Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5 (800) 265-2827 or (519) 429-3966 Fax: (519) 429-3094

EDITOR I Patrick Flannery pflannery@annexweb.com (226) 931-0545

ASSOCIATE PUBLISHER I Ed Cosman ecosman@annexweb.com (519) 429-5199, (888) 599-2228, ext 276

ACCOUNT COORDINATOR I Barb Comer bcomer@annexweb.com (519) 429-5171, (888) 599-2228, ext 210

MEDIA DESIGNER I Alison Keba

CIRCULATION MANAGER I Aashish Sharma asharma@annexbusinessmedia.com 416-442-5600 ext 5206

GROUP PUBLISHER I Martin McAnulty mmcanulty@annexbusinessmedia.com

PRESIDENT & CEO I Mike Fredericks

Publication Mail Agreement #40065710.

Printed in Canada ISSN 0383-7920

email: rthava@annexbusinessmedia.com Tel: 416-442-5600 ext. 3555 Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Subscription Rates Canada- 1 Year $44.00 + tax U.S.A. - 1 Year $77.00

Occasionally, Canadian Rental Service will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request.

Serving the Canadian rental industry for 42 years.

10 A MOVING TARGET

The Atlantic mobile housing business works well for Kent Mobile Shelters.

18 BREAK IT RIGHT

Make perfect pairings between demolition attachments and compact equipment.

EXCAVATION

Here’s how Strongco helped clean up a brownfield. ON THE DOWN-LOW

Low-level scissor lifts have their advantages.

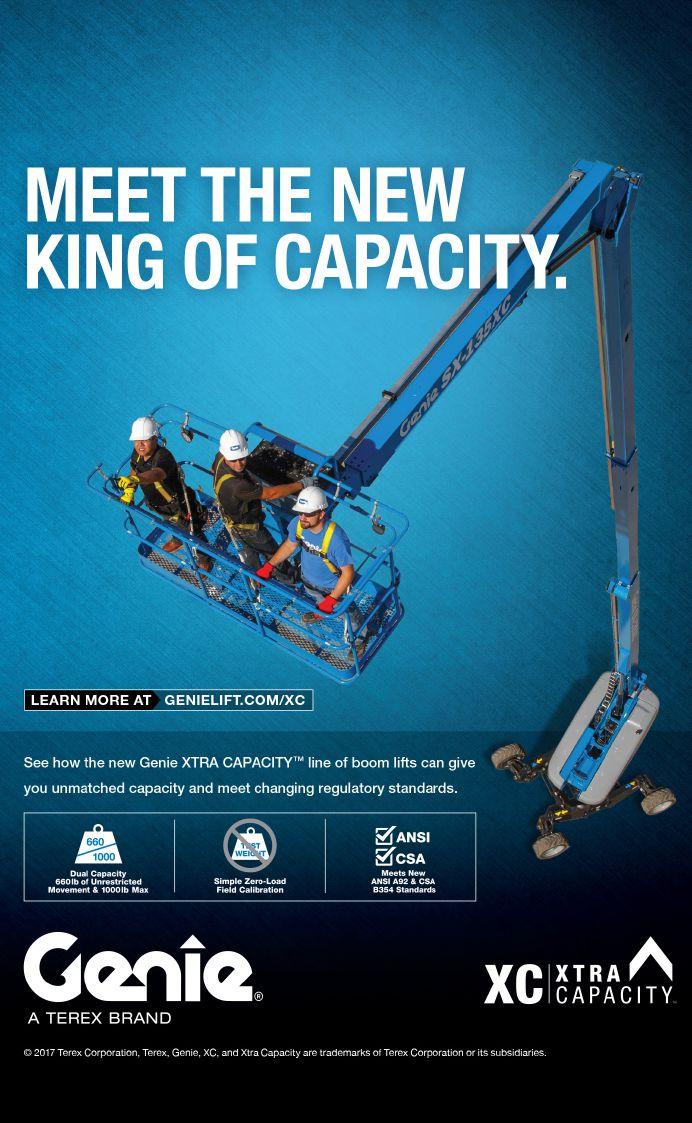

22 THE TALE OF COMPOSITE HOSE

Composite hose is a story of innovation that has helped industry.

40 GET THE LED OUT

Understanding LED lighting for rental operations.

Growth can be as challenging as recession. by Mike Maltby 16

28 AT YOUR SERVICE

There must be 50 ways to lose your customer. Here’s 10 of them. By Russ Dantu

50 SAFETY FIRST AND LAST

Safety can’t be ranked among your goals – it must be part of everything. By Jeff Thorne

Weed, weed, weed in the workplace. Boy, it’s all you hear about these days. The Senate passed the law legalizing cannabis in Canada this summer, but already there’s been a stampede of experts on health, safety and human resources to podiums across the country to tell any industry group that will sit still all about it. It’s been a steady diet of webinars, seminars and even whole-day events. No trade show schedule is complete without at least one speaker talking weed. People like me who organize industry events love the topic because we know more people will sit in if they think they might get a few giggles out of this previously taboo subject. Tips for organizers: schedule the talk for 4:20 p.m. and pass out Cheetos.

Some people won’t like this take but I must say I don’t understand what there is to talk about. Alcohol has been legal for a while now. So have prescription medicines that impair your ability to drive or operate machinery. Somehow, business owners have dealt with all that. You aren’t allowed to show up to work drunk, so I see no reason why showing up stoned would be any different. The smell and the red eyes and the sudden affinity for Bob Marley music are dead giveaways. If you have a prescription, well, you wouldn’t be able to drive if you were on prescribed Oxycontin so you still can’t drive if you are on prescribed reefer.

Did your information change and now you aren’t getting your print issue of Canadian Rental Service? Or did your digital products stop coming? Horrors! Subscribe, update your subscription information and opt in to our digital messages at our

You can find all our print

content online at canadianrentalservice. com. There’s a digital edition browser with the full magazine layout and each story posted in the relevant category as a web story.

by Patrick Flannery

Employers and employees need to work out what else they can do, or talk about what the options are if their medical condition and medication make it impossible for them to do the only job available. These aren’t new problems for anyone.

The only intersection I can see with a potential concern is that a human rights authority might step if in you try to remove a person from their job tasks when they are under the influence of prescribed cannabis. If the weed is prescribed, that means the person is sick or injured. If they are disabled by illness or injury, they must be accommodated in the workplace. That means they can’t be fired or otherwise dismissed just because they are showing up under the influence. But every human resources person I have spoken to has confirmed that you don’t have to let people drive or operate machinery under the influence even if the drug is prescribed. As long as you offer them something else to do, you can’t be slapped with a constructive dismissal suit (and those are hard to prove anyway). Of course, you may be obliged to have a stoned person working in your business. I have news for you: you probably already do.

I suppose it is all part and parcel of the general hysteria over marijuana that has been rampant around the world for the last century or so. I know a lot of people are very worried about the bad side effects, and there are some to be sure. But I’ve been personally convinced by the science showing weed to be no worse for you – and probably quite a bit better – than alcohol and tobacco. Which makes it all the stranger that I elect to drink and smoke cigarettes rather than smoke up...but I digress. The point is, I think maybe the issue is getting more attention than it deserves both in public policy and the workplace. There’s nothing new here in terms of employee relations and no reason why legalization would make it any more permissible for your employees to show up under the influence.

If only we could all find some way to relax. CRS

the most powerful mini skid steer in the industry, the new Ditch Witch® SK1550 delivers maximum muscle to a wide range of jobs. With 44hp and an incredible 1,558lb operating capacity this machine brings the brawn and productivity you need to tackle jobs typically suited for traditional skid steers. With hydraulic power for your high-capacity attachments including trenchers, vibratory plows and planetary augers as well as an exceptional 9-inches of ground clearance the SK1550 is an all-around powerhouse. Count on Brandt for quality products and the support to help keep you productive and profitable, job after job. Nobody works harder to help you succeed. That’s Powerful Value. Delivered.

Bandit Industries owners Mike Morey Sr., Dianne Morey and Jerry Morey announced in June they would sell 100 per cent of the company to their employees in an employee stock-ownership plan. Under the ESOP, Bandit will retain its current leadership and key management personnel will remain in place. It will also allow Bandit to “always remain Bandit.” The announcement comes after two previous attempts to sell Bandit Industries – once to another manufacturer and once to a private investment firm.

“We realized neither was a good fit for Bandit, so we made the decision to sell to our trusted employees,” said Dianne Morey.

“It will be fun to watch our crew take it to the next level,” said Mike Morey, who developed the very first Bandit chipper in 1983 and founded Bandit Industries.

Bandit is growing rapidly with 20 per cent growth per year with two plant expansions currently underway and several new products being introduced later this year. Bandit also recently entered into an agreement with Arjes, a leading slow-speed shredder manufacturer from Germany. Bandit will sell and distribute the Arjes products in the Americas, Australia, New Zealand, South Africa, Indonesia and other parts of the world. The product line is advertised to shred almost anything, including cement with rebar, asphalt, steel-belted tires and complete cars and trucks. Bandit will celebrate its 35th anniversary this September with a dealer meeting and a field day open to the public. All of the Bandit products will be shown, including the new products that are about to be released and the Arjes line of shredders.

“We are a leading supplier in all markets we are in,” said Jerry Morey. “We have a very strong, dedicated dealer organization and a great crew, which is the key to our success. Our employees are experienced, smart and loyal to us. That is why we are so confident that an employee-owned company is the right fit for Bandit. All our employees will have a stake in the company.”

