The world of ‘fermed’ proteins

PRECISION FERMENTATION IS HAILED AS THE ULTIMATE SOLUTION TO ANIMAL FARMING ILLS PG.26

The world of ‘fermed’ proteins

PRECISION FERMENTATION IS HAILED AS THE ULTIMATE SOLUTION TO ANIMAL FARMING ILLS PG.26

The Bells create a new tea category PG. 12

+ TOO GRITTY A YOGURT? MAYBE NOT PG. 18 EXPLORING SENSORY CHALLENGES WITH UPCYCLED POWDERS

Our extensive range of Cream Cheese products are carefully crafted to cater to all your culinary needs.

From delicious cheesecakes , delectable fillings , irresistible frostings , delightful toppings , savory dips , indulgent mousses , or flavorful sauces , we have the perfect Cream Cheese to elevate your creations. Clean ingredients made with wholesome Canadian Milk

AUGUST/SEPTEMBER 2023 • VOL. 83, ISSUE 4

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service

Tel: 416-510-5113 Fax: 416-510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

ED ITOR | Nithya Caleb ncaleb@annexbusinessmedia.com 437-220-3039

ASSOCIATE EDITOR | Monica Ferguson mferguson@annexbusinessmedia.com 416-510-5206

MEDIA SALES MANAGER | Kim Barton kbarton@annexbusinessmedia.com 416-510-5246

MEDIA DESIGNER | Brooke Shaw bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR | Mary Burnie mburnie @annexbusinessmedia.com 519-429-5175 ext. 4175

AUDIENCE DEVELOPMENT MANAGER | Anita Madden amadden @annexbusinessmedia.com 416-510-5183

GROUP PUBLISHER/VP SALES | Martin McAnulty mmcanulty@annexbusinessmedia.com

PRESIDENT/COO | Scott Jamieson sjamieson@annexbusinessmedia.com

Publication Mail Agreement No. 40065710 Subscription

Occasionally, Food in Canada will mail information on behalf of industry related groups whose products and services we believe could be of interest to you. If you prefer not to receive this information, please contact our Audience Development in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com 800-668-2384

No part of the editorial content of this publication can be reprinted without the publisher’s written permission @2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

Mailing address

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Tel: 416-442-5600 Fax: 416-442-2230

ISSN 1188-9187 (Print) ISSN 1929-6444 (Online)

up for Food in Canada

Millennia Tea inspires consumers to switch from bags to frozen cubes for healthy doses of tea

Creativity, intuition, curiosity, imagination will be the most employable skills in the next century, as they can’t be programmed into AI-empowered bots/ robots, said Duncan Wardle, former head of innovation and creativity at Disney.

Wardle was offering a keynote presentation on “Embedding Innovation into Everyone’s DNA” at this year’s IFT FIRST trade show.

Wardle was funny, and from the start, inspired the audience with his playful, idiosyncratic role plays and situations to think ingeniously.

Given the myriad of challenges we’re all facing currently, from climate change to wars, we need to think innovatively to build a sustainable, resilient future. The pandemic revealed the critical gaps in governance, capitalistic-centric business models and existing social structures.

As Wardle stressed, now is the time for food manufacturers to embed a culture of innovation in everyone’s DNA. It might sound herculean, but a good starting point would be to recognize the barriers to innovation. Some of the reasons that were shared at the presentation were lack of time to think; rules that have become constrictive over time; and an aversion to change.

Companies with their rules and protocols and the western education system that trains children to colour within lines have killed creativity, said Wardle. He

reminded everyone about how children don’t need big budgets to keep themselves engaged, as they’re inherently curious, creative, playful, and innovative.

Therefore, he recommended that companies allow employees to actively take breaks to rejuvenate and hone their innovative-thinking skills. This will help employees become more creative, which Wardle defined as, “the habit of continually doing things in new ways to make a positive contribution to work.”

He encouraged businesses to nurture the playful, creative sides of employees, which is crucial for innovation. He highlighted Google’s 20-per cent rule, which allows employees to take off one day a week to work on side projects and learn new skills. Google News and Adsense grew out of these ‘work breaks,’ if one may call it that.

Wardle also asked managers and company heads to always respond positively to ideas and new suggestions with ‘yes and’ instead of the innovativekilling phrase, ‘no because.’ “When you’re listening, let ‘no because’ not be your first response,” he said.

He urged managers to not focus on systemic barriers to ideas, but rather encourage employees to sharpen, expand and build on their suggestions.

Wardle said it’s crucial to bring in new experts or people with different skills sets to foster innovation.

Nithya Caleb

“Diversity is innovation,” he added. We must get out of our rivers of thinking and think differently. He suggested companies use ‘naive experts,’ people who aren’t part of the establishment, when brainstorming new initiatives, as they can offer a perspective that’s often missed by the ‘same-old experts’.

Wardle urged companies to challenge perceived business challenges. ‘What if’ they were not really a challenge?

“The time to ask, ‘what if,’ is now as the world is changing fast,” he said. Another suggestion was to ask, ‘how else’ can this issue be addressed.

His final recommendation was to stop asking, ‘how do I make more money,’ and instead ask, ‘how do I solve the biggest consumer pain point’. Wardle highlighted how this customer-centric approach helped Disney. The biggest pain point in Disney theme parks was long queues. Disney eliminated this by giving all visitors an RFID-enabled tag that can be used everywhere. This ended lines, gave consumers more time at the theme parks, and resulted in Disney earning US$1.3 billion in incremental revenue.

I found Wardle’s talk very inspiring, and I hope you find it useful too.

Nithya Caleb ncaleb@annexbusinessmedia.com

Lactalis Canada takes over premium dessert manufacturer Marie Morin Canada. This acquisition will see Lactalis Canada entering the dessert category in both the Canadian and U.S. markets. The transaction includes Marie Morin Canada’s production facility in Saint-Bruno-deMontarville, Que., and the addition of 52 employees. Marie Morin Canada was established in Quebec in 2004. It manufactures and markets its traditional French recipes in North America.

The truth about aspartame Assessments of the health impacts of the non-sugar sweetener aspartame were recently released by the International Agency for Research on Cancer (IARC) and the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) Joint Expert Committee on Food Additives (JECFA). IARC classified aspartame as possibly carcinogenic to humans on the basis of limited evidence for cancer. JECFA concluded the data evaluated indicated no sufficient reason to change the previously established acceptable daily intake of 0–40 mg/kg body weight for aspartame. The committee therefore reaffirmed it is safe for a person to consume within this limit per day.

The Kraft Heinz Company promotes Simon Laroche as SVP, president of Canada and North America Coffee. Laroche has been with Kraft Heinz for more than four years, most recently in the role of president of Australia, New Zealand, South Korea, and Japan. The company has also moved its Canadian headquarters to downtown Toronto. The office includes an onsite culinary centre to develop and test new products, recipes, and social content.

