Year-round production

Bluegrass Farm has been recognized as one of Ontario’s agricultural innovators. | 16

BY DR. MOHYUDDIN MIRZA

BRIAN MINTER

GARY JONES

Bluegrass Farm has been recognized as one of Ontario’s agricultural innovators. | 16

BY DR. MOHYUDDIN MIRZA

BRIAN MINTER

GARY JONES

Do greenhouses have distinct brand recognition?

Within the industry, the answer would be a resounding “yes.”

But do consumers have that same valuation?

Even though crops are grown under glass/plastic, it’s still pretty much a mystery for most people driving by. They don’t see the technology, growing systems, automation and space-age environmental control.

And this is why we’re such big fans of open houses. There should be more of them, to welcome consumers for a few hours each year. Whenever we’ve attended such events we’re so impressed by the crowds they attract.

Our first experience was in 2009 at the centennial celebrations for the AgCanada research centre in Harrow, Ontario. Featured were extensive tours and demonstrations throughout the day. And while the field crops were popular, there were shoulder-to-shoulder crowds in the greenhouses. Neighbours from the surrounding area were keen to take it all in, mesmerized by the presentations on the latest research given by the AgCanada team and their OMAFRA colleagues.

This is an industry that turns heads...when the doors are open.

My most recent experience was in June at the open house for the new greenhouses at the Vineland Research and Innovation Centre. Several hundred residents attended for an afternoon of touring, totally enthralled by the science on display and the range of innovation being explored.

Greenhouses showcase leading edge technology.

British Columbia has hosted BC Greenhouse Day the past few years, which this year included

open houses by several growers. The public was welcomed for about four hours on a Saturday.

The Maritimes hosts Open Farm Day in September, with many greenhouses taking advantage of the opportunity to welcome consumers.

The Netherlands has long pioneered greenhouse open houses, including a special program geared to children now in its third year. Some 30 classes registered this year.

Nature Fresh Farms, based in Leamington, has its Greenhouse Education Centre, a custombuilt, 38-foot-long mobile microgreenhouse attraction. It travels extensively throughout eastern North America attending community events, schools, summer camps and connecting with consumers at retail events.

What goes on inside greenhouses fascinates consumers. They welcome the chance to check things out, to gain a little more understanding of the greenhouse brand.

The greenhouse sector is very adept at marketing products, but the challenge is in marketing the sector. We need to increase the buzz over the exciting range of products grown indoors throughout Canada, to help retailers win over more customers.

What if a wholesale bedding plant grower held an open house a month before the spring season to give gardeners a preview of what’s in store for them in a very few weeks?

And if open houses are too difficult to host, online video presentations or community outreach programs by staff would also work, taking the message to schools and community associations.

The greenhouse brand is impressive. The more that message is circulated, the better the market opportunities. Consumers will take note.

From seed to table, higher quality with better taste.

A better-quality product for the consumer. An integrated, innovative greenhouse solution for you. That’s what Syngenta provides through quality genetics and new variety innovations. Your customers, and their dinner tables, deserve nothing less than the very best.

To learn more about varieties from Syngenta, contact Plant Products at 519-326-9037 or info@plantproducts.com

Time to pack the suitcase; it’s show time. The Canadian greenhouse conference season will soon be in full swing. Check your calendars, get out your comfiest walking shoes and sharpen a pencil or two for note-taking. Check the websites for the following events: CanWest Show (Sept. 2829, Abbotsford, canwesthortexpo.com); Canadian Greenhouse Conference (Oct. 5-6, Niagara Falls, canadiangreenhouseconference.com), Saskatchewan

Green Trades Conference (Nov. 2-4, Saskatoon, saskgreenhouses.com); Expo FIHOQ (Nov. 1618, Drummondville), and the Green Industry Show and Conference (Nov 17-18, Edmonton, greenindustryshow.com/).

For those close to the U.S. border, there is the FarWest Show (Aug. 25-27, Portland, Ore., farwestshow.com), and the Great Lakes Growers Expo (Grand Rapids, Mich., Dec. 6-8, glexpo.com).

Do you employ or work with an exceptional young person, a potential industry leader?

If you do, we’d like to hear from you. The nomination deadline for this year’s Top 10 Under 40 award program is only weeks away (Aug. 26), but there’s still plenty of time to nominate an employee, co-worker or customer. Now in its third year, the program is sponsored by Paul Boers Manufacturing and

Prins Greenhouses, and presented by Greenhouse Canada.

Canada is full of young, skilled, knowledgeable people helping to drive the industry towards higher goals.

From commercial growers and wholesalers to manufacturers, equipment suppliers and allied trades, they are the best and the brightest in our industry. Who can be nominated? Anyone in the horticul-

ture or associated industries who is under the age of 40 as of Dec. 31, 2016. Equipment and technology suppliers are most welcome.

All nominees should:

• Demonstrate a strong work ethic.

• Show leadership and initiative.

• Actively seek new opportunities for training and education.

• Participate in industry events.

Nominations are now open: To nominate someone to be recognized as one of the Top 10 Under 40, visit greenhousecanada.com/ top-10-under-40 to fill out a nomination form. Nominations close on Aug. 26, 2016. The Top 10 Under 40 will be announced during “The Gathering” at the Canadian Greenhouse Conference (Oct. 5-6 in Niagara Falls) and featured in our November issue. of adults bought flowers or plants as gifts for Mother’s Day in 2015.

$2.8 billion: LED luminaire sales estimate for hort crops by 2024. (Navigant Research)

35% 425: $78,139: 3x’s growth:

$2.4 billion spent on flowers as Mother’s Day gifts in U.S.

indoor space used to grow food expected to more than triple in upcoming decade. (Navigant Research)

$13B: For 2015, the preliminary forecast suggests that farm incomes will be down moderately, but remain historically high. Farm-level average net operating income is forecast to be an all-time

Number of Ontario producers, processors and agri-food groups that have received a Premier’s Award for Agri-Food Innovation Excellence since 2007.

