BY NAOMI SZEBEN

BY NAOMI SZEBEN

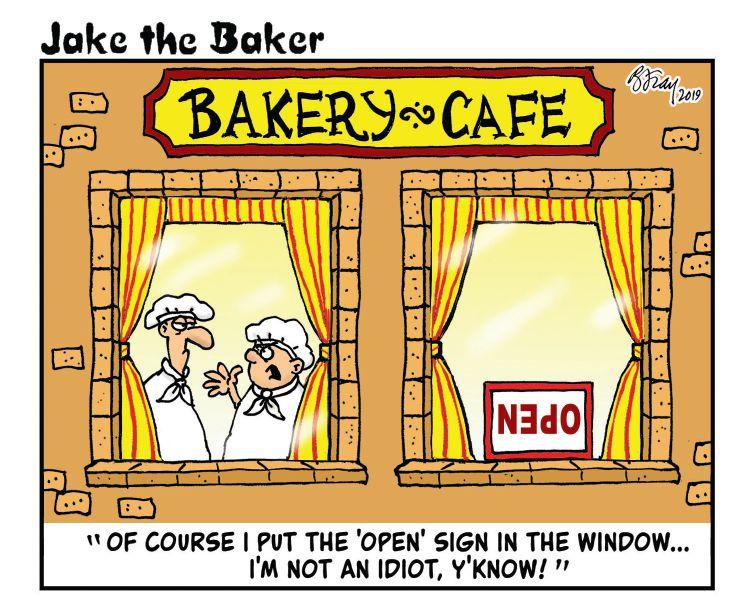

The term, “being schooled” used to be an old-fashioned way of saying getting some education. Nowadays, being “schooled” connotes a correction, or changing someone’s mind through extreme embarrassment.

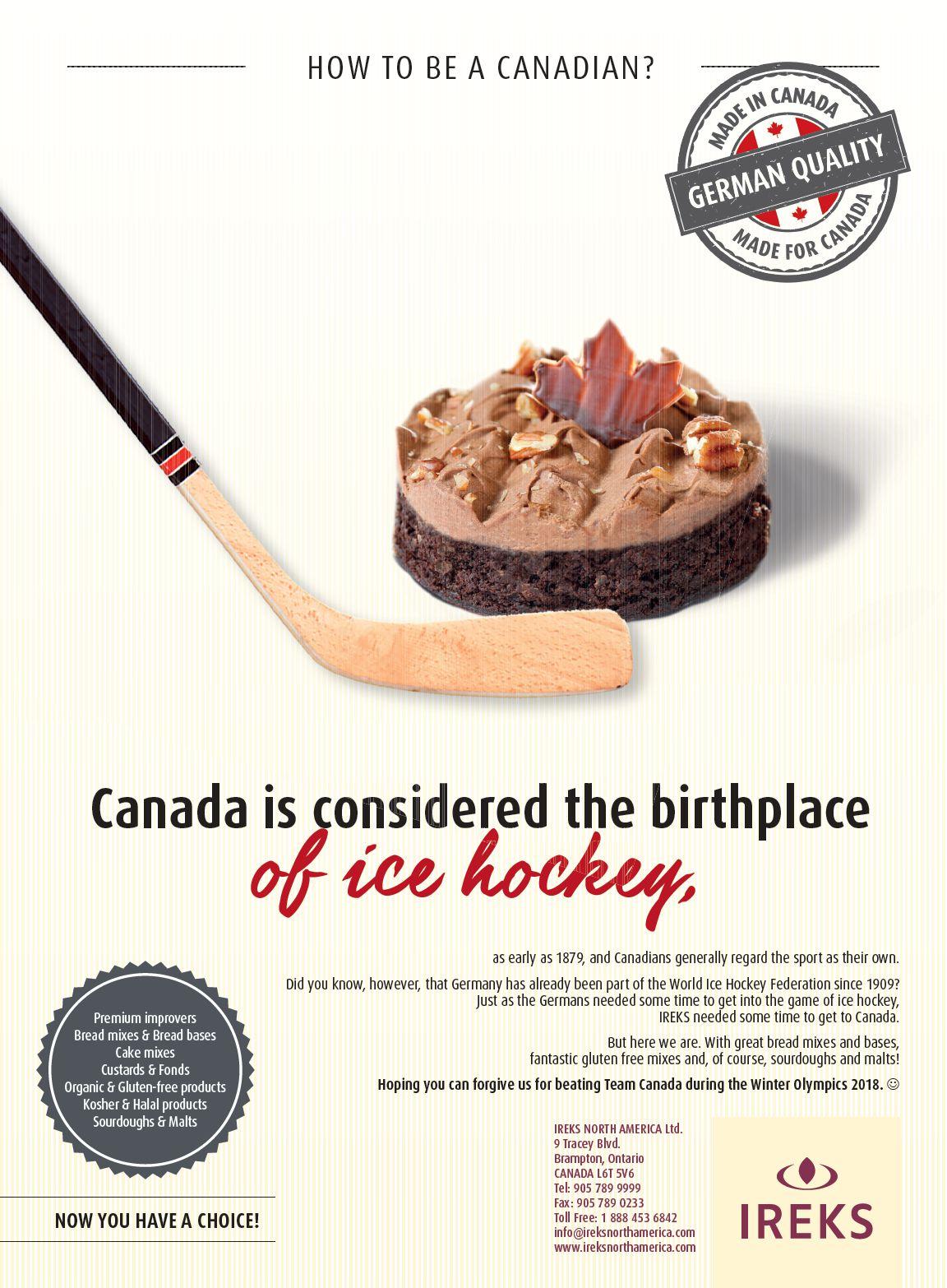

Last month, I got “schooled.” I incorrectly referred to Dawn Foods’ Sweetest Bakery as a charity, but was lucky to be most graciously set right by Ken Weir, the Senior Marketing Consultant at Dawn Foods. As a result, I would like to publish a clarification: Dawn foods Sweetest Bakery in Canada Contest was described incorrectly as a charitable award. Although last year’s winner, Dooher’s Bakery is known for their humanitarian donations, the Sweetest Bakery Contest is a consumer-based award, generated by client’s votes.

I re-learned a valuable lesson in checking the sources and verifying the facts. Back to Communications and Journalism school for me: I got “schooled,” albeit very kindly by Mr. Weir.

Speaking of going back to school: The first sign of autumn is not the nip in the air, nor the foliage’s slow turn to gold. It’s marked by the tsunami of “back to school” ads, flyers and pop-ups that appear on TV, my mailbox and computer screen, respectively. It heralds the promise of change that a new school year will bring. I sometimes miss new challenges, going back to class and turning the page on the former year and being given a fresh start to learn anew.

Becoming a popular bakery is every baking student’s dream. From being the person who made the best cookie, cake or Instagram-worthy cupcake to owning a bakery is a giant leap. The first step in that leap is choosing the right path, and that always starts with learning. In this issue, future Sweetest Bakery award winners will find out which courses will prepare them best for their journey in the food industry.

}Dawn foods Sweetest Bakery in Canada Contest was described incorrectly as a charitable award. Though last year’s winner, Dooher’s Bakery is known for their humanitarian donations, the Sweetest Bakery Contest is a consumer-based vote.

Fledging bakers dream of running a popular shop, where all the locals know them, and the phone rings off the hook. Their Instagram posts spark international trends and celebrities make calls personally to place orders from them. Reality is a different experience for bakers, and the one stepping stone that sets an amateur baker apart from a well-trained and disciplined professional is hard work. Trends may come and go, but once the basics are embraced, there is no limit to what can be achieved by a Master Baker.

The love of the craft and the love of the finished product are not the only things that are needed: The loyalty of customers and the trust in their local communities work together to create your fan base and your customers loyalty. Quality is not enough to keep a bakery afloat, and Bakers Journal wants to keep you informed on breaking baking industry news, innovative trends and the movers-and-shakers who are changing the hospitality, restaurant and catering worlds. With each issue, we aim to keep readers engaged with not only Canadian talent, but the gifted people south of the border who have traveled, sampled and experimented with new techniques and ingredients. We hope you take some time to read the profiles of innovative chefs, like Charley Scruggs. Where some chefs see a weed, Scruggs sees an unusual topping and ingredient for cake. In this issue, you’ll learn about how to make sure your new business won’t fail, how to create loyal customers and when to make the judgment on letting “problem clients” go. / BJ

AUGUST/SEPTEMBER 2019 | VOL. 79, NO. 8

EDITOR | Naomi Szeben editor@bakersjournal.com 416-510-5244

TECHNICAL

EDITOR | Julie Istead, Puratos Canada jistead@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexbusinessmedia.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Kathryn Nyenhuis knyenhuis@annexbusinessmedia.com 416-510-6753

MEDIA DESIGNER | Curtis Martin

CIRCULATION MANAGER l Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-442-5600 ext. 3543

GROUP PUBLISHER/VP SALES | Martin McAnulty mmcanulty@annexbusinessmedia.com

COO | Scott Jamieson

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710.

