Annex Business Media P.O. Box 530, Simcoe, Ontario N3Y 4N5 (800) 265-2827 or (519) 429-3966 Fax: (519) 429-3094

EDITOR I Patrick Flannery pflannery@annexbusinessmedia.com (226) 931-0545

ASSOCIATE PUBLISHER I Ed Cosman ecosman@annexbusinessmedia.com (519) 429-5199, (888) 599-2228, ext 276

ACCOUNT COORDINATOR I Barb Comer bcomer@annexbusinessmedia.com (519) 429-5171, (888) 599-2228, ext 210

MEDIA DESIGNER I Emily Sun

CIRCULATION MANAGER I Aashish Sharma asharma@annexbusinessmedia.com 416-442-5600 ext 5206

GROUP PUBLISHER I Martin McAnulty mmcanulty@annexbusinessmedia.com

PRESIDENT & CEO I Mike Fredericks

Publication Mail Agreement #40065710.

Printed in Canada ISSN 0383-7920

email: rthava@annexbusinessmedia.com Tel: 416-442-5600 ext. 3555 Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Subscription Rates Canada- 1 Year $44.00 + tax U.S.A. - 1 Year $77.00

Occasionally, Canadian Rental Service will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com Tel: 800-668-2374

All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request.

Serving the Canadian rental industry for 42 years.

www.canadianrentalservice.com

4

The U.S. administration should listen to its own manufacturers on tariffs.

26 PUSHING PAPERLESS

Electronic Data Logging will soon be mandatory. Here’s what you need to know.

16 PRESIDENT’S MESSAGE

Vermeer shows how having a plan can save lives. by Mike Maltby

6

NEWS

The Rental Show changes its name...United buys BakerCorp...tornado hits Vermeer...

32 POTHOLE-FREE PAVING

After decades of false starts, a revolutionary roller technology may be ready.

30 AT YOUR SERVICE

Stay friendly with customers, even when they leave. by Russ Dantu

18 FAMILY, EXTENDED Trowelex brings the whole community into its orbit.

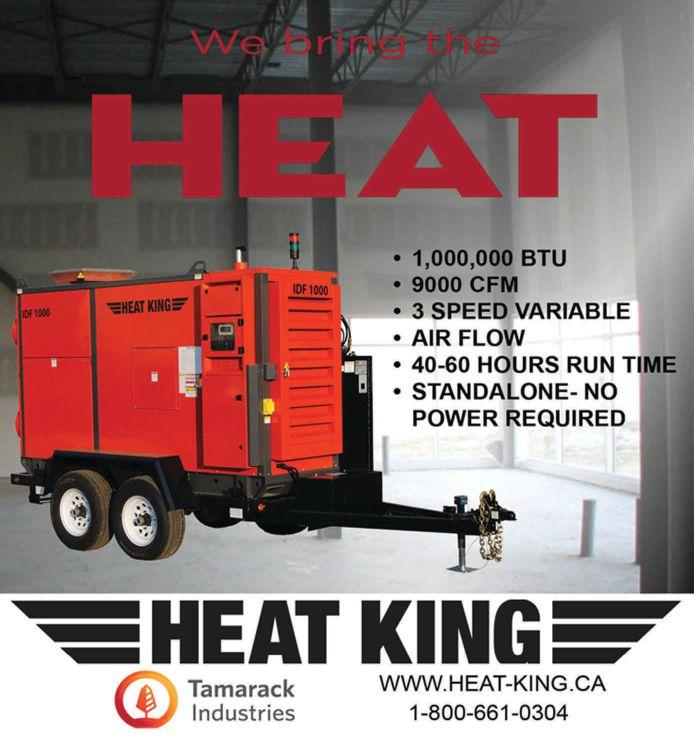

44 CONSTRUCTION HEAT SHOWCASE

Replenish the heart of your fleet with these advanced heat products.

50 SAFETY FIRST AND LAST

Sexual harassment can no longer be ignored. by Jeff Thorne

The Trump administration announced this summer tariffs on around $50 billion worth of imported manufactured goods from China, including such things as compact off-road vehicles, concrete mixers and tractors. So the U.S. Association of Equipment Manufacturers should be thrilled, right? Wrong.

The AEM came out against the tariffs, saying in a June press release that it was “disappointed.” Why should this be, when the measures are ostensibly designed to protect American manufacturers from unfair competition with a trade rival capable of producing comparable equipment for less?

The reason is the AEM, like anyone else who understands trade, realizes that its members stand a lot more to gain from doing business with China than they do to lose. Aside from finished equipment, the tariffs affect a lot of components, tools and instruments that manufacturers use. Even equipment with Made in America proudly stamped on it often contains a lot of parts sourced offshore. Raising the price on those parts means the manufacturer either takes less or asks customers for more –not an appealing choice.

Sure, manufacturers could probably find American parts makers to supply the same things. But they were getting them offshore in the first place because the U.S. suppliers were unable

The @CRSmagazine Twitter feed is a great way to see headlines from around the industry right away without having to check websites and subscribe to email alerts. Follow us today!

Where’s that article?

Remember seeing something in the magazine but can’t find your old print issue? Never fear, Canadian Rental Service content is available online both as a digital edition and in searchable web stories. Just use the search field or browse the magazine covers in our Subscription Centre for instant access to our whole archive.

by Patrick Flannery

to provide them at a competitive price, even considering the costs of shipping and working with people who speak a different language half-way around the world. The tariffs might go some distance toward leveling that playing field, but then manufacturers are still in for a new round of costs as they deal with the disruption of changing suppliers. And who knows how long the tariffs would last under a new administration? The U.S. Senate has already pulled back tariffs imposed by Trump on a broad range of consumer goods.

But the larger concern was China’s reaction, and it was as predicted. It imposed retaliatory tariffs on American exports of similar goods. Now, instead of enjoying equal access to China’s mammoth and growing construction market and dealing with Chinese competition at home, where they have an advantage, U.S. manufacturers only get to play in their home market, which is mature and has very little potential for growth in terms of market share. Whatever opportunities existed to get a foot in the door with huge Chinese contractors (we really can’t conceive of the scale of their industry) has been shelved until the Trumpian trade squall blows over, by which time it may be too late.

What makes Trump’s moves even more mystifying is the impact they are likely to have on global currencies. As demand in the U.S. market for overseas products is constricted, the currency of exporting nations will drop in value. That will have two effects: consumers in those countries will be less able to afford American goods, and the exporting manufacturers will become more competitive as they are able to produce and sell for less while retaining the same margins.

It looks like we might be the next target for tariffs if Trump makes good on his threats and tears up NAFTA. That would be an even bigger blow to AEM’s members, as the U.S. exports more machinery and equipment here than it does to China. Obviously, the cost to all of us who depend on imports of U.S.made equipment for our businesses would be high as well. Here’s hoping the AEM can fight the good fight down there and get its message to penetrate the bad comb-over. CRS

Association of Equipment Manufacturers president Dennis Slater issued the following statement expressing disappointment for the Trump administration’s decision to move forward with tariffs on imported goods from China:

“We’re extremely disappointed with the Trump administration’s decision to move forward with these harmful tariffs. This move jeopardizes many of the 1.3 million good-paying manufacturing jobs our industry supports. The expected retaliatory actions by China also raise costs for equipment manufacturers that rely on a vast supply chain around the world, further eroding the benefits of the recent tax reform. We will continue to fight to end these tariffs immediately.”

The Trump Administration is using authorities provided to it under Section 301 of the Trade Expansions Act of 1974 to place tariffs on goods from China, which includes many different types of construction and agricultural equipment. These tariffs are also being placed on U.S. companies bringing in parts to manufacture equipment using American labour. China has already prepared to respond with countermeasures targeting U.S. products including agricultural commodities. Given depressed U.S. farm incomes, AEM says the move is expected to disproportionately hurt America’s rural economy.

Strongco has announced the appointment of Oliver Nachevski, formerly vice-president of construction equipment, to the position of vice-president and COO.

