Forbidden Fruit wins big

Operation has deep roots in Similkameen Valley | 14

Tomato-tastic

Home-built machine makes harvest better, faster. | 18

Labour

Automation

BY TOM WALKER

TREENA HEIN

BY TREENA HEIN

Forbidden Fruit wins big

Operation has deep roots in Similkameen Valley | 14

Tomato-tastic

Home-built machine makes harvest better, faster. | 18

Labour

Automation

BY TOM WALKER

TREENA HEIN

BY TREENA HEIN

Welcome to Fruit and Vegetable Magazine’s new look, just in time for spring.

There’s nothing like a new haircut and spiffy, fresh wardrobe to boost one’s spirits. It’s a new year and a new growing season, plus a new design.

Don’t worry – some of Fruit and Vegetable Magazine’s old standards are still here. We’ll still be covering the latest and greatest in production research and innovation from coast to coast with a sprinkling of industry news and new products. It will just come wrapped in a fresh, shiny new package.

There will also be some new departments to enjoy. By the Numbers features the latest agricultural statistics involving fruit and vegetable production in Canada and the world presented in easily digestible, infographic nuggets. Growth Trends offers brief news items featuring the latest research developments aimed at helping growers with production and marketing issues. And I’m very happy to welcome Cathy Bartolic, executive director of the Ontario Farm Fresh Marketing Association (OFFMA), to

integrated supply chain that generated $106.9 billion in 2013, accounting for 6.7 per cent of the country’s gross domestic product (GDP). Employment in most industries in the AAFS continued on an upward trend. In 2013, the AAFS provided one in eight jobs in Canada, employing more than 2.2 million people. The foodservice industry was the largest employer in the AAFS, accounting for 5.3 per cent of all Canadian jobs.

Canada was the world’s fifth-largest exporter of agriculture and agri-food products after the European Union (E.U.), the U.S., Brazil, and China in 2013. Canadian export sales grew by 5.5 per cent in 2013 to $46 billion, maintaining its 3.5 per cent share of the total value of world agriculture and agri-food exports. The U.S. remains Canada’s most important agriculture and agri-food export destination, accounting for 50.8 per cent of total Canadian exports, followed by China, Japan, the E.U., and Mexico.

With import sales of $34.3 billion in 2013 – an increase of six per cent over the previous year – Canada

It’s easy to become enthusiastic and optimistic about the future.

Fruit and Vegetable Magazine. Cathy will be penning the magazine’s new column, Marketing Matters, located on the inside back page.

With all this discussion of new ideas and revamped vision, it’s easy to become enthusiastic and optimistic about the future. And so we should be, given the latest information highlighted in Agriculture and Agri-Food Canada’s (AAFC) Overview of the Canadian Agriculture and Agri-Food System 2015, released in mid-April.

According to the report, the Canadian agriculture and agri-food system (AAFS) is a complex and

remained the world’s sixth-largest importer, accounting for 2.9 per cent of the total value of world agriculture and agri-food imports.

With numbers like that, it’s hard to remain pessimistic about the future, although the AAFC report did state that agriculture producers continue to see rising operating costs. These increased by more than 40 per cent over the 2003 to 2013 period. The operating expenses contributing the most to the increase were commercial seed (107 per cent), fertilizer and lime (90 per cent), machinery fuel (80 per cent), and custom work (74 per cent).

MARGARET

The Agri-food Management Institute (AMI), a promoter of best agribusiness management practices for agri-food and agri-based producers and processors in Ontario, recently introduced Arnie Strub, as its new executive director.

Strub comes from extensive experience in business management, marketing and outreach, and the agricultural sector.

“I look forward to developing valuable opportunities to collaborate, educate and

BY

communicate in a non-competitive environment for all stakeholders,” he said.

“As AMI embarks on the 2015-2016 Work Plan, Arnie’s strong administrative aptitude, extensive experience, and enthusiastic vision will be critical ingredients in the formula for success in working closely with and bringing best practices to the Ontario agri-food sector,” said Brenda Lammens, chair of AMI’s board of directors.

Fall may still be several months away, but organizers are already lining up a full slate of competitions, farmfocused entertainment and educational activities for the Royal Agricultural Winter Fair.

Building on investments it has made over the past couple of years, The Royal will

425

introduce new features, entertainment and content for its 10-day run from November 6 to 15, 2015 in Toronto at the Direct Energy Centre and Ricoh Coliseum.

“Each year we try to come up with new ways to introduce people of all ages and backgrounds to a taste of Farm Fresh Fun in

the heart of the city,” said Paul Larmer, president and chairman of The Royal’s board of directors.

At an event earlier in April to officially kick off The Royal’s 2015 season, Larmer said Royal attendance has grown by 9 per cent over the past two seasons. The Royal welcomes more

than 300,000 visits over 10 days each fall, generating more than $42 million in economic activity.

“Our popularity continues to grow, which shows people still love learning about where their food comes from. The Royal is where we celebrate our agricultural roots,” Larmer said.

A total of 50 regional agri-food innovation awards were announced across Ontario in 2014.

Farm-level average net operating income is forecast to be an alltime high.

50 10% Headline

$78,139

For 2015, the preliminary forecast suggests that farm incomes will be down moderately, but remain historically high at 13 billion

Aggregate net cash income for 2014 is expected to reach $14 billion, 10% above the 2013 record. producers, processors and agri-food organizations have received a Premier’s Award for Agri-Food Innovation Excellence since 2007.

