Friends with benefits

Will

Spotted: spider mite resistance

Edible

A mite-y resistance

One of the top resistant pests in the world, the two-spotted spider mite is resistant to over 95 different active ingredients. By Dr. Ian Scott

Friends with benefits

Will

Spotted: spider mite resistance

Edible

One of the top resistant pests in the world, the two-spotted spider mite is resistant to over 95 different active ingredients. By Dr. Ian Scott

GRETA CHIU | @GreenhouseCan

Hello from Germany. Thanks to the generous support from Sunrise Greenhouses and Pöppelmann, I had the opportunity to tour German greenhouses with growers from the United States. It’s been a fantastic experience and, unsurprisingly, technology stole the show at each stop.

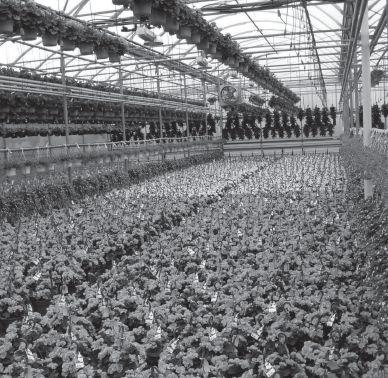

Our first stop was Emsflower, a massive greenhouse-garden centre complex complete with an elegant café, a butterfly garden and a minizoo. Once we peeled ourselves away from the meercats, we saw the beginnings of a hydroponic lettuce trial. Roots were threaded through a thin papery pot and placed on floating rafts, while LEDs bathed the plants in a purple light. 88 hectares of greenhouse space and seven more–to a maximum of 18 – devoted to greenhouse tomato production. The vast majority was ornamental.

The back of the greenhouse was where the technological action took place. Greeted by self-driven, computer-programmed transport carts delivering pots from the loading docks to automated pot spacers, we

them up, then deliver them to their destination on the greenhouse floor while maintaining the same spacing formation with ease. The chains seemed to drive the pots forward during release – just imagine the amount of labour saved with this one piece of equipment. Altogether, the forklift system, the spacer and the accompanying computer system costed 60,000 Euros – roughly $90,800 CAD at today’s exchange rate. But each one has also lasted him 15 years so far.

At Gartenbau Bosch, the grower showed us his ebb-and-flow system on concrete floors. The impressive part was how quickly he could demonstrate this for us. A few seconds on his mobile phone and the floor started to flood from several openings. The area was filled within seconds. Compared to watering from the top, watering by capillary action reduces the chances of disease, negating the need to sanitize the water regularly.

One of our last stops was Bremkens Orchids where they’ve designed a completely new automation system for the young orchid stage. After

...just imagine the amount of labour saved with this...equipment.

arrived at seven sticking machines. Each performed at an average rate of 2,000 cuttings per hour – you do the math. Watching the computer screen, the program was able to recognize which end was the stem, and which end wasn’t – not always easy with the Argyranthemum frutescens at the time, hence the two staff stationed at the end of the sticking line, double checking the machines’ work. It was a sight to behold.

Next, we stopped at Marc Peters’ where we saw our first spacing fork of the tour. After the potted topiaries were arranged with an automated spacer, the forklift driver would pick

staff evaluated plants for disease, 16 photos were taken of each plant by multiple cameras and automatically sorted by size. A second camera station then turned the plant to the correct angle before moving the sorted plants into trays. .

Though each operation was able to reduce their labour use, there was one commonality between them – automation was not 100 per cent perfect. Whether it was double checking the machine’s work or picking up a potted plant that had slipped from the forklift, good human help is still needed - and everywhere you go, hard to find.

and

of

Opinions

in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Count on Selecta One® to supply your full poinsettia program this season. Each variety is specifically bred with a well-branched, V-shaped habit for less breakage –arriving at retail in excellent condition. Plus, their strong roots can stand up to any watering method, supporting lower shrink and higher yield. With Selecta One, your poinsettias will have outstanding shelf life so you can send to retail i with confidence!

Visisit t s l el e ec e taanorthameeriica c .com m to o o ordeer r poiinsettias annd d to finnd d best grrowiing pracctices. .

The Ontario greenhouse vegetable sector has a new online resource.

Run by greenhouse vegetable specialists Cara McCreary and Shalin Khosla of the Ontario Ministry of Agriculture, Food and Rural Affairs, the ONgreenhousevegetables blog is an outlet for growers, supplying timely updates and technical information on a wide range of topics in greenhouse vegetable production.

“Our intention is to utilize this space to share critical information that reaches a wide audience in a timely manner,” note McCreary and Khosla. “We plan to share research updates, pest and disease management issues, and greenhouse climate and production recommendations.”

For growers, it’s another avenue that will contribute to the Ontario greenhouse vegetable sector. Visit medium.com/ongreenhousevegetables

Three big awards were handed out at the Tailgate Garden Party, an annual meeting and social event hosted by the Alberta Greenhouse Growers’ Association during the 2018 Green Industry Show and Conference in Edmonton. The Ornamental Grower of the Year Award went to Jason Anderson, owner and operator of Kathy’s Greenhouses. Since purchasing Kathy’s,

he’s moved and rebuilt existing structures, expanded by 6,500 square feet, and added a Christmas season store and market garden. Passionate about horticulture, his management has transformed the business, reaching the size and level of success seen today.

The Meritorious Service Award went to Kim Wickwire at Olds College. Having worked within the Horticulture

department for the past 30 years, Wickwire has continually inspired future generations with her teachings in landscape and floral design, propagation, as well as greenhouse and field production. She continues to involve her students in greenhouse trials of anything odd and unusual for bedding plant opportunities.

The Herb Knodel Award went to Michiel Verheul, owner of

High Q Greenhouses. From initiating plant donations for fireravaged Slave Lake and Fort McMurray, to bringing forth industry concerns on the carbon levy and employee benefits, Verheul’s many contributions to the AGGA, as well as the Alberta greenhouse industry as a whole, led to this well-deserved recognition. For complete story and photos, visit greenhousecanada.com

Source: Alberta Agriculture and Forestry

PER M2 Highest gross margin is for bedding plants and ornamentals

From fungicides to miticides to biological solutions, Bayer is dedicated to the research and development of the products that keep your crops and business blooming.

NEW IN 2019: Altus Insecticide - for greenhouse tomatoes, peppers, cucumbers, lettuce, ornamentals and in outdoor ornamentals.

This early flowering angelonia is very floriferous, with large blossoms covering the plant all summer long. The Alonia series has good heat tolerance and stays a nice size in the garden. Available in nine stunning colours, Alonia is recommended for quarts and 2.5 quart pots. Bicolour Violet is new for 2019. danzigeronline.com

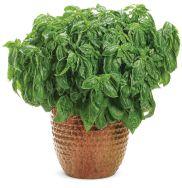

This is a gamechanging plant – the first downy mildewresistant variety of Italian sweet basil. If that weren’t reason enough to grow it, this selection also remains in its vegetative state longer and sets sterile seed. Vigorous, large, well-branched plants produce a higher yield and last all season. The more you harvest, the better it grows. Full sun. 51-91 cm tall, 31-61 cm wide. provenwinners.com

Introducing the first Dümmen Orange-bred family of garden mums. The Ditto family is comprised of matched colours that are wellsuited for monoculture production or in combinations. In this family are four striking colours – Pink, Lemon, Honey, and White.

