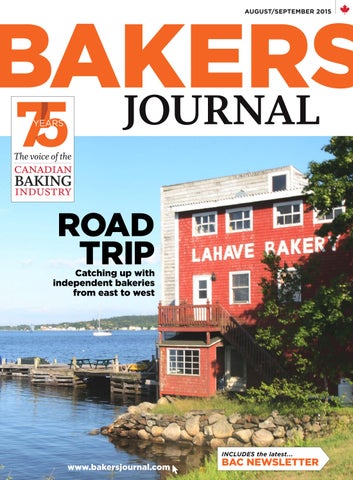

The voice of the canadian baking industry

The voice of the canadian baking industry

Catching up with independent bakeries from east to west

BY BRIAN HARTZ

Trans fats. Sugar. Sodium. Carbs. Cholesterol. Gluten. GMOs. Bakers’ building blocks have been under fire for years now. It’s a miracle anyone still eats bread, given all of the bad press the industry’s essential ingredients have received.

Consumers are hounded left and right to avoid the ingredients listed above. They’re viewed as a rogue’s gallery in which only careless gluttons would indulge themselves.

But as the saying goes, where there’s smoke, there’s fire. For example, partially hydrogenated oils (PHOs) – a major source of trans fats – are regarded as unsafe for human consumption as they’ve been proven to give rise to heart disease, obesity and memory loss.

The U.S. Food and Drug Administration (FDA) in June issued new rules requiring food manufacturers to completely eliminate PHOs from their products within three years. Companies like McDonald’s and Chick-fil-A have already fallen in line.

In Canada, sodium reduction was all the rage, with a major campaign to reduce Canadians’ daily average sodium intake to 2,300 milligrams per day by 2016. Excess sodium consumption has been shown to increase the risk of hypertension, which in turn can lead to heart disease and stroke.

Now, genetically modified organisms (GMOs) and sugar find themselves playing the villain – and drawing the gaze of food regulators.

The GMO debate is particularly perplexing. Major names such as Chipotle have announced that they’ll use only non-GMO ingredients, yet industry research shows that consumers aren’t willing to spend more for non-GMO food. This, despite well over half of adults surveyed by the NPD Group in 2014 expressing concern over GMOs in their food supply.

NPD analyst Darren Seifer thinks confusion over what constitutes genetically modified food is to blame, telling FoodNavigator-USA.com that “when we asked people to tell us what GMOs are, the biggest answer we get is ‘I don’t know.’ We naturally fear what we don’t understand, and think it is bad.”

Sugar, on the other hand, is a known quantity – or is it? Consumers have been told for years that too much sugar is bad. But it turns out that there’s a whole spectrum of ingredients that are, for all intents and purposes, sugar. Their names, however, reflect a different reality: “corn syrup,” “dextrose,” “polyol,” “fruit juice concentrate,” “glucose,” “barley malt.”

Taken out of context, none of these ingredients sound especially egregious. But they constitute a category of ingredients that, heretofore, could be lumped under the catch-all term “added sugars.” Not so, anymore. Health Canada has proposed changes to food labels that would require individual sugary ingredients to be itemized and listed together in one section of the label.

“Our government is breaking new ground with our proposal on the labelling of sugars on foods sold in Canada,” Health Minister Rona Ambrose said in June. “Nowhere else in the world will consumers have the kind of information Canadians will have about the sugars contained in the foods they eat. This information will help them understand how much sugar is in a product, whether it’s a little or a lot of sugar, and where the sugar comes from.”

Most of us could stand to improve our diets. But most of us also have the ability to make good choices and not go around blaming this ingredient or that ingredient for our health woes. Maybe I’m tilting at windmills, but it seems that the ingredients coming under the most fire from regulators are the very ingredients that have sustained humanity since time immemorial. Members of the baking industry should stay abreast of the conversations and developments around GMOs and sugar to ensure they remain in compliance, but also so they can play an active rather than passive role in future debates over ingredients and public health. There are some ingredients bakers can do without, but others they can’t – and the freedom to formulate is one of the most important.

Happy reading. / BJ

AUGUST/SEPTEMBER 2015 | VOL. 75, NO. 7

EDITOR | Laura Aiken editor@bakersjournal.com 416-522-1595 1-888-599-2228 ext. 250

ASSOCIATE EDITOR | Colleen Cross ccross@annexweb.com 519-428-3471 ext. 261

TECHNICAL EDITOR | John McColl, Puratos Canada jmccoll@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Shannon Drumm sdrumm@annexweb.com 519-429-5176 1-888-599-2228 ext. 219

MEDIA DESIGNER | Brooke Shaw GROUP PUBLISHER | Martin McAnulty mmcanulty@annexweb.com

DIRECTOR OF SOUL/COO | Sue Fredericks

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710. RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 Email: subscribe@bakersjournal.com

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Publishing & Printing Inc.

Subscription Rates

Canada — 1 Year $ 30.00 (with GST $31.50 #867172652RT0001, with HST/ QST $33.90)

USA — 1 Year $ 45.00 USD Best pricing is available online at www.bakersjournal.com

Send your subscription request to: Bakers Journal

P.O. Box 530, Simcoe, ON N3Y 4N5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940 Email: subscribe@bakersjournal.com

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2015 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

Not h i n gprotectsy o u r b a k e dpr o d u ctand itsfr e s h ness l i ke R e p a kpack a g ing.

Repak form-fill-seal packaging machines produce high-quality modified-atmosphere packages that protect your baked products, keep them fresh, and extend their shelf-life. The versatile Repak can easily package your entire line of baked products efficiently and cost-effectively It produces safe, hermetic packages with reliable seals that extend freshness And for those bakers producing gluten-free, dairy-free or nut-free products, Repak packaging can protect your product against contamination from other products on the supermarket shelf. The stainless steel Repak features a hygienic design with easy access to its interior for thorough cleaning and sanitation. Plus, the Repak is backed by Reiser and our leading customer support and service team. Test the Repak for yourself. Contact us today to set up a demonstration in your plant or at our Reiser Customer Center

briefly | Lallemand forced to raise prices; GFCP adds to sales team; new yeast targets acrylamide; Fleischmann’s marks 25 years in Memphis | for more baking news, check out our website, www.bakersjournal.com

Vancouver-based Renaissance BioScience Corp., with its wholly owned subsidiary Renaissance Ingredients Inc., has filed a provisional application to the U.S. Patent and Trademark Office for the patent of its non-GMO acrylamide-reducing (AR) baker’s yeast.

The application protects the company’s work over the last two years in developing baker’s yeast strains (Saccharomyces cerevisiae) that naturally reduce acrylamide by up to 95 per cent in a variety of food products by degrading the precursor compound asparagine.

Acrylamide is a World Health Organization Group IIA carcinogen that has been shown to be mutagenic and neurotoxic in a variety of laboratory animal studies. In 2002, acrylamide was identified in a range of common foods including bread, toast, potato chips, fries, cereals, and coffee. Acrylamide is not added to foods, but forms naturally from the amino acid asparagine when foods are heated above 120 °C (e.g. baking, roasting, or frying). The European Food Safety Association

(EFSA) recently announced its latest risk assessment on the continuing widespread presence of acrylamide in these various foods.

This report is one of many issued by food regulatory and health agencies worldwide, including the US FDA, Health Canada, and others.

“Our AR yeast is an important step toward solving the global health concerns posed by dietary acrylamide,” says Renaissance Ingredients president Dr. Matthew Dahabieh.

“Our testing, both in-house and with commercial partners, demonstrates that acrylamide-reducing yeast reduces acrylamide by up to 95 per cent in a variety of foods,” Dahabieh says.

The company’s studies, he explains, “highlight the versatility and efficacy of our AR yeast in reducing acrylamide not only in baked goods and toast, but also in potato products, snack foods, cereal products, and coffee.”

After experiencing another unseasonably warm and sunny winter, British Columbia’s 800 blueberry farmers have been busy hand-picking the first berries of the season since June 20. With what is being called the earliest start to a blueberry season in recent memory, both the food industry and consumers can look forward to an ample supply of blueberries this summer.

“Thanks to Mother Nature blessing us with a warm winter, blueberry lovers can now find B.C. berries in supermarkets, farmers’ markets and produce stores across the province,” said Debbie Etsell, executive director of the B.C. Blueberry Council. This year’s crop is expected to be on par with 2014’s harvest of nearly 68 million kilograms, solidifying British Columbia’s claim as the largest highbush blueberry in the world.

An Alberta success story, Edmonton’s beloved French bakery, Duchess Bake Shop, has released a self-titled debut cookbook.

Duchess Bake Shop became a national best-seller in six weeks by selling over 5,000 copies. It won the prestigious International Gourmand Award for Best Self-published cookbook in Canada. The cookbook costs $45 and is available at Cookbook Co., all Chapters locations, and online at DuchessBakeShop.com and Amazon.com.