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Business Media.

CIRCULATION

lmalicdem@annexbusinessmedia.com

Tel: 416-510-5187

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Subscription Rates

Canada — 1 Year $ 32.00 (with GST $33.50 #867172652RT0001, with HST/ QST $35.90)

USA — 1 Year $ $56.50 USD

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com

Tel: 800-668-2374

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2019 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

“I’m Jeff Zeak and I’m part of the Reiser team of Bakery Specialists who work with customers to improve their bakery applications, including the production of gluten free products. With decades of experience, I can show you how to streamline processes and maximize efficiencies so that you can consistently produce high-quality gluten-free products. Are you ready to improve your gluten free processing? Let me show you how at IBIE.”

Reiser Booth 6217

www.reiserexperts.com

Reiser Canada

Burlington, ON • (905) 631-6611

Reiser

Canton, MA • (781) 821-1290

briefly | Hinds-Bock has a new executive VP | Bosch selling packing machine division | for more news in the baking world, check out our website, www.bakersjournal.com

Bosch plans to sell its packaging machinery business, based in Waiblingen, to a newly incorporated entity managed by CVC Capital Partners (CVC). The company and its Pharma and Food units will remain intact.

Based in Luxemburg, CVC is a leading private equity and investment advisory firm with 24 offices in Europe, Asia, and the United States. It currently manages more than US$75 billion of assets.

The parties signed an agreement on July 11, 2019 effecting the transfer of the entire packaging technology business and its 6,100 associates in 15 countries. It has been agreed that the purchase price and other details of the purchase agreement will not be disclosed. Completion of the sale is subject to the approval of various bodies, including antitrust authorities, and is expected to close at the turn of the year.

Positive prospects for the Packaging

Dr. Alexander Dibelius, Managing Partner of CVC, said in a press release: “Bosch Packaging Technology is a strong company in an attractive market with long-term growth prospects.

Hinds-Bock announced the promotion of Rod Gregg to executive vice president.

Gregg’s career with Hind-Bock started 32 years ago in 1987 when he was hired as a parts and sales person. He was promoted to General Sales Manager in 1992 and in 2012 V.P. of Sales. Gregg is a 25 year member of ASB and has been with BEMA for many years.

Now with more than 30 years experience he will manage the Sales and Marketing departments.

He will also continue to develop relationships with both the Bakery and Protein groups within Middleby, as well as continue as part of the sales team for Auto-Bake Serpentine.

Paul Claro has been named as the new president and CEO of Douglas Machines Corp., replacing the retiring David Ward. Claro possesses over 18 years of experience in industries ranging from product distribution, equipment manufacturing, industrial services, and engineering. He has served as president, general manager and vice president for several large multi-million-dollar companies, including Trojan Battery, Argo Turboserve, Rexnord Industries, NUR Macroprinters, and Harsco Infrastructure

“I am excited to be part of the Douglas team. We have tremendous potential for growth, and I look forward to exploring the possibilities to build on the existing foundation and advance our products and services market share,” stated Claro in a press release.

Paul has a dual bachelor’s degree in Economics and Political Science from

Packaging Technology has an excellent reputation for quality and innovation, a broad product range, a global footprint, and experienced associates. Together with the management team, we will work to take the business forward in the years ahead, and to make it even more competitive.”

Bosch announced a year ago that it was looking for a buyer for its packaging technology business. The company is giving increasing attention to mobility and connectivity over the internet of things. It is focusing its existing resources on areas of future importance, such as shaping the transformation process and preparing for further digitalization. Bosch firmly believes that the Packaging Technology division’s competitiveness, and thus also its future viability, can be further enhanced through this new partnership, and that significant stimuli for growth can be created.

Drew University. He speaks 3 languages (Portuguese, Spanish, Italian) and is a U.S. Navy Veteran.

Douglas Machines Corp. has offered a full line of industry leading automated washing and sanitizing equipment for all containers commonly used in the food processing and distribution industries for 40 years. Over 80 models exist to clean several hundred to several thousand containers an hour.

Without this kind of freshness, the experience can’t be as sweet.

Your customers mentally taste your delightful sweet baked goods before they ever take a bite. With Ultra Fresh Sweet®, that first morsel delivers freshness that never disappoints, no matter when they took it home. Give your cupcake, muffin or snack cake a tender, resilient crumb texture they’ll think about until they can indulge again.

Let’s create deliciously fresh baked goods that stay that way.

From depositors to the latest in new technology, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

Under the motto “100 years of combined passion and know-how,” GEA will be exhibiting advanced bakery technology from its leading brands, GEA Comas and GEA Imaforni, at the International Baking Industry Exposition (IBIE) in Las Vegas from September 8-11, 2019. Both processing and freezing technology will be represented at booth 7547 to demonstrate the company’s innovation, craftsmanship, partnership and knowhow in creating bakery lines that are built to perform and built to last.

aluminum foils and plastic containers for production of cupcakes, muffins, pies and layer cakes and operates at up to 50 cycles/minute. And throwing a little light on things will be the GEA TecLight, the new LED light option from GEA, specifically developed for use under freezing conditions reaching -40 degrees Fahrenheit.

In the food industry, the best recipe for sustainable success is specialisation. Precisma GmbH based in Sipbachzell in Upper Austria is among the leading experts in baking tray cleaning technology and has demonstrated that innovation always provides the foundation for continuing success.

Exhibits will include the high capacity GEA Rotary Molder for making soft dough cookies and shortbreads with different shapes and dough consistencies. Also on display, the GEA Multi-piston Depositor, which works with ovens up to three meters wide and boasts a host of innovative features that result in better products and higher productivity. As well in the spotlight, the GEA Paper Cup Denester, which places paper cups,

GEA experts will also present CALLIFREEZE®, a unique new freezer control system for GEA spiral freezers that continuously monitors the product’s level of frozenness to ensure that products are perfectly frozen without wasting energy; GEA A-Tec spiral freezers which have been designed specifically for the North American market and featuring hygienic design, high product yield, fewer defrosts and low energy consumption; and GEA Packaging Solutions, including vertical form, fill seal and thermoforming systems that maintain food quality throughout the supply chain.

Precisma launched a new combined BELT-OILER-R machine (a cleaning and oiling machine in one). It is a high-quality baking tray-cleaning machine that has been combined with an oiling system specifically designed for use of baking trays. Following automated cleaning and oiling, the baking trays are returned by a conveyor system to the starting point.

• Ideal integration of cleaning, oiling and return processes

• Perfect for many different kinds of baking trays

• Innovative technology ensures perfect cleaning results

• Extremely economical consumption of release agents

• One-man operation

• Low space requirements

• Cost-efficient

These are the characteristics of the machine that make it so compelling. The BELT-OILER-R is capable of dry cleaning and oiling almost all types of baking trays. The efficient and remarkable results of cleaning are attributable to the use of a new form of belt brush that adapts exactly to the contours, recesses and undulations in baking trays, hence ensuring thorough cleaning. Release agents are applied by special sensor-controlled Airmix nozzles that ensure the lowest possible consumption.

The BELT-OILER-R has a wide range of potential uses. It can be employed with flat trays with up to four rims, baguette trays with and without rims, trays with and without perforation and coated and uncoated trays. It can process up to 1200 trays with a width of 600, 800 or 1000 mm every hour, making it the day-to-day workhorse of the baking trade.

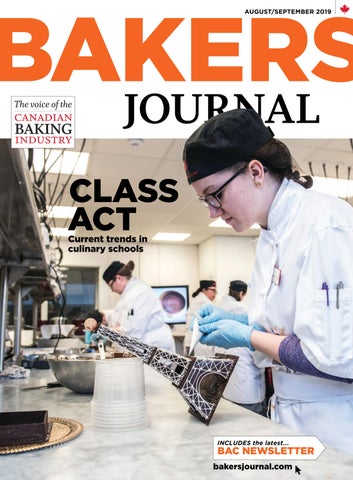

Canada’s baking and pastry schools need to offer the best learning opportunities possible to remain competitive and attract talent. Today’s students are looking for high quality instructors, state-of-the-art classrooms and labs, flexible learning options, specialized courses, apprenticeship and networking possibilities to give them a competitive edge in launching their careers. From coast to coast, Canada’s baking schools offer a wealth of options.