Jungle Parrot is an excellent choice for space-saving gardening. The plants grow strong without support and perform equally well in containers or in the ground. Blocky, bellshaped fruit ripens from dark green to red and

A stunning pastelorange cauliflower that is ideal for the specialty colour market. High levels of beta-carotene provide eye-catching colour. Widely adaptable, provides uniform maturity and consistent performance under

can be eaten at either stage. Mature fruit size is 3 inches; harvest more than a dozen peppers from each plant. Days to harvest: green, 65; red, 75. 30-46 cm tall, 30-46 cm wide. burpeehomegardensbrand. com

different environmental conditions including heat stress. Mediumsized plants produce high yields of smooth, high quality and dense heads. Versatile and suitable for both fresh and processing markets, spring or fall. syngentaflowers-us.com

These four varieties are well matched in vigour, timing, and habit, creating two Confetti Garden mixes: Virgo and Pisces. Easily programmable and highly resilient, Ditto is an easy solution for both shaded and natural season production. dummenorange.com

Peach Sorbet is a show stopper all year long. This compact blueberry is stunning with leaves that are peach, pink, orange and emerald green. White bell-shaped flowers will appear in spring, leading to an abundant summer crop

of tropical flavoured, sweet blueberries. In most climates, this plant will keep its leaves throughout winter and turn a rich eggplant purple. USDA zones 5 to 10, full sun. Mounded. 0.5-0.6m tall. bushelandberry.com

Neon Burst is a compact dogwood with attractive chartreuse foliage and good sun tolerance. Its stems have a rich red hue early in the season. Fall foliage is a rainbow of purple, red, yellow and orange. In winter, stems turn glossy scarlet red. Zones 2 to 7. 1.2-1.5 m tall, 1.2-1.5 m wide. firsteditionsplants.com

JOHN STANLEY | John Stanley Associates

As 2019 becomes the new season, a number of garden trend reports have been released, advising garden retailers on what they need in their marketing strategies for the year. As you would expect, the millennial market is foremost in many people’s minds. Most of these reports mention how this is a generation that does not understand gardening, as it was not taught to them by their parents. The reports also mention that the trend towards nano gardening, both indoors and outdoors, will be a feature moving forward.

expertise with phrases such as ’30 years of experience’ or ‘let our chef cook for you’. This implies they can produce a better finished product than the consumer, while referring to their expertise. For the garden sector, this could be changed to ‘our qualified gardeners have planted these for you’.

Some lazy cooks are also provided with meals in boxes, delivered to their doors with all the ingredients they need, in exact quantities and sometimes pre-chopped. Why not the garden sector?

Delegates of the recent International Garden Centre Congress in the Czech Republic were shown a similar concept using plant bowls in a box. They visited Zahradnictvi Libeznice Garden Centre (zahradnictvilibeznice.cz) situated on the northern border of Prague. This independent garden centre has an online shop that makes up 15 per cent of the company’s overall turnover – onethird hardware, one-third plants and one-third planted window boxes. With the plant bowl kits, customers selected their patio bowl arrangements and the kits were delivered to their homes.

They want it now and they want it provided without hassle.

The focus on specific garden shopper segments, I feel, often misses an opportunity. Yes, the millennial gardener, the eco gardener, and late bloomer coming into gardening as they retire, are markets that we should focus on, but one of the biggest opportunities is the lazy gardener. We often misread them as gardeners who do not have time to spend on their gardens, but there is money to be made by focusing on this category. This consumer is often a millennial, but can also be a Gen X consumer who wants an attractive garden and balcony. They want it now and they want it provided without hassle. These lazy gardeners are also targeted by other retailers. In the food sector, ready meals are one of the fastest growing areas, with a growth of around four per cent per year in most countries. Our job is to take a lesson from the ready-meal sector and adapt it to the garden sector.

The marketing used in the ready-meal industry could be easily adopted by the garden sector. Companies use marketing phrases like ‘don’t lift a finger’, ‘these meals are perfect’ and ‘heat and enjoy’, which could be easily transplanted to say ‘pretend you planted it yourself’, ‘these plant bowls are perfect for spring’, and ‘water and enjoy’. They have identified that time is an issue and relate to the consumer with ‘stop wasting time’. For garden centres, this could be adapted to, for example, ‘save six weeks of growing time’.

Suppliers of ready meals also promote their

Retailers have the opportunity to look at each category that they are selling in and identify a lazy gardener product combination in each – a combination that takes the hard work out of the task and provides a ready-made product. These products are generally less price-sensitive than individual products. As the customer is less likely to do a price comparison, these items can increase the overall gross profit of the category. Products within the edible garden and patio categories are ideal places to start.

Lazy gardeners will continue to be an important group of customers in the future, and it is a group we need to focus on now.

John Stanley is a retail business coach, consultant, speaker and author. His expertise is in customerfocused layout, merchandising, marketing and branding, and customer-focused selling and service. Visit his website at johnstanley.com.au.

Rapid innovation in machinery and computer technology have lowered barriers to entry within automation. New cutting-edge tools, from robots to artificial intelligence (AI), capable of complex tasks are increasingly available – and affordable. For greenhouse farming, however, discussions about automation tend to focus on robots and machinery, leaving little mention of stealth technologies that do important work behind the scenes.

A future where robots replace greenhouse workers is arguably premature and overlooks important greenhouse automation technologies on the market today. One noteworthy development is AI tools that serve as digital assistants, not replacements, for greenhouse workers. Contrary to popular thought, sophisticated smart software can now be trained on tasks in greenhouse farming using big data, which is a lot of digital information on daily greenhouse operations. It can include anything from records of your power consumption to digital photos of your crops. From this, we can train AI software to learn common, repetitive tasks, reinforcing the decision-making capacities of skilled employees. Rather than replace, these AI-automation tools empower and streamline daily operations.

Consider this: Using image data banks of

unseen and you don’t need an elaborate website to access the information. At its most basic form, you could receive the results in an email along the lines of “you will obtain X tomatoes this week” or “your kalanchoe will be ready for sale by date Y”.

We are just beginning to harness the full potential of AI. Gone will be the days of a guessand-check approach. Future AI tools will predict how yield and growth of ornamentals will change if a grower would alter, say, CO2 levels and supplemental lighting. By crunching millions of data points on unseen servers, emerging AI technologies show potential in flagging growing conditions that cause skin cracking and blemishes in produce. The secret to growing the perfect tomato or pepper may thus reside within smart software rather than at the fingertips of a robot.

With the growing availability of big data in greenhouse farming, automation enabled by AI will set new industry standards for efficiency. Expect advancements in areas ranging from fully automated grow protocols at the push of a button and better pricing of produce, to improved labour management and more efficient use of energy.

...automation enabled by AI will set new industry standards...

diseased and infested crops, smart software can learn patterns in spots, scars and insects on plants. You can take a photo of a diseased crop and obtain a diagnosis of the problem, along with a recommended treatment strategy. All the complex computations that automate disease diagnoses are on an unseen computer server far away.

Additional examples arise from your growing conditions. Using records of your heating, lighting, humidity and more, AI software can understand multiple factors that influence the growth of your greenhouse plants. Once known, smart software can analyze current growing conditions and make accurate predictions about the future productivity of your greenhouse, including harvest yields and flowering time, while reducing the time you devote to manual, repetitive plant assessments. Once again, the underlying computations remain

Technology titan Google reduced energy consumption by 40 per cent at one of their facilities once their AI software learned how best to operate cooling systems. This groundbreaking achievement required no major equipment or changes to the building’s infrastructure, just smart software able to predict ahead of time when a facility would heat up and by how much. Expect energy-saving innovations like this to become standard in diverse industries, including agriculture, and influence future policies for clean energy and greenhouse gas emissions. Though they may lack the shine and satisfying mechanical hum of machinery, unseen AI tools could play an important role in automating greenhouse cultivation. The time is now for growers to embrace this reality. Technological progress can soon improve many tried-and-true processes in the greenhouse – or make them obsolete.

Jason Behrmann, PhD, is the senior marketing communications manager at Motorleaf. He can be reached at jason.behrmann@motorleaf.com

What are biopesticides and biostimulants? By choosing the right products and applying them in the right situations, microbial bioproducts could be used to strengthen your biocontrol program.

BY DR. MICHAEL BROWNBRIDGE

As a grower, it’s important to think about ways in which your biocontrol programs can be strengthened. There is an increasing number of biopesticides and a staggering array of biostimulants available on the market. The trick is figuring out which of these materials to use, where and how to integrate them effectively and efficiently into the production system to benefit pest and disease management strategies, as well as meeting other production challenges. This article focuses on microbial bioproducts, and considers ways in which these materials can become valuable allies in crop production.

According to Agriculture and Agri-Food Canada, biopesticides are ‘pest management agents and chemicals derived from natural sources such as microorganisms, plants, animals and minerals.’ They are actively applied to manage pests, weeds or diseases, and because these claims are on the product label, efficacy data needs to be provided to the Pest Management Regulatory Agency (PMRA) as part of the registration process. Their unique modes of action help mitigate resistance, while being very safe for applicators, workers and the environment, and deliver to consumer/market demands around sustainability. Moreover, they are typically compatible with natural enemies, which makes them excellent companion products in biocontrol programs. Most have short REIs and PHIs, so they have minimal impact on routine crop management activities. In Canada, biopesticides fall into three groups:

• Non-conventional pest control products: includes plant extracts and oils, mineral oils, and other materials that are commonly available and known to have pesticidal effects, e.g. vinegar.