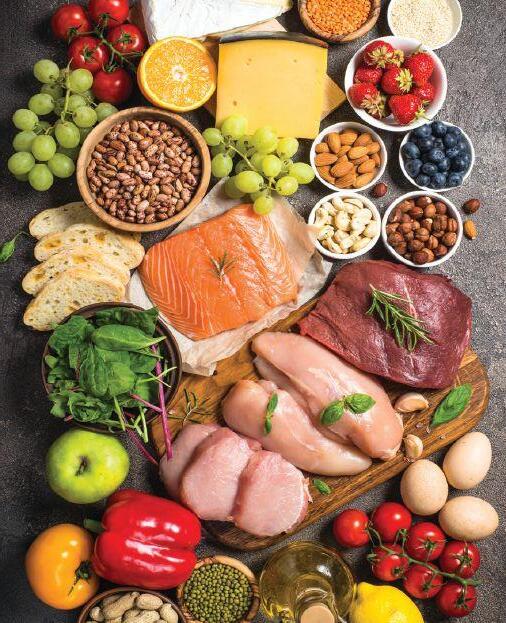

Diets emphasising fruit, vegetables, dairy (mainly whole fat), nuts, legumes and fish were linked with a lower risk of cardiovascular disease and premature death in all world regions, according to a study conducted in 80 countries and published in European Heart Journal. “Our findings suggest the priority should be increasing protective foods such as nuts (often avoided as too energy dense), fish and dairy, rather than restricting dairy (especially whole fat) to very low amounts. Our results show that up to two servings a day of dairy, mainly whole fat, can be included in a healthy diet,” said study author Dr. Andrew Mente of the Population Health Research Institute, McMaster University, Hamilton.

Nestle reveals a sugar reduction technology that can be applied across different product categories. It can also be used to produce low lactose and skimmed milk-based products, while reducing total sugars. Using an enzymatic process, it reduces intrinsic sugar in ingredients such as malt, milk, and fruit juices by up to 30 per cent. There is no need to add sweeteners or bulking agents to replace the volume of the eliminated sugar.

Food Processing Skills Canada (FPSC) launches the Skills Training Across Cana-

da (STAC) program, which is designed for people in supervisor roles or individuals on a path towards a leadership position. With STAC, employers can support their employees in earning block-chain verified certificates and digital credentials in 39 courses. Upon program completion, employees receive one micro-credential and have the opportunity to participate in an additional program at no cost to become a Certified Food Production Supervisor.

The Code and Guide for the Responsible Advertising of Food and Beverage Products to Children is now effective. Under this new standard, only food and beverages meeting specified nutrition criteria may be advertised in a manner that is primarily directed to children, 13 and under.

Canada Bread Company was fined $50 million by the Ontario Superior Court after pleading guilty for its role in a criminal price-fixing arrangement. This is the highest price-fixing fine imposed by a Canadian court to date. The bread producer and distributor pleaded guilty to four counts of price-fixing under the Competition Act. It admitted that it arranged with its competitor, Weston Foods (Canada), to increase prices for various bagged and sliced bread products, such as sandwich bread, hot dog buns and rolls, in 2007 and 2011.

U.S. regulators approve the sale of chicken made from animal cells. The Agriculture Department gave the green light to Upside Foods and Good Meat to sell meat that doesn’t come from slaughtered animals. The move launches a new era of meat production.

Dr. Amy Proulx

nimal agriculture has a mixed reputation for sustainability and climate impact, prompting many organizations to look at novel practices to meet consumer demands. Using cell culture-based meat and protein foods is one strategy, and food safety questions must be addressed before the technology can be fully commercialized.

Food products derived from the culture of cells in biofermentation systems have been produced for decades and approved for sale in Canada. Initially, the emphasis was on enzymes for food production, such as expression of rennet. Other examples include expression of leghemoglobin for use in vegan meat substitutes, or synthesis of fucosyllactose for toddler formulas. What is new is that animal cells are being cultured in mass quantity for the first time with the intent of using the cells as food, rather than using them as biofactories for proteins and molecules.

Given the high precision and control of biofermentation, a high degree of food safety is expected.

The United Nations Food and Agriculture Organization (FAO) and World Health Organization (WHO) held a joint task force on evaluating food safety issues of cell-based meat products. They released their initial findings in April 2023. Their emphasis was on a systematic approach to food safety. They anticipate cell-sourcing, cell growth and production, cell harvesting, and food processing to carry some risks.

Using a risk-based methodology, the FAO-WHO taskforce investigated consumer perceptions for naming cell-based meat products, noting that

Animal cells are being cultured in mass quantity for the first time with the intent of using the cells as food, rather than as biofactories for proteins and molecules.

consistency of factual terms surrounding the tech will help build confidence in the product’s safety and quality.

Codex Alimentarius is also expected to have a framework for standard of identity related to cell-based meat by year end.

In Canada, novel foods are evaluated by Health Canada and CFIA for safety prior to public release. Manufacturers, producers, importers, and other interested parties can apply for approval. It is up to the applicant to provide a comprehensive report evaluating the product’s safety considerations. This officially includes descriptions of the novel food and how the food will be used, typical dietary exposure, nutrition, toxicology, allergenicity, chemical considerations, and other food safety issues.

For novel plants, this would also include potential for gene flow to native species, potential for becoming a weed or invasive plant, and impact on biodiversity. For all novel foods, a method of analysis and detection must be provided in the application. It’s anticipated that Health Canada would use a synthesis of this

methodology when evaluating cell-based meats and other cultured protein products.

Health Canada lists novel foods that have been approved, as well as foods that are deemed not novel. Currently, it has extensive decision-making processes for novel plant-based foods, and it’s anticipated a similar rigour will apply for novel cell-based meat.

Health Canada did a consultation process on labelling of plant-based meat substitutes, and simulated meats in 2020. It found Canadians wanted clarity on labelling requirements. Similarly, the labelling of cell-based meat and protein products will be vitally important for consumer confidence and acceptance.

The technology for cell-based meat is possible, and the technology is available right now. However, substantial research is needed to enhance the affordability of the product compared to conventional meat or other food protein sources.

Canadian companies and academic groups have formed the Cellular Agriculture Canada group to advocate for industry, including regulatory and food safety approvals. As production scales, there will be need for workforce training specific to this industry.

While cell-based meat is capturing a large proportion of attention, there are several Canadian companies who are looking at plant-based proteins to create better quality analogue products. These companies are not facing the same regulatory barriers for novelty as they have emphasized plant-based ingredients with histories of safe use. Instead, their primary regulatory barrier is labelling and general food safety.

At the time of writing this article, no cell-based meat, dairy or seafood products were approved by Health Canada.

Dr. Amy Proulx is professor and academic program co-ordinator for the Culinary Innovation and Food Technology programs at Niagara College, Ont. She can be reached via email at aproulx@niagaracollege.ca.

Gary Gnirss

he Canadian Food Inspection Agency (CFIA) recently shared the results of a consultation process about voluntary guidelines for foods sold through e-commerce. This consultation was conducted in May-June 2022. CFIA and Health Canada are reviewing the feedback to develop voluntary guidelines.

