Building ENVELOPE Technology

What contractors need to know to build high-performance homes

What contractors need to know to build high-performance homes

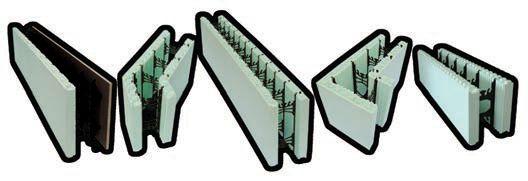

NUDURA ICFs complete the building envelope in one building step.

Building codes today demand buildings and structures be built with greater energy efficiency by utilizing continuous insulation.

NUDURA insulated concrete forms allow you to complete the building envelope with one building product for a stronger and more efficient structure.

Register for a one day training course to learn more about building stronger with NUDURA ICFs on your next project.

ICFs give you the opportunity to build residential, commercial, and a variety of other build projects while achieving the demands of todays building codes. www.nudura.com/training | 1-866-468-6299

By Rob Koci

Irecently visited the renovation site of a Markham, Ont., builder. On the first floor was an old, wood framed, aluminum sided 10 ft. by 12 ft. addition. It was built about three feet above grade on piers with a skirt dropped down from floor to grade to create the illusion of a crawl space. It was no surprise to find out the floor was freezing in the winter, despite insulation stuffed between the floor joists. The dirt-floor crawl space was a shelter for unwelcome urban wildlife.

As troublesome a space as this type of construction is, I have seen dozens of back additions on houses across my neighourhood just like this (including the house I now live in.) Most are between 50 and 80 years old, when tar paper housewrap was still the rage and diagonal boards were used for floor and wall substrates.

In working class neighbourhoods like mine it was mostly homeowners who built these back additions. I learned from an elderly neighbour that the previous owner of my house worked for the railroad. It’s no surprise then that the centre beam of my home’s back addition is an old steel rail. So are two retrofit beams in the basement supporting the first floor joists. Thank goodness they “ain’t built like they used to.”

It is the core of good business for today’s renovator to not only build comfortable new spaces on existing homes, but to bring creative ways to revive old, badly built spaces to today’s higher standards. Another previous owner of my house, after Mister Railroad, installed two-part foam insulation under the floor of my addition. The floor is okay, but still cold. Better would have been to insulate the skirt, leave the floor without insulation and install heat in the crawl space.

My Markham contractor did better. Rather than heat the entire crawl space, he hung a lightweight, insulated subfloor about 1 ½ feet below the existing floor, insulated the skirt between the two floors and installed heat there. It was a nice tidy way to ensure a warm, comfortable floor. He runs a very good, profitable business.

Like him, contractors who understand building envelope science can ensure comfort, energy and money savings for homeowners for a long time to come.

It is the core of good business for today’s renovator to not only build comfortable new spaces on existing homes, but to bring creative ways to revive old, badly built spaces to today’s higher standards.

How to build a high-performance wall system

8 | Fusion Stone

Not all stone veneer is created equal

10 | Feature

Building envelope science: How to control moisture

14 | CanWel

Essential products for building envelope excellence

16 | Nurdura

Eco-friendly Insulating Concrete Forms (ICF)

18 | Column

Five Questions to Ask When Choosing a High-Performance Housewrap

Building Envelope Technology is one of a regular series of technical bulletins brought to you by Canadian Contractor magazine in partnership with selected manufacturers. For enquiries about advertising in future bulletins, please contact Rob Koci, Publisher, Canadian Contractor, rkoci@canadiancontractor.ca

How do contractors build high performance wall systems that are costeffective, easy to install and built to last?

Salvatore Ciarlo, a civil engineer and architectural technologist with Owens Corning answers builders’ questions.

Q: How can contractors reduce a home’s heat loss and improve air tightness, without compromising comfort for the occupant?

A: B uilders can incorporate high performance batt insulation (R-19, R-22 or R-24) in wall cavities with conventional sheathings (OSB or plywood). Alternatively, a combination of foamed plastic insulated sheathing and high-performance batt insulation can be used.

Q: What are the advantages of using foamed plastic insulating sheathings?

A: The main advantages, whether used over wood sheathings or directly on wood studs, is a significant reduction of heat loss from thermal bridging. It will also minimize the risk of condensation by warming up the wall cavity.