Ontario’s agri-food sector supports farmers, communities and the economy — employing more than 760,000 Ontarians and contributing more than $34 billion to the province’s economy.

Pristine® fungicide delivers broad-spectrum control of key diseases with a single product. Pristine also provides the benefits of AgCelence® which may include increased growth efficiency and stress management. Call AgSolutions® Customer Care at 1-877-371-BASF (2273) or visit agsolutions.ca for more information.

Always read and follow label directions. AgSolutions is a registered trade-mark of

New research from an Iowa State University economist has found consumers are willing to spend more for genetically modified potato products with reduced levels of acrylamide, a chemical compound linked to cancer.

Wallace Huffman, Charles F. Curtiss Distinguished Professor in agriculture and life sciences who contributed to the project, said the findings underscore the importance of efforts to educate consumers on the use of biotechnology in the production of healthy food.

Acrylamide has been linked to the formation of cancer in animals. It accumulates naturally in starchy foods cooked at high temperatures. Potato products, like French fries and potato

chips, make up the biggest source of acrylamide consumption in the United States.

Huffman’s research attempts to gauge consumer attitudes toward experimental genetically modified potato products. Genetically modified food has sparked controversy among some, but the results of the research showed a willingness among consumers to pay more for genetically modified potato products that reduce the formation of acrylamide than for conventional potatoes.

For instance, participants were willing to pay $1.78 more for a five-pound bag of potatoes after they received information from a scientific perspective on hazards associated with acrylamide exposure and a potato industry perspective on dramatically reducing acrylamide in potato products using biotechnology. Likewise, the participants were willing to pay an extra $1.33 for a package of frozen French fries after they received materials explaining the scientific implications of human exposure to acrylamide.

While scientific and industry perspectives had a substantial effect on consumers’ willingness to buy genetically modified products, the environmental information had a negative impact, Huffman said.

Move over apples. A new study suggests pears could play a role in helping to manage type 2 diabetes and diabetes-induced hypertension.

Building on previous studies, a research team from North Dakota State University, Fargo, and the University of Massachusetts studied whether the peel, pulp and juice of Bratlett and Starkrimson pears could impact the prevention and management

The government of Prince Edward Island recently announced it was planning on strengthening support for the province’s food sector to establish and promote the province as “Canada’s Food Island.”

“Islanders are proud of our food culture; we are deeply connected to the land and sea, and harvest some of the finest products in the world, including potatoes, shellfish, blueberries and beef,” said Premier Wade MacLauchlan. “Food is a vital component of our provincial economy: 40 per cent of our international exports are from food processing, and food processing and primary agriculture accounts for 10 per cent of our provincial GDP.”

Government hopes to build on the successes the province has achieved to establish Prince Edward Island as home to internationally recognized premium food products and as a destination for culinary excellence.

of type 2 diabetes, hypertension and the bacteria Helicobacter pylori, which plays a role in intestinal ulcers.

The study showed that Starkrimson peel had the highest total phenolic content, and that peel extracts had significantly higher total phenolic content than pulp. The pulp extracts of the Bartlett cultivar had higher total phenolics when compared with Starkrimson.

Headline-grabbing pathogens that can contaminate the food supply are meeting their match, thanks to technology advancements impacting both food producers and consumers.

The World Health Organization (WHO) is planning to release its long-awaited research on the global burden of foodborne diseases in 2015. Ongoing data from the U.S. Centers for Disease Control and Prevention (CDC) already paint a stark picture. One out of every six people in

the U.S. suffers from a foodborne illness every year. Within that group, 128,000 people are hospitalized and 3,000 die. Reducing those numbers is the goal of an army of food safety researchers, according to the latest series of interviews from the Institute of Food Technologists (IFT) FutureFood 2050 publishing initiative. Through 2015, the program will release 75 interviews with the world’s most impactful leaders in food and science. The interviews with food safety leaders are the 12th installment of FutureFood’s interview series.

For more information, visit FutureFood2050.com to subscribe to monthly updates, learn more about the project and read the latest news on food science.

Pristine® fungicide delivers broad-spectrum control of key diseases with a single product. Pristine also provides the benefits of AgCelence® which may include increased growth efficiency and stress management. Call AgSolutions® Customer Care at 1-877-371-BASF (2273) or visit agsolutions.ca for more information.

Always read and follow label directions. AgSolutions

Werner Zurbuchen started an orchard equipment business called Tazu Technology, which imports and distributes mechanical pruners, platform picking machines and other orchard equipment. Contributed photo

With the increases in minimum wage, labour costs have jumped significantly for Ontario horticulture farmers in recent years. While this has been tough on many producers, apple growers have been feeling the bight keenly considering there is more labour required to keep an orchard running.

Some have approached the challenge head-on, aggressively reducing the need for labour through planning, management and intensive production. But one Ontario grower has thrown a lot of effort into doing more with less. For his hard work and experimentation, Werner Zurbuchen, the owner of Zurbuchen Farm in Norfolk County, was recognized with a 2014 Premier’s Awards for Agrifood Innovation Excellence.

“We still have to work long hours at times,” he admits. “But we’re doing significantly more with less.”

