing with Western flower thrips anymore. Here’s how you can tell your thrips apart.

BY DR. SARAH JANDRICIC, ASHLEY SUMMERFIELD, DR. ROSE BUITENHUIS AND DR. CYNTHIA SCOTT-DUPREE

n this industry, it seems like just when we have one thing handled, the Powers That Be throw us something new. Recently, it appears that Western flower thrips (WFT) have decided they aren’t giving us enough of a challenge and have recruited some “friends”. Onion thrips are the most prevalent of these new pest thrips, even outnumbering WFT in some greenhouses. But they aren’t the only ones you need to watch out for.

This new potpourri of thrips species often appears in greenhouses using primarily biocontrol and can cause sudden heavy damage to some of our most common crops. This includes chrysanthemum, gerbera, and spring bedding plants. Although mite-based biocontrol programs generally keep populations of WFT in check, they don’t appear to be

working entirely well against this new suite of thrips, which can throw growers for a loop.

The new reality is that growers will likely have to become familiar with these different thrips species to make the best IPM decisions possible, particularly when unusual thrips damage occurs. Consider this your introductory guide to the new thrips on the block for spring bedding crops and beyond.

Research by Dr. Rose Buitenhuis in 2017 (Vineland Research and Innovation Centre) demonstrated that imported cuttings are a main source of both thrips and spider mite issues for Ontario growers. In summer 2019, OMAFRA summer student Elizabeth Huber-Kidby examined

Adult female (left) and male (right) western flower thrips. Yellow arrows indicate coarse hairs on the top and bottom of the pronotum.

weekly shipments of chrysanthemum cuttings from various suppliers to determine exactly which species of thrips arrive in our greenhouses this way. All thrips that emerged from mum cuttings were WFT, with the exception of a single chrysanthemum thrips.

This tells us that onion thrips and other thrips species are most likely coming in through greenhouse vents and other openings and are able to establish in the greenhouse due to low pesticide use. Although, at this point, we can’t entirely rule out cuttings of other non-mum crops as a possible source for some of these thrips species, especially if you grow multiple crops in the same compartment.

To tell which thrips are causing damage to your plants, the most definitive way is to collect specimens from damaged plants and look at them under a microscope. Dr. Sarah Jandricic, OMAFRA greenhouse IPM specialist, and Ashley Summerfield a University of Guelph M.Sc. student studying new thrips species, have put together an easy set of diagrams that growers can use to tell common thrips apart with minimal effort. You can find this key and instructions for collecting thrips at http://greenhouseipm.org/pests/thripskey/. The following is a quick introduction to these pests.

Light and dark coloured onion thrips (adult females). This variation in body colour illustrates why you should never rely on colour to identify your thrips species.

Western flower thrips

(Frankliniella occidentalis)

Pest status: WFT is still the primary thrips species in most ornamental greenhouses and seem happy living concurrently with other thrips species that may invade. Key features: Larger than the other yellow-coloured thrips you’ll encounter, WFT have bright red ocelli (3 spots between their eyes). They also have plenty of long coarse hairs on the top and bottom of their “shoulders” (called the pronotum). WFT body colour ranges from common pale yellow to a very dark brown (called a “dark morph”). Known host crops: Wide host range Damage pattern: Widespread, dispersed damage in crop; frequently causes damage to flowers

Best ways to monitor: Yellow monitoring cards; plant taps of highly attractive plant varieties.

Onion thrips (Thrips tabaci)

Pest status: Onion thrips is the most prevalent of the “new kids” and has composed up to 80% of the thrips infesting certain crops in Niagara. Present in Ontario for more than a century, they’ve only recently become a concern outside of field crops. Key features: Pale grey ocelli (eye spots); coarse hairs occur only on the bottom of the pronotum (none on top); their bodies range in colour from pale yellow

Winged (left) and wingless (right) chrysanthemum thrips (adult females).

to brown. Smaller than WFT.

Known host crops: Wide host range; has been problematic in chrysanthemums, gerbera, osteospermums, herbs, cyclamen, impatiens and gloxinia in Ontario so far. If your thrips IPM program isn’t working in a different crop, suspect that it may be onion thrips and have them identified.

Damage pattern: Crops damaged in small clusters of plants; heavy damage to the foliage that makes the plant unsellable; less damage to flowers

Best ways to monitor: Yellow monitoring cards and plant taps of highly damaged plants.

Chrysanthemum thrips

(Thrips nigropilosus)

Pest status: Generally unknown, but have caused damage to several chrysanthemum operations to date in Niagara.

Key features: This species has both winged and wingless forms. At first glance, the winged morphs look a lot like WFT but are smaller in size. They have bright red ocelli and no coarse hairs on the top of the pronotum; typically yellow in colour. Known host crops: As the name implies, their primary host is chrysanthemum, but they’ve also been found in marigolds and verbena.

Damage pattern: Unknown

Best ways to monitor: Plant taps, due to the presence of a wingless form.

Tobacco thrips (Frankliniella fusca)

Pest status: Tobacco thrips have been very common in our surveys, although typically only at low numbers. Their actual pest status is unclear at this time.

Key features: As with chrysanthemum thrips, tobacco thrips have a wingless form that is induced by short photoperiods. They are medium to dark brown in colour, meaning their red ocelli are difficult to see. Like WFT, they have coarse hairs on the top and bottom of the pronotum. It is difficult to tell the difference between tobacco thrips and dark morphs of WFT. In our samples from the Niagara region, dark brown thrips have almost always been tobacco thrips.

Known host crops: Although reported to have a wide host range, this is poorly characterized in ornamental crops

Damage pattern: Unknown

Best ways to monitor: Until we are sure that these are actually causing damage, there is no need to monitor for them specifically. However, if you see a lot of “dark” WFT on yellow trap cards in the spring and summer, have them identified before you assume WFT numbers are high in your crop.

Echinothrips (Echinothrips americanus)

Pest status: Echinothrips can be a serious pest for several crops. Since this species does not pupate in the soil, soil-dwelling biocontrol agents (e.g. nematodes, Dalotia and predatory mites) aren’t effective, and control can be difficult.

Key features: Dark brown to black in colour, with highly visible white patches at the base of the wings on live insects. However, this feature isn’t visible on Echinothrips caught on sticky cards or if samples are placed in liquid. Echinothrips also have distinctive orangey-red pigmentation between their body segments. They have no coarse hairs on top of the pronotum.

Known host crops: Poinsettia, gerbera, impatiens, cyclamen, alstroemeria and dieffenbachia are common host plants in Ontario.

TOBACCO THRIPS

Winged tobacco thrips (adult female).

ECHINOTHRIPS

Echinothrips (adult female).

Thrips caught on sticky traps in a side-venting greenhouse. Only distance from the vents affected catch numbers; colour of the trap was not significant.

Damage pattern: Foliar damage; rarely found in flowers. Best ways to monitor: Use small (e.g. 3 cm2) square cut-outs of blue monitoring cards placed horizontally on the leaf surface, since this species doesn’t leave the foliage much.

