Just-in-time jobsites Pg. 12

Aging in place Pg. 14

Condo reno tales Pg. 18

Just-in-time jobsites Pg. 12

Aging in place Pg. 14

Condo reno tales Pg. 18

Level Custom Build’s young owners look like the shape of things to come

High-quality products do more than speak for themselves. They speak for your work, too. When you create your outdoor projects with Deckorators innovative decking and railing products, your clients will notice—and so will their neighbors. Build with Deckorators and get used to the attention. To learn more, visit deckorators.com.

Josh Oladehinde and Alvaro Rodriquez are taking Level Custom Build to new heights with old-school hard work and discipline mixed with modern tools and new ideas.

By Patrick Flannery Editor

” Canadian Contractor promises to depict the industry as it is, not as we might wish it to be. ”

We publish a lot of photos of people working on job sites – it’s one of my favourite kinds of content because I think it brings us together as an industry when we see others around the country doing what we do. Inevitably, some of those photos depict people not executing safety best practices. Lack of PPE; ladders at bad angles; lack of fall protection; power cords snaking around unsecured; standing under the buckets of excavators...etc. etc. When these photos appear, I’ll get a few phone calls and emails complaining about them (which means there are probably hundreds of others thinking the same thing). The complaints come from a very good place. People feel strongly that working safely is important and try hard to promote safe practices on their teams and in the industry as a whole. Often, they’ve been injured themselves and don’t want to see anyone else have the same experience. From there, they go to the position that Canadian Contractor should not depict unsafe practices. The concern is that, by doing so, we might mislead our audience as to what constitutes safes work or diminish the importance of working safely.

This position rests on the assumption that Canadian Contractor is boosting, advertising or otherwise promoting the companies we profile. We are not. We are simply telling their stories, as honestly and effectively as we can, so that you might read them and understand the business world you live in a little better. Our profiles are not intended to present the subject companies as avatars of contracting perfection or examples to follow. They are intended to give you an accurate picture of a fellow business in the industry. It boils down to this: Canadian Contractor promises to depict the industry as it is, not as we might wish it to be.

If we whitewashed our depiction of the industry and only showed workers wearing the hard hats, gloves and goggles they most certainly are not, would that help or hurt the goal of encouraging safe behaviour on job sites? Does pretending a problem doesn’t exist promote resolution of that problem? Or might one of the people inclined to complain about the photo hold that image up in front of their team and use it as an example of what not to do? I’m perfectly comfortable with our content being used in the latter way.

Some may feel the above amounts to a disavowal of our responsibility to promote safe work. In this era of activist journalism, it may surprise you to learn that we acknowledge no such responsibility. Advocacy and persuasion to change the behaviour of the Canadian construction industry is the business of others.

The photos in our profiles are provided by the profile subject or approved by them if we took them. Sometimes readers express concern that the subject will get into trouble with the relevant safety authorities because of unsafe behaviour exhibited. That’s the subject’s concern and they are the one qualified to evaluate their level of exposure to risk.

If you are one of the dedicated and admirable individuals who are passionate about seeing Canadian construction workers work safely and never want to see another image of someone doing something unsafe, I recommend you do everything you can to ensure that actual workers on actual jobsites are not behaving unsafely. Then I won’t be able to get any photos of such behaviour.

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Flip through the digital versions of your favourite past issues of Canadian Contractor. All available in the digital edition archives at canadiancontractor.ca.

Episode #62: Deposit Not Refundable: In an business where trust is perhaps our most valuable commodity, the ongoing presence of dishonest contractors and outright fraudsters hurts us all. Alex Kimmich left the tools to do something about it, establishing the BetterBid online service that connects homeowners to a vetted list of reputable local contractors. He joins The Hammer to discuss the scale of the scamming problem in Canada today and go over some of the creative new methods these criminals are employing. Find The Hammer at canadiancontractor.ca, or wherever you get your podcasts.

Looking for a longer read in your inbox? Each month, Canadian Contractor delivers a full version of one of our features straight to your email. Kick back in your favourite chair and take in an engaging reader profile, an informative technical article or an inspiring project review – right there in front of you.

Sometimes we all just need a break from the chaos in today’s headlines. Canadian Contractor is here for you with a monthly special version of our e-newsletter focused on the happy events in our industry: someone gets a new job, a company makes a nice donation, a reader wins an award, etcetera. It’s a lighter, uplifting read, delivered free to the inbox of our digital subscribers.

Audience Development Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com

Media Designer Graham Jeffrey

Group Publisher Danielle Labrie (226) 931-0375 dlabrie@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

The federal government lifted the counter-tariffs on American imported goods put in place in March on Sept. 1. The Department of Finance website reads: “In recognition of the U.S.’s approach to allow most Canadian goods to enter the U.S. tariff-free under the Canada-United States-Mexico Agreement (CUSMA), Canada is removing counter-tariffs put in place in March 2025 on most U.S. imports, effective September 1. Canada’s counter-tariffs on steel, aluminum and automobiles remain in effect as intensive negotiations with the U.S. continue. This is in recognition that the U.S. maintains tariffs on these sectors, without providing an exemption for CUSMA-compliant goods.”

This means Canadian tariffs will no longer be applied when products the following categories are imported:

• Floor coverings of plastics, whether or not self-adhesive, in rolls or in the form of tiles; wall or ceiling coverings of plastics;

• Self-adhesive plates, sheets, film, foil, tape, strip and other flat shapes, of plastics, whether or not in rolls;

• Baths, shower-baths, sinks and wash-basins;

• Lavatory seats and covers;

• Doors, windows and their frames and thresholds for doors;

• Most pre-cut wood products, including veneer, flooring,

particle board, fibreboard, plywood, wood doors and windows, shutters, post and beams, shingles and shakes, flooring panels, glulam and engineered timber;

• Power, pneumatic, hydraulic and manual hand tools of most kinds;

• Fans: Table, floor, wall, window, ceiling or roof fans, with a self-contained electric motor of an output not exceeding 125W;

• Chandeliers and other electric ceiling or wall lighting fittings, excluding those of a kind used for lighting public open spaces or thoroughfares.

Natural Resources Canada announced on Sept. 17 the Canada Greener Homes Loan (CGHL) program’s funding has been fully allocated and the application portal was to be closed on Oct. 1. Homeowners were told they needed to submit applications with their completed EnerGuide evaluations before the Oct. 1 date in order for their project to be considered, with no guarantee of application approval. EnerGuide evaluations cost around $600 and must be completed before an application can be filed. The program started in May 2021 and provided interestfree loans of up to $40,000 for energy-efficient renovations recommended by an energy advisor audit. Over 120,000 loans have been given out totalling $2.9 billion.

Energy efficiency advocates, Efficiency Canada, are not happy about the termination. “Efficiency Canada is deeply concerned by the federal government’s decision to close applications to the Canada Greener Homes Loan Program,” it said in a release. “The program is the principal way the federal government is helping middle-class Canadians reduce their energy costs and greenhouse gas emissions – offering interest-free loans for upgrades like heat pumps, insulation, windows, and solar panels. It supports careers in the skilled trades, strengthens local supply chains and helps households lower bills while cutting emissions. The sudden announcement mirrors the abrupt end of the Canada Greener Homes Grant last year, which left contractors and homeowners scrambling.

“’This is the second major energy efficiency program to be abruptly shut down in as many years,’ said Brendan Haley, senior director of policy strategy at Efficiency Canada. “These kinds of boom-bust policies drive skilled tradespeople out of the sector, disrupt small businesses, and erode public trust.’”

Royal Homes in Wingham, Ont., has been acquired by a management group led by industry veteran Sid Kerrigan, the long-time president of Brookfield Residential’s Ontario housing division. Royal Homes has built custom prefabricated homes out of its 115,000-square-foot manufacturing facility in Wingham for 55 years.