Stephenson’s Rental Services has opened a new full-service store located at 2382 Stouffville Road in Stouffville, Ont. The new location is just one kilometre east of Highway 404 and will serve the Aurora, Bracebridge, Markham, Newmarket and Richmond Hill areas. Stephenson’s now has 38 locations across Ontario and Alberta.

In its latest five-year forecast, the American Rental Association (ARA) projects Canadian equipment and event rental industry revenue to grow consistently on an annual basis. The forecast calls for equipment and event rental revenue to total $5.4 billion in 2018 and grow each year to reach $6.3 billion in 2022. The construction rental revenue forecast for Canada is for $4.3 billion in 2018, up 4.7 per cent, with growth rates of 4.2 per cent in 2019, 5.3 per cent in 2020, 4.7 percent in 2021 and three per cent in 2022. For general tool in Canada, the forecast is for $860.1 million in rental revenue in 2018, up 4.5 per cent, with expected increases of 2.9 per cent in 2019, 3.5 per cent in 2020, 2.7 per cent in 2021 and 0.7 per cent in 2022. Party and event rental revenue in Canada is expected to total $229.8 million in 2018, up 3.3 per cent, with growth of 4.3 per cent in 2019, 3.2 per cent in 2020, 3.5 per cent in 2021 and 1.5 per cent in 2022.

Aug. 15

CRA Quebec Golf L’Assomption, Que. crarental.org

Aug. 19

CRA Atlantic Golf Hatchet Lake, N.S. crarental.org

Aug. 23

CRA Manitoba Golf Winnipeg crarental.org

Sept. 6

CRA Alberta Meeting Calgary crarental.org

Sept. 18

CRA Ontario Golf Guelph, Ont. craontario.org

Nov. 9 - 11

ARA Leadership Conference Chicago, Ill. ararental.org 2019

Jan. 8 - 10

Landscape Ontario Congress Toronto, Ont. locongress.com

Jan. 22 - 25

World of Concrete Las Vegas, Nev. worldofconcrete.com

Feb. 17 - 20

The Rental Show Anaheim, Calif. therentalshow.com

March 28 - 29

National Heavy Equipment Show Mississauga, Ont. nhes.ca

Bomag Americas has announced Matt Cadnum its new vice-president of sales and marketing. Cadnum will be responsible for strategic sales leadership and support of Bomag’s dealer and rental channel partners, marketing, product management and cultivating new business development growth opportunities. Cadnum is a highly driven industry professional who possesses a strong background in both aftersales and commercial sales responsibilities. The first 15 years of his career were spent in various aftermarket leadership roles with Allied Construction and Atlas Copco Construction Equipment. Most recently, Cadnum held senior management positions as vice-president of sales for Atlas Copco Construction’s rental sales team and vice-president of hydraulic attachments for Epiroc (a division of the Atlas Copco Group).

“Matt’s extensive background in supporting dealer, rental and end-use customers coupled with his hands-on management style, strong technical skills and sales orientation is exactly what Bomag needs to help our customers expand their business with us,” stated Rob Mueckler, president of Bomag.

Cadnum said, “I strongly believe in Bomag’s products, its vision and, most importantly, the dedication the company has to improving overall customer support within the construction equipment industry. Bomag is deeply committed to product innovation and helping generate greater returns on investment for road building customers and I very much look forward to continuing those initiatives.”

Point of Rental

Software’s worldwide team has added Josh Nickell as its director of global strategy.

The former CEO of Georgia-based Nickell Rental will join the company in May, continuing a 20-year career in the rental industry after selling his company to Sunbelt Rentals.

“Joining the team at Point of Rental allows me to combine three of my lifelong passions: technology, rental and building highly engaged, scalable teams,” said Nickell. “There is so much opportunity in data analytics and innovative technologies and no company is better positioned to leverage that than Point of Rental. Being a part of the Point of Rental team just makes sense; having the opportunity to build teams that partner rental businesses with innovative technology – that’s a dream come true.”

As director of global strategy, Nickell will focus on building greater

synergy among Point of Rental’s teams based in Dallas, Texas; Reading, U.K.; and Melbourne, Australia. This will increase company-wide data sharing, open new markets for the software and solidify the company’s core values across an international spectrum.

Nickell is highly invested in the rental industry as a whole. He has served eight years on the ARA of Georgia board in multiple positions and now is serving as president. In addition, he has served as the chairperson of The Rental Show task force, the legislative caucus and various rental industry committees. Nickell has been recognized as the ARA Regional Person of the Year in 2014 and most recently with the ARA’s 2018 Meritorious Service Award for demonstrating exemplary leadership.

Lauren Harris has been named Point of Rental’s director of marketing, making official what’s been known within the company for some time.

“I appreciate the opportunity to work with an amazing team to

POINT OF RENTAL

INTEGRATED WEBSITES

DISPATCH CENTER RELEASED

INDUSTRY FIRST DEVELOPED WIRELESS ALERTS

GPS INTEGRATION RELEASED

RENTAL ESSENTIALS RELEASED

CONTRACT FULFILLMENT RELEASED

NEW PRODUCTS RENTAL

TAKING YOUR BUSINESS TO THE NEXT LEVEL

by JORDAN WHITEHOUSE

In the summer of 1958, New Brunswick industrialist K.C. Irving walked into one of his logging camps in the interior of the province and didn’t like what he saw: cramped worker accommodations, uncomfortable common spaces and inefficient systems.

He knew his employees deserved better, and so he bought a new logging camp in Quebec and had it re-engineered in a Bouctouche, N.B., shop. Installed back in the bush, the camp was a hit. Irving had clearly stumbled on something and he wasn’t one to let an idea like it go to waste.

Sixty years later, it’s clear that he didn’t. That idea has grown into a three-pronged company called Kent Homes Limited that delivers pre-fab houses, modular commercial spaces and mobile offices and shelters throughout Atlantic Canada. It’s still based in Bouctouche (population 2,361, by the way), but it’s now in a 150,000-square-foot facility with views of the Northumberland Strait.

That last prong – Kent Mobile Shelters – is our topic here, and as current director Peter Kinney tells it, the mobile office and shelter piece was a natural add-on to the shelter business K.C. Irving spotted in 1958. “Back in the early ’60s there were major infrastructure projects in the province — things like the Mactaquac Dam, the Irving Oil Refinery and the modernization of Irving Pulp and Paper — and they needed temporary spaces to work out of. So we really hit the ground running.”

Kinney says that the majority of their customers still come from the construction industry, but that they’ve worked with music festivals, mines, and power companies across the east coast as well. They also have a three-person division in Argentia, N.L., to serve clients there along with the seven in Bouctouche.

The other big difference between the Kent Mobile Shelters of yesteryear and today is the range of options for clients. Each trailer is 12

feet wide, but they come in 20-, 30- , 40- and 60-foot-long sizes. The longer trailers can be customized to include multiple offices, kitchenettes and half bathrooms, and all of them can be outfitted with everything from stackable chairs to executive soft-seating chairs to ergonomic seating options to office desks to free-standing tables. Customers can also get dedicated washroom trailers and change rooms.

“We really want to be a one-stop, turnkey solution for our customers so that they can focus on working,” says Kinney. “And even though these are temporary shelters, a lot of the time this is the workers’ home away from home. So we’ve gone from being a supplier to really trying to connect with our customers, to putting ourselves in their shoes to deliver the best solution for them.”

This isn’t to say it’s easy staying in those customers’ shoes, though, says Kinney. Project managers are moving faster and faster these days and their timelines are getting shorter and shorter. Their needs are a lot more urgent than when he started with the company eight years ago. “They’re also demanding a better and brighter workspace, as they should. Twenty years ago, the wall panelling, the lighting, the design, ergonomics — it was all much more basic. Today there are many more options to meet customer expectations.”

The key to keeping up with those fast-changing needs has been good communication up and down the line, says Kinney. Many of their 10 employees are long-term, so they know how to

communicate with customers and one another. Even seemingly standard processes like generating a quote have been maximized for efficient communication. “When a customer decides to pursue the rental, we don’t have to keep going back to them for more information because the quote has it all. We get what we need the first time.”

Good communication also means communicating what you can’t do for a customer, adds Kinney. “If we can’t do something, we’re not going to tell them we can, but we will steer them in the right direction. Anything to help the customer.”

Sometimes, though, good communication is also doing something that a customer might not even know they want. Like waxed floors. “It seems minor, but waxed floors make a big difference in the eyes of the customer,” says Kinney. “It makes them nice and clean, bright and shiny. When I got here, we rarely did it but now it’s a given. This can be someone’s work environment for 14 or 16 hours a day, so it should be bright and clean and we should be providing a really nice place to work.”

Saying that you’re going to provide a really nice place to work and doing so are two different things. The customer has the final say on how well you’ve actually done. Which is why Kent Mobile Shelters uses a net promoter score system to determine customer satisfaction. After the rental is returned, a customer will likely receive a call from an independent third party asking about their experience.

“We have a review every quarter of those scores, and we take them very seriously,” says Kinney.

“It makes you a bit vulnerable, but

that’s the beauty of getting a constructive customer response. It’s an honest picture of what you’re doing right and could improve upon.”

Overall, Kinney says that their service consistently ranks high, a fact he is particularly proud of because he believes it’s their service standards that set Kent Mobile Shelters apart from their two main competitors right now.