The Havana series is a brand new introduction from Dümmen Orange starring heat tolerant, compact lantanas in five colours. The Havana series features advanced genetics with moderate vigour and extra-large umbels. Versatile in full sun containers and beds, the low seed set of this series leads to quicker flower cycles, dramatically increasing the total number of blooms throughout the growing season. Such a striking increase in flower power not only benefits retailers and customers, but the numerous pollinators that rely on the nectar of lantana. dummenorange.com

The first Fuseables to contain the first seed calibrachoa, Kabloom™. The mix includes ‘Kabloom Yellow,’ plus denim and rose (not available separately). Fuseables let you stand out in a world of combos. Grow your “better” price

A new addition to the interspecific series of Unbelievable begonias, ‘Unbelievable Tweetie Pie’ from Dümmen Orange displays extralarge, bright lemon flowers set off by dark foliage, giving it huge impact at retail. Extremely heat tolerant

‘Sweet Kiss’ is truly the ultimate home gardener strawberry. It is an everbearing variety that produces high yields, which means it will flower all summer long. It is Zone 4 hardy so it will last the winter. But the attribute that outshines them all is flavour! ‘Sweet Kiss’ was selected and stands out through many rounds of blind taste tests. It truly offers gardeners an exceptional berry experience whether grown in a container or in the ground. www.ballingenuity.com

with a long bloom season, this variety performs well in both sun and shade. An excellent branching habit means it is incredibly floriferous and remarkably durable during shipping. dummenorange.com

This new calibrachoa series features novelty colours that are truly striking in hanging baskets. StarShine has a stable star pattern and strong greenhouse and garden performance. Grower-friendly, too! It’s available in pink, blue, apricot, cherry and violet. www.selectanorthamerica.com

point with the only combo program from a single pellet! Patented Precision Multi-pellets deliver better-looking, more consistent mixes. Fuseables are instant and innovative: one pellet into one plug into one 15-20 cm pot. panamseed.com

‘Surfinia Heartbeat’ is an adorable novelty petunia with white flowers and a pattern of pink hearts! Plants have a compact mounding and trailing habit and are charming in hanging baskets, containers and window boxes. In addition to the novel pattern, this variety offers the outstanding Surfinia garden performance and weather tolerance. Think of the fun promotions and possibilities at retail for Mother’s Day, your favourite cause, heart health awareness – you name it! suntorycollection.com

GABRIELLE

BioFuelNet is working to improve the steps in the bioproduct supply chain

Murphy’s law states that if anything can possibly go wrong, it will. This may be why the biofuel supply chain – a complex sequence with numerous hurdles – has been identified as a key barrier to the development of a bioproduct industry in Canada.

It’s a barrier that BioFuelNet’s low-cost sustainable feedstock (LCSF) Task Force is determined to break.

ABOVE

A BioFuelNet Highly Qualified Personnel (HQP) team member working on a feedstock project.

“When people interested in running biorefineries talk to us, one of their first questions is whether they can obtain enough feedstock of the type they need and get it to their facilities at a price that makes sense,” says Dr. Kevin Vessey, dean and associate vice-president of research at St. Mary’s University in Halifax and head of the task force’s major initiative, called “animating the Canadian biomass feedstock supply.”

The initiative will focus on a short list of emerging supply chain projects (“case studies”) throughout Canada.

Task force members will bring their collective expertise to bear on these projects, laying the groundwork for supply chains that make logistical and economic sense.

First decision point: What feedstock to use?

It turns out that trees may have distinct advantages. “They’re an underutilized resource that can help biorefiners increase their supply of raw materi-

als,” says Vessey, citing hybrid poplar and willow as examples. “There’s no shortage of land on which to grow them.”

Next challenge: how to cultivate the trees to maximize biomass yield.

To date, research favours “coppicing,” an approach traditionally used with shrubs.

Then there’s the problem of transporting the stuff. Dr. Houman Fei, who works with Vessey on the task force, puts it plainly: “Biomass is heavy. It’s been shown that the business case for biorefineries depends on the biomass being within 100 kilometres of the facility.”

Fortunately, some bioenergy stakeholders are willing and eager to overcome these hurdles. A case in point: The government of Nova Scotia recently approached BioFuelNet for guidance in setting up a biorefinery in the province, with crown corporation Innovacorp taking the lead on the ask.

Once provincial decision-makers settle on a site, they can draw on the task force’s expertise in transportation logistics. Questions to address include:

• How best to contain transportation distance?

• What mode of transportation works best across the short distances required?

The biomass itself will get a boost from seaweed extract, a growth promoter that BFN researchers have found useful in enhancing the yield of trees and grasses. Acadian Seaplants, a Dartmouth, N.S., manufacturer of marine plant products, will be providing the extract.

Looking further ahead, the task force has its sights set on a developing case in the rural North. Helping these communities squeeze the juice out of their natural resources would not only cut out waste, but generate jobs and expertise in a burgeoning field, says Vessey.

The end-game in all these efforts?

“Increasing supply chain efficiencies and reducing economic risk to the point where jurisdictions of all sizes can set up biorefineries – that’s what we mean by animating the supply chain.”

BioFuelNet Canada (BFN) is an integrated community of academic researchers, industry partners and government representatives who engage in collaborative initiatives to accelerate the development of sustainable advanced biofuels. BFN’s research is funded through a mix of government and private contributions, and is structured around the themes of feedstock, conversion, utilization, and social, economic and environmental sustainability.

Strong yet generative is typical for rootstock KAISER RZ F1. With an impressive solid root package this rootstock will carry your top variety till the end of the season maximizing total production. An other choice for tomato rootstock with proven performance in Canadian and European plantings is BRUCE RZ F1.

Distributor for Ontario: RZH Canada Ltd | Phone 1 519 324 0632

Distributor for BC/Alberta: Terralink Horticulture Inc. | Phone 1 604 864 9044

Distributor for Quebec: Seminova Inc. | Phone 1 450 454 5155

Advisor Greenhouse crops: Rijk Zwaan Export B.V. | Marleen van der Torre | Phone 1 226 344 6670 | E-mail m.van.der.torre@rijkzwaan.com

“We are better able … to effectively address the problem”

Almost a year of research is coming to fruition for the “Supporting the Advancement of Women in Agriculture (SAWA)” project and the results indicate that more needs to be done to increase gender diversity in leadership roles in the industry.