Besides WFT, onion thrips are the main species you’ll have to worry about this year. Large mass trapping cards or sticky tape should be an integral part of your IPM program. These help intercept incoming thrips in the spring and summer months. Anything that helps reduce the numbers of these emerging pests and prevents establishment in your greenhouse is helpful at this point. Both WFT and onion thrips are more attracted to yellow than blue mass traps, as confirmed in 2019 tests held in top-venting greenhouses.

However, in side-venting greenhouses, 2016 studies showed the vast majority of card captures occur within a few meters of the vents (see graph). To reduce thrips fly-ins, mass trappings should be more effective in side-venting greenhouses than top-venting ones, especially if cards are concentrated near the vents. Having the cards face the vents (rather than be perpendicular to them) may also increase catches.

As for biocontrol options, we’re still figuring out which products (e.g. nematodes, predatory mites, predatory bugs, microbial pesticides) work best against these new thrips pests. Until then, growers have seen some success with pesticides registered for thrips that don’t normally work on the highly insecticide-resistant WFT. However, in other cropping systems, species like the onion thrips have also shown an ability to become highly resistant to chemical products. Future research on effective biocontrol or cultural control tactics will be key to managing the complex of thrips species we now have to battle.

Acknowledgements: This research was supported by the Canadian Greenhouse Conference.

Sarah Jandricic, PhD, is the greenhouse floriculture IPM specialist for OMAFRA. Ashley Summerfield is an M.Sc. student in the Environmental Sciences Department at the University of Guelph. Her co-advisors on the onion thrips project are Rose Buitenhuis, PhD, (Biocontrol Lab; Vineland Research and Innovation Centre) and Cynthia Scott-Dupree, PhD, (Professor and Bayer Crop Science Chair in Sustainable Pest Management).

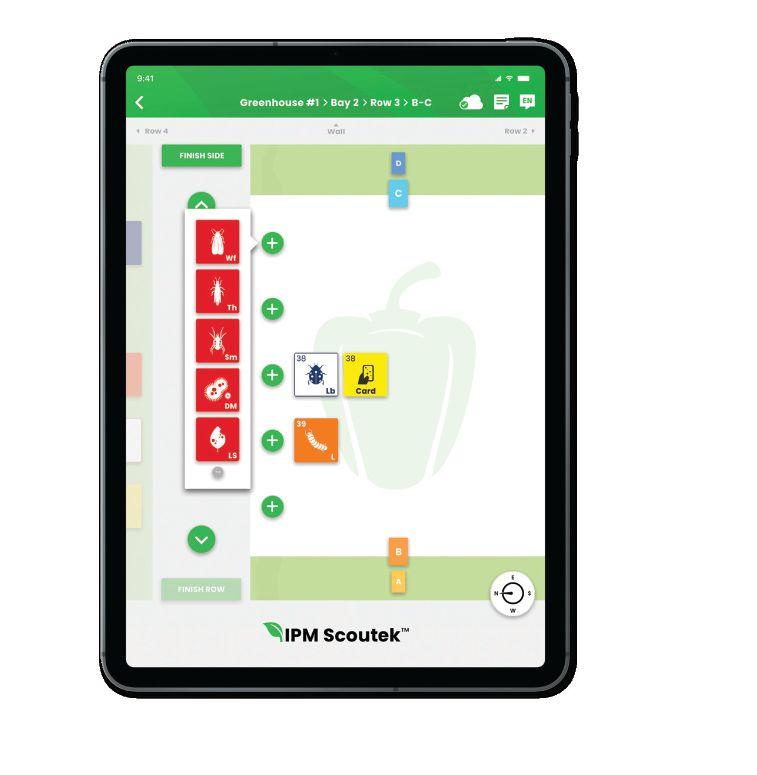

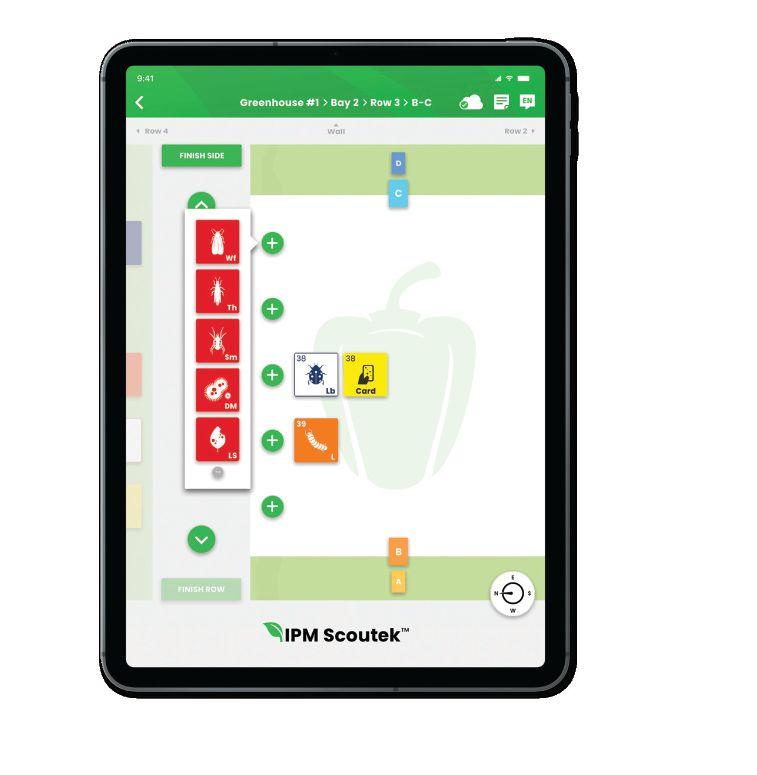

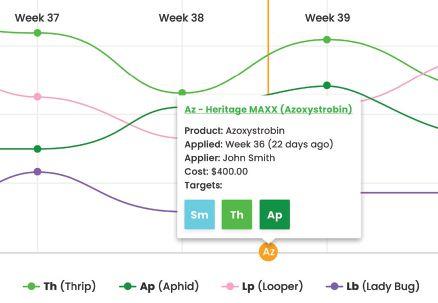

Control Risks in Real Time

Leave Clipboards Behind Powerful Data and Lower Pest Risk

Finally, better and easier pest management

Reduce Costs and Damages

• Lower labour and input costs

• React instantly to pest pressure in every row • At-a-glance crop health

• Reduce pest damage and human error Data-Driven Insights • Analyze trends and patterns to manage risk • Track cost and effectiveness of beneficials /sprays • Analyze scout efficiency

BY Dr. Paul Abram and Tracy Hueppelsheuser

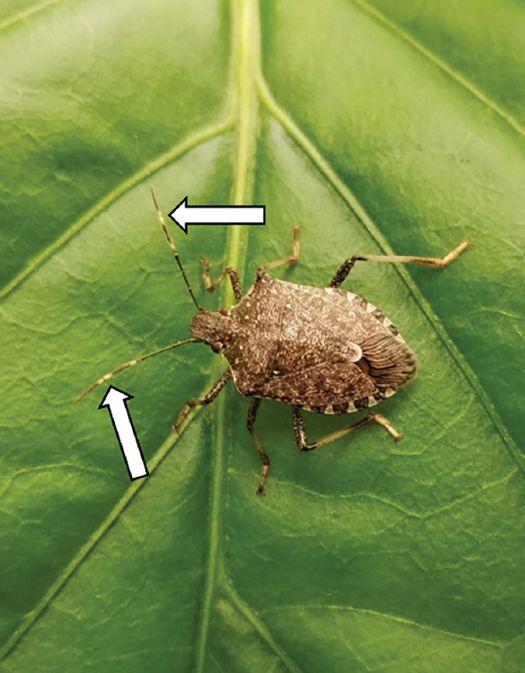

BELOW – FIGURE 1.

