By L Au RA

By L Au RA

}YAUGUST/SEPTEMBER | Vol. 72, no. 7

ou only need to look as far as the statistics page of the Canadian Heart and Stroke Foundation website to see that many of us Canucks are erring on the unhealthy side. Almost 60 per cent of us are considered overweight or obese. About 40 per cent of Canadians have high blood cholesterol. Half of adults only eat half the recommended servings of fruit and vegetables per day. More than 85 per cent of men and 60 per cent of women exceed the recommended upper limit for sodium intake. Nearly half of Canadians over 12 years of age are considered physically inactive. It should be noted that despite all this, the rates of heart disease and stroke have steadily declined over the past 40 years, down 70 per cent from 1956 to 2002. However, the costs of Canadian health care are skyrocketing, with billions attributed to excess weight and inactivity alone.

Fingers are being pointed. People are wondering who’s to blame and the food industry has been painted as a wolf in sheep’s clothing, disguising fat, salt and sugar as nutritious food. The federal government released its voluntary guidelines for sodium reduction in June, and companies who fail to meet these lofty goals will likely further look like villains. The BAC noted in an e-newsletter that the association considers the proposed targets unachievable by the industry, so it is an uphill battle indeed. The food purveyors are the problem; point the fingers.

All of this is really part and parcel of exactly what outgoing BAC chair Pete Plaizier said in his comments at the annual general meeting on May 16 (which were synopsized in the BAC’s July newsletter that ran in Bakers Journal): “Food consumption is no longer seen as the solution to our health problems – it is viewed as the cause of them…No longer can we sit back and rely on others to speak on our behalf about bread’s contribution to good health or say it is OK to indulge oneself with a brownie or cookie as part of a healthy lifestyle. All of us need to speak up and be heard. We make good food – food that is to be enjoyed – not demonized. And we need to start speaking up soon before others permanently convince consumers otherwise.”

People are wondering who’s to blame and the food industry has been painted as a wolf in sheep’s clothing, disguising fat, salt and sugar as nutritious food.

I second this sentiment completely. As a baker, you cannot be complacent about the fact that North American governments appear to be taking a “war on drugs” approach to their people’s consumption of food. Bakers must sit up and ensure that their products are not treated as the “drugs” in the health war.

To do this, you must position yourself as the expert that you are. Your website can be more than a place to share delightful images and company news. You could set up a section with links showing the benefits of many of your ingredients, such as the antioxidants in chocolate or blueberries. The information is out there in abundance, you only need to gather it. You could support an event such as a marathon in your community. Be transparent and unafraid, for you’re not the villain in this piece. State your intentions loud and clear. Remind your customers in many ways that bread enrichment has been a huge factor in the decrease of birth defects and other vitamin deficiencies. Remind people that our mental health needs a cookie now and again too. Cultivate and educate your most loyal customers. It only takes a small influential group to spread a lot of word in this digital age.

Plaizier is right: quality will not speak for itself these days. Be a leading example by speaking for the joy in food and the joy in life. / BJ

EDIToR | laura Aiken editor@bakersjournal.com 416-522-1595 1-888-599-2228 ext. 250

ASSISTAnT EDIToR | Stefanie Wallace swallace@annexweb.com 1-888-599-2228 ext. 278

TECHnICAl EDIToR | John McColl Puratos Canada jmccoll@puratos.com

nATIonAl ADvERTISInG MAnAGER | Stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

SAlES ASSISTAnT | Tara Jacobs tjacobs@annexweb.com 519-429-5183 1-888-599-2228 ext. 219

MEDIA DESIGnER | kelli kramer GRoUP PUBlISHER | Martin McAnulty mmcanulty@annexweb.com

PRESIDEnT | Mike fredericks mfredericks@annexweb.com

Mailing Address P.o. Box 530, 105 Donly Dr. S., Simcoe, on n3Y 4n5

PUBlICATIon MAIl AGREEMEnT no. 40065710. RETURn UnDElIvERABlE CAnADIAn ADDRESSES To: CIRCUlATIon DEPARTMEnT, P.o. Box 530, SIMCoE, on n3Y 4n5 e-mail: subscribe@bakersjournal.com

ISSn 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, oct, nov, Dec) by Annex Publishing & Printing Inc.

SUBSCRIPTIon RATES

Canada — 1 Year $ 30.00 (with GST $31.50 #867172652RT0001, with HST/ QST $33.90)

USA — 1 Year $ 45.00 USD Best pricing is available online at www. bakersjournal.com

Send your subscription request to: Bakers Journal

P.o. Box 530, Simcoe, on n3Y 4n5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940

E-mail: subscribe@bakersjournal.com

occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

opinions expressed in this magazine are not necessarily those of the editor or the publisher. no liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

no part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2012 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

briefly | Almonds have fewer calories than previously thought | More N.S. bakeries catering to celiacs | FOR MORE news in the baking world, check out our website, www.bakersjournal.com

Guelph, Ont. – Discovering the true potential of purple or blue wheat as a natural food colorant and antioxidant source is the goal of an Agriculture and Agri-Food Canada (AAFC) project, in partnership with the University of Saskatchewan, that could lead to more choices for consumers and opening of new market opportunities for Canada’s farmers and food processors.

Until now, much research has focused on fruits and vegetables, paying little attention to the development of this coloured grain as a functional food (a modified food that claims to improve health or well-being by providing benefit beyond that of the traditional nutrients it contains).

Purple or blue wheat bran (495 milligrams per kilogram) is more abundant in anthocyanins than, for instance, red cabbage (250 milligrams per kilogram) or plums (20-250 milligrams per kilogram). Anthocyanins are the phytochemicals

Niagara-on-the-Lake, Ont. – The Canadian Food and Wine Institute at Niagara College in Niagara-on-the-Lake, Ont., is preparing to launch a new bakery and pastry arts Ontario certificate program in September 2013.

The full-time, one-year post-secondary program will run from September to April. Only 24 students will be accepted to the program, with the aim of keeping the classes focused and dedicated. An Ontario Secondary School Diploma with Grade 12 English (or equivalencies) is required to apply, and hospitality or culinary experience is recommended.

Craig Youdale, chair academic, says the college is excited about the school’s first dedicated pastry program and hopes it will become a signature program for the institute. “We have some amazing talent in our pastry staff. We wanted a program to reflect that talent.”

More information will be available this fall at niagaracollege.ca.

responsible for blue, purple or red pigments in highly pigmented grains, fruits and vegetables and have very strong antioxidant activity levels. Antioxidants are substances, such as vitamin E or vitamin C, thought to protect body cells from the damaging effects of oxidation and reduce the risk of chronic diseases such as cancer, heart disease and diabetes.

Dr. Elsayed Abdelaal, a research scientist at AAFC’s Guelph Food Research Centre, has been instrumental in developing a mechanical-chemical separation process to isolate the anthocyanin pigments from the wheat. Once separated, the anthocyanins, or pigments, can be used to protect and colour foods and cosmetic products, and/or as a natural source of colour and antioxidants in food products.

“The demand for anthocyanin-rich foods, such as purple and blue wheat, is steadily increasing due to their role in human health and food coloration,”

explains Dr. Abdelaal. “And, although Canada’s spring wheat is usually red or white in colour, it is possible to breed high-anthocyanin blue pigments in these wheat varieties.”

One of the key goals of AAFC research is to promote human health and wellness through scientific innovation in food products and processes. This focus helps provide consumers with a variety of beneficial choices and opens up new marketing opportunities for Canada’s farmers and food processors.

Franz Streiter, president of Process in Motion, is V-Tech Engineering Inc.’s new exclusive representative in Canada. Streiter brings an extensive background in ingredient processing solutions, with more than 36 years of industry experience ranging from plastic compounding systems to cereal manufacturing to baked goods production. He most recently served as the Canadian representative for Reimelt Corporation for 23 years, and has also represented Shick USA for the past three years. He will be responsible for managing and optimizing relationships within existing and potential key accounts and overseeing sales efforts for the entire Canadian region. Contact Streiter at 905-886-2463 or via e-mail at fstreiter@ gmail.com.

Taylor Harris has joined Puratos as product manager – patisserie. In this capacity Harris will learn about the portfolio of Puratos’ patisserie products and gradually take over from Vikram Chowdhury all the marketing functions related to the range. She will work in close collaboration with sales and product development.

Harris has more than five years of marketing experience, acquired through working in mostly food-related environments in companies such as Tradition Fine Foods, Maple Lodge Farm and Embassy Flavours. She has a bachelor’s degree in business administration from the University of Windsor with a major in marketing, and holds a culinary arts certificate from George Brown College in Toronto.

St-Hyacinthe, Que. – Cacao Barry and Callebaut have appointed Chef Philippe Vancayseele as the new technical director for the Chocolate Academy in StHyacinthe, Que. Vancayseele will be providing technical advice and expertise to the pastry chefs and chocolatiers of Canada.