“A problem has to be properly understood before it can be effectively resolved,” said Portia MacDonaldDewhirst, executive director for the Canadian

ABOVE

The full SAWA Summary Report is available at www.cahrc-ccrha.ca.

Agricultural Human Resource Council (CAHRC).

“So while we are not surprised about the state of women’s leadership in agriculture, it is the ‘how, why and what do we do now’ that is very revealing.”

The research received very strong interest and support from both women and men with the survey and focus groups. While everyone could agree there are some barriers to the advancement of women in leadership roles in agriculture, there were some surprises as to the degree.

• When asked if they believed barriers existed for women, 14.6 per cent of men responded “yes” or “not sure,” compared to 48.9 per cent of women.

• When asked about the overall prevalence of barriers, all survey respondents felt that balancing career and family responsibilities (15.8 per cent), breaking into the “old boys club” (15.7 per cent) and a lack of role models (13.1 per cent) were the most prevalent barriers to women in agriculture. These were also the most prevalent barriers

respondents reported having either witnessed or experiences themselves.

“Now that the industry has a deeper understanding of the specific barriers affecting women in agriculture, we are better able to equip ourselves with the skills and tools needed to effectively address the problem,” said Jennifer Wright, HR program advisor.

The council is working with agricultural women’s groups such as the Ag Women’s Network and the Advancing Women’s Conferences to support the needs of women in the industry in reaching senior management and executive roles.

The council will encourage professional networking and mentoring among agricultural women along with a suite of instructive reference materials for boards and employers to improve the accessibility of opportunities for women.

It will also include an online mechanism to allow quick and easy access to agriculture-related job opportunities and training options as well as searchable information about upcoming events, leadership training opportunities and leadership openings.

“The project will create a one-stop, credible forum for reference material, information exchange, networking and opportunities to support the career success of Canadian women in agriculture,” noted MacDonald-Dewhirst.

The project is being conducted as a partnership-based initiative with extensive support and contributions from national and regional agricultural associations, training and education providers, and women’s groups, and is funded by Status of Women Canada.

“Building on what is already being done was a common theme throughout the research process,” noted the summary.

“Due to the growing awareness of women’s absence in leadership roles there is support throughout the industry to work together to address these issues.”

CAHRC works with industry leaders, governments and educational stakeholders to research, develop and communicate solutions to the challenges in employment and skills development in primary agriculture. It now leads collaborative implementation efforts in support of the national Workforce Action Plan for the agriculture and agri-food sector.

Theresa Whalen is a CAHRC communications and marketing specialist.

When seeking the ideal balance between air porosity, drainage capacity and water retention, PRO-MIX HPCC MYCORRHIZAE is the solution growers select. With unique chunk coir reducing soil compaction and carefully selected peat moss, this formulation provides qualities promoting growth and offering a delicate, well-calculated control over the growing environment. PRO-MIX HPCC MYCORRHIZAE will give growers what they need to optimize the quality of their hanging baskets and long-term crops.

It wasn’t that long ago that vegetable growers across Canada worked in the soil. But there were many problems they had to cope with, and researchers soon took note. The result was the development of new media and growing systems. BY DR.

MOHYUDDIN MIRZA

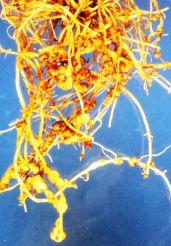

Growing media for greenhouse crops fascinate me because as a greenhouse specialist in the early 1980s, I faced problems with the growing medium in which cucumbers were grown.

It was what I called “Prairie virgin soil” in the Redcliff and Medicine Hat region, along with other areas in Alberta. Cucumber was the major crop with a few tomatoes being grown (Photos 1 and 2). The soil had a low organic matter and growers were not adding peat moss or other amendments to replenish it. At the end of the crop season, growers would add manure, steam the soil and start new crops. Soil was also used as a growing media in many other areas of Canada as well.

But at about this time people noticed that cucumber production per square metre had

stagnated. I remember our best production was around 50 cucumbers/sq.m. and it stayed there for a few years. Growers would add some peat moss, straw or sawdust, steam-pasteurize, and plant the next crop.

Photo 3 and the inset photo atop facing page show a later stage crop the 1980s. When the plants were pulled out (inset), growers often found root knot nematodes. Combined with diseases like pythium, this compelled us to develop information on the use of soilless growing media and hydroponics systems. These pictures depict a historical perspective of soil as a growing medium in the 1980s.

I still remember how my first production guide focused on growing cucumbers in soil;

the recommendations were developed for the use of insoluble fertilizers. A typical fertilizer program included so many pounds of superphosphate, gypsum and mono-ammonium phosphate rototilled in the soil, with magnesium sulphate applied as needed.

(These pictures depict a historical perspective of soil as a growing medium in the 1980s.)

When nematodes became difficult to control even with the use of steam and chemicals, research efforts started with the development and use of soilless cultivation systems. I thought at that time that nematodes had learned to survive. For example, I found that after steaming there were plants with nematode infection near the greenhouse posts. They later moved towards the middle of the greenhouse when steaming was completed.

This was about the time the Cornell mix was developed. It consisted of peat moss, perlite and vermiculite. Dolomite lime was added to counter the acidity contribution from peat moss. Fritted trace elements were added and in some cases a basic nutrient charge was provided. I believe that was the starting point of modern soilless growing media.

In the early 1980s, we started testing various growing media, including straw bales, sawdust, rockwool and various types of peat-based media. Along with these growing media, better nutrient formulations were developed. The development and availability of soluble fertilizers ranging from calcium nitrate, potassium nitrate, mono-potassium phosphate and magnesium sulphate, along with chelated trace elements, really gave a boost to soilless cultivation.

This was also about the time Dr. Allan Cooper from the U.K. reported on his work with the Nutrient Film Technique (NFT). This involves the use of water with all the necessary nutrients instead of a solid growing medium. There was lot of excitement about this approach to grow plants.