“Over the past several years, Strongco has undergone significant change in an effort to reposition the business and focus on our core strengths. The creation of the COO role will provide more centralized leadership, with the goal of delivering greater operational excellence during the next phase of stability, sustainability and strategic growth,” said Robert Beutel, executive chairman. “Oliver’s many years of service at Strongco, combined with his demonstrated leadership, make him well suited to propel our operating initiatives across all of the business units. ”

The Pella, Iowa, manufacturing plant of compact equipment manufacturer Vermeer was hit by a tornado on July 18, causing extensive damage and minor injuries. The incident occured as Vermeer was hosting its dealer and customer conference with over 400 attendees in the facility.

Herc Rentals has announced it will expand its Herc Rentals brand across its North American operations. As a result, the company’s main brand in Canada, Hertz Equipment Rental, will immediately begin to transition to Herc Rentals.

As vice-president and COO of Strongco, Nachevski will oversee all operations, including construction equipment, cranes and finance and will play a key part in coordinating and integrating the business for maximum efficiency and reward.

“This is an exciting time for Strongco in terms of the strategic transformation of the company,” said Nachevski. “In collaboration with our strong team, I look forward to the opportunity to drive the business forward.” Nachevski joined Strongco in 1996 and in that time he has made a significant impact on many facets of the business. He has held many titles such as controller of the western division, where he earned a CGA designation in Alberta. In 2004, he accepted a position at head office as assistant controller and national credit manager and later director of national credit and inventory. In 2008, Nachevski became operations manager of the cranes and material handling division and in 2012 was promoted to lead the implementation of Strongco’s new SAP computer system as director of dealer management system implementation. In 2013, he was appointed regional vice-president of Case and in 2016 promoted to vice-president of construction equipment, which centralized leadership for both Strongco’s Case and Multiline/Volvo divisions.

“While it will take some time to fully convert our signage, fleet and showrooms, we are excited to begin the transition to using Herc Rentals as our main brand across our operations in Canada,” said Larry Silber, president and CEO. “We already operated as a unified North American team; now we are pleased to continue working together to serve our customers across North America under the same powerful Herc Rentals brand.”

Hertz started using the Herc name for its equipment rental operations when it spun them off from its car rental business in 2016. Use of the name was initially blocked in Canada by a legal action by Hamilton Equipment Rental Centre, which had been using the HERC acronym previously. An attempt by HERC to prevent Hertz from using the acronym at all was defeated in court later in 2016 on the grounds that Hertz was not using the acronym in Canada. However, HERC is now going by the name Edge1 Equipment Rentals.

INTRODUCING COMPACTION AND CONCRETE FINISHING BY HUSQVARNA

We strive to be your complete source for high quality concrete equipment and diamon tools. That is why we are proud to introduce a full range of Husqvarna compaction and concrete finishing equipment to supply you with the best equipment through the entire process - from ground compaction to a finished concrete surface. Our range of compaction equipment includes rammers, reversible plate compactors, forward plate compactors and drum rollers. Finishing equipment includes concrete vibrators, screeds and trowels. To try them out for yourself, demonstrations are available nationwide. 800-461-9589

Bartell Global is continuing to expand with the addition of Troy Duplisea, who will serve as western Canadian territory sales manager. Bartell Global has always served western Canada from its head office just outside Toronto until this point. With this addition, Bartell plans to continue great success in the region with the on-the-ground support and expert industry knowledge that Duplisea brings to the table. He will handle all construction and surface-preparation lines in this region. Duplisea has hands-on experience placing and finishing concrete as well as coring and cutting. He also has over 14 years experience selling equipment and accessories in the concrete industry. As Duplisea focuses on western Canada, Tim Windsor, Canadian sales director, will direct his attention back to Central and Eastern Canada and, with the Bartell team, continue to support customers.

For the first time in more than 40 years, The American Rental Association has unveiled a new brand identity to reflect the evolution of the equipment and event rental industry. The move is part of an extensive branding initiative designed to carry the association forward in better serving its members and representing a community of equipment and event rental professionals.

“In order to effectively support this ever-changing and growing industry, we knew we needed to modernize our brand and our communications. As more second-, third- and fourth-generation owners get involved and the large national companies expand, it was necessary for us to evaluate the association’s role and determine how we can best support the industry. This is one step toward enhancing our relevance and value to all who are part of this unique rental community,” says Tony Conant, ARA CEO.

In 2017, the ARA board of directors approved the formation of the ARA Brand Committee to guide the association through the rebranding process. Committee members represented all three segments of the equipment and event rental industry. The goal was to create a cohesive family of brand marks that would work and read well in all facets of communications, represent the entire rental industry and speak to the values of our young professionals and future leaders of the association. The rebranding process also led to a new positioning statement for the association, “Advancing the equipment and event rental community.”

“Our previous identity recognized the members who specialize in equipment rental, but it didn’t specifically speak to those in the party and event segment,” says Conant. “Furthermore, the term ‘community’ is an accurate reflection of who we are as rental professionals and how we operate, like a community of helpful, like-minded people”

All facets of the association’s identity were evaluated during the rebranding process. Updates include new logo marks for ARA Insurance, ARA Foundation, Rental Management and the industry’s annual trade show and convention. During the research, it was discovered that the name “The Rental Show” did not have brand equity and that ARA members didn’t feel that the show was closely aligned with the association. Effective with the rebrand, the new name and accompanying logo for the industry’s premier event is The ARA Show.

The new ARA brand mark reflects a modern and approachable look in terms of colour, typeface and design while paying homage to the previous logo. “We’re focused on continuing the development of the association with a brand update that builds on our rich history of being a unique platform where rental professionals can learn, share ideas and give back to our industry,” says Conant.

Tamarack Industries recently purchased the assets of Thawzall. The Thawzall brand will join the other Tamarack brands including Heat King and Heat Assault. A research and development, service and assembly facility will remain in Alexandria, Minn. Many of the key members of the Thawzall team are joining Tamarack to provide continuity to the Thawzall customer base. The company is committed to retaining the design of the Thawzall glycol and flameless product while continuing to enhance its quality and reliability. Tamarack has been producing Heat King ground thawing and space heating equipment for the rental and construction market for over 20 years and has produced over 3,000 units for customers throughout the U.S. and Canada. Thawzall’s flameless product is an excellent fit as it expands into the resource sector with the HK1500 (1.5-million BTU-perhour glycol) and IDF1000 (one-million BTU-per-hour indirect-fired heater). Thawzall has become well-established in the oil and gas industry by earning a reputation for providing superior products and supporting them aggressively. The company welcomes Thawzall’s customers with a commitment to enhance the product offering through continuous improvement and innovation. Contact information remains the same as do many of the names and faces rental stores are used to dealing with.

SNORKEL S3219E | MAX. WORKING HEIGHT 25 FT | ROLL OUT EXTENSION DECK

T he S no rk e l™ S 3 2 1 9 E is f ar f rom ord i nary. T h is 1 9 f t . ( 5 .7 9 m) elec t r i c sla b sc issor l i f t was designed t o t ake every t h i ng a jo b sit e c a n t hro w a t it - and mo re. I t s super-heavy-du t y s t eel cons t ruc tion and over-eng i neered componen t s, max i m i ze up ti me a n d mi nimi ze own ership costs. Plus, everything is easy to get to, which really cuts down on maintenance time. After al l, the most valuable scissor lift on yo ur jobsite is the one that’s actuall y workin g.

Sales Service Parts

United Rentals and BakerCorp International Holdings have announced they have entered into a definitive agreement under which United Rentals will acquire BakerCorp for approximately $715 million in cash. The transaction is expected to close in the third quarter of 2018. BakerCorp is a leading multinational provider of tank, pump, filtration and trench-shoring rental solutions for a broad range of industrial and construction applications. The company has approximately 950 employees serving more than 4,800 customers in North America and Europe. BakerCorp’s operations are primarily concentrated in the United States and Canada, where it has 46 locations, with another 11 locations in France, Germany, the U.K. and the Netherlands. BakerCorp’s 75-plus years in business have created strong, blue-chip customer relationships in the industrial and construction sectors. The combined company will serve a larger strategic account base with a broader fleet range, including approximately 24,000 units to be acquired at closing. The combination is expected to create significant opportunities for revenue growth and customer service through cross-selling, re-rent conversion and scale. The combination of BakerCorp’s comprehensive solutions across fluid storage, transfer and treatment with United Rentals’ Pump Solutions unit will create an enhanced value proposition for customers across the broader fluid solutions space, with market-leading revenue of approximately $606 million. The integration of BakerCorp into United Rentals will give the acquired locations access to United Rentals’ systems and technology, as well as process and data-driven efficiencies. The combined operations are expected to create approximately $19 million in direct cost synergies across corporate overhead and shared services. BakerCorp’s international operations, which accounted for approximately 15 per cent of total revenue last year, provide an attractive entry into select European markets for the rental of fluid solutions. United Rentals and BakerCorp say they share many cultural attributes, including exemplary safety records, highly engaged employees, deep industry expertise and a commitment to help customers succeed through cost-efficient, productive solutions.

