By LaU ra aI ke N

By LaU ra aI ke N

Over time, your contribution to the baking industry may become more about knowledge than product. For some careers, the final give-back is measured in degrees of inspiration. Just as people breed other people to survive, so bakers must also breed other bakers. Luring the next generation is critical to tackling the labour shortage faced by the foodservice industry as a whole. There are things we can all do. Fortunately, popular culture has been on our side.

At times, reality television has made a mockery of the human intellect (certain Fox programs come to mind), but the baking industry is lucky to lay claim to some of its stars. Shows like Cake Boss and Cupcake Girls have surely helped generate more interest in baking, pastry and chocolate arts. However, inspiring others to make the decision to step into a career is only the first milestone to surviving and thriving. It’s pretty tough to get far without support and mentors. There is nary a success speech without someone to thank. For all the joy your bakery can bring you, some of the purest may be in fostering the love of it in your own staff.

As business owners, you place an incredible amount of trust in your staff. I imagine, for a new entrepreneur, the first couple of hires are among the most nerve-wracking steps to take. The fear of losing trade secrets to an employee who may one day leave and become your competition is a normal feeling to have. But the more success you achieve, the stronger the desire to mentor others can be.

Fortunately, it’s not only pop culture fanning the flames of baking interest. There are many great bakers across Canada whose love of the craft filters through their staff, customers and community. There are many leading artisans teaching others the tricks of their trade. Programs dedicated to baking are proliferating from coast to coast. But we shouldn’t be content with this attention. We still have a very real labour shortage on our hands.

}one simple way to inspire others is to let your passion be infectious. People who love what they do are contagious. Bakers have a lot to be proud about, supplying staples of sustenance and pleasure.

How much focus do you give to your staff? Do you create an environment of flexibility, creativity and innovation? Do you want your staff to succeed as much as you want yourself and your company to succeed? Giving back comes back. What you put in is what you get out. There is no shortage of old adages to point tgo the benefit of taking the scary leap in giving freely of yourself, hoping not to be taken advantage of, ripped off or generally betrayed. The truth is that this will probably happen at some point, even with good common sense and the protection of proprietary information in place. But we must hold close the conviction that the good will outweigh the bad, and remember that we learn from the negative experiences we have.

One simple way to inspire others is to let your passion be infectious. People who love what they do are contagious. Bakers have a lot to be proud about, supplying staples of sustenance and pleasure. If you have found yourself caught up in the grind, perhaps take a moment to reflect on what more you can do for your staff, who will pay you back tenfold in productivity and retention. Make your operation about the people over the product and the product will grow more than you ever dreamed. / BJ

AUGUST/SEPTEMBER 2011 | Vol. 71, no. 7

Editor | laura Aiken editor@bakersjournal.com

416-522-1595

1-888-599-2228 ext. 250

assistant Editor | Brandi Cowen bcowen@bakersjournal.com 1-888-599-2228 ext. 278

tEChniCal

Editor | John McColl, Puratos Canada jmccoll@puratos.com

national advErtising ManagEr | Stephanie Jewell sjewell@annexweb.com 705-826-2254

1-888-599-2228 ext. 268

salEs assistant | Barb Comer bcomer@annexweb.com 519-429-5176 1-888-599-2228 ext. 235

produCtion artist | kelli kramer

group publishEr | Martin McAnulty mmcanulty@annexweb.com

prEsidEnt | Mike fredericks mfredericks@annexweb.com

Mailing address p o box 530, 105 donly dr. s., simcoe, on n3y 4n5

publiCation Mail agrEEMEnt no. 40065710. rEturn undElivErablE Canadian addrEssEs to: CirCulation dEpartMEnt, p o box 530, siMCoE on n3y 4n5 e-mail: lmorrison@annexweb.com

ISSn 0005-4097

published ten times per year (Jan/Feb, Mar, apr, May, Jun, Jul, aug/sept, oct, nov, dec) by annex publishing & printing inc.

SUBSCRIPTIon RATES

Canada — 1 year $ 30.00 (with gst $31.50 #867172652rt0001, with hst/ Qst $33.90) usa — 1 year $ 45.00 usd best pricing is available online at www. bakersjournal.com

Send your subscription request to: bakers Journal p o box 530, simcoe, on n3y 4n5 tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940

E-mail: lmorrison@annexweb.com

occasionally, bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. if you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. opinions expressed in this magazine are not necessarily those of the editor or the publisher. no liability is assumed for errors or omissions. all advertising is subject to the publisher’s approval. such approval does not imply any endorsement of the products or services advertised. publisher reserves the right to refuse advertising that does not meet the standards of the publication.

no part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2011 annex publishing & printing inc. all rights reserved. printed in Canada.

$3,500

Edmonton – Twenty-four bakers from three provinces came together to learn from the masters at the second annual NAIT Bakes workshop.

Master Baker Ciril Hitz, a baking and pastry instructor at Johnson and Wales University, and renowned baker Didier Rosada, a certified French master baker and former head instructor for the San Francisco Baking Institute, were the featured instructors at this year’s NAIT Bakes, which ran June 7 to 10 at the Northern Alberta Institute of Technology (NAIT) in Edmonton.

“Once you’ve attained your journeyman’s certificate, there are still further professional development opportunities available for you,” said Alan Dumonceaux, organizer of NAIT Bakes and chair of the school’s baking program. “We want to make those available for the Canadian baking industry.”

Dumonceaux said his goal is to seek out the best bakers in North America to lead the workshops, which students rotate through over the course of four days.

mysteries of sourdough cultures. This was Rosada’s second time at NAIT Bakes. In 2010, he led a session called Artisan Breads at their Best.

Hitz’s Laminating with Flair workshop taught Viennoiserie techniques for making delicate and flaky breakfast pastries.

Hitz says he looks forward to professional development workshops like NAIT Bakes not only for the opportunity to teach others, but also for the chance to learn new tricks himself.

“For me, it’s a continuous challenge in regards to working with different ingredients you may not be used to,” Hitz said. “The flour may seem like the same white stuff you would get (south of the border) . . . but it’s very different than what we use on a regular basis back in the States.”

“You have to be flexible and adaptive to your environment, like an animal going to different parts of the world. You have to really adapt to it.”

NAIT Bakes was hosted by NAIT’s School of Hospitality and Culinary Arts program. – Frank landry/nait briefly | No break on food prices | Ottawa gives pulse industry a boost | Time to end the war on salt? | for more news in the baking world, check out our website, www.bakersjournal.com

Victoria – The Baking Association of Canada’s B.C. chapter donated a $3,500 bursary in memory of Patsy Frederick, a longtime baker and bakery owner on Vancouver Island.

Frederick started baking in Victoria in the late 1970s. She used her talents to start the Peoples’ Share Collective Bakery, which later morphed into Rising Star Wholefoods Bakery.

She exported her talents to Australia and a few years later returned to Victoria and opened her own Rising Star in Fairfield Village.

During this time she employed many young people, training them in the trade and supporting them to become fine bakers.

Her peasant bread with dates and her cinnamon buns are legendary, but it is her dedication to hard work and the way she stood up for what she believed in that will live on.

Frederick was born in Saskatchewan in 1955. She passed away in January.

The Patsy Frederick bursary will be awarded to baking students at Vancouver Island University over the next seven years.

– Martin b arnett

In this year’s All About Sourdoughs workshop, Rosada unravelled the

From case packers to glove systems, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

The Clean Hands glove system is designed to prevent cross-contamination in the kitchen. A magnetic band holds the glove on the docking station, allowing users to slip the glove on without touching it. When it’s time to remove the glove, that magnetic band holds the glove in place, allowing you to remove the glove and free your hands. The Clean Hands system is produced in accordance with ISO 14001 and is Hazard Analysis Critical Control Points (HACCP) approved. www.cleanhands.it

The Stackable Cupcake Stand by Fiesta Cupcakes is a new acrylic cupcake display that requires no glue or screws for assembly.

The five tier stand breaks down so each tier can be used separately or assembled to height as needed. Made of a high quality 3/16th” acrylic, each tier measures (from top to bottom) 7” /10” /13” /16” /20” and holds about 100 to 120 regular cupcakes or 210 to 215 mini cupcakes.

Stands are laser cut, available in a variety of colours (including clear acrylic) and manufactured in Canada. For more information visit www.fiestacupcakes.com or email Norman Katz at info@fiestacupcakes.com.

Panifrance Parisian macarons feature two meringue-like cookies with a crunchy exterior and a moist interior, sandwiched together with ganache or fruit filling. Panifrance Parisian macarons are imported frozen from France. They are available from distributors across Canada in trays of 36 or 72. www.gastronomia.ca.

Here’s a highlight of recent events making headlines around the world.

U.k.: A new printing technology can make personalized, 3-D chocolates. Researchers from the University of Exeter and University of Brunel produced the printer and interface software that can manufacture 3-D chocolate objects in partnership with software developer Delcam.