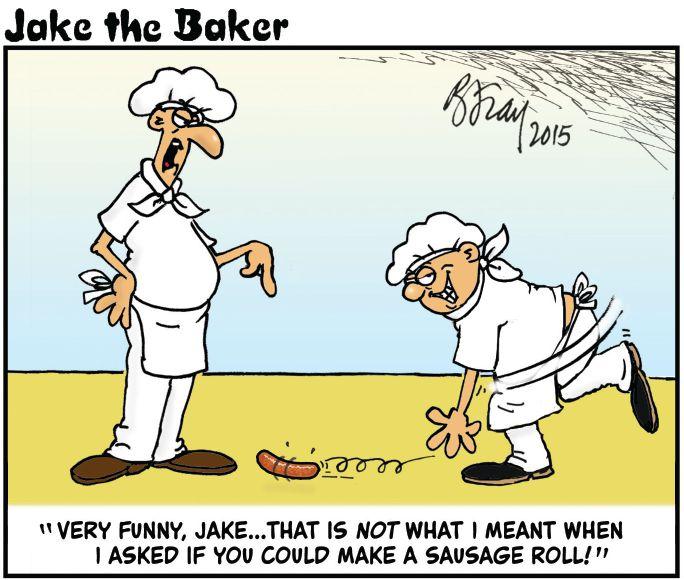

The photo of Jake the Baker Award winner Daniel Vokey was incorrectly credited in the July issue. The photo was taken by Don McCaskill of NightShadows Photography. Bakers Journal regrets the error.

Independent bakeries across Canada open their doors to reveal their signature baked products

Join us on an end-of-summer road trip without leaving your bakery. Stops include a ship’s chandlery and fish processing plant on Nova Scotia’s south shore that houses a charming café and sells breads and other goods wholesale, an Etobicoke, Ont., that celebrates the humble butter tart by offering many varieties – all with gluten-free counterparts – and a bakery in Red Deer, Alta., where longtime staff make a staggering 155 dozen cupcakes on Valentine’s Day.

Canada’s independent bakeries are as diverse as its geography and, in their own way, as enterprising as its resourceful early settlers. Here we highlight their ingenuity and perseverance in baking their signature products both sweet and savoury, sharing their skills and creating places where Canadians can enjoy high-quality treats and soak up the local flavour in unique but universally welcoming settings.

After 40 years in the business, Theo Korthof no longer hides his love of baking. That mindset is transferred to the care that goes into the bread and pastries produced at Korthof’s London, Ont.-based

The Artisan Bakery.

}‘We do a big volume of meat pies, pot pies, which are chicken, potato, carrots and peas with a real gravy.’

– Fred Crawford, Walton’s Bake Shop

The bakery’s small team – including Anne Roche, Ana Maria Hack Hunt and Christine Price – work out in the open in front of customers as they create a total of 19 kinds of bread, both sourdough and regular, including specialties like their famous dill pickle bread as well as red beet, green kale and Swiss chard breads.

“We hand craft every loaf of bread. Our dough gets proofed naturally and we bake with a simple two-deck oven. No computerized buttons are pushed,” Korthof said.

Artisan bakes 1,000 handmade loaves of in-house bread every week, each with no chemical additives or preservatives.

Before emigrating to Canada from his native Netherlands in 1980, Korthof practised his culinary craft as a chef in

his home country and Switzerland.

Settling in Mississauga, Ont., with his wife Gerda, Theo worked for Hilton hotels and the University Club in Toronto. While there, as executive sous chef and later as executive chef, he prepared meals for a number of luminaries and politicians, including former prime ministers Brian Mulroney and Jean Chretien, classical ballet dancer Karen Kain and Paul and Albert Reichmann, founders of real estate development company Olympia & York.

In Mississauga, the couple operated their own catering company before making the move to London. Korthof was retired by then and, as the story goes, he was bored at home when he

decided to start selling apple raisin cinnamon cakes from a modest table at the Western Fair Farmers’ Market.

When demand picked up, the couple rented a booth under the name Flair Pastries, installed an oven, and started baking bread on-site.

The first loaf Theo ever baked was a challenge from Gerda, who didn’t think he could do it. That loaf captured the olfactory senses of a passing Swiss chef, who left with it under his arm. From then on, word spread, sales rose, and the Korthofs were in business.

While bread is Artisan’s specialty, those with a sweet tooth need not worry as they also bake cakes, tarts, pie, doughnuts, strudel, cookies, cinnamon rolls and brownies. Varieties of sausage and cabbage rolls, quiche, crab cakes, pizza, soup and chilli are also on the menu. Those in a hurry can take home readymade meals of lasagne, pot pie, shepherd’s pie, tourtieres, sandwiches and

soups. There is a small area to dine in the bakery for customers who have a little more time to linger.

If the bakery team is not busy enough, they also offer hands-on instruction with workshops in cooking and baking at the Dundas Street East location.

Customers can also find the team at the Western Fair farmers’ market every Saturday morning, as well as at London’s Covent Garden Market and the farmers’ market in St. Jacob’s.

Even after four decades in the kitchen, innovation is still on the menu for Theo Korthof.

“(There) is always something new and (there is) never a dull moment. Our minds never stop creating,” he said.

– Chris McGregor

‘THEY

“Before we opened people were trying to buy our products. It was a unique experience that people were just starting to see in places like Calgary and Edmonton. Before we had the ovens installed, people wanted to try our cupcakes,” says Andrea Fox of Babycakes Cupcakery in Red Deer, Alta.

For Fox, formerly a registered nurse, and Diana Knapton, previously a dental hygienist, their new career had to be both fun and provide a service that put a smile on their customers’ faces. This autumn the company celebrates its seventh anniversary. It’s been busy since the beginning; in its first year, Babycakes won Business of the Year, followed by local Red Hat awards and the Golden Fork.

Fox explains that every cupcake comes with its own “story”; for instance, each week, there are 11 or 12 cupcake flavours and styles baked plus one to three features per week. Fox says she is not much of a full-sized cake decorator, but with cupcakes, she likes to make every single one different. You can order a dozen, and no two are the same for the adventurous cupcake connoisseur.

One of the not-so-secret secrets is that their ingredients are fresh. They use no artificial colouring or flavour, just the juice from natural local fruit to provide a flavour and colour for icing or batter. Additionally, they keep up with current dietary trends and concerns. Gluten free and nut-free cupcakes are easily available in the shop.

“The first month we started we had to talk each other through it. We did the

baking which could start anywhere between 2 a.m. And 5 a.m., then we’d be in the shop between 6 a.m. and 8 a.m., and open for business 10 a.m. to 6 p.m. We decided we had to stop, so we found a baker who comes in and does the baking for us before we open,” says Fox. Cupcakes are baked the same day they are delivered for events, weddings and corporate functions.

All the staff members at Babycakes Cupcakery have been there from the very beginning. Fox alludes to them being like a family. Customer response has been enthusiastic since the start. On Valentine’s Day they make 155 dozen (that’s 1,860 cupcakes) and have to close after five hours because they are gone. Many business offers have come in, Fox says. Using a well-thought out and careful approach to business, Fox and Knapton anticipate a brightly, and naturally, coloured future ahead. – Yvonne Dick

When Gael Watson first saw the building that now houses the LaHave Bakery on Nova Scotia’s South Shore, it needed a lot of work. The back of the building – constructed in 1896, and which once housed a ship’s chandlery and fish processing plant – was falling into the LaHave River situated just behind it. A working wharf connected to the building had long since collapsed. But Watson saw something more in the historic, rundown space.

“It was magnificent,” she recalls. “It was one of those places that drew you to it.”

Watson, her husband and two friends purchased the building.

Each had an idea for a business that could fill the space, but Watson knew a bakery was her first choice. Watson lived off the grid in a home in the woods where the cook stove was always on, boiling water for tea and baking more bread than she could eat on her own.

She quickly became known for her bread-baking skills, often giving away loaves to neighbours and selling others to local markets. Six months into reconstruction, her business partners backed out of the plan. The Watsons opened LaHave Bakery on July 2, 1985.

Homemade bread remains a staple of the bakery’s offerings. The recipes are still Watson’s creations. She uses local ingredients including eggs, honey, milk and wheat. She will often add other ingredients such as potatoes, onions and fresh herbs. “The idea was the bread

itself would be food instead of something to add to a meal,” she says.

The LaHave Bakery grew beyond the former chandlery building. Watson opened a smaller bakery in nearby Mahone Bay in 1991. And between 1995 and 1997, she sold baked goods from her family’s 96-foot boat. But the work took its toll. Besides operating the bakery, she was raising two young children, Sadie and Jessie. In 1997, she reassessed her workload.

“I thought if I don’t stop this degree of labour, it’s going to affect my whole body, life, everything,” she says. “I’ve grown to love it. At first, it was very hard work.”

With a staff of 28, Watson now sells the breads and other goods wholesale to local markets such as Sobeys and Superstore. Besides bread, the staff make granola, muffins, cookies, croissants, cakes and squares. In the café, they serve brunch and lunch, with a variety of homemade pizzas, sandwiches, paninos, burgers and soups. In the winter when the bakery slows down, the staff produce jams, mustards and marmalades. Watson’s son operates a skateboard shop on the second floor. There is also a craft co-op in the space.