Michael Kneeland, CEO of United Rentals, said, “We’re very pleased to announce an agreement to acquire BakerCorp, an expert in fluid solutions and a highly regarded, customer-focused operation. We’re gaining a terrific team that shares our strong commitment to safety and customer service, and operations that complement our North American pump and trench offerings. This transaction will also be our company’s first experience in Europe, where BakerCorp has established an attractive, fast-growing business with significant future opportunity.”

Bob Craycraft, president and CEO of BakerCorp, said, “I’m extremely proud of what our team has built. The value we’ve delivered for our customers has created this new opportunity to be part of the largest equipment rental company in the world. The combination with United Rentals is an exciting development for the future of both our customers and employees.”

Ritchie Bros. Auctioneers has announced that Greg Owens, group president of new sectors and ventures and former CEO of IronPlanet, has resigned from the business to pursue other opportunities.

“I am very proud to have been a part of the team and helping to build such a strong company”, said Owens. “Ritchie Bros. has successfully integrated IronPlanet into the business and has clearly demonstrated that they are the industry leader in both on-site and online marketplaces.”

“I want to thank Greg for his leadership in helping me bring Ritchie Bros. and IronPlanet together and in agreeing to stay on with the combined company through the past 12 months to ensure a successful integration,” commented Ravi Saligram, CEO. “I wish Greg all the best in his future endeavours.”

Steve Ferguson has been named president of Perkins Engines based in Peterborough, U.K. His appointment was announced by Ramin Younessi, who had been Perkins president since 2013 and is now promoted to group president of Caterpillar’s energy and transportation segment.

“Steve has been delivering great results by driving lean and flexible cost-competitive component manufacturing operations at Caterpillar facilities around the world,” Younessi said. “Combined with his business and finance background, his focus on safety and quality, and his ability to connect with customers, Steve will provide exemplary leadership for this exciting and diverse group.”

In addition to his role as Perkins president, Ferguson will lead the Caterpillar industrial power systems division (IPSD), which consists of design, development and sales of all engines (18 litres and below), retail generators and Caterpillar defense spanning the three globally recognized brands of Cat, Perkins and FG Wilson. Most recently, Ferguson was general manager of Caterpillar’s advanced component manufacturing business, overseeing operations at 15 global facilities. He began his career with Caterpillar as an accountant in 1990 and held positions of increasing responsibility in both machine and engine divisions including roles in pricing, business planning, financial analysis, and business resource segments. He holds a bachelor’s degree from Eastern Illinois University and is a graduate of the advanced executive program at Northwestern University’s Kellogg School of Management. Ferguson will report to Younessi. Younessi joined Caterpillar in 2013 to lead IPSD, bringing more than 25 years of outside senior leadership experience. Previous executive responsibility included product development, quality, purchasing and product planning with Navistar, as well as product development and planning for Daimler AG’s commercial vehicle division.

It’s that time of the year, when daylight starts to fade before the work day ends. Don’t leave your customers in the dark.

Generac Mobile Products offers light towers for every application – glare-free lighting for road work, extended run-time towers for remote applications, as well as LED and metal halide options to t any budget.

Whatever the job, count on Generac Mobile Products for reliable and dependable light towers.

CONTACT

Finning Canada opened the doors of its first used equipment centre in Acheson, Alta., just outside Edmonton, on June 15.

“We are so excited to be able to use this facility to provide customers with a one-stop-shop for everything in used equipment,” said Darren Riley, general manger of Alberta core industries. “This consolidation of our used equipment in one central Alberta location makes it easy for our customers to access a broad range of quality used equipment from skid steers to motor graders and see it demonstrated it all in one spot.”

The facility offers access to every piece of used equipment in Finning’s Alberta inventory, prepped and ready to go, plus a dedicated demonstration area where customers can test the equipment in a controlled environment. This retail outlet also offers new equipment and attachments, an on-site simulator and will be utilized as a training centre and site for demonstrating new products and technologies.

Atlas Copco Power Technique has announced Mikael Andersson has been appointed general manager of its North American customer centre. Andersson will lead the company in growing each of its core product categories — air, power and flow — within the contractor, dealer and rental segments across the U.S. and Canada.

“Mikael’s keen leadership, analytical input and broad experience make him an excellent leader for Power Technique North America,” said Andrew Walker, senior executive vice-president and business area president for Power Technique in Antwerp, Belgium.

Andersson brings a wealth of industry and institutional knowledge to his new role. Most recently, Andersson was vice-president of business control for Atlas Copco Compressors U.S., a role he held since 2009. During this time, he significantly upgraded the business control environment in the U.S. customer centre and made important contributions in many other areas including strategy, business development, acquisitions and business intelligence.

“I am looking forward to joining the professional team in the Power Technique customer centre,” Andersson said. “We will continue to work hard to achieve our vision and be the first-in-mind, first-in-choice provider of on-site air, power and flow solutions for the sustainable productivity of our business partners.”

Andersson joined Atlas Copco in 2002 as a production controller for Atlas Copco Rock Drills AB. He holds a bachelor of science in business and economics from Orebro University in Sweden and a bachelor of science in transport management from Gothenburg University in Sweden. Andersson will be based in Rock Hill, S.C.

Wacker Neuson offers heat solutions for any job size during cold weather applications. Increase your winter rentals with hydronic surface heaters for thawing and curing applications, indirectfired heaters for extreme weather conditions, flameless technology for potentially hazardous environments and radiant heaters for concentrated heat. Wacker Neuson has all it takes to improve your bottom line this winter.

Takeuchi-US has introduced Todd Granger as director of dealer sales. Based out of Takeuchi-US headquarters in Pendergrass, Ga., Granger will be responsible for all sales activity through the company’s North American dealer sales channel. Granger brings over 10 years of rental and construction industry experience to the position, including prior employment with Takeuchi as a regional business manager.

“I am excited to be back at Takeuchi among many colleagues I have known and have great respect for,” Granger said. “As evidenced by the company’s growth over the last few years, Takeuchi is thriving and I am looking forward to being a part of this growth and working with a strong dealer network.”

Most recently, Granger served as the vice-president at APT, an Atlas Copco company, where he oversaw sales, marketing and customer service functions. Granger has a business administration degree from the University of North Georgia.

“Todd will be a huge part of continuing our investment and focusing on growing our dealer sales,” said Clay Eubanks, president at Takeuchi-US. “We are very excited to have him back with us. Not only does Todd have the necessary experience to do well in this role, but his previous time here should make for a seamless transition.”

The move comes after former director of dealer sales, Kim Robinson, was appointed to a newly created position at Takeuchi as director of dealer development.

The National Heavy Equipment Show is getting ready for another edition, with dates being announced for March 28 and 29 at the International Centre in Mississauga, Ont. Coming on the heels of its 20th anniversary in 2017, the biennial event features cutting-edge products and big machine displays from the leaders of the heavy equipment and construction industries.

“Planning for our 2019 edition is already well underway,” said Mark Cusack, national show manager. “We saw over 13,000 attendees in 2017 and we anticipate the upcoming show to attract an even bigger and more diverse crowd. With the current focus on major infrastructure projects across the country, we expect buyers to be out in full force with those projects top of mind.”

