NEW PRODUCT

substrates. By: Dr. Brian Jackson

BY DR. MICHAEL BROWNBRIDGE

substrates. By: Dr. Brian Jackson

BY DR. MICHAEL BROWNBRIDGE

GRETA CHIU | @GreenhouseCan

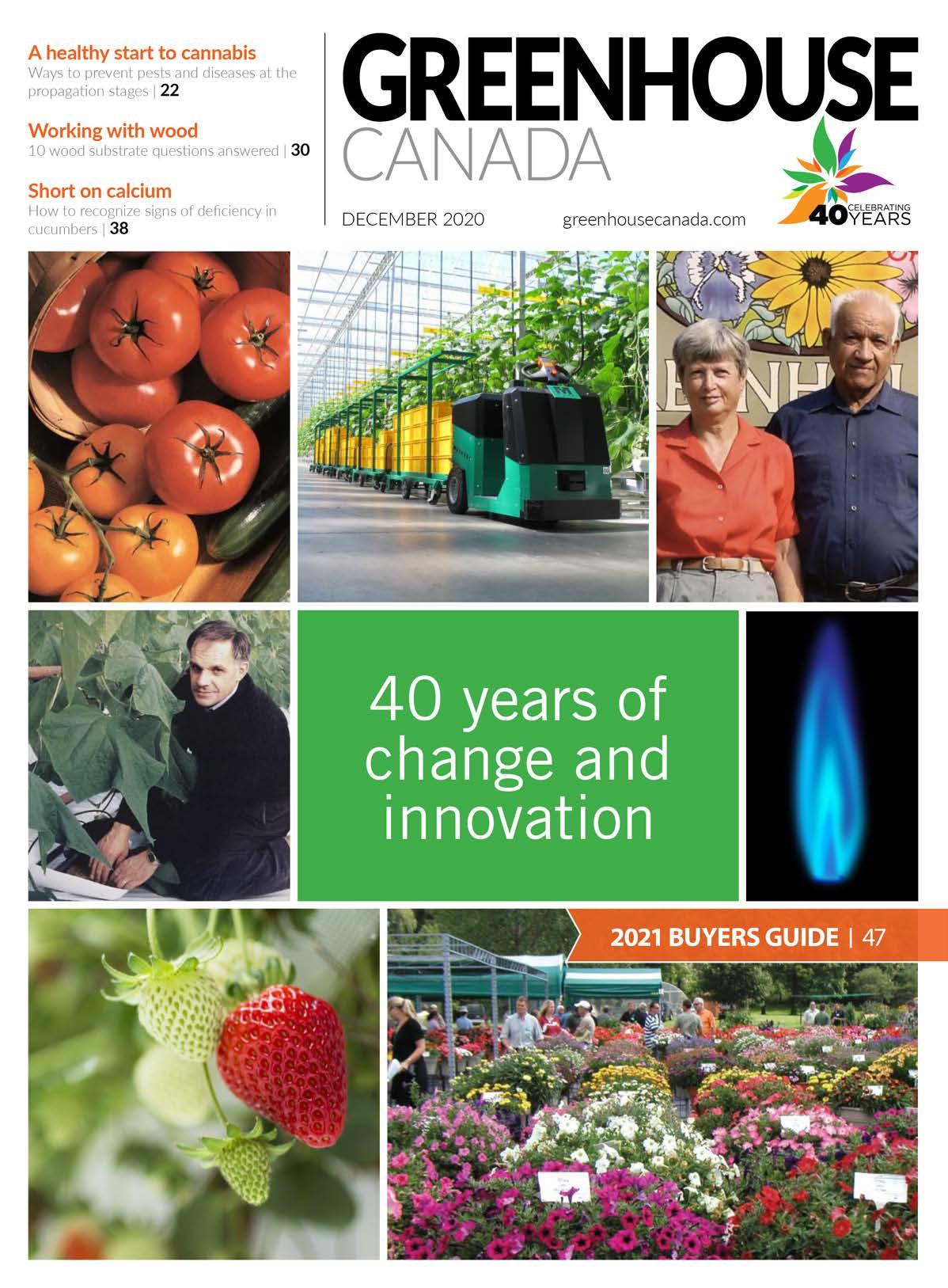

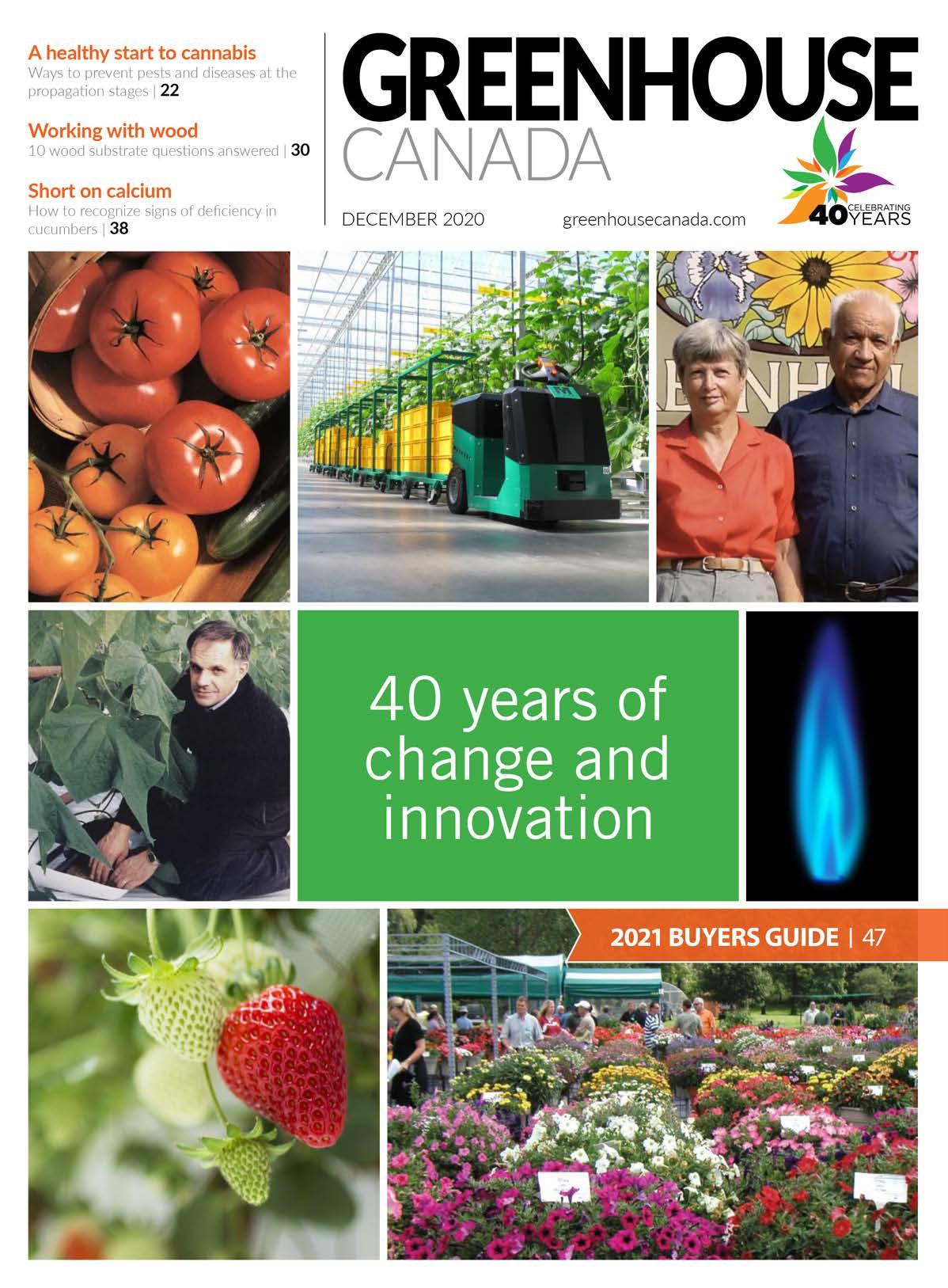

It was exactly 40 years ago, in December 1980, that Greenhouse Canada was first published in newsprint by Growth Publications, under the guidance of then publisher/editor Jim Brown.

us to share knowledge and stories to unite the horticultural sector from coast to coast.

greenhouse@annexweb.com 416.510.5163

Associate Publisher NASHELLE BARSKY nbarsky@annexbusinessmedia.com 905.431.8892

Account Coordinator SHANNON DRUMM sdrumm@annexbusinessmedia.com 416.510.6762 Circulation

...there was discussion around greenhouse raspberries in 1999.

In the December 2015 issue of Greenhouse Canada, my immediate predecessor, Dave Harrison, wrote two important in-depth features: one documenting the first 35 years of the magazine and another highlighting industry growth in those three-anda-half decades. If you haven’t yet read them, I would urge you to comb through our digital editions and take a look. If you’re someone who’s relatively new to the sector like me, then what you find might astound you. For instance, back issues discussed “the impending challenge from South American carnation growers and rose growers” in 1985, and there was already discussion around the potential for greenhouse raspberries in 1999. An issue in 2005 paid tribute to Lois Hole, and 2007 welcomed nowfamiliar columnist, Gary Jones. But if you’ve been around the block a time or two (or three), then you’ll likely re-read the features and bask in the warm glow of how much the Canadian greenhouse sector has grown. Or, you might have some suggestions for the next anniversary feature.

For this month of December, Greenhouse Canada is officially celebrating 40 years in print. You’ve seen it mentioned throughout the year now – on the cover, at Grower Day, in Gary’s column, or perhaps even by word of mouth. The magazine owes its continued success to its readers, expert contributors and advertisers. Thank you for continuing to support this Canadian publication, allowing

In this issue, you’ll find a number of features recounting important milestones, including business anniversaries and retirement celebrations. Each offers a glimpse of how much the sector has evolved. You’ll also find an anniversary feature looking back on pivotal moments of the past four decades and how they’ve impacted the greenhouse sector today, accompanied by commentary from some of the industry’s longest standing voices. To go about this feature, we asked our experts to identify their top four industry innovations or moments that had the greatest impacts on the sector. It was an impossible task – there were simply too many. Some important points that weren’t specific to the industry received notable mention or narrowly missed the cut. The availability of the internet in ‘93 is a particularly good example. As Gary mentioned in his comments, it had a massive impact on marketing, sales, instantaneous information, and more. “The list is endless. And of course, its influence will likely be timeless.” COVID-19 was another important one, but we’re saving that for the impending state of the industry report coming in January. 2021

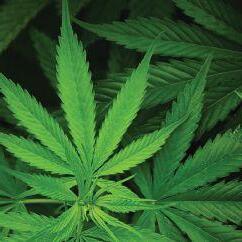

Also fitting for this issue are guest features on some of today’s key topics, including cannabis production and growing in wood substrates. You’ll also find the annual buyers guide, which, according to Dave’s feature, debuted in 1981.

As we head into 2021, don’t hesitate to drop us a line and let us know what you think. Here’s to another 40 years together.