As for suggestions for improvements, some customers used to say that the units could use a little polishing; that they liked how bright some competitor trailers looked when they first arrived onsite. This is when all of that waxing of floors came in, says Kinney. It’s also when they started replacing dark wall panelling with lighter tones and ensuring a strong commitment to maintenance and cleanliness.

As Kinney said earlier, though, good communication is also about making it clear what you can’t do. Sometimes suggestions just can’t be accommodated...yet. “If customers are pointing out

Kent Mobile Shelters delivers portable office units up to 60 feet long all across Atlantic Canada. If they don’t have it right now, they’ll try to get it soon.

features that we can’t necessarily put in every single fleet unit we have, we’ll tell them of course. But we also may be able to start putting those features on our next round of units.”

And what will those future features be? More solar panels and alternative power generators like turbines will be two, says Kinney, but there’s lots of research and

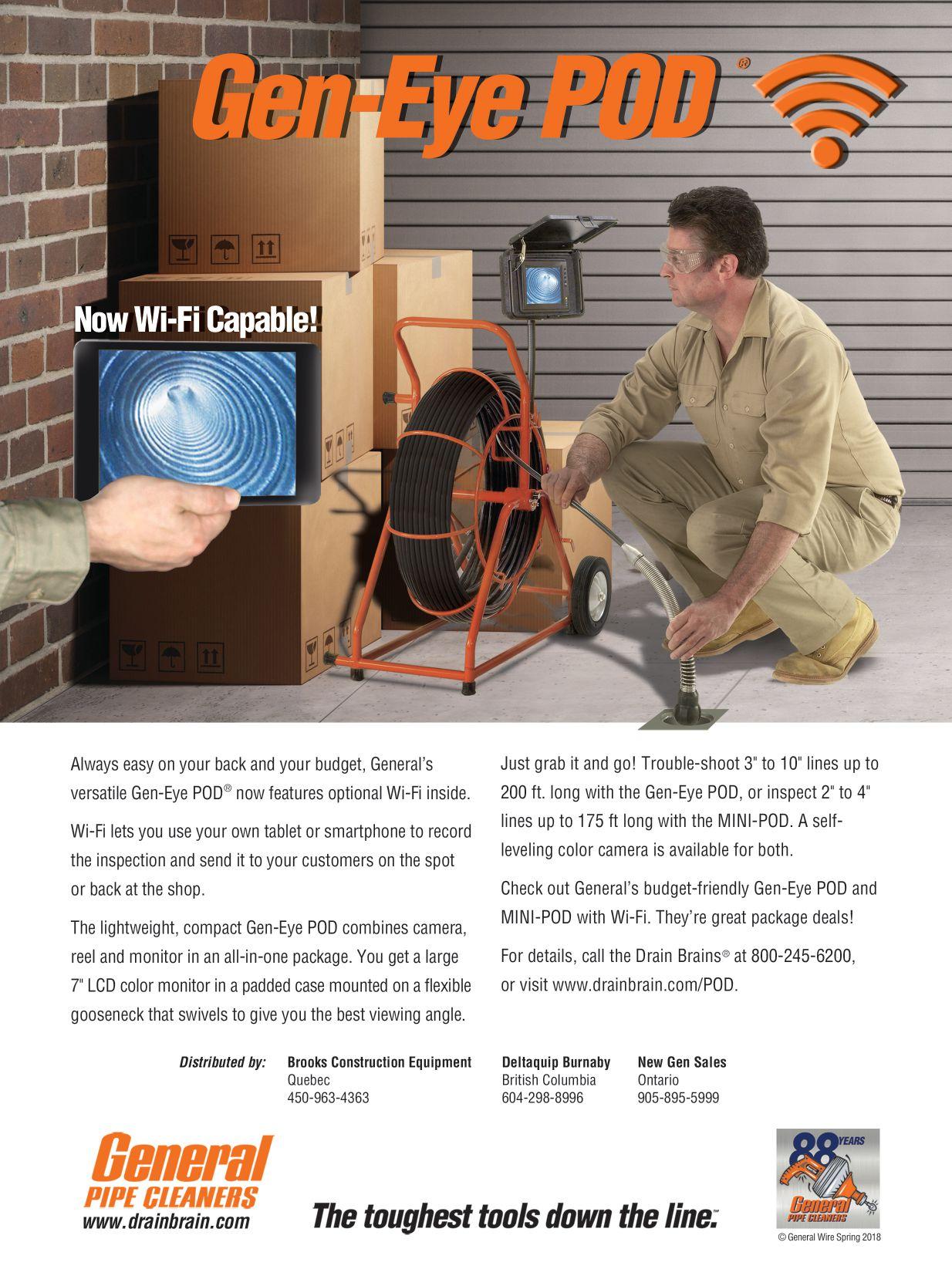

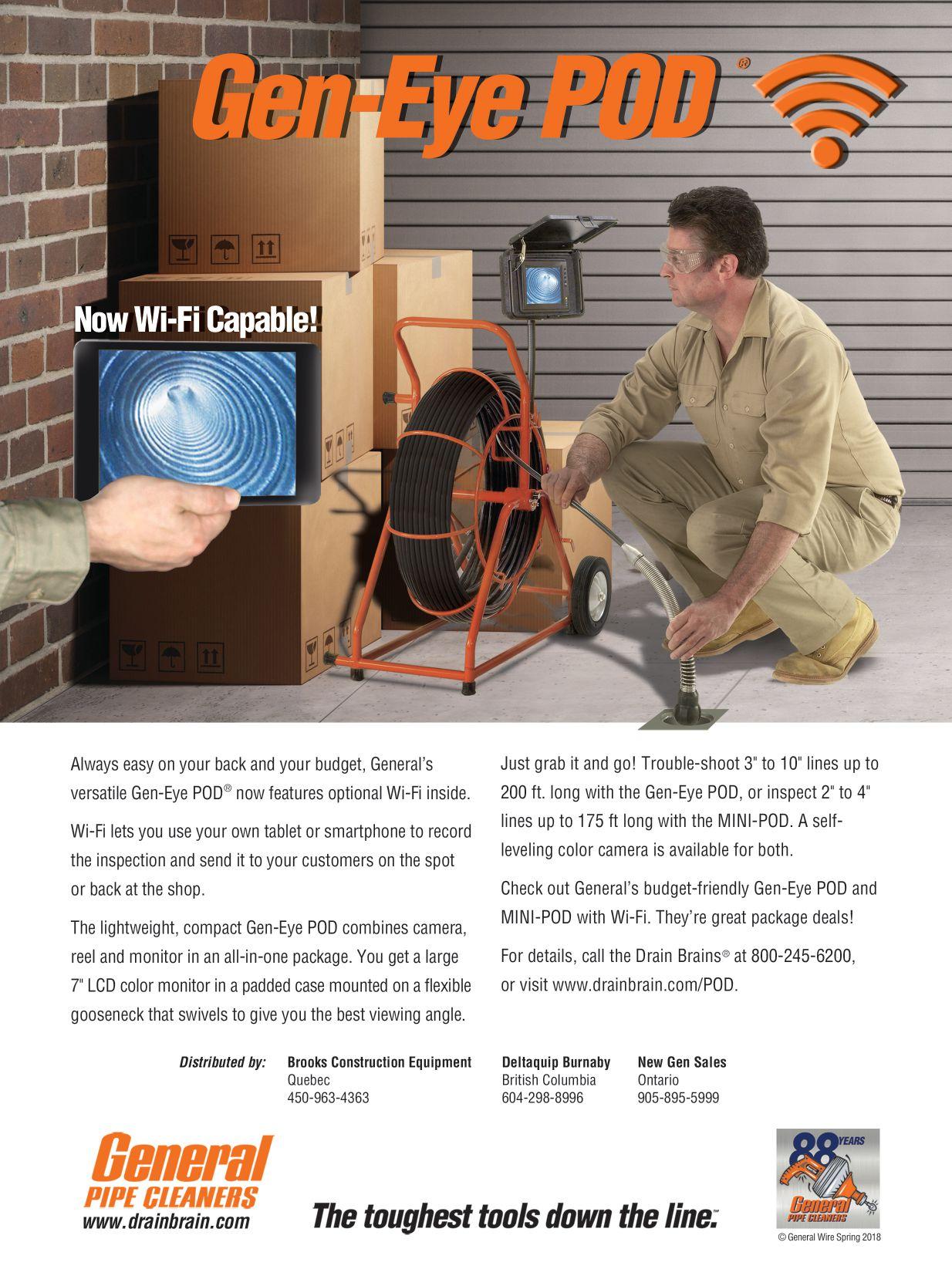

Extra heavy-duty frame constructed of 1-1/4” steel tubing. 12 ” Flex Leader helps negotiate bends and traps. Compact machine with open cage design for easy inspection and cleaning. Belt Guard makes maintenance and repair easier. Cleans 3”– 6” diameter lines up to 100 Ft. Runs either 5/8” or 3/4” diameter galvanized aircraft wire inner core cable – The toughest cable in the industry!

