A new product in the Great Taste & Wellness range allowing bakers to develop new TFA Free cake, meeting consumer requirements for healthier patisserie products.

Our Winter Collection is now available in White & Chocolate.

When it comes to moving and storing dry ingredients, we can –

Automate This!

Delivery, Storage & Inventory

Conditioning (Drying/Cooling)

Sifting

Scaling/Batching

Vacuum/Pressure

Dilute/Dense Phase

Why automate your minor or micro ingredients?

Consistency

Accuracy

Accountability

Cleanliness

Reduce Manpower

Eliminate Waste

Reduce Liability

Integrating process knowledge with the right technology.

Process Definition and Functional

Design Services

Architecture and Hardware

Design Services

Real-Time Software

Development Services

Business Systems

Development Services

Controls Hardware Manufacturing

A single source for all your liquid processing needs.

Bulk Liquid Storage and Delivery

IBC Systems

Water Blending

CIP (Clean-In-Place) Skids

Metering and Dosing Systems

Cream Yeast Systems

Slurry Systems

Liquid Fermentation Systems (Liquid Brew Systems)

BY BRIAN HARTZ

We live in an increasingly skeptical culture in which factual data are constantly under siege from special-interest groups and spin doctors looking to gain a financial or political edge over their opponents by convincing the public they are in sole possession of the truth.

According to the Oxford English Dictionary, to take something with a grain of salt is to “accept a thing less than fully” –to be skeptical. Wikipedia says this phrase comes from an entry in Pliny the Elder’s Naturalis Historia “regarding the discovery of a recipe for an antidote to a poison. In the antidote, one of the ingredients was a grain of salt. Threats involving the poison were thus to be taken ‘with a grain of salt’ and therefore less seriously.” Another possible origin is the idea that food tastes better and is easier to swallow if you add some salt.

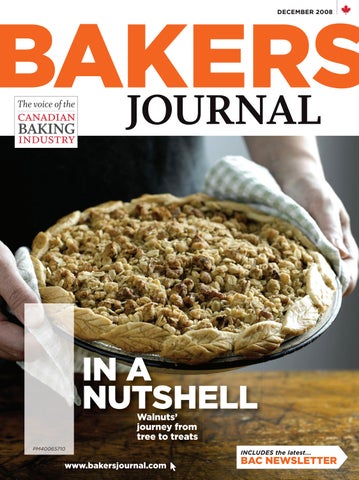

DECEMBER 2008 | VOL. 68, NO. 10

EDITOR | Brian Hartz editor@bakersjournal.com 1-888-599-2228 ext. 250

}It’s tough not to be skeptical about the various nutritional studies making headlines in recent years as their findings are often used to promote someone’s cookbook or self-help manual. One day coffee is good, the next it’s bad. Same with chocolate, red wine, the Atkins diet – and now, sodium.

For a long time sodium has taken a distant backseat to trans fats in the rogues gallery of nutrition. And we tend to count calories and cholesterol while overlooking sodium content. Sure, we have vague notions of its potential for harm if over-consumed, but refined table salt – which is 60 per cent sodium, 40 per cent chloride – is such a staple of the baker’s craft that it would seem impractical to cut back or seek alternatives when there are so many other ingredients and byproducts the government is pressuring food producers to curtail.

It’s tough not to be skeptical about the various nutritional studies making headlines in recent years as their findings are often used to promote someone’s cookbook or self-help manual.

However, with excessive salt consumption linked to so many adverse health effects –hypertension, gastric cancer, osteoporosis and cardiac enlargement, just to name a few –and the average Canadian consuming more than 3,100 milligrams of salt per day, twice as much as the recommended 1,200-1,500 milligrams, it was only a matter of time before the government mounted a campaign to encourage people to reduce their daily sodium intake. That time has come as Blood Pressure Canada is urging us to cut our sodium intake to 1,200-2,300 milligrams per day by the year 2020.

The ramifications for the baking industry are significant, which is why we asked Jane Dummer, a registered dietitian and manager of the nutrition consulting services at Guelph Food Technology Centre, to provide some answers for bakers who might be concerned about how this issue is going to affect their businesses in the years ahead. Jane recently gave a presentation on this topic to the Canadian Pastry Chefs Guild, where her assertions were met with a mixture of surprise, enlightenment and, yes, skepticism. See the story on page 38.

Also this month, we cover some other important topics, including Clíona M. Reeves’ look at food safety in light of the listeria crisis and Tuija Seipell’s profile of a B.C. bakery inspired by Al Gore’s An Inconvenient Truth to make its business practices more environmentally sustainable. On the lighter side, I escort you on a tour of California walnut country during harvest season to see how these most healthful of nuts make it from tree to brownie.

So don’t take this issue with a grain of salt – it could not only help your business, but also save your life. See you in 2009!

Happy holidays,

TECHNICAL

EDITOR | John McColl, Puratos Canada jmccoll@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexweb.com 1-888-599-2228 ext. 268

SALES ASSISTANT | Pauline Cecile pcecile@annexweb.com 1-888-599-2228 ext. 273

PRODUCTION ARTIST | Brooke Shaw

VP/GROUP PUBLISHER | Diane Kleer dkleer@annexweb.com

PRESIDENT | Mike Fredericks mfredericks@annexweb.com

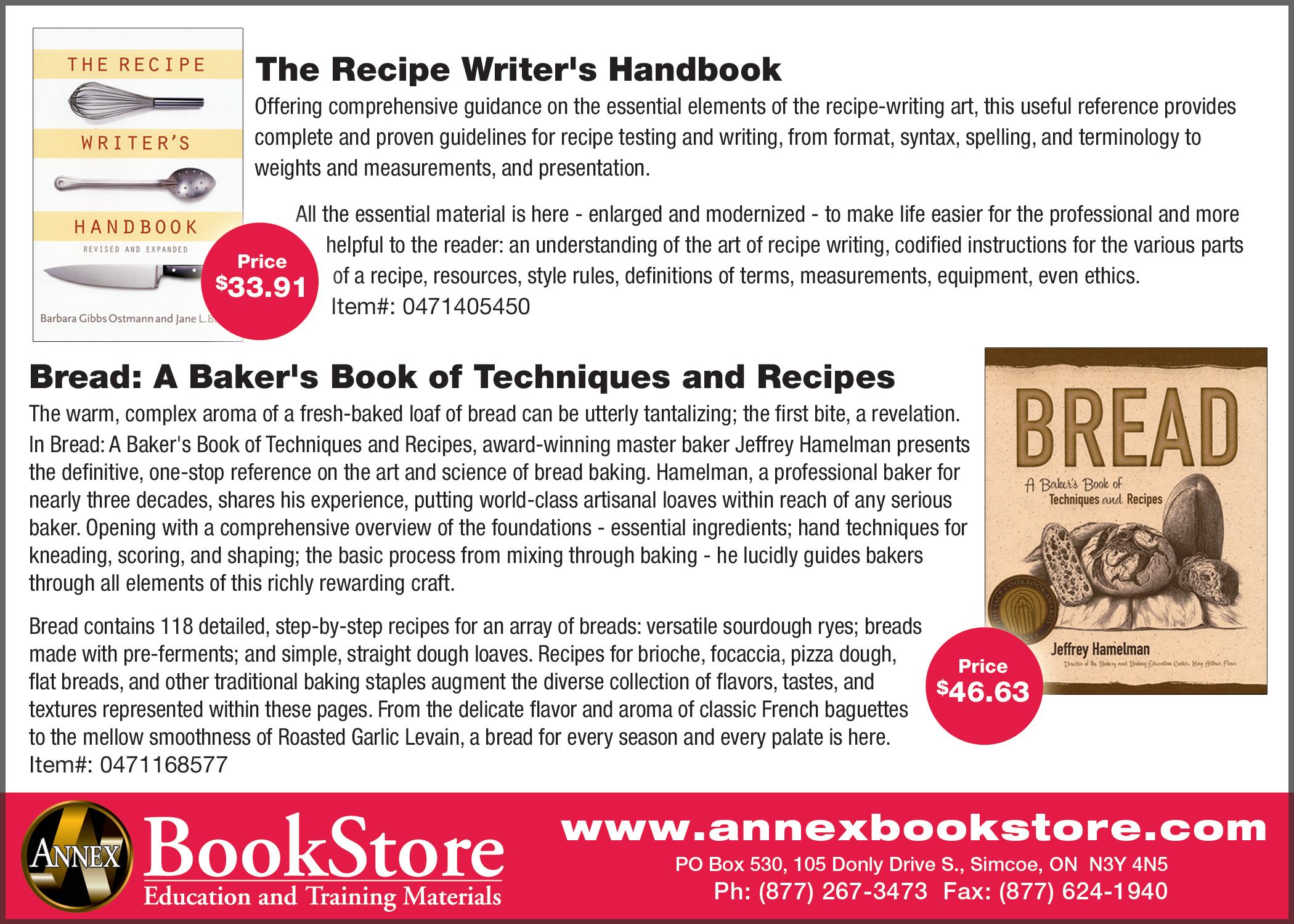

Mailing Address P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710. Return undeliverable Canadian address to: Circulation Department, P.O. Box 530, Simcoe, ON N3Y 4N5 e-mail: sbrady@annexweb.com

Periodicals postage paid at Buffalo, N.Y. (USPS 007-277). US Office of publication c/of DDM Direct.com, 1223 William St., Buffalo, NY 14240. US Postmaster send address changes to: P.O. Box 611, Niagara Falls, NY 14304. ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Publishing & Printing Inc.