Publication Mail Agreement #40065710 Printed in Canada ISSN 0712-4996

CIRCULATION email: blao@annexbusinessmedia.com Tel: 416-442-5600 ext 3552 Fax: 416-510-6875 (main) 416-442-2191

#867172652RT0001

Greenhouse Canada

of

and

If you prefer not to

please contact our circulation department in any of the four ways listed above. No

of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Growers who have been operating out of a nonbusiness banking account can now access the Canada Emergency Business Account (CEBA)

CEBA provides interest-free loans of up to $60,000, expanded from the previous $40,000 limit. Over 85,000 farm businesses will have access to the interest-free loans of CEBA, which equates to up to $5.1 billion – one-third of which is forgivable.

To be eligible, businesses must have been

operating as a business as of March 1, 2020, must successfully open a business account at a Canadian financial institution that is participating in CEBA, and meet the other existing CEBA eligibility criteria. The extended deadline to apply for CEBA is December 31, 2020. Businesses will be required to show the impact of COVID-19 on their operations. CEBA is available at 200+ financial institutions.

Source: Agriculture and Agri-Food Canada

Applications are being accepted for the Emergency On-Farm Support Fund. The federal investment totals $35 million, providing non-repayable funding for emergency COVID-19 response activities. This includes improvements to living quarters and work stations, personal protective equipment, sanitary stations, and other health and safety measures.

For Alta., Sask., Man., N.B., N.L., Y.T., N.W.T.

and Nun., the fund is delivered by AAFC and cost-shared 50:50 with applicants up to $100,000.

For Ont., OMAFRA is delivering funds through the existing Enhanced Agri-food Workplace Protection Program. Claimable amounts for preventive expenses have doubled to $15,000 and there is a new category for small capital projects of up to $100,000.

For N.S., the fund

To help establish minimum requirements for employer-provided accommodations in the TFW Program across Canada, the federal government is inviting input from employers, workers, worker support groups, and other interested parties.

Feedback will be accepted until December 22, 2020 on proposed accommodation requirements in the TFW Program’s primary agriculture stream.

The government is also seeking feedback on potential approaches to strengthen oversight of worker accommodations, both prior to and after workers’ arrivals. The consultations will go towards developing a long-term approach to improve living conditions for workers.

Interested parties should email Employment and Social Development Canada at NC-TFWP-APTPTET-EPA-GD@hrsdc-rhdcc.gc.ca or reach out to your provincial grower association.

covers up to 75 per cent of eligible project costs – maximum $50,000. Applications due December 31, 2020.

For B.C., the fund is administered by IAF and cost-shared 50:50 with applicants up to $100,000. Applications closed Nov 17, 2020.

For P.E.I, applications are accepted through the PEI Department of Agriculture and Land until January 15, 2021. Contributions will be cost-shared 50:50 with applicants, up to $30,000 per farm.

For Que., applications will be accepted through FADQ from December 14, 2020 to February 26, 2021. Provincial regulations may differ in retroactive eligibility. Another 10 per cent may be provided to women, youth, visible minorities, Indigenous Peoples, and persons with disabilities, amounting to a 60:40 split. Contact administrator for details.

Cannabis snapshot in July

9,628,026 packaged units of cannabis were sold across Canada for medical and non-medical purposes:

Source: StatsCan, 2020

In Canada, an adult may possess up to 30 grams of dried cannabis or its equivalent in public, which is equal to:

Licensed areas for cannabis cultivation:

Here’s what you need to know.

Greenhouse growers are in a prime position to take advantage of a new class of legal cannabis production, called “Microcultivation”. The costs are less, the security requirements are less, and the regulatory requirements are (slightly) less. The limits differentiating “micro” licences from standard licences have been established as grow space (200 m2) for growers, or weight (600 kg dried cannabis) for processors within one calendar year. Here are some considerations to take into account:

1. Security clearances are required: Business owners, investors and some staff are required to have clearances. Each clearance costs $1,690.

2. Application: An account on the Cannabis Tracking and Licensing System (CTLS) is need for applications; the fee for micros is $1,675.

3. No residences allowed: Regulations prohibit the conduct of any licensed activity in a dwelling or house – that means no growing, no trimming, no drying, no storage, and no packaging in your home. You could probably get away with printing labels on your home printer, but that’s it. You will need a separately secured facility – a fenced greenhouse and locked shop – in which to conduct ALL your licence-related activities.

4. Size of grow area: The maximum size of an indoor or outdoor grow for a microcultivator is 200 m2, or approximately 2,150 sq. ft. – roughly 30’ x 70’. That’s pretty small, but micros are packing between 100 and 300 plants in that space. If you get one kilogram dried per plant and sell for extracts at $.80 per gram, 100 plants will gross you $80,000. Not bad for an extra 200 m2 of space and some fencing! Minimum fee per licensed site is $2,500. The annual regulatory fee is 1% of revenue below $1 M, 2.3% on revenue beyond $1 M.

5. Secured perimeters: You will need perimeter fencing with locks on the gates to get licenced, More importantly, it protects your crop from theft. Inside a greenhouse, something like portable construction fencing panels with a padlocked gate is ideal and relatively inexpensive.

6. Pesticide requirements are rigid: Basically,

no pesticides are approved because it could be harmful if inhaled by an immune-compromised individual. Biological controls are in wide use, with mixed results. Bugs carry their own microbial contaminants along with them, and can add to the microbial stew that can fail a crop in analytical testing.

7. Storing/processing facilities: Regulations state that regardless of whether you grow indoors or out, harvested cannabis would need to be trimmed, dried, and stored indoors in a GPP-compliant facility. It means a secured space with no exposed wood, non-porous surfaces that can be easily scrubbed, and nothing (like drywall) that can crumble or flake off to contaminate the product. There are lots of solutions in use. From a renovated sea container, to a retrofitted garage or shed, there are lots of good inexpensive alternatives to building new.

Costs, security, and regulatory requirements are fewer or less.

8. SOP requirements: Wait! What are SOPs?! Standard Operating Procedures need to be written for every aspect of a cannabis business, including security, inventory tracking and quality assurance. However, just writing the procedures is not enough. SOPs are constantly changing documents, which require review and revisions as necessary. Once written, staff need to be trained on the procedures and monitored to ensure they are following them and doing so correctly. In other words, you need an SOP for SOP’s as well – welcome to the World of Regulatory Compliance! The best option here is to purchase a proven microcultivation DIY SOP and application kit. There are several in the industry, offering varying degrees of success.

Tamara Follett was the fifth microcultivator to be licensed by Health Canada, the first female-owned micro in the nation, and the first in New Brunswick. Her “facility” covers 2 acres and consists of three small rustic greenhouses and a refurbished single car garage. Find out more by visiting SunLeafMicrocultivation.ca. For more information and discussions on obtaining a Health Canada Microcultivation Licence, visit the author’s Facebook group, Microcultivation for Farmers and Greenhouse Growers: https://www.facebook.com/ groups/763031217761638

Pivotal moments in 40 years of Canadian greenhouse history.

BY GRETA CHIU

To commemorate 40 years of coverage, Greenhouse Canada reached out to some of the industry’s longest standing specialists to highlight pivotal moments in greenhouse history. Here’s what they had to say.