Q: Won’ t a double vapour barrier result if exterior foamed plastic sheathings are used, especially when in combination with a 6 mil polyethylene vapour retarder on the inside?

A: The short answer is that adding exterior insulation in combination with R-19 batts is a good choice.

Canada’s National Research Council studied the risk of moisture condensing in wall assemblies with exterior foamed plastic insulating sheathings compared to reference wall assemblies using OSB exterior sheathing. (Report on “Properties & Position of Materials in the Building Envelope for Houses and Small Build-

ings,” December 2014.) Stud cavity insulations used in the study were fibrous batt type (R-19 and R-24). Exterior foamed sheathing, both over OSB or attached directly to the exterior face of wood studs, were examined. The R-values of the exterior foamed insulations used were R-4, R-5 and R-6. The water vapour permeance of the insulations covered a range of values from 2 (very low) to 1800 (very high) ng/(Pa.sm2).

The study found that there is less risk for moisture condensation in walls with R-19 compared to R-24 fibrous batt insulations in the stud cavity because the temperature of the interior face of the exterior sheathing (OSB or foamed insulating sheathing) is colder with R-24 batts.

Q: Does it matter if there is an OSB interlayer or not?

A: All wall systems incorporating foamed insulating sheathings, with or without an OSB interlayer, result in lower risk of moisture condensation than the NRC’s reference walls sheathed only with OSB and no exterior insulating. Walls with foamed insulating sheathing installed over the OSB showed a slightly lower risk of moisture condensation than walls without the OSB interlayer.

Q: What might be the risk of condensation using this system in dry, cold areas such as Ottawa?

A: It would be low regardless of whether the OSB was used as an interlayer and regardless of the vapour permeance of the foamed insulating sheathing.

Q: What about the risk of condensation in Canada’s driest and coldest zones? How would it fare in Edmonton, for example?

A: The risk of condensation is low for walls with OSB plus foam sheathing regardless of the vapour permeance of the insulating sheathing. Walls without the OSB interlayer showed the risk of condensation was slightly lower with a more vapour permeable insulating sheathing, but all those in the vapour permeance range examined performed better than the reference wall that used only OSB.

Q: What about the risk of condensation in mild, humid, coastal zones like Vancouver and St. John’s, for example?

A: In humid zones, for walls with and without an OSB interlayer, the risk of condensation increases as the vapour permeance of the foamed insulating sheathing increases. This is because the higher outdoor water vapour pressure (humidity) is pushing the water vapour into the wall cavity. Less vapour permeable foamed insulating sheathings will reduce the risk of condensation inside the wall.

Q: How does this affect the National Building Code?

A: Research has demonstrated the benefit of adding exterior insulating sheathings to minimize the risk of condensation in exterior wall assemblies. Accordingly, section 9.25.5 of the NBC 2015 edition, “Properties and Position of Materials in the Building Envelope,” has incorporated revisions with respect to the position of low permeance materials.

Increased insulation plus improved air tightness are an effective way of reducing heat loss without compromising the comfort of the occupant.

Q: Is there a minimum thermal resistance recommended?

A: As long as the sheathing has a minimum thermal resistance of R-4, contractors need not worry about a double vapour barrier—even when low vapour permeance exterior insulating sheathing is used. Builders using OSB structural sheathing can also rest assured that adding foamed insulating sheathings on the exterior of the wall assembly would not result in increased risk of condensation; in fact the risk is reduced. Exterior insulating sheathings help keep wall cavities and critical surfaces warmer thus reducing the risk of condensation. As added benefits, this also makes homes more energy efficient, increases durability and improves occupant comfort.

Salvatore Ciarlo, P.Eng., is the National Codes/Standards and Technical Services Director at Owens Corning Canada. He has 23 years’ experience in the building materials industry, holds a bachelor’s degree in Civil Engineering specializing in building science, and has a professional degree in Architecture Technology. Sal sits on several provincial and national code committees. He can be reached at Salvatore.ciarlo@owenscorning.com

High Performance Roof System

• ® Duration® Shingles

• Deck Defense® underlayment

• Weatherlock® ice & water barrier

• PROPINK®

• raft-R-mate® attic vents

CodeBord® Exterior Air and Moisture Management System

• FOAMULAR® CodeBord® XPS insulating sheathing and taped joints (JointSealRTM tape)

• FlashSealR®

• EcoTouch® PINK® FIBERGLAS® Insulation (R-20/22/24)

High Performance Basement Insulation and Moisture Management System

• FOAMULAR® CodeBord®

• EcoTouch® PINK® FIBERGLAS® Insulation

High Performance Basement Slab System

• FOAMULAR® CodeBord® XPS Insulation with taped joints (Joint Seal-R tape)

Fusion Stone has been a growing brand with contractors across Canada since 2005 – and for many good reasons. Simple and easy installation are core to this popularity but are really just the beginning.