Left – The adult stage of the most common native stink bug species found in pepper houses, the consperse stink bug (note the absence of light bands on the antennae).

Right – The adult stage of a new invasive stink bug species, the brown marmorated stink bug (note the presence of light bands on the antennae indicated by arrows). Some other species of native stink bugs that have been found in pepper houses (not pictured) are similarly shaped but are green in colour.

In the last three to five years, there have been reports of stink bugs causing damage to greenhouse peppers in the Lower Mainland of British Columbia. Stink bugs in pepper houses are not a new issue – there were sporadic problems in the 1990s as well – but there is very little current information available about what species are causing these problems, how they might be monitored and managed, or how persistent or widespread this problem might continue to be in the future. It was also unclear whether a new, high-profile invasive stink bug species in Canada, the brown marmorated stink bug, might be responsible for some of these recent problems. As entomologists, we wanted to start gathering information about this pest problem and how producers are dealing with it so far. Here’s a summary of what we know up to this point and areas where there is still a lot to learn.

WHAT

Stink bugs are large, hard-bodied insects that feed on a wide variety of plant hosts. Their life cycle includes an egg stage, five nymph stages, and an adult stage. Only the adult stage has wings and is able to disperse by flying. Adults are between 1 and 3 cm in body length and lay eggs in distinct clusters of about 10 to 70 pale yellow or green eggs,

depending on the species. The last four nymph stages and the adult stage cause damage to plants, often directly to the fruit, by feeding with their piercing mouthparts. In greenhouse peppers, stink bug feeding results in light discolourations on the fruit that are easily visible and extend below the outer surface.

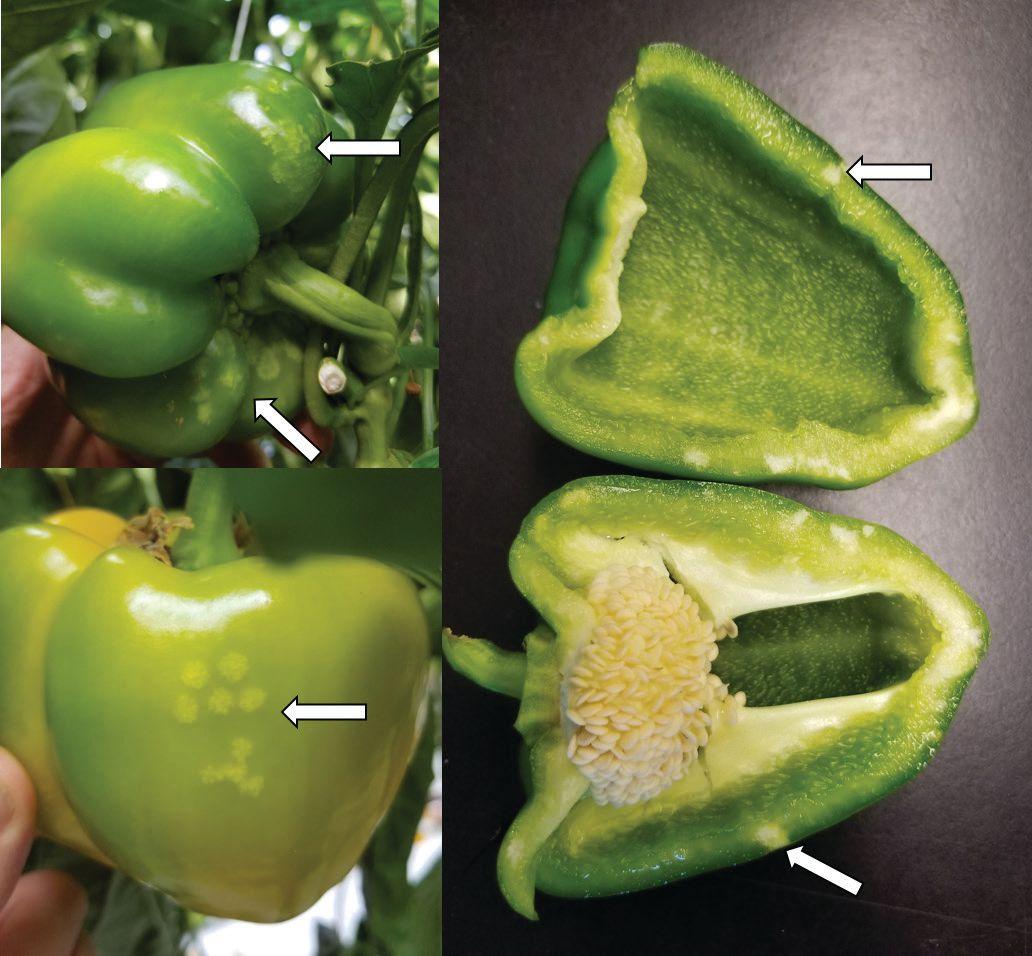

2.

Stink bug feeding causes light discolouration on pepper fruit (left) that extends below the outer surface (right).

The most at-risk period for stink bug entry into greenhouses is from May to July.

From 2016-2019, feeding from stink bugs was sometimes responsible for significant losses in pepper crops in a few Lower Mainland operations, with certain facilities having repeated problems over multiple years. For greenhouse operations with the worst issues in 2018 and 2019, stink bug damage to peppers generally began in the spring (May-June) and sometimes persisted well into the fall (October). Nymphs, adults, and eggs were recorded at different points in the growing season. This suggests that adult stink bugs, after coming out of their overwintering sites in the spring, disperse into greenhouses looking for plants on which to feed and lay their eggs. Their offspring then complete their life cycle in the greenhouse, causing damage to

pepper fruits as they feed. Outdoors in Canada, stink bugs only complete one generation per year. In pepper houses, it is possible that they may be able to keep reproducing after nymphs complete their development into adults. Supporting this theory, one grower observed nymphs well into September of 2018, long after adults are known to stop reproducing outdoors. However, nymphs brought into the laboratory from two pepper houses in 2019 did not lay viable eggs after developing into adults.