Watson continues to make improvements to the building, including to the 100-foot wharf out back. There, boaters can dock and come into the bakery for lunch, making the visit an experience of the river itself. “We wanted that to be a highway, a door to the river,” she says.

She also credits the community for her success. “It couldn’t survive without the community,” she says. “Right from day one, they’ve been supportive.”

Now in her 60s, and still living in her off-the-grid home in the woods, Watson says she hopes her daughter, 32, takes over one day. But for now, she keeps logging full days, six days a week.

“I’d like to keep it as long as I can,” she says. “It’s a part of my life.” –Suzanne Rent

Established by Gilbert and Dora Walton of Cape Tormentine, N.B., in 1975 and purchased by current owner Fred Crawford in 1995, this Moncton-area bake shop does a brisk business five days a week.

Nestled in a mini mall on the side of busy Coverdale Road, Walton’s Bake Shop sees lots of traffic. Enticed by the aroma of freshly baked bread and other

delicious goodies, the shelves empty pretty fast. Walton’s bakes about 400 loaves per day, and some of that bread makes its way out of the province – and the country! There are diet white and whole wheat breads, regular white and whole wheat, raisin, rye, French, flax, multigrain, whole grain and harvest grain.

“The diets and the grains have taken over the (regular) white bread because of so much flak in the papers concerning

how bad white bread is,” Crawford says. “The (regular) white bread has probably dropped to about half, but on the weekends it picks up. People say the hell with it, we’ll have our special stuff.”

Walton’s also offers a variety of rolls (single, sheet and pan) and buns, including hamburger, hot dog and sub buns. Its cheese buns are in great demand, and the secret to the buns’ success is that the cheese is incorporated right into the dough – not just sprinkled

on top. There’s also cinnamon rolls and sticky buns in the product mix, along with tea biscuits, cornbread, sweetbreads, squares, carrot cakes, éclairs, tarts, cookies, doughnuts (no bagels or full-size cakes), muffins, beans, chili, garlic cheese bread – and Walton’s famous meat pies.

“We do a big volume of meat pies, pot pies, which are chicken, potato, carrots and peas with a real gravy. I make a real gravy for them (pies). There’s also beef pies with the same vegetables, and periodically turkey. We do a five-inch deep and a nine-inch deep.”

The recipes used at Walton’s are old family favourites, tried and true. Baking begins at 1 a.m., Tuesday through Saturday (closed Sunday and Monday), and everything is counter-ready by opening time at 9:30 a.m.

Crawford kept the original electric ovens, but has added additional units with expansion to the bakery’s present size of 2,300 square feet – most of which is production space. His products are also wholesaled to a few local clubs and like establishments, and to keep his costs affordable he has to take advantage of the best deals.

“Our meats we buy from Costco, “he explains. “You can’t get any cheaper than Costco. They’re cheaper than the wholesalers. When it comes time for our different pies that we do, the fruit pies – strawberries and blueberries, you can’t afford to buy them for the price they want, so you have to wait ‘til the prices drop and then buy a load of them.”

Christmas and Easter (Walton’s starts baking hot cross buns in February) are the bakery’s busiest times, and understandably January and February are its slowest.

Crawford has had a lifelong penchant for home cooking, which inspired his decision to buy a bakery. It was also a full-circle moment when he did, because it was his great-great-grandfather who owned and operated Shaw Bakery in Saint John, N.B.

At Walton’s Bake Shop, Crawford has “done everything” there is to do during the past 20 years, although now he concentrates his efforts on meat preparation for the meat pies. But he wasn’t in the bakery business very long before one basic fact became abundantly clear.

“I soon found out,” he says with a friendly smile, “that baking and cooking

are two different things.” –Linda Hersey

A bakery in Etobicoke, Ont., is taking the in-store experience to a whole ’nother level with its intriguing combination of butter tart artistry, vintage furniture and collectibles, and jazz music.

It all hinges on the iconic Canadianborn treat. “People have such an emotional reaction to the butter tart,” co-owner Michèle Roberts says.

The bakery’s storefront sign bows to one above it that proclaims “Butter Tarts,” leaving no doubt the sweet pastry treat is the bakery’s focus.

Michèle, who grew up baking with her mother and grandmother, nurtured a dream of baking professionally through years of working in the insurance business. She and Stephen, who has some 25 years in marketing, sales and support, finally made the leap to business owners in September 2012.

She does most of the baking, while he handles deliveries, marketing and the accounting side of the business. With the help of one full-time and one part-time employee, they are able to keep up with store traffic. The bakery is also a café but through the week a lot of their business is in pickups – “People are on a mission,” Michèle says with a laugh.

However, busy Saturdays require at least three of them in the store as customers come – and stay – for the jazz music. Every Saturday the shop plays host to four local bands who play sets of two hours each. The tradition started when a local musician needed a place for his band to play. The couple agreed to let their grand piano and drums take up residence in the shop, and with other musicians eagerly joining the lineup, a tradition was born.

Although Michèle bakes other items, the shop’s specialty is gluten-free tarts, which account for at least 40 per cent of overall sales.

They sell six rotating varieties of butter tart and one lemon curd daily, and all seven items are available in a gluten-free version. Flavours include raspberry, maple walnut and s’more.

“This is a little boy who would eat a piece of bread and be doubled up in pain afterward. It was heartbreaking,” Michele says, adding that she decided then and there to develop a gluten-free tart.

Soon after opening the shop, they began approaching other outlets to sell their tarts, which can now be found in local health-oriented shops such as The Cheese Boutique, Goodness Me and The Big Carrot.

“It’s very hard to pierce through that

barrier with your products,” she says. “Stores ask for an ingredient list and also a sub-ingredient list.” She attributes their success in wholesale to persistence and developing a delicious product: “Because our product is so good, we haven’t had the door slammed in our face.”

What’s next for Tartistry? Michele says she will try to develop a vegan butter tart. “I don’t know if I can do it, but I’m going to give it my best shot,” she says.

–Colleen Cross / BJ

The pair entered the gluten-free market from the get-go after one of six friends on their informal focus group praised the tarts and expressed a wish her son, who suffers from celiac disease, could enjoy the treat.

Depending on how you look at it, frozen dough and par-bake bread are either brilliant innovations or a wolf dressed in sheep’s clothing—“factory” bread posing as “real” bread. Of course, the battle between manufactured bread and scratch bread is hardly new. And while each has its role in the marketplace, rumblings from within the industry are getting louder as

more retail outlets are installing in-store ovens.

Meanwhile, customers are being drawn in by the dizzying aroma of freshly baked bread.

Frozen artisan-style loaves, that is.

But does it matter where the bread dough is made if consumers are happy? Fiera Foods senior vice-president Shawn O’Shaughnessy doesn’t think so.

“Consumers are looking for excellent quality and value for

their dollar,” he says. “They also form a relationship with the products and demand consistency both in the quality of the product and availability.”

Sandra Zanette of Backerhaus Veit says that regardless of where bread dough is made, it must meet two imperatives: food safety and quality.

“As an artisan frozen bread, roll and soft pretzel manufacturer that continues to place these two key areas at the forefront, we believe that par-baked products can be

Some in the baking industry are voicing concern as more and more retail outlets install in-store ovens.

baked at store level and provide customers with ‘scratch-baked’ quality,” Zanette says.

Frozen products, as they grow in variety, availability and popularity, are meeting demand for consistent quality and reliable supply.

“Maximizing sales is also an advantage as with most frozen breads, specifically par-baked. You can be back in business in less than 30 minutes if you run out of a given product,” O’Shaughnessy says. “The

success and growth of par-baked baguettes over the last 15 years is a perfect example of this advantage.”

This has led to whole programs of artisan bread with few or no skilled bakers.

Zanette concurs, adding advantages such as easy implementation of a “hot baked” program, reduced shrink at store level and the ability to provide certified items such as kosher parve, vegan and vegetarian, as well as authentic recipes.

Another advantage: “For inventory purposes, you are dealing with one SKU, not all the ingredients and other requirements to make that specific bread,”

O’Shaughnessy says.

He adds that the responsibility of QA for the manufacturing of the product rests with the vendor of the bread, and further, the QA standard is higher based on the requirements of manufacturers to supply bakery products.

“You cannot overstate the importance of consistency of product from store to store when a retailer has 1,000 stores,”

O’Shaughnessy says.

}“This just cannot be executed from scratch.”

Sounds like a dream for retailers. So what’s the problem?

Perception, for one. Are consumers being given the impression that the bread has been made in the same place it was baked? Especially if the loaves are being removed from the oven right in front of them by someone dressed as a baker?

In some ways, it comes down to definitions and what “fresh” means when it pertains to bread.

According to Andrew Whitley – artisan baker, teacher and author of Bread Matters, and co-founder of the Real Bread Campaign, part of

the UK-based charity Sustain, the alliance for better food and farming – bake-off products are a deception.