I had very good results when I grew my first crop of cucumbers in wooden troughs lined with plastic. I was excited when we got 80 cucumbers/sq.m. with a 100-day crop, however the development of a massive root mass resulted in crop senescence.

Many growers tried this technique in Alberta and abandoned it after some time. There is still one grower in Alberta who is using this method.

This technique, however, has been widely adopted by lettuce and leaf vegetable producers after some modifications, including the use of floating rafts.

After experimenting with various growing media and learning how to use them, most Alberta growers have settled on coir for cucumbers, tomatoes and peppers. In other parts of Canada growers use rockwool and sawdust.

Here are a few facts growers should be aware of before using their growing media:

• They should know the physical characteristics of the growing medium they are using or planning to use.

As an example, when using coir be familiar with its physical consistency. There are three terms used in this context – coir

fibre, coir pith and coir chips/chunks. Coir pith is the most commonly used component in growing mixes. Very fine coir is generally not used for vegetable production. Similarly if peat-based media are used, then one should know the physical characteristics of peat moss, such as its percentage of different types of fibre lengths.

Ask suppliers about water holding capacity, total porosity, air porosity, and cation exchange capacity, and then based on that information, plan your usage accordingly. There are commercial growing media now available with high porosity for rooting, and medium porosity for main production. Once you know these factors, then adjustments can be made with your watering practices. I find one common problem results from growers creating water-logged conditions.

Learn about the supplied nutrient charge. Dolomite lime is used for countering the acidic pH of peat moss. This type of lime provides some calcium and magnesium over a period of time and may also react in two to three weeks to raise the pH. Beside lime, some commercial media contan small amounts of nitrogen from various sources. Knowing about the basic nutrient charge allows growers to adjust their feeding programs.

In a research project, we avoided fertilizing bedding plants for three weeks after transplanting until very early symptoms of nitrogen and phosphorus deficiency showed. The rooting was better in such plants compared to when fertilizing was started immediately after transplanting. Growers can benefit by utilizing the existing nutrient charge.

• There are many fine, newer growing media in the marketplace with different microbes/biologicals added for better root health and disease control. Learn about these additions and manage accordingly.

Growers may have noticed there are growing media with silicon amendments. Take advantage of such microbes for better root health and thus better plants. Silicon is known to provide many plant health benefits. A grower reported much better heat tolerance in tomatoes and an increase in fruit weights.

• Water as a growing medium is now widely used for lettuce, leafy vegetables and salad crops. Learn to manage nutrients and oxygen in water-based systems. Oxygen levels below 4 ppm could hinder root growth. Consider water disinfection systems because the microbial load could increase.

Paying attention to the physical, chemical and biological characteristics of your growing medium will ensure healthy crops and healthy profits.

Dr. Mohyuddin Mirza is an industry consultant. He can be contacted at drmirzaconsultants@gmail.com.

Two winners of the Premier’s Award for Agri-food Innovation Technology showcase their greenhouse technologies, strategies and business models – all part of their recipes for success.

BY TREENA HEIN

You were first introduced to two Premier’s Award winners in our February issue in the cover story on urban agriculture. Here are two more very innovative greenhouse operations in Ontario that deserve a close look.

HEATING FOR YEAR-ROUND PRODUCTION

In Jasper, near Ottawa, Bluegrass Farm owners Leela Ramachandran and Bradley Wright are using heat from below to keep their crops growing well through the long winter. The couple has four greenhouses (10,000 square feet in total) under production, with over 30 cold-hardy crops, including greens and herbs, radishes and spring turnips.

“We had done a couple of years of market gardening and were looking to scale up,” Ramachandran says. “We wanted to find a niche.”

In their second year, Wright approached several

ABOVE

local chefs. “I would have green zebra tomatoes for sale, and the chef would say I was the sixth person that week offering that product. We had to do something unique.”

Wright did a lot of research into winter production methods, starting with Eliot Coleman’s authoritative descriptions in The Winter Harvest Handbook, and discovered small farms in Vermont and New York that were using radiant floor heating to grow cold-hardy crops year-round.

The couple notes that heating the soil is 50 per cent more efficient than heating the air, since the soil holds heat better and root temperature is more critical for plant growth than is leaf temperature.

Wright visited a couple of farms in New York state and Vermont over the winter of 2014. Although Ramachandran remained skeptical, Wright was convinced it would work.

He points out that with the elevation in the Appalachian Mountains, the other farms were

Bluegrass Farm owners Bradley Wright and Leela Ramachandran, with award presenter MPP Sophie Kiwala.

actually one plant hardiness zone colder than Ontario.

“Still,” she says, “our system had to be adapted to our site, soil and climate. Since our soil is quite shallow, often only two feet above bedrock, we had to excavate the soil, drill holes in the bedrock and cement the greenhouse ground posts into the ground. This was a huge undertaking.”

The couple used four-inch thick extruded polystyrene insulation (roofing insulation) for the floor and a shallow perimeter wall. Over the insulation, they placed a thin layer of soil and then laid the plastic tubing system.

“The tubes are filled with water, with a small amount of glycol added as antifreeze,” Ramachandran explains. “The tubes are a closed-loop system so the water never comes into contact with the soil or crops. An outdoor wood boiler heats the water.”

On top of the tubes is 18 inches of soil. The couple uses two layers of floating row cover to insulate the crops at night and on cloudy days when the air temperature goes below zero.

“We’ve found that the insulation

MPP Chris Ballard presents a regional award to Jan VanderHout of Beverly Greenhouses.

is highly effective at retaining heat,” Ramachandran says. “Our main challenge in cold weather is ventilation. The moisture buildup inside the greenhouses leads to condensation and even ice on the plastic, reducing sunlight penetration.”

Bluegrass is one of only a few farms in the region that offers “community supported agriculture” baskets through the winter. Each CSA basket contains fresh greenhouse greens as well as root crops harvested from area farms in the

We specialize in Energy, Blackout and Shade Curtains.

The benefit of Energy curtains has been widely accepted. It’s no longer why get Energy curtains, but when.

Call us and take advantage of our knowledge, competitive pricing, and unique products designed to reduce your maintenance costs, and start lowering your energy costs now!