SUBSCRIPTION RATES Canada — 1 Year $ 31.50 (includes GST – #867172652RT0001) USA — 1 Year $ 40.00 Foreign — 1 Year $ 60.00

Send your subscription request to: Bakers Journal

P.O. Box 530, Simcoe, ON N3Y 4N5

Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940

E-mail: sbrady@annexweb.com

From time to time, Bakers Journal may make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2008 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

briefly | CRFA chief Douglas Needham to step down next year; Culinary Team Canada brings home gold from Germany | for more news in the baking world, check out our website, www.bakersjournal.com

TORONTO – The Canadian Restaurant and Foodservices Association announced in late October that president Douglas Needham has decided to leave the association at the end of June 2009.

“Doug has made an enormous contribution to CRFA and the foodservice industry over the past 26 years, and the board of directors is pleased that he will remain at the helm over the next several months to ensure a smooth transition takes place,” says CRFA chairman of the board Michael Aronovici. “The board has formed a succession committee to oversee the search for a new president.”

Needham joined CRFA in 1982 and led the association through more than two decades of growth and expansion aimed at the betterment of Canada’s food service industry. His accomplishments span government lobbying, industry trade

shows and money-saving services for food service operators.

“Food service is a tremendous industry because of the people involved,” Needham says. “I’ve been privileged to work with an exceptional team of CRFA staff and directors, as well as thousands of food service operators across Canada who personify the entrepreneurial spirit of this great industry.

“My departure from CRFA is a bittersweet decision. I’m excited about trying some new endeavours, but I’ll miss working for such a magnificent organization.”

For more information, see www.crfa.ca.

ERFURT, Germany – Culinary Team Canada, representing the Canadian Culinary Federation and the chefs of Canada, has won four gold medals in four different cooking competition events at the Culinary Olympics held in late October in Erfurt, Germany.

The team placed fifth overall out of 32 teams from around the world in the National Team Category behind Singapore, Sweden, Germany and the new world champions, the great chefs of Norway.

The two cold food categories – the presentation of a display table consisting of canapés, appetizers, buffet platters, vegetarian items, a three-course menu and main courses, plus the third category – the dessert table – yielded three gold medals on the first day of their competition. The final category –cooking a three-course menu for 110 people in front of the general public –resulted in their fourth and final gold medal and their prestigious fifth-place standing.

Working under manager John Carlo Felicella of Vancouver Community College, the team is made up of captain Tobias MacDonald (La Belle Auberge Restaurant, Ladner, B.C.), Scott Jaeger (The Pear Tree Restaurant, Burnaby, B.C.), Hamid Salimian (The Westin Bear Mountain Resort, Victoria, B.C.), and Cameron Huley (St. Charles Golf and Country Club, Winnipeg, Man.). Mickey Zhao (St. Germaine Bakery, Vancouver, B.C.) is the team’s pastry chef.

Bruno Marti, chairman of the Canadian Culinary Federation and culinary coach of the team, was excited with the results.

“This result strengthens the already great reputation that our Canadian chefs have around the world,” said Marti. “They are not just great competitors but incredible cooks who help to make Canada a great culinary destination!” For more information, contact Jane Ruddick, J.R. Food Consultants, at jruddick@shaw.ca or 604-916-9071.

California walnuts star in a major new campaign toward healthful recipe makeovers | BY

BRIAN HARTZ

The next time you’re experimenting with ingredients, you might want to take another look at walnuts. They’ve long been associated with desserts and sweets –brownies, anyone? – but new research reveals that not only is the walnut tops among healthful nuts, it is also one of the world’s most nutrient-dense whole foods and is well suited for inclusion in a diverse range of recipes.

Rich in alphalinolenic acid (ALA), an essential omega-3 fatty acid, walnuts are a key part of the Mediterranean diet that can reduce the risk of heart attack and cardiovascular disease by up to 50 per cent, in addition to lowering LDL or “bad” cholesterol and decreasing the likelihood of developing diabetes. Walnuts also offer benefits in the areas of bone health and weight management.

“One of the easiest ways to improve one’s diet is to eat a handful of walnuts every day,” says Dr. Rickey Yada, a food science professor at the University of Guelph in Guelph, Ont. “Walnut research to date has been very impressive and upcoming studies look very promising, too.”

}But where do walnuts come from and how do they get to bakers in Canada? That’s what the California Walnut Commission of Canada, based in Mississauga, Ont., wanted to illustrate in late September when it took food industry journalists on a walnut harvest tour in northern California, near Sacramento, the state capital.

California produces 99 per cent of the commercial U.S. walnut supply and 66 per cent of the global supply; 98 per cent of the walnuts sold in Canada are grown in California ...

increase in production since 2000. Without a doubt, the state known for Hollywood and the Governator is the undisputed king of walnuts.

“From the time I was 10, I worked on the farm,” says Norene, who studied agricultural science and management at the University of California, Davis, graduating in 1973.

With a mild climate and deep, fertile, well-drained soils providing ideal growing conditions, California produces 99 per cent of the commercial U.S. walnut supply and 66 per cent of the global supply; 98 per cent of the walnuts sold in Canada are grown in California, which in 2005-06 exported more than 15.7 million pounds of walnuts north of the border. The 2008 California walnut crop is estimated at 375,000 tons, representing a 57 per cent

But that kingdom – comprising more than 200,000 acres of farmland worked by 4,000 growers – is built on the hard work of multi-generational family farms, as we discovered during the tour, which began at the orchards of Norene Ranches Inc. near Rio Oso and Wheatland, north of Sacramento.

Donald Norene runs the 750-acre farm with his wife, Sandy, and son Davin. He expanded the operation after taking it over from his father, Roy, who in turn inherited it from his father, who began growing walnuts in the early 1920s.

Norene grew peaches for a few years, but in 1994 he replaced his peach trees with more walnut acreage. Now the orchards produce between 1,200 and 1,500 tons – or 2.4 to 3 million pounds –of walnuts per year.

“We’re looking for three tons to the acre – that’s our yield objective,” he says. But recent harvests have been well above that figure, which, according to Norene, is due to a little bit of luck and a whole lot of investment in cutting-edge harvesting technology.

During the September-November harvest season, Norene deploys a fleet of approximately Zamboni-sized machines to collect walnuts. First up is the shaker, which grips the trunk of a tree and, well, does just what you’d imagine. As we

looked on during a demonstration, the ground beneath our feet also shook.

“The shaking is not a nice massage; it’s kind of a violent act,” Norene says. “But in the past 20 years there have been huge improvements. It’s still a violent shaking, but there’s been improvements such as built-in slippage that prevents the bark of the tree from being stripped off.”

When the dust had settled after only a minute or so of shaking, walnuts blanketed the ground around the tree. The shaker is remarkably efficient – and it has to be, with 80 trees per acre and 750 acres to harvest. And walnut trees can grow up to 100 feet tall, with each tree capable of producing thousands of nuts.

}“Using this equipment to pick them up in a proper manner helps us deliver a fresher, better quality product,” Norene says. “We try to have the orchard properly irrigated and time the harvest for optimal kernel quality. It seems to be working as people are buying more walnuts than ever – and the health benefits don’t hurt, either. Our business is really booming right now. It’s a heckuva lot better than the housing market.”

Rich in alphalinolenic acid (ALA), an essential omega-3 fatty acid, walnuts are a key part of the Mediterranean diet that can reduce the risk of heart attack...

“Some of these trees will be shaken 45 times in 30 years. As they get older and more productive, we might end up shaking them twice in one season,” Norene says. “But with young trees, we don’t want to shake them when they’re real green and succulent, because the bark chips so easily.”

After the shaker comes the sweeper, which gathers the walnuts up into neat rows for the next machine, a sifter that picks up the walnuts and sorts out debris before depositing the nuts in a huge wheeled bin hitched to the back of this third machine.