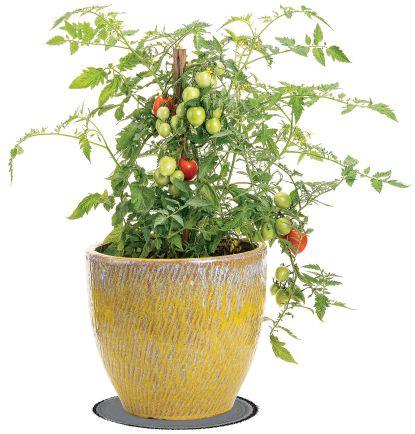

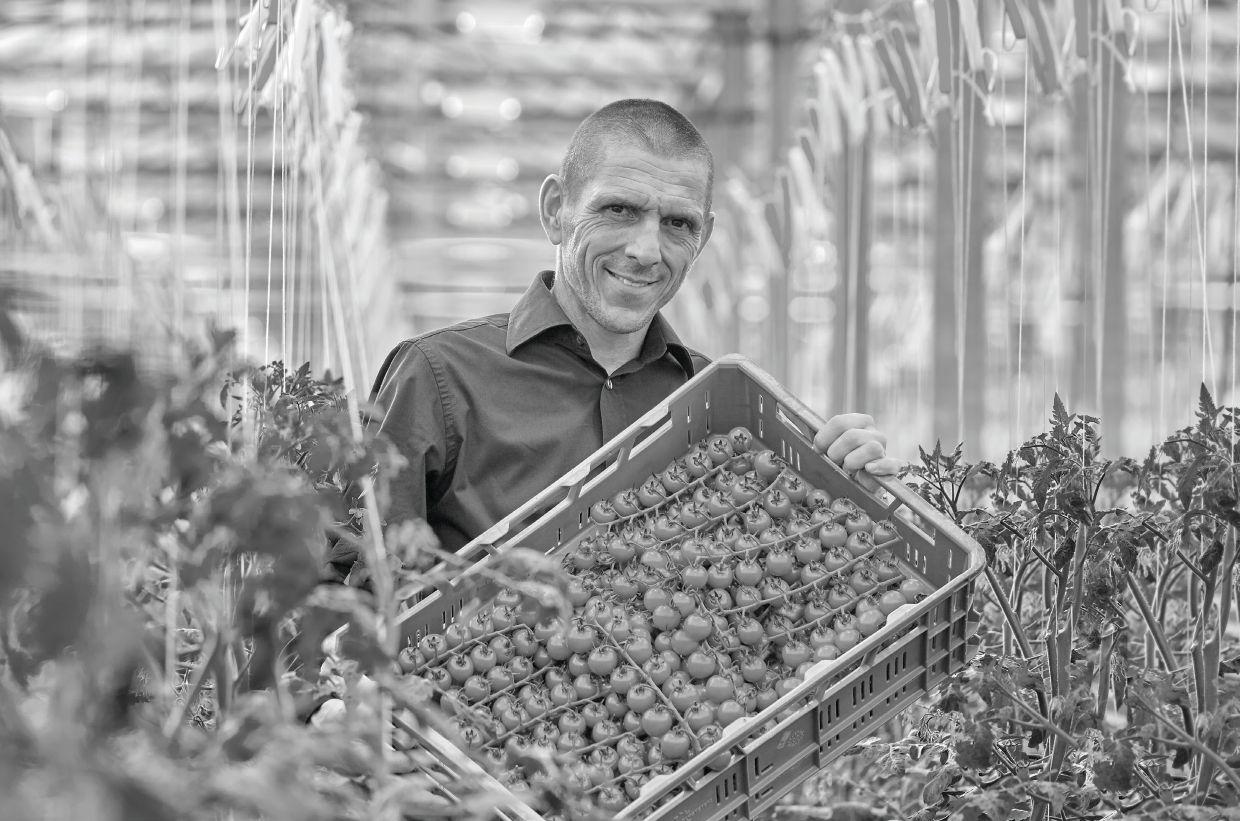

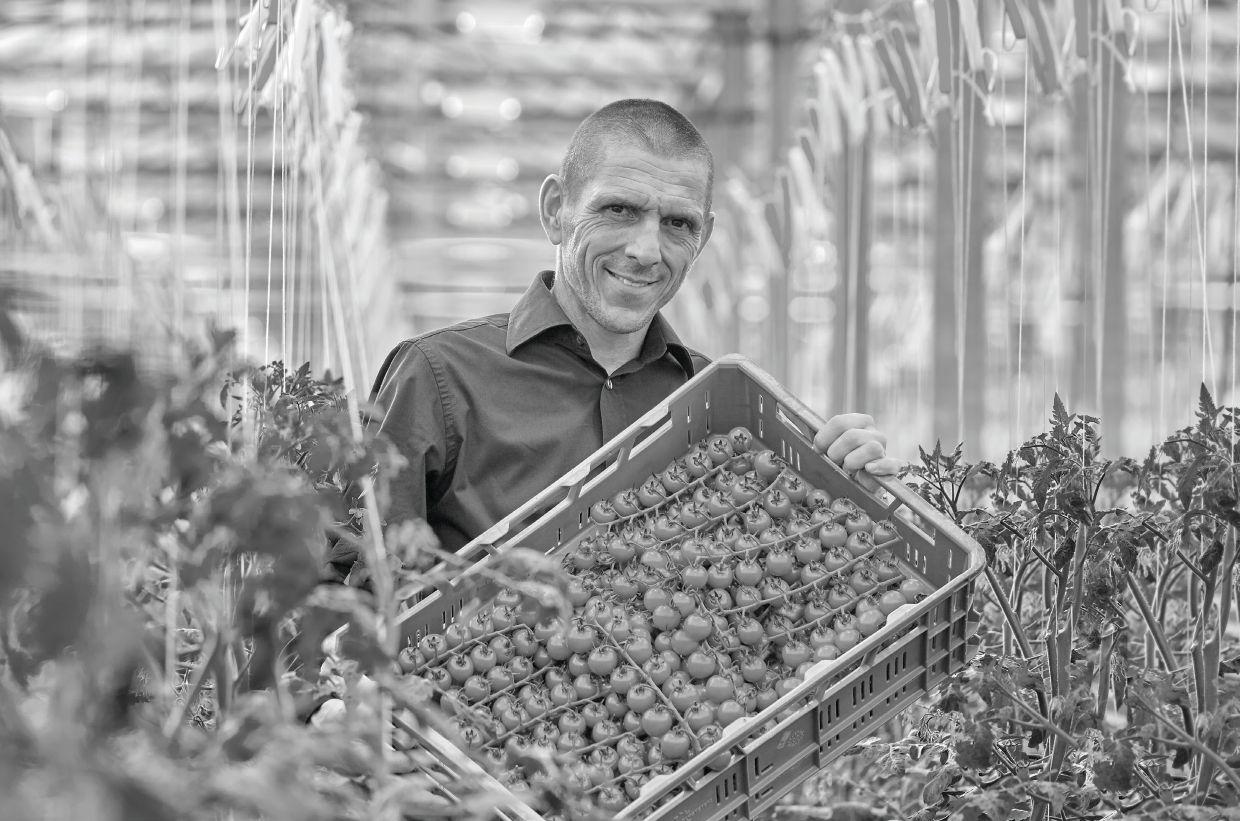

For tomatoes, the early to mid-90’s were characterized by a series of structural and production changes that allowed rapid economic growth, paving the way to U.S. markets. “That’s when the sector really started to move forward,” says Shalin Khosla, former greenhouse vegetable specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA)

During this time, greenhouse vegetable producers adopted rockwool, hydroponics and double-poly greenhouses at an exponential rate. Researchers successfully bred for resistance against fusarium crown and root rot into red tomatoes, allowing producers to diverge from a limited market for resistant pink tomatoes.

Methods for vegetable production evolved again in the 2000’s with the emergence of troughs. “First came tomatoes because of the ease of handling and better [greenhouse] climate,” says Dr. Mohyuddin Mirza, long-time greenhouse consultant in Alberta. Cucumbers closely followed, moving away from the older ‘V’-system to embrace high-wire production.

Aided by higher greenhouse roofs with tempered glass and more efficient coverings that appeared from 2000 to 2010, both greenhouse vegetable and ornamental growers benefited from rapid improvements in light transmission and diffusion, heat retention and air movement.

tanks continue to be “must-have” items for large-scale greenhouse development, says Gary Jones, faculty member at Kwantlen Polytechnic University, B.C. “This technology has had, and continues to have a significant return on investment…”

In line with global outlooks, the current goal is to achieve carbon-neutrality. “Hopefully by 2050, we’ll be able to come close,” says Mirza.

No more manual dials of the thermostat or chain-pulling to open vents. Climate computers emerged in the late 70’s and early 80’s, but progressed to more sophisticated software and a wide range of accompanying sensors in the early 2000’s. “It allowed [growers] more time to work in the crop rather than adjusting vents and heating,” Khosla says. Relying on data, the computers provided efficiency and consistency in the greenhouse environment to improve production and resource use.

ABOVE

“When I started... 50 cucumbers/ m2 was the standard,” says Mirza, “But some are now [at] over 280 cucumbers/m2.” The emergence of energy-managing technologies such as climate screens certainly helped, but grower knowledge of when and how to use them also played a large role.

The very first issue of Greenhouse Canada, dated December 1980.

Generating electricity, heat and carbon dioxide all in one package, co-generation was a big development for Alberta and other parts of Canada. Mirza recalls the use of smaller generators around Medicine Hat, Alta. in the late 90’s and early 2000’s. The interest was clearly there, but it wasn’t until 2015 that the technology became more prominent among greenhouse vegetable growers.

Along the same lines, flue gas condensers and ‘heat dump’

With increasingly sophisticated communications networks in place, growers can send and receive information and data analyses in real-time, adds Mirza. Is the crop under stress? Immediate changes can be made to the greenhouse climate from a mobile device.

As noted by both Greenhouse Canada’s former editor Dave Harrison and Québec greenhouse consultant Michel Senécal, the move towards automated systems has helped lower costs and ensure more uniform and consistent yields and quality. “Whether for internal transport in greenhouses, workers’ tasks, product deliveries (flowers, vegetables, etc.), inventory management, greenhouse climate management, etc., these innovations have significantly reduced production and labour costs,” says Senécal.

Artificial intelligence is also lending an additional perspective. With the many sensors and data being gathered, management and analysis is now critical. “You can monitor the plant more closely, to synthesize data together, give reasons for why your plant might not be performing,” says Mirza.

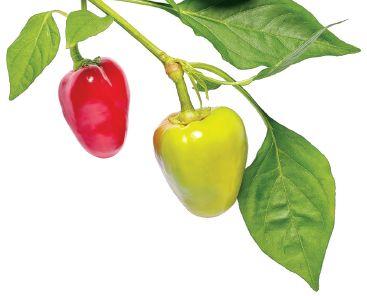

Seedless cucumbers appeared in the early 80’s, followed by peppers in the early 90’s. Along with beefsteak tomatoes, these three crops largely dominated the greenhouse vegetable sector well into the late 90’s.

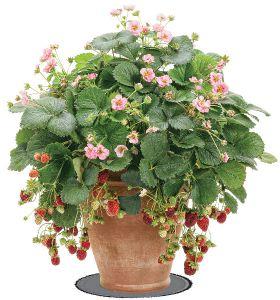

“But that soon changed with the introduction of mini varieties, cluster tomatoes, strawberries and eggplant,” says Harrison. “New crops mean new customers,” and growers continue to explore the cultivation of new crops under cover.

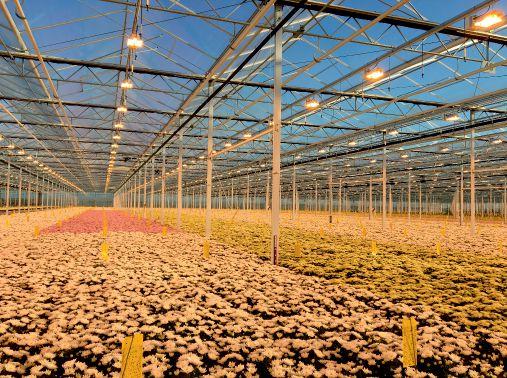

For floriculture, the 2000’s saw a surge in garden mums bred with excellent habits, but their lost hardiness relegated the crop to fall pot production, says Melhem Sawaya, veteran greenhouse consultant in Ont. The number of poinsettia varieties also rose rapidly, with over 200 varieties now available on the market.

Over the last ten years, different and unique crops began taking the place of old favourites. Growers started adopting nursery cultivars, such as flowering shrubs, and repackaging them for containers and gardens, says Sawaya. Impatiens almost completely disappeared from the market due to downy mildew, though new breeding has promised to resurrect the crop. Recent cross-breeding in begonias has led to a surge in its use as bedding plants, particularly as breeders prioritize for vigour.

Unable to import bumblebees being used in European greenhouses, Canadian researchers worked to capture, breed and domesticate native bumblebee populations in the late 80’s/early 90’s. One species worked particularly well in the eastern part of the continent. Trialled for just one season prior to commercial adoption, “that was one of the fastest technology transfers that occurred,” says Khosla.

Previously, growers would use the electric bee, a toothbrush-sized apparatus to vibrate each individual flower. Agitating pollen from the anthers for a greater chance of contact with the stigma, this process was conducted between 10am and 2pm each day. But once the bees arrived, they took on the job 24/7, says Khosla. Good pollination also led to more uniform fruit shape and size from start to finish. He estimates that the bumblebee’s arrival improved production by five to 10 per cent.