We also offer

• Greenhouse parts

• Heaters

• NoW AvAIlABlE Used Equipment Marketplace!

Over 40 available items of used greenhouse equipment. Buy or sell used equipment and supplies for your greenhouse.

Check it out at our website www.westlandgreenhousesupplies.com

Presentation of your products is important, helping you to increase sales. Our shade structures will help you present your products in a favorable way, and give your customers a comfortable environment at a low cost.

MANUFACtUrE oUr oWN HooP HoUSES! Our structures have many competitive advantages:

High straight sides • Reduced wear on plastic • Stronger Arches with oval tubing • Less Expensive than competitors

fall. Bluegrass also sells salad greens to restaurants, stores and wholesalers in Ottawa and nearby communities.

While they did their homework, Ramachandran admits there have been times they’ve been overwhelmed, when

they had questions but no one locally to turn to for answers.

“Winning the Premier’s Award is a recognition of the extra risk and challenges that we have taken on in order to develop an innovative business,” she

says. “It’s a reminder that we are on the right track, and that others can see the value of what we are working so hard to achieve.”

Their CSA sold out the last two years and they are expanding it this year to 150 customers from 120. They are also adding new wholesale customers all the time, and expansion of production is in the works. “We feel that it’s the right time for this business,” Ramachandran says, “now that there is such a strong demand for local food.”

Anyone growing cucumbers contends with insect pests, and the VanderHouts (owners of Beverly Greenhouses in Waterdown, Ontario), are no different. But co-owner Jan, his brother Dale, and other members of the family are doing more than just using traditional controls.

They are actively supporting beneficial predators by using banker plants, where the beneficials can make a home and take a break from pest control.

Over their 20 acres under production, grasses support aphid-destroying parasitic wasps, ornamental peppers (Purple Flash) support Orius (predators of thrips) and mullein supports the Dicyphus predator of whiteflies.

In collaboration with beneficial insect suppliers, the VanderHouts have experimented to find the best locations, watering regimes and pruning timelines.

“We are aiming for as natural production systems as we can,” Jan says. “We were approached by our three suppliers and have been working with them closely. It’s a complex system to enter into, because you have to go all in. You cannot use anything harsh in terms of chemical control if you’re going to use beneficials. It limits the fungicides you can choose from and there have been some hard decisions.”

All are must haves in a busy Greenhouse. Whether it’s loading pots into trays, filling different type and sizes of pots, trays or containers or planting/sticking an endless variety of cuttings or plugs, it seems as if there is never enough people or hours in a day – Well help is at hand! We have a range of machines designed and built to help overcome just those problems and help your workday go smoother. – Innovative solutions from Bouldin & Lawson –

He adds that at times “we must accept a certain amount of damage from a pest or disease in order to maintain the biological balance. Small amounts of pesticide residues can have a significant impact on establishing the required beneficial insect population to maintain reasonable pest control.”

In terms of the best locations for the banker plants, Jan says they tried the easy ones first, under the canopy of the main crop.

Our fall season really begins in summer, extends through Thanksgiving and Halloween, and on into the Christmas season. It should be our second mini spring. Fall is loaded with opportunities if we do some creative thinking and careful strategic planning. Frankly, most of us do half the job when full throttle is needed. Setting the tone creates the sales.

In folks’ gardens, fall is changeover time, and they need some help planning the transition from annuals to fall perennials. Grasses, colourful conifers, hardy violas, heucheras, heucherellas and eye-popping mums are the sparks that light up this new season. Even tired summer containers need an autumn lift that can later give way to Christmas greens for the holiday season.

We have had great success with both fall containers and moss hanging baskets created especially for a fresh new look right from autumn going into winter. We use the many new colourful varieties of evergreen carex grasses that spill nicely, and blend in smaller burgundy toned heucheras and cool ‘Wave’ pansies. As focal points in these eye-catching containers, we use vibrant columnar broadleaves like ‘Sky Pencil’ holly and ‘Green Spire’ euonymus, along with yellow conifers like thujas ‘Forever Goldy’ and ‘Yellow Ribbon.’ These plants are surprisingly cold hardy, and when

Pumpkins were created for display. We start this season in August and extend it until Halloween. Have you seen the diversity of pumpkins, gourds and squash these days? Wow! For food, crafts, table centres and indoor and outdoor décor, they rule. Add in corn stalks, all sizes of hay bales and fall branches in pots and it’s a fall sales bonanza. Differentiating ourselves from the box stores and produce stands by value-adding will significantly increase the fall experience and sales in your store. Starting early is important.

Fall transitions into the positive and familyoriented Halloween, a holiday opportunity that is now dominated by large retailers, but by being wise and strategic, we can get a nice share of that market back too. It should be a fun, funny and happy experience. Stay away from the gory, dark stuff. We love resin or plastic pumpkins that can be planted up or used as candy holders. We like cutesy scarecrows, witches, goblins, spiders and garlands that can be adapted to pots, balconies, doorways and arches – all are an easy sell.

Planning the transition from annuals to fall perennials.

Christmas greens are added, they continue to look fresh and fabulous as holiday porch pots and baskets.

Mini pumpkins, gourds, dried corn, dried grain stems and mini rushes added to fall plants, planters and arrangements create huge sales appeal as well as value. Display them as gift items as well as with your home décor merchandise. Done well, this will give your customers ideas of how they can recreate the look on their own using all your décor material. You also need outrageous “Lady Gaga” containers to inspire the millennial demographic!

All this effort to attract an expanded customer base and increase sales should be synergized with other fall sales. Is your fall bulb display mouthwatering and “over the top?”

Colourful fall produce offers one of the most stunning store décor punches of the year.

As folks move inside from the summer patio, refreshing the indoors with resilient tropical plants is an opportunity I think we can vastly improve upon. By using the “value-added” themes of not only beautifying our inside décor but also demonstrating the scientifically proven ability of plants to clean the air of toxins and to make us feel better in terms of wellness, we continue to offer our clients more than just a plant. Recommending easy-care varieties that will tolerate the lower light levels of fall and winter is important. The dracaena family, pothos and philodendrons are great options. For blooms, peace lilies and the new varieties of anthuriums are great additions to any home, as is the colourful foliage of aglaonemas.