Indeed, with 2008 delivering dry weather perfectly suited to walnut growing, the current crop looks set to be about 16 per cent larger than last year’s, he says.

But harvesting the walnuts is only part of the process. They have to be removed from their green outer hulls and then dried out and shelled. Some walnuts are left in their shells to serve the in-shell nut market – popular around the holidays, of course – but the vast majority are shelled. This is done at facilities such as Carriere Family Farms in Glenn, Calif., northwest of Norene Ranches Inc., run by Bill Carriere, a fifth-generation walnut farmer,

and four of his cousins.

In addition to operating two hulling and drying centres, an in-shell packing plant and shelling plant, Carriere grows walnuts on 1,500 acres of land. Remarkably, Carriere’s processing facilities are operational for only about two months every year, during harvest season.

But those two months require an enormous amount of energy. During our

tour, Carriere said he’s had solar panels installed on the roof of the hulling and drying facility because of its huge electricity consumption. “We’re hoping to generate up to 90 per cent of our own electricity requirement,” he says.

The hulling machinery was quiet on the day we visited, but the drying room – picture a huge sauna the size of a hockey rink – was going full-bore and greeted us with a blast of hot, dry air as we walked along a platform between its two enormous vats of walnuts. These are divided into bins with labels specifying to which client they belong, because the nuts are still considered an agricultural product and the property of the grower. Eventually, after charging a processing fee, Carriere will buy the nuts from the grower; at this point they are considered a commercial product and are taken to the shelling plant where they’re shelled, sorted and packaged for shipping to markets around the world. Coincidentally, our tour of the shelling plant ended at a group of pallets stacked high with boxes of walnuts about to be exported to Canada.

• cakes, cookies and breads.

Add chopped walnuts to enhance the flavour of muffins,

• Top bars, squares or icings with walnuts for a tasty,

Add ground walnuts to crusts of cheesecakes and pies.

• decorative finish.

Before sending us back to Canada, the California Walnut Commission gathered some U.S. food and nutrition luminaries for a presentation on the Smart Menu campaign, which aims to make popular holiday and everyday recipes more nutritious by using walnuts and other healthful ingredients. TV doctor Michael Roizen – known for the RealAge and YOU health improvement books, the latter written in collaboration with Dr. Mehmet Oz – teamed up with Moosewood Cookbook author Mollie Katzen for a holiday cooking demonstration at Mulvaney’s B&L, a gourmet restaurant in Sacramento. Its owner, acclaimed chef Patrick Mulvaney, joined Roizen and Katzen on stage for the demo after introductions by walnut commission CEO Dennis Balint and California Secretary of Agriculture A.G. Kawamura.

“You can change the way your body works, and the way you feel, with the food you eat,” says Roizen, citing research by Progressive Grocer showing that in 2007 U.S. consumers spent more than $69 billion on candy, snacks, soft drinks and bottled water compared to just under $67 billion on fresh produce. Katzen adds that their goal is “to find the most appealing and delicious ways to prepare and present fruits, vegetables, whole grains, good oils, legumes, nuts and meat and dairy – and to get people eating smart and feeling and looking wonderful.”

The pair’s first targets are the celebratory and comfort foods, including baked goods, in which people are prone to overindulge during the holiday season, but their ultimate goal is to make over a total of 50 popular recipes, one season at a time. So far, they have reinvented dishes such as turkey with stuffing and gravy, winter meatloaf, pasta, soups and stews to be up to 33 per cent lower in fat and calories. / BJ

For more information about California walnuts, including recipes and nutritional data, see www.walnutinfo.com.

M. REEVES

Food safety stories are never absent in the news these days. From updates about the Maple Leaf listeria crisis and resulting deaths, to overseas stories about melamine in dairy products manufactured in China, to Cadbury’s late September recall in Asia and Australia, we are constantly reminded how interconnected our food supply is.

But neither of these examples has anything to do with the baking industry, so bakeries and their suppliers need not worry, right?

}Nope. Not by a long shot.

“The challenges are real,” says Paul Medeiros, manager of consulting services at the Guelph Food Technology Centre, a training and consulting firm in Guelph, Ont., “and it doesn’t help that margins are tight, which can constrain resources and time to deal proactively with food safety. But misconceptions are even more dangerous. Commonly, people assume that any microbes will be killed in the heat of baking, but microbes are not the only threat, and bread is not a bakery’s only product. Products with fillings or icings – custards, for example – may look fine when baked, but may not have reached sufficient internal temperature to kill microbes, such as salmonella, lurking in the egg. Likewise, there are additional threats from physical hazards, such as glass fragments, or

chemical hazards, such as contaminants in ingredients. For example, do you know your supplier well enough to be sure that the whey powder you just received does not contain melamine?”

Dealing effectively with suppliers is an art in itself.

Simply assuming that ingredients are safe is a dangerous gamble. “You may not be buying your ingredients from the manufacturer,

properly labelled to declare intentionally added allergens, such as nuts, that they alert consumers that a product may contain other unintended allergens, and that they make every effort to prevent cross-contamination.”

More easily said than done.

“We did a paper for CFIA on the ability of sesame seeds to migrate through a plant, from pre-production, to baking, to cooling,” Hetherington says.

A good traceability plan is another essential. No one wants a recall, but it is vital to be able to track and backtrack ingredients, and to follow each batch of product leaving your facility ...

but rather from a broker, who may have minimal or even non-existent knowledge of food safety,” Medeiros says. “And even if you’re buying directly from a manufacturer, they may have combined raw ingredients from multiple sources to prepare your order.”

Beyond the headline-grabbers of listeria and salmonella lurks the equally deadly realm of food allergens.

“Allergens are a major challenge for the baking industry because the ingredients we use come from every category of 10 priority allergens the Canadian Food Inspection Agency (CFIA) has identified,” says Paul Hetherington, CEO of the Baking Association of Canada. “Wheat, dairy and egg are regularly used, and often soy, nuts and other serious allergens are major ingredients as well. As a result, it is vital that bakery operations ensure that their products are

“The structure of allergens makes them very difficult to keep out, but precautionary statements are no substitute for good manufacturing practices.”

Medeiros agrees, cautioning that “adding ‘may contain’ statements to a label is not a get-out-of-jail-free card. CFIA evaluates all issues on a

case-by-case basis and may ask for a recall anyway.”

So what is a bakery operator to do? There are many steps they can take, but there are two overriding concerns.

“First,” says Medeiros, “you must have the solid, unwavering commitment from management to provide adequate staffing and resources to achieve food safety objectives. And the system must be just that, a

Baked goods made with eggs risk contamination from microbes if internal temperature is not sufficient.

system which everyone follows, not just a project dumped on the HACCP co-ordinator, and dependent on whether his boss is around to breathe down his neck every day. The system must be shared across the organization, and must be robust enough to survive staffing changes. In fact, it should be a co-ordinated effort through the entire value chain, going beyond employees and management to include suppliers and distributors.”

What should this system consist of? “You need good manufacturing practices (GMPs) to ensure a safe manufacturing environment, such as ensuring proper sanitiation and ventilation,” Medeiros says. “Then HACCP, or Hazard Analysis Critical Control Points, identifies potential areas in the manufacturing process where

hazards could arise and builds safeguards in to prevent them, and to alert operators that something has gone wrong. Allergen control programs are needed to prevent crosscontamination during manufacturing. And finally, supplier quality assurance programs are needed to ensure that the ingredients you receive are safe. After all, if your product is compromised by contaminated ingredients, it is still your customers who are at risk, and your brand which can be damaged.”

A good traceability plan is another essential. No one wants a recall, but it is vital to be able to track and backtrack ingredients, and to follow each batch of product leaving your facility, enabling you to recall it voluntarily before it reaches consumers and causes illness – or worse!

Having a great plan is only the beginning. Now you have to implement it and document it. Without clear documentation, you have no way of knowing whether you are actually achieving what you laid out in your plan. Unless you record equipment maintenance and cleaning, temperatures in

storage areas, and other important measures, you will not be able to demonstrate the safety of your product – or to backtrack a problem to its source, and correct it.

The heart of a reliable food safety plan is the HACCP team, a group of people from each

In October, European Breads Bakery in Vancouver became one of the first Canadian bakeries to start selling its breads in biodegradable bags. This bold and groundbreaking move will prevent approximately 200,000 plastic bags from potentially hitting the landfills each year.

“If we can convince just four more bakeries to do the same, we’ll have a million fewer plastic bags littering the world,” says Vera Kobalia. She is the 27-year-old daughter of the bakery’s founder, Otari Kobalia, and the person responsible for the bakery’s switch to biodegradable packaging.

