Cannabis aphids on the rise They are becoming one of the most prevalent pests | 9

Benchmarking in Ontario Comparing operations’ finances | 44

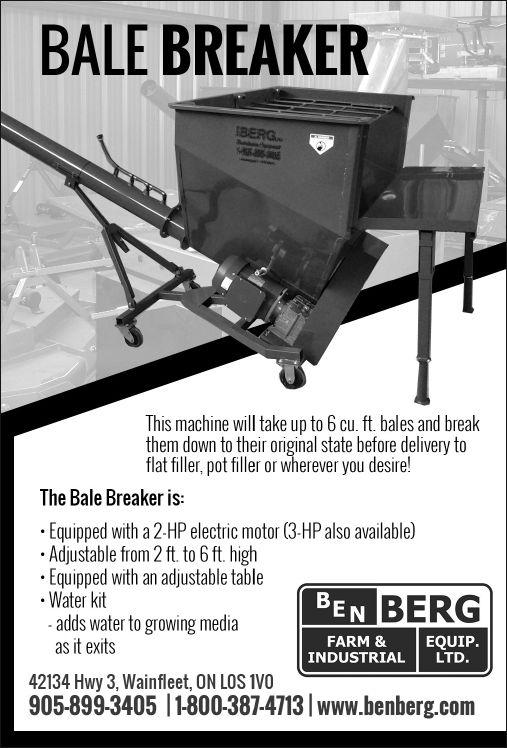

Growing media trends Supply challenges continue to impact industry 48

DECEMBER 2022 greenhousecanada.com

Cannabis aphids on the rise They are becoming one of the most prevalent pests | 9

Benchmarking in Ontario Comparing operations’ finances | 44

Growing media trends Supply challenges continue to impact industry 48

DECEMBER 2022 greenhousecanada.com

When soilborne and foliar diseases threaten fruits and vegetables, growers deserve natural, dependable protection that helps them maximize marketable yields. Taegro® 2 biofungicide is an OMRI-Listed solution from Novozymes BioAg, it’s easy to use and a great fit for integrated pest management (IPM) programs.

Powered by naturally occurring Bacillusamyloliquefaciens bacterium, Taegro 2 provides exceptional protection against powdery mildew, botrytis, blights and soilborne diseases like rhizoctonia, fusarium and sclerotinia It employs three modes of action that not only attack diseases, but also help the plant heal and mount a defense against them for better tolerance in the future.

This biological activity makes it an ideal tool for IPM programs because it won’t contribute to resistance issues and offers flexible application options.

Growers can apply via drench to transplants to help prevent root rot and give plants a strong start or mid-to-late season as a foliar to help keep blights, rots and spots from taking over after fruits are set.

Taegro 2 is also a durable and safe tank-mix partner that provides protection with a low use rate.

It’s stored as a spore with a hard cased capsule that activates when it reaches other living things. This gives it a shelf life of three years. Just 2.6-5.2 oz. per acre provides protection, and growers can spray one day and harvest the next.

Find out how Taegro 2 can enhance your IPM program. Talk to your retailer today!

Identifying the plant nutrient uptake under different N concentrations and evaluating the impact of P and K supply.

Identifying

BY ALIA REEVES

Sawaya Garden Trials: Part 2

We look at another 40 key examples of varieties from the 2022 trials.

BY MELHEM SAWAYA

Growing media trends

Supply challenges continue to impact industry.

BY ANDREW SNOOK

A new resource was recently released to help licensed producers optimize their indoor cannabis production, and it looks to be a fantastic resource for growers and students looking to tackle any aspect of growing. The Handbook of Cannabis Production in Controlled Environments, edited by Dr. Youbin Zheng, professor at the University of Guelph, showcases fantastic research from experts within the cannabis sector. Here’s a brief breakdown:

Chapter 1: Introduction

An introduction to basic biology, phytochemical constituents, and controlled environment production of cannabis.

Chapter 2: Growing Facilities and Environmental Control

An overview of the science and technology behind the control of temperature, humidity, carbon dioxide, air distribution and lighting, and discusses how these key environment factors affect cannabis growth and development.

cannabis cultivation and integrated rootzone management for different cultivation systems.

Chapter 6: Lighting and CO2 in Cannabis Production

This chapter discusses how CO2 affects cannabis production and should be supplied during cultivation.

Chapter 7: Canopy Management

Reviews plant canopy management from the viewpoint of plant physiology, and describes how to manage canopies for stock plants for production of cuttings, and to manage vegetative and flowering plants.

Chapter 8: Management of Diseases on Cannabis in Controlled Environment Production

This discusses general plant pathology, disease management principles and specific disease control practices for cannabis production.

“A great resource for growers and students.”

Chapter 3: Genetics and Plant Breeding of Cannabis sativa for Controlled Environment Production

This section outlines cannabis genetics and breeding.

Chapter 4: Cannabis Propagation

This section is about propagation by seeds, stem cuttings and in vitro technologies.

Chapter 5: Rootzone Management in Cannabis Production

Discusses water sources, water quality, water and nutrient solution treatments, nutrition and fertilization, growing media and their selection, different rootzones used in

Chapter 9: Management of Insect Pests on Cannabis in Controlled Environment Production

This introduces the basic concepts of IPM for controlled environment cannabis cultivation, and the biology and management strategies for major insect pests of cannabis.

Chapter 10: Harvest and Post-Harvest

This covers when and how to harvest, post-harvest trimming, drying, curing and storage.

The handbook can be purchased at the VitalSource Bookshelf online or at www.routledge.com.

Sun Gro Horticulture, a North American industry leader in the manufacturing and distribution of growing media products, announced it has finalized a deal to acquire Pelemix Mexico and Pelemix USA.

The company also announced Sun Gro’s export sales vice-president, Kirk Johanson, will lead the Pelemix Mexico, Central and South America, and Caribbean businesses.

The Mexican operations, including their distribution facilities, will continue to be managed from their existing office in Guadalajara, Mexico. The Pelemix U.S. and Canadian operations will be integrated into Sun Gro’s existing organizational structure in both countries.

Sun Gro will continue to work collaboratively with Pelemix to leverage their global operations and source high quality coir and finished products from the Pelemix facilities in Sri Lanka, India, and Thailand.

“Sun Gro Horticulture is an industry leader in growing media and growing media product innovation,” said Phil Jones, CEO of Sun Gro. “Similarly, Pelemix is a global leader in the coconut coir substrate markets. This acquisition will allow Sun Gro to expand is growing media offerings, adding coconut coir substrates, and expand its geographical footprint further into Mexico, Central and South America and the Caribbean to meet the growing needs of all our customers.”

Pelemix coir is used worldwide as a growing media for hydroponic crops, plant propagation, fruit and vegetable production, potted plant and bedding plant production. The merger of Pelemix USA and Mexican businesses with Sun Gro strengthens both product portfolios and enables customers to have a single source for all their Coir and Peat needs, the company stated.

AdeptAg recently announced the acquisition of Bellpark Horticulture. With the addition of Bellpark, AdeptAg is expected to expand its product offerings, sales and support further into the automated horticulture systems industry. Based in Surrey, B.C., Bellpark has been involved in horticulture automation solutions for more than 20 years. The company has worked with suppliers such as

Visser Horti Systems, Logitec Plus, Mayer, DryGair, Unifortes, and KG Systems.

“Bellpark is a great addition to the AdeptAg platform,” said AdeptAg CEO Rick Parod. “Their strong reputation as

best-in-class reflects the same DNA as the current AdeptAg platform and pairs perfectly with our strategic leadership position in providing solutions in controlled environment agriculture.”

BY

Average farmland values continued to increase in most parts of Canada, despite higher interest rates in the first half of 2022, according to a mid-year review by Farm Credit Canada (FCC).

The highest average farmland value increases were reported in Ontario (15.6 per cent), Prince Edward Island (14.8 per cent) and Quebec (10.3 per cent), followed by Saskatchewan (8.4 per cent), which was closest to the national average increase of 8.1 per cent. More modest increases were reported in the rest of the provinces. There were insufficient transactions in the Yukon, Nunavut, Newfoundland and Labrador to fully assess farmland values.

ABOVE

Nearly 10 years ago, Vineland Research and Innovation Centre (Vineland) initiated, in collaboration with the Ontario Greenhouse Vegetable Growers (OGVG) and Agriculture and Agri-Food Canada (AAFC), the only greenhouse tomatoes-on-the- vine (TOVs) breeding program in Canada.

As the majority of tomato varieties have been developed by European seed companies, Vineland’s program focused initially on developing flavourful greenhouse TOVs adapted to the unique climate in southern Ontario, the epicentre of modern greenhouse vegetable production in North America.

However, the focus shifted in late 2019, when OMAFRA and OGVG invested in additional research at Vineland to identify a source of resistance to the Tomato Brown Rugose Fruit Virus (ToBRFV) and develop the necessary tools to add resistance to Vineland’s breeding program.

First identified in Israel in 2014, ToBRFV is a newly emerged virus mainly affecting tomatoes and peppers, which has since spread worldwide and was detected in Canada in 2019. Discoloured leaves and crinkled brown or yellow spots on the fruit are the hallmark symptoms of the disease.

Although not a food safety concern, it reduces the market value of the fruit and threatens global food security.

The Vineland team has since been involved in two separate efforts to combat this virus. First, a collaboration with researchers at AAFC to screen Vineland’s collection of diverse tomato lines for ToBRFV resistance. Secondly, a partnership with two global seed companies to screen a wide collection of tomatoes in Europe for ToBRFV resistance and to develop tools to efficiently breed that resistance into Vineland’s elite, Canadian-adapted TOVs.