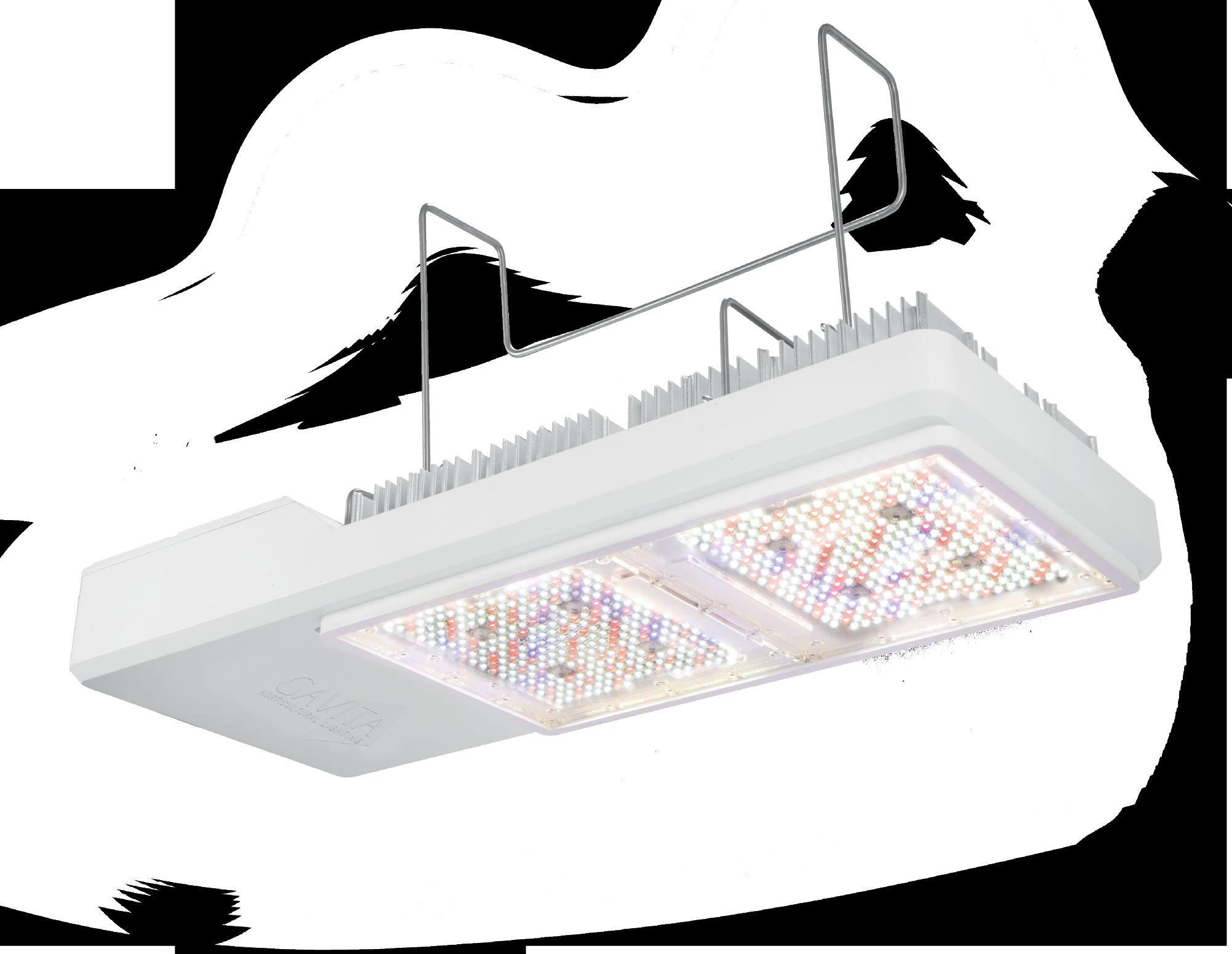

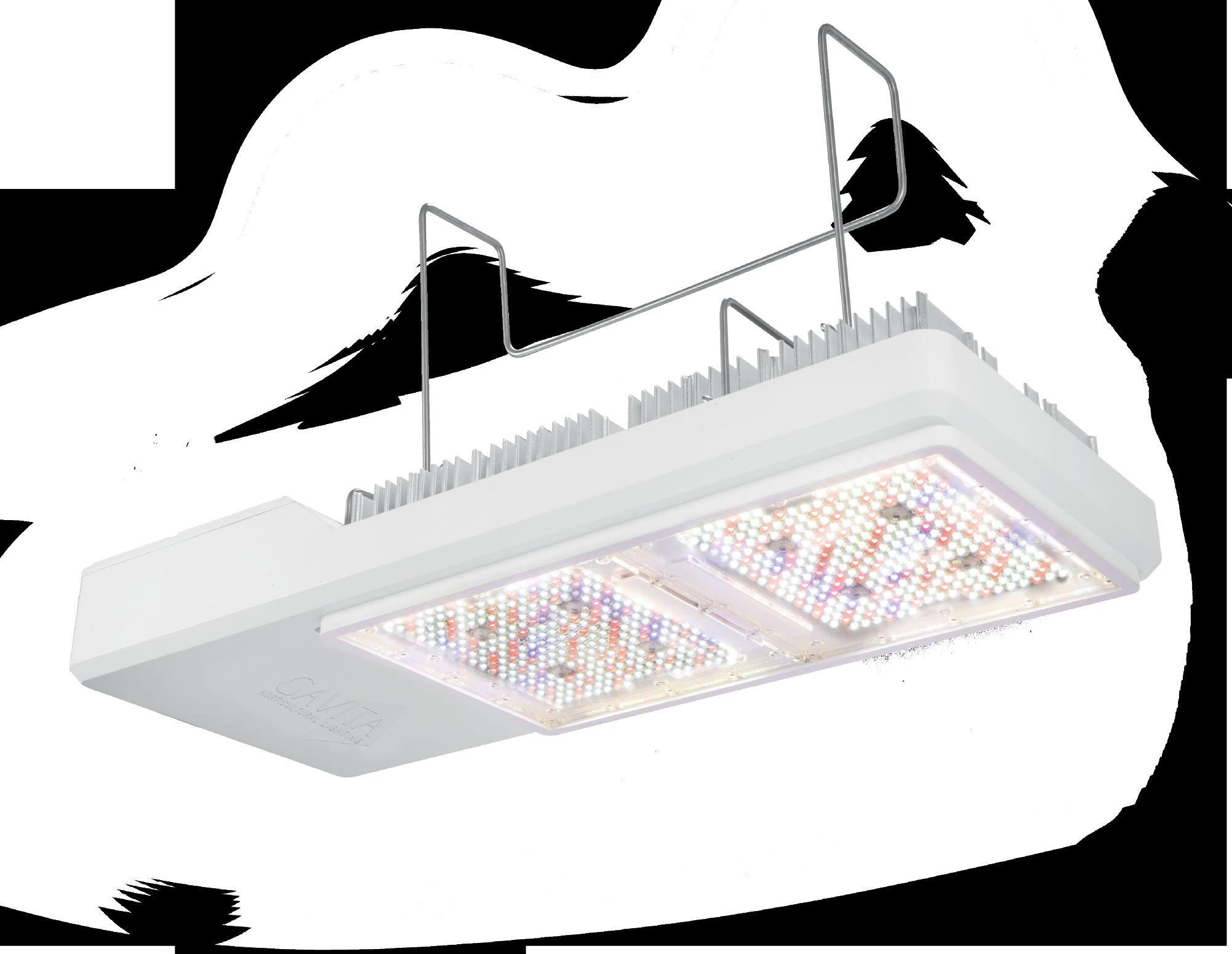

Some of the earliest lighting work on cut roses was led by Dr. Jim Tsujita at the University of Guelph, recalls Sawaya. Sparse LED use started to surface in floral production in the 90’s, but it wasn’t until the 2010’s that lighting was adopted on a larger commercial scale.

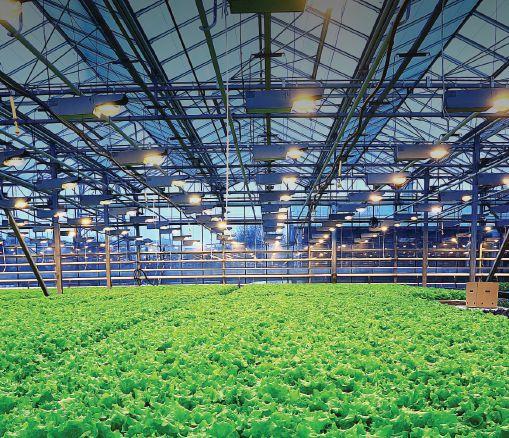

“Production seasons used to largely reflect natural light levels and meant winter shut down,” says Harrison. “But research on lighting has led to more growers able to consider year-round production, something so critical in assuring retailers they can expect greenhouse produce virtually year-round.”

In Ontario, supplemental lighting has allowed for winter production, opening new markets and gaining market share. Productivity increased 1.5 to 2 times for cucumbers, and 15 to 20 per cent in tomatoes, says Khosla. Light research for peppers started in the late 2000’s and improved production by 10 to 20 per cent

While metal halide and high-pressure sodium fixtures were, and continue to be, used in floriculture and vegetables, a new form of lighting is taking centre stage.

The low-energy input of LEDs makes “year-round vegetable production a real possibility in many places that could otherwise not entertain the idea,” says Jones. “[It] has spawned a whole new area of science in developing light recipes specific to individual crop species [and management of] … previously unthinkable plant characteristics….”

While producers experiment with a mixture of top HPS and LED interlighting, says Mirza, one Albertan grower has successfully grown tomatoes under LEDs for the past four years. It’s also increased yields, adding 4 to 8 kg/m2 to yearly totals.

What’s holding LED back from largescale adoption? High initial costs and a lengthy return-on-investment period, says Sawaya. But once the technology becomes more affordable and established, he adds, “I can see some of the imported [floricul-

Greenhouse Canada through the ages

ture] stock materials from Africa and South America being produced locally at a lower cost and with better quality, even though labour costs are much higher here.”

Jones relates the rise of urban agriculture to horticultural innovations such as LEDs, along with keen interests in renewable energy and local food production. “[Urban agriculture] has seen a gradual creep into the everyday consciousness over several decades, but really exploded in the last decade in large cities here.”

Near the end of the 70’s, a new ornamental technique emerged in the form of plugs. “The idea that each seed be sown individually in a cell in a multicellular tray was revolutionary at that time,” says Senécal, who attributes the work to David Koranski, Roger Styer and Melhem Sawaya. “Producers quickly adopted this technique, which has become the standard even today.”

Machines used for seeding plug flats followed in the early 80’s. With these mechanical transplanters, a crop and a half was easily achievable, says Sawaya.

Another hallmark of the 80’s was Impatiens walleriana, a new crop that took the sector by storm. “[In] some greenhouses, 70 per cent of their flat production was Impatiens,” says Sawaya, “and [it] was the first item to run out.” Growing Impatiens was relatively straight forward, and it greatly simplified production for those cultivating a large proportion of it. “The synergy of producing plug flats under [metal halides] cut production time drastically [and produced] a better-quality product for the consumer,” says Sawaya. They made up for the increasing costs of labour, production and transportation at the time, without needing to increase prices.

Marked by the opening of Home Depot in 1978 and Costco in 1983, big box stores opened up retail sales on a large scale, providing growers with mass volume customers and allowing economies of

scale that were unknown before, says Jones. “Their influence on market trends is enormous. But…they also have had a massive influence on prices with deep discounting and a consequent influence on margins,” impacting the consolidation of the industry.

A surge in vegetative cuttings appeared in the 90’s, promoting greater uptake of larger container sizes to absorb the higher plant material costs, says Sawaya. Bedding flat production dropped while patio containers rose. A combination of production efficiency and lower retail prices led to production based on speculation and resulted in oversupply.

In comparison, the 2000’s saw more production programs taking place between buyers and growers in Ontario, says Sawaya. There was less speculation and more production to order. This period also saw the emergence of consumer-facing brands, such as Proven Winners, Simply Beautiful and Flower Fields, as well as pay-by-scan among certain chains.

More recently, COVID was, and still is, having a large impact on ornamental consumption. Foreign workers, consumers, containment, open or closed retail shops and garden centres – it was a flurry of activity, says Senécal.

“COVID-19 made us realize how much consumers love plants and gardening,” says Sawaya. By equipping the consumer with quality product and the right knowledge for plant care success, he hopes this will help keep this momentum going.

“Biological control with predators and parasitoids appeared more commercially towards the end of the 1980’s,” says Senécal. Later in the early 90’s, the use of biopesticides emerged, encom-

Known consultant, trial coordinator and advocate for the floriculture sector celebrated milestones with growers.

BY GRETA CHIU

Veteran greenhouse consultant Melhem Sawaya celebrated his business’ 30th anniversary with his closest customers, friends and family last fall.

“I am thankful to everyone who attended,” says Sawaya. The founder of Focus Greenhouse Management, Sawaya has worked with and garnered the respect of many greenhouse floriculture producers in Ontario for over three decades.

A known supporter and vocal advocate of the horticultural industry, Sawaya is involved in a number of initiatives, such as programming for the Canadian Greenhouse Conference and Grower Day, as well as regularly contributing to Greenhouse Canada magazine. He’s also coordinated the annual Sawaya Garden Trials in Simcoe, Ont. for the past 20 years. What first began with 150 varieties, the

trials now showcase over 3,000 annually, allowing growers to see how new varieties perform in the southwestern Ontario climate.