Current federal food labelling laws, such as the Food and Drug Regulations (FDR), and the Safe Food for Canadians Regulations (SFCR), focus on prepackaged products. Most consumer food labelling requirements were written with the idea that a food would be sold to consumers in a package in a physical store.

Currently, there are no rules requiring online vendors to provide food labelling information similar to the one on the actual packaging. Unless the online vendor voluntarily provides information, a consumer may not have access to sufficient data in terms of ingredients, allergens, and nutrition to make an informed purchase, as they would when making an in-store purchase. While some online vendors provide this information, it is not a universal practice. Inconsistency and the lack of uniformity in providing key information before a purchase can be frustrating for consumers.

You may wonder why CFIA is not making it mandatory for e-stores to provide label information like that on a physical package.

In the long run, such regulatory modernization will be needed for uniformity. In the short term, industry,

CFIA and Health Canada may not have sufficient information to create comprehensive and effective regulations. Further, the absence of online labelling information does not pose immediate health concerns as the required information will be on the packaged product.

CFIA and Health Canada will likely aim at learning more voluntary guidelines are being implemented. This is not an unusual approach to rule making. It is great if objectives can be attained by guidelines. If not, rules will follow. Similar considerations were in place prior to mandatory nutrition and allergen labelling.

One of the larger concerns with online retailers providing label information is the assurance that information on the website is consistent with what’s on the actual product label. I have found U.S. label on foods sold to Canadians online.

Also, when a formulation is updated, how quickly will the ingredient or allergen information on the website be updated? How can online information be more integrated to that on the current inventory of foods sold?

The goal is to provide consumers with reliable information. This, even in our highly technologically linked world, seems to have obstacles. Overcoming these obstacles might be more readily available to large retailers. Small online retailers

might find themselves at a disadvantage. The voluntary guidelines, hopefully, will provide an easy-to-adopt framework for websites to share accurate information.

Canadian food laws also cover advertising. Concerns related to foods misrepresented on e-commerce platforms can be dealt with by current laws. Enforcement may, however, be more challenging for CFIA as they seem to be more active in a physical space. Online images of package food are often a hero shot. This is an image of the packaged product. It may not include mandatory information such as net contents or indicate if the food contains artificial flavours. There is nothing illegal about a hero shot, unless it misrepresents the food.

Claims, including nutrient content or health representations, are subject to the same rules as an any other food. Such claims fall under advertising. The manner in which supporting information is provided might be slightly different than that on a food label, as there are specific rules governing advertising. In general, what is prohibited on a label is prohibited in advertising.

Statistics Canada reported that in 2020 the sale of grocery and household items in Canada reached $3.9 billion. Canada Post reported that an average online shopper in 2022 placed 26 e-commerce orders. Online shopping is here to stay, so it’s important to have some guidelines around labelling of foods sold online.

Gary Gnirss is a partner and president of Legal Suites Inc., specializing in regulatory software and services. Contact him at president@legalsuites.com.

Alex Barlow

ood loss and waste is a pervasive problem, occurring throughout the Canadian food supply chain. As a result, all stakeholders have a responsibility to tackle food waste in their operations. For F&B manufacturers, that means finding sustainable methods of preventing food waste during the production process or collaborating on creative ways to convert ‘waste’ into usable ingredients. According to Second Harvest’s twoyear Food Loss and Waste Implementation Project report, released in January 2023, 58 per cent of food produced for Canadians annually is either lost or wasted, with 47 per cent of that loss—totalling 16.77 million metric tonnes—occurring during manufacturing and processing.

The study also revealed that by working with advisors to reduce food loss and waste in their processes, food manufacturers were able to prevent 3.1 million kg per year of food from being wasted, and 100,295 kg of food to be redistributed. Not only did the companies significantly reduce their energy use and greenhouse gas emissions, but they also collectively saved an average of $205,800 annually by retaining food that was being lost or wasted.

Thanks to a growing number of Canadian foodtech companies, several solutions are available. For many manufacturers, it starts with an analysis of their internal processes and supply chain. Enviro-Stewards from Elmira, Ont., works with manufacturers to identify the root causes of food waste and loss and determine sustainable solutions. The company takes a holistic approach to assessing and implementing a plan that prevents waste, while conserving resources and improving financial performance.

New technology, such as X-ray reclaim services from Plan Automation, is also making it easier to reduce food loss. Plan Automation allows manufacturers to ship potentially contaminated food and beverages to its Bolton, Ont., facility to scan for contaminants, thereby reducing the volume of wasted products. In 2022, the company inspected more than 2.5 million kg of products worth over $10 million, diverting it from landfill.

Meanwhile, digitized supply chain innovations provided by companies such as Bluicity (Grimsby, Ont.) are helping manufacturers manage their value chain more effectively and prevent waste due to improper handling. By using smart sensors and cloud-based algorithms, Bluicity proposes to monitor the movement of goods to provide manufacturers with automated, real-time data on factors such as temperature and humidity, allowing them to quickly take action to prevent food loss through spoilage.

In addition to adjusting their logistics and production processes, manufacturers attempting to lessen their food waste are turning to businesses offering collaborative ways to deal with edible product that is either leftover or not of any value as a sellable item. For instance, there’s now technology for dehydrating, fermenting, and processing, which can be applied to food waste to capture the nutritional and caloric value and turn the ‘waste’ into valuable ingredients.

TrendiTech, Burnaby, B.C., uses robotics and automation to upcycle wasted fruits and vegetables into a variety of nutrientdense ingredients.

When some food waste is unavoidable, companies such as Ottawa’s Food Cycle Science are stepping in to offer advanced solutions for composting. The company is developing a large-scale, enzyme-enhanced composting unit that can be installed at QSR facilities. Their solution reduces the weight and volume of waste by up to 90 per cent and converts it into resources for enriching soil. This onsite, ‘one-bin system’ of large-scale food composters will allow restaurants to easily manage food waste.

“We understand the difficulties, costs and complexities our clients face when it comes to waste management,” explains CEO Brad Crepeau. “We believe that our technology can be adapted to also process bioplastics onsite, which would help to eliminate many of the challenges our customers face. This will make it easier for our clients, municipalities, and recycling and composting site operators to widely adopt and manage bioplastics.”

Resolving food waste is a complex topic, and one that food and beverage manufacturers do not need to address in a silo. There are many partners who can help you assess your food waste issues. There are also many tools to adopt that could help solve the problem.

As Crepeau says, “The challenges we face are multifaceted, and it will take many people with different backgrounds and perspectives to develop effective solutions. We need diverse partnerships to offer new and divergent ways of thinking and promote innovation.”

Alexandra Barlow is vice-president, programs, Canadian Food Innovation Network (CFIN), a free, national, member-based organization stimulating innovation across the Canadian food sector. Contact her at alex@cfin-rcia.ca.

Offset up to of incremental project costs 50%*

Not sure where to start on energy efficiency measures?

Schedule a complimentary site walkthrough with an Energy Solutions Advisor from Enbridge Gas. We’ll help you find the right solutions for your needs to drive down operating costs and reduce emissions.