If current efforts are successful, it is anticipated that Vineland will be able to begin testing new, high-yielding varieties in commercial greenhouses in two years, using the newly identified resistance and breeding tools.

This past August, Vineland showcased its research facility to a group of participants during the International Tomato Brown Rugose Fruit Virus Symposium. Hosted by OGVG in partnership with OMAFRA, AAFC and Flowers Canada Growers, researchers from around the world met to address the issue of ToBRFV by discussing a number of topics including: ongoing research, crop management strategies and mitigation approaches.

This research program has been funded through AAFC, Genome Canada, Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) and OGVG.

They are quickly becoming one of the most prevalent pests on cannabis crops

CBY ALIA REEVES

annabis aphids (Phorodon Cannabis) are quickly becoming one of the most prevalent pests on cannabis crops. Fortunately, their physical and behavioural characteristics allow them to be easily identified and distinguished from other aphid species.

The cannabis aphids’ most defining feature is their antenna tubercules, which appear as horn-like structures at the top of their heads, and can be observed with the use of a microscope. Their colouration can range from yellow-green, green, or pink-brown and may have vertical stripes running down their bodies. Winged morphs are generally brown and green and appear to have harder more chitinized bodies.

Cannabis aphid feeding behaviour is somewhat unusual compared to other foliar aphids. Many other foliar aphids generally have a preference for feeding on leaves and select stems as a food source once their population reaches a certain threshold. Cannabis aphids, however, seem to have as much of a preference for feeding on stems as they do leaves. In areas of low infestation, they have been observed feeding on stems just as often, if not more so, as on leaves.

Aphids are able to reproduce sexually and asexually. Sexual reproduction occurs during the fall in preparation for overwintering; aphids overwinter as eggs that require a cold snap before that are able to hatch the following spring. In warmer climates and greenhouses where temperatures remain well above freezing, aphids reproduce asexually by parthenogenesis. In this case, aphids give birth to living and already pregnant female offspring. It is estimated that cannabis aphids birth one to five aphids daily during their three- to four-week lifespan.

excretion. As aphids feed on plant sap, they secrete a honeydew that falls from the feeding aphids on the underside of leaves to the top surfaces of the leaves below. This causes the top sides of the leaves or flowers to become sticky. Brown sooty mold is attracted to this honeydew and as it feeds and grows, it inhibits photosynthesis and causes contamination. Exoskeletons shed by the aphids also stick to the honeydew, which can further contaminate flowers.

Preventative and mechanical: Crops should be scouted and monitored regularly with clear documentation of pest pressures. Plants should be examined

Cannabis aphids are sap-sucking insects that not only cause feeding damage that weaken plant health, but also transmit viruses and contaminate products through their honeydew

by flipping leaves to detect early infestations. Sticky cards should be hung near the plants – but avoid touching – and monitored. Winged aphids looking to establish within the crop, or looking to disperse from an already established hotspot, can be found on cards and indicate corrective action will need to take place. Corrective action can include removing infested leaves, releasing beneficials or applying pesticides. Keeping accurate records will help determine if control methods were successful.

Releasing beneficials preventatively can aid in ‘scouting’ as they hunt for prey. However, specialized aphid predators will have to be replaced weekly or bi-weekly as they may starve due to a lack of food. Depending on the predator and/or release rate, they may only provide suppression by slowing the population growth.

Maintaining a crop pruning schedule can remove any colonies that have not yet been discovered. However, it is only effective if plant material is removed from the facility, otherwise, it may act as a re-entry point. Scheduled pruning and de-leafing will also allow for better spray coverage and air flow. It also aids scouting as it is more effective to be able to see through plants rather than just the exterior leaves.

Maintaining a strong biosecurity program should be part of any IPM program. Personnel should arrive with clean or facility-specific clothing. New biomass should be quarantined and monitored prior to introducing to the rest of the crop. This will help prevent the introduction of any new pest.

Anystis baccarum

Anystis baccarum is a large generalist predatory mite that targets aphids, spider mites, thrips, and whiteflies. They hunt indiscriminately by crawling in a circular pattern until they come into contact with a prey item. They can reproduce asexually through parthenogenesis which has significant implications for rapid population growth if provided with enough prey items. To take advantage of this reproductive strategy, A. baccarum are better suited towards longer lived crops, such as greenhouse vegetables or field cannabis, rather than greenhouse cannabis crops that are harvested after

Cannabis aphids are sap-sucking insects that not only cause feeding damage that weaken plant health, but also transmit viruses and contaminate products through their honeydew excretion.

approximately eight to 10 weeks. As a predator specifically for cannabis aphids, they are capable of consuming all aphid developmental stages, including winged forms, but are more successful at catching first and second instars; larger aphids often required multiple attempts. They move quickly and are able to travel long distances. This attribute makes them better suited for prevention as they tend to leave hotspots even when infestations remain high. Their potential as an intraguild predator has not yet been fully explored, but due to its indiscriminate nature, any predator it comes into contact with that is smaller than the mite will likely become prey. Unfortunately, they are currently sold at a relatively high price point and do not appear to fill a niche that other aphid predators are incapable of.

Aphidius spp.

Aphidius spp. are parasitoids, or parasitic wasps, that inject their eggs into pest hosts. A single egg is laid into individual aphids where the egg hatches, the larva consumes and develop the host from within, and finally pupates and emerges turning the aphid into a mummy. After the larva pupates within the host, the adult wasp emerges and leaves an exit hole in the aphid mummy. The colour and texture of the mummy depends on the parasitoid species and can range from brown, pink, shiny, or fuzzy. They can be released preventatively to seek out aphid hotspots and slow down population growth. Aphidius matricariae and A. colemani currently appear to be the most successful species at parasitizing cannabis aphids. However, A. matricariae tend to leave greenhouse crops during the warmer months in search of more favourable environments while A. colemani tend to remain as long as there are appropriately sized aphids to parasitize. If released in large enough quantities at the right time, they may be able to control cannabis aphids or, at the very least, provide significant suppression. A. matricariae and A. colemani pair well with most other aphid predators. In the absence of prey, they will need to be released weekly or biweekly as they cannot continue to survive without a food source.

Aphidoletes aphidimyza are gall midges with predatory larvae that can consume up to 100 aphids in a week. Unfortunately, larvae undergo diapause and I found them to be unable to establish on vegging or flowering plants. It is not recommended to use this species as a control for cannabis aphids.

Hoverfly adults are pollinators, that mimic the colouration of bees and wasps, and their larvae are predatory. Some species are migratory, arriving in Canada around April and leaving in September/October. From my experience, their larvae are voracious and may be able to provide control of cannabis aphids. However, during times of high cannabis aphid infestation, hoverflies have been observed to pupate

on flowers which can reduce product quality. This may happen without directly releasing them into the facility as they can be attracted from the wild and enter through greenhouse vents or establish themselves in field crops. If hoverflies are to be released, do so during low severity cannabis aphid infestations on vegging plants. They may be able to provide control and move on before the plants flower. While hoverflies are efficient predators, their benefit should be weighed against their potential risk.

There are two types of lacewings available in Canada: brown lacewings (Micromus variegatus) and green lacewings (Chrysoperla carnea). Brown lacewings are predatory as adults and larvae; however, there are not sold by many suppliers and they are often sold in small quantities making them expensive. Green lacewings are predacious as larvae and are commonly available. While the recommended curative release rates were used at both low and high cannabis aphid infestations, green lacewings were unable to provide control. However, they

likely slowed cannabis aphid population growth. Exceeding the recommended high curative rate and releasing lacewings while aphid pressure is low could result in control, however, determining such rate and timing is challenging.

Both ladybird beetle adults and larvae are predatory, and the most commonly sold species is Adalia bipunctata. Many species are migratory and arrive in North America around May and leave around August/ September. If released into the facility outside of these months, they are likely to leave through greenhouse vents. They may be a risk for product contamination as they may pupate on flowers. Ladybird beetles are effective aphid predators, however, my experience with wild ladybird beetles in a field crop was that they were able to provide suppression.

Scymnus spp.

Scymnus spp. is a type of ladybird beetle that is native to North America and overwinters rather than migrates. They can be attracted into the facility and sustained with the use of banker plants

and forgo overwintering. Both the adult and larva are predatory and were observed to gain control of cannabis aphids in a closed system. The larvae show a preference for pupating on solid structures such as the underside of pot lips rather than the plants themselves. They do not appear widely available for sale, but I recommend attempting to attract and sustain them with banker plants if you have the resources to do so. During my breeding program, they were found frequently throughout the facility hunting cannabis aphids.

Of the currently registered pesticides for cannabis, insecticidal soap was observed to be the most efficacious in controlling cannabis aphids. Insecticidal soap is a contact spray, so it is important to ensure adequate spray coverage. This can be achieved by maintaining an effective pruning/crop schedule and using appropriate spray equipment. A vertical boom with numerous nozzles pointed upwards at a 45-degree angle to target stems and the undersides of leaves should provide the best coverage.

Identifying the plant nutrient uptake under different N concentrations and evaluating the impact of P and K supply.

BY MARTINE DORAIS, CAMILLE LEBLANC, THI THUY AN NGUYEN AND ANNIE BRÉGARD

During the last few years, an increasing number of studies have evaluated the impact of the mineral nutrition on growth, flower yield and cannabinoid and terpenoid profiles of cannabis. As a result, scientific-based N, P and K optimal ranges have been proposed. However, little is now about the nutrient uptake of cannabis during its development.