“I just want to say how much we appreciate your friendship,” says Andy Vander Hoeven of Vander Hoeven Greenhouses, echoing the sentiments of many other growers who attended that night. “You’ve been a real confidant to us. Just a real treasure. We really appreciate everything.”

Originally from Lebanon, Sawaya exhibited his entrepreneurial spirit from an early age. At 17, he built a tennis court and started Sawaya Tennis Courts in his hometown, clearing the area of trees with his own hands. It’s been well-loved by locals and formed the seed for a whole generation of excellent tennis players in town and within the

TOP Sawaya celebrates three decades with customers who have become friends.

BOTTOM Ken Tigchelaar shares fond memories and takes part in some light roasting.

Neudorff North America is an innovative leader in ecologically responsible pest solutions for nursery and greenhouse growers, farmers and turf professionals.

Our effective and affordable solutions for disease, insect pests, pest slugs and snails have limited impact on applicators, and the environment. They are an important part of integrated pest management programs.

Powerful disease protection for your greenhouse vegetable and ornamental crops with a fraction of the copper found in other copper fungicides.

Fast-acting insecticidal soap. Controls aphids, mites and whiteflies on ornamentals, herbs, spices, vegetables, including cannabis. Effective as a cutting dip to control whitefly nymphs.

A summer and dormant oil. Controls all life stages of insects and mites. Suppresses powdery mildew of greenhouse ornamentals, fruit, vegetables and cannabis grown indoors.

Fact acting. Controls moss, algae and liverworts in and around greenhouses.

A durable pelleted iron phosphate bait. Provides excellent protection of greenhouse crops from slugs and snails.

A durable, fast-acting pelleted spinosad bait that is active against a wide range of ants in greenhousegrown vegetables and ornamentals.

Inside and outside. Neudorff protects.

immediate family, he says. Sawaya Tennis Courts continue running to this day.

At his sister’s insistence, Sawaya enrolled in a university pre-med program, but he quickly realized that this wasn’t the right choice for him. Looking at the courses he took – chemistry, biology, and math – he realized he could apply these same credits to a different program. “That’s how I ended up in horticulture.”

Never one to take the road well-travelled, Sawaya embarked on a student-exchange program to Canada where he met his future wife Maureen – on a tennis court. Eventually, the couple began thinking about starting a family, but Sawaya’s migrant status didn’t help on the job front and making 35 cents an hour was no way to support a family. “I sent out around 70 applications – not even an answer,” he says, describing an experience that many foreign professionals still run into today. By taking courses and making connections at the University of Guelph, he was eventually offered a job at Fernlea Flowers.

“I started as a water boy,” he recalls, before progressing through the ranks to manage different areas of production. Seeing a need, he started grower supply company Pro Gro under the umbrella of Fernlea Flowers, supplying grower products to other producers.

After 12 years at Fernlea Flowers, Sawaya decided to try the consulting business, filling a need that he saw in the industry. Starting at a 50 per cent pay cut in the first four months, the business

exceeded his expectations in the next six, confirming that his decision was the right choice. At one point, Sawaya says, he was working with 55 different operations, amounting to approximately 90 per cent of the greenhouse floriculture volume in Ontario. “It is now down to 44 operations because some customers sold to cannabis,” he says, sticking by his decision to not work with cannabis operations.

“Through the shift from Fernlea to consulting, I would not have been able to do it without the support of my wife,” he says of Maureen, with whom he would be celebrating their 43rd anniversary together this year.

“My mom used to count the slices of bread to make sure there’s enough sandwiches for the week so we can go to school,” says Sawaya’s daughter Lara, a professional event planner and entrepreneur who organized the evening’s festivities. “That’s how you support your family business.”

“I learn from every situation. The bad ones make me stronger and the good ones make me thankful,” Sawaya says. Acknowledging everyone in the room for their years of support and collaboration, he expressed his gratitude to Fernlea for

taking a chance on him and continuing to work with him today, making them the longest-serving customer he’s worked with at 42 years and counting. Always thinking of the horticultural sector, he adds, “Don’t be afraid to ask for help… and don’t be afraid to lean on the strengths of others.”

Whether it’s his family or his clients, Sawaya puts people first and treasures every moment – a fact that is evident in his photography and the camera that never leaves his side.

“He lives his life behind the lens,” says Lara. “I think our whole life was ‘What do you want for breakfast?’ Click. ‘What time are you getting on the bus?’ Click. We have more printed photos than I think any child or family should have. But we’re grateful for it.”

“After all, a picture is better than a thousand words,” adds Sawaya. “Especially for a guy [who speaks] English as his second language.”

Over 150 people were in attendance at the 30th anniversary event for Focus Greenhouse Management, held in Brantford, Ont. in October 2019.

For more photos from the celebration, visit greenhousecanada.com

You trust Grodan GroSens to give you unparalleled insights into your rootzone. Imagine what you can do with insights into your climate and root zone in every room of your grow.. With e-Gro you can leverage Grodan’s 50+ years of Precision Growing excellence with leading edge tools such as big data, Internet of Things and AI to dial in your climate, irrigation, crop and harvest data. It gives you real-time powerful control 24/7, anywhere on any device.

Join us on the leading edge of growing technology. Sign up for an e-Gro demo: www.grodan101.com/e-Gro

Part of the ROCKWOOL Group

Relevant data from various sources in your facility is collected and displayed clearly in a single place, in real-time.

Smart recommendations help you to optimize your irrigation strategy and guide your crop to the desired balance. Get alerts and notifications when your facility is out of your chosen ranges to help you prevent problems.

e-Gro is a web-based software that integrates valuable insights about your crop including climate and root zone. You get remote access to your crops data anywhere, anytime.

Jean-Pierre Fortin

ver the past few years, demand for organic products has continued to rise, so much so that organic crops can now be found in all industry sectors including fruit and vegetable production, ornamental growing and even cannabis farming. By promoting healthy nutrition and ecofriendly practises, the organic growing philosophy has decidedly become the trend of the future. Nevertheless, embracing this trend for commercial crop production does have its share of challenges…

In organic growing, preference is given to natural and organic fertilizers. Although these perform as well as their synthetic counterparts, plants do not easily assimilate the essential elements they contain. How to rectify this situation and make the most of your organic soil? With conditioning!

What does organic soil conditioning involve?

Organic soil consists of natural ingredients. It contains elements that are essential for plant growth deep inside its structure, making them difficult to access. Conditioning helps to trigger nutrient mineralization. It also activates the growth of microorganisms, which process the nutrients into a form that can be absorbed by the roots and assimilated by the plant.

Why is conditioning good for organic soil?

There are several benefits to organic soil conditioning, for instance under the following circumstances:

It compensates for shorter crop growth and short time to market

Products like tomatoes and peppers are long crops, giving the mineralization process the time it needs to unfold.

Inversely, leafy vegetables, fine herbs and sprouts make their way to supermarket shelves after just a few weeks – before mineralization is naturally triggered in time to satisfy short crop needs.

It synchronizes the availability of these elements with crop growth

Leafy vegetables need a lot of nitrogen over a short time. Tomatoes need a steady supply of nitrogen however they need a lot of potassium during fruit production. Sprouts need all the elements over a period of 2 to 3 weeks. Conditioning allows the elements to be mineralized as needed.

It enables the more sustainable and ecological management of natural resources

Several producers satisfy the immediate needs of their organic crops by increasing their organic fertilizer application in a way that is disproportionate to actual needs. Conditioning helps to reduce the quantity of fertilizer used by increasing the availability of the elements already present.

It promotes access to nitrogen

Nitrogen is among the most – if not the most –recalcitrant in terms of organic availability. Nitrogen is mainly imprisoned in proteins and amino acids. Proteins are in fact composed of chains of relatively complex amino acids. Every amino acid traps at least one nitrogen molecule. This nitrogen only becomes available if the protein chains and the amino acids that compose them are hydrolyzed. Hydrolysis is an enzymatic reaction that splits the proteins and amino acids. The microorganisms lead this process, drawing their nutrients and energy from many organic molecules including the proteins they break apart. The nitrogen is freed by the end of the process in an ammoniacal form not used by plants. Another class of microorganism, nitrifying bacteria, can convert ammoniacal nitrogen into nitrate, which is easily absorbed and assimilated by plants.

To effectively condition the soil, we need to stimulate the microorganisms by providing them with an environment and with nutrients conducive to their growth.

Oxygen

Just like humans, bacteria draw their energy from breathing, which involves burning carbon hydrates (sugars). They have a constant need for oxygen.

Water

Hydrolysis occurs in the presence of water. In fact, one water molecule is used during each step of decomposition. Water is also essential in maintaining the cellular structure of

bacteria and it participates in numerous metabolic reactions. A water supply is essential to microorganism development.

Just like plants, microorganisms perform best at specific temperatures. Temperatures above 28 °C are preferable for certain species. Nonetheless, studies show that mineralization occurs rapidly between 20 °C and 25 °C.

Although some microorganisms can accommodate a pH that is either very low or very high, optimal pH for mineralization is between 7.6 and 7.8, which is more alkaline. The bacteria involved in the process are nonetheless able to adapt to the soil’s pH (5.5 - 6.5).

Time is the final factor that contributes to successful conditioning. The microorganism population must peak to ensure an effective mineralization rate. It takes a minimum of 2 weeks to achieve optimal cruising speed.

Studies have demonstrated the effectiveness of conditioning. We compared the analyses of unconditioned organic soil to soil conditioned for 2 to 4 weeks. The results were conclusive, indicating low nitrogen levels in the unconditioned soil. Moreover, this nitrogen was nearly entirely present in ammoniacal form. Testing revealed 2.5 times more nitrogen at the end of 2 weeks of conditioning. Additionally, 90% of the nitrogen was in nitrate form. Conditioning prior to use helps to release the nutritional elements in a form that can be directly assimilated from the time of planting.

Conditioning involves four steps: remove the soil mix from the packaging; moisten it until its humidity level reaches between 60 and 80% (on a weighted basis, water weight/soil weight); leave it to swell to incorporate oxygen; and let it rest long enough for the mineralization process to occur.

As illustrated on this graph, the feather meal was incubated and regularly tested to monitor the nitrogen forms following the mineralization process.

Ammoniacal nitrogen was clearly the first nitrogen form to register. The nitrogen was converted into nitrate only after 2 to 3 weeks of incubation.

Compliments of the ScottsMiracle-Gro R&D Department, all rights reserved.

For long crops, conditioning can take place directly in growing containers or tubs. For medium duration crops (potted fine herbs, vegetable plants, leafy vegetables), the containers can be filled up in advance, stored, and kept moist for planting. Finally, short crops require more organization. For these, the soil must be stored under proper conditions until the germination trays are planted. Ideally, a special soil conditioning space could be organized near the potting room. The size of this area should correspond to required weekly volume.

Conditioning is an additional step in growing preparation, but it is vitally important because it helps to guarantee the crop’s efficiency and success!

Jean-Pierre Fortin is a Growing Media Technical Expert for Scotts/Hawthorne.

