The M VersaPro® (MVP) Dicer, by Urschel, provides a sanitary (IP69K) design and versatile cutting (VFD-equipped 5HP Crosscut) of proteins. Patented fluted crosscut. Deeper circular knife penetration. It outperforms the M6 by a resounding 33%.

Explore the MVP to improve your line.

NOVEMBER/DECEMBER 2023 • VOL. 83, ISSUE 6

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service

Tel: 416-510-5113 Fax: 416-510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

ED ITOR | Nithya Caleb ncaleb@annexbusinessmedia.com 437-220-3039

ASSOCIATE EDITOR | Monica Ferguson mferguson@annexbusinessmedia.com 416-510-5206

ASSOCIATE PUBLISHER | Kim Barton kbarton@annexbusinessmedia.com 416-510-5246

MEDIA DESIGNER | Alison Keba akeba@annexbusinessmedia.com

ACCOUNT COORDINATOR | Mary Burnie mburnie @annexbusinessmedia.com 519-429-5175 ext. 4175

AUDIENCE DEVELOPMENT MANAGER | Anita Madden amadden @annexbusinessmedia.com 416-510-5183

GROUP PUBLISHER/VP SALES | Martin McAnulty mmcanulty@annexbusinessmedia.com

PRESIDENT/COO | Scott Jamieson sjamieson@annexbusinessmedia.com

Publication Mail Agreement No. 40065710

Subscription rates

Canada 1-year – $84.95 per year

Canada 2-year – $124.95

Single Issue – $15.00 United States/Foreign – $159.95 All prices in CAD funds

Occasionally, Food in Canada will mail information on behalf of industry related groups whose products and services we believe could be of interest to you. If you prefer not to receive this information, please contact our Audience Development in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com 800-668-2384

No part of the editorial content of this publication can be reprinted without the publisher’s written permission @2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

Mailing address

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Tel: 416-442-5600 Fax: 416-442-2230

ISSN 1188-9187 (Print) ISSN 1929-6444 (Online)

A recent study found that the higher the consumption of ultra-processed foods, the higher the risk of suffering from multimorbidity, which is a combination of chronic diseases such as cancer, diabetes and heart disease.

The multinational study involved 266,666 men and women from seven European countries, and the University of Vienna, in collaboration with the International Agency for Research on Cancer. Co-funded by the Austrian Academy of Sciences, Cancer Research UK, the French National Cancer Institute and World Cancer Research Fund International (WCRFI), the new research is based on data from the European Prospective Investigation into Cancer and Nutrition.

The researchers discovered that the more ultra-processed foods consumed, the greater the risk of multimorbidity.

Specifically, associations were noted with animal-based products and artificially sweetened beverages (e.g. soft drinks).

Given that the term, ‘ultra-processed foods,’ has been bandied about a lot this year, let’s first define it. In 2010, Brazilian researcher, Carlos Monteiro, and his team, came up with the NOVA system of food classification. According to the 2019 article, “Ultra-processed foods: what they are and how to identify them,” from the Public Health

Nutrition journal, “NOVA classifies all foods and food products into four groups according to the extent and purpose of the industrial processing they undergo. It considers all physical, biological, and chemical methods used during the food manufacturing process, including the use of additives.”

Unprocessed and Minimally Processed Foods are, as the name suggests, fresh fruits and vegetables, nuts, seeds, grains, eggs, milk, fish, etc., that do not contain added sugar, salt, fat, or additives. The next group is Processed Culinary Ingredients, such as oils, fats, and vinegars.

The third group of Processed Foods refer to tinned goods, cheese, salted nuts, and smoked and cured meats that are minimally processed.

According to WCRFI, “ultra-processed foods are convenient (long-shelf life, ready-to-eat), industrially manufactured foods with added ingredients or additives (e.g. modified starch, hydrogenated oils) that are typically found in fast food restaurants or sold via supermarkets.”

Soft drinks, sweet or savoury packaged snacks, processed meat, and pre-prepared frozen or shelf-stable dishes would be considered ultra-processed foods.

However, not all ultra-processed foods are unhealthy. This raises interesting questions about the current classification system. According to WCRFI, vegetablebased pasta sauces, whole-grain breads and cereals and fruit yogurts “offer

Nithya Caleb

nutritional value, as they contain fibre, as well as macro- and micro-nutrients. Foods that are needed for medical or nutritional purposes are also in this category, such as gluten-free foods or fortified plant-based milk alternatives.”

Heinz Freisling, co-author and study lead at IARC, said, “These [recent] findings are of concern because ultraprocessed foods comprise nowadays more than half of our daily food intake. Critics of the classification of certain foods as ultra-processed argue that the definition is impractical and that some foods classified as ultra-processed make important contributions to the nutrient intake of specific population groups (e.g. older adults). Such criticism should certainly be considered. However, our study emphasizes that it’s not necessary to completely avoid ultra-processed foods; rather, their consumption should be limited, and preference be given to fresh or minimally processed foods.”

While this study focused on the European population, the findings have important lessons for the North American food manufacturing sector. It’s clear the food classification system needs a revamp. Additionally, consumers are seeking clean label products. The question is how effectively and quickly the industry will respond to these demands.

Nithya Caleb ncaleb@annexbusinessmedia.com

Unilever is granting a free non-exclusive license to the ice cream industry for 12 reformulation patents. This will help the industry reformulate ice cream products that remain stable at the warmer freezer temperature of -12 C, rather than the current industry standard of -18 C. It is hoped that this sharing will help move the industry toward more energy-efficient freezer cabinets across the globe. Industry partners can contact icecream.reformulations@unilever.com to receive further information about obtaining a license.

Breadsource receives $5M funding boost

The Federal Economic Development Agency for Southern Ontario invests $5 million in Breadsource Corporation. This investment will support Breadsource in equipping a next-generation, energy-efficient bread production facility in Scarborough, Ont., that will allow the company to enhance production and offer 40 new bakery products, including gourmet potato rolls and sourdough breads.

Quebec-based innovators develop hyperspectral tool to assess marbling

The Canadian Agri-Food Automation and Intelligence Network is investing $301,428 in Montreal’s MatrixSpec Solutions. The project, valued at $844,081, will improve the evaluation of marbling, one of the most important criteria used to determine red meat quality. MatrixSpec’s Marbling Meter is a handheld device that uses hyper

New tabbed container liners from TekniPlex

spectral imaging to ‘read the marbling and return a grade quickly, objectively, and without damaging the product.’