In 1993, Zurbuchen and his family decided to sell their broiler operation and orchard/vineyard in Switzerland and immigrate to Canada. They purchased a broiler chicken farm in the Waterford area, which featured 185 workable acres of loam soil that has since been systematically drained. During his first autumn on the new farm, Zurbuchen got going right away with apple growing. He planted 100 apple trees and also grafted other varieties to test how they would

perform in the Ontario climate. Once he saw them doing well, he budded 17,000 trees on rootstock in his own nursery, and then planted them on 17 acres. From 2009 to 2012, Zurbuchen and his family expanded the orchard to 50 acres. The farm now has 48 acres of apples (with 10 being mature, high-density cultivation), two acres of pears, and the rest supporting a rotation of corn, soybeans and wheat.

“The apple crop estimate for 2015, if things go well, is about 1,000 bins,” Zurbuchen says. “In terms of what we grow, over the past two years, we have cut out our Spy, Mutsu and Macintosh cultivars because these varieties aren’t favoured today, and are now growing a majority of newer varieties. By today’s standards, we plant a mediumdensity orchard of 1,000 trees per acre and train them as tall spindle.”

Tall spindle tree care, once the trees reach their maturity, is timeconsuming in terms of taking care of the upper section beyond normal arm reach from the ground.

“If you use a ladder for this – and for thinning, tying, trellis installation and harvesting – it’s quite expensive because of the labour involved,” Zurbuchen says. “In addition, ladders and heavy bags of apples can be dangerous.”

Zurbuchen had already designed the high-density part of the orchard for mechanization, so when labour

Automation has cut labour significantly and improved safety. Zurbuchen Farm has cut pruning and harvesting time by 35 per cent plus thinning and trellising by 50 per cent.

BY TREENA HEIN

costs started increasing around 2010, he went the automation route and bought machinery. (He also welcomed his son-in-law Joseph Taylor to the farm as mechanic and, after some training, as seasonal field manager.) Zurbuchen’s first purchases were an imported European mechanical thinner, a Frumaco platform/ harvest-aid and a bin trailer. In 2011, he bought a Feucht windfall pick-up machine, and in 2013, a Fama mechanical pruner.

The Frumaco platform has performed as expected, boosting operational efficiency by a significant amount.

“It cuts both pruning and harvest time by 35 per cent, and thinning and trellis/tying worktime each by 50 per cent,” Zurbuchen says. “I can’t provide an accurate figure for the mechanical pruner right now as we’re still experimenting with it, but together with the platform, we are hoping for at least a total 50 per cent reduction in pruning time. We have used it a lot in a leased orchard with standard planting density and with varieties prone to dropping, and we can pick up at least 50 bins in seven hours with two men running it.”

While worker safety has also been improved with the machinery additions, Zurbuchen says that proper instruction for each worker is still critical in order to keep the risk of accidents to a minimum.

Because he thought there might be other growers besides himself interested in mechanizing, Zurbuchen also started an orchard equipment business called Tazu Technology. The company imports and distributes mechanical pruners, platform picking machines and other orchard equipment.

“We stand by what we sell because we have firsthand experience with it,” he says.

There are six Frumaco harvesters currently being used in

Quebec and Ontario orchards, and Zurbuchen believes that number will increase.

“There’s been a lot of interest from growers and we’re confident that in the coming years, more farmers will move forward in mechanising their operations,” he says. “We are currently in the process of purchasing a Lipco twin row tunnel sprayer which will be able to spray two rows at once, recycling lost chemicals while not being effected by the prevailing winds we seem to have quite often.”

Zurbuchen is also thinking seriously about buying a Frost Buster – a propane air blast heater that will help combat night frost in the spring and also assist with pollination.

The current challenges for this operation include planting new varieties that will be strong market leaders for many years to come. Replacing some of the less desirable older varieties with newer ones will also help to fill out the orchard’s harvesting window. Zurbuchen also wants to continue honing his integrated pest management (IPM) program, as well as his strategies for finding committed local labour.

“It’s also a challenge these days to deal with more and more paperwork, not only related to employees but also to comply with regulations and burdensome red tape,” he says.

Of winning the award, Zurbuchen says he’s happy that it’s brought some positive attention to the apple industry.

“It is our hope that the government understands that for Ontario farmers to be successful in a very competitive market is a very real challenge,” he says. “We are thankful to the premier and her staff who put the work into recognizing the hardworking people in the agriculture industry.”

To be selected, they need to be protected.

Use DuPont™Exirel™ insecticide, powered by Cyazypyr™ , early in the season to give your onions the head-start they need during the most critical stage of development. Exirel™ has fast acting, translaminar and xylem systemic movement so you’ll be protecting new growth, from difficult chewing and sucking pests including thrips.

Exirel™ , powered by Cyazypyr™ , an important part of an integrated pest management program.

Questions? Ask your retailer, call 1-800-667-3925 or visit exirel.dupont.ca

Organic fruit and vegetable operation has deep roots in the Similkameen Valley

BY TOM WALKER BELOW

Forbidden Fruit Winery winds along the Similkameen River, the southern-most property in the valley, located just before the river crosses the Canada-US border. Contributed photo

This past winter, Forbidden Fruit Winery in Cawston, BC, became the first winery in the Pacific Northwest to win top honours in both fruit wine and grape wine categories in the same competition. Wine Press Northwest magazine held it’s 15th annual Best of the Best competition, which only accepts entries that have won other awards. Forbidden Fruit received double platinum for its 2013 apricot-based Caught Mistelle and its 2011 Earth Series Merlot.