Rugged stainless steel housed 1.68” dia. color camera for inspecting 3”–10” lines. Sapphire lens with 20 LED light ring and high resolution CCD element. Flexible camera spring designed to navigate 3” P-traps. Auto iris adjusts lighting automatically. Industry standard 512HZ sonde. 5.4” LCD monitor with AR film for optimal viewing in sunlight. Video output jack for recording option. 200 Ft. of braided Fiberglass premium 1/2” dia. push rod. Secure-locking reel brake and a heavy-duty screen cover. • Standard with One-Touch USB recording

• On-screen footage counter

• 8”wheelsforeasytransport and maneuverability. Distributed in Canada by Rentquip 800-818-1199

Lo ad ed w it h fe at ur es t ha t be nefit both the o wner and o p erato r, the S n or k e l S4732E is bu ilt tou g h to h an dl e th e de ma nds of the jobsite . Constructed from heavy-d uty st eel, the Snorkel S4732E ca n l i ft t 3 49 kg t o a wo rk i n g he ig h t of 11.8m. Eas y- en t r y saloon -s ty le g a t es, smoo t h p ro po r ti onal con t rols, in cl ud i n g de scen t , a nd i n t egra t ed powe r ou t le t s i n t he pla t form make opera ti ng t he S473 2 E a plea sure. K e ep in g th e S473 2E at wo rk is also easy, thanks to inside-out access to all components, and a si n g le w heel nu t des ig n t ha t m i n i m i zes ma i n t enance ti me. F o r more information , contact Ahern Canada at 780-467-0600

development coming down the pike in general. Almost all of it is being done to keep up with the pace of those project managers and what they need in a modern office: efficiency and comfort.

Right now, though, the biggest innovations are actually happening online and Kinney doesn’t see that ending any time soon. “I can see that interest in customers wanting to order a trailer online really picking up steam. It just

makes their lives a lot easier.”

He can also see Kent Mobile Shelters adopting a similar online design tool that Kent Homes will launch soon. That tool allows customers to design-build their own home with a layout of their choice and receive a quote right away.

It’s a necessary innovation, but the homebuyer and the mobile office renter have very different needs and wants. That’s a big challenge that will have to

be overcome, says Kinney. “We want to be able to make it as easy as we can for the customer to receive the job trailer that works best for them. But when your job trailer is 60 feet long and you’re kind of going in blind because everything was done online and you didn’t get a chance to talk, it can be a challenge. The last thing you want is to have the wrong product or the wrong trailer for the application. So it’s finding that happy medium and I’m sure we will. Direct contact is still vital to the process.”

As for the size of Kent Mobile Shelters, Kinney is happy with where they are operationally and geographically. Any rental guy would like to have more new units built, but he thinks their growth will come from modernizing their rental fleet year over year and keeping their units fresh.

Which really means, of course, that Kent Mobile Shelters’ growth will come from the efforts of its own people. And that can only happen when there is a deep level of respect shown to those employees, as K.C. Irving did when he walked into that logging camp in 1958 and as Peter Kinney is doing now.

“I’m most proud of our people and what we can achieve in a very lean organization,” says Kinney. “We’re a big family and we’re all fortunate to have each other. Everybody cares about each other and the customer. I’m very lucky I walked into this situation. It blows me away every day.”

Not content to see great success for Kent Mobile Shelters, Kinney is giving back through involvement with the Atlantic Canadian Rental Association. He recently became its vice-president. “This is my first year involved with the association,” Kinney says. “I have worked in the rental industry for 13 years, eight of which have been with Kent Mobile Shelters. After attending the Rental Show in Orlando I felt it was important to join the association to not only expand my knowledge and contacts but also to help others in the industry, just like the industry veterans helped me when I first began in 2005.” CRS

Take advantage of interim tier diesel generator savings by securing remaining Tier 3 or Interim Tier 4 mobile diesel generators. Availability is limited - contact Generac Mobile Products today.

by MIKE MALTBY, CRA PRESIDENT

ARA Rentalytics has officially been relaunched. The forecast calls for equipment and event rental revenue in Canada to total $5.4 billion in 2018 and grow each year to reach $6.3 billion in 2022. The construction rental revenue forecast for Canada is for $4.3 billion in 2018, up 4.7 per cent, with growth rates of 4.2 per cent in 2019, 5.3 per cent in 2020, 4.7 per cent in 2021 and three per cent in 2022. For general tool in Canada, the forecast is for $860.1 million in rental revenue in 2018, up 4.5 per cent, with expected increases of 2.9 per cent in 2019, 3.5 per cent in 2020, 2.7 per cent in 2021 and 0.7 per cent in 2022. Party and event rental revenue in Canada is expected to total $229.8 million in 2018, up 3.3 per cent, with growth of 4.3 per cent in 2019, 3.2 per cent in 2020, 3.5 per cent in 2021 and 1.5 per cent in 2022. All in all, we can say our industry is doing well and looks to keep improving.

Rental operations in Canada are struggling with shortages of skilled labour, ever-increasing regulatory compliance costs, tax changes, uncertainties surrounding the ongoing NAFTA re-negotiations and the unknown consequences of our ongoing tariff war with our neighbour to the south. Members have shown resilience and are set to continue to grow despite all of this uncertainty. With growth comes additional challenges. One of those challenges is a need for better-trained staff to keep up with increasing demand. Canadian Rental Association members have access to a number of programs to help.

ARA Technical Training Grants are awarded quarterly and provide up to $1,000 U.S. for technical training for your staff. Employees must have 1,000 hours of service with your company to qualify. Grants cover a wide variety of technical training that supports a career in the rental industry, including, but not limited to mechanical, carpentry, electrical, welding, commercial driving, tenting, hospitality services, the Certified Event Rental Professional (CERP) program and accounting/administration.

The ARA Professional Driver Education Program is a rental-specific online certificate program for construction and general tool employees. Designed with all aspects of the driving and delivery process in mind, this nine-course program features nearly seven hours of instruction on topics from loading and unloading to regulations and customer service.

The Certified Event Rental Professional (CERP) program is the only rental-specific certification program for those in the party and event rental industry. This in-depth, selfstudy program is for individuals who seek a competitive edge and professional credentials. Remember that CERP training also qualifies for the Technical Training Grant.

The Learning Center and Rental U offers a mix of stand-alone courses and educational tracks for owners, managers and employees. The mix of free and affordable training options will not only help improve overall efficiency and performance, but also boost employee’s confidence and morale.

Ready-to-go Tags are our number-one risk management tool and learning how to use these tags properly will make it easy to streamline your equipment safety program and keep your service records up to date. CRA members receive a sizable discount and those insured by the CRA Insurance program receive additional savings.

If you have any questions or would like to receive additional information on these or any other program offered to CRA members, please contact member services or speak with any of our volunteer leaders during any of your local chapter golf tournaments or upcoming members meetings. CRS

Canadian Rental Service is a proud media partner of the CRA. Find association news and a complete archive of past President’s Messages at canadianrentalservice.com > Canadian Rental Association.

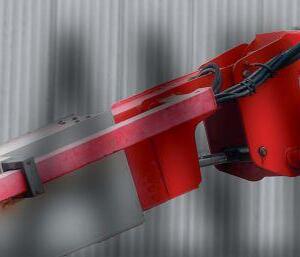

It could be argued a good beer goes well with just about anything. After a hot summer day on a demolition job, though, a light beer with lime will probably taste more refreshing than a heavy stout. Finding that perfect malt after a long day feels great, and finding a perfectfitting demolition attachment will get that beer served up a lot sooner.

By FRANCOIS MARTIN, general manager, Kinshofer North America

LEFT: Grapples are a good choice for lighter materials because of their mobility and the option to move material around after the initial tear-down.

RIGHT: Got rebar? Pulverizers work well for these applications because they reduce the concrete to small chunks and shear through iron bars.

With hundreds of sizes and styles of demolition attachments on the market — from small grapples to massive pulverizers — it’s not as easy as picking one, attaching it to an excavator and expecting top production. Like a good beer, some tools just fit better at different times.

Knock out jobs faster by refining the demolition attachment selection process. Consider the application, the carrier, the return on investment and more to determine the perfect match.

First, consider the type of work the attachment will perform. From primary to secondary demolition and from rebar-enforced concrete to wood and brick, the application should be the first factor to guide an attach-

ment choice.

When starting to demolish a structure, multi-quick processors, shears, crushers, pulverizers and demolition grapples tend to be the top picks for primary demolition. The choice between them depends on the type of material and how it needs to be broken up.

Crusher and pulverizer attachments, for example, best tackle jobs made up of mostly concrete. Choose a crusher — or “cracker” — if the structure is composed of concrete with little or no rebar and if it’s necessary to break the concrete into chunks large enough for easy sorting and recycling. A pulverizer attachment better handles concrete that’s heavily reinforced with rebar. Unlike the crusher attachment, the pulverizer will break the concrete into small pieces and cut through

Looking for a strategy you can bank on? Select the ultimate in reliability, ease of maintenance and parts availability for all of your equipment under 115 horsepower. Run your fleet and power your business success with Kubota engines.

Once

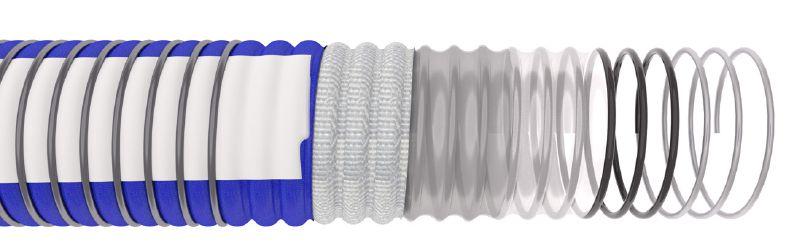

Cby STEVE URH, product manager for composite hose products, National Hose

omposite hose is non-vulcanized and constructed of multiple layers of thermoplastic films and high-density reinforcing fabrics, normally polypropylene, polyethylene, PTFE and polyester. An abrasion-, ozone- and weather-resistant cover protects the internal materials. All materials are tensioned between internal and external spiralled wires.