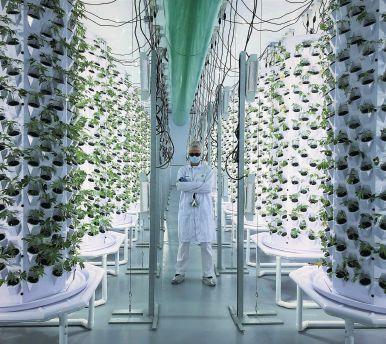

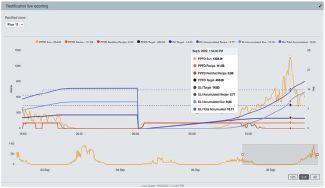

To determine the nutrient requirement of drugtype cannabis during the flowering phase, we studied at the commercial site (IsoCanMed Inc., Louiseville, Que.) the impact of two N concentrations (150 and 250 ppm) on plant growth development, plant nutrient uptake of N, P, K, Ca and Mg, flower yield and their cannabinoid and terpene content. Six growth cycles were performed in a vertical indoor aeroponic growing system with two high THC

ABOVE

genotypes (Critical Orange Punch, COP, and White Shark, WS) (figures 1A-D). The plantlets were transferred into a flowering room having 42 vertical aeroponic towers (264 plants per tower; total of 12,672 plants per growth cycle) and submitted to a vegetative phase (16-h photoperiod) of two weeks or directly submitted to the flowering phase (12-h photoperiod; PPFD of 445 µmol m-2 s-1 provided by 1000 W HPS and 315 W LEC lamps; 500-1500 ppm CO2; day/night temperature of 22/18oC; 55-70% RH). Plants were irrigated with a complete nutrient solution, which was collected into a 2,000 L reservoir and reused. Twice a day, the nutrient solution was adjusted for the EC and pH, and the plant nutrient consumption was measured daily (samples taken before and after the nutrient solution adjustment). The nutrient solution was renewed weekly.

To determine the nutrient requirement of drug-type cannabis during the flowering phase, studies were undertaken at the commercial site of IsoCanMed Inc. in Louiseville, Que.

A greenhouse experiment conducted at Laval University was also conducted to examine within a randomized complete block design with four replicates the response of one genotype (WS) grown in deep-water culture system of 40 L having three plants per system (total of 40 systems and 120 plants) with five P (25, 50, 100, 150 and 200 ppm) and two K concentrations (175 and 250 ppm) (figure 1E). Upon their transplantation, the plantlets were submitted into the flowering phase with a 12-h photoperiod supplied with 1000 W HPS providing a PPFD of 321 µmol m-2 s-1 at the plant level; 22/18oC day/night temperatures and 63% RH. The nutrient solution was renewed every two weeks or every week.

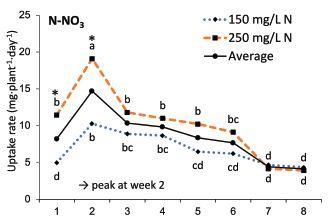

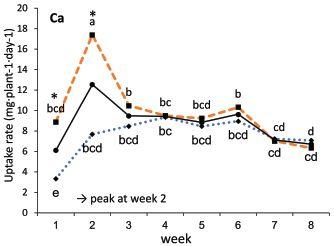

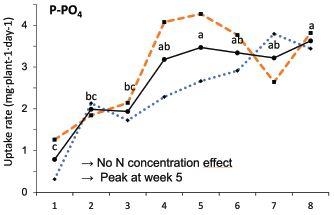

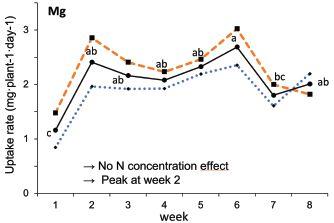

During the six growing cycles, the pH and EC of the nutrient solution ranged from 5.74 to 6.02 (average of 5.79 for 250 ppm N and 5.97 for 150 ppm N treatments) and 1.28 to 2.94 mS/cm (average of 2.29 mS/cm for 250 ppm N and 1.93 mS/cm for 150 ppm N treatments) , respectively, while the daily plant water uptake ranged from 100 (150 ppm N) to 111 (250 ppm N) mL per plant. Our results showed that N, K and Ca uptake increased at the beginning of the flowering phase and then decreased, while P and Mg demand increased and then remained constant (figure 2). High N concentration increased N, K and Ca uptake only at week 2 of development, with no effect afterwards. P uptake increased

Evolution of the averaged daily N-NO3, P-PO4, K, Ca and Mg uptake per plant of C. sativa grown under 150 and 250 ppm N concentrations during the flowering phase. Different letters above the means represent significant differences between treatments by LSD protected by Fisher (P < 0.05). * is indicated when significant different at P≤0.05 between 150 and 250 ppm. (Note : mg L-1 = ppm)

FIGURE 3

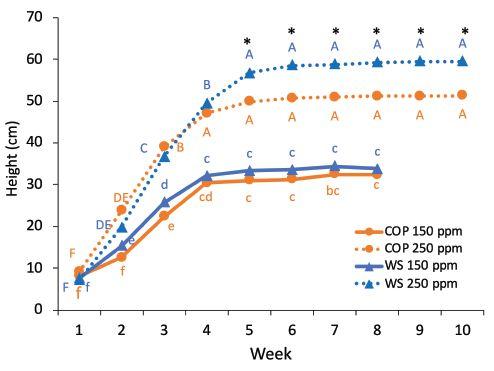

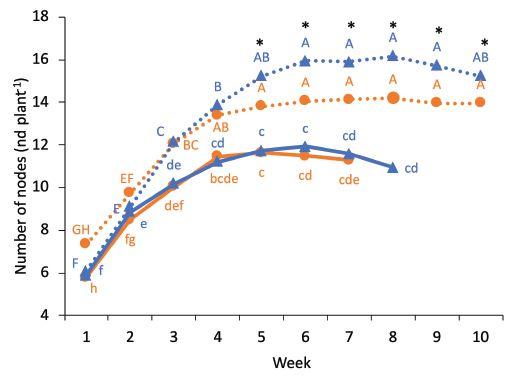

Weekly evolution of plant height and the number of nodes of WS and COP grown under 150 ppm N-NO3 (plain line) and 250 ppm N-NO3 (dotted line). Different lowercase letters above the means represent significant differences between the weeks and genotypes grown under 150 ppm N-NO3 by protected Fisher’s LSD test (P<0.05), while uppercase letters indicate differences for plants grown under 250 ppm N-NO3

*indicates a significant difference between the two cultivars at 250 ppm N-NO3. (Note : mg L-1 = ppm)

until week 5 and then reached a plateau. This corresponds at the time that flower buds were rapidly growing and gained weight. The reduction of the leaf P content at weeks 4-5 (data not shown) and the increase of the plant P uptake both suggest that flowers constitute a sink for P, with an averaged of 1.3% P content. The K leaf accumulation decreased at week 3, which can be related to the plant K uptake decrease, while Ca leaf content slightly increased during plant development as it is an important structural component for the cells (data not shown). The leaf Mg content of COP decreased after 8 weeks, while its content gradually increased for the WS until week 5, and then decreased, which suggest a genotype specificity (data not shown).

The genotypes, N treatments and weeks had a significant impact on the plant height and the number of nodes per plant (figure 3). Plants reached their maximum height at week 4, except for WS grown at 250 ppm N, which was delayed by one week. N treatment had a strong impact on the height as plants were 1.5 times taller under high N level. From weeks 5 to 10, there was a significant difference between WS and COP grown at 250 ppm for the plant height and the number of nodes per plant.

The high N concentration (250 ppm) did not impact significantly the flower yield of COP (average of 4.24 dry g per plant) but increased the yield of WS by 29% (4.50 dry g per plant) compared with the low N concentration (150 ppm; 3.50 dry g per plant). Under 150 ppm N, the flower yield of COP was 27% higher than WS, while no difference was observed under 250 ppm N. However, increasing the N concentration from 150 to 250 ppm N decreased by 9.5% the total THC content of both genotypes (from 17.66% to 16.13). The concentration of THCA already decarboxylated into Δ 9-THC in the dried flowers was, nonetheless, higher under 250 ppm N (0.31% compared with 0.14%). No significant effect of N on the other cannabinoids (CBDA, CBD, CBDV, CBN, CBG, CBGA and CBC) was observed. WS had 1.5 fold more CBN than COP (0.36% compared with 0.24%). Regardless of N concentration, the total THC and CBD potency were similar within both genotypes (16.89% and 0.14%, respectively).

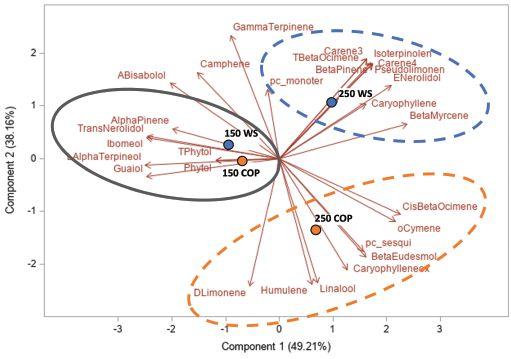

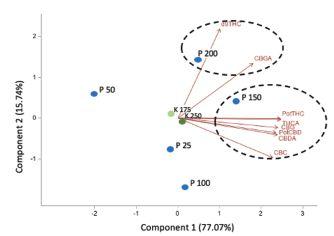

The principal component analysis (Figure 4) shows that different terpenes are related to a specific genotype when

grown under a high N concentration (two difference clusters indicated in bleu dotted line for WS and orange dotted line for COP), while other terpenes are related to both genotypes under a low N concentration (same cluster indicated in black line).

For example, the high N concentration for WS was related to a high flower content of β-pinene, Trans-β-ocimene, carene, isoterpinolen, pseudolimonen, E-nerolidol, caryophyllene and β-myrcene, while a high N concentration for COP was related to caryophyllene oxide, linalool, β-eudesmol, humulene, D-limonene, o-cymene and cis-β-ocimene. On the other hand, a low N concentration for both genotypes was related to α-pinene, trans-nerolidol, I-bomeol, L-α-terpineo, guaiol and phytol.