EU: The 27 member states of the European Union backed the safety of the natural, intense sweetener steviol glycoside (Stevia) at a recent European Commission

Schneider Packaging Equipment Co.’s WCP-35 is a side loading, stainless steel, five-panel wraparound case packer with 90 degree discharge. The packer loads product onto the blanks, then forms and seals the flaps around the product before the case enters the flap detection system to ensure all sealing is completed. The case packer magazine can hold twice as many wraparound case blanks as standard cases. www.schneiderequip.com

Caravan Ingredients introduces the Invisible Goodness Natural Base, a new base for single serve, yeast raised bakery items. Invisible Goodness Natural Base is also offered in a concentrate to accommodate a range of manufacturing setups. It is designed to produce an end product with a 21-day post-bake shelf life at ambient temperature. www.caravaningredients.com

(EC) committee meeting. This could put products containing stevia on shelves in 2012, reported www.foodnavigator.com.

Camden, new Jersey: Cambell Soup Company has announced that they’re putting some salt back in some of their soups, a u-turn on previous sodium reduction efforts.

Chicago: When consumers taste a chocolate bar they think is made in Switzerland, they prefer it over one supposedly made in China, according to a study in the Journal of Consumer Research.

Verona, Italy: The Italian Federation of bakers, confectioners and related trades will be bringing the 10th International Bakery, Pastry, Confectionery, Pasta and Pizza Exhibition back in 2013.

Zurich, Switzerland: Barry Callebaut has signed the sale of its European consumer business, Stollwerck, to the Belgian Baronie Group.

Wormer, netherlands: Cargill is expanding its farmer training program to support cocoa producers in Cameroon, the world’s fourth largest coca producer.

By Dr. Joh N M IC hae LID es

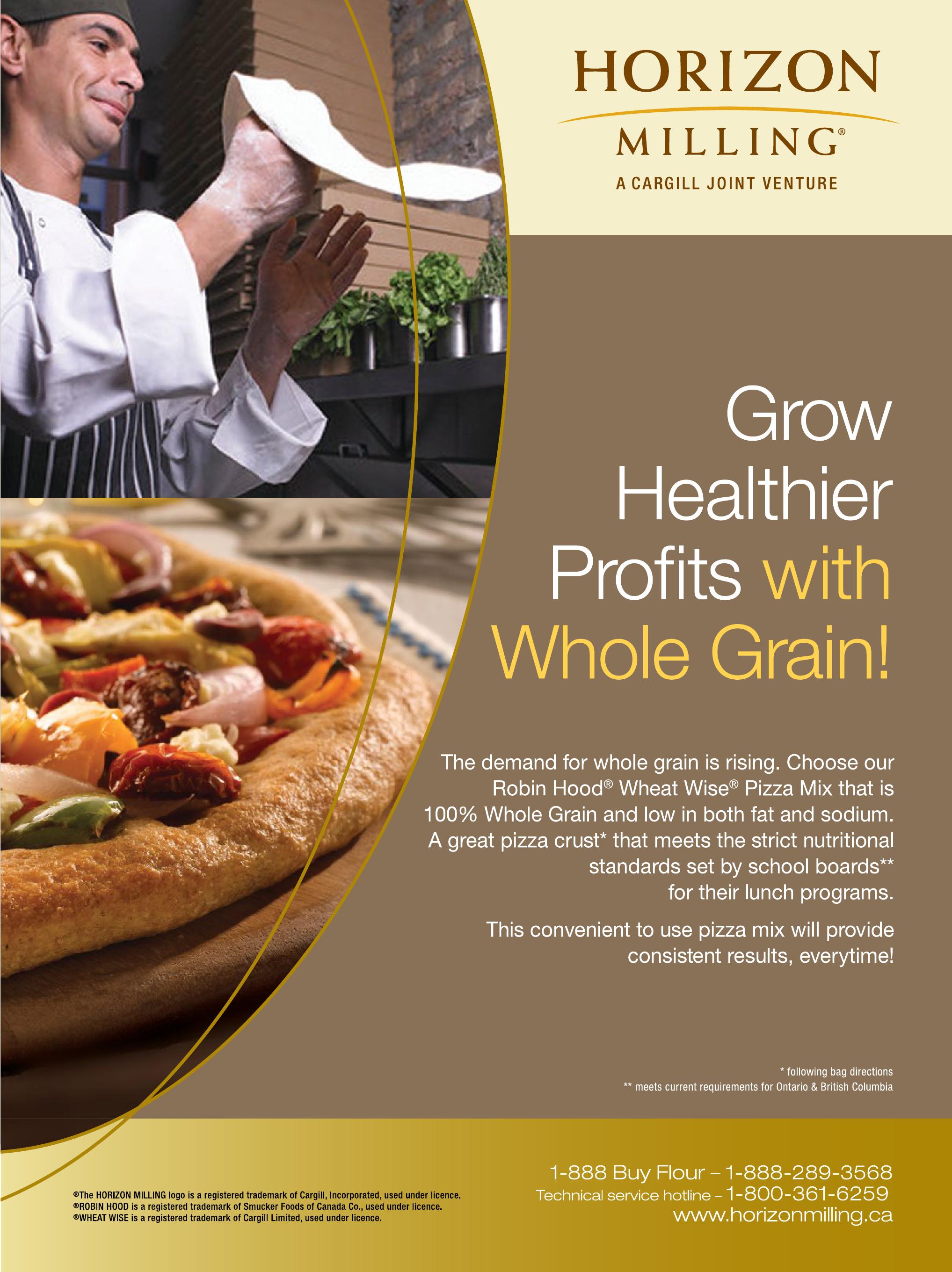

GMOs have gained a bad rap, but they may be the secret to improving food safety

We may not know it, but one or more of the ingredients in many of the foods we eat may be sourced from genetically modified organisms (GMOs). These ingredients are processed from seeds, grains or other parts of plants, or are derived from animals or micro-organisms that have been altered through genetic manipulation.

Classical genetics was based on the work of many great scientists such as Charles Darwin and Gregor Mendel, who discovered hybridization between plants and established the laws governing heredity, or how traits are passed on from generation to generation. These discoveries led to the development of classical breeding techniques that gave us the crops of the industrial revolution, and we have been growing them ever since. Genetic manipulation allowed us to breed many new varieties of wheat, barley, oats, corn and rice, among other crops. These varieties can produce greater yields, be resistant to diseases or offer higher proportions of components such as protein, oil or starch.

}splice them together to develop recombinant DNA (or rDNA) in test tubes. Genetic engineering then transfers rDNA from one organism into another. Today, new technologies and tools allow us to carry out these manipulations more effectively.

The first genetically modified crop developed was the soybean. In 1988, soybeans resistant to the herbicide glyphosate were developed, creating glyphosate-tolerant soybeans. Other genetic modifications to soybeans include nutritional enhancements, such as a gene from the Brazil nut that enables a soybean to produce a higher amount of the amino acid methionine. To date, this variety has not been commercialized due to concern that the allergenic protein from the nut may be transferred to the soybean. Still, more than 70 per cent of the soybeans grown around the world are genetically modified in some way.

The other major crop to undergo

Many ingredients used in the baking industry may originate from GMos. These ingredients can range from flours, proteins, starches and oils, to ingredients such as emulsifiers, gums and enzymes.

The introduction of genetically modified wheat in North America was planned for 2004; however, the application for approval was withdrawn prior to approval. Because both Canada and the United States are major exporters of wheat, introducing this variety will limit available export markets. This would have grave economic implications for both countries.

At present, no commercially grown genetically modified wheat is available in Canada. Australia has allowed field testing of a wheat variety modified to be tolerant to drought. The only genetically modified cereals commercially produced are corn and rice. Neither is used for baking in Europe; however, many secondary ingredients are produced from these cereals.

These crops are very important, given the food supply problems facing many parts of the world. Diverting grains towards biofuels, combined with climate change, is resulting in ingredient and food shortages. In turn, this causes the prices of commodity crops and other foods to rise. Projected population growth in the coming years will exert further pressure on the food supply.

Developing new varieties using classical breeding techniques is, however, a long and tedious procedure and often random rather than specific. But with today’s scientific advancements, we are witnessing the second wave of the agricultural revolution.

This next generation transfers traits more efficiently and develops new varieties through genetic engineering. This engineering is based on James Watson and Francis Crick’s discovery of DNA in the 1950s. The scientific advances that followed have allowed us to transfer DNA material from one species to another, transferring traits from the donor to the recipient species. Enzymes are used to cut and paste certain sequences of DNA and

genetic modification is corn. Genes that enable the plant to produce the Bacillus thuringensis (Bt) protein, which is toxic to insects and certain pests have been added to corn. In the 1990s, this was commercialized in StarLink corn; however, due to regulatory uncertainties surrounding the protein, the StarLink variety has only been approved for use in animal feed. Another Bt corn was developed by DuPont’s Pioneer Hi-Bred International. This variety did not face any regulatory issues and has been approved for use in Canada and the United States.

Developing genetically modified crops has often focused on developing resistance to micro-organisms and fungi. Major research efforts are directed towards resistance to Fusarium infection, which would eliminate vomitoxin and other mycotoxins from wheat flour supplies. Other research efforts to enhance the safety of grains include the introduction of genes to reduce accumulation of toxic heavy metals such as cadmium in durum wheat.

The possibilities for enhancing production of cereals and other crops through genetic engineering are endless. Many ingredients used in the baking industry may originate from GMOs. These ingredients can range from flours, proteins, starches and oils, to ingredients such as emulsifiers, gums and enzymes. Determining if an ingredient is produced from a genetically modified organism is very difficult and testing can be very costly.