Among these groups, microbial biopesticides are probably the best known and most widely used. Predominantly based on bacteria, fungi and viruses, they contain living microorganisms so they have to be stored and applied in ways that preserve their viability. Several products contain microbes with the same or similar names, but that doesn’t mean they all have the same spectrum or level of activity. For example, BotaniGard (BioWorks Inc.), BioCeres (Anatis Bioprotection) and Velifer (BASF Corp.) all contain Beauveria bassiana as the active ingredient, but are based on three different isolates of the fungus. It’s important to select the right tool for the job and, depending on the disease or pest being targeted, ensure that they are directed to the site of infection or infestation.

Gliocladium catenulatum (active in Prestop) parasitizing a fungal strand of Rhizoctonia solani.

• Microbial: contain living microorganisms and associated metabolites (or by-products).

• Semiochemicals: cause a desired behavioural response in a target organism, e.g. insect sex pheromones or aggregation pheromones, which are used in monitoring traps.

Generally, biopesticides are applied as foliar sprays or to the substrate. They are functionally compatible with other biocontrol agents and often highly complementary. In chrysanthemums, for example, bioinsecticides such as BotaniGard are routinely used together with insect-parasitic nematodes and foliar and soil-dwelling predatory mites to control thrips. Good spray practices are critical to efficacy. Hydraulic sprayers, when used to apply fine spray mists rather than a heavy wet spray, can provide excellent coverage of upper and lower leaf surfaces. Automated low volume mist (LVM) sprayers like Dramm’s AutoFOG can also be used to apply bioinsecticides and will give similar levels of leaf coverage.

Microbial biopesticides for disease control can have several modes of action:

• Antagonism: metabolites produced by the growing

microbes will kill or inhibit growth of pathogenic microorganisms.

• Predation/parasitism: the microbe literally attacks or parasitizes the pathogen; fungi like Gliocladium (Prestop) and Trichoderma (RootShield) can do this.

• Competition: these organisms colonize the root surface, using plant root exudates as nutrients, and outcompete pathogens for living space and nutrients.

• Induced resistance: microbes produce molecules which activate a plant’s natural defences.

Biofungicides often have more than one mode of action which contributes to the control or suppression of diseases and may confer other plant benefits as they colonize the root surface. Some Trichoderma and Bacillus species/isolates, for example, also produce phytohormones which enhance root development, or form biofilms over the root surface, which enhance plant resilience to drought. In this respect, they also perform biostimulant functions.

The most recent addition to the biofungicide arsenal are materials that induce plant defense mechanisms. LifeGard (Certis USA), is a foliar-applied biological plant activator that triggers an induced resistance (IR) response in plants. Based on a naturally occurring bacterium,

Number of B. bassiana spores (BotaniGard 22WP) on the top and bottom leaf surfaces of chrysanthemum. Applied by hydraulic (Rittenhouse 200L with twin head, 4 hole (#45) swirl plate and D4 disks) or LVM (Dramm AutoFOG) sprayers.

Bacillus mycoides, the organism has no direct effect on plant pathogens. Rather, it activates or induces the plant’s innate defenses so that the plant protects itself against infection. It is not a curative treatment, but is applied to prevent disease development. Although it is not registered for greenhouse crops, this mode of action is probably representative of what we can expect in many next generation biofungicides and bioinsecticides.

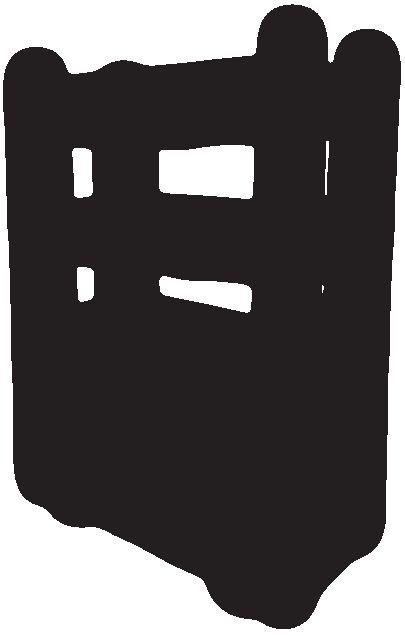

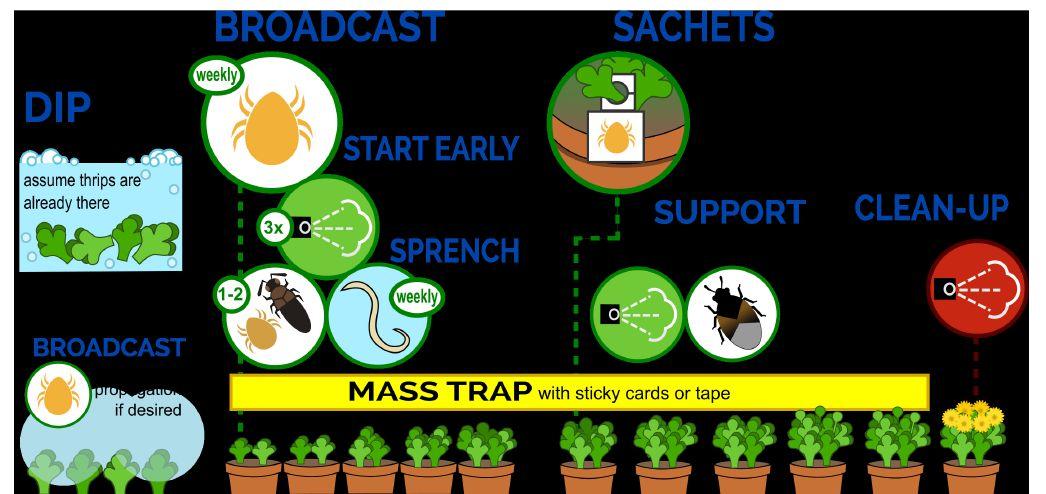

The value proposition presented by biopesticides in greenhouse production lies in their compatibility with other natural enemies. Applied at strategic points in a production cycle, they complement the activity of other biocontrol agents, allowing some crops to be managed ‘biologically’ from start to finish. Using chrysanthemums as an example (see infographic), a bioinsecticide dip can be used to clean up thrips on incoming

3.

Points at which biopesticides are often used in chrysanthemum production. Arrows indicate where applications are frequently made (light arrows = bioinsecticide dips or sprays; dark arrow = soil treatment with a biofungicide).

cuttings, a biofungicide can be applied to the growing medium to protect against soil-borne pathogens, and bioinsecticide sprays can support the bioprogram later in the growing cycle.

The term biostimulants incorporates a diverse group of product technologies and includes microbial inoculants, biochemical materials, amino acids, humic acids, fulvic acids, seaweed extracts and more. They are sold on the promise of bringing multiple benefits to the crop they are applied to. In a nutshell, they promise to improve overall plant health and resilience, which enhances productivity. They carry no claims around pest or disease control, so they are not regulated by the PMRA – yet.

There is a large number of products sold as ‘crop boosters’ or ‘enhancers’, so which do you choose? Particularly when you may not actually see significant and measurable benefits in what may be considered a normal growing year, or in hydroponic systems where plants are provided with all the nutrients they need. Also in many cases, the instructions for use are often vague or incomplete. Different biostimulants can induce different plant responses, and effects are influenced by the timing of application, plant species/cultivar, plant growth stage, soil or substrate type, management practices (inputs) and environmental factors. The benefits may only be observed when plants are under stress. Understanding the interactions between biostimulants, plants and the environment is essential to realizing the promise offered by these materials.

Field data obtained from multi-locational trials of microbial biostimulants provide insights to the potential value these products can bring to greenhouse horticulture. Synergro from Concentric Ag contains a consortium of microbes. Its use in the production of organic field tomatoes increased yields, and levels of nitrogen in tomato leaf tissue were higher in treated plants, suggesting that applications of the product may improve uptake or plant access to this critical macronutrient. In field-grown lettuce, use of the product resulted in a 4.5 per cent yield increase and a reduction in culls (i.e. more marketable produce) under standard

fertilization rates. The trial also showed how using this product enabled reductions in nitrogen inputs to be made without significantly compromising yield. This is significant for jurisdictions where there are strict regulations around nitrogen leaching and runoff; a slight reduction in yield may be an acceptable trade-off to conform to environmental regulations.