Winery owners Steve Venables and Kim Brind’Amour are no strangers to the podium. The fruit and grape wines they’ve been making for 10 years are multiple award winners. But it’s the organic fruit they’ve been growing for nearly 40 years that brings them the most satisfaction.

“It’s always been about growing food,” says Steve. “I am proud that we started as food producers and we still are food producers.”

The winery takes in only 10 per cent of the Ven ‘Amour Farm crop, while the remaining 90 per cent is sold fresh.

Sumac Road winds down along the Similkameen River, the last turn before Highway 3 begins to climb over Richter Pass to that “other” B.C. fruit-growing valley, the Okanagan. A self described “pony-tailed fruit picker” Steve had been working summers in the valley for five years, pruning and picking, while he searched for the perfect piece of land. His 142-acre farm, plus the adjacent 150-acre parcel he later leased and

purchased, is the southern-most property in the valley, located just before the river crosses the CanadaUS border.

Forbidden Fruit Winery owners

Steve Venables (right) and Kim Brind’Amour won big this past winter, taking top honours in both fruit wine and grape wine categories in the same competition. Contributed photo

Winery owners Steve Venables and Kim Brind’Amour are no strangers to the podium.

“There was nothing here but sage brush,” recalls Steve. “I moved down in the spring of 1977 and we grew lots of squash and tomatoes. We started planting an orchard and when we got the well in, we began expanding down the road and up the hillside.”

Kim joined him in 1981 and they’ve worked as a team ever since. The farm is now a series of southwest facing terraces that climb up from the river.

“It was organic from day one, absolutely,” Steve says. “It was our lifestyle.”

He adds: “Early Sterile Insect Release trials in 1979 helped organic growers get a foothold. Prior to that, we were loosing 60 per cent of our crop to coddling moth.”

The original pilot program totally eradicated the moth for two to three years and allowed a lot of organic

growers to get into apples and pears.

Some of the conventional growers looked askance at this Forbidden Fruit that came from organic methods.

“But in the early 80s, we saw a lot of commercial growers going ‘Huh, he’s getting $800 a bin and I’m getting two. Hmm … I can do that,’” Steve recalls. “By the time the late 90s rolled around, that $800 bin was down to $250, $300, which is where it’s at now.”

His friends call him a “variety hound” with 60 different tree fruits and six varieties of grapes.

“The model we’ve built, both with stores and our own sales, is to have something different consistently through the whole season, right into the fall. We are full on with Rainer cherries by the 20th of June. People are so happy for something fresh.”

Vista Bella, Williams Pride and Sansa get the apple market going. Steve was the first grower in the valley to bring in white peaches and is known for his Asian pears.

“We are as far south here as you can go. I can get a ripe peach the end of the first week of July and we ship them all out, even though the farmer’s markets are clamoring for them.”

Steve’s favourite apple right now is Tsugaru, the number two selling variety in Japan, after Fuji.

“I’ve been cropping it for four years and it’s huge and dark and sweet. All I have to say is ‘Tsugaru’ and they say ‘Send me all you’ve got.’”

Early wholesales went to Calgary stores.

“Calgarians were right there at the door,” Steve says.

They also supply the Kootenay Coop in Nelson, retail outlets in the Okanagan Valley and have just picked up a distributor on Vancouver Island.

When returns on their fruit

flattened, they added a guesthouse for agri-tourism. But they were looking for more diversification.

“We would sit in the guesthouse hot tub during the winter and ask ourselves: ‘What else are we going to do? Did we want to start taking our fruit to the coast to sell at farmers markets?’ We didn’t want that, we wanted to be at home, so we started making wine.

“It’s really a value added product,” Steve says. “It’s got good cash flow, and it works because we already have the fruit.” And those multiple varieties pay off.

“We can offer something a bit more exotic than the regular cherry or apple wines. We make a lovely Pear-suasion from our Asian pears and the Japanese plums go into our Plum Noir.”

game in the fall before the acids will drop because of our cooler nights. I end up with a bit more alcohol content in the wine.”

Steve and Kim’s children have been involved with the wine from the very beginning. Son Nathan is now the viticulturist and wine maker after attending Okanagan College. His red seal carpenter certification comes in handy around the farm and family houses as well. Daughter Tesha is the social media person and is farming small-scale crops, such as asparagus (for which the valley was noted 30 years ago) on river bottom soil up the valley.

It’s the organic fruit they’ve been growing for nearly 40 years that brings them the most satisfaction.

The family brought in fruit wine specialist Dominic Rivard, now with Muwin Estate Winery in Nova Scotia, who helped them get up to the next level with their wine.

Keeping visitors happy was part of the reason behind grape wines.

“You can see them at the shows,” says Steve. “They make a wide arch around our table. I like the idea that people will drive down off the highway to visit us.”

Sauvignon Blanc, Vidal, Cabernet Sauvignon, Cabernet Franc, Merlot and a small plot of Tannat make up their grape plantings.

“I want to put in more of the Cabs up against the bank,” says Steve. “The heat really develops the sugars, but it is a waiting

Forbidden Fruit produces around 2,000 cases a year, ranging from about 30 for a Tannat-Malbec blend, up to about 300 cases of Sauvignon Blanc. Most other varieties range between 150 to 200 cases.