Vancayseele trained as a patissierchocolatier at the Brussels Culinary Institute and quickly began his working career in two famous patisseries in Belgium. In 1985 he moved on to work in the chocolate industry for a number of years before he began teaching at the Culinary Institute in Brussels. In 1994, Vancayseele joined Callebaut as worldwide technical advisor and demonstrator. He also became a lecturer at the famous Chocolate Academy in Wieze (Belgium). He was head of the academy from 2004 to 2012. In his capacity as the Callebaut

worldwide technical advisor, he demonstrated the Callebaut 100 Year demonstration at Humber College in Toronto, inspiring attendees with his expertise and passion for his craft.

DPB BAkInG CoMPAny APPoInTS DIRECToR of SAlES AnD MARkETInG

DPB Baking Company of Calgary has appointed Randy MacDonald to director of sales and marketing. In this role, MacDonald will be responsible for sales and marketing of DPB Baking Company products worldwide, along with additional operational functions. Prior to joining the company, MacDonald spent eight years with P&H Milling Group. He was previously vice-president of sales and marketing for Byblos Bakery in Calgary. Randy is past chair of the executive committee with the Baking Association of Canada (Alberta chapter) and is a current director with the Alberta Food Processors Association.

Mississauga, Ont. – Wladyslaw Lizon, member of parliament for Mississauga East–Cooksville, on behalf of Agriculture Minister Gerry Ritz, announced June 28 an investment of more than $240,000 to S. Gumpert Co. of Canada to purchase and install new packaging equipment in its facility in Mississauga, Ont.

S. Gumpert specializes in products such as cake mixes, icing, and pie fillings for use

in the baking industry. The investment will be used to purchase new packaging equipment. Currently, the company must transport some of its products to a co-packer, as its equipment does not have the capacity to package all of its mixes. The new and faster equipment will be able to handle larger volumes of food and enable the company to package everything on site.

These improvements will enhance the company’s productivity and competitiveness, increase domestic and export sales, and reduce transportation and production costs. The project will also support the creation of new jobs and will result in an increased demand by the company for agricultural commodities such as flour and shortening, which in turn will benefit Canadian farmers.

Toronto – Effective July 18, C.K. Foods Inc. and its CK Nutritional Ingredients division became a single entity named CK Ingredients Inc.

The company says there will be no change in ownership. In addition to the change in name, CK Ingredients has moved to a new larger location and has also redesigned its website. The new address, phone and fax numbers can be found at www.ckingredients.com.

Toronto – Dufflet Pastries’ production bakery was recently awarded the BRC ‘Grade A’ global standard for food safety (version six) certification.

Following an intensive systems and practices audit by Global Food Safety Initiative (GFSI) certifying body SAI Global, Dufflet Pastries says this certification demonstrates a commitment to quality and food safety.

“We are proud to have met the challenge of this examination of our food safety programs and systems,” said Dufflet Rosenberg, company founder and CEO.

Montreal – Lallemand’s new Technical & Distribution Centre, located in Anjou, outside of Montreal, Quebec, will house the baking development and analytical laboratory facilities, as well as space for technical, sales and distribution personnel.

The 21,000-square-foot facility offers a testing and training environment for customers and provides support for customer applications and longer-term development projects. The new bake centre is equipped to simulate and evaluate a wide variety of products and processes for fresh and frozen bakery customers.

The warehouse is equipped with four loading docks and cold storage, as well as temperature-controlled and dry storage.

Dealers Ingredients offers you the knowledge, expertise and experience to deliver product performance solutions –naturally. Since 1976, Dealers Ingredients has supplied quality ingredients to leading food manufacturers and processors across Canada. We specialize in supplying natural source ingredients that improve the quality and value of your products. We have a world of technical knowledge that can help you solve complex problems with answers to questions about your specific products.

Vancouver and Nanaimo, B.C. – Andrew Whitley, baking instructor, author of Bread Matters and founding member of the Campaign for Real Bread in the U.K. will host two afternoon workshops in British Columbia. Attendees will have the opportunity to hear about the state of the bread industry in the U.K and Europe, trends in artisan baking and the gluten-free phenomena. Whitley will also demonstrate bread techniques with hands-on student involvement.

A private workshop (open to Vancouver Community College students only) will be held on Tuesday, Sept. 18 from 1 p.m. until 5 p.m. at Vancouver Community College.

Another workshop, held Thursday, Sept. 20, from 1 p.m. until 5 p.m. at Vancouver Island University in Nanaimo, will be open to the public. Cost is $10 per person, $5 for students.

For more information, e-mail martin. barnett@viu.ca, rita.gower@viu.ca or ejang@vcc.ca.

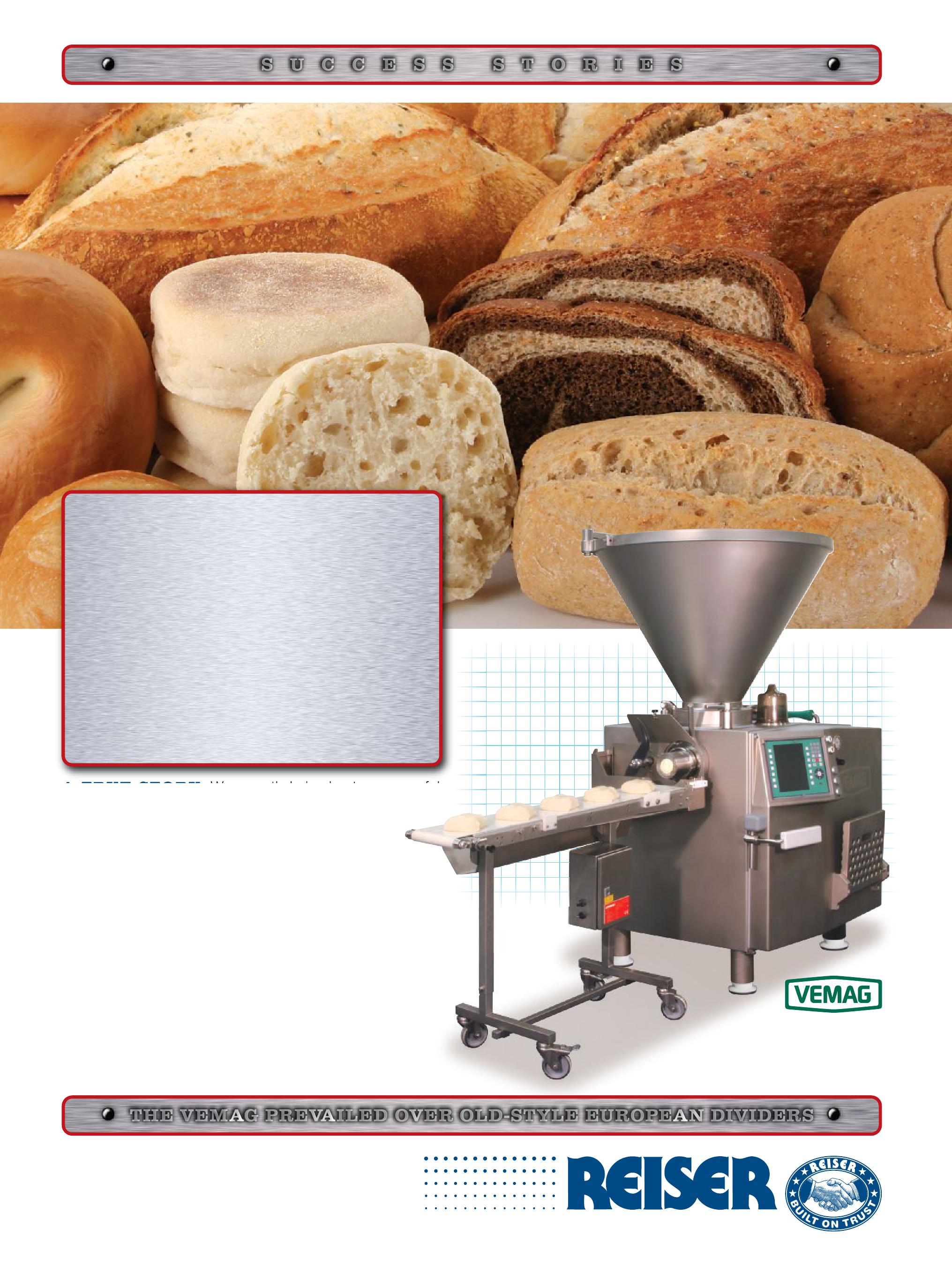

A T R U E S T O R Y : We recently helped out a successful, high-end bread producer He discovered that his European dividers were wearing out and needed to be replaced He tested other dividers, but none were able to duplicate the quality of his European and American breads He was also concerned ab out the drawbacks of simply buying the same units again – the lack of dividing accuracy, the expense of mineral oil, and the frequent service that the units required

Still, he placed the order During the long lead time for the new machines, he decided to try our Vemag Dough Divider on his products Working with one of our on-staff Reiser bakers, this customer was able to equal or exceed the quality on all of his breads He was absolutely delighted with the Vemag and cancelled his order for the “old-style” European dividers. His plant now runs five Vemag Dough Dividers – all producing the highest quality breads with excellent weight control, no mineral oil, and Reiser service and support just a phone call away.