THE GREAT GARBAGE PATCH

Unless you have lived in a complete media block-out, you have most likely heard about the Great Pacific Garbage Patch. It is the ever-growing island of garbage gathered up over the last

century in one of the most remote spots of open water in the world, the North Pacific Gyre. Alternately described as being the size of Texas or twice the size of Texas, this massive, ever-growing floating disaster forms because all the trash in the water rides the ocean currents and eventually ends up in this one spot.

The people responsible for this disaster are us – the three generations of the “Plastic Era.” Prior to the past century, everything in the world was biodegradable. When stuff floated into the gyre, it broke down into nutrients for fish and other marine life. But all the plastic ever made in the world still exists, and that is bad news for the environment and consequently for the human race.

These facts began to concern Vera Kobalia in 2005 after she attended a lecture at the University of British Columbia by former U.S. Vice President Al Gore. This speaking tour preceded

A loaf of European Breads’ barley bread in the bakery’s new biodegradable packaging.

the 2006 documentary An Inconvenient Truth, which won the documentary Oscar in 2007 and helped earn Gore the 2007 Nobel Peace Prize.

Not only did Vera hear what Gore had to say, she decided to do something about it. By doing so, she has joined the impressive list of leading manufacturers, retailers and other companies around the globe who have made environmental concerns and sustainability part of their basic company values.

After the lecture, Vera started doing research into environmental packaging, and into recycled, recyclable and biodegradable options. “I was glad that stores had started to promote reusable bags at the check-outs, but what about food that already came in plastic bags, like our breads?” she asked.

She asked her Vancouver-based supplier, Ango Promotions, to start looking as well. Was there a biodegradable option they could use? She also attended food industry trade shows and realized that the concept of biodegradable bags was still young and there were no local manufacturers. Eventually, Ango found a bag manufactured in China. It is not clear, but slightly opaque. It costs about 7 per cent more than European Breads’ previous, conventional bags, but the bakery has not increased its prices because of it.

Being environmentally conscious fits well with the overall philosophy of European Breads Bakery, established in 2001 by

Otari, who wanted to honour the thousands of years of baking tradition of his homeland, Georgia, a former Soviet Republic perched on the transcontinental divide between Europe and Asia, and Russia and Turkey.

Dedication to quality and the use of the best possible ingredients are part of the old style of bread making, as are the passion, feel and touch that each baker brings to each handmade loaf.

“When you love the process, everything works well,” Otari

Call our Canadian Distributors to request our catalog:

BakeMark of Canada 3202 - 9th Street S.E. Calgary, Alberta T2G 3C3 (800) 663-CAKE (604) 303-1700

Cake Top Inc.

151 Carling View Drive, Unit 2 Etobicoke, Ontario M9W 5S4 (800) 584-9883 (416) 798-1777

Catalog Sales Division (800) 428-4413

L & M Bakers Supply Co. 2501 Steeles Ave.W., Unit 1 Downsview, Ontario M3J 2P1 (800) 465-7361 (416) 665-3005

Nicholson Equipment Ltd. 3975 Kitchener Street Burnaby, B.C.V5C 3L9 (800) 668-3722 (604) 291-1901

Nicholson Equipment Ltd. 11640 - 147th St. Edmonton, AB T5M 1W2 (800) 661-9026 (780) 451-6262

Traynor's Bakery Wholesale 191 Victoria Ave.S., Hamilton, Ontario L8N 3C8 (800) 263-9239 (905) 522-2730

Vincent S.Varietes Ltd.

433 Rue Saint Paul LeGardeur, Quebec J5Z 4C7 (800) 263-1687 (450) 585-1687

Vixit Products Ltd.

290 Henri Bourassa Ouest Montreal, Quebec H3L 1N7 (800) 463-8782 (514) 337-0814

(Fax) www.decopac.com

says. “You cannot make a film or a painting if you don’t love it. Baking is the same.”

The bakery specializes almost entirely in wholesale, although its small storefront cafe is a regular stop for those who love the heavier, stronger Eastern European artisan breads. Baked with organic ingredients by bakers from Georgia; St. Petersburg, Russia; Ukraine and elsewhere, European Breads’ 25 different kinds of loaves have become a common sight at nearly 60 food stores and restaurants in British Columbia. These include Urban Fare, Meinhardt’s, Capers/Whole Foods Markets and Stong’s Market.

The composition of the degradable bags is 80 per cent high-density polyethylene (HDPE) mixed with 20 per cent ST+MD.

ST+MD is a type of a degradable material made of corn amylum. After the bag is used or buried underground, the animalcule in the air or underground will “eat” the HDPE, causing the bag to disappear, usually within three to five months.

The bakery’s bestselling bread is the earthy, organic Georgian Baguette that Vancouver Sun food critic Mia Stainsby described as being “shaped like a long baby alligator” and having a “satisfying teeth tug and inviting hollows for fillings.” The same loaf earned a spot on Vancouver Magazine’s 101 Things to Taste Before You Die, a list that was compiled from the best of British Columbia’s tasty food experiences.

One of the first stores to receive European Breads loaves in the new biodegradable bags was the Capers/Whole Foods Market on Cambie Street in Vancouver. Bakery team leader Huguette LeBlanc says that the move to the new bags is extremely positive.

“These are challenging times for the bakery industry so it is doubly positive to see European Breads make this move,” she says. “We are really excited to see this happen as it fits perfectly with our core values. And it just makes us love European Breads bakery even more.”

By late October, after nearly a month, LeBlanc had not received any complaints from customers about the opaque bag.

“Our customers are pretty empowered consumers, so we’d know if our customers didn’t like the bag,” she says.

With concerned consumers tugging at one end and ecominded retailers pulling at the other, biodegradable bags will most likely become more common. The Kobalias hope that more bakeries, other food producers and non-food manufacturers will move into biodegradable plastics sooner rather than later. “When there is a good demand, some local manufacturer will start making them, and then we can all buy biodegradable bags made in Canada and that would make them even more eco-friendly,” says Vera Kobalia. / BJ

FOR MORE INFORMATION:

• Ango Promotions: www.angopromo.com

European Breads Bakery: www.europeanbreads.com

• About the Great Pacific Garbage Patch:

• www.vbs.tv/shows/toxic/garbage-island/

Many years ago when my kids were very small, one of their favorite television programs was Sesame Street with all those wonderful characters including the Cookie Monster. For those of you who are of a similar age you will probably remember that Cookie had a song that bakers would especially appreciate, it went “C is for cookie ….” Well the 2008 version of that song with all apologies to Cookie would have to be “C is for Crisis!”

In looking back over the past 11 ½ months we appear to have lurched from one crisis to the next. We began the year with the growing crisis in the price of agriculture commodities. Whether it was wheat, canola – you name it – agriculture commodities skyrocketed to unprecedented heights in a mere matter of weeks.

The rapid escalation of such basic ingredients to the baking process caught bakers, flour millers and consumer by surprise. The industry was under incredible pressure to deal with doubling or tripling of prices for ingredients. With no way to absorb these type of cost increases the effort then focused on preparing consumers for the inevitable price adjustments at retail as these costs made their way through the system. I recall doing more than 30 media interviews during this period about the hard times bakers were having as this story

become national news.

We have seen relief in wheat and other ingredient pricing since the highs. But while world demand is down now how long will it be before prices begin to head north again?

Since I am touching on commodities let’s not forget the crisis in energy costs. Like agriculture these commodities also hit prices considered impossible a short while ago. We all remember oil at $140+ a barrel and gas prices exceeding $1.40 a liter. The rising costs of energy meant problems for all industries, especially those that do daily deliveries like bakers. Thankfully there has been some relief in this area.

We have also had a crisis in our export markets with a significant impact on bakers. The overwhelming export market for Canadian bakers is the U.S. and the rapid appreciation of the loonie to the US greenback was responsible for a decrease in overall bakery exports of almost 10%. We have since seen the loonie dive to some 75¢ and rebound to the mid 80¢ range. How much this will help exports will be very dependent on the U.S. economy.

During the summer we had the start of the U.S. housing crisis which led to a banking crisis, followed by a credit crisis to an overall worldwide financial crisis. One comment I read in October suggested that watching the stock market on a daily basis was like watching a heart monitor with

Continued on page 2

Continued from page 1

its staggering ups and downs.

So if in 2008 C stood for crisis, what will it mean in 2009? I think realistically that in 2009 we can expect C to stand for Challenging. How challenging will depend on many things, the depth of the recession that has been forecast and some say is already here, where you live, etc. I have heard one baker say that people still have to eat so take that to heart.