“If [frozen dough manufacturers] think that freshness doesn’t relate to the temporal span between production and consumption, then what are they doing promoting bread with a sort of theatre production coming out of an oven, suggesting the freshness that they are selling you is related to its having been recently made?”

One of the key demands of the Real Bread Campaign is for meaningful new definitions of “fresh” and “freshly baked.”

Legally, however, in Britain and in Canada, “fresh” refers to the recent preparation of the food rather than the freshness of its ingredients or components and regardless of whether the product or its ingredients contain preservatives or are preserved by other means. Thus, according to Canada’s Food Inspection Agency, recently baked bread made with frozen dough may

Zanette recalls having this conversation when she was on the retail side.

“CFIA [Canadian Food Inspection Agency] had concluded that it did accept terms such as ‘fresh baked’ and many others using ‘fresh’ as being acceptable and to clarify the claim, they deemed it should be accompanied by a ‘packed on’ date.”

Advertising standards say it would only be misleading if the bread were advertised as “scratch” bread.

“I’ve never liked ‘from scratch.’ An itch or rash or something like this,” says Carol Culhane of International Food Focus.

However, she adds, it is a convenient term because everyone knows what it means. Any new labelling would have to be very precise in order to be meaningful and useful to consumers.

“If there were to be a regulation specific to In-store bakes versus made from scratch by an artisanal baker,

But does it matter where the bread dough is made if consumers are happy? . . . .In some ways, it comes down to definitions and what “fresh” means when it pertains to bread.

be described as “fresh.”

Advertising Standards Canada, which is completely separate from labelling in Canada, says that if bread is freshly baked and advertised as such it is not misleading – no matter how far that loaf travelled before it was put in the oven.

Zanette agrees.

“With the quality and technology of what is available today, there is no reason not to consider frozen bread as ‘fresh baked,’” she says. “I know there is a case brewing in the United States because par-baked products are being merchandised as ‘fresh baked.’”

This isn’t the first time this topic has been brought up.

ent,” Barnett adds. “The Canadian public aren’t stupid. We don’t pretend that a Big Mac is anything different and we buy millions!”

When it comes to bread legislation, all roads lead to France. Since Sept. 13, 1993: Décret n° 93-1074 has dictated the criteria for how traditional French bread is made, marketed, and sold. It must be made without additives and be fully kneaded, shaped and baked in the place where it is sold to the final consumer or sold elsewhere, but still sold by the baker who made it.

While establishing similar legislation may be the goal of Whitley’s Real Bread Campaign, it may be too extreme for Canada.

For one thing, the French law specifically prohibits dough or bread from being frozen at any point in the process, something that would be impractical even for scratch bakeries. Barnett says freezing dough is a legitimate way to control production costs.

the proponents of that regulation would have to demonstrate clearly to the regulator that consumers are being misled,” Culhane says. “How would that be achieved?”

For Martin Barnett, BAC director and program chair at Vancouver Island University, it is a simple, honest declaration:

“You just declare whether you’re a bakery or not, actually making stuff from scratch, and if you’re not, you should say, ‘We’re not a bakery. We’re a bake-off operation.’ That’s the honest thing to say.

“I am not judging the use of frozen or par-baked or pre-proofed or even thawand-serve – just be transpar-

“I’m making a batch of dough today and I’m going to bake some of it today and some of it’s going to go into the freezer to be baked tomorrow and the next day.”

O’Shaughnessy believes French bread makers had taken a big step backward and the quality and consistency suffered.

“There is a need to reestablish their ‘cultural’ position as the perceived great bread makers by imposing rules and regulations to improve the quality and authenticity,” he says.

Another consideration around legislation is whether consumers even care where their bread was made.

O’Shaughnessy believes they don’t.

“[Consumers] care about the ingredients, quality, consistency and value. If you told a consumer the bread

they love is not made from scratch but only baked in the store, they may be surprised but I doubt that it would be a deal breaker for them to stop purchasing the product.”

So, by the same token, if premade products are declared “processed in another plant and frozen” – as Barnett suggests – that shouldn’t be a problem for consumers either.

Or would it?

“What many people seem to forget is

that the food regulations were not written for industry – they’re written for consumers,” Culhane says.

In most cases, that is.

“Sometimes, it is the industry that can see the disparity much more clearly than consumers, and when the industry wants clarity, we often do get very good regulations,” Culhane adds.

By way of example, Culhane says Canada’s natural health product regulations were a result of consistent

Like you, successful bakers know the secret to a profitable bakery starts and ends with high quality, great tasting products. For over 80 years, the American Almond® Products Company has provided successful bakers everywhere with premium quality nut pastes, nut butters, nut flours and a wide range of unique, customer-pleasing ingredients. Let American Almond® help you turn that quality into profits for your bakery.

Call your distributor today or dial 800.8ALMOND for a distributor near you. Visit www.americanalmond.com for more information and profit building recipes.

lobbying by the industry to level the playing field – and they proved consumers could be harmed because of inconsistent quality.

While that could be looked at as a model for the bread industry, she adds that it isn’t a sure thing because there has to be a demonstration of harm to the consumer.

And according to Whitley, there is a demonstration of harm connected to the processing additives used to extend shelf life and shorten fermentation times.

“These would include possible effects on the digestibility of bread, which are brought about by creating this change in its molecular structure which is attendant on the use of enzymes,” Whitley says.

“Does this create a greater burden on the human digestive system to actually process those proteins and starches which are held in that particular chemical configuration in industrial bread?”

Whitley refers to something that has become increasingly prevalent in the past 20 to 25 years: gluten intolerance or non-celiac gluten sensitivity.

Whitley also believes there are health problems connected to the radical reduction in fermentation time in some manufactured bread.

“Research shows that only by fermenting bread properly, yeasted or sourdough, are you going to get the breakdown of those anti-nutrients that do exist in bread, particularly in whole grain bread,” he says.

In Britain and in Canada, processing aids do not have to be listed on labels. In fact, in Canada, there isn’t even a regulatory definition for “processing aid.” However, the Food Directorate of Health Canada has defined a processing aid as “a substance that is used for a technical effect in food processing or manufacture, the use of which does not affect the intrinsic characteristics of the food and results in no or negligible residues of the substance or its by-products in or on the finished food.”

Unlike food additives, processing aids are not considered ingredients and, thus, do not have to be declared on prepackaged food.

But do all frozen bread manufacturers use processing aids?

“If the additives in question are ‘natural’ and are not allergen concerns, I do not see where this is an issue for the consumer,” O’Shaughnessy says. “All great bread requires time for the dough to develop;

however, depending on the usages of the bread, there are different fermentation times for different products.”

O’Shaughnessy adds that Fiera Foods ferments and develops dough for the same length of time as a corner bakery and doesn’t agree that frozen bread has reduced fermentation times.

Zanette holds a similar view. In Backerhaus Veit’s 25 years in business, one thing has remained constant: “All batches were to be produced in small batches to respect time, temperature, and fermentation to provide optimum results.”

She adds that the company has been using fermentation and natural preservatives to extend shelf life, as well as natural colours and flavours, non-bromated flours, and “other cleaner options” for many years – before it became what it is today: a necessity to do business.

Barnett says the additives aren’t different for doughs that are frozen in-house, and they are mostly “green label” now. He uses a little extra malt and vitamin C to protect frozen dough.

“Some of the additives used in a manufacturing facility are used as processing aids and the portion of that additive impacting the customer is negligible,” Zanette says.

But should they be labelled?

“If they are natural and they are not allergens, my position is no they should not be required to be listed,” O’Shaughnessy says.

So then why, Whitley asks, if industry thinks there is nothing harmful in using processing aids, don’t they voluntarily put them on the label?

“The perception if you don’t label them, even though you’re not required to by law, is that you’ve got something to hide,” Whitley says.

A public information campaign may be a way to test consumer reaction.

“It might be then useful to have some private projects in particular areas, maybe in Quebec or [in Toronto] where we have the ACE Bakery baguettes. It might be useful to see how they work,” Culhane says.

Whitley has some experience with public reaction. In the year after he released Bread Matters, he did 60 or 70 talks to various groups.

“I noticed that my direct action ideas went down very well with this predominantly young group of people,” he says. “There was a sort of egalitarian and political understanding of the relation-

ship between real bread and food sovereignty – not just food security.”

He adds that there is a shift taking place, where bread production is localized into “micro and artisan bakeries run by skilled people from within the community … and respected and loved by their customers because they know and can see that they’re trying to do the best by their fellow citizens.”

On the other side, O’Shaughnessy, who used to be a scratch baker for Steinberg’s

and Loblaws before they switched to frozen, says, “Technology today delivers bread with the same characteristics as hand-made breads from days of old.”

He says that when the bakeries went frozen, sales increased, consistency improved, overall quality improved, and in-stock position improved.

“You cannot argue with these advantages,” he says. “Great bread is great bread.”

And it’s also food for thought. / BJ

Profi requires minimal formulation adjustments in almost any application. Through a proprietary formulation of vegetable protein isolates, Dealers Ingredients Inc. combines the health benefits of both protein and fiber into a single source food enhancer.