Project incentives†

“Our relationship with Enbridge Gas was and remains instrumental to our projects. Incentives and guidance are available, even if you don’t know where to start.”

Incentives for energy assessments, studies, meters Behzad Hosseinpour Manager of Energy and Sustainability, Maple Leaf Foods

$0.20 m3 for the first 50,000 m3 saved $0.10 m3 for each m3 beyond 50,000 m3 saved Up to 50% of costs

Ready to find cost-saving opportunities?

Contact Michael Gu, Supervisor, Industrial Energy Solutions michael.gu@enbridge.com enbridgegas.com/manufacturing

Award-winning Millennia Tea inspires consumers to switch from bags to frozen cubes for healthy doses of tea

— BY MONICA FERGUSON

—

Tea is the second most popular beverage on earth, only after water. Tea, the Camellia sinensis plant to be exact, has been around for thousands of years with roots as a medicinal beverage.

In 2016, Rory and Tracy Bell, founders of Millennia Tea, had a health scare in their family. They began to consider how food can be used to naturally prevent and reverse damage and disease. The health concern brought them to question what functional nutrition is and how food can play a role in helping people live longer and healthier. This moment in time was the impetus that sent the Bells on a journey, which eventually morphed into Millennia Tea.

Doing the groundwork

With an aspiration to use food as medi-

cine, the duo began researching. Based in New Brunswick, neither of the Bells had previous experience in the tea or food business; Tracy was working as the head of public affairs for a provincial emergency medical services organization and Rory is a pilot.

“We did a deep dive into tea,” said Tracy. “Green tea and matcha kept coming up for their ability to help protect cells from disease. We learned that the tea plant, if you pick and consume it in full form, is the most powerful and purest version of tea.”

All black tea, green tea and matcha comes from the same plant: Camellia sinensis. The Bells zeroed in on one specific antioxidant in tea, EGCG (epigallocatechin gallate), which is said to be effective at neutralizing free radicals and protecting cells. University of Kansas research found EGCG is 100 times more effective than

vitamin C and 25 times more than vitamin E at protecting cell’s DNA from damage by free radicals.

“We went looking for tea suppliers and tea farmers who could provide us with real raw tea without drying [mainly] for the health of our family, and not because we wanted to start a business. We wanted food as medicine, literally,” said Tracy.

Bemused that they couldn’t find this sort of fresh tea in North America, the couple devoted three years to researching, sourcing, and travelling to tea-producing countries to find a way to preserve this mighty medicinal plant in its purest form.

They spent time in the fields with farmers in Kenya, travelled to the rainforest in Colombia and sourced from China and Hawaii amongst other countries.

During their travels, they partnered with small-scale family farms and worked and lived with them, learning how they

processed the leaves. Tracy recalled harvesters plucking and eating the leaves straight from the plants, which “was a really fun moment for us because that was our whole hypothesis. If you consume the leaf in full, it is really good for energy, immunity and inflammation, all of which tea is associated with.”

Not yet satisfied with the final product, they travelled to Sri Lanka as industry friends suggested the Camellia sinensis there naturally produces high antioxidants, thanks to the altitude, geography, and growing conditions.

Eventually, the couple found the tea plant they were looking for in the mountains of central Sri Lanka, 8000 ft above sea level. The Bells have now partnered with organic certified and fair-trade farmers at Marginalized Organic Producers Association (MOPA) who harvest the leaves. The leaves are then taken to a BRC-certified facility in Sri Lanka itself.

“What we learned, tested, outsourced third-party lab work for and then went on to get patents for, is a process to maximize the antioxidant content in the tea leaf,” said Tracy.

Tracy remembers the moment she made the decision. They had done their research and collected the first samples.

“The day we got the results of the analyses we knew we had something special, something that could help families like ours have more good time with their loved ones. That week I gave my notice to fully dive into making this dream a reality,” she recalled.

It was exactly two years later, in 2019, that Millennia Tea’s first product, Superfood Tea Cubes, was ready for market. In February 2020, weeks before the pandemic hit, they had their first scalable product, which could reach a large consumer base.

“What we do is really simple. We pick the same beautiful organic tea leaves used for quality loose leaf green tea. But

after the plant is picked, we do the opposite of every conventional tea company out there,” she explained.

EGCG properties degrade with exposure to heat, light, and air, which is how all dried teas are processed to ensure they are shelf stable.

“We treat the tea plant as organic produce. We wash and flash freeze the plant on the day it is harvested. We keep it in its real raw form to try and give that freshfrom-the-field experience and give the tea plant new uses as a functional ingredient to promote health,” Tracy explained.

The entire process happens in Sri Lanka. The leaves are plucked, taken to the MOPA plant, and then packaged into individual frozen cubes. The frozen cubes stay fresh for up to 36 months in the freezer and can be enjoyed by steeping into a tea (which can be reused multiple times as the antioxidant count goes up on the second infusion), tossing into a smoothie, or adding extra nutrients to cooking or baking.

The leaves and stems are both encouraged to be eaten. The stems are said to contain an even higher level of L-theanine than the leaves. L-theanine is an amino acid that is supposed to help ease anxiety and promote clarity, good sleep, and brain function.

Commercializing their idea was challenging since the Bells were working with small-scale organic family

farmers in remote places on the other side of the globe.

“It took time to build trust, and lots of experimentation, and really capable partners both here and at home, as well as at source, to bring it all together and create a consistent and scalable product,” said Tracy.

The duo bootstrapped the product during the many years of R&D and product development. They sold what they could sell and invested savings to get Millennia Tea off the ground.

“Once we had a really compelling product that delivered on the promise to help people scientifically, along with compelling early consumer feedback, and felt we had de-risked the business model as much as possible, we partnered with external shareholders.”

Today, they have a mix of angel investors and institutional partners, including Natural Products Canada, and a couple of specialized U.S. venture capital funds.

Millennia Tea can now be found in grocery stores across the country, including Real Canadian Superstore, Sobeys, Whole Foods and, most recently, Healthy Planet.

Looking to the future, the brand will continue to support the areas where they are already doing business while also actively exploring opportunities to be an ingredient in other products, such as smoothies and kombucha, thereby expanding their reach and making their tea more accessible to a broader consumer base.

Millennia Tea is currently pilot testing with local companies, including New Brunswick-based kombucha company, Tea of Life, and a smoothie shop in St. Andrews, N.B.

“We are looking beyond having a brand on a shelf, and how we can be an ingredient that boosts the nutritional value of already existing consumer products,” said Tracy. “The reason we exist as a company is to help people live better longer. We have a product that quite literally can help people with feeling better while supporting their long-term wellness. We want to be able to be as accessible and get this into the hands of as many people as possible.”

They are also developing a new unfrozen product that will act like a freeze-dried powder, identical in appearance to matcha, addressing the need for a convenient, on-the-go option for consumers.

By reintroducing tea in its purest form, Millennia Tea is changing the way we perceive tea and its potential to promote health and longevity.

Carol Zweep

he Canadian Cannabis Regulations were amended to include regulatory framework for edible cannabis in October 2019. Edible cannabis is intended to be consumed in the same manner as food. Edibles have grown in popularity in Canada, especially in beverages, gummies, chocolate and caramels, chews, and taffy.