Attendees and exhibitors can look forward to the following features in 2019:

• Rock To Road magazine’s “Top 10 under 40”

• Winter management products, services, equipment, and technology for snow and ice removal

• The Gravel Pit: A large display of working aggregate machinery

• The Rental Pavilion: Equipment, tools, and products for contractors and road-building professionals

• Safety products for employee safety and worksite security

• The “Recruiting Here” program connecting job seekers with hiring companies

The 2019 show website is now live at nhes.ca.

The Toro Company has announced a new partnership with Kinetic GPO, a cooperative purchasing organization established for public sector and MASH (municipalities, academics, school boards, health and social services) entities across Canada. The partnership will remain in effect until May 23, 2021, with an option to extend the term for an additional period of up to two years. The contract provides exclusive pricing and access to Toro groundskeeping equipment to public entities in Canada and helps these organizations reduce procurement costs by leveraging group purchasing power and simplifying the overall procurement process. Included in the portfolio of products available under the contract are Toro’s line of commercial mowers, snow blowers and utility vehicles, among other product lines across Toro’s commercial, residential and landscape contractor and sitework systems businesses.

“Kinetic is pleased to partner with Toro on this contract to streamline groundskeeping equipment procurement processes for our members,” said Chris Penny, CEO of Kinetic GPO. “Our evaluation team, which consists of several former procurement officials, stated that Toro’s response was as robust as any that they have ever seen. Public sector MASH entities and non-profits are able to leverage their spend while receiving the high levels of quality and customer service that Toro and their distributors are known for.”

Group purchasing organizations are widely used in Canada, especially in the medical health and education sectors. Kinetic says it is advancing the purchasing power of entities across Canada by taking what has worked, expanding on those strategies and offering a portfolio to a full range of public sector and MASH entities.

“We believe that this newfound partnership with Kinetic GPO will open up a number of opportunities in Canada,” said Richard M. Olson, chairman and CEO of Toro.

The “next level of aeration productivity” for the ultimate in ROI this fall!

• Intuitive hydro-drive controls with variable speed self-propelled rear wheel drive & front casters allow feathering speed with fingertip control.

• Variable hole density (VAD™) from 8 to 45 holes per sq. ft. in a single pass

• Produces 45 holes/sq. ft. for patch repair and overseeding at .5 mph

• Patent pending EZ Lift N Drop™ tine system for uninterrupted aerating

• Patent pending EZ Lift™ rear foot pedal lifts and locks tines for transport or reversing

• In-Ground steering for ease of operation and unmatched maneuverability

• No-tool flip-up hoods for easy access to inside of machine and belt service access

• Water weight tank positioned over tines for better tine depth and wheel traction in drier conditions

• Reciprocating action drives plugs up to 2x the depth of drum models and aerates in wet or dry conditions

Vermeer shows how having a plan can save lives and your business.

by MIKE MALTBY

On July 19 the Canadian Rental Association executive committee was in Moline, Ill., at the American Rental Association office meeting with the ARA board of directors and staff in order to provide a Canadian perspective into the development of the latest iteration of the ARA strategic plan. While we were meeting a Category F3 tornado made a direct hit on the Vermeer manufacturing facility in Pella, Iowa. Having a facility struck by a tornado is horrific enough, but Vermeer was in the middle of its 2018 customer conference and had more than 400 customers and dealers on site at the time.

According to Jason Andringa, CEO of Vermeer, once they were alerted of severe weather the company quickly activated its emergency response system. Alarms were sounded in all buildings. Customers, dealers and employees were directed to tornado shelters inside each of the company’s facilities on the Vermeer campus. Despite the extensive damage that Vermeer’s property and buildings received, the people escaped mostly unscathed. Of the hundreds of employees, dealers, and customers on site when the tornado struck, seven received what were described as minor injuries and all were released the same day.

Despite your best efforts to avoid them, disasters and other types of emergencies can and do occur. Your best strategy for avoiding or reducing disaster-related losses and liabilities is to develop a thorough emergency plan that addresses both emergency preparation and disaster-response activities that protects your assets and limits your risk. Because Vermeer had taken the time to develop a plan for dealing with a disaster they were able to quickly put their planning into action when it was needed. Within minutes they were able to usher their customers, dealers and employees to safety and prevent a disaster from turning into a tragedy.

According to the U.S. Federal Emergency Management Agency, more than 40 per cent of businesses never reopen after a disaster and of those that do only 29 per cent were still operating after two years. One week after the tornado struck, Vermeer was rebuilding and more than 70 per cent of its workforce was back on the job. Is your business prepared for an emergency or disaster?

Did you know that your association has an emergency/disaster preparedness guide to help you begin planning for an event like a tornado or other disaster? Remember that disasters are not always weather-related.

• What would happen if you lost all your business data?

• What if most of your staff was sick at the same time?

• What if your access road is closed?

• What if your telecommunication network failed?

• What if your natural gas or water stops flowing?

• What if you are taken hostage?

Emergency planning can be as broad or as detailed as you see fit. How differently would July 19 have turned out for Vermeer if it’s leadership hadn’t taken the time and devoted the resources to not only planning but practicing it’s emergency response. CRS

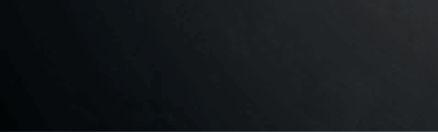

During the busy season, it is often difficult to stop and ensure all precautions are taken to avoid theft. Canadian Rental Association would like to remind you of a few housekeeping items that can save you time, money and headaches. In order to protect your business, we encourage you to use and share the helpful tips below provided by the CRA Insurance program.

1. Heavy Gauge Chain Link Fencing

At least 7 feet high, topped with barbed wire or razor wire (check with local authorities for restrictions).

2. Drive Through Barriers

Concrete barriers (2 - 3 ft. high, lane dividers or large blocks) installed along the inside of the fence will prevent equipment from being removed through, or over the fence.

3. High-Security Locks on All Gates

Install at least two high-security padlocks with protected shackles or enclosed steel boxes.

4. Siren and Strobe Light

An outside siren and a strobe light connected to the alarm system and mounted on top of the building.

5. Burglar Alarms

Should be installed in the yard or on the fence with contacts mounted on the gates.

6. Alarming Equipment in the Yard

Use alarmed cables (extension cord type) which run through the units at night and plug into alarm outlets on the building.

7. Yard Lighting

Should be tamper/vandal proof, activated by motion detectors.

1. Always request to see photo ID

Check that renter matches the photo on the ID and make a copy. Check that signature on rental contract matches the one on the ID

2. Ask for a second piece of ID from first-time renters

3. Record vehicle information for walk-in renters

Make, model, colour, license plate number and company name/ logos if applicable

4. Double check phone orders by calling back prior to delivering the equipment

Confirm orders with a known contact person. Get name of person that will receive at job site.

5. Do NOT leave equipment unattended at a job site

Deliver it to an employee of the renter and get his / her signature and ID. If not sure – double check with office or do not leave equipment.

6. Pick up equipment as soon as possible after renter is finished

7. Make sure renters know they are responsible for equipment until it is returned or picked up

by ROGER KNOX

You won’t find homemade french fries among the items for rent or sale at Trowelex Rentals and Sales, located in Castlegar in B.C.’s West Kootenays, 600 kilometres east of Vancouver and 600 kilometres west of Calgary.

But, like the portable toilets, man-lifts, pumps and work clothing they do rent and sell, the fries would be a top item among the public, as demonstrated at a recent open house the company held to celebrate its 50th year of operation – its way of saying thank you to the community for its support.

“We had burgers and homemade fries. The fries were a big hit,” said current Trowelex owner, Harold Chernoff, 51, son of late company founder Nick Chernoff. “The open house was excellent. We saw a lot of people we haven’t seen in a long time. It wasn’t a sales pitch. No sales pitches, no nothing. We just wanted to do this as Trowelex to say thank you to the community.”

Born in Saskatchewan but growing up in Appledale, about 40 minutes north of Castlegar, Nick Chernoff decided at an early age school wasn’t for him.

Real early.

He dropped out after grade two, never returning to any classroom. A lifelong stutterer, Chernoff also survived a nearly three-year stint in a Shriner’s Hospital in Spokane, Wash., the result of a nasty dog bite that prevented his leg from growing.