STEfAnIE WAllACE

Canada’s multicultural population has brought a unique flair to our cuisine, but there are some dishes that are distinctly Canadian. Each year we celebrate Canadian baking, but this year we’ve decided to find out what makes each province and territory famous by exploring local ingredients and specialties from coast to coast to coast.

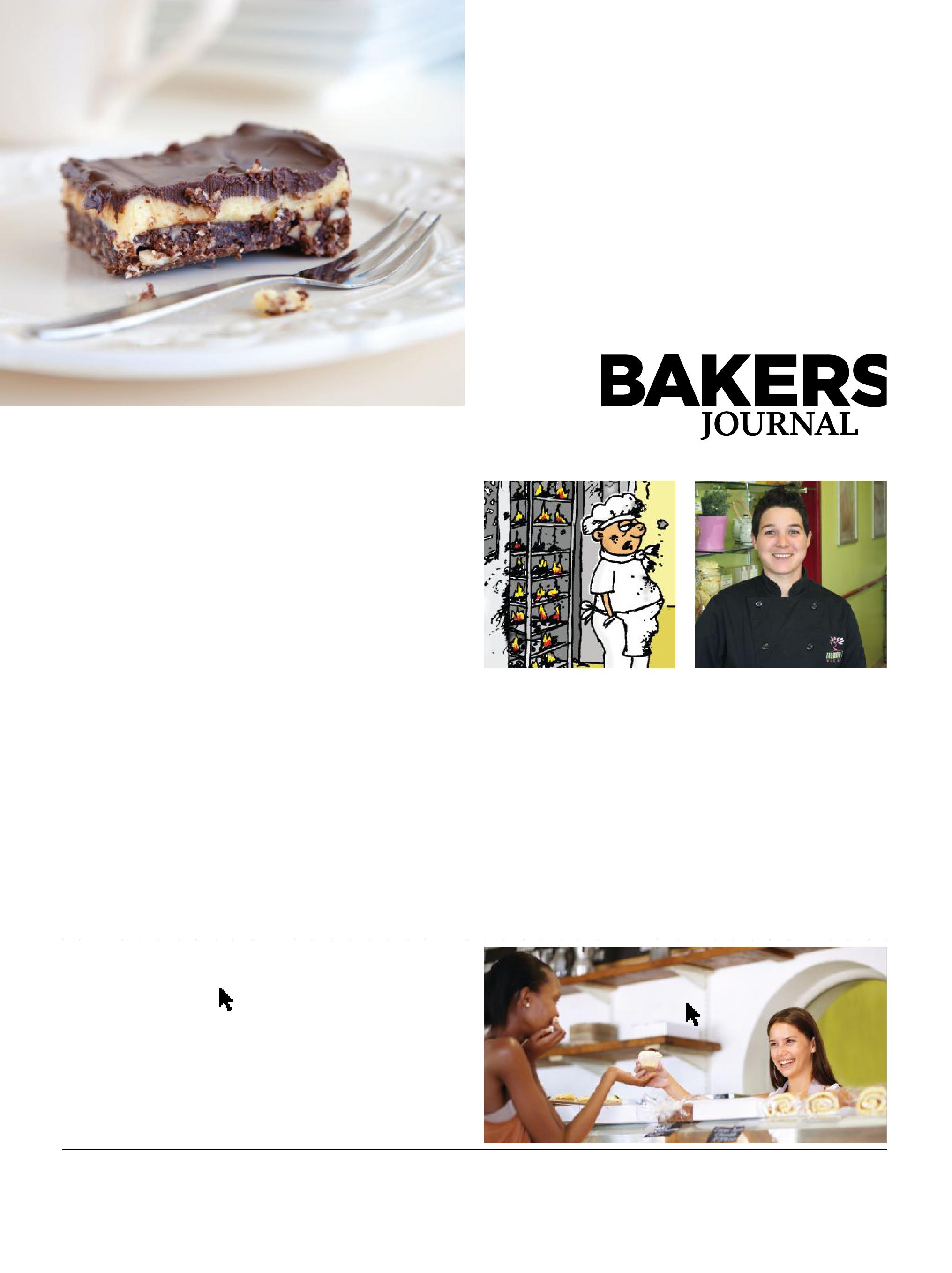

The cookie wafer base, flavoured butter icing and chocolate topping are a scrumptious combination only found in Nanaimo bars. This dessert is said to have originated in the 1950s in Ladysmith, Vancouver Island, south of Nanaimo, when a housewife named Mabel Jenkins submitted her recipe to the annual Ladysmith and Cowichan Women’s Institute Cookbook. The earliest confirmed printed copy of the Nanaimo bar recipe appears in His/Her Favourite Recipes, Compiled by the Women’s Association of the Brechin United Church, published in 1957, submitted by Joy Wilgress, a native of Baltimore, Md. It has since received national acclaim: a 2006 National Post reader survey deemed Nanaimo bars Canada’s favourite confection. The City of Nanaimo takes pride in this, with a special page of its website dedicated to the creamy, chocolaty treat, including a detailed guide of where to find different variations of Nanaimo bars in the city. From the traditional square bar to a Nanaimo bar cupcake, or a Nanaimo bar latte or martini, there’s surely a variety for everyone.

}Pulse is the term for the edible seeds of a legume, including dry peas, beans, lentils, chickpeas and soybeans. They’re high in fibre and complex carbs, low in fat, and are a good source of folate.

Canadian total). Alberta Beef Producers participates in community programs to inform Albertans about the benefits of beef, including educational initiatives to teach students about nutrition, environmental care and animal safety. Use Alberta beef to add some protein to your baked goods via classic comfort foods such as shepherd’s pie or tourtiere.

While fresh fruit growers are plentiful in the west, Alberta will always be known for its beef. The province’s cattle industry dates back to the late 1800s. Today, 53 per cent of Alberta producers have beef cattle, and the province has 1.95 million breeding beef cows and heifers (39 per cent of the

The city of Saskatoon got its name from the deciduous saskatoon shrub found mainly in the Prairies. But besides bearing a name for a city, the shrub bears saskatoon berries, a sweet, violet-coloured fruit perfect for jams, jellies and desserts. The city’s namesake shrub can also be found in

the Northwest Territories, the Yukon, British Columbia and northwestern and north central United States. Fresh saskatoon berries – also known as serviceberries or juneberries – are available in Saskatchewan between mid-July and late August. The Saskatchewan Fruit Growers Association offers several recipes for jams and sauces, but its Saskatoon Berry Dream Cake stands out among them. A fluffy white cake with a layer of fresh berries – the name says it all.

Manitoba is also known for its beef and pork, but let’s not forget about pulses. Pulse is the term for the edible seeds of a legume, including dry peas, beans, lentils, chickpeas and soybeans. They’re high in fibre and complex carbs, low in fat, and are a good source of folate. They’re also gluten free, and are great ingredients to incorporate into baked goods to accommodate gluten-free

Pulses, the edible seeds of legumes, are perfect for adding to baked goods for your gluten-free customers.

Saskatoon berries are a sweet, purple fruit, great for preserving and incorporating into desserts.

customers. The Manitoba Pulse Growers Association offers several recipes, including a gluten-free chocolate cake featuring a black bean puree that looks almost sinful.

The butter tart has been called the quintessential Canadian dessert. Stories of origin vary, but the earliest documented recipe was found in the Women’s Auxiliary of the Royal Victoria Hospital Cookbook, printed in 1900 in Barrie, Ont. The fillings may vary, but the base recipe calls for butter, eggs and sugar in a pastry shell. Some traditional recipes have raisins or other dried fruits, and pecans or walnuts are

Potatoes are a staple in Prince Edward Island, and the secret to keeping scones moist and delicious.

common ingredients too. Butter tart enthusiasts in Wellington County have compiled the Butter Tart Trail, a list of shops and bakeries in the area that carry this tasty treat.

Quebec offers several savoury meal staples, but La Belle Province is also home to many delightful delicacies. One highlight of Quebec cuisine is nougabricot, a preserve consisting of apricots, almonds and pistachios that’s perfect for spreading on pancakes or waffles or drizzling over ice cream. If confectionary goods are more your style, try your hand at making sucre à la crème, a traditional Québécois treat. Ingredients vary slightly

from recipe to recipe: some call for just brown sugar, white sugar and heavy cream, and others include butter, maple syrup and vanilla extract. The concept is similar to fudge, but with a slightly granular texture that melts in your mouth.

New Brunswick’s strong Acadian culture comes alive through the many traditional dishes the province is known for. Not to be confused with french fries covered with cheese curds and gravy, poutines à trou (also called poutine routies) are mouth-watering Acadian square pastries, filled with cranberries, raisins and apples and baked in the oven. Dessert was not traditionally served with Acadian meals,

so this was considered a special treat, and is still considered the most delectable of Acadian desserts.