In the late 19th century, W.H. Willcox & Co. manufactured the first composite hose – calling it “wire-bound hose” – in London, England, patented as “Jones-Willcox hose.” It was marketed as “armoured” inside and out so it would not kink or collapse. According to the Willcox literature, internal layers consisted of “specially prepared canvas. Rubber was not used in its manufacture, therefore the hose will not perish and is most useful where oil or spirit has to be conveyed.”

Since the invention of vulcanization in 1939, natural rubber demand had been booming. Vulcanization improved natural rubber making it stronger, better able to retain shape, resistant to abrasion and to extreme temperatures. The demand increased for rubber in tires, shoes, hoses, sheeting, industrial banding and other products. After 1900, the demand intensified with demand for cars and bicycles. Synthetic rubber would be another decade away.

Vulcanization transformed markets but it created other problems. Supply uncertainty

seemed to be the greatest issue. High-cost production, political controls and environmental concerns caused a great deal of supply interruption. Wild natural rubber could not grow fast enough to meet demand. Such issues did not limit the production of non-rubber wirebound hoses.

Due to its armoured construction, wirebound hose was good for both suction and discharge and available in diameters from ½ to 10 inches. Applications at the time included “contractors’ pumping of water, tar, oil, and manure; unloading tank steamers; tank wagons; fire engines; oil storage; rail cars; and conveying gas, oil and greasy liquids.”

Composite hose is used for many of these applications and more today.

Because wire-bound hose contained no rubber, it was especially supportive during the World Wars for fuel and oil delivery. During World War II, Japan attacked Malaysia, which cut off the world from natural rubber. This intensified demand for wire-bound hose.

Composite hose uses layers of plastic and fabric combined with an internal wire to create a product with superior durability, flexibility and ease-of-use.

Introducing the world’s first 12,000 lb telehandler with no engine aftertreatment. JCB pioneered the telehandler more than 40 years ago and is the world’s biggest selling brand. Now, the company that started it all, offers the first and only 12,000 lb telehandler that requires no DEF, DPF or other engine aftertreatment

And just like all JCB telehandlers, the new 512-56 74 hp telehander features an all-JCB drivetrain, for unmatched performance and efficiency, and JCB’s unique U-pressed steel boom for unbeatable durability

Learn more about the world’s most popular telehandlers at www.jcb.com

/JCBNA @JCBNA JCBNA @ www.jcb.com

From the late 19th century through to the mid 20th century, discoveries in plastics and innovations in polymer chemistry were occurring. In the 1950s, polypropylene and PTFE became commercially available. With these two plastics in particular, the modern-day composite hose was created. Wire-bound hose faded into history. The new composite hose, still armoured inside and out, is now made of performance plastics

and fabrics. It has opened up opportunities for transferring a vast range of aggressive chemicals and petroleum products at very low and to very high temperatures at higher pressures.

Global demand for composite hose is expected to continue growing. Developing countries and emerging markets are now in the top 40 on GDP league tables according to the International Monetary Fund. Combined

with the existing output of advanced economies, demand for composite hoses will rise along with new global manufacturing.

The growth in world economies is one aspect but is linked to an upsurge in other new developments. Advanced and developing economies need resources. Demand for ships, rail cars, tankers and other forms of transporting petroleum is rising rapidly in these economies. New, larger types of ships are being produced faster than ever to fulfill the global need for fuel, food, and chemicals. Composite hose can be produced faster than rubber hose.

AS A WORLD LEADER OF SUBMERSIBLE PUMPS, TSURUMI OUTLASTS THE COMPETITION IN PUMP LIFE, PRODUCT OFFERING AND COST SAVINGS.

New techniques and extreme regions are being accessed in the hunt for fossil fuels. Hydraulic fracturing is a prominent method that utilizes composite hose in the process of extracting shale gas. Oil companies are exploring extreme low-temperature climates as well. In extremely cold temperatures, composite hose remains light and flexible for easy handling.

Concerns about climate change may cause economies to turn away from fossil fuels. Biofuels and biodiesel have been developed to fill the gap. Biofuels tend to be more environmentally friendly. But they are more aggressive and attack traditional and lower-cost materials. More expensive compounds are required for resistance. In this situation, composite hose is a suitable and more affordable option and resistant to a wide range of bio and alternative fuels.

LPG and LNG liquid gases are in high demand. These are transferred at ultralow temperatures. Composite hose is the perfect solution versus rubber given its cold-temperature capabilities.

Composite is also a great solution for the chemical industry. Typically polypropylene-lined composite hose handles 90 per cent of chemicals while a variety of rubber hoses may be needed for different service conditions. This makes the composite hose a more universal and overall more affordable option when calculating the total cost of ownership over time. Customizing a composite hose to suit service conditions is quick and easy.

Flexibility: Composite hose is kink-proof,

requires minimal force to bend and is lightweight for easy handling. It maintains flexibility even in low temperatures.

Failure mode: The multi-layer construction of composite hose prevents catastrophic failure. During a failure the hose will not burst, spraying liquid. It will simply collapse or passively leak a few drops forming a puddle

Universality: Every model of composite hose is capable of both suction and discharge. One hose can be use in a wide range of applications

Durability: Composite hose is weather-proof and does not degrade with age. It resists abrasion and does not fatigue from use and pressure. It’s ultravioletand ozone-resistant. If damaged, composite hose can repaired quickly.

Customizable: Composite hose is easily customized to suit service conditions with colours and private labelling.

Regulated: Composite hose assemblies can be tested and certified by nationally recognized organizations to verify their capabilities, good construction and safety. Look for certification from NAHAD (Association for Hose and Accessories Distribution) or CSA (the Canadian Standards Association).

Composite is a very light, flexible and user-friendly hose. It is by construction both a suction and discharge hose, handling full vacuum and typical working pressures up to 200 pounds per square inch. Whether you are pumping water, contaminated water or light slurry, a composite hose is an ideal solution. It can sit outside in the sun and all kinds of weather from dry hot days to the coldest days with lots of snow while remaining, strong, flexible and intact. It will not rot or deteriorate. It can be produced with a variety of materials to handle the worst of service conditions and be durable enough to take the abuse your rental customers can dish out. Composite hose can be produced with aluminum wires and lighter construction to be easy to handle, often allowing one person rather than two to make connections with even the largest sizes. Composite hose should be a standard part of any rental fleet where customers need to rent hoses. CRS

•

•

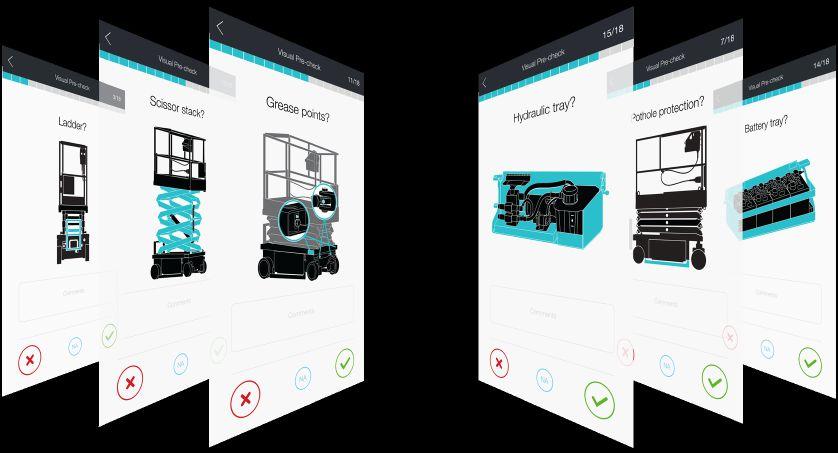

If work is being done in this industry, machines are being used. Safety achieved through true visibility means connecting the operator directly to the machine. This translates into paperless processes, digitally tracked operating time, and in-app tracking of machine damage.

Elevate your processes and get your fleet back to work quicker, safer, and more efficiently. Learn more at skyjack.com/elevate.

by Russ Dantu

It never ceases to amaze me how many employees don’t seem to understand that they receive a paycheque because of customers. Sometimes, the way they treat customers is like they never want to see them return again. Like they are an inconvenience and just disrupting their day. When hiring employees, sometimes we need to remind them of how important the customer is to them having a job. If you truly want to lose a customer, here are some guidelines your employees can follow to ensure they are never bothered by anything customer-related – or business-related – again.

1. Never answer your phone when it rings. Always make the customer leave a message and then take your time returning a call, or better yet don’t bother ever returning the call.

2. When a customer visits your office avoid eye contact or recognizing they are there, especially when you are with someone else. There is no point in getting their hopes up that they might actually get some service sometime soon.

3. If you see someone who needs service, turn the other way so they cannot see you. Hiding is an excellent way to make sure you don’t have to speak to someone. Make sure you are in range of an aisle or door at all times so you can quickly slip away. Sticking your head into an open box is also a great way to avoid contact and look like you’re working at the same time.

4. Pass the buck. If something has gone wrong and the customer wants to talk to you about it, don’t let it happen. Make sure you pass them off to someone else and then have that person pass them off to someone else.

5. If you cannot provide them with what they are wanting, never refer them to another company who can. Going above and beyond would be silly. The customer may actually come back if you do this.

6. Always be sarcastic. If people ask silly questions, they deserve sarcasm. Use this as often as you can and hold contests with other employees to see who can do it the most each day.