He turned to concrete, working as a foreman for companies in his late teens through early 20s. He married Vera, a young woman from the neighbouring community of Glade, and the Chernoffs had four children: Kevin, Nick Jr., and twins Harold and Shelly.

In 1968, Chernoff decided to branch out on his own. With a concrete trowel in mind, Chernoff wanted to call his fledgling company

Trowel Concrete Contractors. He applied to register the name with the provincial government in Victoria. The government told Chernoff, sorry, that’s too broad of a name. “Maybe put an E-X behind it.”

“Dad said, ‘OK, let’s do it,’” laughed Harold. “Trowelex Concrete Contractors is the legal name, and we’re doing business as Trowelex Rentals.”

With very little money, Chernoff bought a small building on Columbia Avenue in Castlegar then added a small trailer for an office. Today’s Trowelex building was constructed a few years later on the same piece of property. The building has been expanded about eight times.

“He cheaped out where he could,” said Harold. “The floor was only poured with twoby-four thickness to save money. And, 50 years later, there still is not a crack in it.”

Chernoff was selling things like compactors and snowmobiles. The fact he always had his own equipment was the main reason he got into the rental business. “People would ask to borrow his equipment overnight, or real quick – like a wheelbarrow or power trowel,” said Harold. “He would do it but would say he needed it back for his own work. One time, somebody forgot to return a piece of equipment they borrowed before Dad had to go work at 5:30 or 6 the next morning. He then said, ‘People have to pay from now on to borrow stuff.’”

Since that time Chernoff kept his company in the family and grew it into a business with a stellar reputation. Trowelex is Castlegar’s official Honda marine and power equipment

dealer, along with being the city’s full-service Bobcat dealer. Trowelex rents portable toilets, pumps, material handling, man-lifts, portable power and heating, cooling and ventilation. It also rents out properties it owns. Inside the shop, Trowelex sells pre-cast products, protection systems, grout, safety clothing and gear, first aid equipment, personal protective equipment and tarps as just part of a lengthy list.

Trowelex does businesses with companies to Creston in the east; Rock Creek-Midway, B.C., to the west; Revelstoke to the north and beyond. They have supplied and serviced a mine site in Tuktoyaktuk in the Northwest

Territories; supplied materials and services to sites in Quebec and Ontario and shipped supplies as far south as Brazil. “We have supplied specialty tooling and materials for Voith Hydro to facilitate building runners (turbines) used in hydroelectric work,” said Trowelex general manager, Rob Planiden, 52, who is in his 30th year with the company. “Far and wide, locally, provincially, nationally, internationally, we have a great reputation.”

Trowelex’s main customer, for more than 40 years, is 22 minutes down Highway 22 in Trail, B.C.: Teck Resources, formerly known as Teck Cominco. “We supply Teck all of their

rental needs, as well as to all the contractors that come on to their site,” said Planiden.

The company used to operate stores in Nelson, 45 minutes northeast of Castlegar, and in Campbell River, on B.C.’s Vancouver Island, but found it was hard for an independent company to have multiple stores. Personnel and good management people were needed to run things properly and the Chernoff family found it tough. So they focused on Castlegar, where the city has been the benefactor of Trowelex’s generosity for decades.

In 2017, the company donated more than $35,000 in cash and in-kind donations

to many community events and projects. They are the exclusive supplier and main title sponsor of the Kootenay Country Music Festival. They have sponsored works of art along the city’s Castlegar Sculpture Walk. They sponsor a hockey player on Castlegar’s Selkirk College Saints hockey team. Trowelex longtime employee, Jean Bonin, has a three-page list of all the events and organizations Trowelex donates to, something that was very important to Nick. “Nick started it because he was in Rotary,” says Harold. “It’s all aspects of the community we donate to and deal with. We do a lot with grad (Stanley Humphries Secondary School), Communities in Bloom, the city. We are probably one of the first places people come to in the first place because we can help out. It’s really important for us to be community-oriented.”

Community-oriented, yes. Trowelex is also family-oriented. Ask Bonin and Planiden, the longest-serving of the 11 full-time staff, combining for 78 years of

service with Trowelex. Bonin has been with the company for 48 years, hired from a Redi-Mix firm in Trail by Nick Chernoff. Her office, on this day, is laden with paper as she prepares a tax audit. Her office door is a sheet of plastic,

placed by workers after a break-in at the store a couple years ago. Bonin discovered the plastic helped keep the heat in the office and she has warned that anybody thinking of replacing the plastic with an actual door will be “thrown out of here.” She is lovingly referred to by all employees as “Mom,” because, as she points out, she’s old enough to be everybody’s mother. She eschews job titles. “It’s like any business. I do what’s necessary,” said Bonin. “We are a family outfit, basically. The employees are like family members.” She tells the stories of two former employees, both of whom started as high school students after school cleaning out the shop. On Saturdays, they would learn how to run the equipment. One became so adept at operating a Bobcat he performed Bobcat square dancing in a local Castlegar festival. That student, on reference from Trowelex, applied for a job with the city of Castlegar and is still working there today.

The other student, said Bonin, went

to university but would return home at the end of April and pop into the shop to see if his summer job was still available. He would work until Labour Day, then return to university. Several years prior to his death, Nick Chernoff underwent knee replacement surgery in Kelowna, in B.C.’s Okanagan region. A doctor at the hospital visited Nick after seeing Chernoff’s name on the list of surgeries. It was the student. “He went to medical school and stopped in to thank Nick for all the support and for basically putting him through medical school,” said Bonin.

Planiden, too, speaks highly of Chernoff. In 1988, Planiden, then 22, was working as a forest-fire fighter and heard through the grapevine that Trowelex was looking for a Class Three driver. He phoned Chernoff at his home on a Sunday. Chernoff and his son, Kevin, were in the midst of packaging up a mattress for Shelly’s move to Calgary when Chernoff told Planiden to come to his home for an interview. “They were having trouble packaging the mattress. I jumped in, assisted, and Nick said I start tomorrow,” said Planiden, who estimates he’s only missed two days of work in 30 years, such is his love for the job and the pride he feels in Trowelex. He loves going to work every day. Sometimes, after helping out a customer with a middleof-the-night emergency, Planiden will grab a few hours sleep at the shop then start another work day. “There’s never a day that’s the same,” says Planiden. “There’s never a day that a customer doesn’t come in with a problem, asking for advice.

Nick taught me when I started here one of the most important things I’m going to find out is I’m going to learn something new every day. Once I stop learning something new every day,

it’s time to move on. And I’m still learning something new every day.” Planiden has done almost every job at Trowelex. He was thrown into the general manager position on May 27, 2016, when then-general manager Kevin Chernoff –also a city councillor in Castlegar – died suddenly. His death came 10 months after Nick Sr. died of a heart attack while getting a haircut. Two years earlier, Nick Jr. had died of medical complications.

With Shelly working for the Calgary city police, that left Harold to run the company. He is grooming his son, Cole, 19, to take over. Like his father, Cole started working for Trowelex when he was 12. “I swept the floors, did all of my grandfather’s dirty jobs,” laughed Cole, halfway to a business degree from Selkirk College. “I learned everything from my grandfather and I’m learning every day from my dad. He teaches me every day, saying ‘Let’s do this together,’ or, ‘I’ll show you how to do this.’” Cole sees Trowelex being around another 50 years, with him running it in 2068. He’s

got big dreams for the company, he says, dreams that are currently in the ideas stage.

His father agrees that Trowelex will still be serving customers a half-century from now. “We have it down pretty good, our system here, how we do our rentals,

deal with our customers,” said Harold. “We’re very diversified.” CRS

For more industry profiles, visit canadianrentalservice.com > Profiles

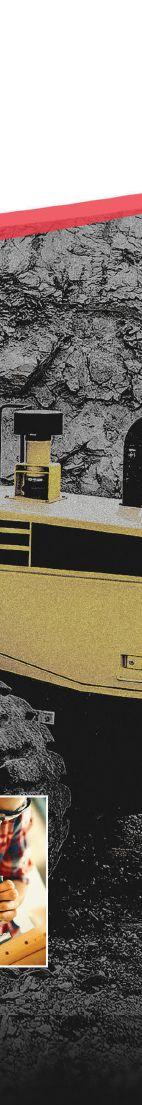

It has been almost a full year since the U.S. implemented its electronic logging device (ELD) and hours of service (HOS) mandate and now the Canadian Council of Motor Transport Administrators (CCMTA) plans to roll out a similar mandate.

by PAUL MILES segment manager, Trimble Field Service Management

RIGHT: Everyone hates forced change, but the mandate for electronic logging devices in trucks is likely to benefit drivers and owners in the long run.