Scallops, oysters, lobster . . . the list of popular seafood fare in Nova Scotia is endless. But the central region of Nova Scotia is known for wild blueberries. The province is the largest processor of wild blueberries in the world and the second largest on earth (second to Maine). The blueberry is Nova Scotia’s provincial berry and its antioxidant health benefits are abundant. Nova Scotia produces more than 40 million pounds of wild blueberries and the province’s wild blueberries are exported to several countries, including the United States, Japan, Germany and the United Kingdom. Van Dyk’s Health Juice Products in Queens County, N.S., produces pure wild blueberry juice perfect for incorporating into sauces and desserts, like its recipe for blueberry crème caramel. And of course, you can’t go wrong with a classic, old-fashioned wild blueberry muffin.

Seal flipper pie is a unique dish from the Rock. The filling of this savoury meat pie is made of seal flippers, which are boiled and then baked with onions, then added to a dumpling pastry with vegetables. The pie is traditionally served at Easter, often with mashed potatoes and boiled cabbage or other greens. A customary dessert best follows a customary dish, and figgy duff, a traditional raisin pudding that’s boiled and served steaming hot, is the way to go.

PRInCE EDWARD ISlAnD

Prince Edward Island is, without a doubt, potato country. The starchy vegetable has been farmed in P.E.I. since 1790, and potatoes are the province’s primary cash crop, according to the Prince Edward Island Potato Board. The Island is Canada’s leading potato province, responsible for nearly a third of Canadian production. Different varieties are put to different uses: Yukon Gold, russets and Norland potatoes are best used in baking. The board offers several recipes for incorporating potatoes into every meal on its website. Its recipe for P.E.I. Potato Scones uses whole-wheat flour and raisins (and/or other candied fruit). But the namesake ingredient – mashed P.E.I. potatoes – is key to keeping the scones moist.

A specialty in the northern parts of our country, especially in many First Nations communities, is bannock, a typically round quick bread. The version prepared by First Nations people usually uses white or wholewheat flour, baking powder and water. The dough is kneaded and spices or dried fruits can be added before it is pan fried or baked in an oven. Some say

bannock came from a Scottish source, while others say it was unknown in North America until the 1860s when the Navajo people created it. These items may be special to certain provinces and territories, but that doesn’t mean you can’t try them. Pay tribute to the rest of Canada by featuring one of these items as a special feature, or create your own specialties based on what your province or territory is known for. / BJ

At AB Mauri, our baking technicians are passionate about innovation and quality. Partnering with you to deliver a holistic solution that exceeds your expectations is why we “rise” out of bed every morning. Your success is the sole measurement for our success.

Partner with the AB Mauri Team today. Call 1.503.570.7501 and challenge us to perform.

Food safety, security and quality are all critical to food processing companies, retailers and food service. In our last Tech Talk, we discussed the technical and scientific side, as well as root causes of concern relating to food safety and security. This article will address the various programs that enable food manufacturers and handlers to protect food from contamination. In addition, we will discuss some aspects of food quality and how it relates to food safety.

Various programs have been developed over the years that help the food industry to effectively manage food safety and quality. These programs are often voluntary but at the same time necessary to safeguard companies from disastrous situations and ultimately protect the consumers. As we all know, legally it is the responsibility of the food manufacturer to produce and sell safe food.

}Baked goods are generally considered safer because of the heat applied to the finished product, but cross-contamination is still a threat.

Consumers demand convenience and with that, food processing becomes more complex with many production steps that provide opportunities for contamination.

Food safety programs are becoming more and more important for many reasons. The earth’s population has increased dramatically and the business of food is now global. Contamination of food is also global and affects both ingredients and finished products. Consumers demand convenience and with that, food processing becomes more complex with many production steps that provide opportunities for contamination.

The basic practices, policies, procedures and rules that promote effective hygiene and the production of safe food in the food chain are collectively referred to as “Good Manufacturing Practices” or GMPs. These include day-to-day activities that control hazards associated with people and plant operations and environment.

These are also called “Prerequisite Programs.” The GMP program provides the framework around which all practices are developed. It includes written programs that describe policies, procedures, frequency, records and other details of the various food-safety activities. It will also include training documents and records that prove employees have been trained. In addition, it will include verification documents and records that show activities were carried out according to the GMP. In general, the program dictates and documents the day-to-day handling practices of everyone in the plant and provides the basic conditions to ensure safe food production. Such policies and procedures include raw ingredients and product flow within the plant, personal hygiene practices, general sanitation and others in order to minimize cross-contamination of finished food products. For example, the FIFO principle (which means “First In First Out”) of ingredients and products is a practice that ensures

safety, maximizes quality and minimizes waste and loss of profits. Other programs include shipping and receiving, storage and handling, sanitation, pest control, preventive maintenance and recall.

An allergen control program is another important aspect of food safety. This is of paramount importance because allergies can be fatal. An allergen control program will apply to product development and formulation, purchasing and receiving of ingredients and labels, weighing, blending, mixing and other formulation procedures, use of rework, finished product labelling, disposal of obsolete materials, procedures to prevent cross-contamination and any other activities that potentially can allow an allergen to enter the food product. Many more practices can be described here as part of the GMP program. We must remember that the ultimate responsibility of consumer food safety is with the manufacturer; thus, these programs are very important.

Beyond the GMPs, the actual production of food requires additional tighter monitoring in its own program, which is the Hazard Analysis Critical Control Point system (HACCP).

HACCP identifies the risks associated with different points of production and allows us to take corrective actions. In some countries, food manufacturers are legally obligated to have a valid HACCP plan for the production of low-acid canned foods, juices and seafood, among others. Guidelines exist identifying what critical control points should be established in the production of these products.

There are no such guidelines for baking. Although baked goods are generally considered safer due to the application of heat to the finished product, there still a danger of cross-contamination and an HACCP plan is still an asset. Also, your corporate clients are likely to demand it.

An HACCP plan is normally based on the following seven principles:

1. Conduct hazard analysis: this begins with a flow chart of the process. For the baking plan it may begin with the weighing of flour and other ingredients, blending, mixing, forming, resting, proofing, baking, cooling and packaging. The possible biological, chemical and physical hazards would be identified for each step of the process.

2. The critical control points on the process are identified.

3. The critical limits for each point are established.

4. Monitoring procedures for each point are established.

5. Establish corrective actions for the deviations from each critical limit.

6. Establish verification procedures for the control points. This involves making sure that the parameters you are measuring at each point are accurate and correct.

7. Establish an effective record-keeping system.

Baked goods are exposed to heat during baking and are normally low-moisture products and may not support growth of pathogens; however, post-baking contamination and the addition of fillings and icings would present a risk. Because physical and chemical hazards are not affected by the heat and moisture, a bakery HACCP plan should take into consideration such possible sources of hazards.

Food safety efforts are embraced by the global community and various programs are attempting to harmonize them. One such effort is the Global Food Safety Initiative (GFSI). The various food-safety programs constitute an important part of any company’s safeguard against potential harm to the consumer and ultimate losses or damage to its brand’s image. In addition to safety, these programs help ensure the quality of the food. Such quality is perceived by the consumer based on the five senses and is a determinant factor for their buying habits. Vision, smell, taste, feel and hearing all contribute to the sensory parameters that determine the overall quality of the product. / BJ

For more information, or fee-for-service help with food technical and processing issues and needs, please contact Dr. John Michaelides at John Michaelides & Associates at 519-743-8956, or at Bioenterprise at 519-821-2960, ext. 226, or by e-mail: j.jmichaelides@gmail.com. Bioenterprise is a company of experienced professionals that coach and mentor emerging agri-technology companies from planning to startup to profitability and beyond.

Revital “Revi” Zephrani was studying interior design when she realized life in an office wasn’t going to cut it. She needed something to do with her hands that was also going to give her creative freedom. Her brother attended cooking school, which seemed like an option except she wasn’t too keen on butchering meat. So she tried out some night classes in baking at George Brown College in Toronto instead. The phase in her life where she wasn’t sure what to do with her career came to an abrupt halt. Zephrani jumped right into baking, graduated in 2006 and in 2009 opened The Lemon Tree Bakery in Barrie, Ont.

The Lemon Tree is a scratch baking, slick operation that gives the impression of many specialists at work behind the scenes. But Zephrani is cookie maker, chocolatier, cake designer and all-around craftsman to an impressive array of goods. While we seem to be in a niche era with cupcake boutiques and cookie shops opening all around us, The Lemon Tree offers a wide array of goods. The menu runs the gamut from savoury meals and soups to truffles, celebration cakes, cookies, all sorts of pastries and more. The bakery was honoured with the City of Barrie Strategy and Economic Development Office’s Best New Business Award and she’s working on getting her next location open.

Revi Zephrani proudly showcases her lemon squares in The Lemon Tree Bakery.