Complete Vegetable Protein —

Contains All Essential Amino Acids in Proper Proportions. Profi can replace Soy, Dairy and Meat as a complete vegetable protein source

GMO Free

Good to Excellent Source of Fiber

Immediate Protein Boost

Label friendly

Contains Dietary Fiber

Neutral to Mild Sweet Taste—No Masking Required

Can Be Used in Almost Any Food Application

Blends Well in Both Water and Oil Based Food Systems

Halal and Kosher Certified Light Ivory Colour

Cake Competition featuring 300+ Cakes • Demonstrations Sugar Art Fashion Show • Stage Performances Classes & Competitions • Live Theatre Presentations Chocolate Zone • Wedding Zone • Kids Zone • Sugar Art Zone 30,000+ Expected Attendance September

3M is launching its upgraded Petrifilm Rapid Aerobic Count Plate in Canada, which the company says can detect aerobic bacteria counts in just 24 hours for most food matrices.

The 3M Petrifilm Aerobic Count Plate was developed 30 years ago to ensure the quality and safety of food manufacturers’ products while also freeing space and productivity in their labs.

The device provides faster results, the company said in a press release. It is designed to require less labour and allow more time and resources for monitoring processes, ensuring tighter process control and improving product quality. The faster result times help to improve productivity overall and decrease retesting costs.

It makes interpretation easier through a dual-sensing indicator technology that resists distortion often caused by spreader colonies and makes it easier to interpret the results of testing.

An added foam barrier around the inoculation area makes the process easier, and the device can be used on all foods.

The product recently received certification from the AOAC International Performance Tested Methods program inserts. Specific studies performed as part of this certification involved comparison tests to the FDA BAM and USDA reference methods, along with robustness and lot-to-lot/stability testing. www.3mcanada.ca

Ingredient manufacturer BENEO highlighted natural food and beverage options for energy management by launching its next-generation sugar, Palatinose, at the recent IFT Food Expo in Chicago. Derived from beet sugar, Palatinose delivers energy in a balanced and sustained way naturally.

“According to market research commissioned by BENEO, consumers of all ages are seeking natural sources that will provide the delivery of sustained energy throughout the day,” says BENEO president Jon Peters. “But they feel that existing energy drinks simply provide an initial alertness burst and subsequent crash effect.”

The need for options to better manage energy naturally is a concern for endurance athletes as well for consumers leading a hectic lifestyle, including multiple demands from jobs, households and family lives with kids.

Consumers are looking to gain energy in a natural way, without the boost and crash delivered by commonly known sugars such as sucrose, high-fructose corn syrup or maltodextrin. At the same time consumers try to avoid other products like caffeine or guarana that only provide “energy” by manipulating our central nervous system but do not provide actual energy for body cells.

“Our low-glycemic-sugar Palatinose provides body cell energy in a balanced and sustained way and promotes enhanced fat oxidation during physical activity – characteristics that matter to consumers,” Peters says. www.beneo.com

For more news about the baking industry, please visit www.bakersjournal.com.

BAC has told the federal government that its proposal to apply up to 100% tariffs on imports from the U.S. in code 19.05: bread, pastry, cakes, biscuits and other bakers’ wares, would actually end up punishing Canadian bakers’ competitiveness resulting in a loss of business and jobs. The federal government has proposed these tariffs in response to U.S. Country of Origin Labelling (COOL) requirements imposed on imports of Canadian beef and pork which have been ruled illegal by the World Trade Organization.

While BAC expressed sympathy with Canadian exporters of beef and pork, it views the imposition of retaliatory tariffs on U.S. products covered under 19.05 as a case of “shooting oneself in the foot” due to the negative consequences it would have on Canadian bakers.

In its submission, BAC pointed out that the Canadian baking industry is well integrated into the North American marketplace with the U.S. being the industry’s largest trading partner. According to Industry Canada, last year Canada’s baking industry exported some $1.9 billion in goods in the 19.05 category while importing $1.23 billion for a trade surplus of some $634 million.

The industry’s North American supply chain means that many U.S. imports into Canada are bakery ingredients. These ingredients are key inputs used by Canadian bakers in the production of finished product for consumption both domestically and in exports – specifically the U.S. BAC members have identified that tariffs on these inputs would substantially raise their production costs and leave them faced with either absorbing these costs or attempting to pass them along in a hyper competitive marketplace both at home and abroad.

BAC also advised that the baking industry has North American based production with Canadian bakers having production facilities on both sides of the Canada- U.S. border. Tariffs on imports of finished baked goods made in U.S. facilities would cause disruption in the $10 millions with little to no opportunity to reallocate production from U.S. to Canadian facilities.

Lastly BAC has called for the federal government to undertake and make public an impact assessment on consequences to Canadian bakers related to the potential imposition of these tariffs.

The U.S. has been responding to the calls for changes to COOL. In June the U.S. House of Representatives passed a Bill to repeal COOL and efforts are currently underway with the U.S. Senate to change the requirements. U.S. Agriculture Secretary Tom Vilsack has also called on Congress to change the law to avoid retaliation.

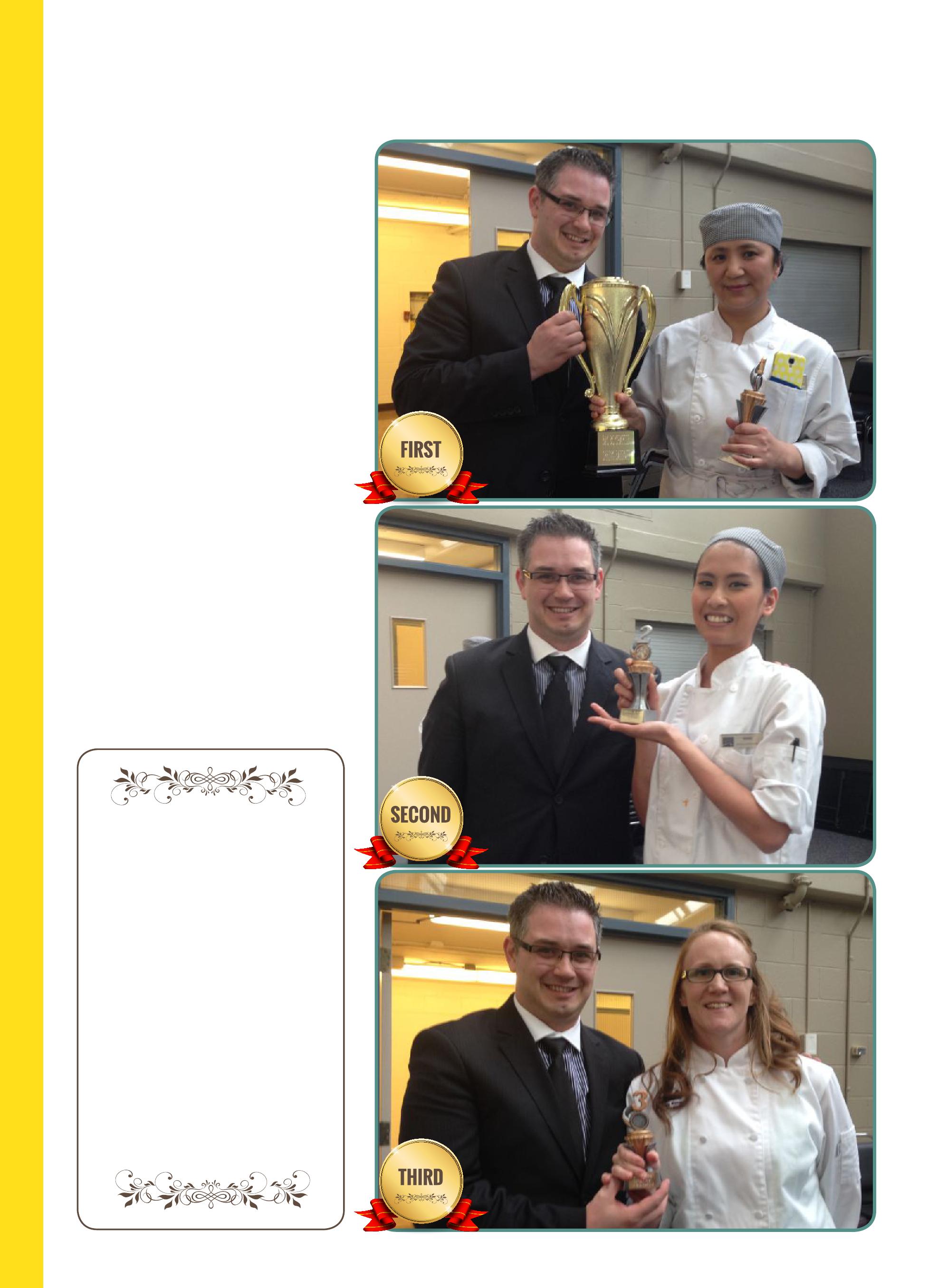

On April 29th, the BC Chapter hosted the first annual spring bake-off competition in Vancouver.