“Our market needs a faster, more efficient way to construct and deliver new homes, and Royal Homes will play a lead role in driving that innovation forward”, said Kerrigan.

To scale up the business, the Wingham manufacturing facility will see a significant financial investment that is expected to create hundreds of new jobs over the next three to five years.

“Royal Homes is an integral part of the Wingham community. We are committed to growing our investment,” Kerrigan added.

Mattamy Homes CEO, Peter Gilgan, is launching Stelumar Advanced Manufacturing (SAMI), a technology company that will harness automation, robotics and AI to create modular housing solutions on a large scale. Backed by Mattamy Asset Management (the parent company of Mattamy Homes), SAMI will specialize in the advanced manufacturing of residential building components including modules, wall panels, floor systems, cabinetry and millwork, all designed to streamline and accelerate the construction of sustainable and livable homes that are more affordable. SAMI sees an opportunity to collaborate with all three levels of government in Canada to help scale production capacity and deliver thousands of homes annually for Canadian families. With deep industry expertise and alignment with the federal government’s ambitions for modular housing, SAMI feels it is well-positioned to contribute meaningfully to the effort to expand Canada’s housing supply and address the housing crisis. SAMI’s manufacturing facility, expected to be online next year in the Greater Toronto Area, will be a highly advanced, automated and data-driven production plant. While it has a strategic relationship with Mattamy Homes – both as investor and key customer – SAMI will operate independently, serving a broad spectrum of homebuilders across the industry.

“I’ve been thinking about the prospects in this space for some time, and as technology started catching up to the vision, we started to seriously look at the opportunity in the last couple of years,” said Gilgan. “I’ve got an extraordinary passion to make this work, to provide livable and sustainable housing that is more affordable for Canadians across the country.”

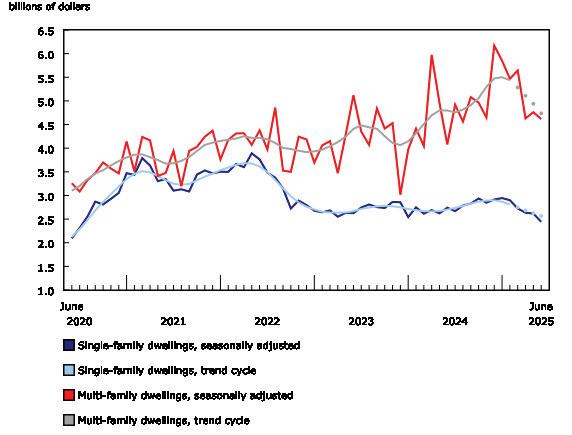

The total value of building permits in the second quarter 2025 was down $1.9 billion to $36.7 billion, following five consecutive quarterly increases. The residential sector (down $3.8 billion) drove the decrease, while Ontario’s non-residential sector (up $2.5 billion) tempered losses in the second quarter. Residential construction intentions declined 15 percent, totalling $21.7 billion in the second quarter. The multi-family component (down $3 billion) drove the decline, fuelled by losses in Ontario ($1.6 billion) and British Columbia ($1.3 billion). Ontario’s decrease was driven by the Toronto area (down $1.4 billion), which experienced a second consecutive quarterly decline. The Toronto area recorded its lowest constant dollar value since the series started in 2018, despite having significantly contributed to the growth in the fourth quarter of 2024. The Vancouver area (down $1.2 billion) drove the decline in British Columbia in the second quarter of 2025, after leading growth in the national multi-family component in the first quarter. In the second quarter, the single-family component decreased by $874.3 million to $7.7 billion, led by Ontario ($645.1 million) and supported by Alberta ($207.1 million). A total of 305,400 single-family and multi-family units were authorized for construction from the third quarter of 2024 to the second quarter of 2025, an increase of 37,900 units (14.2 percent) compared with the 267,500 units authorized over the same period one year earlier.

Most municipalities in the Greater Golden Horseshoe, including the city of Toronto, have been given a failing grade in a comprehensive new report done by the University of Ottawa’s Missing Middle Initiative for the Residential Construction Council of Ontario (RESCON). Disturbingly, of the 34 municipalities that were graded, 22 received an F, another five received a D, and the other seven municipalities received a C or higher. Brantford had an A-plus and Milton an A. Municipalities were graded in five categories related to housing starts and sales.

The assessment is based on data obtained from Canada Mortgage and Housing Corporation and Altus Group. Researchers did a deep dive on housing starts, sales and industry employment across municipalities in the Greater Toronto Area and Greater Golden Horseshoe region over the first six months of 2025, relative to the same time period in the previous four years (2021-25). In the first six months of this year, housing starts were down an average of 40 percent in the 34 municipalities. Condo apartment starts over the first six months were down 54 percent relative to 2021-24 while purpose-built rental starts were up eight percent. Starts for everything other than apartments were down 42 percent, showing the weakness is not just confined to condos. In the city of Toronto, starts in the first six months of 2025 were down 58 percent and sales declined 91 percent compared to the same period between 2021-24, causing employment to fall by an estimated 10,209 jobs.

Level Custom Build looks and feels like the shape of things to come.

By Patrick Flannery

The late David Bowie made a comment about the singer, Lorde, when she was topping the charts a few years ago. “She sounds like the future, doesn’t she?” You get the same feeling when meeting Josh Oladehinde and Alvaro Rodriquez, co-owners of Level Custom Build in Toronto. Rodriguez, 32, has an incredible backstory. He was born and spent his early childhood in Bogota, Columbia. When he was seven, in 2000, his mother was forced to flee instability in the country with him and his brother. The

family entered the United States. But the U.S. asylum system was very slow and difficult to navigate, forcing the family to live undocumented for three years. She heard about the Canadian asylum program and applied. That, too, was a long process but eventually successful and with the help of friends moved to London, Ont. Rodriguez went to high school there, then to the University of Toronto where he got a degree in... biotechnology and genetics.

That’s right, Rodriguez is a construction contractor with a genetics

degree. How did he end up in the trades? “I was always interested in property management,” Rodriguez says. “And I’ve always been handy with my hands.” So when future business partner, Joshua Oladehinde, approached him (they met at school) asking for help to incorporate his construction startup, Rodriguez asked to be more involved. “I was interested to see what he wanted to do there,” Rodriguez remembers.

It turned out Rodriguez was a natural, picking up the basics of building after briefly watching others.

“Even our plumber was impressed,” Oladehinde laughs.

Oladehinde’s family also fled strife in another country, albeit before he was born. His mother, grandfather and uncle fled civil war in Nigeria in the ‘70s, taking advantage of a University of Toronto immigration program for students. Oladehinde was born in Toronto in 1990. Decades later he followed in his grandfather’s footsteps and went to U of T for... political science and philosophy.

So how the heck did a geneticist and a political philosopher end up starting a Toronto construction contracting company called Level Custom Build?

Like many young students, Oladehinde, 35, had odd jobs in the trades doing paving, demolition and drywall for friends. He says he was fortunate to have bosses who threw him into things and gave him a chance to learn. So he had contact with the industry.

But still, the creation of Level Custom Build almost didn’t happen. After university, Oladehinde joined the Armed Forces as a reservist and trained for six years as an intelligence analyst. “It was just what I studied: political science,” he recalls. “I was kind of a cool fit.” But Oladehinde’s contract was Class A (part-time) and he needed more work. His old friend, Eric, needed him for some demolition. It was just supposed to be one day, but Oladehinde found he enjoyed being back working with his hands so he decided to stay at it while he waited for a full-time contract. As the months went past, the Class B contract was not coming through and Eric had made him project manager for the jobs he was working on. Oladehinde says, “I just got this feeling, like, ‘This is what I’m supposed to be doing.’”