BY DR. MICHAEL BROWNBRIDGE

The cannabis sector is a young and vibrant part of the horticulture industry. With legalization across Canada, opportunities to grow the crop at scale emerged overnight. This has brought significant challenges as growers adapt from ‘basement growops’ to multi-acre facilities. Because cannabis has some unique features that it shares with many other greenhouse crops, growers can transfer some well-established IPM technology from other horticultural sectors to prevent many of the pests and diseases they have in common.

The intent of this two-part article series is to provide information on pest and disease management tools that are currently approved for use in Canada. It does not cover a wish list of products and materials that could be used. Serving as a companion to the Greenhouse Canada webinar presented in September 2020 (greenhousecanada.com/webinars), this article series addresses common production issues and available solutions at each stage of crop development, allowing us to consider ways in which they may be prevented or managed at that point in time. This is especially important as the use of a biopesticide/biocontrol agent in one stage may differ from how it can be applied in another. Furthermore, successful use in one stage inevita-

bly impacts what occurs at the next. In this way, I hope to bring more of a ‘whole program’ approach to pest and disease management through the lifecycle of the crop, from propagation to harvest. And last, the methods discussed are essentially for indoor production of cannabis – greenhouse or grow facility – but the methods described for propagation can be applied to production of transplants for either outdoor cannabis or hemp.

Now that that’s out of the way, where to begin? To avoid diluting the information by trying to cover too much, the focus is on implementation of functional IPM programs for cannabis, highlighting use of biopesticides and biological control agents, considering the best fit of the different components, and how they can be integrated into a crop protection scheme.

Let me first digress a little to stress the importance of plant nutrition in IPM, as it has a direct impact on plant health. By optimizing growing practices, we create a more resilient crop that is not only more productive, but inherently less prone to pests and diseases. However, high nitrogen levels in plant tissue can also dramatically increase plant susceptibility to pests and diseases. This has been

shown in a variety of other crops ranging from cereals, to flowers, vegetables and fruits, and studies have documented a particularly strong correlation between high levels of applied (synthetic) nitrogen fertilizer and growth of pest populations. Populations of pests such as two-spotted spider mite, green peach aphid and western flower thrips will expand rapidly when high levels of synthetic N are applied. This then raises the question – can fertilizer inputs be reduced without affecting crop quality or production time? Can the type of fertilizer inputs be managed to avoid rapid accumulation of high N levels in plant tissues while ensuring sufficient supply for growth? And is there latitude to reduce fertilizer inputs as a means of slowing pest population growth?

We know that plants require different types and levels of nutrients at different stages of development and growth, and essential nutrients (N, P and K) are manipulated to fulfill those changing requirements. In cannabis, some nutrients (particularly N) are ‘pushed’ at flowering to promote larger blooms. But this can compromise plant tissue formation and increase susceptibility to diseases like powdery mildew and Botrytis. Recent changes to Health Canada regulations on the application of nutrients by foliar spray is a significant development as it may allow reductions in salt-based nutrient inputs without compromising yield. Research has shown that application of foliar nutrients at times of peak nutrient demand and prior to stress events (rapid growth, bloom, and flower development, drought, temperature extremes, major changes in light and humidity) will enhance plant stress tolerance. Use of some sprayable nutrients can also enhance uptake and translocation of elements like calcium (Ca), an essential component of plant cell walls. Stronger cells, especially in flowers, can reduce susceptibility to diseases like Botrytis. This has been demonstrated in petunia where susceptibility is linked to poor movement of Ca into flowers and deficiencies increase susceptibility to the disease. Higher Ca concentrations enable more pectic bonds to be formed in flower cell walls, improving resistance to breakdown by enzymes produced by Botrytis, thereby reducing susceptibility to infection by the fungus. This has yet to be tested in cannabis, but observational evidence suggests that use of such nutritional supplements may help combat Botrytis.

ABOVE

A beneficial fungal product applied during propagation can improve root development in cannabis cuttings and increase yield. (Pictured: trial with Rootshield Plus)

Sanitation and prevention are at the heart of any IPM program, especially ones utilizing biological inputs. At its core, biocontrol is a preventative strategy and not a curative one. Biocontrol agents and biopesticides should be applied proactively to prevent pest or disease problems from developing, as opposed to controlling them. This is particularly important in cannabis as there are no (legal) rescue products that can save a crop if pests or diseases get the upper hand.

What is true in life is also true in cannabis, look after your mother! Sanitation starts from the very beginning of a production cycle. If you maintain your own stock plants, the area in which they are kept should be dedicated to keeping plants healthy in a stress-free, clean growing environment, ideally with systems and mechanisms in place to prevent ingress of bacterial and fungal spores and insects.

Limiting access to the room further reduces the risk of pests and diseases being transferred into the area. Pests and diseases readily hitch a ride on crop workers, so restricting plant care to a few individuals will go a long way to reducing risk. Maintain a strict ‘order of entry’ for those workers. In other words, all work on the mother plants and in the propagation space should be done first before they go into the main production areas. Once entering the production area, there should be no return to the stock plants until the following day. In addition, ask staff whether they grow plants at home. This is a tough question, but pests/diseases do not care and can be transferred via those workers from home to the production facility.

The order of entry and movement of workers will be unique to every greenhouse/grow facility. It is well worth the effort to develop a work schedule that eliminates the potential of pest/disease movement around the facility and enforces restrictions on staff movement to avoid spread. Think of the arrows that are prevalent in supermarket aisles these

days. They ‘encourage’ a unidirectional flow of customers to reduce close contact and aid in social distancing practices as we all strive to reduce the chances of COVID transmission.

Test plants regularly to ensure they are free from viruses and other diseases. Stay on top of bioprograms and sprays to ensure plant health and prevent diseases and pests on mother plants, as they will transfer with clones. Keep mother healthy and happy, and her offspring will get a much better start in life!

When we say ‘sanitation,’ I’m sure many think about this process being solely applied to the production space. And certainly, growing spaces and rooms should be thoroughly cleaned (removing any and all debris) and sanitized after a crop is harvested, and then again before a new crop is brought in. This reduces the risk of pests and diseases carrying over from one crop cycle to the next. But good sanitation practices should be applied in every stage of production.

Send in the clones

The goal of every grower should be to start clean. This will reduce problems later in production. It starts with the mother plants as discussed and extends into the propagation of clones. Hydrogen peroxide-based materials (e.g. ZeroTol) can be used to sanitize tools and surfaces as well as any flats and trays used for the young plants. Don’t forget to sanitize irrigation lines between crops, as biofilm layers can develop inside them and harbour diseases. Stabilized hydrogen peroxide products are extremely effective at eliminating biofilm build-up. After harvest, charge the lines with a peroxide solution (use label rates), leave them overnight and then flush with clean water before using them again. In addition, peroxide can be drenched onto the rooting medium or cubes the day before sticking to sterilize the medium. The beauty of using peroxide is that it breaks down rapidly and leaves no residues. If bringing in clones, then assume they will carry something. I have heard many stories of greenhouses claiming to have had “…no root aphid issues until we brought in clones from…” for example. At some point, especially with recent incidents of virus-infected clones arriving from propagators, I’m sure there will be calls for some form of phytosanitary certification to accompany cloned material, but until and even after such time, sanita-

tion is your best friend. Dips in biopesticides (e.g. BotaniGard) or horticultural oils are ways to reduce or eliminate pests (thrips, aphids, whiteflies, mites) coming in on clones. Can you quarantine clones and new plants to avoid transmission should they be infested? Again, limiting access to personnel and having a specific ‘order of entry’ plan in place can go a long way to reducing movement of pests. Consider sending out samples for analysis (e.g. DNA multiscan) to confirm plants are free from disease before transferring to the main production areas. Yes, there is a cost to this service, but it is minor compared to the costs of control or crop loss.

These are important steps to initiate right from the beginning. Protect your investment.

After taking care of mother, you must nurture your babies. Prevention starts here, nipping pest and disease problems in the bud, and taking steps to promote healthy root development. These are important steps to initiate right from the beginning for protecting your investment.

Managing root diseases is part of doing business in any greenhouse crop, and cannabis is no exception. Pythium and Fusarium species, for example, are well-known pathogens on other crops and quite happily use cannabis as a host. Unfortunately, they are readily transferred in irrigation water, in soil, and on people, and can easily come in via infected clones. We’ve already touched on some of the sanitation steps that can be taken to reduce inoculum levels on hard surfaces and in propagation media, and it’s also worth testing your water supply to ensure it is free from these diseases. Be sure to test before and after any water sterilization process to ensure it works.

There are also biological tools that can be used to prevent diseases. Beneficial fungi can be used to colonize and grow on developing plant roots, protecting them from many soilborne pathogens. These biocontrol fungi work by bringing several different modes of action to the system. For example, Trichoderma (RootShield) and Gliocladium (Pre-Stop) protect roots through

a combination of antagonism, competition, predation/parasitism, and induction of plant resistance. These tools also deliver other plant benefits, including stimulation of root growth and solubilization of nutrients in the soil so they are more accessible to the plant, promoting plant growth and health. In trials conducted on cannabis, Trichoderma applied at sticking (in the form of RootShield PLUS) resulted in improved root development in clones, which ultimately translated to a 4% increase in flower yield at harvest.

In terms of pests, those of primary concern in propagation are mites, aphids, thrips and fungus gnats.

Mites: Right now, three species are problematic in cannabis – hemp russet mite, broad mite and two-spotted spider mite (TSSM). And before you ask, yes, all three often come in on clones. All three species share certain characteristics: they have a high capacity for rapid population increase; they are hard to detect owing to their small size, and the first sign of an infestation may be symptoms of damage, and by then it may be too late to effect control. As we only have tools to prevent pests from increasing, we must act early, using biopesticides to provide a relatively quick knock down, supported by early introduction of biological control agents (BCAs).

Of the biopesticides, mineral oils will control several problem pests including mites (all stages, including eggs), thrips, aphids, and whiteflies. Two products approved for use in cannabis are Suffoil-X and PureSpray FX. Both are based on horticultural oils, but their formulations impart slightly different characteristics to each product. As a sidenote, Suffoil-X is also known to suppress powdery mildew and will complement a foliar biofungicide program. Application rates (1 to 2%) are similar for both products, which should be re-applied every 7 to 14 days. Thorough spray coverage is essential to efficacy.

Use caution when applying to newly stuck cuttings; at this stage, we recommend using the 1% rate and ideally waiting until plants have developed roots before spraying (approx. 7 to 10 days after sticking). Be aware that use of spray oils will leave a sheen on the leaves, but this does not interfere with transpiration. Dipping is also on the Suffoil-X label, and immersion of cuttings in a 0.1% suspension is a very efficient method of cleaning up clones prior to sticking.

BCAs for mites include Amblyseius

andersoni which is moderately effective against hemp russet mite; Neoseiulus (=Amblyseius) cucumeris, a highly efficacious choice for broad mite; and Amblyseius (=Neoseiulus) fallacis which is a good option at this stage in production for TSSM. For hemp russet mite, early treatment of clones by dipping provides the best knockdown of an incoming or resident population, followed by two to three successive foliar sprays. Although oils will kill predatory mites and other BCAs on contact, they leave no toxic residues when dry; that means they will not harm mites in sachets or BCAs released after the spray program has been completed.