Open to all, multiple facets of the industry participated ranging from students, suppliers, chains, manufacturers as well as independent bakeries. All were there to present an entry as well as show their support.

With a very broad requirement for entry (butter based, single serve pastry) the event saw products ranging from raspberry tarts to mini wedding cakes. A good time was had by all with over 60 people showing up in attendance - the treats went quickly!

With every competition, there must be winners. BC Chapter Chairperson Jesse Lamb presented the winners with their well deserved trophies.

Jane Xu VCC, ENTRY Puff Pastry with Black Bean Paste

Diane Almario VCC, ENTRY: Filled profiteroles

Carley Seney Snow Cap, ENTRY: Brown Butter Almond Scone w/Chantilly Cream and Berry Compote

WEBER MARKING

Email / Courriel info@webermarking.ca www.webermarking.ca

Booth/Stand

Mills Road, Unit Barrie, ON L4N 705-722-4100 Email / Courriel www.wellbake.com

Email www.wellbake.com

Exposition offre à haut d’après Wellbake industriels, doseuses

Exposition : Wellbake offre les meilleurs à haut rendement d’après les tests! Wellbake pour petites industriels, ainsi doseuses à biscuits

WEBER MARKING SYSTEMS

Booth/Stand #808

Booth/Stand #808

6180 Danville Road

Danville Road Mississauga, ON L5T 2H7

Mississauga, ON L5T 2H7

905-564-6881, 800-265-9974

Email / Courriel : info@webermarking.ca www.webermarking.ca

905-564-6881, 800-265-9974 / Courriel : info@webermarking.ca www.webermarking.ca

Wellbake seront en démonstration dans notre stand. Venez voir également une présentation vidéo de nos lignes de production automatiques.

Wellbake seront en démonstration dans notre stand. Venez voir également une présentation vidéo de nos lignes de production automatiques.

WELLBAKE EQUIPMENT

WELLBAKE EQUIPMENT INC.

Booth/Stand #805

Booth/Stand #805

Mills Road, Unit N

Wellbake seront en démonstration dans notre stand. Venez voir également une présentation vidéo de nos lignes de production automatiques.

Wellbake seront en démonstration dans notre stand. Venez voir également une présentation vidéo de nos lignes de production automatiques.

Wellbake seront en démonstration dans notre stand. Venez voir également une présentation vidéo de nos lignes de production automatiques.

TExhibiting: Wellbake Equipment offers the best baking and energy efficient Rack Oven according to test! On display will be Wellbake small and industrial Spiral Mixers along with Wellbake Muffin and Cookie Depositors. Come to our booth to see our video display of automatic lines.

Barrie, ON L4N 6H4

30 Mills Road, Unit N Barrie, ON L4N 6H4

705-722-4100

705-722-4100

Exhibiting: Wellbake Equipment offers the best baking and energy efficient Rack Oven according to test! On display will be Wellbake small and industrial Spiral Mixers along with Wellbake Muffin and Cookie Depositors. Come to our booth to see our video display of automatic lines.

D’Italiano ; Weston Première Fournée ; Tortillas Casa Mendosa ; Craquelins D’Italiano

Exhibiting: Wellbake Equipment offers the best baking and energy efficient Rack Oven according to test! On display will be Wellbake small and industrial Spiral Mixers along with Wellbake Muffin and Cookie Depositors. Come to our booth to see our video display of automatic lines.

Booth/Stand #808 6180 Danville Road Mississauga, ON L5T 2H7 905-564-6881, 800-265-9974

D’Italiano ; Weston Première Fournée ; Tortillas Casa Mendosa ; Craquelins

D’Italiano

D’Italiano ; Weston Première Fournée ; Tortillas Casa Mendosa ; Craquelins D’Italiano

Exhibiting: Wellbake Equipment offers the best baking and energy efficient Rack Oven according to test! On display will be Wellbake small and industrial Spiral Mixers along with Wellbake Muffin and Cookie Depositors. Come to our booth to see our video display of automatic lines.

Exhibiting: Wellbake Equipment offers the best baking and energy efficient Rack Oven according to test! On display will be Wellbake small and industrial Spiral Mixers along with Wellbake Muffin and Cookie Depositors. Come to our booth to see our video display of automatic lines.

D’Italiano ; Weston Première Fournée ; Tortillas Casa Mendosa ; Craquelins D’Italiano

he latest edition of the Bakery Congress 2015 Show on May 31st & June 1 at Palais des congrès de Montréal was a resounding success. Almost 1400 highly qualified individuals from the baking industry visited the trade show floor. The theme for this year’s event was Innovation through Tradition .

Exhibiting: Gadoua bread and rolls; D’Italiano bread, rolls and bagels; Weston Première Fournée; Casa Mendosa Tortillas; D’Italiano Snacks

D’Italiano ; Weston Première Fournée ; Tortillas Casa Mendosa ; Craquelins D’Italiano

Email / Courriel : info@webermarking.ca www.webermarking.ca

Exhibiting: Gadoua bread and rolls; D’Italiano bread, rolls and bagels; Weston Première Fournée; Casa Mendosa Tortillas; D’Italiano Snacks

Exhibiting: Gadoua bread and rolls; D’Italiano bread, rolls and bagels; Weston Première Fournée; Casa Mendosa Tortillas; D’Italiano Snacks

Exhibiting: Gadoua bread and rolls; D’Italiano bread, rolls and bagels; Weston Première Fournée; Casa Mendosa Tortillas; D’Italiano Snacks

on a continuous basis during both show days. Winner of the competition was Gérald Loersch of Première Moisson.

Exhibiting: Gadoua bread and rolls; D’Italiano bread, rolls and bagels; Weston Première Fournée; Casa Mendosa Tortillas; D’Italiano Snacks

Marques / Brands: Gadoua, D’Italiano, Weston Première Fournée, Casa Mendosa

Marques / Brands: Gadoua, D’Italiano, Weston Première Fournée, Casa Mendosa

Marques / Brands: Gadoua, D’Italiano, Weston Première Fournée, Casa Mendosa

Marques / Brands: Gadoua, D’Italiano, Weston Première Fournée, Casa Mendosa

Marques / Brands: Gadoua, D’Italiano, Weston Première Fournée, Casa Mendosa

Booth/Stand #805

30 Mills Road, Unit N Barrie, ON L4N 6H4 705-722-4100

/ Courriel : info@wellbake.com www.wellbake.com

Email / Courriel : info@wellbake.com www.wellbake.com

LIMITED

LIMITED Booth/Stand #621

LIMITED

Bakery Congress 2015 was organized by BAC in collaboration with Le Conseil de Boulangerie Québec (CBQ), with the exhibitor and attendee participation being larger than the previous Montréal edition in 2011.

The educational sessions on both show days were presented by industry’s recognized experts; the sessions were very well attended and focused on the Innovation through Tradition theme. The educational sessions during BAC events have grown in popularity year after year, adding a solid value to the Show.

Email / Courriel : info@wellbake.com www.wellbake.com

Wellbake Equipment meilleurs fours à chariots rendement énergétique

Booth/Stand #621

LIMITED

Booth/Stand #621

Booth/Stand #621 Products

Booth/Stand #621

Exposition : Wellbake Equipment offre les meilleurs fours à chariots à haut rendement énergétique d’après les tests! Nos pétrins à spirale Wellbake pour petites pétrissées ou industriels, ainsi que nos calibreusesdoseuses à biscuits et muffins

Exposition : Wellbake Equipment les meilleurs fours à chariots haut rendement énergétique d’après les tests! Nos pétrins à spirale Wellbake pour petites pétrissées ou industriels, ainsi que nos calibreusesdoseuses à biscuits et muffins

muffins

Equipment à chariots énergétique pétrins à spirale pétrissées ou calibreusesmuffins

2700 boul. Jacques Cartier est Longueuil, QC J4N 1L5 450-448-7246

tests! Nos pétrins à spirale petites pétrissées ou que nos calibreusesbiscuits et muffins

2700 boul. Jacques Cartier est Longueuil, QC J4N 1L5 450-448-7246

2700 boul. Jacques Cartier est Longueuil, QC J4N 1L5 450-448-7246

2700 boul. Jacques Cartier est Longueuil, QC J4N 1L5 450-448-7246

2700 boul. Jacques Cartier est Longueuil, QC J4N 1L5 450-448-7246

L’Association des Boulangers Artisans du Québec had organized the first ever artisan bakers competition on the trade show floor, the competitors prepared a variety of dazzling baked products

Email / Courriel : lori.thompson@ boulangeriesweston.ca

Email / Courriel : lori.thompson@ boulangeriesweston.ca

Email / Courriel : lori.thompson@ boulangeriesweston.ca

Email / Courriel : lori.thompson@ boulangeriesweston.ca

Email / Courriel : lori.thompson@ boulangeriesweston.ca

Exposition : Pain et petits pains Gadoua ; Pain, petits pains et bagels

Exposition : Pain et petits pains Gadoua ; Pain, petits pains et bagels

Exposition : Pain et petits pains Gadoua ; Pain, petits pains et bagels

Exposition : Pain et petits pains Gadoua ; Pain, petits pains et bagels

Exposition : Pain et petits pains Gadoua ; Pain, petits pains et bagels

The next event by Baking Association of Canada will be Bakery Showcase 2016, to be held May 1-3, 2016 at The International Centre, Toronto (Mississauga). For more Information vist www.baking.ca

Exposition : Wellbake Equipment offre les meilleurs fours à chariots à haut rendement énergétique d’après les tests! Nos pétrins à spirale Wellbake pour petites pétrissées ou industriels, ainsi que nos calibreusesdoseuses à biscuits et muffins

avec le Conseil de

L’ACB, d’une valeur de 5

a pour mission de promouvoir les

We are pleased to announce that you will be able to register your group for the fall tournament either as a play your own ball or as a scramble team. This dual format will ensure an enjoyable pace of play and promotes the competitiveness of the traditional fall tournament as well as an enjoyable team format of scramble for our social members.