So while 2009 will be challenging, BAC will be introducing a number of new programs for members to assist them in tackling 2009 in as positive a fashion as possible. New services will provide cost saving opportunities to return more profit to the bottom line. There will be new communication services to keep members abreast of what is happening within their province and around the country. BAC will also be making

enhancements to existing programs such as our Training Library and an exciting new project to develop training materials for in-store bakers and cake decorators. Look for these announcements in the coming weeks and months.

Lastly, this is the year end edition of our newsletter and many would say that for this special time of year “C is for Christmas”. So a Happy Holiday and a safe and prosperous New Year to all. Let’s hope the original words to Cookie’s song are the most appropriate for the coming year!

Paul Hetherington President & CEO Baking Association of Canada

Treasurer

On behalf of the Baking Association of Canada – Ontario Chapter I would like to take this opportunity to introduce the volunteers individually and recognize their assistance with chapter activities throughout 2008.

Frank Safian, Kingsway Brokerage

Dieter Claassen, Del’s Pastry

Education

Frank Lucente, Metro

Social Co-Chairs

Dan Peroff, Olympic Wholesale Ltd

Tom Nowak, Lallemand Distribution

Member-At-Large

Maurice Corsi, Caravan Ingredients

Mark Jones, Traynor’s Bakery Wholesale

Phillip Lee Wing, The Food Development Group

This past year was a special year in that we honored three industry leaders with Honorary Memberships: Flemming Mathiasen, Peter Scholtes & Benno Mattes. On behalf of the Baking Industry we thank them for their efforts throughout the many years of volunteer service. In addition, special mention of the efforts put forth by Mark Jones needs to also be made. Mark has been a part of the Ontario Chapter for over 22 years and has fulfilled many volunteer positions. Mark will be leaving his position at the end of his term this December. We all wish Mark the very best on his future endeavors.

Our first event of the year was the Annual “Night at the Races” held at Woodbine Racetrack and was organized by Dan Peroff, Social Chairperson and his committee. This event was followed by the Decorative Bread Baking Contest held during

Bakery Showcase 2008. Frank Lucente, Education Chair was successful in bringing back the Decorative Bread Baking Contest at Showcase 2008. Cash prizes were awarded to both professional and non professional participants, and plans are already in place to expand this event for Bakery Showcase 2010.

Dan Peroff and Co-Chair Tom Nowak also planned and executed two golf tournaments. The June Spring event was a four Man Scramble held at Carlisle Golf Course where once again we enjoyed an excellent day of weather. The Fall event was a modified team format held in September at Glen Eagles Golf Club. Funds generated from both golf tournaments supported the Chapter‘s Decorative Bread Baking Contest held during Bakery Showcase 2008.

Our Fall Dinner Programs included two guest speakers. In September, Brian Hinton & Annie Lok presented the business activities of the Resourceful Purchasers in Action (RPIA) a newly developed industry buying group. This was followed by Judy Seyler – Client Officer Cereal, Bakery, Milling Business Development Branch from the Ontario Ministry of Agriculture and Rural Affairs (OMAFRA). Judy’s presentation provided insight on Ministry funding available to Bakery operations across Ontario. This presentation also detailed the new marketing programs that feature the “Foodland Ontario” symbol.

The Annual Holiday Social was held Friday November 28 and featured a night of great food, great door prizes, entertainment and the election of the new 2009-10 Chapter Executive.

The Baking Association of Canada – Ontario Chapter would like to thank the BAC National Office and staff for their assistance and all those industry professionals who attended this years activities, we look forward to your support in 2009.

Frank Safian Kingsway Brokerage Sales Ontario Chapter Chair

For 2008, the Atlantic Chapter produced two social events for the industry both of which were well attended. Highlights from both events are listed below.

The BAC Atlantic golf tournament took place at the Magnetic Hills golf course in Moncton NB on Monday September 15th. Forty-three Golfers representing various bakeries and suppliers took place in the scramble tournament, on a windy but warm fall day. This was the largest field of players in the event’s history.

Over $2000 in prizes were up for grabs and lots of fun was had by all eleven teams. Special awards went to Most Honest Team: Darryl Chapman & Clovis Leblanc, Horizon Milling; Doug Hill, BMS Distributing and Ken White, Gennoe’s Bakery.

The Championship Team this year was Paul Nieuwenstein & Neil MacMillian from Farnell Packaging and Jeff Sarsfield from Apple Valley Farms. All in attendance enjoyed a great steak

dinner and went home with a special gift from the draw. Next year’s tournament is scheduled for Monday September 14th 2009 at The Magnetic Hills golf course.

The Atlantic BAC Hockey night took place back on Tuesday, January 29th at the Halifax Mooseheads game versus St John’s Fog Devils. Association members and guests enjoyed a great hockey game in a private VIP Box. The hometown Moose won the game. A scoring pool took place during the game at the end of each period and a number of lucky attendees went home with a little extra cash. The event will take place again in 2009 on Thursday February 26th as the Mosseheads play the PEI Rockets

We look forward to new opportunities to serve the industry in 2009 through our continued events.

We are fast approaching the end of a very interesting and challenging year. 2008 brought our industry challenges we haven’t faced for decades. Ingredients cost went through the roof and qualified labour shortage is currently at an all time high. Bakery and pastry manufacturers who are in the export business faced additional challenges from the strong Canadian currency.

All of the above was a major wake-up call for the retail baker, pastry chef, in-store bakeries, commercial wholesale or industrial bakery or pastry producers. Ingredients manufactures weren’t immune against the high ingredients cost and high fuel prices either. Looking ahead, the major lessons we learned this past year about how we do business will need to continue in order to produce the best quality product at the most efficient and economical way.

This brings me to the BAC BC Chapter Board of Directors. They are volunteers who work very hard to bring our industry together. We have a great variety of industry people on the board and they represent the following categories: educational institutions, retail bakers, pastry chefs, in-store bakeries, wholesale bakeries, millers, equipment companies, ingredients manufacturers and suppliers. They are the ones who help organize educational seminars and social events on the Main Land as well as on Vancouver Island. I would like to emphasize to everyone, that they volunteer their time and that 100 % of the proceeds raised in 2008 went back to our industry.

For example the Vancouver Island Committee raised monies towards building a brick oven at the University. The BC Chapter sponsored Baking Team Canada’s trip to Toronto in order to increased their exposure within the industry at Bakery

Proposed

BAC- BC Chapter Committee Executive

2009/2010 term

Chairperson

John MacKenzie, Anita’s Organic Mill

Vice Chairperson

Christian Mitzel, The Original Cakerie

Secretary Director

Gary Humphreys, Dawn Food Products Canada

Treasurer Director

Ron De Laet, Weston Bakeries

Entertainment Directors

Nicole Higgins, National Starch Food Innovation

Randall Winters, RF Bakery Equipment

Membership Directors

Melissa Timewell, Thrifty Foods

Nina Sanford, Weston’s Bakeries

Education Director

Parry Robinson, Vancouver Community College

Past Chairperson

Ralf Tschenscher, Lesaffre & Red Star Yeast.

Showcase. We also sponsored the BC winner for Skills Canada to participate at a National level. Vancouver Community College and Vancouver Island University, formerly Malaspina University College, Baking and Pastry Departments will receive funding as well.

Acknowledged should be the entire board of the 2008 BAC-BC Chapter for their strong commitment and support in promoting our great industry.

Vice Chairperson

Debbie Fawcus, BakeMark Canada

Secretary Treasurer

Mike Dandenault, Overwaitea Food Group

Education Directors

Martin Barnett, Vancouver Island University

Parry Robinson, Vancouver Community Colleague

Entertainment Directors

Mike Dandenault, Overwaitea Food Group

Christian Mitzel, The Original Cakerie

Membership Directors

Ron De Laet, Weston Bakeries

Nina Sanford, Weston Bakeries

Past Chairperson

Gary Humphreys, Dawn Food Products Canada

Directors at Large

Rick Barnes, BakeMark Canada

Gerrit Doruiter (retired)

Nicole Higgins, National Starch Food Innovation

Jack Kuyer, Valley Bakery

Tony Llewellyn, Snow Cap Enterprises

John MacKenzie, Anita’s Organic Mill

Jae Park, Bread N Buns

Paolo Pero, The Pastry Box

Melissa Timewell, Thrifty Foods

Alfredo Uncao, EM Bakery Equipment

Sebastian Wasaznik, Overwaitea Food Group

Randall Winters, RF Bakery Equipment

2008 is as well the year to elect a new Board of Directors for 2009 & 2010. The two years went like a “flash” and I have to say it was a wonderful experience and opportunity for me to work with great professional people in the baking industry. I would like to thank the Board for their great support and friendship. I am proud to announce the new Executive for the Board of Directors, a strong team who will continue to show their passion and commitment to our great industry.