Oladehinde decided he wanted to see how far he could take this thing. He went to work for 6ix Build, being upfront that his goal was to learn as much as possible with a view to eventually going out on his own. 6ix Build owner, Michael Cheng, impressed Oladehinde with his skills and knowledge and he learned the basics of general contracting over his two years there. But the final spark to go out on his own came when COVID hit and work initially slowed down. “I needed money,” Oladehinde remembers. “I thought it was about time I take the plunge. There was nothing else really going on.” So in 2020 he reached out to Rodriguez, bought some tools with their savings and started pursuing home improvement jobs. They were joined by Edgardo and Dmytro, who remain with the company today. Other key employees include Vlad and Calvin.

Growth was slow at first, but Oladehinde and Rodriguez were disciplined about re-investing their profits back into the business rather than taking home cash. They estimate their inventory of tools and vehicles has doubled every year. “The boats and vacation homes are not really happening yet,” Oladehinde laughs. “Maybe not happening for a while.”

Early opportunity came from insurance jobs. Flooding in Toronto’s Liberty Village condos meant drywall and flooring replacements. Oladehinde and Rodriguez did a good job with those and were, by their own admission, probably charging too little. So those led to larger projects fixing drywall and

re-tiling whole condo units.

The Liberty Village work ran out after about six months, but Oladehinde and Rodriguez wanted to move on anyway. Their goal had always been interior renovations, not restoration. So they incorporated under the Level Custom Build name and used online lead generation services to find their first renovation job: a bathroom in a townhouse near where they had done all that condo restoration work.

Their timing, in the most unpredictable way possible, was perfect. Few could have known that COVID would cause a surge in renovation demand the likes of which has never been seen in the market before. Established renovators were swiftly overwhelmed and Level Custom Build was there to pick up the overflow. Oladehinde figures that for the first three years they never went more than two weeks without a job, and then only once or twice.

According to Rodriguez, scaling up Level Custom Build required two steep learning curves: how to price work properly and knowledge of the trades. Learning estimating and gaining the confidence to demand fair and safe margins is probably a lesson every contractor has to learn at first. In Level’s case, it came on one of their first big contracts, a large kitchen renovation, where they forgot to price in the cost of replacing the stairs. Another challenge was information about market prices. Without the experience to know the competitive

cost of materials, they feel sure today they sometimes ended up paying more than they should have. Now, with few years under their belt, the details of an estimate no longer overwhelm them and they have a much better handle on what things cost.

Coming out of academia, as both Rodriguez and Oladehinde did, there was extra pressure to gain strong enough familiarity with the technical aspects of a job to be able to evaluate the work their trades did. Luckily, one thing university prepares you for is to be a fast learner and, as noted, Rodriguez finds he’s good at picking up trade skills quickly.

Their youth was also a hurdle to overcome. Early sales pitches would be met with some raised eyebrows and questions about how long they had been in business. It took some extra talking to satisfy clients that they knew what they were doing. It was really a matter of finding someone who would give them a chance so they had a portfolio of work to point at.

Administering the growing business and running the business as a business provided its own challenges. Initially, it was Joist for invoicing and Excel for most everything else. But Oladehinde describes a process where, with each

job, they would think about different metrics they should track and ways to create an established process that would catch all the details and be the same every time. Pre-project budget reviews. Change orders. “We realized that the only way we’re going to be able to compete at a high level is if we make these adaptations each time and we learn from our mistakes,” Oladehinde explains. “The software got bigger, – we use BuilderTrend now – the process became more refined, everything became more formulaic. I think this is something a lot of contractors have experienced that don’t have formal business training. The big thing we realized is that we didn’t really understand how to run a business and weren’t too proud to admit this to ourselves.”

Part of their secret for getting through this period was they never, according to Oladehinde, “punished” their clients. They took pride in delivering whatever was contracted to the clients’ satisfaction, even if it cost them. The referrals and leads, over time, have more than made up for any of the extra costs they had to incur.

Another big challenge the Level Custom Build team had to overcome was

the post-COVID supply shock that sent prices through the roof and made many materials simply impossible to get in a timely manner. “The LVL shortage was a horrible thing,” Oladehinde remembers. “In 2022 we had to drive to Peterborough four hours to grab three LVL beams then drive another three hours.” Again, Oladehinde and Rodriguez dealt with it by refusing to transfer the pain to their clients. There was no change order for the Peterborough trip or the other logistical snafus caused by the shortages.

Today, Level Custom Build has grown to 14 employees with more on the way and is managing three or four projects at a time. They are executing large additions and renovations with extensive structural elements, but the dream of a full custom build is still on the horizon. Getting into custom homes is tough. Oladehinde points to market data that shows only one out of 1,000 custom home bids is successful. He’s also seen bids for very expensive luxury homes go to contractors that are, in his opinion, “suspect.” Companies without a website or a homebuilder licence. He’s unwilling to compete with others who will say anything and undercut the quote to get a job, then not be able to execute.

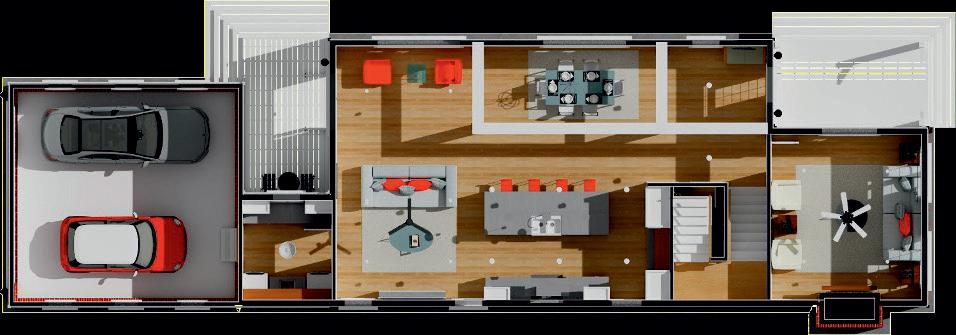

Rather than sit idle waiting for opportunity in a crowded custom home market, Level Custom Build has pivoted to a niche that will likely prove very lucrative as Ontario struggles with its housing shortage: alternative dwelling units. Municipalities across the province are loosening rules for building secondary dwellings on the same lot as the principal residence or converting basements into apartments. But even with the relaxed regulations (which used to ban such projects outright in some jurisdictions), there are still considerations when building ADUs that are different from a regular renovation or custom home build. Oladehinde and Rodriguez have made themselves experts on this topic. (For a more comprehensive look at Level Custom Build’s ADU experience, listen to The Hammer podcast Episode #60: Much ADU

Something.)

As befits their backgrounds, Oladehinde and Rodriguez are able to get philosophical about the construction business. Here are some collected quotes:

On the perpetual productivity lag in the Canadianconstruction industry:

Rodriguez: “You still have a lot of old cats who are still set in their ways. They are still very pen and paper. That’s why they implemented the whole Canada digital adoption plan where the government tried to get people to adopt some of these new technologies but you still don’t see a lot of people use that because they don’t want to go tech. Younger guys like us, we’re very open to technology and which is the new innovation.

On the incoming generation of contractors:

Oladehinde: The way I simplified in my mind is that the motivations for the small construction contractor from, let’s say the ‘70s, is incredibly different than small construction contractors who started recently. I think the motivations are different. There’s alignment in terms of profit motivation. But, for example, us, we’re a little bit more idealistic in the way we view this in that we do want to make money but we maybe, because we’re also educated, we see there’s a process here, right? And there’s a bigger picture than just making that immediate profit off each job.