Regarding the impact of K and P concentrations, no significant effect was observed on plant growth parameters (average values: total plant biomass of 160.5 g dw/plant; leaf biomass of 105 g dw/plant; root biomass of 11.5 g dw/plant; growth index of 1673; shoot diameter of 13.2 cm; number of leaves per plants of 292; chlorophyll content index of 61.8; and maximum quantum yield of photosystem II of 0.82), flower yield (27.9 g/plant) and water use efficiency (1.28 g/L), except for leaf area where the higher K concentration (250 ppm), regardless of the P concentrations, increased its value by 1.6 times compared with the 175 ppm K treatment (11,015 cm3/ plant vs 6,878 cm3/plant).

After 80 days of growth, N and K leaf content decreased compared with their content at 25 days, while Ca and Mg increased (data not shown). On the other hand, the N and P concentrations in the flowers increased, which suggest that flowers may constitute a sink for N and P due to the high energy demand for the biosynthesis of cannabinoids and terpenes. Under moderate P concentrations, the high K concentration (250 ppm) increased the leaf K content compared with 175 ppm K, which may suggest a “luxury consumption” of K. The leaf Ca content at 80 days was 36% higher than its content at 25 days of growth, which might be due to a higher transpiration rate as Ca transportation from the roots to the leaves is highly related to the transpiration stream.

In addition, no significant effect of P and K concentrations on the cannabinoid content (THCA, Δ9-THC, CBDA, CBD,

FIGURE 4

Principal component analysis of the terpenoids found in two genotypes (WS and COP) of C. sativa grown under 150 and 250 ppm N. The Principal com-ponent 1 accounted for 49.21% of total variance whereas the Principal Component 2 accounted for 38.16%.

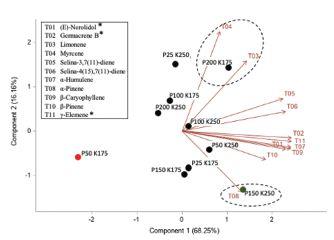

CBGA, CBG, CBC) were observed with 14.08 to 16.24% for total THC and 0.05% for total CBD. The averaged terpene content of the flowers was 19.56 mg g-1; 75% of the terpenes were sesquiterpenes followed by the monoterpenes, while the remaining 1% were diterpenes. From the 60 terpenes identified, 11 terpenes representing 72% of the total terpene content had more than 0.50 mg g-1 and is known as having pharmacological metabolites of interest. β-caryophyllene was the terpene found at the highest concentrations with an averaged value of 2.64 mg g-1 followed by germacrene B, selina-3,7(11)-diene and α-pinene with 2.45, 1.72 and 1.50 mg g-1, respectively. Only three terpenes were impacted significatively by the 50 ppm P x 175 ppm K treatment. Figure 5 shows the relationship between the P and K concentrations and the flower content in cannabinoids (figures 5A and 5B) and terpenoids (figure 5C).

In summary, our N experiments showed that N, K and Ca plant uptake peaked at week 2 and then decreased, while Mg and P uptake increased until weeks 2 and 5, respectively, and stay relatively high throughout the flowering phase. At the beginning of the flowering phase, high N fertilization promoted the N, K and Ca plant uptake. The high N fertilization increased the flower yield of White Shark by 29%, while no effect was

observed for Critical Orange Punch. For both genotypes, 250 ppm N fertilization reduced by 9.5% of the total THC content compared with 150 ppm. Therefore, growers may modulate the N supply according to the developmental stage of their genotype to avoid any N overfertilization and overgrown plants. However, further studies are needed to identify the optimal N concentration as neither genotype responded similarly. Regarding our P x K experiment, we did not observe any significant beneficial effect of higher P and K concentrations on flower yield, but we had a 60% higher leaf area under 250 ppm of K compared with 175 ppm, and higher plant biomass at 100 ppm of P and 250 ppm of K, while lower N flower content was observed under 50 and 100 ppm of P and 175 ppm of K. The cannabinoid concentrations in the inflorescences of plants grown in a hydroponic growing system were not significantly affected by the P and K studied concentrations, although total THC was related to high P content (P 150 ppm). Only three main terpenes were affected by P x K fertilization where the 50 P x 175 K ppm treatment reduced their content. High P concentrations (150 or 200 ppm) were related to some terpenes such as pinene, myrcene and limonene. Overall, our results suggest that hydroponic cannabis growers do not need to use a concentration above 25 ppm for P and 175 ppm for K as those levels were sufficient for an optimal plant development and yield. However, a high level of P (150 and 200 ppm) was positively related to the cannabinoids and some terpenes as shown in figure 3. These levels may vary according to the genotype and the light growing condition, as our P x K experiment was conducted with only one genotype and under relatively low light conditions. Additional studies with a large number of genotypes and under different growing conditions (e.g. growing media, lighting) are needed to better characterize the impact of the N, K and P management on the cannabinoids and terpene content.

The authors thank the Natural Sciences and Engineering Research Council of Canada (NSERC) and IsoCanMed Inc. for the final support for this research. We are also grateful to Nathalie Delisle, Erik Bertacchini and Juliano Bertacchini for their trust and greatly appreciated technical assistance making this study possible as well as Rejean Bacon from Laval University for his support regarding the administrative and scientific aspects.

Complete results could be find at: https://corpus.ulaval.ca/entities/ publication/a6217be6-1cce-4f9d-bb5d-042f479dcdc7

FIGURE 5

Principal component analysis of the cannabinoids and terpenoids found in the flowers of C. sativa WS grown under 10 combination treatments of P (25, 50, 100, 150, and 200 ppm) x K (175 and 250 ppm). A) Simple effect of P or K on the flower cannabinoid content; B) P x K combined effect on the flower cannabinoid content; C) P x K combined effect on the flower terpenoid content.

Growers know that when it comes to controlling and monitoring a production environment, a simple, flexible, sustainable control system is crucial. This is why you can depend on Reliable Controls. Our nationwide network of factory-certified Authorized Dealers will help you design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective, Canadian-made solution, please contact a Reliable Controls

Authorized Dealer near you.

Canada: 403.561.4148

Canada: 647.982.7412

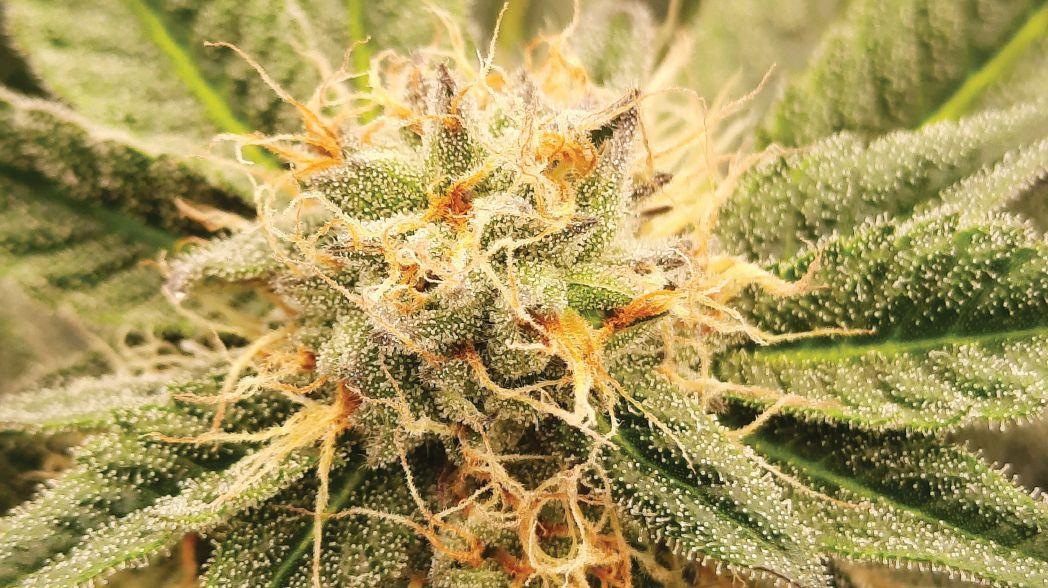

This image shows an example of a ripe bud where pistils have turned amber in colour and trichomes are no longer translucent.

Undeniably, growing cannabis is a tedious yet rewarding process. All cannabis crop management practices affect the post-harvest quality, which determines the product outcome. Post-harvest quality parameters will also vary with the end use of the cannabis flower. One of the most important aspects of growing quality cannabis comes when you are ready to harvest your plant.

The image (above) shows an example of a ripe bud where pistils have turned amber in colour and trichomes are no longer translucent. The number of days in flower will vary by strain. Typically, indica plants will be ready for harvest in approximately 50 to 60 days, and sativa usually between 60 and 70 days.

Harvesting plants too early or too late can affect potency and yield, potentially lessening the flower’s quality. The number of days from flower to harvest will also influence the way plants are grown, vegetatively or generatively. Growers follow three main practices while gathering buds for drying and processing:

1. Harvest the entire plant and hang it up, then harvest the buds when they’re dry.

2. Remove the branches with the buds intact, hang them and then harvest the buds after drying.

3. Remove the buds from the stem to save space, and dry buds in boxes or on trays.

When the entire plant is hung up, usually it takes longer to dry. During handling, the dried leaves and buds may fall or crumble.

Drying: Several factors such as microbial activity, moisture content, room temperature, and duration of light, affect the post-harvest quality and sustainability of cannabis. Drying is the most effective technique for controlling microbial activity and enabling long-term storage while maintaining potency, taste, and medicinal properties.