On Dec. 18 of last year the United States Department of Transportation’s Federal Motor Carrier Safety Administration (FMCSA) instituted a mandate that requires motor carriers and drivers to retain supporting documents to verify their driving hours. But the biggest change the rule instituted is requiring drivers track their hours of service using an electronic logging device.

First, it’s important to know that the ELD mandate includes a number of provisions intended to help reduce crashes and bring everyone home safe at the end of a shift. The Canadian government also realizes that in order to support trade between the U.S. and Canada, it

must take action.

The ELD mandate establishes the following:

• Replacement of paper logs with a compliant ELD

• A rule for the mandatory use of ELD by drivers that requires preparing HOS as a part of records of duty status

• Standardized measures to address errors, logbook tampering and driver harassment

• Requirements concerning HOS supporting documents

ELDs sync with a truck’s on-board systems to capture additional data points such as power status, motion status, miles driven and engine hours to demonstrate compliance. Under the mandate, all of this information should be

available to authorized safety officials during roadside inspections and as part of on-site or other reviews.

To accommodate the time required for carriers and other affected parties to implement the technology and train staff, the Canadian government has considered a two-year, phased-in compliance period. The Canadian ELD rule compliance deadline is 2020, when ELDs meeting National Safety Code technical standard become mandatory. The extended compliance date is 2022 for those already using ELD

At this point, it is unclear whether Canada will provide an additional grace period for rental and leasing companies. In the U.S., the Truck Renting and Leasing Association (TRALA) worked with the FMCSA to provide a 90-day waiver for short-term rentals, allowing companies to use paper logs to record HOS if the rental time frame is 30 days or less. Rental vehicle operators were required to print and carry the federal

register in their vehicle at all times.

There are many benefits to drivers and rental companies implementing an ELD solution beyond merely being compliant. Transport Canada estimates the combined savings to be $255.4 million, annualized at $36.4 million. The cost savings and benefits are expected to come from a few different areas. One is benefit to the driver. Many drivers are used to relying on memory when filling out logs. With ELD, drivers no longer need to worry about recording their drive times – the ELD does this automatically for them. The ELD also gives the driver a clear display indicating how long they have been driving, how many hours of drive time they have left and when they need to take a break. This information is calculated automatically by the ELD and eliminates the need for drivers to spend time making calculations and verifying hours driven.

Another positive benefit is improvement to efficiency. With ELD, fleet supervisors and managers receive the logs of their drivers in real time and

no longer have to wait for drivers to return from trips to hand them in. This information is stored in a database and the data can be used to monitor trends

At the core of General's drain cleaning machines is our Flexicore cable. Your customers count on it to get the drain open. You count on it to stand up to the most abusive customers. And you count on it to keep your maintenance costs down and your profits up. There really is a big difference in cables – Flexicore is the best!

across the entire fleet even at different locations. ELD data is also useful in the event of an audit. Federal regulations require carriers to retain at least six months of logs for all drivers in the organization. ELD makes this easy and hassle-free.

Transport Canada expects to see fleet costs lowered by ELD because ELD helps to keep drivers safe and reduce costly incidents. Driver behavior can be monitored and drivers can be encouraged to support good habits that help to increase fuel efficiency, reduce idling time and improve overall utilization of the vehicle. It has been found that electronic logging devices can reduce traffic violations by as much as 35 per cent. In addition, ELD can save as much as 40 minutes per day for each driver, which can result in thousands of dollars per year in reduced costs.

Because of the need for reliability and ease of use, dedicated hardware

integrated with a fleet management system is the most common type of solution available today. The hardware is installed in the cab of the truck and includes a tablet for displaying hours of service information to the driver, including the number of hours driven, the on-duty hours recorded and the remaining available hours. In addition, the tablet is connected via a wired or wireless connection to a telematics device in the truck, which is connected to the on-board vehicle systems.

When compared to a personal mobile device-based ELD solution, a dedicated hardware solution is more reliable, more rugged and is not reliant on a driver’s mobile device for communication. Data transmitted to the back office allows fleet managers, safety managers and dispatchers to review HOS information in near-real-time. When the vehicle is not in operation, dedicated solutions still provide drivers with flexibility and allow for extended productivity. Drivers may take the tablet outside the cab to

perform walk-around vehicle inspections and complete proof-of-delivery forms.

Transitioning your company from manual to electronic logging systems means more than simply changing or implementing the hardware and software. The change will affect most aspects of your company, including the culture. For this reason, leadership must establish a clear vision with a transparent implementation plan. Whether the plan unfolds all at once or is implemented in stages, it is essential that all involved parties are continually updated and informed of the process. Your ELD supplier should be able to provide advice as to how to achieve a successful rollout, and provide the necessary training and ongoing support. CRS

Paul Miles is a segment manager with Trimble Field Service Management division. He can be reached at Paul_Miles@Trimble.com.

n Heavy gauge wire coiled tightly around 49-strand aircraft type wire rope

n Kink-resistant

n Unequaled strength with the right amount of flexibility

n Low maintenance

n So tough, it's backed by the best warranty in the business

For more information, call the Drain Brains ® at General at 800-245-6200, or visit www.drainbrain.com/rentall

by Russ Dantu

Stay friendly with customers, even after they leave.

Ihave two businesses. As you already know, I’m a professional speaker. But I also run a company called Syner G Apparel and Solutions. I help customers differentiate themselves from their competitors through the use of promotional products and corporate apparel. We brand these items with logos and information to give to their customers, potential customers and staff.

With the economic downturn in Alberta the past few years, some of my customers have had to cut back and the first thing to go is discretionary spending...like the items mentioned above. I always keep in touch with my customers through email, phone calls and an in-person visit if I am in the area. For one customer, in particular, I always got the same answer: “Sorry Russ. It’s really slow right now and we have to be careful with what we spend. We will definitely call you if we need anything.” They were a smaller customer, but every customer is important, regardless of the amount they purchase. It all helps contribute to the bottom line. It had been a year since I had received an order from this customer so I decided to drop by and say hello. Susan was very honest with me.

“Russ, we had a guy come in here a few months ago with an unbelievable sale on some shirts. We had no choice but to buy them from him,” she told me.

“Susan, you always have a choice. I wish you would have called me as I’m sure I could have done something for you. How did it work out?” I asked.

“Well, it seemed like an amazing deal at the time and we did get the shirts eventually, but once the guy saw the size of our order he really wasn’t interested in dealing with us. It took a long time and the communication was poor,” she answered.

“I’m sorry to hear that, Susan. Well, not super sorry, as I’d love to have you back as a customer.”

“Russ, we learned our lesson. You’ve always

taken good care of us when we needed something. We won’t go anywhere else again. You’re our guy!”

This customer had been a customer of mine for about six years. They didn’t spend a lot each year but I really liked them and you never know what they will do down the road or who they will introduce you to. I have had two great referrals from them to customers who have been using me for about five years now. It hurt to think that they went somewhere else but I appreciated her honesty.

A few things come to mind with this situation above.

1. Always keep in touch with your customers. Use the touch points they appreciate you using. Don’t keep phoning them if they prefer to be reached by email, but if you don’t get a reply, a quick call is all right.

2. Don’t take it personally. Don Miguel Ruiz wrote The Four Agreements and one of those agreements was to not take it personally. People are free to work with whomever they like. It doesn’t mean they don’t like you or you have done something wrong. All you can do is be there to help them and keep in contact with them. The more you do for your customers, the better chance you will have of keeping them as a customer.