Although many are skeptical about its safety implications, genetic engineering provides us with powerful tools to address some of the emerging challenges facing the agriculture and the food supply. GMOs may just be the next agricultural revolution. / BJ

Dr. John Michaelides is an independent food industry consultant to the Guelph Food Technology Centre (GFTC). For more information, or fee-for-service help with product or process development needs, please contact him at 519-821-1246 ext. 5052, by fax at 519-836-1281, by e-mail at jmichaelides@ gftc.ca or j.jmichaelides@gmail.com.

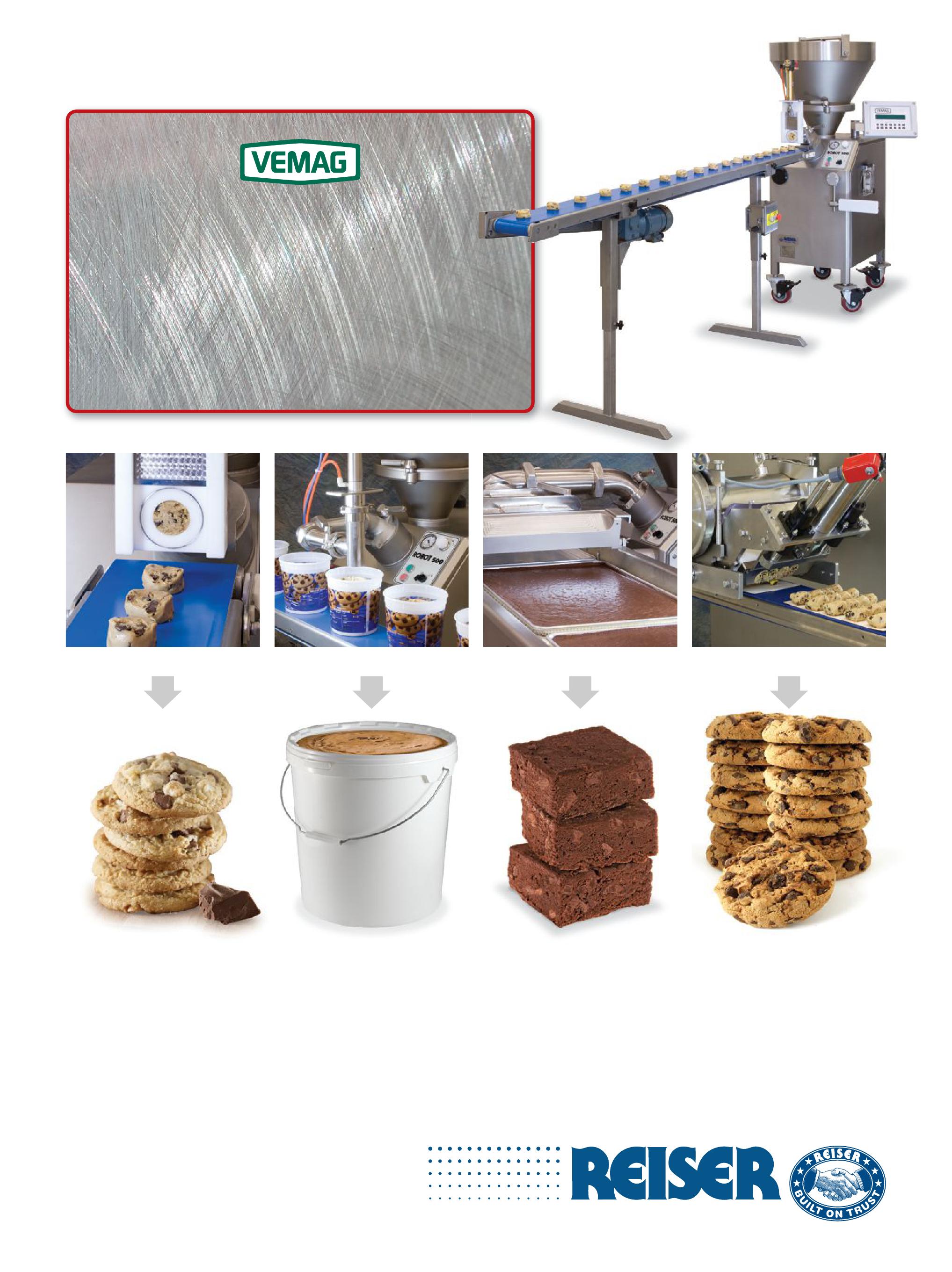

The Vemag 5 00 is an incredibly versatile machine that allows you to easily produce a wide variety of products. The Vemag incorporates a number of innovative attachments that provide you with the flexibility to not only expand your product line, but to react quickly to the ever-changing tastes of your customers Attachments can be swapped out in minutes Use a single-lane Guillotine attachment to produce individual cookie dough portions Change over to a Dripless Valve attachment and use your Vemag 500 to fill tubs with that same cookie dough, or use it to portion fillings into pie shells and tarts, or batter into pans Then change over to a Rotary Sheeter attachment to extrude smooth, uniform sheets of brownie batter And when business takes off and you need higher production volumes, use that same Vemag 500 with our Waterwheel flow divider attachment for multiple-lane production. You’ll find that the versatile Vemag offers the highest levels of portioning accuracy, speed and product quality Let us help you expand your product line and grow your business with the one and only Vemag 500

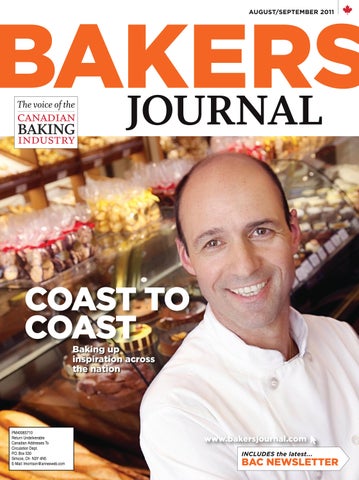

Take a trip from coast to coast with Bakers Journal as we highlight the diversity and success of bakeries across Canada.

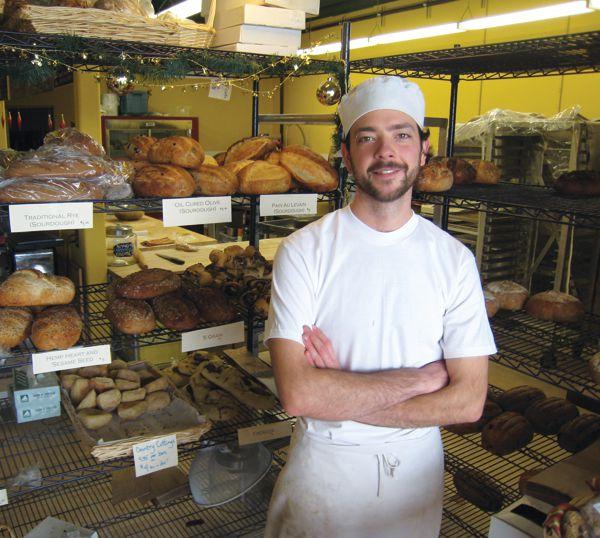

Mark Engels, co-owner and operator with wife Valerie Bubby Rose’s Bakery, Victoria, B.C. www.bubbyrosesbakery.com

With two locations and climbing, Bubby Rose’s Bakery exemplifies giving back to its community. The bakery donates its award winning products to local school fundraisers as well as theatre, arts and environmental groups and various Victoria events. The husband-and-wife team are from Montreal.

What is one of your most memorable moments in the bakery?

Being stopped on the street to be told how valuable we have been as a part of the community.

What are you most proud of when you think of Bubby Rose’s?

Maintaining the integrity of our products by not cutting corners – we use high-quality, natural ingredients, NO chemicals and we make small batches to ensure quality and consistency are as high as we can go!

Paul Larsen, president Elite Bakery, Burnaby, B.C. www.elitebakery.ca

}loyal customers.

We’re near schools so if we can donate anything towards, let’s say, a picnic for the community, we’re always ready for that. Or if some student wants to come in for work experience as far as baking goes, we always have our doors open. We just try to keep our

“obviously as a kid, as a teenager, I didn’t appreciate the knowledge my father was passing down to me. once I had to start running the business myself, I realized how valuable those moments were.”

Elite Bakery has been serving up traditional Danish treats since 1968. Founder Magnus (Mark) Larsen left his hometown of Farvejle, Denmark, and travelled to Canada, bringing along an incredible repertoire of recipes and techniques. He ran the bakery until his death in 1997. At that point, Larsen’s son, Paul, took the reins. Today, Elite Bakery sells delicious Danish products from its storefront, and wholesale, through coffee shops, hotels and major retailers like Ikea.

What’s the secret to staying in business for more than 40 years?

I would say the secret would be a high quality consistent product, a communitybased atmosphere at the business and

bakery alive and well in all the events and activities that are going on in the community. Actually, we look for things to donate our products for and sometimes we don’t even tell them where the products came from.

What is your favourite baking memory?

I think my favourite baking memories are the ones I have of baking with my dad. Obviously as a kid, as a teenager, I didn’t appreciate the knowledge my father was passing down to me. Once I had to start running the business myself, I realized how valuable those moments were. I always remember the little tips he used to tell me. Sometimes I’ll remember something that I heard him say and then I apply it to what I’m doing. When he passed away, I wasn’t working for the

bakery at the time, so I kind of took it for granted that he owned a bakery. I wasn’t even sure I was going to be a baker.