To date, most of these problems appear to be caused by species of stink bugs that are native to Canada. By far the most common culprit has been the consperse stink bug (Euschistus conspersus). The adults of this species are mottled brown with green undersides, while nymphs are green and brown-coloured. The consperse stink bug is mostly known as an occasional pest of berry, tree fruit, and vegetable crops throughout western North America, but it also feeds on many wild plant hosts including a wide variety of trees and shrubs. There have also been occasional records of two other stink bug species in British Columbia pepper houses: a large green species called the conchuela stink bug (Chlorochroa ligata) and a smaller green-coloured species with subtle red markings, the red-shouldered stink bug (Thyanta pallidovirens). The latter two species are also occasional pests of other horticultural crops, but have not been significant issues so far compared to the consperse stink bug in greenhouse peppers. Particular pepper houses seem to have the same stink bug species from year to year, suggesting that the vegetation surrounding each greenhouse may be important in determining whether stink bugs are a problem and what species are present.

Continued on pg 22

In recent years, many traditional pesticide companies have come under fire due to human and environmental health hazards. This negative exposure has stigmatized pesticide products.

In recent years, many traditional pesticide companies have come under fire due to human and environmental health hazards. This negative exposure has stigmatized pesticide products.

It is important to note some pesticides have attributed to negative health effects, such as cancer and respiratory complications, plus many have been found to be detrimental to the environment. The concern with some conventional pesticides is the repercussions of them are not always immediately known.

It is important to note some pesticides have attributed to negative health effects, such as cancer and respiratory complications, plus many have been found to be detrimental to the environment. The concern with some conventional pesticides is the repercussions of them are not always immediately known.

According to the government of Canada (Can-

According to the government of Canada (Can-

ada.ca) the definition of a “pesticide” is: “A pest control product. Any product, device, organism or substance that is manufactured, represented, sold or used as a means for directly or indirectly controlling, preventing, destroying, mitigating, attracting or repelling any pest.”

ada.ca) the definition of a “pesticide” is: “A pest control product. Any product, device, organism or substance that is manufactured, represented, sold or used as a means for directly or indirectly controlling, preventing, destroying, mitigating, attracting or repelling any pest.”

BioSafe Systems strives to change the notion that all pesticides are created equal, as this is not the case. We take pride in being at the forefront of sustainable IPM programs for growers around the world. It is imperative for growers to be more conscious when choosing products to ensure worker safety and protection of nearby ecosystems.

BioSafe Systems strives to change the notion that all pesticides are created equal, as this is not the case. We take pride in being at the forefront of sustainable IPM programs for growers around the world. It is imperative for growers to be more conscious when choosing products to ensure worker safety and protection of nearby ecosystems.

After starting from a sanitized and disinfected grow area, pests are the next variable that must be met with effectiveness. BioCeres G WP is the perfect solution to implement for one of the most common problems growers have: the control of whiteflies, aphids, and thrips. Using a proprietary strain of the Beauveria bassiana fungus, the active ingredient adheres to the insect’s cuticle (outer shell), infects the pest, and results in death. BioCeres G WP is labeled for greenhouse use on tomatoes, cucumbers, peppers, herbs and spices, sweet potato slips and ornamentals, along with cannabis grown commercially indoors. Apply as a foliar spray and even tank mix with other pesticides.

After starting from a sanitized and disinfected grow area, pests are the next variable that must be met with effectiveness. BioCeres G WP is the perfect solution to implement for one of the most common problems growers have: the control of whiteflies, aphids, and thrips. Using a proprietary strain of the Beauveria bassiana fungus, the active ingredient adheres to the insect’s cuticle (outer shell), infects the pest, and results in death. BioCeres G WP is labeled for greenhouse use on tomatoes, cucumbers, peppers, herbs and spices, sweet potato slips and ornamentals, along with cannabis grown commercially indoors. Apply as a foliar spray and even tank mix with other pesticides.

Another major issue growers face is fungal diseases, such as botrytis and powdery mildew. These challenging pathogens can often spread and cripple a healthy crop cycle. ZeroTol®, a no residue chemistry, is made to eliminate pathogens on soft and hardy vegetation, fulfilling the need for a fungicide, bactericide, and algaecide. ZeroTol is labeled to control a long list of diseases including, alternaria, anthracnose, fusarium, phytophthora, pseudomonas, rhizoctonia, xanthamonas, as well as treating algae. ZeroTol’s versatility offers growers multiple application options, such as mist propagation, fogging, foliar sprays, and drenching.

Another major issue growers face is fungal diseases, such as botrytis and powdery mildew. These challenging pathogens can often spread and cripple a healthy crop cycle. ZeroTol®, a no residue chemistry, is made to eliminate pathogens on soft and hardy vegetation, fulfilling the need for a fungicide, bactericide, and algaecide. ZeroTol is labeled to control a long list of diseases including, alternaria, anthracnose, fusarium, phytophthora, pseudomonas, rhizoctonia, xanthamonas, as well as treating algae. ZeroTol’s versatility offers growers multiple application options, such as mist propagation, fogging, foliar sprays, and drenching.

StorOx® is a proven combatant of botrytis, works on contact, and utilizes its activated peroxyacetic acid chemistry to destroy bacteria, fungus and fungal spores. StorOx, another non-residue chemistry, has been used and tested on a multitude of greenhouse crops and plant materials. While StorOx can be used on a wide array of crops, it has been found to be the most effective on greenhouse grown tomatoes.

StorOx® is a proven combatant of botrytis, works on contact, and utilizes its activated peroxyacetic acid chemistry to destroy bacteria, fungus and fungal spores. StorOx, another non-residue chemistry, has been used and tested on a multitude of greenhouse crops and plant materials. While StorOx can be used on a wide array of crops, it has been found to be the most effective on greenhouse grown tomatoes.

OxiDate® is an incredibly useful product for greenhouse growers. Using our trusted peroxyacetic acid + hydrogen peroxide formula (PAA), OxiDate can be used to control many diseases on greenhouse grown crops such as: blueberries, grapes, strawberries, apples, apple pears, sweet cherry, watermelon, tomatoes, cucumbers, lettuce, cauliflower, broccoli, celery, hydroponically grown lettuce, pumpkin and zucchini. As for diseases controlled on these crops, here are some examples: mummy berry, phomopsis twig

OxiDate® is an incredibly useful product for greenhouse growers. Using our trusted peroxyacetic acid + hydrogen peroxide formula (PAA), OxiDate can be used to control many diseases on greenhouse grown crops such as: blueberries, grapes, strawberries, apples, apple pears, sweet cherry, watermelon, tomatoes, cucumbers, lettuce, cauliflower, broccoli, celery, hydroponically grown lettuce, pumpkin and zucchini. As for diseases controlled on these crops, here are some examples: mummy berry, phomopsis twig

media. It is also an excellent option as a disinfectant on hard, non-porous surfaces. Additionally, OxiDate’s PAA chemistry allows it to have no residue or mutational resistance, making it an ideal product for conventional, organic and IPM management practices.

media. It is also an excellent option as a disinfectant on hard, non-porous surfaces. Additionally, OxiDate’s PAA chemistry allows it to have no residue or mutational resistance, making it an ideal product for conventional, organic and IPM management practices.