3. When times are tough, people may not be able to buy what they will usually buy from you. Find ways to make what you sell more affordable or see if you can offer them more economical options so they continue to use your services. CRS

Russ Dantu is a 30-year veteran of the rental industry and has been delivering workshops, seminars and keynotes on customer service for over 15 years. For more information, visit russdantu.com or email russ@russdantu.com.

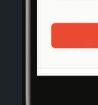

ELEVATE gets rid of unnecessary manual processes, inaccurate information, piles of paper, unruly spreadsheets, and reading hour meters. If it’s not making it easier, it’s not doing anything.

Speed up service calls, remotely diagnose user issues, and decrease the cost of providing exceptional customer service. Learn more at skyjack.com/elevate.

Since the construction of the first roads, potholes have plagued road infrastructure around the world and people have been trying to find ways to make them disappear.

by ANDREW SNOOK

RIGHT: Developing the new paver has been a team effort. From left, Trevor Smith, asphalt foreman, Dr. A.O. Abd El Halim, and Russ Perry, vice-president of Tomlinson Group’s Heavy Civil division for Tomlinson Group.

So when I first heard about a revolutionary compaction technology designed by Carleton University’s director of the Infrastructure Protection and International Security Master’s Program, Dr. A.O. Abd El Halim (“Halim” to his friends and colleagues), I was extremely excited to meet the man and his technology.

I drove to the Ottawa area to meet the man behind the technology at a pub in Gloucester, Ont. Shortly after I arrived and we exchanged pleasantries, a waitress came to take our order.

Halim asked her for two raw eggs in a dish – a strange lunch order, I thought. He quickly explained that the eggs were not for eating, but for an experiment that required my participation. When the eggs arrived, Halim asked me to take a butter knife and begin tapping the top

of the egg gently inside the dish. I tapped the egg until cracks began to form at the top.

Halim then handed me the second egg and asked me tap it gently in the same spot as the first one, but this time with my fingertip. I tapped several times and nothing happened. He then asked me to tap harder, so I did. Nothing happened. He asked me to tap it harder a third time, at which point the egg slipped loose from my other hand, bounced off Halim (as I watched in horror), then fell to the floor and broke.

“I’m so sorry,” I said to both Halim and the waitress that came by to clean the mess.

“That’s all right,” Halim replied. “Did you see how the egg cracked when the metal tapped it? And how it didn’t crack with your finger? This

is basically how my technology works.”

Back in the mid-1980’s, Halim invented a rubber-belted asphalt compactor that was designed to compact without leaving the small cracks in the roads that were being left by some traditional steel and rubber rollers. The idea behind the technology was that the softer, rubber-belted compactor could sit on a section of asphalt for a longer duration of time while exerting lower pressure than traditional rollers, and this would allow for longer continuous contact with the asphalt that would produce crack-free asphalt pavement during the compaction process. He named his compactor “AMIR” after his son.

The first version of the paver (AMIR) was a non-motorized, single-belt system. It was developed and field-tested in Egypt in the mid-80s through financial assistance from the Canadian and Egyptian governments. The Egyptian AMIR motivated National Research Council Canada (NRC) and Torontobased Lovat Tunnel Equipment Inc. to join Carleton University and Halim to build the first motorized version: AMIR I. Approximately a dozen field tests were performed on the machine, compacting layers of sand as well as asphalt layers. Newspapers and magazines around the world showcased his technology through the mid-80s and into the 1990s, calling it revolutionary to the industry. Halim tried to get it licensed and manufactured by several OEMs, but contract negotiations were unsuccessful.

Olympic Village and continued to use it for several years,” Halim says.

Despite successful field tests over the years in Egypt, Australia and Canada, negotiations continued to be unsuccessful with various OEMs to try and get the compactor manufactured. After decades of hard work on the technology

project on hold and placed the AMIR I compactor in storage and focused on his other research and work as a professor at Carleton University.

The AMIR-I compactor sat collecting dust until Halim received a surprise

AS A WORLD LEADER OF SUBMERSIBLE PUMPS, TSURUMI OUTLASTS THE COMPETITION IN PUMP LIFE, PRODUCT OFFERING AND COST SAVINGS.

But in 1996 an Australian contractor named Pioneer Road Services decided to have Halim’s compactor shipped to them for further development. The company invested approximately $750,000 into the technology, and developed a dual-belted version of the compactor. This version of the machine was 1.6 metres wide and 12.5 metres long and weighed 16 tonnes. This version would come to be known as the HIPAC compactor – the second generation of AMIR. The company was planning on using the technology during the construction of roads for the 2000 Summer Olympics.

“They used it to construct a road leading from the Sydney airport to the

“I got a call in Quebec City from a friend that said, ‘The MTO (Ministry of Transportation of Ontario) needs your roller, can you present about it?’” Halim recalls. “I went to Kingston and gave a presentation. It took two years but the MTO were very kind. They gave me budget. I had a chance to prove its functionality. The MTO started to give up on asphalt on roads and [in some cases] were replacing it with concrete.”

The research budget was used to add engineering capabilities and mechanical improvements, which produced AMIR II.

“MTO has contributed to the project in several ways,” says Don Rowat, head of quality assurance with the Ontario Ministry of Transportation operations’ eastern region. “Research funding has been provided to Carleton University through the Highway Infrastructure

Innovations Funding Program (HIIFP) and also by direct assignment of research grants. Theory has to be put into practice and the MTO has been there for the incremental developments and provided our highways for real-life test sections.”

The first field tests of the AMIR II in Ontario took place in 2011. They did not go according to plan. Two contractors that were selected by the MTO to fieldtest the equipment were unable to successfully use the technology. Fortunately, Russ Perry, vice-president of Ottawabased Tomlinson Group’s heavy civil division, saw the potential of the technology and decided to take on the project with a significant investment from his company in 2012.

“He’s a very progressive engineer,” Halim adds. “They have a mechanic that is a genius.” (Stewart Allen.)

When coming up with a name for the new prototype of the final commercial version of AMIR technology, Halim and the Tomlinson Group decided to call it TRAK, an acronym short for “Tomlinson-Russ-Amir-Kit.”

The first drastic change that was required on the existing AMIR II compactor was an idea brought up to Halim by his father-inlaw, who was a highway contractor in Calgary, during a conversation about his struggles to get an OEM on board.

“He told me nobody will buy my compactor,” Halim recalls, adding that the cost to replace a company’s roller fleet would be too expensive.

This generated an idea that totally changed the way Halim looked at his compactor. Instead of trying to sell a new compactor to the industry, why not just sell the rollers as a kit? Halim, Perry and Allen all worked on developing a roller kit that uses the AMIR II paving technology but could be retrofitted to just about any existing compactor on the market.

“We wanted to make sure that if we built it, it was multi-purpose,” Perry says. “We’ve got 20 existing rollers, ourselves. We don’t want to scrap them – no one will.”

By focusing on developing a retrofitted roller kit instead of a brand-new compactor,

POINT OF RENTAL FOUNDED

INDUSTRY FIRST WINDOWS-BASED RENTAL SOFTWARE

INTEGRATED WEBSITES

DISPATCH CENTER RELEASED

INDUSTRY FIRST DEVELOPED WIRELESS ALERTS

GPS INTEGRATION RELEASED

RENTAL ESSENTIALS RELEASED

CONTRACT FULFILLMENT RELEASED

NEW PRODUCTS

RENTAL ELITE SYRINX

INSPECTION APP RELEASED

TAKING YOUR BUSINESS TO THE NEXT LEVEL

Perry was able to solve some of the biggest challenges that plagued the AMIR II prototype: manoeuvrability and training employees to use the machine.

“We needed a system that would keep the belts aligned so we developed a track with lugs similar to a paver or bulldozer that allowed the track to run smoothly and stay in place,” Perry explains. “We also needed a better system for tensioning the belts so we adapted technology from other tracked equipment to ensure we had proper tension, which ensured adequate traction that eliminated slippage when engaging the drives. The last issue was developing a set of tracks wide enough to provide similar coverage as the existing machines so this kit could be interchanged with drums so that contractors could save on having to buy additional machines.”

The AMIR II was difficult to steer and required advanced knowledge of how the machine functioned. This was highly impractical in the field. By equipping an existing paver that can use a 60- to 66-inch compactor – in this case, a CAT 534B – anyone with experience and proper training using a compactor can operate the new prototype.