}While we seem to be in a niche era with cupcake boutiques and cookie shops opening all around us, The Lemon Tree offers a wide array of goods.

The venture is a partnership with her mother, Jocelyn Zephrani, who handles many of the behind-the-scenes details of running a business. Her father, Motti Zephrani, a tradesman, built the interior of the bakery and the kitchen. He is still the go-to maintenance man for The Lemon Tree. Zephrani says she had a very clear vision for the bakery right from the start, pretty much down to the colours, and the development of the business plan involved visiting 200 to 300 bakeries. Well prepared and well

supported by family, Zephrani had the right foot in front of the left as she faced 18- to 20-hour days in the beginning days of business. She credits her mum’s creativity and ability to open her mind to new things in helping Zephrani keep spreading outside her comfort zone in the bakery.

“At first, when you’re starting out, it’s scary to try to new things,” she says. “You don’t want a recipe not to come out but it’s a part of growing with the business… embracing what can work.”

Zephrani has figured how to make a

lot of things work by picking up various skill sets here and there. She took bits and pieces from the bakeries she worked at between school and the start of her own. She had a talented part-time cake designer for a while and picked up many tips and tricks from her. She spent three days at the Barry Callebaut Academy in Chicago, sharpening her skills with chocolate.

“I took a little piece from every place I worked, but with the cakes, it was a lot of trial and error. I didn’t really have any experience,” she says. However, like all products on display inside The Lemon Tree, the celebration cakes look nothing short of absolutely delightful.

The interest in interior design may be the drive behind why presentation is

executed so well at The Lemon Tree, from the cleanliness to the pure eye candy presented in various ways –shelves, display fridges, tables, windows, glass jars. There is just so much to see.

“Every day, everybody here steps outside of the store and looks at everything as if they were a customer – is it clean, organized – what do they see? For me, cleanliness is the biggest thing. Not a speck of dust, not a crumb – presentation is everything. I like when my store is sparkling clean and smells like baking.”

But the product’s exterior isn’t what makes this bakery unique, Zephrani says. She says it’s the high-quality ingredients, the scratch baking and real wholesome ingredients that make the difference. She tries to buy the best ingredients she can and uses local ingredients where it makes sense. She’s positioned herself upmarket, while knowing she still needs to give her customers the correct value for their money.

“We sell our brownies for $2.95 and it’s not a lot [portion-wise]. I think people have forgotten what a portion is. But it’s extremely rich. It satisfies the craving. You don’t need a huge slice.”

When she first opened up, she spent “a lot of money” trying different kinds of advertising to see what worked for the bakery, but in the end word of mouth has been the big driver. She likes to switch up the various methods of advertising and plans to get more involved in social media. There are five people working in the bakery on a daily basis, including Zephrani. She has a sous chef in Krystal Vandervelden. Now that the bakery has been up and running for a while, and everyone, including Zephrani, knows their job, she is back to working regular hours and even taking vacations.

“I wear a lot of hats but I rely a lot on my team. I have a great team.”

For the first year and a half the bakery was open seven days a week from 7 a.m. to 7 p.m. until Zephrani could get a feel for when the weakest sales periods were. Now she closes Sundays and has reduced the hours –the bakery is open to 11 a.m. to 5 p.m. Monday and 10 a.m. to 7 p.m. Tuesday to Saturday. Initially, her concept for a bakery included customers being able to sit down and have coffee in it. Her roots are in Israel, where there is a strong late-night coffee and dessert

culture. Her family moved from Israel nine years ago, first to Toronto for three years and then to Barrie, where they settled. However, she wasn’t allowed to serve coffee and dessert where she chose to locate because there was a Tim Hortons in the same plaza. Her next location, which she hopes to open in the fall, will fulfil her café desires. This busy entrepreneur has stuck to her guns in her marketplace, and it looks like it’s going to pay

off in growth.

“Most small business can’t compete with [grocery stores], so you have to compete on quality and quality alone because you can’t compete on price. You have to just put yourself in a position where you’re unique and stick to what you want to do and what’s your passion. Other people are going to see that, and it’s contagious, like when someone smiles at you it’s hard to not smile back.” / BJ

What If…you had a SINGLE INGREDIENT that provided CONSISTENT PERFORMANCE, to make yummy gluten-free cakes and muffins?

What If…you could EASILY IMPROVE VOLUME and ENHANCE EATING QUALITY of gluten-free bread or rolls?

What If…you could develop gluten-free baked goods, noodles or pastas DELICIOUS enough for the whole family to enjoy?

Living a gluten-free lifestyle is no longer for just those diagnosed with celiac disease A lar ger por tion of the gener al population has some sensitivity to gluten, and other s just feel better after removing gluten from their diet.

Removing gluten-containing wheat, bar ley or r ye flour s from baked goods is now easier than ever with a host of gluten-free flour s and starches that are available today

KELTROL® Advanced Perfor mance provides a simple , single ingredient solution that enables these flour s and starches to be used to create high quality baked goods with excellent eating texture and visual consumer appeal.

KELTROL Advanced Perfor mance products show better perfor mance in gluten-free applications than other standard xanthan gums available With fast and unifor m hydr ation, processing is quick and easy, and leavening perfor mance enhanced KELTROL Advanced Perfor mance is proven more efficient, so less gum is needed to obtain the r ight texture , saving money and time

Let CP Kelco help turn your “What If...” ideas into YOU C AN! solutions.

GLOBAL HEADQUARTERS

CP Kelco U.S., Inc. Cumberland Center II 3100 Cumberland Boulevard, Suite 600 Atlanta, GA 30339 Tel: +1 678 247 7413 w

By STEfAnIE WAllACE

The rich, decadent flavour and flaky, melt-in-yourmouth texture of a croissant is hard to resist. To a patissier, the quality of a croissant is paramount, and it’s easy to spot a component that’s just not quite right.

Nadège Nourian’s baking experience and expertise allows her to be a pretty good judge of croissant quality. Nourian is a fourth-generation patissier from Lyon, France, who prides herself on the high calibre of her products. When she moved to Canada three years ago, Nourian opened Nadège Patisserie in Toronto, with the expectation that she would be able to market and sell the croissants, pastries, cakes and confectionary items in Toronto as she did in France. She quickly realized that something was not quite right. As she layered her thin sheets of butter and dough to make her croissants, she noticed the butter was cracking, and as they were baking, the layers didn’t puff up and separate as they should. Her ganache suffered too.

“The ganache was pleating all the time. I couldn’t understand, I thought it was the cream,” she recalls. “Then, I realized on top of the big block of butter, I could see water [gathering].” Since butter is an emulsion, the increase in butterfat results in an offsetting reduction in moisture. The high moisture content of Canadian butter was affecting the baking process. When Nourian saw water gathering on the butter, she knew something was not right. “Instantly I thought, wow, we have a problem with the butter.”

A croissant’s flaky, melt-in-your-mouth texture and decadent flavour is dependent on butterfat content.

}In France, the minimum is 82 per cent, and for her croissants, Nourian typically used butter with at least 84 to 86 per cent fat.

After a bit of research, Nourian realized exactly where the problem stemmed from. “The fat content [of the butter] was 80 per cent,” she said, which is the standard minimum of butterfat content in Canada. In France, however, the minimum is 82 per cent, and for her croissants, Nourian typically used butter with at least 84 to 86 per cent fat. A taste

test of the butter was another sign: the taste of the Canadian butter was nothing compared to the full, rich flavour she was used to. “The more fat you have, the more flavour – and I will say that the most important thing is the flavour, for sure,” she says Nourian began experimenting and adapting her recipes. “I tried different types of butter, but it didn’t change at that point because all I could find was 80 per cent,” she says. After trying several different brands, Nourian concluded she would have to create a brand new croissant recipe, adapting her technique to suit her Canadian ingredients (even the yeast and flour were different than what she was used to). Several test

batches later, Nourian had eventually created a brand new croissant recipe that she was satisfied with – for the time being. “In France I had better results, but I think we reached a very high quality. I know they could be better, but I’m happy with the results,” she says, adding, “I’m always in search of perfection.”

Her search is constant, and she has come one step closer to her goal. Earlier this year, Nourian heard that Stirling Creamery in Stirling, Ont., was beginning to produce higher-fat butter. “Right away I contacted Stirling to get a sample of it,” she says. Before even baking with it, Nourian could taste the difference. Her croissants reaped the benefits of it, too. “With that butter, I will say, the quality is certainly better in terms of the layers, but the taste is the big thing.”

Nourian has not found another company in Canada that is producing higher-fat butter (Bakers Journal was

unable to locate any either). Stirling’s higher-fat butter is named Churn84, referencing the company’s old-fashioned barrel-churn process, and the product’s butterfat content. But while Canadian law stipulates butter must have a minimum butterfat content, there is no maximum butterfat content outlined. So why hadn’t anyone thought of producing a higher-fat butter?

Greg Nogler, the director of corporate marketing and sales for Stirling Creamery, says the potential demand for the product prompted him to start researching it.