Aron Weber has been a Pastry and Baking Arts Instructor at the Southern Alberta Institute of Technology (SAIT) in Calgary for six years. When he started off as a student in a culinary program in British Columbia, he soon switched into the baking stream after the pastry chef took him under his wing and helped him discover baking as his true passion. It’s that very mentality of “find your passion,” says Weber, that all SAIT instructors aim to pass on to students in the school’s two-year baking diploma program.

Weber says one of SAIT’s most popular courses is cake decorating. Many students often arrive inspired by cake creations they see on Instagram and television competition shows, and want to try their own hand at the craft. Because of this course’s popularity and student demand, SAIT will be offering a specialized 15-week cake decorating course as of 2020 for students who want to exclusively focus on the art. Notably, the school also offers a Special Projects class, which focuses on creating spectacular desserts for events, which can range from an annual harvest dinner to a weekly dessert buffet.

From bread-making to confectionery and patisserie, students need a wide range of skills.

}“We stress skill development, but there is no feeling like executing your first professional looking cake and getting positive feedback from friends and family.”

From his experience, what Weber sees as a trend in Canadian baking schools is a push towards getting out of the classroom and gaining hands-on experience through an apprenticeship or co-op placement.

Like a number of the country’s top baking programs, SAIT offers a Restaurant class, which Weber describes as a big “eye-opener for students”. The bakers-to-be have the chance to get direct experience preparing à la carte, fine dining and dessert services at a busy restaurant setting in downtown Calgary.

SAIT prioritizes staying on top of trends in the baking world. Since 2016, SAIT and other Western Canada baking and pastry programs have held annual

conferences, with each school taking a turn playing host. Faculty from each program present on a variety of relevant topics related to the industry. Each conference also includes a tour of the host’s facility as well as visits to local bakeries, enabling the instructors to pass along valuable industry information to students.

At the Pacific Institute of Culinary Arts in Vancouver, students can opt for professional training programs with a variety of schedules to suit their life. There are combined baking/culinary one-year and two-year programs, as well as a six-month baking diploma or a three-month baking certificate, all of

which are full-time. “Apart from our professional training programs in the Baking & Pastry Arts, our ‘Basics in 8’ program is very popular for those who love baking,” explains Sylvia Potvin, the school’s Proprietor of Special Projects. The course takes place over eight consecutive Saturdays and is a skill-building series covering everything from bread-making and lamination to custards and creams. “I believe it has a very approachable format for home baking enthusiasts with lots of information and without overloading anyone,” says Potvin. She adds that another popular class is their sourdough. “Vancouver loves sourdough!”

With a maximum student to instructor ratio of 15:1, Potvin says that staff can respond to requests and feedback from students very efficiently. “As we are a small training academy, we are able to get to know our students intimately and are able to enrich their education on a personal level,” she says. “Having access to top quality ingredients and produce in Vancouver gives us the advantage of being able to utilize local, ingredients so we can stay seasonal.”

At Toronto’s George Brown College, there are two avenues to learn baking, either through full-time studies or Continuing Education. If students plan to study full-time, they can opt for a two-year Baking and Pastry Arts Management diploma, or a one-year certificate in Baking Pre-Employment.

Jennifer Lakhan-D’Souza, program coordinator for the one of the full-time programs, explains that the college also

offers a post-graduate French Pastry program for those that wish to learn more advanced pastry skills, which requires a semester studying and working in French.

On the other hand, George Brown’s Continuing Education (CE) courses are for those who wish to study baking as a hobby or are currently working and want to take classes outside of ‘nine-to-five’ hours. The general baking courses in the Baking Arts certificate, which cover essentials like pies, cookies and cakes, tend to be the most popular. The newest class in the CE program is Asian desserts, where students can try their hands at sweets like mochi, Japanese cheesecake and bubble tea. Other classes that tend to fill up are the specialized courses that run during the holidays and focus on seasonal baking. In addition, the school offers workshops based on student feedback and requests, such as sculpted cakes and macarons.

“While we may not teach how to make fad items such as the cronut, students’ education with us will give them the knowledge and skill to produce such items,” she explains. “We inject skills and subjects into the curriculum where we see trends are becoming more mainstays, for example, gluten-free baking.”

In general, the instructors must have a minimum of 10 years of industry experience and must be Red Seal certified before being able to teach at George Brown. The students, says Lakhan-D’Souza, come from every facet of life. Some are straight out of high school, and others have already attended

other post-secondary institutions but want to make a big change. “We get many mature students looking to change careers and we also get students from all over the world. Our full-time programs are made up of approximately 20 per cent international students coming to us from all over the world including Asia, India and South America.”

And what draws students to George Brown? According to Lakhan-D’Souza, the school’s downtown Toronto location makes it convenient for students from across the GTA. “Our programs are very well established,” she says. “Our Centre for Hospitality opened in 1987 with state-of-the-art bake specific facilities. We have amazing relationships and support from our industry partners which allows us to stay current.”

At Humber College in Etobicoke, “students are usually drawn to the courses that allow them to be artistic and creative, such as cake decorating and dessert plating,” says faculty member Susan Joseph. “We stress skill development, but there is no feeling like executing your first professional looking cake and getting positive feedback from friends and family.”

According to Joseph, the program receives a diverse group of students each year. “There are always students that come straight from high school, but there are also many mature students who have been in a non-rewarding career and are finally pursuing their passion for baking and pastry. We also have a growing number of International students who want to come to Canada for their education and hope to get the skills necessary to pursue employment here.”

One recent trend that faculty have noticed, based on classroom feedback, is that students want courses that are strictly industry related.

“We have specific courses where we study trends, brands, products and product development, but the majority of our practical classes involve skill development as opposed to recreating on-trend products and recipes. For instance, if a student learns how to make a perfect meringue, a perfect pastry cream and a perfect pâte sucrée, they can apply these skills to many different items,” says Joseph.

“ At this time, we have not needed to recruit much due to a high amount of interest in baking—hopefully our program will continue to thrive as we move into the future.” / BJ

ROSY MAZZANTI AND SIMONE ZAVETTIERI

Design, trends and visual appeal are the focus of HostMilano 2019. Television and social media influencers have altered the way people perceive bread and pastry making. The bakery industries are evolving where bread (including pizza) and pastries are exploring new ingredients and new technology to become more gourmet.

Visitors to HostMilano, held at Fieramilano from October 18 to 22, 2019 are invited to discover the latest in food industry innovations. Seven months prior to opening, this premier event for HORECA industries already registered 50 countries. A total of 1,653 companies will be represented, of which 949 (57.41 per cent) are Italian and 704 (42.59 per cent) are international.

According to the Ulisse Information System, industrial kitchen equipment specializing in “machinery for bakeries, pastry and biscuit making” totalled EU2.5 billion in 2017. Despite having slowed down over the last few years, the market is in an upswing for the 20192021 projection (+3.8 per cent yearly average).

The strongest growth will be the premium-priced products which, in 2018 accounted for about 30 per cent of the world total alone. In terms of imports, the United States, China, Germany, Russia and Canada are the “richest” main markets for the sector, with a particular growth recorded in the last five years in the USA and Russia, mainly in the high

Bakeries, especially smaller ones, seem to be less aware of the health implications of trans fats.

range segments.

Italy is the market leader for international exports with a global market share at 30.6 per cent, and is predicted to climb until 2021. Despite these numbers, the leadership of Italy was undermined by the growth of Austria, specializing mainly in the premiumprice segments, over the past five years.

Thanks to a more sedentary lifestyle and the advent of social media, a “new wave” of bakery has reached Italy cross-pollinating artisanal and commercial elements. For example, chefs and pastry chefs have started to take an interest in bread-baking, and even supermarkets are seeking skills of

artisan bread bakers.

Hand-crafted bread, slow rising doughs and recipes that put a twist on tradition, are being highlit in bread making. Pizza, for instance, is another everyday dish that is being re-interpreted in gourmet approaches. The trend of adding new ingredients, from grains with lower gluten content and sourdough, to the use of special salts to result in a healthier, more digestible and naturally tasty pizza.

And there is more. Bread’s new status as gourmet food has boosted the opening of points of sales including cafés and pastry shops, and extended its consumption for lunch and appetizers. In terms of exposure, it is always important to have attractive products that can enhance a shop’s display, due to the wide influence of social media on the bakery world.

In the bakery as in pastry sector alike, however, serving good products is no longer enough to win consumer loyalty: Luxury, style and food design have become the new must of gourmet patisserie.