7. Under no circumstances ever smile at a customer. This will lead them to think they may be valuable to your business.

8. Never post contact information on your website. This will just lead to people trying to connect with you. Make it as difficult as possible for a customer to reach you or the proper department they need to reach. If they find a general phone number to call in, do not give them the option to talk to an operator/receptionist. Give them a long list of options but never the option to speak to a live person. If they press zero, make sure this leads to having the call cut off.

9. When things have gone wrong, never tell the truth or admit guilt. Be as creative as you can in making up stories. Hold monthly contests and offer good prizes for the most ridiculous excuses offered to upset customers

10. If, for some reason, the customer tricks you into helping them, take as long as possible to do this so they will never want to come back again. Ask lots of silly questions like you don’t understand what they want. Walk around slowly pretending to search for something. Maybe even stop to chat and joke around with other employees while the customer is waiting.

Obviously the list above seems absolutely ridiculous but I continue to observe or hear of these practices actually taking place. There is no quicker way to destroy a business than to follow the steps above. If you don’t want your business to be one of the hundreds that leave the market each year, I recommend you share this list with your staff so they understand the importance of treating customers like gold. CRS

Russ Dantu is a 30-year veteran of the rental industry and has been delivering workshops, seminars and keynotes on customer servicce for over 15 years. For more information, visit russdantu.com or email russ@russdantu.com

OF OWNERSHIP WITH THE JLG® 742 TELEHANDLER.

Designed to lift up to 7,000 lb, the 742 telehandler gives you just the right capacity, power and reach for the job. It has a standard 74 hp engine that doesn’t require DEF and meets Tier IV Final regulations. Without the need for DEF, fluid costs are reduced. Plus, extended service intervals and durable components decrease overall maintenance needs. See how No DEF engines can help you lower total cost of ownership at jlg.com/no-def

When equipment manufacturers started promoting the use of excavators and articulated haulers together as earthmoving teams, they found a firm believer in David McCrossan.

by STRONGCO CORPORATION

Remediation work requires surgical excavation with careful handling of the removed material.

President of The Cannington Group, a family-owned contracting firm in the Greater Toronto Area, McCrossan says the combination of Volvo crawler excavators and articulated rock trucks sourced from Strongco is the only way to do it here.

“Here” is a 75-acre parcel of prime land on the shore of Lake Ontario in the resurgent Port Credit area of Mississauga, Ont. The long-time former home of a bulk oil storage facility, the property will eventually be developed as one of the region’s prime residential communities. As a specialist in soil remediation and other environmental applications, The Cannington Group is currently on site for 14 months in what McCrossan describes as “a surgical excavation” project.

“We’re excavating, stockpiling, segregating and hauling off soils that exceed the site criteria. In some areas, we are taking two feet

of dirt off, in some areas, we are taking three, four, even 10 feet off. The depth is all over the place,” he says. “Scrapers just wouldn’t work here with the select areas we have to excavate and the varying corresponding depths.”

Says McCrossan: “This is not a bulk excavation job.”

Having worked in various sectors and in varying company configurations over the years, The Cannington Group is today in the business of working equipment, not fixing equipment, explains McCrossan. That, he says, is what makes the relationship with Strongco and key account manager, Daniel Hili, so important to the success of the specialized contracting company.

“We do a lot of research on the equipment,” says McCrossan. “It’s my job in the company

OPERATING WEIGHT

7,418 LBS MAXIMUM DIG DEPTH 7.8 IN 10 FT

to a) get the work, and b) provide the guys with the right tools to get that work done. With the support of Daniel, Strongco, Volvo and Volvo Finance, I have done that. They have collectively stepped up and provided us some fantastic equipment and really, really reasonable rates. It’s a very good package.”

The Volvo excavators and articulated haulers have not only earned a collective thumbs-up from his operators for their ergonomics and ease of operation but also McCrossan’s own top grade for meeting their fuel efficiency and cost of operation claims.

Some pieces in The Cannington Group’s Volvo fleet were procured specifically for the Mississauga job “but we’ve also had long-term and multiple leases,” says McCrossan. “It’s a long-term relationship that we’re in with Strongco and it’s going to continue.”

Through the relationship with Strongco, The Cannington Group was an early adopter of Volvo’s total maintenance and repair (TMR) program. This, says Hili, has provided “a threeway win” particularly when teamed with the contractor’s equipment leasing package.

With the confidence of knowing his fixed costs, the customer is highly productive. He has new equipment that is fully supported by the dealership in combination with a modern service team that keeps the equipment running in top shape.

This, in turn, keeps the equipment’s residual values high for the manufacturer and allows the dealership to give the customer a better deal on new replacement machines down the road.

For McCrossan, a construction lifer, it’s all good.

“I’m not going anywhere,” he says. “Like I often say, I’m on the Freedom 85 program, so that gives me another 35 years to go. I don’t think this equipment, as good as it is, will last 35 years. So, we’ll definitely be trading and getting new equipment. For sure.”

Along with a 38-metric-ton class Volvo EC380E and two 22-metric-ton class Volvo EC220E excavators on the Mississauga soil remediation job, The Cannington Group added one of its two new 48-metric-ton-class Volvo EC480E excavators specifically for the project.

“We wanted to have the biggest excavators that are going to be usable on other jobsites as well,” explains McCrossan. As one of the larger excavators you’ll find in a relatively urban construction setting, “the EC480E is pretty well the biggest one you can float in without having to take it apart.”

It is expected the Mississauga work will wind down around Christmas of this year. “Most of the work we do will be smaller jobs after this until we get that next big project,” says McCrossan. As such, the equipment “needs to be flexible and available” to be dropped off, put right to work and picked back

At the core of General's drain cleaning machines is our Flexicore cable. Your customers count on it to get the drain open. You count on it to stand up to the most abusive customers. And you count on it to keep your maintenance costs down and your profits up. There really is a big difference in cables – Flexicore is the best!

up again every few weeks.

The choice of teammates for the various Volvo excavators on the Mississauga site was likewise strategic, albeit for different reasons. All four of the Volvo articulated haulers are 25-ton A25G models. “We did the numbers on 30-ton rock trucks, even 40-ton rock trucks, and we found the 25s with the low ground pressure are just the ones to go here,” explains McCrossan. “It’s a smallish site, there’s close dumping, so there just wasn’t any advantage in using bigger, costlier trucks that also cost more to run.”

Having owned and managed a fleet of articulated haulers during one of The Cannington Group`s earlier eras as a larger sewer and water main contractor, “we’re very familiar with how to use them, and the best uses for them,” he says, “and this is the perfect application.”

Unlike the mass excavation of virgin or agricultural land for future development, a remediation jobsite almost becomes dozens if not hundreds of small excavations of varying widths and depths.

“There are other contractors who have priced this as a bulk excavation job and they were actually cheaper than us,” says McCrossan, “but the client went with us because of our experience with remediation and what is basically a surgical excavation. It’s slow, it’s methodical, and there is a lot of direction in

Strongco provides a Volvo EC380E and two EC220E excavators. The Cannington Group added one of its two new EC480Es.

n Heavy gauge wire coiled tightly around 49-strand aircraft type wire rope

n Kink-resistant

n Unequaled strength with the right amount of flexibility

n Low maintenance

n So tough, it's backed by the best warranty in the business

For more information, call the Drain Brains ® at General at 800-245-6200, or visit www.drainbrain.com/rentall

the field from the consultants.

“You can’t just haul away clean materials as impacted. It’s just too expensive.”

The remediation contractor is continually dealing with different contaminants, different depths of contamination and different types of soil, along with the seasonal factors of rain, snow and frost that left the Mississauga site almost bog-like in the spring. Despite the muddy and even flooded conditions, the Volvo A25E articulated haulers were able to bear down and work their way around the site and keep the project moving.

“The job changes by the day, sometimes by the minute, and if we’re waiting for samples and we’re waiting for results and the consultant hasn’t gotten back to us, we need to be able to go from one area to the next and keep working,” says McCrossan. “There needs to be a lot of coordination, a lot of flexibility on-site for us to be able to continue to keep moving.”

When the environmental consultants need to do their testing at key excavation spots the operators can move their machines elsewhere on-site and continue being productive with stockpiling or other maintenance duties.

When lining up a job such as this, the remediation contractor is provided the scope of work, including depths of excavation, known locations of contamination and estimated quantities of material, says McCrossan. “Then it’s up to us as the contractor to look at the resources we need to be able to perform the work,” he explains. “With this one, we basically took their 24-month schedule and said, ‘Not a chance. We can do it in 14.’

“It’s 75 acres in total, but we’re working our way out of space about five months in,” McCrossan explains. “The more we excavate, the bigger the piles of clean material get and the less real estate we have to drive on and to stockpile on.

“It’s going to continuously get tighter.”

With the support of Strongco and Volvo Construction Equipment, McCrossan is right at home doing environmental contracting.

“We’re back to what we do and what we do well,” he says of The Cannington Group. “It’s a good market, it’s an invited market, so we very rarely need to get into public work. With this field, we’re invited to site meetings, we’re invited to bid jobs, and we work on sole-source jobs.

“We’re pretty good at what we do and the industry knows that.” Maximizing the technologies available for its niche work, the company has most recently launched a vibrant UAV or drone program that provides services both on projects in-house and available for outside contract work.

Speaking of being right at home, the site being remediated in Mississauga is actually one of three conjoined properties and The Cannington Group actually worked on preparing the other two properties for their respective next lives.