On using social media to market the business:

Oladehinde: I’d say our success has largely been due to our social media presence. And it’s not even like it’s a large presence, but it does help with our credibility and trust. People see our work. People see our faces on camera, at our job sites, they’re seeing the details. We’re not afraid to show people. You know our work up close.

Rodriguez: We debated for a long time whether or not to go on Tik Tok, but one of our recent jobs was a full bathroom and I was doing a debrief with the client after and she was like, “Yeah, I saw you guys on Tik Tok. Loved what you were showing so I went on your website.” And then that’s why they called us.

Oladehinde: I understand it’s not easy to have the time to address your marketing if you’re too busy on the tools. Our saving grace was, honestly, we’re just not greedy, so we are willing to take our own money and profits and pay it to someone else to help us with that so that we can get more work.

With their dedication to reinvestment, exploration of market niches, use of social media, overabundance of education and diverse backgrounds, Oladehinde and Rodriguez are bringing a fresh approach to this business. It looks like the future, and let’s hope it is. cc

A practical guide to just-in-time material delivery.

By Nick Fryer

Excess inventory on construction sites creates clutter, increases costs and risks theft or damage, a challenge Canadian contractors face daily. In Canada, construction, renovation and demolition activities contribute significantly to waste, with estimates suggesting CRD accounts for about 12 percent of all solid waste, based on Statistics Canada data. For 2022, total waste generated was 36.5 million tonnes, implying CRD waste could be around 4.4 million tonnes.

Just-In-Time delivery tackles this by syncing material arrivals with project needs, cutting waste and storage costs. Proven in manufacturing, JIT is

gaining traction in construction, helping contractors manage tight budgets and rising material costs. This guide outlines practical steps to implement JIT, from choosing reliable delivery partners to integrating it into your workflows.

JIT delivery has been shown to reduce waste and enhance performance on construction sites. Here’s how:

By holding off on inventory deliveries until they’re needed, construction sites save the excess clutter of having to store and hold on to materials for weeks before they go into use. At best, the clutter simply gets underfoot and adds

organizational pressure, but at worst it can expose projects to serious risk.

When materials are sitting around for long periods, that’s when they’re most likely to get damaged or stolen. It’s too easy for things to get lost in the chaos of an active construction site, especially during renovations which are notoriously tight on time and space.Even the best-planned construction projects have their unexpected accidents. Sometimes it’s a burst pipe. Other times, it’s building owners stepping into a construction zone that they shouldn’t have. Either way, the less unnecessary

inventory kept on site, the better, as it means that if things go wrong, expensive materials aren’t damaged in the process.

A breakdown in the supply chain can be a nightmare for a renovation. Delayed deliveries, missing items, or reaching for materials only to find they’ve been damaged in storage can grind construction to a halt and cost teams both the trust of their client and their ability to follow through with other work. By implementing JIT delivery, construction teams can reduce the chance of this happening.

The nature of any renovation project is that things will change. Sometimes the client changes their mind, or a structural issue appears that requires a fresh approach. This is where JIT provides a notable advantage. Most suppliers won’t accept returns after delivery but, until then, there’s usually room for

modification. By holding off on delivery until needed, construction teams give themselves a valuable window in which they can be more flexible and responsive to a client’s needs.

Spreading out deliveries across a renovation also helps ease cash flow issues. It gives the contractor and the client a chance to space out final payments with each delivery. This prevents spending too much upfront and avoids cash shortages later.

Test their communication. JIT delivery requires responsive communication to run properly. Take note of how quickly and effectively a delivery partner responds to queries.

Find out what their contingency plans are. The best delivery partners are the ones who have a plan for every outcome. Make sure to ask about contingency and risk strategies in the case of the unexpected.

“Justin-time delivery keeps construction sites clear of unnecessary materials, expenses and risks.”

Late material arrival can hold up critical tasks, delaying projects and weighing down projects with labour they’re paying for but can’t use effectively. In instances where a delivery can be pushed up, it usually comes with a premium that few renovation budgets can take.

Materials that arrive too early are also a problem. Most renovation sites don’t have adequate storage space and lastminute off-site options are expensive. That’s why proper material timing is such an important part of keeping construction projects running smoothly.

Here’s how to pick a reliable delivery partner who will provide all the advantages of a JIT strategy without the hassle of implementing it yourself.

Check their history. It’s important that delivery partners have strong construction experience and prior clients who can vouch for their consistency and punctuality.

Ask about their scheduling and tracking approach. The best companies will be using the best technology and systems. Real-time tracking, automated updates and data-driven scheduling software are critical technologies to have on hand. They help keep deliveries on time and ensure greater transparency.

Implementing a new delivery strategy can seem daunting but here’s how to start using JIT without disrupting your workflows.

• Test it with a controlled rollout. Use JIT on certain tasks or areas of a site before expanding it. Many even find that a hybrid approach is what sticks best in the long term;

• Add buffering time to your JIT schedule in the early stages as teams nail down the process;

• Take time to ensure proper communication so that delivery plans are aligned with on-site activity;

• Use logistics partners that offer local warehousing and flexible deliveries as you streamline your JIT approach.

JIT delivery keeps construction sites clear of unnecessary materials, expenses and risks. It’s a vital part of building lean projects that deliver better outcomes while costing less. As construction teams face increasing materials costs, this has never been more important.

Transitioning to this approach, however, requires excellent scheduling and delivery partners. Investing in these two areas will ensure that your projects get all the advantages that JIT can offer – from fewer site delays and less clutter, to better flexibility and cash flow management.

Nick

Fryer is vice-president of marketing for Sheer Logistics.

Aging-in-place renovations present an ongoing opportunity.

By Treena Hein

The population of Canada is aging.

According to the National Research Council, Canadians 65 and older are the fastest-growing demographic and are expected to make up 25 percent of our population by 2050.

A vast majority of these older Canadians would prefer to “age in place,” meaning, live in their own homes for as long as they can.

“As Canadians enter their golden years, their housing priorities often change, but no one size fits all,” said Caroline Baile, a real estate broker with Royal LePage Sussex, and accredited seniors agent. “[They] are thinking about their long-term needs much earlier than previous generations. Even before retirement, many buyers are thinking about the features of a home that will help them transition into old age with ease.”

In fact, Baile says that many middleaged clients have seen their elderly parents go through a transition, and this has encouraged them to consider their own future needs.

Overall welfare and financial security play in important role in this decisionmaking. According to the Royal LePage survey, “Canadians Aging in Place,” 74 percent of respondents are increasingly interested in aging in place due to the cost of living in a senior care facility, and 59 percent are concerned for their health and well-being at such a facility.

Meanwhile, the Canadian Home Builders’ Association says nearly 90 percent of Canadians wish to stay in

their homes for as long as possible. Of course, as we age, our mobility and physical abilities change, making it challenging to navigate our homes. But there are adaptations homeowners can make to ease this transition, making their homes safer and more accessible.

Common renovation solutions include:

• Snow-melt systems for driveways and walkways;

• Vertical platform lifts at front porchs or steps;

• Good lighting, especially hallways and stairways;

• Motion-sensor lights;

• Easy-to-reach electrical outlets;

• Elevator or stair lifts inside, for homes with multiple levels;

• Smart home systems for controlling various features (lighting,

temperature, security) using voice commands or an app.

“More and more, Canadians are choosing to right-size rather than downsize as they age,” added Baile, noting that some will opt “to renovate their existing properties to accommodate their changing needs”.

All this represents a huge opportunity for renovation professionals to provide forward-thinking homeowners with the supports they need now (or will need down the road), but only if they understand how support systems related to mobility, cognitive challenges and medical conditions can make aging in place a reality.