Why Fusion Stone?

Not all stone veneer is created equal.

Fusion Stone’s popularity stems from many advantages, which aren’t easily found in other stone veneer products:

• It can be attached to most surfaces, including metal, wood, brick and cement

• Lighter than normal stone makes it easier to handle and install

• Installation involves the use of minimal tools, because it’s easy to cut and attach

• Fusion Stone is affordable and increas-

es home value

• It’s available in a wide variety of styles and colours. Choose from Great Lakes, Peninsula Ledgestone or Dry-Stack

• Fusion Stone is water repellent and mold resistant

• It’s ideal as a building envelope but has many other applications such as making a fireplace pop, adding style to an office or as a stunning feature wall

• Since it’s manufactured here in Canada, Fusion Stone leaves a smaller environmental footprint than stone quarried outside the country

• Fusion Stone comes with a lifetime guarantee, which promises a lifetime of maintenance-free performance

Word of mouth is just as important as ever, and one of the things people are talking about is the complete installation support that comes with Fusion Stone. On their website the company offers installation videos and guides to make your project quick and stress-free.

Fusion Stone products are easy to use, reliable and of the highest standard.

Fusion Stone can be seen at some of the top home, cottage and renovation shows every year. The company also runs a summer long demo tour in Ontario and Quebec. Visit big box stores like Home Depot and Home Hardware to see how easy it is to work with Fusion Stone.

Fusion Stone is a third generation family-owned company that’s 100% Canadian. Fusion Stone products are distributed across Canada in over 1,500 locations.

Controlling moisture is job one. Here’s how to get it done.

By Paul Duffy, M.A.Sc., P.Eng.

The enemy of buildings is moisture. In the presence of moisture: wood rots, concrete spalls, steel rusts and gypsum turns to mush. For building contractors, controlling moisture is job one.

Too often moisture wins. Either some important detail gets missed, or flaws get covered up, or worse, the whole design is fundamentally flawed. A few years back, the condo crisis in Vancouver proved that a lack of understanding of moisture wasn’t just isolated, it was widespread. Much of Vancouver is in a climate zone that could be classed as a “temperate rainforest”. Though certainly not at the extremes in terms of temperature, Vancouver gets more than 200 days per year of rain. Things get wet and never dry out. So it is not surprizing that a moisture-related crisis first appeared there.

However, moisture problems are prevalent across the country because the same lack of understanding of moisture control is not confined to the west coast. To fully control moisture, you must first realize that it moves via several “mechanisms”.

First, it can appear in bulk. Wind-driven rain and snow can be forced inward from the exterior, primarily. Anticipating a moisture assault and deflecting it away is the key function of exterior building elements. The single most important way of controlling bulk moisture is by lapping materials shingle fashion. That ensures any water getting past one layer will be caught by the next and deflected back to the exterior. Ultimately, through wall flashings at major intersections—such as changes

The single most important way of controlling bulk moisture is by lapping materials shingle fashion.

in materials at penetrations such as windows and doors, and at regular intervals, such as intermediate floors—what ever does penetrate can be carried back to the exterior where it belongs.

Second, moisture can be sucked up like a sponge. Porous materials like wood and concrete are particularly vulnerable. Innovations like air gap membranes around foundation walls have been widely accepted as necessary measures to control basement leaks. Few realize the simple genius that an air gap stops moisture from being sucked up into the concrete via capillary action. The air gap helps ensure water moves vertically downward towards the perimeter drain versus inward to more moisture-sensitive materials.

The air gap is not just important in below-grade construction. Above grade, many building papers are micro perforated and can wick moisture inward if not applied with an air gap over them. Tyvek, Typar and even the lowly, felt paper will perform best when an air gap exists over top of them. An air gap is standard behind brick veneer, but is also built into premium Exterior Insulation Finish Systems (EIFS—Stucco). Many siding manufacturers also recommend an air gap, accomplished by applying them over strapping for example.