“We are noticing that there is a lot of competition out there (299 wine licenses says the BC Wine Institute) and you need to be on the ground in Vancouver and Victoria. We do have an agent and we do pound the pavement, but I like to go more grass roots.”

Steve favours Rotary wine festivals across the province.

“I can tell people our story, pour our wines and tell them where they can buy them.”

These are the people who will stop on their way through the valley, or will make a special trip over from the southern Okanagan. However, he does admit that 35 wine shows last year were not keeping him at home.

Last summer, a change in BC liquor laws opened up wine sales at farmers markets and they have been pouring and selling wine, along with their fruit, in Penticton.

“We’re pretty lucky with pests,” says Steve. “We don’t get much mildew, we don’t have scab, and we don’t have brown rot, which the Okanagan can have with its higher humidity. The river is always moving here and we get lots of wind.

“I’m what you call a low impact organic grower. I’m still back in the 70s.”

Steve will put out oil if he has a really bad outbreak of scale and perhaps BT for twig borer and he finds it important to apply sulphur to the grapes.

“But if it’s not kicking me economically, I live with it. I’ve got to the point in my business where I can deal with challenged fruit, either in the winery or seconds for the canning market.”

His biggest problem is poison ivy. Although it doesn’t affect the fruit, it is hard on the workers and impossible to control organically.

“We have to dig it out with a mini excavator, but that only works when we are replanting.”

A new sweeper allows them to clean up the ground before harvest.

For the time being, they are staying out of the VQA program.

“They don’t recognize fruit wines and we kind of left it that way,” says Steve. “For me, what’s better than VQA is 100 per cent BC certified organic. We list in private and government liquor stores, but we are kept out of the 15 or so VQA stores.”

Future crops include the Wendy strawberry from Nova Scotia.

“We would be able to get it out of the way before the cherries.” Steve says. “I’m interested in planting some of the Austrian Gruner Veltliner, and I’m also tempted by Tempranillo. But sometimes Kim tells me I bring too much stuff home.”

Home-built machine makes harvest better, faster

BY TREENA HEIN

If you aren’t a tomato farmer, you might have a hard time guessing what Dennis Driedger’s machine is for. It’s a bit of a strange-looking contraption, with cutting disks, belts and conveyors all whirring in different directions and angles when it’s up and running. But odd appearance aside, it does the job well – and it earned Driedger a Minister’s Award in the 2014 Premier Award for Agri-Food Innovation Excellence competition.

The machine was created because Driedger knew there had to be a better way to harvest his crop. At the time, the only tomato harvesting method and machinery commercially available – a pusher unit that sat at the front of a tractor –posed a problem for tomato farmers who wanted to deliver high quality whole pack fruit to their customers. Simply put, in order for harvest to proceed with large tractors and transport trailers, they were required to “open the field” and push

ABOVE

plants out of the way to be able to straddle the rows. This resulted in product being wasted, split and squished by tractor tires and dump carts. A new harvesting method and machine, if one could be devised, would need to be able to lift and move entire crop rows, making room for the harvesting equipment and protecting all fruit from damage. If it could be done, this new method would also speed things up, with tomatoes loaded directly onto trailers and transported directly to the processing plant. But to create a better way to harvest his 150 acres of tomatoes in Wheatley Ont., Driedger was on his own. That is, it would be up to him, his parents Abe and Helga, wife Karen and ”right hand man” Pete Peters to get the job done. (Son Jesse will be graduating from Ridgetown College this spring and will be joining the farm then, while daughter Karlee is in nursing school.)

“There are so few of us tomato growers, and there just aren’t the equipment options out there,

The Dreidgers added a 1,000 pound counter-weight on the right side of the machine to balance the weight of the cross conveyor hanging out to the left. Contributed photo

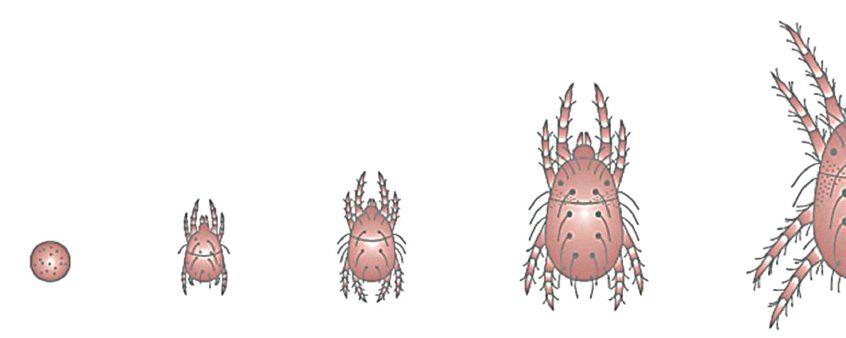

We have a technical name for every stage of a spider

mite’s life.

New Nealta™ controls harmful spider mites at all life stages, including eggs. Yet at the same time, it’s safe for bene cial insects, including bees and predatory insects and mites. And thanks to its unique mode of action, Nealta even controls tolerant and resistant populations. So why wait? Control spider mites at every phase of their miserable little lives. Call AgSolutions® Customer Care at 1-877-371-BASF (2273) or visit agsolutions.ca for more information.