Contractors should to be able to talk knowledgeably with both mature and older customers (and caregivers) about

these considerations, then recommend the appropriate systems and solutions to enable aging in place.

And, because installations are guided by standards, what standards could apply to aging in place?

CSA Group says it is collaborating with industry partners, interested parties and persons with lived experiences to create “world-class standards and guidelines” to help meet the needs of Canadians who choose to age in place... whether in their homes or within their communities.

The standards CSA B651 Accessible Design for the Built Environment, CSA/ ASC B652 Accessible Dwellings and CSA B651.2 Accessible Design for Self-Service Interactive Devices Including Automated Banking Machines have been developed to help improve the lives of those livings with disabilities, including the elderly.

Aging in place with dignity... and lots of tech

“We’re bringing together emerging technology, aging adults, industry partners and clinical expertise,” says Bruce Wallace, executive director of the Sensors and Analytics for Monitoring Mobility and Memory (SAM3) Age-Well National Innovation Hub. “It’s time to get this technology out of the laboratory and into the community.”

This team of Carleton researchers, in partnership with the Bruyere Research Institute and Age-Well Network of Centres of Excellence, is developing “supportive smart home systems to help older adults age in place safely and with dignity,” writes Carleton’s Dan Rubinstein

So what does a supportive smart home system looks like?

Wallace stresses that “ambient sensing” (sensors placed strategically throughout the dwelling) is key to aging in place. “If you look at sensors that are worn [on the body], people forget to wear them, so it can be hard to know if they are functioning properly,” he explains. “With ambient sensing, you just live your life as always.”

Looking at power, Wallace says you could have wireless, battery-based sensors (similar to today’s home security

Cameras and sensors can be placed unobtrusively around the home and feed their data back to caregivers.

systems) but that would involve a rather large battery count and would just be another challenging thing for seniors and caregivers to manage.

“Instead, we’re seeing companies using the wiring harness of the house but with USB power using USB outlets in house wall plugs,” he explains. “Also, there are now sensor units that are placed directly within the outlet. That is,

a licensed electrician swaps out an existing light switch or outlet for one of these units. It’s still a switch or outlet but can have motion and temperature and odor sensors powered directly off 120-volt. Control of the switch is achieved by the switch itself with preset settings and/or a motion sensor and/or voice activation.”

Back-up power is also very important for various critical systems, such as charging cellular devices, notes Jim Closs, national director at a Torontobased firm called Age Safe Canada and owner of a consulting firm called Live Easy. He has 30 years of experience in accessible design and will be using emerging technologies in some upcoming aging in place projects.

Closs notes that if you’re looking to add an accessibility product like a stairlift or home elevator – even if they are battery-operated – it’s also important to have these devices on their own circuit based on the manufacturer’s specification so they are charged at all times.

Ark Tsisserev, principal at Vancouver-

based AES Engineering, adds the important note that if the electrical equipment in a home is upgraded or added upon, then the size of the service – including the rating of the service box and ampacity of the consumer’s service conductors – might have to increase.

For years, contractors have been involved in running power for stair lifts, automated doors and additional lighting. (Lighting is especially important on stairs to prevent injury, says Wallace, but also in every room.) In addition, open/ closed sensors on exterior doors are already being installed in the homes of those with dementia.

In terms of what’s new to support aging in place, Wallace points to bed sensing, not just for ongoing data on the health and well-being of seniors, but to support their caregivers. Typically USB-powered, these sensors are placed between the mattress and box spring, or under a bed foot. They detect bed exits and movement that could indicate restless sleep (due to pain) or whether the person is moving enough to prevent bedsores. Some even detect vital signs.

For caregivers, these sensors, when paired with other supportive home

In general, ambient sensors, like these bed-movement sensors, are better than worn sensors. But they are best with a battery-free power supply.

automation, can make all the difference for an individual to successfully age in place.

It’s very important for caregivers to get adequate sleep, says Wallace. He’s conducted trials where the detection of a bed exit is paired with the automatic switch-on of lights in the bedroom, hallway and washroom, thereby enabling a person with mobility issues or dementia to handle washroom trips alone (noting that dementia, as it progresses, includes disorientation from

time and place).

“Our experiments show that this set-up can help the caregiver get eight hours of continuous sleep,” he reports, adding that back-up power for this system should be installed once it’s established to maintain the routine.

Night wandering can also be part of dementia, and Wallace explains that one root cause is the fact that those losing cognitive function generally spend a great deal of time indoors and are therefore much less exposed to changes in the daily natural light wavelength spectrum. This can be mitigated by using light bulbs that create a “solar day” inside the house by changing the light wavelengths emitted (via an app).

Other noteworthy sensors include in-socket sensors that detect current at the outlet. “If we can measure current use everywhere, we can see if something has been left on,” explains Wallace. “A stove element is the most common occurrence. We can also have heat sensors at the stove.”

For overall activity sensing, technologies are being created that can perform monitoring while also safeguarding the occupant’s privacy. For example, Altumview of British Columbia builds a system that, yes, has cameras, but its software renders occupants as stick-figures so they are

not actually filmed.

Wallace adds that light detection and ranging technology is also being flexed for supportive smart homes. LIDAR is a remote sensing method that works by emitting a laser beam and measuring the time it takes for the light to return after reflecting off a surface. It is used on autonomous cars for object detection and monitoring.

“It now comes in a very inexpensive chip form,” Wallace notes. “It’s a whole new mechanism for monitoring activity in the home, like a 3D motion sensor, but also for health. Walking speed, for example, is a vital indicator of health and well-being.”

Whatever sensors are installed in the supportive home, they should be able to send notifications. “How are the messages sent and who do they go to?” Wallace urges us to ask. “Notification goes to people in the house first through an alarm and/or a text, but you could also choose to add a text alert to a person living nearby.” This would be especially important for things like door exits for those with dementia.

CHBA’s Adaptiv Home Renovation Course is for professionals who want to learn more about the aging in place market and the related growing business opportunities. The emphasis of this course is on improving design by addressing safety, security, ease of use, comfort, accessibility and occupant health. This course is the first step, says CHBA, toward becoming part of a network of professionals who offer services to homeowners who want to live in their home safely and comfortably for as long as possible, regardless of age, ability, size, or circumstance.

A How-To online course on home safety assessments for seniors is offered by an Ontario company called Age Safe Canada (adapted from Age Safe America).

Another way to find out more is to google “universal design”, which the Centre for Excellence in Universal Design defines as “the design and composition of an environment so that it can be accessed, understood and used to the greatest extent possible by all people regardless of their age, size, ability or disability.” The tenets of universal design apply do not just apply to libraries, courthouses, public transit, etc., but to someone’s home, too.

Wallace suggests that contractors could also connect with occupational therapists who treat seniors, adding that therapists “cannot refer specific companies to their clients, but they can refer them to industry associations.”

An estimated 10.4 million Canadians will be 65 or older by 2037, according to Rubinstein. Roughly 90 percent will want to live in their own homes for as long as possible, despite becoming less independent. This demographic shift signals significant opportunities for contractors who are ready for the coming surge of home renovations and retrofits that accompany aging in place. cc

Shared by Electrical Business magazine with our thanks.

Eurodale Design Build’s development manager, Brenden Charters, tells Canadian Contractor about their renovation of a penthouse condominium unit in downtown Toronto.

By Patrick Flannery

Charters: “The client got it for what I thought was a good price. My business partner and I both thought it would would be more expensive. But it was a little bit awkward in that it’s marketed as a two bedroom, two bathroom, but the master bedroom didn’t actually fully close off from the family room area and the second bathroom, which served the second bedroom, was only a powder room.