Product restrictions are in place for edible cannabis. There are also packaging and labelling restrictions to ensure consumer safety. The maximum amount of THC (delta-9-tetrahydrocannabinol) allowed is 10 mg per package of edible cannabis. Regulations prohibit the addition of vitamins or minerals to edibles. The product must not contain nicotine or added alcohol. There are also limits on caffeine amounts. Edible cannabis cannot be sold or distributed as a product that requires refrigeration or in a hermetically sealed container with pH exceeding 4.6

and water activity exceeding 0.85 at 22 C.

Similar to the Canadian labelling regulations for food, bilingual mandatory information is required on edible cannabis packaging, including common name, net quantity, ingredient list, allergen declaration, nutrition facts table, and durable life date (if 90 days or less). Other information required for edible cannabis includes the standardized cannabis symbol, THC and CBD (cannabidiol) content, contact information of the license holder, class of cannabis, lot number, recommended storage conditions, packaging date, cannabis possession statement (equivalency to dried cannabis) and warning statement. Health and dietary claims cannot be made.

There are specific regulations with regards to the packaging that is intended to reduce the accidental consumption and appeal of edible cannabis product to youth while still providing information to consumers.

In Canada, plain packaging and labelling are required on cannabis-related products. Additionally, there are restrictions on logos, colours, and branding.

Plain packaging and labelling are required with restrictions on logos, colours, and branding. Specifically, the container must be a single uniform colour (no fluorescent or metallic hues), have smooth texture, no special features (i.e. heat-activated ink, sound, or scent emission), no inserts, pamphlet or tags, no windows, and no images. Child-resistant packaging must be used, and packaging must include a health warning message.

The packaging in direct contact with edible cannabis must meet the Canadian Food Packaging Regulations The regulations prohibit the use of packaging that may impart any substances to the food, which may be harmful to the consumer.

Another important consideration is the role packaging plays in the shelf life of the food product. Depending on the nature and sensitivity of the food, the packaging should have the appropriate barrier properties to oxygen and moisture to maintain the quality of the edible cannabis product for the duration of the product shelf life.

Plastic pollution is a global concern. With a mind to reduce the amount of packaging waste, the federal government is permitting flexible use of packaging materials. The use of innovative, environmentally friendly packaging within the regulatory constraints is encouraged.

Producers of edible cannabis are challenged with strict packaging and labelling regulations. Restrictions on the ability to brand, design, and market their product make it hard to distinguish them in the marketplace.

However, it is important to ensure that appropriate measures are in place to provide necessary information in order to safeguard consumers while still producing a quality product that has safe packaging.

Carol Zweep is food consulting manager for NSF. Contact her at czweep@nsf.org.

Whether it’s used to preserve, build flavour or health objectives, fermented foods are having a moment — BY JANE DUMMER —

Dating back to the Egyptians, fermented foods are among humanity’s oldest attempts to preserve food. Traditional fermentation involves micro-organisms, such as yeast and bacteria, enzymatically breaking down carbohydrates to produce carbon dioxide, organic acids, or alcohol.

Fermentation contributes to food sustainability through preservation, safety, and production of food components. The desirable flavour of fermented foods is predominantly due to the acid, sugar, and volatile flavour compounds.

Whether it is for preservation, flavour, texture, health benefits or a combination of these reasons, fermented foods are thriving. Research suggests fermented foods can support both gut and immune health. Health-conscious consumers are still making sourdough bread, creating fermented vegetables, and enjoying fermented dairy. Therefore, consumers are open to techniques that create breads and baked goods with better tastes, textures and enhanced nutritional value.

Deb Anderson, director new business development, the Protein Brewery, explains, “Many consumers are seeking more natural, fresh, and less processed

foods. Fermentation is perceived to be a natural process. Consumers are more conscience of the gut microbiome and its health benefits, and fermented foods have a long history in providing healthy gut microflora. Consumers will continue to seek better-for-you bakery products. However, they will not compromise on the experience, which includes decadent flavours and delicate textures.”

Sourdough bread is a consumer favourite when it comes to fermented foods. Sourdough provides an old, traditional method of fermentation for artisan bread

making. However, let’s look beyond the bread application.

Adriana Fazzina, vice-president of marketing, Puratos Canada, describes, “With over 2,400 registered sourdoughs in our Puratos’ Quest for Sourdough project, we were able to learn that sourdoughs used to make laminated goods (croissant) typically have a less fruity taste profile; and a more pronounced lactic sourness when compared to other sourdough baked goods. But this difference in taste profile is not the main reason why sourdough is used in laminated and other rich baked goods. It was texture. By combining the data with all our consumer surveys and

consumer taste tests, we found a consumer preference for a ‘melting’ or ‘buttery’ croissant, and sourdough croissants rate very well on those factors.”

The plant-based baked goods segment is evolving, thanks to advancements in fermentation technology. From alternative protein ingredients to enzymes, the baking industry now has options to create desired flavours and textures in plant-based cookies, cakes, and other baked goods.

Anderson explains the Protein Brewery’s technology is considered biomass fermentation. It is a non-sterile process combined with a proprietary fungi strain that converts water efficient crop side streams, such as potato or corn (golden

remains) into a high-quality protein, insoluble dietary fibre, essential fatty acids, vitamins, and minerals. Due to the nature of the conversion process, the protein is essentially inert or not ‘bossy’ in bakery formulations. As a result, bakeries can develop a permissible indulgent bakery treat without compromising flavour or texture. Its target applications in the current format are better-for-you bakery, bars, snacks, and tortilla.

Enzyme technology is a must-have solution in baking today. It provides a consumer-friendly label solution while increasing shelf life.

Fazzina identifies, “Plant-based baked products are becoming better as far as tastes and textures are concerned. This can be attributed to the development of

enzyme technologies. Enzymes can replace several ingredients, while maintaining the original functionality in the finished product.”

Fermentation is a vital step to chocolate making. Fermentation allows the bitter, otherwise tasteless, cacao seeds to develop the rich flavours associated with chocolate.

“Beans are dried and fermented before being transformed in chocolate liquor,” explains Fazzina.

The art and science of fermentation has a promising future in the baking industry. From the ancient role of preservation to the modern role of creating desired textures, fermentation technology advances are impacting the industry.

Cut the complexity from flavour sourcing and get the tastes that build loyalty by partnering with FlavorSum. We support your success and speed your time to market with:

• Inspirational insights

• Tech docs on demand

• Taste modulation solutions

• Scale-up validation

• Operational excellence

• Accessible technical expertise

study found

Upcycled fruit and vegetable powders are made from material that otherwise would not have gone to human consumption, such as carrot and onion peels or apple pomace that are left over after juicing. These by-products are desirable ingredients because they contain valuable nutritional and functional components as well as provide an opportunity to help reduce food waste. In recent years, there has been a proliferation of healthy, clean label

and sustainable foods containing added fruit and vegetable powders.