Suat Tuzlak, owner

Alpine Bakery, Whitehorse www.alpinebakery.ca

In 1984, Suat Tuzlak announced he was moving from Calgary to Whitehorse and opening a bakery. His friends were skeptical. They pointed to Calgary’s much larger market, and his support network in the city as reasons to set up shop there instead. But Tuzlak heeded the call of the north and followed his dream. Twenty-seven years later, Alpine Bakery is still going strong.

What kinds of challenges do you face in operating a bakery so far up north?

It’s a much smaller market. With the workforce, people come and go here and it’s hard to keep them.

There’s an inconsistent market that’s very much weather oriented. If it’s too cold, they won’t come; if it’s too hot, like we’re having now, they won’t come either. There is a strong tourist business, except during the summer locals go to see relatives in big cities. It doesn’t make up the difference. Summers up here are quieter than the rest of the year.

What’s your favourite baking memory?

Coming to Whitehorse from a big city for

Disney Channel presents Disney Princess Movie Marathon Fall 2011

the first time. I knew only one person and was doing something I hadn’t done before. That’s excitement. And of course, it all happened because of coming here to open the bakery.

Friends were wondering, ‘Why not in Calgary? It’s a much bigger market.’ The difficulties I was sharing with you wouldn’t have existed in Calgary. There was a strong market and I knew lots of people. It would have been much easier, but the Yukon’s call was one reason to open it here.

Manuel Latruwe, owner/head baker

Manuel Latruwe Belgian Patisserie and Bread Shop, Calgary http://manuellatruwe.com

This European-style bakery focuses on creating contemporary recipes out of timeless traditions while using high-quality and local ingredients. Manuel Latruwe’s career has taken him to Brussels, Antwerp and France, where he won the Grand prix Internationale de la Patisserie Mandarine Napoleon.

What is your favourite product to bake and why?

Croissants and viennoiserie are my favourite products to make. I love working with the laminated dough, the challenge of the simplicity of the recipe and the complexity of the process that requires a high level of craftsmanship to create that perfect product. Nothing can beat the smell of the perfect croissants and pains au chocolat when they come fresh out of the oven, the crunchiness and satisfaction you experience with the first bite.

What have been the most important factors to your success in preserving your European traditions in Calgary?

The key factors have been my customers and my passion for baking. I have customers who started to come to the store from the first year I opened my bakery in Calgary in 1998 and they still come. I never stop searching for the best ingredients and packaging, improving recipes and training the best employees in order to serve my city the best quality European baking. Sometimes it means a lot of extra hours and persistence. For example, some ingredients and equipment are very hard to find in Canada. My customers pay me back with their appreciation. The best feeling in the

world is when the cashier at Costco reads your name on the membership card and tells you how much their family loves the cake they get for their special family reunions or a couple comes for the wedding photo shoot to your bakery because they had their first date there.

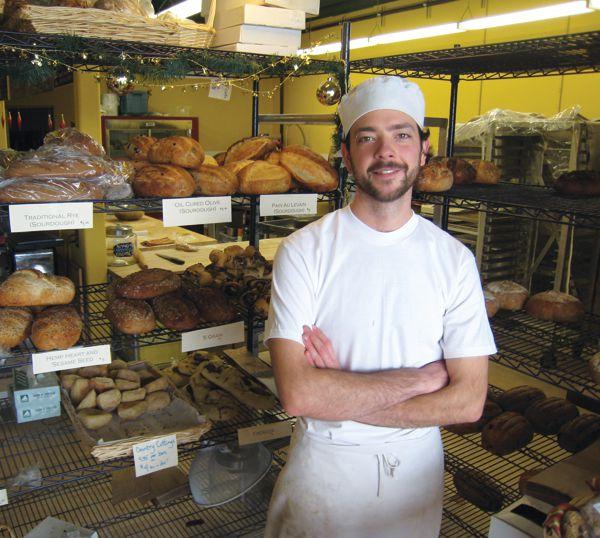

Trent Loewen, owner

Earth Bound Bakery and Delicatessen, Saskatoon earthboundbakery.blogspot.com/

For a bakery located deep in the national breadbasket, working with local grains is a no brainer. Earth Bound Bakery and Delicatessen’s organic breads are all made from Saskatchewan grains, milled by the farmers who grow them.

Why did you decide to open an organic bakery?

Mostly because nobody in the Prairies is really doing it. I got inspired by some local flour producers that I’d known for some time and I just really wanted to use their product, which happened to be organic. It’s value added to the product. Not everybody cares, but those that do care a lot, so as long

as it’s a good product and it’s organic, you’re reaching more customers.

What are your bestselling products?

The bestselling is probably my hemp heart and sesame seed bread. It’s a basic country bread like pain de campagne with a pate fermente, and I just add some toasted natural and black sesame with hemp heart. It’s got a nutty flavour, a taste of sesame and hemp and it looks really nice. The top of it is dipped with the mixture, so there’s the black sesame, the white sesame and then the hemp, which is kind of green. It looks almost like camouflage.

Next is the power bread, which has a lightening bolt on it. It has

lots of what you would call power grains – hemp, quinoa, amaranth and chia seeds. When I made it first, maybe a year and a half ago, I just wanted to make something that had lots of grains in it. I started using all these grains that are high in omega-3 acids and proteins. It just needed something to adorn it and make it look very unique. My baker Jason said, ‘power like lightening?’ so we did that and it just kind of stuck.

Andreas Ingenfeld and Friederike Brandt, owners

The Crusty Bun Bakery and Café, Winnipeg www.crustybun.com

After working in their native Germany, as well as in Switzerland, Great Britain, and Japan, the husband-and-wife team behind The Crusty Bun Bakery and Café decided to bring their European-style baking to Canada. Their artisan breads and baked goods have become staples in their adopted community.

You’ve worked all over the world. Why did you decide to set up shop in Canada?

Ingenfeld: The opportunity here was great because there are so many Germans. We are obviously from Germany, and there was no real German bakery – modern bakery – like this. We decided this would be a really great opportunity for us, with our background in German bread and breakfast and those kinds of things.

What’s your bestselling product?

Ingenfeld: Pumpkin seed buns and pumpkin seed breads are our bestsellers. We have a very busy lunchtime, so we do all our sandwiches with our own bread, obviously, and we do our own soup. Everything is made from scratch – no artificial flavours, colouring or preservatives. It’s old-fashioned baking.

Brandt: And the bestselling cake is the bee sting. It’s a yeast dough with a vanilla cream filling – half vanilla, half whipping cream – and roasted almond with honey, hence the bee sting, on top.

If you were in your own kitchen one afternoon and had all the ingredients to make anything you wanted, what would you bake?

Brandt: Develop a new kind of bread or something?

Ingenfeld: Yeah, that’s probably it. What we try to do is always improve our recipes and also try to create new recipes. It’s really important these days to keep the store interesting to the public.

Chicory root inulin is a rich, soluble fibre that has been cropping up in trendy organic baked snacks, brand name granola bars and yogurts and ice creams, just to name a few. It has little taste and possesses a smooth and creamy texture. Fibre is a pretty big buzzword these days for consumers, recognized for its ability to aid digestion and restore a healthy intestinal balance gof bacteria.

Chicory root’s ability to help achieve that balance is what caught the eye of Shasha Navazesh, CEO of Shasha Co., an artisan bakery in Toronto. Shasha Co. is heavily focused on research and development that strives to make their products healthier while ensugring they can be broken down easily in the digestive system. Chicory root inulin is exactly the type of ingredient Navazesh looks for.

“The inulin is not absorbed through the small intestine, so it passes through to the large intestine where it keeps your flora – the gut bacterium – healthy, and that’s why people are interested in it,” he says.

Adapting existing recipes to include inulin does take some time. The additive reacts differently with various ingredients.

}Navazesh has been working with inulin g for more than three years, and currently uses inulin in Shasgha Co.’s Buckwheat Snacks, a raw product that launched in February.

The chicory plant dates back to ancient Egypt, when it was used to aid in digestive health.

adapting existing recipes to include inulin does take some time. The additive reacts differently with various ingredients.

“It’s a beautiful product as far as fibre and the support of the bacteria in your gut is concerned, but it does have some other functionality in the formulas,” Navazesh says. “It makes things sweeter. It creates crust. It makes things a little drier and it also hags a binding agent, sgo it binds very quickly when you put a liquid to it. It gums. These are a few characteristics, but generally one has to see how it reacts depending on what application

you use it for because it’s very diverse.”

Side-effects associated with chicory root inulin are similar to those of other high-fibre ingredients. These include excessive gassiness and bloating. Although some people dog not experience any side-effects from inulin, others have described flatulent-filled nights in which entire families were sent running for the door.

Dr. Erin Wiley, a member of the Ontario Association of Naturopathic Doctors and co-founder and clinic

director of Toronto’s Integrative Health Institute, explains the science behind soluble fibre’s effect on the body.

“If you are taking a therapeutic dose of fibre, as determined by your naturopathic doctor or health-care provider, it can help with the health of your digestive system. We view the digestive system as an ecosystem or an environment that we are trying to nurture and bring back to health. Every digestive system contains good and bad bacteria and we always want to create a healthy balance.”