“I certainly felt there was a need for it,” he says. “I noticed a number of retailers in downtown Toronto importing a high fat product, coming in primarily from France and a little bit from Italy . . . the prices, to my way of thinking, were exorbitant.”

Nogler wondered why a similar product hadn’t yet been produced locally, and began discussions with Stirling’s production team to find out if it was possible to create a high-fat butter.

“I had a discussion with Chet Blair, he’s our master butter maker, and he felt pretty confident that he could produce the product even though we had not done it previously, so I let him have a go at it,” Nogler says. Blair’s first batch tested at 84.5 to 85 per cent butterfat – not bad for a first try.

“Mostly the bakers are using this in laminated dough applications [like croissants and danishes], so it’s layer upon layer of butter and pastry,” he says, noting that higher-fat butter works well in a chocolate ganache, or shortbread. The increase of butterfat means about 20 per cent less moisture content. “As you bring up the butterfat content, the moisture content has to be reduced accordingly . . . it really has a key impact on the performance of the product.”

Churn84 is available to the foodservice sector in an unsalted version in 25-kilogram packages, and in a salted version available in select retail locations as well. “I am looking at alternate formats as we start to get this established,” Nogler says, noting that bakers should expect the unsalted version of Churn84 to be between 20 and 25 per cent higher in price than standard butter.

In developing Churn84, Stirling was not restricted by a maximum butterfat

law, but Nogler says one thing the company had to consider was the return on the product. “If you produce a butter with higher butterfat, it’s hard to get the value back from it, because the question becomes, will people pay for it?” he says. The answer, he says, is yes – “If there’s a specific need for it, and people understand what you are offering them.” So far, Nogler says the demand is small, but growing. “We’ve had requests for the product all across

Canada, all the way out to B.C.” Nourian expects the demand to grow as word gets around, and has a feeling other companies may begin to offer similar products. She has already had anonymous phone calls asking her questions about her use of the product and expects that other creameries will be developing their own version of high-fat butter. “Now that it’s available, [companies] should be more approachable for bakers who want it.” / BJ

For over 50 years L.V. Lomas has supplied ingredients and logistics services to the healthy baked goods sector. We’ve learned to think the way our customers do to help keep their supply chains well fed. We’ve continuously expanded our offering of products from the world’s highest quality Principals. And we’ve folded into our mix such organizations as ISO and HAACCP to verify our own quality standards.

When you make Lomas your partner, we make our success contingent upon yours.

By DAv ID F ILICE

When times are tough, cash matters more than earnings. Learn how to keep your dough on hand.

The current economic climate seems to be uncertain for business owners. The Canadian economy has been uncertain for more than a year now, due to the European and American debt crises continuing to have negative effects in Canada.

In a recent survey, Harris-Decima randomly sampled 1,000 Canadians via telephone. When asked about rising interest rates, 48 per cent of the respondents said a significant interest rate hike would pose a challenge to them in keeping up with mortgage or debt payments. Of that group, 29 per cent said they would have difficulty making payments if rates went up by two percentage points. It is not certain when interest rates will increase in the current economy, but it is certain that interest rates will eventually rise. This puts significant pressure on Canadian companies as consumers are losing confidence, negatively affecting consumer demand. Lower consumer demand could result in lower revenue and may tip many companies into a loss position.

}Having this mentality also causes a lot of stress on business owners as they are constantly worrying about having enough cash to fund operations.

You need to know where you are financially and have a plan for covering your obligations. Your business will have fixed expenses that have to be covered every week and month, such as payroll, loans, rent and utilities. In addition, you likely have variable expenses that are tied to your sales activity. When your sales rise and fall, variable expenses do the same.

Create a monthly cash flow budget and monitor it weekly. If your sales are falling short of your predictions, cut back on your expenses.

2. Maintain controls over accounts receivable and promote quicker payment terms

Monitor aging accounts receivable and quickly address any problem

Create a monthly cash flow budget and monitor it weekly. If your sales are falling short of your predictions, cut back on your expenses.

accounts that are past due. Consider offering a discount to obtain a quick payment of the overdue amount.

Understand your clients and the industries they operate in to gauge whether stricter credit terms should be implemented to counter the increased risk in certain industries.

the sales levels of the company. Make tough decisions about payroll costs and don’t look back.

4. Bargain for credit terms with suppliers

By evaluating your supplier base, you may decide to consolidate your suppliers and be in a position to purchase more from one or two suppliers. This will allow you to obtain more favourable credit terms for the increased volume you will be providing to the remaining suppliers. Furthermore, as many suppliers will be hungry for cash in tough economic conditions, you may be able to obtain early payment discounts.

5. Track inventory and supplies

Consider carrying less inventory than normal during tough times. Customers may be willing to wait a bit longer for orders if your suppliers can provide you with inventory on a just-in-time system. Try to identify waste in supply purchases.

6. Get smarter on tax

Don’t make tax payments any earlier than you need to. Many businesses remit taxes monthly when they may qualify to be quarterly or even yearly instalment filers.

7. Have a back-up plan

Cash is the lifeblood of any business and matters more than earnings in a tough economy. Here are some important steps to take to maximize your cash flow.

1. Implement cash flow budgeting and management

When you first start a business, cash is usually very scarce and most people are forced to either live within their means or fail. Being in survival mode can be helpful if you maintain the same mentality as your business profits grow.

Promote credit card payment or cash payment discount at the time the order is placed. If clients are always asking for terms, get their credit card number as security for payment.

3. Continue to slash costs where possible

Tough economic conditions with falling sales volumes require costcutting measures wherever possible. When sales volumes are expected to decline, costs need to be closely monitored. Reduce spending on items that can easily be cut without affecting

Correction: Bakers Journal ran the incorrect photo of Sloan Levett with July’s Business Advisor column.

Always include a cash reserve as part of your cash management plan. Plans can sometimes take a negative path, and if a strategy is not in place for such emergencies, the business will be put under significant stress. Consider keeping some low-interest-rate credit cards with zero balances. However, be sure to keep the balance zero in non-emergencies.

If you are concerned about the viability of your business, remember that without sufficient cash flow, even a needed financial restructuring cannot be implemented. Many businesses end up closing down or filing for bankruptcy as they did not have the cash flow resources to go through a restructuring process that takes time while the business continues to operate. / BJ

David Filice is a senior vice-president and partner in the restructuring and insolvency practice of Fuller Landau LLP, Chartered Accountants and Business Advisors. Contact him by calling 416-645-6506 or e-mailing dfilice@fullerlandau.com

In June, the Provincial and Territorial Health Ministers released a report entitled “Reducing the Sodium Intake of Canadians”. The report is in response to what the provinces and territories see as a lack of leadership by the federal government on the sodium file, particularly the lack of a formal monitoring of sodium in the food supply. The Provincial/Territorial report echoes many of the themes of the National Sodium Working Group’s recommendations for a voluntary approach with a focus on implementation at the provincial levels.

In particular the Provincial/Territorial report recommends:

• developing consistent healthy food guidelines and nutriton criteria for the sale, serving and marketing of foods in publicly funded places by March 2013

• continuing to collaborate with the restaurant and food services industry and others to reduce sodium in foods and beverages and explore using B.C.'s Informed Dining program as a model for nutrition information by March 2013

• asking the food industry to join governments in publicly committing to the 2016 reduction goal

• encouraging the food industry and others to use

sodium reduction messages from the report in healthy living and nutrition information and activities to increase public awareness

• continuing to share evaluation results and, by fall, establish an expert-based committee to oversee the development of consistent evaluation standards and practices in evaluation

• providing a forum by fall 2012 to discuss monitoring and evaluation and identifying options to monitor sodium reduction in the food supply

To date the provinces of BC, AB, MN, NS and NB have released the report separately with acknowledgment of their individual support.

BAC continues to consult with Health Canada regarding the overall sodium reduction issue. This consultation included submitting a study early this year demonstrating substantial reduction in overall sodium used in the production of pantry breads. While breads and other baked goods are acknowledged to have relatively low sodium levels, the volume of daily consumption has resulted in them being identified as the food category contributing the largest percentage of sodium to the diet.

The revised allergen labelling regulation that came into effect in August may have the unintended consequence of broadly expanding precautionary statements and further confusing consumers. The Canadian National Millers Association and other food industry associations including BAC have been expressing concern to Health Canada that one of the results of the allergen regulations will be to require flour millers to apply precautionary statements regarding the potential content of soy and mustard in wheat flour. The co-mingling of grains and oilseed is unavoidable in Canada’s grain production, handling and transportation systems. This unavoidable comingling is recognized in Canada’s wheat grading system which allows for low level tolerances for such things as soy and mustard. The milling process cannot completely remove such low level presence and therefore has been permissible for decades under

the Canada Grains Act.

The application of a precautionary statement for soy and mustard on wheat flour will in turn most certainly require flour users to apply such statements to their own products. While Health Canada endorses the use of precautionary statements there is food industry concern regarding the value to allergic consumers that these statements would provide.