“So the whole building’s an exposed loft. Exposed concrete, exposed heating systems, ducting systems, plumbing, all that kind of stuff. So to work some of those things we had to get the building to completely shut the risers down so we could move gas lines. There were no in-suite shut offs for gas or plumbing. So we had to shut the whole building down then we added in-suite shut offs. Anytime you build in a condo it is always a challenge in that you have to be respectful of all the other residents and their housing situation. But it can be very difficult to navigate not just the condo board but the condo management, and that’s always a careful stick handle, especially when you’re affecting common elements like the exterior glazing, like the mechanical like the plumbing systems that are tied into other units. That’s very, very tricky to do. They didn’t let us shut down the building. I think the parameters were if it was minus five or lower, or if it was a cloudy day, we weren’t allowed to shut it down. So we had all this rescheduling that was having to happen because they were afraid the whole building was going to freeze and we were going to take too long even though it was only 15 minutes to install these shut offs. But you just go through it. There’s lawyers on these boards and you have to appease everyone and they’re looking out for all the residents. So it’s a stickhandle in condos sometimes.”

“One of the elements that was a real challenge was the kitchen, because it’s very efficient for them to just run services up one wall. The island they had had no sink in it – didn’t even have power in it – because it wasn’t a requirement when it was built. And so the kitchen run was fridge, sink, stove. There was no counter space. Microwave with a hood fan integrated into it. Everything was on one wall and it was just this jumbled mess. And there was no prep space other than the island, which was on the other side. So one of the things we did was we extended the cabinets against the glass because it was stepped back three feet in for the island, and stepped a couple feet for the main kitchen run. And by jamming it up against the glass and doing a waterfall counter, you see the counter from the street. It’s butted up against it, but it gives you more counter space. And then we moved the sink into the what became a peninsula. We did that with some with some pump system plumbing to be able to move it so the dishwasher and sink are now opposite. So that freed up all this space for prep space around the stove. We built this custom gangway where the power and the plumbing all ran into the peninsula but we ran it along the edge of the wall so it didn’t run in the walk space. It was all along the baseboard of the window drain line because with a mechanical pump you’re able to only have an inch-and-ahalf drain line that’s running through with a macerator. So it created way more space. “

“The homeowner stylishly picked all kinds of swanky finishes and made it look really nice. And so we’ve got touch-actuated latch, doors and drawers that that are power operated. We built up to the ceiling so there was a big gap at the ceiling. Eight-foot stock builder/developer type cabinets. We carried custom stuff 10 feet up to the ceilings.

“This is porcelain slab. It took us a long time to get and it creates a bit of a wow factor, especially when you’ve got some stone clad shelves. But it is large-format porcelain.”

”So on the right side where the TV is, there was a concrete column there, quite narrow. And so they had a TV set up on a credenza at the bottom. So we devised packing it out and building it out. Originally, we were going to clad the whole thing and leave an extended concrete column to build on that industrial style, but the homeowners liked a little bit more of a polished finish. So we actually clad it in the same millwork as the kitchen and made it big and wide enough that you can have a large-size TV there, and tied it in with base cabinets that that are to the right of it, under the window, that house all the electronics. So your cable box and all that type of stuff, your gaming machines, all of those things are tucked in there and out of sight. You don’t see any wires, all that stuff’s in the conduit in behind the TV. In that photo you can see the waterfall edge on both sides of the peninsula on that same side of the main kitchen wall, because there’s an open window. So when you’re down on Queen Street or down on John Street, you can see the pattern of the stone from the street. You don’t just see a dead cabinet. And the nice thing that they did was they included that same stone on the backsplash and on the backer of that peninsula, so instead of just being a horizontal surface you see that vertical surface. It really is a dominant art piece in the space. Really contrasts well against the dark espresso cabinets. Off the left side of the image, just past the couch, is where they had a barn-style glass door, but it hung on the wall and didn’t extend the ceiling. It was just hanging from some from suspension rods from the ceiling.”

{Prework photo] ”This couple has a young kid, a teenage son. Anytime he wanted to take a shower, he had to walk through their closet and into their bathroom. Also, the condo needed more storage. It needed updated finishes and all that good stuff, but fixing the bedroom situation so they actually have a master or primary bedroom that is closed off and developing a real three-piece bathroom for the son to use was not easily done in a condo. So we stole closet space from his bedroom and pushed out that bathroom and created a walk-in shower. And we delicately sloped our quarter-inch-perfoot to the drains that are in behind because you can’t chip a slab or anything like that. So we just fit this in. And it was, you know, a hope and a prayer, and we were able to make it work.”

“So you had this glass partition barn door that slid across and it took up space in the bedroom. You had to turn sideways to walk by the bed and you were rubbing in against the door. If you were talking in the bedroom it was open. There was a duct that came through there, and there it was totally open. So there was no real privacy. We actually moved that whole length of wall six inches to give more room to that bedroom, just enough, and made a pocket door instead of the barn door. So that resulted in an 11-inch savings of space in the bedroom. You didn’t notice six inches lost in the family room, but the 11 inches gained in the bedroom allowed you to walk freely past the bed. We also changed the bed to a custom built-in and reduced the headboard and the kick plate so that you were able to actually walk past the bed without snapping your tibia on the side of the bed. That is hardwood floor, engineered hardwood. We tucked in and hid all the laundry in custom millwork and then we ripped out their master closet and created all custom millwork for it with lighting inside for the owners’ clothing and shoes. We tucked cabinets in around columns just to built around the bed and created a custom bed with pull out drawers because you can never have enough storage. I think the term storage is the most searched term in on the website Houz, because we’ve all got so much damn stuff.”

“People may look at this and say, ‘Oh, geez, this looks like a big step up.’ Which it is, but it’s still a legal step. It’s under eight inches. But that’s what we were tasked with, was making sure we had a single step. We didn’t have room to put another step in because the toilet was right there. We needed to make sure we had slope to the drain and then from within the shower and then from the drain to the main stack. So it was figuring all those things out, staying within code and making something function spatially and create a shower in from a closet. So we pushed a little bit wider into the bedroom and that created a nook, a cubby, that we were able to make into a desk space, a homework space for their son. Just on the other side of that shower.”

“Here you see those system 22 receptacles just over the Kleenex box there that are cut into the slab tiles, and we’ve got a facelit LED medicine cabinet. So again, a storage item that looks fine here. Took a ton of work to create the framing box in behind because the plumbing risers ran right up through that space. No shutoffs under the cabinet for the water supply. And so that’s another reason why we had to shut the building down. Shut those off and move those risers out of the way. So we moved them around the where the medicine cabinet was going to be and then recessed the frame for that medicine cabinet. When it was off it also allowed us to raise the ceiling up from what was about seven feet. We pushed it up another eight inches or so to gain more height. The condo builds are like, ‘Okay, here’s the pipe we need to run this through.’ Then they drop the ceiling to the to the easiest level, then the guys come through. In our situation, we can move all those things. And if you can save six, eight inches of extra space, yeah, it takes more time but you end up with a with a space that feels much more voluminous and open, so the customers are willing to incur the cost of making that bigger, brighter space. And it allows us to move the shower heads up as well. I’m six-foot-three and there’s nothing I hate worse than a shower head right in your face. Making that change can be quite impactful. This was a powder room. All it was was a toilet and a sink and now it’s a three-piece bathroom with a full walk-in shower.