Always read and follow label directions.

is a trade-mark of

and we have to be innovative,” he explained. “It’s all about delivering quality.”

He was ready to take on the challenge, because over his 30 years of farming, he’s made or modified numerous other machines and implements.

“I’ve made specialized equipment before such as a fertilizer applicator and I like doing it,” he said. “Ten years ago, we designed and built our own tomato harvester as there was no self-propelled offset-style tomato harvester on the market. With it all in one machine, it’s easier to handle and does the job better. The tomato business in Canada is just that way. There aren’t very many of us, and because of the different weather conditions and growing season and soil types that we have here compared to the U.S., the standard equipment that’s available doesn’t suit our needs very well. It doesn’t work terribly well with a wet harvest, handling mud.”

Driedger started with an old harvester and tore it down to the chassis. He envisioned something that would lift, cut and gather like a harvester, but that would also gently deposit the plants and dirt three rows over. It also needed to

be a self-propelled machine because even a pull-type version would need a tractor out in front, which would defeat the purpose. By the end of the first season, he and his father, son and Pete had built an operational machine – a tomato row opener with a disc head assembly installed in front of the chassis.

for whole pack, instead of paste, with the former obviously providing a higher price per tonne. We were pleasantly surprised that the results were that good. We saw the benefits the first year in how we were graded at the factory.”

And the machine’s usefulness has gone beyond the original intent of just opening

According to Dennis Dreidger, there are few tomato growers left in Ontario and there aren’t the equipment options out there. “We have to be innovative,” he said. Contributed photo.

“After the first build, we took it to the field and brought it back many times to the farm shop to make changes,” Driedger remembered. “The angle of the incline had to be reduced because the plants weren’t going up all the way. They were rolling back. The top of the header chain had to be shortened because the plants weren’t hitting the centre of the cross conveyor, but were shooting overtop.”

They also had to add a counter-weight of 1,000 pounds on the right side of the opener to balance the weight of the cross conveyor that was hanging out far to the left. Driedger said they did all the work themselves, only needing to talk to a hydraulic specialist when it came to driving all the motors. The harvester they’d started with had a lot of hydraulic capacity, so they had to scale that down to run the opener, which is smaller and has fewer moving parts. In the second year, all that was needed was tweaking – things like adding some shielding and rubber belting here and there at points where tomatoes were escaping from the conveyors.

Driedger was extremely pleased with the machine, which speeds up harvesting by almost 20 per cent.

“On average, 10 per cent of our tomato crop would be lost in opening a field,” he said. “So we have 10 per cent more going

a field for the harvester. Driedger also uses it to widen the headland at the end of the rows in the field to allow the harvester more room to turn and get into the rows.

“We used to do that by hand every day, moving what we required for that day of harvesting. We used to call this 45 minutes our morning exercise.”

Two fellow growers in the neighbourhood have since built their own “tomato row opener” machines.

“They came to the farm and I was happy to show them this one and help them,” Driedger said. “That’s the way we are, the group of guys around here, we help each other and share. I am sure there [are] others interested, at least those in the whole pack business instead of those growing for paste. But everyone would likely have to do things differently, because they might not have an old harvester but have some other piece of equipment as a base to start with.”

Driedger and everyone else on the farm were very excited about winning a Premier’s Award and then being chosen for the Minister’s Award.

“We had a great day in Toronto with the Ontario Ministry of Agriculture, Food and Rural Affairs staff and at the summit with the premier and agriculture minister,” Driedger said. “It was a great pleasure.”

There’s nothing to see here. Nothing at all, except your healthy vineyard. That’s because Alion ® is hard at work. This pre-emergent broad spectrum herbicide stops weeds before they start, so you won’t see them all season long. Apply it once for complete residual protection against both broadleaf and grassy weeds including glyphosate-, triazine- and ALS-resistant weeds. When it comes to weed control in your vineyard, there’s simply nothing better.

“We were lucky that most of the renovated portion was left undamaged,” Karen explains. “The trellis system we had put in place proved to be an amazing support to the trees.”

The Ferri’s postponed their move to Clarksburg and extended the lease on the Brampton farm. However, in 2010, while they made progress with their new orchard, another major setback came knocking. They had taken precautions for rodents, but the product didn’t do its job, and in the end, rodent damage resulted in more than 3,000 trees having to be replanted.

By the end of 2011, they had moved T&K Ferri Farms permanently to Clarksburg. But their troubles weren’t over. Like everyone else in 2012, the Ferri farm experienced an early spring followed by many freezing nights, and there was very little to harvest.

“We’re thankful that 2013 and 2014 went well,” Karen says.

in a timely fashion.

“We’ve been paid in-full anywhere up to 10 months after shipping, and we can be charged storage fees by buyers until they sell the apples,” Karen says. “It’s a baffling system.”

The fact apples can be dumped into the Canadian market and permitted onto grocery store shelves without tariff is also a challenge, she notes.

“Canadian farmers don’t have the assurance from our federal government, as farmers in many other countries do, that cost of production will be covered,” she says.

The Ferri’s also note that some of the funding programs available are confusing to comprehend in terms of what they apply to and how funds are distributed, in addition to being time consuming to apply for.

“Other funding opportunities are based on a competitive model and the aforementioned concerns remain the same,” Karen notes.