A person ingesting tgoo much inulin can experience serious side-effects. “In high doses, you could get bowel disruption, just like you could get bowel

Is it time for your growing business to switch to an enterprise resource planning software system?

Most businesses start managing their financial lives using an off-theshelf accounting system like QuickBooks or Simply Accounting that works well initially. There comes a point when it is time to move beyond an off-the-shelf accounting system and find the right business management tools that will position your company for long-term growth.

Today more than ever, advances in technology and global competition are forcing businesses of all sizes to do everything they can to meet the needs of their customers. Small-business owners, including bakery owners, now have access to new markets that once belonged to large companies. However, a small business has to realize that in order to compete with large companies, it will have to deal with the same challenges and scrutiny that large companies do.

}With all these things to think about, small business owners increasingly are asking an all-important question: Do we need to replace our off-the-shelf accounting program and implement an enterprise resource planning (ERP) business software system?

Typically that’s a tough question for business owners because the common perception is that implementing and maintaining an ERP system is expensive, time consuming and too complex for a family business. However, the good news is that advances in technology have also altered the makeup of ERP systems. These systems now give small businesses the tools they need to compete with larger companies without breaking the bank. An ERP doesn’t have to be taken on with a big bang approach. Some mid-size businesses just don’t have the capital investment for a full-blown ERP system. One

Many small businesses start with the basics and implement additional functionality year after year to ramp up, but also manage the amount of change that occurs with a new system.

Small businesses face many of the same challenges as medium-sized and larger companies, including pressure from competitors; the instability of the economy; the need to attract and retain new customers; and the need to cut costs and increase profitability. They also have other constraints, including limited access to financial resources and higher operating costs. Those that have larger companies for customers and/or suppliers have to adopt electronic data interchange (EDI) or other systems to connect with these enterprises and exchange orders and documents in the appropriate format.

These factors can slow down growth and complicate business processes.

option to consider is building your foundation first. Many small businesses start with the basics and implement additional functionality year after year to ramp up, but also moderate the amount of change that occurs with a new system.

Although implementing a full ERP system has faster payback, your business can also benefit from implementing an ERP system using a phased approach. For instance, phase 1 of the project could incorporate general ledger, accounts payable, accounts receivable, finished goods inventory management, and sales. This type of phase 1 project is less costly to implement, is less intrusive to your business, and gives your business a stronger foundation to build gon.

If you’re thinking about investing in an ERP system, the first thing you should do is clarify your vision and your needs. An ERP system is never about the

technology. You have your own unique characteristics and your own critical success requirements. The question that we ask is how will an ERP system help you achieve your critical success requirements?

Over the years Fuller Landau IT advisory group has guided a number of our food and beverage clients through this complex process. Here are some key questions to keep in mind when you embark on this journey:

• What changes is your business likely to see as it matures?

• What are the key challenges that your business is likely to face during this period?

• How will your customer or supplier base changeg?

• Is it likely that you will be selling to larger companies in this time frame?

• Will you add new operating/ warehousing locations or new retail locations?

• Will you sell to customers in foreign countries?

• Will you sell your products or services via the Internet?

• Will your business purchases expand to include goods from foreign countries?

It’s no secret that as a family-owned and/or small business you have fewer financial resources available for IT projects, and you’re more susceptible to the volatile economy as well as the consequences of flawed business decisions. That means you have to be absolutely sure you are investing in the right ERP system.

Choosing the right ERP business management system for your bakery can be a daunting task, but it should be thought of as a system for life. It can give your business the tools needed to drive faster growth, operate efficiently and deliver greater profitability as you take your business to the next level. / BJ

Vlad Guzenberg is president of the Fuller Landau Information Technology Group in Toronto, which has been recognized for its technology initiatives with several North American and global technology awards. www.fullerlandau.com

Demand for halal products is growing across Canada and around the world | EHSAn SAIRAlly

The world is experiencing tremendous change in terms of consumer gdemographics and market demand for halal foods.

This growing demand presents new market opportunities for food producers and marketers. Canada is a country blessed with an abundance of clean water, clean air and rich agricultural soils. Hence, the country’s agri-food sector has the ability to supply the growing global market with halal-compliant raw materials, ingredients and processed foods, as well as

}halal technology and know-how.

The demand for halal consumer products is rapidly increasing, growing at a rate of 2.9 per cent worldwide each year – greater than the growth rate of the world population. Currently there are approximately 1.6 billion halal consumers around the globe. The current value of the global halal market is estimated at $600 billion per year; the Canadian market

Processors may find that halal compliance requires minimal adjustments to current practices. In fact, many processors –particularly those producing non-meat products – may already be compliant.

pro v e p ro duc t q ual i ty, per fo rm anc e, nutri t io n al v alu e an d pro fi t m argin s Whe th e r yo u a re bu yi n g Bas e I ngred i e nts, i mpro v i ng yo u r pro duc t 's val ue p ro pos it i on or twe aki n g margi ns, trus t De al e rs I ngred i e nts to d e l iv e r re su l ts.

But te r Bu ds

Butter, cre am an d che e se natu ral dai r y c once ntrat e s re du ce f at w hi l e enha nc i ng f lav o ur c harac te ri sti c s a t a lower t ot al co st Im pro ve y ou r pro du ct per fo rm anc e – nat ural l y Citr i- fi

Ci tri - fi offe rs ex ce pt io n al v alu e an d per form an ce b y im pro vi ng m o is ture m an age me n t, r e duc i ng f ats a nd cal o ri e s w hi l e e nh anc i ng tast e a nd t e xtu re It 's a wi n ni ng f o rmu l a fo r yo u an d yo u r co nsu m ers – nat ural l y

P rod uct of t he Un i t ed S ta te s

for halal products is worth an estimated $1 billion per year.

This presents tremendous economic potential for traditional food industry sectors, including the meat, dairy, grain, oilseed, fruit and vegetable sectors, as well as beverage makers.

It also presents opportunities for nutrient supplements, pharmaceutical and cosmetic producers. Halal encompasses all types of foods; it is not restricted to meat products.

These are two Arabic words. Halal means permissible/allowed and haram means prohibited/unlawful. The standards for halal are based on the Holy Qu’ran, the religious book for mankind. Halal originates from the Qu’ran, where it says “O mankind Eat from that which is lawful and pure on earth” (2: 168).

The concepts of halal and haram are extremely important in all spheres of Muslim life, be they moral, spiritual, medical, biological, and all dietary aspects.

Therefore, the halal concept is not applicable to food only. It covers the non-food segment too; for instance, cosmetics, materials, packaging, equipment, sanitation and cleaning solutions.

As a rule of thumb, everything is halal except:

• Alcohol/drugs/intoxicants

• Blood

• Carnivorous animals or birds of prey

• Dead animals (birds that died naturally)

• Swine and its byproducts

• Animals slaughtered without ritual blessing, not mentioning the word God

However, halal is a global concept of food that is “Tayyib,” meaning wholesome, pure, nutritious, and safe. Therefore, the key element that will

OCTOBER 2-4, 2011

RENAISSANCE

drive the halal food concept, is the basic understanding of halal and its implication. This potential market is underserved.

It is generally understood that, because of natural land resource capacity, non-Muslim countries are well poised to address the needs of the expanding global halal market. Canada is a good example of a country that has the resources to address that market. Canada’s advantages in supplying the

global halal market include:

• High agricultural land resource capacity, as well as abundant water and clean air

• Well-developed agriculture and food sectors

• Sustainable production processes

• Established food safety and regulatory systems

• Well-developed infrastructure (i.e., highways and rail lines for transportation)

Good taste has always been our strength.

For 50 years, we’ve redefined the business of supplying fine ingredients to the food industry. How? By representing only foremost Principals. By matching our product-service offering to customers’ supply chains. And by welcoming organizations like ISO and HACCP to verify our operations.

When you make Lomas your partner, we make our success contingent upon yours.

• A reputation as a strategic, reliable trading partner

Halal food production is not complicated. Mainstream food processors in Canada may find that halal compliance requires minimal adjustments to their current practices. In fact, many processors – particularly those dealing in non-meat products – may already be compliant and may need only to be certified.

Certification by a food-sciencebased agency is the key to consumer acceptance of halal foods. Like any other business decision, going halal must satisfy the quality needs of halal consumers as well as the business needs of the producer. It has to be a win-win situation. Certification includes several steps, including submitting a list of your ingredients, having your ingredients, raw materials, processing techniques and sanitation reviewed, and if all goes well and a contract is agreed upon you can be certified and use a recognized symbol that will provide trust and credibility with your customers. Certifications of any kind require dialouge and a diligent commitment, so it is wise to investigate the full breadth of what will be required of your products and systems to earn halal certification. Muslim and non-Muslim consumers worldwide are interested in natural, healthy foods and beverages, as part of a healthy lifestyle. That’s exactly what the halal concept is all about: eat what is good and wholesome for your soul.

The halal food concept focuses on improved nutrition, food safety, healthy lifestyles, eco-friendly products and sustainable production methods. Halal covers all aspects of the food supply chain, from farm to fork.

As the halal market picks up momentum, it will gain recognition as a benchmark for healthy and safe food and production practices. / BJ

Ehsan Sairally is president of Halal Product Development Services. The company provides Halal Certification services and audits for the Canadian agri-food industry, and has expertise in processing, formulation, logistics and market trends, with respect to halal products. For more information, visit www.halalproductservices.com.