The plant growth promoting rhizobacterium (PGPR) Bacillus amyloliquefaciens strain IT45 (soon to be marketed in North America under a new trade name of “LALRISE Start Vitae-YE” [formerly Rhizocell]; Lallemand Plant Care) colonizes the rhizosphere (the area surrounding plant roots) using root exudates as nutrients. As bacterial communities develop on the root surface they secrete a mucilaginous coating, or biofilm, comprised of proteins, complex sugars (polysaccharides) and nucleic acids. The biofilm helps maintain the integrity of the bacterial communities on the roots, and also benefits the plant by providing a buffer against environmental stress factors and desiccation. Consequently, plants are better able to tolerate periods of water stress or drought. In addition, the bac-

terium solubilizes soil-bound phosphorous and chelates minerals such as iron, enabling better uptake. It also produces phytohormones that stimulate root development. The biostimulant has been tested in a wide variety of field crops; in all cases, there were yield benefits in the range of 6 to 10 per cent.

Although biostimulants may be used at different points in the production cycle to achieve different goals, a common outcome is more uniform crop development and enhanced yield. Essentially, these materials improve plant health and resilience, so plants invest less energy dealing with stressful conditions and additional energy can go into production. Clearly, we still have more questions than answers around the role biostimulants can play in greenhouse crops, but considering the significant benefits obtained in field crops, there is a tremendous opportunity to capture this potential in greenhouse production.

Michael Brownbridge, PhD, is the research director for horticultural production systems at Vineland Research and Innovation Centre. This work was funded in part by the Canadian Agricultural Partnership.

The two-spotted spider mite has known resistance to over 95 active ingredients.

BY DR. IAN SCOTT

Horticultural crops in Canada, although grown on a smaller acreage than field crops, are of increasing importance to the agricultural economy. Greenhouse tomato production in Ontario contributes over $354 million annually, but insect and spider mite pests reduce the yield of the tomato crop and are the target of many management programs.

Chemical pesticides have been the mainstay of pest management practices, but public perception and environmental concerns have led to restrictions and demands for safer products. One of the most problematic pests, the two-spotted spider mite (TSSM) Tetranychus urticae (Fig.1) is an economically important pest that feeds on more than 150 crops worldwide, including greenhouse tomato. TSSM is also at the top of the list of global pests that are resistant to pesticides, specifically acaricides, the chemical products developed to control spider mites. TSSM have known resistance to over 95 active ingredients.

Agriculture and Agri-Food Canada (AAFC) researchers have studied greenhouse TSSM

populations that growers have reported difficulty controlling with acaricides, aiming to confirm the presence of resistance or reduced susceptibility. The results of the surveys can provide the grower and industry with information to develop a resistance management strategy for the next season.

Acaricide resistance arises through natural selection of TSSM with resistance genes that enable them to survive the acaricide treatment and to pass this trait onto the next generation of mites. Together, heritable resistance traits and intensive, repeated acaricide applications have led to the fast increase of resistance in TSSM. Further applications of acaricides with the same mode of action will increase the selection for resistant mites, as the susceptible mites in the population decrease in number. With continuous selection pressure, the acaricide will become ineffective at the recommended application rate. The two main resistance mechanisms in spider mites are increased metabolism and target site

Choosing the right insecticide makes all the difference to your production and profitability. FMC has you covered, with three proven control products to protect your high-value crops.

Use Exirel® insecticide early to give cucumber, pepper, tomato and eggplant foliage the protection it needs during the most critical stage of development. Translaminar and locally systemic movement, plus rapid absorption ensures the product moves through the plant quickly to control cabbage looper, whiteflies, pepper maggot, pepper weevil1 and thrips1

Coragen® insecticide is a unique broad-spectrum, Group 28 active that controls pests resistant to other insecticides. It quickly stops insects feeding and delivers control at all growth stages. Protect your cucumbers, tomatoes, eggplant and pepper plants from cabbage looper and lepidoptera leafminers.

Beleaf® 50SG insecticide, a Group 29 product, targets piercing and sucking pests effectively. Protect your strawberries, cucumbers, peppers and tomatoes from thrip, aphid, lygus bug and whitefly feeding damage.

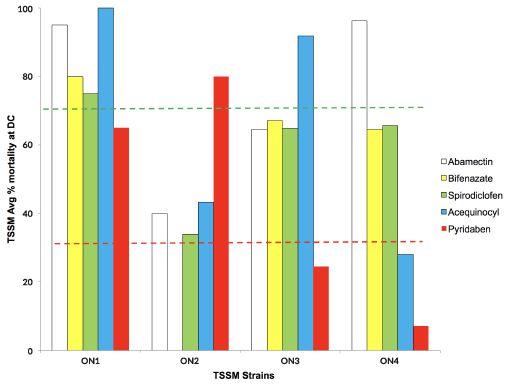

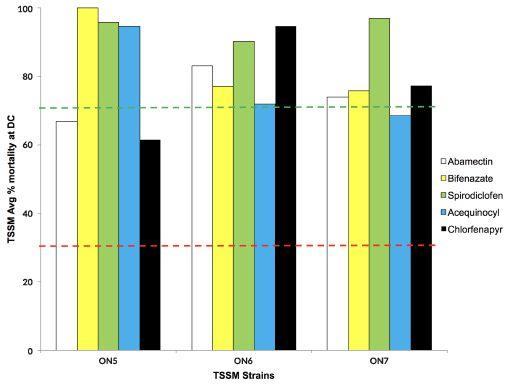

Figure 2. Mean per cent mortality of seven two-spotted spider mite (TSSM) greenhouse populations collected from Ontario greenhouses in 2011-13 (A) and 2016 (B) exposed to a diagnostic concentration (effective against 90 per cent of the population) for six registered acaricides. Mortality above the green dashed line indicates susceptibility, while mortality below the red dashed line indicates resistance to that product.

mutation. Metabolic resistance is the most common mechanism, and it occurs when internal enzymes in the resistant mites detoxify the acaricides faster than in susceptible mites. Resistant populations may possess enzymes at higher levels, in more efficient forms or with a broad spectrum of activity that can degrade many different acaricides. A gene mutation or gene substitution can lead to alterations at the acaricide target site in the mite. This modification can prevent the acaricide from binding, thereby reducing or eliminating the toxic effect of the acaricide.

The rate of resistance development depends on several factors, including how fast the pest reproduces, migration and host range of the pest, availability of nearby susceptible populations, persistence and specificity of the crop protection product, as well as the rate, timing and number of product applications made. Resistance increases faster in environments such as greenhouses where insects or mites reproduce quickly due to relatively stable temperatures and lighting, with no pressure from natural enemies unless biological controls are present. Greenhouses also provide an environment where there is little or no immigration of susceptible individuals. The term ‘pesticide treadmill’ is commonly applied to situations where continued applications over time cause pests to evolve resistance to the pesticide, and the resistant strain becomes increasingly difficult to control at the labeled rate and frequency. If growers respond with more frequent applications of the pesticide, both the intensity of resistance and the frequency of resistant individuals in the population increase. Problems of control continue to worsen as more product is applied. The overuse of acaricides can not only lead to resistance, but the increasing number of treatments will disrupt other components of the pest management program (ie. biological controls), leading to severe spider mite outbreaks.

Resistance management refers to preventative actions that reduce or slow the development of resistance. Two components of resistance management are the use of economic thresholds and integrated pest management (IPM) strategies. Growers are always encouraged to consult their crop advisors about the economic

thresholds of each target pest prior to spraying pesticides. For example, acaricides should be used only if mites are numerous enough to cause economic losses that exceed the costs of the application. Exceptions would be the use of preventative treatments (ie. Dichlorvos/DDVP for cleanup at the end of the season) for early/late season pests that will usually reach damaging levels as soon as a new crop is started. Applications of acaricides must be timed correctly, typically before populations of TSSM are out of control. The use of spray rates and application intervals recommended by the manufacturer, and in compliance with local agricultural extension regulations, is essential. Apply acaricides carefully, as the margin for error in terms of dose, timing, coverage, etc., takes on even greater significance as resistance increases.

A key element of effective resistance management is the use of alternations, rotations, or sequences of different acaricide classes with different modes of action (MoA). Resistance or cross-resistance could result from repeated use of products with the same chemistry or of related products in the same MoA class, either within the crop cycle or year after year. Cross-resistance is the discovery of resistance to one pesticide in a pest population that had no previous exposure to it, except that the population was already resistant to a second product with the same MoA. There are several classes of acaricides registered in Canada and recommended for use on spider mites in greenhouse tomatoes. A few of these products have been registered for many years, including abamectin and pyridaben (over 20 years), bifenazate, spirodiclofen and acequinocyl (over 10 years), whereas chlorfenapyr and etoxazole were registered within the past five years.