Experts believe that amateur pastry professionals will disappear, but high-quality and the fusion of culinary cultures will prevail. But more importantly, pastries must be delicious. In other words, although the trend in pastries is in the direction of elegance, sharpness and beauty, quality is always the underlying factor, driven by customers who are increasingly better informed and who ask for local products.

The growing need for smaller square footage capitalises on transparent display cases, posable lighting and boutique-like furnishings to enhance products and create spaces for traditional pastry take-away and also for on-site enjoyment, from breakfast to appetizers.

Hospitality and innovation are two qualities that make Hostmilano the hotspot for solutions that shape the future of hospitality. Thanks to the Smart Label Host Innovation Award. The competition organised by Fiera Milano and HostMilano, in

partnership with POLI.Design (Milan Polytechnic Consortium) and sponsored by ADI (the Italian Association for Industrial Design), have over the past three events handed out more than 150 awards and 20 special awards to prime players in the Italian and international hospitality industry.

This year the five-member international jury of university professors, professionals and international experts with extensive experience in design, hospitality and energy saving will vote on innovation and the smartest solutions. The panel will assess the candidates’ products, services and projects, under the following criteria: efficiency and effectiveness of the products and services, and ease of use of services, and innovative usability, technologies and benefits for its users.

In addition to meeting with some of the most important national and international companies in the HORECA

sector, the booths of Hostmilano 2019 will also include focus seminars, training on the hottest topics of the day and contests featuring the most important names in the hospitality industry. For instance, the biennial European Pizza Championship, organised by Pizza e Pasta Italiana and by Scuola Italiana Pizzaioli brings together European pizza makers to challenge each other in an exciting contest.

The spotlight will also be on the 2019 edition of the Cake Designers World Championship and of the World Trophy of Pastry, Ice Cream and Chocolate, organized by the Federazione Internazionale Pasticceria Gelateria Cioccolateria. Organised once every two years, the championships will be held for the third time during Hostmilano, respectively on October 19 and 20, 2019 and on October 21 and 22, 2019. The theme for both competitions will be the art and tradition of each participant’s country. Points will be awarded for appearance and taste.

9048LA_Quarter page AD.pdf 1 2019-08-12 2:28 PM

For updates, go to www.host.fieramilano.it, @HostMilano, #Host2019. / BJ

BY KATE ZABRISKIE

Sometimes, the client isn’t always right. Here’s how to break up professionally.

Goodbye customer! It’s nothing personal (at least not usually). Sometimes customers’ expectations can’t be met, other times customers require an inordinate amount of time, and on rare occasions, a customer’s behaviour may expose an organization to undue peril. When any of those situations occur, it’s best to say “goodbye” and to do so quickly in a way that creates the least resentment on both sides.

5 SIGNS IT’S TIME TO PART WAYS AND HOW TO SAY “SO LONG”

1. They cause 80 per cent of your problems and don’t contribute close to 80 per cent of your revenue. Occasionally, any customer could require more energy than others. Those high-demand situations are normal. What isn’t normal, however, is the perpetual squeaky wheel that routinely disrupts normal business operations. Customers who buy very little and cost a lot time, personnel, or mental energy to service may not be the customers you want to keep—especially if serving them prevents you from taking care of customers or clients who are more profitable and easier to help. Goodbye Move: When customers are more work than it’s worth to you, the easiest way to say goodbye is to rely on the classic “It’s not you, it’s me” approach. If after that they insist on staying anyway, consider raising your rates accordingly.

2. They are abusive to your employees. When management allows customers to abuse employees, it’s the same as perpetrating the abuse directly. Do customers swear, yell, demean, or harass your employees? If so, it’s time to draw a

line in the sand and let them know what behaviour is and isn’t acceptable.

“Julie, we have a no profanity rule here. Respect is one of our core values, and we’ve agreed that we don’t yell and swear at our clients or each other.”

If the bad behavior continues, the relationship should stop. “But she’s our best customer. She has a lot of sway.” Maybe so. She’s also the poison that potentially exposes the organization to a lawsuit, erodes morale, and negatively affects the culture.

Goodbye Move: When someone is abusive, it’s best to say goodbye and to do so in a calm and professional manner.

“Julie, you’re obviously unhappy, and my employees are too. For the benefit of everyone, at this point I think it’s best that we part company. We both deserve better.”

3. Their behavior is out of touch with your ethics policies and practices. You are the company you keep. If you are enabling your customers to act in a way that is in disagreement with your organization’s values or the law, it may be time to say goodbye. Do you really want to associate yourself and your organization with those whose business practices are illegal, immoral, or routinely questionable? When you like the people on a personal level, it can feel like a tough decision when you’re making it. The good news is once you do, you won’t look back.

Goodbye Move: When someone or an organization exposes you to unneeded risk, it’s prudent to disassociate yourself and your organization from them pronto.

“We’re a very conservative organization. While we understand others have a more robust appetite for risk, it’s typically something we avoid. For that reason, another vendor is probably going to better meet your needs. At this point, we’re really just not a good fit.”

4. They expose you to unneeded financial risk. If you spend more time chasing payments than performing work, it’s time to consider a new payment plan at a minimum or a permanent breakup if that step doesn’t solve the problem.

Goodbye Move: Just as it doesn’t make sense to stay involved with someone who exposes you to ethical and legal risks, an organization that puts your pocketbook on the line is probably best avoided.

“Janet, I know we’ve tried a range of payment options to make this relationship work. At this point, we simply don’t have the financial appetite to accommodate your payment schedule. For that reason, I’m asking you to find another vendor. We can’t accommodate the work.”

5. You’re no longer a good fit. Sometimes people and organizations grow apart. Nobody has done anything wrong; the two parties are just in different places and it’s time to say goodbye.

Goodbye Move: This last goodbye is the hardest. When you find you and your customer are no longer compatible, it’s a good idea to start the conversation with something open-ended.

“Bill, tell me a little bit about how you see your business growing in the next few years.”

Assuming Bill isn’t planning for growth, you might continue with:

“It’s good to hear that you’re comfortable where you are. That’s a nice place and a future goal of ours. As you may know, we’re on a growth strategy and have been for a couple of years. What concerns me is our ability to give you the attention in the future that we’ve been able to give you in the past. I think you deserve to work with a partner company that can make your work priority number one, and right now I don’t think that’s us.”

No matter the reason, prolonging a relationship that isn’t working does no one any favours. It’s usually not fun to say “goodbye,” but once you do, you’ll have more time to say “hello” to customers who should conduct business with you. / BJ

Kate Zabriskie is the president of Business Training Works, Inc., a Maryland-based talent development firm. She and her team help businesses establish customer service strategies and train their people to live up to what’s promised. For more information, visit www.businesstrainingworks.com.

BY DIANE CHIASSON

How to avoid bankrupcy and keeping your product lineup in check.

Opening your own business is one of the biggest risks one can take in life -- especially in the foodservice business. It’s a sobering fact that more bakery and foodservice operations fail than succeed. But if you do succeed, it can be very rewarding.

In this article, we will take a look at a few key areas to concentrate on to improve your chances of success!

1. NOT CALCULATING FOOD COSTS PROPERLY

Take the time to cost out how much each and every single product you use and purchase for your bakery will be, how much it costs to produce every single item in your bakery and whether or not you are making a profit on each item. Once you have analyzed your food costs properly, you may need to adjust your recipe, change the packaging, or remove that product from your bakery altogether. The point of owning a business is to make money, so if the product isn’t making you a profit, it’s not worth it to sell it!

2.

}produce more loaves of bread doesn’t seem like it makes sense in the beginning, but when you factor in time and labour costs to do the work manually, the math will add up

“The point of owning a business is to make money, so if the product isn’t making you a profit, it’s not worth it to sell it!”

in the end. Having capital will also allow you to purchase in bulk, which, in the long run, will save you money.

Avoid purchasing any of your food items or supplies from supermarkets and retail stores. In order to save money, you must purchase all your supplies in bulk from wholesaler and distributors. Take the time to research your suppliers properly, and ensure that you are getting the best price on the market.

3. NOT HAVING ANY CAPITAL

It’s hard to start a bakery operation already, and even harder if you start one without any money in your pocket to invest in the proper equipment. Perhaps spending a few thousand dollars on a machine that will

Avoid throwing out anything that can be reused or recycled into another product. For example, the tops of cakes can be used to make cake sand, or pressed together to make cake pops. Extra frosting can be used for fillings. Being innovative with your leftovers will help you turn a profit instead of literally throwing your money into the garbage.