BAC has aggressively defended the past and ongoing efforts by Canada’s bakers to improve the nutrition of baked goods in its submission to the Public Health Agency of Canada’s consultation on healthy weights and childhood obesity. The Public Health Agency of Canada is conducting a national consultation on healthy eating and childhood obesity and its results will be presented this fall to a meeting of federal, provincial and territorial health ministers.

BAC is particularly concerned that this consultation will be used to promote a wide range of policy initiatives that could include “fat taxes”, marketing bans, front of pack or “stop light” labelling, regulation of ingredients such as sodium and others, and which would negatively affect bakers of both breads and sweet goods. This initiative could have similar outcomes to those of the U.S. Interagency Working Group on Food Marketed to Children, whose proposed guidelines are so restrictive that they would ban the marketing of bread to children.

For almost 60 years, flour has been enriched with thiamine, riboflavin and niacin. As a result, the incidence of beriberi (thiamin) and pellagra (niacin) were virtually eliminated in North America. These nutrients have also been shown to reduce the rate of strokes in the U.S. and Canada and the addition of iron to flour has helped to decrease the incidence of iron deficiency anemia.

In 1996 Canada’s food industry agreed with Health Canada to the voluntary addition of folic acid to white wheat flour, enriched pasta and

enriched cornmeal as a public health measure to reduce the incidence of neural tube defects. Folic acid fortification of these food ingredients became mandatory in 1998 at the urging of the Canadian National Millers Association and Baking Association of Canada.

Nutrient intake surveys conducted after mandatory fortification reveal improved dietary folate intakes, with 86% of women meeting the Estimated Average Requirement (EAR) of 320μg/ day, compared to only 36% prior to fortification. As a result, both Canada and the United States have observed a decrease in rates of neural tube defects. In Ontario, two separate studies observed a significant decrease in the incidence of NTD.

The first study compared 1995 rates to 1999 rates and found a 47% decrease. The second study compared prevalence rates before fortification with rates following fortification and found a reduction of 38% (Ray 2002). Similar, but more striking, results were observed in Nova Scotia and Newfoundland, where incidence of NTDs fell by 54% and 78%, respectively, after fortification (Liu 2004, Persad 2002). Similar reduction rates of 47% were observed in a more recent study in Canada (De Wals 2007).

In addition to the benefits in neural tube defects, a systematic review and meta-analysis of 27 studies found that folic acid fortification decreased one of the perceived risks associated with developing colorectal cancer (Kennedy 2011).

Billions of dollars saved with folic acid fortification

Economic impacts were estimated for the U.S. to determine the benefits/costs of increasing folic acid fortification levels from 140 to 700 mcg/100 grams of enriched grains; the greatest benefits were predicted in the prevention of myocardial infarctions followed by colon cancer and neural tube defects; a small number of additional B12 deficiency cases were also predicted. The quality adjusted life years gains were 266,649 and the cost savings were predicted to be $3.6 billion (Bentley 2009).

In 2010, the Sodium Working Group released its strategy report which recommended the reduction of sodium intakes of Canadians. One arm of the strategy was the reduction of sodium in the food supply. Bakers face unique challenges

in removing salt from bakery products due to its functional nature in the baking process. However, Canada’s bakers began a number of years ago to reduce sodium in breads by reformulating existing products and by development of new lower sodium breads and rolls. Consumer acceptance of the changes in the taste profile of the lower sodium products will be critical in the success of the overall sodium reduction initiative.

The industry is committed to this initiative in order to keep this important grain product a staple in the Canadian diet.

In addition to working hard on sodium reduction, Canada’s bakers have been diligent in reducing the amount of trans fat in many products. In 2006 the Trans Fat Task Force called for the elimination of the use of trans fat due to health concerns related to coronary heart disease and stroke. The stated objective or outcome of the Trans Fat Task Force recommendation was to: “reduce the average daily intake of trans fat by Canadians to less than 1% of energy intake, consistent with current dietary recommendations.”

In response, bakers and the food industry alike began the process to voluntarily reformulate tens of thousands of products with measurable and dramatic success. According to Health Canada, the average contribution of trans fat as a percentage of energy to the Canadian diet has been reduced substantially over the years:

• 1995: it was 3.7%

• 2004: it was 2.0%

• 2008: it was 1.4%

based on results of 4th set of trans fat monitoring data

It should be noted however that bakers and the food industry have continued to reformulate products since the last monitoring report. Based on continuing reformulations and the declining contribution to diet trend, it is very conceivable that the reduction objective of the Trans Fat Task Force has been met.

Bakers continue to be innovative in providing health benefits through enriched breads and baked products. Examples include:

• Use of white wheat kernels to add whole grains to white bread without changing appearance:

✓ A number of breads, specifically enriched white bread, popular with children, have added flour made from a white wheat kernel. This allows the addition of whole grain flour to the enriched white bread while maintaining the taste, texture and appearance of white bread. In this way, the industry is adding value to the products by providing additional benefits found in whole grains.

• Addition of ingredients such as inulin (chicory root) or flour from legumes, seeds and other grains to increase the fibre content:

✓ Part of the benefits of wheat and whole grain is the contribution of fibre to the diet of Canadians. Many baked products, including breads, have the addition of inulin or whole grain flours made from soybeans, corn, amaranth, oat, etc., to boost the fibre content of their products. Fibre is a key nutrient for maintenance of a healthy gastrointestinal tract and for its role in lowering blood cholesterol, a risk factor in heart disease.

• Addition of nutrients such as omega-3 fatty acids and vitamin D:

✓ Omega-3 fatty acids are primarily found in fish, some plants and nut oils. These essential fatty acids play a crucial role in growth and development as well as brain function. There is also a role in the prevention of heart disease. A number of bakery products have added omega-3, providing another source of this key polyunsaturated fat that is limited in our diet.

✓ In addition to its role in the development and maintenance of healthy bones and muscles, vitamin D research shows that this nutrient may reduce the risk of some types of cancers. Living in Canada, exposure to the sun during the winter months limits the production of vitamin D in our bodies. Although some products such as milk are fortified with vitamin D, the recent approval by Health Canada permitting the voluntary addition of vitamin D to bakery products has resulted in the addition of vitamin D in some bread. This will provide an added benefit to the vitamin D status of Canadians.

The mean intake of grain products is 6.9 servings per day for Canadian men and 4.9 servings per day for women, with about 30% of the adult population not eating the minimum number of

five servings daily based on Canada’s Food Guide to Healthy Eating (Gray-Donald 2000, Pasut 2001, Health Canada 1990). The same survey found intakes for male and female teens was 7.6 and 6.0 servings, respectively. The percentages not meeting minimum servings of grain products is likely higher now as the food guide was revised in 2007 with the current recommendations being 6 for teens and adult women and 7 servings for adult men (Health Canada 2007).

The 2004 Canadian Community Health Survey indicates that more than a quarter of children aged four to eight do not eat the recommended daily minimum of five servings of grain products. And for both sexes, the proportion of people not meeting the minimum tends to rise with age.

At all ages, females are much more likely than males to fall short of the recommended level. For instance, at ages 14 to 18 years, 33% of girls, compared with 6% of boys, have fewer than five daily servings of grain products. The revised Canada’s Food Guide recommends six to seven servings per day of grain products for 14-18 year-olds.

The focus of the baking industry is to ensure that children consume adequate amounts of food from the four food groups in Canada’s Food Guide. With taste preferences for enriched white and wheat bread in mind, the industry is adding value to these products that will benefit and encourage adequate consumption.

Grain products play an essential role in the foundation of a healthy, nutritious diet, especially for children. Yet more than a quarter of children aged four to eight do not eat the recommended daily minimum of five servings of grain products and evidence indicates the proportion of Canadians not meeting the minimum tends to rise with age.

In view of this challenge to a healthy diet, BAC called for more effort by the Public Health Agency, health related NGOs and the federal/provincial/territorial governments in expanding efforts in communicating the positive nutritional messages regarding the consumption of grain-based foods.

BAC continues to participate in ongoing discussions with governments and health professionals to enhance their collective understanding of the efforts by bakers to improve nutrition and the need for an increased consumption of grains by children.