“The former model was far more complicated, you basically needed to be a rocket scientist to drive it,” Perry says.

Halim praises Perry for having the practical experience and knowledge that he lacked when developing the first prototypes.

“A lot of the things Russ saw, I didn’t see,” Halim says. “This is the difference between a researcher and a user.”

Another design issue addressed by using existing compactors were the paving issues experienced by the AMIR II when working around curbs.

“The old machine had no guidance system,” Perry says, adding that the belts had a tendency to come off the track when dealing with superelevation. “The belt itself has lugs down the centre track so the track is contained. It can’t come off anymore.”

Another issue that needed to be addressed on the prototype was working with additives and polymers that make asphalt mixes stickier – an issue that didn’t need to be addressed when the original prototype was built. To help solve this issue, Tomlinson worked with an oil company in Hamilton to create different types of non-oil based lubricators that can prevent the asphalt from sticking to the belts (due to the patent-pending process, additional information about the lubrication could not be disclosed at this time).

The MTO see a huge potential for savings if the technology reaches its full potential.

“MTO’s main driver for funding the project was evaluating a revolutionary technology that could potentially extend the life of asphalt pavements and save significant taxpayer dollars. MTO was also interested in determining if the technology could produce a low-permeability asphalt surface on bridge decks to help reduce the ingress of chlorides into the concrete and lengthen the service life of the structure,” Rowat says. “With the capabilities of the new third-generation AMIR equipment, MTO hopes to construct asphalt pavements with lower permeability on larger projects, not just bridge decks.

If the permeability of the pavement is lower, the damaging effects of water will be reduced and the pavements will last longer.

“The new third-generation ‘AMIR III’ was recently used (in November 2017) to construct a test section on Didsbury Road in Ottawa, in partnership with the City of Ottawa. The AMIR III was tested in a side-by-side comparison with the most modern asphalt compaction equipment available in the marketplace and the results are very impressive. The AMIR III produced a superior quality product, which is clearly visible and measurable in terms of lower permeability, which is critical for the next step: writing the specifications for use in future trial contracts. The compaction using the AMIR III is equal to or better than conventional equipment and the AMIR III does not produce cracks in the asphalt.”

Rowat says that even a slight increase in the lifetime of asphalt pavements would produce significant savings for the province.

“A 2016 analysis indicated that if asphalt pavements on MTO’s highways could last even one year longer, the province would save, on average, $50 million annually,” he says.

Tomlinson invested about $500,000 in developing the new roller kit prototype. The company believes there is potential for the technology to reduce the amount of equipment and the number of operators needed on a jobsite. One compactor with the new roller equipped could replace three rollers in a train for certain applications, reducing the number of drivers required, Halim says. “At present, the industry uses three different rollers, which typically need between 20 to 26 passes. Our roller needs only six to eight passes.”

“We’re hoping, by adapting the rollers further, to change that to four passes,” Perry adds.

Retrofitting the roller kit onto an existing compactor currently takes between four and five days. After the retrofit is completed, it takes one day to swap out the prototype for another type of roller.

In addition to road paving applications, Halim says there is potential for the roller kit to be used on airport runway new construction and rehabilitation projects, if the roller was manufactured a little wider than the existing prototype.

If all goes as planned, Tomlinson could soon see labour and maintenance costs in its paving division decrease substantially in the future – and with lower operating costs comes more competitive bidding for future jobs. And if that happens, you’ll likely be seeing roller kits inspired by Halim’s work on a lot of jobsites in the future. If that happens, it would be a nice sendoff for a man soon to retire, who dedicated a lifetime of research to improving road infrastructure around the world. Enjoy your retirement, Halim. May your future journeys on the road of life be pothole-free.

*Halim acknowledges the continuous financial support of The Natural Sciences and Engineering Research Council of Canada in supporting his research.

This story appeared originally in the June 2018 issue of Rock to Road.

Great equipment design is the first step toward more uptime and ROI, but ultimately a machine is only as good as it’s treated. Rental centers want the greatest bang for their buck, so it’s in their best interest to train customers on operation and cleanliness to optimize equipment longevity.

by BUCK STORLIE, ASV Holdings testing and reliability leader

LEFT: Rubber track treads accumulate cuts and missing chunks over a lifetime, but these are often cosmetic and may not affect performance. This track is still usable but should be monitored because the damage may worsen.

RIGHT: The average rubber track life is about 2,000 hours The tread in this track is gone, so it is at the end of its serviceable life.

It’s also a good idea to closely monitor equipment to nip potential problems in the bud. When it comes to rubber track undercarriages these tips couldn’t be more applicable. Simply taking the time to implement these steps can help rental centers get a lot more mileage from their machines. That saves money in replacement costs and makes money by keeping the machines out on rental longer.

Improper or aggressive operation is a major contributor to excessive wear. In addition, certain applications result in much higher wear than others. To minimize damage, train customers on proper operation before renting them the equipment.

Counter-rotations, or sharp changes of direction, are a big cause of premature undercarriage wear. This is especially true when driving over highly abrasive material, such as shale, granite or ragged materials commonly found on demolition sites. Not only do counter-rotations often lead to cuts in the track, they also result in material build-up on the tracks’ outer edge that gets into the undercarriage. Track systems with rubber wheel designs have the advantage of being open, compared to closed steel designs, allowing material to spill out. But it’s still possible for the abrasive material to get stuck among the roller wheels, lugs and track. Although the mostly rubber components are more forgiving to each other than steel-onrubber designs, materials can cause chips and cuts. To reduce the risk, encourage customers

Don’t let extreme temperatures put the freeze on operations. Norseman ducts bring warmth and comfort to temporary or permanent covered jobsites. Strong. Flexible. Safe. Brightly coloured for added safety

• Arctic Helix HT (High Temp): Highly flexible 500°F (260°C) premium duct with exceptional abrasion resistance. Available in 12” and 16” diameters.

• Arctic EconoRush: An exceptional low cost heat delivery solution for a number of different applications. Available in 12” and 16” diameters.

Ask about our full line of heater ducts.

Call: 1.800.268.1918

Visit: norseman.ca

Email: sales@norseman.ca

to use three-point turns.

Operators should also avoid spinning the tracks, especially on abrasive surfaces. Like counter-rotations, spinning can result in cuts in the rubber and unnecessary undercarriage wear.

It isn’t always possible to choose the types of jobs and conditions machines will be used in, but it is important to be aware of the toll different applications can have on track life. Jobs involving a lot of abrasive material, such as demolition, scrap and quarry applications, usually cause extra wear. The potential damage is much greater, so it’s especially important to avoid counter-rotating and spinning in these applications. On the other hand, tasks such as landscaping or golf course work that involve sand, soft dirt or turf, result in minimal wear.

Daily cleaning is usually sufficient for rubber tracks, but operators should adjust the frequency based on application.

Aside from teaching proper operating techniques, rental centers and their customers should regularly clean a compact track loader’s undercarriage since its cleanliness directly impacts the wear rate.

The cleaning frequency depends on the applications and materials operators use the machines in, but daily cleaning is usually sufficient. Remove cohesive and abrasive material, such as mud, clay and gravel, as often as possible, even several times a day. This limits wear to undercarriage components or material buildup that can increase track tension. Remind customers that cleaning off materials such as mud at the end of the day is easier than trying to remove it the next morning after it has dried.

Pay close attention to cleaning around the front and rear roller wheels, where material can accumulate. Use a pressure washer, if available, otherwise a small shovel or similar tool is sufficient. The most important items to remove are highly abrasive objects, such as sharp rocks and demolition material, including rebar, concrete and scrap metal. All of these can damage the inside of the track and undercarriage components. Also, look for strands of material, such as metal wire, that can wrap around components.

Rental centres need to closely inspect rubber track undercarriages after customers return the machines. First look at the

track, the part of the compact track loader that gets the most abuse. The average rubber track life is about 2,000 hours but can be as high as 5,000 if maintained well. On the other hand, neglecting a rubber track can result in a wear life as low as 500 hours. To get the longest track life, check track tension and condition daily, conduct visual checks for damage and lubricate grease points.