Put your foursome together, or if you are only one or two we will arrange playing partners for you. Single or double entries may be subject to filling in open positions for either a scramble group or individual play depending on where space is available. Please enter your group as one or the other only.

“GOOD GOLFING”

Station Creek Golf Club 12657 Woodbine Ave. Gormley Ontario prize donations greatly appreciated!

MaxiMuM of 144 GoLfers – reGister earLY – don’t Be disappointed!

TUESDAY SEPTEMBER 15, 2015

Station Creek Golf Club - Take Hwy 404 North to Stouffville Rd.; Go east on Stouffville Rd. to Woodbine Ave.; North on Woodbine Ave. 2 km; Station Creek Golf Club is on the right hand (East) side. Registration & BBQ lunch starting at 10:00 a.m. until 11:15 a.m.

Shotgun - SCRAMBLE – Starts 12 noon

TICKETS @ $195 (golf, cart, lunch & dinner)

TICKETS @ $80 (dinner only)

TICKETS @ $205 (golf, cart, lunch & dinner)

TICKETS @ $110 (dinner only)

Please reserve X $60 Hole Sponsorship

Company Name (as

BC Chapter Presents:

DATE: Wednesday September 23rd 2015

TIME: 2:00 pm to 7:00 pm

LOCATION: Vancouver Island University

Professional Baking and Pastry Program, Building 185, 900 5th Street, Nanaimo BC

Join us for an informative afternoon of baking and demonstrations at VIU in Nanaimo with Wayne Caddy. Wayne is Director of The Essential Baker providing New Product Development to the baking and pizza industry. More recently he represented Team UK in the Coupe Louis Lesaffre and is the first UK baker to compete in the prestigious Masters de la Boulangerie; only a handful of the top bakers from around the world are selected.

Wayne is also Head of Baking at the world famous School of Artisan Food based near Nottingham, training full-time advanced bakery diploma students, creating the next generation of artisan bakers with a current 90% employability rate.

Wayne will be talking about the newest innovations in bread from Europe and demonstrating his pioneering techniques.

Program will conclude with a Pizza supper served from VIU’s Wood-Fired Brick oven (which was sponsored in part by BAC and other industry partners.)

Complimentary Bus Transportation is available to and from the Island Ferry with your registration.

DON’T MISS THIS UNIQUE OPPORTUNITY FOR THE BC BAKING INDUSTRY! Space is limited.

To register, please fill in the attached registration form and send it to the BAC office. A confirmation will be emailed to all registrants.

With Special Guest Presenter Wayne Caddy Wednesday September 23rd 2015 Vancouver Island University Professional Baking and Pastry Program, Building 185, 900 5th Street, Nanaimo BC 2:00 pm to 7:00 pm

Complimentary Bus transportation to and from the Island Ferry (only if indicated below) Yes -

(to be

Card Number: Expiry Date: Cardholder: Signature: Fill Out the Print, Scan & Email/Fax: Registration Form with VISA / MC /AMEX information Mail cheque and form to (Cheques payable to B.A.C): Baking Association of Canada, Attn Gillian Blakey, 7895 Tranmere Dr., Suite 202, Mississauga ON L5S 1V9 www.baking.ca Phone: (888) 674-2253, ext 21 Fax: (905) 405-0993 or Email: gblakey@baking.ca

Dave Avila

Bakery Technology Unit I

Miranda Odorico

Bakery Technology Unit II & Unit III

Xhevrije Qelaj

Bakery Technology Unit III

Certified Bakery Specialist (C.B.S.)

Diploma Recipient: David Greeley

For information on correspondence courses for baking industry employees and the Certified Bakery Specialist (CBS) program, please contact ext. 21 at the BAC office or check out our website at www.baking.ca.

Karen Blumel

Graphic Packaging International Canada

Gary Charles

Paleotteria

Ian Harris

Hot Chocolates

Lisa Plener

B2Bwraps.com LIMITED

Sherief Sadek

Tasty Habits Ltd.

Blake Stickle

The Rolling Pin It’s Show Time!

Exhibiting information is now available for Canada’s national baking industry trade event Bakery Showcase 2016. Visit www.baking.ca for more information or if you would like to receive the information by email please contact Ahmed Mutaher at 905-405-0288 extension 22 or email amutaher@baking.ca.

BY JOHN MICHAELIDES

Ensure food safety and quality by using the correct additives

Baked goods, like all other foods, must be safe when consumed. At the same time, they need to be of good quality, delivering excellent taste and texture. Over the many years of producing such foods, the baking industry has relied on a multitude of ingredients to ensure safety and quality.

When discussing the safety of baked goods, we are primarily concerned with microbiological contamination as well as the danger of chemical contamination with natural toxins such as mycotoxins, which are usually controlled by close monitoring of these toxins in the flour supply. Bakers rely on suppliers to provide certificates of analysis confirming levels of such toxins.

Microbiological contamination, however, with the exception of sporeforming bacteria, mostly occurs after the baking process. For this reason, preservatives are used in baking formulations to ensure microbes are controlled and do not grow during the shelf life of the product. These ingredients provide safety by controlling possible pathogens, and they ensure quality by preventing the growth of spoilage organisms. They can be synthetic chemicals or natural extracts.

Some commonly used synthetic antimicrobials or preservatives in baked goods are benzoates and sorbates, specifically the potassium and sodium salts of such compounds. Benzoates are weak antimicrobials that work best against fungi, yeast and some bacteria in foods that are acidic (low pH). For this reason, they are commonly used in beverages like fruit juices, sparkling drinks, soft drinks and other acidified foods such as pickles.

Propionates are also antimicrobials that are used in bakery products. They are considered more natural since propionic acid occurs naturally in some fruits, grains and cheese. Propionates work well against

bread moulds and the spore-forming bacteria that cause “ropy” bread condition. Most bakers are familiar with this condition. It can contaminate the whole bakery, and where the bread crumb loses its structure, it has a characteristic pinkish colour and smells like melon.

Some of the popular natural antimicrobials include vinegar (making the food more acidic) and other natural acids, raisin juice concentrate, as well as juice concentrates from other fruits. Some spices such as cinnamon may also act as antimicrobials.

Preservatives do not necessarily mean that they function as antimicrobials alone. They can usually be grouped into: antimicrobials, which are described above and act against bacteria, moulds or yeasts; and antioxidants, which slow the oxidation of fats and lipids (a process that, in turn, leads to rancidity), prevent spoilage and extend the life of fruits and vegetables from over-ripening after harvest by retarding the activity of certain enzymes.

For example, after apples and potatoes are cut or peeled they will turn brown due to an enzyme naturally present in these foods. Certain acids such as ascorbic acid (vitamin C) and citric acid prevent or slow down this process by reducing the pH at levels that prevent the activity of this enzyme. So, when you buy sliced apples to make apple pies, remember that these most likely have been treated with these acids to prevent the onset of browning.

Another spoilage mechanism of foods relates to the oxidation of fats and oils and specifically those we consider healthy such as the mono and poly unsaturated lipids. These are much more prone to oxidation than saturated fats. The oxidation process is caused by the activity of certain enzymes such as lipases and peroxidises or due to the auto-oxidation phenomenon when these lipids are exposed to oxygen. Therefore, as soon as the grain kernel is broken open the oxidation process begins.

By exposure to heat it is possible to deactivate these enzymes and extend the shelf life of cereal ingredients such as wheat germ and bran. However, the auto-oxidation process will continue and

Preservatives are usually either antimicrobials, which are described above and act against bacteria, moulds or yeasts; or antioxidants, which slow the oxidation of fats and lipids, prevent spoilage and extend the life of fruits and vegetables.

the addition of antioxidants will be required to further extend the shelf life of these products or ingredients.

Several antioxidants are available for use in the market. These include synthetic such as butylated hydroxy anisole (BHA), propyl gallate (PG), tertiary butyl hydroxy quinone (TBHQ) and natural such as rosemary extract, tocopherols (vitamin E), cloves and cinnamon and honey.