BAC has expressed its own concern to Health Canada on behalf of bakers on what it sees is a dramatic extension of precautionary labelling which in turn would trigger questions and confusion with all consumers. Health Canada has proposed undertaking an industry/health professional consultation to review this matter and assess the perspectives of these groups on the implications to allergic consumers. BAC is supporting the consultation which is anticipated to occur this fall.

After a wide consultation that included BAC, Health Canada has provided its position relating to gluten free claims that now provide a tolerance of 20ppm for cross contamination. The policy is in response to the revised allergen labelling regulations that went into effect on August 12 which had a zero tolerance for such claims, yet recent medical evidence indicated a minimum tolerance of 20ppm would be acceptable to those with celiac disease and gluten intolerance. The gluten tolerance level of 20ppm is supported by the Canadian Celiac Association. The tolerance level does not apply when low levels of gluten are intentionally present. The following are extracts from Health Canada’s notice and the full document may be found through the link provided.

“Based on the available scientific evidence, Health Canada considers that gluten-free foods, prepared under good manufacturing practices, which contain levels of gluten not

After seven years from when it was originally proposed, Health Canada has finally released its decision not to approve a health claim for whole grains and coronary heart disease. According to Health Canada’s website “…the evidence to date from clinical trials and prospective cohort studies was not sufficient to support a whole grains and coronary heart disease risk reduction claim in Canada”. As a result Health Canada concluded that a whole grain and coronary heart disease health claim would be misleading if applied to grains that are not high in betaglucan fibre.

Health Canada, however, does continue to support the consumption of whole grains as they offer many nutrients important for health, including fibre, vitamins, minerals and trace elements.

exceeding 20 ppm as a result of cross-contamination, meet the health and safety intent of B.24.018 when a gluten-free claim is made.

“Based on the enhanced labelling regulations for allergens and gluten sources, any intentionally added gluten sources, even at low levels (e.g. wheat flour as a component in a seasoning mixture which makes up a small proportion of the final food), must be declared either in the list of ingredients or in a ‘Contains’ statement. In these cases, a gluten-free claim would be considered false and misleading. If, however, a manufacturer using a cereal-derived ingredient includes additional processing steps which are demonstrated to be effective in removing gluten, then the food may be represented as gluten-free.”

8 www.hc-sc.gc.ca/fn-an/securit/allerg/cel-coe/glutenposition-eng.php

The US Federal Register for 1 August 2012 included an announcement of FDA's domestic and foreign rates for facility re-inspections and other activities related to FSMA. The announcement provides the methodology used to calculate the fee rates. It is likely that these rates would also be used to calculate the costs for FDA inspections of foreign firms.

More information can be found at: 8 www.regulations. gov/?source=govdelivery#!documentDetail;D=FDA2012-N-0799-0001

Re-registration to start in october:

The first period for registration will open on 1 October 2012 and close on 31 December 2012. Canadian facilities covered by FSMA should begin preparations for re-registration. Guidance on the new requirements and the process can be found on FDA’s Food Facility Registration web page: 8 www.fda.gov/ Food/FoodDefense/Bioterrorism/FoodFacilityRegistration/ default.htm and for online registration at: 8 www.fda. gov/Food/GuidanceComplianceRegulatoryInformation/ RegistrationofFoodFacilities/OnlineRegistration/default.htm

Produced by:

Christine Best Bakery Technology Unit II

Adam Hatim Operating A Successful Bakery

Samantha Nalin

Nuwarapaksha Food Hazard Control: Sanitation

Judy Ngo Bakery Technology Unit I

Kelly Swanson........................... Bakery Technology Unit I & Unit II

Linda LoFaro Bakery Technology Unit I

Lennard TenHove Bakery Technology Unit I & Unit II

Clark Adams Certified Bakery Specialist

Diploma

For information on correspondence courses for baking industry employees and the Certified Bakery Specialist (CBS) program, please contact ext. 21 at the BAC office or check out our website at www.baking.ca.

your year in sales your store buzz with excitement something distinctive a positive impact on the bottom line your customers happy a name for yourself

By M ARIO F ORTIN

There are many kinds of cinnamon. What type of cinnamon is the most suitable for a bakery?

Cinnamon is used to flavour several bakery products, such as bread, raisin bagels, brioches, doughnuts, Danishes, cakes, biscuits, tarts…the sky’s the limit for cinnamon and its uses.

Cinnamon is one of the most well-known spices. We can read of its existence in the oldest treaty of Chinese botany dating back to 2500 BC. This spice is used to do everything from cook food to make marinades and even pharmaceutical products.

Cinnamon is dried bark from the cinnamon tree, which is in the same family as the laurel and the avocado tree. We obtain cinnamon by cutting small branches from a three-year-old tree. As it dries, the bark winds itself, creating the sticks of crisp cinnamon we commonly see. There are many varieties of cinnamon trees with differing aroma properties but the two most marketed are the Ceylon and the tree of China (called also cassia).

}American market. We find this cinnamon under three names: Batavia, Saigon and Korintje.

The cinnamon tree of Ceylon is cultivated particularly in India, in Seychelles, in Jamaica, in South America and in Madagascar. Its slender, smooth and fine bark is a light matte brown and the most aromatic of all. The paler cinnamon is, the better its quality. This is the cinnamon of Ceylon. We also find it used in essential oils.

There is no specification to meet the various uses that we make with cinnamon. However, Table A gives some indications of American standards for content.

The Canadian Food Inspection Agency recommends the following specifications: 2% maximum of insoluble ash, 6% of total ash, 13% maximum of humidity and 1.2%

Leaving cinnamon exposed to ambient air will cause a loss of flavour and aroma. Cinnamon lasts a year or more if it is stored in good conditions.

minimum of volatile oil. The higher the percentage of volatile oil, the better the quality of cinnamon.

In the case of brioche, cinnamon is added to the dough before it is rolled, to minimize damage to the yeast.

brioche, the cinnamon is added to the dough before being rolled, causing less fatal effect.

The cinnamon tree of China has a flavour stronger and pricklier than that of the cinnamon tree of Ceylon. This sort is found in the wild state in Indochina and is cultivated in Indonesia and in Asia. It costs less and occupies almost all of the North

Store cinnamon in a hermetic bowl, shielded from light and humidity. Leaving cinnamon exposed to ambient air will cause a loss of flavour and aroma. Cinnamon lasts a year or more if it is stored in good conditions.

For fermented bakery products, Korintje cinnamon brings a good efficiency and causes less damage in the yeast than other varieties when it is mixed in the dough. In the case of

Table A

As for the difference in taste, nothing is better than trying the various types in your products to find out what is most popular. There are also some modified products in the flavour of cinnamon, such the flakes of fat of cinnamon and the nuggets of cinnamon. These mix well into the dough to leave a mark of cinnamon in the crumb after the cooking. The labelling of these products will have to include all of the ingredients according to the data sheet of the supplier. When used in some products, it may be declared as “spice”; however, in certain other products, such as brioche, it is better to be more specific and declare it “cinnamon.”

When we use some ground cinnamon, it may be declared as “spice”; however, if the product is a brioche, it is better to be more specific and declare it “cinnamon.”

The department of research and development of BSA INC, importer and transformer of spices, supplied the technical information for this article. Many thanks to Nathalie and MarieJosée. / BJ

Mario Fortin is an international bakery consultant and owner of FORMA-LAB, consulting services to Bakers and Suppliers. If you need technical information, send your question to info @forma-lab.com.

By lAURA AIkEn

Bakers Journal touched down in New Orleans this June for a few days of culinary delight for the 48th International Dairy Deli Bakery Association’s (IDDBA) show.

The IDDBA’s Dairy-Deli-Bake ran June 10-12 in the immense and extremely well airconditioned Ernest N. Morial Convention Center. Inside the show, aisle after aisle showcased a bevy of what’s trendy for the

tongue and timely in technology. In a theatre above the show, people had the opportunity to hear everyone from comedian John Pinette to politician Sarah Palin.

Here’s a roundup of our favourite moments at the show.

One of the first nifty things to catch our eye was Mr. Kipling’s single-serve cakes. These lemon or vanilla flavoured cakes are packaged in

Bakers Journal tried delightful doughnut muffins at HannahMax Baking.

individually wrapped slices, providing the ideal amount to satisfy a cake craving. The U.K. product is set to hit U.S. shelves in September, says Rupesh Patel, vice-president of sales for Protrade, who manages U.S. exports for Mr. Kipling. Patel says eyes are set on Canada and talks are on with a major grocery chain. HannahMax Baking served up nifty doughnut muffins. Billed as a “freshly baked cake doughnut, with a hint of

nutmeg, dipped in sweet warm butter and tossed in cinnamon and cane sugar,” these sweets simply melt in your mouth. HannahMax also introduced their Cookie Chips at the show, which are designed to taste like a cookie but eat like a chip. They were a pretty tasty novel concept too.