Over the past six years, surveys of acaricide susceptibility by AAFC researchers in Ontario greenhouses have indicated that the overuse of the same product, or a related product, were responsible for observed reductions in acaricide susceptibility. For example, where no or few products were applied, bioassays with registered acaricides indicated that TSSM populations remained susceptible to all or most products tested (ON1 and

ON3 populations in Fig. 2A). In contrast, in greenhouses that used mainly one or few alternate products repeatedly, more instances of reduced susceptibility or resistance were observed (ON2 and ON4 populations in Fig. 2A). There were also incidences where resistance occurred with products not previously applied in the greenhouse; these were cases where cross-resistance was suspected. Fewer incidences of reduced susceptibility or resistance to acaricides were observed in greenhouses where alternations or products from two or more classes were applied, or spot spraying of mite outbreaks was used (ON5, ON6 and ON7 populations in Fig. 2B). Caution should be taken by growers in selecting and using acaricides and implementing a resistance management plan.

IPM is the incorporation of as many different control strategies as possible, including synthetic pesticides, biopesticides, beneficial insects (predators/parasites), cultural practices, transgenic plants (where allowed), crop rotations, pestresistant crop varieties and chemical at-

tractants or deterrents. TSSM can be controlled biologically by the predatory mite, Phytoseiulus persimilis. Other predatory mites used against TSSM include strains that are tolerant to high temperatures or pesticides. For example, the predatory mite Amblyseius californicus can reportedly better tolerate dry conditions, while A. fallacis is resistant to some pesticides. Amblyseius andersoni is another predatory mite that has a wide range of temperature tolerances. Many Ontario growers have had good success with these predators.

In sum, acaricide resistance is a growing concern for greenhouse tomato growers who are dependent on foliar acaricide treatments for TSSM control. This reliance has led to resistance in an increasing number of TSSM populations. Timely use of bioassays to detect reduced susceptibility or resistance is an important part of a resistance management program, and the development of molecular diagnostic tools would improve the speed of resistance detection. Other solutions to combat mites are the focus of current research at Western University in London, Ontario. Researchers are developing novel strategies for TSSM control based

on genomic and metabolomic platforms. The two-fold approach is to identify new biopesticides from: 1) plant-produced defense metabolites that decrease mite performance and 2) candidate genes that can be targeted by RNA interference (RNAi) for development of next generation RNA-based pesticides. There is a critical need for the development of new and sustainable TSSM control measures, ones with different modes of action relative to existing pesticides, with specificity for TSSM and without impact on beneficial predators and the environment.

Acknowledgements: AAFC gratefully appreciates acaricide samples provided by Arysta LifeScience Canada Inc., BASF Canada, Bayer CropScience Canada Inc., Corteva Agriscience, Gowan Canada and Syngenta Crop Protection Canada Inc. and greenhouse spider mite collections by staff from the Ontario Ministry of Agriculture, Food and Rural Affairs in Harrow, Ontario. Thank you to Dr. V. Zhurov, Western University, and S. Krolikowski, AAFC London, for editorial assistance.

Ian Scott, PhD, is a research scientist at Agriculture and Agri-Food Canada. He can be reached at ian.scott2@canada.ca.

We’re proud to finance the people, the dreams, and the future of Canadian agriculture. Here’s to Canadian Agriculture. Here’s to you.

With trends in food gardening, the edible plants category attracted consumer and culinary attention at the University of Guelph’s Vineland container trials in 2018.

BY RODGER TSCHANZ

BELOW

Each year, a few vegetables are entered into the University of Guelph’s Vineland container trials as candidates for vegetables in small urban spaces. This edible plant category attracted attention at the trials, not only from the public, but from culinary professionals as well. Here are some of the highlights from this past season.

The 2018 trial was the first time that Proven Winners submitted edibles for trialing purposes. Amongst the submissions were basil and tomatoes. The two tomato entries from PW originated from a tomato breeding program at the University of Florida, with the goal of replicating the flavour of an heirloom tomato. Garden Gem produced large quantities of small, snack-sized fleshy tomatoes; many of the fruit had a pointed end. One plant growing in a 16-inch container produced 557 fruit before the trial season ended in early September. The growth habit is semi-determinate, and while it is possible to grow this plant in a container, it will develop into a large plant needing support of some kind. The second tomato in the series is Garden Treasure. The fruit is considered to be mid-sized and the growth habit of the plant is indeterminate. Like Garden Gem, it will need support in both ground beds and containers. The 16-inch container trial in Vineland produced 130 fruit per plant by the first week of September. Both Garden Gem and Garden Treasure were selected for tolerance for growing in hot, humid conditions, disease tolerance and having an heirloom taste. Informal

tasting sessions by visitors to the trial garden elicited very favourable comments.

The Italian sweet basil, Amazel, proved to be both prolific and disease tolerant as well, growing well into September without disease issues such as downy mildew. We didn’t do a yield trial on this plant which would have required us to continually cut the plant back before it produced flowers. As with most basil selections, once the plant blooms, the fragrant foliage becomes somewhat bitter to the taste; the best flavoured leaves came from the fresh tender shoots. That said, the unpruned plants in our 2018 ground bed trials reached heights of 79 cm and a spread of 110 cm, producing a welcome fragrance in the garden.

Primero Red is a new habanero pepper that has relatively mild and flavourful flesh. (Note: the seeds and midrib are still extremely spicy). The plant habit is upright, compact and suitable for containers. One 16-inch container planted with three plants in the Vineland trial produced 536 peppers by mid-September. Hospitality services at the University of Guelph used this pepper to produce a very flavourable hot sauce for use on campus. When covered in ripe fruit, this plant is quite attractive. At the 2018 Royal Agricultural Winter Fair in Toronto, pots of Primero Red from the summer trial were used for display purposes.

Snackabelle Red is a small, attractive bite-sized bell pepper with good sweetness and a tougher skin than most normal-sized bell peppers. This is another excellent choice for container growing.

Butterbaby is a small butternut squash with fruit length ranging from 7-18 cm with an average weight of 300400 g depending upon harvest location. The individual squash fruits are single/ double-serving sized. The executive chef on the University of Guelph campus described the flesh colour after cooking as being quite sweet with a nice yellow colour, making it attractive for plated meals. This plant’s habit is quite vigorous and is therefore not the best for container growing but it can be done; especially with trellis support for the vines. In our 16-inch container trials, three plants produced 27 mature fruit and 38 immature fruit by the time the trial was terminated in early September.

CONSUMERS ARE HUNGRY FOR EDIBLES

Overall, characteristics such as high yields,

ornamental/edible dual purposes, container friendliness, unique and desirable flavours and disease tolerance were all in demand by visitors to the garden trials.

Container vegetables can be very easily marketed, especially when they contain great flavour, have good fruit size, and display disease tolerance for the most part. Small fruit functions as ready-made single portion sizes and can produce an attractive display either by being left on the plant or in culinary preparations.

To help consumers succeed though,

other supportive items may need to be available at garden centres. Tomatoes may need a cage or the squash may need a trellis system. Mesh or repellents may be needed to deter wildlife such as rabbits, deer or squirrels. Garden centres should have items like these on hand, as well as trained staff in place, to ensure the customer has everything they need to start.

Rodger Tschanz is the trial garden manager at the University of Guelph. He can be reached at rtschanz@uoguelph.ca

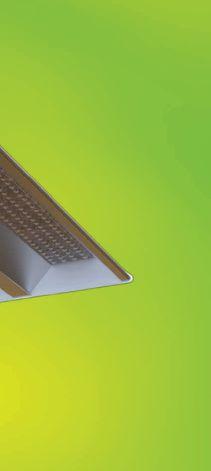

3,100+ μmol/sec/sq ft

ture h ECGGL L LED ly active radiation) lField es and

Engineered using the science of nature, the ECGL LED that under-deliver PAR (photosynthetically active radiation). Increase yields utilizing our proven PPFD FullField™ Coverage. provide proven 15% greater yield, shorter ripening times and under two years. EcoGROW Technology gives you more, so you get more.

ALSO AVAILABLE FROM

ECG Full Spectrum LED Grow Light Powered with EcoGROW Technology and featuring an optional mounting frame precisely engineered for optional integrated winch system allowing easy height adjustments to accommodate plant growth.