What most new bakery owners don’t realize is that having great tasting products and good service are only half the battle in running a successful business. The other half is marketing and managing the business. It is crucial to collect data and analyze the buying habits of your customers. You need to know how many people are coming into your bakery and buying products each

day/shift/hour, which items they are buying, how many of each item they are buying, what is the gross profit of those items, what is your labour compared to your budget, how many labor dollars you spend per sales dollar, what your sales are compared to what they should be and what is your profit and loss per week.

The biggest mistake new bakery owners make is relying on “word-of-mouth” to market their bakery. Of course, it’s great to have word-of-mouth, but the best way to market your bakery is by collecting data from every single customer who walks through your door, and then market to them. Marketing to existing customers is a much greater opportunity than to spend time and money to try to reach new customers.

© 2019 Chiasson Consultants Inc. All rights reserved. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 30 years. She is recognized as the industry leader in providing innovative and revenue-increasing foodservice and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or chiasson@ chiassonconsultlants.com , or visit www.chiassonconsultants.com

On June 21, 2019, the Senate of Canada rose without providing final approval of Bill S-228, the unhealthy food marketing to children legislation. S-228 will expire if it does not receive Senate approval (correct term is concurrence) before the start of the 2019 Federal election.

BAC has opposed S-228 as it would result in foods such as breads being classified as unhealthy for children and also move beyond advertising prohibitions with additional labelling and merchandising restrictions. In place of S-228 BAC has proposed Federal adoption of the Quebec child-directed food advertising prohibitions which have been in place

for more than 30 years.

While S-228 will likely expire in the Senate, the issue of food advertising restrictions to children remains at the forefront. Health Minister Ginette Petitpas Taylor recently stated “A ban was promised by cabinet in 2015 but

never passed: any re-elected Liberal cabinet will reintroduce a bill to ban junk food advertising to children. It will absolutely be a priority.”

BAC would welcome the opportunity

to revisit the intent of Bill S-228 and continues to support the prohibition of all child-directed food advertising, based on the successful Quebec model.

The Government of Canada is pursuing a number of initiatives to modernize the Canadian regulatory system and improve its performance for both Canadians and businesses. To inform the direction of these initiatives, the Treasury Board of Canada Secretariat is inviting input on the following four initiatives related to its regulatory modernization agenda: Targeted Regulatory Reviews (Round 2); Review of the Red Tape Reduction Act; Legislating changes to regulator mandates; Suggestions for the next annual Regulatory Modernization Bill.

BAC has and will continue to comment on the misalignment within Canada (between provinces and territories) and between other international jurisdictions which increased unnecessary burden on industry and is a barrier to trade, competitiveness and growth.

Discover the world of Puratos as Morgan introduces us to the Puratos World Sourdough Library, demonstrates Pain a la Coupe, innovative brioche shapes, the use of specialty grains, lamination with grains, Belgian sugar waffles, steamed buns and bao, and finally, wood-fired pizza featuring a 24 hour fermented dough using Puratos’ Otentic and Softgrain inclusions. Please join us for a day with this dynamic and knowledgeable baker.

About the Guest

Morgan Clementson joined the baking industry at the tender age of 27 after a career that included race car driving, website design, and managing petrol stations. She graduated from TAFE Ilawara, Australia with qualifications in Bakery and Patisserie and Small Business Management, earning TAFE apprentice of the year, and Hospitality and Cookery student of the year. Upon completing her apprenticeship, Morgan won the New South Wales Training Awards apprentice of the year which launched her travels to Europe and USA where she trained with renowned bakers in France, England and America. Upon returning to Australia, Morgan was awarded an Australian Overseas Foundation Scholarship which enabled her to embark on a traineeship with Puratos in Belgium. This led to her applying for her current position at Puratos as a Technical Advisor for Bakery where she travels all over the world helping clients to create innovative products and training local teams. Above all else, Morgan is passionate about bread and the importance of retaining and enhancing the art and craft of sourdough bread making.

JOIN US!

DATE: Wednesday, October 23rd 2019

TIME: 2:00 pm to 7:00 pm

LOCATION: Vancouver Island University

Don’t miss out on this informative and educational session!

A gourmet supper will be produced and served by VIU’s culinary students.

Professional Baking and Pastry Program, Building 185, 900 5th Street, Nanaimo BC

Please contact the BC Chapter for transportation questions from Vancouver and Victoria

Tess Mitchell, BC Chapter Chair TMitchell@imcdca.com 604-314-1944 (cell)

Rita Gower, BC Workshop Coordinator rita.gower@viu.ca 250 740 6114 (office)

Please fill in the attached registration form and send it to the BAC office. A confirmation will be emailed to all registrants.

Wednesday October 23rd 2019 Vancouver Island University Professional Baking and Pastry Program Building 185, 900 5th Street, Nanaimo BC 2:00 pm to 7:00 pm

THANK YOU TO OUR ONTARIO CHAPTER GOLF SPONSORS: GOLD SPONSORS: SILVER SPONSORS: BRONZE SPONSORS: Attention BAC Members:

If you work for a Baking Association of Canada member bakery or supplier company, you are entitled to receive the bi-weekly complimentary BAC E-Newsletter. For more information or to be added to our distribution list, please email info@baking.ca

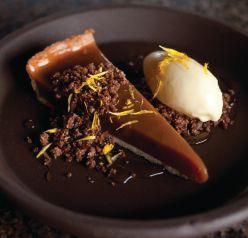

Pastry Chef Charley Scruggs of Terra restaurant in North Carolina, USA, sees something in dandelions that most chefs overlook. Where fresh dandelion greens appear in salads or vegetable mixes, Chef Scruggs uses the dandelion heads and not the leaves; the petals are garnish and the heads are distilled into a bright gold syrup.

“Dandelions are either super-bitter, or if you pick it at the right time, it’s actually not very bitter at all, like young arugula, almost. You have to pick it while it’s very young. We harvested it next to an organic farm in town, or in our own home gardens. What I started doing with the tops, we’d use the petals as garnish, but I’ve always wanted to find a way to make the oils from the petals shine a bit more.”

Scruggs started getting into foraging about two and a half years ago, when he worked in a Columbia, N.C. restaurant called Tallulah. When he moved to Terra, Scruggs decided to keep the practice going, on a smaller scale with his own twist.

}“A technique I’ve used with other wild flowers, where you take the dandelion heads themselves, and you simmer them in water with a little bit of apple slices for the pectin, a little bit of lemon juice and you really just make a tea. Bring it to a boil, and let it steep for 30 minutes: What happens is that all the oils get pulled out from the petals, and it turns that tea bright yellow, which is really cool.”

“I think in modern times we’ve lost a lot of the connection that we have with what grows around us. Even if you don’t use it, it’s kind of fun, to be aware of what is actually growing in your yard. A lot of it is edible - a lot of people don’t realize that.”

Scruggs adds that it was the colour of his infusion that inspired his desserts and even sparked some interest with the bartenders at Terre, where he is currently pastry chef.

“What I wound up doing was making a simple syrup from that tea and depending on what I would use it for, and

what the bar would use it for, you could cook it longer. I kind of cook it a bit thicker, almost like maple syrup and drizzle it over things, but you could also use it as a simple syrup for cocktails or whatever and you don’t get a lot of bitterness you associate with dandelions.” Scruggs adds that the petals by themselves have an earthy, flower-like flavour, doesn’t have the bitter punch of the greens usually found in a salad mix. When foraging, Scruggs strongly advises chefs to find out how the soil was treated; Even if the land the dandelions grow on was not sprayed with pesticides or weed-killers, there

might be run-off from land that had been sprayed. He also cautions foragers to ask for permission to approach the land first, even though the dandelion is considered a weed. This presents an opportunity for cost-effective ingredient sourcing for chefs who want local produce on a tight budget.

“The farms that do grow it for salads won’t let it grow to the point where it becomes a flower; That’s where all the bitterness starts. But if there’s a lot that they aren’t using - it’s a very invasive weed - they’ll either burn it or clear out the land entirely. If you can catch them in time, or if you have an agreement with them, they’ll give you a heads up: ‘Hey, we’re about to clear out the weeds, so help yourself.’”

Scruggs adds that when it comes to foraged ingredients, he tries to keep them as fresh as possible. “I don’t do

too much to it. Especially when it comes down to the greens. When you start cooking them, or altering them too much, you’re going to lose a lot of the nuances in flavour when it comes to that specific green and it starts tasting like any other sautéed green.