At the Qzina Institute of Chocolate and Pastry booth, Bakers Journal sampled a yogurt mousse, another interesting concept that

turned out to have a lovely light and summery texture.

Canadian based Create-a-Treat showed off a new Giant Gingerbread Man kit, which looked like all sorts of festive fun. Italian Home Bakery, part of the Toronto community since 1955, was on hand to sample their new stuffed bread bites. Delicious!

Ever progressive ACE Bakery showed us their new resealable packaging for fresh baguettes.

Over at Satin Ice, we saw the new retail packs designed for bakeries or grocery to sell to their customers, officially endorsed by the Cake Boss himself. Buddy Valastro was a fixture for photo ops at the show. He wasn’t the only celebrity, however; Bakers Journal’s national sales manager Stephanie Jewell snuck in for a snap with Paula Deen at the Springer Martin Farms booth.

The IDDBA highlighted some of the hot trends for us in the event’s Show & Sell Centre. In the United States, the new normal is how consumers define value and they want transparency. Retailers and their customers are into repurposing products to take sustainability to the next level. People are still buying pricey items but they are quieter about their purchases in deference to less wealthy friends or family. Experiential shopping is heading in the direction of “unservice,” where customers make it, bake it, wrap it, weigh it, etc., themselves.

Carol L. Christison, executive director of the IDDBA, summarized many key trends in her seminar Leading the Food Parade: Consumers, Trends and New Products. Aside from emphasizing our increasingly digital world, Christison highlighted some

interesting phenomena in the food world.

The American Culinary Federation’s surveyed 1,791 of its members for top trends. Here are the top five: Locally sourced meats and seafood, locally grown produce, healthful kids’ meals, hyper-local sourcing (restaurant gardens) and sustainability (full list available on www.iddba.org).

The newest trend in food trucks is

PUB_BAKER JOURNAL_JUIN_Mise en page 2 12-06-27 13:53 Page1

cocktail trucks, although Chrisison noted the Food Truck Association had a 70 per cent drop in membership this year. She noted that Starbucks used four shipping containers to create a mobile store and has applied for LEED certification; and that 7 to 9 a.m. is the new Happy Hour, with free coffee and two-for-one breakfast promos. Around the world, she pointed to the

The Opportunity with Lallemand yeast Bread - a daily source of vitamin D spread the news

All Lallemand yeasts (Eagle®, Lallemand®, Instafer m®) are non-fortified and vegetarian sources of vitamin D that can enhance the vitamin D content of baked goods. Bread can now be a natural source of vitamin D, with no impact on taste!

expansion in various parts of the globe of subway/train station food kiosks. In her handout, she referenced marketing giant J. Walter Thompson’s 100 Things to Watch (complete list at www.jwt.com). Among them, antique eats and all things Heirloom, curbing food waste, screen dining and shopping (think self-order kiosks) and a reduction in mega-size/bulk products.

Speakers who’ve experienced controversy

generally hook folks into attending. The IDDBA found two interesting stories in inviting Sarah Palin and Paula Deen to be part of their lineup for 2012.

Paula Deen talked more about her life than about food. Her 20-year struggle with agoraphobia, the moment her life changed when she accepted the truth in the Serenity Prayer, having a gun held to her head in a bank robbery, praying for years for a neighbour to love and eventually meeting her husband, who was her nieghbour. Deen

started her career in food as the “bag lady” making bag lunches and having her children deliver them.

“Food is that wonderful vehicle that can get us in situations we want to be in,” said Deen of her primary desire to bring people and families back to the table. Food puts people in the room together, she added.

Deen took flak in the media for waiting three years to announce that she had Type 2 diabetes while still promoting her high-fat southern style of cooking. Further criticism was triggered by her simultaneous announcement that she also would be a paid spokesperson for drug maker Novo Nordisk’s Victoza, which prompted many to wonder why she appeared to wait until she had a paying endorsement before revealing her diagnosis, reported CBS News.

Sarah Palin, Tea Party promoter, and former vice-presidential running mate, is no stranger to controversy and opinion. Perhaps it is no surprise that her speech centred on determination, tenacity, and having the ability to ignore your naysayers and carry on.

“Life comes down to how we react to less than ideal circumstances,” said Palin. “Even the best runners get tired and real inner strength shows when no one’s cheering you on, on the thankless lonely miles…there is great joy in finding out what you’re made of.” / BJ

There were plenty of Canadian companies exhibiting at this year’s show. Here’s who made the trip to New Orleans:

From Ontario: Enjay Converters, Summer Fresh Salads, ACE Bakery, Create-A-Treat, Garavogue, Cube Plastics, Elite Sweets Brands, Enfold Packaging Innovations, Give and Go Prepared Foods, Haliburton International Foods, Handi Foods, Lockwood Manufacturing, Nafta Foods and Packaging, Oakrun Farm Bakery, Ozery Bakery, Prime Pastries, Starr Culinary Delights, Strubs Food, Tiffany Gate Foods

From Quebec: Agri-Food Export Group, Expresco Foods, Fountain of Health, La Petite Bretonne, O’Sole Mio, Saputo Bakery, St-Methode Bakery

From British Columbia: Country Prime Meats, Gourmet Baker, Nana’s Kitchen & Hot Sauces, The Original Cakerie, Unifiller Systems

From thermometers to cupcakes, Bakers Journal keeps you “in the know.” FOR MORE on new products for the baking industry, check out our website, www.bakersjournal.com.

Brandy baskets now available from in2food

With a rich, golden colour and sweet maple flavour, in2food’s new brandy baskets are a foundation for fresh fruit or ice cream

desserts. Brandy baskets are in stock now and available in three sizes. For more details, visit www.in2food.com

LeMatic’s palletizing system receives

stacks of loaded baskets and holds them in a queue until needed. Then, the single basket stack indexes into a stack transfer conveyor, which gently loads it onto a rotating pallet table where a distribution pallet receives it. After receiving each stack of baskets, the pallet table rotates to receive the next stack until it is full. Once loaded, the stacked pallet is transferred into a pallet wrapper, which quickly wraps the basket stack tightly and they are ready for distribution. The entire process is run by one control system for unified and easy operation. www.lematic.com

The model K30-1FT-SS sifter from Kason Corporation minimizes height requirements while increasing screening capacity. The sifter employs two unbalanced-weight gyratory motors mounted on opposing exterior sidewalls of the unit, instead of one motor positioned beneath the screening chamber, significantly reducing overall height. www.kason.com

Enjay Converters Ltd. has added OneWay disposable piping bags into its bakery packaging line of products. Enjay became the exclusive Canadian distributor of OneWay bags on May 31. www.enjay.com

Manufacturing’s patented steel can trough and return idlers include two tapered roller bearings in each hub (four per idler). Elite Rollers are available in several diameters and are available for belt widths of 18 inches to 96 inches, with an optional polyurethane coating. Made with universal shafts, the products fit any manufacturer’s brackets. www.eliterollermanufacturing.com

By D IANE Ch IASSON

Eight easy ways to make more money with a better back-toschool marketing plan

Even when summer has just begun, it is time for your bakery operation to start planning for the back-toschool season. September is generally a very busy time, especially for families who have just returned home from holidays, or are busy shopping, stocking up on new clothes, school supplies and other things. Take advantage of these busy times by helping families ease back into school life with healthy, convenient products, good deals and liaising with schools to help your community.

lIST flyER

}Back to school means parents must get back into the habit of packing lunches for their kids everyday. Create a clever marketing campaign with a flyer that features a menu and shopping list of all the items necessary from your bakery to fill a week’s worth of lunches including bread, cheese and deli (if you sell), and cookies and bars for snacks.

Twists, etc. Make one for savoury treats and one for sweet treats.

Some parents of older children and teenagers prefer to give their kids lunch money instead of packing them a lunch every day, so entice these cash-rich students to purchase their lunch from your bakery by offering a student lunch special that includes a sandwich, drink and treat for a reasonable price.

Attract high school and college students by engaging in social media and mobile texting. Today’s youth are glued to their smartphones, so send out deals and text blasts/messages an hour before the lunch bell, offer check-ins for prizes, and use Twitter to notify

Work together with local retailers to create a back-to-school promotion that will help families save on food and on necessary items for back-to-school.

your followers of specials of the day.

Parents are always on the lookout for healthy and convenient items to pack in their children’s lunch bags. Create a marketing campaign around your bakery products such as pizza buns, ham and cheese croissants, spinach and cheese croissants, and other items that are suitable and easy to pack. Advertise the health benefits and convenience.

Create a package that includes five different treats – all packaged and ready to go – that parents can easily and mindlessly slip into their kids’ lunch bags each morning. Name each treat with the day of the week – for example Monday Macaroons, Tuesday

Schools always send home an information package to each and every family at the beginning of the school year. Many of these packages include coupons for various activities, lessons, clubs or restaurants. Ask if the school can include coupons for your bakery, and offer a donation in return.