The J.M. Smucker Co. sells its Bick’s pickles, Habitant pickled beets, Woodman’s horseradish and McLarens pickled onions brands to TreeHouse Foods. The all-cash transaction is valued at approximately US$20 million. In related news, J.M Smucker sell its Sahale Snacks brand to Second Nature Brands. The transaction includes all trademarks and the company’s leased manufacturing facility in Seattle, Washington, including about 100 employees who will transition with the business.

TekniPlex Consumer Products introduces a series of tabbed container liners that are compatible with a broad array of bottles and jars. Edge Pull is available in half-moon and offset tab configurations, while Simply Tab features a dual tab design. Each features an induction heat seal for barrier protection, and thick, durable tabs for ease of grip. www.tekni-plex.com/consumer

Kellanova (formerly known as Kellogg Company) completes the previously announced spin-off of its North American cereal business (WK Kellogg Co), resulting in two independent, public companies. This also marks the beginning of two standalone legal entities in Canada: Kellanova Canada and WK Kellogg Canada. As part of the news, Kellanova Canada announced a newly appointed leadership team. Kellanova Canada includes brands such as Pringles, Cheez-It, Pop-Tarts, Kellogg’s Rice Krispies Treats, RXBAR, Eggo, Nutri-Grain, and MorningStar Farms.

Antares Vision Group launches an x-ray scanner system designed for inspecting food ingredients and raw materials such as cereals, rice, legumes, coffee, and sugar. Incorporating a vertical piping system, the company’s XR Bulk unit utilizes gravitational fall to inspect for contaminants. The machine also features a proprietary custom sensor that is sealed and protected from potential dust. www.antaresvisiongroup.com

n

Dr. Amy Proulx

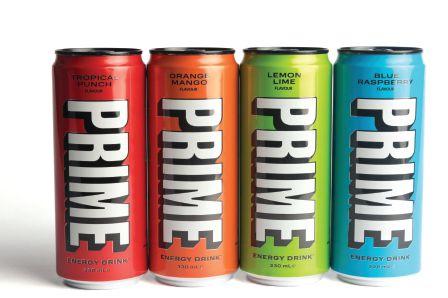

ore than 30 energy drink brands have been recalled by the Canadian Food Inspection Agency (CFIA) for a range of non-compliance, including exceeding the limit of permitted caffeine, not having precautionary statements regarding health impact of consumption, and labelling not meeting bilingual and Nutrition Facts standards required for sale in Canada. Thirty brands at the same time are a lot of products, which prompts questions about import inspection.

According to the World Bank’s World Integrated Trade Solution data from 2021, Canada imported over $22 billion worth of food products. Given the sheer volume, it’s just not possible to look at every product entering the country.

Many products receive offshore preinspection, which is done within the exporting country, and not by CFIA. This is in place to reduce the number of rejected shipments in transit and at the border. Import compliance is first verified even before product leaves the exporter’s loading dock. Importers are required to file documentation with CFIA’s Automated Import Reference Service. This system identifies regulations that are necessary for a vast range of commodities and processed products. It also provides Harmonized System codes for statistics, trade, and taxation purposes. Documentation is prepared to accompany the shipment confirming regulations have been met in the receiving country. Depending on the product and the exporting country, in some cases, product is precleared at the point of export, and therefore subject to very low re-inspection rates on arrival in

Canada. This occurs mostly with highly trusted countries of export, such as the United States, and for low-risk products like shelf stable and canned goods.

Many shipments are visually screened by CFIA upon arrival in Canada to ensure the contents are matching the bills of lading, and that they comply with Canadian regulations. Due to the sheer volume of foods, it is impossible to do a full inspection on every container. According to the CFIA Blueprint for Imports Guidance, between five and eight per cent of shipments are manually inspected, and the rest by automation. Manual inspection could imply a rapid visual inspection, or more rarely, an organoleptic inspection with full evaluation of product and packaging. This all suggests there is a realistic potential for non-compliant product to get through the system.

While it’s not likely the case in the caffeinated sports beverage case, there have been many incidents where individuals use their personal exemption for importing products, and bring in small quantities, which they then sell at small-scale retail stores or online. There are also importers who play the risk, anticipating that their product will be automatically evaluated on arrival at the border, rather than getting a full inspection.

What occurred with the non-compliant energy drinks is an element of tort law, where there was a breach of regulations. Within tort, negligence happens when a company makes a mistake or omission in compliance, but otherwise, has the plan of doing right within the regulatory system. Being non-compliant with full knowledge that they’re circumventing regulations is breaching the regulation with intent and has a different set of penalties in tort law.

The import system has many prompts and reminders regarding regulations, such as labelling, composition, permitted and non-permitted ingredients, language of labels, and Nutrition Facts requirements, suggesting that this particular case of noncompliance is not a matter of negligence.

When companies are found in noncompliance, usually corrective action is the first step from CFIA. This reflects on a continuous improvement mindset that most non-compliance is negligence, where a company made a mistake or omission within a complex regulatory system but is otherwise demonstrating commitment to good standards of compliance. When non-compliance with intent occurs, establishments can be subject to a range of penalties. This can include license suspensions or cancellations or revocation of certifications, such as organic. In some other cases, annotated monetary penalties may be applied, which are a form of regulatory fine. In the most severe cases, criminal charges can be laid against establishments and the management for intentionally disregarding regulations.

At the point of publication, no fines or penalties have been published for this incident. However, CFIA is known for doing detailed enforcement proceedings, which take time. Time will tell if this was a case of massive negligence, or a calculated risk done with intent to circumvent regulations.

Dr. Amy Proulx is professor and academic program co-ordinator for the Culinary Innovation and Food Technology programs at Niagara College, Ont. She can be reached at aproulx@niagaracollege.ca.

Nestor Gomez

oncerns over counterfeiting and labelling claims have led Canada’s seafood and fisheries sector to provide greater transparency and traceability into their supply chains. New technology has emerged to help those efforts, while preventing fraud and providing more efficient inventory management and quality control. Having traceability at all stages of seafood processing means being able to document a product’s path from catch through to final customer. In other words, a seafood company can prove a product’s provenance, sustainability, and safety at each step in the process. Traceability also enables businesses to demonstrate responsible sourcing practices and compliance with government regulations, which gives consumers more confidence in the business.

Unfortunately, mislabelling and fraud have become common in the seafood sector in practices such as species substitution, incorrect weights for products, and misrepresentation of a product’s origin. Without some form of transparent traceability system, companies may face health and contamination concerns, as well as legal measures such as fines or other penalties. Governments and organizations are working to improve label accuracy through certifications and standardization. There are technologies for tracking products, such as barcodes, QR codes, and other digital markers, but because of their format, they have traditionally had limited use in the seafood sector. New technology coming onto the market hopes to

address those barriers, and boost their use, while adding greater automation to the seafood processing sector.