With over twenty years of experience working with growers of every kind, BioSafe Systems consistently strives to provide the most effective and reliable prod ucts. Continuously pushing the standard of sustain ability, BioSafe Systems endeavors to create solutions to align the needs of the grower with the well-being of the environment for many generations to come.

With over twenty years of experience working with growers of every kind, BioSafe Systems consistently strives to provide the most effective and reliable products. Continuously pushing the standard of sustainability, BioSafe Systems endeavors to create solutions to align the needs of the grower with the well-being of the environment for many generations to come.

blight, downy mildew, cane and leaf spot, fruit rot, powdery mildew, Botrytis cinerea, Erwinia amylovora, scab, black rot, Cercospora beticola, Didymella bryoniae, Cladosporium fulvum, bacterial wilt and alternaria. OxiDate is appliable as a foliar spray and by fogging on plant

blight, downy mildew, cane and leaf spot, fruit rot, powdery mildew, Botrytis cinerea, Erwinia amylovora, scab, black rot, Cercospora beticola, Didymella bryoniae, Cladosporium fulvum, bacterial wilt and alternaria. OxiDate is appliable as a foliar spray and by fogging on plant

Continued from pg 19

In addition to native stink bug species, there is a new invasive stink bug that we are keeping a close eye on, the brown marmorated stink bug (Halyomorpha halys). Originally from Asia, this invasive stink bug was first detected in 2003 in eastern North America and has caused extensive damage there to a variety of crops, including many fruits and vegetables such as peppers grown outdoors. This species was first found in Ontario in 2011 and in British Columbia in 2015, and although it has not caused any significant crop damage in Canada to date, its populations appear to be building and it is now widespread and common in natural habitats and backyard gardens in the Lower Mainland of British Columbia. Until recently, it was not clear whether this species was a threat to greenhouse vegetables. However, in 2018 and 2019, we have had reports that the brown marmorated stink bug has caused major losses of greenhouse peppers in Switzerland. Most recently, this invasive stink bug was detected in a single British Columbia pepper house in 2019, causing very limited damage to a small number of pepper plants. Damage was very similar to that caused by native stink bugs, and in general, the life cycle of this species is similar to native species as well. It remains to be seen whether this invasive stink bug will become a larger problem in the future, but in the meantime, we suggest reporting any finds to pest management professionals so that its spread and impact can be tracked. The brown marmorated stink bug can be distinguished from native stink bug species by the presence of alternating white bands on the antennae of both nymphs and adults.

The best way to monitor for stink bugs is to train staff to look for them and the damage they cause during harvesting, scouting, and plant maintenance. Monitoring can start during the most at-risk period for stink bug entry into greenhouses, from May to July. Stink bug nymphs seem to stick around in the areas where they

feed, so if there is pepper damage on a given plant, there is likely to be several stink bugs on that same plant or its neighbours. Often, stink bugs can be found on the fruit. It is important to check closely around the calyx end, as smaller nymphs can sometimes hide between the stem and the pepper fruit. Because stink bugs are relatively large compared to other pests, they can be removed by hand into a container of soapy water over the course of a day and then routinely disposed of. Putting them in the freezer to euthanize them works well. The producers we have spoken to find that training and rewarding greenhouse staff for finding and collecting stink bugs can make a very important contribution to effective management (e.g. put out a cash bounty for every 20 stink bugs found).

Right now, other options for stink bug monitoring and management are limited. In terms of monitoring, there are pheromone traps that are commercially available for monitoring some stink bug species, but in our opinion, they do not have much promise for making management decisions in pepper greenhouses above and beyond the information provided by direct observations during harvesting, scouting, and maintenance. For management, there are unfortunately no insecticides currently registered for stink bug control in greenhouse vegetables, and to our knowledge, there is no trial data from greenhouse settings to indicate which insecticides may be effective, if any. No commercially available biological control agents have any potential to aid in stink bug management, either. Currently being studied by entomologists including ourselves, there are a few species of parasitic wasps known to kill stink bug eggs. However, while these wasps may currently help to keep outdoor stink bug populations at low levels, their potential to be effective biocontrols in vegetable greenhouses is still not known.

Clearly, there is still a lot to learn about stink bugs as pests of greenhouse peppers. For example, we still do not know whether

this is a sporadic problem, limited to a few specific greenhouses that will diminish again as it did in the 1990s, or whether it will persist or get worse in the coming years. As populations increase outdoors, it still remains to be seen whether the invasive brown marmorated stink bug will eclipse the native stink bug species in importance and become a pest of major concern for greenhouse peppers. There is also much to learn about how vegetation management around the periphery of greenhouses

FIGURE 4.

A parasitic wasp on top of a stink bug’s egg cluster. Some species of parasitic wasps lay their eggs inside stink bug eggs, with the wasp offspring’s development causing the death of the developing stink bug embryo. While these parasitic wasps may be currently helping to reduce stink bug populations outdoors, their potential as biocontrols inside greenhouses has not been properly tested.

could help reduce the numbers of stink bugs that are entering greenhouses in the spring. If stink bugs do start to become a more widespread problem in greenhouse vegetables, it would certainly be worth putting more effort into researching and registering both chemical and biological control options, as well as continuing to refine monitoring and cultural management techniques.

Acknowledgements: We thank Heidi Balla, Richard Wierks, Anita Vandeburgt and Jacob Kerkoff for their collaboration, sharing of information, and for providing samples of stink bugs for identification. We also thank Warren Wong, Peggy Clarke, and Jason Thiessen for help collecting specimens.

Paul Abram, PhD, is a research scientist in biological control of insect pests at Agriculture and Agri-Food Canada based in Agassiz, BC. Tracy Hueppelsheuser is an entomologist at the BC Ministry of Agriculture in Abbotsford.

Quality, environmentally friendly growing containers for single-use plastic solutions.

Browse containers, download a catalog or request free samples at hc-companies.com

Most poinsettia growers in Ontario shipped all that they grew in 2019. But was it profitable? Here are some cost-saving measures learned from this past year.

BY MELHEM SAWAYA

Other than a few growers who were looking for a few specific colours, there was no demand for extra poinsettias this year. Because a few buyers were hunting for product last season, some growers were optimistic this year and grew a small percentage based on speculation, and yes, you guessed it – these growers were stuck with the few poinsettias that they speculated on. Later on when we discuss costing, you will realize that every plant that we cannot ship takes away from the profits of ten plants sold.

In Ontario, most poinsettia growers

shipped all that they grew, as long as they did not speculate. The question is, did we make any money on the poinsettia crop last year? The answer is only known to those who calculated the cost of growing poinsettia as a separate crop; not pooled together with the rest of their other crops and awaiting their year-end statement to know whether they were profitable or not.

Here are some observations from a few growers who shared their costs with me.

Soil, pots, and cuttings do not vary much from grower to grower. However, the number of cuttings per pot makes a big difference. Most

MAIN One cutting in a 6.5” pot has 10 blooms and can easily fit a 7”.