Several drying methods have been used to dry the flowers, including hot air drying,

oven drying, vacuum freeze-drying, atmospheric freeze-drying, and microwave-assisted drying. While carrying out the drying process, keep the following points in mind:

• If you are drying the entire plant, then ensure that everything is set up prior to harvest — racks are properly placed and disinfected in advance;

• Don’t overcrowd the drying rooms. Keep the dry rooms well-ventilated with proper air flow to maintain ideal temperatures and humidity levels, which decreases the chances of mould and mildew;

• Some growers use higher temperatures for the first three to five days to get rid of moisture quickly, and then drop to lower temperatures;

• We recommend using Vapor Pressure Deficit (VPD) as a guideline rather than temperature and humidity independently. VPD indicates the difference of water activity inside the buds as compared to outside of them;

• A good range for proper loss of

water from buds is suggested to be between seven to nine millibars. Temperature and RH adjusted to achieve proper VPD will help to avoid condensation and mould;

• Measuring the moisture content of cannabis buds determines the effectiveness of drying and curing techniques, which also affect the terpene concentration and chemical profile of the finished product;

• The moisture content of adequately cured cannabis flower should be less than 13 per cent.

Curing: Curing is essentially a process of “ripening the buds” where dried buds are placed into airtight containers and stored in a dark environment between 15.5 to 20 degrees, with around 60 per cent humidity. Measuring water activity (aW) in cannabis buds helps determine how vulnerable the product is to microbial contamination. Mitigating water activity reduces the chance of microbial growth and allows the product to be stored for extended periods. Growers often mistakenly assume that higher moisture content in the flower

means a higher water activity but that’s not always correct. It is possible to have low moisture content in the product and still have water activity that is more than 0.65 aW. It is recommended that dried cannabis be stored in sealed containers with water activity below 0.65aW.

Storing the product with poor drying conditions under high humidity encourages the formation of microbial spores and harmful microbial toxins such as aflatoxin, as well as powdery mildew and botrytis, which causes the deterioration of cannabis.

The therapeutic potential of cannabis products depends heavily on the initial quality of the plant material, as influenced by the harvesting time, harvesting technique, and postharvesting technologies. This also helps to determine the chemical composition and quality of the buds.

Safety has been the biggest concern, however, since no proper standardized procedures are present, it’s difficult to enforce. Thus, having controlled process- ing systems in place, in alignment with the scientific evidence, is essential.

To get the most out of your greenhouse biocontrol program, start with preventative strategies.

BY CAMERON SCOTT AND DR. ZAMIR K. PUNJA

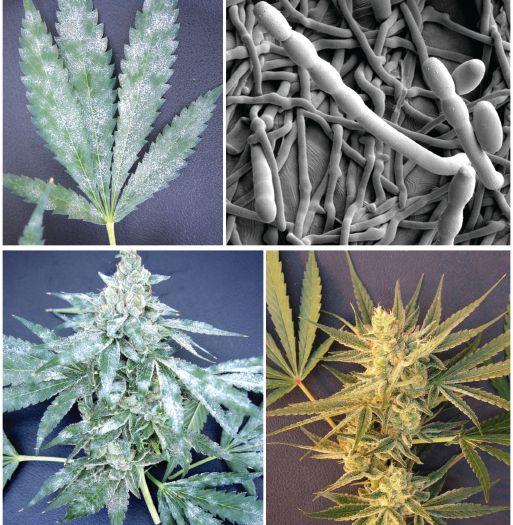

Powdery mildew diseases affect a wide range of host species including important greenhouse crops such as tomato, pepper and cucumber, and are caused by different fungal pathogens. On cannabis (Cannabis sativa L.), powdery mildew is caused by Golovinomyces ambrosiae and far less commonly by the pathogen Podosphaera macularis (specifically under field conditions). This disease is easily identified by the characteristic white powdery growth on the upper surface of leaves, as well as on flower tissues or stems of cannabis plants (Figure 1).

Spores of powdery mildew may originate from infected plants within or near the greenhouse, from surfaces that were not sufficiently cleaned between crops and infected plant debris. These spores are moved easily through the air but may also be spread by workers. Following spore germination and infection, fungal colonies that develop can limit photosynthesis and reduce nutrient availability to the plant, causing premature leaf drop as well as reducing overall vigour and potential yield of plants. Powdery mildew infection on cannabis can significantly reduce the quality and marketability of flowers, due to the visible growth of the pathogen on flower tissues (Figure 1).

In general, powdery mildews are managed by fungicide application or use of other chemical products, as well as biological control agents, induction of disease resistance, and development of cultivars with genetic resistance. Powdery mildew management on cannabis relies on cultural control methods, such as removal of diseased leaves (deleafing), maintaining relative humidity at levels not conducive for pathogen development, and application of biocontrol products or reduced risk chemicals.

There are currently no synthetic chemical fungicides registered for powdery mildew control on cannabis in Canada unlike on other crops. Several reduced risk chemical products are approved for use by Health Canada, and include potassium bicarbonate, hydrogen peroxide and lactic acid, among others. Other potential methods for disease control, including biological control agents, application of ultraviolet (UV) light, or use of disease resistant cultivars, have not been previously evaluated for cannabis.

FIGURE 1

Powdery mildew symptoms on cannabis plants include a white powdery growth of the pathogen on leaves (top left) which is due to mycelial growth and spore production as seen under the scanning electron microscope (top right). Comparison of powdery mildew development on a highly susceptible genotype of cannabis (bottom left) compared to a resistant genotype (bottom right). Both were grown side by side and powdery mildew developed from natural infection under greenhouse conditions. Photographs were taken at harvest time.

In this study, we evaluated potential disease control methods for powdery mildew management on cannabis. Three biological control agents, namely Actinovate SP (containing Streptomyces lydicus strain WYEC 108), Rhapsody ASO (containing Bacillus subtilis strain QST 713) and Stargus (containing Bacillus amyloliquefaciens strain F727) were tested. Chemical treatments

Full spectrum output that dynamically recreates Sunlight from anywhere in the world. Fully Dynamic

Unlimited dynamic lighting zones equipped with custom light recipes. Multi-zone light management

Sollum’s

(“SUNaaS”) is the nerve center of

UV-C treatments used daily reduced powdery mildew development (top right leaf) compared to untreated plants (top left leaf). Mildew developed extensively on untreated plants (bottom left) compared to treated plants (bottom right).

evaluated included MilStop (potassium bicarbonate), ZeroTol (hydrogen peroxide) and the plant defence inducer Regalia Maxx (containing an extract of Reynoutria sachalinensis). In addition, the efficacy of UV-C light to manage powdery mildew was also examined by daily exposure of leaves. Finally, the susceptibility of different cultivars (genotypes) of cannabis to disease development was assessed to determine their resistance to powdery mildew.

All treatments were applied to cannabis cultivar Copenhagen Kush, which is highly susceptible to powdery mildew. Cuttings were rooted and grown in an indoor room with 24-hour lighting. To initiate powdery mildew infection, a diseased cannabis plant grown in a licenced facility in British Columbia provided a source of spores used to infect plants. A single heavily infected plant was placed in the centre of the room and allowed to release conidia. This ensured that background levels of inoculum in the indoor room where the experiments were conducted were sufficient for the disease to establish naturally. Rooted plants received one spray of MilStop to minimize any variance in the initial levels of infection. The plants were then maintained for seven days in the growing room before treatments were applied.

At the start of the experiment (week 0), plants were assessed for powdery mildew infection, after which they received the appropriate treatment. Plants received four weekly sprays in total and five disease assessments were made at weekly intervals. Disease was assessed on the 30 most diseased leaflets (assessed visually) per group by placing them into one of five categories, based on the percentage coverage of leaves by mildew. These ratings were then utilized to calculate a disease rating score for each plant. The experiments were conducted three times per treatment group.

The disease progression on treated and control (untreated) plants was plotted on a graph to generate a disease progress curve which could be used to compare the efficacy of treatments. Based on these comparisons, the most effective treatments, which significantly reduced disease in all three trials, were Regalia Maxx, MilStop,

Rhapsody ASO and Stargus. Treatments of Actinovate SP and ZeroTol showed less efficacy and were only effective in managing powdery mildew in one or two trials, respectively (Figure 2).

An ultraviolet treatment was also tested for powdery mildew control. The treated plants received daily exposure to UV-C light from a handheld CleanLight Pro unit over four weeks. Plants were treated for 3s to 5s per day (equal to 3–6 mJ/cm2 of radiation, as per the manufacturer) by moving the unit uniformly over and around the plants at a distance of 5 cm away. Treated and control plants were rated for disease as described above. In two trials, UV-C light significantly reduced powdery mildew development, and after 30 days, the plants were free of infection on new growth (Figure 3). Scanning electron microscopic observations of treated cannabis leaves showed that mildew spores had not germinated, and mycelial growth was inhibited, suggesting a direct toxic effect from these treatments.

CANNABIS GENOTYPES DIFFER IN SUSCEPTIBILITY

A comparison was made of 12 genotypes of cannabis grown for two weeks under a humidity dome in the presence of infected Copenhagen Kush plants. Entire plants were rated for disease by placing them into one of five categories based on the percentage coverage of powdery mildew on the leaves, as described previously. The average disease score per genotype was determined and significant differences were determined using statistical tests. The experiment was conducted twice. Among the 12 genotypes, seven showed partial or complete resistance to infection (Figure 4). Differing levels of susceptibility to powdery mildew infection have also been observed among hemp cultivars. Efforts are underway in several research laboratories to identify the resistant genes involved which will also allow them to be used in marker assisted breeding

of cannabis with improved powdery mildew resistance.