Vancouver, B.C.-based ThisFish, which now operates globally, provides TallyVision, an artificial intelligence solution for seafood traceability and production workflows designed to boost business efficiency, transparency, and compliance in seafood supply chains. The company’s software, combined with sensors and industrial hardware, such as scanners, digital scales, and computer vision technology, help seafood processing plants automate data collection and digitize information systems to produce real-time insights that can be used to improve traceability and quality control, while reducing waste. The software also provides for the use of QR code labels, allowing customers to track seafood through retailing and processing back to the farm or fishing vessel that harvested it.

Toronto’s Index Biosystems offers a different route toward traceability. The company uses biotechnology to turn baker’s yeast into microscopic biotags to trace products through the supply chain. In August 2022, Index Biosystems received funding through the Canadian Food Innovation Network’s (CFIN’s) Innovation Booster program to pilot a project with its automated biotag application system to tag and trace grain.

Another company offering fisheries and seafood processors help to both manage

An enhanced traceability system can mitigate labelling and fraud concerns by offering verifiable information on a product’s origin, processing, and distribution.

inventory and trace the movement of products through the supply chain is Sydney, N.S.-based Mabel Systems. Mabel provides a data capture platform that allows seafood companies to digitize receiving and production, giving them more control over inventory, food safety, and demand forecasting, while allowing for accurate, real-time tracking of products. When combined with hardware such as advanced computer vision technology, the software allows processors to easily share information with retail customers, consumers, and regulators.

As more fish and seafood companies turn to innovative technology for improving efficiencies and compliance while alleviating concerns about fraud and mislabelling, consumers will continue to benefit with fully traceable products and more information about the sector.

Nestor Gomez is chief technology officer for the Canadian Food Innovation Network (CFIN), a national, member-based organization stimulating transformative and transferrable innovation across the Canadian food sector. Visit CFIN at www.cfin-rcia.ca.

Gary Gnirss

n October, the Canadian Food Inspection Agency (CFIA) updated its guidance for simulated meat and poultry products after more than 40 years. The rules governing simulated meat and poultry products are found in Division 14 and 22 of the Food and Drug Regulations (FDR). They were last amended in 1982.

While Health Canada has not formally amended simulated meat and poultry rules, they have altered their course on how protein ratings may be determined. The current rules governing simulated meat and poultry are not food standards, but they lay out nutritional requirements involving a protein rating and the content of fat, vitamins, and minerals. A protein rating is to be determined by Official Method #1 (FO-1), which was last updated on October 15, 1981. A protein rating is based on the protein efficiency ratio (PER) of the protein source. Unless there are published and representative PER values for a protein source, which are not so common these days, the only remedy is to determine PER by FO-1. This is based on an animal study, measuring growth (grams gain per gram of protein) in contrast to a standard protein diet based on casein. If a manufacturer is developing a vegan simulated meat or poultry product, it raises some interesting questions!

In late 2020, Health Canada and CFIA announced that they will accept either a PER method based on FO-1 or a PDCAAS (protein digestibility corrected amino acid score) method, with the intention to eventually update FDR. The PDCAAS method is used to calculate an estimated PER value, which is then used to calculate the protein rating based on the amount of protein per reasonable daily intake of food. The PDCAAS method

Terms like ‘burger,’ ‘loaf,’ ‘patty,’ ‘jerky,’ and ‘sausage’ can be used to describe a non-simulated meat/poultry product as long as it is not mistaken for a meat/poultry product.

considers the fecal true digestibility percentage of the protein source, which can be based on published values. Those values are derived from animal studies. The PDCAAS method offer some advantages over FO-1, as it is more adaptable, particularly when the protein content is based on multiple sources.

In the past, one of the biggest concerns with simulated meat and poultry was the definition—“has the appearance of a meat/poultry product”. Tempeh by its nature could resemble meat and tofu strips could look like chicken. The question was who decides the product ‘has the appearance of meat/poultry’. CFIA’s updated guidance attempts to provide a more predicable approach to this question. The revised guidelines make it clear as to which food products must meet comprehensive nutritional and labelling requirements (i.e. include the word, “simulated,” in the name as well as the statement, “contains no meat/poultry.”). In the updated guidance, CFIA acknowledges that while some foods may have certain visual characteristics (e.g. colour, texture, shape) that are similar to

meat/poultry products, that alone is not a factor for them to be called simulated meat/ poultry. As unstandardized foods, these products would be identified by a common name meeting the new definition in B.01.001, FDR,, and also CFIA’s new rules on the true nature of food.

Appearance, however, is still a factor. If a product is made to look like pork ribs, it is likely going to be classified as simulated meat. Terms like ‘burger’, ‘loaf,’ ‘patty,’ ‘jerky,’ and ‘sausage’ can, however, be used to describe a non-simulated meat/poultry product as long as it is not mistaken for a meat/poultry product. If the label of such products implies it has a relationship to meat/poultry products, it will likely be considered as simulated meat. However, it would be ok to label non-simulated foods as ‘chicken flavoured.’ For clarity, nonsimulated meat/poultry products are not expected to contain products of slaughter but may contain other animal products such as eggs or milk.

Having simulated meat/poultry rules is a good thing, as it establishes nutritional equivalency. Similar rules, however, do not apply to other commodities such as simulated fish, eggs and dairy foods. If such foods are represented as being nutritionally equivalent to their counterparts, it could be considered as a misrepresentation.

One drawback of these kind of simulated foods is that there are no provisions for fortification. Health Canada is, however, considering further amendments to FDR to provide a broader range of discretionary fortification for conventional foods. For now, at least the old simulated meat/poultry rules provide manufacturers options and CFIA’s guidance provides relief for those foods, which were not intended to be captured as simulated meat/poultry products.

Gary Gnirss is a partner and president of Legal Suites, specializing in regulatory software and services. Contact him at president@legalsuites.com.

Carol Zweep

lant-based or bio-based packaging uses organic plant sources to make packaging material. The use of a renewable resource is a good alternative to nonrenewable petroleum-based packaging, as petroleum-based plastics are made from crude oil using energy-intensive extraction processes. Offering plantbased packaging resonates with positive consumer perceptions of environmentally friendly packaging. Some plant-based packaging is also biodegradable.

Biodegradation describes the process of breaking material down into natural substances within a certain timeframe after disposal. When biodegradation occurs under different conditions, different terms are used, such as composting, anaerobic digestion, and biodegradation in soil and in marine water.