The third mechanism for moisture movement is via air leakage. Moisture is often entrained in air. An air leak carries the potential for that moisture in the air to be deposited in the interior of the building. Many energy efficiency programs emphasize the importance of an air barrier in controlling energy losses. I like to think of it as a measure for controlling moisture as well.

A continuous air barrier limits the potential for moist interior air from migrating outward, thereby condensing on cold

surfaces such as sheathing and fasteners. It also makes the air gap and the layered materials on the exterior perform more effectively. By stopping air coming in from the exterior, the inward wind that is driving rain and snow into a building is also stopped. The air gaps and layered design of exterior elements, combined with suitable weep holes and strategic use of caulking, can work its magic protecting the interior moisture-sensitive materials from damage.

The astute builder will realize I have come this far and haven’t once mentioned the words “vapour barrier”.

The astute builder will realize I have come this far and haven’t once mentioned the words “vapour barrier”. Surely that must be a mistake. No it is not a mistake. That is because vapour diffusion control, typically by means of a vapour barrier, is the final, and perhaps least important, of the moisture control mechanisms. The language of the Building Code notwithstanding, a vapour barrier, that is far from continuous, can do a more than adequate job of protecting your building, that is, provided you have done the other stuff correctly. And nowhere in the Code is polyethylene mandated as a requirement in all building envelope assemblies. Vapour barrier paints, spray foams, extruded polystyrene foams and other materials can meet Code requirements.

The take away is that it is extremely important to get the first three concepts correct. Proper layering, drainage gaps, and a continuous air barrier are the most important aspects of good design. A continuous vapour barrier is less so.

At the leading edge of construction, builders are starting to question the wisdom of a continuous layer of polyethylene on the interior of buildings. If, for example, you build a wall with a high level of continuous insulation on the exterior (i.e. more than RSI 3.0 on the exterior of the sheathing), and you have used spray foam or a sealed “peel and stick” membrane on the exterior of the wall sheathing, you start to be concerned about whether a vapour barrier on the interior will limit drying of the wall. Ideally such assemblies should be able to dry to the interior. Eliminate the interior vapour barrier and it is much more likely that incidental moisture, from a minor defect in the wall, can dry to the interior.

Good luck getting this type of innovation through the approvals process on your own, however. My best advice is to go into your local building department early in the design process armed with a review by a competent Building Science engineer. Most building departments are not going to approve such an innovation without professional review—some kind of analysis of the potential for condensation, and perhaps use of a software package such as WUFI—to look at the assembly in a thorough way. Manufacturers reps can be a big help putting you in touch with experts who can help pave the way.

In buildings with very high insulation levels, there is another issue to be concerned about. Highly insulated walls and roofs have less thermal energy escaping to the exterior so there is less

Few realize the simple genius that an air gap stops moisture from being sucked up into the concrete via capillary action.

drying potential in exterior spaces. It becomes even more important that exterior elements be well thought out.

A lot of the focus is on window and door penetrations. Immediately after hurricane Andrew a few years back, much of the damage that occurred was traced to leakage failures in window systems. A number of manufacturers have since come forward with systems for flashing and sealing rough openings around windows and doors. If the window or door element ever leaks, there is a secondary flashing and sealing system around the window to capture the moisture and re-direct it to the exterior. For high-end builders, this represents an important differentiator in their houses. As one builder put it, I am confident in what I can control—caulking and sealing as necessary—I am less confident that window and door frames will not have the odd defect I cannot see.

We see UV rays for what they are. But where even limited exposure can cause other contenders to deteriorate, TYPAR® MetroWrap can be left uncovered on commercial projects for up to 12 months, while TYPAR® BuildingWrap gives structures below five stories an unrivaled six months of protection.

As a final note, I thought I should say a few words about caulking. In my opinion, caulking should never be the primary defense against moisture. You should never attempt to achieve a perfect seal via caulking on the exterior. If you do, those caulked joints have to withstand all the wind pressure driving rain inward. The result can be disastrous: a minor leak allows moisture behind the caulking and now the caulking actually prevents drying. Caulking should be used to bridge gaps, to minimize moisture getting into drainage cavities and to improve aesthetics. Always leave openings, at the base of walls and at through wall flashings for drainage.