This article summarizes results of experiments conducted as part of Cameron Scott’s M.Sc. study at Simon Fraser

FIGURE 4

Comparison of powdery mildew development on leaves of three genotypes of cannabis. From left to right: ‘Space Queen’, ‘Pennywise’, ‘Sweet Durga Mata’.

University. More detailed results from this study have been published as an open access scientific paper in the Canadian Journal of Plant Pathology. This manuscript is available at the following weblink: https://www.tandfonline.com/doi/full/10.10 80/07060661.2020.1836026

We look at another 40 key examples of varieties from the 2022 trials

BY MELHEM SAWAYA

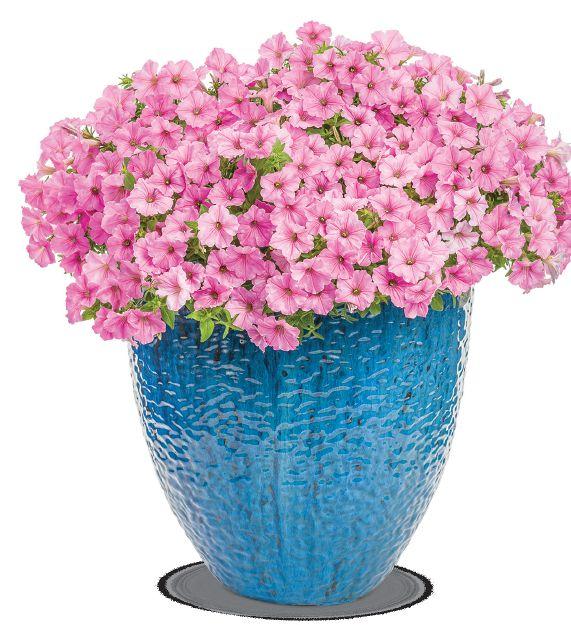

In the previous issue of Greenhouse Canada , we looked at success factors for cultivars and the first 42 varieties from the 22nd consecutive year of the trials. In this second part of the Sawaya Garden Trials 2022 report, we look at another 40 key examples of varieties from those trials:

Lantana (43) Landmark Gold is a vigorous lantana that has an excellent performance in our trials, with a continuous flower power. Landmark should be grown in large containers or planted in large landscapes that will cover 4 sq. ft. Minimal deadheading needed.

Lantana (44) Lucky Yellow is a more compact lantana compared to Landmark lantana. Lucky is great to sell in smaller containers for landscapes where it will not overpower the rest of the cultivars in a bed. All lantanas get better with high light and temperature and that is why lantanas, in general, are a must for summer landscape. In

addition to their flower power and beauty, they are a hummingbird favourite.

Lavandula(45) Javelin Forte Deep Rose have large blooms on strong stems with well branched habits, and continuous flowers from May until frost. It is Zones 7-9.

Lavandula angustifolia (46) LaDiva Vintage Violet is a very floriferous plant that is programable to flower the first year, with a strong upright habit and hardy to Zone 4.

We did not see any powdery mildew on any of the lavender varieties that we had this year without any chemical treatment.

Lobelia – Hot + White(47) and Lobelia erinus (48) Techno Lilac, in addition to more lobelia varieties, flowered the whole summer long most probably because of the cooler summer compared to other years – or the breeders are working on heat-tolerant varieties. Next trial year, if the lobelias are to perform

ABOVE Petunia (63) Supertunia Mini Vista Yellow have loads of medium-sized flowers on vigorous plants that could be in pots for landscape or hanging baskets and combinations.

good in hot weather, then lobelia will increase in production double and triple fold.

Lobularia (49) Lavender Stream is one colour of the stream varieties that is gaining popularity with gardeners due to its impressive performance in the gardens in full sun and tolerating shade locations. At Sawaya Gardens, we are going to encourage the use of Lobularias not just for their looks and performance but for their excellent host for orius; a predatory mite that controls thrips, mites, and lepidopteran eggs in soybeans. Lobularias are used in large scale in strawberry fields as biocontrol’s orius host to avoid chemical sprays.

Mandevilla (50) Tourmaline Fuchsias is one variety of the many Mandevilla on the market that proved over and over their resilient performance and flowering power through the whole season. Mandevilla improves in performance September on, while many of the other genera are slowing down. Mandevilla works very well in combinations as well as alone.

Muehlenbeckia (51) Proven Accents – Big Leaf.

Muehlenbeckia (52) Muehlenbeckia Big Leaf is the larger leaf of the Muehlenbeckias on the market. Both Muehlenbeckias are excellent fillers that enhances flowering or non-flowering combinations without taking over.

Nemesia(53) Nesia Tropical also performed very well compared to other years trials for the same reasons as Lobelia, a cooler summer, improved genetics, or both. We will keep close eye next year on their performance taking into consideration the average temperatures.

Passionflower – Betty Miles Young (54) and Passionflower - Betty Miles Young (Purple) Flower (55)

and plant are the standards for excellent growth, growth and very beautiful flowers.

Petunias are the lion’s share of the annuals, and that is because they come in so many different sizes, shapes, flower sizes and amazing flower designs that they will be great in small pots or gallons and large hanging baskets or combinations. Here some outstanding examples:

Petunia (56) Bee’s Knees, which is the favourite yellow petunia for the past few years.

Petunia (57) ColorRush Merlot Star Improved, the name describes it very well with massive amounts of star-like, medium-sized flowers.

Petunia (58) Crazytunia Mayan Sunset flowers change colours with age to think you planted more than one variety.

Petunia (59) Itsy Bitsy Pink, the one colour of the Itsy’s series. Itsy have loads of small flowers on a very tight foliage plant that never need dead heading and rain seems to enhance it.

Petunia (60) Red Carpet RIMarkable. Each flower is a piece of art that are in a large collage. It takes the rain well without any diseases.

Petunia (61) Supercal Light Yellow is a strong petunia that is hardy to cool temperatures with loads of mediumsized flowers. The Supercal light yellow is one variety of a whole series.

Petunia (62) Supertunia Mini Vista Hot Pink and Petunia (63) Supertunia Mini Vista Yellow have loads of mediumsized flowers on vigorous plants that could be in pots for landscape or hanging baskets and combinations.

Petunia Hybrida (64) Dekko Lavender Eye is one colour of the Dekko series that have medium-sized flowers that are

very resistant to diseases. Dekkos recover very fast after rain without any negative effect. Great in hanging baskets and combinations.

Rudbeckia (65) Goldsturm is the work horse of perennials that is hardy to zone four. loads of flowers slow to wake up in the spring. Gold strum flower beds you see from far away and put on a pleasant show year after year.

Rudbeckia (66) Minibeckia Flame is barely hardy to Zone 5, but it has super flowers the whole summer. It flowered more than 12 weeks.

Rudbeckia (67) Sunbeckia Maya and Rudbeckia (68) Sunbeckia Sarah are a series hardy to Zone 7 with extremely beautiful large flowers. In our area they can be used as an annual. Plant in large containers or landscape to enjoy the whole summer.

Salvia (69) Hummingbird Falls is a very vigorous trailing salvia. If not controlled, the vegetative part will overshadow the flowering part. Hummingbird Falls is great for hanging in baskets or landscape.

Salvia (70) Midnight Candle is a freely branching salvia that will lead to loads of blue flowers that last a long time without deadheading.

Salvia (71) Unplugged So Blue, like other salvias, attract pollinators and hummingbirds. It is great in landscape and containers.

Scaevola (72) Scala Pink vigorous and Scaevola (73) Surdiva Pink Fashion compact are only two varieties of many Scaveola varieties where all of them have excellent garden performance. No deadheading and blooms the whole summer long. Rain does not negatively affect scaveolas, and loves the heat.

Sedum (74) Double Martini have a contrasting maroon stem and olive-green foliage. Hardy to Zone 4 and drought tolerant.

Sedum (75) Peach Pearls another sedum all the characteristics of the double martini with a twist in its bloom different shades of star shaped rose-gold flowers.

Normally I do not appreciate verbena, since they need

lot of care deadheading and have powdery mildew susceptibility. This summer I was surprised and impressed by verbena, in general, because with minimal deadheading and no sign of powdery mildew, the plants looked great most of the time. That is why we insist on trialing some of the old varieties, so we learn their habit in the long run, here are some examples:

Verbena (76) Lascar Black Velvet, Verbena (77) Lascar Mango Orange, and Verbena (78) Superbena Sparkling Amethyst. These are a few of the over 50 varieties of verbena we had in the trials.

Vinca is the new impatiens. They have excellent bloom colours, are disease resistant, self-branching, love the heat and are tolerant to cool temperatures better than impatiens. So yes, vinca is for the north climate, and more and more vincas are grown in many landscapes.

new series that put on a great show the whole summer and visitors complemented on its performance. It is on the vigorous side, which makes it great for large containers and cover a large area of landscape.

This is the second part of the two-part series covering the trials. Just remember what we always say, promising new varieties are for you to try, not to make big programs with. Then if all goes well, the next season

plan on larger programs. Also, it will be the time to cancel the unprofitable or duplicate programs.

We do trials for the growers and consumers, so any suggestions that serve the whole or part of the horticulture gardening community are welcomed. Just drop a line or a phone call.

Next year’s Sawaya Gardens Trials open house date is July 19, 2023.

See you at the gardens!

“Just remember what we always say, promising new varieties are for you to try, not to make big programs with. Then if all goes well, the next season plan on larger programs.”

Vinca F1 (79) Titan Lavender Halo, and Vinca F1 (80) Valiant Lilac are only two that represent their series, plus more F1 varieties are available.