Bakery Showcase 2012

May 6-8

International Centre

Toronto (Mississauga), ON

Atlantic Chapter

September 12

Annual Golf Tournament

Magnetic Hill Golf Course Moncton, NB

Ontario Chapter

September 20

Fall Golf Tournament

Glen Eagle Golf Club Bolton, ON

November 25

Holiday Social Pavilion Royale Mississauga, ON

Laura Kennedy Hallmark Insurance Brokers Ltd

Helen Racette

Our Place In The Prior

David Spence

Aromatics & Flavours

Martin Barrera

Bakery Technology Unit I

Rekha Bjardwaj

Bakery Technology Unit I

Ruth Bleijerveld Food Hazard Control:Sanitation

Crystal de Jong

Bakery Technology Unit II

Bradley Gosselin

Bakery Technology Unit II

Tavia Pasqualucci

Bakery Technology Unit I

Annette Siu

Operating A Successful Bakery

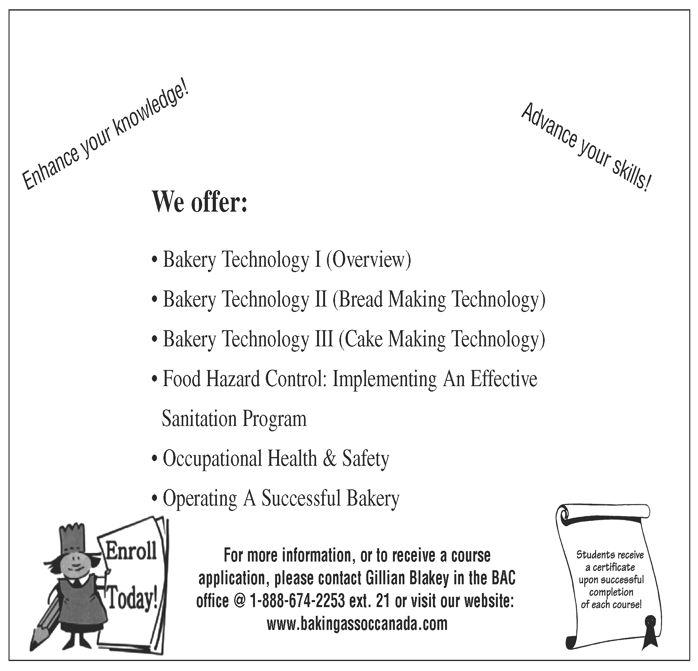

For information on correspondence courses for baking industry employees and the Certified Bakery Specialist (CBS) program, please contact ext. 21 at the BAC office or check out our website at www.baking.ca.

By Mar I o For TIN

Steam injection makes a big difference in the quality, appearance and flavour of your bread

The injection of steam, or vapour, during baking plays an important role in the development of bread. The beautiful scarification (knocks from a blade), the sharpness of the crust and the shine of the bread can all be altered with steam or vapour. The quantity of vapour to be injected is variable according to the following factors: the desired qualities of the finished product, the type of oven and the baking temperature.

Breads baked with vapour are more attractive to consumers than other varieties. Place a few breads baked without vapour beside their vapourbaked counterparts and you will see the difference. When baking breads such as a rustic round loaf, vapours change the crust and improve the flavours of the bread.

}flake from the friction of breads in the packaging if allowed to form too early. Vapour is also important during the second stage of baking par baked goods, which restores the colour of the bread and further prevents the crust from peeling off.

There are several types of ovens that can be used:

• fixed or rotating deck ovens with a sole of stone or gmetal

• the rotative rack oven with single or double racks

• rotative shelf ovens, including four to 10 tablet mobiles or a traveller for 12 tablets or more

• vertical or horizontal tunnel ovens

• convection ovens

These ovens may be heated with oil, natural gas, propane, electricity or wood.

Par baked breads necessitate baking with steam to avoid colouring the bread and forming a crust during the initial bake. The colour change means caramelization occuring during the formation of a crust

Par baked breads necessitate baking with steam to avoid colouring the bread and forming a crust during the initial bake. The colour change means caramelization occuring during the formation of a crust. The crust will

The bigger the oven, the bigger the baking chamber will be, and the more steam will have to be supplied. In the case of a very big oven, an independent kettle is connected to the oven to supply the vapour.

The timing of the vapour injection will vary according to the system used and the specifications for the finished product. The injection time may be as

Bread variety

Enriched white bread

Vapour requirements

Not required

Soft rolls (hot dog, hamburger) Not required

Crusty bread (any shape)

Required for a beautiful crust

Crusty rolls (round, long or kaiser) Moderate

Baguette (on the sole, pan or net) Important for open cuts

Cereal bread Necessary to avoid tearing

Sourdough bread (miche au levain)

Rye bread (any variety)

Par baked bread (any variety)

Needed to prolong development

Required throughout baking

Essential at beginning and end of baking

short as three seconds or injection may happen continuously during baking. It all depends on the variety of bread.

The steam injected during baking has to condense on the surface of the bread to develop a finer crust and avoid drying out the bread. This moist vapour also softens the dough and allows gthe knocks of a knife blade of open cuts in the loaf.

Baking determines the appearance and the taste of the final product. The oven temperature should be between 425 and 480 F (220 and 250 C). It is important to have a hot oven because the addition of vapour can facilitate the transfer of heat in products. The injection of steam brings a drop in temperature and, if the oven is not hot enough, the baked bread will have to stay in the oven longer and will lose weight as a result.

The bread enters the oven at a temperature of 77 to 95 F (25 to 35 C), depending on whether it is fermented in a proofer or on a couche at room temperature. At 130 F (54 C) the starch in the bread begins to swell. At 145 F (63 C) the yeast dies. At 165 F (74 C) the coagulation of the gluten begins and at 190 F (88 C) all activity stops. Excess humidity is liberated, some as carbon dioxide and some as alcohol. Finally, at 208 F (98 C), the bread is baked. Throughout the baking process, the temperature of the crust can exceed 392 F (200 C).

It is important to know how long it takes to heat your oven to the desired temperature; it must reach this temperature before you start baking the bread. Some vapour systems inject steam by a water inlet on the internal wall of the oven and if this is not warm enough, you will not have the right quantity of steam. Determine the type of production your bakery requires before purchasing an oven to ensure your new equipment will meet your needs. / BJ

Mario Fortin is an international bakery consultant and owner of FORMA-LAB, a consulting service for bakers and suppliers. For technical information, send your questions to info@forma-lab.com.

disruption if you ended up taking too much of any kind of fibre, like psyllium, for example,” Wiley says.

The amount of fibre in a product is something that Navazesh pays close attention to.

“I pay attention to how much fibre I want to feed my customers. I don’t want to give them diarrhea. Different people have different objectives of what their nutrition needs to be where fibre is

concerned. We pay a lot of attention to body function and we don’t want to give you too little or too much. We say nothing less than two grams per serving. For some people, they can consume more, but in a regular product usually you stay around two grams per serving.”

Navazesh also recommends that anyone wanting to incorporate inulin into their products should do their R&D first, since it is not an ingredient that can simply be added to existing formulas.

“They should pay close attention to

heat, moisture, coagulation and taste requirement. You also have to look at the catalyst to see what reaction it creates with the other ingredients that you have [in the recipe]. Anything in a powder shape or liquid it will act in.”

Manufacturers of Quality Bakery Machinery Since 1972.

Model: CG/BF Serie�s

Blast your way into Profitability while maintaining Quality!

The G. Cinelli – Esperia® Corporation BLAST FREEZER was designed and built to maintain the quality of your product and furthermore, to drastically reduce the amount of time, space and expense required in doing so.

For those who wish to preserve inherent quality or distribute a product that is of the highest qualitative standard such as any dough, bread, cake or pastry product and even foods and saucessimply put, one of the main contributors to preserving high quality is for it to be frozen or chilled as rapidly as possible – our line of Blast Freezers guarantees this quality like no other.

The Blast Freezers or alternatively sometimes called Blast Chiller, can offer 2 modes of operation;

• BLAST FREEZING – from +90/70°C (190/158°F) to -18°C (-0.4°F) at product core

• BLAST CHILLING – from +90/70°C (190/158°F) to + 3°C (37.4°F)

– Mainly used for Gastronomy but not limited thereto.

Compared to normal cold storage freezers or refrigerators; Not only do they freeze extremely fast, the Blast Freezer can maintain the correct degree of product moisture content that is necessary for the proper product condition in its subsequent stage of product life and/or endowing it with the properties for optimal regeneration. Furthermore, it drastically reduces ice crystal formation avoiding “freezer burn” and other unpleasant aesthetic changes.

With the G. Cinelli – Esperia® Corporation Blast Freezer, it is now within reach for anyone to properly preserve or distribute their product.

Although this fibre-packed ingredient is now gaining ground on supermarket shelves, the chicory plant is certainly not new. In fact, it has a history stretching back to ancient Egyptian times, when the plant was cultivated on the banks of the Nile River and used to aid in digestive and liver health. It has also been used throughout Europe and North America as a coffee substitute, particularly in times of war when coffee beans were scarce and people were craving a good old cuppa joe.The Praeventia product line by Leclerc talks about their use of inulin on their website (www. praeventia.ca/en/prebiotics), on which they state: “The prebiotic dietary fibre inulin used in Praeventia products is, a non-digestible carbohydrate found in plant sources such as garlic, leeks, chicory, asparagus, etc. Chicory root is rich in inulin, which is why this root is a preferred choice for extracting inulin for industrial use.” Leclerc also outlines differences between probiotics and prebiotics on their site and this may be good knowledge to have on hand for your customers as well, as chicory root is considered a prebiotic.

There are inulin manufacturers popping up all over the United States and around the world. A few manufacturers are located right here in Canada. Although the full extraction process used by manufacturers is something of a trade secret, there are two ways it can be done. One method of extraction is natural, the other chemical.

On the whole, consumers and bakeries are giving inulin a glowing report, and that good reputation is driving growing demand.

“Customers are happy with it, I’m happy with it, my gut is happy with it,” says Navazesh. “The attributes are huge with inulin. We make a lot of ingredients as humans and not all of them are really good for us. Now and then we make some nice ingredients too, and this is one of them.” / BJ

Julie Fitz-Gerald is a freelance writer based in Uxbridge, Ont., and a regular contributor to Bakers Journal and Canadian Pizza magazine.