RIGHT As shown here, a larger pot allows for more space and results in sturdier stems for the poinsettia above.

growers use two cuttings in an 8” pot, not three, and the quality of the two cuttings is much better because they have more space and can receive higher light intensity throughout the whole growing cycle. This leads to stronger, healthier plants that will have better shelf-life in stores and greater consumer success. The same goes for 10” or 12” pots with three cuttings, which tend to show larger blooms and last longer.

For the few that grow in 7” pots, it is a crime to put in more than one cutting, especially when you see how one cutting looks in a 7”. This is my favourite pot-toplant size ratio, resulting in a good number of blooms and a healthy, durable product. Big plants in small pots is a recipe for failure from the get-go.

Utility overhead costs vary only depending on spacing, which is determined by the finish size of the plant. Poinsettia is a crop that needs its space, and crowding the crop in many cases leads to an unshippable product.

Labour costs were underestimated because no employee is 100 per cent efficient. Good employees are 80 per cent efficient in most cases. This varies, of course.

Many growers did not properly calculate the indirect cost, which includes all expenses that occur even if the greenhouse is empty. It is normally calculated as a percentage of total sales, and that cost is naturally higher if sales are lower.

Shipping varies among growers and is mainly due to distance, how full the truck is, and whether the grower is picking up racks. Many times the cost triples, which eats up any little profit that exists and definitely is not the type of green-thinking that many stores are trying to adopt. One solution is to buy different products from the same grower or have different products from different growers go on the same truck.

It is very important to calculate your costs in detail. This will help you see where you can be more efficient and prevent you from selling below cost. Flip to the next page for a template for calculating costs.

With cool nights and higher-than-average light levels, weather conditions were optimal for flower initiation. On average, every greenhouse crop was ready a week earlier than other years. Yes, Mother Nature rules.

Micro drenches of Bonzi can be used at any stage of production, and it will not decrease the bracts to an unsellable state. Proper application of Bonzi will produce a much higher quality product. Here are guidelines to consider when using Bonzi:

• Applications should be uniform, especially if you are using a drip system. Use lower rates with high volumes so that the whole root ball is covered.

• Treatments are more effective when applied to plants in the

fast-growing stage. This goes for any growth regulator.

• Avoid any Bonzi applications overhead, but if that is the only way you can apply it, then rinse with clear water using your sprayer and not watering nozzles.

Note that if you are spraying Cycocel, be aware of your clear water EC. High EC’s will cause leaf damage. For Botrytis control, the best solution is to lower humidity.

All in all, timing is the best growth regulator. If a later crop sale date is required, grow a later flowering variety in its own section where you can control the temperature separately without affecting other cultivars. Some crops that were shipped later in the season, but not programmed for it, showed signs of botrytis on the bracts, flowers or both.

The best crops are produced when all aspects of production are done on time. It’s also a big part of growing ‘green’, because fewer to zero chemical treatments are needed. You may remember seeing this from my previous articles, and this will not be the last time: to grow crops successfully, 15 per cent is knowledge, 15 per cent is application of said knowledge, and 70 per cent is doing everything on time.

ABOVE

A Cycocel application led to damaged leaves because of the high EC clear water.

There were many new, promising poinsettia varieties. At the poinsettia open house at Jeffery’s Greenhouses late last year, we saw some very interesting varieties that were improvements over the older ones, allowing you to choose some that could fit a certain pot size or shipping date.

Varieties that are good for one pot size may not necessarily be good for other sizes without changing the timing and culture. The same goes for shipping dates.

There were varieties that flowered by November 10th without any blackout treatment. They can be grown in any sized pot with adjustments in scheduling.

Sales history tells us that those early in-store poinsettias lead to low sell-through and greater shrinkage.

Red poinsettias make up at least 93 per cent of the total colours grown, along with 4 per cent white, 2 per cent pink and 1 per cent miscellaneous

Regardless of which variety you choose, growing media should not be flush with the pot rim. This gives the stores and home owners a small reservoir to be able to water the plants more effectively.

TABLE 1.

A sample spreadsheet for calculating costs per pot of poinsettia. Values are not actual costs and should be used as an example only. This spreadsheet can be adapted for any crop, with columns and rows deleted or added as needed. Download this tool online at greenhousecanada.com.

TABLE 2.

A sample table for calculating the amount of time (in minutes) it takes for an employee to complete each task for a single pot of poinsettia. This is how “total minutes” was calculated for Table 1 under ‘Labour Costs.’

Almost all growers experienced no issues with any kind of disease, except for a few Erwinia incidents that were directly related to plant stress before sticking.

There were no known root problems, and no preventative fungicides were applied. Diseases do not want anything to do with happy plants, and happy plants do not welcome diseases. Proper watering, regularly checking EC and PH values and proper environmental conditions lead to healthy plants with no need for fungicides.

The whitefly saga continues. Some growers who properly applied biological control treatments on poinsettias encountered no issues with whitefly, some had to clean the crop at the end with chemicals, and others who only used chemicals had a very rough road all the way, especially if the cuttings had not been dipped.

At the end of the season, this was the consensus on how to best control whiteflies in poinsettias:

1. Before propagation and planting, the planting areas should be thoroughly cleaned. No pet plants or other crops should be left around.

2. Open the boxes in a cool room and dip the cuttings in a BotaniGard solution, then put them in a cool room at 10 degrees overnight or at least 4 hours before sticking, making sure the cuttings are never dehydrated.

3. Before sticking, dip the cuttings in an insecticidal soap.

This is what an overdose of Fascination can look like.

4. Before planting, dip the cuttings in a mixture of Botanigard and horticultural soap.

5. Start biocontrol treatments soon after, until around October 10 or 15.

6. Shift to chemicals if needed at finish.

Here are the key takeaways from last season:

• Grow varieties that you are familiar with and try new ones on a small scale.

• Calculate your cost for any required specs and do not forget about packaging and shipping.

• Take an order when there is still some margin and not just dollar sales.

• Never grow on pure speculation.

• When you run out of plants at the end of the season and you need to buy more, that is when you are starting to make headway profit-wise.

• Do not cheat on what the crop needs to grow properly; it will cost you much more at the end if you do.

• Start a study group with the growers in your vicinity. Last but not least, if all the factors that took place last year are repeated in the next, and all the suggestions in this article are taken, then growing poinsettia could be profitable.

Three years ago, a study group of growers and educators in southwestern Ontario met once a month starting in June to discuss production issues, but they mainly concentrated on whitefly control this past season. The study group met in different greenhouse operations, had discussions and toured the host grower’s crop in a very informal and beneficial way. Next season, we are planning to do the same and will try to include more topics than just whitefly control. If you are interested in being a part of the group, send me an email with your contact information.

Melhem Sawaya of Focus Greenhouse Management is a consultant and research coordinator to the horticultural industry. Contact him at mel@focusgreenhousemanagement.com.

Consumers may want to see less plastic in their ornamental products, but eliminating it may not be the answer.

BY ANNE-MARIE HARDIE

Whether it’s pots, trays or wraps, single-use plastic is becoming a mounting concern for growers, retailers and the end consumer. This is not a new challenge for the industry as discussions around more sustainable solutions have been ongoing for the past decade. However, the conversation has become amplified lately as Canadians have grown increasingly aware of their plastic waste.