As we pursue ever more energy efficient, near net zero and even off-the-grid housing, it’s important not to lose focus on moisture control in all its aspects. Without keeping wind-driven rain, absorbed, condensed and diffused moisture under control, the benefits of more energy efficient construction will be short lived.

About the author

Paul Duffy, M.A.Sc, P.Eng, is principal and lead consultant of Paul Duffy and Associates. He provides strategic management and engineering consulting, specializing in building science and performance improvement. He served as vice-president engineering for Icynene Inc., a building envelope product manufacturer. He was also president of BLP Engineers from 1989 to 2008. Paul can be reached at jpaduffy@gmail.com.

Time studies show that RigidStack lap siding built on LP SmartSide with its heavy duty spline installs up to 22 per cent faster than standard 16’ lap. Diamond Kote re-manufactures LP SmartSide into a hidden fastener siding system that offers a more efficient installation. The end result is a flawless finished product that can be enjoyed for years to come. Available in 30 prefinished Diamond Kote colors with a custom colour option backed by a 30Year No Fade Warranty.

Just Screw it to the Wall and it’s “Hooked for Life”

Contractors are constantly on the lookout for better, easier, and more profitable ways to provide quality products and performance to their customers. Fusion Stone can help with that – proven consumer appeal, multiple indoor and outdoor applications and ease of installation are just the beginning. A patented innovation, Fusion Stone is a thin stone veneer that is easily installed with the included stainless steel clips & screws. Look for their new profile www.fusionstone.ca.

Nichiha Cement board Cladding with an Integral Rainscreen System

Nichiha offers a line of panelized fiber-cement siding installed with special clips that hold the panels away from the sheathing to provide a rainscreen exterior to control water intrusion and increase the durability of the entire wall system. The panels are ship-lapped on four sides and have the appearance of bricks, shakes, or stone. (A lap siding is also available.) Most panels come in 6’, 8’, or 10’ sections, in heights ranging from approximately 8” to 18” and thicknesses ranging from 1/2” to 1”.

A building wrap like NovaWrap Aspire is a critical element in the building envelope system which is the physical separation between the interior and exterior of a building, just like a jacket provides you protection on a wet or windy day. Installed behind the exterior cladding, NovaWrap reduces both air and water infiltration into the building envelope preventing drafts and water damage. The material science of the coating enables NovaWrap to be breathable, allowing water vapour to escape should it get into a wall system, but still act as a barrier against air infiltration. Unlike Grade D or felt building papers, NovaWrap does not absorb water, is much stronger, and is UV resistant.

CanExel Siding: A product with integrity builders can trust

With a beautiful finish, lasting durability and an authentic wood-grain look, CanExel siding creates products you can enjoy for years. With 21 colours and endless styles, it’s easy to find the perfect match.

The Ridgewood D-5 lap siding has the genuine look and warm appeal of Dutch lap siding. Ced’R-Vue lap siding delivers the stunning beauty and durability of cedar without the drawbacks. UltraPlank lap siding combines style and versatility. All LP CanExel products offer a 25-year limited warranty against peeling, separating, and chipping, a 15-year limited warranty on the finish, and a 5-year, 100% labour and replacement feature.

James Hardie fiber cement siding offers beauty and character

James Hardie fiber cement offers the beauty and character of wood, as well as resistance to weather, insects and flame spread. Where available, ColorPlus technology includes a factory-applied, baked-on finish that lasts up to two times longer, has 30 per cent better fade resistance and provides optimal color accuracy.

IKO Ener-Air Wall Insulation is a rigid, polyisocyanurate foam insulation with high thermal properties. It is constructed from closed cell polyisocyanurate foam core bonded on each side to coated fiberglass facers during the manufacturing process. IKO Ener-Air is designed to be a non-structural sheathing in cavity wall, stud wall or cathedral ceiling construction. It is a dimensionally stable air barrier with a high water vapour permeance and excellent water shedding capabilities. The product is lightweight, easy to handle and can be sized with ease.

BP Enermax Four-function Panel - Vapour Barrier, Insulation, Soundproof and Air Barrier

Home comfort is a combination of several factors: air infiltration and moisture permeability, together with insulation are the most basic. BP Enermax is the only structural board that combines these factors with a quiet environment, an integral part of the “total” home comfort equation. Efficient, environment-friendly and affordable , these all-natural wood fibre panels are the ideal solution for residential projects like home theatre, playrooms, and laundry rooms.