“For me, foraging is kind of a hobby that I try to bring into my career at the moment. There’s a lot to learn; there’s definitely some chef friends of mine who are more well-versed in it than I am, so they know what to look for,” states Scruggs. “I’m still kind of learning and getting into it… I think in modern times we’ve lost a lot of the connection that we have with what grows around us. Even if you don’t use it, it’s kind of fun, to be aware of what is actually growing in your yard. A lot of it is edible - a lot of people don’t realize that. It just depends on when you pick it, how much you use in a mixture or how you’re going to process it.”

The syrup can last “months” if refrigerated, and Scruggs adds that it can even be frozen though he warns that it might crystallize. He suggests

processing it in a canner to make it shelf-stable for easier storage.

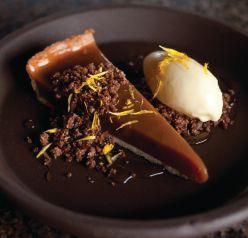

Currently, Scruggs favourite use for his summery-tasting syrup is his English-style toffee tart with a little bit of honey in the tart mixture itself and then its garnished with a crumb that has cocoa, almond flour, lime zest. “The goats milk ice cream kind of helps balance and brighten everything up,” explains Scruggs.

“One thing the owner [Mike Davis] and I have been working on is trying to use the local produce in a lot of the new ingredients that we are able to get from the region with new farmers coming in, and giving us new products and still trying to use it in a way that’s approachable and familiar to people in the area. It probably won’t change drastically, but there will be a stronger focus on the produce we’ll be able to get at the time, and try to match the menu that Mike has for the rest of the menu.”

The inventive pastry chef believes that interest in foraging is growing. He’s doing what he can to bring something different to the region, without alienat-

ing long-time residents. “The trend that we’re starting to see state-wide, and I definitely see it in Columbia, people are interested in trying new flavours, they’re interested in trying new techniques, and different cuisines that you wouldn’t usually see…dishes that have several different elements that they are not used to, is something that the world has seen for a while, but I think Columbia and South Carolina are starting to see, and I think they’re actually embracing it.”

Scruggs laughs, and says, “The funny thing about foraging, it’s not an altogether foreign concept. From the perspective of going to a restaurant and having that served to you, that’s a little different, but when you talk to people - especially the older generations - it’s something that they’ve already done but they haven’t thought about it. They don’t see it so much as a “trend” as it is in the culinary world. For them, it was just life. It’s not something that they would expect to see in a restaurant, but when it’s done well, it’s something that clients are interested in trying.” / BJ

The key to excellence in baking is mastering the formulas for entire classes of baked goods. A perfect puff pastry, for example, is a prerequisite for turnovers, napoleons, and torta Milanese. The Baker’s Manual includes 200 new, tested, and proven interpretations of classic formulas that you can use to create a wide range of breads, pastries, custards, and more.

Providing reliable recipes that can be assembled into any number of desserts, The Baker’s Manual gives you the know-how you need to meet any baking challenge with absolute confidence.

$37.95 Item #0471405256

BY MATT HALE

Low temperature evaporation saves time, money and overall hydro costs for food processing techniques

}There are two main methods of reducing the water content of food products and ingredients: drying and evaporation. Materials with a low dry matter have often been dried, while liquids are more frequently evaporated. Many food processors are now combining low temperature evaporation with drying to provide an efficient and energy-saving moisture removal process for a variety of products, not just liquids. Reasons for drying range from extending shelf life extension and preventing spoilage, to quality preservation or as part of food processing, such as concentrating or dehydrating products. As a result, a number of different drying systems have been developed, with the main technique being spray drying. Other less common techniques include tunnel drying and drum drying, but all these methods are designed to move air over the product to dry it without damage. Other specialist techniques including freeze drying and vacuum drying may also be employed in certain situations.

quality or preventing a barrier layer (which will inhibit the drying process) from forming, need to be considered. One thing that most drying processes have in common is the use of direct or indirect heat to drive moisture from the product. This is frequently inefficient in terms of energy use, requiring high inputs and taking a relatively long time to achieve the required level of moisture reduction. The Carbon Trust has therefore recommended considering alternatives to conventional process heating, such as, microwave drying (which is expensive and not suitable for many products) or using lower temperature processes, such as evaporation. There is also an increasing overlap between using evaporation and drying techniques, and a combined approach is becoming more common.

Drying is frequently inefficent in terms of energy use, requring hign inputs and taking a long time to achieve the right consistency.

Drying rates will vary with the method used, but general considerations include:

1. The nature of the material, including its physical and chemical composition, moisture content, etc.

2. The size, shape, and arrangement of the materials to be dried

3. The relative humidity, or partial pressure of water vapor, in the air being used for drying

4. Air temperature

As well as the energy required, other factors such as preserving product

By using evaporation to reduce the water content of fluid products before they are sent to a spray drier, the overall amount of energy used by the process can be significantly reduced, improving efficiencies and lowering both the cost and environmental impact of the process. In some cases using a combined technique can double the output of an existing spray dryer. Low temperature evaporation combines the use of a vacuum to reduce the boiling point of the liquid to be removed, together with traditional high temperature evaporators based on heat exchanger technology.

The type of heat exchanger used will depend on the nature of the products being treated. For materials with low or medium viscosities, such as brines, sugar solutions or evaporated milk, using the HRS K Series as an

evaporator module provides high heat transfer rates with good resistance to fouling. For more challenging and viscous materials, such as purees, malt extracts, liquid cheeses and whey protein concentrates, the HRS Unicus Series contains a self-cleaning scraper mechanism which reduces fouling and maintains heat transfer rates (and therefore operational efficiency).

As can be seen, for non-solid materials with low water content, such as gels, jellies and some emulsions, low temperature evaporation can significantly reduce running costs compared with other drying systems. Where you have a process which requires the removal of water from a food product it may be worth speaking to a heat exchange specialist before you commit to traditional drying methods. / BJ

Matt Hale is the International Sales and Marketing Director for HRS Heat Exchangers.

NAOMI SZEBEN

Master Baker, Marcus Mariathas, is the Sr. director of Product Development at Ace Bakery. He’s noticed that the trends that have gained the most ground over the years and is becoming more widespread is the request for natural, clean-label and organic breads. “These are things that people are starting to appreciate more widely…that’s already our foundation. That’s been our concept for about 25 years, now.”

“When I originally started in 1995, I was actually going to University of Toronto, studying business and finance. I needed a

job to pay for all my expenses, so I started at Ace as a job. But then, a journey master baker at Ace Bakery showed me how to shape the breads and how to make the starter, and how to make old fashioned, European soft bread. They started teaching me about the aroma, the taste and I got more and more in love with it, and I learned the right way how to develop recipes, how to shape breads.”

Mariathas’ keen mind for business saw how the trends were shifting towards artisanal breads. “I thought baking would be a good business opportunity. These breads are very important to the Canadian and American consumers. It was an oppor-

tunity that kind of fell in my lap, and I took it on. The people I work with helped me to gain knowledge.” This bakery experience was put to good use: Mariathas later competed — and won — the American Championship in the World Cup of Baking. That award led to other accolades, as well.

“Because won the championship, we were automatically qualified to participate in the World cup of baking in the Coupe du Monde in 2016, and that was the first time Canada ever qualified at that level at that competition.”

Mariathas familiarity with bread trends and the growing love for sourdough made him the natural choice to talk about

par-baked baked artisanal dough. He speaks of how sourdough is starting to develop a cult-like following. Social media channels are blowing up on the subject of sourdough. Some believe that sourdough is easier to digest than other types of bread, and many feel that they have a connection to their community when they buy a loaf made from local wheat. Mariathas believes that “consumers are asking more questions about bread, and that’s a good thing for bakeries.”

“How you treat your flour, how your product is made: Consumers are becoming more aware of sourdough bread. There’s a mania around it: There’s talk of people making their own starter, they’re naming the starter, they’re making bread with that starter. It’s becoming a thing on social media: People want to eat good bread.”

}an hour, to the maximum of one hour. That’s the amount of time the product needs to be frozen. It has to come to a certain cold temperature before it gets to the frozen trailers and then distributed to the customers.”

“When you do that, you’re trapping the moisture, everything in the same format it came in out once it’s cooled down, that way you don’t lose moisture, the products won’t go stale, especially the products that we make. We don’t add any chemical leavening, or any chemical ingredients, so we need to make sure that everything is

routine and a process set in place for larger-scale manufacturing. From issues like environmental controls for fermentation, to maintaining proofing temperatures to keep the breads’ attributes consistent.