“The shower has got a bit of a raised step to it. We had to build that up for a couple reasons. One, we always install a custom fiberglass pan underneath that tile to make sure it’s completely impervious to water. We don’t have to do that. You can just do a rubber membrane and some dry pack to make the slope. But we use that system on every project because I never want to have a shower leak, especially in a multiunit building like this where it’s going to destroy the neighbors below you and have all the repairs and you won’t even know that it’s leaking until they let you know. So you see that strip drain right at the front face of the shower? We had to do that because we had to move the drain close to the toilet main to be able to tie that shower drain in without having to chip the slab. In the master bedroom, we have a centre drain in that shower. On this one, we had to go all the way to the wall to be able to catch a quarter-inch-per-foot to get the proper slope to tie into that existing main waste. We could have used a pump but it was a last resort option. Until we gutted this place and mapped it all out with the plumber on-site and my business partner, Jim, who’s our production manager, they spent a ton of time making sure, yes, this is going to be compliant, yes, this is going to work. And then you’ve got some neat little tricks like that LED strip cove light up tucked under the drywall, just on that inside edge.

“You see the waterfall edge of the counter there next to the sink within that island. Now it’s a deeper island, so you’ve got bar seating at it with a good 15-inch overhang. You’ve got some some draperies that come down. This is southwest-facing and gets a lot of light coming in there, so they’ve got some power-operated blinds that come down. It’s like the movie Big. It’s real swanky. You push a button and they all come down in unison just make the space comfortable. They’ve actually got an existing really nice patio, which is concrete as well, so you’re talking about flooring and moisture. It can definitely migrate through

the slabs. You can see at the roof edge where the glass is sticking in there. Moisture can find its way through a concrete slab quite easily.

“The big panes right beside the kitchen were definitely blown out. We were fortunate to have those changes. We pushed that peninsula back towards the edge of that glass, where you can see where the kitchen faucet is. So we grew the space between the kitchen run a little bit. Every little move we made here was a change of inches, but the impact of the inches is massive on how the how you move about the space with others in the space as well. A kitchen is a work space, typically for more than one person. You have guests that congregate at the island. So making these spaces as comfortable as possible and moving two, three, four inches one way or the other can have a huge, huge impact on the comfort of those working in the space as well as those lounging in the space.

“We looked at it and had conversations with Andy Oding for this site because we had just gone through the window stuff. It was in the spring when Building Knowledge did the whole thing on windows and we said, ‘Do we want to do it with that 3M film on the fourth side of the glass? What is it going to do? Is it going to bubble? Is it going to make condensation?’ He said it depends what kind of glass it already is. So we said let’s just go with good window coverings. Let’s not film the glass because, for one, the warranties on the thermal panes. You can be putting a lot more stress on those thermal panes by adding something where it wasn’t designed to be on there to begin with.

Native Trails has introduced Anacapa, the newest bath sink in its award-winning NativeStone Collection of concrete products. This 21-inch undermount sink aims for quiet sophistication, transforming a rectangular bathroom sink into a study of balance, proportion and craft. Generous in scale yet unexpectedly lightweight, Anacapa installs with ease while the sink’s broad, smooth basin enhances daily usability. Each sink is individually hand-formed by skilled artisans. To enhance performance, every sink is sealed with NativeStone Shield, a sealer that penetrates the surface on a molecular level. Hand-applied in a meticulous, multi-step process, the finish creates an barrier that resists water, oils, food, acids and scratches while amplifying the natural beauty of the concrete blend. Artisan-crafted in Vietnam using NativeStone, a proprietary concrete blend of cement and natural and renewable jute vegetable fiber, each tub is 40 percent lighter than normal concrete products, as well as being stronger and more sustainable. Anacapa is available in 10 versatile finishes, ranging from neutrals like Pearl, Ash, Slate, Earth, Charcoal and Sand to such earthy, natureinspired tones as Ocean, Sage, Forest and Terracotta. The newer hues – introduced to the NativeStone palette in 2025 – are designed to foster a sense of calm and connection to the outdoors. Each sink comes equipped with durable steel mounting brackets for secure installation and easy integration into a range of design environments.

Richelieu has introduced an array of kitchen storage systems and accessories available in an elegant palette of grey finishes. A warm and calming Dark Grey finish elevates popular elements such as the Axial drawer box system, while a sleek Anthracite finish adds style to products like Liro pull-out systems, Optimiz-R drawer boxes, and the retractable iMove system, which brings items stored in upper cabinets down to eye-level. While white interiors have long been a mainstay in European-made kitchen cabinetry, grey is quickly becoming a signature neutral that offers a clean-feeling esthetic and timeless appeal. With grey interiors, the inside of kitchen cabinets can now look just as good as the outside. Pull-out pantry systems, such as the Liro collection, featuring optional wood inserts, add warmth while enhancing functionality. Corner storage organizers, including Liro’s Magic Corner I with a pull-out door and Magic Corner II for hinged doors; the ultra-sleek Lemans II pivoting tray system; and the uniquely shaped and highly efficient Trigon II 600 System make the most out of often-hard-to-reach corners. In warm grey tones, all of the elements create a look that’s clean and modern, infusing both style and substance into the kitchen. And, speaking of clean, Richelieu’s practical-yet-stylish trash organizers, the Euro-Cargo II and the SE Cargo (both available in Dark Grey) offer discreet waste management with premium features like over-travel slides, integrated metal lids to reduce odors and soft-closing mechanisms for ease of use. Drawer organization also gets a sophisticated upgrade. The Optimiz-R (in Anthracite) and AXIAL (in Dark Grey) metal drawer box system provide streamlined storage with clean, symmetrical lines. For added grip and style, anti-slip Deco Mat in Anthracite lines drawers with textured protection. Meanwhile, Separado multipurpose divider trays in Dark Grey help neatly organize cutlery, utensils, spices, and more. Richelieu’s specialized interior fittings, like the LIDO softopening arm and the iMove lift-down system, merge elegant design with smart engineering.

DAP 2in1

Wall-and-Ceiling Textured Spray Repair is designed for efficiency and precision for tradespeople looking to streamline their work. Suitable for professionals and enthusiastic DIYers alike, the product features exclusive Aim Tech technology with a 60-degree adjustable nozzle angle allowing for precise application in vertical, overhead and hard-to-reach areas, making it a great choice for large-scale renovations and detailed repair work. The adjustable nozzle offers selectable texture levels from fine to heavy for improved control and flexibility in achieving the desired finish. The reliable built-in lock function secures the can during transport and storage. The Orange Peel, Knockdown and Popcorn textures are water-based formulas with a 30-minute paint-ready time. The Popcorn texture is bright white and does not require painting (unless required in high moisture areas or for cosmetic match) while Knockdown features a 30-second dry time before tooling to allow for a seamless finishing process.

Vicaima has launched a new collection of high-resistance laminate finishes called Dekordor HD Expressions. Engineered to fuse the authentic beauty of wood-look with superior resistance, the range offers sophisticated esthetics while assuring developers, contractors and property owners enduring, certified performance. A key advantage of the Expressions range is its ability to create fully coordinated interiors. The finishes can be applied across Vicaima’s extensive product portfolio, including doors, frames, wall panels and skirting. The finishes are available with Vicaima’s certified performance solutions, including Portaro and Easi-fit fire-rated (up to 90 minutes), acoustic (up to 45dB), and security door sets (up to SBD). All products are available with FSC certification on request.

25_008058_Canadian_Contractor_OCT_CN Mod: August 8, 2025 11:17 AM Print: 08/19/25 page 1 v2.5

MASTERGRAIN™ fiberglass entry door systems are built for strength, structural integrity and consistent quality across every project.

Trusted by professionals. Chosen by homeowners.

by Richard Lyall

“Houston, we have a problem.”

Thisdry understatement uttered by Apollo 13 commander Jim Lovell to Mission Control in Texas back in 1970 seems an apt description of the residential construction industry these days. The wheels have all but fallen off new home starts and sales, both across Canada and in Ontario.