ICF construction provides eco-friendly, sustainable development

One of the leading movements today in building envelope technology is the focus on sustainable development and achieving Net Zero. The expression might sound complex, but in fact, Net Zero is the concept that a building should produce as much energy as it uses. Construction with Insulated Concrete Forms - commonly referred to as ICF - follows the principles of sustainability to promote a better quality of life for present and future generations by helping to achieve a Net-Zero building envelope. ICF constructed buildings are sustainable, qualify for LEED (Leadership in Energy and Environmental Design) certification, and allow architects and engineers to create longer-lasting structures that use less natural resources.

The first step to creating a sustainable building is to make a checklist. Look for the

latest energy-efficient technology in walls, windows, siding, drainage, solar power, water management, ventilation, plumbing, heating and cooling systems, suggests Keven Rector. He is technical services manager at NUDURA, a leader in ICF technology, which is setting the tone for today’s focus on eco-friendly development.

To achieve the most insulated building envelope, Rector advises contractors specify the latest advancement in wall construction with reinforced concrete instead of the “outdated wood-framing method”. He adds, “NUDURA’s ICF system creates an envelope of superior strength, continuous insulation, conservation and energy efficiency. It provides tighter construction by way of its monolithic concrete core combined with two continuous layers of EPS foam insulation, which enables the walls to conserve energy. Subsequently, monthly

energy consumption bills are considerably reduced.”

A compelling aspect of ICF walls is they offer a “six-in-one” formula. ICF walls simultaneously provide a form system, structural strength, insulation, vapour barrier, sound barrier, and attachment for drywall and exterior finishes in one simple step. Rector adds, “A building using ICFs is guaranteed to minimize maintenance and repair, lower energy consumption and operating costs, and function brilliantly in adverse conditions.”

Another advantage of ICF walls is that they are highly effective as sound barriers. But more than that, they provide a healthier indoor environment. As there is no organic material used, the growth of mold, mildew and other harmful microorganisms is drastically reduced, hence resulting in healthier indoor air. Long-term, concrete houses definitely

require less maintenance and repair than wood-frame houses. Concrete and ICFs are not prone to rot or deterioration as is the case with lumber.

At the construction site, the insulating concrete forms lock together, like Lego, to build the walls far quicker and with less waste than wood framing. Whatever waste remains is recyclable making ICF a sustainable building solution. Once the ICF system is interlocked it creates one monolithic wall with a thickness from 10 to 30 centimeters (4 to 12 inches). This immediately gives the house excellent wind and fire protection, superior sound resistance, improved temperature control, healthy indoor air and many additional occupant comforts. The result, Rector explains, is a stronger, sustainable house with a warm, inviting and healthy atmosphere.

1. Superior energy efficiency

ICF systems installed in cold climates are proven to be 58% more energy efficient compared to R-20 values with wood structures, which risk thermal bridging. The less energy required to heat and cool the home’s interior, the greater the savings on the electricity bill. The insulating properties of ICFs also prevent heat and humidity from damaging buildings. It keeps buildings cool in the summer and warm during harsh Canadian winters.

2. ICFs can withstand extreme weather conditions

Designed to stay in place as part of the wall assembly, ICFs have the advantage of concrete wall construction. They can withstand extreme weather conditions such as strong winds, seismic forces, hurricanes and tornados. ICFs have been proven to be one of the strongest and energy-efficient wall systems used in residential and commercial construction.

3. Improved indoor air quality and comfort

Even temperature throughout the house leads to a more comfortable environment for the occupant, thanks to the high insulation of the ICF system. Indoor air quality is improved as it is far less prone to mold and mildew associated with wood. That’s what makes ICFs perfect for constructing buildings in moisture-prone areas.

4. ICFs are sound resistant

A combination of rigid foam insulation and the thermal mass of the concrete offers a system that buffers a building’s interior from outside noise. The result is a quieter home. NUDURA ICFs have a 40% better sound transmission rating than a wood-frame constructed home. They deliver a sound transmission class (STC) of 52.

5. ICFs are fire resistant

Concrete is the most fire-resistant of all construction materials. It does not burn like wood, or soften like steel. NUDURA ICF-constructed buildings, using a core thickness of 15 cm (6”) or greater, offer a fire protection rating of up to four hours.