A variety of bio-based materials can be used for packaging. Cellulose is derived from cotton, trees, hemp, and wood pulp. It can be made into bag applications for dried fruits, biscuits, rice, dried beans, pasta, tea leaves, coffee beans, sweets, and herbs. Mushroom packaging can be made by mixing fungus sprouts or mycelia with seedlings or other residues from agriculture. Mycelium is lightweight and easy to mold. Its properties are similar to Styrofoam. Bagasse is a pulpy residue left over from crushed sugarcane stalks. It can be made into foodservice packaging. Coconut husk can be pressed and formed into packaging, which can often look like cardboard. Chitin is the polysaccharide found in the shells of shrimps and other crustaceans. Chitin with fibroin (an insoluble protein found in silkworms) makes a plastic-like material that can be used to develop a biodegradable

alternative for food packaging. A biodegradable and edible product can be made from brown seaweed extract and calcium chloride to create a gel-like material. It can be used to replace plastic bottles with an edible water container.

Bioplastics are a type of plastic that is bio-based and biodegradable. Two examples of bioplastics are polylactic acid (PLA) and polyhydroxyalkanoate (PHA). PLA is a type of polyester made from fermented starch from corn, cassava, maize, sugarcane, or sugar beet pulp. PHA is a polyester synthesized directly by fermentation of a carbon substrate inside a micro-organism. PLA and PHA are used as conventional plastic packaging alternatives. PLA is often used for plastic films, bottles, food and deli containers, salad boxes, coffee cups, and compostable cutlery. PHA is used for single-use packaging for foods, beverages, and consumer products.

Not all bio-based plastics are biodegradable. Bio-based plastics are defined as materials for which at least a portion of the material is produced from renewable raw materials. Common commodity plastics like polyethylene terephthalate, polyamide, and polypropylene have been manufactured from fermentation byproducts of biological feedstocks such as sugarcane, sugar beets, and corn. Although biobased, these plastics are chemically identical to petrochemical-based plastics and therefore not biodegradable.

There are environmental benefits for using bio-based packaging. Bio-based packaging is made from renewable plant sources. Unlike petroleum-based materials, feedstocks from plant-based

Unlike petroleum-based materials, feedstocks from plant-based materials remove carbon dioxide from the atmosphere during their growing phase, thus reducing the carbon footprint of the material.

materials remove carbon dioxide from the atmosphere during their growing phase, thus reducing the carbon footprint of the material. Plant-based products can help reduce landfill waste by offering recycling and composability options. Plant-based alternatives to traditional plastics, along with improved collection infrastructure, can prevent litter from ending up in water bodies.

Bio-based packaging is under constant development with the objective of overcoming resource depletion and counteracting plastics pollution. Transparency about environmentally friendly packaging will allow consumers to make informed purchasing and disposal decisions. Package functionality and end-of-life disposal should be considered during the innovation process. New tech for the production of bio-based materials using urban, agricultural, and food waste as feedstock will establish a sustainable production value chain for the future design of bio-based packaging.

Carol Zweep is food consulting manager for NSF. Contact her at czweep@nsf.org.

Revealing the legacy, brands, and flavours that position Oceanfood Sales for success

— BY MARK CARDWELL —

Rob Graham makes no bones about the quality of seafood products his family’s company has been making and importing for more than 50 years.

“Everything we sell is top tier. We only deal in the best stuff,” said Graham, chief operating officer of Oceanfood Sales. “Our products are for people who understand quality and know what they want.”

Headquartered in Vancouver’s Downtown Eastside, Oceanfood Sales makes two house brands and imports another half-dozen brands from partner companies around the world. Most of those frozen seafood products are destined for the foodservice market, as well as to major food retailers across Canada.

Graham said Oceanfood Sales’ premium house brand—Nanuk, the Inuit word for polar bear—was originally developed for the foodservice industry. But its popularity among chefs led to it becoming a retail item.

The brand is produced at Oceanfood Sales’ smoking facility on Mitchell Island in the Fraser River. More than 100 people work at the 30,000-sf facility, where wild and farmed salmon, steelhead, trout, mackerel, albacore tuna, yellow fin tuna and black cod are filleted, salted, smoked, and packaged into 18 items across the Nanuk brand’s three product lines: cold smoked, hot smoked, and filets, portions and loins.

“Smoked salmon is a luxury item that is meant to taste good,” said Graham, who runs the company with his sister Louise, and vice-president Ted Kim. “My job is to find the best salmon, the best cod, the best everything.”

The company’s second house brand, which is called Voyageur, is a co-packed line developed exclusively for Canadian restaurateurs, chefs, and suppliers. It features a dozen raw and cooked tuna, shrimp,

salmon, ground fish, crab, squid, and scallop products from around the world. Imported seafood brands that Oceanfood Sales buys and markets across Canada include King & Prince, Mrs. Friday’s, Pride of Alaska, Coldwater Prawns, Dutch Harbour, Orca Bay Foods, and Upper Crust Enterprises.

Graham said strong and growing demand for his company’s products across Canada has led to the opening of sales and distribution offices in Calgary, Toronto, and Montreal.

The company’s quest for quality began with Graham’s father John, who moved to B.C. from Ontario in the late 1950s with the intention of studying medicine at the University of British Columbia. Instead he got a job on a salmon fishing boat in Namu, a now-abandoned fishing port on the B.C. coast.

Namu was then a hub in a flourishing West Coast commercial fishing industry. It was notably home to a large cannery owned by B.C. Packers, Canada’s largest fish processing company until the 1990s, when the fishery floundered.

“Dad got a job with B.C. Packers and spent several years there in processing and sales,” said Graham. “That’s where he learned the seafood business, which is really a primary resource industry like mining or logging.”

Graham was just five when his father struck out on his own and founded Oceanfood Sales in 1970.

“He started buying and selling troll-caught B.C. salmon to smokers in Europe, predominantly France and Denmark,” said Graham.

He said five kinds of wild salmon were then being harvested by the millions using hooks or nets along Canada’s West Coast, including Coho, chum, pink, spring and sockeye, the most prized species.

“Troll salmon are the best quality because they’re caught using lines and hooks and can be bled and dressed on the boat,” said Graham. “You can’t do that with scoop nets because they are too many fish. Plus, with nets you get other problems like bruising.”

In addition to exporting salmon, Graham said his father also began importing truckloads of breaded shrimp from Fish King in Los Angeles and wild frozen shrimp from Alabama and Louisiana.