Whatever your formulation needs, choose from the AB Mauri Fleischmann’s family of yeast and bakery ingredients—and tap into the industry experience and proven critical thinking of our talented team.

W e’re committed to a relationship-oriented partnership—serving a s your total resource for process optimization and custom formula solutions.

makes a really big difference to the overall appeal.” – Mark Camu

WHAT SIMIlARITIES CAn BE DRAWn BETWEEn fREnCH AnD CAnADIAn CUISInE? WHAT DIffEREnCES?

“The major difference I find between French and Canadian cuisine lies in simply how they approach food in their lives. Being from North America and living such a fast-paced lifestyle, we rarely have time to enjoy our food and really dine. The French make this a huge part of their lives, and meals can take anywhere up to four hours. They have a very specific structure to their dining experience. It will begin with aperitifs, followed by a light appetizer, then mains, then cheese . . . followed by dessert and coffee. Dining for them is very social and relaxing.” – Stephanie Duong

“I found that there is little to no spiciness in French cuisine. Even the mustard had no kick to it. In French food, it was the ingredients in the meal that were the stars. Most of the food was simply prepared, and the fresher the food, the better the meal. I loved that we had Le Puy lentils in many of our meals, which showcased the local and very delicious lentils made many different ways, but always showcasing the taste of them.” – Cynthia Shao

“The differences that I noticed between French and Canadian cuisine were that each small town had their own specialty. In one town we ate a lot of duck in another we ate a lot of pork. When we visited Regis Marcon’s restaurant, that town was known for their mushroom and that was predominantly shown in his menu. They had fewer fried food restaurants then we did. Their meals tend to last at least three courses, one of which is always cheese. Their breakfast is lighter compared to ours. They tend to have croissants and a piece of bread whereas we have eggs, bacon, sausage and pancakes. The similarities between the two cuisines are that they both don’t serve a lot of vegetables and fruits. It would have been nice to eat more of those when travelling.” – Margret Tran Le

“One of the biggest differences I found was in the pastries. They put so much time and effort into their desserts. They make them taste like you’re enjoying it for your first time, every time, and make you feel like the only thing you want to do is salivate for another. The colours, aromas and ingredients alone will give

you an indescribable high that can last until your next visit to that very same patisserie. The bakeries carry your nose in on the scent of their fresh baked breads and the whole thing is just unbelievable to see, smell and taste.”

– Adam Vogler

WHAT Do yoU fEEl THAT yoUR

ExPERIEnCE In fRAnCE

ConTRIBUTED To yoUR

DEVEloPMEnT AS A CHEf?

“As a chef, it’s always important to keep moving, keep learning. The best way I feel, to learn about a culture, and to immerse yourself in a culture, is to experience the culture through its food . . . from the way they approach their cuisine, to the ingredients used, to the overall eating experience of that culture. I think that the quality of ingredients in France, from their butter to their eggs, is much different than the quality we find in Canada. And the French accept nothing but the besgt for their pastriegs . . . something that I find sometimes is forgotten in North America. I feel that after witnessing and experiencing the level of perfection that the French strive for in their food, I want to make that my own standard when I go into industry, wherever I am.” – Stephanie Duong

“To see how committed and focused the chefs were on making their food the best was truly inspiring. It was a mind-opening experience, seeing that success doesn’t necessarily mean having to be on television to get publicity. Even after achieving three Michelin stars at his restaurant, Regis Marcon was still happy and willing to show 16 students

his kitchen and hotel, and allow us to scavenge his field for wild flowers and herbs.” – Cynthia Shao

“It had showed me flavour combinations that I wouldn’t even think of. Using wild herbs and wild fruits can make such a difference in your food. This trip overall was an eye opener for me. It made me more motivated and determined to work hard and travel more . . . . This trip taught me that it’s not always good to rush, sometimes it’s better to slow down and enjoy what you’re doing.” – Margret Tran Le

“Going on this very special trip to France has inspired me to continue to learn – about pastry and about wine. I want to travel, and visit other countries to see how their pastries differ from the French. As a chef, I want to grow. I want to experience as much as I can and learn as much as I can and be the best that I can be to ensure that my love and my passion for food and pastry gets carried on to other people.” – Adam Vogler

“France has definitely opened my eyes to how different foods are around the world. Both in preparation and in the final product, there is a noticeable difference between the two cultures. They are so dedicated to their profession, and the amount of dgetail that is put ignto their pastries is amazing. Seeing all the different markets and the freshness of their food, I have also gained a new respect for ingredients. The trip was a once-in-a-lifetime experience and has made me push myself to become a better pastry chef.” – Mark Camu / BJ

*Answers have been condensed and edited

We provide ovens for the professional bakers in every category, from small countertop ovens to our 703 that holds 4 racks.

Contact us to learn how you can improve the quality of your bake, increase the efficiency of your operations and reduce your costs for energy and maintenance!

Alot of work goes intgo the development of a newg culinary program in the Ontario college system. There are many questions that need answering prior to starting the process. A new program is developed to meet student, social and labour needs, and to complement the strategic direction of the college.

A new program must meet the college’s curriculum standards, industry committee apprenticeship regulations, and the approval of the Ontario Ministry of Training, Colleges and Universities. A list of courses – the program outline – for any culinary program should attract a student much like a well-written menu does a customer. Educators, much like chefs, will tell you that it’s all in the menu planning. There are many stages and steps to creating a new educational

program. From concept to design, and development through implementation, it’s an elaborate and cumbersome undertaking.

There are a number of ways in which new programs emerge but primarily they come about in response to an additional program offering in the college system or in response to current industry trends. Development principles are subject to rigorous scrutiny to ensure that colleges are able to prepare students with the basic knowledge of industry terminology, specific working certifications, and discipline and work ethics. Trying to help students prepare for their chosen field has its challenges. Educators are always learning about how to better connect students with the industry. They are focused on building symmetry between prospective employees and ready employers.

Teaching and preparing students for today’s job market is about getting students to apply skills and techniques. These learning outcomes are developed through a scope of practice. This is the technical descriptiogn of activities thgat constitute the work that is part of a trade. Our role is to help students achieve and become better on-the-job learners. Teachers need to focus on learning that is measurable and calculated. Helping students figure out how they learn and assimilate knowledge is paramount in obtaining a deep andg positive understanding of subject matter. Students need to focus on the fugndamental skills and g techniques that will make them a marketable commodity in the industry. A well put-together program should take the student through all stages of the learning process and allow them to build upon their skills through active experi-

mentation. All students become successful if they gcan develop the confidence to apply real on-the-job skills. Achievement through education brings a confident, employable person to the work force. It’s up to industry to show students how to succeed from there.

An educational program should allow students to learn, gformulate new interpretations and critique their work. Most culinary programs attract learners through a sense of the trade history and the art of craftsmanship. But not all students make a choice to attend a college based on the reputation of a program alone. Much as it is during the hiring process , “fit” seems to be at the forefront of the decision-making process.

Smaller class sizes and increased face-to-face time with instructors are what interest students. Some colleges design their curriculum and present program outlines in a tidy and wellwritten list that conjures up images of modern and contemporary learning. It all has a look and feel that excites the curious learner until they arrive in the classroom, where they may feel disconnected from their surroundings and experience a quick lgesson with the smoke-and-mirrors approach to learning. Developing courses agnd content should mean more than trying to make a program appear cutting edge using convoluted language. The focus should always be about delivering a quality education through learning and selfimprovement.

These qualities are complex and burden faculty throughout the development of a new program. They require constant attention and continual review in order to achieve the right mix in the classroom. A good faculty team that invests the time because its members care and believe in this process helps develop the best graduates. Individuals that go forth into the industry and become successful ugnderstand that learning never ends g– completing one aspect of an educatgion moves them to g the next step on a cgontinuum of lifelongg learning.

Two of the top 10 college programs that have been steadily growing over the past few years are cooking and baking. Serving and consuming good food has become a conscious priority in our social fabric. Food has seen a resurgence in the mainstream culture, which has translated into huge growth in cooking schools and

post-secondary programs. The demand for qualified cooks has been on the rise, with a special demangd for those skilled gin international cuisine and baking. The culinary arts field is a challenging one and staying current on new trends in taste and nutrition are a must for any foodservice worker. A career in cooking or baking can be an extremely rewarding one with a number of ways to diversify and expand in the future. Educational institutions have a responsibility to create new programs, renew current

ones, provide students with proper training and supply industry with skill-based workers. And that’s exactly the direction in which we are going. / BJ

Anthony Borgo, CCC, CBS, is the co-ordinator of culinary programs at Georgian College. In addition to educating cook apprentice, culinary and hospitality management students, Borgo is planning new programming that will enhance employment opportunities for students in central Ontario.

Tony Blak, co-owner Blak’s Bakery, Windsor, Ont.

This family-owned bakery has history and has been creating eastern European breads, cakes and pastries in its community for 93 years.

What is the cornerstone of your bakery’s longevity?

We have been in business since 1918, when my grandfather moved to Canada from the U.S. He had immigrated to the U.S. in 1905 and spent 10 years in Rochester, N.Y., working for Denniger Brothers Bakery. He then moved to Detroit for a couple of years before coming to Canada. We still use the original oven he built and in the same location. My sister Valarie Blak-Gill and myself believe in keeping traditional baking alive, and it seems the market is coming full circle and is now demanding better bread all the time.