All fruit and vegetable by-products are rich sources of complex carbohydrates including various types of fibre, starch, and pectin. Apple pomace, potato peels, tomato pomace, onion peel and carrot peel all have between 45 to 60 per cent fibre content (dry basis). Apple pomace also contains pectin (15 per cent). Potato peel has starch (20 per cent). The fibre and complex carbohydrate content of these by-products can enhance water-hold-

ing capacity, thickening properties and extend shelf-life of diverse foods. It could also have applications as prebiotics. Several fruit and vegetable by-products such as potato peels, tomato seed meal and cucumber peels are sources of plantbased proteins. Antioxidants and natural colours are other valuable components found in fruit and vegetable by-products. Antioxidants exhibit both health-promoting and food formulation benefits including enhanced shelf-life and natural colour. For example, onion skin

n High-quality, exact-weight portions

n Inline grinding for excellent color, clear structure, and uniform particle distribution

n Automatic loading into trays

powder can be added to yogurt to produce a stable red colour (Mourtzinos et al. 2018)1. Tomato powder can be used to add red colour (lycopene) while decreasing lipid oxidation in meat patties and sausages (Dominguez et al. 2020)2

While fruit and vegetable powders offer many benefits, there are challenges and sensory considerations to address to incorporate them as functional ingredients into foods. One of these sensory challenges is the potential of the powders to contribute a gritty mouthfeel to smooth products. Our research team at Vineland Research and Innovation Centre (Vineland), Vineland Station, Ont., has completed a study with apple pomace powder to investigate how to overcome this limitation.

Apple pomace is a by-product of juice and cider processing consisting of skin, flesh, seeds, and stems and can be dried and ground into a powder. Currently, there are several commercially available apple pomace powders including some that are marketed as apple fibre. Apple pomace has been used in a range of food products to increase water-holding capacity, thickening and nutritional fibre. It is also used as a filler to replace a portion of flour in formulations. However, apple pomace powder is generally limited to applications with inherent coarse textures, such as bran muffins or sausages, due to its ability to impart a gritty or floury mouthfeel. We conducted a sensory study at Vineland to determine if the applicability of apple pomace powder could be extended to smooth-textured products, like yogurt, by reducing particle size and determining the required size to fall below the human threshold of grittiness perception.

For our study, apple pomace samples were received from an Ontario commercial cider manufacturer and then dried and milled by Guelph Food and Innovation Centre, Guelph, Ont. Apple pomace powders were prepared by adjusting the refining time to create powders with seven different particle sizes (166 μm, 208 μm, 320 μm, 363 μm, 471 μm, 569 μm, and 642 μm). Particle size was measured after 24 hours of rehydration to mimic the size in a food sample at the time of consumption and is reported as Dv(90) (90 per cent of particles in the sample were at or below the reported size). After milling, apple pomace powder samples were added to fruit fillings in stirred yogurt products. Since apple pomace powder contains a high amount of pectin, one potential application is to use it to replace pectin as a thickener in

fruit fillings. Yogurt samples were prepared with strawberry fillings that had five per cent apple pomace powder of each particle size (these were the target samples) or by omitting apple pomace powder and using 1.75 per cent pectin (these were the blank samples). Sensory threshold testing was completed with 71 consumers using blind tastings to compare target and blank samples to determine at which size the apple pomace powder would impart a gritty texture to the yogurt.

Results showed the particle size threshold for perception of grittiness was 259 μm, indicating that at sizes below 259 μm, apple pomace powder was not perceived as being gritty by the average participant. Commercial apple pomace powders are typically around 100 to 200 μm when dry, meaning they are far larger than the threshold size after rehydration. However, we found that milling to a smaller size could be an effective strategy for manufacturers to prevent grittiness in smooth products, thus extending apple pomace powder to a wider range of products.

We also found that participants had a wide range of sensitivity to particle size. Some participants could detect grittiness from the smallest particle sizes in our study, while others could not detect grittiness from

Fruit and vegetable powders offer many benefits but there are sensory challenges in incorporating them as functional ingredients into foods.

the largest particles, which were nearly four times larger than the smallest particles. We identified three clusters of participants, those with high sensitivity (44 per cent of participants), medium sensitivity (31 per cent of participants) and low sensitivity (25 per cent of participants) to particles in yogurt and calculated thresholds for each group. This diversity in sensitivity presents a challenge for product developers.

It is possible to mill upcycled powders such as apple pomace to below the average threshold of perception for grittiness in smooth products (259 μm). However, there is a large range of sensitivity, so one must decide whether to reduce the particle size to below the threshold of grittiness perception for the average consumer or to below the threshold of the most sensitive consumers (151 μm) to satisfy all potential customers.

The cost of refining the particle size to below the threshold of the most sensitive group must be weighed against the risk of alienating this segment of the population.

This study highlights the importance of consumer-focused research to ensure that when using fruit and vegetable powders, sensory properties, such as texture, align with consumer acceptance and liking. Future investigations will be key to optimizing all aspects of upcycled foods from functionality to sensory profiles.

This study was supported by the Canadian Agricultural Strategic Priorities Program (Agriculture and Agri-Food Canada), Martin’s

Family Fruit Farms and the Canadian Agricultural Partnership (the Partnership), a five-year initiative. The study’s authors are grateful to their funders, without whom this research would not have been possible.

1. I. Mourtzinos, P. Prodromidis, S. Grigorakis, P.D. Makris, C.G. Biliaderis, and T. Moschakis (2018). Natural food colourants derived from onion wastes: Application in a yoghurt product. Electrophoresis, 39(15), 1975–1983. https://doi.org/10.1002/elps.201800073.

2. R. Domínguez, P. Gullón, M. Pateiro, P.E.S. Munekata, W. Zhang, and J.M. Lorenzo (2020). Tomato as potential source of natural additives for meat industry. A review. Antioxidants, 9(73). https://doi.org/10.3390/antiox9010073.

Amy Blake, MSc., is senior research technician, Consumer Insights Vineland Research and Innovation Centre.

23_005616_Food_In_Canada_AUG_SEP_CN Mod: August 2, 2023 1:52 PM Print: 08/02/23 1:52:37 PM page 1 v7

This October marks the fourth anniversary of legalized cannabis edibles and beverages in Canada, providing an opportunity to gain further perspective on new directions.

From a December 2022 Statistics Canada survey, 70 per cent of the respondents who use cannabis preferred smoking in the past 12 months (down from 74 per cent in 2021), while 53 per cent used edibles, and 19 per cent consumed beverages. Among more regular users (those consuming cannabis in the past 30 days), 29 per cent used edibles, and eight per cent beverages.

Cannabis beverages in Canada have broken through the novelty phase of their development. However, carbonated cannabis beverages saw some growth in the past year. It is THC-infused gummies and chews that sell well and are growing as a category in Canada, especially because of their precise dosing, unique flavour profiles, and discretion in social settings.

In recent data collected by Headset on the Canadian cannabis market (tracking only for British Columbia, Alberta, Saskatchewan, and Ontario, or about two-thirds of the population), edibles sales grew nearly 24 per cent between 2022 and 2023, while

beverages grew five per cent. In edibles, chews and caramels grew 210 per cent, while candies, lozenges and gums grew 126 per cent.