“It turns out, I knew more about this site than the current owners did,” he says. “I used to come in here on the knee of my dad in his dump truck.”

As the land itself passes from one generation to the next, it seems only fitting The Cannington Group is the one doing the careful nurturing. CRS

Congratulations to our 2018-2019

ARA Foundation Trade/Technical/Vocational

Scholarship - $3,000 USD

Matthew Paton

EZE Rent-It Centre, Chilliwack, BC

Dorothy Wellnitz Scholarship - $1,500 USD

Chris Hrdlicka

Spectrum Rent-All, Edmonton, AB

Doug Mitchell Scholarship - $1,500 USD

Myra Altwasser

BRK Equipment Rentals, Brooks, AB

Sunday, February 17, 2019

Regular members will be able to register for this event via the 2019 ARA Show registration starting September 4th at arashow.org

CRA Suppliers visit crarental.org to register and learn more about Sponsorship & registration Opportunities

Common: a word to describe something that’s well-known by the masses, whether it’s common knowledge or a common way of doing something. But nowhere in the definition of “common” does it say, “the best solution.” Such is also the case with 19-foot scissor lifts.

by JUSTIN KISSINGER, marketing manager, Custom Equipment

Self-propelled low-level lifts weigh as little as 1,273 pounds and feature dual front wheels that distribute the weight, resulting in low wheel loads. Contractors can get on to fresh concrete sooner and work on finished floors such as tile, raised floor panels and laminate, with minimal risk of damage.

While these units are the most common pieces of equipment used to reach workat-height jobs, they are not always the best solution. In fact, in most cases, a 19-foot lift is overkill in the height department and, when it comes to accessibility, lifting capacity and maintenance, its performance falls short. The best solution? A not-so-common self-propelled low-level scissor lift.

What’s classified as a low-level lift? Low-level scissor lifts feature a platform height between eight and 14 feet, allowing users to work at 14 to 20 feet. Most general contracting jobs, such as framework, electrical and HVAC, fall within this range, making low-level lifts ideal for use on these types of projects. But they do more than just elevate to the right height. They raise productivity thanks to several features that enhance ease of use, ergonomics and capacity.

A low-level scissor lift offers as much as 250 pounds more platform capacity than its taller counterparts, resulting in significantly more opportunity to carry materials and an extra person. More materials in a single trip saves time and money, not to mention hassle, resulting in a more profitable job.

While low-level lifts can hold more weight, they actually are lighter than 19-foot lifts. Nineteen-foot models weigh about 2,800 pounds on average, which equates to higher wheel loads that can damage finished floors and prolong the time before they can be used on green concrete.

Self-propelled low-level lifts, on the other hand, weigh as little as 1,273 pounds and feature dual front wheels that distribute

the weight, resulting in low wheel loads. Contractors can get onto fresh concrete sooner and work on finished floors, such as tile, raised floor panels and laminate, with minimal risk of damage.

For example, let’s say an insulator needs to wrap ductwork in a computer lab. The floor is finished with 24-inch-square raised floor panels that can withstand a rolling wheel load as high as 600 pounds. A rolling wheel load is the lift’s weight divided by the number of wheels, so four. This means that the 3,160-pound lift

rom a very inauspicious beginning n a small blacksmith shop originally started in 1882 by Edward Brunner and Severin Lay, Brunner & Lay, Inc. and its affiliated companies have become ed as the quality leaders, as well ufacturer of paving breaker tools.

Today, using the latest state of the art equipment in its facilities throughout the world, Brunner & Lay, Inc.’s entire output is devoted to the manufacture of pneumatic and hydraulic tool accessories for the construction, rental, mining, and demolition industries.

The worldwide operations encompass manufacturing plants and warehouses on three different continents. These include seven facilities in the United States, three in Canada, three in Great Britain,

one in Germany, and two in Australia.

Brunner & Lay products are divided into three major categories: tools used for the demolition or cutting of concrete and stone, drill steels and carbide tipped bits which are used to drill blast holes in quarries, mines, and construction projects, and small chipping and electric hammer tools which are used by the general construction trade.

It is with great pride that the Brunner & Lay organization can point to the many wonderful highways, dams, airfields, mines & quarries, and national monuments it has shaped. These include, but are not limited to Mt. Rushmore, Hoover Dam, the Chunnel connecting England and France, the Eisenhower Tunnel in Colorado, and Olympic venues worldwide.

Brunner & Lay is confident that its products will contribute to worldwide health, growth, and prosperity far into the future.

Low-level scissor lifts feature a platform height between eight and 14 feet, allowing users to work at 14 to 20 feet. Most general contracting jobs, such as framework, electrical and HVAC, fall within this range.

cannot be used since it has a 790-pound rolling wheel load. Now the insulator has two options: either use a ladder or consider a low-level lift. Even the tallest of low-level lifts, a 14-foot model, has a low enough rolling wheel load – 412 pounds – to work on this raised floor without causing damage. And because it offers as much as 15.63 square feet of platform space to load with supplies and is inherently safer and more ergonomic than a ladder, the lift is the optimal choice.

The ergonomics of low-level lifts versus ladders are a no brainer, but are they any more ergonomic than 19-foot lifts? One might think that a lift is a lift and the benefits of one model to the next are the same. But upon closer inspection there are some key differences that can impact ease of use and injury risk.

Entry height is one of those features. Nineteen-foot lifts have entry heights as high as 42 inches, which includes multiple steps up and onto the platform. What’s more, a contractor can’t simply step up and on to the lift’s platform. They must first undo a chain or lift a bar – a cumbersome task when loading materials by oneself, let alone when carrying materials onto the lift. The step-up height and not-so-user-friendly entrance on to 19-foot platforms leaves ample room for injuries, from trips to strains.

Conversely, low-level lifts offer swing-open gates so contractors can focus on productivity rather than avoiding injuries. They also keep entry height to a minimum: as low as 20 inches.

Once work gets rolling, being able to quickly and easily move from one spot to the next within a confined jobsite is critical to maintaining productivity. Nineteen-foot lifts can take up nearly five square feet more than low-level units, so

they can be challenging to get into tight areas and manoeuver through doorways. Also, the wider the lift, the wider the turning radius, so manoeuvering around tight corners can be a challenge as well. Nineteen-foot lifts have taller stowed heights, too, which leaves little clearance for getting under doorways. Personnel elevators are a challenge as well since the lifts are often over the weight capacity. Low-level lifts offer shorter stowed heights and are generally more compact, yet offer ample platform space so they are ideal for construction tasks in tight jobsites and finished spaces.

Getting the lift into the space is just one part of the equation; leaving that space the same way it was found is another. A person wouldn’t wipe their muddy feet all over a friend’s $800 wool area rug and, likewise, when working in a finished space, a lift operator shouldn’t leave unsightly scuff marks or hydraulic fluid leakage for someone to slip on.

The operator can, of course, clean up scuffs and fluid, but they also can nearly avoid them — and the related cleanup time and expense — with low-level lifts. Low-level units with a hydraulic system that only powers the lift up and down, with battery power for the driving and steering, only have two hydraulic connection points. Compared to larger lifts, which typically have more than 20 connection points because hydraulics power the steering, driving and lifting, the chance of a hydraulic fluid leak is greatly reduced. Some low-level lift hydraulic systems even feature a pump and cylinder that are combined, eliminating hoses. This minimizes the risk of a leak that can lead to potential carpet damage and slip hazards. In addition, counter-rotating wheels reduce friction, which allows users to manoeuver over tile or carpeting without marking or causing tears.

It’s common to think a 19-foot scissor lift is the best option for work-at-height tasks but a closer look at low-level lifts reveals that taller isn’t always better. Whether it’s their lower wheel loads or higher platform capacities, low-level lifts are designed to take on nearly any project while keeping ergonomics, safety, ease of use and productivity as top priorities. CRS

You’ve seen the ads. Your electrical utility has probably tried to incent you to buy it for your house. And your new car is full of it. But does LED lighting have a place in your rental lighting equipment?

by BRIAN ASTL, president of Lind Equipment

Choosing the correct colour temperature of your lighting is important for your customers’ comfort. The best option is the same as the sun: around 4,500 Kelvin.

LED technology has certainly come a long way. Even as recently as 2017, there was not a cost-effective way to replace large metal halide tower lights with an equivalent LED option. But just because it’s possible to have LED in all your rental lighting, does that mean it’s something that you should do? Is there a return on investment for equipment rental in moving to LED? And if so, where does the ROI come from?

We’ll talk about how to find the ROI. And, if the ROI is there, how do you fight through all the specs on lumens, lux, colour temperature and more to select the right LED lighting?

ROI can come from non-intuitive places. For example, replacing your household lights with LED lights does not make sense on the power savings alone. You just don’t run your household lights for long enough to pay back the difference in price via power savings. The ROI in switching to LED is when you hit the

number of hours where your old CFL bulb would burn out but the LED is still working. It’s avoiding having to replace the CFL bulb that gives you the ROI from investing in LED for your house. There is a similar argument for equipment rental.

Since you (the equipment rental company) is not actually operating the lights, there is no value to you in the energy saving ability of LED lights. Sure, LED can use 80 per cent less power than traditional bulbs and put out the same light, but the customer is not plugging into your power. So where are the savings for you?

With well-built LED lights, a tremendous amount of maintenance disappears. Maintenance work that you can’t charge for and just results in expenses.