“He was one the first people in Canada to do that,” said Graham. “He was like a trader, buying and selling salmon and shrimp to distributors and wholesalers.”

He said his father’s friends and clients in Europe later sold him on the idea of getting into the salmon smoking business.

“Dad bought a small plant right downtown, not far from where our

offices are now,” said Graham. Both he and his sister started working in the plant in the 1980s while studying, respectively, marketing and accounting at the British Columbia Institute of Technology.

Both siblings joined their parents in the family firm after graduating.

“It was an easy transition because we grew up in the business,” he said. “It was the main topic of conversation around the family table. Dad would often bring friends and clients home for supper. You learned a lot just by osmosis.”

Graham said he also often accompanied his father, who is now retired, on his frequent trips around the world in search of new seafood products and partners.

“My father is a very engaging person and was an excellent salesman who was well respected,” said Graham. “My sister and I were lucky to have him as a mentor.”

Graham said the decision to build a state-of-the-art smoking facility 20 years ago on Mitchell Island on the Fraser River, which separates the cities of Vancouver and Richmond, was the key to unlocking the growth and development of the company’s top-selling Nanuk brand.

“We were turning people away before and we couldn’t pursue the customers we wanted,” said Graham.

He said the new smoking facility was designed “like a circle that’s always moving forward” for the manufacture of products and to eliminate the possibility of cross contamination.

Raw materials—much of it now aquaculture salmon works— enter the one-floor facility on one end and are put into a holding freezer before being racked and moved to a thawing room.

Once thawed, fish are processed through fillet, pin bone and brining machines before being smoked, sliced, vacuum packed, frozen, and then put into boxes for pick up by third-party reefer carriers.

Graham said he and his sister are in the plant almost daily, though they no longer pitch in to help on the single-day shift or with clean up.

“Louise and I have built a strong team from the foundation we inherited and we continue to grow the business together with our employees, which are our most valuable asset,” he said.

Graham added he and his sister also regularly visit trade shows and other smoking facilities to stay abreast of the latest technologies.

“The seafood business is constantly changing and evolving,” said Graham. “We continue to strive to make the best possible product by adapting to new ways of doing and to our customers wants and needs.”

Aligning sustainability with consumer needs can support an environmentally and economically sustainable food system — BY

JONATHAN KERSHAW —

Imagine you are hiring an employee to lead your company’s sustainability efforts. What would the ideal candidate be like? Perhaps you imagined someone who is passionate about recycling, drives an electric vehicle (or doesn’t drive at all), composts, conserves water and energy, and maybe even chooses to sail across the Atlantic Ocean to avoid a greenhouse gas-emitting flight. However, what if this same person couldn’t draft a coherent email, work on a team, or carry on a conversation without interrupting? Clearly, there is a minimum skill set that is required to do any job, regardless of fit or enthusiasm. Likewise, consumers of eco-friendly foods care about the sustainability profile of the food and they expect the food to meet ‘minimum qualifications’. Messaging for sustainable products must communicate the environmental benefits and reassure consumers that product can do its functional job (spoiler alert: taste is key). Understanding why consumers ‘hire’ certain foods and positioning products to align with those needs will help companies deliver on sustainability promises while being successful in the marketplace.

Effective resumes contain information about a candidate’s education, skills, and requirements to help prospective employers identify interviewees; similarly, a certain level of information is required to help consumers understand the benefit of sustainable products. In some of my recent collaborative work, I explored strategies to increase consumer acceptance of aquaponics, a sustainable food production system where fish and vegetables are grown in the same water-circulating system to reduce inputs while maximizing outputs.1 When consumers were given a brief description of aquaponics, they preferred wild-caught fish. However, when a detailed description of the fishing methods was provided, their purchase intention for aquaponic fish exceeded that of wild-caught fish. Interestingly, the increase in purchase intention was driven by the impact of the message on expected tastiness and healthiness. Sustainability messages often create a ‘halo’ effect, a phenomenon when positive feelings created by one attribute elevate the perception of unrelated attributes. Strategic education about sustainability benefits can positively improve a product’s appeal in areas beyond the environmental benefits alone.

After preparing a basic resume, savvy jobseekers will seek to understand the goals and values of the prospective company. Likewise, it is critical to understand the values and beliefs of the target consumer. We recently demonstrated that the impact of a sustainability message depends on the characteristics of the person receiving it. 2 For example, text messages promoting plant-based eating had a bigger impact on intention to reduce meat and increase plant protein consumption when the person receiving it valued health, thought that plant-based eating was morally the right thing to do, and when they felt like others would approve of their plant-based eating. Recently, we explored how an increasingly prominent personal identity—political ideology—could influence sustainable food choices.3 We found that U.S. liberals were more open to plant-based meat alternatives than conservatives. Beyond simply intending to purchase plant-based meat alternatives more often, U.S. liberals expected the products to even taste better. Since taste experiences are connected with value systems, strategic messages resonating with the target consumer may improve

sensory experiences. Understanding the consumer is a key to choosing the right promotional sustainability message.

After researching a potential employer, many job candidates will tailor their resume to highlight how their experiences can best meet the position requirements. Likewise, foods and beverages will be more successful if the product’s value aligns with the sustainability claim. Consumers ‘hire’ products for different purposes—sometimes the food must meet a functional need such as ‘fuller longer’ or ‘healthy snack’ while other times it may have a more hedonic function such as ‘indulgent dessert’. Therefore, the effectiveness of product claims will differ by product category. For example, organic is a popular claim that appeals to many consumers. However, adding an organic certification does not always increase product appeal. Although an organic seal generally does increase improve acceptance of products marketed as a healthy choice, it can actually lower the evaluation of products that promise an indulgent experience or an ingredient-specific functional benefit.4 We recently found that effect of framing a substantively identical claim with either a self or environment-focused claim depended on the product type.5 Framing the environmental claim as a personal benefit worked better when the product’s purpose was hedonic (brownies). Likewise, when the product had a more functional use (granola), framing the claim as “better for the environment” worked better. We hypothesize that the “better for you” claim worked better for an indulgent product because people ‘hire’ brownies for a more egotistic reason and thus a self-focused claim complemented the goal of consuming the product. Claims supporting (rather than distracting from) the product’s value proposition will be more successful.

Credibility and trust are also critical to a successful message. Many consumers are skeptical and unsure about what sustainability claims mean. Therefore, building trust in the brand and company are key prerequisites to effective messages. It is important to also ‘walk the walk’ and not just ‘talk the talk’. Companies should examine their culture and how other aspects of the brand align with sustainability.