Tom does the majority of the work and sets the direction for the farm. His brother. Joe, works in the orchard alongside Tom from spring to fall, and also provides IT support and statistical analysis. Karen manages the office, runs the retail market, looks after advertising, local networking, grass cutting and some tractor driving during harvest.

The planting system reduces labour costs because handpicking can be done from a mechanized platform moving between the uniform tree rows, instead of using ladders.

“When the retail market is running, a niece works in the market and drives the tractor for harvest,” she says. “We have two other full-time employees throughout the spring and summer and about four workers are hired for harvest. We are lucky to have two local teenagers who help during busy weekends in the market.”

Varieties include Honey Crisp, Mac, Mutsu, Ambrosia, Gala, Cortland and Golden Delicious.

Where most orchards in North America have about 1,200 trees per acre, the Ferri’s have 2,500 to 3,000 – a density greater than most tall spindle systems which was chosen to accommodate the orchard’s climatic conditions and soil type. The orchard is the first in Ontario to have a super-spindle system, which is the industry term for high-density planting.

“The plunge was taken because it means less limb training, a true fruiting wall is achieved, and the trees fill their space faster, allowing for full production sooner,” Karen explains. “It takes just three to five years to achieve full production.”

The system also reduces labour costs because handpicking can be done from a mechanized platform moving between the uniform tree rows, instead of being done with time-consuming ladders. In addition, the Ferri’s “beyond-super-spindle” system requires lower rates of crop protection products. The tightly packed trees have less foliage than those in a regular orchard and getting the products on the apples is easier.

“Without the use of the platform, we would need two or three more employees for the summer pruning and hand thinning, and four or five more for harvest,” Karen says. “The chemical cost has been reduced considerably. We’ve been able to achieved return on investment in four to five years with Honey Crisp.”

The Ferri’s say their biggest orchard challenge has been the poor quality of trees received from Ontario nurseries. They’ve dealt with this by replanting or adjusting orchard techniques. In terms of current business challenges, the thorniest is being paid

“Food safety certification programs, such as Canada Gap, are applaudable. But we’re unconvinced the same requirements are secured from apples coming from other countries, such as China. This leaves Canadian farmers at a distinct disadvantage because it costs more to produce Canadian food and imported foods are offered into the Canadian market at cheaper prices.”

During 2015 and beyond, the Ferri’s would like to plant an acre of McIntosh in super spindle, and will be expanding their cold storage to support Honey Crisp requirements.

“We participated in a research trip to Italy recently, and we will continue to watch for new varieties suitable for our area,” Karen says. “Currently, Honey Crisp is one of the few apples which returns a reasonable margin to any apple grower.”

The Ferri’s are beginning to establish their own retail market and would like to work more closely with several local entrepreneurs who use their apples in various products. They also want to continue to expand their involvement with the culinary-agritourism within the Georgian Triangle area (Apple Pie Trail, Grey-Bruce Agricultural & Culinary Association), and work to brand the area for its apple production. They have already hosted an international apple growers’ tour and an international tour guide’s visit, which were both positive experiences.

“We also need to continue to add to our weather mitigation, with one or two more wind machines for frost protection, and we need to do some structural improvements to our lane to better accommodate tractor trailers used for shipping,” Karen says. “Applications for funding support for the wind machine have been repeatedly rejected. But we’re not prepared to give up on our quest, and will apply this year again for funding. We have received some funding support towards structural improvements to our lane. We also require another mechanized platform to deal with our increasing harvest volumes.”

Karen says it’s very pleasing that Tom’s efforts have been recognized with the Premier’s Award for AgriFood Innovation Excellence.

“He is a very hard worker and he is very innovative with improving the efficiencies in apple farming,” she says. “Tom also has a natural intuition about what is ailing a particular tree and is able to take action very quickly. It’s amazing.”

BY DAN WOOLLEY

John Lewis, a berry crops specialist with Perennia, recently reported recovery from Nova Scotia’s strawberry virus epidemic is now ahead of schedule and a normal crop is expected in 2015.

Speaking at the 2015 Scotia Hort Congress, Lewis was at pains to note the two viruses –strawberry mild yellow edge and strawberry mottle virus, which have plagued the province’s berry growers since 2013 – did not combine or mutate as reported in several media articles. Instead, when plants were infected by both viruses, there was an added synergistic effect, causing more problems in the plants than would have been caused by each virus on its own.

“We have always operated under the premise that the plants are unaffected by a single virus infection and it is only when there are two or more that the plant is compromised,” Lewis said.

Virus effects vary from strawberry cultivar to cultivar and the infection duration also seemed to

play a role, “but these variables are only now being figured out,” Lewis said. “The effects of the mixed infection is sometimes referred to as a strawberry decline disease and I think that is a good general description.”

It has been suggested that the disease started in 2012 in nursery plants and moved to the fresh fruit crop in 2013, but Lewis disagreed. “There is no evidence of a sudden arrival of either virus,” he said. “It is probable that a slow increase from base levels in the environment, likely in wild strawberries, facilitated by sustained favourable weather, led to the outbreaks in 2012 and 2013.”

About 50 per cent of 2013’s fresh fruit crop was lost due to combined acreage reduction (crop destruction by growers) and virus impacts on yield and fruit quality. The resulting smaller berry crop in 2014 was mostly due to the reduced crop acreage associated with the aggressive crop destruction in 2013 and the spring of 2014.