The CMHC figures we must build between 430,000 and 480,000 homes each year over the next decade to restore affordability to the market. However, we are nowhere near those numbers. In 2023, 240,267 housing units were built in Canada and in 2024 we saw construction started on 245,360 units. In the decade between 2011 and 2021, the nation built an average of only 204,000 units a year. The provincial government in Ontario, meanwhile, set a target of building 1.5 million homes between 2023 and 2031. However, forecasts show the province missing the goal by a wide margin, despite widening its definition of a home to include retirement home suites and student dorms. The CMHC said in its latest report that housing starts in Ontario for the first seven months of 2025 fell around 25 percent compared to the same time last year. At the current pace, it’s projected that Ontario could fall short by a staggering 708,000 units over the nine-year period.

Experts say the shortfall could cost Ontario 41,000 jobs and drain more than $6 billion a year in combined tax

revenue from all levels of government. Projections from the CMHC indicate that annual housing starts in Ontario could drop to the low-60,000 range until 2031 – far below the target of around 175,000. Latest data from a tracker, meanwhile, shows 70 percent of Ontario municipalities failed to meet their housing targets in 2024, and the gap is expected to grow.

The tracker was established to gauge progress as part of the $1.2-billion Building Faster Fund that rewards municipalities that reach at least 80 percent of their annual target with funding. Bonus funding is available for municipalities that exceed their targets. Thirty-five out of 50 large municipalities in Ontario fell short of their targets in 2024. In 2023, 31 out of 50 municipalities missed their targets. Some of the notable cities that missed included Toronto, London, Barrie, Cambridge, Guelph, Hamilton, Mississauga and Ottawa. Some of the prominent municipalities that exceeded their target included, Kingston, Sudbury, Kitchener, Niagara Falls, Oakville and Sarnia.

The residential construction industry is entering a massive correction and being weighed down by massive taxes, fees and levies on new housing, as well as the slow approvals and red tape. The tax burden accounts for 36 percent of the cost of a new home today, up from 24 percent in 2012. The increase has crippled the market as the costs are ultimately passed on to the buyers. Development charges are the worst offenders. They are the most regressive taxes ever created

in the history of our country. The people they hurt most are the ones who can least afford housing.

To help spur the market, the federal government has scrapped the fivepercent GST on new homes up to $1 million for first-time buyers retroactive to May 27, although the purchaser won’t get the actual rebate until the fall when it goes through the legislative phase. The feds are also reducing the sales tax for first-time buyers on a sliding scale for homes purchased between $1 and $1.5 million. We would like to see the provincial government step up to the plate and reciprocate by ditching the provincial sales taxes for first-time buyers of new homes. To further spur housing construction, we also strongly feel that both levels of government should be looking at axing the sales taxes on all new homes – not just for those buying their first one.

Governments must also take aim at DCs. They have become a runaway train and need to be rolled back. Future hikes should be geared to the rate of inflation. In the city of Toronto, for example, DCs for single and semi-detached homes increased by 464 percent between 2014 and 2024, whereas incomes only went up 29 percent. Thankfully, Ontario has brought in legislation which permits builders to defer development changes until occupancy as opposed to when a building permit is issued. This means they won’t have to finance the charges while projects are being built. However, the charges are still too high.

There will be significant economic repercussions due to the housing meltdown. In Ontario, the construction industry contributes seven to eight percent of Ontario’s GDP, with the residential sector accounting for a big chunk of that. To turn the situation around and support recovery, governments must embrace new policies that lower the tax burden and speed up approvals. The consequences of not doing so will be catastrophic.

Richard Lyall is president of the Residential Construction Council of Ontario (RESCON). media@rescon.com

ALIGN® Composite Cladding delivers the realistic texture of freshly painted wood and ease of upkeep that customers prefer. Its efficient installation––thanks to lightweight materials, no touch-ups and no caulking––is one that you’ll appreciate. And now, ALIGN has accessories that create a seamless, high-end finish to bring the total solution together.

Whether in 7" Plank or 12" Board & Batten, ALIGN Composite Cladding delivers high-end aesthetics in 20 colours that give homes added character.

Impact resistance protects against dents, dings, and hail while moisture resistance protects against swelling and warping.

Insulating performance protects against energy loss.

LIFETIME LIMITED WARRANTY COMES STANDARD

SCAN TO SEE MORE. Find ALIGN Composite Cladding and ALIGN accessories at your closest Gentek retailer. gentek.ca/align

Brendan has been engaged to renovate a condo unit in a large multi-storey building. It’s an older concrete building and in order to execute the owners’ vision, his team is are going to need to do some work behind the walls moving plumbing, wiring and natural gas lines. All the utility shutoffs are centralized for the whole building, so shutting down the unit means shutting down everyone for at least as long as it takes to install a shutoff for the unit.

The condo board is not happy. They are throwing up multiple roadblocks – denying requests for shutdowns, demanding noise be kept to very low levels, saying heat and cooling can only be shut off within certain outdoor temperature ranges, restricting use of service elevators and forbidding any drilling, cutting or chipping of the concrete superstructure. They won’t even give them a parking pass. Brendan can’t be sure his team will be able to proceed with a given day’s work when they show up, as a board member could show up at any time with another complaint.

The delays and obstructions are threatening their ability to get the job done on budget.

Mark Bernier of Mapletop Enterprises wins our Q3 prize for this multi-pronged solution to Kraeg’s problem of workers never showing up on time.

Start with a meeting to explain, without chastising, how late/no shows affects the business and his ability to continue to pay them. Then start a formal sign in/out process. Maybe just a text system as all messages are time stamped. Text the boss “starting now” then “leaving now” might be all that is required. I would also add a bonus payment for attendance over say, a full quarter.

I think a one-on-one meeting to find out what each worker is expecting or planning is important as well. Trying to get people who are currently working with him as better than missing rent are clearly motivated differently from someone who likes to build.

Regarding the “going rate” that might need some research. If Timmy’s is paying the same for an inside job as you are for running a wheelbarrow you can see the problem. Another piece to seriously look at is whether the staff is ever allowed to follow a project or do any task that is not just menial or manual. If the person who wants to build never gets to hold a hammer or learn how anything works motivation drops off like a rock.

So in summary. A little introspection, a little research, a little structure and a carrot or two should help retention.

What should Brendan do?

1. Turn on the charm. Ask for a meeting with the board and try to negotiate a plan that everyone can live with. Though some of those board members are pretty snarky...

2. Call his lawyers. The board has no right to prevent them from doing work on a privately owned unit and their restrictions fall outside of its authority.

2. Pass the baton. Tell the unit owners the work can’t proceed until they get the board on side then down tools until some agreement is reached.

4. Burn the midnight oil finding ways to do the work without encroaching on any of the board’s demands. Eat the additional costs as a lesson learned about working in condos.

5. Something else?

Email your answer to Brendan’s Dilemma to pflannery@ annexbusinessmedia.com to be entered for a chance to win!

Entries close Oct. 31 The winner will be announced online in November.

20V Max XR two-speed hammer drill

20V Max XR two-speed hammer drill and impact two-tool combo kit with XR Powerpack batteries. Valued at $499. For more information visit dewalt.ca.

JELD-WEN’S WINDOWS AND DOORS ARE BUILT TO PERFORM AS THEY ARE ENGINEERED FOR ENERGY EFFICIENCY AND DESIGNED TO LAST.

JELD-WEN’s Canadian-made windows and doors are built for performance—engineered to meet code, cut energy costs, and install with ease. Designed for Canada’s toughest climates and most ambitious builds, our products deliver precision, durability, and style that contractors can count on.

From blueprint to build, we help you deliver homes that perform beautifully.

EXPLORE OUR FULL LINE OF CANADIAN MADE ENERGY-EFFICIENT WINDOWS AND DOORS AT JELD-WEN.CA