In 2022, gummies made up nearly 70 per cent of edibles sales. During this same time, there has been a proliferation of edibles brands in Canada, up 74 per cent in 2022.

Older consumers are more drawn to edibles compared to smoking. In the U.S., for example, consumers over 41 years old make up 37 per cent of total cannabis sales, but 51 per cent of edibles sales. Additionally, female consumers make up 37 per cent of total sales, but 46 per cent of edible sales.

Creative and targeted marketing for

these consumer demographics, potentially with wellness messaging, could be effective. This is only possible if restrictions on marketing and promotional materials were eased in Canada.

A persistent issue with cannabis edibles in Canada remains limits on dosages, which are currently regulated at 10 mg per packaged product. Industry insiders and advocates state some consumers prefer the option of higher THC limits.

Some brands have been able to creatively re-classify their products as concentrates to allow for higher dosage amounts. In the first half of 2023, 20 per cent of edibles sales have been with products containing well over 10 mg per package.

Cannabis lozenges by Edison Cannabis accounted for 87 per cent of their total sales in 2022. Sold as concentrates in 100-mg packs, the Jolt edibles are gaining segment and consumer demand.

Edible dosing in the U.S. is determined at the state level, with some degree of variation. In Michigan, packages can contain up to 200 mg of THC. Most of the states have a maximum of 100 mg. In the U.S., edibles as a total of cannabis sales in 2022 were just under 12 per cent, compared to roughly six per cent in Canada. Canadian industry advocates, such as the Edibles Caucus, and companies like Indiva, have spoken about the consumer segment seeking higher potencies, who remain largely served by legacy markets.

The recently published 2023 Cannabis Act review by the Competition Bureau, submitted to Health Canada, addresses edibles. The review says Canada needs to ease restrictions on dosing quantities, allow packaging to be more customized and attractive to draw more consumers away from the illegal market, and especially for smaller, craft edibles brands, address excise duties, and licensing costs associated with compliance for edibles to compete with the legacy market.

A creative direction for cannabis edibles and beverages could also be found in marketing and product offerings. Chefs, food product developers, restaurants, cafes and bars could eventually be allowed to customize dinner and drinking experiences, utilizing the diversity of cannabinoids and terpenes found in the cannabis plant. In the U.S., cannabis brands are working with food brands for mutual promotion.

Fatburger (a restaurant chain) is partnering with Kiva Confections (a producer of cannabis edibles) to roll out cannabis-infused ketchup for a limited time. The condiment contains 10 mg of THC and is available at partnering cannabis stores in the Los Angeles area. Wings Over (another restaurant chain) offers CBD-infused garlic parmesan on potatoes, wings and chicken tenders, and customers can add CBD oils.

In the beverage world, the movement toward no or low amounts of alcohol is gaining reception, especially with millennials and Gen Z. Cannabis-infused ‘mocktails’ could be served at bars.

As of mid-2023, a state bill in California is seeking to formally allow for cannabis cafes, which has existed in various forms in the Netherlands for decades. In Los Angeles, Calif., ‘the Original Cannabis Cafe’ brands itself as one of the first-of-its-kind in the U.S., and where, for an extra cost, patrons can opt to add 25 mg of THC or CBD to any dish. Nevada and Illinois legalized cannabis consumption lounges in 2021.

In Canada, cannabis retailers could also partner to develop cafes, thereby diversifying and differentiating their businesses. Ontario began to look at the viability of opening consumption lounges through a public consultation process in 2020. Among Canadian cannabis users, there is interest and demand to consume at licensed and regulated establishments, whether at an outdoor cafe, restaurant or even a retreat centre.

At the Bend Cafe and Lounge (adjacent to a cannabis store), in Grand Bend, Ont., the owners provide customers and the local community an area to safely consume cannabis, with experienced staff helping to explain products. Representatives from the Ontario Cannabis Store reviewed the cafe and did not raise any concerns.

Initiatives such as this, or the Farm Gate program in Ontario (and other provinces), which offer customized experiences for local cannabis purchasing at the source, are part of the process of helping to intelligently, and safely, grow the cannabis edibles and beverages category.

Mark Juhasz is CEO and founder of Harvest Insights. He has more than 20 years of experience in the agri-food industry. He can be reached at www.harvestinsights.com.

Endress+Hauser introduces generation 2.0 of its Itherm TrustSens TM371/TH372 self-calibrating RTD thermometer for hygienic operations. Gen 2.0 includes a wider operating temperature range (-40 to 190 C), explosion protection, optional Bluetooth/WirelessHeart connectivity and potential integration with Netilion, Endress+Hauser’s cloud-based IIoT ecosystem. www.ca.endress.com

Dypipe was developed specifically for producers of pumped goods. The X-ray inspection system from Minebea Intec detects foreign bodies made of metal, stone, plastic, bone, and glass and ejects defective or contaminated products. The Dypipe is equipped with a test piece insertion system that ensures specimen validation in live operation. The Dypipe X-ray inspection system comes with a range of separators, connections, and mounting options. It is made of stainless steel and has a protection class of either IP 65 or IP 69. www.minebea-intec.com

releases dual-arch bulk bag conditioner

A new hydraulic bulk bag conditioner from Flexicon features arched doorway masts that increase overhead clearance for palletized bulk bags using a forklift. The conditioner loosens hygroscopic chemicals, spice blends, heat-sensitive products, and other bulk materials that have solidified during storage and shipment, returning the material to a free-flowing state, and enabling bulk bag unloaders to discharge the material through bag spouts.

Cremer launches the HQ 3100*2 Counting and Packaging Machine, designed for producing multi-flavour and variety pack assortments of candies, confectioneries, and chocolates. Utilizing a two-in-one frame, the new HQ 3100*2 counting and dispensing machine features six channels, each of which can be divided in half. This means the machine can process up to two flavours or varieties, double the amount possible with the original HQ 6100. The HQ 3100*2 works in tandem with a bulk dosing system with in-feed hopper and incline dosing conveyor.

www.cremer.com

www.flexicon.com

With a lot of precision, fermentation is creating novel products while addressing climate change — BY

NITHYA CALEB —

This summer, at the IFT FIRST trade show, I had the opportunity to sample Perfect Day’s ice cream and barista milk. U.S.based Perfect Day is revolutionizing the dairy industry with its animal-free milk protein made by precision fermentation. The company claims its whey protein makes dairy products “more sustainable and just as craveable, creamy, whippable, spreadable, and delicious.”

Earlier this spring, California-based New Culture unveiled its animal-free mozzarella cheese. New Culture uses precision fermentation to make the casein protein that gives cheese its distinctive ability to

shred, stretch, crumble, and melt.

Perfect Day’s mission is to build “a kinder, greener tomorrow” and New Culture wants to create a “more sustainable food system that has a lighter, less harmful imprint on the world, and a kinder relationship with animals.”