With this I would like to wish you and yours a healthy and prosperous New Year.

Ralf Tschenscher

Lesaffre Yeast – Red Star Yeast

BC Chapter Chair

Afunfilledevening&ChristmascelebrationwithfriendsfromtheBakingIndustry Saturday, January 10th, 2009

CoastHotel&CascadesCasino

Summit Theatre 20393FraserHighway Langley,BC

6:00pmCashBar

7:00pmBuffetDinner 9:00pm–1:00amDancing

IndividualTickets$60.00(includesGST) ReservedTable(8people)-$450.00(includesGST)

RaffleTicketsavailable

**HotelroomsareavailableattheCoastHotel** untilDec11for$95.00/night

Pleasecall(604)530-1500forReservations-AskfortheirChristmasRate

****Allguestsmustbe19yrsofage***** NAMECOMPANYPHONE#E-MAIL 1.__________________________________________________________________________________________

Mailchequeandregistrationformto:Orfax/e-mailcreditcardinformationto: BAC(Attn:GillianBlakey)Fax:(905)405-0993 Suite202-7895TranmereDr.E-mail:gblakey@baking.ca Mississauga,OntarioL5S1V9Phone:1(888)674-2253ext.21

ChequePayabletoBAC Ticketstobepickedupatthedoor

Pleasechargemy:Visa_______MasterCard______#______x$60.00=$_______

The baking industry in Alberta during 2008 has had many challenges from government regulations. The ongoing nutritional labeling requirements although mandatory now, still are not being placed on packaging. In fact, many companies simply do not put nutritional panels on products or use panels that can be generated through lab testing or basic software analysis. These procedures often lead to misleading information.

The Trans-Fat initiative that started in Calgary has now spread to the entire province, which means the small baker has had to source Non Trans shortenings that don’t turn to thick soup in the summer (cake icing being the test) - in our bakery, we have had to put the Hobart mixer in the walk-in fridge to solve this one. And let’s not forget about the doubling of the cost for a cube of shortening.

The baking industry although not recession proof, will in the year ahead hold its core customers. The petro dollars are still flowing in Alberta, and current government programs that are helpful to the food industry remain fully funded.

Bakery Education in Alberta continues to be provided by both SAIT and NAIT, both schools will be providing two-year Baking and Pastry Arts programs in the future (NAIT awaits government funding). SAIT has been running the program for 2 years and has 160 applicants for 48 places. Starting in 2009 SAIT will also offer a post-diploma program in Entrepreneurship where graduates can implement the bakery

management course of setting up a business. The Apprentice Baker program (delivered by SAIT and NAIT) maintains a steady growth with 271 registered in the province, out of which 163 are women (60% and second only to hairstylists for trades).

Alberta has signed off on the TILMA (Trade and Industry Mobility agreement ) with British Columbia, and is in the process of implementing the AIT (Agreement on Internal Trade) initiative with the federal goverment. These agreements allow for recognition of trade qualifications throughout Canada.

Outlook for 2009 remains positive for the Baking industry in Alberta with further expansion of boutique style grocery stores that have fresh baking as a major component.

In Alberta, the premier event for the baking industry is our Golf Tournament, held in July of this year. It continues to be successful and I would like to thank all of the attendees and sponsors. As well I would like to thank the Golf Committee who worked hard organizing the tournament: Jay Strauss, Kim Twarynski, Randy McDonald, Ross Benedict, Chris Grdina, John Biglin, Scott Deboer, Ken Tynan and Mike Tynan. Funds raised from the tournament are used to help the baking industry in Alberta with donations being sent to both SAIT and NAIT.

The Alberta Chapter would also like to acknowledge the efforts of Bob Grebinsky of Ellison Milling and Pete Plaizier of Sunrise Bakery. Both of them sit on the BAC National Board of Directors and hail from our beautiful province of Alberta.

Brian Hinton Lakeview Bakery Alberta Chapter Chair

Mark Campbell

Occupational Health & Safety

Farhad Mehrabi Nejad

Bakery Technology III

BC Chapter

January 10, 2009

Annual Christmas Dinner & Dance

Coast Hotel & Cascades Casino

Langley, BC

Atlantic Chapter

February 26, 2009

Hockey Night in Halifax

Halifax Metro Centre

Halifax, NS

September 14, 2009

Annual Golf Tournament

Magnetic Hills Golf Club

Moncton, NB

For information on correspondence courses for baking industry employees and the Certified Bakery Specialist (CBS) program, please contact ext. 21 at the BAC office or check out our website at www.bakingassoccanada.com.

Richard Gerow British Canadian Importers

Christabel Padmore

Little Piggy Food Services Inc

Dina Valino

Dulce Catering & Desserts

BY MICHELLE

Small businesses have the flexibility to quickly identify and fix inefficiencies in their production, staffing, merchandising and point-of-sale procedures.

If you ever meet someone from a large company like General Electric or Motorola who says their title is “Master Black Belt,” there’s no need to dive under the nearest coffee table.

These folks are trained experts in a field called process innovation. At its core, process innovation is about eliminating defects by understanding, measuring and improving processes. In shorthand, these companies are able to make better products at a lower cost, which in turn leads to enhanced profits.

}Never before has the bakery industry needed to embrace this philosophy more. Costs for ingredients are rising, the minimum wage is always inching upwards and a tight economy means customers aren’t going to be looking for prices to go up ... au contraire. When the top line is being squeezed the only place to go is the bottom line and streamlining your business operating systems is one area worth focusing on. But wait – aren’t these fancy programs just for Fortune 500 companies? How can small businesses even know where to begin?

by Maidstone Bakeries of Brantford, Ont. In a November 2007 press release Maidstone declared: “By identifying areas of production waste and leftover dough and oil, Maidstone eliminated 80 per cent of the waste, improved its environmental efficiencies and saved significant dollars in the process. While many companies avoid changing their quality management methodologies because of the perceived investments in time and money, Maidstone has proven that the transition has already paid for itself tenfold.”

Production is a logical place for you to begin as well. Take one product per day and review the production steps with a fresh eye – watch your team as they go about their work. Are there multiple trips for ingredients? Is the staging area close to the mixer? Could similar base dough be used in different products? How much waste do you get in an average week?

Bakers by nature take pride in making

It’s largely believed that GE’s success came because it operated like many small companies and remained nimble and able to adapt to changing markets.

everything from scratch but ask yourself if everything on your product list must be made from scratch. Perhaps lower volume products that still sell fairly well, but aren’t signature items, could be produced using a top-quality frozen dough? This might lower ingredient spoilage and waste. It might also free up valuable mixer time and power to make products that truly define your business as unique.

now charged each time, the store collects $600 more per week selling exactly the same products in the same quantities to the same customers. This is literally ‘found money’ that we did not collect before because of errors. This improvement alone has paid for the price of the system.”

General Electric is a conglomerate – a large company comprised of many different smaller companies. Most conglomerates traditionally struggled under their massive inefficiency and weight while GE thrived. It’s largely believed that GE’s success came because it operated like many small companies and remained nimble and able to adapt to changing markets. As a small business, you already have flexibility as an advantage, so view this as giving you a leg up over the big guys.

A form of process innovation known as Six-Sigma (a statistical term referencing 99.9997 per cent efficiency) has already been implemented in the baking industry

Perhaps another bakery owner in a different market would let you observe how they do things in case there are “best practices” that can be shared. Any professional Six Sigma Black Belt will tell you that SWIPE stands for “steal with integrity and pride from everywhere” and best practices are supposed to be shared.

Your team, merchandising and point-ofsale (POS) systems can provide other areas of “found money.” Is pricing clearly displayed to the customer and the team member? As Bakers Journal online reports, Marc Tilkin, general manager of La Baguette & L’Echalote on Vancouver’s Granville Island, says that with his new POS system, “because correct prices are

This is process innovation in action. While investing in a brand new POS system may not be in the cards immediately for you – ensuring that staff are ringing up correct prices by creating a cheat sheet with pictures of the products and pricing will go a long way toward ensuring you get your deserved profit. You will also want to make sure that you have your strongest team on deck when it really counts. Those long Saturday morning queues need to be served by staff who can take care of them quickly and confidently. Sometimes the more seasoned team members will want to avoid working weekends – they may reason that they’ve earned it after years of service. Make sure that these veterans understand how important their experience is to the efficiency of the operation especially at peak traffic times.