Each of these examples illustrate how crafting the right message, for the right consumer, for the right product can strengthen the evidence that the product meets the ‘minimum qualifications’ of taste and quality that consumers seek when ‘hiring’ a food or beverage. By remembering that consumers primarily buy food to eat it (not necessarily to save the planet), environmental benefits can be framed so that they also support the product experience. Aligning sustainability with consumer’s product ‘job descriptions’ can support a food system that is both environmentally and economically sustainable.

References

1 Kralik, B., Weisstein, F., Meyer, J., Neves, K., Anderson, D., & Kershaw, J. (2022). From water to table: A multidisciplinary approach comparing fish from aquaponics with traditional produc-

tion methods. Aquaculture, 552, 737953. https://doi.org/10.1016/j. aquaculture.2022.737953.

2 Lim, T. J., Okine, R. N., & Kershaw, J. C. (2021). Health- or Environment-Focused Text Messages as a Potential Strategy to Increase Plant-Based Eating among Young Adults: An Exploratory Study. Foods, 10(12). https://doi.org/10.3390/foods10123147.

3 Research currently under review.

4 Nadricka, K., Millet, K., & Verlegh, P. W. J. (2020). When organic products are tasty: Taste inferences from an Organic = Healthy Association. Food Quality and Preference, 83, 103896. https://doi. org/10.1016/j.foodqual.2020.103896.

5 Weisstein, F. L., Meyer, J., & Kershaw, J. (2023). A matter of alignment? Effects of product types and environmental claim framing on consumer evaluation of sustainable foods. Business Strategy and the Environment (n/a). https://doi.org/10.1002/bse.3565.

Jonathan Kershaw is an associate professor of food and nutrition at Bowling Green State University.

Discover the journey of a Colombian brand that’s fostering positive change in cocoa-growing regions —

BY ALEXANDRA EMANUELLI —

While hot chocolate is savoured over skiing slopes and around Christmas trees in most of the world, the drink is a breakfast staple in Colombia. Turning a traditional, artisan beverage into an accessible everyday option for households, Luker Chocolate started their business with sweetness and scruples in mind.

“It’s a company that started with the idea of bringing hot chocolate to all families in Colombia, but [the idea was] also to see how through that product, and through developing hot chocolate, they could also bring development and well-being to cocoa-growing, rural families in Colombia,” said Marcela Jaramillo, VP of marketing for Luker Chocolate, a 120-year-old family-owned business.

When we think of Columbian crops, cocoa might not be top of mind. But Colombia is the 1010 largest cocoa producer in the world. It produced 62,000 tons in 2022. What sets the country apart is that 95 per cent of the country’s cocoa for export is fine flavour cocoa. A special quality classification designated by the International Cocoa Organization, fine flavour cocoas have nutty, floral, or even fruity flavour profiles and is ideal for chocolates.

“[This cocoa] allows us to develop dark chocolates, for example,

an 85 or 90 per cent, and still taste all the aromas and flavours that we love about chocolate, without having to add too much to the chocolate,” said Jaramillo.

Cocoa farming is also a safe and sustainable alternative to illicit activities such as drug trafficking and the violence that goes along with it. Remote and isolated, Colombia’s countryside and cocoa-growing regions have been especially affected by the 50 years of narco trafficking.

“Cocoa is a great income option for communities that live in lower altitude areas where illegal crops are grown. So, cocoa is a strong option to also drive peace in the countryside,” added Jaramillo.

In 2005, Luker expanded from hot chocolate to a line of couverture chocolates that are used by manufacturers to produce a wide range of products like baked goods and ice creams. Luker’s heritage recipe portfolio includes everything from 90 per cent dark chocolates to 36 per cent white chocolates.

Exporting to 40 countries, Luker Chocolates’ ingredients are used by manufacturers like GoodSam Foods, Petit Pot, and Lacey’s (Desserts On Us). The company employs more than 600 people with offices in Europe, the U.K., the U.S., and Colombia. Luker entered the U.S. market in 2008 and Canada in 2015. It acquired a

majority stake in Lyra group in 2022, a leading Slovakian chocolate manufacturer. Last year, Luker’s net revenue was over $110 million.

In 2008-09, Luker launched a private label division that now produces custom bars, snacks, chocolate-covered fruits and nuts, and a hot chocolate stick. Serving around 12 per cent of their total sales, the private label is manufactured in Colombia and in the recently acquired production facility in Slovakia. These facilities are certified BASC and FSCC2200, as well as offer kosher and non-GMO options. Jaramillo believes in “really working with brands to see how we can grow together and help them grow and find those business objectives that they have.”

In 2021, Luker launched an oat beverage-based chocolate. It was challenging to capture the indulgence and creaminess of the traditional line with novel ingredients, but after many trials and errors, they managed to formulate an oat beverage-based chocolate that mirrors dairy chocolate in taste and texture.

Other innovations include working with coconut

sugar and creating sugar-free alternatives to cater to health-conscious consumers. In recent years, Luker has also been selling single-origin (i.e. country, region, estate) chocolates. Like wine, Jaramillo noted that each region provides a different flavour profile for the chocolate.

While many companies have adopted sustainable practices, Luker Chocolates takes it one step further. In 2018, Luker signed the Cocoa and Peace initiative that prevents deforestation in cocoa-growing regions. Chocolate Dream, launched in 2018, teaches farmers how to protect local biodiversity, avoid water contamination and ensure responsible use of natural resources.

With a holistic approach to sustainability, Luker is also working to improve the lives of their workers. By 2027, the company is aiming to boost the incomes of 1,500 farmers by 20 per cent. They aim to do so by supporting education, gender-focused entrepreneurship, and reinforcing the human rights of 5,000 families. They are also working to achieve 90 per cent adherence to the Women’s Empowerment Principles, and in 2022, they changed policies emphasizing gender equality and fair pay for women.

Currently, all their cocoa can be traced to the first purchasing point, which the team at Luker says is crucial to ensure farmers are paid fairly and crops are grown sustainably. By 2027, Luker aims to conserve 5,000 hectares of land in the regions of Necocli, Tumaco, Huila, Casanare, Sur de Bolivar and Caldas. The company is well on its way to achieving this goal, as last year they protected 2,670 hectares by documenting the whole supply chain, demonstrating farmer’s payments and geo-referencing images. It plans to achieve net-zero carbon emissions by 2030. Having already achieved carbon neutrality across all their operations (including their farms), they are now tracking their carbon footprint and the footprint of their suppliers.