Younger folks still love tillandsias and bromeliads, especially creatively planted in funky and fun glassware, or grown upside down as your very own pet “jellyfish!”

Fall is a season of new opportunities! Taking it to the next level is very important because we all need that little boost before the Christmas season begins.

Brian Minter is co-owner of Minter Country Garden Store in Chilliwack, B.C.

Time spent scouting increases when there is higher pest pressure and when plants are tall and dense, because scouting takes longer on carts than it does on foot.

BY DR. ISHTIAQ RAO

Crop Defenders Ltd. considers pest management as having three major foundations: (1) good cleanout, (2) proficient scouting, and (3) timely/proactive treatment with biological control agents (biologicals). Why your greenhouse needs scouting. Scouting is done to gain insight into the pests, diseases and beneficial insect activities in crops. Proper scouting provides early detection of pest problems that saves money and hassle; tracks long-term and short-term trends in population levels of the pest or biologicals; enables the grower to identify the optimal time and method for treatment; and measures the effectiveness of a management action (biological control, or chemical insecticide treatment).

Materials for getting started. To start scouting, collect the following scouting supplies:

• A hand lens (ideally 10-40X) or an optivisor.

• Disposable gloves to touch diseased or infested plants.

• Glass vials or plastic baggies for collecting unknown insects for identification.

• Clean, white lab coat. Scouts should never wear bright colours, especially yellow or blue. Bright colours attract insects, and scouts will carry pests from hot spots to other areas of the facility while inspecting the crop.

• Sticky cards.

• Coloured survey flags/flagging tape. At Crop Defenders, we colour code our flagging tape

ABOVE Crop Defenders crop advisor Nicole Stewart scouting for thrips on a greenhouse cucumber flower. INSET Dr. Ishtiaq Rao of Crop Defenders wears appropriate scouting gear (gloves, lab coat, booties) while inspecting the underside of a tomato leaf for whiteflies.

(pink is spider mite, orange is a spider mite hot spot, blue for aphids, green for whitefly and yellow for miscellaneous diseases and other pests).

• Hand counter.

• A small brush.

• Potato disks (for fungus gnat monitoring).

• Clipboard, paper, pencil, permanent marker.

Record your discoveries. Keeping records is essential in order to monitor pests and beneficial insects over time. The type of information you will want to keep record

of includes completed scouting forms, greenhouse maps, information on biological control use or pesticide applications, fertilizer rates, pesticide label fact sheets, virus testing results, and anything else you believe could inform pest control decisions. Pick a day and time at which scouting should be done, and do it the same time every week. When setting the schedule, don’t scout on the same days that pesticides are applied. Check with the grower about re-entry intervals. When selecting a time, high noon is recommended, because the lighting is

ABOVE Beans at the end of a row act as indicators for pest presence in this tomato crop.

good and the pests will be most active.

Take your time. Spend at least 45 minutes per acre. Time spent scouting increases when there is higher pest pressure and when plants are tall and dense, because scouting takes longer on carts than it does on foot.

Determine an action threshold for each pest. An action threshold is the population level for a pest at which control is needed to avoid economic loss or aesthetic damage to a crop. Setting ideal action thresholds may come with practice.

Tolerance for infestations depends on numerous factors such as type of pest, crop, stage of crop development, type of damage and time until sale. Thresholds vary from grower to grower.

Formulate a method for scouting; will you count actual numbers of pests on each plant, use presence versus absence, or per cent infestation?

Create a data recording form. This will help keep observations consistent from scout to scout.

Establish a route. Map out your greenhouse. Maps need to be permanently numbered or labelled by area. These maps should have spaces for information (e.g. date, crop specifics, scale of size, comments about the findings, and actions taken), and include information on walkway placement or irrigation/heat zones.

Your route between rows should be random, to ensure a good sample of the area. Inspect 10-20 locations per unit. Visit high-risk hot spot areas regularly. This

includes the areas with previous pest history, areas of high heat, near entrances, around circulating fans and along the perimeter of the greenhouse.

Monitor using traps. This includes sticky cards, indicator plants, potato disks, and others. The sticky trap in each section must be mounted four to eight inches above the plant canopy, accessible for detection and counting and not easily disturbed by workers. It should be fixed with the flat side against the flow of air to capture more pests.

Indicator plants, such as bush beans for monitoring thrips and spider mites in tomato greenhouses, provide an early indication of pest invasion. In our experience, bush beans in tomato greenhouses are more attractive for thrips than even blue sticky cards.

If your indicator plants are highly infested, you should remove them from the growing area and replace them. Don’t spray your indicator plants, because they will no longer attract pests.

A quarter-inch slice of raw potato on the medium is a good method for trapping pest larvae of fungus gnats for easier detection and counting.

Scouting: the art of observation. While scouting, observe the entire plant. Randomly inspect plants along established routes for insects, natural enemies, diseases or physical abnormalities.

Every 10 steps, switch from checking new growth to middle canopy and to lower canopy.

Check leaves for discoloration; yellow specks could indicate early spider mite

infestation and white flecks (honeydew) could indicate an aphid infestation.

Take flower samples and cut them open to check for adult thrips.

Use laminated sheets of white paper under leaves and gently tap plants to dislodge insects after inspecting the undersides of foliage.

If you’re using biological control, also keep count of the beneficial insects, their percentage of kill (ask your biocontrol provider to train scouts to recognize signs of parasitism), and the effectiveness of control that the

biological insects are providing.

A good scout can recognize different instars of pests and beneficials, and this information can greatly inform population trends and help in making management decisions.

Check sticky cards to monitor increases and decreases in populations of pests. Mark results on the scouting form. Evaluate the data and determine if management action is required.

Dr. Ishtiaq Rao is the business manager with Crop Defenders Ltd., www. cropdefenders.com.

2016 marks 10 years of proven performance for SunPatiens®. No other annual brings truly reliable flower power in such a variety of colors and applications. It’s no wonder SunPatiens are trusted by growers, retailers and landscapers for flourishing blooms in both sun and shade, spring through fall.