Your brand is your reputation. It’s what customers say about you behind your back. Call it process innovation, Six Sigma or efficiencies – it’s all about providing better service and that’s your true and most profitable point of difference. / BJ

Michelle Brisebois is a marketing professional with experience in the food, pharmaceutical and financial services industries. She specializes in helping companies grow their brands and can be reached at briseboismichelle@sympatico.ca.

BY JOHN MICHAELIDES

What are pulses and how do they fit into the baking industry as healthful and alternative ingredients?

Pulses are the edible seeds of crops mainly from the legume family, such as beans, peas, lentils and chickpeas. These seeds are normally found in pods.

However, not all of the crops producing seeds in a pod are classified as pulses. Those that contain a substantial amount of oil that can be commercially extracted are categorized as oilseeds. Some examples of these are soybeans and rapeseed or canola.

The legume family represents a vast number of varieties found throughout the world. Within the groups of beans, peas, lentils and chickpeas, many varieties are grown as food. Within the bean group, many varieties – such as black, navy, cranberry, pinto, dark red kidney and light red kidney – are known. Many common names of these pulses can be found within the different geographical regions of the world.

}that may reduce the risk of certain diseases and promote overall human health.

Consumers now are focusing on foods that provide additional health benefits other than basic nutrition. These foods are collectively called functional foods, and legumes certainly satisfy this definition.

Numerous investigations have identified a number of phytochemicals in pulses that can act as antioxidants or have other positive effects in preventing the onset of chronic diseases. For example, studies have shown that baked bean consumption reduces serum cholesterol in hypercholesterolemic adults; pinto beans have been identified as reducing the biomarkers for heart disease risk; phytochemicals of black bean coats have been identified to act against cancer cell proliferation; diet supplementation with chickpeas was shown to result in a small but significant

Many researchers have investigated the nutritional aspects of pulses. They are known to contain a wealth of nutrients, making them an excellent source of healthful food for the human diet.

The legume family of crops represents a substantial portion of farming efforts in Canada. The majority of these crops are dried or processed whole. Dried legumes are used in canning and other food preparations and a major portion is exported to other countries for further processing.

Many researchers have investigated the nutritional aspects of pulses. They are known to contain a wealth of nutrients, making them an excellent source of healthful food for the human diet. They contain substantial amounts of good quality protein and complex carbohydrates, including soluble and insoluble fibre, and are low in fat content. They are a good source of vitamins and minerals such as B complex vitamins, calcium, potassium, iron, phosphorus and zinc. Legumes also offer many other health benefits beyond regular nutrition. They contain components such as antioxidants

reduction of total and low-density lipoprotein cholesterols in adult women and men; intake of legumes such as dried beans, split peas and lentils was found to be associated with a significant reduction in colorectal cancer (81 per cent) possibly due to their dietary fibre and other phytochemical content that may play a role in reducing adenoma formation.

Beans also contain a chemical compound that acts as an amylase inhibitor. This “starch blocker” sends undigested starch directly to the colon, where it is fermented like resistant starches and acts as a prebiotic. Phase 2 starch neutralizer (also known as Phaseolamin 2250 and Phase2) is a commercially isolated ingredient from white kidney beans that has been clinically studied to reduce the absorption of calories from starch by inhibiting the digestive enzyme alphaamylase. There is potential for Phase2 white bean extract to be a novel ingredient in products that will reduce the glycemic index (GI) without modifying the ingredient profile.

Legumes certainly have a low glycemic value, making them ideal for people with a risk of diabetes. For example, compared to white bread with a GI value of 100, the approximate GI values for chickpeas are 40, lentils 42 and split peas 45, while beans can vary from 40 to 55. Legumes are also known to promote satiety. There is a great potential in this area for consumers concerned about weight control and reduction of the risk of other chronic diseases associated with obesity. Information about these health benefits is gradually finding its way to consumers and for this reason the consumption of foods containing legumes around the world and in North America is on the rise.

But the use of pulses as ingredients in North America and Europe has been greatly underdeveloped. Pulses in general tend to be consumed whole. A limited supply of ingredients derived from these pulses is used in food products. However, their potential for the development of healthful ingredients – especially weight control, lower GI and prebiotic markets is great. Bean, pea and other flours are available in the market and are finding their way into gluten-free and other food products.

Some dietary fibre ingredients from pulses have also been developed and marketed, but the potential for greater utilization for production of both soluble and insoluble dietary fibre is great. In addition, protein and starch ingredients with specific functional properties have been developed.

Suppliers of ingredients from pulses include Grain Process Enterprises of

Scarborough, Ont.; Bob’s Red Mill products of Milwaukie, Ore.; Heartland Ingredients of Ubly, Mich.; and other small operations. The most successful producer of these ingredients is Best Cooking Pulses in Manitoba, which produces pea fibre and pea flour. Its main product is the pea hull fibre, which is being used in many food products, while the company’s Best Pea Fibre is a dietary fibre ingredient approved by Health Canada.

Best Cooking Pulses’ pea flour is produced by grinding green or yellow peas and is primarily exported to the United States for use in bakery products. Roquette, a French ingredient manufacturer, supplies a pea protein under the brand name Nutralys, which is highly purified and extracted without chemical solvents. Pea protein is an excellent emulsifier and thus improves texture and ensures better cooking results. It is a concentrated source of protein with a well-balanced amino-acid profile, and is easily digestible due to the elimination of anti-nutritional factors during the manufacturing process. As it has a neutral taste and is in a granular form, it can be easily incorporated into many types of products without forming dust, foam or lumps.

Current research is being carried out on better processing techniques for lentils and other legumes, development of specialty ingredients such as flour mixtures that will reduce the fat absorption of fried foods, de-flavouring of bean flours as well as fractionation and separation of starches and proteins.

One of the results of recent research efforts is the development of composite flours that contain wheat and legume flours. The University of Manitoba food science department is actively involved in this area and students in this department have developed prototypes of extruded snacks that contain both wheat and bean flour. Extruded snacks represent a good opportunity for utilization of these flours and researchers at the U.S. Agricultural Research Service developed a process to make a crunchy snack from lentils and other legumes.

Flours from pre-cooked and raw navy, pinto, black, cranberry, light red, dark red, romano and great northern beans are also being explored. These flours could be used to improve the nutritional value of products such as muffins, tortillas and gluten-free breading and batters. They

could also be used as thickening agents for soups.

The Canadian International Grains Institute has developed muffin recipes using pea flours and pea fibre. Pea fibre has proved to be more advantageous than pea flour by significantly increasing fibre content in the muffins. Pea flours tend to have a stronger flavour, so product formulations would need to be adjusted to compensate.

One of the most recent advances in the application of ingredients from legumes in foods deals with the development of gluten-free food products – especially baked goods. For the gluten-free baked goods industry, alternatives to wheat flour are difficult to find. Rice flour is extensively being used, but legume flour is becoming popular and its application is becoming more extensive.

Research in the technology of application of certain enzymes to legume flour in order to improve its performance in gluten-free baked goods has been initiated recently. In particular, the enzyme transglutaminase is being investigated because of its ability to link certain amino acids within a protein matrix or from different proteins, thus forming complexes that can perhaps mimic the action of gluten in baking systems. This enzyme can link together the amino acids glutamine and lysine, both of which are present in legumes.

Ingredients from pulses represent a great opportunity for the baking industry. They are much more nutrient dense, possess more health-promoting characteristics than wheat flour and have no known allergenic properties. Unlike several other crops they are also not yet subject to pressure from biofuels and bioproducts and they may present a cheaper alternative as a source of healthful food ingredients in the near future. / BJ

Funding for this report was provided in part by Agriculture and Agri-Food Canada through the Agricultural Adaptation Council’s CanAdvance Program. For more information, or fee-for-service help with product or process development needs, please contact the GFTC by phone at 519-821-1246, by fax at 519-836-1281, or by e-mail at gftc@gftc.ca.

Dr. John Michaelides is director of research and technology at the Guelph Food Technology Centre, www.gftc.ca.

Pizzey’s Whole-Milled BevGradTM and SelectGradTM flaxseed is an excellent source of Omega-3 fatty acid (22%). Also a good source of dietary fiber and protein, Pizzey's flaxseed does not require refrigeration and is gluten free.

Email: sales@pizzeys.com www.pizzeys.com

As a baker, your reputation is only as good as the quality of your products. That is why your business simply can’t afford to be associated with anything that would jeopardize consumer confidence, including a fly infestation.

In addition to being a nuisance, flies are filthy insects that can slough off numerous dangerous bacteria every time they land. Carrying more than 100 pathogens, flies can transmit foodborne illnesses such as E. coli and salmonella. Their presence also leaves you vulnerable to negative attention from your customers, third-party auditors and the media – sometimes resulting in expensive litigation.