Viola (81) Admire Lemon Purple Wing and all the series flowered the whole summer and got better towards the fall. If a plant takes the cold that does not mean it cannot tolerate the heat, and the new breeding of viola is an example that. Viola takes the cold extremely well and thrives in the heat.

Zinnia marylandica (82) Zydeco Deep Yellow is a colour of the Zydeco

No matter what challenges your greenhouse or outdoor ornamentals are facing, Bayer is ready with the right solutions. Altus™ is registered for use in vegetable and floriculture production and provides systemic, broadspectrum control of aphids, whiteflies and leafhoppers through flexible foliar spray or drench applications.

Ed Bloodnick, Director of Grower Services, Premier Tech

Various biological additives are now available for agriculture and horticulture. The definition of “active ingredients” could be subject to several articles. Some can be applied above soil line to reduce plant diseases or reduce insect pests. Others can be incorporated into growing media to enhance plant growth and/or reduce plant root diseases. Greenhouse and nursery growers often ask if active ingredients are effective, if they can replace chemical treatments, if they can be used in combination with chemical treatments and provide a return on investment. Here is an overview for the use of active ingredients for the plant root zone.

Compared to mineral soil, growing media used in greenhouses and nurseries are ”constructed” with organic based materials, such as peat moss, bark, coconut coir and/or other materials. Other ingredients, such as aggregates, fertilizers, limestone, etc., are added to make blends that have specific physical and chemical properties. Unless active ingredients are added, growing media generally contains low levels of microbes, making them virtually free of the biological component.

If we were to take a sample of mineral soil from an untouched environment, we would find a wide array of diverse biology. Some microbes convert organic matter into nutrients for plants, some fix nutrients in the soil for plant uptake and others interact to protect and stimulate plant root systems. In mineral soil, there can be any combination of microbes consisting of actinomyces, bacteria and/or fungi. Of these microbes, there are saprophytes, which feed on dead material; pathogens, that feed on and damage plants; symbionts that assist plants; and competitors, which can attack or compete with other microorganisms.

Over the years, scientists have isolated and cultured various beneficial microbes for use in agriculture and horticulture. These microbes are produced in laboratories to be sure that strains remain true and continue to provide the desired benefits. Various microbes commercially available to growers can be placed into two general categories by the benefits they provide: biocontrols and biostimulants. Biocontrols are active ingredients that reduce the incidence of plant diseases or insects. They may directly attack the pathogen or insect, or indirectly control by creating barriers, producing a metabolite, blocking food source or excluding a pathogen. Compared to biostimulants, which are microbes that stimulate plant growth or assist plants in acquiring nutrients and/or water to improve the overall growth of plants. Some Bacillus species and mycorrhizae are among popular biostimulants. Bacillus pumilus is a bacterium that induces the proliferation of the root hairs for better nutrient uptake. Mycorrhizae (endomycorrhizae) are symbiotic associations between a fungus and a plant. The fungus grows in and around plant roots to form an extension of the root system and draw nutrients and water for the plant, which often are inaccessible to the plant roots. Mycorrhizae enable plant to be better protected and to resist the stresses caused by transplanting, drought and heat, while maintaining an optimal growth rate.

One of the main advantages of using beneficial organisms is that they are safe to use. They have little to no toxicity to plants, humans or animals. Most have been discovered in mineral soil and are naturally occurring, not genetically modified. Because they are part of the normal checks and balances of soil biology, there is less potential for pathogen resistance. Most active ingredients that suppress pathogens or insects are preventative, not curative; therefore, they prevent the onset of plant disease before it has a chance to affect crops. For insects, they may reduce fungi that insects feed on, hence reducing their populations. Most beneficial active ingredients remain in the root zone of the plant for an extended period, while some can remain with the plant for life. If you are growing organic certified crops, a major advantage is that most active ingredients are certified or listed for use with organic crops.

Unlike chemical fungicides that are wide spectrum, biological controls generally interact with specific pathogens, therefore their range of pathogen control can be narrower that their chemical counterparts. If used in combination with chemical controls or other biological additives, be sure to check the compatibility of the microorganism with the chemistry and other bioadditives used.

The major advantage of having active ingredients in growing media before you plant is that these microbes are present in the root zone before root diseases have a chance to get establish. Most beneficial microbes are packaged in granular form, powder or liquid format. Some of the liquid products can be applied in the greenhouse with injectors through the irrigation system. Most of the powders can be drenched, however there is added labor and time to apply products in this method. If you add beneficial microbes yourself, the easiest method is to add products to the mixing line. Another choice is to speak with your growing media supplier, since most manufacturers can add active ingredients to growing media for you. Often the best value and return on investment is to have the beneficial microbes added for you. Keep in mind that if the product you are adding to growing media is a PMRA registered biopesticide, handling and use regulations must be respected.

The use of active ingredients is becoming popular for plant growth enhancement and natural suppression of plant root diseases. They are readily available, predictable in the results they provide and are cost effective, offering growers a safer alternative and an additional tool for plant culture.

Vineland creating technology roadmap for horticulture.

BY ANDREW SNOOK

Vineland Research and Innovation Centre (Vineland) is building a technology roadmap for horticulture in northern Ontario.

To meet this goal, the Niagara Region-based, non-profit research organization has teamed with the Northern Ontario Farm Innovation Alliance (NOFIA) and the Rural Agri-Innovation Network (RAIN), and the three organizations are conducting a study aimed at identifying barriers and challenges faced by stakeholders in the region’s horticultural sector.

The goal of the project is to provide growers, stakeholders, and communities with information to bring about improvements in the quantity, quality, and availability of fresh local produce in northern Ontario.

The project is being funded in part by FedNor through the Northern Ontario Farm Innovation Alliance.

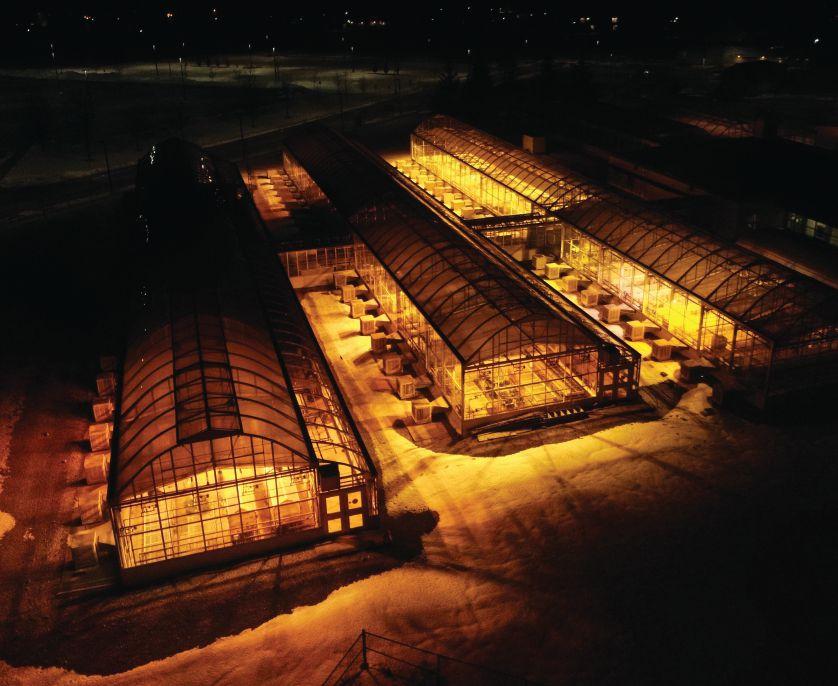

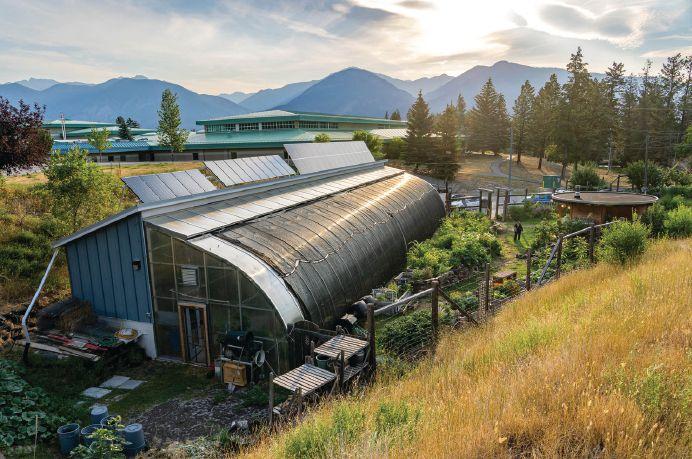

ABOVE

Vineland has been conducting these technology roadmaps since early 2021. As part of the COVID-19 response, OMAFRA (Ontario Ministry of Agriculture, Food and Rural Affairs) funded all of the growers associations in Ontario to conduct these technology roadmaps to understand how the labour disruption caused by travel restrictions would impact the labour available to each sector; and what technological solutions there would be in the short-, medium- and long-term in terms of development to mitigate some of the risks of labour shortages, explains Dan Bath, research scientist, Horticultural Automation, Vineland.

“And so, Vineland was commissioned by three different growers associations to conduct these technology roadmaps. And from that, we really learned what a positive impact they can have on the organizations,” he says.

Vineland has now taken that concept

Vineland’s Dan Bath says a lot of new technologies are coming out for controlled environment agriculture, including several for vertical farming applications.

and applied it to several different organizations where it can perform industry research and market research to assess the technological needs of a given group. Earlier this year, Vineland arranged with NOFIA to conduct a technology roadmap specifically for horticulture in northern Ontario.