Dinner guests dine on local food and drink at a Petals & Plates dinner hosted by Rosa Flora in Dunnville, Ontario.

What could be better than savouring smoked lake trout in cracked mustard dressing at a table surrounded by row upon row of deep pink and warm orange gerberas? Add a lounge singer, a bar full of local drinks, enthusiastic company and flower crowns; you have a night to remember.

“It’s kind of like going to a wedding, except nobody gets married,” says Dejan Kristan describing Petals & Plates, a series of dinner events that highlight Canadian flower growers. Kristan, marketing director of Flowers Canada (Ontario) (FCO), says when he and marketing coordinator Jess Gough started their roles, their brainstorming led them toward experiential marketing – and eventually Petals & Plates.

Kristan says it seemed like the logical choice over advertisements, billboards and other similar marketing avenues. “With the younger generation, millennials specifically, it’s all about experiences [...] and flowers are all about how they make you feel,” says Kristan. “You’re buying a feeling.”

An experience is right. Starting with a cocktail reception and live music, guests are invited to make their own flower crowns as demonstrated by a local florist. The evening continues with a tour of the greenhouse, where guests are encouraged to ask any questions they have about

the industry. Finally, the evening is concluded by a four-course dinner and introductions from the chef.

The first Petals & Plates was held at Rosa Flora in September 2017, with three others since then at CosMic Plants in Lincoln, Van Geest Bros in St. Catharines and Creekside Growers in Delhi. While the event is attended by people of all ages, they are starting to see more interest from the younger generations, which Kristan says is a great sign as the industry continues to develop the next generation’s relationship with flowers.

“There’s a lot of gardeners, there’s a lot of flower lovers in the older generation,” he says. “But part of the fear is the newer generation, the millennial generation; they don’t have the same relationship with flowers.” Petals & Plates is one way to get people looking at flowers in a new light.

For example, there’s the flower crown bar during the event. “It’s not your classic flower crown that you’re thinking of that has 100 flowers and maybe some fruit in it,” says Kristan. “These are very subdued.” People are keen to wear them as fashion accessories.

Demonstrating the relevancy of floriculture is not the only goal of Petals & Plates, however. “There’s a

The Petals & Plates dinner series demonstrates what the flower industry brings –delightful experiences.

BY KAITLIN PACKER

lot of misconceptions with the industry,” says Kristan. By inviting people to see how flowers are grown and brought to the marketplace, Petals & Plates provides a venue for greenhouse operators to clarify misconceptions and instill pride in the industry. “Allowing people to come see what goes on in these greenhouses goes a long way to dispelling those rumours,” he says.

According to Ed Vermolen, sales manager at Aldershot Greenhouses and volunteer member of the FCO marketing committee, Petals & Plates is the perfect opportunity to be a passionate flower ambassador. “With folks I meet, I will ask them, when was the last time you got or bought flowers, what were they and why [and] how did that make you feel,” says Vermolen, who had a hand in developing Petals & Plates. “When you tie those together, they get it.”

He hopes the event will highlight how flowers and plants contribute to daily life by enhancing it, improving the work environment, adding to people’s creativity and energy, as well as minimizing stress. Besides how they make you feel, flowers are also an effective communication tool. “Flowers exude happiness, joy, offer condolences, congratulations, say I love you, and say I’m sorry,” says Vermolen.

Petals & Plates not only shines light on the flower industry, but it also brings other aspects of agriculture to the table, so to speak. By partnering with other agricultural commodities, the event is able to include food that is supplied from local sources. “We want to showcase the freshness and variety of all Ontario agricultural products,” says Gough. Even the bar is stocked with local flavours.

There’s perhaps no one who brings out these flavours more than Jan-Willem Stulp – or simply “Chef” as the event organizers call him. Stulp, executive chef at Grand Oak Culinary Market in Vineland, has worked with FCO from the outset on this event. With over 20 years of experience as a chef, Stulp sees the importance of giving people a dining experience.

While he’s been part of the collaboration process to develop the concept of the event, one of his main tasks is creating the menus. Given the venue, there are many specific considerations that need to be made beforehand. “It needs to be classy enough to be memorable, but we have to execute the menu out of a loading

dock,” he says. “So it takes some prethought, and lots of ingenuity and flexibility.” The challenge is also what makes it fun and unique, he adds.

With the chef present, guests get a behind-the-scenes glimpse at the culinary process. Stulp introduces each course, sharing some background behind the food on the menu and how each dish is made.

The chef sees gourmet food as simply another way to bring floriculture to light. “The core of most meals is built around plant-based materials: vegetables, starches, salads and even wine,” he says. “Many foods, especially fruit, are the result of floral success.” According to Stulp, it’s also not uncommon for flowers to be part of a meal. This is evident in his past menus that have included items such as organic baby greens with floral petals as a starter or lavender and wild ginger syrup on baked apple and quince ‘tatin’ for dessert.

The event itself is a reflection of another growing trend in agricultural advocacy. According to Gough, it’s becoming more prevalent for farmers to pursue transparency and industry support by inviting the public to come and see their operations firsthand.

The results? Other than increased awareness for the industry, Vermolen says some guests at the Rosa Flora dinner were able to see a production greenhouse for the first time. “When they saw the gerbera house, it was like a magical moment,” he says. “They were so happy they were speechless.”

The event is also good bang for the buck. Kristan says he’s asked guests whether they think they’re getting a good return on their ticket. “A lot of them say, ‘If we were just to get a four-course meal in downtown Toronto, we would probably be paying more than we are here,’” he says. With ticket prices averaging out around $100, it’s a small price to pay for a full evening event that includes a fourcourse meal.

It’s not just the guests who have such a positive experience at these dinner events. Since growers are accustomed to seeing their greenhouses every day, Kristan says the event allows them to see 200 metres of blooming gerberas through the eyes of someone who’s never seen that before.

Petals & Plates dinner arrangement at CosMic Plants in Lincoln, Ontario.

Gough agrees that it gives the growers a boost. “They love seeing the smiles, the amazed faces on the guests when they walk in and see the product of all their hard work,” she says.

Arielle DeBoer, co-owner of Rosa Flora with her husband Ralph DeBoer and brother Josh Bulk, says they jumped at participating in the first dinner event because they saw it as a great opportunity to promote their business and the industry. While it takes coordination to make sure the dinner is hosted during a time that would showcase the flowers and work within the schedule of the greenhouse operation, it’s worth the effort. “I personally felt that people appreciated the whole event as well as us as a business,” says DeBoer, who is hosting their second Petals & Plates dinner in early March.

Given the success of the dinner series in the past year, there’s another dinner planned at Waldan Gardens in late March –with plans for more. FCO is also discussing the possibility of taking the event to a national level, starting in British Columbia.

As Kristan says, loving flowers is not a requirement for enjoying this event. Petals & Plates is a fun event with something for everyone. That said, he’s never met anyone who says they don’t like flowers.

“People are better with flowers,” says Vermolen, “in the garden, in the house, in their life.”

Attracting new customers who seek to grow their own food is different from selling to familiar customers.

BY SHELLEY LEVIS

As garden centre owners and seasonal edible grow ers, our window to capitalize on sales is limited to just a few short months each year. But, it doesn’t have to be. With the proper products and a little marketing, you can triple your edible sales and in crease repeat customer traffic throughout the year.

I wear a lot of hats in the nursery industry, from buyer to manager to garden writer. My experience has taught me that just carrying edible plants isn’t enough to encourage year-round sales. Once the peak spring season is over, we are limited to a small bump of edible sales in late summer through our fall transplants, and from there it takes a nose dive until the following year.

Developing a marketing strategy, incorporat ing inspiring displays and stocking easy-to-use

TOP: Add colour to the vegetable department with props and products.

BOTTOM: Visually show customers how vegetables can be grown in their gardens.

Greater certainty for the biological control of spider mite with Spical Ulti-Mite. This 100% industrial compostable sachet always performs consistently, under any climatic circumstances. Compared to regular sachets Ulti-Mite Spical performs up to three times better.

Reinforced hook

Low and high humidity resistant

3 times greater emergence of mites

Optimum breeding conditions

100% industrial compostable

An eye-catching red band makes it easy to find in the crop ww w.koppert .ca

vegetables encourages customers to shop in an otherwise completely green department. Use creative displays that signal ‘homegrown’ and ‘organic’ to further inspire first-timers to try their hand at growing their own food.