Because flies can cover large distances very quickly, it doesn’t take them long to contaminate large amounts of product. Drawn indoors by decaying organic matter and sugars, flies will make a home in your building if they have access to their essential survival needs – food, water and shelter.

There is no doubt that flies are a big concern for bakeries, but fortunately you can implement an integrated pest management (IPM) program that incorporates specific fly prevention and treatment options. IPM focuses on proactive sanitation and facility maintenance, thereby reducing the need for regular spraying and reactive chemical treatments.

Your first step in implementing IPM is to contact a pest management professional who is trained in pest biology and behaviour and can identify which types of flies are affecting your bakery. Fly control treatments work best when used for specific insect species and/or insects in certain growth stages. Your pest management professional should inspect your facility for any evidence of breeding sites and/or the recent history of fly activity, to ensure the most effective treatment is recommended. After the inspection, he or she will likely include some of the following sanitation and facility maintenance tips to treat current problems and prevent future infestations:

Sloughing off dangerous bacteria every time they land and carrying more than 100 pathogens, flies aren’t welcome in bakeries.

• around the facility.

Immediately clean any spills or standing water in or

Because flies like to frequent sink and floor drains, use a

• biological drain cleaner with naturally occurring bacteria and enzymes to remove leftover organic material. Consider washing the floor with an organic cleaner to help remove any elements that attract flies in the first place.

Take the trash out on a regular basis and line and cover all

• trash cans to limit food sources for flies. Place dumpsters and compactors as far away from the building as possible, so that smells emitting from the trash draw flies away from your building.

Use sodium vapour lights in areas

• where you traditionally use mercury vapour or fluorescent lights, as flies are less attracted to the light emitted from sodium vapour bulbs. Also, position exterior lighting so that it is located away from the building, shining back towards the building instead of the traditional positioning above doorways.

Positive airflow helps prevent

• flies from entering your facility. The airflow from your building should push flies out when they try to get in through an open door or window. Test your facility’s airflow by dropping a tissue paper in front of an open door. If the tissue blows toward the outside, you have positive airflow. Work with your HVAC professional to

Immediately clean any spills or standing water in or around the facility to eliminate food and moisture sources for flies (left). Installing plastic strips from the top edge of doors will help prevent flies entering storage areas through open entryways (right).

correct the building’s airflow if needed.

Professional air curtains are

• high-speed fans that will push flies out of entryways that remain open for a considerable amount of time.

You can also place fans near loading docks and other high traffic areas to create an air current that flying insects cannot penetrate.

Install plastic strips from the top

• edge of doors, to prevent flies from entering storage areas through these open entryways.

keeps accurate and updated records, including service reports, corrective actions, pest activity reports, trend data, pesticide usage logs, material safety data sheets (MSDS) and floor plans. Keep all

records in a central location for easy access. These documents will help you track your progress and serve as evidence that your IPM program takes steps to prevent and effectively manage infestations.

Remember, it is not enough for you and your pest management provider to implement IPM initiatives. Even the most rigorous program depends on the active co-operation of your staff to be effective. Educate your employees on the specific actions they can take to support your efforts, such as keeping their workspaces clean and notifying you of any sanitation or facility maintenance issues they notice in and around the facility. This will go a long way in preventing fly infestations and upholding a reputation for quality. / BJ

Bill Melville is the quality assurance director for Orkin PCO Services. He has 35 years of experience in the industry and is an acknowledged leader in the field of pest management. For more information, e-mail him at bmelville@pcocanada.com or visit www.orkincanada.com.

Keep windows and doors closed to

• keep flies from gaining entrance to your facility.

Replace all window and door

• screens with No. 16 mesh screens, which prevent even the smallest fly from squeezing through. Install weather stripping around

• doors and windows to prevent flies from entering through small crevices.

Install insect light traps inside

• entrances to storage and baking areas. The ultraviolet light attracts flies to a non-toxic sticky board that your pest management professional can use to keep track of how many and what types of flies have been trapped within your facility.

Detailed documentation is also an important component of an IPM program, not to mention one that auditors scrutinize closely. Make sure your pest management professional

Authentic flavor for your Mediterranean dishes, or a subtle nuance of quality that sets your creation apart— Olive Oil Buds makes it possible.

Our proprietary process unlocks the full, natural flavor in extra-virgin olive oil then encapsulates it in powdered form. The result is a concentrate that delivers plenty of flavor at low usage levels, with just a tiny amount of fat.

Use it in hummus, couscous, paella, marinades, seasonings, pasta and so much more. For everything from Middle East exotic to American mainstay, Olive Oil Buds is the perfect way to give your foods that come-back-for-more flavor. Call for a sample today!

WHAT BEST DESCRIBES YOUR BUSINESS AT YOUR LOCATION?

❏ Bakery (including Delicatessens, Pastry, Donut/Muffin Shop, Supermarket)

❏ Baking Wholesaler

❏ Restaurant, Caterer

❏ Hotel, Resort

❏ Institution, Hospital

❏ Baking Supplier

❏ Other

PAYMENT:

specify

Cheque - Payable to Annex Publishing & Printing Inc

Visa MC Amex Account #: ___________

Expiry: ________________________________

Signature: _____________________________

Date: _________________________________

department, including the plant floor, each of whom brings a unique awareness of a different part of the environment and process. No one knows the manufacturing line as intimately as the people who work with the equipment, day in and day out, and they can point out problems that might never have occurred to others in the company.

In addition, training for everyone is – or should be – a central pillar in a good food safety plan. Everyone, not just the HACCP team, is responsible for the safety and quality of the products they manufacture. This is a team effort, and if anyone drops the ball, everyone can be hurt. The organization must train its people, and the employees themselves must apply that training in their work, helping each other to ensure that the rigorous procedures are carried out at all times. This can mean something as seemingly minor as reminding each other to wash hands thoroughly, or as large as spotting and reporting a problem with a piece of equipment.

The goal of all this hard work is to ensure that consumers can enjoy safe, healthful foods, and can rely on your brand as safe for their

families. Food safety may not be as “sexy” as quality, novelty and convenience, but it is a non-negotiable starting point, as well as a legal and moral duty of everyone in the food industry.

“As food safety stories emerge in other sectors, consumers are becoming more aware of the issue generally, and are demanding more information about the products they buy,” Hetherington says.

The more this trend grows, the greater the opportunity for those who can make unimpeachable food safety an important part of their brand. / BJ

Baking Association of Canada: www. • baking.ca

Canadian Food Inspection Agency • (CFIA): www.inspection.gc.ca, www.inspection.gc.ca/english/fssa/ polstrat/haccp/haccpe.shtml

Guelph Food Technology Centre: www. • gftc.ca

Clíona M. Reeves, MA, is a freelance writer based in southern Ontario who has worked in communications in the food industry for the past 17 years.

The George Weston Bakeries Heart Choice bread products in the New Products section of October’s Bakers Journal are available in the United States, but not Canada, due to CFIA restrictions on phytosterols. George Weston Bakeries is the name of the U.S. company; in Canada it’s known as Weston Bakeries Ltd. Bakers Journal regrets the error.

Organic Oatmeal and Whole Wheat Bread • Loaves: 12 • Dough required: 12 kg

An astute reader pointed out some fuzzy math in our August/September formula. Here is the correct formula. See www.bakersjournal.com for the method.

4N5

e-mail: sbrady@annexweb.com www.bakersjournal.com

GST#867172652RT0001 1208BJ

RICHARD

richardr@kwiklok.com

GRANDE CAROLINE, ROUGEMONT, QUEBEC J0L 1M0

TELEPHONE: (450) 469-2554 FAX: (450) 469-3085 CELL: (450) 531-2002

SHELDON DRIVE, CAMBRIDGE, ONTARIO N1R 7K1

(519) 623-5140 FAX: (519) 623-1421 1-888 KWIK LOK (594-5565)

or 1-519-429-3112

FOR SALE – SOUTHWESTERN ONTARIO Area’s #1 Bakery/Deli operating since 1939 - 7,000 Sq. Ft. retail/production. Retail sales in excess of $700k. Showing excellent profit. Present owner for last 30 years retiring. Transition assistance. Generous long term lease or property purchase including 4 bedroom. Brick Home. Contact John or Mary at 519-688-2023 or email: marapeaz@ hotmail.com

MIDLAND BAKERY FOR SALE – Euro Buns. Well-known Midland Bakery since 1988. Approx. 1,500 retail customers plus over 100 wholesale customers. See website for business background overview. www.brianjacques.cawww.midlandcommercial.ca.

Brian Jacques, Royal LePage In Touch With Reality Brokerage 1-800-850-8095