A similar aspiration is the driving force behind the Every Company’s ‘fermed’ animal-free egg proteins, made using yeast and sugar.

Precision fermentation is the technology that’s helping these companies achieve their goals. You’re probably wondering what the heck is precision fermentation.

Well, “precision fermentation has at its core synthetic biology. It is essentially based on recombinant DNA technology, which has been around for many decades. Microbes are engineered to produce a single product. What is exciting nowadays is that we can produce complex molecules in these cell factories to create foods for human consumption. The microbes themselves are not consumed; only the products which are released or extracted from them,” explained Mehmet Caglar Tulbek, PhD, president, Saskatchewan Food Industry Development Centre (the Food Centre).

The Food Centre is building a new fermentation facility with scale up pro-

REVIVE & THRIVE OCTOBER 20-21, 2023

MEAT & POULTRY ONTARIO, OCTOBER 20-21 FOR THE MEATING PLACE CONFERENCE IN MUSKOKA

Join us at the beautiful JW Marriott Muskoka for a one-of-a-kind event dedicated to inspiring and bringing together leaders in the meat industry. The Meating Place Conference in is back, and this year, we are taking our theme to new heights with “Revive and Thrive.”

Are you ready to harness the power of leadership and drive your organization towards unparalleled success? Then mark your calendars for October 20 – 21 and secure your spot at this premier gathering of industry professionals, thought leaders, and visionaries.

A block of rooms are being held at the beautiful JW Marriott Muskoka at the special rate of $229/night. The rate will be available until September 22 or until the room block is sold out.

FRIDAY

An Evening with Handtmann

Ontario’s Ultimate Burger Competition

- People’s Choice

SATURDAY AM

Speaker Program

SATURDAY PM

TableTALK 2023

Dave Tiller People’s Choice Competition

Ontario’s Finest Butcher Competition

SATURDAY NIGHT

Red Carpet Gala - Dinner and Awards Silent Auction

Polytarp Products Power Play Pub

duction of up to 20,000 L to cater to the demand for some intermediate level of production. This facility will act as a bridge for companies to test and produce their precision fermentation products and assess commercial success prior to establishing their own largescale production facilities.

“Precision fermentation is just basically adding a little bit of precision to the fermentation process. In that sense it is very similar to brewing beer. You use a micro-organism, such as yeast or bacteria. The micro-organism is typically engineered by adding additional pieces of genetic code or protein. Instead of brewing alcohol, you’re actually making the targeted protein or chemical from it. In the context of food industry, we will be making alternative protein, for example, or flavours and fragrances,” added Fei Luo, co-founder and CEO, Liven Proteins, Mississauga, Ont. Liven makes animal-free protein ingredients like collagen using precision fermentation.

As you can see, precision fermentation has diverse applications. Per Good Food Institute, “Precision fermentation can produce enzymes, flavouring agents, vitamins, natural pigments, and fats.” It is also not a new technology. Precision fermentation-based rennet has been used for more than 30 years. Today, as Luo said, 99 per cent of mozzarella in the world is made using precision fermentation-based rennet.

Perfect Day’s and New Culture’s ingredients aren’t available in Canada, but most of us are familiar with Impossible Foods. Heme, which gives Impossible Beef its ‘meaty’ taste, is made via “fermentation of genetically engineered yeast.”

well as reducing greenhouse gas emissions from animal farming.

“It can address a lot of our current concerns relating to environmental sustainability since land and water resources use can be minimized. Additionally, precision fermentation will allow production of more healthy and nutritional foods with natural flavours, aroma, tastes, vitamins, and many of the components of plant-based alternative meat without chemical additives,” said Tulbek.

Precision fermentation holds the potential of making animal proteins without animals.

– Fei Luo

Many food industry professionals believe precision fermentation is going to help us meet the arduous task of feeding nine billion people by 2050 while addressing the loss of arable lands due to global warming as

A good example of this would be collagen, the protein that Liven biomanufactures. Typically, collagen or gelatin is made by crushing cow or fish bones or fish scales, boiling it in strong acids and then using a separation process.

“This conventional process is not sustainable. It is also polluting if you’re thinking about the wastewater generated from it. By using precision fermentation, we will be able to make this protein without relying on the animal industry,” explained Luo. “It is a game changer for the supply chain because the animal industry is vulnerable to climate change as well as diseases. The source of the collagen material is volatile. For example, marine collagen is consumed worldwide, but a lot of times, fish have heavy metal issues because of what we did to the ocean. Also, fish is an allergen. So,

A comprehensive sectorby-sector snapshot of food and beverage processing and manufacturing industry performance and innovation.

Read about important industry issues and trends, with emphasis on a well-researched quantitative and qualitative outlook.

> Key Growth Areas

> Commodities & Pricing

> Mergers & Acquisitions

> Retail Landscape

> International Trade

> Industry Health

> Industry Leaders’ Outlook

> Domestic Market

> Innovation

> New Products

> Sector-by-sector reports

> Consumer Consumption Trends

by [using] this brewing process, you’re basically getting the same protein that’s conventionally made from animals without heavy metal contamination or viruses and allergens. You will also be able to craft design the protein. If you harvest the protein from animals, you don’t have a choice. When we precisely brew this protein, we can actually design the genetic code needed to give the protein the required functionality.”

We are hearing a lot about precision fermentation in the alternative protein space these days because it can address many of the pain points in the animal industry.

“In 2050, we will have a $1 trillion protein deficit. We can eat plant-based foods but unfortunately, we cannot really make the whole world eat lentil soup. Precision fermentation holds the potential of making animal proteins without animals,” said Luo.

Further, the technology has also been around for a long time and has proven to be safe for food production, as Dr. Amy Proulx explains in her column on Pg 8.

Indeed, as Tulbek said, “precision fermentation is opening new opportunities for Canadian companies to contribute to healthy and nutritious food and the Food Centre is helping to advance this technology. It can also be used to contribute to a circular economy by engineering microbes to derive value from waste

feedstocks coming from breweries, grain processing industries, where additional proteins, sugars, vitamins, bioactive compounds can be recovered, thereby reducing wastes going to landfills.”

However, the technology is expensive. The major challenge will be to keep production costs economical so that ‘fermed’ products are affordable for the public.

“Precision fermentation requires highly specialized equipment for production at large scales in the order of 100,000 to 1 million L capacities for sustainable, economical, and routine production. For many of the SMEs, the cost of establishing such infrastructure may be prohibitive,” explained Tulbek.

“A lot of capacity building needs to be done to reach price parity with animal proteins. Investments and funding are required because precision fermentation needs upfront financing. The regulatory landscape is also not very transparent right now,” added Luo, who also stressed on the need to develop the talent required to power Canada’s bioeconomy.

One can’t ignore the significance of consumer education. Unless consumers perceive ‘fermed’ products as safe, nutritious, clean label, this tech will not create the impact that has become its major selling point.

The Comitrol ® series delivers continuous single-pass operation. High capacity, precision particle size reduction. Incrementally shears product without significant temperature rise. Now available with equipped HMI to offer even more processor benefits. Thousands of proven reduction applications worldwide.