In attempting to use these ingredients, either to preserve quality or ensure safety of food products, we need to make sure they are permitted to be used in foods in Canada and any other country to which we are planning to export the finished products. / BJ

For more information, or fee-for-service help with food technical and processing issues and needs, contact Dr. John Michaelides at John Michaelides Consulting at 519-7438956 or j.jmichaelides@gmail.com, or at Bioenterprise by calling 519-821-2960. Bioenterprise is a company made up of experienced professionals who coach and mentor emerging agri-technology companies from planning to start-up to profitability and beyond.

Don’t let their size fool you; small flies can be one of the biggest pest threats to bakeries.

Attracted to the dough, yeast and moisture found inside, bakeries provide everything these pests need to survive and can be ideal breeding grounds if proper fly control is not maintained.

Small flies should be a concern for several reasons: they reproduce rapidly; they can contaminate food and damage your reputation; and they can be costly.

As a result, fly control is imperative. The best strategy for managing small flies is implementing an ongoing fly control program that utilizes integrated pest management (IPM) practices such as sanitation, facility maintenance and exclusion.

Here is a look at common small fly species that infest bakeries, and the steps that can be taken to help keep them away from your business.

Some of the most common small fly species to infest bakeries are drain flies, fruit flies and phorid flies.

Drain flies are about 2 to 4 millimetres long and often referred to as moth flies because they are covered with long fuzzy hairs. They breed in biofilm in drains or on the surface of moist, slimy decaying organic matter in drains, sewages or other similar moist environments – including under building slabs where broken pipes may be located. The developing larvae bury themselves into the film while breathing with respiratory tubes pushed through the surface of the film.

}Small fly infestations can be extremely difficult to control . . . . it’s important to locate and eliminate the source of the infestation and conditions that support it.

Need to know fact: While drain flies breed in raw sewage and other decaying organic matters, they are not known to transmit human diseases.

Fruit flies are a little bigger, with an average body length of 3 to 5 millimetres. They can be identified by their usually large, bright red eyes. Fruit flies are

attracted to fermenting, sugary, organic matters and lay their eggs on or near fruits, vegetables and other decaying organic matter. They also thrive in fermented materials often found in floor drains and trash cans. The common fruit fly is known for its ability to reproduce rapidly – eggs can hatch within two days and new adults can be found after only eight days.

Need to know fact: If consumed, fruit fly larvae can cause stomach distress or illness.

Phorid flies are easily recognized by their humped backs and small head relative to body, although sometimes

they are mistaken for gnats. They range in size from 1 to 4 millimetres long. Phorid flies flourish in thick, decaying organic material in drains, at the bottoms of moist trash containers, under kitchen equipment and in mop heads or over-watered potted plants.

Need to know fact: The phorid fly is known in some regions as the coffin fly because they are also fond of decaying flesh and capable of creating sustainable communities in coffins.

The most noticeable sign of any small fly infestation is the appearance of adult flies. If you suspect your facility has small flies, it’s important to contact a pest management professional for help. Small fly infestations can be extremely difficult to control and typically cannot be resolved by only using insecticides.

Keep exterior dumpsters as far away from the building as possible, and rotate them regularly.

Instead, it’s important to locate and eliminate the source of the infestation and conditions that support it.

Here are several IPM practices you can implement on a regular basis to help protect your bakery from small flies.

There are several steps you can take to ensure your entrances aren’t providing flies easy access to your bakery. First, remind employees to keep doors closed whenever they are not in use. Next, seal all doors and windows with weather stripping and correctly fitting door sweeps. Work with an HVAC professional to make sure you have positive airflow, meaning air flows out, not into your building when doors are open. You can add a second layer of protection by installing two sets of doors, which add an extra boundary line for flies to get through. Air curtains, or wall-mounted fans that create a wall of air pests can’t fly through, can also be installed at entrances.

Odours are one of the key attractors for small flies. To keep odours to a minimum, line and regularly empty garbage cans and recycle bins, and be sure to remove wet garbage as often as possible. Keep exterior dumpsters as far away from the building as possible, and rotate dumpsters on a regular basis. Clean up any spills immediately and use a bacterial cleaner to dissolve organic material on drains and floors.

Continually be on the lookout for potential small fly breeding or feeding sites. Focus on dead-end spaces in machines, equipment footing and other hard-to-reach areas, and inspect all

incoming shipments for signs of fly activity. Look for adult flies rather than eggs. Use a drain scope to check for pipe cracks. Remember, broken pipes can lead to moisture under building slabs, which can create an ideal breeding site. Monitor for fly activities using various fly traps in high fly-risk areas such as a yeast room or dough fermenting room.

Small-fly infestations can be difficult to control once established. Work with your pest management professional to develop a customized small fly control program to help minimize conducive conditions and attractors, and keep these pests from negatively affecting business. / BJ

PUB_JUILLET2013_Mise en page 2 2013-08-12 08:45 Page1

Alice Sinia, Ph.D., is a resident entomologist with Orkin Canada. She focuses on government regulations pertaining to the pest control industry. With more than 10 years of experience, she manages the quality assurance laboratory for Orkin Canada and performs analytical entomology as well as provides technical support in pest/insect identification to branch offices and clients. For more information, email her at asinia@orkincanada.com or visit www.orkincanada.com.

Lallemand Bakers Yeast delivers nutrition in every loaf.

Lallemand is helping to restore the wholesome qualities of bread by offering Bakers Yeast that can significantly contribute to the nutritional value of baked products. Lallemand Bakers Yeast is a natural and proven source of essential minerals and vitamins, including Vitamin D. Make your bread a non-fortified and vegetarian source of Vitamin D with Lallemand Bakers Yeast

Three creative star chefs and Cacao Barry chocolate proved an irresistible combination for students of George Brown College’s baking program.

In June, the Canadian Pastry Chefs Guild partnered with Cacao Barry and the college to present three interpretations of “Modern Techniques for Chocolate, Pastry and Dessert.”

Chef John Placko, culinary director of the Modern Culinary Academy, showed a roomful of novice chefs how to use molecular cuisine principles to infuse their creations with subtle, consistent flavours.

Placko established the academy in 2012 to teach chefs, pastry chefs and foodies about the innovative cooking and baking method that encompasses scientific techniques, high-tech equipment and new ingredients.

The chef performed a little magic by turning Cacao Barry Ocoa chocolate into crumbs he called “chocolate snow” or “chocolate soil.” To do this, he used maltodextrin, an additive he said absorbs oils.

Placko then made a chocolate micro sponge, which can be made using either sweet or savoury ingredients. Using a whisk or any other mixing method will work, he said, as long as you strain the mixture through a fine sieve. He used a paper cup to shape the sponge and recommended you use as porous a cup as much as possible and avoid using a plastic one, which will fall after rising. Ideally, in 45 seconds, the half-cup will rise to a full cup.

Using a sous vide machine he cooked rhubarb at 80 per cent power. “This is a neat way to infuse flavour,” he said. The machine cooks food very slowly, which helps regulate temperature and prevent overcooking. In this case, the rhubarb cooks in its own juices but also takes on flavours of what’s cooked inside the machine with it, he said.

The audience was particularly curious when he mixed into the juice a handy starch product called “ultra-sperse” that is useful for thickening mixtures such as

gravies, puddings and creams and creating a creamy mouthfeel.

One element of Placko’s dessert plate was an eggless mint meringue made using a whipping blade. In answer to a question from the audience, he said you can use fruit juice as the liquid but don’t use fats or oils; and too much alcohol impedes the process. It’s a delicate meringue that will dissolve if brought into contact with fats.

Raspberries he had separated by dipping in liquid nitrogen were deemed too cold to incorporate, so Placko put them into the freezer to warm up. He shared the warmed-up raspberries with fellow chef Royce Li, and the two amused the audience with their icy, visible breath.

Li, a George Brown professor and World Chocolate Masters finalist, followed up with a demo of his own and shared his thoughts about modern techniques.

3D moulds are the future and can help bakers create edible moulds in every size and shape imaginable, Li said. He said he uses these tools to achieve consistent measurements and a high level of uniformity in competitions.

Li delighted the audience by making a comfort-food favourite. With the help of an assistant, he used wood chips in a smoke machine to flavour a chocolate ganache for an authentically smokeytasting smore bonbon with an edible – and flammable – wick of vermicelli.

Chef Rodney Alleguede of Ma Maison in Etobicoke said that to him modern baking means finding a new twist on the traditional. “In the world of pastry, sometimes it’s about going back to the essentials and making it taste as good as it can,” he said.

Alleguede made a choux paste using a traditional ganache consisting of cream, coconut and coconut puree with no sugar added. He used a 150-degree

convection oven for between 45 minutes and an hour. The choux paste is temperamental, he cautioned.

With ganache, the secret is to get twice the volume by adding a high percentage of chocolate, he said. He used pineapple, passion fruit, cream and Cacao Barry Alunga chocolate for the ganache. Using 90 per cent chocolate to one per cent cream gives it “a nice feel,” he said. He said that using cornstarch ensures you don’t need to add sugar to the pineapple.