According to the 2019 Economic Study of the Canadian Plastic Industry, Canada throws away 87% of its plastics, valued at $7.8 billion. Canada’s recycling statistics are dismal as the report shows how Canada recycles just 9% of its plastic

waste. The Canadian government has announced that it is time to change, including a plan to ban single-use plastic by 2021, working with partners to deliver their vision of zero plastic waste.

Each year, the horticulture industry sells its products in single-use plastic pots, trays and wraps – the majority of which end up in landfill. Recycling programs, such as the one for horticultural plastics launched by Landscape Ontario in 2008 and run by the Canadian Nursery Landscape Association, were shut down when China closed its doors to poor quality and certain types of plastic. Other Asian countries similarly heightened

ABOVE As consumers become more aware of single-use plastic waste, retailers look for alternatives.

their restrictions on acceptable plastic or banned plastic waste imports altogether.

Recycling single-use pots and trays in Canada is extremely challenging. Soil and debris need to be removed to prevent cross-contamination and containers have to be separated based on their various plastic films. Because the plastic makeup of standard black pots cannot be identified by near-infrared (NIR) light used at most recycling facilities, those containers cannot be sorted and recycled.

fate after disposal. According to Pöppelmann, the product must satisfy three conditions to close the material loop: it must be recyclable, it must be made from post-consumer recycled plastic and it must return to the same point in the recycling process from where the source material was acquired.

To this end, the plastics manufacturer developed a four-level classification system used to describe their product lines:

‘Circular360’ pots are made from 100% post-consumer household waste. They can be easily sorted at recycling and directed back to plastic manufacturers for new pots to be made. Pots are indicated by their distinctive ‘circular blue’ colour.

‘PCR Recyclable’ pots contain 100% post-consumer recycled plastic. This may include sources other than household waste, such as garden furniture.

materials that are technically recyclable, the black colour renders the pots unreadable by NIR and therefore not processed by most recycling facilities.

Pöppelmann’s goal was to design a range of pots that responded to a variety of sustainability concerns, while still retaining the design and performance elements of their original products. The cost of these pots range from ten to thirty-five per cent more than the standard pot.

‘RECYCLED’ DOESN’T MEAN ‘RECYCLABLE’

There are risks to adopting more sustainable solutions, including higher upfront investments and ensuring that the containers retain the same functionality as their single-use alternatives. To make these solutions work, growers may need to charge a higher premium. But can the current economic environment adapt to this price increase? If the retail industry is any indicator, now is the time to explore sustainable alternatives. The 2019 Canadian Consumer Insights Survey reported that 42% of Canadian consumers actively seek to avoid plastic packaging in their groceries, and 32% are willing to pay more for non-food items that are sustainably packaged.

“We’ve seen a steadily increasing demand for sustainable pot alternatives. Consumers are willing to pay more for pots that they know are 100% recyclable and made from post-consumer recycled material,” says Lindsay Childers, TEKU sales manager for Pöppelmann.

Three years ago, Pöppelmann launched their corporate ‘blue’ initiative to close the material loop, aiming to put post-consumer plastic waste back into the production of new pots. “Just because a pot is marketed as being made from recycled material, doesn’t mean it is 100% recyclable,” says Childers, underscoring the importance of knowing where the material for the pots came from and their

‘Recyclable’ pots are made from a mixture of post-consumer, post-industrial and some virgin material. Post-industrial materials are sourced from waste generated through industrial plastic processing.

The fourth and final level of classification is for black pots. Though made from a mixture of post-industrial and virgin

JVK is one Canadian supplier that has added Pöppelmann’s blue pots to its product line. “All plastic is recyclable; the challenge is whether your municipality will accept it and if not, what the consumer can do with that material,” says Chris Johnston, vice president of sales and marketing at JVK. With the blue pots, not only are the products created from post-consumer household waste, they come in a colour that can be read and recycled by local municipalities.

As Johnston explains, the loop in Canada is different from the one described by Pöppelmann. The plastic isn’t going back to the region in which it was produced as most horticultural container manufacturers are located elsewhere. “However,’

ABOVE

Pöppelman’s Circular360 products come in a distinctive ‘circular blue’ colour.

he adds “we could have a closed loop where plastic is reused in the area in which it is first sold to or used by consumers.” As demand picks up, he foresees more post-consumer household waste being diverted towards resin pellets for manufacturers to use. “Thus, multiple-use plastic with what could be a low-carbon footprint, if done regionally.”

In some cases, plastic may be the more sustainable solution. “For production, you need plastic, but retailers can choose to have the trays returned for reuse or opt for recyclable plastic,” says Johnston.

Instead of eliminating plastic, Herkuplast International has focused on creating something that will fulfill their customers’ propagation needs while reducing single-use products. Their Quickpot trays are crafted from durable, polystyrene film, with the average tray lasting anywhere from 8 to 10 years. “It’s simply a better investment both financially and environmentally,” states Alfred Boot, sales director at Herkuplast International. “Although the initial cost is approximately three times more than a single-use tray, the durable trays work extremely well on fully automatic lines and can be reused for several years.”

When considering sustainable options, it is important to investigate the entire carbon footprint of the product, including the process involved in creating it and disposing of it. Where available, biodegradable solutions may appear to be the better solution. However, it may be more sustainable for growers to

choose alternatives that can be sanitized and reused or ones that are created from recycled materials. “If we are able to pick up old plastic and only need to add a small percentage of new material to create a new product, then that may be a better solution than opting for a new product that is biodegradable,” says Boot. Ultimately, it is up to the grower to determine what works best for their operation.

Johnston emphasizes that when looking at sustainable alternatives, growers would benefit by paying attention to their entire operation and seeking options that would help decrease the amount of plastic waste generated. This may include biodegradable containers, cardboard carriers to transport non-plastic pots, or containers created from recycled plastic. But the key to successful acceptance of these sustainable alternatives is ensuring that the end consumer understands. “We need to start communicating when we are using sustainable packaging,” says Johnston. “If this one is greener or more sustainable, shoppers will probably lean towards that solution – but growers and retailers need to communicate that information.”

Aileen Flicki, product manager at Decowraps, echoes Johnston’s statement about there being multiple ways to integrate sustainability into a growing facility. “We are helping our customers find materials and tools to help them tell their story,” says Flicki. “But before doing that, growers need to discover what their story is.”

The narrative is much more extensive than simply eliminating single-use plastic. It should include the source of the product, how it is produced, and what happens to the product at the end of its life. Decowraps’ vast product selection allows their clients to connect with their customers and select materials to help them share the story. New materials are sometimes sourced to fit production needs. Current options include clear, compostable PLA made from corn, kraft paper that has been FSC-certified for sustainable production, as well as others in the works. They also offer a flexible and opaque Bio-LDPE made from sugarcane that carries the “I’m Green” seal, a recognized certification that helps the consumer identify packaging products made with bio-based resin Bio-PE, a polyethylene made from renewable resources.