“Where I started in a small bakery cafe, there were no temperature controls. In the summer, bread proofed differently. There were variances; the proofing temperatures were not right. There was no control as to how long bread was going to take to proof. Sometimes, two hours, sometimes two hours and thirty minutes; there’s not a lot of control in a lot of small bakeries.” Mariathas adds, the other advantages to par-baked dough are planning and financial. Using par-baked goods not only yields a consistent product, but also saves time and could result in more productivity.

“That’s the beauty of it. You don’t have to go through the routine of making a starter, forming the dough, having a skilled baker on site… you can’t find a lot of experienced bakers, these days. Par-baked alleviates staffing issues and still yields a great bread.”

kept intact to give the same experience at the consumer level.”

“Whatever other products you make, if you make it consistent, then you can make sure they reach beyond what the consumer wants. One of the key things, when you do a frozen, par baked product like this, you could reach out to anybody in North America with the same results, because all they have to do is put it in the oven for 8 minutes, 10 minutes, and you have a fresh loaf sitting at your table. That’s the beauty of it. You don’t have to go through the routine of making a starter, forming the dough, having a skilled baker: That’s a rare thing. You can’t find a lot of experienced bakers, these days. That’s another issue we face in the industry, these days. Par-baked alleviates staffing issues and still yields a great bread.

The former business major knows that the key to providing an artisanal bakery experience in a wholesale or retail grocery experience lies in how they freeze their dough and the efforts made to create an artful experience prior to baking. Getting that old fashioned-taste in a modern facility is a trick that the Ace Bakery has long had up its sleeve.

“As a frozen concept, you’re dealing with a different product, so we want to make sure that our breads are mixed to the full stage, and have a finished appearance before it leaves our bakery.” Mariathas knows that timing is of the essence when it comes to dough bakery. “When it comes to this kind of freezing, you have to flash-freeze. We don’t typically freeze stuff for 24 hours or 30 hours. It’s typically half

The master baker knows that there are challenges to flash-freezing. “We need to have controlled temperatures throughout the process. From the mixing to the way you’re proofing, the way you’re fermenting, to the time and the way you’re shaping the breads, when you’re baking the bread: Time and temperature is very, very important for the dough. So, we need to create an environment that’s all controlled and monitored. And you need to freeze it for the right amount of time: If you don’t follow the rules, you’re going to compromise the quality of the product for consumers.”

“Our goal is to provide a boutique bakery quality of bread, but in a scale that we will be able to produce.” He adds that the key advantage to par-baked over freshly baked goods lies in having a

“What I’ve noticed so far, in North America, nobody has the amount of starters that we make in-house in order to produce our products. We have nine different starters that we make in house and maintain over time. I’m tempted to say that nobody in North America right now has more starters than we do. Maybe they have two starters, but nobody has nine different starters. That’s the difference for us. “

Mariathas feels that having multiple starters is a “key advantage.” Ace bakery sometimes uses different starters in the same dough in order to develop a unique texture or taste profile. The Master Baker notes that the starters are used to replace the use of artificial flavours or additives to create a flavour. “We do it with our own starters, which is basically flour and water. That’s what creates beauty.” / BJ

BY ANATOLI NAOUMOV

learn how something as simple as changing your lightbulbs can save your bakery big bucks.

Effective energy management in industrial baking revolves around two key areas: production and cost. In most cases, once the energy consumption involved in production is made efficient and free of inconsistencies, costs will decrease too.

Even a small difference in energy use can have a profound impact on production and quality. With that in mind, the ultimate goal of energy management is to maintain or increase production and quality, while reducing costs and energy waste.

}Energy doesn’t just disappear during production process; it’s applied to your product. As a result, too much energy can be as bad as too little when it comes to production quality. Fluctuations in energy consumption not only signal a deviation in your equipment’s technological process, they often cause loss of quality and product itself.

impressive cost cutting.

Optimizing refrigeration systems can cut electricity use by 30 per cent: Industrial refrigeration plants are commonly set to run at higher-than-necessary levels of condensing pressure. By working with an energy expert, however, operators can often reduce these set-points while supporting the same energy load.

In a pilot project at Sons Bakery in Brampton, energy use was cut by 13 per cent through a reduction in condensing pressure and operational changes alone. A roadmap was devised to reduce electricity consumption by another 25 per cent through the installation and proper setting of VFDs on condenser fans, brine pump, and circulation pump as well as further optimization of set-points. Optimization of the refrigeration system also released its

Energy conservation will lead to a 10 per cent decrease in your utility (water, electricity and natural gas) costs, increasing your bakerys gross profit margin.

cooling capacity, allowing the bakery to stick closer to its recipe.

savings can seem small and inconsequential, they’re the easiest costs to manage at plant level.

Cutting back on labour, or negotiating lower prices for raw materials, are far more challenging ways to reduce your expenses. One can mean dealing with unions, labour disputes, and lost productivity – the other is often at the mercy of market conditions. Every single dollar saved on energy directly bolsters profit. To add the same $1 to profit, a typical industrial bakery need to sell, produce, and ship $20 worth of product.

Some of the benefits of energy use analysis were made abundantly clear by the energy consumption data analysis we performed for Weston Bakery Sudbury. Through such analysis Weston Bakery was able to find operational inefficiencies, improve product costing, create more accurate gas budget for better procurement, and quantify various energy saving opportunities.

While energy in all its forms is what allows your bakery to do what it does, the smallest of differences in energy use can affect your production and costs in a very big way.

As part of an energy project at Weston Bakery Sudbury, for example, we investigated production and gas consumption at oven level to determine what was triggering a gradual increase in energy use. Our analysis revealed that a simple maintenance procedure flaw was responsible for the following:

• deviation from the technological process,

• waste of natural gas, and

• compromise of product quality, leading to possible reputational damage

Following our findings, the oven’s faulty temperature sensor calibration procedure was fixed, and the bakery was rewarded with a 4 per cent savings of natural gas. Refrigeration systems are a perfect example of how energy optimization at the production level can lead to

Lighting retrofits are another energy management solution that can yield lucrative – and sometimes surprising –results. One industrial bakery manager stated that, energy costs aside, shortage of freezing capacity required them to use 3rd party freezer to meet demand for their product.

As it turned out, the bakery’s walk-in freezer housed 12 metal-halide light fixtures that were never turned off. The fixtures emitted 6.6kW of heat that had to be constantly evacuated. So, not only was the freezer generating a 42 per cent annual energy waste, its reduced capacity meant the bakery was forced to use a 3rd party holding freezer to store some of its product.

A retrofit to LED lighting increased production throughput, reduced product and energy waste, and eliminated need for 3rd party freezer and logistics. All in all, a $3,000 lighting retrofit saved the bakery a mind-boggling $413,400 a year.

Consider that the easiest way to increase your bakery’s profitability is to reduce your utility and energy costs. While energy

As a minimum, harvesting the low-hanging fruits of energy conservation will lead to a 10 per cent decrease in your utility (water, electricity, natural gas) costs, directly increasing your bakery’s gross profit margin. And all of that is achievable with next to no capital investment.

Managing your company’s electric, gas, or water-driven energy consumption shouldn’t add to your managerial burden. It should, in fact, make your life simpler. Partnering with an energy management consultant - and taking steps to measure and analyze your energy consumption data - can help your industrial bakery streamline throughput, sustain production quality, and ultimately cut costs. / BJ

Anatoli Naoumov is a managing director at GreenQ Partners, which helps identify, implement and report energy-saving projects. He has been named a Certified Measurement and Verification Professional (CMVP) by the Association of Energy Engineers (AEE) and the Efficiency Valuation Organization (EVO).

for the baker

Are you looking to learn a new skill? Hone a specific craft? Welcome to the Bakers Journal Professional Courses Guide 2019. Continuing education is essential to today’s success. As new trends become mainstream and techniques continue taking tradition up a notch, it’s imperative to

CACAO BARRY & CALLEBAUT CHOCOLATE ACADEMY

Training Center Montreal Montreal, QC 1-855-619-8676

We are proud to present the 2018-2019 course program at the Chocolate Academy™ Training Center Montreal. Offering classic, specialized

and innovative classes with our skilled technical advisors as well as with talented Chefs from here and abroad in both French and English for professional chocolatier and pastry chefs. Guest Chefs include: Ryan Stevenson, Amaury Guichon, Emmanuel Ryon, Thierry Bamas, Marike Van Beurden , Arnaud Larher. Register now! chocolate-academy.com

North Bay, ON Correspondence and online courses offered, including

Join our French patisserie program, a specialized French food and culture postgraduate certificate

Learn from the experts here in Canada and then live, learn and get work experience in France!