Recently, Luker earned B-Corp certification, a designation that highlights the company’s high social and environmental performance. The certification is a commitment not just to earning a profit but to their workers, the community, and the environment. Additionally, initiatives like the Chocolate Dream anchor their sustainability plans through a collaborative approach to sustainability and social well-being.

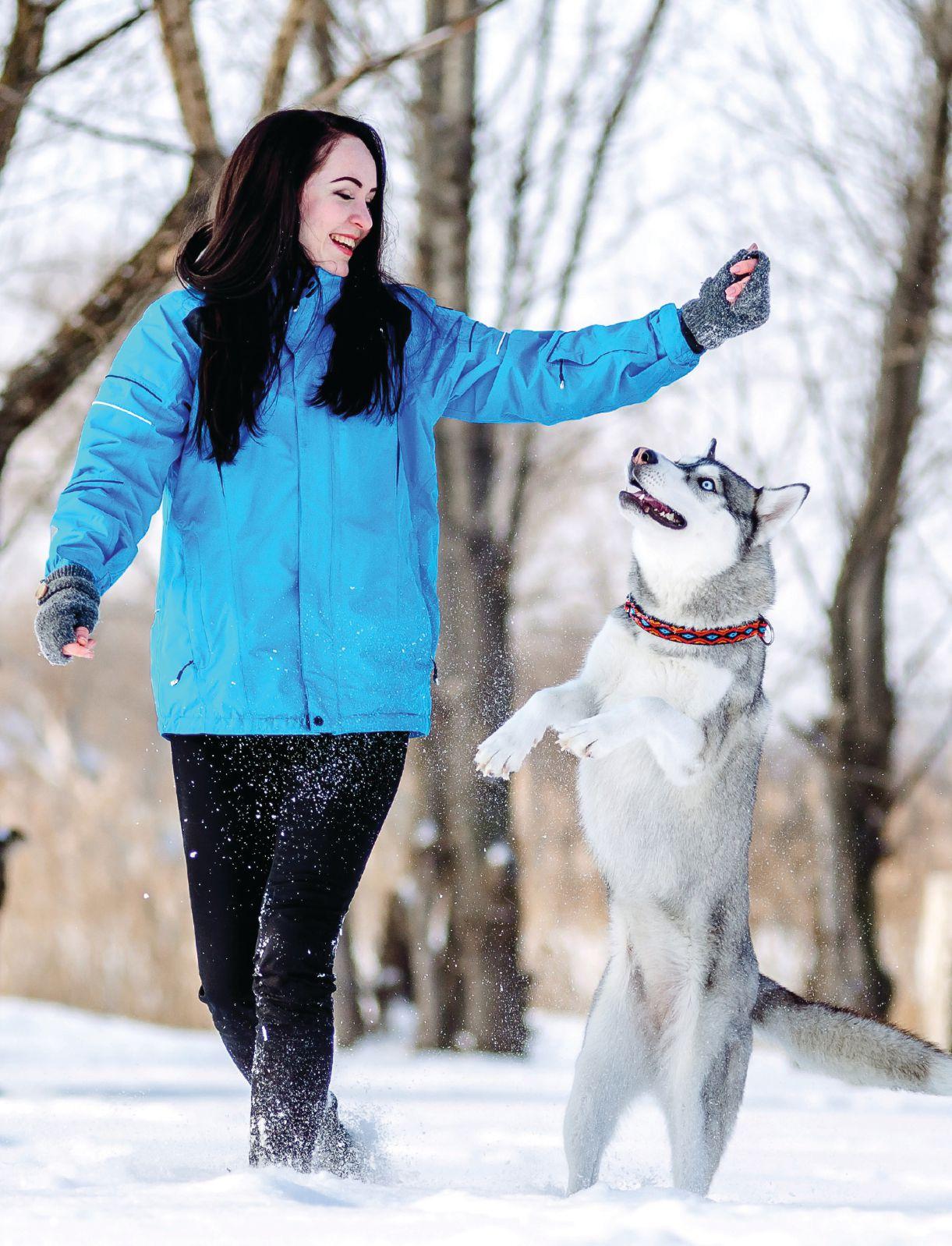

BY MARK JUHASZ

The COVID-19 pandemic marked a deepening acceleration of an existing trend in human-pet interaction and dynamics. As more people moved toward working from home and hybrid work arrangements, the companionship of pets became further entrenched. Demographically, many are having fewer children in urban environments. Pets also offer a well-known social and psychological benefit. Now, with the worst of the pandemic hopefully behind us, pet parenting is further established. Over half of Canadians own either a dog or cat and spend billions on their pets. The relationship between owners and their pets has also changed significantly, to what could be called ‘humanization’, ‘personalization’ and ‘premiumization’, and this is especially evident in the innovation underway in formulating pet foods and the ingredients going into these new products. With approximately one billion domestic pets globally, how these animals are nourished is increasingly of concern to those who see their companions as a member of the family. Further, pets and humans share a supply of farmed animal proteins, and significant numbers of farmed animal products not eaten by humans go into pet foods. While there is growing diversity in human plant-based food offerings, there is a concurrent trend in pet foods to find healthier and

more sustainable ways to feed our furry friends. For example, as recently as 2016, in the E.U., insect-derived proteins were allowed to be used in companion animal feed and insect-based pet foods.

Meanwhile, in Canada, companies like Snuf are producing a range of pet foods containing insect protein (specifically, black soldier fly protein, which is claimed to be hypoallergenic), chamomile and ashwagandha. Snuf labels their product as containing ancient grains, hypoallergenic, all natural, and planet friendly. Another example would be California-based Noochies, which uses nutritional yeast as the primary ingredient in its line of freeze-dried pet foods. Nutritional yeast is an all-natural product made by the process of culturing, which creates plentiful, bioavailable protein and B vitamins. Arguably, foods being provided to companion animals are becoming increasingly like what humans eat.

Further to the customization and premium orientation of new pet foods, owners are also looking for functional ingredients that can address or highlight functions for the unique age, breed, size, and specific health condition of their dog or cat, such as joint health, digestive health, or weight management. Healthy ingredients might include probiotics, prebi-

otics, and superfoods with micronutrients. High-quality protein sources, such as lean meats and fish, are featuring more prominently in pet food formulations, including the content and sourcing of the protein. Pet owners are seeking grain-free and limited ingredient lists for pets with food sensitivities and allergies, a trend in response to canine dilated cardiomyopathy.