To order, contact your preferred supplier.

Joe Sleiman doesn’t see automation so much as a means of reducing overall labour requirements, but of improving product quality and worker productivity.

BY DAVE HARRISON

An Ontario-based agricultural automation leader in North America is now eyeing worldwide markets.

Ag-Tronic Control Systems, owned by Joe and Samia Sleiman, designs and manufactures automated packing and labelling solutions for greenhouse and outdoor fresh fruits and vegetables. It has customers throughout Canada, the U.S. and Mexico.

Last year was the silver anniversary for the company now celebrating its 26th year in business.

Ag-Tronic was started by the Sleimans in the basement of their house in Wheatley, Ontario, in January 1991. They have since been joined by their four children in the business, something the family takes great pride in.

Joe is a graduate of the electromechanical engineering technician program at St. Clair College. “My job was to take an engineer’s designs and make a working product, but I quickly realized that I preferred to be the designer.”

He had been working at a farm equipment

ABOVE

dealership for a few years before the economy slowed and the position was cut. But what seemed like a setback was a springboard to a new phase of his career, that of entrepreneur.

In southwestern Ontario, there are two major industries – automotive and agriculture. The former was steeped with automation companies, but not so much the latter.

“I wanted to design things, something I had been doing for a while, and there was no one else doing it in our area at the time in agriculture. We knew that agriculture is a pretty stable industry. When people stop eating, let me know,” Joe quips.

And the industry needs automation because of the competition from imported fruits and vegetables that come from countries with much lower wage rates. “I knew automation would help improve the bottom line for growers here. We took a chance and obviously it paid off.”

He doesn’t see automation so much as a means

of reducing overall labour requirements, but of improving product quality and worker productivity.

Ag-Tronic’s first product was a height control system for field tomato harvesters, and its success attracted a lot of attention. They then moved on to watering systems for transplanters and a tractor steering system, among others.

The greenhouse industry had taken note of their design success, and Joe was soon at work on a pair of new projects. One was to develop a system to count the number of tomatoes

For over 30 years, Hillen Nurser y Inc. has remained dedicated and passionate about the nursery industr y.

We invite you to visit our website with easy access to our complete up-to- date listings of hundreds of varieties, look ing good photo's and more........

Mark Endicott

General Manager 23078 Adelaide Rd. Mount Br ydges, ON N0L 1W0 Cell: 647.923.5182 • Fax: 519.264.1337 mark@hillennursery.com

in a tray to interface with a labelling system. The second was to design a system to measure the length, width and curvature of greenhouse cucumbers.

‘A

Both were extremely successful. “They had a slingshot effect of moving us forward.”

The key to problem solving, he notes, is being a good listener. “You have to understand clearly what the customer wants.”

He adds that you also have to know what applicable technology is available, and that any solution has to be based on a good return on investment.

He’s a perfectionist. The first cucumber system was 97 per cent accurate, but he wasn’t satisfied. He then tweaked the software and boosted it to 99.8 per cent accurate, more in line with his standards. “I felt we could stop there. If you make it to 99.8 per cent, there is no room for competition.”

Quality allows you to set a price that ensures you remain profitable, he explains. At the end of the day, if your system is saving a customer money, they will pay for it. And, of course, they will tell their friends.

A year after designing the cucumber machine he began working on a system to automatically pack them in a box, and to do it at almost three times the speed of comparable systems from Europe. “It was a big hit.”

He then developed a labelling system for cluster tomatoes that applies a PLU sticker on each piece of fruit. “We had done market research for a couple of years and couldn’t find a comparable labelling system, so I thought, why don’t I just build one.”

He and his team didn’t waste much time. It took only fourand-a-half months from the concept stage to a prototype tray labeller that “exceeded expectations.”

This led to the creation of a spinoff company – Accu-Label –that Joe formed in August 2001.

The ORB-it® G-2 Print & Apply Labelling system is used with a variety of fruits and vegetables. It is versatile and means growers don’t have to carry a large inventory of labels to

These are some of the products eligible for the Vetoquinol Club points program. Sign up today at vetoquinolclub.ca and reap the benefits. club points program.

• Low or no wax formulations

• Grains and food grade oils ingredients

• Greater acceptance for better results

• Different actives for rotation

GIVE THEM BAITS THAT THEY WILL LIKE!

match up with different varieties. The labels also include traceability coding as part of food safety measures.

The move into more international markets has been prompted by the positive response received at trade shows. Interest has been shown by growers and packers in South Africa, Chile, Argentina, Italy and New Zealand, to name a few.

Getting into these markets will take a lot of time, “and we’re still trying to enjoy our grandkids,” says Joe with a chuckle.

“Getting more market share is difficult because we don’t have a large sales team yet,” says Joe. “We’re working on it.”

Growth has been a constant, and largely fuelled by word of mouth endorsements from growers. The company has moved three times over the years to larger facilities.

STAGES OF GROWTH

ABOVE

Accu-Label’s custom engineered TOV (cluster tomatoes) conveying system.

• From 1994 to 1998, they operated in a 1,350-square-foot facility in Leamington and added three employees.

• From 1998 to 2010, they operated in a 6,000 sq. ft. building in Leamington and added four more employees.

• From 2010 to the present, they’ve worked in a 20,000 sq. ft. facility in Lakeshore, with employment now at 20.

The company has won a pair of awards over the years.

In 2000, it received the Business Excellence Award in Leamington, and last year it won an international technology award in Taiwan.

“You have to provide a very good product at a fair price that at the end of the day is helping the customer save money.”

MORE “HANDLING SYSTEMS” STORIES ARE IN THE “STRUCTURES & EQUIPMENT” SECTION AT GREENHOUSECANADA.COM

“It was too dark so we then tried above the canopy and that has worked well,” he explains.

“We are using big plants, and they create a bit of a shadow but they are mostly out of the way. Watering is by sensor, like the cucumbers, in conjunction with a timer. We did a little too much pruning at first, so now we just prune less, about every six weeks.”

The Vanderhouts have tried alyssum, which they have found is messy but a good Orius host, and some other banker plants including hot pepper.