“Northern Ontario is not typically a place for horticulture, due largely to the climate being less amenable to horticulture than other places in Canada, particularly southern Ontario. Also, the parameters of the soil are not very conducive to horticulture. So, we’ve been working with NOFIA as well as RAIN to work on this roadmap,” Bath says. “Our process starts with interviewing key members of the group – in this case, northern Ontario horticulturalists. We’ve interviewed farmers, key stakeholders in the community to assess what the demand issues are faced by people in the horticulture sector in northern Ontario.”

Based on those interviews, Vineland conducted an online survey that was distributed more widely across the sector, where it could have participation from both consumers and producers of horticultural products in Ontario.

“In the last phase, we use that information to conduct industry research and market research. At Vineland, we have horticultural scientists as well as market researchers who dive into the issues that are identified through the interviews and surveys to try to see what technologies or technological solutions might be out there that may not be used to their full potential at the moment in the area,” Bath explains.

The project is still ongoing, and Vineland’s team is finishing up the industry research phase.

“What we’re doing now is making sure we’re having a look at how we think the research will impact various communities in northern Ontario, in particular, Indigenous communities. We will be meeting with representatives of Indigenous communities in the next month to ensure that our research will impact all communities in northern Ontario, including the Indigenous,” Bath says.

Once that process is complete, Vineland will release a report to NOFIA and the association will disseminate it through their website. Vineland is also planning on presenting its findings at the Ontario Agricultural Conference early next year.

Northern Ontario growers face a variety of challenges when it comes to operating in the horticultural sector. The first one they struggle with is a low population density.

“The population density is much lower than other places, so the access to labour is much more restricted. In particular, the access to skilled labour because it’s so far from larger cities,” Bath says.

Another challenging factor is the geography.

A

- Irrigation

- Lighting - Ventilation

“Because communities are so spread far apart, there is a need for transportation of supplies for horticulture, as well as for the produce itself, those costs go up considerably,” Bath says. “One pretty interesting solution that we’ve encountered in our research along the way comes from a company called AgriTech North in Dryden. They are developing a distribution network for produce and related products and supplies, trying to maximize the efficiency with which materials are

Humidity - Heating - Temperature

Operations management Equipment automation

Real-time data

Instant alerts of any irregularities

Remote access

greenhouse@maximus-solution.com 1 877 445-6556

maximus-solution.com

Dan Bath, research scientist at Vineland, says transportation issues not only impact the price of goods for the consumer, but also the freshness and quality.

transported for food production in northern Ontario.”

He adds that transportation issues not only impact the price of goods for the consumer, but also the freshness and quality.

“Produce that even comes from southern Ontario, or other places in North America, going to northern Ontario has anywhere from one day to several days of additional travel time, which reduces the quality of the produce that’s available to consumers,” Bath says. “This really highlights the need for a more local production in northern Ontario.”

He adds that local production in northern Ontario could take on several different forms.

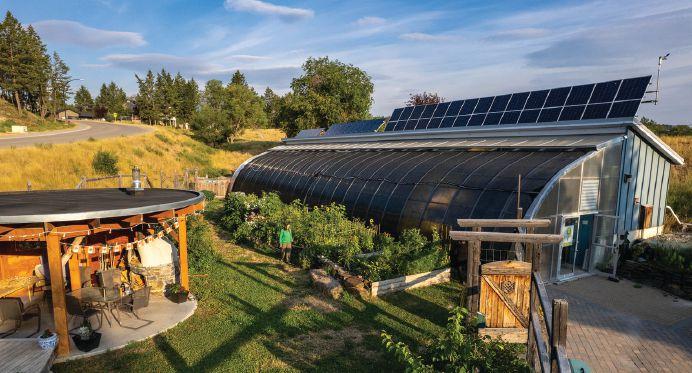

“There may be some technological solutions to increase the possibilities for outdoor agriculture, a more traditional style of agriculture. But also, we’re seeing a lot of new technologies coming out for controlled environment agriculture,” Bath says. “That could be

as simple as placing row covers onto outdoor agriculture, all the way up to vertical farming applications that are using entirely LED lighting, completely controlled climate fertilizers, and other inputs.”

Vineland is also noticing that growers in northern Ontario are paying significant attention to what the inputs are for their agricultural pursuits.

“In southern Ontario we take advantage of the fact that we can just drive to the hardware store or the farm supply store and have access to basically anything we need. Whereas, especially in remote communities in northern Ontario, they really have to think about how they might access equipment and supplies for their horticultural pursuits,” Bath says.

“We’re also finding there are new strategies and technologies coming out for how to simplify the logistics of getting supplies needed for agriculture. Some controlled environment

agriculture solutions also try to build a circular economy of supplies. Some controlled agriculture solutions are making efforts to use waste products from the horticulture as inputs, either as energy inputs through biodigesters or through various composting methods to reuse materials as fertilizers. Controlled environment technology producers are also keeping in mind how to address the problem of replacing parts when they fail. And there are some pretty interesting strategies on how to do that as well.”

In the end, Vineland’s main goal for producing these technological roadmaps is to help growers and consumers throughout northern Ontario.

“Our No. 1 goal is to have a positive impact on the region’s horticulture. That could take many forms. It could be simply raising awareness of technologies that are available or identifying gaps in technologies – basically problems that need solutions,” Bath says.

Without proper management strategies, light emitted from greenhouses during nighttime hours can potentially be disruptive to neighbouring residents

BY ONTARIO MINISTRY OF AGRICULTURE, FOOD, AND RURAL AFFAIRS (OMAFRA)

An increase in the use of supplemental lighting in greenhouses has been accompanied with an increase in the amount of light emitted from greenhouses at night during fall and winter months. Without proper management strategies, light emitted from greenhouses during nighttime hours can potentially be disruptive to neighbouring residents. As a result, the objective of this document is to outline the latest research in greenhouse light management for producers and to provide information on managing nuisance complaints should they arise.

Highlights of greenhouse light management research:

• While many studies have investigated the effects that

different lighting strategies have on plant production, there has been little examination of light emissions from greenhouses.

• The amount of light emitted from greenhouses using supplemental light is dependent on many factors including light abatement curtain use, crop stage, and light intensity (Snow et al.; 2022a, 2021a, 2021b).

• Sky brightness levels near greenhouses using supplementary lighting can be affected by light levels emitted from other sources in the region (e.g., infrastructure, industry, residences and businesses).

Cloud conditions, air quality and moon phase also impact sky brightness (Snow et al.; 2022a,

Examples of available light abatement curtain models and their manufacturer specifications. This is not a comprehensive list.

2021a, 2021b).

• Research to determine optimal light management strategies for greenhouse production is ongoing, with the goal of developing strategies that create growing environments to support plant health, yield, energy efficiency and compatibility with neighbouring land uses.

The amount of light emitted from greenhouses using supplemental lighting at night depends on light intensity, closure of light abatement curtains and amount of vegetation.

1) Light intensity of the fixtures installed in the greenhouse

In general, crops that produce fruits like high wire vegetables or large flowers such as cannabis require more light than potted ornamental plants or lettuce (Faust, 2021). The use of higher intensity supplemental lighting in greenhouses is associated with higher light emissions when light abatement curtains are not being used (Snow et al.; 2022a, 2021a).

2) Closure of light abatement curtains over the crop and on side and end walls

There are many models of light abatement curtains on the market that are made of different materials to suit the needs of greenhouse producers for managing the greenhouse environment for the crop (Table 1). These curtains reduce the amount of light emitted from greenhouses by reflecting the light back into the greenhouses. Current ceiling light abatement curtains allow less than 1% light transmission and wall light abatement curtains allow less than 2% light transmission when fully closed. This

allows for greater use efficiency of the supplemental lighting since most of the light is contained inside the greenhouse to be used by the crop.

Light emitted from the sides and ceiling of greenhouses using supplemental lighting at night may impact neighbouring land uses. These light emissions can be minimized by using ceiling, side and end wall light abatement curtains. As ceiling light abatement curtains are opened to different gapping degrees (10%, 20% gapping, etc.), there is an increase in the amount of light emitted that is somewhat proportional with the gapping (Snow et al., 2021b).

Furthermore, light emitted from the top of greenhouses using supplemental lighting at night may be observed further from the source by artificially illuminating the night sky. These emissions can be reduced by using light abatement curtains

Provide Agro offers complete automation packages for a variety of crops to limit worker risk and increase productivity. Working with our partners we tailor a solution to your specific needs and goals, to get the most out of the technology.

change in sky brightness when fully closed light abatement curtains are opened to a 10% gap, but as light abatement curtains are fully opened there may be a significant increase in sky brightness near the greenhouse (Snow et al., 2022a).

3) Amount of vegetation in the greenhouse

More light is emitted from walkways and areas with less plant volume than areas in full production. This is most likely due to more light being reflected by surfaces than plants (Snow et al., 2022a).

Curtains designed for light abatement (keeping supplemental light in the greenhouse) or blackout (keeping sunlight out of the greenhouse; typically used in cannabis or ornamental production) offer potential energy savings especially when used in combination with energy curtains as a double layer over the

crop (Hanifin, 2022).

The use of light management curtains can impact the climate in the greenhouse, which in turn can negatively impact plant growth and yield. Therefore, it is important to research production practices and technologies that can address potential humidity and temperature concerns.

Strategies to maintain a consistent environment in greenhouses with deployed light abatement curtains are being researched (Nauta et al.; 2022). Using new technology, such as air-mix fans, may help growers maintain a consistent environment under light management conditions. Air-mix fans blend air from above light abatement curtains with air from below the curtains when curtains are fully closed. The cooler air above the curtains is pulled below the curtains and mixed with the warmer air to cool it down before being blown into the greenhouse. These fans are typically installed below the curtains with a duct leading through the curtain to the space above the curtains (Table 2). This technology may assist in maintaining a constant climate in a greenhouse where light abatement curtains are closed.