Understand the wide range of customers you are trying to appeal to. Don’t just gear your displays toward experienced gardeners. Think of the middle-aged fellow who prides himself as the king of the BBQ and loves to grow hot peppers for his famous BBQ sauce. Or a young mother who is trying to find a wholesome hobby to enjoy with her family. By visiting your edibles department, she could pick out some easy-to-grow vegetables that she can plant with her kids.

This past year, I decided to renovate an area just behind the annual greenhouse and created four small-space garden designs. This zone had previously been shut off to the public and was literally a dumping zone for fixtures and pallets that needed to be hidden from view. There isn’t a nursery on the planet that doesn’t have an area like this. How can you turn an otherwise useless space into something that sells your products?

To see vegetable plants growing in a realistic garden setting allowed customers to visualize how they could incorporate this into their own gardens. It also became an area where we could hold seminars, park extra plant carts during the peak season and showcase other products like raised planter boxes, garden stakes and trellises.

Educating customers with living displays resulted in higher sales and repeat visits. Marketing in our industry is not just about selling plants, it’s about selling an experience. Our customers can easily buy vegetables from a grocery store and not get their hands dirty. What they

1. Target customers in the 25-45 age range to include professionals, foodies, youth and household decision makers by promoting the benefits of growing their own food.

2. Create dynamic displays that inspire your customers to grow. Make them ‘Instagram’ worthy.

3. Don’t just talk to customers about gardening with edibles, show them.

4. Get online and get social.

ABOVE:

Encourage year-round growing with the right products and information on how to use them.

desire when they purchase edible plants is the feeling they get when they are the creators of their own food.

Later in the season, when a customer came to us seeking answers about why their zucchini plant was all flower and no fruit, we were able to walk them to our display gardens and educate them visually about the difference between a male and a female flower. The gardens were planted again for fall harvest, giving us a minimum of three seasons to promote edibles.

In the writing of my book Countertop Gardens, I focused on indoor growing devices and various companion products, many of which were offered at the independent garden centre I manage. Over the course of a year, I tested these products and shared the findings in my book, complete with photographs and step-by-step instructions. Currently displayed in our edibles and growing department alongside our seeds, devices and growing media, the book serves as a good reference for both staff and customers. The staff use it daily as a manual and how-to instructional guide when working with customers to find products best suited for their growing needs.

If you are going to carry supplies that encourage growing indoors and gardening throughout the year, then be sure to provide instructions on how to use them. Simplify the fertilizers, growing media and various growing trays and domes to just a few that remain on display year-round.

As buyers for our stores, it’s easy to get carried away with all the latest products on the market, however, this can actually kill sales if we overwhelm the customer with too many choices.

The emerging trend for the home gardener is hydroponics. This form of gardening is mostly foreign to retail garden centres since we focus most of our products around containers or garden beds when it comes to edibles. To help the customer, I explored this growing method in my book and trialed products that are simple to use for the beginner. While this category brings with it a whole new kettle of fish, we can choose to carry some simplified products and fertilizers. Easy options can assist customers looking to get started in hydroponic growing.

In an effort to increase sales yearround, continuous marketing of growing media, seeds and various devices need to go beyond our peak months. Holidays and special occasions are great times to help customers see the potential of these products as gifts. Have a tray growing microgreens at all times and a mason jar with sprouts on the go parked beside your year-round seed rack. Then post it on Facebook and Instagram, feature it in newsletters and promote instore sales with full-colour graphics.

Once customers come to identify your garden centre as the go-to for growing products all year long, they will choose to shop at your store over big box centres that pack up gardening merchandise to make room for the next big season.

Shelley Levis is a horticulturalist, speaker, garden writer and foodie in Langley, BC. Her book, Countertop Gardens is available internationally in Australia, the UK, and North America. Visit Amazon or email Kristina at kkoski@ mandagroup.com for wholesale inquiries. For more from Shelly, visit sowanddipity.com.

Since 1963 we have been providing high quality insurance protection to our clients from coast to coast.

How was the 2018 poinsettia season? Not bad. Here’s a recap of pests and diseases, new varieties trialled with and without blackout curtains, as well as tips for 2019 production.

BY MELHEM SAWAYA

This is the first time in 12 years that I have been called to see if any growers have poinsettias for sale. I had to look hard to find some that fit the requirements. It was great that production quantities were matching, or were slightly under sales.

This year had great weather for poinsettia sales and shipping. Light snow, no frozen loads, and no blizzards to keep shoppers away. The slow start was only for outlets who put out poinsettias before Remembrance Day. As I’ve mentioned in previous years, poinsettias are for Christmas, and any push to try selling them early is a recipe for sales shrinkage. Early

ABOVE

Steve

products that hit stores, but do not move, start to look bad. When the consumer is ready to buy, all they find are poinsettia that are dead or far from fresh. Timing is everything, and no, we do not need snow to sell poinsettias. 70 per cent of the poinsettias grown are sold in regions that never get snow.

75 per cent of the poinsettia crop that was grown in Ontario was sold in Ontario this past year. The low Canadian dollar helped move a higher percentage. As in past years, because growers and buyers establish their programs six to 12 months ahead, last-minute or spot buying is almost nonexistent. Buyers for large chains need to have consistent suppliers for

more than one product. That is why spot buying is the last choice for buyers. A buyer managing over 100 stores does not want to deal with too many suppliers. This is positive because pre-arranged programs will prevent price cutting, and both grower and buyer will know what they are getting into right from the start.

The cost of shipping has gone up in the last few years by 30 per cent even with low fuel costs. Labour is also up, along with input costs of plant material because of shipping and the low Canadian dollar. All plant material is sold in US dollars and shipped from the States, so for a Canadian grower who sells their product in Canada, their cost per 6” is up by a minimum of 50 cents, not including the increase in delivery costs. This triggered cooperation between growers to grow product for stores closer to their area, and buyers to find suppliers close to their stores. Calculating costs does and should include every aspect of growing and selling the crop. I do not know of any growers who grow poinsettias as a hobby, without wanting to make some profit. Cooperation between the grower, broker and retailer is a winwin situation for every party, and at the same time, creates a product that provides value to the consumer.

There are relatively newer sizes for more successful production, and they give consumers a better chance at having longer-lasting plants. Pot sizes of 2”, 5” or 7” should have one plant per pot, while 10” pots should have three plants each.

Too many cuttings per pot makes an inferior product for the consumer. Because the plant is crowded and the ratio of roots to soil is too high, that shrinks the shelf life of the poinsettia or any other plant in store and at home.

The consumer appetite is for smaller poinsettias, not only for the price point, but also the size of living quarters. The largest optimum pot size is 10” with only three cuttings, which can be placed into a 12” pot for looks, and is more practical for growing, shipping, shelf life and most importantly, the consumer.

Upgrading the plants with some holiday picks and ornaments, and as long as it is not overdone, will increase the plant’s value without hurting the plants.

The size of new varieties in a 6” pot is much larger and has many more blooms, which makes it necessary to use a 7” pot. This could be sold at a higher price than

An example of one cutting that is too big for a 6” pot, but perfect in a 7”.

the 6” since the 7” holds more volume and is much better for the consumer.

I know it is hard to change from the old traditional sizes, but by working with your buyer and advertising the benefits, you will be ahead of the curve in providing a much better product.

With different poinsettia varieties, different production schedules are needed for different sizes. By following these sizes, plants are produced for maximum potential at the most economical cost.

Most of the stock producers are doing a better job every year, with good quality cuttings and being fairly pest-free depending on the source. Whiteflies were almost negligible in some greenhouses while it was a losing battle in others. The main difference was the source of the cutting material and whether biologicals or chemicals were used. The hot, dry summer also helped to limit the field whitefly, and even the tomato fields had much fewer whiteflies than normal. But this same weather enhanced the flourishing of spider and Lewis mites, especially with greenhouses that were using biological control. Normally, mites are not a serious problem in poinsettia production and predators that control whiteflies do not work on spider mites. But all in all, a much better year for pests.

The most effective control seems to be a combination of biologicals at the beginning, then finishing with chemicals. But if the quest is for chemical-free

greenhouses, biological producers have to come up with beneficial predators that can clean the last of the whiteflies at a reasonable cost.

This was the best and worst year ever for rooting poinsettia cuttings, depending on the condition of the cuttings that arrived at the growers’. Good cuttings that arrived on time and of much healthier stock plants were more successful. Also, the much improved skill of detailoriented propagators came up with the best procedures for healthy, strong-rooted cuttings, especially the rooting stations.

• Bracts of the same variety are larger with fewer growth regulators (rates and frequency).