Aphids: Rice root aphids can quickly grow out of hand unless you get on top of things early. Drenching rooting blocks with an approved Beauveria bassiana formulation (e.g. BotaniGard 22WP) is a good tactic in propagation. Make sure cubes are thoroughly wetted so that infective Beauveria spores permeate the entire block and come into contact with aphids on the roots. This must be repeated as aphids multiply rapidly. Later in production, root drenches should be accompanied by foliar sprays to target winged adult aphids.

Thrips: I am convinced that western flower thrips can survive on any plant. It might not be completely true, but they can cause a lot of damage in cannabis and often accompany cuttings. There are two fungal biopesticides registered as foliar sprays: BotaniGard 22WP/ES and BioCeres G WP/EC. Several different predators can also be incorporated into a biocontrol strategy. These include N. cucumeris (sachets on sticks preferred) which feeds on first instar thrips on the foliage, as well as soil-dwelling predators Stratiolaelaps scimitus (formerly Hypoaspis miles) and Dalotia (formerly Atheta) coriaria which feed on pupating thrips.

These BCAs provide simultaneous control of other pests, such as cucumeris for broad mites, while Stratiolaelaps and Dalotia feed on fungus gnat larvae. Last, the nematode Steinernema feltiae may be a useful addition to the program if needed, applied as a drench to the rooting cubes every two weeks. It is important to remember that the biopesticides and BCAs are applied to control different life stages of thrips and will remain with the plants when potted up in the main production area.

Fungus gnats: These are perhaps more of a nuisance problem than anything else, but they can passively vector soilborne diseases such as Fusarium, and high numbers of larvae in the growing substrate may cause significant feeding damage to freshly stuck clones. Cultural practices such as not overwatering will help limit populations, and the BCAs used to manage soil-dwelling stages of thrips are equally effective against fungus gnat larvae. Yellow sticky cards used to monitor for flying stages of pests can also make a significant contribution to the overall removal of adult pests, including fungus gnats and thrips.

All being well, investment in good sanitation and prevention practices through propagation will mean that everything is under control as plants move into the vegetative phase of their growth, but you cannot afford to relax. Steps taken in propagation should be maintained. Watch this space for cannabis IPM part 2: vegetative growth phase to early flowering.

Michael Brownbridge, PhD, is a Biological Program Manager at BioWorks Inc. He can be reached at mbrownbridge@bioworksinc.com

SUNSHINE® MIX #1, #4 and #5 are our most versatile formulations that expert growers choose for the production of a wide variety of crops including cell packs, large patio pots, and fabric containers.

All three are excellent for propagating cuttings in both indoor and outdoor growing situations and where increased drainage is a priority.

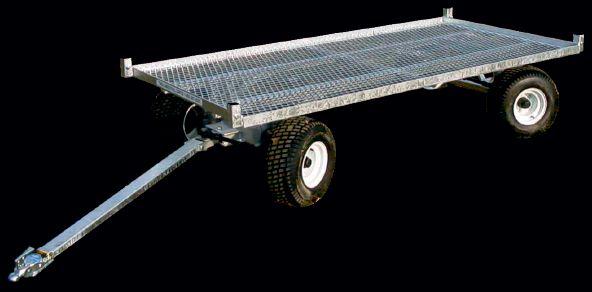

Answers to the most frequently asked questions on incorporating wood products.

BY DR. BRIAN E. JACKSON

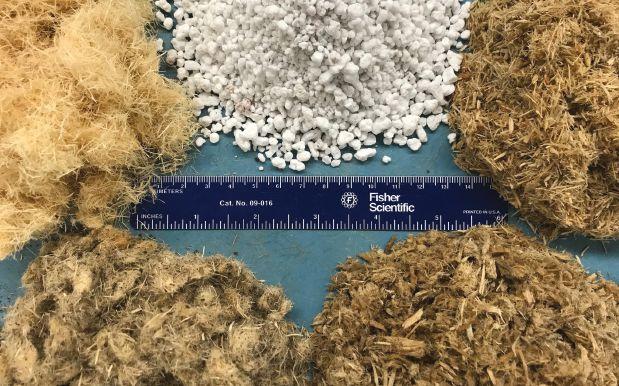

With change comes challenges, or at least modifications, particularly when growers consider switching to soilless substrates containing wood products. Over the past 15 years of research on wood substrates, plus countless interactions with substrate manufacturers and growers, I am often asked a similar set of questions. Here are some that I encounter most often:

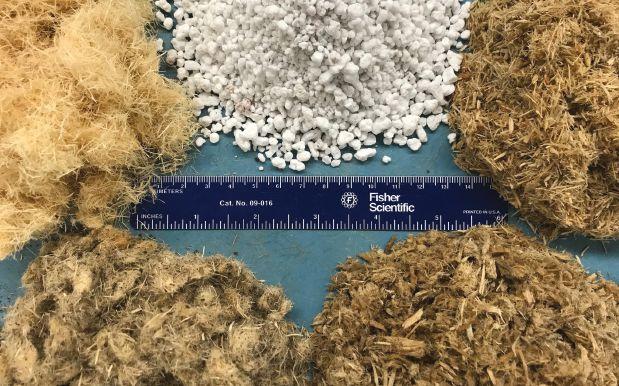

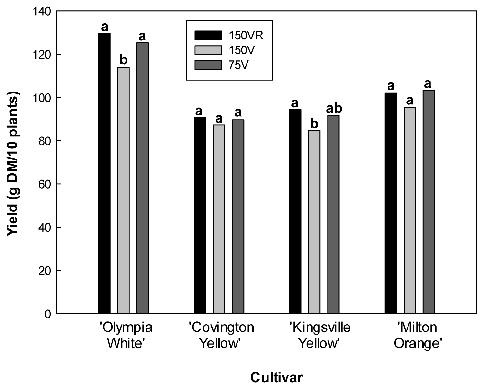

1) Will wood substrates tie up nutrients and cause nutrient deficiencies? Research has shown that microbial populations are higher in substrates containing fresh wood products (mostly due to higher carbon content) and those microbes are indeed immobilizing nitrogen. However, the good news is that the severity of nitrogen microbial immobilization is not as high (or insurmountable) as once thought or feared. This greatly depends on the wood product’s particle size, its processing and preconditioning, as well as the length of time it remains in a container during subsequent

ABOVE

production. Nitrogen immobilization issues are also dependent on the percentage of wood added to substrates. Many researchers and growers have found that 20% wood incorporation (in peat) leads to little change in available nitrogen. Above that percentage, and depending on the type and age of the wood, nitrogen can become limited.

Microbes in wood substrates will immobilize nitrogen as well as sulfur and some phosphorus to lesser extents, but so do other organic substrates, just in lower amounts. Growers who naturally fertilize their crops at lower levels (i.e. 75 to 90 ppm nitrogen) and switch to a mix with over 20% wood will most certainly see some nutrient deficiencies depending on the crops being grown. However, growers who customarily fertigate at higher rates (i.e. 150 ppm) will likely see no change in their crops. In short, the particle size of the wood materials and the percentage incorporated will dictate the rate and extent of nutrient tie-up. The

Traditionally, perlite (top center) has been the main component amended with peat to create substrates, but wood products are now commonly used in mix creation.

Growers know that when it comes to controlling and monitoring a production environment, a simple, flexible, sustainable control system is crucial. This is why you can depend on Reliable Controls. Our nationwide network of factory-certified Authorized Dealers will help you design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective, Canadian-made solution, please contact a Reliable Controls Authorized Dealer near you.

economics of wood components often outweigh the cost of extra fertilizer if/ when needed.

2) Are wood substrates toxic to plants? If wood products have not been aged, treated, or processed in machinery that allows chemicals in fresh/green wood to be removed (solubilized or volatilized), then there can be issues with seed germination and/or severe plant stunting. The majority of reported issues have been with freshly produced, hammer-milled pine wood substrates. Commercial products on the market today have not had these problems widely reported.

3) Are there changes to substrate pH?

Wood has an inherently high pH compared to peat moss or pine bark. When you replace a fraction of those materials with wood, you increase the percentage of a higher pH material while decreasing the percentage of a lower pH material. Coupled with the lower pH buffering capacity of wood, this can quickly shift the pH upwards. Growers using less than 40% wood in their substrates should not notice a drastic change in pH, however, it should be monitored regularly. Lime amendment rates could be lowered as the percentage of wood increases.

4) Will wood substrates decompose in the pot and affect my crop? There is little evidence to suggest that wood substrates will degrade during the production time of most any crop. However, this depends on the wood type and species. If growers are making/using their own wood materials that contain hardwood or sawdust, there can be negative issues with substrate decomposition, discolouring, and shrinkage. Commercial products on the market today are made from pine, fir, or spruce, which are species known to be highly resistant to decay.

5) Should plants grown in substrates containing wood products be irrigated in the same way? For some growers, one of the biggest learning curves has been in adjusting irrigation practices for mixes with more than 20% wood product. Properties of the mix will affect how water is held, moved and released, and this will change with the percentage and type of wood fiber being incorporated. The grade of peat has an impact as well. As a result, some growers say their mixes hold more water, while others say less. It should not be assumed that mixes containing wood will behave like peat-lite mixes. The most notable difference may be the increased surface drying that oc-

curs in wood mixes. This can cause some growers to irrigate when, in reality, there is still plenty of water left in the pot.

6) Can wood substrates be used with existing pot-filling equipment and protocols? Most reported challenges have involved substrates containing more than 20% disc-refined wood fibers. The higher the incorporation rate into peat, the “fluffier” the substrate becomes. This can create challenges for growers using certain flat/pot-filling machines, especially as the container size gets smaller. Growers and substrate suppliers have found several solutions: adjusting the moisture of the mix before potting, over-filling the pots, vibrating tables/conveyers to settle the mix, or using other practical methods to ensure adequate fill. Wood fiber properties and container sizes are the two biggest variables that can influence pot filling.

7) Do PGR’s work the same way on crops grown in wood substrates? Several research trials have shown no significant changes in plant growth response to PGR drenches when grown in substrates amended with up to 50% wood. Of course, this may not be true for all PGR products and formulations or for all wood products, especially when used at higher incorporation rates above 50%. Growers have generally been successful with numerous crops treated with PGRs while using substrates with wood products.

8) If I blend wood with peat moss, will the volume of the final mix be the same? It depends, but likely not. When two or more substrate components (raw materials) are blended together, the end volume will often be lower than expected. It depends on the density of the materials, as well as the particle size, shape, and inherent characteristics. Depending on

the type of wood product being blended, as well as the method of blending, the final product/mix yield will decrease. In other words, 1 + 1 will likely yield 1.6 to 1.9 and not 2.0. Wood materials made with hammer mills are the easiest to blend, while disc-refined products are the most difficult. Buying premixed products avoids this issue.

9) Are there any consistency issues with commercial wood substrates? Few if any. Different manufacturing methods used to create different wood products offer varying product sizes, shapes, and qualities. At present, the most consistent wood materials are disc-refined or extruded. Though materials made by hammer mills (pine tree substrates, for example) can be made with a high degree of precision and reproducibility, less is known about how to achieve the same consistency on a commercial scale. It is believed that with further research on hammer-mill processing of pine, these products can have the same consistency and reproducibility of other manufacturing methods. This could be important as hammer-milled wood materials are cheaper to produce compared to extruded and disc-refined methods.