Lewis believes the crop acreage should be back to normal this year and he expects a normal crop yield, “with respect to viruses, even though we are still measuring modest levels.”

Two virus-testing surveys were done in 2013, the first to determine the distribution of the two viruses around Nova Scotia and the second in late summer to ascertain the level of infection in newly planted fields. In some cases, it was recommended to remove some newly planted fields for virus controls, said Lewis.

A virus infection survey was also done in the fall and spring of 2014 of all newly planted commercial fields. According to Lewis, levels of the two viruses in the 2014 survey had dropped to 15 per cent for strawberry mild yellow edge and two per cent for the strawberry mottle virus.

“Considering that both viruses are required to cause decline disease, we know from these numbers that we can have no more than two per cent disease. For this reason, coupled with acreage recovery, I am predicting a normal crop in 2015, at least with respect to virus effects.”

Aphids are known to spread the viruses and Lewis stressed the industry still needed to be vigilant.

“If you have a bad aphid year, everything will go right back up and we will be back in the same boat.”

This means growers will need to carefully manage aphids throughout 2015, he said, adding aphid populations will be measured again in the fall.

“We can then, hopefully, take our foot off the gas next year.”

Lewis attributed the Nova Scotia strawberry industry’s quick recovery, in part, to its small size [relative to other provinces].

An example of strawberry mild yellow edge and strawberry mottle virus infecting a plant at the same time.

He added the active participation of growers, who destroyed more than 150 acres of strawberry plants to eradicate the infection, worked to solve the problem.

A federal-provincial strawberry assistance program also facilitated the removal and replanting of infected fields, Lewis said, and the availability of virus-tested stock from local nurseries ensured that newly planted fields would be disease free.

A strategy has now evolved involving aggressive removal of infected fields, followed by replanting with virus-tested stock, Lewis said. This program is being assisted by aphid monitoring, which was started in 2013.

Lewis believes the two viruses are in Nova Scotia to stay. Their combined level needs to be reduced below five per cent before crop production and field management can return to normal levels, he explained.

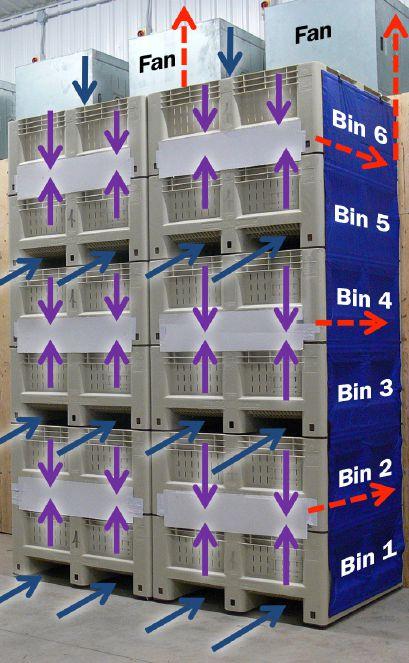

The serpentine airflow system has centrifugal fans atop a plywood plenum that pull refrigerated air (blue arrows) into the uncovered forklift openings and through the “hot” fruit where it warms (purple arrows). It‘s then drawn through the slots in the plywood (red arrows) and upward towards the evaporator coils to be re-cooled. Photo courtesy of Hugh Fraser, OMAFRA

can be a day and a half before they all get cooled,” he said.

Fraser identified the six components needed to make a forced-air serpentine system.

Need one squirrel-cage centrifugal fan per column of bins. The fan should be able to draw one cubic foot of air per minute (CFM) per pound of fruit at 10 mm (0.4 inches) of static pressure. This translates into one 3,000 CFM fan for six stacked bins of fruit holding about 500 pounds.

“The good news is that every piece of fruit in these bins is at virtually the same temperature when you are done,” he said.

Be wary of any undue restrictions on the fan due to holes that are too small in the bin, or cross-section of forklift opening. You want about two square feet of opening for every 1,000 CFM of airflow.

“So with a 3,000 CFM fan you would like about six square feet of cross section so you are not choking the fan and putting an undue load on it,” he said.

Most plastic bins used by Ontario tender fruit producers are ideal for serpentine cooling because they have straight side walls, they fit like LEGO™ blocks and have long, slotted floor vents. A full 25 per cent of the area perpendicular to the airflow is open.

“If you want to do this right, you have to make sure the air flows through the produce so you have to make sure there are no spots where the air is going to sneak through,” Fraser said.

Put bins together nice and tight, use bumper pads to fill gaps and cover forklift openings correctly. Use foam on the wall for good seal. Use a static pressure gauge to measure if the system is tight.

Ensure you have enough refrigeration capacity to pull the heat out quickly. The hot air pulled from the fruit is directed toward the evaporator coils where it is cooled, then blown back into the cold storage where it is picked up again by the serpentine system.

Monitoring is simple and tells you how effective your system is. In one particular case, the cold air going into the bins measured at 36 F, while at the fan, the hot air coming out was about 51 F.

“That hot air is about half way between the cold air going in and what the fruit temperature actually is. In this particular case, the fruit averaged about 64 degrees which is close to half way,” he said.

By monitoring the temperature of the cold air going in and the hot air coming out, you can predict when the thermostatically controlled fan should be turned off.

“I can’t emphasize enough that virtually every piece of fruit in that bin [should be] about the same temperature when you are done,” he said.