Jan says it was exciting to have won the Premier’s Award and nice to have the recognition for their hard work.

“As a consumer, I hope this sort of work can spread and into different parts of agriculture to clean up the food supply,” he says. “We have an open door policy, and the insect companies are also spreading the knowledge, so hopefully use of beneficials will grow.”

Treena Hein is a freelance writer in Ontario.

PRODUCTS greenhousecanada.com

Greenhouse Canada’s annual search for young industry leaders is again underway! Canada is full of young, skilled knowledgeable people helping to drive the industry towards higher goals. From commercial growers and wholesalers to manufacturers, equipment suppliers and allied trades, they are the best and the brightest in our industry. Join us as we celebrate the future of greenhouse horticulture in Canada.

Anyone in the horticulture or associated industries who is under the age of 40 as of December 31, 2016. Equipment and technology suppliers welcome. all nominees

• demonstrate a strong work ethic

• show leadership and initiative

• actively seek new opportunities for training and education

• be involved in industry associations nominations aRe

To nominate someone to be recognized as one of the Top 10 Under 40, visit greenhousecanada.com/top-10-under-40 to fill out a nomination form.

Nominations close on August 26th, 2016.

Sellick Equipment Limited has launched a new model of rough terrain forklift.

The S150 (15,000 pound capacity at 24” load centre) is powered by an economical 74 HP four-cylinder intercooled tier 4 final electronic engine that produces 295 ft/lbs of torque. www.sellickequipment.com

Following the launch of a new LED product line by parent company Hortilux Schréder in Europe, PL Light Systems is releasing the HortiLED products in North America as well. www.pllight.com

It’s that time of year again already. Except it’s not! Level 1 water restrictions came into effect in Metro Vancouver on May 15, two weeks earlier than in previous years, the result of requiring Level 3 restrictions last summer for the first time since 2003.

Added to this, the new B.C. Water Sustainability Act (WSA) was brought into force on Feb. 29 (as briefly noted in a previous “Inside View”). The WSA updates and replaces the previous B.C. Water Act, bringing in a number of important changes for existing and new surface water and groundwater users.

So, what’s horticulture to do?

First off is something we’ve mentioned before and greenhouse vegetable growers may already have tried. CubeCap® is a simple plastic “cap” placed on top of grow blocks that prevents evaporation and reduces algae growth. A unique, patented propagation feature built right into the DripCap eliminates the need for drip stakes. Steve Gallo of CubeCap says savings of nearly 33 per cent of resource costs are possible. For a large user of water and fertilizers, that’s significant. To try this product, connect with Gallo at CubeCap.2

Or you could try the “Imec” (Mebiol Inc.) system. This Japanese hydroponics system utilizes small amounts of growing medium in the form of a thin film of hydrogel. Isolated from the soil,

tanks, to cleanse effluent.”4 The idea was to “turn a wastewater treatment facility into a resource facility,” said Sechelt mayor Bruce Milne.”4

“The Sechelt system consists of four underground tanks (each four metres deep) with raw sewage piped into the first where insoluble material is screened out as well as any grit flushed into the wastewater system. It then goes into the ‘Organica’ system, which is a second tank of sequencing batch reactors where the roots of the greenhouse plants extend through a growing medium into the effluent below. The plants (while they thrive on the nutrients in the water) do not do the break down but their roots provide the environment for advanced organisms and increase the biomass in the reactor. When you increase the biomass you increase the biodiversity and that is key. Sludge, along with any fallen roots, land on the chamber’s bottom. The sludge is removed, dewatered, and sent to composting. The remaining water goes through an ultra-fine membrane filtration in a third chamber and ultra-violet disinfection in a fourth.”5

If all else fails, you could just make your own water.

the system uses water efficiently and Japanese trials comparing Imec with coco-peat-based conventional hydroponic systems indicate onetenth to one-fifth the usual water use and high Brix tomatoes, albeit sacrificing some yield.3

Taking a lead from the greenhouse industry, the University of British Columbia (UBC) has upgraded its food garden and replaced old, inefficient sprinkler systems with a new refined zoned system that allows measurable, more timely and accurate water placement.

Remember the adage, “if you can’t measure it, you can’t manage it.”

“A new $25 million wastewater treatment facility located in the District of Sechelt, [B.C.], … is leading Canada in innovative technology borrowed from Europe that utilizes the root bacteria from plants, located in a greenhouse over treatment

With our existing glasshouse infrastructure, horticulture ought to be able to develop this further. If all else fails, you could just make your own water. According to its website, Watergenics Inc. is a Canadian-based private company that holds the exclusive worldwide licence to the patent-pending Hybrid Atmospheric Water Generator (HAWGen), an atmospheric water generation technology invented in the Laboratory for Alternative Energy Conversion at Simon Fraser University in B.C.6 Watch this space!

1More information at BC Govt.: http://www2.gov. bc.ca/gov/content/environment/air-land-water/water 2CubeCap, Steven Gallo info@cubecap.ca

3Contact Patrick Bray: pbray@ pacificvisionpartners.com

4HortiDaily.com May 2016

5www.Journalofcommerce.com May 2016

6http://watergenicssolutions.com/company/ about/

Gary Jones is co-chair of horticulture at Kwantlen Polytechnic University, Langley, B.C. He serves on several industry committees and welcomes comments at Gary.Jones@kpu.ca.

Thursday, September 15 Leamington,

To become familiar with our varieties, you will be taken for a guided tour. Please book your appointment in advance by Marleen van der Torre at m.van.der.torre@rijkzwaan.com or call our office at 1 519 324 0632.

We are looking forward to seeing you from 10 AM - 5 PM!

Distributor for Ontario: RZH Canada Ltd | Phone 1 519 324 0632

Distributor for BC/Alberta: Terralink Horticulture Inc. | Phone 1 604 864 9044

Distributor for Quebec: Seminova Inc. | Phone 1 450 454 5155

Advisor Greenhouse crops: Rijk Zwaan Export B.V. | Marleen van der Torre | Phone 1 226 344 6670 | E-mail m.van.der.torre@rijkzwaan.com