If you currently have bulb-based lighting to rent, whether it be floodlights or tower lights, take a look at how much time is spent internally on changing bulbs and ballasts. Bulbs have intrinsically weak points in the filaments and the glass covers. They break

from being transported, being used and eventually just from old age. The same goes for the ballast, a critical part of large-output bulbs, which can be damaged in myriad ways and need replacing. A well-built LED light can come off rent, be given a hose-down if it’s dirty then put right back into service.

Additionally, LED lights can be more cost-effective than bulb-based lights. Take the traditional four-1,000watt-bulb metal halide generator light tower, for example. Since the lighting technology is so inefficient, the tower needs to have a large generator permanently attached to it. This generator is so significant that most of the cost and weight in the light tower can be directly attributed to it. An LED tower can use 80 per cent less energy and not require a large generator, making it a less expensive asset to buy. Paying less but renting at the same amount is a direct ROI contributor.

There is also value for customers to renting LED lighting. LED tower lights, floodlights and cart lights provide your customers with features they will appreciate, which will secure your competitive advantage over their other options.

As mentioned before, LED rental lighting will make bulb changing a thing of the past, which means your customer is always receiving the light they need. LEDs are also significantly more energy-efficient than bulb-based lighting, which means the operating costs for your customers are significantly reduced (especially if they work off generators). LEDs also give off very little heat and start up instantly, creating a safer work environment.

In addition, if built right, LEDs can also create a more flexible work environment. The low energy usage means most LED rental lighting can be either plugged into external power or run off a small suitcase generator. Well-built LED lights are designed with consideration for how the customer uses them, providing for ease of use and easy movement around the job site. Taking advantage of LED technology is simply not enough; there must be innovation

in how the LED lighting is deployed to give real value to the end customer.

Since there is the potential for reduced maintenance and asset cost while providing a better solution to your customers, it seems that LED rental lighting might be a no-brainer. However, like any product, there are good LED lights and bad LED lights and everything in between. Knowing how to evaluate a potential LED product is the best way to ensure that you and your customers are happy.

Let’s dive into some of the terminology used, and how you should think about it.

Lumens is a measure of the entire light put out by a source of light. This is an objective way of saying how bright the light is. There is no way you should buy an LED light that isn’t as

bright as the bulb-based lighting that your customers are used to. It’s just a potentially more expensive way to give your customers less.

That being said, it’s not always easy to match apples to apples when talking about bulb-based lumens and LED lumens. One of the questions that we get on a regular basis is why LED light data sheets show a smaller lumen number than the bulb-based lights they are replacing. If they are truly the same brightness, then shouldn’t the lumen value be the same between the LED light and the traditional bulb?

Take for example our LE980LED large-area LED light, which replaces a 1,000-watt metal halide bulb. The LE980LED produces 30,000 lumens versus the 100,000 lumens reported for a metal halide bulb. How can we claim that they are the same brightness?

It all comes down to the differences in the lighting technology behind LEDs and bulb-based lights. While bulbbased lights may show a higher lumen

number, what really matters is how much of that light is actually useable. A 1,000-watt metal halide bulb typically comes in at 100,000 lumens. But that’s the total amount of light it produces. Half of that light comes out of the bulb going in the wrong direction – back into the light fixture housing and not towards the work area. Light fixture reflectors really do very little to reflect the light back, and so you immediately lose half your 100,000 lumens right away.

Of the 50,000 lumens that are projected towards the job site, 40 per cent of that deteriorates in the very early part of the life of a 1,000-watt metal halide bulb. As the bulb ages, its ability to produce light is reduced, and in metal halide bulbs that’s a very quick reduction.

So now you end up with 60 per cent of 50,000 lumens, or 30,000 useable lumens from a 1,000-watt metal halide light. And that’s the same lumens projected by equivalent LED lights that send all their lighting to the job site and have very little light-power deterioration over time.

Ask your potential LED lighting supplier to get to the heart of the issue. Your customers need a certain level of light to do their job and don’t want to be disappointed post-rental.

You may be surprised to learn that a white light may actually be bluewhite, or yellow-white. Sometimes called “cool white” or “warm white,” this range of white is called the colour temperature and is measured in Kelvin. LEDs can be made anywhere along the spectrum, from a warm white 2,700 K to a cool white 5,000 K or more.

The best LEDs are those that match the light temperature that our eyes have evolved to use best: that of sunlight (around 4,500 K). LED lights that are lower Kelvin will look more yellow, which makes it hard for the eyes to discern detail. LED lights that are higher Kelvin will look more blue or purple, which is simply strange to work in and foreign to our eyes.

However, it is cheaper to make high Kelvin (over 5,000 K) LED lights, so

you can get an indication right away of the quality of the light by the colour temperature.

To truly get ROI from your rental equipment, you need to ensure it can be used again and again without needing maintenance or repair. Again, you will not be surprised to learn that there are varying degrees of durability associated with LED lighting.

LED retrofit bulbs (those that can twist into existing bulbbased sockets) are the least durable and are typically made only for indoor use where they will not be subject to physical shocks. While these are cheap to make, customers often find themselves replacing these LED bulbs, which is counter to the value that LED was supposed to add in the first place. Selecting a purpose-built LED light with a strong outer housing and a truly weatherproof construction is the optimal solution for equipment rental. Look for the ability to be used in “wet” areas, not “damp” areas, as you never know where your equipment will be placed on a job site.

In summary, there are plenty of reasons to move to LED rental lighting for your business, from lower maintenance to a better customer experience. However, be sure to do your homework when buying. We’ve spoken to many equipment rental companies who were soured on LED technology because they bought a light that wasn’t bright enough, or didn’t last very long in the field. Get references, carefully read the specs and ask questions, just like you would when buying any other rental asset. CRS

Brian Astl is president of Lind Equipment, a manufacturer of portable electrical equipment for the toughest workplaces. Brian holds an MBA from Harvard (with honours) and is a recipient of the 2018 Canada’s Clean50 award, which offers recognition to Canada’s leaders in clean capitalism.

Continued from page 20

When determining the attachment best suited for the application and power rating, look for a product that is durable and easy to service. Some attachments may seem great up front, but end up being a nightmare of downtime and repair costs.

One method for choosing a low-maintenance attachment is to find a tool with no or very few protruding parts, such as hydraulic hoses. These can be easily damaged during operation, particularly in harsh demolition environments. Look for attachments with these components enclosed within the tool yet are easy to access through service openings.

Also keep wear parts in mind. Shear and crushing attachments’ cutting edges and teeth need to be replaced when worn. Exchangeable cutting edges are an industry standard, but it’s still smart to ensure they are available.

When considering multi-quick processors, pay attention to how quickly jaws can be switched out. Some manufacturers build multi-quick processors with jaws that operators can change within minutes on site, compared to the hours needed to bring many other attachments back to the shop to exchange. Workers only need to manually remove one pin from quick-exchange models during change-outs, compared to three from many other manufacturers’ processors. The rest of the jaw exchange process is done hydraulically from the safety of the cab. This system not only removes the hassle of pounding out two or three pins, but virtually eliminates the danger of the jaw falling and injuring a worker after the last pin is removed.

Just like with beer, the best tool depends on the situation. Seasoned buyers and industry newbies can all benefit from taking a careful look at their options and requirements while searching for a new attachment. CRS

Construction Electrical Products has introduced two new products to its LED lighting line. Models 6710-I and 6125-I are two new economy LED fixtures complete with a set of features for jobsites that need reliable, low-amperage work lights at a great price. Both fixtures utilize the latest in chip-on-board LED technology, providing 3,500 lumens per head. While the 6125-I is a single stubby fixture, the 6710-I twin head provides the added bonus of a 6.5-foot tripod or built-in floor stand. Both models include an aluminum housing and polycarbonate lenses.

atlascopco.com

Atlas Copco has launched three new electric plugand-light LED light towers to the North American market. The HiLight P2 Plus, V2 Plus and V3 Plus light towers can be powered directly from an auxiliary power

source, a portable generator or the grid. The three energy-efficient additions offer easy portability, safe transportation and durability. Excellent for construction and roadwork, the HiLight V2 Plus and HiLight V3 Plus are housed on a four-wheel trailer for ease of transportation. Both compact models come with a heavy-duty steel frame, stainless steel mast and protective polyethylene bumpers designed to the same standards as the Atlas Copco HardHat canopy. The HiLight V2 Plus offers a 320-watt LED light source covering 21,528 square feet. The HiLight V3 Plus is equipped with four 160-watt LED bulbs with specially designed directional glass optics capable of illuminating an area of up to 32,292 square feet. Both the V2 Plus and V3 Plus have manually operated vertical masts that extend up to 18 feet. The towers are designed to withstand wind speeds up to 51 miles per hour. Ideal for almost any application, the HiLight P2 Plus features the same special lighting optic as the HiLight V2 Plus. The floodlight provides 360-degree coverage across a 21,528-square-foot

illumination area — a much greater area compared to traditional balloon-style light towers. The light source is housed within a weatherproof cylindrical polyethylene housing with built-in cooling for no burnout and a longer operating lifetime. The housing does not require air pressure or complicated mechanisms to operate. The entire HiLight P2 Plus assembly weighs just 99 pounds, yet is robust and designed to withstand wind speeds up to 32 miles per hour. The manually elevated vertical mast provides a maximum operating height of 11 feet. The LED lamps on all three new models have a life expectancy of more than 30,000 hours. LED HiLight tower lamps have an aluminum casting which provides heavy-duty protection, even during transportation.

COMPACT AND TOUGH

ca.wackerneuson.com Wacker Neuson has added