6. ICFs offer design flexibility

ICFs can be cut and placed into any shape for unique home designs or site conditions. Forms come in a variety of shapes and in 4”, 6”, 8” 10” and 12”cavity widths. Possible exterior aesthetic designs can include stone, brick, wood, and vinyl siding, among others. On the inside, beautiful architectural shapes like slopes, arches, bay windows and specific doors can easily be achieved for a spectacular design.

Find more information online at www.nudura.com.

Tip #1: Don’t mix water with wood. Tip #2: Don’t let damp wood stay wet. Intuitive? Of course it is. Wet wood rots. Yet, this is a lesson the building industry has had to learn the hard way – and more than once – since necessarily stringent building codes have gone into effect in recent years. The well-intended codes are our industry’s effort to create airtight buildings. Good news for energy consumption but bad news for damp walls.

Fortunately, building science has taught industry professionals a thing or two about the movement of air and moisture in and around the building envelope. We can now create airtight buildings that also fend off unwanted, unavoidable moisture that originates both inside and outside of a building.

Use of housewrap is no doubt a best practice in builders’ efforts toward airtight construction. There is a high demand for housewrap and as a result, there are several products on the market. How do you know which one performs the best? Before buying one brand over another, ask these five questions to make sure you’re selecting the highest performing housewrap.

1. Is the housewrap durable?

It’s an obvious question, but an important one. A durable housewrap is one that stays in place, has exceptional tear strength, and can stand up to surfactants and UV rays.

Avoid common jobsite do-overs by opting for a high-performance material that has exceptional tear resistance and is designed to withstand heavy winds and jobsite rigors. Additionally, housewraps with superior surfactant resistance will minimize water penetration and the resulting component degradation. Finally, it is best to work with a high-performance material that incorporates UV inhibitors into its coating and fibres, preventing deterioration that can occur from UV exposure.

2. Does the housewrap breathe?

A building wrap must breathe to prevent moisture vapour from getting trapped in the wall cavity. Builders should work with high-tech housewraps that can balance water holdout with an optimal perm rating of 10 to 20 perms. This perm rating ensures that while water is prevented from entering the wall cavity, ideal levels of moisture vapor are allowed to escape.

It is not too lofty a goal to expect a housewrap to perform as an air barrier that helps reduce air infiltration.

3. Can the housewrap serve as an effective air barrier?

It should. It is not too lofty a goal to expect a housewrap to perform as an air barrier that helps reduce air infiltration. High-performance housewraps serve as effective air barriers by reducing convective wind washing against sheathings and air infiltration into stud wall cavities. When installed as part of an air barrier assembly, a housewrap has the ability to reduce drafts in homes and increase indoor comfort and decrease energy use by reducing the amount of non-conditioned air that enters and exits conditioned wall cavities.

4. Does the housewrap come with a system warranty? A good warranty speaks volumes about the quality of a product. Some high-performance housewraps on the market back builders with excellent warranties. If fact, the TYPAR Weather Protection system offers an industry-leading Lifetime Limited System Warranty for added peace-of-mind. Be sure to choose a housewrap that offers one.

5. Is the housewrap part of a holistic system?

Housewraps do not operate in a vacuum. They are part of a holistic approach to airtight construction, or at least they should be. As such, they require thorough, comprehensive integration with other elements of the building envelope in order to retain system integrity. In other words, be sure the housewrap includes compatible tapes for seaming and adhesive flashings for openings as these details vastly improve the air and moisture resistance of the housewrap.

Your search for that reliable, go-to product is over.

Fusion Stone is a top-quality, fast and profitable way to beautifully upgrade any project. Available in three textures and multiple colours, all with a Lifetime Guarantee, Fusion Stone can be installed on practically any surface.

TV personality and building expert

Damon Bennett is giving away $5,000 worth of GRK fasteners AND a brand new Paslode nailer, to the builder of the best GRK project he can find. It's all part of our

Show Us Your GRK Project

Damon will pick the winner for a Canadian Contractor Stuff We Like feature in the Nov/Dec 2018 issue. "ENTER

Go to Canadiancontractor.ca, search ITW contest, then send three photos of your best project where you used GRK fasteners.

Explain why your GRK project is the best ever.