10) Which is the best commercial wood substrate product on the market? Whichever one you choose. Of the commercial products available as 100% raw wood material or as pre-blended mixes, suppliers across North America have ensured that these products are uniform and ready for use. Having worked with nearly all, if not all, wood materials on the market today, I know there are differences in how the materials behave, but they can all be used successfully by tweaking production practices. Purchasing a product that fits your operation (existing machinery, pot size, irrigation system, etc.) from a reputable substrate supplier is a key decision to be made.

We may not yet fully understand all of the challenges and potentials of using wood substrate materials in our growing systems, but we know more now than we did at the start 15 years ago. Grower experiences coupled with independent research results will continue to answer these questions as well as others that arise in the future.

Brian E. Jackson, PhD, is an Associate Professor and Director of the Horticultural Substrates Laboratory at NC State University. Brian can be reached at Brian_Jackson@ncsu.edu.

Ridder is quickly becoming a household name when it comes to energy-saving screens. From our RES series with the highest light transmittance and energy savings to our RBO series with its high moisture permeability, low heat-transmission and the highest possible blackout capability. They all contribute to Ridder’s Dutch standard of quality and excellence. Made in Holland.

BY GRETA CHIU

After more than three decades of public service with the provincial government, David Woodske retired from his role of 22 years as the BC industry specialist for ornamentals and greenhouse vegetables.

“To get to go around and talk to growers one-on-one,” says Woodske just prior to retirement, “I will certainly miss that.” Another highlight was collaborating with ministry colleagues and industry partners to resolve the sectors’ challenges.

“Dave has been a go-to source for up-to-date information on any topic ‘greenhouse,’” says Gary Jones, a faculty member at Kwantlen Polytechnic University who had collaborated with Woodske for over 15 years. “He’s one of those folks who just quietly gets on with things in the background, while being reliable, honest and bringing great insight because of his wide net of industry connections.” In 2016, the BC Greenhouse Growers’ Association presented Woodske with the Meritorious Service Award for his contributions to the greenhouse vegetable industry.

Though he first began as the province’s nursery specialist in 1998, Woodske’s position grew to include floriculture and greenhouse vegetables as colleagues departed and roles were consolidated. It was a large and diverse portfolio of crops, but with Woodske’s well-rounded repertoire of skills and experiences – including research on microbial biocontrol for powdery mildew in cucumbers, managing a tissue culture lab for greenhouse nursery propagation, and running greenhouse vegetable production trials – few would have excelled at the job’s duties as he did.

Woodske estimates that he’s invited four to five hundred speakers to various events. “It’s rewarding, but it’s challenging because we don’t have [as many] researchers in BC to tap on the shoulders,” he says. Speakers are often from outside of the province and can be snowed in or have family emergencies leading to last-minute cancellations. For that, he’s very appreciative to those making it out in the middle of winter.

As the industry matured and information became increasingly accessible, Woodske observed a general decline in attendance at horticultural conferences. “Webinars alone are something that I’ve seen more and more [of], and they’re fantastic. The quality….is so much better than where it was 10 or 15 years ago, and I think that’s going to start putting even more pressure on these short course programs.” He expects there to be more consolidation across smaller tradeshows as larger ones continue to expand –similar to the sector.

“One of the first projects I [worked on] was sudden oak death in BC,” Woodske recalls. “It was a very difficult period because you saw the impact it was having on nurseries.” Large sections of nursery operations were destroyed after finding evidence of the disease. “It was harmful, especially in the beginning when there was no compensation.” Led by the BC Landscape and Nursery Association, Woodske worked in collaboration with the CFIA, the BC Ministry of Agriculture and other industry stakeholders to develop best management practices for reducing the introduction of the pathogen and its effects.

His passion for the industry showed. In addition to his extension duties, Woodske was particularly active in organizing provincial and regional conferences. Over the past two decades,

“The industry has changed a lot,” Woodske remarks. “The mid-90s were an interesting time because there was one marketing agency who [growers] sold all of their produce to – BC Hot House Foods,” says Woodske. “They won awards for some of their work …[which] did increase consumption of greenhouse vegetables and helped everyone in the greenhouse sector in North America.” Working with Jim Portree, who was BC’s greenhouse vegetable specialist at the time, Woodske describes how there was one study group for each greenhouse commodity, allowing producers to gather at a local greenhouse and discuss production issues. “It helped the whole sector,” he says, and the quality from BC Hot House Foods benefitted from these collaborations. Since then, multiple marketing agencies emerged over the years and information became less readily shared.

He also notes that margins are much smaller today than they were in the late 90’s/early 2000’s, particularly with foreign competition from countries like Mexico. “The industry is still doing well, but I think it’s a little tougher.” With greenhouses consolidating, but still expanding in acreage, Woodske takes it as a good sign.

Expecting his first grandchild at the time, Woodske had no immediate plans to consult. “At this point, my plan is family time, gardening and travel…I will miss colleagues and the interaction with industry but it’s time to move on,” he says. “My garden will look better than it’s looked before.”

Nowadays, cultivators are under pressure to produce high-quality plants while minimizing production costs and maximizing yields and profits. This can be achieved by having total control over the aerial environment and the rhizosphere. To properly control both environments, it is necessary to closely monitor crops, assess the value and execute the proper actions to maintain the right environment for the plant to reach its maximum genetic potential. One important input for crop culture is the management of crop fertility. In this article, we will discuss the use of Electrical Conductivity (EC) to measure the ions in a solution.

Growers should frequently monitor the mineral content in the water, nutrient solution and the growing medium before and during the crop cycle. An easy way to evaluate this value is to know the EC of the nutrient solution, however sometimes a grower may respond with “282 ppm” or “450 ppm”. Unfortunately, those values do not mean anything when we are trying to evaluate the mineral content in water, nutrient solution or growing medium. In a solution, the EC is the ability of the solution to transmit an electrical current, which is measured in units as μS/cm, mS/cm or dS/m. Total Dissolved Solids (TDS) is the weight of the solids that were in a solution after the water is evaporated; these units are measured in ppm or mg/l. Since the TDS is estimated by a gravimetric method, which is time consuming; this value can be obtained indirectly by measuring the EC of a solution. In the previous example, the cultivator’s answer is in TDS, however this is inaccurate because the value can vary depending on the sensor conversion factor into EC. The conversion factors for 1 dS/m to ppm are between 0.4 and 1; the most common conversion factors are 0.5 and 0.7. The main difference between both factors is the amount of salts contained in the solution, thus the sensor might have to be adjusted during the crop cycle because the salt content increases as the plant grows. In general, well water has low mineral content (low EC) while a nutrient solution, which has all essential elements, has a higher EC. In

contrast, distilled water or RO water will have an EC close to 0 dS/m, since all nutritive elements are removed. As a result, a concentrated nutrient solution will conduct more electricity, which means higher EC than a lowconcentration nutrient solution.

Source: Premier Tech

Knowing the EC and pH of the water, nutrient solution, drainage and other characteristics of the growing medium are important to avoid plant development and growth problems. The water EC can be used to evaluate its quality. For example, high EC values usually means high content of K, Na and Cl. The EC of the nutrient solution helps us to see if the injection rate or the fertilizer concentration is at the desired level. In most fertilizer labels, it is common to find the relationship between the content of ppm of N and its corresponding EC for a specific injection rate. In one hand, if the water quality is good, high EC means high nutrient concentration. On the other hand, a little difference in water and nutrient solution EC means low nutrient concentration. Therefore, by knowing the nutrient solution’s EC, it is possible to estimate the concentration of essential elements. Another method is to measure the leachate or drainage EC to give us an idea of how much water the plant is using and if it is necessary to increase the percent drainage to avoid salt built up in the medium. Similarly, the medium EC and pH give us an idea of the salt content (including essential elements) in order to make a decision on watering frequency and if it is necessary to lower or increase the pH.

Fig 2: When measuring EC of in-use growing medium, select samples from multiple containers. Remove the upper ½ inch of growing medium and discard, since salts can concentrate at the surface and give inaccurate readings. Use core samples of media from container of same crop, and of same age, and blend together. For testing with the SME method (Saturated Medium Extract), add deionized or distilled water to blended sample and mix until surface of growing medium is glistening on surface, as shown in the picture above. Wait 1 hour, then take measurements with EC and pH meter placed into the ‘mud’. Always calibrate meter before use. Source: Premier Tech

Fig 2: When measuring EC of in-use growing medium, select samples from multiple containers. Remove the upper ½ inch of growing medium and discard, since salts can concentrate at the surface and give inaccurate readings. Use core samples of media from container of same crop, and of same age, and blend together. For testing with the SME method (Saturated Medium Extract), add deionized or distilled water to blended sample and mix until surface of growing medium is glistening on surface, as shown in the picture above. Wait 1 hour, then take measurements with EC and pH meter placed into the ‘mud’. Always calibrate meter before use. Source: Premier Tech

Let’s do a quick calculation (Table 1). Based on recommendations, the cultivator needs to fertigate the crop with 20-10-20 peat lite fertilizer at a rate of 100 mg/l. The injector rate is set at 1:128 and in this case well water is used. The well water pH is 7.5 and the alkalinity (CaCO3) is 150 ppm. By using 20-10-20 peat lite, the medium pH will decrease over time if the cultivator is using this fertilizer as the only source of nutrients. This is because this fertilizer has an acidic reaction. These are the results:

Let’s do a quick calculation (Table 1). Based on recommendations, the cultivator needs to fertigate the crop with 20-10-20 peat lite fertilizer at a rate of 100 mg/l. The injector rate is set at 1:128 and in this case well water is used. The well water pH is 7.5 and the alkalinity (CaCO3) is 150 ppm. By using 20-10-20 peat lite, the medium pH will decrease over time if the cultivator is using this fertilizer as the only source of nutrients. This is because this fertilizer has an acidic reaction. These are the results:

Table 1. Concentration of the essential elements in the nutrient solution.

Table 1. Concentration of the essential elements in the nutrient solution.

(mg/l or

The well water EC is 0.5 dS/m, the fertilizer adds 0.6 dS/m to the well water. Therefore, the EC of the nutrient solution will be 1.1 dS/m (Table 2). For this example, we will use three sensors with different conversion factors:

The well water EC is 0.5 dS/m, the fertilizer adds 0.6 dS/m to the well water. Therefore, the EC of the nutrient solution will be 1.1 dS/m (Table 2). For this example, we will use three sensors with different conversion factors:

Table 2. EC and TDS measurements from three different sensors.

Table 2. EC and TDS measurements from three different sensors.

Based on this example, the use of EC is the same for all sensors. However, the TDS is different for each sensor depending on the conversion factor each sensor uses. If the cultivator is measuring TDS and he asks for an advice to see if the fertilizer application rate is enough, the answer could be one of the three values 550 ppm, 704 ppm or 770 ppm. However, if the cultivator says 1.1 dS/m, the technical advisor can relate the nutrient solution’s EC with the EC that the fertilizers adds to the well water.

Based on this example, the use of EC is the same for all sensors. However, the TDS is different for each sensor depending on the conversion factor each sensor uses. If the cultivator is measuring TDS and he asks for an advice to see if the fertilizer application rate is enough, the answer could be one of the three values 550 ppm, 704 ppm or 770 ppm. However, if the cultivator says 1.1 dS/m, the technical advisor can relate the nutrient solution’s EC with the EC that the fertilizers adds to the well water.