Fresh, refrigerated, frozen and raw pet foods continue to gain recognition as pet parents look for alternatives to dry and canned foods. Smithville, Ont.-based Big Country Raw provides a range of raw pet foods for dogs and cats, and uses a combination of meats from turkey, lamb, and beef to salmon. Big Country Raw also produces Thrive, a pet probiotics brand. Combined, the raw food and probiotics provide the nutrients and micronutrients for pets including omega-3 fatty acids, essential vitamins, minerals, digestive enzymes, and prebiotic fibre agents for a healthy digestive tract in dogs and cats. Toronto-based Carna4 offers a synthetic-free, whole food nugget for dogs that is quick baked and air dried, as a ‘convenient alternative’ to raw pet food. The company also places emphasis on clean labels and minimal processing.

Additional ingredients finding their way into pet food formulations include turmeric, CBD, and adaptogens, all believed to provide anti-inflammatory, calming and overall well-being to pets.

Some owners are turning to homemade and DIY pet food, under the support of veterinarians and pet nutritionist, to have more control over ingredients and quality. For example, with lack of exercise, pet obesity is a growing concern, so pet foods targeting increasing demand for weight management diets and portion control recommendations can help maintain healthy weight in pets.

A growing demand for transparency in the pet food supply chains leads pet parents to want to know where ingredients come from and how the food was produced, and companies are now providing this information. Tails.com offers personalized pet menus as well as applications where pet parents can customize their pet’s diet based on its age, breed, health condition, and individual needs and preferences, refined with online questionnaires, and consultations with veterinarians, pet nutritionists, and even endorsed by organizing bodies such as the World Small Animal Veterinary Association (WSAVA).

Whether it is legacy companies such as General Mills, Purina, Royal Canin, and Tyson, or newer firms such as Natural Pet Food, Big Country Raw, The Chompery (producing pet snacks from all-natural ingredients, sourced and made in North America), Champion Pet foods (Orijen and Acana), who are renowned for high-quality, biologically appropriate pet foods using fresh,

regional ingredients, or Open Farm, who are recognized for ethically sourced, sustainable pet foods with humanely raised meats and ocean-caught fish, the landscape of pet foods has permanently shifted to one of customized, personalized and conscious pet food purchasing. Canada is particularly well positioned to remain a leader in companion animal nutrition innovation with leading research centres such as the University of Guelph, and investment companies like Dane Creek Capital, who specialize in supporting companies that are the future of pet food.

Mark Juhasz, CEO of Harvest Insights, has over 20 years of experience in the agri-food sector. He can be reached at www.harvestinsights.com. 23_007766_Food_In_Canada_NOV_DEC_CN Mod: September 12, 2023 3:34 PM Print: 09/22/23 2:31:31 PM page 1 v7

HelloFresh launches new pet food brand

HelloFresh debuts a premium pet food brand. Developed in partnership with veterinarians, the Pets

Table offers human-grade fresh and air-dried recipes customized for the exact caloric needs of each dog.

Holdings acquires Perfection Pet Foods

Post Holdings acquires the assets of Perfection Pet Foods for $235 million. Perfection is a manufacturer and packager of private label and co-manufactured pet food and baked treat products. The acquisition includes two manufacturing facilities in Visalia, Calif., which will provide Post with additional manufacturing capacity to insource a portion of its current pet food business and an entry point into the private label and co-manufacturing pet food category.

Mills acquires Fera Pets

General Mills acquires Fera Pets, a vet-founded pet supplement company, bringing new health-focused offerings to General Mills’ pet portfolio. This represents General Mills’ first step into the pet supplement category and first acquisition by its newly launched growth equity fund.

Kemin Nutrisurance opens pilot lab for wet pet food

Kemin Industries opens its first pet food pilot lab at its global headquarters in Des Moines, Iowa. With a dedicated space to develop wet pet food, as well as test dry kibble coating, Kemin can now provide customers with detailed analyses, from raw meat products and packaging to pet satisfaction.

Muenster Milling Company, a manufacturer of freeze-dried and extruded pet food, appoints Jim Holdrieth as president and CEO. Most recently, Holdrieth served as CEO of Florida Food Products (FFP). Holdrieth is a veteran food ingredient executive with over 30 years of manufacturing experience. During his tenure at FFP, he successfully expanded manufacturing operations and commercialized new technologies that enabled customers to launch innovative products. Previously, Holdrieth led the North American Food Ingredients business of Balchem, including its sensory effects division.

The Pet Sustainability Coalition (PSC) launches a packaging supplier marketplace to help companies that are looking for sustainable packaging solutions. The marketplace is an online tool for PSC Packaging Pledge signatories to search, filter, and evaluate a pre-vetted directory of packaging suppliers that offer sustainable packaging options including recyclable, refillable, or compostable solutions.

To be featured in the marketplace, packaging suppliers complete a supplier application, which will be vetted and approved by PSC. This application collects information about the company’s participation in sustainability certifications and regulations (i.e. How2Recycle), the forms of packaging provided (i.e. flexible film pouch), and specs regarding product testing (i.e. ASTM standards).

The marketplace has suppliers like TC Transcontinental packaging and Tempo Flexible Packaging from Canada.

Post Holdings’ CEO Robert V. Vitale takes an unexpected medical leave of absence. At this time, it is too soon to know the course of treatment and recovery time. Consistent with Post’s emergency succession protocol, Jeff A. Zadoks, Post’s COO, takes over as interim CEO. Zadoks has held various positions within Post since 2011. He has worked closely with Vitale and the board. William P. Stiritz, chair of Post’s board of directors, said, “Our thoughts and best wishes go out to Rob as he recovers. We are grateful to Jeff for stepping in during Rob’s absence.”

CANADA’S ONLY BUSINESS-TO-BUSINESS BAKING EVENT

Join Canada’s baking industry professionals from bakeries (artisan, retail, wholesale, commercial, in-store, pizzerias), grocery and foodservice outlets at Canada’s ONLY Business-to-Business Baking Event!

MAY 5 - 6, 2024 I TORONTO

• Connect with suppliers and learn about the latest ingredients, bakery equipment and services for the baking industry!

• Benefit from education sessions exploring such topics as top bakery trends, scaling up your bakery, succession planning, automation, marketing your artisan bakery and more!

• Learn what the Baking Association of Canada has been up to on your behalf and get the latest technical updates.

• Take in a lively state-of-the-industry panel!

• Watch top bakers demonstrate cutting-edge techniques!

• Showcase your signature baking in a professional artisan competition!

• See what the future holds via an exciting student competition (and enter if you’re a student)!

• And much more!

IT’S A YEAR’S WORTH OF MARKET RESEARCH AND NETWORKING – ALL IN ONE PLACE OVER TWO DAYS!

“We flavour the world” ®