• Under the same treatments, including same air temperature, plants under curtains were more advanced by an average of 12 days because the bract temperature was two to four degrees warmer than the air. Where there was no curtain, air temperature was very close to bract temperatures. This was evident in the poinsettia trials at Jeffrey’s. What we can learn from this is, if we want to grow the same variety for different ship dates, all we have to do is have a differential of two degrees between the two ship dates through the crop’s short-day time and you end up with 10 to 12 days’ difference in finish dates.

• Fall is always cloudy in Ontario, but this year we didn’t see the sun for very

USA Office: 125 Chenoweth Ln. · Louisville, KY 40207 Phone (502) 895-0807 · Fax (502) 895-3934 · maryv@jelitto.com

German Headquarters: P.O. Box 1264 · D-29685 Schwarmstedt Fax 01149-5071-9829-27 · www.jelitto.com · info@jelitto.com

long stretches. Growers who lowered the temperature during the day ended up with a sturdier and stronger crop. There’s no use in having high temperatures on cloudy days because the plants will benefit positively from higher temperatures only when the light levels are higher.

• Very little shrinkage.

• Whitefly pressure only on varieties where the cuttings producer had a problem with whiteflies.

• Negligible disease pressure even though most of the growers do not practice preventative fungicide drenches; instead they practice preventative cultural practices.

• With the new varieties, we never see bract edge burn which used to be a big problem with the old breeding.

• Proper scheduling and proper cultural practices; Botrytis almost does not exist.

• New varieties do not need extra molybdenum; most growers use regular fertilizers without the addition of molybdenum, with no symptoms of deficiencies in the last 10 to 12 years.

• Most importantly, there was very little or no shrinkage.

• The best crops were the ones where all aspects of growing were done on time.

• When growing crops, 15 per cent is knowledge, 15 per cent is knowing how to apply this knowledge and 70 per cent is doing everything on time.

Few new poinsettia varieties are being produced for 2019. Repeating the same advice: try new varieties, then decide whether to include them in your program or not, and remember to drop

Whiteflies shown at all stages, few but some varieties looked like this at shipping time.

your least desirable variety. Some varieties looked promising at the trial this past November. Over 150 varieties were tried –some were new, while others were introduced two to four years ago but not adopted much in greenhouse production programs. Anyone interested in the list and photos of poinsettia varieties from the trials, send me an email and we will get them to you. Varieties that are good for 5” are not necessarily good for 10”, or at least you need to modify the production schedule drastically to use the same variety for every size. Read the variety specs and try them in the newer sizes.

Red poinsettias make up at least 93 per cent of the total colours, with 4 per cent white, 2 per cent pink and 1 per cent miscellaneous.

Regardless of which variety you grow, make sure that when filling pots with planting media, the media is not flush with the pot rim. This is to give the stores and home owners a reservoir to be able to water the plants more effectively.

Insects – The whitefly is the main pest in poinsettia, but with increased use of targeted biological control, other insects are popping up like echino thrips and spider mites. And for the first time, we have seen mealy bugs on a couple cultivars that came with the cuttings. Greenhouses with cuttings from clean stock producers ended up with minimal whitefly problems. The problem was severe for growers with stock from a producer that was not clean, independent of whether biocontrol, chemical control or a hybrid was used by the greenhouse grower.

Diseases – With great weather, great cultivars and attention paid to cultural practices, diseases were not an issue this year. There were no problems at all, even without the use of any fungicides, biological or chemical.

The only exception was that some cuttings got infected with Erwinia at propagation time, but this was due to shipment delays or heating during shipping.

Physiological disorders – Heat delays in a couple spots because of heat valve malfunctioning, and another location where one light bulb in a side walk kept a 50-foot circle green, but was shipped just before Christmas.

ABOVE

Comparing Christmas Beauty North Pole finished under blackout curtains [top] and without curtains [bottom].

IN SUMMARY

• Grow varieties that you are familiar with and try new ones on a small scale.

• Calculate your costs for any required specs and do not forget about packaging and shipping.

• Take an order when there is still some profit margin and not just dollar sales.

• Never grow on pure speculation.

• Running out of plants at the end of the season and needing to buy some – that is when you are starting to make headway profit-wise.

• Do not cheat on what the crop needs to grow properly; it will cost you much more in the end if you do.

• Start a study group with the growers in your vicinity. Three years ago a study group of growers and educators met once a month starting in June to discuss production issues, but mainly concentrated on whitefly control for this season. The study group met in different greenhouse operations and toured the host growers’ crop in a very informal and beneficial way. Next season we are going to do the same thing and try to include more topics other than just whitefly control.

• If the same conditions occur again next year, then growing poinsettias could be profitable.

T: (519) 429-3966 • F: (519) 428-3327

CLASSIFIED RATES: Minimum order $75.00 or 84¢ per word, word ads must be pre-paid. CLASSIFIED DISPLAYS: $72.00 per column inch. GENERAL INFORMATION: Payment must accom- pany order. Copy required on publication close date. All advertising copy subject to the approval of the publisher. Send order and remittance to: Classified Dept., Greenhouse Canada, P.O. Box 530, Donly Dr. S., Simcoe, ON N3Y 4N5 Canada

Cleaver Brooks Boilers 100 HP each in very good condition, with heat exchanger, chimneys, full service records $4500 each or both for $8500. Pickup in Vineland.

Spring Carts SPECIAL!

22x59 with 3 shelves NEW $275 Cdn

24x67 Carts with 3 shelves $315

Lightly Used VRE 42×44 base & 2 shelves $245

Spring Cart RENTALS!

New and Used Carts Available Cart Tuggers and Pallet Lifts

Javo Potting Machine - $2350 Heaters, Sprayers, Generators

Call NIAGARA GREENHOUSE EQUIPMENT 905-329-9409 02/1t/pd

In last month’s Inside View, we looked at the most pressing critical issues affecting the greenhouse sector. The catastrophic effects of the ruptured gas pipeline in northern BC, continuing effects of the shift of the glasshouse landscape as it accommodates legal recreational cannabis production, labour availability, recruiting and costs, construction and planning bottlenecks, and the perennial topics of politics, globalization and international pests. We didn’t look at the changes to drivers’ time regulations in the US and how that is affecting deliveries across the border, or a host of other issues, but it can’t all be bad news. In these interesting times, there must surely be some silver linings among the clouds.

Carbon tax: How on earth can this be a silver lining? In essence, it depends on where you live really. The disparity of tax rates to date in the provinces across Canada has seen something of a little evening out recently, but this is a complicated issue. It may be good news if you run your business in areas where you were previously considered to be somewhat disadvantaged. So, it depends on your perspective I guess.

Recruiting: Wasn’t this mentioned as a major challenge in the previous Inside View? Well, if you’re young and starting out on your horticultural journey, opportunities for new entrants to see

Adding to the range of plant species are the ‘new’ growing systems and opportunities abound. Urban agriculture, for example, is offering new opportunities, both in terms of method and location, for those wanting to produce food. Rooftops, warehouses, converted shipping containers, and even right-instore entrepreneurs with countless new avenues to explore. Indeed, with this comes many new methods of growing, marketing and distributing food and floriculture crops.

Retail trends: Who knows where we’ll be in just a few years’ time with regards to how we sell our products? Already, your ‘smart fridge’ can order more tomatoes and lettuce for you before you run out, and you can order groceries ‘virtually’ on your way home from work to have them delivered to your house as you get there. How will this affect how we predict what and how much we grow and how we sell it?

Globalization: We often see this as a threat from the viewpoints of competition and the rapid spread of pest and disease organisms, but as we see huge new areas of greenhouses going up in Eastern Europe, Russia, China… well, the opportunities for export of expertise and supplies, and new career openings, create a sense of ‘kid in a candy store’ for those willing and able to grasp these chances.

“...what new crops will we be growing in another decade’s time?”

horticulture as a rewarding career choice have never been higher, given the number of job postings seen at trade shows, in the classifieds and coming to jobs boards at schools like KPU. Job openings are diverse, interesting and available in all kinds of new disciplines (urban agriculture, high-tech growing, cannabis to name just three), and the sheer quantity is bewildering. It has to be an exciting time to start a career in horticulture. New crops, systems: Take a look at the range of crops grown, say, just 10 years ago. Now, I challenge you to make a list of crops grown by today’s industry. Who would have predicted some of those? It therefore begs the question ‘what new crops will we be growing in another decade’s time?’ Will your company be pioneering any of these?