The key is ensuring that adopted solutions are both economically viable and sustainable. In most cases, this may mean that growers would need to increase the price of the product. “These options may be a bit more expensive, but with the right message, consumers are open and willing to pay for these sustainable solutions,” says Johnston. “The Pöppelmann blue pots, for example, are different than other products on the market because they are made from consumer household waste. It is these types of stories that need to be shared with the end consumer to help drive the demand.”

To help make this shift as an industry, growers need to find a way to market their products’ sustainability story; this includes focusing on what sustainability means to them, as a company, and how they want to present this to the end consumer. “It’s really about the story you want to share on the product, and the packaging solution connects to that story,” says Flicki.

The conversation is starting with consumers and moving up to retailers. Greater pressure will then be placed on suppliers to reduce plastic waste. In time, this movement will drive the sector to adopt more sustainable solutions as a long-term approach to reducing waste from single-use plastic.

As greenhouse production changes, so, too, must IPM programs. Here were the latest innovations spotted at ABIM in Switzerland.

BY DR. MICHAEL BROWNBRIDGE

IPM programs are never static. They have to continually evolve as production techniques change, new crops are grown and pest dynamics shift. They also change in response to consumer demands and, critically, to our changing climate. IPM systems evolve to accommodate new knowledge and technologies, and every year, advances are made that enhance IPM outcomes and success. Biological inputs are playing a greater role in IPM than ever before, as we seek to improve the economic and environmental sustainability of our production systems. At its core, biocontrol is a preventative strategy and the developments presented here should directly improve the efficacy of bio-centric programs in one way or another, without adversely affecting the biological control agents within them. Collectively, these will allow us to move further along the ‘biologically-based’ IPM track rather than remaining on or reverting to traditional pesticide-based programs.

I was fortunate enough to attend the Annual Biocontrol Industry Meeting (ABIM) in Basel, Switzerland in October (https://www. abim.ch/home.html). This is a meeting focused on the business of biocontrol, bringing together producers and vendors of biological control agents, biopesticides, biostimulants and products that promote and support their activity from around the world. This year, there were 90 exhibitors and 1,227 visitors from over 50 countries and 530 companies. It truly is an amazing event that demonstrates the continued growth, vibrancy and importance of biocontrol to the future of agriculture. Among many other things, the meeting provides a platform for companies to showcase new innovations and services.

prevent populations of generalist predators from collapsing or dying out at times of prey shortage. This means that predators will remain in the crop for an extended period, improving performance and reducing the need to continually replenish them, potentially cutting costs in terms of product and labour. Overall, supplemental foods can improve the outcome and economics of biocontrol programs.

Supplemental foods include Ephestia eggs, prey mites (used in breeder sachets), and pollen (e.g. Nutrimite), but one of the newest and most intriguing supplements are decapsulated Artemia cysts. Several research studies support the potential use of Artemia cysts as a supplement to enhance the establishment and activity of predatory species (insects and mites) in greenhouse crops or as a food source for mass-rearing such species. Biobee has built on these findings to develop commercial products for a range of generalists. Artemia cysts are very nutrient-rich and boost fecundity and longevity. They also have some logistical advantages over the other types of supplemental food in that they can persist in the crop for several weeks, and can be stored in a refrigerator for at least three years. This stability means that their quality is maintained even if there are breaks in the cold chain during distribution and during use.

Artemia cysts for predators.

Presented in no particular order, here are five technologies that caught my eye and could benefit the Canadian greenhouse industry in one way or another.

First of all, why consider using supplemental foods in a crop? There are a number of really good reasons behind this. Their use can promote predator establishment in the crop even before pests arrive (the ‘standing army’ approach), and they help

Artemia cysts enhance the establishment and performance of generalists such as predatory bugs (e.g. Orius), mirids (e.g. Macrolophus) and mites (e.g. swirskii, limonicus). Available in bulk as BioArtFeed, cysts are sprinkled or blown into the crop to feed the predators, which are released before the pests arrive. The goal is to establish the predators in the crop, so that once pests such as thrips or spider mites arrive, there is a ‘standing army’ in place to combat them. The supplement can be re-applied throughout the crop cycle to support predators when pest numbers are low.

For crops where extended feeding is required, or where it is undesirable for there to be any residues on the leaves – ornamentals, strawberries and cannabis, for example – the company has developed the alternative formulation, BioArtLine. Two lines of cysts are attached to the edges of plastic tape which is run through the crop. The food is readily accessible to predators,

serving as an in-crop source of nutrition over an extended period (up to 10 weeks) without leaving residues on the leaves.

As the list of predators that benefit from this food resource continues to grow, it could also be a game-changer for predators that are more difficult to mass-rear inexpensively, providing a means whereby they could be inoculated in smaller numbers and established in a crop, rather than applying large numbers from the get-go.

Tomato russet mite (TRM), Aculops lycopersici, is a tiny eriophyid mite, much smaller than the two-spotted spider mite and virtually invisible to the naked eye. It can be a severe pest on other solanaceous crops as well, such as eggplant, pepper and petunia.

Because of their size, these mites are rarely noticed until damage symptoms are observed. Damage by russet mites occurs on stems, leaves and fruits, and is caused as they pierce the cells to feed on the contents. The cells then dry out, leading to symptomatic ‘russeting’ on the affected plant parts. If not controlled, crop losses can be severe. TRM was first reported in Australia in the late 1930s and has subsequently spread around the world. Finding effective biological controls for this pest has been challenging. Several commercially available predatory mites will feed on this eriophyid, such as cucumeris, californicus, and montdorensis, but control under greenhouse conditions has been poor. The sticky glandular trichomes which cover the leaves and stems of tomato plants impede the movement and activity of many predatory species.

Instead of going big, Biobest decided to go small and discovered two predatory tydeid species, Homeopronematus anconai and Pronematus ubiquitous, which can move easily around the trichomes and will consume all growth stages of TRM. In trials on tomato where Pronematus were introduced in a preventative program, they stopped TRM populations from building. When applied at a high use rate, they virtually eliminated all TRM on the plants. In both cases, plant damage symptoms were significantly reduced. These predatory mites are excellent candidates for use in this manner, and populations can establish and build rapidly in the absence of prey when pollen (Nutrimite) is supplied. Thinking small can pay big dividends, and these diminutive predators may be just the solution for TRM and other eriophyid mite pests in crops such as blackberry, hemp and ornamentals.

Winner of the International Biocontrol Manufacturers’ Association’s (IBMA) prestigious Bernard Blum Award for novel biocontrol solutions, Andermatt Biocontrol’s Tutavir is the first granulovirus on the market that will selectively control the tomato leafminer, Tuta absoluta

Although Tuta has not been found in Canadian greenhouses, most greenhouse tomato growers are aware of the threat posed by this pest. Many believe it is more a matter of ‘when’ rather than ‘if’ it will arrive. The moth is native to South America but has spread rapidly around the world and is now prevalent in tomato-growing regions of Europe and North Africa. It has caused major problems in greenhouse tomatoes in the Mediterranean Basin and Northern Europe, where the lack of effective biocontrols has led to the indiscriminate application of broad-spectrum