Find out more: georgebrown.ca/patisserie

maintain a passion for learning. What better place to ignite your creativity than back in lab’s lap at school?

The institutions listed in the Bakers Journal Professional Courses Guide 2019 are proud to serve the baking community. Check out what our education system can do for you.

nutrition, sanitation and safety, food preparation and communication and customer service canadorec.on.ca

Toronto, ON Correspondence and online courses offered, including nutrition and health, sanitation and safety, kitchen equipment and food preparation, and workplace communication centennialcollege.ca

COLLEGE OF THE NORTH ATLANTIC

Newfoundland and Labrador 9-month Baker program (fulltime) offered at Bay St. George campus 9-month cook program (fulltime) offered at several campus locations

Marine Cook program also available cna.nl.ca

CONESTOGA COLLEGE

Waterloo, ON

Continuing education courses in food processing supervisor and advanced sanitation practices Distance learning courses in creative cooking and food service worker conestogac.on.ca

Thunder Bay, ON Evening, on-campus classes in cake design confederationc.on.ca

DURHAM COLLEGE

Whitby, ON Advanced Baking & Pastry Arts

Culinary Management Hospitality Management-Hotel, Restaurant and Tourism Special Events Planning 905.721.3000 durhamcollege.ca/cff

FLEMING COLLEGE

Peterborough, ON Online and on-campus continuing education courses in advanced food safety training, quality food preparation, communication and the food service worker and cake decorating flemingcollege.ca

GEORGE BROWN COLLEGE CHEF SCHOOL

Toronto, ON

Continuing education programs and courses in baking arts, baking and pastry management, culinary management and culinary arts. georgebrown.ca/chefschool

GEORGIAN COLLEGE

Barrie, ON

Continuing education programs and courses in bake theory, patisserie, techniques and baking. georgianc.on.ca

Culinary programs also include courses in Baking & Pastry Arts 416-675-6622 hrt.humber.ca T a ke your career to t he next level.

HUMBER COLLEGE

Toronto, ON

2-Year Diploma: Baking & Pastry Arts Management

New bake labs coming January 2017

Learn from expert Pastry Chefs in state-of-the-art facilities

Sarnia, ON

Part-time food service worker program, offered online lambton.on.ca

Ottawa, ON and international (France, U.K., Spain, Australia, Japan, Korea, Mexico, Peru)

Short-term (one-day) courses at Ottawa and international campuses on varying subjects Continuing education classes at Paris campus, including master of food and food cultures and Hautes Etudes du Goût cordonbleu.edu

LETHBRIDGE

Lethbridge, AB

Continuing education classes in food safe sanitation lethbridgecollege.ca

Moncton, NB

One-evening on-campus classes available in cooking and candy making nbcc.ca

Teaching excellence at the Canadian Food and Wine Institute.

Located at Niagara College’s breathtaking Niagara-onthe-Lake Campus, nestled in the heart of Niagara’s rich wine and culinary country, the Canadian Food and Wine Institute (CFWI) provides students with valuable handson experience and academics in all aspects of culinary, baking, food innovation, wine, spirits and beer.

Niagara College is home to Canada’s first teaching brewery, teaching Distillery and commercial teaching winery, along with a world-renowned full-service teaching restaurant that focuses on local and seasonal cuisine.

Fortified by the teaching

vineyards, hop yards, and organic gardens, CFWI delivers an unmatched learning environment.

Niagara College offers the following programs:

• Artisan Distilling

• Wine Business Management

• Baking and Pastry Arts

• Culinary Skills

• Brewmaster & Brewery Operations Management

• Culinary Management (Co-op)

• Winery & Viticulture Technician

• Culinary Innovation & Food Technology (Co-op)

• Cook Apprenticeship

Please note that both the Culinary Skills/Management and Baking programs are now continual intake. CFWI will be accepting students in September, January and May. canadianfoodandwineinstitute.ca

NORTHERN ALBERTA INSTITUTE OF TECHNOLOGY (NAIT)

Edmonton, AB

NAIT is a leader in culinary education, with full-time, part-time and apprenticeship options:

Culinary Arts diploma

Hospitality Management diploma

Baking certificate

Retail Meatcutting certificate Baker and Cook apprenticeship training

Numerous evening/weekend courses

1.877.333.6248 nait.ca

NOVA SCOTIA

COMMUNITY COLLEGE

Dartmouth, NS

Short-term, on-campus continuing education classes in pies and tarts, croissants and danishes, fondant and cake decorating for beginners and restaurant desserts nscc.ca

RED RIVER COLLEGE

Winnipeg, MB

Food services management continuing education program (some courses available by distance delivery) rrc.mb.ca

SASKATCHEWAN INSTITUTE OF APPLIED SCIENCE AND TECHNOLOGY (SIAST)

Saskatoon, SK

Distance education options for food service worker and food nutrition management

Evening and weekend on-campus cooking and baking classes, including European pastry and torte preperation siast.sk.ca

ST. CLAIR COLLEGE

Windsor, ON

Part-time classes in kitchen management and culinary skills and techniques stclaircollege.ca

VANCOUVER COMMUNITY COLLEGE

Vancouver, BC

Continuing education/part-time programs and courses in baking and pastry arts vcc.ca

VANCOUVER ISLAND UNIVERSITY

Nanaimo, BC

Professional Baking and Pastry Dept.

Foundation, Apprentice and Leisure Courses in Artisan Baking, Viennoiserie, Decorating and Wood Fired Baking. 2.viu.ca/baking

A UNIQUE SPACE DEDICATED TO THE EXPLORATION OF FLAVOURS, THE ART AND EXPERTISE OF CHOCOLATE!

DISCOVER OUR PASTRY AND CHOCOLATE COURSES FOR PROFESSIONALS.

BY CODY J. RIEBE

Traditional advertising could be cost-effective and less invasive than more modern ways of catching potential clients’ attention

It’s no secret that small and mediumsized bakeries often find themselves having difficulty competing against the big guys. Making the best bear claws in town doesn’t matter if no one is coming in to try them. Learn how billboards can be an affordable and effective way to attract customers and establish your brand.

For newer bakeries, one of the most important things you can gain from advertising is brand recognition. Before anyone will try your sweet treats, they need to know you exist and where to find you. Seeing your goods on a billboard during their commute every day is a fantastic way to make potential customers aware of you. It begins to establish your brand and also starts to create an emotional connection with them. A well-designed billboard will also generate interest and be shared on social channels like Facebook, Instagram, and Snapchat, all at no additional cost to you!

People have gotten good at ignoring or skipping most ads; Billboards are loud and big, but they are also considered to be one of the least annoying types of ads.

Billboards on roads let drivers know where they can quickly satisfy their sweet tooth. In more downtown or urban areas, they can perk up foot traffic, too. Sometimes all the persuasion consumers need to try a new place is an image on a delicious-looking sign to entice them. Billboards lead customers right to your front door.

Cost is likely the most important factor in deciding how to advertise. This is especially true for smaller and newer bakeries that don’t always have thousands of dollars in their advertising budget. Billboards and other outdoor

ads are affordable on nearly any budget. Generally speaking, they’re more affordable than newspaper, magazine, and television ads. We’re talking around 30 dollars a day.

While all sorts of different ad formats can be effective, people have gotten good at ignoring or skipping most of them. Many people find digital ads frustrating. Billboards are loud and big, but they are also considered to be one of the least annoying types of ads. 85 per cent of all consumers believe outdoor ads are useful, with 83 per cent believing they informative. Why use an ad format that you know will annoy your audience?

Outdoor ads work. They’re huge! They’re colorful! They’re memorable! Just how impactful? According to the Outdoor Advertising Association of America, of those who have seen an outdoor ad:

• 41 per cent are more likely to learn about the brand being advertised

• 70 per cent say outdoor ads are very, or somewhat likely, to influence a purchase

• 58 per cent search the web as a direct result of seeing an ad

• 55 per cent use mobile and social media to share information while viewing an outdoor ad

• 35 per cent buy a product after seeing an ad. / BJ

Cody J. Riebe is a Public Relations and Content Specialist for BillboardsIn.com, an online marketplace for outdoor ads.

•

The essence of baking is chemistry, and anyone who wants to be a master pastry chef must understand the principles and science that make baking work.

This book explains the why’s and how’s of every chemical reaction, essential ingredient, and technique, revealing the complex mysteries of bread loaves, pastries, and everything in between.

For both practicing and future bakers and pastry chefs, How Baking Works, Third Edition offers an unrivaled hands-on learning experience.

BY JANE DUMMER, RD

Sustainable efforts range from bamboo straws to bakery school classes